Page 1

OPERATION AND PARTS MANUAL

MODEL HBC19B

MODEL HBC25B

REBAR CUTTER

(PORTABLE ELECTRIC)

Revision #1 (03/07/12)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

HBC19B/HBC25B REBAR

CUTTER

Table of Contents .................................................... 2

Parts Ordering Procedures ..................................... 3

Safety ...................................................................... 4

Rules and Regulations ......................................... 5-6

Specifications .......................................................... 7

General Information ................................................ 8

Components ............................................................ 9

Operation ......................................................... 10-11

Maintenance..................................................... 12-13

Explanation of Codes in Remarks Column ........... 14

Suggested Spare Parts ......................................... 15

COMPONENT DRAWINGS

Nameplate and Decals..................................... 16-17

HBC19B Rebar Cutter Assembly ..................... 18-21

HBC25B Rebar Cutter Assembly ..................... 22-25

Tools ................................................................. 26-27

Wiring Diagram ..................................................... 28

TABLE OF CONTENTS

Terms and Conditions Of Sale — Parts ................ 29

NOTICE

Specification and part number are subject to change

without notice.

PAGE 2 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 3

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

Choose from three easy options:

January 1

Effective:

st

, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

N View Parts Diagrams

N Order Parts

N Print Specification Information

Goto www.multiquip.com and click on

Order Par ts

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

to log in and save!

Order via Phone:

If you have an MQ Account, to obtain a Username

and Password, E-mail us at: parts@multiquip.

com.

To obtain an MQ Account, contact your

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Note: Discounts Are Subject To Change

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

When ordering parts, please supply:

R Dealer Account Number

R Dealer Name and Address

R Shipping Address (if different than billing address)

R Return Fax Number

R Applicable Model Number

R Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

R Specify Preferred Method of Shipment:

UPS/Fed Ex DHL

N Priority One Tr uck

N Ground

N Next Day

N Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 3

Page 4

SAFETY

FOR YOUR SAFETY AND SAFETY OF OTHERS!

Safety precautions should be followed at all

times when operating this equipment. Failure to read and understand the Safety Messages and Operating Instructions could result

in injury to yourself and others.

NOTICE

This manual has been developed to provide complete

instructions for the safe and efficient operation of this

equipment.

Before using this equipment ensure that the operating individual has read and understood all instructions in this

manual.

SAFETY MESSAGE ALERT SYMBOLS

The three Safety Messages shown below will inform you

about potential hazards that could injure you or others.

The Safety Messages specifically address the level of exposure to the operator, and are preceded by one of three

words: DANGER, WARNING, or CAUTION.

DANGER

HAZARD SYMBOLS

Potential hazards associated with the operation of this

equipment will be referenced with Hazard Symbols which

appear throughout this manual, and will be referenced in

conjunction with Safety Message Alert Symbols.

WARNING — Respiratory Hazards

ALWAYS wear approved respiratory

protection when required.

CAUTION — Rotating Parts Hazards

NEVER operate equipment with covers or

guards removed. Keep fingers, hands, hair

and clothing away from all moving parts to

prevent injury.

CAUTION — Accidental Starting Hazards

ALWAYS place the equipment ON/OFF

switch in the OFF position when the

equipment is not in use.

You WILL be

INJURED

directions.

WARNING

You CAN be KILLED or

KILLED

or

SERIOUSLY

if you DO NOT follow these

SERIOUSLY INJURED

CAUTION — Eye and Hearing Hazards

ALWAYS wear approved eye and hearing

protection.

if you DO NOT follow these directions.

CAUTION — Equipment Damage Hazards

Other important messages are provided throughout this

manual to help prevent damage to your equipment,

CAUTION

You CAN be

INJURED

if you DO NOT follow

other property, or the surrounding environment.

these directions.

PAGE 4 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 5

WARNING — Read This Manual

Failure to follow instructions in this manual may lead to

serious injury or even

operated by trained and qualified personnel only! This

equipment is for industrial use only.

GENERAL SAFETY

DO NOT operate or service this equipment

before reading this entire manual.

This equipment should not be operated by

persons under 18 years of age.

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, steel-toed boots and other

protective devices required by the job.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the

influence of drugs or alcohol.

DEATH

! This equipment is to be

RULES AND REGULATIONS

DO NOT wear loose clothing or jewelry. Contain long

hair. Keep hair, clothing, and gloves away from moving

parts. Rotating parts can cause injury if contacted.

ALWAYS keep work area clean and free of foreign matter

and debris. Also keep work area well lit.

NEVER operate the equipment in an

explosive atmosphere or near combustible

materials. An explosion or fire could result

causing severe

death.

DO NOT overreach. Keep proper footing and balance at

all times.

NEVER leave the equipment unattended. When not is

use, before servicing, and when changing accessories,

always unplug the equipment from the power source.

USE this equipment for its intended purpose only.

KEEP equipment clean for better and safer performance.

Keep handles dry, clean, and free from oil and grease.

INSPECT the equipment after each use. Replace any

damaged or worn parts immediately. Do not use

equipment if defective.

If a malfunction occurs, immediately unplug the

equipment from the power source and correct the

problem. If problem cannot be corrected, contact the

nearest MQ service center.

bodily harm or even

ALWAYS store the equipment in a clean, dry location

NEVER use accessories or attachments that are not

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

Manufacturer does not assume responsibility for any

accident due to equipment modifications. Unauthorized

equipment modification will void all warranties.

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult to read.

ALWAYS check the equipment for loosened threads or

bolts before starting.

MAINTAIN equipment is a safe operating condition at

all times.

KEEP bystanders, children, and visitors away while

operating the equipment. Distractions can cause loss of

control.

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 5

out of the reach of children.

EMERGENCIES

ALWAYS know the location of the nearest

fire extinguisher

ALWAYS know the location of the nearest

first aid kit

In emergencies,

of the nearest phone or

Also know the phone numbers of the nearest

ambulance, doctor

information will be invaluable in case of emergency.

.

.

always

and

know the location

keep a phone on the job site

fire department

. This

.

Page 6

RULES AND REGULATIONS

ELECTRICAL SAFETY

■

ALWAYS test the

POWER

switch on the equipment before

operating. The purpose of this switch is to shut down the

power.

■

NEVER use a extension cord that is frayed or damaged

where the insulation has been cut.

■

NEVER carry the equipment by its power cord or

disconnect it by yanking the cord from the power outlet.

■

ALWAYS make certain that the proper extension cord

has been selected for the job. See Extension Cord

Gauge Selection Table.

■

NEVER allow power cord to

■

NEVER

■

When connecting the unit to a power receptacle, make

stand in water

lay in wate

r.

while operating the equipment.

sure the receptacle circuit is connected to either a GFCI

receptacle or a receptacle protected by a 20 amp circuit

breaker.

■

When plugging the unit into a power receptacle, check

the nameplate for the correct operating voltage.

Operating the rebar bender at the wrong voltage will

damage the electrical components. ALWAYS read the

nameplate before applying power.

■

This unit is equipped with a 3-prong male power plug.

DO NOT use a 2-prong adapter when plugging into a

wall outlet. This will defeat the purpose of the ground

circuit. If the plug does not fit into the receptacle, contact

a qualified electrician to install a 3-conductor wall

receptacle (outlet).

■

Avoid body contact with grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an

increased risk of electrical shock if your body is

grounded.

■

DO NOT expose the hydraulic power unit to rain or wet

conditions. Water entering the power unit will increase

the risk of electrical shock.

■

When operating the unit outdoors, be sure to use the

appropriate outdoor extension cord. This type of

extension cord reduces the risk of electrical shock.

■

ALWAYS remove the AC power cord from the power

source before performing any service or maintenance

on the unit. This preventative safety measure reduces

the possibility of accidental starting.

When operating near an arc welder, it is important the

both the unit and the welding equipment be connected

to the same earth ground. If they are not, server damage

to the unit, particularly to the power cord could occur.

Personal injury may also occur.

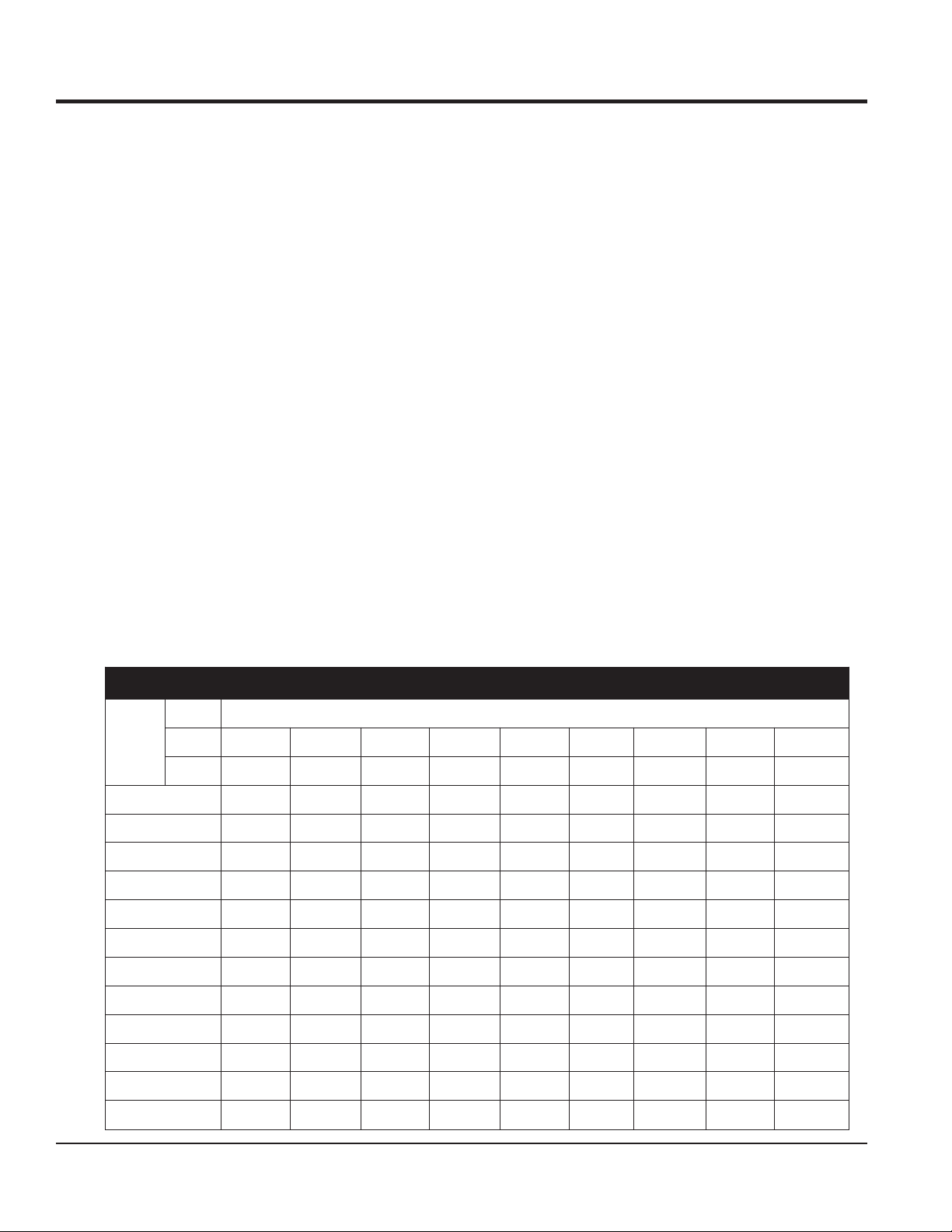

noitceleSeguaGdroCnoisnetxE

stloV teeFnidroCfohtgneL

erepmA

gnitaR

egnaR

V511 .tF52 .tF05 .tF001 .tF051 .tF002 .tF052 .tF003 .tF004 .tF005

V032 .tF05 .tF001 .tF002 .tF003 .tF004 .tF005 .tF006 .tF008 .tF0001

2-0 81 81 81 61 61 41 41 21 21

3-2 81 81 61 41 41 21 21 01 01

4-3 81 81 61 41 21 21 01 01 8

5-4 81 81 41 21 21 01 01 8 8

6-5 81 61 41 21 01 01 8 8 6

8-6 81 61 21 01 01 8 6 6 6

01-8 81 41 21 01 8 8 6 6 4

21-01 61 41 01 8 8 6 6 4 4

41-21 61 21 01 8 6 6 6 4 2

61-41 61 21 01 8 6 6 4 4 2

81-61 41 21 8 8 6 4 4 2 2

02-81 41 21 8 6 6 4 4 2 2

PAGE 6 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 7

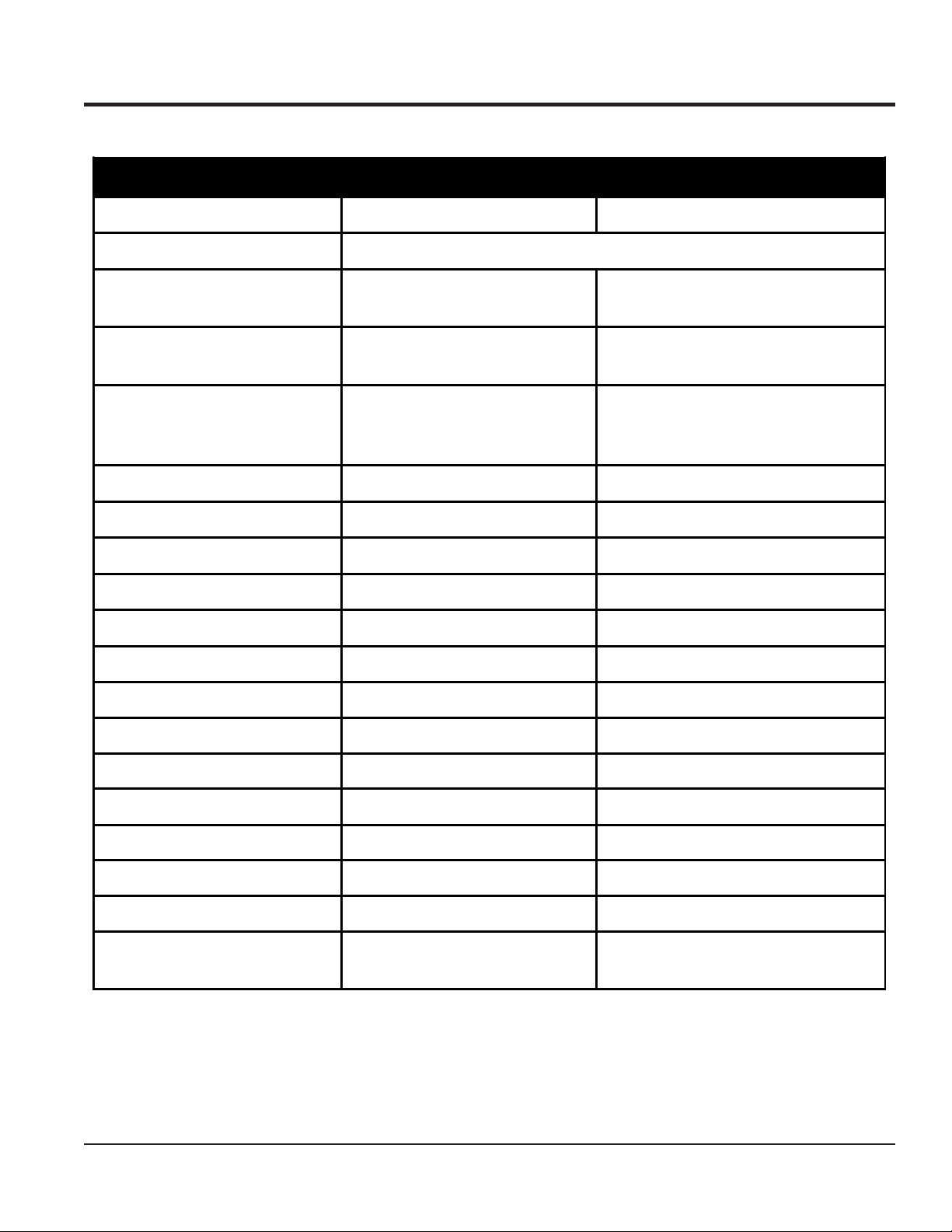

Model HBC19B HBC25B

Maximum Cutting Capacity

SPECIFICATIONS

Table 1. Specifications

Intermediate Grade (40)

70,000 psi (45 kg/mm

2

Hard Grade (50)

80,000 psi (55 kg/mm

2

High Tensile Strength

Grade (60)

90,000 psi (65 kg/mm

2

Cutting Speed

Rated Power

Amps

Power Source

Weight

Dimensions

Length 15.6 in (396.2 mm) 18.9 in (480 mm)

Width 4.4 in (111.8 mm) 5.4 in (137.2 mm)

)

)

No. 6, Size 3/4 in (19 mm) No. 8 Size 1 in (25 mm)

No. 6, Size 3/4 in (19 mm) No. 8 Size 1 in (25 mm)

No. 6, Size 3/4 in (19 mm) No. 8, Size 1 in (25 mm)

)

2.5 sec 3.5 sec

1330 W 1430 W

11 A 13 A

115 V single-phase AC 115 V single-phase AC

27 lb (12.25 kg) 48.5 lb (22 kg)

Height 8.7 in (221 mm) 10.6 in (269.2 mm)

Standard Equipment

Hydraulic Oil 5 oz (150 ml) 5 oz (150 ml)

Carrying Box Wooden Box Wooden Box

Allen Wrench 4 pieces (M3, 4, 5, 6) 4 pieces (M4, 5, 6, 8)

Open-End Wrench 0.67 x 0.75 in (17 x 19 mm)

0.55 x 0.67 in (14 x 17 mm)

0.94 in (24 mm)

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 7

Page 8

GENERAL INFORMATION

GENERAL INFORMATION

The

MQ HBC19B/HBC25B Rebar Cutters

to be used as a portable on-site rebar cutter, capable of

cutting in-place rebar safely and efficiently with the squeeze

of a trigger. Labor time and injuries are greatly reduced

from manually cutting rebar. The cutter can virtually handle

any rebar cutting job, from slabs and masonry walls to large

buildings and bridges.

The rebar cutter contains a built-in hydraulic pump with

innovative magnetic particle filtering. All parts are machined

to tight tolerances for maximum performance.

are designed

At approximately 27 to 49 pounds, the cutter is easily carried around job sites. Even overhead work takes minimum

effort.

The cutting rod returns to the starting position when the

operating switch is released after the rod makes its full

cutting stroke. The cutting rod will not move if the cutting

stroke is not finished. The operating switched must be held

long enough for cutting rod to complete stroke.

The HC19B/HBC25B come with a return valve that allows

the cutter rod to return to the starting position when the

cutter blade jams and stops during cutting of a rebar.

PAGE 8 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 9

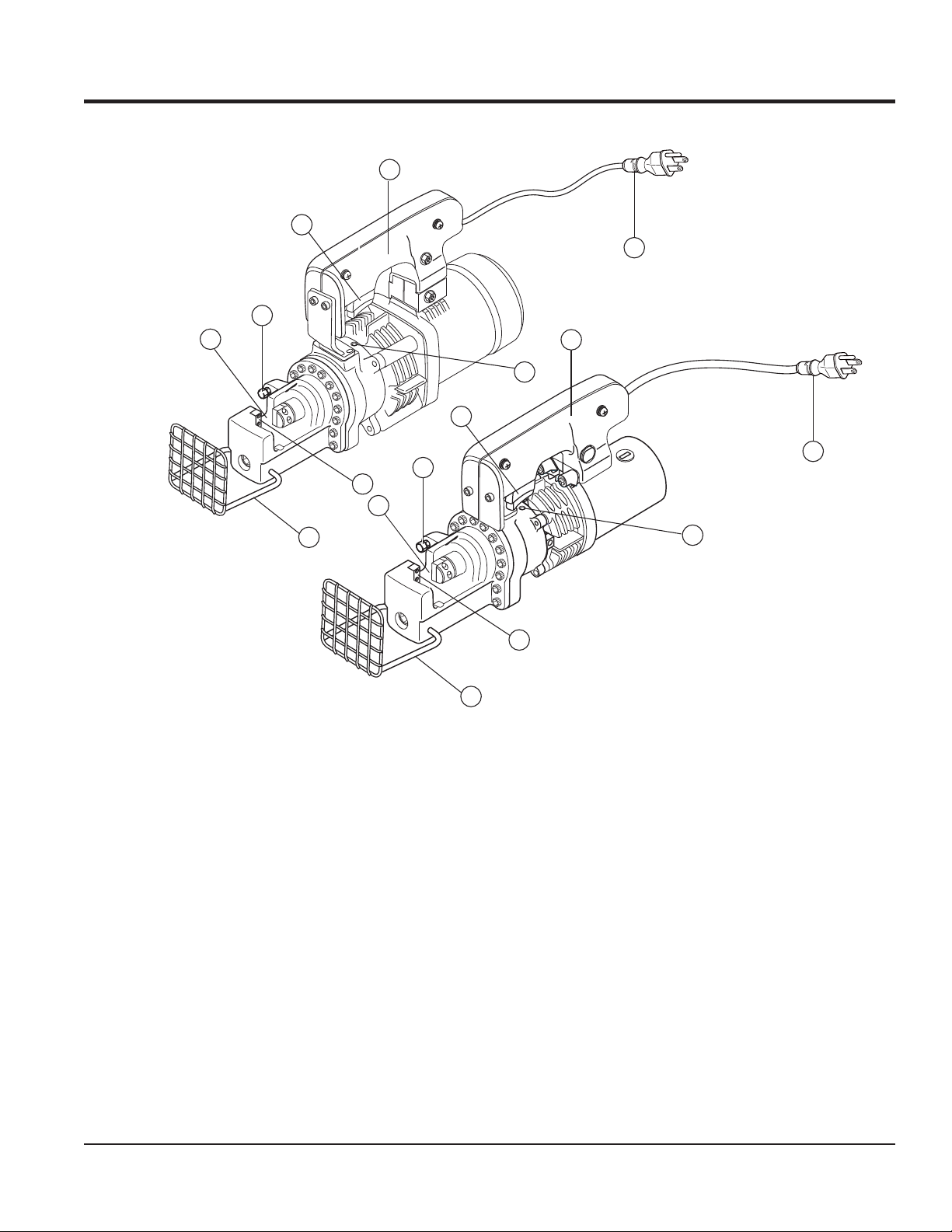

COMPONENTS

6

5

8

HBC19B

2

3

5

6

7

2

1

3

4

1

4

Figure 1. HBC19B/HBC25B Components

Figure 1 shows the components of the HBC19B/HBC25B

Rebar Cutter. These components are described below.

1. Blade (set of two) - Cuts the rebar that is set on the

6. Handle - Used to lift the rebar cutter.

holder between the blades.

7. Return Valve - Returns the cutter rod to the starting

2. Spacing Bolt and Nut - Allows rebar of different

diameters to be cut by adjusting the space between

the blades.

3. Rebar Holder - Holds the rebar to be cut.

4. Protector - Covers the rebar while cutting to prevent

position when the cutter blade jams and stops the

cutting of a rebar. This is done by rotating the return

valve half a turn in a counterclockwise direction with

the hexagonal wrench supplied with the unit.

8. Power Plug - Connects to a 150 V, 60 Hz power source.

rebar fragments from flying out.

HBC25B

7

8

5. ON/OFF Switch - Starts the cutting of the rebar when

the trigger switch is squeezed. When released, cutting

is stopped. Do not release release switch until the rebar

is completely cut.

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 9

Page 10

OPERATION

CUTTING PROCEDURE

WARNING

Make sure that the bar is resting fully within the blades

and protector is in the upright position. If the rebar is

not properly set, the cutting piece or fragments of the

rebar may scatter as soon as rebar is cut and the cutter

can also be damaged.

1. Adjust the spacing bolt according to the diameter of

the rebar being cut. Bolt must allow rebar to be flush,

at 90° to the blades.

2. Connect the electric plug from the cutter to a proper

power source (115 volts, 60 Hz).

3. Place the rebar in the rebar holder. Rebar must rest

fully within the blades. See Figure 2. Position the

protector over the surface to be cut.

Figure 2. Rebar Placement

4. Tighten the spacing bolt and jam nut to hold the rebar

in place.

WARNING

Do not cut rebar when it is not properly supported by

the spacing bolt or if the spacing bolt is not properly

adjusted. When cutting, hold the rebar on the spacing

bolt side as shown below. If not, the cut piece may fly

off and cause serious injury to the operator or

bystanders.

NEVER use worn or damaged blades. Replace

immediately before using cutter again.

WARNING

Replace damaged (broken and cracked edge) or

deformed cutter as soon as possible. Damaged cutter

could cause the rebar to be get out of place or cracked

during cutting. This may cause a serious accident. Do

not cut rebar that is less than 8 inches (200 mm) in

length asthis may cause rebar to fly off and result to

personal injury.

CAUTION

5. Squeeze the ON/OFF switch to start cutting the rebar.

Keep holding the ON/OFF switch until the cuting rod

completes cutting cycle. Do not attempt to partially cut

through the diameter of the rebar. This will cause

damage to the blades and cause the rebar to fly out.

6. At the end of the cutting cycle, release the ON/OFF

switch. The cutter rod will retract automatically.

7. If cutter reaches 158° F or higher, stop cutting operation

and allow machine to cool before using again.

8. Periodically inspect oil level and electric motor brushes.

Refer to Maintenance section for details.

PAGE 10 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

WARNING

Keep hands and face away from the blades

and other rotating or sliding parts during

operation.

RETURN VALVE OPERATION

The return valve is used when the cutter blade jams and

stops during cutting of the rebar.

1. Rotate the return valve half a turn in the

counterclockwise direction with the allen wrench (no. 4)

supplied with the unit. See Figure 3 for location.

Page 11

RETURN VALVE

REMOVE 2 BOLTS

TO REMOVE COVER

USE STANDARD

SCREWDRIVER

TO REMOVE CAP

CARBON

BRUSH

Figure 3. Return Valve

2. The cutter rod will retract and return to its starting

position.

3. Once the cutter rod returns to its starting position,

tighten the return valve before resuming rebar cutting.

DANGER

OPERATION

5-6 MM

(1/4 INCH)

Figure 4. Carbon Brush Size

1. Make sure that the power plug is not connected to the

power source.

2. For the HBC19B, remove the 2 bolts holding the cover

using a 4mm allen-head wrench then remove the cover

to access the two carbon brush caps (one on each

side). See Figure 5.

During operation of this rebar cutter, there

exists the possibility of

electrical shock or burn,

cause

severe bodily harm

electrocution,

which can

or even

DEATH!

To avoid these hazards:

NEVER use damaged or worn cables

WET

HANDS

when plugging the rebar cutter into

an AC power receptacle.

NEVER grab or touch a live power

cord with wet hands.

POWER

CORD

(POWER ON)

NEVER stand in water and touch a live power cord.

WARNING

Unplug unit from power source before replacing carbon

brushes.

REPLACING CARBON BRUSHES

Figure 5. Replacing Carbon Brushes (HBC19B)

CARBON BRUSH CAP

Figure 6. Replacing Carbon Brushes (HBC25B)

3. Remove the carbon brush cap of the motor outer frame

using a standard screwdriver. See Figures 5 and 6.

When the carbon becomes less than 5 or 6 mm (1/4 inch)

the motor force deteriorates because of low rectification

(Figure 4). The carbon brushes need to be replaced at this

4. Replace the carbon brushes with new ones (two for

the HBC19B and one for the HBC25B).

5. Put back the cap after brush is installed.

time. It is also recommended that the brushes be replaced

after 200 hours of use.

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 11

6. For the HBC19B, replace cover and tighten 2 bolts.

Page 12

MAINTENANCE

REPLACING OIL

The rebar cutter uses hydraulic action to operate. If there

is insufficient, dirty, or improper oil in the cutter, it will not

operate at full capacity. If unit is not operating properly,

check oil level and condition. If necessary, replace oil as

follows:

1. Loosen oil fill bolt with the supplied open-end wrench

Remove oil fill bolt and lay cutter to allow to oil to drain

out. See Figure 7.

REMOVE

BOLT

Figure 7. Removing Oil Fill Bolt

Model HBC19B HBC25B

Quantity 5 oz (150 ml) 5 oz (150 ml)

Oil Type

Above grades are blended to viscosity values that

conform to the ISO (International St

Organization) viscosity classification system.

3. Shake the cutter up and down to release any air bubble

4. Overfill with oil again.

5. Replace bolt in fill port and wipe off any excess oil.

6. Connect the cutter power cord to the power source.

Table 2. Oil Type

Shell Tellus Oil #46

Exxon Teresstic #46

that may be present.

Place a 3/16-inch diameter steel rod in bar holder.

Squeeze ON/OFF switch to activate the cutter and

allow the blade to touch the rod then turn off then

release the ON/OFF switch.

Shell Tellus Oil #32

Exxon Teresstic #32

andards

2. Turn cutter so that the oil fill port is on the top side. Fill

with oil until it overflows. See Figure 8. See Table 2 for

oil type and quantity.

FILL WITH OIL

Figure 8. Oil Fill

7. Turn cutter so that the oil fill port is on the top side

once again. Repeat oil fill procedure.

8. Squeeze ON/OFF switch again to continue and finish

cutting operation started earlier.

9. When cutting is complete, filling procedure is done.

WARNING

Unplug unit from power source before troubleshooting.

PAGE 12 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 13

MAINTENANCE

gnitoohselbuorT.3elbaT

motpmySmelborPelbissoPnoituloS

?tneiciffusnisiliO

oteudyletelpmoctcartertondiddorrettuC

dnaredwopnori,spihcleetstnemecrofnier

ehtfonoitropgnidilsehtnitneserptrid

.kcutssidorrettuC

?edalb

?tneiciffusnisiliO

?reporpmi

orrettuC

tuosemocd

sirewopgnittuctub

.rabertucotkaewoot

?notsip

?redlohrabehtdnadorrettuc

telpmoctcartertondiddorrettuC

?gnirpsnruterdorrettuckaewa

?nekorbevlavesaelersI.evlavesael

oteudyle

dorrettucfognillewsronoitrotsideht

oteudyletelpmoctcartertondiddorrettuC

evlavesaelerdnarednilycneewtebtcatnoC

si)rednilycninoitcejorpfoecafruspit(

dnarednilycneewtebecnaraelcreporpmI

.noitces

iT

.edalb

ces

.noit

erecalpeR

itcurtsnieeS.lioddA

.gnirpsnruterecalpeR

erehttahterusekaM

.tridroredwopnori

.notsipdnarednilycecalpeR

ecnanetniaMnisno

.dorrettucnaelC.dorrettuckcabhsuP

dorrettucecalpeR.stlobedalbnethg

ecnanetniaMnisnoitcurtsnieeS.lioddA

tasehctarcsonera

kcutsynanaelC.rednilycfoecafrusfopit

reporpmI

?evlav

.gnikaelsiliO

?egatlovtcerrocnI

etatortonseodrotoM

rotomroopro

.noitator

.erutamrafo

?sehsurbnobracfonoisarbA.sehsurbnobracecalpeR

ETON

decivresebdluohsstnenopmoclacirtcelelladna

esotlennosrepdezirohtuanu

dnarednilycneewtebtcatnoc

?gnikcaprebburrednilycnekorB.gnikcaprebburecalpeR

casrelevellionekorbrodehctarcS.trapevitcefedecalpeR

?k

?rednilycdnaredilsredlohrabdehctarcS.trapevitcefedec

?esacpmupdnareniltniojrednilycnekorB.trapevitcefedecalpeR

?tlobllifliofogninethgittneiciffusnI.tlob

sdnehtobtasgniraebdemrofedronekorB

resesuacdluoctahtsnoitidnocotdaelnacstnenopmoclacritcele

alpeR

aM

.ecruos

.tnempiuqetcerrocehthtiwlennosrepdeniartylreporpybenodebtsumpmup

.evlavdnarednilycecalpeR

lliflionethgiT

rewopreporpottcennocsitinuerusek

niraebecalpeR

.sg

evitisneserasecnaraelcesolcyrevevahaeranotsipdnapmupciluardyhehtfostnenopmoclanretniehT:

sidehT.gnildnahreporpmirodiulfciluardyhehtfonoitanimatnoc,trid,tsudmorfegamadot

.ytnarrawehtdiovlliwrettucraberehtfostnenopmoclanretniecivr

ehtfoylbmessa

fognicivresreporpmiehT

stnenopmocnotsipdnapmupehT.yrujnisuoi

ybtpmettaynA.retnecriaperdezirohtuayrotcafayb

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 13

Page 14

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

SAMPLE PARTS LIST

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ......................1 .....INCLUDES ITEMS W/%

2% WASHER, 1/4 IN. ...........NOT SOLD SEPARATELY

2% 12347 WASHER, 3/8 IN. ...1 .....MQ-45T ONLY

3 12348 HOSE ..................A/R ...MAKE LOCALLY

4 12349 BEARING ..............1 .....S/N 2345B AND ABOVE

NO. Column

Unique Symbols — All items with same unique

symbol

QTY. Column

Numbers Used — Item quantity can be indicated by a

number, a blank entry, or A/R.

A/R (As Required) is generally used for hoses or other

parts that are sold in bulk and cut to length.

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Column.

REMARKS Column

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

to describe the item can also be shown.

Assembly/Kit — All items on the parts list with the

same unique symbol will be included when this item is

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

PART NO. Column

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarified in the “Remarks” Column.

Serial Number Break — Used to list an effective serial

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use — Indicates that the part

is used only with the specific model number or model

number variant listed. It can also be used to show a

part is NOT used on a specific model or model number

variant.

Indicated by:

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally” — Indicates that the part can

be purchased at any hardware shop or made out of

available items. Examples include battery cables, shims,

and certain washers and nuts.

“Not Sold Separately” — Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

for sale through Multiquip.

PAGE 14 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 15

SUGGESTED SPARE PARTS

HBC19B/25B REBAR CUTTER

1 to 3 Units

Qty. P/N Description

2 6415710 ............. BRUSH CAP (FOR HBC19B)

2 6402520 ............. BRUSH CAP (FOR HBC25B)

2 6415730 ............. CARBON BRUSH (FOR HBC19B)

2 6402510 ............. CARBON BRUSH (FOR HBC25B)

2 H9T4495400 ....... BLADE, SET OF 2 (FOR HBC19B)

2 H5T4495500 ....... BLADE, SET OF 2 (FOR HBC25B)

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 15

Page 16

HBC19B/HBC25B — NAMEPLATE AND DECALS

2

OPERATING INSTRUCTIONS

1. Place rebar in rebar holder. Rebar must rest fully

within the blades.

2 Adjust spacing bolt so it holds rebar flush against

stationary cutting block.

3. Tighten spacing bolt and jam nut to hold rebar in place.

4. Place protective cover in the upright position.

5. Press and hold ON/OFF switch to begin cutting

procedure.

6. Continue holding ON/OFF switch until cutting rod

completes cutting cycle.

7. Cutter rod will retract automatically at end of

cutting cycle.

8. Never use worn or damaged blades. Replace as

needed.

9. Periodically inspect oil level and electric motor brushes.

3

HBC19B

MODEL

SERIAL NO.

4

HBC25B

WARNING

1

WARNING

Toprevent injury from flying fragments.

1.Always wear safety goggles and full face

shield.

2.Keep bystanders away from machine

whencutting.

Keephands clear while

3.Use extreme caution when cutting pieces

machineis operating.

8”length or shorter.

4.Steel bar must be fully seated within

cutterblades before cutting.

5.Always adjust and tighten spacing bolt

beforecutting.

6.Keep fingers away from cutting edges

duringoperation.

7.To prevent electrical shock, do not use

cutterwhen damp.

5

PAGE 16 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 17

HBC19B/HBC25B — NAMEPLATE AND DECALS

NO. PART NO. PART NAME QTY. REMARKS

1 8006660 SAFETY WARNING DECAL 1

2 8006670 OPERATING INSTRUCTIONS DECAL 1

3 8006680 MQ LOGO 1

4 NAMEPLATE ........................................................ 1 ......... CONTACT MQ PARTS DEPT.

5 8001180 BOX WARNING DECAL 1

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 17

Page 18

16

S/N 300280

AND BELOW

HBC19B — REBAR CUTTER ASSEMBLY

10

17

9

11

84

4

3

2

1

5

2

3

8

7

6

14

D

C

12

9

14

15

B

D

2

16

S/N 300500

AND ABOVE

GREEN

35

86

33

32

85

30

31

34

39

38

37

36

40

42

41

43

44

18

19

20

21

C

A

15

26

27

25

22

24

27

23

26

29

2

3

49

50

1

51

52

53

54

46

47

48

45

B

46

59

75

78

76

77

74

73

79

72

80

71

68

84

70

69

82

68

83

63

67

62

66

65

61

65

64

60

58

49

57

56

51

52

50

53

54

1

54

53

52

55

51

46

NOTES:

ITEM 50, SPRING HOLDER

REPLACED BY O-RING

1

S/N 300281 AND ABOVE

ITEMS 85 and 86 (STAR

WASHER/TERMINAL RING)

2

INCLUDED WITH ITEM 16.

49

50

1

PAGE 18 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 19

HBC19B — REBAR CUTTER ASSEMBLY

NO. PART NO. PART NAME QTY. REMARKS

1 7513090 BOLT HB6 X 22 2

2 030208200 SPRING WASHER SW6 ...................................... 8 ..........REPLACES H9SW060100

3 7600030 WASHER WM6 8

4 4500720 HANDLE BRACKET A 1

5 H9HB062000 BOLT HB6 X 20 2

6 6415810 DUST COVER 1

7 6415820 PAN-HEAD SCREW M4 x 16 1

8 6415880 SWITCH 1

9 6415750 HANDLE SET (PAIR) .......................................... 1 .......... SET OF 2 (LEFT AND RIGHT)

10 6415910 STRAIN RELIER 10 1

11 6415930 CORD CLAMP WASHER 1

12 6415830 PAN-HEAD SCREW M4 x 18WR 2

14 6415840 PAN-HEAD SCREW M5 X 25 2

15 6415010 HANDLE SHAFT 2

16 6301430 POWER CORD S/N 300280 AND BELOW .......... 1 .......... NO LONGER AVAILABLE

16 9005380 POWER CORD S/N 300500 AND ABOVE .......... 1 .......... INCLUDES ITEMS W/%

17 6415040 NUT M6 2

18 6415030 SPRING WASHER 6 2

19 6415020 WASHER 6 2

20 4500730 HANDLE BRACKET R 1

21 4500740 HANDLE BRACKET L 1

A 6013530 MOTOR ASSEMBLY ............................................ 1 .......... INCLUDES ITEMS W/#

22# 6415800 HALF OPEN COVER 1

23# 6415860 BOLT M5 X 16 2

24# 6415870 SPRING WASHER 5 2

25# 6415740 MOTOR HOUSING SET 1

26# 6415710 BRUSH CAP 2

27# 6415730 CARBON BRUSH 155 (SET) 1

29 7513160 BOLT HB6 X 85 4

30# 6415510 STATOR 115V 1

31# 6415770 O-RING 30 1

32# 6415760 BALL BEARING 6200DDW 1

33# 6415940 WASHER 1

34# 6415790 BOLT M5 X 55 2

35# 6415610 ARMATURE 115V 1

36 H9B6202RU0 BEARING 6202RU 1

37 H9MHS15257 OIL SEAL MHS15257 1

38 3214000 PUMP CASE 1

39 H9SB101500 BOLT SB 10 X 15 (DRAINING/REFILLING) 1

40 H9SEALW100 SEAL WASHER (DRAINING/REFILLING) 1

41 7411070 STOP RING H28 (RTW28) 1

42 H9T4344700 NEEDLE HOLDER 2

43 H9B12410A0 NEEDLE BEARING 1

44 H9B6080000 BEARING 608 1

45 4601570 LINER B 1

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 19

Page 20

16

S/N 300280

AND BELOW

HBC19B — REBAR CUTTER ASSEMBLY

10

17

9

11

84

4

3

2

1

5

2

3

8

7

6

14

D

C

12

9

14

15

B

D

2

16

S/N 300500

AND ABOVE

GREEN

35

86

33

32

85

30

31

34

39

38

37

36

40

42

41

43

44

18

19

20

21

C

A

15

26

27

25

22

24

27

23

26

29

2

3

49

50

1

51

52

53

54

46

47

48

45

B

46

59

75

78

76

77

74

73

79

72

80

71

68

84

70

69

82

68

83

63

67

62

66

65

61

65

64

60

58

49

57

56

51

52

50

53

54

1

54

53

52

55

51

46

NOTES:

ITEM 50, SPRING HOLDER

REPLACED BY O-RING

1

S/N 300281 AND ABOVE

ITEMS 85 and 86 (STAR

WASHER/TERMINAL RING)

2

INCLUDED WITH ITEM 16.

49

50

1

PAGE 20 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 21

HBC19B — REBAR CUTTER ASSEMBLY

NO. PART NO. PART NAME QTY. REMARKS

46 H9T4344800 MAGNET 3

47 6505300 O-RING S-4 1

48 3501420 RETURN VALVE 1

49 H9T4424800 URETHANE RUBBER PACKING ......................... 3 .......... S/N 300280 AND BELOW

49 4500530 PACKING ............................................................. 3 .......... S/N 300281 AND ABOVE

50 H9T43446N1 SPRING HOLDER ............................................... 3 .......... S/N 300280 AND BELOW

50 6505590 O-RING ................................................................ 3 .......... S/N 300281 AND ABOVE

51 H9T43449N1 CHECK VALVE SPRING 3

52 H9T4344500 CHECK VALVE 3

53 H9T4345000 PISTON RETURN SPRING 3

54 3500350 PISTON 3

55 3200940 CYLINDER ........................................................... 1 .......... S/N 300280 AND BELOW

55 3200940A CYLINDER ........................................................... 1 .......... S/N 300281 AND ABOVE

56 H9T43679N1 RELEASE VALVE SPRING 1

57 H9HB040600 BOLT HB4 X 6 2

58 H9HW040100 WASHER HW4 3

59 H9T4367700 STOPPER PLATE 1

60 4005050 VALVE RETURN SPRING 1

61 H9T44078N2 RELEASE VALVE 1

62 H9USI00200 PACKING 1

63 H9T44061N1 CUTTER ROD 1

64 7511010 BOLT HB4 X 8 1

65 H9T43898N1 CUTTER ROD KEY 1

66$ H9HB051500 BOLT HB5 X15 (BLADE-CUTTER ROD) 2

67$ H9HW050000 WASHER HW5 2

68 H9T4495400 BLADE (SET OF 2) ............................................. 1 .......... INCLUDES ITEMS W/ $

69 H9T4389700 CUTTER ROD RETURN SPRING 1

70 H9USH00100 ROD SEAL PACKING 2

71 6505700 O-RING S-95 1

72 3100240 BAR HOLDER 1

73 H9NM1201M0 NUT NM12-1 (SPACING BOLT) 1

74 H9T43902N1 SPACING BOLT 1

75$ 7513030 BOLT HB6 X 18 (BLADE-BAR HOLDER) 2

76$ H9HW060100 WASHER HW6 (BLADE-BAR HOLDER) 2

77 H6SW100100 WASHER SW10 1

78 H9T4390100 BOLT (OIL LEVELER SACK) 1

79 H9HB082500 BOLT HB8 X 25 (BAR HOLDER) 14

80 H9HW080100 WASHER HW8 14

82 H9T4390000 BUSHING 1

83 H9T43899N1 OIL LEVELER SACK 1

84 3505510 PROTECTIVE COVER 1

85% 7620110 WASHER, STAR M5 1

86% 6102050 TERMINAL RING 1

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 21

Page 22

HBC25B — REBAR CUTTER ASSEMBLY

11

17

S/N 400430

AND BELOW

39

2

S/N 400500

AND ABOVE

40

78

17

38

77

37

36

76

42

1

75

41

86

9

D

12

10

4

3

2

5

2

3

8

7

6

B

87

88

89

C

15

18

20

21

D

13

9

15

16

19

A

C

GREEN

92

91

29

24

26

25

31

70

32

33

34

65

68

64

61

30

48

63

60

51

52

1

53

54

55

56

57

59

62

60

61

57

56

55

54

53

1

52

51

58

50

49

48

47

55

44

54

45

53

44

43

52

1

B

46

57

56

48

51

35

66

67

73

74

72

71

71

79

72

80

81

82

90

85

84

67

NOTES

ITEM 52, SPRING HOLDER

REPLACED BY O-RING

1

S/N 400361 AND ABOVE

ITEMS 91 and 92 (STAR

WASHER/TERMINAL RING)

2

INCLUDED WITH ITEM 17.

PAGE 22 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 23

HBC25B — REBAR CUTTER ASSEMBLY

NO. PART NO. PART NAME QTY. REMARKS

1 7513090 BOLT HB6 X 22 2

2 H9SW06100 SPRING WASHER SW6 4

3 7600030 WASHER WM6 4

4 4500750 HANDLE BRACKET A 1

5 H6HB062000 BOLT HB6 X 20 2

6 6415810 DUST COVER 1

7 6415820 PAN-HEAD SCREW M4 X 16 1

8 6415880 SWITCH 1

9 6415750 HANDLE SET (PAIR) .......................................... 1 .......... SET OF 2 (LEFT AND RIGHT)

10 6400770 RUBBER PIN 2

11 6415910 STRAIN RELIER 10 1

12 6415930 CORD CLAMP WASHER 1

13 6415830 PAN-HEAD SCREW M4 X 18WR 2

15 6415840 PAN-HEAD SCREW M5 X 25 2

16 6415010 HANDLE SHAFT 1

17 6301430 POWER CORD S/N 400430 AND BELOW .......... 1 .......... NO LONGER AVAILABLE

17 9005380 POWER CORD S/N 400500 AND ABOVE .......... 1 .......... INCLUDES ITEMS W/%

A 6014150 MOTOR ASSEMBLY ............................................ 1 .......... INCLUDES ITEMS W/ #

18# 6402520 BRUSH CAP 1

19# 6402510 CARBON BRUSH 1

20 4500760 HANDLE BRACKET (R) 1

21 4500770 HANDLE BRACKET (L) 1

24# 6402450 MOTOR HOUSING SET 1

25 7512100 BOLT HB5 X 40 4

26 7610030 SPRING WASHER SW5 4

29# 7539080 BOLT M6 X 30 2

30# 6402380 MOTOR FLANGE 1

31# 6402420 STATOR 115V 1

32# 6402390 BOLT M5 X 80 1

33# 7105020 BALL BEARING 1

34# 6402320 WASHER 1

35# 6402610 ARMATURE 115V 1

36 H5B60032RC BEARING 6003 2RS 1

37 6504170 OIL SEAL MHS17287 1

38 3210810 PUMP CASE 1

39 H6SB101500 BOLT SB10 X 15 (DRAINING/REFILLING) 1

40 H9SEALW100 SEAL WASHER (DRAINING/REFILLING) 1

41 7513110 BOLT HB6 X 55 4

42 H6HW060100 WASHER HW6 4

43 H5RTW30000 STOP RING H30 (RTW30) 1

44 H5T4438500 NEEDLE HOLDER 2

45 H9B12410A0 NEEDLE BEARING 1

46 H9B6080000 BEARING 608 1

47 4601590 LINER B 1

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 23

Page 24

HBC25B — REBAR CUTTER ASSEMBLY

11

17

S/N 400430

AND BELOW

39

2

S/N 400500

AND ABOVE

40

78

17

38

77

37

36

76

42

9

D

12

10

4

3

2

1

5

2

3

8

7

6

B

87

88

89

C

15

18

20

21

D

13

9

15

16

19

A

C

GREEN

92

91

29

24

26

25

31

70

32

33

34

65

68

64

61

30

48

63

60

51

52

1

53

54

55

56

57

59

62

60

61

57

56

55

54

53

1

52

51

58

50

49

48

47

55

44

54

45

53

44

43

52

1

B

46

57

56

48

51

41

75

35

66

67

86

73

74

72

71

71

79

72

80

81

82

90

85

84

67

NOTES

ITEM 52, SPRING HOLDER

REPLACED BY O-RING

1

S/N 400361 AND ABOVE

ITEMS 91 and 92 (STAR

WASHER/TERMINAL RING)

2

INCLUDED WITH ITEM 17.

PAGE 24 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 25

HBC25B — REBAR CUTTER ASSEMBLY

NO. PART NO. PART NAME QTY. REMARKS

48 H9T4344800 MAGNET 3

49 6505300 O-RING S-4 1

50 3501420 RETURN VALVE 1

51 H9T4424800 URETHANE RUBBER PACKING ......................... 3 .......... S/N 400360 AND BELOW

51 4500530 PACKING ............................................................. 3 .......... S/N 400361 AND ABOVE

52 H9T43446N1 SPRING HOLDER ............................................... 3 .......... S/N 400360 AND BELOW

52 6505590 O-RING ................................................................ 3 .......... S/N 400361 AND ABOVE

53 H9T43449N1 CHECK VALVE SPRING 3

54 H5T4438400 CHECK VALVE 3

55 H5T4506600 PISTON RETURN SPRING A 3

56 H5T4506700 PISTON RETURN SPRING B 3

57 H5T4438300 PISTON 3

58 3201320 CYLINDER ........................................................... 1 .......... S/N 400360 AND BELOW

58 3201320A CYLINDER ........................................................... 1 .......... S/N 400361 AND ABOVE

59 H5T4420300 RELEASE VALVE SPRING 1

60 H5HB051000 BOLT HB5 X10 3

61 H5HW050100 WASHER HW5 3

62 H5T4419600 STOPPER PLATE 1

63 H5T44195N1 VALVE RETURN SPRING 1

64 H5T44201N2 RELEASE VALVE 1

65 H5USI00200 PACKING 1

66 H5T31153N2 CUTTER ROD D40 1

67 H5T4495500 SP BLADE (SET OF 2) ....................................... 1 ..........INCLUDES ITEMS W/ $

68 H5T44194N1 CUTTER ROD KEY 1

70 7600020 WASHER WM5 4

71$ H5HB062000 BOLT HB8 X 20 4

72$ H5HW080100 WASHER HW8 4

73 H5T4419800 CUTTER ROD RETURN SPRING 1

74 H5USH15257 ROD SEAL PACKING 2

75 6505240 O-RING (S115) 1

76 3100500 BAR HOLDER 1

77 7700070 NUT NM16 1

78 H5T44200N1 SPACING BOLT 1

79 H9T4390100 BOLT (OIL LEVELER SACK) 1

80 H6SW100100 WASHER SW10 1

81 7515040 BOLT HB10 X 30 14

82 H5HW100100 WASHER HW10 14

84 H9T4390000 BUSHING 1

85 9004920 OIL LEVELER SACK 1

86 3505520 PROTECTIVE COVER 1

87 6415040 NUT M6 1

88 6415030 SPRING WASHER 6 1

89 6415020 WASHER 6 1

90 4500540 SHIELD ............................................................... 1 .......... S/N 400301 AND ABOVE

91% 7620110 WASHER, STAR M5 1

92% 6102050 TERMINAL RING 1

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 25

Page 26

ALLEN

WRENCHES

3MM

4MM

5MM

6MM

1

ALLEN

WRENCHES

HBC19B/HBC25B — TOOLS

3

14 MM

17 MM

7

17 MM

24 MM

19 MM

6

HYDRAULIC

OIL

4

5

4MM

5MM

6MM

8MM

8

2

PAGE 26 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 27

HBC19B/HBC25B — TOOLS

NO. PART NO. PART NAME QTY. REMARKS

1 ALLEN WRENCH SET, HBC19B ......................... 1 .......... REPLACE LOCALLY

2 ALLEN WRENCH SET, HBC25B ......................... 1 .......... REPLACE LOCALLY

3 8201010 OPEN WRENCH (14mm X17mm), HBC25B 1

4 8201070 OPEN WRENCH (24mm), HBC25B 1

5 8201020 OPEN WRENCH (17mm X19mm), HBC19B 1

6 HYDRAULIC OIL W/ OILER (150 ml), HBC19B ... 1 .......... SUPPLIED WITH UNIT

6 H9OILIS046 HYDRAULIC OIL W/ OILER (1 liter), HBC19B ..... 1 .......... REPLACEMENT PART

6 HYDRAULIC OIL W/ OILER (150 ml), HBC25B ... 1 .......... SUPPLIED WITH UNIT

6 H5OILIS032 HYDRAULIC OIL W/ OILER (1 liter), HBC25B ..... 1 .......... REPLACEMENT PART

7 H9J2387000 CYLINDER RING (TOOL), HBC19B .................... 1 .......... NOT PROVIDED W/ UNIT

7 9004040 CYLINDER RING (TOOL), HBC25B .................... 1 .......... NOT PROVIDED W/ UNIT

8 8101050 WOODEN BOX, HBC25B 1

8 8101060 WOODEN BOX, HBC19B 1

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 27

Page 28

HBC19B/HBC25B — WIRING DIAGRAM

ON/OFF SW

HBC19B

BRUSHES

HBC25B

ARMATURE

1

STATOR

GREEN

GREEN

BLUE

BLUE

BLACK

ON/OFF SW

WHITE

BLACK

WHITE

120V

60 Hz

BRUSHES

ARMATURE

1

STATOR

BLACK

BLACK

120V

60 Hz

NOTES:

CONNECT GREEN GROUND

WIRE TO STATOR BOLT.

1

REFERENCE REBAR CUTTER

ASSEMBLY.

PAGE 28 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 29

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Terms of payment for parts are net 30 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a

signed manifest has been obtained from the

carrier, and any claim for shortage or damage

must be settled between the consignee and

the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip

is $15.00 net. Customers will be asked for

instructions regarding handling of orders not

meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and

credit will be allowed, subject to the following

provisions:

A Returned Material Authorization 1.

must be approved by Multiquip prior to

shipment.

To obtain a Return Material Authorization, 2.

a list must be provided to Multiquip

Parts Sales that defines item numbers,

quantities, and descriptions of the items

to be returned.

The parts numbers and descriptions a.

must match the current parts price

list.

The list must be typed or computer b.

generated.

The list must state the reason(s) c.

for the return.

The list must reference the sales d.

order(s) or invoice(s) under

which the items were originally

purchased.

The list must include the name e.

and phone number of the person

requesting the RMA.

A copy of the Return Material Authorization 3.

must accompany the return shipment.

Freight is at the sender’s expense. All 4.

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

Parts must be in new and resalable 5.

condition, in the original Multiquip

package (if any), and with Multiquip part

numbers clearly marked.

The following items are not returnable:6.

Obsolete parts. (If an item is in the a.

price book and shows as being

replaced by another item, it is

obsolete.)

Any parts with a limited shelf life b.

(such as gaskets, seals, “O” rings,

and other rubber parts) that were

purchased more than six months

prior to the return date.

Any line item with an extended c.

dealer net price of less than

$5.00.

Special order items.d.

Electrical components.e.

Paint, chemicals, and lubricants.f.

Decals and paper products.g.

Items purchased in kits.h.

The sender will be notified of any material 7.

received that is not acceptable.

Such material will be held for five 8.

working days from notification, pending

instructions. If a reply is not received

within five days, the material will be

returned to the sender at his expense.

Credit on returned parts will be issued 9.

at dealer net price at time of the original

purchase, less a 15% restocking

charge.

In cases where an item is accepted, for 10.

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

Credit issued will be applied to future 11.

purchases only.

PRICING AND REBATES

Prices are subject to change without prior

notice. Price changes are effective on a

specific date and all orders received on or

after that date will be billed at the revised price.

Rebates for price declines and added charges

for price increases will not be made for stock

on hand at the time of any price change.

Multiquip reserves the right to quote and

sell direct to Government agencies, and to

Original Equipment Manufacturer accounts

who use our products as integral parts of their

own products.

SPECIAL EXPEDITING SERVICE

A $35.00 surcharge will be added to the

invoice for special handling including bus

shipments, insured parcel post or in cases

where Multiquip must personally deliver the

parts to the carrier.

LIMITATIONS OF SELLER’S LIABILITY

Multiquip shall not be liable hereunder for

damages in excess of the purchase price of

the item with respect to which damages are

claimed, and in no event shall Multiquip be

liable for loss of profit or good will or for any

other special, consequential or incidental

damages.

LIMITATION OF WARRANTIES

No warranties, express or implied, are

made in connection with the sale of parts or

trade accessories nor as to any engine not

manufactured by Multiquip. Such warranties

made in connection with the sale of new,

complete units are made exclusively by a

statement of warranty packaged with such

units, and Multiquip neither assumes nor

authorizes any person to assume for it

any other obligation or liability whatever in

connection with the sale of its products. Apart

from such written statement of warranty,

there are no warranties, express, implied or

statutory, which extend beyond the description

of the products on the face hereof.

Effective: February 22, 2006

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 29

Page 30

OPERATION AND PARTS MANUAL

©

HERE’S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER ON-HAND WHEN CALLING

UNITED STATES

Multiquip Corporate Office MQ Parts Department

18910 Wilmington Ave.

Carson, CA 90746

Contact: mq@multiquip.com

Service Department Warranty Department

Tel. (800) 421-1244

Fax (800) 537-3927

800-427-1244

310-537-3700

Fax: 800-672-7877

Fax: 310-637-3284

800-421-1244

310-537-3700

Technical Assistance

800-478-1244 Fax: 310-943-2238

Fax: 310-537-4259 800-421-1244

310-537-3700

Fax: 310-943-2249

MEXICO UNITED KINGDOM

MQ Cipsa Multiquip (UK) Limited Head Office

Carr. Fed. Mexico-Puebla KM 126.5

Momoxpan, Cholula, Puebla 72760 Mexico

Contact: pmastretta@cipsa.com.mx

Tel: (52) 222-225-9900

Fax: (52) 222-285-0420

Unit 2, Northpoint Industrial Estate,

Globe Lane,

Dukinfield, Cheshire SK16 4UJ

Contact: sales@mult

iquip.co.uk

Tel: 0161 339 2223

Fax: 0161 339 3226

CANADA

Multiquip

4110 Industriel Boul.

Laval, Quebec, Canada H7L 6V3

Contact: jmartin@multiquip.com

COPYRIGHT 2012, MULTIQUIP INC.

Multiquip Inc

of their respective owners and used with permission.

This manual

The information and specifications included in this publication were in effect at the time of approval for printing. Illustrations, descriptions, references and technical data contained in

this manual are for guidance only and may not be considered as binding. Multiquip Inc. reserves the ri

in this publication at any time without notice and without incurring any obligations.

, the MQ logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or altered without written permission. All other trademarks are the property

MUST accompany the equipment at all times. This manual is considered a permanent part of the equipment and should remai

Tel: (450) 625-2244

Tel: (877) 963-4411

Fax: (450) 625-8664

n with the unit if resold.

ght to discontinue or change specifications, design or the information published

Your Local Dealer is:

Loading...

Loading...