Page 1

PARTS AND OPERATION MANUAL

Bullfloat — HAL 150 & 300

© COPYRIGHT 2001, MULTIQUIP INC.

Revision #2 (03/12/01)

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-537-4259

E-mail:mq@multiquip.com • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT:

Page 2

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

Page 4

Here's How To Get Help .......................................... 3

Table Of Contents ................................................... 4

Parts Ordering Procedures ..................................... 5

Explanation Of Codes In Remarks Column ............ 6

BULLFLOAT HAL 150 & 300

Safety Instructions ............................................... 7-8

Specifications .......................................................... 9

What is a Bullfloat ............................................ 10-11

Operation ......................................................... 12-14

Trouble Shooting ................................................... 15

Maintenance and Repair ................................. 16-17

HAL 150 & 300

Frame ...........................................................18-19

Electric Drive Unit & Switch .........................20-21

Electric Drive Unit Components...................22-23

Gas Drive Unit & Gas Throttle ..................... 24-25

TABLE OF CONTENTS

ROBIN ENGINE EC0250G6004

Crankcase & Cylinder ................................... 26-27

Crankshaft & Piston ...................................... 28-29

Muffler & Air Cleaner .................................... 30-31

Recoil Starter & Housing ..............................32-33

Carburetor & Fuel Tank ................................34-35

Coil & Spark Plug..........................................36-37

Terms and Conditions Of Sale — Parts ................. 38

NOTE: Specification and part number

are subject to change without notice.

PAGE 4 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 5

PARTS ORDERING PROCEDURES

n

Dealer account number

n

Dealer name and address

n

Shipping address (if different than billing address)

n

Return fax number

n

Applicable model number

n

Quantity, part number and description of each part

n

Specify preferred method of shipment:

UPS Ground

•

UPS Second Day or Third Day*

•

UPS Next Day*

•

Federal Express Priority One (please provide us with your Federal

•

Express account number)*

Airborne Express*

•

Truck or parcel post

•

*Normally shipped the same day the order is received, if prior to 2PM west coast time.

Earn Extra Discounts when

you order by FAX!

All parts orders which include complete part numbers

and are received by fax qualify for the following extra

discounts:

Number of

line items ordered Additional Discount

1-9 items 3%

10+ items** 5%

Get special freight allowances

when you order 10 or more

line items via FAX!**

n

UPS Ground Service at no charge for freight

n

PS Third Day Service at one-half of actual freight cost

No other allowances on freight shipped by any other carrier.

**Common nuts, bolts and washers (all items under $1.00 list price)

do not count towards the 10+ line items.

Extra Fax DiscountExtra Fax Discount

Extra Fax Discount

Extra Fax DiscountExtra Fax Discount

for Domestic USAfor Domestic USA

for Domestic USA

for Domestic USAfor Domestic USA

Dealers OnlyDealers Only

Dealers Only

Dealers OnlyDealers Only

Now! Direct TOLL-FREE access

to our Parts Department!

Toll-free nationwide:

800-421-1244

Toll-free FAX:

*DISCOUNTS ARE SUBJECT TO CHANGE*

Fax order discount and UPS special programs revised June 1, 1995

800/6-PARTS-7 • 800-672-7877

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 5

Page 6

EXPLANATION OF CODE IN REMARK COLUMN

How to read the marks and remarks used in this parts

book.

Section 1: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Section 2: Items Found In the “Items Number” Column

All parts with same symbol in the number column:

*, #, +, %, or ■, belong to the same assembly or kit.

Note: If more than one of the same reference number is

listed, the last one listed indicates newest (or latest) part

available.

NOTE: The contents of this parts catalog are subject to

change without notice.

PAGE 6 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 7

SAFETY INSTRUCTIONS

The Bullfloat models HAL 150/300 have been developed and

tested in accordance with strict International Safety Standards.

This section contains general advice.

Regular maintenance of the Bullfloat promotes safe

operation.

■

When in doubt and/or when you are operating the Bullfloat

for the first time, always read the necessary instructions in

this manual.

■

Wear safety shoes with extra protection (steel caps and

anti-slip soles).

■

Place the wires between the electrical source and the work

area in such a way that they can not be damaged or your

co-workers cannot trip over them.

■

Do not leave any tools or parts laying around on the work

floor, as this can cause accidents.

■

Watch where you are going; the ground can be slippery.

■

Take care that you do not injure yourself on objects, such

as scaffolding and reinforcement materials, which can be

found directly or indirectly in the working area.

■

Pay attention to your own safety and that of your fellow

workers.

■

Be careful when lifting and carrying the Bullfloat. Do not

bend forwards when picking up the apparatus, but bend

your knees. Ensure that the working area is within your

reach, so that you do not have to bend forward.

The following safety-aspects specifically apply to those

Whiteman products which are equipped with a

gas-engine.

■

Wear working-gloves, safety glasses and protective

clothing during refueling.

■

Make sure that there is sufficient ventilation during refueling.

■

Refuel only after the engine has cooled off sufficiently.

■

It is strictly forbidden to refuel:

• in the direct vicinity of a open fire or other flammable

materials,

• in explosion endangered places.

■

Do not use the Bullfloat with a

gas-engine

places, such as pits etc.

■

ventilation in spaces which are surrounded

by walls. Never inhale exhaust gases, they

can damage your health and that of your

fellow workers.

Refueling of fuel, while the engine is hot,

might lead to a very dangerous situation

including an explosion and fire.

indoors or in poorly ventilated

Make sure that there is sufficient

■

Ensure that you are qualified (familiar with the contents of

this manual) to operate and carry out light maintenance

work to the Bullfloat.

■

Check that the electrical source complies with the local

regulations.

■

Use grounded extension cords, when it is necessary to

use extension cords.

■

Use an electrical source which is provided with a ground

leakage switch between the electrical mains and the

Bullfloat.

■

Ensure that the wall socket and possible connections

between the extension cords are protected against

dampness.

■

Do not pull the plug out of the wall socket or extension

cords by it’s cord, use the plug.

■

To avoid getting an electric shock, do not

touch the high-tension cable or spark plug

cap while the engine is running.

General Safety Instructions

■

When operating the Bullfloat wear ear protection, safety

glasses, a safety helmet, gloves which do not conduct

electricity and protective clothing.

■

Ensure that all symbols on the Bullfloat — can always be

clearly read.

■

Regularly check the Bullfloat’s connections.

■

When cleaning the Bullfloat, ensure that no water or

cleaning detergents, under high pressure, get into the

motor housing or plug connections.

■

When the Bullfloat is not being used for long periods of

time, then it must be store in a dry and clean area.

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 7

Page 8

Important Safety Checks for the electrical Bullfloat

■

Check the feeder cable and extension cords outer casing

before you connect the Bullfloat to the electrical mains.

■

Check the feeder cable’s attachment on

the bullfloat, before you connect the Bullfloat

to the electrical mains. The cable must be

correctly attached to the Bullfloat.

■

Ensure that the feeder cable does not

graze past any sharp objects.

■

The use of extension cords are permitted, if they are

completely watertight.

■

Switch the Bullfloat “off” when the electrical

power cuts off.This prevents the Bullfloat from

starting suddenly when the electrical power

comes on again.

■

Check the feeder cable and extension cord’s attachments

regularly. When the Bullfloat is in operation, the plugs can

loosen due to the vibrations.

SAFETY INSTRUCTIONS

■

Connect the Bullfloat to an alternating voltage source of

115VAC, which is provided with a ground switch, with a

frequency of 60 Hz.

■

Check that the ventilation openings in the motor housing

are free from dirt and moisture.

■

Regularly check the connections of the feeder cable to

the switch.

Explanation of the utilized safety symbols.

■

Disconnect the electrical supply to the Bullfloat, before you

start to clean or service the Bullfloat.

1. Safety glasses, safety helmet and ear protection

compulsory.

2. Gloves compulsory.

3. Safety shoes with extra protection compulsory.

4. Dangerous electrical voltage.

5. Before opening the motor housing remove the plug.

6. Inflammable material.

7. Pls. read the operation-instructions

8. Careful, danger!

Tip: Ask the manufacturer for clarification, if you have any

questions about any of these safety instructions.

PAGE 8 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 9

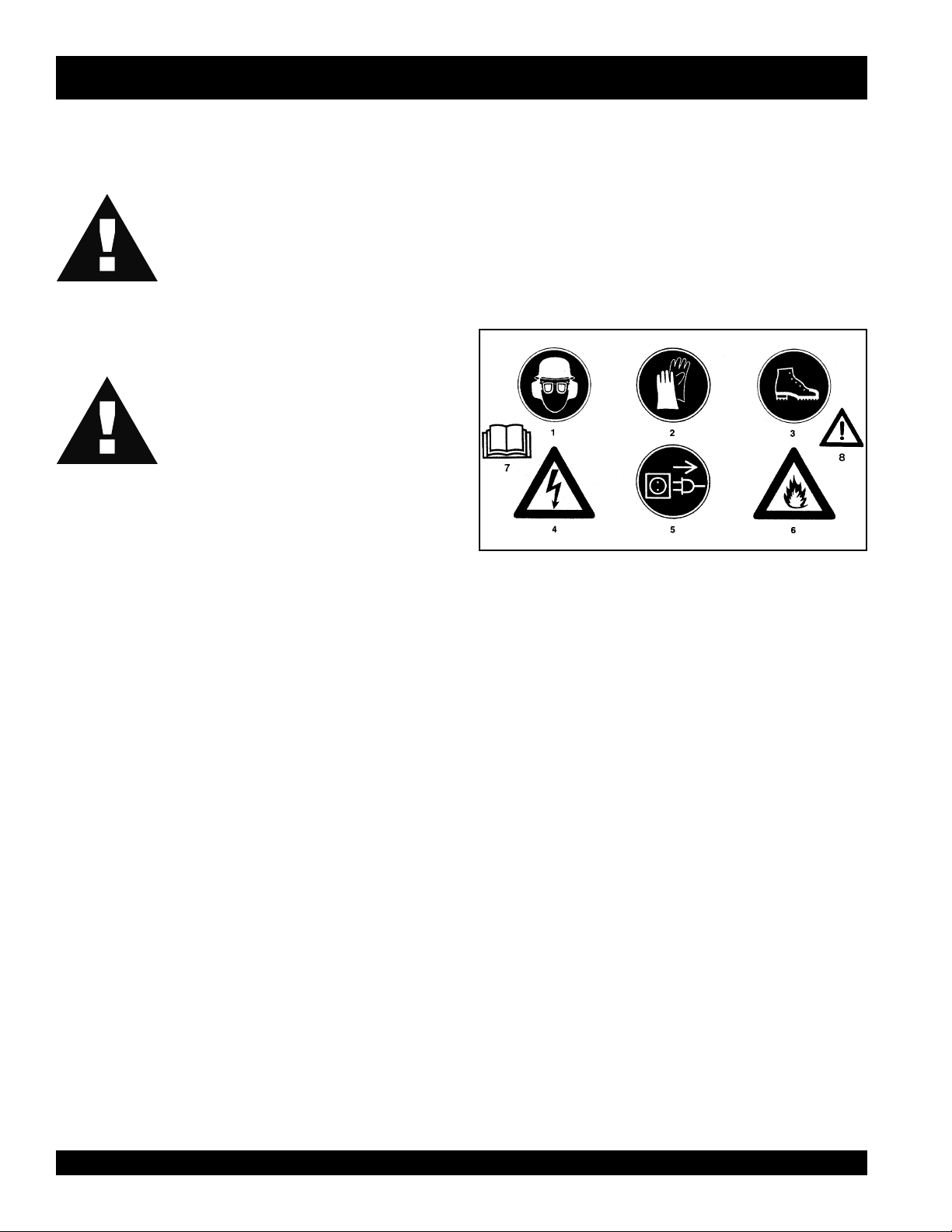

SPECIFICATIONS

)CAV511(LAH )enigne-sagekorts2(LAH

egatloV

yticapaC

snoituloveR

lagufirtneC

ecrof

ssaM

leuF

erutxiM

gnilaeS

noitalusnI

rotoM

noitcetorp

ngiseD

CAV511

zH06/esahP1

W053 W025

nim/r00021 nim/r00021

).sbl504(N0081 ).sbl504(N0081

).sbl3.42()gK11(m1 ).sbl3.42()gK11(m1

).sbl6.82()gK31(m5,1 ).sbl6.82()gK31(m5,1

).sbl1.33()gK51(m2 ).sbl1.33()gK51(m2

).sbl5.73()gK71(m5,2 ).sbl5.73()gK71(m5,2

).sbl9.14()gK91(m3 ).sbl9.14()gK91(m3

— )erutxim(ekorts-2

— 52:1

foorphsalps,45PI foorphsalps,45PI

IIssalC

detalusnIelbuoD

foorpkcohsdnatcapmI —

elbatroP elbatroP

—

—

(11.8 in.)

(1.4 in.)

(11.8 in.)

(9.1 in.)

tinu-evirdsnoisnemiD

htgneL

htdiW

thgieH

).ni1.7(mm081 ).ni9.5(mm051

).ni9.5(mm051 ).ni9.7(mm002

).ni5.5(mm041 ).ni7.8(mm022

Figure 1.1

Dimensions in mm. of the HAL 150 & 300

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 9

Page 10

HAL 150 AND 300 — WHAT IS A BULLFLOAT

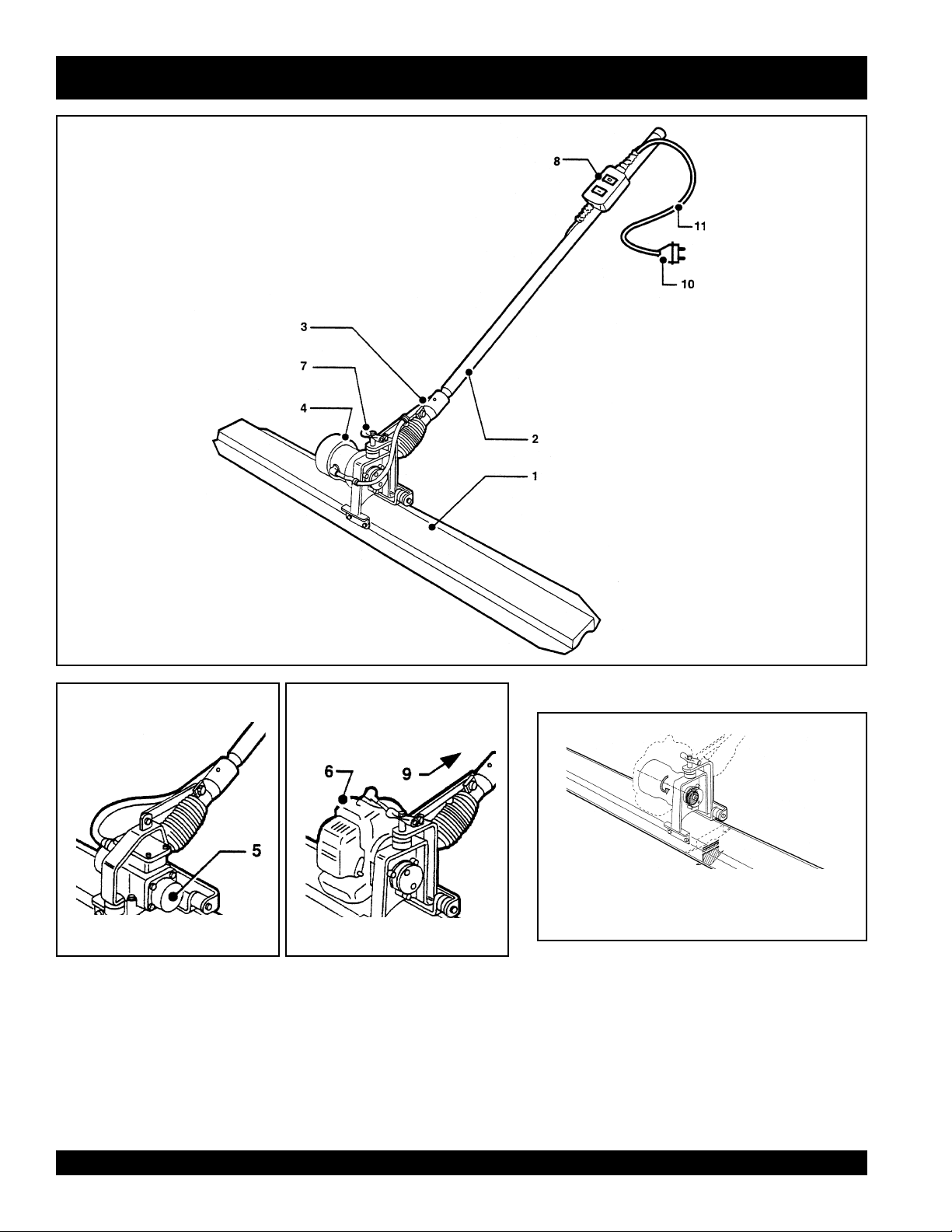

Figure 1.0

The bullfloat’s drive

1. Aluminium profile

2. Operating handle

3. Pitch control

4. Drive-unit 115 VAC

5. Vibratory Unit

6. Gas engine

7. Grip

8. ON/OFF-switch

9. Gas throttle

10. Plug

11. Cable

PAGE 10 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 11

HAL 150 AND 300 — WHAT IS A BULLFLOAT

What is a Bullfloat?

A Bullfloat is an apparatus with a vibrating alloy blade that

smooths and compacts the top layer of freshly poured

concrete, without the need for guiding rails.

Before the Bullfloat is brought into action, the concrete should

be distributed and compacted by means of a vibrator.

The vibrator is used in combination with a laser, in order to

adjust and control the height of the concrete floor.

The Bullfloat consists of an operating handle, an electrical or

gas-engine vibrating-unit and an aluminium blade, available

in 5 lengths: 1m, 1.5m, 2m, 2.5m, and 3m.

The switch is located on the operating handle with which the

electrical vibrating-unit is switched ‘ON’ and ‘OFF’. The gas-

engine vibrating-unit is operated by means of a gas throttle

also located on the operating handle.

Operation

The drive-unit of the Bullfloat is started by turning the knob of

the electric-speed-regulator to the ‘ON’ position (electrical), or

by pulling the recoil-starter of the gas-engine.

An excentric part is set in motion by the drive-shaft of the motor.

This rotating motion sets the aluminium blade in vibration. The

vibrating motion of the blade smooths and compacts the

surface of the concrete.

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 11

Page 12

HAL 150 AND 300 — OPERATION

This section describes the operation of the HAL 150 &

300 Bullfloats.

Tip: For the location and description of the Bullfloat’s parts,

which are mentioned in the text, refer to the illustration figure

(page. 9): What is a Bullfloat.

How to assemble the HAL 150 & 300 Bullfloats.

When delivered the Bullfloat is not ready for use.You only have

to carry out the following procedures to assemble them:

1. Connect the switch (an electronic speed regulator, or a

gas throttle), to the operating handle by means of the

bracket and the butterfly nut. Now lock the bracket by

tightning the butterfly nut. (Fig. No. 2.0)

2. Stick the operating handle into the shaft of the motor unit

frame.Make sure that the operating handle is locked

properly.

GAS ELECTRIC

Operation and use of the Bullfloat

This section describes how to operate and use the Bullfloat.In

the text are numbers in brackets. These numbers are position

numbers and they correspond to the numbers in the parts list

of the corresponding figures.

Careful: Read the safety instructions before you switch

on the apparatus.

Careful: Prevent the Bullfloat, from sinking into the concrete.

After the motor has been switched on, immediately move the

Bullfloat backwards.

Tip: Before the Bullfloat is brought into action, first compact

the freshly poured concrete floor with a poker-vibrator while at

the same time adjust the height of the floor by means of a

laser device.

Tip: Pour concrete lanes of approx. 3 ft. wide and approx. 15

ft. long. You can finish this surface in one pass without any

problem.

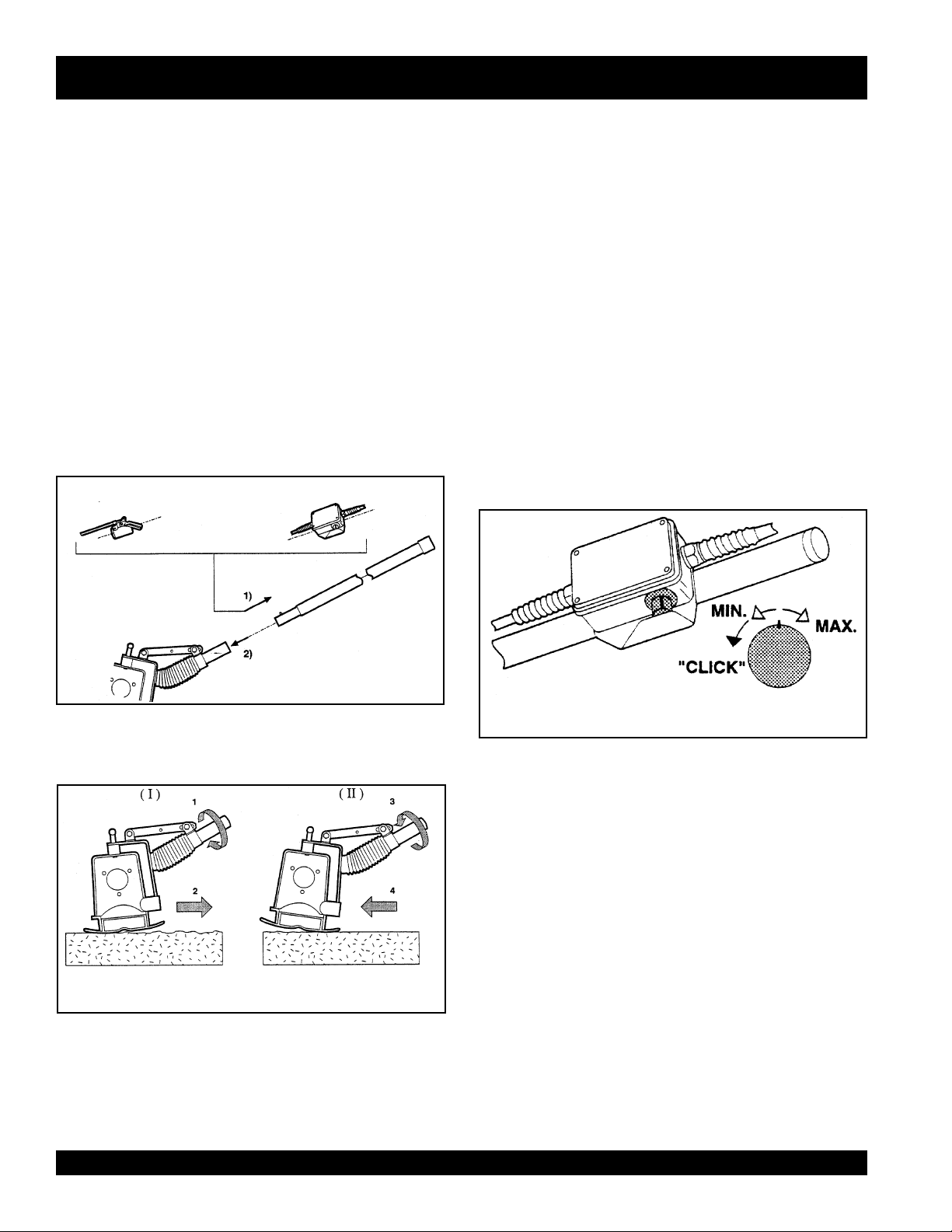

Figure 2.0

Assembly of the controls

How to adjust the trowel blade angle.

Figure 2.1

Adjusting the blade-pitch

Use position (I), when smoothing freshly poured concrete.

(Fig. No. 2.1)

Use position (II), in the event you want to smooth the same

lane once again.(Fig. No. 2.1)

Tip: When using a low slump concrete, move the Bullfloat

slowly across the surface of the concrete. When using a high

slump concrete, move the Bullfloat faster across the surface

of the concrete.

Figure 2.2

Types of switches

PAGE 12 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 13

HAL 150 AND 300 — OPERATIONS

Operation of the Electric Bullfloat

1. Check that the Bullfloat is properly assembled and that

the switch is in the ‘OFF’ position.

2. Put the plug of the drive-unit’s feeder cable in the wall

socket.

3. Place the Bullfloat in the direct vicinity of where you are

going to smooth the surface of the concrete-floor.

4. Place the Bullfloat on the surface of the freshly poured

concrete, and turn the speed regulator slowly to the

required revolutions.

5. Adjust the trowel blade angle.(read paragraph 2, on page

11)

6. Now start to smooth the surface of the concrete floor by

moving the Bullfloat backwards in a slow but steady

motion.

7. After having finished one lane of concrete, switch off the

Bullfloat immediately, by turning the speed regulator’s

knob to the position ‘Minimal’. You will hear a “CLICK”.

(Fig. 2.2, on page 11)

Operation of the Gas Bullfloat

a. Throttle cable

b. Spark plug

c. Overflow pipe

d. Starter rope

e. Fuel cap and fuel filter

f. Fuel tank

g. Air filter

Figure 2.4

Components of the gas-engine

h. Carburetor

Figure 2.3

Work situation during smoothing and

compacting of the concrete floor.

Tip: If the processed concrete-surface is

enough, repeat the procedures 5

8. Pull the plug of the feeder cable out of the wall socket.

9. After use, place the Bullfloat on a dry and stable surface.

,6,7 and 8.

not smooth

or level

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 13

Page 14

HAL 150 AND 300 — OPERATIONS

Starting Procedure

1. Check that the Bullfloat is properly assembled, and the

fuel tank is filled.

2. Place the Bullfloat in the direct vicinity of where your are

going to smooth the surface of the concrete.

3. Adjust the throttle-lever (1) to the idle-position.(Fig 2.5)

Figure 2.5

Idle position of the throttle-handle and

components of the carburator

10. After allowing a three-minute warming-up period set the

Smoothing concrete

11. Adjust the right trowel blade angle. (read paragraph 2,

12. Smooth the freshly poured concrete.

Tip: Repeat procedure 12 in the event the treated surface is

not smooth or level enough.

13. Switch “off” the Bullfloat after you have finished the

throttle handle to the desired engine speed. The Bullfloat

is now ready for use.

page 11)

concrete lane:

— Put the throttle lever (1) in the idle position. (Fig 2.5)

4. Put the choke-lever (2) in the upper position.(Fig 2.5)

5. Push simultaneously the black priming pump (3) and the

tickler lever (4) (Fig 2.5) until fuel comes out of the

overflow pipe (c). (Fig 2.4)

Careful! : When pushing the tickler lever (4) half way down,

create

the fuel will flow directly into the engine and will

sure

problems. Be

Careful! : Never change the adjustment of the main jet screw

on the carburetor

6. Open the throttle-handle half way.

7. Give the starter rope (6) (Fig 2.6) a rapid vigorous pull

until the engine fires.

WARNING:

might break. Use 3/4 of the starter rope’s length.

8. If you have executed the starting procedure in the correct

Do not pull the starter rope all the way. The rope

way, the engine will run after approx. 2 pulls of the starter

rope.

to push the tickler lever fully down.

(5).(Fig 2.5)

starting

Location of the starter rope and the stop button

14. If you do not expect to use the engine for a long period

15. After use, place the Bullfloat on a dry and clean surface.

WARNING! Make sure to refill the fuel tank before you run out

of fuel during operation. Do not let the engine run until all the

fuel is used. This might cause starting problems. The average

operation time is approx. 45 min. (per tank).

Figure 2.6

— Press the black stop-button (7) for a couple of

seconds until the engine stops. (Fig 2.6)

of time, drain the fuel tank of fuel and let the engine run

at idle speed until the fuel in the carburetor is used and

the engine stops.

9. Allow the engine to run for approx. 10 seconds. Push the

choke lever (2) (Fig 2.5) slowly down. The period of time

depends on the ambient temperature.

PAGE 14 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 15

HAL 150 AND 300 — TROUBLE SHOOTING

Problem: The Bullfloat does not vibrate in the ON position.

Cause: Fault in the electrical connections of the feeder

cable.

Solution: Check the electrical connections to the

Bullfloat, switch, plug and feeder cable for breakage.

Replace the faulty part(s).

Problem: The Bullfloat does not get into the required

number of revolutions.

Cause: Voltage drop, due to the feeder cable being too

long.

Solution: Move the electrical source closer to the

working area. Be certain you have the correct wire gauge

size for the distance and amp draw.

Problem: The electrical motor rotates irregularly and

makes a lot of noise.

Cause:

1. The bearings are worn out, and/or

2. an electrical defect in the stator, and/or

3. a break in the feeder cable.

Solution:

1. Replace the bearings, and/or

2. replace the stator, and/or

3. repair or replace the feeder cable.

Problem: Gas engine does not start.

Problem: The engine starts but runs irregularly.

Problem:The engine runs in idle position but stops when

increasing the revolutions.

Problem: Engine smokes excessively.

Cause: There is no, or too little, fuel in the fuel tank. The

starting procedure was not carried out in the correct way.

Solution: Fill the fuel tank or repeat the starting

procedure.

Cause: The spark plug, the fuel filter or the air filter are

dirty.

Solution: Clean or replace the spark plug, the fuel filter

or the air filter. See paragraph 4-4 on the next page.

Cause: The choke lever has not been pushed down

completely, after the starting procedure.

Solution: Repeat the starting procedure. (Do not prime

again). See Section 3, 4 & 5 on page 13.

Cause:

1. Choke lever has not been pushed down all the way.

2. The carburetor is worn out.

3. The engine is worn out.

4. Wrong mixture. (Possibly to much oil)

Solution:

Problem: The connected and running Bullfloat rotates

irregularly and does not get into the required revolutions.

Cause: Insufficient current supply.

Solution:

Electrical supply via electrical mains; check the plug

connections for defects.

Problem: The electrical motor runs irregularly.

Cause: The carbon brushes are worn out.

Solution: Replace the carbon brushes. (Replace every

6-12 months).

1. Check the position of the choke lever.

2. Replace the worn out parts of the carburetor, (please

consult your dealer or the manufacturer).

3. Replace the gas engine.

4. Replace the mixture for the right mixture with the

correct proportion: 1 part 2-stroke oil to 25 parts of

normal gasoline (1: 25).

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 15

Page 16

HAL 150 AND 300 — MAINTENANCE AND REPAIR

Maintenance

Although the Bullfloat has few moving parts, regular

maintenance promotes a long and trouble-free life.

Warning: Never use a high pressure cleaner to clean a

Bullfloat with an electrical or gas drive unit.

Lubricating the blade pitch control

Lubricate the blade pitch control, after long periods of storage,

or at least twice a year, by using a hand grease gun. (Fig. 4.0)

Figure 4.0

Lubricating the blade pitch control

Maintenance after 20 hours of operation

— How to clean the fuel filter.

1. Remove the fuel tank cap.

2. Pull out the black rubber tube from the fuel tank. At the

end of the tube is the felt-weight assembly. Remove the

felt and the felt-weight from the tube and wash out both

parts in clean fuel.

3. Insert the felt and the felt-weight into the fuel tank again.

How to clean the air filter.

1. Unscrew the black filter cap from the carburator.

2. Take out the filter element.

3. Wash out the filter element in clean fuel and wring

4. Re-install the filter and the black filter cap.

(Removal Procedure)

out the filter element.

4.3 Cleaning and servicing of the electrical drive unit.

Warning: Cut off the electrical supply to the Bullfloat before

carrying out any maintenance activities to the Bullfloat.

In order to achieve a maximum cooling effect the ventilation

slots of the electrical drive unit must stay free from dirt and

grease. Check them at the end of each working day.

If necessary, clean the motor with a brush or a damp cloth.

4.4 Cleaning and servicing of the gas engine. (refer also

to engine manual)

WARNING!: When the engine operates in dusty conditions,

clean the air filter each day or after each 10 hours of operation.

Daily maintenance

— In order to achieve a maximum cooling effect the

ventilation openings must stay free from dirt or grease.

Check them at the end of each working day.

If necessary, clean them with a brush or a damp cloth.

— For a proper functioning of the carburetor’s control

mechanism, it is necessary to check the carburetor for

concrete or dirt, each time after use. If necessary clean

the control mechanism with a brush or a damp cloth.

Figure 4.1

Location of the fuel and air filters

PAGE 16 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 17

HAL 150 AND 300 — MAINTENANCE AND REPAIR

Maintenance after 50 hours of operation

■

Cleaning of the piston.

Remove the carbon from the upper side of the piston,

from the exhaust-ports in the cylinder, from the

combustion chamber and from the exhaust.

■

Cleaning of the spark plug.

Clean off carbon deposits on the spark plug electrode

using a plug cleaner or wire brush.

Check electrode gap. If necessary adjust it to between:

0.6 to 0.7 mm.

Longtime storage

1. Remove the spark plug and pour 3 to 5 cc of new

engine oil into the plug-hole.

Pull the recoil starter several times and reinstall the

spark plug.

2. Slowly pull the recoil starter until resistance is felt. The

piston is in its compression stroke.

3. Clean the engine thoroughly with an oiled cloth.

4. Store the engine in a clean and dry place.

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 17

Page 18

HAL 150 AND 300 FRAME

PAGE 18 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 19

HAL 150 AND 300 FRAME

HAL 150 & 300 type E, ER and B frame

NO. PART NO. PART NAME QTY. REMARKS

1 BF230010 BLADE, ALUM. 1.0 m — 3 ft. 1

BF230015 BLADE, ALUM. 1.5 m — 5 ft. 1

BF230020 BLADE, ALUM. 2.0 m — 6½ ft. 1

BF230025 BLADE, ALUM. 2.5 m — 8 ft. 1

BF230030 BLADE, ALUM. 3.0 m — 10 ft. 1

3 BF23003 MOTOR ASSEMBLY BRACKET 1

4 BF0060 RUBBER BUFFER 3

5 BF0124 BOLT M8 X 10 5

6 BF0173 UNDULATED RING 2

7 BF0093 NUT M10 3

8 BF0115 BOLT M8 X 150 2

9 BF0107 NUT M8 2

10 BF0172 RETAINING RING 2

11 BF0156 WASHER M 10 4

31 BF230031 ASSEMBLY BRACKET 1

34 BF0140 BOLT 1

35 BF0212 RETAINING RING 1

36 BF23036 GRIP 1

37 BF23037 SPACER 1

49 BF2348 OPERATING HANDLE 150 CM 3

50 BF2350 PITCH CONTROL 1

51 BF23051 RUBBER SLEEVE 1

53 BF23053 ADJUSTABLE STRIP 1

54 BF0131 BOLT M10 X 25 2

56 BF23056 SPACER 4,2 mm 2

58 BF0203 LOCK-RING 2

59 BF23059 LUBRICATING NIPPLE & CAP 1

60 BF0133 BOLT M10 X 50 1

61 BF23061 SPACER 32 mm 1

63 BF23063 BRASS NUT M8 1

64 BF0125 BOLT M8 1

66 BF23066 PLASTIC CLAMP 1

68 BF23068 LOCKING CLIP 1

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 19

Page 20

HAL 150 AND 300 ELECTRIC DRIVE-UNIT AND SWITCH

22A

22

22B

22C

22D

73

PAGE 20 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 21

HAL 150 AND 300 ELECTRIC DRIVE-UNIT AND SWITCH

HAL 150 & 300 type-E-,ER drive-unit and switch

NO. PART NO. PART NAME QTY. REMARKS

1 BF2301 N EXCENTER-HOUSING 1

2 BF2302N EXCENTER-SHAFT 1

6 BF2306B RUBBERSEAL 1

7 BF2307 ADAPTOR - BOLT (SHORT) 2

8 BF2308 ADAPTOR - BOLT (LARGE) 1

10 BF0155 WASHER 3

11 BF2311N COVER&BEARING, EXCENTER 1

12 BF231213 EXCENTER 1.0 - 1.5 m. 1

BF231217 EXCENTER 2.0 - 2.5 m. 1

13 BF0201 LOCKRING 1

14 BF2314 EXCENTER-BEARING 1

16 BF2316 O-RING 1

20 BF2320 DRIVE-UNIT 1

21 BF0051 RUBBERBUFFER 3

22 BF2325 COUPLING- SET 1 INCLS. ALL ITEMS W/

22A

*

22B

*

22C

*

22D

*

23 BF0172 RETAINING RING M8 3

24 BF0088 CAPNUT 2

29 BF0017 CABLE 2 X1,5 mm2 + PLUG 220V 10

33 BF0086 CAPNUT (HIGH) 1

35 BF2335 CABLE-CLAMP 1

44 BF0004 CABLE 1

69 BF2369ER SWITCH ASSEMBLY BRACKET (ER) 1

73 BF0325 WING-SCREW 1

74 BF23074 SWITCH COMPLETE 1

78 BF0122 SCREW 1

90 BF0420 PACKING BOX 2

91 BF0421 NUT 2

92 BF2392 SPEED-REGULATOR (ONLY) 1

93 BF2393 SWFTCH-BOX (SPEED-REGULATOR) 1

94 BF2394 POTENTIOMETER & SWITCH 1

95A BF2395A KNOB (POTENTIOMETER) 1

95B BF2395B KNOB-CAP 1

95C BF2395C FIGURE DIAL 1

95D BF2395D STATOR 1

97 BF2397 TERMINAL-BLOC 1

98 BF2398 SPEED-REGULATOR COMPL. (INCL. BRACKET) 1

99 BF2399 SPEED-REGULATOR COMPL. (EXCL. BRACKET) 1

BF2323 CATCH, DRIVESHAFT 1

BF0273 SCREW 1

BF0154 WASHER 1

BF2322 SPRING 1

*

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 21

Page 22

HAL 150 AND 300 ELETRIC DRIVE-UNIT COMPONENTS

PAGE 22 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 23

HAL 150 AND 300 ELETRIC DRIVE-UNIT COMPONENTS

HAL 150 & 300 type- E, ER drive-unit

NO. PART NO. PART NAME QTY. REMARKS

3A BF2303A VENTILATION RING (SMALL) 1

3B BF2303B VENTILATION RING (LARGE) 1

3C BF2303C VENTILATION HOUSING 1

40 BF0428 RUBBERING 1

41 BF0421 PLASTIC NUT 1

42 BF0430 PACKING BOX 1

43 BF1101220240 REAR-BEARING 1

45S BF2345S STATOR 1

45R BF2345R ROTOR 1

46 BF2346 FRONT SHIELD 1

47 BF0249 SELF TAPPING SCREW 5

52 BF1101220170 VENTILATOR-COVER 1

53 BF1101220200 SCREW 2

54 BF1101220250 SPRING SOURCER 2

55 BF1101220220 BRUSH-COVER 2

56 BF1101220180 MOTOR-HOUSING 1

57 BF2357 CAPACITOR 1

58 BF2358 CAPACITOR-CLAMP 1

59 BF0248 SELF TAPPING SCREW 3

60 BF2360 TERMINAL-BLOC 1

61 BF1101220230' SET OF BRUSHES 1

62 BF0230 SELF TAPPING SCREW 3

63 BF0231 SELF TAPPING SCREW 3

64 BF0154 WASHER 3

65 BF0417 PRESSING RING 2

66 BF0415 CABLE-SLEEVE 1

67 BF0416 CABLE-PACKING-BOX 1

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 23

Page 24

HAL 150 AND 300 GAS DRIVE-UNIT AND GAS THROTTLE

22A

22

22B

22C

22D

PAGE 24 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 25

HAL 150 AND 300 GAS DRIVE-UNIT AND GAS THROTTLE

HAL 150 & 300 type- B drive-unit and gasthrottle

NO. PART NO. PART NAME QTY. REMARKS

1 BF2301 N EXCENTER-HOUSING 1

2 BF2302N EXCENTER-SHAFT 1

6 BF2306 B SEAL, RUBBER 1

7 BF2307 ADAPTOR-BOLT (SHORT) 2

8 BF2308 ADAPTOR-BOLT (LARGE) 1

10 BF0155 WASHER 3

11 BF2311N COVER&BEARING (EXCENTER HS.) 1

12 BF231213 EXCENTER 1.0 - 1.5 m. 1

BF231217 EXCENTER 2.0 - 2.5 m. 1

13 BF0201 LOCK RING 1

14 BF2314 EXCENTER-BEARING 1

16 BF2316 O-RING 1

18 BF2318N ENGINE BRACKET 1

20 BF2302666020 GAS ENGINE, KAWASKI 1

20A BF2320A ENGINE ADAPTOR 1

21 BF0055 RUBBER BUFFER 3

22 BF2325 COUPLING - SET 1 INCLS. ALL ITEMS W/

22A

*

22B

*

22C

*

22D

*

23 BF0172 RETAINING RING M8 3

24 BF0088 CAPNUT 2

28 BF2328 SPACER 3

33 BF0086 CAPNUT (HIGH) 1

69 BF2369B LEVER, GAS & BRACKET 1

70 BF2302666700 LEVER, GAS (ONLY) 1

71 BF2371 THROTTLE-CABLE (OUTER) 1

72 BF2372 THROTTLE-CABLE (INNER) 1

73 BF0325 WING-SCREW 1

75 BF2375 ASSEMBLY-BRACKET 1

76 BF2376 THROTTLE-CABLE STOPPER 1

78 BF0122 SCREW 1

79 BF0123 NUT 4

83 BF2383 SPRING 1

84 BF2384 DRIVE-SHAFT ASSY 1

BF2323 CATCH, DRIVESHAFT 1

BF0273 SCREW 1

BF0154 WASHER 1

BF2322 SPRING 1

BF23510 UNIT ASSY (ENGINE & COMPONENTS), KAWASAKI 1

*

KWAAIR ELEMENT, AIR FILTER KAWASAKI ENGINE 1

0650140460 SPARK PLUG, KAWASAKI ENGINE 1

NOTE: For the balance of the Kawaski Engine Parts, call your local Kawaski Engine

distributor refering to engine model TGO 18D-CA 51

For the Robin Engine spare parts, refer to the engine section of this book.

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 25

Page 26

ROBIN EC0250G6004 — CRANKCASE & CYLINDER

PAGE 26 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 27

ROBIN EC0250G6004 — CRANKCASE & CYLINDER

CRANKCASE & CYLINER

NO. PART NO. PART NAME QTY. REMARKS

10 525100300 CRANKCASE ASSY 1 INCLS. ITEMS W/

15 5231502202 GASKET 1

30

*

40

*

95 0140059520 SCREW 3

170 5231502304 GASKET 1

510 5251500200 CYLINDER 1

630 0119059730 SOCKET HEAD BOLT 2

0440129970 OIL SEAL 2

0600129920 BALL BEARING 2

*

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 27

Page 28

ROBIN EC0250G6004 — CRANKSHAFT & PISTON

PAGE 28 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 29

ROBIN EC0250G6004 — CRANKSHAFT & PISTON

CRANKCASE & PISTON

NO. PART NO. PART NAME QTY. REMARKS

10 5252001001 CRANKSHAFT 1

55 0011306160 BOLT & WASHER ASSY 1

65 0031206000 WASHER 1

350 5232502600 PISTON PIN 1

360 5232501902 PISTON 1

370 5242500701 PISTON RING 1

380 0565089970 CLIP 2

390 0610089990 NEEDLE BEARINGS 1

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 29

Page 30

ROBIN EC0250G6004 — MUFFLER, AIR CLEANER

PAGE 30 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 31

ROBIN EC0250G6004 — MUFFLER, AIR CLEANER

MUFFLER, AIR CLEANER

NO. PART NO. PART NAME QTY. REMARKS

310 5253015000 MUFFLER 1

320 5253500000 MUFFLER COVER 1

340 5233504302 GASKET 1

345 5253500101 GASKET 1

360 0119059660 SOCKET HEAD BOLT 2

370 0043705160 SCREW ASSY 1

510 5203004030 AIR CLEANER ASSY 1 INCLS. ITEMS W/

515

*

520

*

540 5233014000 INSULATOR CAP 1

550 5253500200 GASKET 1

560 5103502800 GASKET 1

562 5256501200 GASKET 1

563 5256501100 O’RING 1

580 0043305650 SCREW ASSY 2

581 0140059500 SCREW ASSY 2

5253004010 CLEANER BODY ASSY 1

5203004010 ELEMENT, AIR CLEANER 1

*

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 31

Page 32

ROBIN EC0250G6004 — RECOIL STARTER & HOUSING

PAGE 32 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 33

ROBIN EC0250G6004 — RECOIL STARTER & HOUSING

RECOIL STARTER & HOUSING

NO. PART NO. PART NAME QTY. REMARKS

10 5255500001 BLOWER HOUSING 1

13 5215500300 BUFFLE PLATE 1

20 5259500000 DECAL 1

40 0043505160 SCREW AND WASHER ASSY 3

50 5255500401 CYLINDER COVER 1

51 0140059490 SCREW 1

52 0200070010 WASHER 1

55 5503503001 SPACER 1

210 5255001000 RECOIL STARTER ASSY 1 INCLS. ITEMS W/

213

*

214

*

215

*

216

*

217

*

218

*

219

*

220

*

221

*

222

*

230 0140059480 SCREW 1

5225004020 STARTER KNOB 1

5025001020 SPIRAL SPRING 1

5235024022 STARTER ROPE 1

5025001010 REEL 1

5255001020 SET SCREW 1

5215002040 FRICTION PLATE 1

5105015050 FRICTION SPRING 1

5105015020 RATCHET 1

5105015060 RETURN SPRING 1

5255001040 DAMPER 1

*

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 33

Page 34

ROBIN EC0250G6004 — CARBURETOR & FUEL TANK

PAGE 34 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 35

ROBIN EC0250G6004 — CARBURETOR & FUEL TANK

FUEL TANK, CARBURETOR

NO. PART NO. PART NAME QTY. REMARKS

10 5256500502 FUEL TANK 1

20 5259503500 LABEL, MODEL 1

30 5216004003 CAP 1

35 0043705160 SCREW ASSY 4

40 5236503900 FILTER 1

65 5256012001 TUBE ASSY 1

140 5256002000 PLATE 1

145 0230059970 SPACER 2

147 0230059950 SPACER 1

210 5256007000 CARBURETOR ASSY 1 INCLS. ITEMS W/

227

232

233

234

235

236

237

246

247

253

254

255

256

350

355

357

360

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

5236046050 SPACER 1

5246001030 COVER 1

5246001040 DIAPHRAGM 1

5316005250 DIAPHRAGM ASSY 1

5236046040 GASKET 1

5246001150 PUMP 1

5236046010 SCREW 4

5256007010 BODY ASSY 1

5016004010 SCREEN 1

5236046060 BODY ASSY 1

5316005120 RING 1

5236018040 SWIVEL 1

5206008030 SCREW 2

5256500100 CABLE BRACKET 1

5216008010 ADJUSTER SCREW 1

5316005150 NUT 1

5219500000 HOLDER 1

*

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 35

Page 36

ROBIN EC0250G6004 — COIL & SPARK PLUG

PAGE 36 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 37

ROBIN EC0250G6004 — COIL & SPARK PLUG

COIL & SPARK PLUG

NO. PART NO. PART NAME QTY. REMARKS

10 5257001010 FLYWHEEL 1

11 5257001020 IGNITION COIL 1

35 0140049920 SCREW 2

60 0660000371 SWITCH ASSY 1

70 0043304100 SCREW & WASHER ASSY 2

81 5257500300 GROMMET 1

95 0654009931 SPRING, PLUG CAP 1

100 0650149721 SPARK PLUG 1

110 5237503301 SPARK PLUG CAP 1

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 37

Page 38

Effective: July 1, 2000

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Terms of payment for parts are net 10 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a

signed manifest has been obtained from the

carrier, and any claim for shortage or damage

must be settled between the consignee and the

carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip

is $15.00 net. Customers will be asked for

instructions regarding handling of orders not

meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and credit

will be allowed, subject to the following

provisions:

1. A Returned Material Authorization must

be approved by Multiquip prior to shipment.

2. To obtain a Return Material Authorization,

a list must be provided to Multiquip Parts

Sales that defines item numbers,

quantities, and descriptions of the items

to be returned.

a. The parts numbers and descriptions

must match the current parts price

list.

b. The list must be typed or computer

generated.

c. The list must state the reason(s) for

the return.

d. The list must reference the sales

order(s) or invoice(s) under which

the items were originally purchased.

e. The list must include the name and

phone number of the person

requesting the RMA.

3. A copy of the Return Material

Authorization must accompany the return

shipment.

4. Freight is at the sender’s expense. All

5. Parts must be in new and resalable

6. The following items are not returnable:

7. The sender will be notified of any material

8. Such material will be held for 5 working

9. Credit on returned par ts will be issued at

10. In cases where an item is accepted for

11. Credit issued will be applied to future

PRICING AND REBATES

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

condition, in the original Multiquip package

(if any), and with Muiltiquip part numbers

clearly marked.

a. Obsolete parts. (If an item is listed

in the parts price book as being

replaced by another item, it is

obsolete.)

b. Any parts with a limited shelf life

(such as gaskets, seals, “O” rings,

and other rubber parts) that were

purchased more than six months

prior to the return date.

c. Any line item with an extended dealer

net price of less than $5.00.

d. Special order items.

e. Electrical components.

f. Paint, chemicals, and lubricants.

g. Decals and paper products.

h. Items purchased in kits.

received that is not acceptable.

days from notification, pending

instructions. If a reply is not received

within 5 days, the material will be returned

to the sender at his expense.

dealer net price at time of the original

purchase, less a 15% restocking charge.

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

purchases only.

Prices are subject to change without prior

notice. Price changes are effective on a specific

date and all orders received on or after that date

will be billed at the revised price. Rebates for

price declines and added charges for price

increases will not be made for stock on hand

at the time of any price change.

Multiquip reserves the right to quote and sell

direct to Government agencies, and to Original

Equipment Manufacturer accounts who use

our products as integral parts of their own

products.

SPECIAL EXPEDITING SERVICE

A $20.00 to $50.00 surcharge will be added to

the invoice for special handling including bus

shipments, insured parcel post or in cases

where Multiquip must personally deliver the

parts to the carrier.

LIMITATIONS OF SELLER’S LIABILITY

Multiquip shall not be liable here under for

damages in excess of the purchase price of the

item with respect to which damages are

claimed, and in no event shall Multiquip be

liable for loss of profit or good will or for any

other special, consequential or incidental

damages.

LIMITATION OF WARRANTIES

No warranties, express or implied, are made

in connection with the sale of parts or trade

accessories nor as to any engine not

manufactured by Multiquip. Such warranties

made in connection with the sale of new,

complete units are made exclusively by a

statement of warranty packaged with such

units, and Multiquip neither assumes not

authorizes any person to assume for it any

other obligation or liability whatever in

connection with the sale of its products. A part

from such written statement of warranty, there

are no warranties, express, implied or statutory,

which extend beyond the description of the

products on the face hereof.

PAGE 38 — Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99)

Page 39

NOTE PAGE

Bullfloat HAL 150 & 300 — PARTS & OPERATION MANUAL — REV. #1 (05/27/99) — PAGE 39

Page 40

PARTS AND OPERATION MANUAL

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

MULTIQUIP INC.

POST OFFICE BOX 6254

CARSON, CA 90749

310-537-3700 • 800-421-1244

FAX: 310-537-3927

E-MAIL: mq@multiquip.com

WWW: multiquip.com

Quebec, Canada • Manchester, UK • Rio De Janiero, BR • Guadalajara, MX

Atlanta • Boise • Dallas • Houston • Newark

Loading...

Loading...