Page 1

OPERATION AND PARTS MANUAL

SERIES

MODEL HHN31VTCSL5

RIDE-ON POWER TROWEL

(B & S VANGUARD DM950 GASOLINE ENGINE)

Revision #8 (05/03/12)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

PN: 20382

Page 2

PROPOSITION 65 WARNING

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingandotherconstructionactivities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of these chemicals are:

Leadfromlead-basedpaints.

Crystallinesilicafrombricks.

Cementandothermasonryproducts.

Arsenicandchromiumfrom chemically

treatedlumber.

Your risk from these exposures varies,

dependingonhowoftenyoudothistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

PAGE 2 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 3

SILICOSIS/RESPIRATORY WARNINGS

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 3

Page 4

TABLE OF CONTENTS

HHN31VTCSL5 Ride-On

Power Trowel

Proposition 65 Warning ........................................... 2

Silicosis/Respiratory Warnings ................................ 3

Table Of Contents .................................................... 4

Parts Ordering Procedures ...................................... 5

Training Checklist .................................................... 6

Daily Pre-Operation Checklist ................................. 7

Safety Information ..............................................8-13

Specifications/Dimensions ................................ 14-15

General Information ............................................... 16

Components ..................................................... 18-19

New Machine Setup .............................................. 20

Basic Engine .......................................................... 21

Inspection .............................................................. 22

Operation .......................................................... 23-24

Maintenance ..................................................... 25-41

Maintenance (Old Style Clutch) ...................... 28-32

Maintenance (New Style Clutch) .................... 33-35

Troubleshooting ..................................................... 42

Troubleshooting ..................................................... 43

Troubleshooting ..................................................... 44

Troubleshooting ..................................................... 45

Wiring Diagram ...................................................... 46

Explanation Of Code In Remarks Column............. 48

Suggested Spare Parts ......................................... 49

NOTICE

Component Drawings

Nameplates And Decals ................................... 50-51

Pivot/Gearbox (Right Side) Assembly. .............. 52-53

Pivot/Gearbox (Left Side) Assembly. ................54-55

Gearbox Assembly. ........................................... 56-59

Control Steering (Assist) 1 Assembly. ..............60-61

Control Steering (Assist) 2 Assembly. ..............62-63

Twin Pitch Assembly. 1 (Left/Right) ................... 64-65

Twin Pitch Assembly. 2 (Left/Right) ................... 66-67

Engine Mounting & Throttle Assembly. ............. 68-69

Engine Cradle Mounting Assembly. .................. 70-71

Engine Air Cleaner/Radiator Assembly. ............ 72-73

Engine Muffler Assembly. ................................. 74-75

Engine Clutch Assembly. (Old Style) ................ 76-77

Engine Clutch Assembly. (New Style) ............... 78-79

Engine Fuel Assembly. ..................................... 80-81

Drive Assembly. (Old Style) .............................. 82-83

Drive Assembly. (New Style) ............................. 84-85

Spider Assembly. (Left) ..................................... 86-87

Spider Assembly. (Right) .................................. 88-89

Stabilizer Ring Assembly. ................................ 90-91

Seat And Frame Assembly. .............................. 92-93

Frame And Components ...................................94-95

Foot Pedals Assembly. ...................................... 96-97

Throttle Foot Pedal Assembly. .......................... 98-99

Battery Assembly. ......................................... 100-101

Spray Assembly. ........................................... 102-103

Front Panel Assembly. .................................. 104-105

Top Right Panel Assembly. ........................... 106-107

E-Z Mover And Lift Handle Assembly. .......... 108-109

Specifications and part numbers are subject to change

without notice.

PAGE 4 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Terms And Conditions Of Sale — Parts .............. 110

Page 5

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

If you have an MQ Account, to obtain a Username

Effective:

Choose from three easy options:

January 1st, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specifi cation Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

and Password, E-mail us at: parts@multiquip.

com.

To ob ta in an MQ Account , contac t yo ur

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Truck

■ Ground

■ Next Day

■ Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 5

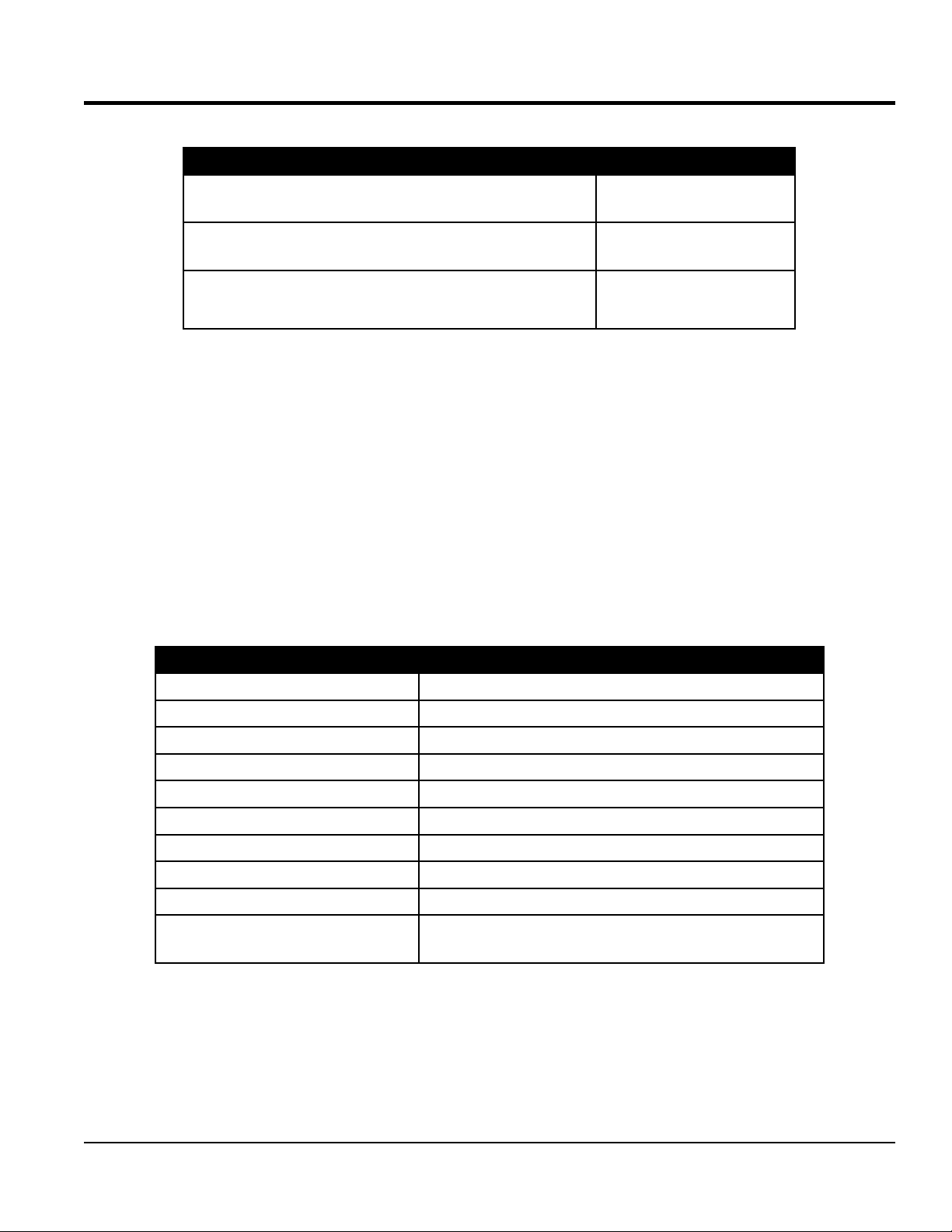

Page 6

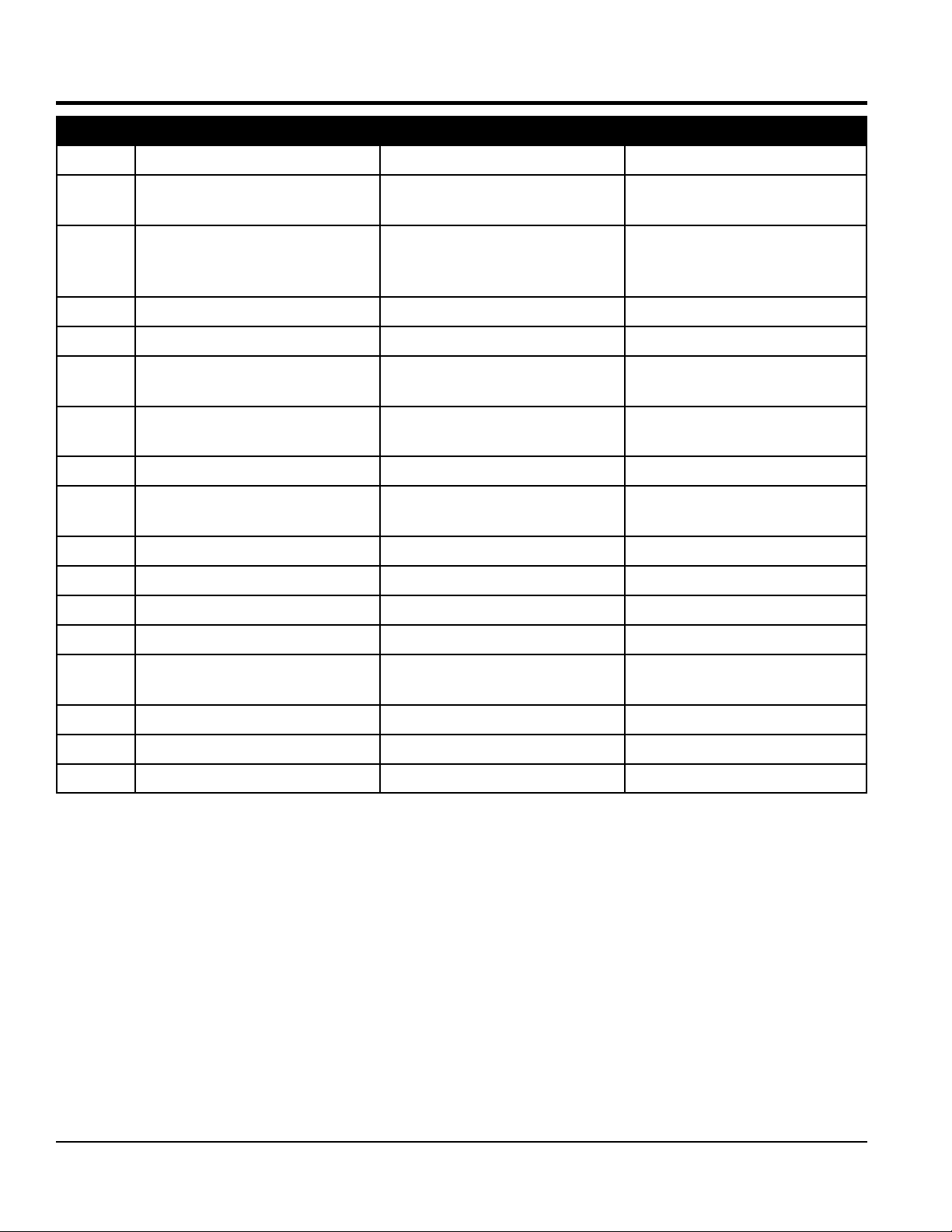

TRAINING CHECKLIST

Training Checklist

No, Description OK? Date

1

2

3 Fuel system, refueling procedure.

4 Operation of spray and lights.

5

6

7 Emergency stop procedures.

8

9 Maintaining a hover.

10 Maneuvering.

11 Pitching.

12 Matching blade pitch. Twin-Pitch™

Read operation manual

completely.

Machine layout, location of

components, checking of engine

oil levels.

Operation of controls (machine

not running).

Safety controls, safety stop switch

operation.

Startup of machine, pre-heat,

engine choke.

13 Concrete fi nishing techniques.

14 Shutdown of machine.

15 Lifting of machine (lift loops).

16 Machine transport and storage.

PAGE 6 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 7

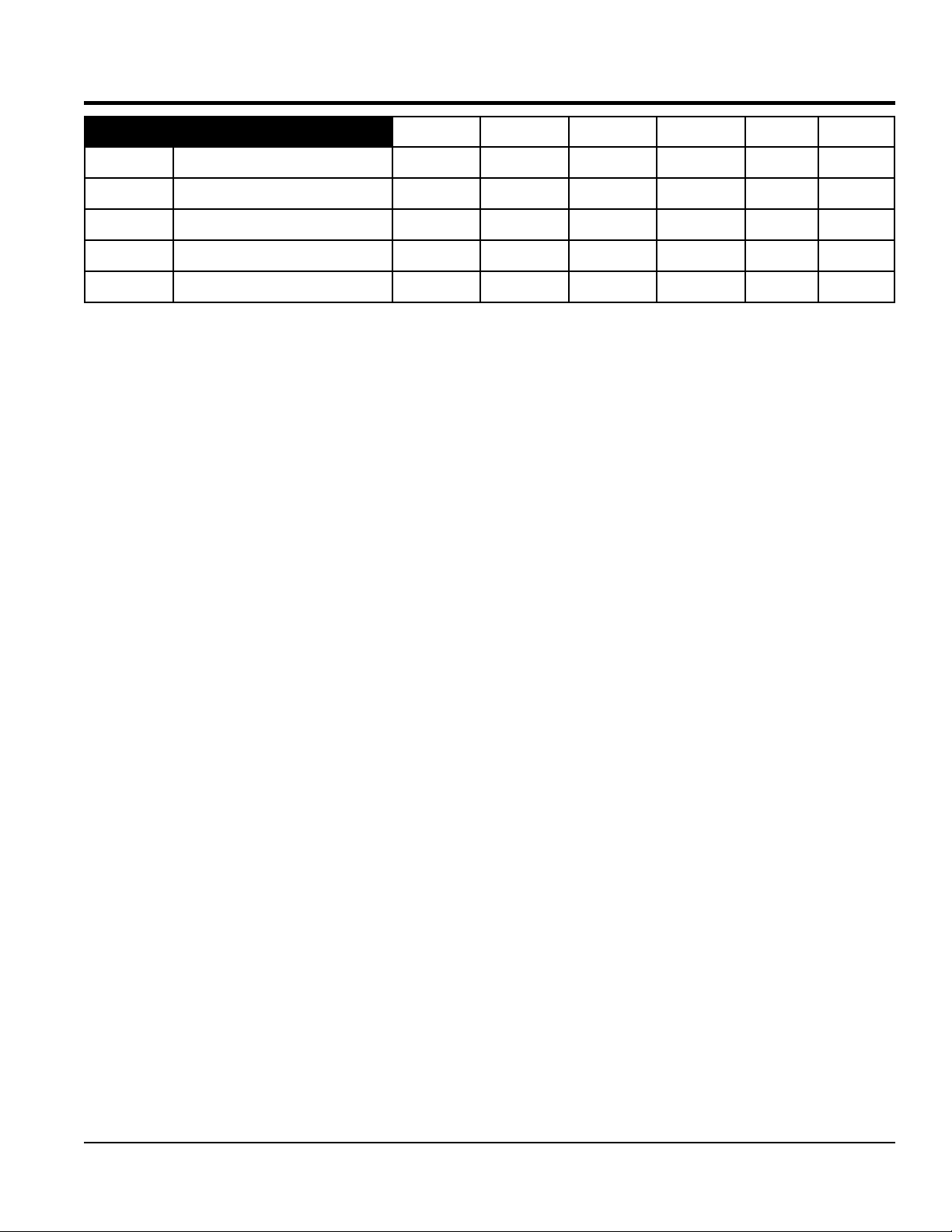

DAILY PRE-OPERATION CHECKLIST

Daily Pre-Operation Checklist

1 Engine oil level

2 Condition of blades

3 Blade pitch operation

4 Safety stop switch operation

5 Steering control operation

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 7

Page 8

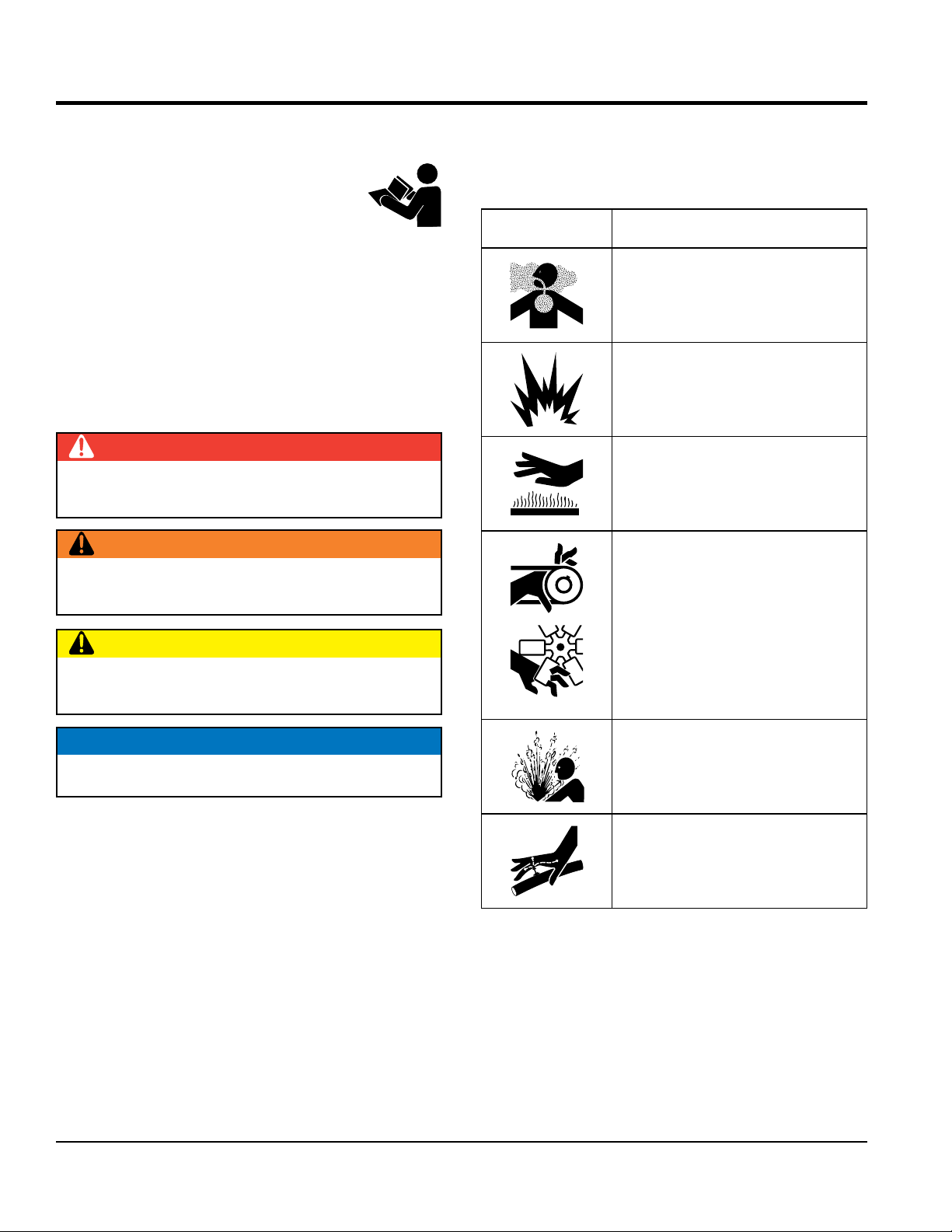

SAFETY INFORMATION

Do not operate or service the equipment before reading

Potential hazards associated with the operation of this

the entire manual. Safety precautions should be followed

at all times when operating this equipment.

Failure to read and understand the safety

messages and operating instructions could

result in injury to yourself and others.

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION or NOTICE.

SAFETY SYMBOLS

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

CAUTION

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

Symbol Safety Hazard

Lethal exhaust gas hazards

Explosive fuel hazards

Burn hazards

Rotating parts hazards

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

Pressurized fluid hazards

Hydraulic fluid hazards

PAGE 8 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 9

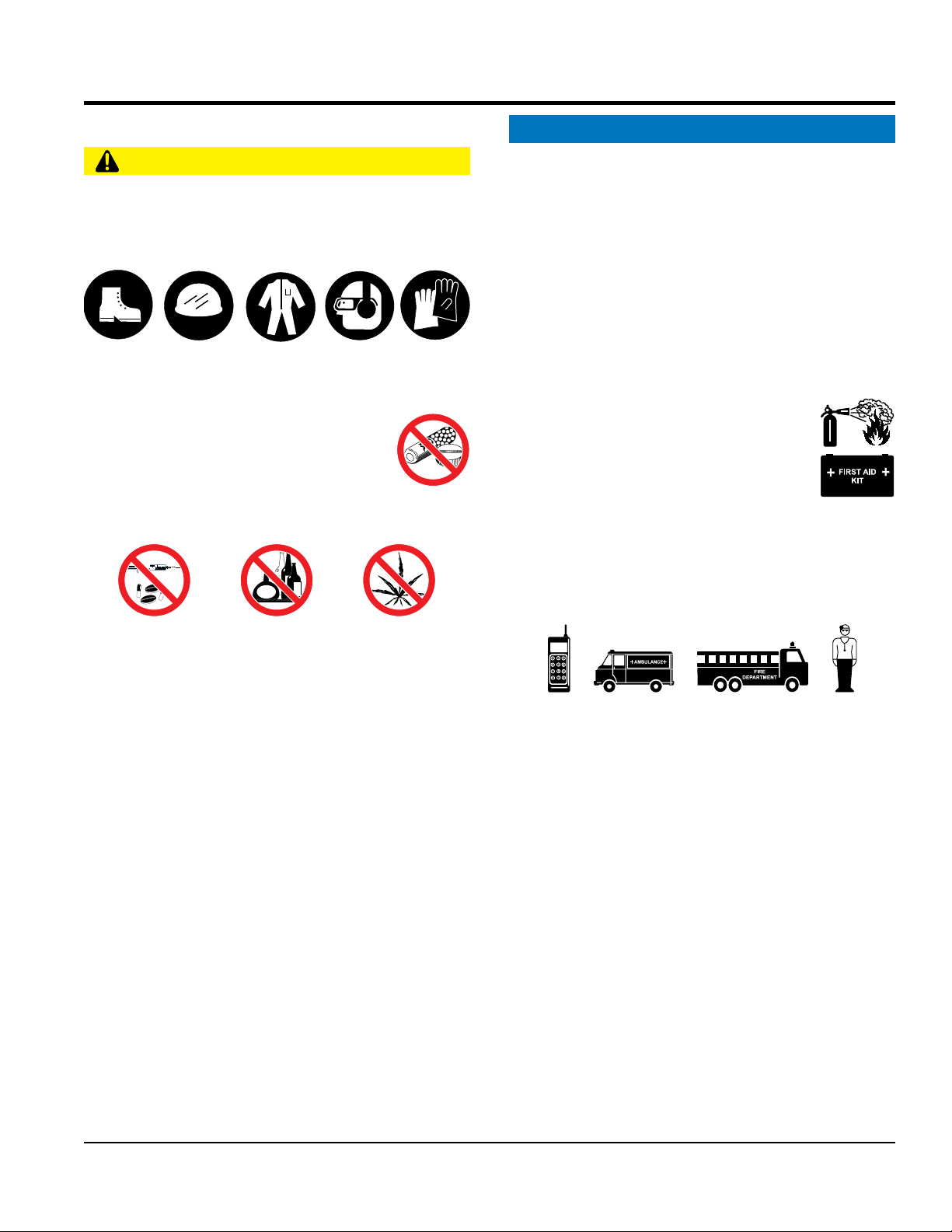

GENERAL SAFETY

NOTICE

This equipment should only be operated by trained and

Whenever necessary, replace nameplate, operation and

accident due to equipment modifi cations. Unauthorized

recommended by Multiquip for this equipment. Damage

keep

Also, know the phone numbers

fi re department.

SAFETY INFORMATION

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

Avoid wearing jewelry or loose fi tting clothes that may

snag on the controls or moving parts as this can cause

serious injury.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the

infl uence of drugs or alcohol.

ALWAYS clear the work area of any debris, tools, etc.

that would constitute a hazard while the equipment is

in operation.

qualifi ed personnel 18 years of age and older.

safety decals when they become diffi cult read.

Manufacturer does not assume responsibility for any

equipment modifi cation will void all warranties.

NEVER use accessories or attachments that are not

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

ALWAYS know the location of the nearest phone or

a phone on the job site.

of the nearest ambulance, doctor and

This information will be invaluable in the case of an

emergency.

No one other than the operator is to be in the working

area when the equipment is in operation.

DO NOT use the equipment for any purpose other than

its intended purposes or applications.

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 9

Page 10

TROWEL SAFETY

NOTICE

keep the machine in proper running condition.

store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel.

Association of Equipment Manufacturers (AEM) can be

engine is hot. High pressure boiling water will gush out

SAFETY INFORMATION

DANGER

Engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

cause death if inhaled.

The engine of this equipment requires an adequate free

fl ow of cooling air. NEVER operate this equipment in any

enclosed or narrow area

where free fl ow of the air is

restricted. If the air fl ow is

restricted it will cause injury

to people and property and

serio u s dama g e to t he

equipment or engine.

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

WARNING

If applicable, NEVER use your hand to fi nd

hydraulic leaks. Use a piece of wood or

cardboard. Hydraulic fl uid injected into the

skin must be treated by a knowledgable

physician immediately or severe injury or

death can occur.

DANGEROUS

GAS FUMES

ALWAYS

Fix damage to machine and replace any broken parts

immediately.

ALWAYS

A safety manual for operating and maintenance

personnel of concrete power trowels produced by the

obtained for a fee by ordering through their website at

www.aem.org.

Order FORM PT-160

ENGINE SAFETY

WARNING

D O NOT pl ace hands o r fi ngers inside e ngine

compartment when engine is running.

NEVER operate the engine with heat shields or

guards removed.

Keep fi ngers, hands hair and clothing away

from all moving parts to prevent injury.

DO NOT remove the radiator cap while the

ALWAYS keep clear of rotating or moving

parts while operating the trowel.

NEVER di sco nne ct an y emerg enc y

or safety devices. These devices are

intended for operator safety. Disconnection of these

devices can cause severe injury, bodily harm or even

death. Disconnection of any of these devices will void

of the radiator and severely scald any persons in the

general area of the trowel.

DO NOT remove the coolant drain plug

while the engine is hot. Hot coolant will

gush out of the coolant tank and severely

scald any persons in the general area of

the trowel.

all warranties.

DO NOT remove the engine oil drain plug while the

CAUTION

NEVER allow passengers or riders on the trowel during

operation.

NEVER lubricate components or attempt service on a

running machine.

NEVER place your feet or hands inside the guard rings

while starting or operating this equipment.

engine is hot. Hot oil will gush out of the oil tank and

severely scald any persons in the general area of the

trowel.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

PAGE 10 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 11

NOTICE

BATTERY SAFETY

drop the battery. There is a possibility that the

keep the battery charged. If the battery is not

charge battery if frozen. Battery can explode.

environment to avoid the risk of a dangerous concentration

NEGATIVE battery terminal

keep battery cables in good working condition.

SAFETY INFORMATION

NEVER run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

frequently to prevent engine malfunction.

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

FUEL SAFETY

DANGER

DO NOT start the engine near spilled fuel or combustible

fl uids. Fuel is extremely fl ammable and its vapors can

cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

ALWAYS use extreme caution when working with

fl ammable liquids.

DO NOT fi ll the fuel tank while the engine is running

or hot.

DANGER

DO NOT

battery will explode.

DO NOT expose the battery to open fl ames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases and liquids come into contact with a

fl ame or spark, an explosion could occur.

WARNING

A LWAYS wear safety glasses when

handling the battery to avoid eye irritation.

The battery contains acids that can cause

injury to the eyes and skin.

Use well-insulated gloves when picking up

the battery.

ALWAYS

charged, combustible gas will build up.

DO NOT

When frozen, warm the battery to at least 61°F (16°C).

DO NOT overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

DO NOT smoke a round or ne ar th e

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

ALWAYS recharge the battery in a well-ventilated

of combustible gases.

If the battery liquid (dilute sulfuric acid)

comes into contact with clothing or skin,

rinse skin or clothing immediately with

plenty of water.

If the battery liquid (dilute sulfuric acid) comes into

contact with eyes, rinse eyes immediately with plenty

of water and contact the nearest doctor or hospital to

seek medical attention.

CAUTION

ALWAYS disconnect the

before performing service on the equipment.

ALWAYS

Repair or replace all worn cables.

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 11

Page 12

SAFETY INFORMATION

TRANSPORTING SAFETY

TOWING SAFETY

make

Make sure the hitch and coupling of the towing vehicle

NEVER

tow a trailer with defective hitches, couplings, chains, etc.

Trailer tires should be infl ated to 50 psi cold.

safety

attach trailer’s safety chains to towing

make sure the vehicle and trailer directional,

The maximum speed for highway towing is 55 MPH unless

posted otherwise. Recommended off-road towing is not to

Avoid sudden stops and starts. This can cause skidding,

CAUTION

NEVER allow any person or animal to

stand underneath the equipment while

lifting.

Ride-on trowels are very heavy and

awkward to move around. Use proper

heavy lifting procedures and DO NOT

attempt to lift the trowel by the guard rings.

NOTICE

The easiest way to lift the trowel is to utilize the lift loops

that are welded to the frame. These lift loops are located

to the left and right sides of the operator’s seat.

A strap or chain can be attached to these lift loops,

allowing a forklift or crane to lift the trowel up onto and

off of a slab of concrete. The strap or chain should have

a minimum of 2,000 pounds (1,000 kg) lifting capacity

and the lifting gear must be capable of lifting at least this

amount.

NEVER transport trowel with fl oat pans attached unless

safety catches are used and are specifi cally cleared for

such transport by the manufacturer.

NEVER hoist the trowel more than three feet off the

ground with fl oat pans attached.

Before lifting, make sure that the lift loops are not

damaged.

Always make sure crane or lifting device has been

properly secured to the lift loops of the equipment.

ALWAYS shutdown engine before transporting.

CAUTION

Check with your local county or state safety

towing regulations, in addition to meeting

Department of Transportation (DOT)

Safety Towing Regulations, before towing

your trowel.

In order to reduce the possibility of an accident while

transporting the trowel on public roads, ALWAYS

sure the trailer that supports the trowel and the towing

vehicle are mechanically sound and in good operating

condition.

ALWAYS shutdown engine before transporting

are rated equal to, or greater than the trailer “gross

vehicle weight rating.”

ALWAYS inspect the hitch and coupling for wear.

Check the tire air pressure on both towing vehicle and

trailer.

Also check the tire tread wear on both vehicles.

ALWAYS make sure the trailer is equipped with a

chain.

ALWAYS properly

vehicle.

ALWAYS

backup, brake and trailer lights are connected and

working properly.

DOT Requirements include the following:

NEVER lift the equipment while the engine is running.

Tighten fuel tank cap securely and close fuel cock to

prevent fuel from spilling.

Use adequate lifting cable (wire or rope) of suffi cient

strength.

DO NOT lift machine to unnecessary heights.

ALWAYS tie down equipment during transpor t by

securing the equipment with rope.

PAGE 12 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

• Connect and test electric brake operation.

• Secure portable power cables in cable tray with tie

wraps.

exceed 15 MPH or less depending on type of terrain.

or jack-knifi ng. Smooth, gradual starts and stops will

improve towing.

Avoid sharp turns to prevent rolling.

Page 13

Trailer should be adjusted to a level position at all times

when towing.

Raise and lock trailer wheel stand in up position when

towing.

SAFETY INFORMATION

Place chock blocks underneath wheel to prevent rolling

while parked.

Place support blocks underneath the trailer’s bumper to

prevent tipping while parked.

Use the trailer’s swivel jack to adjust the trailer height to

a level position while parked.

ENVIRONMENTAL SAFETY

NOTICE

Dispose of hazardous waste properly.

Examples of potentially hazardous waste

are used motor oil, fuel and fuel fi lters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 13

Page 14

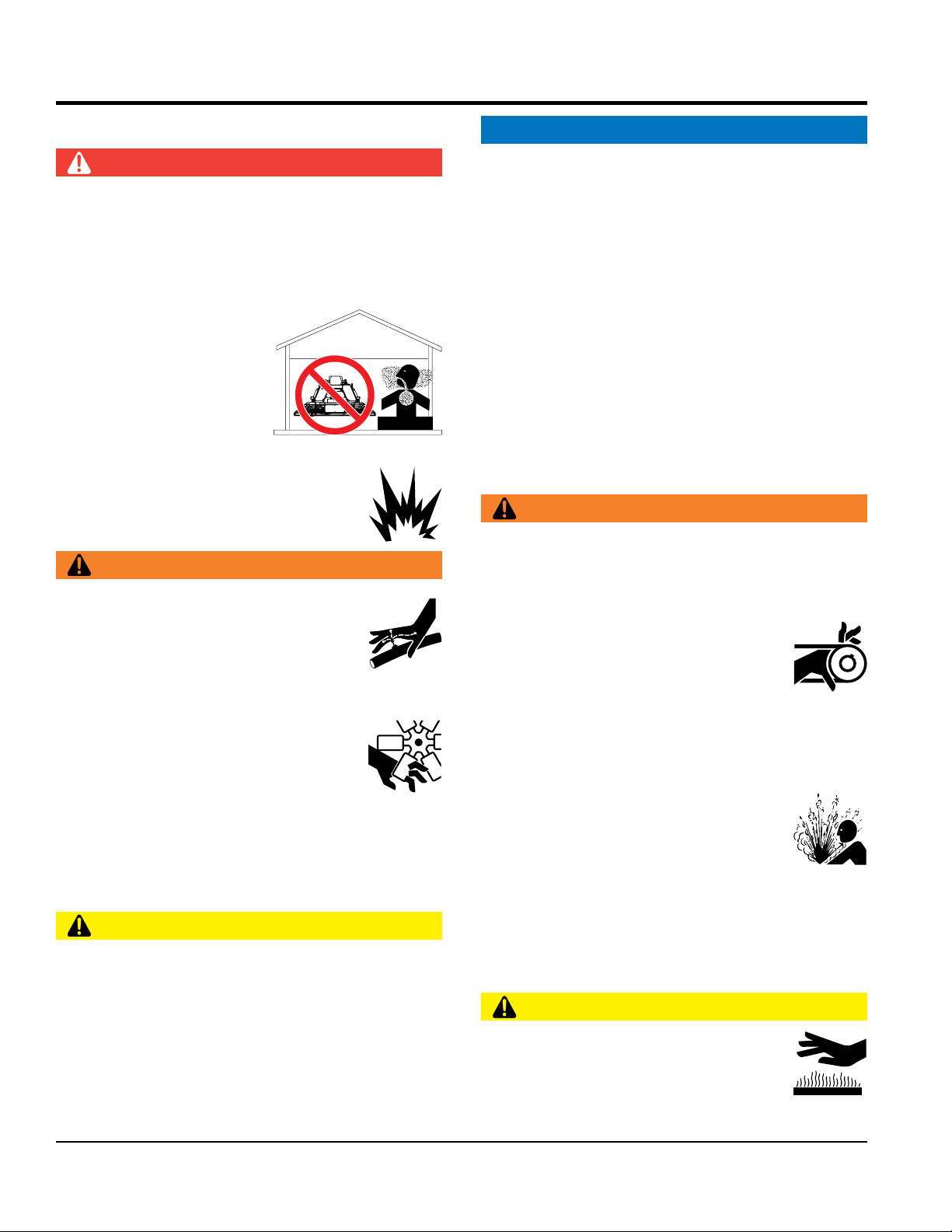

SPECIFICATIONS/DIMENSIONS

C

HEIGHT

1

LENGTH

A

Figure 1. HHN31VTCSL5 Dimensions

Table 1. HHN31VTCSL5 Dimensions/Specifications

Specification Parameter HNN31V (Vanguard)

A–Length – in. (cm) 97.0 (246.4)

B–Width – in. (cm) 50.0 (127)

C–Height – in. (cm)

1

46.0 (117)

Weight – lbs. (kgs.) Operating 1,042 (477)

Weight – lbs. (kgs.) Shipping 1,224 (555)

Engine – H.P. 31

Fuel Tank – gallons (liters) 5 (19)

Rotor – RPM 60 to 160

Path Width – in. (cm) 91 (231)

Lubrication Oil ISO 220 GR 5EP

Gear Box Oil Capacity 144 OZ.

Fuel Consumption (Full Load) 0.54 LB/BHP-HR

Radiator Capacity 1.0 GAL.

B

WIDTH

PAGE 14 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 15

Table 2. Noise and Vibration Emissions

SPECIFICATIONS

Guaranteed ISO 11201:2010 Based

Sound Pressure Level at Operator Station in dB(A)

Guaranteed ISO 3744:2010 Based

Sound Power Level in dB(A)

Whole Body Vibration Per ISO 2631-1:1997+A1:2010

2

in m/s

∑A(8)

97

117

0.19

NOTES:

1. Sound Pressure and Power Levels are “A” weighted Measures per ISO 226:2003 (ANSI S1.4-1981). They are measured with the operating

condition of the machine which generates the most repeatable but highest values of the sound levels. Under normal circumstances, the sound

level will vary depending on the condition of the material being worked upon.

2. The vibration level indicated is the vector sum of the RMS (Root Mean Square) Values of amplitudes on each axis, standardized to an 8 hour

exposure period, and obtained using operating condition of the machine that generates the most repeatable but highest values in accordance

with the applicable standards for the machine.

3. Per EU Directive 2002/44/EC, the daily exposure action value for whole body vibration is 0.5 m/s

1.15 m/s2 ∑A(8).

2

∑A(8). The daily exposure limit value is

Table 3. Engine Specifications

Model Briggs & Stratton Vanguard DM950G

Type Gasoline Engine

Cylinders 3

Piston Displacement 58.1 cu.in. (952 cc)

Bore and Stroke 2.83 in.x 3.07 in. (72 mm x 78 mm)

Max. Torque 51.7 ft lbs (70.1 N·m) @ 220rpm

Engine Oil Capacity 3.5 qt. (3 liters)

Fuel Tank 5 gal.(18.9 liters)

Dry Weight 159 lbs. (72.1 Kg)

Dimensions (L x W x H)

17.09 in. x 17.44 in. x 20.54 in.

(434 mm x 443 mm x 522 mm)

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 15

Page 16

GENERAL INFORMATION

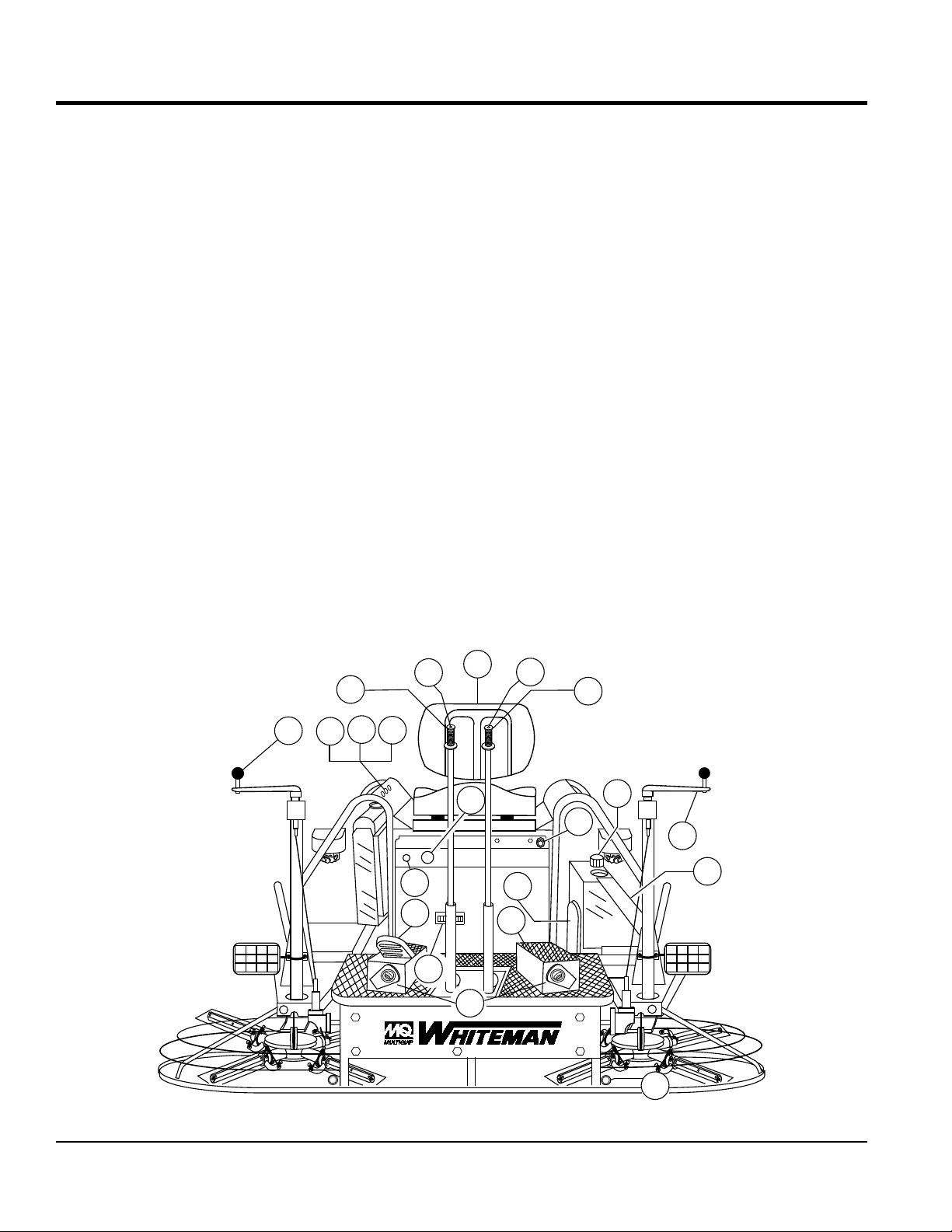

HHN RIDE-ON TROWEL FAMILIARIZATION

The HHN series Ride-On Power Trowel is designed for the

floating and finishing of concrete slabs.

Take a walk around the HHN Ride-On Power Trowel. Take

notice of all the major components (see Figure 2 and Figure

3) like the engine, blades, air cleaner, fuel system, fuel shutoff valve, ignition switch etc. Check that there is always oil

in the engine, and gear oil in the gear box assembly.

Read all the safety instructions carefully. Safety instructions

will be found throughout this manual and on the machine.

Keep all safety information in good, readable condition.

Operators should be well trained on the operation and

maintenance of the HHN Ride-On Power Trowels.

Look at the operator control levers. Grab the control levers

and move them around a bit. Look to see how moving the

control levers causes the gearboxes and frame to move.

Notice the foot pedal which controls the engine speed. Also

take a look at the main driveline of the trowel. Take note

and reference how the belts look, this is the way the belts

should look when adjusted properly.

Before using your HHN Ride-On Power Trowel, test it on

a flat watered down section of finished concrete. This trial

test run will increase your confidence in using the trowel

and at the same time it will familiarize you with the trowel’s

controls and indicators. In addition you will understand how

the trowel will handle under actual conditions.

ENGINE

The HHN Ride-On Power Trowel is equipped with a liquid

cooled 31 HP Vanguard gasoline engine. Refer to the

engine owner’s manual for specific instructions regarding

engine operation. This manual is included with the rideon trowel at the time of shipping from Whiteman. Please

contact your nearest Multiquip Dealer for a replacement

should the original manual disappear.

Figure 2 and Figure 3 show the location of the controls,

indicators and general mainte nance parts. Each control

may perform more than one function.

GEARBOXES

The HHN Ride on Power Trowel consist of two separate

gearbox assemblies that are enclosed in rugged cast

aluminum gear cases.

The gearbox casing holds 50% more oil capacity than

competitors, which allows more lubrication to be provided

to critical points.

STEERING ASSIST

Dual control levers located in front of the operator's seat

are provided for steering the HHN Ride on Power Trowel.

The control levers are linked to two spring loaded cylinders.

Push the left control lever forward and pull the right control

lever backward and the trowel will rotate clockwise on

approximately a center axis. Pull the left control lever

backward and push the right control lever forward and

the trowel will rotate counterclockwise. See Table 4 for

a complete description on the control levers directional

positioning.

CONSTANT VELOCITY JOINTS (CV-JOINTS)

Constant velocity joints insure the efficient transfer of power

to the drive shaft and maintain the timing of the gearboxes

without any chance of slippage.

TRAINING

For training, please use the “TRAINING CHECKLIST”

located in the front of this manual. This checklist is not

intended to be a substitu te for proper training but will

provide an outline for an experienced operator to provide

training to a new operator.

BLADES

The blades of the ride-on power trowel finish the concrete

as they are swirled around the surface. Blades are classified

as combination (10 or 8 inches wide) and finish (6 inches

wide). The HHN ride-on power trowels are equipped with

five blades per rotor equally spaced in a radial pattern and

attached to a vertical rotating shaft by means of a spider

assembly.

PAGE 16 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 17

NOTES

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 17

Page 18

COMPONENTS

1. Seat — Place for operator to sit. Engine will not start

unless operator is seated. Seat is adjustable, fore and

aft for operator comfort.

2. Steering Control Lever (right side) — Allows the unit

to move in either a forward, reverse left or right direction.

3. Retardant Spray Control Buttons — When pressed

allows retardant spray to flow through the spray nozzle

located at the front of the machine.

4. Twin Pitch Control — Adjusts the blade pitch for right

side of the trowel. Turn the crank as marked on its top

surface to increase or decrease blade pitch.

5. Twin Pitch Control — Adjusts the blade pitch for left

side of the trowel. Turn the crank as marked on its top

surface to increase or decrease blade pitch.

6. Steering Control Lever (left side) — Allows the unit to

move in either a forward, reverse left or right direction.

7. Light Switch — When activated, turns on four halogen

lights. Lights offer better visibility when working indoors.

8. Ignition Switch — With key inserted turn clockwise

to start engine.

9. Oil Indicator Light — Lights red when oil pressure is low.

10. Water Indicator Light — Lights red when water

temperature is high.

11. Charge Indicator — Lights red when electrical system

is not charging properly.

12. Hour Meter — Indicates number of hours the key

switch is in the "ON" position.

13. Choke Control Lever — In cold weather pull this lever

forward about half way to start engine. After engine

warms push knob all the way in.

14. Fuel Gauge/Filler Cap — Indicates the amount of fuel

in the fuel tank. Remove this cap to add fuel.

15. Fuel Tank — Holds 5 gallons of unleaded gasoline.

16. Spare Belt Carrier — Contains a spare belt. Belt is

used on the drive pulley.

17. Left Foot Riser — Operator foot rest pedal.

18. Spray Nozzles — Spray nozzle for retardant.

19. Right Foot Pedal — Controls blade speed. Slow blade

speed is accomplished by slightly depressing the foot

pedal. Maximum blade speed is accomplished by fully

depressing the foot pedal.

3

2

10

4

9

11

7

19

12

1

8

18

3

6

14

13

5

15

16

17

20

Figure 2. HHN Components (Front)

PAGE 18 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 19

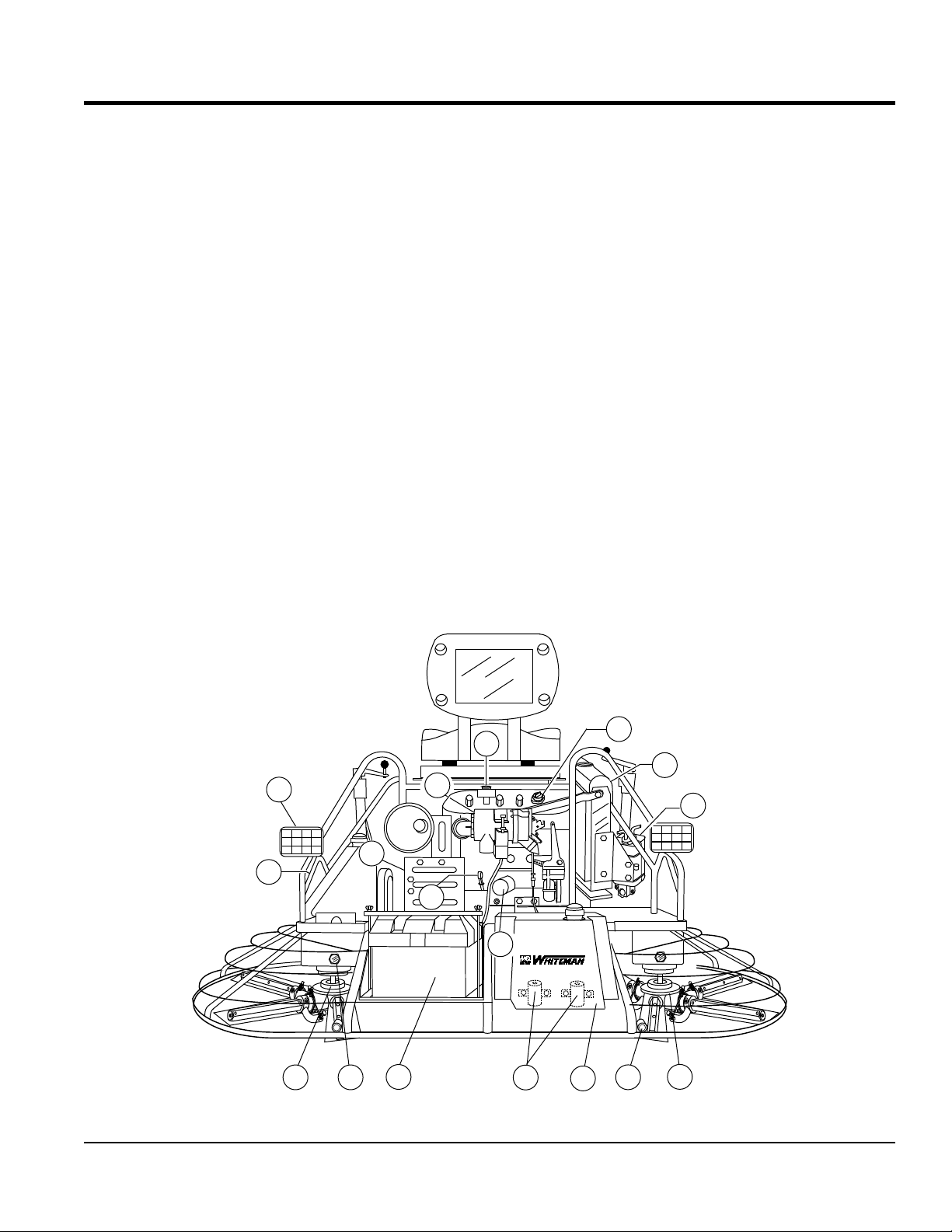

COMPONENTS

34

20. EZ- Mover Boss — Front -side insertion point for EZ

Mover. Used when the transporting of the trowel is

required.

21. Radiator/Filler Cap — Holds coolant or water

necess ary to keep engine at a safe operating

temperature. Remove this cap to add water or

antifreeze. DO NOT revove this cap when the engine

is warm.

22. Lift Loops — Located on both the left and right sides

of the main frame. Used when the trowel must be lifted

onto a concrete slab.

23. Lights — Four 12 volt halogen lights are provided

with this unit.

24. Right-Side Spider — Consists (basic) of trowel arms,

blades, wear plate, and thrust collar etc.

25. Left-Side Spider — Consists (basic) of trowel arms,

blades, wear plate, and thrust collar etc.

26. Safety Kill Switch — Shuts down engine when

operator is not sitting in seat.

27. Engine Oil Filler Cap — Remove this cap to add

engine oil.

28. Overflow Bottle — Supplies coolant to the radiator

when radiator coolant level is low. Fill to indicated level

as shown on bottle.

29. Engine Air Filter — Prevents dirt and other debris from

entering the fuel system. Lift locking latch on air filter

cannister to gain access to filter element.

30. Engine Dip Stick — Indicates engine oil level. Add

oil as required.

31. Oil Filter — Provides oil filtering for the engine.

32. Battery — Provides +12V DC power to the electrical

system

33. Retardant Spray Motors — Used in conjunction with

the left and right spray control buttons.

34. Retardant Spray Tank — Holds 5 gallons of retardant.

35. Belt Guard — Encloses drive belt used in conjunction

with clutch.

36. EZ- Mover Boss — Back- side insertion point for EZ

Mover. Used when the transporting of the trowel is

required.

37. Oil Sight Glass — Indicates the level of the hydraulic

oil in the gear box.

27

36

21

28

24

22

23

25

26

29

35

30

31

RETARDANT ONLY

37

32

Figure 3. HHN Components (Rear)

33

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 19

Page 20

NEW MACHINE SETUP

The purpose of this section is to assist the user in setting

up a NEW trowel. If the trowel is already assembled, (seats,

handles, knobs and battery), this section can be skipped.

NOTICE

A new ride-on trowel cannot be put into service until the

following installation instructions are completed. These

instructions only need to be performed at the time of

unpacking a NEW trowel.

Before packaging and shipping, this ride-on power trowel

was run and tested at the factory. If there are problems,

please let us know.

CONTROL HANDLE ASSEMBLY

The steering control handles are not attached to the trowel’s

two lower handles at the time of shipment. To attach the

steering control handles to the lower handle assemblies,

perform the following:

1. Remove the bolts from the plastic bag tied to the

control towers.

SEAT ASSEMBLY

The seat is not installed on the trowel for shipping purposes.

To attach the seat, perform the following:

NOTICE

H-series trowels have a seat that is mounted on tracks,

similar to an automobile seat. This seat can be adjusted

fore and aft via the control lever under the front of the seat.

1. Remove the seat from the protective wrapping.

2. Remove the bolts on the bottom of the seat, and place

seat on the seat mounting plate, then insert the bolts

through the holes or slots on the seat mounting plate

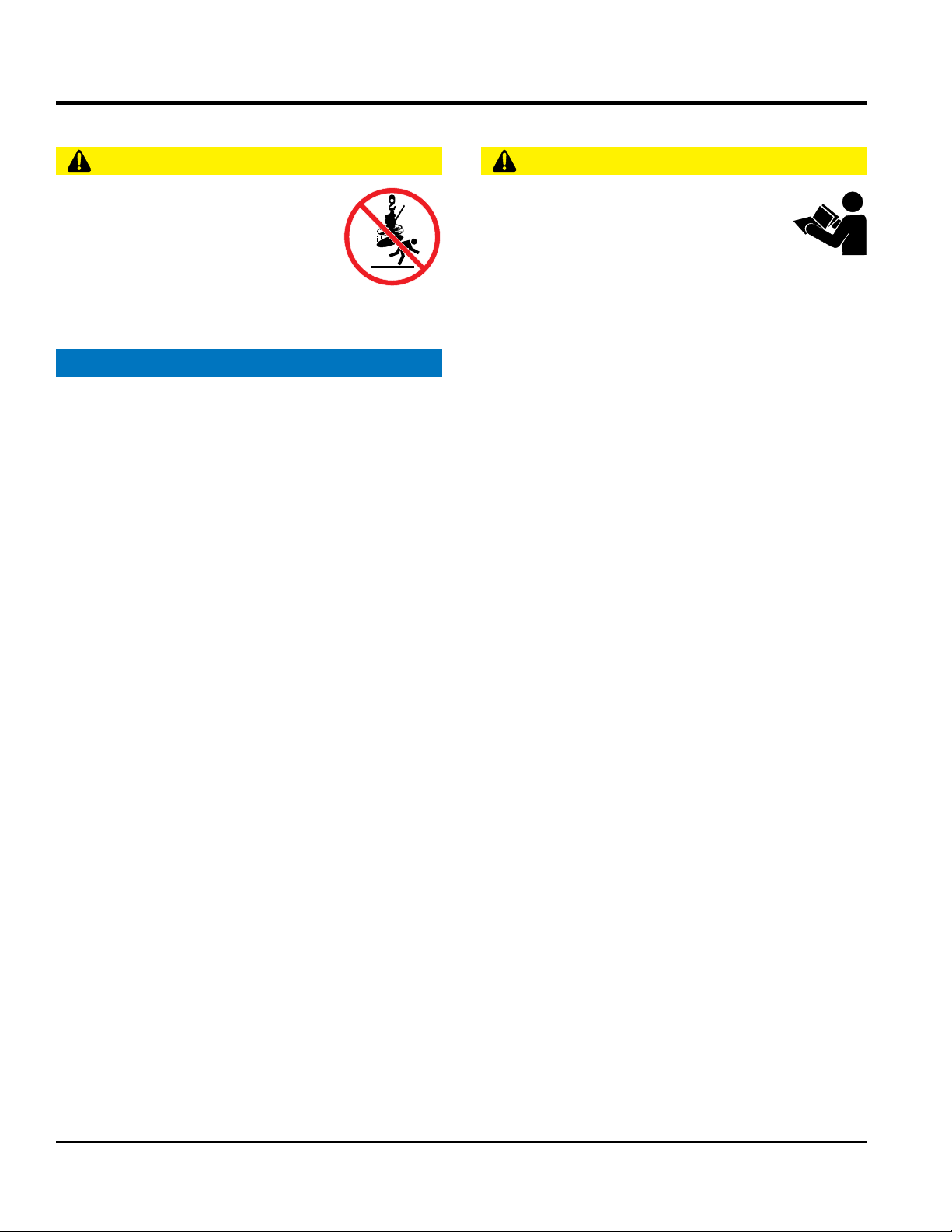

and tighten.

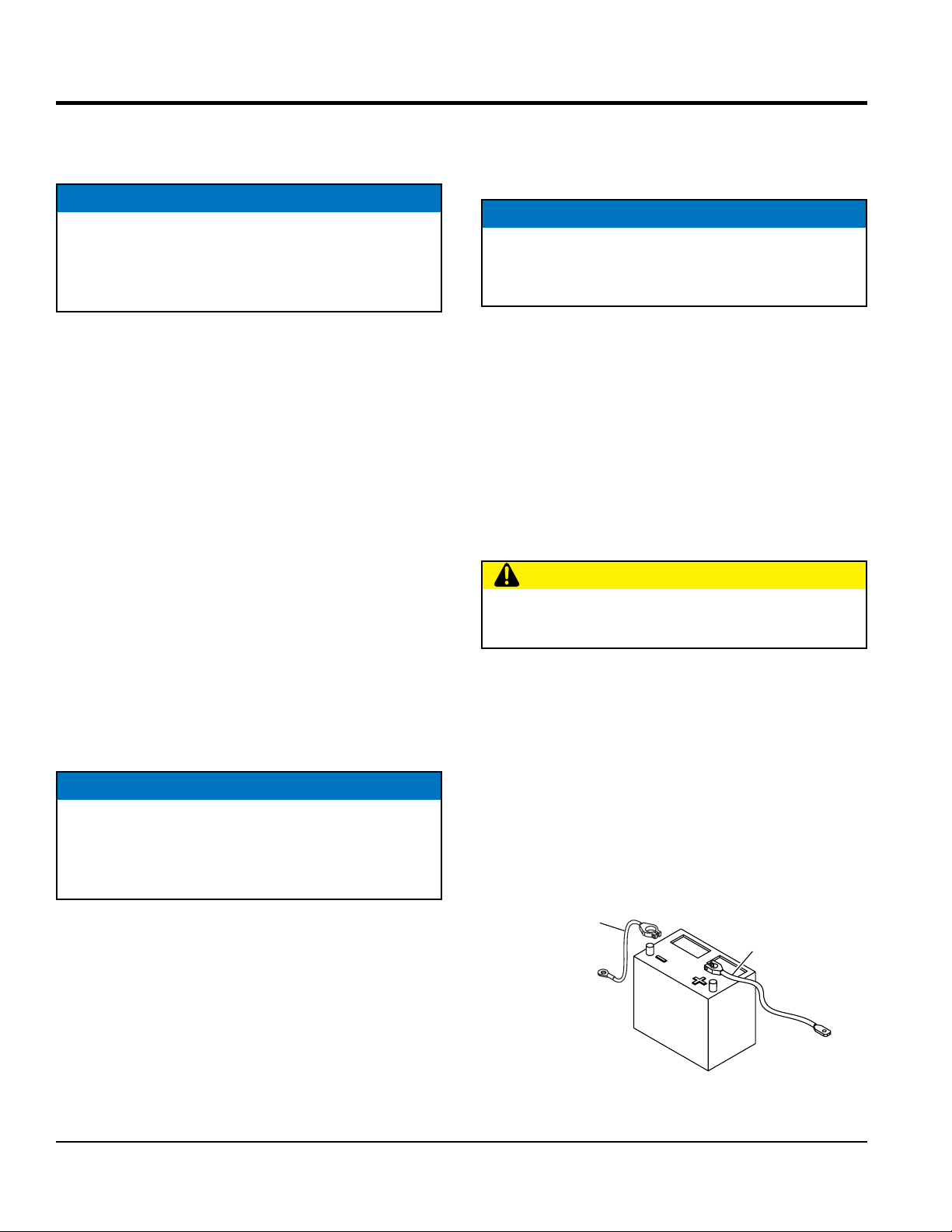

BATTERY SETUP

This trowel was shipped with a wet charged battery. This

battery may need to be charged for a brief period of time

as per the manufacturer instructions.

CAUTION

2. Remove all protective wrapping and straps from the

control handles.

3. Slip the top (loose) control handle piece into the base

of the corresponding handle, making sure to line up

the holes.

4. Install the bolt through the lined up holes and tighten

the acorn nut onto the threaded end.

NOTICE

Models equipped with adjustable height handles are

adjusted by placing the bolt through the set of holes

that bring the handles to a height most comfortable for

the operator.

5. Pay close attention to any wires that may be inside

the control handles. DO NOT pinch or cut any wires

during installation.

6. Remove the two knobs from the plastic bag for the

pitch control tower cranks and install the knobs onto

the tower crank levers.

Use all safety precautions specified by the battery

manufacturer when working with the battery.

To install the battery on the trowel, make sure that the

battery is well seated in the battery box. The positive cable,

normally red, is associated with the "+" symbol on the

battery. The negative cable, normally black, is associated

with the "-" symbol on the battery. See Figure 4. Connect

the positive cable to the positive terminal on the battery

first, then connect the negative cable to the negative

terminal. Close the plastic battery box cover and secure

the battery box.

NEGATIVE

CABLE

(BLACK)

POSITIVE

CABLE

(RED)

Figure 4. Battery Cable Orientation

PAGE 20 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 21

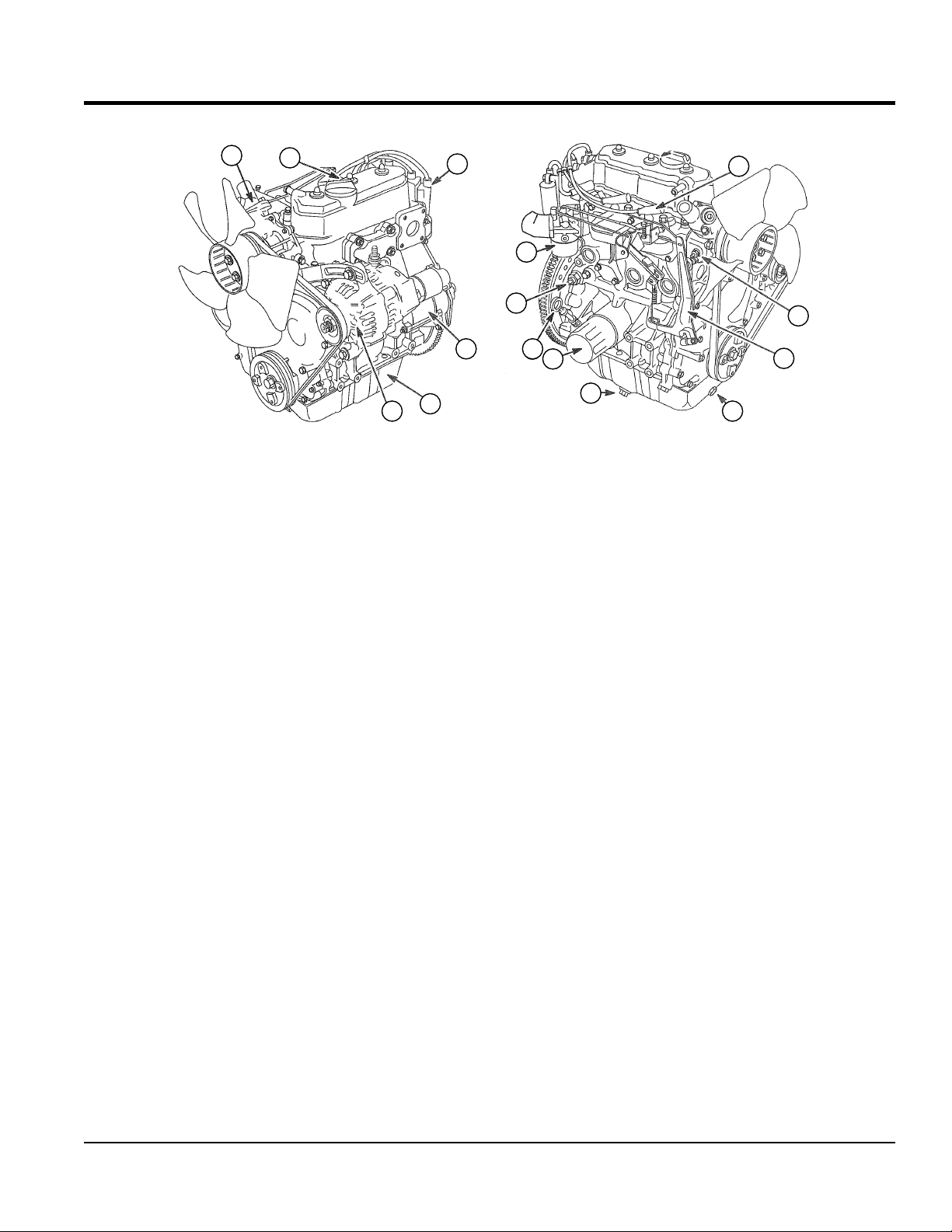

BASIC ENGINE

1

2

6

Figure 5. Engine Components

3

4

5

INITIAL SERVICING

The engine (Figure 5) must be checked for proper

lubrication and filled with fuel prior to operation. Refer to the

manufacturer’s engine manual for instructions and details

of operation and servicing. The engine shown above is a

Briggs & Stratton Vanguard Gasoline engine. Operation for

other types of engines may vary somewhat.

1. Thermostat — Regulates the temperature of the

engine coolant.

7

14

13

12

11

10

10

8

9

8. Coolant Temperature Sending Unit — Device that

measures coolant temperature.

9. Governor Lever — This lever restricts engine speed

(high idle or low idle) through a speed control device

linked to the accelerator system.

10. Oil Drain Plugs (2) — Remove to drain crankcase

oil. Always dispose of used oil and oil filters in an

environmentally safe manner. DO NOT allow used oil

to drain onto the ground or into a water runoff drain.

2. Oil Filler Cap — Remove to add engine oil.

3. Ignition Coil — Regulates coolant temperature

11. Oil Filter — Spin-on type, filters oil for contaminants.

12. Oil Dip Stick — Remove to check amount and

condition of oil in crankcase.

4. Electric Starter — Starts engine when ignition key is

rotated to the "ON" position.

13. Oil Pressure Sending Unit — Device that measures

engine oil pressure.

5. Oil Pan — Holds a maximum of 3.5 quarts (3.3 liters)

of motor oil.

14. Carburetor — Low-emission carburetor equipped

with an idle mixture valve with a limiter which allows

6. Alternator — Provides charge for battery and voltage

adjustment.

for the +12 VDC electrical system.

7. Spark Plug — Provides spark to the ignition system.

Set spark plug gap to 0.028 ~ 0.031 inch (0.6~0.7 mm).

Clean spark plug once a week.

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 21

Page 22

This section is intended to assist the operator with the initial

OPERATING

(OIL CHECK)

FILL PLUG

inspection of the HHN trowel. It is extremely important that

this section be read carefully before attempting to use the

trowel in the field.

DO NOT use your trowel until this section is thoroughly

understood.

CAUTION

Failure to understand the operation of the HHN trowel

could result in severe damage to the trowel or personal

injury.

See Figure 2 and Figure 3 for the location of any control

or indicator referenced in this manual.

ENGINE OIL LEVEL

INSPECTION

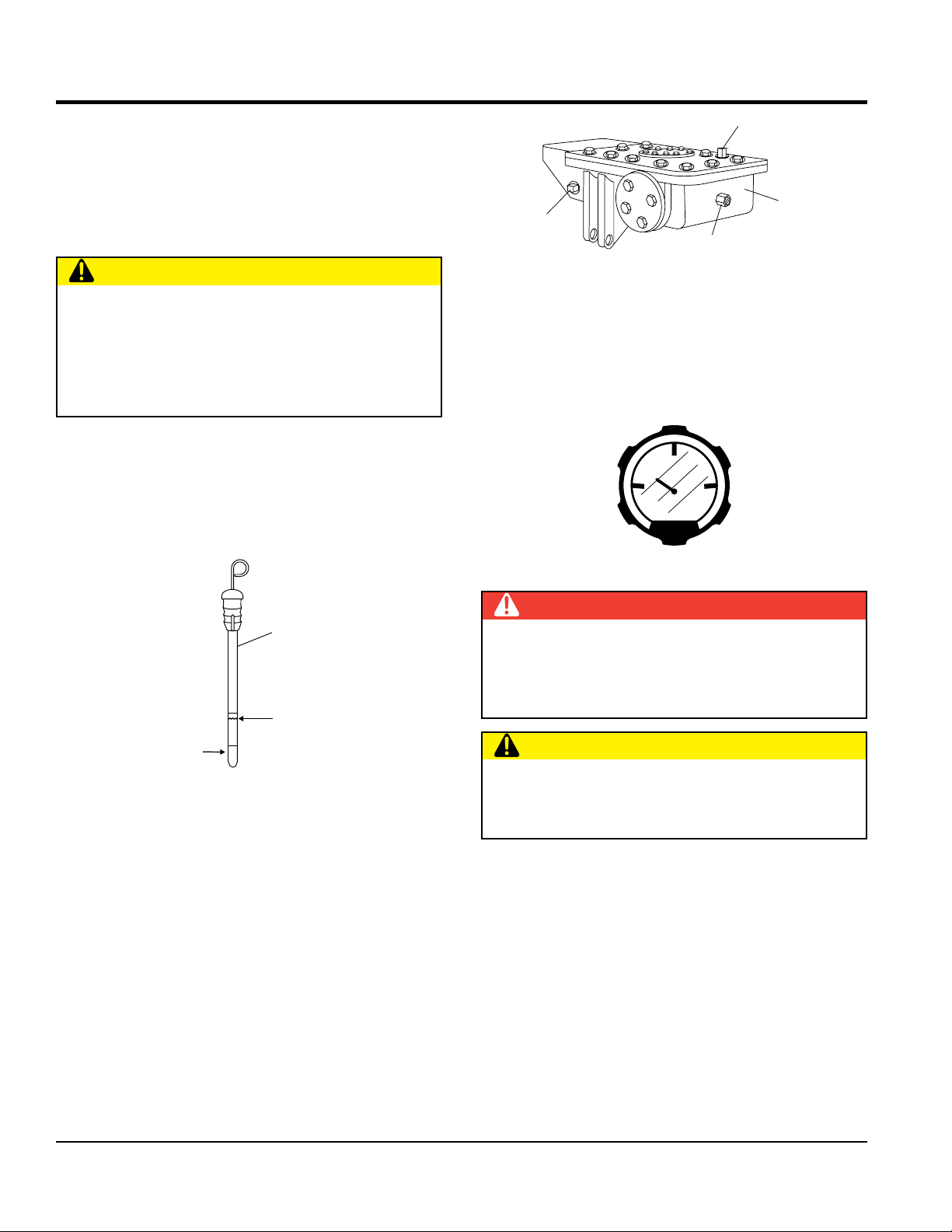

GEAR BOX

DRAIN PLUG

SIGHT GLASS

Figure 7. Gearbox Oil Plugs/Sight Glass

FUEL

Determine if the engine fuel is low (Figure 8). If fuel level

is low, remove the fuel filler cap and fill with appropriate

engine fuel. The HHN31V uses diesel fuel.

1. Pull the engine oil dipstick from its holder.

2. Determine if engine oil is low (Figure 6), add correct

amount of engine oil to bring oil level to a normal safe

level. (See Table 5).

ENGINE OIL

DIPSTICK

SAFE

OIL LEVEL

ADD

ENGINE

OIL

MAX

MIN

Figure 6. Engine Oil Dipstick

GEARBOX OIL LEVEL

1. Check the gearbox oil level in both gearboxes by

viewing the sight glass at the rear of the gearbox. See

Figure 7.

FUEL

E F

Figure 8. Fuel Gauge

DANGER

Handle fuel safely. Motor fuels are highly flammable

and can be dangerous if mishandled. DO NOT smoke

while refueling. DO NOT attempt to refuel the ride-on

trowel if the engine is hot or running.

CAUTION

Never store the ride-on trowel with fuel in the tank for

any extended period of time. Always clean up spilled

fuel immediately.

2. The oil level of the gear box should be at the half-way

point of the sight glass (Figure 7). The gear box oil

capacity is 1 U.S. Gallon, (3.79 liters). If additional oil is

required, unscrew the oil fill plug located on top of the

gearbox, and refill with ISO 220 A GMA GR 5 EP oil.

PAGE 22 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 23

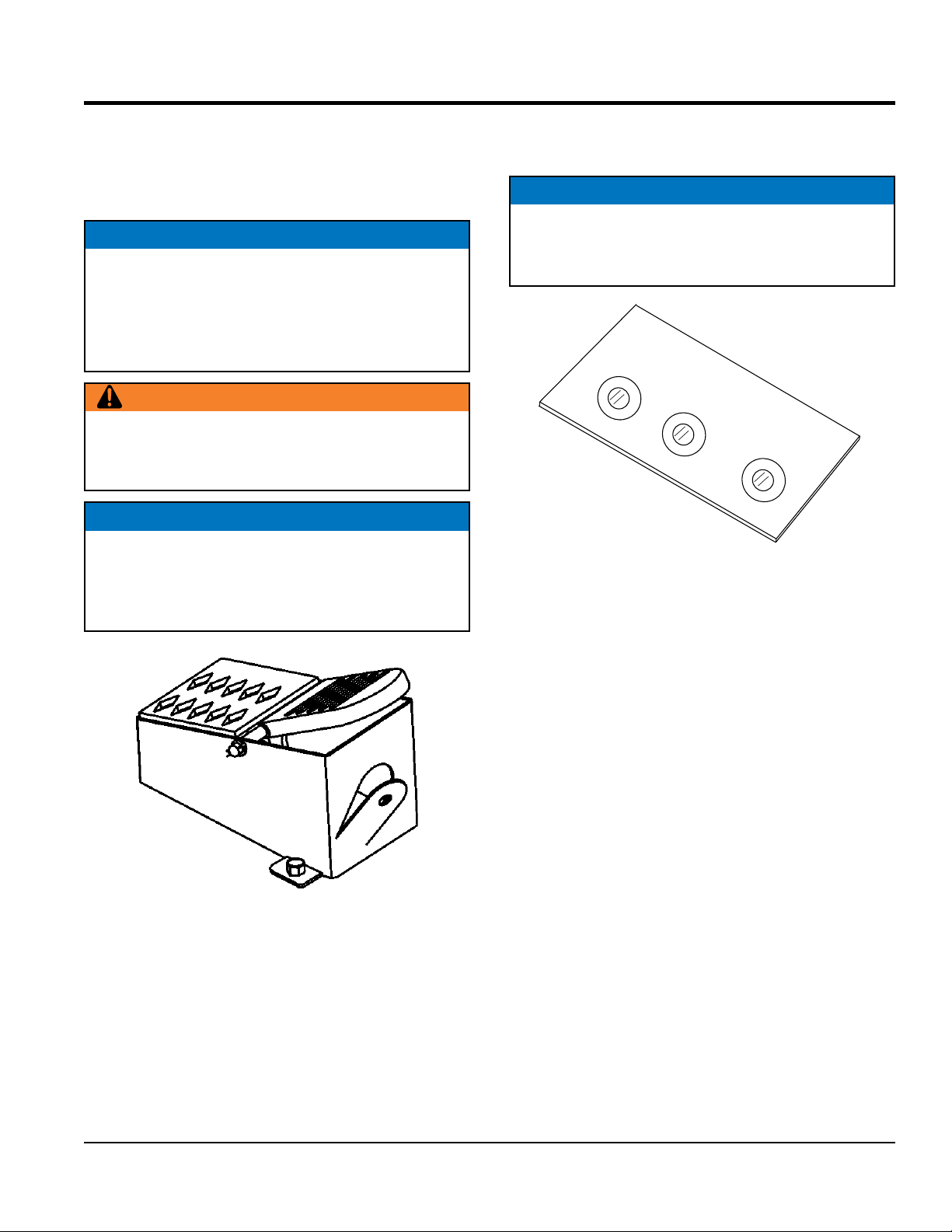

OPERATION

STARTING THE ENGINE

1. Place one foot on the trowel’s platform, grab ahold of

any part of the frame, lift yourself onto the trowel, then

sit down in the operator’s seat.

NOTICE

The HHN31V trowel is equipped with a safety stop

switch that will not allow the engine to start unless an

operator is sitting in the operator’s seat. The weight

of an operator depresses an electrical switch, which

allows the engine to start.

WARNING

NEVER disable or disconnect the safety stop switch. It is

provided for the operator’s safety, and injury may result

if it is disabled, disconnected or improperly maintained.

NOTICE

Using the safey stop switch to stop the engine after

every use will verify that the switch is working properly.

Remember to turn the key to the “OFF” position after

stopping the machine. Not doing so may drain the battery.

5. Turn the ignition key clockwise to the (start) position.

The oil, charge, and preheat indicator lights (Figure

10) should be ON.

NOTICE

OIL, CHARGE, and PREHEAT indicator lights come on

when ignition switch is in the ON position, and the engine

is NOT running.

OIL

W

A

T

E

R

CH

A

RG

E

Figure 10. Oil and Charge Indicator Lights

6. Turn ignition key fully clockwise and listen for engine

to start. Once engine has started release ignition key.

Figure 9. Blade Speed Control Foot Pedal

2. The right foot pedal (Figure 9) controls blade and

engine speed. The position of the foot pedal determines

the blade speed. Slow blade speed is obtained by

slightly depressing the pedal. Maximum blade speed

is obtained by fully depressing the pedal.

3. Keep your foot OFF the pedal (right foot pedal). Start

the engine at idle (without touching the foot pedal).

7. If the engine fails to start in this manner, consult the

engine owner’s manual supplied with the trowel.

8. Test the safety stop switch by standing up briefly. The

switch under the seat should cause the engine to stop.

If the switch fails to shut down the engine, turn off the

engine with the key switch and fix the safety stop switch.

See Troubleshooting tables for possible problems.

Repeat this section a few times to get fully acquainted with

the engine starting procedure.

4. Insert the ignition key into the ignition switch.

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 23

Page 24

OPERATION

STEERING

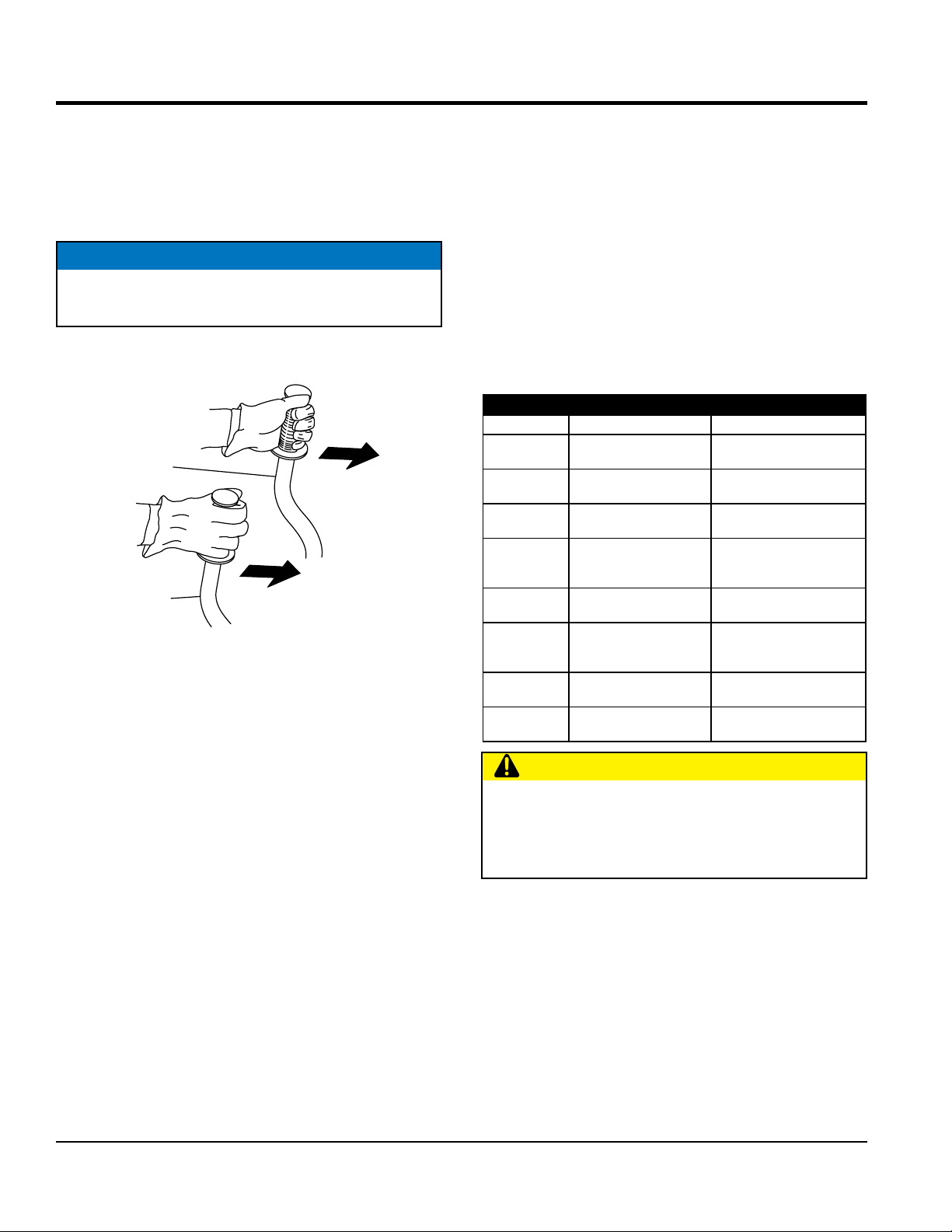

Two control levers located in front of the operator’s seat

provide directional control for the HHN trowel. Table 4

illustrates the various directional positions of the joysticks

and their effect on the ride-on trowel.

NOTICE

All directional references with respect to the steering

control levers are from the operator’s seat position.

1. Push both the left and right control levers forward. See

Figure 11.

LEFT

CONTROL

LEVER

RIGHT

CONTROL

LEVER

Figure 11. Left and Right Control Levers

2. With your right foot, quickly depress the right foot

pedal halfway. Notice that the ride-on power trowel

begins to move in a forward direction. Return both

joystick controls to their neutral position to stop forward

movement, then remove your right foot from the right

foot pedal.

3. Practice holding the machine in one place as you

increase blade speed. When about 75% of maximum

blade speed has been reached, the blade will be

moving at proper finishing speed. The machine may be

difficult to keep in one place. Trying to keep the ride-on

trowel stationary is a good practice for operation.

FORWARD

DIRECTION

4. Practice maneuvering the ride-on trowel using the

information listed in Table 4. Try to practice controlled

motions as if you were finishing a slab of concrete.

Practice edging and covering a large area.

5. Try adjusting the pitch of the blades. This can be done

with the ride-on trowel stopped or while the trowel is

moving, whatever feels comfortable. Test the operation

of optional equipment like retardant spray and lights

if equipped.

6. Push both the left and right joysticks backward and

repeat steps 3 through 6 while substituting the word

reverse for forward.

Table 4. Control Lever Directional Positioning

Control Lever Direction Results

Left

Left

Right

Right

Left and Right

Left and Right

Left and Right

Left and Right

Move Control Lever

Forward

Move Control Lever

Backward

Move Control Lever

Forward

Move Control Lever

Backward

Move Both Control Levers

Forward

Move Both Control Levers

Backward

Move Both Control Levers

to the Right

Move Both Control Levers

to the Left

Causes the ride-on trowel to

move forward and to the right.

Causes the ride-on trowel to

move backward and to the left.

Causes the ride-on trowel to

move forward and to the left.

Causes the ride-on trowel to

move backward and to the

right.

Causes the ride-on trowel to

move forward in a straight line.

Causes the ride-on trowel to

move backward in a straight

line.

Causes the ride-on trowel to

move to the right.

Causes the ride-on trowel to

move to the left

CAUTION

Trowel arms can be damaged by rough handling or by

striking exposed plumbing or forms while in operation.

ALWAYS look-out for objects which might cause

damage to the trowel arms.

PAGE 24 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 25

MAINTENANCE

When performing maintenance on the trowel or engine,

follow all safety messages and rules for safe operation

stated at the beginning of this manual.

See the engine manual supplied with your machine for

appr o priat e engin e maint enanc e sched u le and

troubleshooting guide for problems.

WARNING

Accidental starts can cause severe injury

or death.

ALWAYS place the ON/OFF switch in the

OFF position before performing maintenance.

Disconnect negative battery cable from

battery before servicing.

ALWAYS allow the engine to cool before

servicing. NEVER attempt any maintenance

work on a hot (muffler, radiator, etc.) trowel.

MAINTENANCE SCHEDULE

3. Replace gearbox lubricant.

4. Check and adjust blade speed.

WARNING

Cer ta in ma inte nance ope rati ons or ma c hine

adjustments require specialized knowledge and skill.

Attempting to perform maintenance operations or

adjustments without the proper knowledge, skills or

training could result in equipment damage or injury to

personnel. If in doubt, consult your dealer.

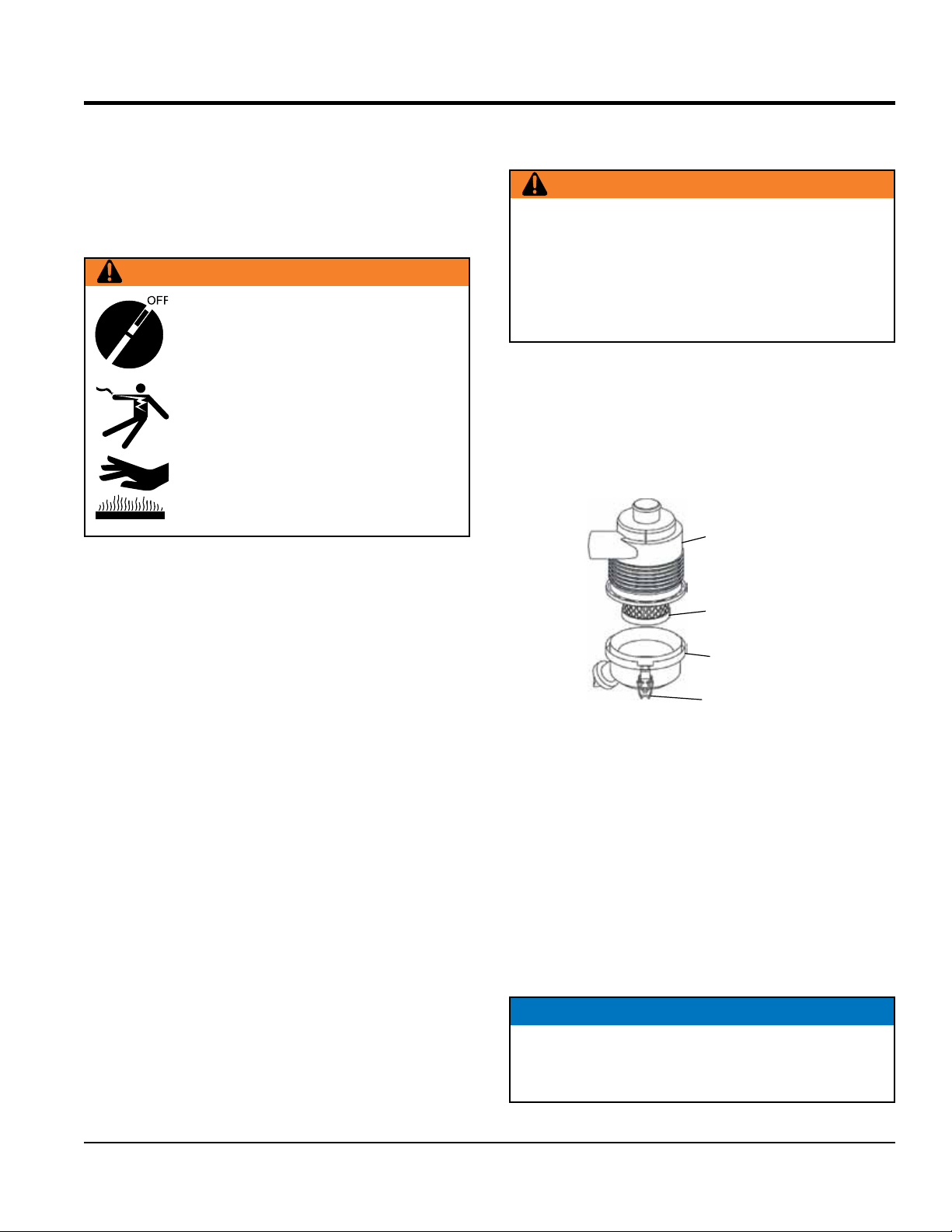

AIR CLEANER (DAILY)

The Vanguard engine is equipped with a replaceable, highdensity paper air cleaner element. Check the air cleaner

daily or before starting the engine. Check for and correct

heavy buildup of dirt and debris along with loose or

damaged components (Figure 12).

AIR CLEANER

BODY

Daily (8-10 Hours)

1. Check the fluid levels in the engine and gearboxes, fill

as necessary.

2. Check V-belt.

Weekly (30-40 Hours)

1. Relube arms, thrust collar and steering links.

2. Replace blades if necessary.

3. Check the engine air filter and change as necessary.

4. Replace engine oil and filter as necessary, see engine

manual.

Monthly (100-150 Hours)

1. Remove, clean, reinstall and relube the arms and thrust

collar. Adjust the blade arms.

2. Replace gearbox lubricant after the first 100 hours of

operation. Replace every 500-600 hours.

3. Check drive belt for excessive wear.

Yearly (500-600 Hours)

1. Check the arm bushings, thrust collar bushings, shaft

seals and belts. Replace if necessary

2. Check pitch control cables for wear.

CARTRIDGE

COVER

LATCHES

(COVER CLAMPS)

Figure 12. Air Cleaner Components

1. Unlock the cover clamps and remove cover.

2. Remove cartridge from air cleaner body.

3. Clean cartridge by gently tapping the end with the

handle of a screwdriver. Replace cartridge if very dirty

or damaged.

4. Carefully clean out the air cleaner cover.

5. Install cartridge in body.

6. Install cover and lock cover clamps.

NOTICE

Operating the engine with loose or damaged air cleaner

components could allow unfiltered air into the engine

causing premature wear and failure.

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 25

Page 26

MAINTENANCE

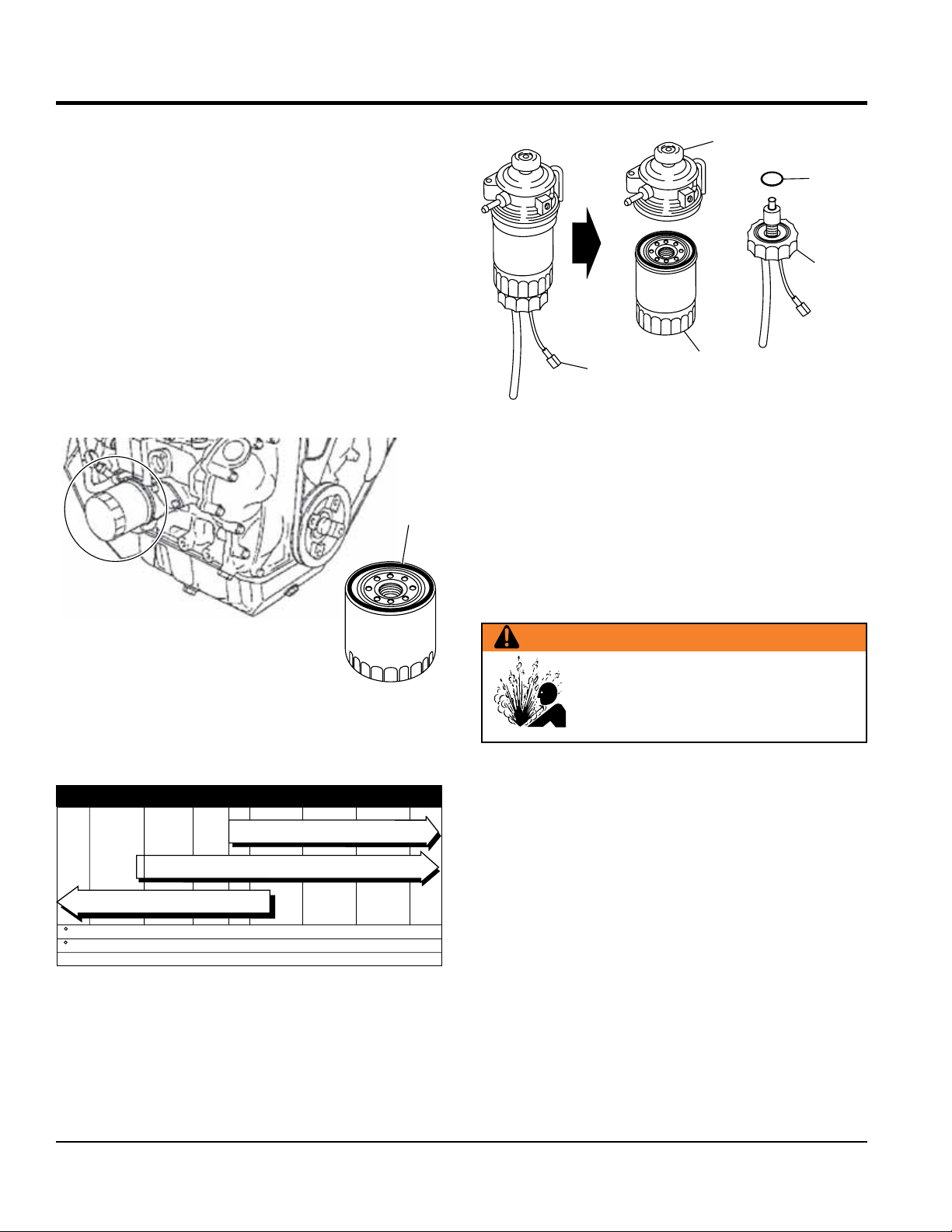

PRIMING

ENGINE OIL AND FILTER

1. Change the engine oil and filter after the first 5 hours

of use, then change oil every 6 months or 150 hours.

2. Remove the oil filler cap (Figure 5), and fill engine

crankcase with recommended type oil as listed in Table

5. Fill to the upper limit of dipstick.

3. Crankcase oil capacity with oil filter replacement is

6.72 qts. (7.4 liters).

Oil Filter (300 Hours)

1. Replace the engine oil filter (Figure 13) every other oil

change or 300 hours. Refer to your engine manual for

specific details to perform this operation.

SEAL

PUMP

O-RING

DRAIN

PLUG

SENSOR

WIRE

FUEL

FILTER

Figure 14. Fuel Filter

OIL AND FUEL LINES

Check the oil and fuel lines and connections regularly

for leaks or damage. Repair or replace as necessary.

Replace the oil and fuel lines every two years to maintain

the line's performance and flexibility.

Figure 13. Oil Filter

2. Be sure to coat the seal of the new oil filter with clean

engine oil.

Table 5. Recommended Viscosity Grades

30

10W-30, 10W-40, 10W-50

5W-30

-20

F

C

-30

TEMPERATURE RANGE EXPECTED BEFORE NEXT OIL CHANGE

0

-20

32 40 60 80 100

-10

20

10

0

20 30 40

FUEL FILTER

Replace the engine fuel filter (Figure 14) every 800 hours.

Refer to your engine manual for specific details to perform

this operation.

RADIATOR/COOLING SYSTEM

WARNING

Hot coolant can cause severe burns.

DO NOT remove cap if radiator is HOT.

1. Check and clean radiator fins.

2. Check cooling water.

3. Check radiator hoses for fatigue or cracking.

4. Check radiator cap seal.

Refer to your engine manual for additional information.

PAGE 26 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 27

BATTERY/CHARGING SYSTEM

DANGER

Flammable, explosive gas. (produces

hydrogen gas while charging or during

operation). Keep area around battery well

ventilated and keep from any fire source.

Battery electrolyte contains corrosive, toxic

chemical. (dilute sulfuric acid). Avoid

contact with eyes and skin.

Sh ock or fi re due to el ectric short circuit. Disconnect battery cables before

inspecting electrical system and never

“spark” battery terminals to test for charge.

1. Check and clean battery terminals for corrosion.

2. Check and keep battery electrolyte between upper and

lower limits indicated on the battery. Never operate or

recharge without sufficient fluid in the battery.

MAINTENANCE

3. Never attempt to charge a battery that is frozen. The

battery can explode unless first allowed to thaw.

4. Disconnect the negative terminal ( - ) of the battery

during storage. If unit will be stored where ambient

temperature will drop to -15° C or less, remove and

store battery in a warm, dry place.

LONG TERM STORAGE

Remove the battery.

Drain fuel from fuel tank.

Clean exterior with a cloth soaked in clean oil.

Store unit covered with plastic sheet in moisture and

dust-free location out of direct sunlight.

CAUTION

Never store the ride-on trowel with fuel in the tank for

any extended period of time. Always clean up spilled

fuel immediately.

ENGINE TUNE-UP

See the engine manual supplied with your machine for

specific information on tuning up your engine as well as

appropriate maintenance schedule and troubleshooting

guide for problems.

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 27

Page 28

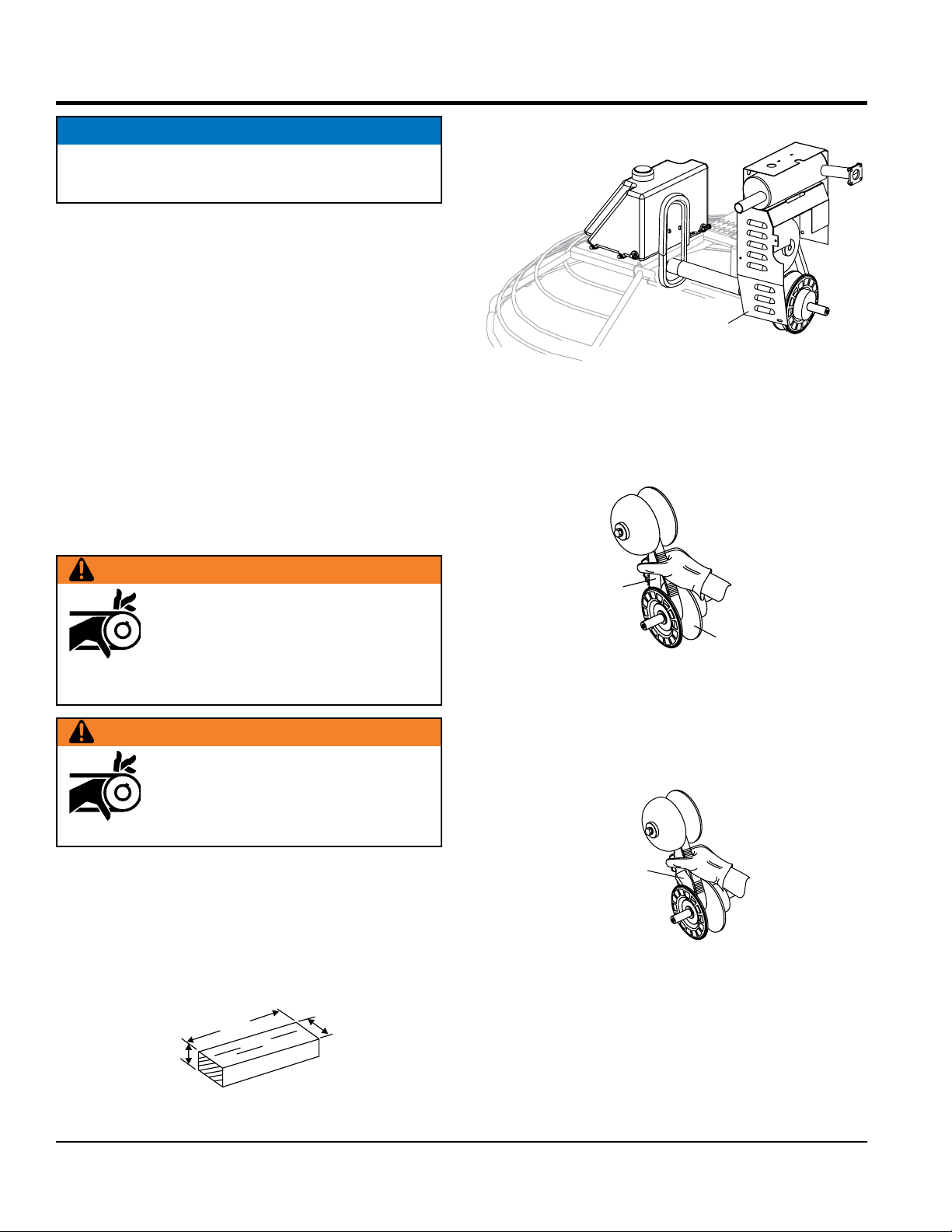

MAINTENANCE (OLD STYLE CLUTCH)

WIDTH

NOTICE

This section is intended to aid users in the maintenance

of drive assemblies with an old style Comet clutch.

CHECKING THE DRIVE BELT

The drive belt needs to be changed as soon as it begins

to show signs of wear. DO NOT reuse a belt under any

circumstances. Indications of excessive belt wear are

fraying, squealing when in use, belts that emit smoke or a

burning rubber smell when in use.

Under normal operating conditions, a drive belt may last

approximately 150 hours. If your trowel is not reaching this

kind of life span for drive belt wear, check the drive belt for

proper pulley alignment and spacing .

To gain access to the drive belt, remove the drive belt guard

cover, then visually inspect the drive belt for signs of

damage or excessive wear. If the drive belt is worn or

damaged, replace the drive belt.

WARNING

DO NOT attempt to insert hands or tools into

the belt area while the engine is running and

the safety guard has been removed. Keep

fingers, hands, hair and clothing away from

all moving parts to prevent bodily injury.

WARNING

DO NOT remove the V-belt guard cover

until the muffler has cooled. Allow the entire

trowel to cool down before performing this

procedure.

REMOVING THE DRIVE BELT

1. Remove Drive Belt Guard Cover. See Figure 16.

DRIVE

BELT

COVER

Figure 16. Drive Belt Cover

2. Squeeze the drive belt as shown in Figure 17, and pull

the belt upwards. This will spread open the faces of the

lower drive pulley.

DRIVE

BELT

LOWER

PULLEY

Figure 17. Expanding Lower Drive Pulley

3. Insert the wooden block (Figure 17) between the moveable

face and the fixed face of the lower drive pulley. See Figure

20. This block will help keep the lower drive pulley faces

open while installing the new drive belt.

WOOD

BLOCK

Leave the existing drive belt intact until instructed to cut it.

Leave the engine in place for this procedure. It is not

necessary to slide the engine to replace the drive belt.

Have a 3/4 x 1 x 3-1/4 inch wooden block available.

LENGTH

HEIGHT

.75 IN.

Figure 15. Wooden Block for Spacer

PAGE 28 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

3.25 IN.

1.00 IN.

4. If the belt is not being reused (recommended), CUT

the drive belt. Ensure all belt remnants are removed

from the pulleys.

Figure 18. Wood Block

Page 29

MAINTENANCE (OLD STYLE CLUTCH)

SPARE BELT

INSTALLING DRIVE BELT

(USING REPLACEMENT DRIVE BELT)

The HHN31V Ride-On Power Trowel is equipped with a

replacement drive belt (spare) carrier, which is mounted

on the inboard side of the fuel tank near the clutch. Make

sure that there is ALWAYS a spare drive belt in the drive

belt carrier before the trowel is placed on a slab to finish

concrete.

In the event of a drive belt failure, the spare (replacement)

drive belt can be used for quick replacement at the job site

to continue trowel operation.

1. If necessary, refer to the “Removing the Drive Belt”

section. Ensure all remnants of old belt have been

removed from pulleys.

2. To replace the drive belt with the spare drive belt,

remove the 2 bolts that secure the drive belt carrier.

(Figure 19) This will allow free movement of the belt

for installation. Take care with to not contaminate the

relplacement belt with grease or dirt.

3. With the wood block holding the lower pulley open,

place the replacement belt into the lower pulley first.

Work the belt over the upper drive pulley into the pulley

groove.

4. Squeeze the belt enough to remove the wood block.

With the block removed, release the tension on the belt.

5. Reinstall the spare belt carrier and the drive belt guard.

6. Replace the spare belt before the next trowel use. See

“Spare Drive Belt Replacement” procedure.

HOLDER

CV-JOINT

DRIVE

BELT

Figure 19. Installing Drive Belt

LOWER

PULLEY

WOOD

BLOCK

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 29

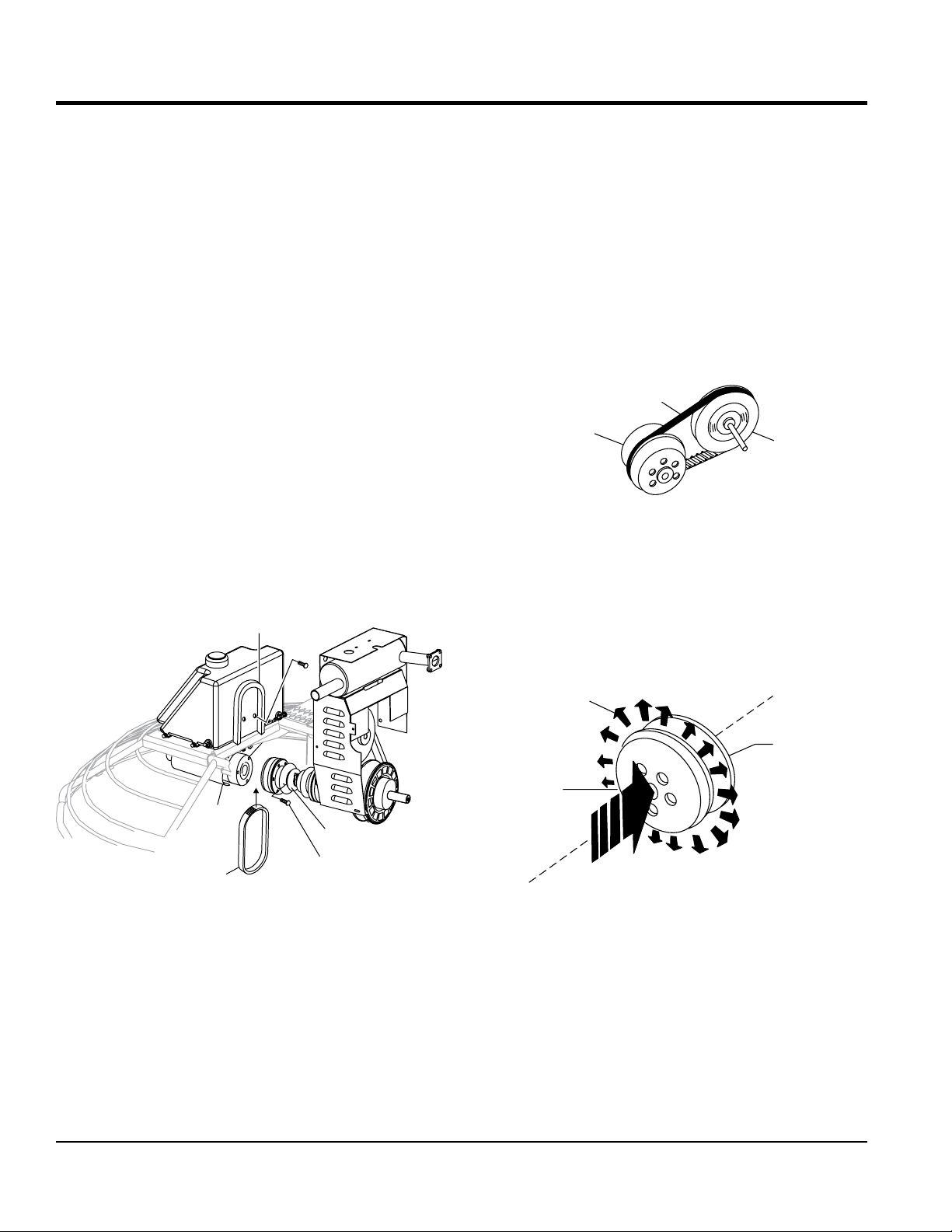

Page 30

SPARE BELT

MAINTENANCE (OLD STYLE CLUTCH)

DRIVE

CENTRIFUGAL

SPARE DRIVE BELT REPLACEMENT

To replace a spare drive belt, be prepared to disconnect the

CV-joint from the left-side gearbox. See Figure 20.

1. Place the trowel on suitable supports and observe all

safety precautions.

2. Remove the three screws that secure the CV-joint to

the left-side gearbox coupler.

3. Once the CV-joint has been separated from the leftside gearbox, push the CV-joint inward so that a gap

exists between the gearbox and the CV-joint. Slide

the spare V-belt between the gearbox coupler and the

CV-joint. Avoid contaminating the replacement belt with

grease or oil when sliding it between the CV-Joint and

gearbox coupler.

4. Place the spare drive belt inside the drive belt carrier,

and secure the spare belt carrier to the inboard side

of the left gearbox.

5. Install the three screws that secure the CV-joint to the

left-side gearbox coupler.

TORQUE CONVERTER

The HHN31V trowel is equipped with a Torque Converter

which supplies torque to both the left and right gear boxes.

The function of the a torque converter is to automatically

deliver the correct amount of torque required by the trowel

under all load conditions. This enables the trowel to deliver

the necessary torque for float pan applications and the high

rotor speeds required for burnishing concrete.

The torque converter is of the variable pitch pulley type,

(Figure 21) connected by a drive belt.

BELT

TORQUE

CONVERTER

VARIABLE

PITCH

PULLEY

Figure 21. Torque Converter/Variable Pitch

Pulley

DRIVE PULLEY

HOLDER

LEFT

SIDE

GEARBOX

NEW

SPARE

BELT

CV-JOINT

BOLT

(REMOVE

3 PLACES)

Figure 20. Replace Spare Belt

The drive pulley uses centrifugal force (Figure 22 and

Figure 23) to create a belt squeeze force transmitted at the

pulley faces. This condition functions as an automatic clutch.

FORCE

FIXED FACE

VARIABLE

FORCE

BELT

SQUEEZE

FORCE

Figure 22. Torque Converter (Centrifugal Force)

PAGE 30 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 31

MAINTENANCE (OLD STYLE CLUTCH)

DRIVE

As shown in Figure 22, centrifugal force pushes the

roller arms (Figure 23) against the ramp plate, forcing the

moveable face toward the fixed face and squeezing the belt

.

DISTANCE

MOVEABLE

FACE

TRAVELS

MOVEABLE

FACE

CENTRIFUGAL

FORCE

DRIVE PULLEY

LOW ENGINE RPM

DRIVE PULLEY

HIGH ENGINE RPM

LOW OUTPUT SPEED

HIGH OUTPUT SPEED

Figure 23. Pulley Interaction

MOVEABLE

DRIVEN

PULLEY

DRIVEN

PULLEY

FACE

The “Variable Pitch Pulleys” have one fixed face, and one

moveable face. The drive pulley (Figure 24) moveable face

is controlled by roller weight arms and springs, which

change position according to engine speed. The driven

pulley moveable face is controlled by a spring and belt

tension.

HOW IT WORKS

Refer to Figure 25.

A B C

NEUTRAL LOW

SPEED

Figure 25. Pulley Conditions

Condition A:

Engine Idling

Drive Pulley: Small

Belt: Loose and Stationary

Condition B:

Engine Accelerating

Drive Pulley: Small But Increasing

DRIVE PULLEY

DRIVEN PULLEY

HIGH

SPEED

BUSHING

SPRING

ROLLER

PULLEY

ARM

WEIGHT

Figure 24. Variable Pitch Pulley

RAMP

PLATE

Driven Pulley: Large But Decreasing

Belt: Approaching Tightness

Condition C:

Engine At High Speed

Drive Pulley: Large

Driven Pulley: Small

Belt: Tight

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 31

Page 32

MAINTENANCE (OLD STYLE CLUTCH)

CLUTCH

This clutch system provides a high pulley ratio (a low gearso to speak) to start out and a low pulley ratio ( a high

gear- so to speak) for a high speed operation, with infinite

variation between the two.

This means that it will not be necessary to give full throttle

in order to “break the blades/pans loose”. The machine can

slowly be brought up to speed.

The torque sensitive pulley (Figure 26) utilizes a spring and

cam bracket. Peak performance results from proper

interaction between the driven pulley spring and the ramp

angle of the cam bracket.

SPRING

DRIVEN

CAM

BRACKET

PULLEY

MOVEABLE

FACE

Figure 26. Pulley Spring and Cam Bracket

FIXED

FACE

NOTICE

If replacement of the clutch is required, use clutch replacement kit, P/N 22581, to upgrade to Multi-Clutch system. New

style drive assembly must be installed per instruction sheet, P/N 23444, included with clutch replacement kit.

Old style Comet clutch is no longer available. Multi-Clutch components are not interchangeable with the prior Hoffco

Comet drive system. The Hoffco Comet CVT system must be replaced for combatibility with the new equipment.

PAGE 32 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 33

MAINTENANCE (NEW STYLE CLUTCH)

NOTICE

This section is intended to aid users in the maintenance

of drive assemblies with a new style Multi-Clutch.

CHECKING THE DRIVE BELT

The drive belt needs to be changed as soon as it begins

to show signs of wear. DO NOT reuse a belt under any

circumstances. Indications of excessive belt wear are

fraying, squealing when in use, belts that emit smoke or a

burning rubber smell when in use.

To gain access to the drive belt, remove the drive belt

guard cover, then visually inspect the drive belt for signs

of damage or excessive wear. If the drive belt is worn or

damaged, replace the drive belt.

WARNING

DO NOT attempt to insert hands or tools into

the belt area while the engine is running and

the safety guard has been removed. Keep

fingers, hands, hair and clothing away from

all moving parts to prevent bodily injury.

BELT MEASUREMENT

Long life can be expected with this new drive assembly as

long as the belt is kept properly aligned.

The clutch will not shift correctly if the belt width is below

1.14". Measure the CVT belt every 100 hours of use to

make sure it is within the specified tolerance. See Figure 27.

CVT BELT

CALIPERS

Figure 27. Belt Measurement

WARNING

DO NOT remove the V-belt guard cover

until the muffler has cooled. Allow the entire

trowel to cool down before performing this

procedure.

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 33

Page 34

MAINTENANCE (NEW STYLE CLUTCH)

REMOVING THE DRIVE BELT

1. Remove Drive Belt Cover. See Figure 16.

2. Disconnect the left-side CV Axle from the left-side gearbox

and the lower drive pulley coupler. See Figure 28.

NOTICE

CVT BELT

(P/N 23365)

Note that the 3 bolts securing the CV axle to the coupler

are shorter than those securing the CV axle to the

gearbox. Remember bolt orientation for reassembly.

UPPER DRIVE

PULLEY/CLUTCH

CVT

BELT

LEFT-SIDE

GEARBOX

SHORTER

SCREWS (3)

GEARBOX

COUPLER

CV AXLE

COUPLER

LOWER

DRIVE

PULLEY

Figure 28. Remove Left-Side CV Axle

3. If the belt is not being reused (recommended), CUT

the drive belt. Ensure all belt remnants are removed

from the pulleys.

PULL UPWARDS

AND TOWARDS

REAR OF TROWEL

FIXED

FACE

VEABLE

MO

FACE

LOWER

PULLEY

Figure 29. Holding Lower Pulley Open

2. Place free end of CVT belt into upper pulley grooves.

CLUTCH

UPPER

PULLEY

INSTALLING DRIVE BELT

1. Place new CVT belt over the lower pulley. Squeeze the

belt Figure 299) and pull the belt upwards and towards

the rear of the trowel. This will spread open the faces

of the lower drive pulley.

LOWER

PULLEY

Figure 30. Upper Pulley Belt Installation

3. Reconnect left-side CV Axle Assembly. to the left side

gearbox and lower drive pulley coupler. See Figure 28.

PAGE 34 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 35

MAINTENANCE (NEW STYLE CLUTCH)

HOW IT WORKS

The Multi-Clutch functions much like a standard CVT

system. As the engine RPM’s increase, the drive or primary

clutch closes, forcing the belt to ride outwards on the drive

sheaves. The closing of the drive clutch also forces the belt

to open the driven or secondary sheaves. The opening and

closing of these sheaves creates a ratio variation… hence

CVT or Continuously Variable Transmission.

Belt protection is achieved within the Multi-Clutch through

the use of a series of centrifugal clutches. While most CVT

systems have a loose or slack belt while the engine idles,

the sheaves of those systems are constantly rotating and

wearing on the belt.

Those systems also require the stationary belt to be

pinched by the constantly rotating sheaves during startup.

The relative rotation of the sheaves to the belt causes

unnecessary wear on the belt. With traditional CVT

systems, wear on the belt happens any time the engine is

idling and at every start up of the driven equipment. This is

where the Multi-Clutch differs from the other CVT’s.

The Multi-Clutch utilizes two centrifugal clutches (the starter

clutch system) to drive the sheaves of the drive (primary)

clutch. What that means is that the belt can remain tight in

the sheaves, and that both the sheaves and the belt are

stationary while the vehicle is idling. This eliminates the belt

wear at an idle, and during start up, while also providing

one additional form of belt protection.

The centrifugal clutches (starter clutch) can act as overload

protection as well. In cases where too much torque is trying

to be transmitted to the belt, the centrifugals can slip before

the maximum load on the belt is achieved. What this means

is that instead of the belt slipping on the sheaves during

an overload, the centrifugals will first slip further protecting

the belt from damage.

HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12) — PAGE 35

Page 36

MAINTENANCE

OPERATING

BLADE PITCH

Matching Blade Pitch for Both Sets of Blades

Sometimes it may be necessary to match blade pitch between

the two sets of blades. There are some signs that this may be

necessary. For example, the differences in pitch could cause

a noticeable difference in finish quality between the two sets

of blades. Or, the difference in blade pitch could make the

machine difficult to control. This is due to the surface area in

contact with the concrete (the blade set with the greater contact

area tends to stick to the concrete more).

Single Pitch™

On a Single Pitch™ trowel each spider assembly can be

pitched individually, forcing the operator to constantly make

adjustments on each pitch tower.

Twin Pitch™

Trowels equipped with Twin Pitch™ controls may need

to have blade pitch between the two sets of blades

“syncronized”. If the blades need to be syncronized this is

easily accomplished by performing the following procedure.

Refer to Figure 31.

Blade Pitch Adjustment Procedure

Maintenance adjustment of blade pitch is made by adjusting

a bolt (Figure 32) on the arm of the trowel blade finger.

This bolt is the contact point of the trowel arm to the lower

wear plate on the thrust collar. The goal of adjustment is to

promote consistent blade pitch and finishing quality.

Look for the following indications if blades are wearing

unevenly. If so, adjustment may be necessary.

Is one blade completely worn out while the others look

new?

Does the machine have a perceptible rolling or bouncing

motion when in use?

Look at the machine while it is running, do the guard

rings “rock up and down” relative to the ground?

Do the pitch control towers rock back and forth?

SPIDER PLATE

TROWEL LEVER (FINGER)

1. Lift the pitch adjustment handle on either side. Once

lifted, that side is now disconnected from the Twin

Pitch™ system.

2. Adjust to match the opposite side.

3. When adjusted, lower the handle to Twin Pitch™

operating position.

POSITION

TWIN PITCH™

DISENGAGED

(ONE SIDE)

Figure 31. Pitch Towers

WHIT EMAN

SERI ES

TROWEL ARM

BLADE PITCH

ADJUSTMENT BOLT

Figure 32. Blade Pitch Adjustment Bolt

The easiest and most consistent way to make adjustments

on the trowel arm fingers is to use the Trowel Arm Adjustment

Fixture (P/N 9177). It comes with all the hardware necessary

to properly accomplish this maintenance and instructions

on how to utilize this tool.

If a trowel arm adjustment fixture is not available and

immediate adjustment is necessary, temporary field

adjustment can be made if you can see or feel which blade

is pulling harder by adjusting the bolt that corresponds to

that blade.

A better way to determine which blades need adjustment

is to place the machine on a known FLAT surface (steel

metal plate) and pitch the blades as flat as possible. Look

at the adjustment bolts. They should all barely make contact

with the lower wear plate on the spider. If you can see that

one of them is not making contact, some adjustment will

be necessary.

PAGE 36 — HHN31VTCSL5 RIDE-ON TROWEL • OPERATION AND PARTS MANUAL — REV. #8 (05/03/12)

Page 37

MAINTENANCE

Adjust the “high” bolts down to the level of the one that is not

touching, or adjust the “low” bolt up to the level of the higher

ones. If possible, adjust the low bolt up to the level of the

rest of the bolts. This is the fastest way, but may not always

work. Verify after adjustment the blades pitch correctly.

Blades that are incorrectly adjusted often will not be able

to pitch flat. This can occur if the adjusting bolts are raised

too high. Conversely, adjusting bolts that are too low will