Page 1

OPERATION AND PARTS MANUAL

SERIES

MODEL HHN-31VMODEL HHN-31V

MODEL HHN-31V

MODEL HHN-31VMODEL HHN-31V

RIDE-ON POWER TROWEL

(B & S VANGUARD GASOLINE ENGINE)

Revision # 5 (03/02/07)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

P/N 20382

Page 2

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingand other constructionactivities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of these chemicals are:

Leadfromlead-based paints.

Crystallinesilica frombricks.

Cementand other masonryproducts.

Arsenicandchromiumfromchemically

treatedlumber.

Your risk from these exposures varies,

dependingon howoftenyoudo thistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

Page 3

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

Page 4

TABLE OF CONTENTS

MQ WHITEMAN — HHN-31V

GASOLINE POWERED RIDE-

ON TROWEL

Proposition 65 Warning ............................................ 2

Silicosis/Respiratory Warnings ................................. 3

Table Of Contents .................................................... 4

Training Checklist ..................................................... 5

Daily Pre-Operation Checklist .................................. 6

Parts Ordering Procedures ...................................... 7

Rules For Safe Operation .....................................8-9

Operation And Safety Decals ................................. 10

Specifications ......................................................... 11

General Information ............................................... 12

Controls and Indicators ..................................... 13-14

New Machine Setup Instructions ........................... 15

Initial Start-Up ...................................................16-18

Maintenance ..................................................... 19-24

Troubleshooting ................................................25-26

Explanation Of Codes In Remarks Column ........... 27

Suggested Spare Parts .......................................... 28

Name Plate And Decals ....................................30-31

Pivot/Gear Box-Right-Side Assy. ....................... 32-33

Pivot/Gear Box-Left-Side Assy. .........................34-35

Gearbox Assy. ................................................... 36-37

Control Steering (Assist) Assy........................... 38-41

Twin Pitch Assy. (Left/Right) ..............................42-45

Drive Assy. ........................................................ 58-59

5-Blade Spider Assy. (Left) ............................... 60-61

5-Blade Spider Assy. (Right) .............................62-63

Stabilizer Ring Assy. ........................................... 64-65

Seat and Frame Assy. ........................................ 66-67

Frame and Components .................................... 68-69

Foot Pedals Assy. ............................................... 70-71

Throttle Foot Pedal Assy. ................................... 72-73

Battery Assy. ...................................................... 74-75

Spray Assy. ........................................................ 76-77

Front Panel Assy. ............................................... 78-79

Top Right Panel Assy.......................................... 80-81

E-Z Mover and Lift ............................................. 82-83

Wiring Diagram ....................................................... 84

Terms and Conditions Of Sale — Parts .................. 85

NOTE

Specifications and part

numbers are subject to

change without notice.

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 4

PAGE 4 — HTN 31V

Page 5

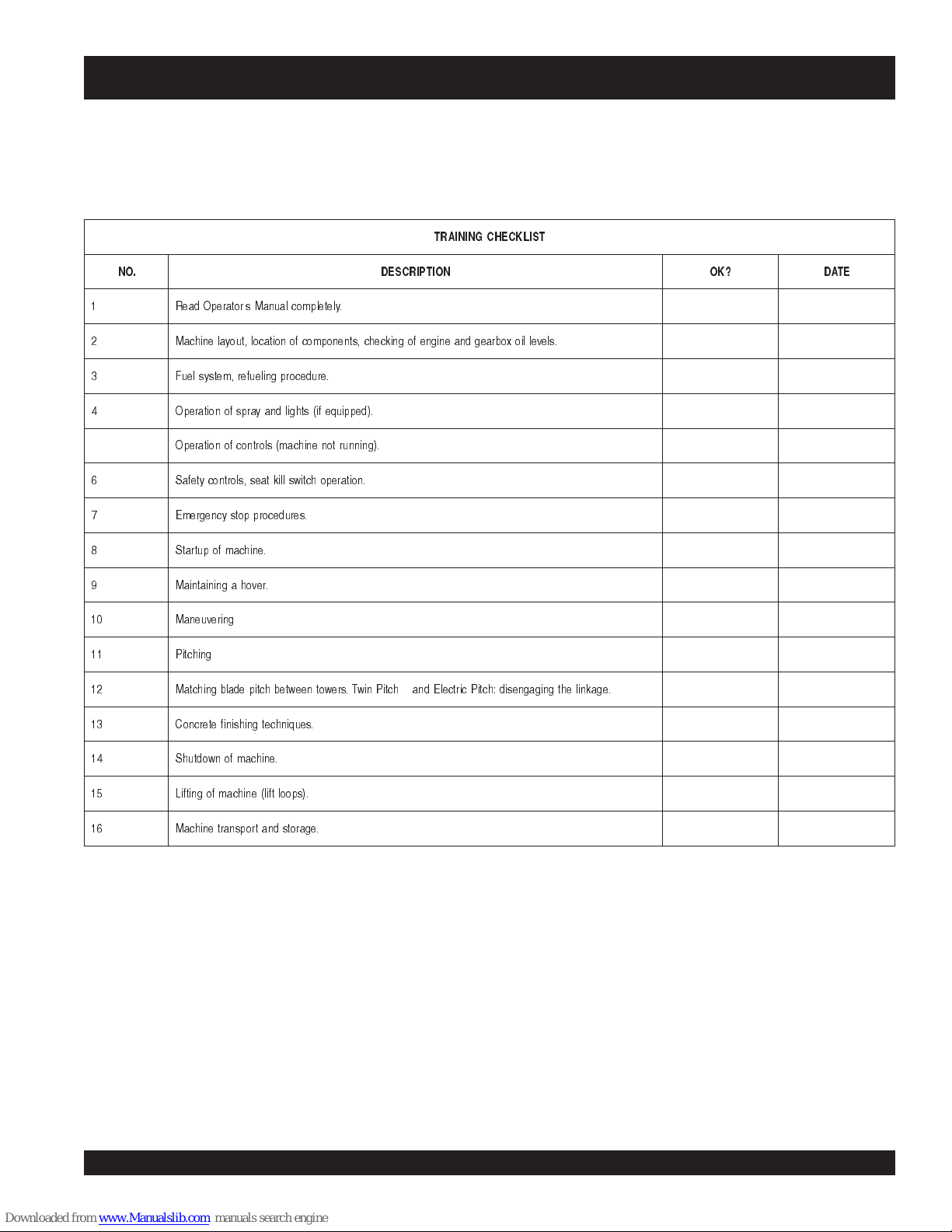

TRAINING CHECKLIST

TRAINING CHECKLIST

This checklist will lists some of the minimum requirements for machine maintenance and operation. Please feel free to detach it and

make copies. Use this checklist whenever a new operator is to be trained or it can be used as a review for more experienced

operator’s.

TSILKCEHCGNINIART

.ON NOITPIRCSED ?KO ETAD

! "#$

"$

% &'

( )

* '

+

,

-

.-)-&0&&

#1

! &'

2 "$3

%

Operator _________________________________________ Trainee __________________________________________

COMMENTS:

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 5

Page 6

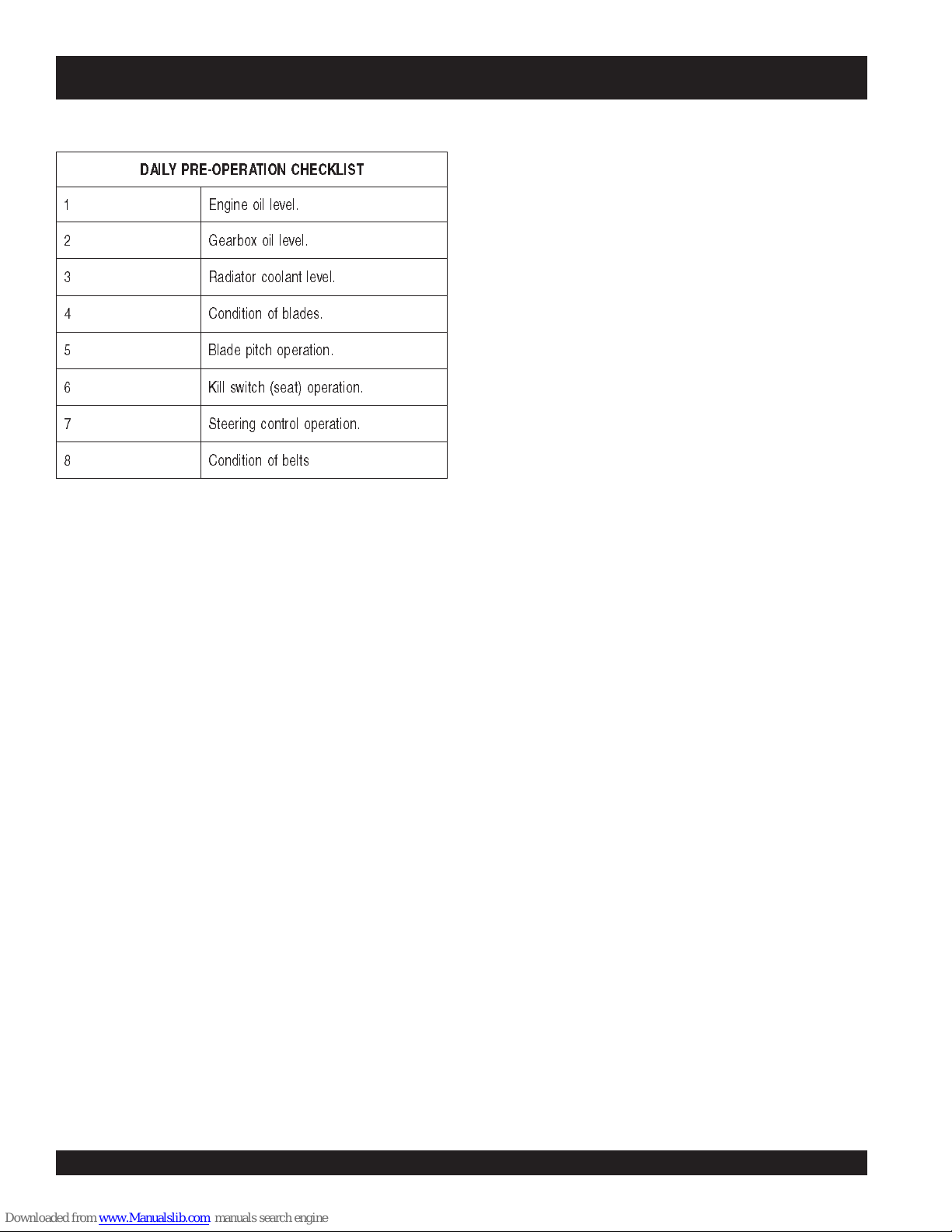

DAILY PRE-OPERATION CHECKLIST

1 .levellioenignE

2 .levellioxobraeG

3 .leveltnaloocrotaidaR

4 .sedalbfonoitidnoC

5 .noitarepohctipedalB

6 .noitarepo)taes(hctiwslliK

7 .noitarepolortnocgnireetS

8 stlebfonoitidnoC

COMMENTS:

DAILY PRE-OPERATION CHECKLIST

TSILKCEHCNOITAREPO-ERPYLIAD

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 6

PAGE 6 — HTN 31V

Page 7

Effective: January 1st, 2006

Ordering parts has never been easier!

PARTS ORDERING PROCEDURES

Choose from three easy options:

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■

View Parts Diagrams

■

Order Parts

■

Print Specification Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

If you have an MQ Account, to obtain a

Username and Password, E-mail us at:

parts@multiquip.com.

To obtain an MQ Account, contact your

District Sales Manager for more information.

internet

Use the

on

Standard orders

complete part numbers.*

Fax

your order in and qualify for a 2% Discount

on

Standard orders

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

and qualify for a 5% Discount

for all orders which include

for all orders which include

International Customers

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

should contact

When ordering parts, please supply:

❒❒

❒

Dealer Account Number

❒❒

❒❒

❒

Dealer Name and Address

❒❒

❒❒

❒

Shipping Address (if different than billing address)

❒❒

❒❒

❒

Return Fax Number

❒❒

❒❒

❒

Applicable Model Number

❒❒

❒❒

❒

Quantity, Part Number and Description of Each Part

❒❒

NOTE

www.multiquip.com

All orders are treated as

and will ship the same day if received prior

to 3PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 7

❒❒

❒

Specify Preferred Method of Shipment:

❒❒

✓

UPS/Fed Ex

■

■

■ Next Day

■

Standard Orders

Priority One

Ground

Second/Third Day

✓ DHL

✓

Tr u c k

Page 8

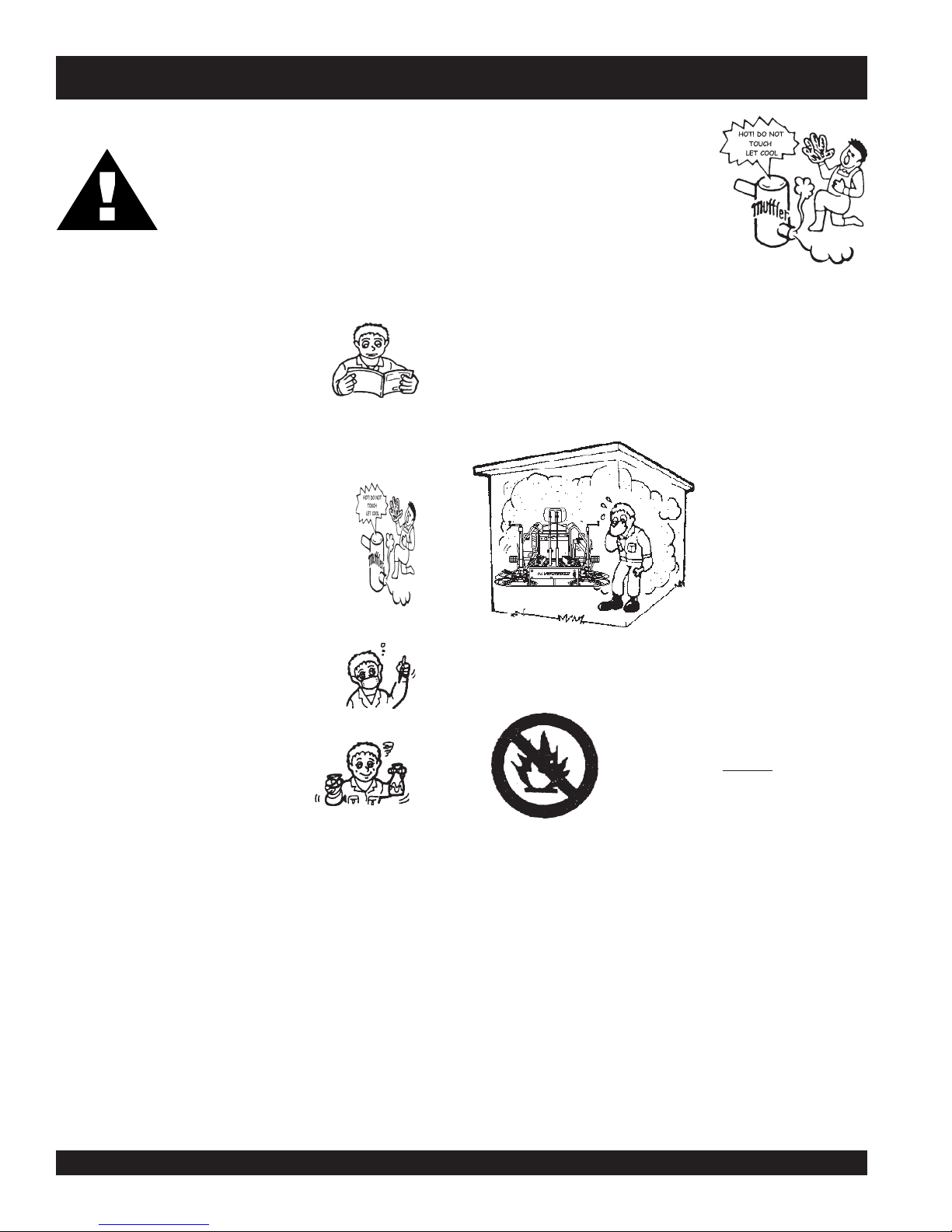

HHN-31V— RULES FOR SAFE OPERATION

■

CAUTION:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is for

industrial use only.

The following safety guidelines should always be used when

operating the trowel.

GENERAL SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated by persons under

18 years of age.

■

NEVER operate this equipment without

proper protective clothing, shatterproof

glasses, steel-toed boots and other

protective devices required by the job.

NEVER touch the hot exhaust

manifold, muffler or cylinder. Allow

these parts to cool before servicing

engine or trowel.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot

with

■

The ride-on trowel engine requires an adequate free flow of

cooling air. Never operate the ride-on trowel in any enclosed

or narrow area where free flow of the air is restricted. If the air

components can cause serious burns.

flow is restricted it will

cause serious damage to

the trowel or engine and

may cause injury to

people. Remember the

trowel's engine gives off

DEADLY carbon monoxide

gas.

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or

taking medicine.

■

NEVER operate this equipment under

the influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any accident

due to equipment modifications.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

Always check the machine for loosened threads or bolts

before starting.

■

■

■

Always refuel in a well-ventilated area, away from sparks

and open flames.

n Always use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it

to cool. DO NOT

the trowel. Fire or explosion could result

from fuel vapors, or if fuel is spilled on a

hot engine.

NEVER operate the trowel in an explosive atmosphere or

near combustible materials. An explosion or fire could result

causing severe

Topping-off to filler port is dangerous, as it tends to spill fuel.

bodily harm or even death.

smoke around or near

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 8

PAGE 8 — HTN 31V

Page 9

HHN-31V— RULES FOR SAFE OPERATION

The following safety guidelines should always be used when

operating the HHN Ride-on Power Trowel:

GENERAL SAFETY

■

DO NOT operate this equipment unless all guards and safety

devices are attached and in place.

■

Always use proper heavy lifting techniques when moving

equipment. This ride-on trowel is very heavy. It should be

lifted only with a lifting device (i.e. crane, forklift, etc.) with a

lifting capacity of at least one ton.

■

Always check to make sure that the operating area is clear

before starting the engine.

■

Always test the safety kill switch before operating the

equipment.

■

NEVER place your feet inside the guard rings while starting

or operating this equipment.

■

Always keep clear of rotating or moving parts while operating

this equipment.

■

NEVER leave the machine unattended while running.

■

Always refuel in a well-ventilated area, away from sparks

and open flames.

MAINTENANCE SAFETY

■

Disconnect the battery and spark plug wires before attempting

any type of service.

■

Securely support any machine components that must be

raised.

■

NEVER lubricate components or attempt service on a running

machine.

■

Always allow the machine a proper amount of time to cool

before servicing.

■

Keep the machinery in proper running condition.

■

Make sure that there is no buildup of concrete, grease, oil or

debris on the machine.

■

Fix damage to the machine immediately and always replace

broken parts.

■

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

■

DO NOT use food or plastic containers to dispose of

hazardous waste.

■

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source.

■

Moving Parts - Shut down the engine and disconnect battery

before performing service or maintenance functions. Contact

with moving parts can cause serious injury.

Moving the Ride-On Trowel

CAUTION:

CAUTION:

Temperatures

■

High Temperatures – Allow the machine

and engine to cool before adding fuel or

performing service and maintenance functions.

hot

Contact with

serious burns.

CAUTION:

Emergencies

■

extinguisher

location of the nearest telephone. Also know

the phone numbers of the nearest

doctor

will be invaluable in the case of an emergency.

Always know the location of the nearest

and

components can cause

and

first aid kit

fire department

. Know the

ambulance

. This information

The HHN series Ride-on Power Trowel is designed to be moved

and handled several ways.

The easiest way to lift the ride-on trowel is to utilize the lift loops

that are welded to the frame. These lift loops are located to the

left and right sides of the operator’s seat (Figure 3, Page 11).

fire

A strap or chain can be attached to these lift loops, allowing a

forklift or crane to lift the ride-on trowel up onto a slab of concrete.

The strap or chain should have a minimum 2,000 pounds (1000-

,

kg) lifting capacity and the lifting gear must be capable of lifting

at least this amount.

This ride-on trowel is very

awkward to move around. Use proper heavy

lifting procedures and DO NOT attempt to lift

the ride-on trowel by the guard rings.

heavy

and

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 9

Page 10

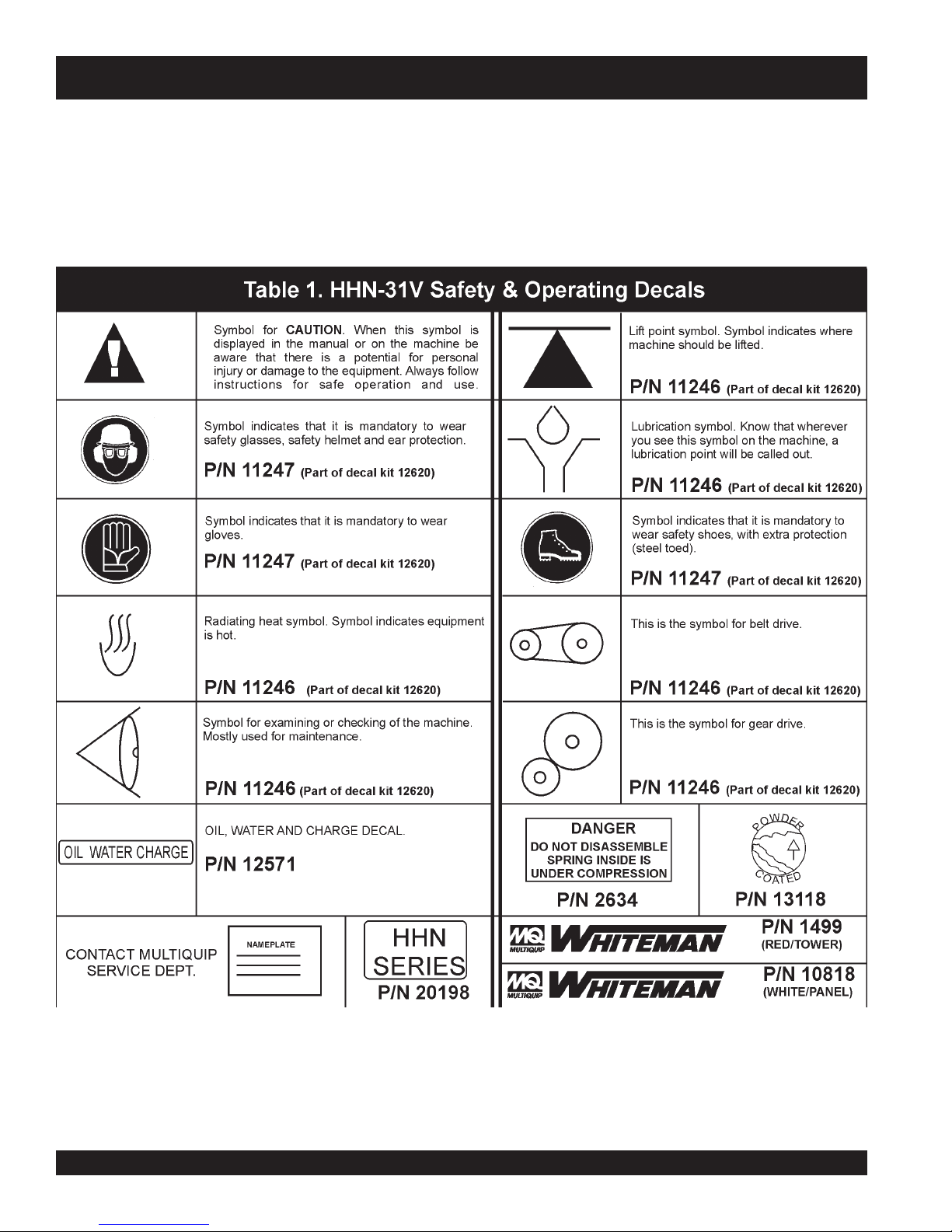

HHN-31V— OPERATION AND SAFETY DECALS

Machine Safety Decals

The HHN series Ride-on Power Trowel is equipped with a number of safety decals. These decals are provided for operator safety

and maintenance information. Table 1 below illustrates these decals as they appear on the machine. Should any of these decals

become unreadable, replacements can be obtained from your dealer.

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 10

PAGE 10 — HTN 31V

Page 11

HHN -31V — SPECIFICATIONS

Figure 1. HHN Dimension Specifications

snoitacificepSNNH.2elbaT s

RETEMARAPNOITACIFICEPS )DRAUGNAV(V13-NNH

)mc(.ni–htgneL–A )4.642(0.79

)mc(.ni–htdiW–B )721(0.05

1

)mc(.ni–thgieH–C

gnitarepO).sgk(.sbl–thgieW )774(240,1

gnippihS).sgk(.sbl–thgieW )555(422,1

2

ABd–erusserPdnuoS

2

s/tf–noitarbiV

3

s/m(2)

.P.H–enignE 13

)sretil(snollag–knaTleuF )91(5

MPR–rotoR 061ot06

)mc(.ni–htdiWhtaP )132(19

liOnoitacirbuL PE5RG022OSI

yticapaCliOxoBraeG .ZO441

)daoLlluF(noitpmusnoCleuF RH-PHB/BL45.0

yticapaCrotaidaR .LAG0.1

NOTE:

1. This value does not include seat height. To obtain total

height (seat ) add 4 inches (10.2 cm.).

2. Sound pressure is "A" weighted . Measured at the operators

ear position while the ride-on trowel is operating at full

throttle on concrete in a manner most often experienced in

normal

“

” circumstances. Sound pressure may vary

depending upon the condition of the concrete. Hearing

3. The vibration level indicated is the maximum RMS (Root

Mean Square) value obtained at the handle grip while

operating the ride-on trowel on curing concrete in a

manner most often experienced in “

circumstances. Values were obtained from all three axes

of motion. The values shown represent the maximum RMS

value from these measurements.

protection is always recommended.

)711(0.64

59

)5.2(0.8<

normal

”

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 11

Page 12

HHN -31V — GENERAL INFORMATION

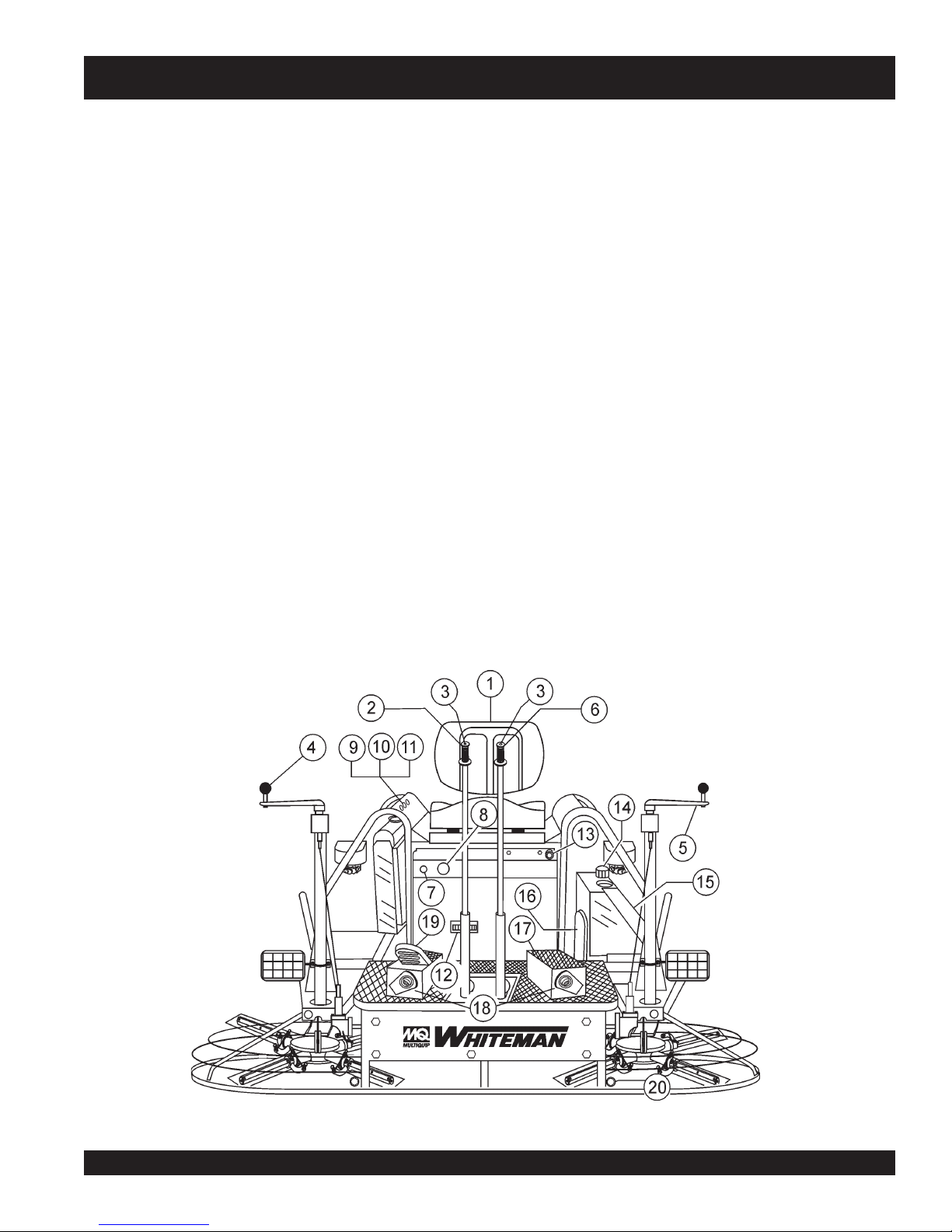

HHN RIDE-ON TROWEL FAMILIARIZATION

The HHN series Ride-On Power Trowel is designed for the

floating and finishing of concrete slabs.

Take a walk around the HHN Ride-On Power Trowel. Take notice

of all the major components (see Figures 2 and 3, pages 13 and

14) like the engine, blades, air cleaner, fuel system, fuel shut-off

valve, ignition switch etc. Check that there is always oil in the

engine, and gear oil in the gear box assembly.

Read all the safety instructions carefully. Safety instructions will

be found throughout this manual and on the machine. Keep all

safety information in good, readable condition. Operators should

be well trained on the operation and maintenance of the HHN

Ride-On Power Trowels.

Look at the operator control levers. Grab the control levers and

move them around a bit. Look to see how moving the control

levers causes the gearboxes and frame to move.

Notice the foot pedal which controls the engine speed. Also take

a look at the main driveline of the trowel. Take note and reference

how the belts look, this is the way the belts should look when

adjusted properly.

Before using your HHN Ride-On Power Trowel, test it on a flat

watered down section of finished concrete. This trial test run will

increase your confidence in using the trowel and at the same

time it will familiarize you with the trowel’s controls and indicators.

In addition you will understand how the trowel will handle under

actual conditions.

Engine

Gearboxes

The HHN Ride on Power Trowel consist of two separate gearbox

assemblies that are enclosed in rugged cast aluminum gear

cases.

The gearbox casing holds 50% more oil capacity than

competitors, which allows more lubrication to be provided to

critical points.

Steering Assist

Dual control levers located in front of the operator's seat are

provided for steering the HHN Ride on Power Trowel. The control

levers are linked to two spring loaded cylinders.

Push the left control lever forward and pull the right control lever

backward and the trowel will rotate clockwise on approximately

a center axis. Pull the left control lever backward and push the

right control lever forward and the trowel will rotate

counterclockwise. See Table 3 on page 15 for a complete

description on the control levers directional positioning.

Constant Velocity Joints (CV-Joints)

Constant velocity joints insure the efficient transfer of power to

the drive shaft and maintain the timing of the gearboxes without

any chance of slippage.

Training

For training, please use the “TRAINING CHECKLIST” located

in the front of this manual (Page 5). This checklist is not intended

to be a substitute for proper training but will provide an outline

for an experienced operator to provide training to a new operator.

The HHN Ride-On Power Trowel is equipped with a liquid cooled

31 HP Vanguard gasoline engine. Refer to the engine owner’s

manual for specific instructions regarding engine operation. This

manual is included with the ride-on trowel at the time of shipping

from Whiteman. Please contact your nearest Multiquip Dealer

for a replacement should the original manual disappear.

Blades

The blades of the ride-on power trowel finish the concrete as

they are swirled around the surface. Blades are classified as

combination (10 or 8 inches wide) and finish (6 inches wide).

The HHN ride-on power trowels are equipped with five blades

per rotor equally spaced in a radial pattern and attached to a

vertical rotating shaft by means of a

Figures 2 and 3 show the location of the controls, indicators and

general maintenance parts. Each control may perform more than

one function. The functions of each control or indicator is on

pages 13 and 14.

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 12

spider assembly.

PAGE 12 — HTN 31V

Page 13

HHN -31V — CONTROLS AND INDICATORS

1. Seat – Place for operator to sit. Engine will not start unless

operator is seated. Seat is adjustable, fore and aft for

operator comfort.

2. Steering Control Lever (right side) -Allows the unit to

move in either a forward, reverse left or right direction.

3. Retardant Spray Control Buttons – When pressed

allows retardant spray to flow through the spray nozzle

located at the front of the machine.

4. Twin Pitch Control – Adjusts the blade pitch for right side

of the trowel. Turn the crank as marked on its top surface to

increase or decrease blade pitch.

5. Twin Pitch Control – Adjusts the blade pitch for left side

of the trowel. Turn the crank as marked on its top surface to

increase or decrease blade pitch.

6. Steering Control Lever (left side) -Allows the unit to move

in either a forward, reverse left or right direction.

7. Light Switch – When activated, turns on four halogen

lights. Lights offer better visibility when working indoors.

8. Ignition Switch – With key inserted turn clockwise to

start engine.

9. Oil Indicator Light - Lights red when oil pressure is low.

10. Water Indicator Light - Lights red when water temperature

is high.

11. Charge Indicator - Lights red when electrical system is

not charging properly.

12. Hour Meter - Indicates number of hours the key switch is

in the "ON" position.

13. Choke Control Lever. - In cold weather pull this lever

forward about half way to start engine. After engine warms

push knob all the way in.

14. Fuel Gauge/Filler Cap - Indicates the amount of fuel in

the fuel tank. Remove this cap to add fuel.

15. Fuel Tank - Holds 5 gallons of unleaded gasoline.

16. Spare Belt Carrier - Contains a spare belt. Belt is used on

the drive pulley.

17. Left Foot Riser – Operator foot rest pedal.

18. Spray Nozzles – Spray nozzle for retardant.

19. Right Foot Pedal – Controls blade speed. Slow blade

speed is accomplished by slightly depressing the foot pedal.

Maximum blade speed is accomplished by fully depressing

the foot pedal.

20. EZ- Mover Boss – Front -side insertion point for EZ Mover.

Used when the transporting of the trowel is required.

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 13

Figure 2. HHN Controls and Indicators (Front)

Page 14

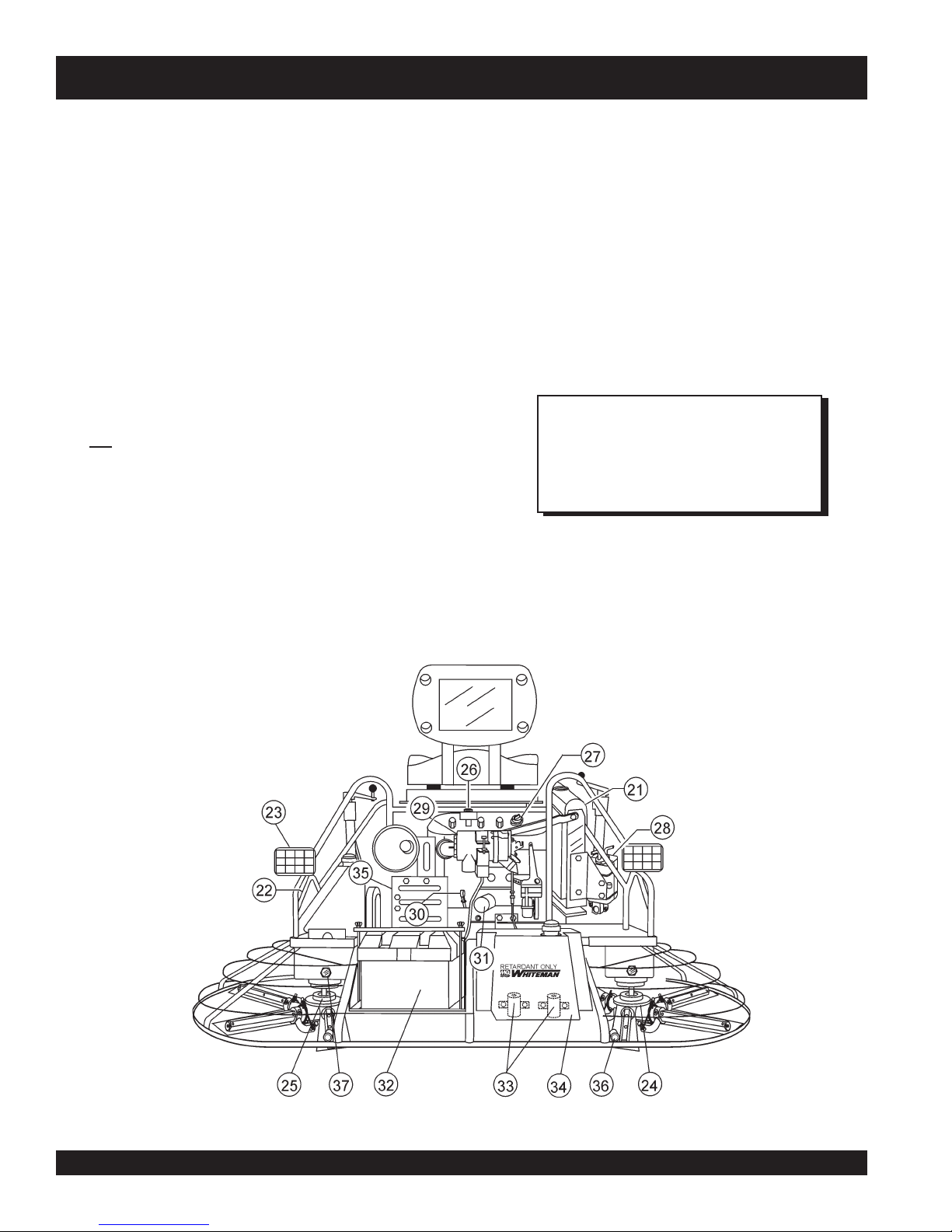

HHN -31V — CONTROLS AND INDICATORS

21. Radiator/Filler Cap – Holds coolant or water necessary to

keep engine at a safe operating temperature. Remove this

cap to add water or antifreeze. DO NOT revove this cap

when the engine is warm.

22. Lift Loops – Located on both the left and right sides of the

main frame. Used when the trowel must be lifted onto a

concrete slab.

23. Lights – Four 12 volt halogen lights are provided with this

unit.

24. Right-Side Spider – Consists (basic) of trowel arms,

blades, wear plate, and thrust collar etc.

25. Left-Side Spider – Consists (basic) of trowel arms, blades,

wear plate, and thrust collar etc.

26. Safety Kill Switch – Shuts down engine when operator is

not sitting in seat.

27. Engine Oil Filler Cap - Remove this cap to add engine oil.

28. Overflow Bottle - Supplies coolant to the radiator when

radiator coolant level is low. Fill to indicated level as shown

on bottle.

29. Engine Air Filter – Prevents dirt and other debris from

entering the fuel system. Lift locking latch on air filter

cannister to gain access to filter element.

30. Engine Dip Stick – Indicates engine oil level. Add oil as

required.

31. Oil Filter – Provides oil filtering for the engine.

32. Battery – Provides +12V DC power to the electrical system

33. Retardant Spray Motors – Used in conjunction with the

34. Retardant Spray Tank – Holds 5 gallons of retardant.

35. Belt Guard – Encloses drive belt used in conjunction with

36. EZ- Mover Boss – Back- side insertion point for EZ Mover.

37. Oil Sight Glass - Indicates the level of the hydraulic oil in

The following section is intended as a basic guide to the rideon trowel operation, and is not to be considered a complete

guide to concrete finishing. It is strongly suggested that all

operators (experienced and novice) read “

published by the American Concrete Institute, Detroit Michigan.

left and right spray control buttons.

clutch.

Used when the transporting of the trowel is required.

the gear box.

NOTE

Read this entire instruction manual

completely before attempting to

operate trowel.

Slabs on Grade

”

Figure 3. HHN Controls and Indicators (Rear)

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 14

PAGE 14 — HTN 31V

Page 15

HHN -31V — NEW MACHINE SETUP INSTRUCTIONS

Trowel Pre-Set-Up Instructions

The purpose of this section is to assist the user in setting up a

NEW

trowel. If your trowel is already assembled (seats, handles,

knobs and battery, then this section can be skipped.

NOTE

The new ride-on trowel cannot be put into service

until the pre-setup installation instructions are

completed. These pre-setup instructions only need

to be performed at the time of unpacking a

trowel.

Before packaging and shipping this Whiteman Ride-On Power

Trowel was run and tested at the factory. If there are problems,

please let us know.

Control Handle Assembly

The steering control handles are not attached to the trowel's two

lower handles at the time of shipment. To attach the steering

control handles to the two lower handle assemblies perform the

following:

1. Remove the bolts from the plastic bag tied to the control

towers.

2. Remove all protective wrapping and straps from the control

handles.

3. Slip the top (loose) piece into the base of the corresponding

handle, making sure to line up the holes.

4. Install the bolt through the lined up holes and tighten the

acorn nut onto the threaded end.

NEW

Seat Assembly

The seat is not installed on the trowel for shipping purposes.

To attach the seat perform the following:

There are two types of seats, depending on what type

of trowel you have. J and B series trowels have slots

on the seat mounting plate that allow fore and aft

adjustment of the seat. H-series trowels have a seat

that is mounted on tracks, similar to an automobile

seat. This seat can be adjusted fore and aft via the

control lever under the front of the seat.

1. Remove the seat from the protective wrapping.

2. Remove the bolts on the bottom of the seat, and place seat

on the seat mounting plate, then insert the bolts through

the holes or slots on the seat mounting plate and tighten.

Battery Setup

This trowel was shipped with a wet charged battery. This battery

may need to be charged for a brief period of time as per the

manufacturer instructions.

CAUTION:

NOTE

Use all safety precautions specified by the

battery manufacturer when working with the

battery.

NOTE

Some models are equipped with

adjustable height handles. Adjust the

height by placing the bolt through the

set of holes that corresponds to the

most comfortable height.

5. Pay close attention to any wires that may be inside the

control handles. DO NOT pinch or cut any wires during

installation.

6. Inside the plastic bag of parts are two knobs for the pitch

control tower cranks. Install these two knobs onto the tower

crank levers.

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 15

To install the battery on the trowel, make sure that the battery is

well seated in the battery box and the terminals are properly

connected. Close the plastic battery box cover and secure the

battery box.

Page 16

HHN -31V — INITIAL START-UP

This section is intended to assist the operator with the initial

start-up of the HHN series Ride-On Power trowel. It is extremely

important that this section be read carefully before attempting to

use the trowel in the field.

DO NOT use your ride-on power trowel until this section is

thoroughly understood.

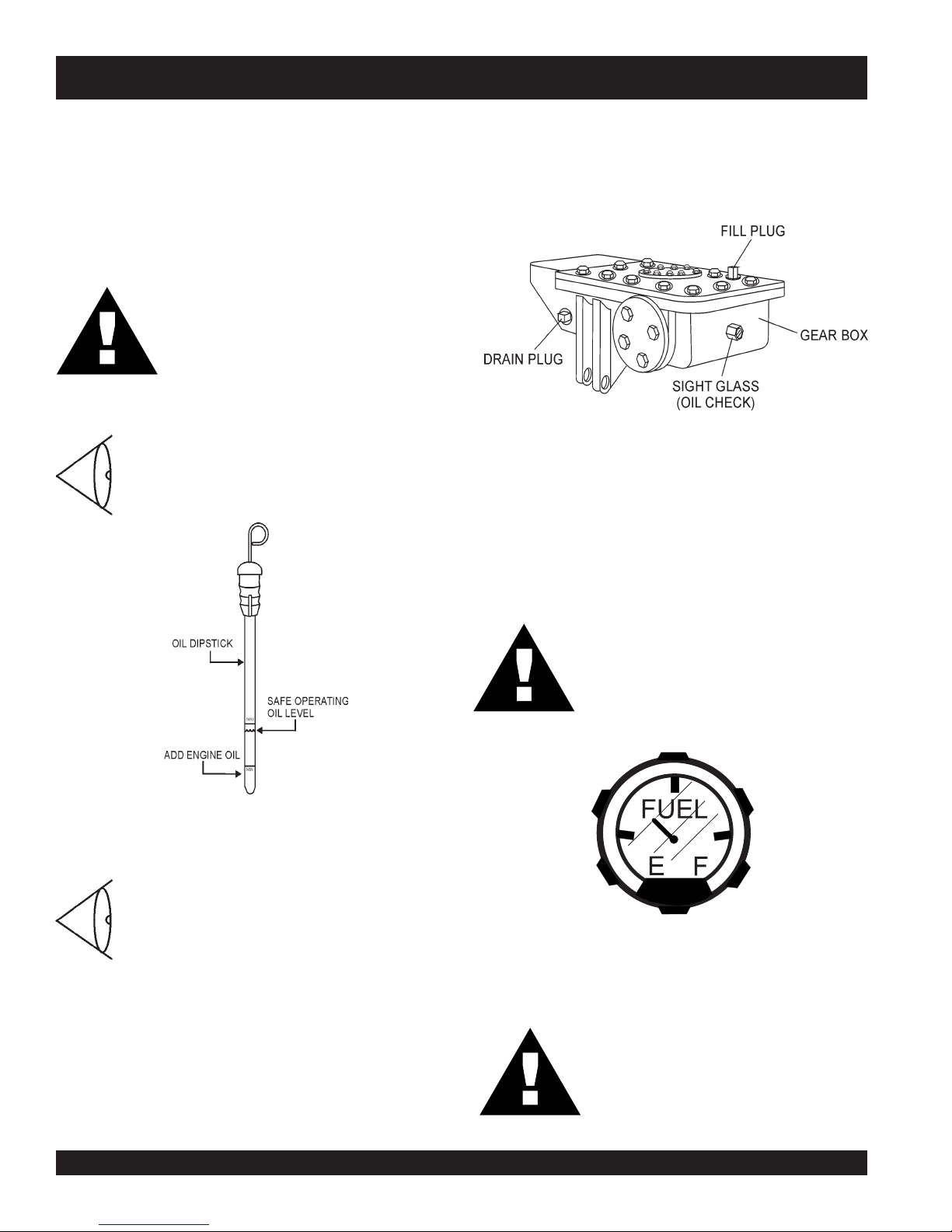

2. The oil level of the gear box should be at the half-way point

of the sight glass (Figure 5). The gear box oil capacity is

144 oz. If additional oil is required, unscrew the oil fill plug

located on top of the gearbox, and refill with ISO 220 A

GMA GR 5 EP oil.

CAUTION:

Failure to understand the operation of the HHN

Ride-ON Power Trowel could result in severe

damage to the trowels or personal injury.

See Figures 2 and 3 (Pages 13 and 14) for

the location of any control or indicator

referenced in this manual.

Engine Oil Level

1. Pull the engine oil dipstick from its holder.

2. Determine if engine oil is low (Figure 4), add

correct amount of engine oil to bring oil level

to a normal safe level.

Figure 5. Gearbox Oil Plugs/Sight Glass

Fuel

1. Determine if the engine fuel is low (Figure 6). If fuel level is

low, remove the fuel filler cap and fill with unleaded gasoline.

Figure 4. Engine Oil Dipstick

Gearbox Oil Level

1. Check the gearbox oil level in both gearboxes

by viewing the sight glass at the rear of the

gearbox. See Figure 5.

CAUTION:

Handle fuel safely. Motor fuels are highly

flammable and can be dangerous if

mishandled. DO NOT smoke while

refueling. DO NOT attempt to refuel the ride-

on trowel if the engine is hot or running.

Figure 6. Fuel Gauge

CAUTION:

Never store the ride-on trowel with fuel in the

tank for any extended period of time. Always

clean up spilled fuel immediately.

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 16

PAGE 16 — HTN 31V

Page 17

HHN 31V-TC — INITIAL START-UP

Starting the Engine

1. With one foot on the ground and the other foot placed on

the trowel's platform, grab hold of any part of the frame and

lift yourself onto the trowel. Then sit down in the operator's

seat.

2. The Whiteman Ride-On Power trowel is equipped with a

kill switch

safety

assembly. Remember the engine will not start unless an

operator is sitting in the operator’s seat. The weight of an

operator depresses an electrical switch, which will allow

the engine to start.

. This switch is located beneath the seat

CAUTION:

NEVER disable or disconnect the kill switch. It

is provided for the operator's safety and injury

may result if it is disabled, disconnected or

improperly maintained.

3. It is recommended that the kill switch be used to stop the

engine after every use. Doing this will verify that the switch

is working properly and presents no danger to the operator.

Remember to turn the key to the “OFF” position after

stopping the machine. Not doing so may drain your units’

battery.

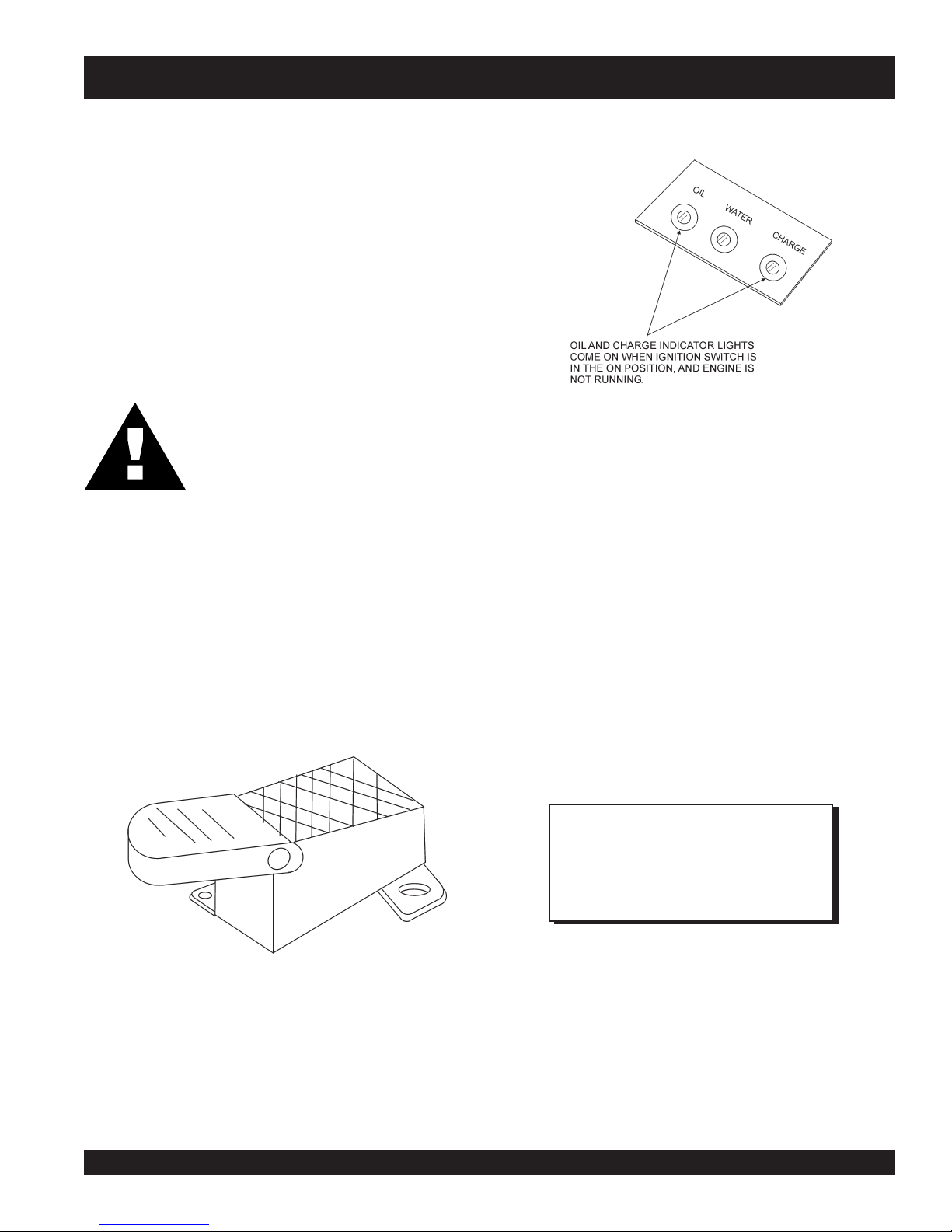

4. The right foot pedal (Figure 7) controls blade and engine

speed. The position of the foot pedal determines the blade

speed. Slow blade speed is obtained by slightly depressing

the pedal. Maximum blade speed is obtained by fully

depressing the pedal.

7. Turn the ignition key clockwise to the (start) position. The

oil

Figure 8. Oil and Charge Indicator Lights

8. Turn ignition key fully clockwise and listen for engine to

start. Once engine has started release ignition key.

9. If the engine fails to start in this manner, consult the engine

owner's manual supplied with the trowel.

10. Test the safety kill switch by standing up briefly. The switch

under the seat should cause the engine to stop. If the kill

switch fails to shut down the engine. Turn off the engine

with the key switch and fix the safety kill switch. See Table

4 (Troubleshooting ) for possible problems.

11. Repeat this section a few times to get fully acquainted with

the engine starting procedure.

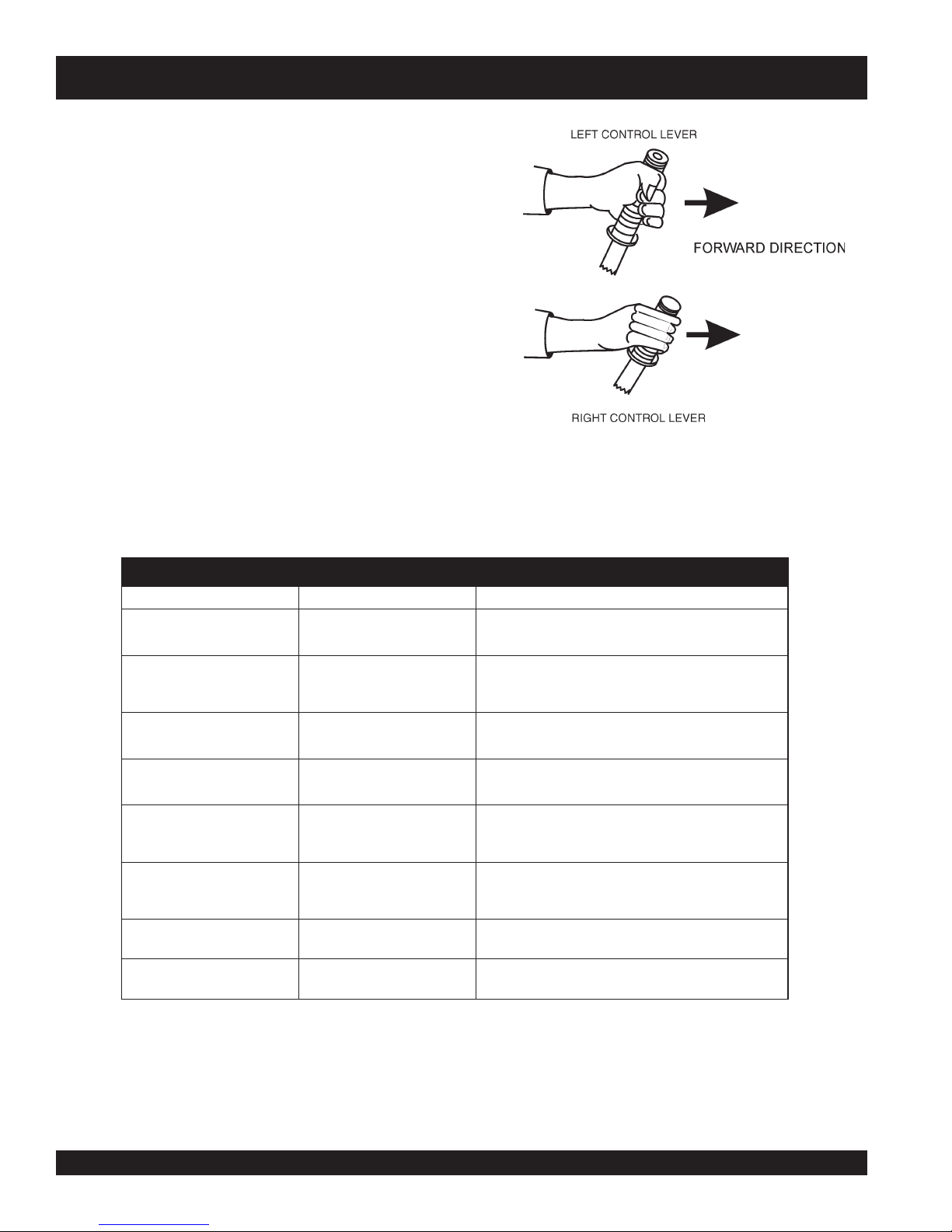

Steering

Two control levers located in front of the operator’s seat provide

directional control for the HHN Ride-On Power Trowel. Table 3

(Page 18) illustrates the various directional positions of the

joysticks and their effect on the ride-on trowel.

and charge indicator lights (Figure 8) should be on.

Figure 7. Blade Speed Control Foot Pedal

5. Keep your foot OFF the gas pedal (right foot pedal). If the

engine is cold, adjust the choke but in all circumstances,

start the engine at idle (without touching the gas pedal).

6. Insert the

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 17

ignition key

into the ignition switch .

NOTE

All directional references with respect

to the steering control levers are from

operator’s

the

2. Push both the left and right control levers forward. See

Figure 9.

3. With your right foot quickly depress the right foot pedal

halfway. Notice that the ride-on power trowel begins to move

in a forward direction. Return both joystick controls to their

neutral position to stop forward movement, then remove

your right foot from the right foot pedal.

seat position.

Page 18

4. Practice holding the machine in one place as you increase

blade speed. When about 75% of maximum blade speed

has been reached, the blade will be moving at proper

finishing speed. The machine may be difficult to keep in

one place. Trying to keep the ride-on trowel stationary is a

good practice for operation.

5. Practice maneuvering the ride-on trowel using the

information listed in Table 3. Try to practice controlled

motions as if you were finishing a slab of concrete. Practice

edging and covering a large area.

6. Try adjusting the pitch of the blades. This can be done with

the ride-on trowel stopped or while the trowel is moving,

whatever feels comfortable. Test the operation of optional

equipment like retardant spray and lights if equipped.

7. Push both the left and right joysticks backward and repeat

steps 3 through 6 while substituting the word reverse for

Figure 9. Left and Right Control Levers

forward.

HHN -31V — INITIAL START-UP

REVELLORTNOC NOITCERID STLUSER

tfeL

tfeL

thgiR

thgiR

thgiRdnatfeL

thgiRdnatfeL

thgiRdnatfeL

thgiRdnatfeL

reveLlortnoCevoM

drawroF

reveLlortnoCevoM

drawkcaB

reveLlortnoCevoM

drawroF

reveLlortnoCevoM

drawkcaB

htoBevoM

drawroFsreveLlortnoC

htoBevoM

drawkcaBsreveLlortnoC

htoBevoM

thgiRehtotsreveLlortnoC

htoBevoM

tfeLehtotsreveLlortnoC

gninoitisoPlanoitceriDreveLlortnoC.3elbaT

otlewortno-edirehtsesuaC

.thgirehtotdnadrawrofevom

otlewortno-edirehtsesuaC

.tfelehtotdnadrawkcabevom

otlewortno-edirehtsesuaC

.tfelehtotdnadrawrofevom

otlewortno-edirehtsesuaC

.thgirehtotdnadrawkcabevom

lewortno-edirehtsesuaC

nidrawrofevomot

.enilthgiartsa

lewortno-edirehtsesuaC

drawkcabevomot

.enilthgiartsani

lewortno-edirehtsesuaC

.thgirehtotevomot

lewortno-edirehtsesuaC

tfelehtotevomot

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 18

PAGE 18 — HTN 31V

Page 19

MAINTENANCE PROCEDURES

.

See the engine manual supplied with your machine for

appropriate engine maintenance schedule and

troubleshooting guide for problems.

At the front of the book (Page B) there is a “Daily Pre-Operation

Checklist”. Make copies of this checklist and use it on a daily

basis.

Disconnect spark plug wires and battery cables before

attempting any service or maintenance on the ride-on trowel.

MAINTENANCE SCHEDULE

Daily (8-10 Hours)

NOTE

Checking The Drive Belt

The drive belt needs to be changed as soon as it begins to show

signs of wear. DO NOT reuse a belt under any circumstances.

Indications of excessive belt wear are fraying, squealing when

in use, belts that emit smoke or a burning rubber smell when in

use.

Under normal operating conditions, a drive belt may last

approximately 150 hours. If your trowel is not reaching this kind

of life span for drive belt wear, check the drive belt for proper

pulley alignment and spacing .

To gain access to the drive belt, remove the drive belt guard

cover, then visually inspect the drive belt for signs of damage or

excessive wear. If thedrive belt is worn or damaged, replace the

drive belt.

HHN -31V — MAINTENANCE

1. Check the fluid levels in the engine and gearboxes, fill as

necessary.

Weekly (30-40 Hours)

1. Relube arms, thrust collar and steering links.

2. Replace blades if necessary.

3. Check and clean or replace the engine air filter as

necessary.

4. Replace engine oil and filter as necessary, see engine

manual.

Monthly (100-125 Hours)

1. Remove, clean, reinstall and relube the arms and thrust

collar. Adjust the blade arms.

2. Replace gearbox lubricant after the first 100 hours of

operation. Then replace every 500-600 hours.

3. Check drive belt fro excessive wear.

Yearly (500-600 Hours)

1. Check and replace if necessary the arm bushings, and

thrust collar bushings, shaft seals and belts.

2. Check pitch control cables for wear.

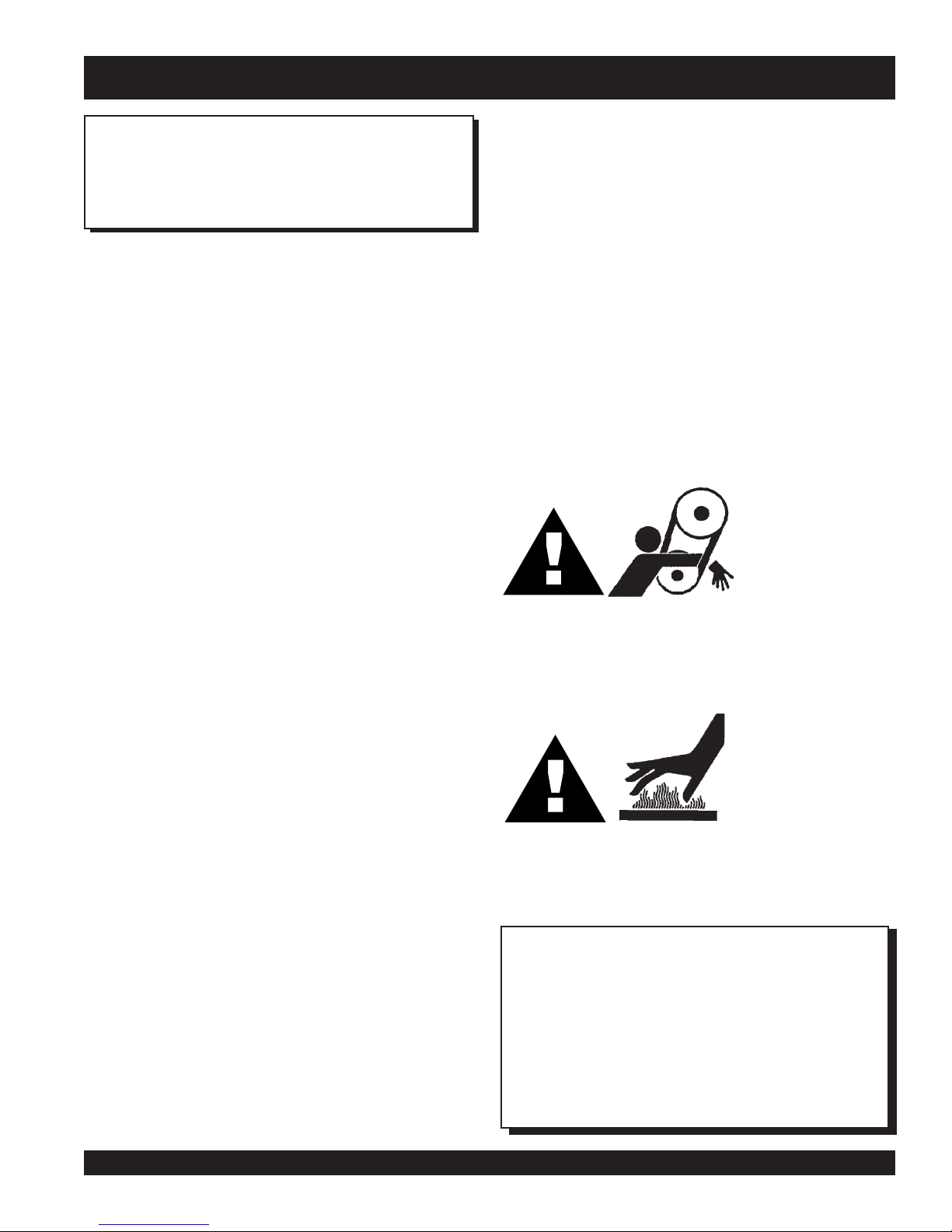

WARNING:

DO NOT attempt to insert hands or tools into the belt area while

the engine is running and the safety guard has been removed.

Keep fingers, hands, hair and clothing away from all moving

parts to prevent bodily injury.

WARNING:

DO NOT remove the V-belt guard cover until the muffler has

cooled. Allow the entire trowel to cool down before performing

this procedure.

3. Replace gearbox lubricant.

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 19

NOTE

zz

z

Leave the existing drive belt intact until instructed

zz

to cut it.

zz

z

Leave the engine in place for this procedure. It is

zz

not necessary to slide the engine to replace the

drive belt.

zz

z

Have a 3/4 X 1 X 3.25 inch wooden block available.

zz

Page 20

Removing the V-belt

1. Remove the seven HHC screws that secure the V-belt

guard cover as shown in Figure 10. Please note that the

screw under the muffler is some what difficult to remove.

2. Remove the drive belt guard cover from the trowel and set

aside.

.

HHN -31V — MAINTENANCE

Figure 11. Lower Drive Pulley

Figure 10. Drive Belt Guard Cover

3. Once the drive belt "Guard Cover" has been removed,

squeeze the drive belt as shown in Figure 11, and pull the

V-belt upwards. This will spread open the faces of the

drive pulley.

4.

Insert

the 3/4" X 1" X 3.25" block between the moveable

face and the fixed face of the lower drive pulley. This block

will help keep the lower drive pulley faces open while

installing the new V-belt.

5. Work the drive belt over the lower drive pulley as shown in

Figure 12, position it over the CV-joint boot, then pull the

belt over the upper drive pulley also shown in Figure 12.

6. Once drive belt is free from both the upper and lower pulley's

CUT

the drive belt.

lower

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 20

Figure 12. Drive Belt Removal

PAGE 20 — HTN 31V

Page 21

HHN -31V — MAINTENANCE

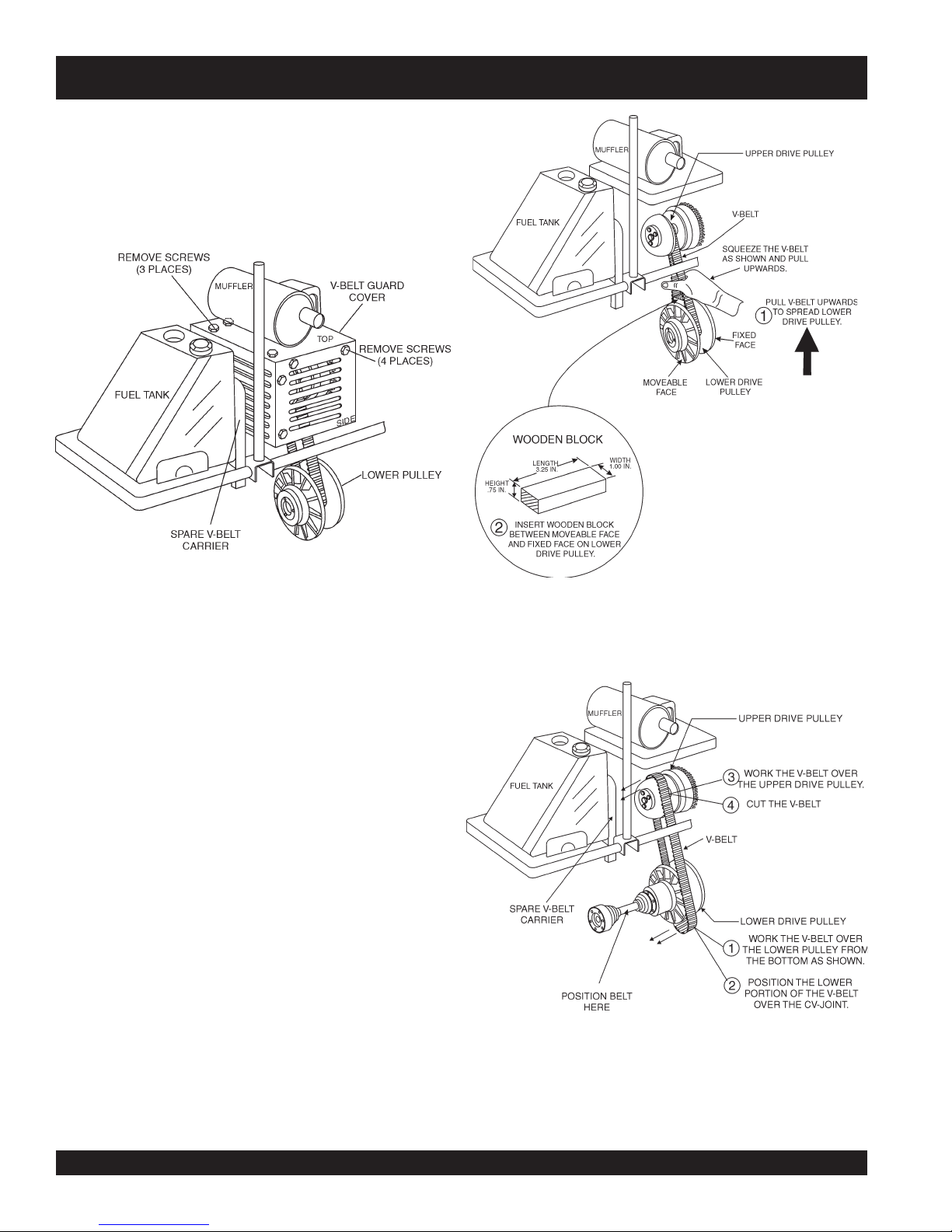

Installing the Replacement Drive Belt

The HHN trowel is equipped with a replacement drive belt (spare)

carrier (Figure 13), which is mounted on the back-side of the fuel

tank opposite the clutch. Make sure that there is ALWAYS a spare

drive belt in the drive belt carrier before the trowel is placed on a slab

to finish concrete.

1. To add a replacement drive belt for use on the upper and

lower drive pulleys, remove the 2 screws that secure the

spare drive belt carrier.

2. Remove the spare drive belt carrier from the trowel, and

free the replacement drive belt.

3. Slide the replacement drive belt over the upper and lower

pulleys reversing steps 1 thru 5 on page 20.

NOTE

It will be necessary to disconnect the CV-Joint from the

left-side gear box coupler. This means the removal of the

three screws that secure the CV-Joint to the gear box.

Spare Drive Belt Replacement

To replace a spare drive belt, be prepared to disconnect the CVjoint from the left-side gear box.

1. Place the HHN trowel on jack stands, and observe all safety

precautions.

2. Remove the three screws that secure the CV-joint to the

left-side gear box coupler.

3. Once the CV-joint has been separated from the left-side

gearbox, push the CV-joint inward so that a gap exist

between the gearbox and the CV-joint (Figure 13). Slide

the spare V-belt between the gear box coupler and the CVjoint. If any grease or oil is present on the replacement

drive belt, remove it.

4. Place the spare drive belt inside the drive belt carrier, and

secure the spare belt carrier to the back-side of fuel tank.

5. Install the three screws that secure the CV-joint to the leftside gear box coupler.

It may be necessary to disconnect the CV-Joint from the

lower pulley coupler. This means the removal of the three

screws that secure the CV-Joint to the pulley.

NOTE

Figure 13. Spare V-Belt Replacement

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 21

Page 22

HHN -31V — MAINTENANCE

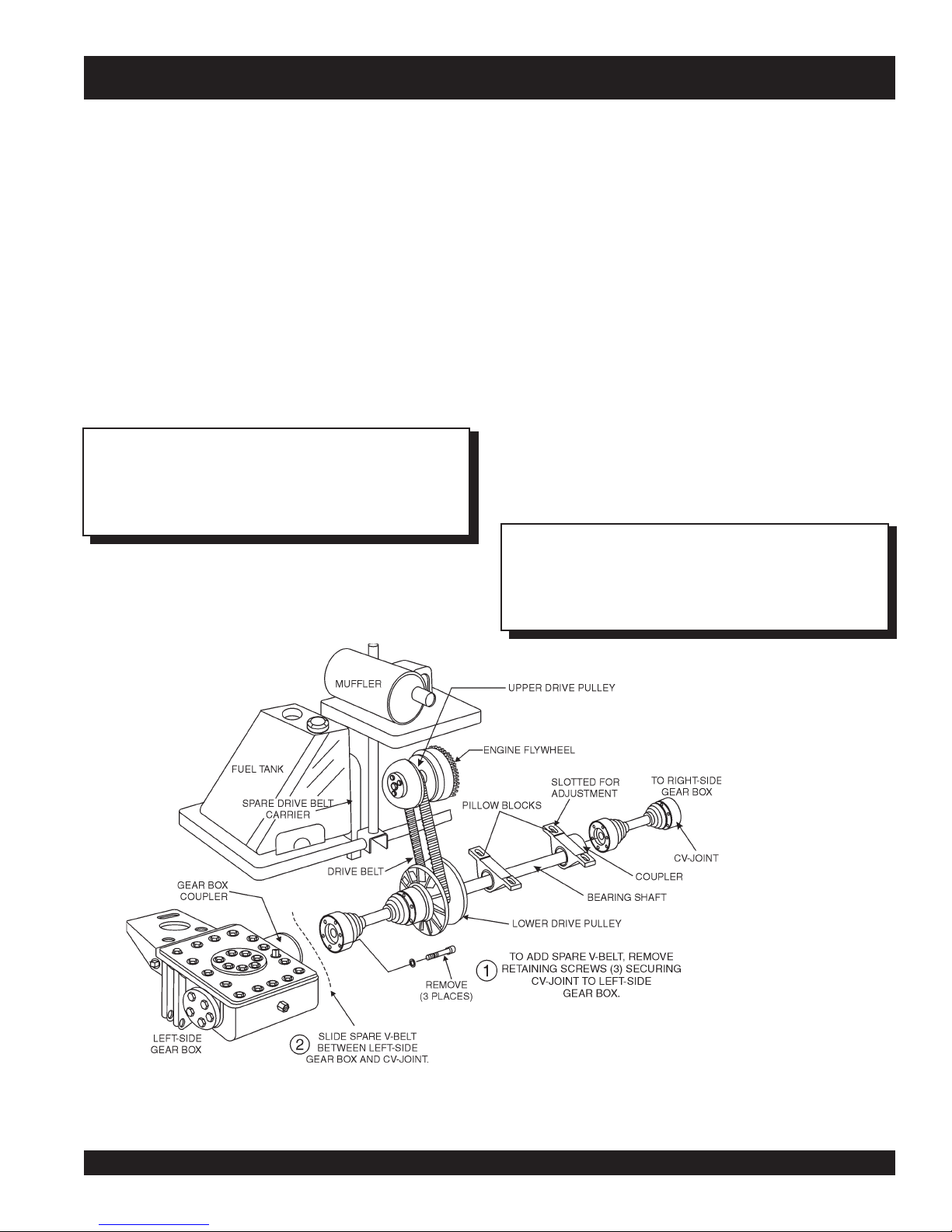

The HHN trowel is equipped with a "Torque Converter" which

supplies torque to both the left and right gear boxes.

The function of the a torque converter is to automatically deliver the

correct amount of torque required by the trowel under all load

conditions. This enables the trowel to deliver the necessary torque

for float pan applications and the high rotor speeds required for

burnishing concrete.

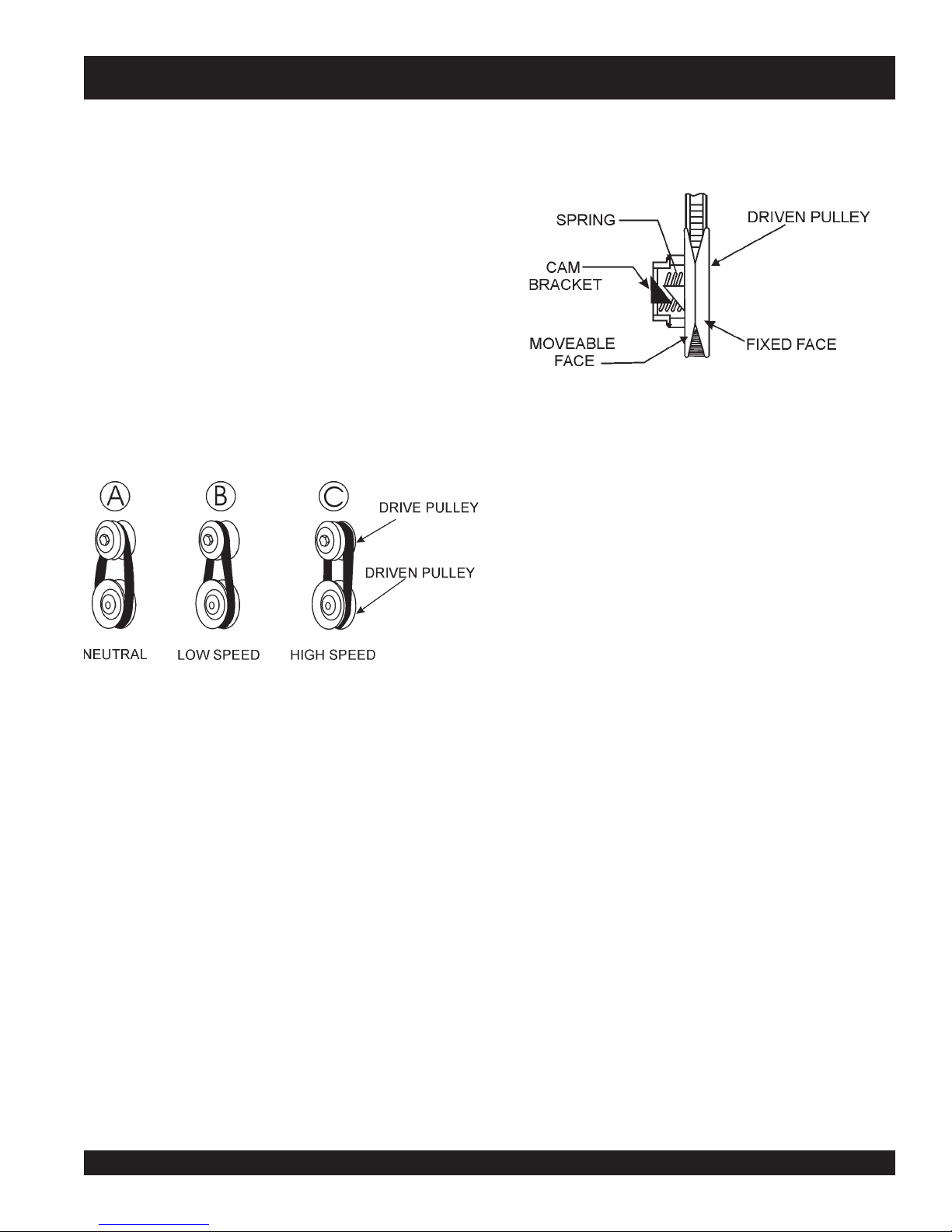

The torque converter used in the HHN series trowels is of the

variable pitch pulley type (Figure 14) connected by a drive belt.

Fig. 14. Torque Converter/Variable Pitch Pulley

As shown in Figure 16, centrifugal force pushes the roller arms (see

Figure 17 below) against the ramp plate, forcing moveable face

toward fixed face squeezing belt.

The "Variable Pitch Pulleys" have one

. The

face

is controlled by roller weight arms and springs, which change

position according to engine speed. The

is controlled by a spring and belt tension.

face

Fig. 16. Pulley Interaction

fixed face

drive

pulley ( torque converter, Figure 17) moveable face

, and one

driven

pulley

moveable

moveable

Drive Pulley

The "Drive Pulley" uses centrifugal force (Figures 15 and 16)

to create a belt squeeze force transmitted at the pulley faces.

This condition functions as an automatic clutch.

Figure 15. Torque Converter (Centrifugal Force)

Fig. 17. Variable Pitch Pulley

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 22

PAGE 22 — HTN 31V

Page 23

HHN -31V — MAINTENANCE

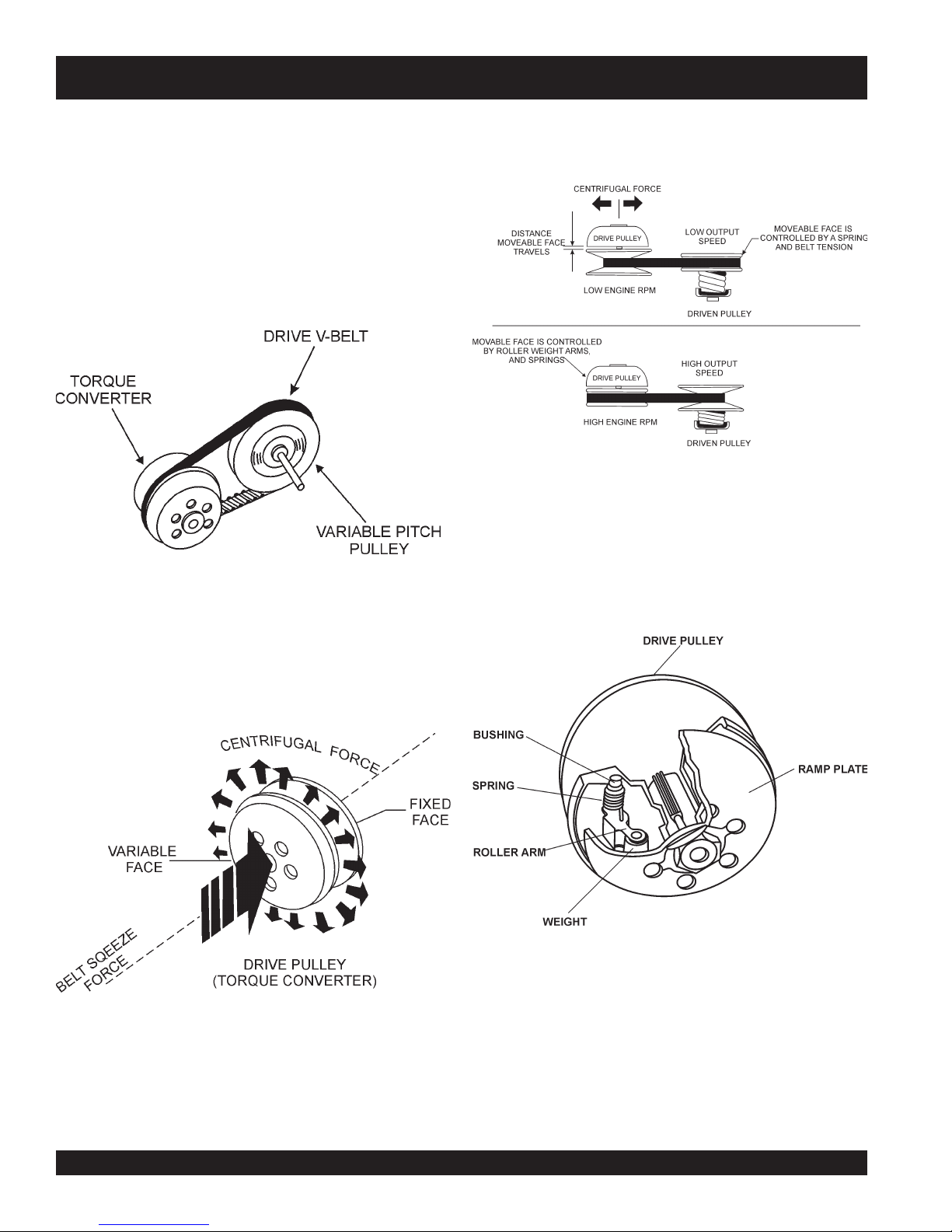

How It Works (Figure 17)

Condition A:

Condition B:

Condition C:

zz

z

Engine Idling

zz

zz

z

Drive Pulley: Small

zz

zz

z

Driven Pulley: Large

zz

zz

z

Belt: Loose and Stationary

zz

zz

z

Engine Accelerating

zz

zz

z

Drive Pulley: Small But Increasing

zz

zz

z

Driven Pulley: Large But Decreasing

zz

zz

z

Belt: Approaching Tightness

zz

zz

Engine At High Speed

z

zz

zz

z

Drive Pulley: Large

zz

zz

z

Driven Pulley: Small

zz

zz

z

Belt: Tight

zz

Figure 17. Pulley Conditions

The torque sensitive pulley (Figure 18) utilizes a spring and cam

bracket. Peak performance results from proper interaction between

the driven pulley spring and the ramp angle of the cam bracket.

Figure 18. Pulley Spring and Cam Bracket

Blade Pitch

Matching Blade Pitch for Both Sets of Blades

Sometimes it may be necessary to match blade pitch between

the two sets of blades. There are some signs that this may be

necessary. For example, the differences in pitch could cause a

noticeable difference in finish quality between the two sets of

blades. Or, the difference in blade pitch could make the machine

difficult to control. This is due to the surface area in contact with

the concrete (the blade set with the greater contact area tends to

stick to the concrete more).

™™

Single Pitch

™

™™

Clutch

This clutch system provides a high pulley ratio (a low gear- so to

speak) to start out and a low pulley ratio ( a high gear- so to

speak) for a high speed operation, with infinite variation between

the two.

This means that it will not be necessary to give

order to "break the blades/pans loose". The machine can slowly

be brought up to speed.

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 23

full throttle

On a Single Pitch™ trowel each spider assembly can be pitched

individually, forcing the operator to constantly make adjustments

on each pitch tower.

in

Page 24

HHN -31V — MAINTENANCE

Blade Pitch Adjustment Procedure

The maintenance adjustment of blade pitch is an adjustment

that is made by a bolt (Figure 19) on the arm of the trowel blade

finger. This bolt is the contact point of the trowel arm to the lower

wear plate on the thrust collar. The goal of adjustment is to promote

consistent blade pitch and finishing quality.

There are some things to look for when checking to see if

adjustment is necessary. Is the machine wearing out blades

unevenly (i.e. one blade is completely worn out while the others

look new)? Does the machine have a perceptible rolling or

bouncing motion when in use? Look at the machine while it is

running, do the guard rings “rock up and down” relative to the

ground? Do the pitch control towers rock back and forth? These

are some of the indications that the blade pitch may need to be

adjusted using the adjustment bolts on the trowel blade finger.

It will be possible to adjust the “high” bolts down to the level of

the one that is not touching, or adjust the “low” bolt up to the level

of the higher ones. If possible, adjust the low bolt up to the level

of the rest of the bolts. This is the fastest way, but may not always

work. Verify that after adjustment, the blades pitch correctly.

Often times, if the blades are incorrectly adjusted, they will not

be able to pitch flat. This occurs when the adjusting bolts have

been raised too high. Conversely, sometimes the adjusting bolts

are too low and the blades cannot be pitched high enough for

finishing operations.

Changing A Blade

Whiteman recommends that all the blades on the entire machine

be changed at the same time. If only one or some of the blades

are changed at one time, the machine will not finish concrete

consistently and the machine may wobble or bounce.

1. Place the machine on a flat, level surface. Adjust the blade

pitch control to make the blades as flat as possible. Note

the blade orientation on the trowel arm. This is important

for ride-on trowels as the two sets of blades counter-rotate.

Lift the machine up, placing blocks under the main guard

ring to support it.

Figure 19. Blade Pitch Adjustment Bolt

The easiest and most consistent way to make this adjustment is

to use the Trowel Arm Adjustment Fixture (P.N. 9177) . This fixture

will allow consistent adjustment of the trowel arm fingers. It comes

with all the hardware necessary to properly accomplish this

maintenance and instructions on how to properly utilize this tool.

Adjusting the trowel arm fingers without a fixture requires a special

talent.

If a trowel arm adjustment fixture is not available and immediate

adjustment is necessary; we suggest the following procedure. If

you can see or feel which blade is pulling harder, adjust the bolt

that corresponds to that blade.

Another way to determine which blades need adjustment is to

place the machine on a flat surface and pitch the blades as flat

as possible. Now, look at the adjustment bolts. They should all

barely make contact with the lower wear plate on the spider. If

you can see that one of them is not making contact; some

adjustment will be necessary.

2. Remove the bolts and lock washers on the trowel arm, and

then remove the blade.

3. Scrape all concrete and debris from the trowel arm. This is

important to properly seat the new blade.

4. Install the new blade, maintaining the proper orientation

for direction of rotation.

5. Affix the bolts and lock washers.

6. Repeat steps 2-5 for all remaining blades.

Steering Adjustment

The steering assist adjustment is to be performed only by

qualified service technicians. For HHN steering adjustment

instructions, reference MQ Whiteman service bulletin 200925

Clean-Up

Never allow concrete to harden on the power trowel. Immediately

after use wash any concrete off the trowel with water, be careful

not to spray a hot engine or muffler. An old paint brush or broom

may help loosen any concrete that has started to harden.

Ttt

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 24

PAGE 24 — HTN 31V

Page 25

NOTE PAGE

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 25

Page 26

HHN -31V — TROUBLESHOOTING

GNITOOHSELBUORT.4ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?noitcnuflamhctiwslliK

.lla

tatonrohguorgninnurenignE

?leuF

?noitingI

?smelborprehtO .launams’rerutcafunamenignetlusnoC

.gninoitcnuftonhctiwsllikytefaS

?stcatnocdaB .hctiwsecalpeR

?sedalB

?redipS

?snoitcennoceriwesooL .yrassecensaecalpeR.gniriwkcehC

?smraleworttneB

gneeht

.yltcerrocgninoitcnuf

iniF

.yrassecenfihctiwsecalper;detaes

.rabedalbehtotlellarapdna

.yletaidemmitiecalper,tnebylthgilsnevesismra

sirotarepoehtnehwgninoitcnufsihctiwsllikehttahterusekaM

otdeilppusgniebleufsierehterusekaM.metsysleufehttakooL

.deggolctonsiretlifleufehttahterusneotkcehC.eni

sidnarewopsahhctiwsnoitingiehttahterusneotkcehC

.nrowylevissecxeton,noitidnocdoognierasedalbniatrecekaM

ehtmorf)mm05("2nahtsselonerusaemdluohssedalbhs

onerusaemdluohssedalbobmoc,egdegniliartehtotrabedalb

thgiartsebdluohsedalbfoegdegniliarT.)mm98("5.3tahtssel

saelgnahctipemasehttateserasedalbllatahtkcehC

rofelbaliavasiloottnemtsujdadleifA.redipsehttaderusaem

tnempiuqElanoitpOees(smralewortehtfotnemtsujdathgieh

.)

ehtfoenofI.smraleworttnebrofylbmessaredipsehtkcehC

sllor,secnuob“lewortfI

nevenusekamro,etercnoc

.”etercnocnislriws

?hctipedalB

?tfahsniaM

elbitpecrepasahenihcaM

.gninnurelihwnoitomgnillor

?ekoY

?sedalB

?sgnihsubmraleworT

er

?ralloctsurhT

?gnihsubralloctsurhT

?nrowgniraebtsurhT

.yrassecen

.yrassecenfisnoitcurtsni

.tnioptnemhcatta

.sedalbrehtollasahctip

.ralloctsurhtehtnignihsubehtecalper

.yrassecensaekoyecalpeR.gniraebtsurhteht

ybenodebnacsihT.ssenthgitrofsgnihsubmralewortehtkcehC

"8/1nahteromsierehtfI.nwoddnapusmralewortehtgnivom

ebdluohssgnihsubeht,mraehtfopitehttalevartfo)mm2.3(

.emitemasehttadecalperebdluohssgnihsubllA.decalp

.redipsehtnotignitatorybralloctsurhtehtfossentalfehtkcehC

.ralloctsurhtehtecalper)mm5.0("20.0nahteromybseiravtifI

tlitnactifI.redipsehtnotignikcorybralloctsurhtehtkcehC

,].D.Oralloctsurhtehttaderusaemsa[)mm4.2("23/3nahterom

fiecalpeR.eerfgninnipssititahteesotgniraebtsurhtehtkcehC

noitcesecnanetniaMreptsujdA.hctiptnetsisnocrofsedalbkcehC

ebdluohsylbmessaxobraegehtfotfahstuptuoniamehT

dnathgiartsnurtsumtfahsniamehT.ssenthgiartsrofdekcehc

dipsehttadnuorfotuo)mm80.0("300.0nahteromebtonnac

re

noylnevesserpekoyehtfosregnifhtobtahterusekamotkcehC

emasehtevahotdetsujdasiedalbhcaetahterusneotkcehC

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 26

PAGE 26 — HTN 31V

Page 27

HHN -31V — TROUBLESHOOTING

)DEUNITNOC(GNITOOHSELBUORT.4ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

hctiwsffo/noretsamehtgnidulcni,snoitcennoclacirtcelellakcehC

.gnikrowton)lanoitpo(sthgiL

ton)lanoitpo(yarpstnadrateR

.gnikrow

rohgihootsitroffegnireetS

.evisnopsernu

?gniriW

?sthgiL .nekorbfiecalpeR.doogllitserasblubthgilfieesotkcehC

?tnadrateR

?gniriW

?hctiwsdaB

?pmupyarpsdaB

fotuosegaknilgnireetS

?tnemtsujda

?stnenopmocnroW .nrowrotneberatahtstrapllaecalpeR

.yrassecensaecalpeR

.yrassecen

.pmupehtecalper,doog

.strohsonhtiwnoitidnocdoognisigniriwfieesotkcehcdna

saknatlliF.tneserpsitnadratererusekamotknatehtkcehC

hctiwsffo/noretsamgnidulcni,snoitcennoclacirtcelellakcehC

.yrassecensagniriwdnastnenopmocecalpeR.snoitcennoc

.nekorbfiecalpeR.hctiwsffo/noretsamfoytiunitnocehtkcehC

tub,nodenrutsihctiwsehtnehwtneserpegatlovasahpmupfI

erapmupehtotsnoitcennoclacirtcelednaetarepotonseod

eeS.eldnahehtfoesabehttadnuofegaknilgntcennocehttsujdA

.529002nitelluBecivreS,"snoitcurtsnItnemtsujdAgnireetS"

?stovipxobraeG .sexobraegfotnemevomeerferusneotkcehC

sinoitisopgnitarepO

.elbatrofmocnu

esolcooteraseldnahlortnoC

.traparafootrorehtegot

hsiggulsrognippilshctulC

otgnidnopsernehwesnopser

.deepsenigne

hctiPniwTnoegakniL

.gnikrowton)lanoitpo(

.tsafoottuogniraewstleB

?tnemtsujda

?noisnettleB

?stlebnroW .ecalpeR

?hctulCytriD .hctulcehtnaelcdnaelbmessasiD

?xobraeg

?seldnahknarC

?trapdegamaD .yletaidemmistrapdegamadllaecalpeR

?noisneT

?rotareporoftsujdataeS .taesehtfotnorfehtnodetacolrevelhtiwtaestsujdA

fotuosegaknilgnireetS

?seldnahlortnoctneB .tneberatahtstrapllaecalpeR

?hctulCtuonroW .hctulceritneecalper,pirG-isoP.hctulcnoitcirfnoseohsecalpeR

?xobraegnisgniraeBnroW

nisraegnekorbronroW

sgniraebtfahsevirdnroW .yrassecenfiecalper,sgniraebenilevirdtcepsnI

?tnemngilayellupevirD

.tnemtsujdagnireetsnonoitceseeS

tlebevirdehtnidetonsaecnatsidretnectlebehttsujdA

.noitcestnemtsujda

,ytluciffidhtiwsetatortfahsfI.dnahybtfahstupnixobraegetatoR

tupniehtkcehc

.tesasamrow

.hctulc

.tcerrocsi

.yrassecenfiecalpeR.sgniraebtfahstuptuodna

setatortfahstuptuoxobraegehttahtyfirevotralucitrapnikcehC

dnaraegmrowehthtobecalpeR.detatorsitfahstupniehtnehw

sarafsanwoddehsuperaseldnahknarchtobtahterusekaM

.degagnesiegaknilehttahtserusnesihtgnioD.elbissop

ehthtiwdengilayltcerrocsiyellupevirdrewolfieesotkcehC

ecnatsidretnecenilevirdottfahsknarcehttahterusneotkcehC

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 27

Page 28

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and remarks

used in the Parts section of this manual. Use the help numbers

found on the back page of the manual if there are any questions.

The contents and part numbers listed in the parts section are

subject to change

guarantee the availibility of the parts listed.

Sample Parts List:

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ....................... 1 .... INCLUDES ITEMS W/

2

*

2*12347 WASHER, 3/8 IN. ....1 ....

3 12348 HOSE .................... A/R .. MAKE LOCALLY

4 12349 BEARING ................ 1 .... S/N 2345B AND ABOVE

NO. Column

Unique Symbols - All items with same unique symbol

, #, +, %, or >) in the number column belong to the same

(

*

assembly or kit, which is indicated by a note in the “Remarks”

column.

Duplicate Item Numbers - Duplicate numbers indicate

multiple part numbers are in effect for the same general item,

such as different size saw blade guards in use or a part that

has been updated on newer versions of the same machine.

NOTE

without notice

WASHER, 1/4 IN. ...........

When ordering a part that has more

than one item number listed, check

the remarks column for help in

determining the proper part to order.

. Multiquip does not

NOT SOLD SEPARATELY

MQ-45T ONLY

QTY. Column

Numbers Used - Item quantity can be indicated by a number,

a blank entry, or A/R.

A/R (As Required) is generally used for hoses or other parts

that are sold in bulk and cut to length.

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Column.

REMARKS Column

Some of the most common notes found in the “Remarks”

*

Column are listed below. Other additional notes needed to

describe the item can also be shown.

Assembly/Kit

symbol will be included when this item is purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use

only with the specific model number or model number variant

listed. It can also be used to show a part is NOT used on a

specific model or model number variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

- All items on the parts list with the same unique

- Used to list an effective serial number

- Indicates that the part is used

PART NO. Column

Numbers Used - Part numbers can be indicated by a number,

a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a part that

has not been assigned a formal part number at time of

publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will be

clarified in the “Remarks” Column.

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 28

“Make/Obtain Locally”

purchased at any hardware shop or made out of available

items. Examples include battery cables, shims, and certain

washers and nuts.

“Not Sold Separately”

purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available for

sale through Multiquip.

PAGE 28 — HTN 31V

- Indicates that the part can be

- Indicates that an item cannot be

Page 29

HHN -31V — SUGGESTED SPARE PARTS

31 VANGUARD ENGINE

1 to 3 Units

Qty. P/N Description

4 ............ 0189 ................. HANDLE GRIP

4 ............ 2267 ................. HANDLE GRIP (RIGHT SIDE)

1 ............ 11430 ............... SWITCH

2 ............ 12460 ............... CABLE, PITCH

1 ............ 1617 ................. LEVER ASSY. TROWEL ADJUSTMENT

2 ............ 2737 ................. KNOB ASSY.

1 ............ 10208 ............... MUFFLER W/CLAMP

1 ............ 10434 ............... CLAMP

1 ............ 10463 ............... CLAMP

4 ............ 10937 ............... BELT (B-37)

1 ............ 11771 ............... BRACKET ENGINE THROTTLE CABLE

1 ............ 12168 ............... HEADER PIPE

1 ............ 2124 ................. THROTTLE CABLE

5 ............ 2829 ................. ARMS

2 ............ 9005 ................. LEVER TROWEL ARM (L.S.)

20 .......... 0166A .............. WASHER

20 .......... 1876 ................. JAM NUT

20 .......... 0164B .............. SCREW

5 ............ 11039 ............... BUSHING

2 ............ 9111 ................. SPRING (L.S.)

20 .......... 1875 ................. WASHER

20 .......... 1322 ................. SCREW ASSY., ARM RETAINING

2 ............ 12611 ............... SPIDER PLATE

20 .......... 1162A .............. CAP GREASE FITTING

20 .......... 16602 ............... SCREW (HHC 3/8 -16 X 3/8)

20 .......... 1456 ................. NUT (3/8 -16)

20 .......... 12097 ............... SCREW (SQH 3/8-16 X 1 3/4 CONE)

2 ............ 2143 ................. SPRING (R.S.)

2 ............ 1986 ................. LEVER TROWEL ARM (R.S.)

2 ............ 12005 ............... SAFETY KILL SWITCH

20 .......... 0181B .............. WASHER 1/4 IN

2 ............ 11418 ............... FUEL CAP/GUAGE

20 .......... 4514 ................. SCREW (HHC 1/4-20 X 5/8)

Qty. P/N Description

2 ............ 2124 ...................... CABLE THROTTLE (RT)

10 .......... 10031 .................... WASHER 1/4 IN.

2 ............ 11692 .................... BRACKET BATTERY

2 ............ 11693 .................... BOLT BATTERY

6 ............ 2509 ...................... WING NUT

2 ............ 12548 .................... SPRAY PUMP

2 ............ 2108 ...................... CAP SPRAY TANK

2 ............ 10958 .................... SWITCH, IGNITION

1 ............ 19301 .................... TERMINAL STRIP (10-POLE)

1 ............ 2580 ...................... CHOKE CABLE

1 ............ 2673 ...................... CIRCUIT BREAKER 30 AMP, 12V

2 ............ 4682 ...................... TOGGLE SWITCH

2 ............ 8381 ...................... BOOT, TOGGLE SWITCH

1 ............ 11792 .................... ACCESSORY SOLENOID

4 ............ 11078 .................... KEYS, IGNITION (SWITCH)

2 ............ 2655 ...................... HOUR METER

NOTE

Part numbers on this Suggested

Spare Parts List may supercede/

replace the P/N shown in the text

pages of this book.

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 29

Page 30

NAME PLATE AND DECALS

HHN -31V — NAME PLATE AND DECALS

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 30

PAGE 30 — HTN 31V

Page 31

HHN -31V — NAME PLATE AND DECALS

NAME PLATE AND DECALS

NO PART NO PART NAME QTY. REMARKS

1 11246 DECAL: LIFT .................................................. 2............ PART OF DECAL KIT12620

2 1499 DECAL: MQ WHITEMAN (RED/TOWER) 2

3 2634 DECAL: DANGER (COMPRESSION) 2

4 11246 DECAL: LUBRICATION .................................. 4 ............ PART OF DECAL KIT12620

5 12571 DECAL: OPERATING LIGHTS 1

6 11247 DECAL: HELMET, HAND AND FOOT ............ 1 ............ PART OF DECAL KIT12620

7 11246 DECAL: RADIATING HEAT ............................. 1 ............ PART OF DECAL KIT12620

8 20198 DECAL: HHN SERIES 1

9 13118 DECAL: POWDER COATED 1

10 10818 DECAL: MQ WHITEMAN (WHITE/PANEL) .....1

11 DECAL: NAME PLATE .................................... 1 ............ CONTACT MQ SERVICE DEPT W/ MODEL & S/N

12 11246 DECAL: CHECK HYDRAULIC OIL.................. 2............ PART OF DECAL KIT12620

13 11246 DECAL: GEAR DRIVE ....................................2 ............ PART OF DECAL KIT12620

14 11246 DECAL: BELT DRIVE ...................................... 1 ............ PART OF DECAL KIT12620

SEE DECAL ILLUSTRATIONS ON PAGE 10.

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 31

Page 32

HHN -31V — PIVOT/GEAR BOX-RIGHT SIDE ASSY.

PIVOT/GEAR BOX- RIGHT SIDE ASSY.

VIEW FROM OPERATOR’S SEAT

1

2

R

E

D

W

O

P

D

E

T

C

A

O

3

1

5

4

3

1

5

6

4

8

RIGHT-SIDE

GEARBOX

9

NOTES:

SCREWS ARE PART OF

RIGHT-SIDE GEAR BOX

ASSEMBLY. TO ORDER

1

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 32

PAGE 32 — HTN 31V

Page 33

HHN -31V — PIVOT/GEAR BOX-RIGHT SIDE ASSY.

PIVOT/GEAR BOX- RIGHT SIDE ASSY.

NO PART NO PART NAME QTY. REMARKS

1 1023 SCREW, HHC 3/8 -16 X 1-1/4 8

2 0166A WASHER, LOCK 3/8 MED 8

3 9154 SCREW 4 PART OF GEAR BOX

4 12713 ROCKER BLOCK 2

5 12725 BLOCK, ROCKER 2

6 12716 TRUNNION W/A 1

7 12704 GEARBOX, COMPLETE 1

8 12859 PLATE G.B. SPACER 1

9 12856 BRACKET, DIRECTION CONTROL 1

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 33

Page 34

PIVOT/GEAR BOX- LEFT SIDE ASSY.

VIEW FROM OPERATOR’S SEAT

HHN -31V — PIVOT-LEFT SIDE ASSY.

1

2

R

E

D

W

O

P

D

E

T

C

A

O

1

3

1

3

5

1

4

3

1

8

LEFT-SIDE

GEARBOX

9

2

10

2

6

5

NOTES:

SCREWS ARE PART OF

1

LEFT-SIDE GEAR BOX

ASSEMBLY. TO ORDER

SCREWS USE P/N 9154.

USE ITEMS 9, 10 AND 11

TO MOUNT RIGHT-SIDE

2

GEAR BOX.

11

2

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 34

PAGE 34 — HTN 31V

Page 35

HHN -31V — PIVOT-LEFT SIDE ASSY.

PIVOT/GEAR BOX- LEFT SIDE ASSY.

NO PART NO PART NAME QTY. REMARKS

1 1023 SCREW, HHC 3/8 -16 X 1-1/4 8

2 0166A WASHER, LOCK 3/8 MED 8

3 9154 SCREW 4 PART OF GEAR BOX

4 12719 PIVOT, GEAR BOX W/A 1

5 12725 BLOCK, ROCKER 2

6 12859 PLATE G.B. SPACER 1

7 12703 GEARBOX, COMPLETE 1

8 12856 BRACKET, DIRECTION CONTROL 1

9 0176 NUT, NYLOC 1/2-13 2 USE ON RS GEAR BOX

10 0447 WASHER, FLAT 1/2 SAE 2 USE ON RS GEAR BOX

11 2549 SCREW, HHC 1/2-13 X3 2 USE ON RS GEAR BOX

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 35

Page 36

GEARBOX ASSY.

HHN -31V — GEAR BOX ASSY.

15

44

41

21

31

11

35

1

20

4

45

30

29

17

14

36

9

3

1

5

24

39

32

7

28

20

13

30

4

23

42

21

31

4

2

22

10

24

25

3

18

6

26

32

43

16

8

37

27

33

2

38

1

18

4

24

43

12

19

2

4

USE SILICONE SEALANT

1

UNDER RETAINER; LOCTITE #30518.

TORQUE TO 30 FT-LBS.

2

USE SILICONE SEALANT

3

AT SPLICE; LOCTITE #30518.

BEARING CONE FOR OLD STYLE

4

GEARBOX IS NOT INCLUDED IN KIT.

19

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 36

PAGE 36 — HTN 31V

Page 37

HHN -31V — GEAR BOX ASSY.

GEARBOX ASSY.

NO PART NO PART NAME QTY. REMARKS

1$ 0166 A WASHER, LOCK 3/8 MED 16

2$ 0181 B WASHER, LOCK 1/4 MED 8

3$ 0205 SCREW, HHC 3/8-16 X 1 8

4$ 0730 SCREW, HHC 1/4-20 X 1 8

5$ 10136 WASHER, FLAT, 3/8 SAE 8

6$ 11584 SIGHT GLASS, 3/4 MALE PIPE 1

7$ 11682 FITTING, PLUG, 1/8 MP SQ HEAD 1

8$ 12599 CASE, GEAR MACHINED 1

9$ 12600 COVER, GEAR BOX 1

10$ 12601 CAP, GEARBOX INPUT 1

11$ 12602 CAP, GEARBOX IDLER 2

12$% HUB, INPUT SHAFT ............................................ 1 ................... NOT AVAILABLE SEPARATELY

13$+ GEAR, 85T HELICAL........................................... 1 ................... NOT AVAILABLE SEPARATELY

14$

*

15$

*

16$% PINION, 15T BEVEL ............................................ 1 ................... NOT AVAILABLE SEPARATELY

17$+ SHAFT, OUTPUT ................................................ 1 ................... NOT AVAILABLE SEPARATELY

18 12691 BEARING, CONE TIMKEN #M84249 .................. 2 ................... OLD STYLE GEARBOX

18$% 21803 BEARING, CONE SKF 32305 J2 ....................... 2 ................... NEW STYLE GEARBOX

19 12692 BEARING, CUP TIMKEN #M84210..................... 2 ................... OLD STYLE GEARBOX

20 12693 BEARING, CONE TIMKEN #2793 ....................... 2 ................... OLD STYLE GEARBOX

20$

21 12694 BEARING, CUP TIMKEN #2729 .......................... 2 ................... OLD STYLE GEARBOX

22$% 12696 COUPLER, GEARBOX 1

23$ 12697 PIN, DOWEL 0.375/.3752 X 3/4 2

24$%# 12698 O RING, SIZE - 151 BUNA N 4

25$# 12700 SEAL, CASE 0-RING HHN 0.103 X 46. 38 1

26$%# 12701 SEAL, NATIONAL #471424 1

27$# 12702 SEAL, NATIONAL #470682 1

28$

29$+ 12736 KEY, HARDENED 3/8 X 1-1/2 1

30 12796 BEARING, CONE TIMKEN #26882 ..................... 2 ................... OLD STYLE GEARBOX

30$+ 21801 BEARING, CONE SKF 33109 Q ......................... 2 ................... NEW STYLE GEARBOX

31 12797 BEARING, CUP TIMKEN #26823 ........................ 2 ................... OLD STYLE GEARBOX

32$ 20932 SHIM, INPUT. 0.002 THICK 3

33$% 1313 SCREW, FHSC 3/8 - 24 X 3/4 PLAIN 1

34$% 26034 KEY, 3/16 X 17/32 1

35$ 4196 SCREW, HHC 3/8 - 16 X 3/4 8

36$ 911064 FITTING, PLUG 1/2 MP SQ HEAD 1

37$ 911329 FITTING, PLUG 3/8 MP MAGNETIC 2

38$% 9120 RETAINER, DRIVEN PULLEY 1

39$ 9154 SCREW, HHC 3/8 - 16 X 1-3/4 4

40 20933 KIT, BEARING/SEAL HHN HELICAL ................... 1 ................... INCLUDES ITEMS W/ #

41 21854 GEARBOX ASSY., RIGHT ................................... 1 ................... INCLUDES ITEMS W/ $

42 21853 GEARBOX ASSY., LEFT ...................................... 1 ................... INCLUDES ITEMS W/ $

43 21853854INPUT KIT, INPUT PINION/HUB/COUPLER .................. 1 ................... INCLUDES ITEMS W/ %

44 21853854INTER KIT, INTER PINION/GEAR .................................. 1 ................... INCLUDES ITEMS W/

45 21853854OUTER KIT, OUTPUT SHAFT/GEAR .............................. 1 ................... INCLUDES ITEMS W/ +

21802 BEARING, CONE SKF 32307 J2 ........................ 2 ................... NEW STYLE GEARBOX

*

12735 KEY, 3/8 X 3/4 1

*

PINION, 17T HELICAL ........................................ 1 ................... NOT AVAILABLE SEPARATELY

GEAR, 60T HELICAL ........................................... 1 ................... NOT AVAILABLE SEPARATELY

*

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 37

Page 38

HHN -31V — CONTROL STEERING (ASSIST)

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 38

PAGE 38 — HTN 31V

Page 39

HHN -31V — CONTROL STEERING (ASSIST)

CONTROL STEERING (ASSIST)

NO PART NO PART NAME QTY. REMARKS

1 0131 A SCREW, HHC 1/4-20 X 3/4 12

3 0447 WASHER, FLAT, 1/2 SAE 12

6 10024 NUT, NYLOC 1/4-20 16

7 10133 NUT, NYLOC 3/8-16 8

8 10136 WASHER, FLAT,3/8 SAE 16

9 10176 NUT, NYLOC 1/2-13 13

10 1023 SCREW, HHC 3/8-16 X 1 1/4 8

11 11127 LEVER, STEERING CONTROL W/A 2

13 11139 BEARING, FLANGE HOUSING 40M-2 6

14 11141 SPACER, ROD END 5

15 11142 ROD END, 1/2-20 MALE RH 9

16 11143 ROD END, 1/2-20 FEMALE RH 7

19 11146 NUT, HEX JAM 1/2-20 11

21 11150 BEARING, SB-201-8 6

22 11170 SCREW, HHC 1/2-20 X 1.1/2” 2

25 11205 ROD, L/R MOTION 1

26 12193 LEVER, L/R CONTROL W/A 1

34 5054 A WASHER, LOCK, 1/2 MED. 2

36 6159 A SCREW, HHC 1/2-13 X 2 13

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 39

Page 40

HHN -31V — CONTROL STEERING (ASSIST)

HHN 31V • RIDE-ON POWER TROWEL — OPERATION & PARTS MANUAL — REV. #5 (03/02/07) — PAGE 40

PAGE 40 — HTN 31V

Page 41

HHN -31V — CONTROL STEERING (ASSIST)

CONTROL STEERING (ASSIST)

NO PART NO PART NAME QTY. REMARKS

2 2267 GRIP HANDLE, LEFT-RIGHT 2

3 0447 WASHER, FLAT, 1/2 SAE 12