Page 1

SAFETY AND OPERATIONS INSTRUCTIONS FROM:

PLEASE READ THIS INFORMATION CARFULLY PRIOR TO

OPERATING EQUIPMENT

Page 2

SAFETY

FOR YOUR SAFETY AND SAFETY OF OTHERS!

Safety precautions should be followed at all

times when operating this equipment. Failure to read and understand the Safety Messages and Operating Instructions could result

in injury to yourself and others.

NOTICE

This manual has been developed to provide complete

instructions for the safe and efficient operation of this

equipment.

Before using this equipment ensure that the operating individual has read and understood all instructions in this

manual.

SAFETY MESSAGE ALERT SYMBOLS

The three Safety Messages shown below will inform you

about potential hazards that could injure you or others.

The Safety Messages specifically address the level of exposure to the operator, and are preceded by one of three

words: DANGER, WARNING, or CAUTION.

DANGER

HAZARD SYMBOLS

Potential hazards associated with the operation of this

equipment will be referenced with Hazard Symbols which

appear throughout this manual, and will be referenced in

conjunction with Safety Message Alert Symbols.

WARNING — Respiratory Hazards

ALWAYS wear approved respiratory

protection when required.

CAUTION — Rotating Parts Hazards

NEVER operate equipment with covers or

guards removed. Keep fingers, hands, hair

and clothing away from all moving parts to

prevent injury.

CAUTION — Accidental Starting Hazards

ALWAYS place the equipment ON/OFF

switch in the OFF position when the

equipment is not in use.

You WILL be

INJURED

directions.

WARNING

You CAN be KILLED or

KILLED

or

SERIOUSLY

if you DO NOT follow these

SERIOUSLY INJURED

CAUTION — Eye and Hearing Hazards

ALWAYS wear approved eye and hearing

protection.

if you DO NOT follow these directions.

CAUTION — Equipment Damage Hazards

Other important messages are provided throughout this

manual to help prevent damage to your equipment,

CAUTION

You CAN be

INJURED

if you DO NOT follow

other property, or the surrounding environment.

these directions.

PAGE 4 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 3

WARNING — Read This Manual

Failure to follow instructions in this manual may lead to

serious injury or even

operated by trained and qualified personnel only! This

equipment is for industrial use only.

GENERAL SAFETY

DO NOT operate or service this equipment

before reading this entire manual.

This equipment should not be operated by

persons under 18 years of age.

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, steel-toed boots and other

protective devices required by the job.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the

influence of drugs or alcohol.

DEATH

! This equipment is to be

RULES AND REGULATIONS

DO NOT wear loose clothing or jewelry. Contain long

hair. Keep hair, clothing, and gloves away from moving

parts. Rotating parts can cause injury if contacted.

ALWAYS keep work area clean and free of foreign matter

and debris. Also keep work area well lit.

NEVER operate the equipment in an

explosive atmosphere or near combustible

materials. An explosion or fire could result

causing severe

death.

DO NOT overreach. Keep proper footing and balance at

all times.

NEVER leave the equipment unattended. When not is

use, before servicing, and when changing accessories,

always unplug the equipment from the power source.

USE this equipment for its intended purpose only.

KEEP equipment clean for better and safer performance.

Keep handles dry, clean, and free from oil and grease.

INSPECT the equipment after each use. Replace any

damaged or worn parts immediately. Do not use

equipment if defective.

If a malfunction occurs, immediately unplug the

equipment from the power source and correct the

problem. If problem cannot be corrected, contact the

nearest MQ service center.

bodily harm or even

ALWAYS store the equipment in a clean, dry location

NEVER use accessories or attachments that are not

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

Manufacturer does not assume responsibility for any

accident due to equipment modifications. Unauthorized

equipment modification will void all warranties.

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult to read.

ALWAYS check the equipment for loosened threads or

bolts before starting.

MAINTAIN equipment is a safe operating condition at

all times.

KEEP bystanders, children, and visitors away while

operating the equipment. Distractions can cause loss of

control.

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 5

out of the reach of children.

EMERGENCIES

ALWAYS know the location of the nearest

fire extinguisher

ALWAYS know the location of the nearest

first aid kit

In emergencies,

of the nearest phone or

Also know the phone numbers of the nearest

ambulance, doctor

information will be invaluable in case of emergency.

.

.

always

and

know the location

keep a phone on the job site

fire department

. This

.

Page 4

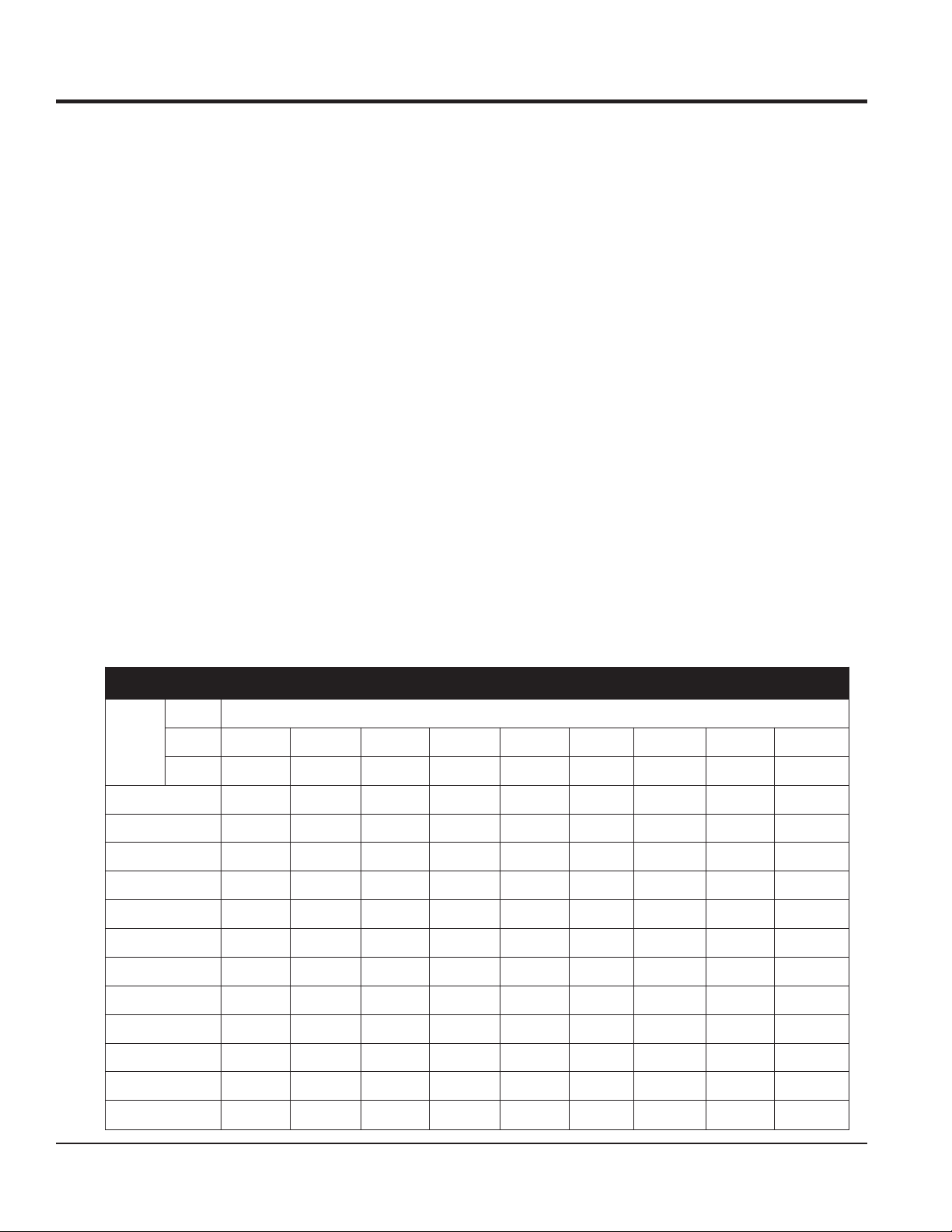

RULES AND REGULATIONS

ELECTRICAL SAFETY

■

ALWAYS test the

POWER

switch on the equipment before

operating. The purpose of this switch is to shut down the

power.

■

NEVER use a extension cord that is frayed or damaged

where the insulation has been cut.

■

NEVER carry the equipment by its power cord or

disconnect it by yanking the cord from the power outlet.

■

ALWAYS make certain that the proper extension cord

has been selected for the job. See Extension Cord

Gauge Selection Table.

■

NEVER allow power cord to

■

NEVER

■

When connecting the unit to a power receptacle, make

stand in water

lay in wate

r.

while operating the equipment.

sure the receptacle circuit is connected to either a GFCI

receptacle or a receptacle protected by a 20 amp circuit

breaker.

■

When plugging the unit into a power receptacle, check

the nameplate for the correct operating voltage.

Operating the rebar bender at the wrong voltage will

damage the electrical components. ALWAYS read the

nameplate before applying power.

■

This unit is equipped with a 3-prong male power plug.

DO NOT use a 2-prong adapter when plugging into a

wall outlet. This will defeat the purpose of the ground

circuit. If the plug does not fit into the receptacle, contact

a qualified electrician to install a 3-conductor wall

receptacle (outlet).

■

Avoid body contact with grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an

increased risk of electrical shock if your body is

grounded.

■

DO NOT expose the hydraulic power unit to rain or wet

conditions. Water entering the power unit will increase

the risk of electrical shock.

■

When operating the unit outdoors, be sure to use the

appropriate outdoor extension cord. This type of

extension cord reduces the risk of electrical shock.

■

ALWAYS remove the AC power cord from the power

source before performing any service or maintenance

on the unit. This preventative safety measure reduces

the possibility of accidental starting.

When operating near an arc welder, it is important the

both the unit and the welding equipment be connected

to the same earth ground. If they are not, server damage

to the unit, particularly to the power cord could occur.

Personal injury may also occur.

noitceleSeguaGdroCnoisnetxE

stloV teeFnidroCfohtgneL

erepmA

gnitaR

egnaR

V511 .tF52 .tF05 .tF001 .tF051 .tF002 .tF052 .tF003 .tF004 .tF005

V032 .tF05 .tF001 .tF002 .tF003 .tF004 .tF005 .tF006 .tF008 .tF0001

2-0 81 81 81 61 61 41 41 21 21

3-2 81 81 61 41 41 21 21 01 01

4-3 81 81 61 41 21 21 01 01 8

5-4 81 81 41 21 21 01 01 8 8

6-5 81 61 41 21 01 01 8 8 6

8-6 81 61 21 01 01 8 6 6 6

01-8 81 41 21 01 8 8 6 6 4

21-01 61 41 01 8 8 6 6 4 4

41-21 61 21 01 8 6 6 6 4 2

61-41 61 21 01 8 6 6 4 4 2

81-61 41 21 8 8 6 4 4 2 2

02-81 41 21 8 6 6 4 4 2 2

PAGE 6 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 5

Model HBC19B HBC25B

Maximum Cutting Capacity

SPECIFICATIONS

Table 1. Specifications

Intermediate Grade (40)

70,000 psi (45 kg/mm

2

Hard Grade (50)

80,000 psi (55 kg/mm

2

High Tensile Strength

Grade (60)

90,000 psi (65 kg/mm

2

Cutting Speed

Rated Power

Amps

Power Source

Weight

Dimensions

Length 15.6 in (396.2 mm) 18.9 in (480 mm)

Width 4.4 in (111.8 mm) 5.4 in (137.2 mm)

)

)

No. 6, Size 3/4 in (19 mm) No. 8 Size 1 in (25 mm)

No. 6, Size 3/4 in (19 mm) No. 8 Size 1 in (25 mm)

No. 6, Size 3/4 in (19 mm) No. 8, Size 1 in (25 mm)

)

2.5 sec 3.5 sec

1330 W 1430 W

11 A 13 A

115 V single-phase AC 115 V single-phase AC

27 lb (12.25 kg) 48.5 lb (22 kg)

Height 8.7 in (221 mm) 10.6 in (269.2 mm)

Standard Equipment

Hydraulic Oil 5 oz (150 ml) 5 oz (150 ml)

Carrying Box Wooden Box Wooden Box

Allen Wrench 4 pieces (M3, 4, 5, 6) 4 pieces (M4, 5, 6, 8)

Open-End Wrench 0.67 x 0.75 in (17 x 19 mm)

0.55 x 0.67 in (14 x 17 mm)

0.94 in (24 mm)

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 7

Page 6

GENERAL INFORMATION

GENERAL INFORMATION

The

MQ HBC19B/HBC25B Rebar Cutters

to be used as a portable on-site rebar cutter, capable of

cutting in-place rebar safely and efficiently with the squeeze

of a trigger. Labor time and injuries are greatly reduced

from manually cutting rebar. The cutter can virtually handle

any rebar cutting job, from slabs and masonry walls to large

buildings and bridges.

The rebar cutter contains a built-in hydraulic pump with

innovative magnetic particle filtering. All parts are machined

to tight tolerances for maximum performance.

are designed

At approximately 27 to 49 pounds, the cutter is easily carried around job sites. Even overhead work takes minimum

effort.

The cutting rod returns to the starting position when the

operating switch is released after the rod makes its full

cutting stroke. The cutting rod will not move if the cutting

stroke is not finished. The operating switched must be held

long enough for cutting rod to complete stroke.

The HC19B/HBC25B come with a return valve that allows

the cutter rod to return to the starting position when the

cutter blade jams and stops during cutting of a rebar.

PAGE 8 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 7

COMPONENTS

6

5

8

HBC19B

2

3

5

6

7

2

1

3

4

1

4

Figure 1. HBC19B/HBC25B Components

Figure 1 shows the components of the HBC19B/HBC25B

Rebar Cutter. These components are described below.

1. Blade (set of two) - Cuts the rebar that is set on the

6. Handle - Used to lift the rebar cutter.

holder between the blades.

7. Return Valve - Returns the cutter rod to the starting

2. Spacing Bolt and Nut - Allows rebar of different

diameters to be cut by adjusting the space between

the blades.

3. Rebar Holder - Holds the rebar to be cut.

4. Protector - Covers the rebar while cutting to prevent

position when the cutter blade jams and stops the

cutting of a rebar. This is done by rotating the return

valve half a turn in a counterclockwise direction with

the hexagonal wrench supplied with the unit.

8. Power Plug - Connects to a 150 V, 60 Hz power source.

rebar fragments from flying out.

HBC25B

7

8

5. ON/OFF Switch - Starts the cutting of the rebar when

the trigger switch is squeezed. When released, cutting

is stopped. Do not release release switch until the rebar

is completely cut.

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 9

Page 8

OPERATION

CUTTING PROCEDURE

WARNING

Make sure that the bar is resting fully within the blades

and protector is in the upright position. If the rebar is

not properly set, the cutting piece or fragments of the

rebar may scatter as soon as rebar is cut and the cutter

can also be damaged.

1. Adjust the spacing bolt according to the diameter of

the rebar being cut. Bolt must allow rebar to be flush,

at 90° to the blades.

2. Connect the electric plug from the cutter to a proper

power source (115 volts, 60 Hz).

3. Place the rebar in the rebar holder. Rebar must rest

fully within the blades. See Figure 2. Position the

protector over the surface to be cut.

Figure 2. Rebar Placement

4. Tighten the spacing bolt and jam nut to hold the rebar

in place.

WARNING

Do not cut rebar when it is not properly supported by

the spacing bolt or if the spacing bolt is not properly

adjusted. When cutting, hold the rebar on the spacing

bolt side as shown below. If not, the cut piece may fly

off and cause serious injury to the operator or

bystanders.

NEVER use worn or damaged blades. Replace

immediately before using cutter again.

WARNING

Replace damaged (broken and cracked edge) or

deformed cutter as soon as possible. Damaged cutter

could cause the rebar to be get out of place or cracked

during cutting. This may cause a serious accident. Do

not cut rebar that is less than 8 inches (200 mm) in

length asthis may cause rebar to fly off and result to

personal injury.

CAUTION

5. Squeeze the ON/OFF switch to start cutting the rebar.

Keep holding the ON/OFF switch until the cuting rod

completes cutting cycle. Do not attempt to partially cut

through the diameter of the rebar. This will cause

damage to the blades and cause the rebar to fly out.

6. At the end of the cutting cycle, release the ON/OFF

switch. The cutter rod will retract automatically.

7. If cutter reaches 158° F or higher, stop cutting operation

and allow machine to cool before using again.

8. Periodically inspect oil level and electric motor brushes.

Refer to Maintenance section for details.

PAGE 10 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

WARNING

Keep hands and face away from the blades

and other rotating or sliding parts during

operation.

RETURN VALVE OPERATION

The return valve is used when the cutter blade jams and

stops during cutting of the rebar.

1. Rotate the return valve half a turn in the

counterclockwise direction with the allen wrench (no. 4)

supplied with the unit. See Figure 3 for location.

Page 9

RETURN VALVE

REMOVE 2 BOLTS

TO REMOVE COVER

USE STANDARD

SCREWDRIVER

TO REMOVE CAP

CARBON

BRUSH

Figure 3. Return Valve

2. The cutter rod will retract and return to its starting

position.

3. Once the cutter rod returns to its starting position,

tighten the return valve before resuming rebar cutting.

DANGER

OPERATION

5-6 MM

(1/4 INCH)

Figure 4. Carbon Brush Size

1. Make sure that the power plug is not connected to the

power source.

2. For the HBC19B, remove the 2 bolts holding the cover

using a 4mm allen-head wrench then remove the cover

to access the two carbon brush caps (one on each

side). See Figure 5.

During operation of this rebar cutter, there

exists the possibility of

electrical shock or burn,

cause

severe bodily harm

electrocution,

which can

or even

DEATH!

To avoid these hazards:

NEVER use damaged or worn cables

WET

HANDS

when plugging the rebar cutter into

an AC power receptacle.

NEVER grab or touch a live power

cord with wet hands.

POWER

CORD

(POWER ON)

NEVER stand in water and touch a live power cord.

WARNING

Unplug unit from power source before replacing carbon

brushes.

REPLACING CARBON BRUSHES

Figure 5. Replacing Carbon Brushes (HBC19B)

CARBON BRUSH CAP

Figure 6. Replacing Carbon Brushes (HBC25B)

3. Remove the carbon brush cap of the motor outer frame

using a standard screwdriver. See Figures 5 and 6.

When the carbon becomes less than 5 or 6 mm (1/4 inch)

the motor force deteriorates because of low rectification

(Figure 4). The carbon brushes need to be replaced at this

4. Replace the carbon brushes with new ones (two for

the HBC19B and one for the HBC25B).

5. Put back the cap after brush is installed.

time. It is also recommended that the brushes be replaced

after 200 hours of use.

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 11

6. For the HBC19B, replace cover and tighten 2 bolts.

Page 10

MAINTENANCE

REPLACING OIL

The rebar cutter uses hydraulic action to operate. If there

is insufficient, dirty, or improper oil in the cutter, it will not

operate at full capacity. If unit is not operating properly,

check oil level and condition. If necessary, replace oil as

follows:

1. Loosen oil fill bolt with the supplied open-end wrench

Remove oil fill bolt and lay cutter to allow to oil to drain

out. See Figure 7.

REMOVE

BOLT

Figure 7. Removing Oil Fill Bolt

Model HBC19B HBC25B

Quantity 5 oz (150 ml) 5 oz (150 ml)

Oil Type

Above grades are blended to viscosity values that

conform to the ISO (International St

Organization) viscosity classification system.

3. Shake the cutter up and down to release any air bubble

4. Overfill with oil again.

5. Replace bolt in fill port and wipe off any excess oil.

6. Connect the cutter power cord to the power source.

Table 2. Oil Type

Shell Tellus Oil #46

Exxon Teresstic #46

that may be present.

Place a 3/16-inch diameter steel rod in bar holder.

Squeeze ON/OFF switch to activate the cutter and

allow the blade to touch the rod then turn off then

release the ON/OFF switch.

Shell Tellus Oil #32

Exxon Teresstic #32

andards

2. Turn cutter so that the oil fill port is on the top side. Fill

with oil until it overflows. See Figure 8. See Table 2 for

oil type and quantity.

FILL WITH OIL

Figure 8. Oil Fill

7. Turn cutter so that the oil fill port is on the top side

once again. Repeat oil fill procedure.

8. Squeeze ON/OFF switch again to continue and finish

cutting operation started earlier.

9. When cutting is complete, filling procedure is done.

WARNING

Unplug unit from power source before troubleshooting.

PAGE 12 — HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12)

Page 11

MAINTENANCE

gnitoohselbuorT.3elbaT

motpmySmelborPelbissoPnoituloS

?tneiciffusnisiliO

oteudyletelpmoctcartertondiddorrettuC

dnaredwopnori,spihcleetstnemecrofnier

ehtfonoitropgnidilsehtnitneserptrid

.kcutssidorrettuC

?edalb

?tneiciffusnisiliO

?reporpmi

orrettuC

tuosemocd

sirewopgnittuctub

.rabertucotkaewoot

?notsip

?redlohrabehtdnadorrettuc

telpmoctcartertondiddorrettuC

?gnirpsnruterdorrettuckaewa

?nekorbevlavesaelersI.evlavesael

oteudyle

dorrettucfognillewsronoitrotsideht

oteudyletelpmoctcartertondiddorrettuC

evlavesaelerdnarednilycneewtebtcatnoC

si)rednilycninoitcejorpfoecafruspit(

dnarednilycneewtebecnaraelcreporpmI

.noitces

iT

.edalb

ces

.noit

erecalpeR

itcurtsnieeS.lioddA

.gnirpsnruterecalpeR

erehttahterusekaM

.tridroredwopnori

.notsipdnarednilycecalpeR

ecnanetniaMnisno

.dorrettucnaelC.dorrettuckcabhsuP

dorrettucecalpeR.stlobedalbnethg

ecnanetniaMnisnoitcurtsnieeS.lioddA

tasehctarcsonera

kcutsynanaelC.rednilycfoecafrusfopit

reporpmI

?evlav

.gnikaelsiliO

?egatlovtcerrocnI

etatortonseodrotoM

rotomroopro

.noitator

.erutamrafo

?sehsurbnobracfonoisarbA.sehsurbnobracecalpeR

ETON

decivresebdluohsstnenopmoclacirtcelelladna

esotlennosrepdezirohtuanu

dnarednilycneewtebtcatnoc

?gnikcaprebburrednilycnekorB.gnikcaprebburecalpeR

casrelevellionekorbrodehctarcS.trapevitcefedecalpeR

?k

?rednilycdnaredilsredlohrabdehctarcS.trapevitcefedec

?esacpmupdnareniltniojrednilycnekorB.trapevitcefedecalpeR

?tlobllifliofogninethgittneiciffusnI.tlob

sdnehtobtasgniraebdemrofedronekorB

resesuacdluoctahtsnoitidnocotdaelnacstnenopmoclacritcele

alpeR

aM

.ecruos

.tnempiuqetcerrocehthtiwlennosrepdeniartylreporpybenodebtsumpmup

.evlavdnarednilycecalpeR

lliflionethgiT

rewopreporpottcennocsitinuerusek

niraebecalpeR

.sg

evitisneserasecnaraelcesolcyrevevahaeranotsipdnapmupciluardyhehtfostnenopmoclanretniehT:

sidehT.gnildnahreporpmirodiulfciluardyhehtfonoitanimatnoc,trid,tsudmorfegamadot

.ytnarrawehtdiovlliwrettucraberehtfostnenopmoclanretniecivr

ehtfoylbmessa

fognicivresreporpmiehT

stnenopmocnotsipdnapmupehT.yrujnisuoi

ybtpmettaynA.retnecriaperdezirohtuayrotcafayb

HBC19B/HBC25B REBAR CUTTER • OPERATION AND PARTS MANUAL — REV. #1 (03/07/12) — PAGE 13

Loading...

Loading...