Page 1

PARTS AND OPERATION MANUAL

DS-Series

DuoScreed

(CHINA)

© COPYRIGHT 2001, MULTIQUIP INC.

Revision #0 (09/19/01)

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-537-4259

E-mail:mq@multiquip.com • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT:

Page 2

l

PAGE 2 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 3

Page 4

TABLE OF CONTENTS

Here's How To Get Help ............................................ 3

Table Of Contents ..................................................... 4

Parts Ordering Procedures ....................................... 5

Rules For Safe Operation ...................................... 6-7

Operation and Safety Decals .................................... 8

Specifications ............................................................ 9

General Information ................................................ 10

Multiquip DS-Series —

Vibratory DuoScreed

Components (DuoScreed) ...................................... 11

Components (Honda GX31SA Engine) .................. 12

Assembly Instructions ........................................ 13-15

Starting ................................................................... 16

Application/Operation......................................... 17-20

Maintenance ...................................................... 21-22

Troubleshooting (DuoScreed) ................................. 23

Troubleshooting (Honds GX31SA Engine).............. 24

Explanation Of Codes In Remarks Column ............ 26

Suggested Spare Parts ........................................... 27

Main Assembly ................................................... 28-31

Name Plate And Decals ..................................... 32-33

Honda GX31SA Engine

Crankcase Assembly .........................................34-35

Camshaft Assembly ...........................................36-37

Piston Crankshaft Assembly ..............................38-39

Carburetor Assembly .........................................40-41

Recoil Starter Assembly.....................................42-43

Flywheel/Ignition Coil Assembly.........................44-45

Fuel Tank............................................................46-47

Air Cleaner Assembly.........................................48-49

Muffler Assembly ...............................................50-51

Clutch/Fan Cover Assembly ............................... 52-53

Engine Cover Assembly .....................................54-55

Terms and Conditions Of Sale — Parts .................. 56

l

NOTE

Specification and part number

are subject to change without

notice.

PAGE 4 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 5

PARTS ORDERING PROCEDURES

n

Dealer account number

n

Dealer name and address

n

Shipping address (if different than billing address)

n

Return fax number

n

Applicable model number

n

Quantity, part number and description of each part

n

Specify preferred method of shipment:

UPS Ground

•

UPS Second Day or Third Day*

•

UPS Next Day*

•

Federal Express Priority One (please provide us with your Federal

•

Express account number)*

Airborne Express*

•

Truck or parcel post

•

*Normally shipped the same day the order is received, if prior to 2PM west coast time.

Earn Extra Discounts when

you order by FAX!

All parts orders which include complete part numbers

and are received by fax qualify for the following extra

discounts:

Number of

line items ordered Additional Discount

1-9 items 3%

10+ items** 5%

Get special freight allowances

when you order 10 or more

line items via FAX!**

n

UPS Ground Service at no charge for freight

n

UPS Third Day Service at one-half of actual freight

cost

No other allowances on freight shipped by any other carrier.

**Common nuts, bolts and washers (all items under $1.00 list price)

do not count towards the 10+ line items.

Extra Fax DiscountExtra Fax Discount

Extra Fax Discount

Extra Fax DiscountExtra Fax Discount

for Domestic USAfor Domestic USA

for Domestic USA

for Domestic USAfor Domestic USA

Dealers OnlyDealers Only

Dealers Only

Dealers OnlyDealers Only

Now! Direct TOLL-FREE access

to our Parts Department!

Toll-free nationwide:

800-421-1244

Toll-free FAX:

*DISCOUNTS ARE SUBJECT TO CHANGE*

Fax order discount and UPS special programs revised June 1, 1995

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 5

800/6-PARTS-7 • 800-672-7877

Page 6

DS-SERIES DUOSCREED — RULES FOR SAFE OPERATION

■

CAUTION:

Failure to follow instructions in this manual

may lead to serious injury or even death!

This equipment is to be operated by trained

and qualified personnel only! This

equipment is for industrial use only.

The following safety guidelines should always be used when

operating the DuoScreed

GENERAL SAFETY

■

DO NOT operate or service this equipment before

reading this entire manual.

■

This equipment should not be operated by persons under 18

years of age.

■

NEVER operate this equipment without proper

protective clothing, shatterproof glasses, steeltoed boots and other protective devices required

by the job.

NEVER touch the hot exhaust

manifold, muffler or cylinder.

Allow these parts to cool before

servicing engine or Duoscreed.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot

with

■

The DuoScreed engine requires an adequate free flow of

cooling air. Never operate the DuoScreed in any enclosed or

components can cause serious burns.

narrow area where free flow of the air

is restricted. If the air flow is restricted

it will cause serious damage to the

DuoScreed or engine and may cause

injury to people. Remember the

DuoScreed's engine gives off DEADLY

carbon monoxide gas.

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate this equipment under the

influence or drugs or alcohol.

■

l

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any accident

due to equipment modifications.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

Always check the machine for loosened threads or bolts before

starting.

■

■

Always refuel in a well-ventilated area, away from sparks and

open flames.

■

Always use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it

to cool. DO NOT

the machine. Fire or explosion could

result from fuel vapors, or if fuel is spilled

on a hot engine.

NEVER operate the DuoScreed in an explosive atmosphere

or near combustible materials. An explosion or fire could result

causing severe

Topping-off to filler port is dangerous, as it tends to spill fuel.

bodily harm or even death.

smoke around or near

PAGE 6 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 7

DS-SERIES DUOSCREED — RULES FOR SAFE OPERATION

■

Always read, understand, and follow procedures in Operator’s

Manual before attempting to operate equipment.

■

Always be sure the operator is familiar with proper safety

precautions and operations techniques before using

DuoScreed.

■

Refer to the

technical questions or information.

■

NEVER use accessories or attachments, which are not

HONDA Engine Owner's Manual

for engine

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

NEVER Run engine without air cleaner. Severe engine

damage may occur.

■

Always service air cleaner frequently to prevent carburetor

malfunction.

■

Always store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

Transporting

■

■

■

■

Emergencies

■

Maintenance Safety

■

■

Always shutdown engine before transporting.

Tighten fuel tank cap securely and close fuel cock to prevent

fuel from spilling.

Drain fuel when transporting DuoScreed over long distances

or bad roads.

Always tie-down the DuoScreed during transportation by

securing the DuoScreed with rope.

Always know the location of the nearest

and

first aid kit

. Know the location of the nearest telephone.

Also know the phone numbers of the nearest

doctor

and

fire department

. This information will be

fire extinguisher

ambulance

,

invaluable in the case of an emergency.

NEVER lubricate components or attempt service on a running

machine.

Always allow the machine a proper amount of time to cool

before servicing.

■

Keep the machinery in proper running condition.

■

Fix damage to the machine immediately and always replace

broken parts.

■

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

■

DO NOT use plastic containers to dispose of hazardous

waste.

■

DO NOT pour waste, oil or fuel directly onto the ground,

down a drain or into any water source

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 7

Page 8

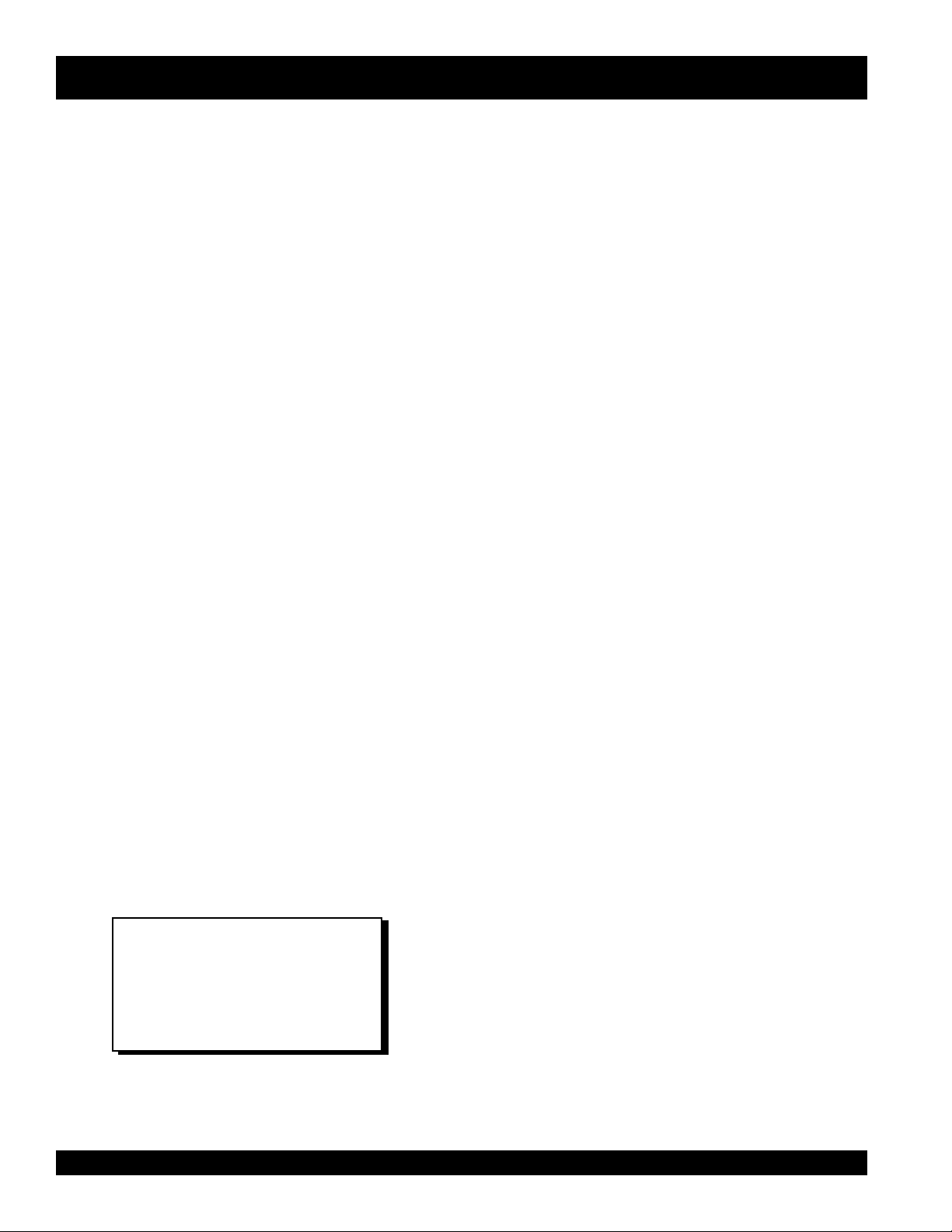

DS-SERIES DUOSCREED — OPERATION AND SAFETY DECALS

Machine Safety Decals

The DUOSCREED is equipped with a number of safety decals. These decals are provided for operator safety and maintenance

information. The illustrations below shows these decals as they appear on the machine. Should any of these decals become

unreadable, replacements can be obtained from your dealer.

l

PAGE 8 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 9

DS-SERIES DUOSCREED — SPECIFICATIONS

ledoMtinUrewoPUPG-SD

snoitarbiVforebmuNnim/v005,5

metsySevirDtfahSelbixelF

)riAnepO(esioN)A(Bd05

SNOITACIFICEPSDEERCSOUD.1ELBAT

noitareleccAnoitarbiVces/m5.1

thgieWgnitarepO).gK61(.sbl53

noitcurtsnoCedalByollAmunimulAdedurtxE

shtdiWedalB

sthgieWedalB.tf/.bl8.2.xorppA

ekaMenignEADNOH

ledoMenignEAS-13XG

epyTenignEenignEenilosaGVHOekortS-4

thgieWenignE)gK3.3(.sbl5.7

srednilyCfOrebmuN1

2

.tf6.91,0.81,4.61,9.31,3.21,8.9,2.8,2.6,9.4

)sretem0.6,5.5,0.5,52.4,57.3,0.3,5.2,9.1,5.1(

SNOITACIFICEPSENIGNE.2ELBAT

3

tnemecalpsiDmc13(ni.uc9.1

)

tuptuOmumixaMmpr000,7/PHB5.1

edarGliO03-W01EAS

yticapaCliO)sretil01.0(/.tq11.0

epyTleuFdedaelnU

yticapaCknaTleuF)sretil56.(/.lag271.

paGgulPkrapS

epyTgulPkrapS

hcni820.0-420.0

)mm070-06.0(

)KGN(BSH5RC

)OSNED(BU-RSF61U

dohteMgnitratStratSlioceR

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 9

Page 10

DS-SERIES DUOSCREED — GENERAL INFORMATION

Introduction

This DuoScreed is a hand held vibratory screed designed to

strike-off and consolidate concrete slabs. It is comprised of two

major components, the power unit (gasoline engine), and the

strike-off blade. Generally this screed operates ideally in

concrete with a slump of 2 inches or greater. Its applications

include patios, driveways, sidewalks and floor slabs.

Assembly

There are no tools required to assemble the DuoScreed. The

power unit (engine) is connected to the to the blade by means of

a spring-loaded clamp. Springs within the clamp assembly

prevent vibration from loosening the power unit from the blade.

It takes approximately 2 minutes to assemble the DuoScreed.

Handle Adjustments

The handle assembly on the DuoScreed is height adjustable for

operator comfort. The handle design used on this screed allows

the operator to remain upright at all times and can be quickly

adjusted without any tools.

Vibratory System

The vibratory system of the DuoScreed produces low amplitude

high frequency vibrations, designed to level and compact

concrete. This vibratory system is mounted at an angle to transmit

vibration laterally and vertically through the blade to produce a

strong, dense slab.

Engine

The DuoScreed is equipped with an Honda Model GX31SA, 1.5

HP, mini 4-cycle gasoline engine. This engine is lightweight

and requires no fuel mixing.

Drive System

The Honda 1.5 HP engine drives a flexible shaft that requires no

greasing. Its short one piece design runs directly to the vibrator

housing and does not bend. This type of design eliminates a

major source of friction and reduces the likelihood of shaft failure.

Maneuverability

End caps are provided on each side of the DuoScreed's blades

to allow the screed to be easily maneuvered around pipes or

obstructions.

Transport

To transport your DuoScreed simply unclamp the power unit

from its base. Additionally, the handles can be folded down for

storage. The power unit weights approximately 34 pounds while

the blades weigh approximately 2.8 pounds per foot.

The engine drives a two piece eccentric weight by means of a

one-piece flexible shaft. This weight produces a vibratory action

which simultaneously allows the DuoScreed to level the slab

and consolidate the concrete beneath the surface.

Blades

The DuoScreed can utilize blades ranging in lengths from 4.9 to

19.6 feet (1.5 to 6 meters). Since different length blades will

require varying amounts of vibration, the DuoScreed features

adjustable eccentric weights. It is also recommended that two

power units be used if 16, 18, or 20 foot blades are required.

The blade of the DuoScreed offer a unique design with two

distinct edges and is manufactured from reinforced extruded

aluminum alloy. A curled edge is provided for applications that

allow the blade to ride on top of forms or rails. A smooth edge is

provided for wetscreed applications where the machine rides

entirely on concrete. Plastic end caps allow the blade to maneuver

around obstructions without marring the surface.

l

PAGE 10 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 11

Figure 2. DuoScreed Components

DS-SERIES DUOSCREED — COMPONENTS

Figure 1 shows the location of the components of the DuoScreed.

The function of each component is described below:

1. Oil Cap – Remove this cap to add engine oil.

2. Fuel tank – Remove the fuel tank cap to add unleaded

fuel ONLY! DO NOT mix fuel. DO NOT over fill. Tank

holds approximately .172 gallons (.65 liters)

3. Throttle Control – Move the throttle lever to the

position for full throttle (max RPM's), for engine idle, move

up

the throttle lever to the

4. Handle Bar Adjustment Knobs – Loosen these two

knobs to adjust the handle bar to a suitable working position.

5. Handle Bar – Used in the steering of DuoScreed.

6. Hand Grip – When operating the DuoScreed use this hand

grip to maneuver the machine.

7. Support Stand Latch – Use this latch to lock support

stand in place when DuoScreed is in operation.

8. Engine ON/OFF Switch – Set this switch in the ON

position to start the engine, set in the OFF position to stop

the engine.

9. Support Stand – Use this stand to support the DuoScreed

when not in use.

position.

down

11. Spring-Loaded Wing Nuts– Turn these 3 spring loaded

wing nuts counterclockwise to release the blade from the

aluminum clamping strip, turn clockwise to secure the blade

to the clamping strip.

12. Blade – The DuoScreed comes in various blade sizes

ranging from 4.95 to 19.6 feet.

13. Locking Nuts – These 3 locking nuts are used in

conjunction with the 3 spring loaded wing nuts which

secure the blade to the aluminum clamping strip. Important!

always cover the two outer nuts with the provided plastic

cap. This will prevent concrete and other debris from

entering the quick disconnect system.

14. Eccentric Cover – Encloses the adjustable eccentric

weights.

15. Gasoline Engine – This DuoScreed uses a HONDA

GX31SA engine. Refer to the

engine information and related topics.

16. End Caps – Allows the DuoScreed to be maneuvered

around pipe or obstructions.

17. Flexible Drive Shaft– Connected to the drive shaft of the

engine, provides the vibrational force for the eccentric

weights.

HONDA

owners manual for

10. Shock Mounts – Used to absorb the vibration generated

by the DuoScreed. These shock mounts minimize the

transfer of vibration to the operator.

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 11

18. Lifting Bar– To lift or transport the DuoScreed, grab this

bar .

Page 12

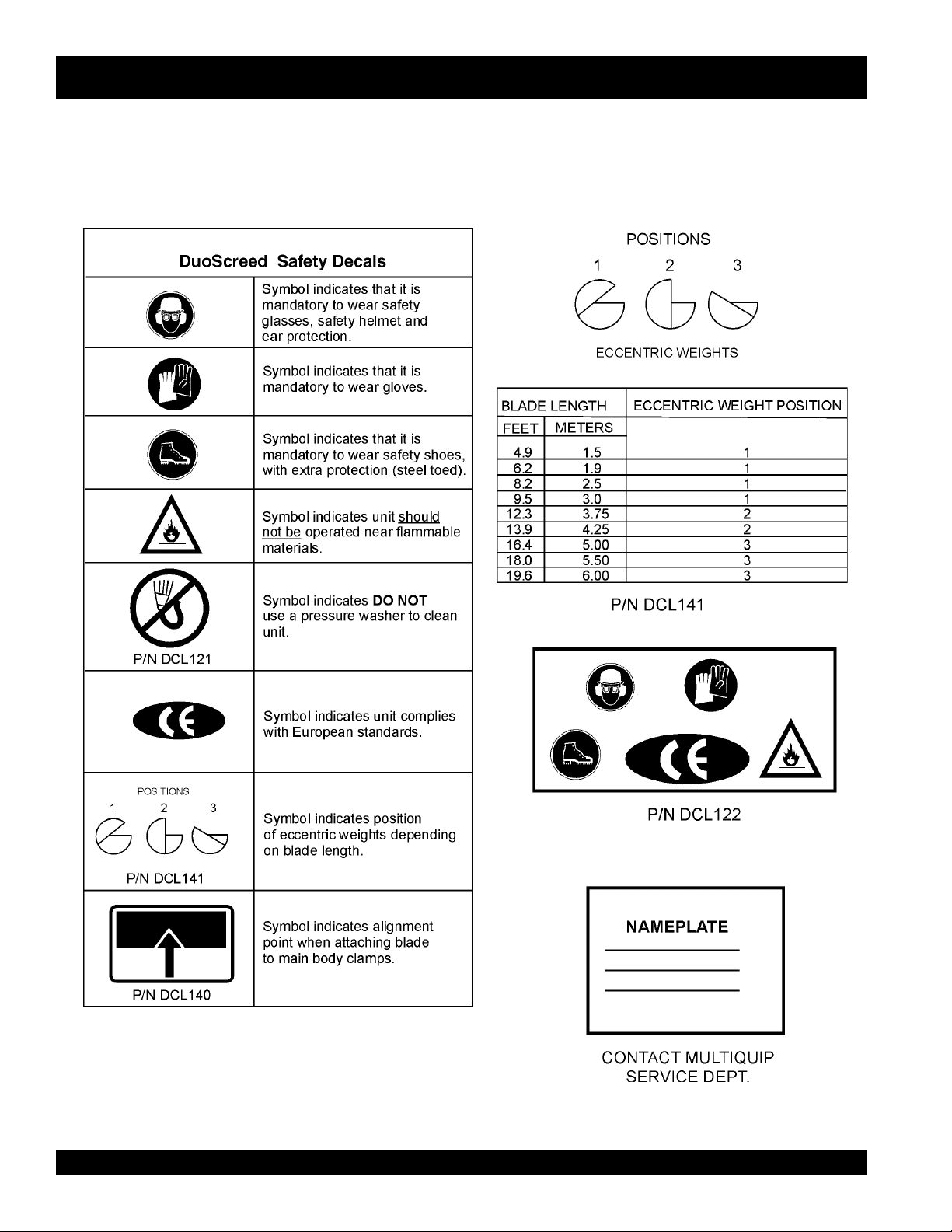

DS-SERIES DUOSCREED — COMPONENTS (HONDA GX31SA ENGINE)

Figure 2. HONDA GX31SA Components

1. Spark Plug – Provides spark to the ignition system. Set

spark plug gap to 0.6 - 0.7 mm (0.024 - 0.028 inch) Clean

spark plug once a week.

2. Muffler – Used to reduce noise and emissions. DO NOT

touch muffler while engine is running, let engine cool before

performing any maintenance.

3. Spark Arrester – Prevents sparks from leaving the engine

exhaust system, which could ignite flammable materials.

4. Starter Grip – Grip this handle to start engine. See engine

starting section of this manual.

5. Recoil Starter (pull rope) – Type of engine starting method.

6. Oil Filler Cap – Remove this cap to add engine oil. Engine

oil capacity is 0.11 quart (0.1 liters). Use SAE 10W-30.

PAGE 12 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

l

7. Fuel Tank – Holds .65 liters (approximately .172 gallon) of

8. Fuel Filler Cap – Remove this cap to add unleaded

9. Priming Bulb – Used in the starting of a cold engine or an

10. Air Cleaner – Prevents dirt and other debris from entering

11. Choke Lever – Used in the starting of a cold engine, or in

unleaded gasoline.

gasoline to the fuel tank. Make sure cap is tighten securely.

DO NOT over fill.

engine that has run out of fuel. Press the priming bulb

repeatedly until fuel can be seen inside the clear plastic

bulb.

the fuel system. Release latch on side of air filter

compartment to gain access to filter element.

cold weather conditions. The choke enriches the fuel mixture

for starting a cold engine.

Page 13

DS-SERIES DUOSCREED — ASSEMBLY INSTRUCTIONS

Assembly Instructions

This section will explain how to assemble the DuoScreed.

NOTE

It is recommended that you familiarize yourself with the

DuoScreed’s components. For assistance identifying

components called out in the text, refer to the Figure 1.

1. The DuoScreed is comprised of two major components.

The power unit (HONDA GX31SA Engine) and the strikeoff blade. This DuoScreed is equipped with a quick

disconnect system, with which the power unit can be

mounted onto two aluminum clamping strips with ease.

2. The aluminum clamping strip (retaining plate) is located at

the base of the power unit. This clamping strip is what

holds the blade in place with the aid of three quick

disconnect spring loaded wing nuts (Figure 3) that can

either be tighten or loosened by hand.

3. Determine whether you will be using the DuoScreed on

forms

unit will be mounted

screed the wing nuts should be located above the smooth

edge of the blade. If the DuoScreed will be used on forms

(Figure 3) the wing nuts should be located above the

curled edge of the blade.

4. Loosen each of the three wing nuts about 1/4 inch (8 mm).

It is not necessary to completely remove the wing nuts from

the aluminum clamping strip.

5. Locate the two red indicator arrows (Figure 4) on the top of

the blade. The power unit should be placed squarely

between the two markers.

or as a

wet screed

. This will decide how the power

.

If the DuoScreed will be used as a wet

Figure 3. Blade Quick Disconnect System

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 13

Page 14

DS-SERIES DUOSCREED — ASSEMBLY INSTRUCTIONS

Figure 4. Blade Mounting Diagram

6. Place the front of the power unit over the blade (Figure 3)

until the front of the clamp is seated within the front blade

collar.

7. Ease the power unit back to allow the rear clamp to seat

itself within the rear blade collar. It may be necessary to

further loosen the wing nuts to allow the clamp to fit around

the blade collar.

8. Securely hand tighten each of the three wing nuts. The

wing nuts are spring loaded to prevent them from coming

loose during operation.

l

9. Two handle bar adjustment knobs (Figure 5) are located at

the base of the steering handle bar. Loosen these two knobs

to adjust the height of the steering handle bar to a suitable

working position.

10. The DuoScreed is now ready for operational use.

Figure 5. Handle Bar Adjustment Knob

PAGE 14 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 15

DS-SERIES DUOSCREED — ASSEMBLY INSTRUCTIONS

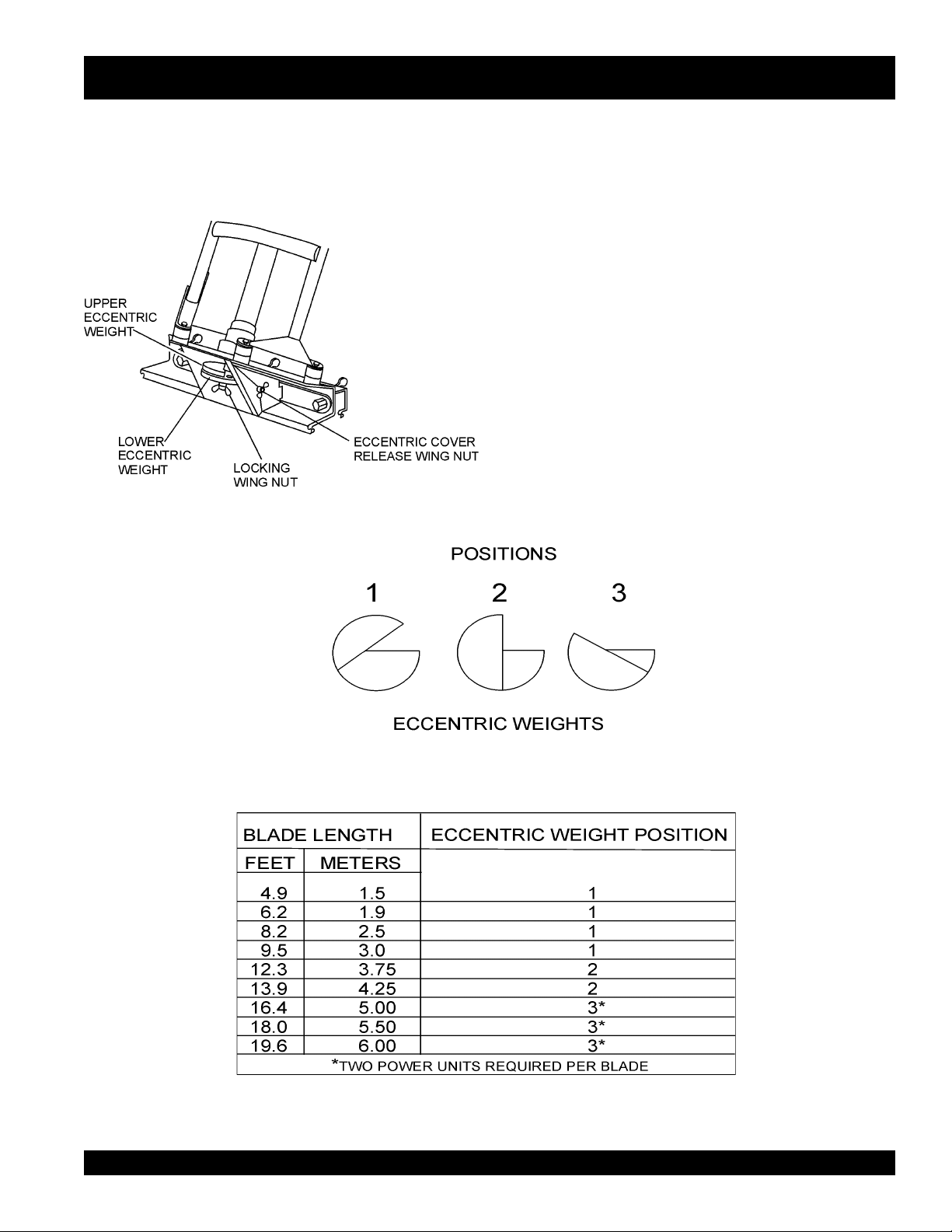

Eccentric Weight Adjustment

There are two eccentric weights (Figure 6) that are supplied

with the DuoScreed. These weights are located inside the

eccentric weight compartment, which is located at the bottom of

the unit.

Figure 6. Eccentric Weight Location

These weights determine the amount of vibration that will travel

down the blade. Depending on the type of blade that is used, will

determine the position of the two eccentric weights. Reference

Figure 7 in determining how your eccentric weights should be

positioned.

1. To gain access to the eccentric weight compartment, loosen

the two wing nuts on each side of the compartment and lift

the cover.

2. Loosen the eccentric locking wing nut.

3. Use the chart in Figure 7 to determine what position your

eccentric weights should be in (position 1, 2 or 3).

Example:

A 13.9 ft. (4.25 meters) blade will place the eccentric weights in

position 2.

Figure 7. Eccentric Weight Positions

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 15

Page 16

DS-SERIES DUOSCREED — STARTING

Engine Pre-Check

1. Fill the fuel tank (Figure 8 ) with unleaded gasoline. DO NOT

over fill. Topping-off to filler port is dangerous, as it tends to

spill fuel. Wipe up any spilled fuel immediately.

Figure 8. Fuel Tank

1. Place the engine in a level position.

2. Check the engine oil level by unscrewing the engine oil dip

stick (Figure 9) from its holder.

3. If oil is not observed at the edge of the oil filler hole, fill with

oil until oil is present at edge of oil filler hole. Remember to

add oil slowly to avoid overflowing, as the engine oil tank

capacity is small.

2. Press the priming bulb (Figure 11) repeatedly until fuel can

be seen inside the clear plastic bulb.

3. Set the engine ON/OFF switch (Figure 12) to the ON position.

Figure 11. Priming Bulb Location

Figure 9. Engine Oil Dipstick/Oil Filler Hole

4. Reinstall the engine oil dipstick securely.

Starting The Engine

1. To start a cold engine, move the choke lever (Figure 10) to

the CLOSED position. If restarting a warm engine leave the

choke lever in the OPEN position.

Figure 10. Choke Lever

l

Figure 12. Engine ON/OFF Switch

4. Pull the starter rope (Figure 13) lightly until you feel resistance, the pull briskly. Return the starter rope gently.

Figure 13. Engine Starter Rope

5. Once the engine has started, allow it to idle for 3 to 5 minutes.

PAGE 16 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 17

Application/Operation

DS-SERIES DUOSCREED — APPLICATION/OPERATION

1. Before placing the DuoScreed in concrete for screeding,

it is a good idea to apply

frame parts that may come in contact with the concrete.

This form oil will become useful when cleaning the

DuoScreed. Make sure to

amount of form oil.

2. Prepare a grid of #5 rebar pins (Figure 14) equally spaced

approximately every 9 to 11 feet. If a 10 ft. screed blade

is going to be used space the grade pins every 9 feet, if

a 12 ft. screed blade is required, space the grade pins

every 11 ft. Make sure to drive the pins deeply into the

ground.

3. Use a

string line

The grade should be to the top of the grade pins. Remember, before any concrete is to be poured, make sure that

the top of the pins are dead on grade.

or

form oil

saturate the unit with a good

laser

to set the pins to grade (height).

to the blade and all

4. Once all the grade pins have been placed correctly and

are dead on grade, concrete can then be poured on top

of grade pins.

5. Level, and form the concrete as close as possible to

grade. Mark the top of each pin so that its exact location

will be known. Use a hand trowel to float the edges and

plumbing grade pins.

6. If chalk lines are used for grade against forms, walls or

existing concrete, float out the grade with a hand float

along the edge.

7. Two workers will be required to assist the DuoScreed

operator when making the 12-18 concrete bases, one on

each side. These workers will rake the concrete in toward

the center of the DuoScreed away form the bases to avoid

changing base elevation.

Figure 14. DuoScreed On Forms and Grade Pins

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 17

Page 18

DS-SERIES DUOSCREED — APPLICATION/OPERATION

14. Remember to build the bases in long parallel strips

across the pins and on the hand floated edges and

against plumbing or other outs, leaving the long unfinished areas about 8 or 9 feet wide. Once the bases are

built, the workers can more accurately shape the concrete

to grade.

15. When

his two workers can begin to work down the long parallel

unfinished 8 to 9 foot wide middle portions. When moving the

DuoScreed down the middle portions, the ends of the

Figure 15. Throttle Lever

NOTE

Before placing the DuoScreed in concrete, make certain

the unit has been set up (blade) for

can be verfied by observing that the operator's toes are

pointing towards the smooth side of the blade (Figure 3),

from the operators's position (handle bars).

8. Set the DuoScreed blade down in the concrete base in the

left

most corner of the grid between the two grade pins as

shown in Figure 16. Adjust the DuoScreed's handle bar

to a height where the operators is not bending over, but

standing upright with arms extended forward.

9. To begin screeding move the engine throttle lever (Figure

15) midway between idle and full throttle. Notice that the

DuoScreed's vibration will cause the blade to sink into the

concrete base until it touches the top of the grade pins

10. Pull the DuoScreed from the edge of the grid's

corner, horizontally toward the

DuoScreed passes over the grade pins a small circle of

concrete around the grade pins will appear. This indicates

that the Duoscreed has vibrated the grade pin, and that

the operators is

11. Keep the DuoScreed blade level and create a level base

between 12-18 inches wide.

12. After a complete pass over the first set of grade pins has

been made, remove the DuoScreed from the concrete

base and position it over the second set of grade pins

(Figure 16), overlapping the first set of grade pins between 12-18 inches. Repete this process until all

grade pins have a level base between 12-18 inches wide.

dead on grade

wet screeding

center

. Notice that as the

l

.

. This

top left

left

edge

DuoScreed blade should be resting on the bases, and the

leading edge of the blade should be approximately 1/8 to

1/4 inch above each base depending on the slump and

condition of the concrete. Have workers adjust the concrete

along the face of the DuoScreed's blade to assure that the

base is level with no high or low areas ahead of the blade.

16. Keep the engine throttle between 1/2 to 2/3 of full speed, if

necessary readjust the DuoScreed's vibration to meet the

condition of the concrete. Remember to move rapidly and

watch both ends of the blade to assure that the blade remains

1/8 to 1/4 of an inch above the concrete base. Always keep

the workers alert for concrete height changes.

Shut-Down

1. NEVER

speed.

2. Move the engine

speed position (idle).

3. Set the engine ON/OFF switch (Figure 12) to the OFF

position.

4. Remove the DuoScreed from the slab surface.

Cleaning

1. Allow the engine to

has cooled, use a damp and a mild detergent to remove all

concrete and foreign debris. DO NOT spay the engine with

water.

2. To remove all concrete and foreign debris from the

DuoScreed, wash the DuoScreed's blade and frame using

water and a mild detergent. Remember, if form oil was

applied before the machine was placed in concrete, the

cleanup will be much easier.

all

the bases have been completed, the operator and

stop

the engine suddenly while running at high

throttle lever

cool

before cleaning. When the engine

(Figure 15) to the low

13. Repeat steps 9 through 12 pulling the DuoScreed from

the edge of the grid's

the center.

PAGE 18 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

top right

corner, horizontally toward

Page 19

DS-SERIES DUOSCREED — APPLICATION/OPERATION

TOP LEFT

CORNER OF

GRID

STEP 1

PLACE # 5 REBAR GRADE PINS

AND FORM RECTANGULAR GRID.

BLADE OVERLAP

12-18 INCHES

STEP 2

POUR CONCRETE

AND FORM TO GRADE

12-18 INCH

BASE

HORIZONTAL

DIRECTION

DUOSCREED BLADE

HORIZONTAL

DIRECTION

HORIZONTAL

DIRECTION

HORIZONTAL

DUOSCREED BLADE

DIRECTION

STEP 7

DUOSCREED BLADE

VERTICAL

DIRECTION

STEP 7

SET SCREED BLADE DOWN ON

UNFINISHED 8 TO 9 FT. WIDE

MIDDLE SECTION, PLACING

BOTH ENDS OF THE BLADE

ON THE 12-18 INCH BASES.

STEP 7

12-18 INCH

BASE

HORIZONTAL

DIRECTION

HORIZONTAL

DIRECTION

HORIZONTAL

DIRECTION

HORIZONTAL

DIRECTION

DUOSCREED BLADE

BLADE OVERLAP

12-18 INCHES

DUOSCREED BLADE

TOP RIGHT

CORNER OF

GRID

STEP 3

MAKE 12-18 INCH

BASE (LEFT SIDE)

STARTING IN THE TOP LEFT CORNER OF GRID,

BUILD 18 INCH WIDE PARALLEL CONCRETE BASES

ACROSS GRADE PINS FROM TOP TO BOTTOM OF GRID.

STEP 4

APPROX.

8-9 FT.

RECTANGULAR

GRID

STARTING IN THE TOP RIGHT CORNER OF GRID,

BUILD 18 INCH WIDE PARALLEL CONCRETE BASES

ACROSS GRADE PINS FROM TOP TO BOTTOM OF GRID.

STEP 6

Figure 16. DuoScreed Wet Screeding Application

STEP 5

MAKE 12-18 INCH

BASE (RIGHT SIDE)

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 19

Page 20

DS-SERIES DUOSCREED — APPLICATION/OPERATION

Important Tips to Remember

■

Do not allow the engine to run out of fuel as this may cause

problems with starting. Always maintain an extra supply of

fuel on the job site.

■

Always keep the DuoScreed moving backwards during

operation. Allowing the DuoScreed to vibrate in the same

location for too long will cause it to sink into the concrete.

■

When using the DuoScreed with low slump (dry) concrete do

not attempt to walk it quickly across the slab. Walk slowly to

allow the vibratory action to consolidate and level the slab

surface. When using the DuoScreed with high slump (wet)

concrete you will be able to walk the machine across the slab

at a faster pace.

■

In applications where the Duoscreed is being used as a wet

screed it is recommended that grade or height of the concrete

slab be adjusted with a laser device.

■

Proper vibratory force is essential to producing a

durable

eccentric weights

troubleshooting section of this manual.

■

When screeding using forms or rails, always size your screed

blade appropriately for the job. It is best to have the blade

extend beyond the forms, by about 6-inches on each side.

slab. If the DuoScreed is vibrating too strongly the

will require adjustment. Refer to the

level, hard

■

■

■

■

■

■

■

,

When screeding make sure the blade is kept straight. DO

NOT let blade turn.

DO NOT run the DuoScreed with one part of the blade on

forms and the other on base. The blade must either be placed

on forms or float (wet screeding), but not a combination of the

two techniques.

DO NOT stand in the concrete with the engine throttle

engaged. This will cause the DuoScreed to sink.

If the concrete appears too wavy, you are moving too slowly,

increase your backing-up speed.

Always keep the workers back far enough too allow the

operator to see the cutting face of the blade as it rides on the

wet screed base.

The operator should keep the screed blade about 1/8 to 1/4

inch above the concrete base at all times.

Should the DuoScreed stick to the wet concrete slab, DO

NOT attempt to lift it. Quickly increase engine rpm's while

pushing forward on the handles to free the machine.

l

PAGE 20 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 21

DS-SERIES DUOSCREED — MAINTENANCE

Maintenance

3. Use a low pressure water hose, soft brush, wiping cloth

CAUTION:

DO NOT clean the DuoScreed with a

pressure washer

.

1. NEVER clean the DuoScreed with the engine running.

2. Allow the engine to cool down before cleaning.

NOTE

DO NOT allow concrete to

harden

on the

DuoScreed. Wipe all concrete off the chrome

frame and any other parts including the engine

of the DuoScreed.

)3(NOITPIRCSEDNOITAREPOEROFEB

4. Keep the drive unit free from grease, dirt and grime as this

30 - Day Storage Procedure

For storage of the DuoScreed for over 30 days, the following is

required:

l

l

l

l

TSRIF

HTNOM

RO

.SRH01

and a mild cleaning detergent and remove all concrete

from the DuoScreed. Be careful not to get excessive amounts

of water in the engine compartment.

can effect the performance of your DuoScreed

Drain the fuel tank completely.

Run the engine until the fuel in the injection system is

completely consumed.

Completely drain used oil from the engine crankcase and

fill with fresh clean oil, then follow the procedures described

in the engine manual for engine storage.

Cover DuoScreed and engine with plastic covering or

equivalent and store in a clean, dry place.

eludehcSecnanetniaMenignE.3elbaT

YREVE

SHTNOM3

RO

.SRH52

YREVE

SHTNOM6

RO

.SRH05

YREVE

RAEY

RO

.SRH001

YREVE

SRAEY2

RO

.SRH002

liOenignE

renaelCriA

stloB&stuNllA

gulPkrapS

sniFgnilooCKCEHCX

retserrAkrapSNAELC X

knaTleuFNAELC X

retliFleuFKCEHC X

seohShctulCKCEHC)2(X

deepSeldITSUJDA-KCEHC )2(X

ecnaraelCevlaVTSUJDA-KCEHC )2(X

senilleuFKCEHC )2()yrassecenfiecalper(sraey2yrevE

KCEHCX

EGNAHCX

KCEHCX

EGNAHC)1(X

fInethgit-eR

yrasseceN

NAELC-KCEHCX

ECALPER X

X

nidesunehwyltneuqerferomecivreS)1( YTSUD .saera

yllacinahcemeradnaslootreporpehtevahuoysselnu,relaedcivresruoyybdecivresebdluohssmetiesehT)2(

serudecorpecivresroflaunaMpohsADNOHehtotrefeR.tneiciforp

.slavretniecnanetniamreporpenimretedotnoitarepofosruohgol,esulaicremmocroF)3(

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 21

Page 22

DS-SERIES DUOSCREED — MAINTENANCE

Air Cleaner

1. The air cleaner element should be cleaned because a

clogged air cleaner can cause poor engine starting, lack of

power and shorten engine life substantially.

2. Before opening the air cleaner compartment, wipe any dirt

or foreign matter from the air cleaner body and cover, using

a moist cloth. Be careful to prevent dirt from entering the

carburetor

3. Press the latch tab on the top of the air cleaner cover (Figure

16), and remove the cover. Check the filter to be sure that it

is clean and in good condition.

3. Remove the spark plug with 5/8-inch wrench.

4. Inspect the spark plug. Replace it if the electrodes are worn,

or if the insulator is cracked or chipped. Clean the spark

plug with a wire brush if you are going to reuse it.

5. Set the spark plug gap (Figure 18) using a suitable gauge.

The gap should be between 0.024-0.028 inch (0.60-0.70

mm).

6. Carefully install the spark plug by hand to avoid cross

threading, the tighten

Figure 18. Spark Plug Gap

7. Attach spark plug cap.

Figure 16. Air Cleaner

Spark Plug

1. Make sure the engine is off and cool.

2. Disconnect the spark plug cap ( Figure 17), and remove

any dirt from around the spark plug area.

l

Figure 17. Spark Plug Removal

PAGE 22 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 23

DS-SERIES DUOSCREED — TROUBLESHOOTING

GNITOOHSELBUORTDEERCSOUD.4ELBAT

MOTPMYSESUACELBISSOPNOITULOS

tessirotarbivehtfoecroflagufirtnecehT

?woloot

ehttluserasadnatneiciffusnisetarbiV

dnadelevelebtonnacroolfetercnoc

.yawreporpehtnidehtooms

?egral

-mrofasadesunehwdeercSouDehT

dnahcumootsetarbivdeercsmrof-ot

liarehtssorcaylhtoomslevarttonseod

.stroppus

deercsehtsa"YVAW"skooletercnoC

.tirevosessapedalb

tewgnirudstopsWOLroHGIHgnivaeL

.gnideercs

?hctamton

?ylwolsootgnivomrotarepO

?etercnoc

etercnocfostnuomaevissecxesierehT

?edalbehtfoegdegnidaelehtgnola

ootsiedalbehtfohtdiwnesohcehT

odsthgiewcirtneccednaedalbdetceleS

foepytehtrofnoitarbivhcumooT

?edisenonowolrohgihootetercnoC

.deeps

.edalbehtmorf

)senigne2(.tf02

.ecap

sthgiewcirtnecceehttsujdA

enigneesaercniro7erugiFrep

etercnocevissecxeehtevomeR

edalbrellamsahtiwkroW

sihtdiwmumixamrebmemeR

otsthgiewcirtneccetsujdA

.htdiwedalbdetceleshctam

.7erugiFecnerefeR

retsafatasdrawkcabklaW

klawdnadeepsenigneecudeR

.ecapretsafatasdrawkcab

ehtepahssrekrowevaH

otelbissopsaesolcetercnoc

fohcni1tuobaniatniaM.edarg

fotnorfehtssorccaetercnoc

.semitllataedalbeht

.etercnoctewotnisgidedalB?yltcerrocdenoitisopedalbsI

tsumedalbehtfodnehcaE

.ecafrusemasehtnoedir

edalbehtfodnehcaerehtiE

tew(etercnocrosmrofnosedir

.htobton)deercs

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 23

Page 24

DS-SERIES DUOSCREED — TROUBLESHOOTING

GNITOOHSELBUORTENIGNE.5ELBAT

MOTPMYSESUACELBISSOPNOITULOS

?gnigdirbgulpkrapS

ontub,elbaliavasileuf",tratsottluciffiD

."gulpkrapstaKRAPS

?noitalusni

?evitcefedliocnoitingI.liocnoitingiecalpeR

dna,elbaliavasileuf",tratsottluciffiD

."gulpkrapsehttatneserpsiKRAPS

?gnitiucric

?epytleufgnorW

?gulpkrapsnotisopednobraC .gulpkrapsecalperronaelC

gulpkrapstneicifedoteudtiucrictrohS

?paggulpkrapsreporpmI.pagreporpotteS

?detrohssihctiwsFFO/NO

?yrtridstniop,pagkrapsreporpmI

trohsronrownoitalusniresnednoC

?gnitiucrictrohsronekorberiwgulpkrapS

.nrowfiecalper

.hctiws

.stniopnaelc

.gniriw

ronoitalusni,pagkcehC

.gulpkrapsecalper

,noitalusnigulpkrapskcehC

ecalper,gniriwhctiwskcehC

dnapagkrapstcerrocteS

.resnednocecalpeR

gulpkrapsevitcefedecalpeR

ecalperdna,metsysleufhsulF

.leuffoepyttcerrochtiw

kraps,elbaliavasileuf",tratsottluciffiD

"lamronsinoisserpmocdnatneserpsi

?ytridrenaelcriA .renaelcriaecalperronaelC

?nepOekohC.ekohCesolC

l

kraps,elbaliavasileuf",tratsottluciffiD

"wolsinoisserpmocdnatneserpsi

?ylreporpdenethgit

?degamad

?deggolcretlifleuF.retlifleufecalpeR

.blubgnimirpedisnitneserpleufoN

?enilleufniriA.enilleufdeelB

?metsysleufnitsudroretaW.metsysleufhsulF

?dedurtorprokcutsevlavtsuahxe/noitcuS.sevlavtaes-eR

?nrowrednilycro/dnagnirnotsiP

tongulpkrapsro/dnadaehrednilyC

teksaggulpkrapsro/dnateksagdaeH

?knatleufnielbaliavatonleuF .leuffoepyttcerrochtiwlliF

?deggolcelohrehtaerbpacknatleuF .packnatleufecalperronaelC

rodnasgnirnotsipecalpeR

.notsip

dnastlobdaehrednilyceuqroT

.gulpkraps

gulpkrapsdnadaehecalpeR

.steksag

PAGE 24 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 25

NOTE PAGE

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 25

Page 26

DUOSCREED — EXPLANATION OF CODE IN REMARKS COLUMN

How to read the marks and remarks used in this parts

book.

Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Items Found In the “Items Number” Column

All parts with same symbol in the number column,

■

, belong to the same assembly or kit.

If more than one of the same reference number is

listed, the last one listed indicates newest (or latest)

part available.

, #, +, %, or

*

l

NOTE

NOTE

The contents of this catalog are

subject to change without notice

PAGE 26 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

.

Page 27

DUOSCREED — SUGGESTED SPARE PARTS

DUOSCREED 1 TO 3 UNITS WITH HONDA

GX31SA ENGINE

1 to 3 Units

Qty. ....... P/N .............................. Description

2 ............ BF2648 ....................... HANDLE GRIP

1 ............ BF2647 ....................... THROTTLE GRIP

2 ............ BF2645 ....................... THROTTLE CABLE

1 ............ BF2621 ....................... FLEXIBLE SHAFT

1 ............ BF2609 ....................... ECCENTRIC COVER

3 ............ BF2607 ....................... COMPRESSION SPRING

1 ............ BF2605 ....................... ALUMINUM CLAMPING STRIP

3 ............ BF0176 ....................... WASHER

3 ............ BF2606 ....................... CLAMP

1 ............ BF2643 ....................... STOP SWITCH

3 ............ BF0325 ....................... WING NUT M6X12

3 ............ 9805655757 ................ SPARK PLUG

3 ............ 17211ZM3000 ............. ELEMENT AIR

1 ............ 15620ZM3003 ............. CAP, OIL FILLER

1 ............ 28400ZM3003ZA ........ RECOIL STARTER ASSY.

NOTE

Part numbers on this Suggested

Spare Parts List may supercede/

replace the P/N shown in the text

pages of this book.

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 27

Page 28

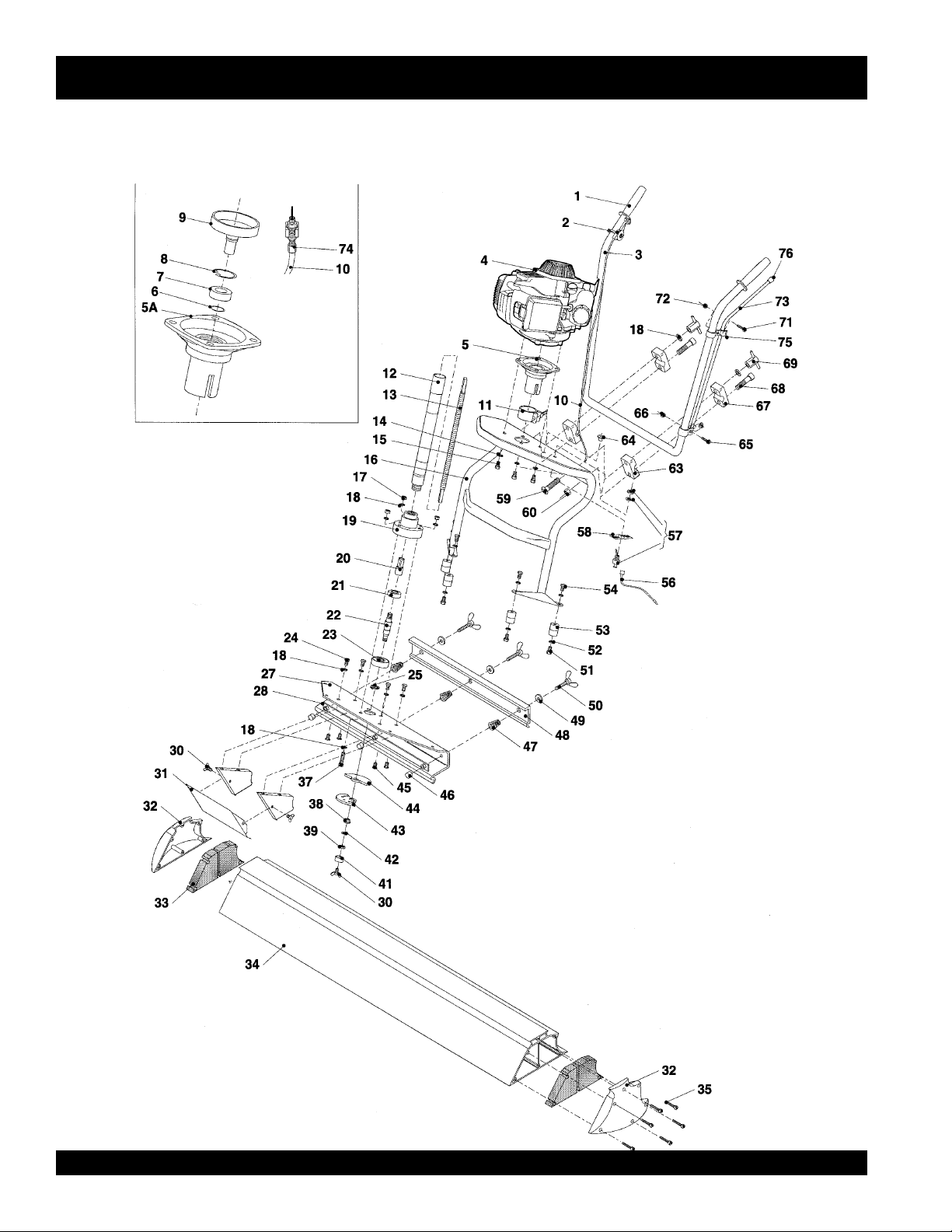

DUO SCREED MAIN ASSY.

DS-SERIES DUOSCREED — MAIN ASSY.

l

PAGE 28 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 29

DS-SERIES DUOSCREED — MAIN ASSY.

DUO SCREED MAIN ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 BF2648 HANDLE GRIP 2

2 BF2647 THROTTLE HANDLE 1

3 BF2633 UPPER OPERATING HANDLE 1

4 BF2640A ENGINE HONDA GX 31SA (USA) 1

5 BF2641 CENTRIFUGAL CLUTCH HOUSING 1

COMPLETE ( EXCLUDING CLAMP 11 )

5A BF2641 CENTRIFUGAL CLUTCH HOUSING 1

WITH ALUMINUM RING

6 BF0201 RETAINING RING 17 X 1 MM 1

IN CENTRIFUGAL HOUSING

7 BF2642C BEARING IN CENTRIFUGAL HOUSING 1

8 BF0205 RETAING RING ( BIG ) 1

9 BF2642 CENTRIFUGAL DRUM 1

10 BF2645 THROTTLE ASM. CABLE 100CMS. 1

11 BF2626 CENTRIFUGAL HOUSING CLAMP 1

12 BF2625 RUBBER HOSE WITH CONNECTORS 1

13 BF2621 FLEXIBLE SHAFT 1

14 BF0178 SPRING WASHER M6 TYPE B 4

15 BF0165 SOCKET HEAD BOLT M6 X 25 4

16 BF2632 LOWER OPERATING HANDLE 1

17 BF0101 SELF LOCKING NUT M8 3

18 BF0155 FLAT WASHER M8 8

19 BF2611 ECCENTRIC HOUSING 1

20 BF1100000008 COUPLING DRIVE PIN 1

21 BF2619 BEARING (SMALL) 1

22 BF2612 ECCENTRIC SHAFT 1

23 BF2314 BEARING (BIG) 1

24 BF0125 TAP BOLT M8 X 16 4

25 BF0201 RETAINING RING 17 X 1MM 1

27 BF2604 ECCENTRIC ASSEMBLY PLATE 1

28 BF2610 STRIP & NUTS FOR ALUMINUM CLAMP 1

30 BF0325 WING NUT M6 X 12 3

31 BF2609 ECCENTRIC COVER 1

32 BF2602 ENDCAPS SET 1

33 BF2602A ALUMINUM BLADE SEALS SET (1 SIDE) 1

34 DUOSCREED BLADE 1.5 MTR. - 5 FT. ...................... 1 ........... ACCESSORY ITEM ORDER

DUOSCREED BLADE 1.9 MTR.- 6 FT. ....................... 1 ........... FROM UNIT SALES DEPT.

DUOSCREED BLADE 2.5 MTR. - 8 FT. ...................... 1 ........... "

DUOSCREED BLADE 3.0 MTR. - 10 FT. .................... 1 ........... "

DUOSCREED BLADE 3.75 MTR. - 12 FT. .................. 1 ........... "

DUOSCREED BLADE 4.25 MTR. - 14 FT. .................. 1 ........... "

DUOSCREED BLADE 5.0 MTR. - 16 FT. .................... 1 ........... "

DUOSCREED BLADE 5.50 MTR. - 18 FT. .................. 1 ........... "

DUOSCREED BLADE 6.0 MTR. - 20 FT. .................... 1 ........... "

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 29

Page 30

DUO SCREED MAIN ASSY.

DS-SERIES DUOSCREED — MAIN ASSY.

l

PAGE 30 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 31

DS-SERIES DUOSCREED — MAIN ASSY.

DUO SCREED MAIN ASSY.

NO. PART NO. PART NAME QTY. REMARKS

35 BF0277 SELF TAPPING SCREW M5 X 20 12

37 BF0129 TAP BOLT M8 X 40 3

38 BF2614 ECCENTRIC HINGE BUSHING 1

39 BF0177 NUT M12 (FINE) 1

41 BF2613 ECCENTRIC CLAMPING BUSH 1

42 BF0175 RETAINING RING M12 1

43 BF2615A ECCENTRIC PLATE (SMALL) 1

44 BF2615B ECCENTRIC PLATE (BIG) 1

45 BF0229 COUNTERSUNK HEADSCREW 8.8 M8X20 4

46 BF2617 PLASTIC PROTECTION CAP M12 3

47 BF2607 COMPRESSION SPRING FOR CLAMPING STRIP 3

48 BF2605 ALUMINUM CLAMPING STRIP 1

49 BF0176 WASHER M12X6 3

50 BF2606 CLAMP FOR CLAMPING STRIP 3

51 BF0285 TAP BOLT M8X12 3

52 BF0212 INTERNAL TOOTHING RING M8 8

53 BF0056 RUBBER BUFFER 30X30 M8 4

54 BF0124 TAP BOLT M8X10 4

56 BF2643A EARTH WIRE FOR STOP SWITCH 1

57 BF2643 STOPSWITCH ...................................................................... 1 ..........INCLUDES ITEMS W/

58

*

59 BF0283 CARRIAGE BOLT M8X50 2

60 BF0089 SELF LOCKING FLANGE NUT M6 2

63 BF2635 LOWER ALUMINUM CLAMP 2

64 BF2649 RUBBER SLEEVE 1

65 BF0258 TAP BOLT M6X20 1

66 BF0100 SELF LOCKING NUIT 1

67 BF2635A UPPER ALUMINUM CLAMP 2

68 BF0284 SOCKET HEAD BOLT M6X40 2

69 BF2636 CLAMP FOR HEIGHT ADJUSTMENT 2

71 BF0261 SCREW M5X12 1

72 BF0099 SELF LOCKING NUT M5 1

73 BF2637 SUPPORTING LEG 1

74 BF2644 GAS THROTTLE ADJUSTMENT BOLT 1

75 BF2639 CLAMP FOR SUPPORTING LEG 1

76 BF2634 RUBBER PROTECTION CAP FOR SUPPORT LEG 1

ON-OFF INDICATION PLATE 1

*

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 31

Page 32

DS-SERIES DUOSCREED — NAME PLATE AND DECALS

NAME PLATE AND DECALS.

l

PAGE 32 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 33

DS-SERIES DUOSCREED — NAME PLATE AND DECALS

NAME PLATE AND DECALS.

NO PART NO PART NAME QTY. REMARKS

1

*

2

*

3 PLATE, SERIAL NO. ......................... 1 ............ CONTACT MQ SERVICE DEPT. W/MODEL & S/N

4

*

SEE DECAL ILLUSTRATIONS ON PAGE 7.

DCL121 DECAL, PRESSURE HOSE 1

DCL122 DECAL, SAFETY 1

DCL140 DECAL, ALIGNMENT ARROWS ..... 2

DCLDS-SERIES KIT, DECAL ....................................... 1 ............ INCLUDES ITEMS W/

*

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 33

Page 34

CRANKCASE ASSY.

HONDA GX31SA ENGINE — CRANKCASE ASSY.

l

PAGE 34 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 35

HONDA GX31SA ENGINE — CRANKCASE ASSY.

CRANKCASE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 11010ZM5000 CRANKCASE SET.................................... 1.....

1 11010ZM5010 CRANKCASE SET.................................... 1..... INCLUDES ITEM W/

2 04102ZM3000 COVER COMP., HEAD ............................. 1..... INCLUDES ITEM W/# USE UP TO SN1040026

2 12310ZM3000 COVER COMP., HEAD ............................. 1..... INCLUDES ITEM W/# USE FROM SN1040027

3 12312ZM3000 GASKET, HEAD COVER .......................... 1..... USE UP TO SN1040026

3 12312ZM3010 GASKET, HEAD COVER .......................... 1..... USE FROM SN 1040027

4 14121ZM5000 COVER, CAMSHAFT 1

5

15511ZM3000 COVER, OIL OUTLET VALVE 1

*

6 15571ZM3003 VALVE, OIL OUTLET 1

7 15572ZM3000 PLATE, STOPPER 1

8 15620ZM3003 CAP, OIL FILTER 1

9 15625ZE1003 GASKET, OIL FILTER CAP 1

10*90003ZM3000 BOLT, FLANGE (5X55) 4

11*90005ZM3000 BOLT, FLANGE (5X18) 6

12 90011ZM3000 SCREW, PAN (6X8) 1

13 90002ZM3000 BOLT, FLANGE (5X14).............................. 1..... USE FROM SN 1040026

13 90101P4V000 BOLT, FLANGE (5X12).............................. 1..... USE UP TO SN 1040027

14 90001ZM3000 BOLT, FLANGE (5X22).............................. 2..... USE FROM SN 1040026

14 90112GK8010 BOLT, FLANGE (5X22).............................. 2..... USE UP TO SN 1040027

15 90481GW3000 WASHER, SEALING (6.5MM) 1

16# 91501ZM3000 COLLAR, HEAD COVER .......................... 2..... USE UP TO SN 1040026

16# 91501ZM3010 COLLAR, HEAD COVER .......................... 2..... USE FROM SN1040027

17# 91502ZM3000 COLLAR, HEAD COVER .......................... 1..... USE UP TO SN1040026

17# 91506ZM3000 COLLAR, HEAD COVER .......................... 1..... USE FROM SN 1040027

18 934010401600 BOLT-WASHER (4X16) 5

19 93500030050A SCREW, PAN (3X5) 1

20 95005700033M BULK HOSE, VACUUM(7X3000) (7X68) 1

21 9805655757 SPARK PLUG (U16FSR-UB) 1

21 9805655777 SPARK PLUG (R5HSB) 1

INCLUDES ITEM W/

*

*

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 35

Page 36

CAMSHAFT ASSY.

HONDA GX31SA ENGINE — CAMSHAFT ASSY.

l

PAGE 36 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 37

HONDA GX31SA ENGINE — CAMSHAFT ASSY.

CAMSHAFT ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 14100ZM3000 CAMSHAFT ASSY. 1

2 14126ZM3000 ROLLER (5X23.8) 2

3 14410ZM3000 ROD, PUSH 2

4 14431ZM3000 ARM, VALVE ROCKER 2

5 14451ZM3000 PIVOT, ROCKER ARM 2

6 14711ZM5000 VALVE, IN. 1

7 14721ZM3000 VALVE, EX. 1

8 14731ZM3003 LIFTER, VALVE 2

9 14751ZM3000 SPRING, VALVE 2

10 14771ZM3000 RETAINER, VALVE SPRING 2

11 41313PL3000 ROLLER (4X28) 1

12 90206ZM3000 NUT, TAPPET ADJUSTING 2

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 37

Page 38

HONDA GX31SA ENGINE — PISTON/CRANKSHAFT ASSY.

PISTON CRANKSHAFT ASSY.

l

PAGE 38 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 39

HONDA GX31SA ENGINE — PISTON/CRANKSHAFT ASSY.

PISTON CRANKSHAFT ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 13010ZM5000 RING SET, PISTON 1

2

3

4 13310ZM5000 CRANKSHAFT COMP. 1 INCLUDES ITEM W/* USE UP TO SN 1040026

4 13310ZM5020 CRANKSHAFT COMP. 1 INCLUDES ITEM W/* USE FROM SN 1040027

5 91213ZM3003 OIL SEAL (12X25X6) 1

6 91213ZM3003 OIL SEAL (12X25X6) 1 USE UP TO SN 1040026

6 91214ZM3003 OIL SEAL (15X25X6) 1 USE FROM SN 1040027

13101ZM5000 PISTON 1

*

13111ZM5000 PIN, PISTON 1

*

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 39

Page 40

CARBURETOR ASSY.

HONDA GX31SA ENGINE — CARBURETOR ASSY.

l

PAGE 40 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 41

HONDA GX31SA ENGINE — CARBURETOR ASSY.

CARBURETOR ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1

2

4

5

6

7

8#

9#

10#*16020ZM3004 SPRING, METERING LEVER 1

11#*16021ZM3004 SCREW, METERING LEVER PIN 1

12#*16022ZM3004 PIN, METERING LEVER 1

13#*16023ZM3004 LEVER, METERING 1

14

15

16

17

18

19

20

21

22

24 16100ZM5804 CARBURETOR ASSY. .................... 1 ....... INCLUDES ITEMS W/

25 16211ZM3000 INSULATOR, CARBURETOR 1

26 16212ZM3000 GASKET, INSULATOR 1

27 16221ZM3000 GASKET, CARBURETOR 1

28 19651ZM3000 GUIDE, AIR IN. 1

29 938940501000 SCREW-WASHER (5X10) 1

30 90010ZM3000 BOLT, HEX. (5X75) 2

31 90112GK8010 BOLT, FLANGE (5X22) 2

32 90659680013 CLIP, WIRE HARNESS 1

33 91301ZM3000 O-RING (14.8X2.4) 1

34

34

34

16010ZM3004 GASKET, METERING 1

*

16011ZM3014 GASKET, PUMP 1

*

16013ZM3004 DIAPHRAGM ASSY., 1

*

16014ZM3004 DIAPHRAGM, PUMP 1

*

16015ZM3004 BODY ASSY., PUMP ...................... 1 ....... NCLUDES ITEMS W/#

*

16017ZM3004 BODY ASSY., AIR PURGE 1

*

16018ZM3004 SCREEN, INLET 1

*

16019ZM3004 VALVE, IN. NEEDLE 1

*

16024ZM3004 RING, SPRING RETAINING 1

*

16025ZM3004 O-RING 1

*

16026ZM3004 COVER, PRIMER PUMP 1

*

16027ZM3004 SWIVEL 1

*

16028ZM3004 SCREW, THROTTLE COLLAR 2

*

16029ZM3004 SCREW, PUMP COVER 4

*

16030ZM3004 SPRING, PUMP 1

*

16031ZM3004 WASHER 1

*

16032ZM3004 PUMP, PRIMER 1

*

99101ZM30380 JET (#38) (OPTIONAL) 1

*

99101ZM30390 JET (#39) (OPTIONAL) 1

*

99101ZM30400 JET (#40) 1

*

DIAPHRAGM

METERING

*

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 41

Page 42

RECOIL STARTER ASSY.

HONDA GX31SA ENGINE — RECOIL STARTER ASSY.

l

PAGE 42 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 43

HONDA GX31SA ENGINE — RECOIL STARTER ASSY.

RECOIL STARTER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 28400ZM3003ZA RECOIL STARTER ASSY. .............. 1 ....... INCLUDES ITEMS W/

2

3

4

5

6 28447ZM3000 FAN, RACHET 1

7 28451ZM3003 PULLEY, RECOIL STARTER 1

8

9

10

11 90005ZM3000 BOLT, FLANGE (5X18) 4

12

13

14

28414ZM3003 CASE, RECOIL STARTER 1

*

28421ZM3003 REEL, RECOIL STARTER 1

*

28433ZM3003 GUIDE, ROPE 1

*

28442ZM3003 SPRING, RECOIL STARTER 1

*

28459ZM3003 SWING ARM 1

*

28461ZM3003 KNOB, RECOIL STARTER 1

*

28462ZM3003 ROPE, RECOIL STARTER 1

*

90012ZM3003 SCREW, SETTING 1

*

91504ZM3003 COLLAR 1

*

91505ZM3003 COLLAR 4

*

*

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 43

Page 44

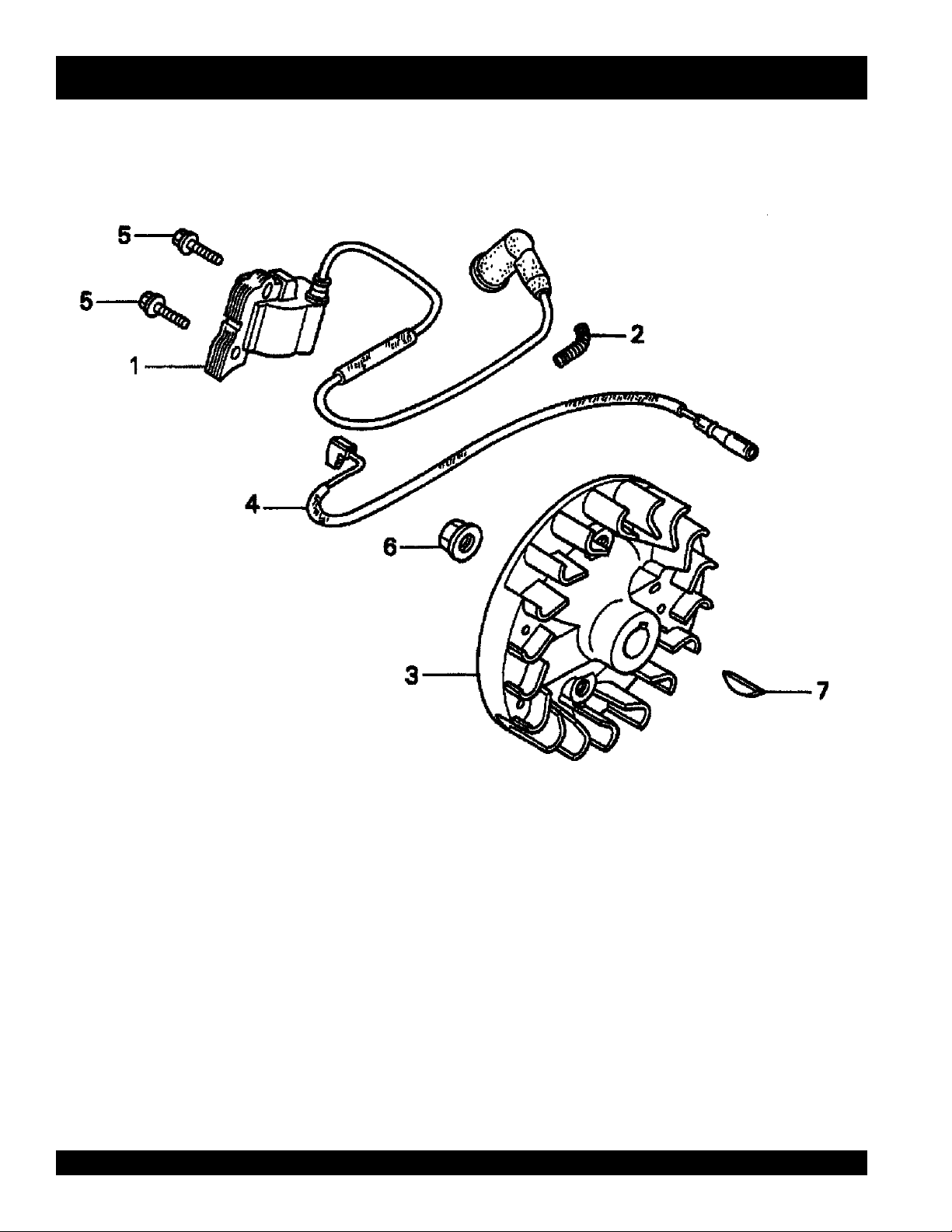

HONDA GX31SA ENGINE — FLYWHEEL/IGNITION COIL ASSY.

FLYWHEEL/IGNITION COIL ASSY.

l

PAGE 44 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 45

HONDA GX31SA ENGINE — FLYWHEEL/IGNITION COIL ASSY.

FLYWHEEL/IGNITION COIL ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 30500ZM3003 COIL ASSY., IGNITION 1

2 30519ZM3000 TUBE A, CORRUGATED (7X18) 1

3 31110ZM5003 FLYWHEEL COMP. ....................... 1.......... USE UP TO SN 1040026

3 31110ZM5013 FLYWHEEL COMP. ....................... 1.......... USE FROM SN 1040027

4 32195ZM3000 WIRE, STOP SWITCH 1

5 934010501600 BOLT-WASHER (5X16) 2

6 9405008000 NUT, FLANGE (8MM) .................... 1.......... USE UP TO SN 1040026

6 9405010000 NUT, FLANGE (10MM) .................. 1.......... USE FROM SN 1040027

7 9440116120 KEY, WOODRUFF (16X12) 1

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 45

Page 46

FUEL TANK ASSY.

HONDA GX31SA ENGINE — FUEL TANK ASSY.

l

PAGE 46 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 47

HONDA GX31SA ENGINE — FUEL TANK ASSY.

FUEL TANK ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 17504ZM3003 GROMMET, FUEL TUBE 1

2 17511ZM5003 TANK, FUEL 1

3 17532ZM3000 RUBBER, TANK MOUNTING .......... 1 ....... USE UP TO SN 1040026

3 17532ZM3010 RUBBER A, TANK MOUNTING ...... 1 ....... USE FROM SN 1040027

3 17533ZM3000 RUBBER B, TANK MOUNTING ...... 1 ....... USE UP TO SN 1040026

4 17561ZM3000 STAY, FUEL TANK........................... 1 ....... USE UP TO SN 1040026

4 17561ZM3010 STAY, FUEL TANK ........................... 1 ....... USE FROM SN 1040027

5 17620ZM3023 CAP ASSY., FUEL TANK ................ 1 ....... USE UP TO SN 1064797

5 17620ZM3033 CAP ASSY., FUEL TANK ................ 1 ....... USE FROM SN 1040027

6 17672ZM3003 FILTER, FUEL 1

7 17701ZM3003 TUBE, FUEL 1

8 17702ZM3003 TUBE, FUEL RETURN 1

9 91401ZM3003 CLIP, TUBE 2

10 17532ZM3000 RUBBER, TANK MOUNTING .......... 2 ....... USE UP TO SN 1040026

10 17533ZM3000 RUBBER B, TANK MOUNTING ...... 2 ....... USE UP TO SN 1040027

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 47

Page 48

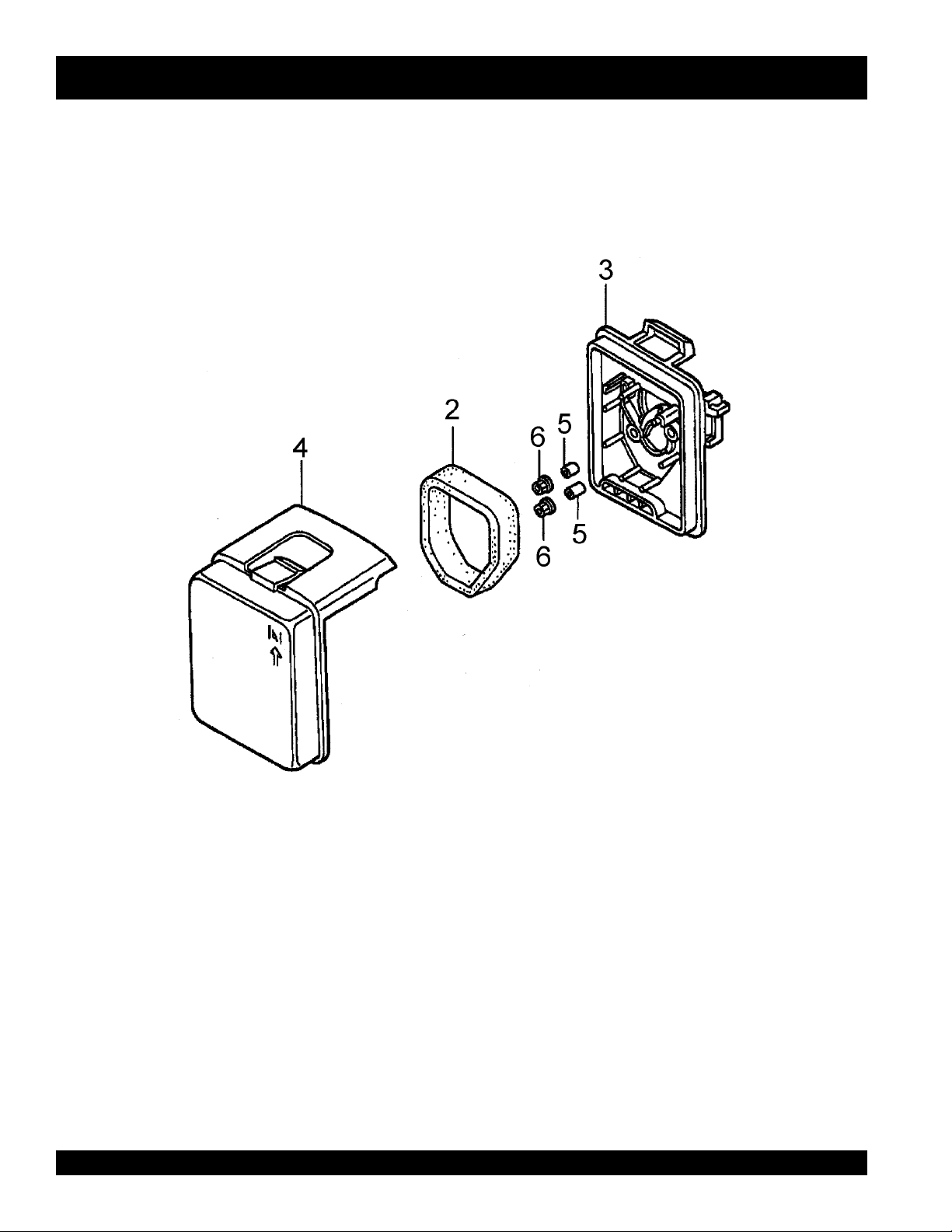

AIR CLEANER ASSY.

HONDA GX31SA ENGINE — AIR CLEANER ASSY.

l

PAGE 48 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 49

HONDA GX31SA ENGINE — AIR CLEANER ASSY.

AIR CLEANER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

2 17211ZM3000 ELEMENT, AIR CLEANER 1

3 17220ZM3000ZA HOUSING COMP., AIR CLEANER .......... 1........... BRIGHT RED

4 17231ZM3000ZA COVER, AIR CLEANER ........................... 1........... BRIGHT RED

5 91503ZM3000 COLLAR, AIR CLEANER 2

6 9405005000 NUT, FLANGE (5MM) 2

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 49

Page 50

MUFFLER ASSY.

HONDA GX31SA ENGINE — MUFFLER ASSY.

l

PAGE 50 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 51

HONDA GX31SA ENGINE — MUFFLER ASSY.

MUFFLER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 18310ZM3800 MUFFLER COMP. 1

2 18355ZM3801 ARRESTER ,SPARK 1

3 18515ZM3000 GUIDE, AIR EX. 1

4 19722ZM3000 INNER COVER, TOP ...................... 1 ....... USE UP TO SN 1007272

4 19722ZM3810 INNER COVER, TOP ...................... 1 ....... USE FROM SN 1007273

5 90004ZM3000 BOLT, FLANGE (5X50) 2

6 90055ZE1000 SCREW, TAPPING (4X6) 1

7 938910500800 SCREW - WASHER (5X8) 1

8 938940501000 SCREW - WASHER (5X10) 1

9 938940501600 SCREW - WASHER (5X16) 1

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 51

Page 52

HONDA GX31SA ENGINE — CLUTCH/FAN COVER ASSY.

l

PAGE 52 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 53

HONDA GX31SA ENGINE — CLUTCH/FAN COVER ASSY.

CLUTCH/FAN COVER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 19611ZM5000 COVER, FAN 1

2 22000ZM5003 CLUTCH ASSY. 1

3 22253ZM5003 BOLT, CLUTCH (8MM) 2

4 22254ZM5003 WASHER, CLUTCH (8X17) 2

5 90005ZM3000 BOLT, FLANGE (5X18) 2

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 53

Page 54

HONDA GX31SA ENGINE — ENGINE COVER ASSY.

l

PAGE 54 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 55

HONDA GX31SA ENGINE — ENGINE COVER ASSY.

ENGINE COVER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 19720ZM3000ZA COVER COMP., TOP *R8* .............. 1 ....... BRIGHT RED

2 90112GK8010 BOLT, FLANGE (5X22) 2

3 91502ZM3000 COLLAR, TOP COVER 2

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 55

Page 56

Effective: July 1, 2000

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Terms of payment for parts are net 10 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a signed

manifest has been obtained from the carrier,

and any claim for shortage or damage must be

settled between the consignee and the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip

is $15.00 net. Customers will be asked for

instructions regarding handling of orders not

meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and credit

will be allowed, subject to the following

provisions:

1. A Returned Material Authorization must

be approved by Multiquip prior to shipment.

2. To obtain a Return Material Authorization,

a list must be provided to Multiquip Parts

Sales that defines item numbers,

quantities, and descriptions of the items to

be returned.

a. The parts numbers and descriptions

must match the current parts price

list.

b. The list must be typed or computer

generated.

c. The list must state the reason(s) for

the return.

d. The list must reference the sales

order(s) or invoice(s) under which

the items were originally purchased.

e. The list must include the name and

phone number of the person

requesting the RMA.

3. A copy of the Return Material

Authorization must accompany the return

shipment.

l

4. Freight is at the sender’s expense. All

5. Parts must be in new and resalable

6. The following items are not returnable:

7. The sender will be notified of any material

8. Such material will be held for 5 working

9. Credit on returned parts will be issued at

10. In cases where an item is accepted for

11. Credit issued will be applied to future

PRICING AND REBATES

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

condition, in the original Multiquip package

(if any), and with Muiltiquip part numbers

clearly marked.

a. Obsolete parts. (If an item is listed

in the parts price book as being

replaced by another item, it is

obsolete.)

b. Any parts with a limited shelf life

(such as gaskets, seals, “O” rings,

and other rubber parts) that were

purchased more than six months

prior to the return date.

c. Any line item with an extended dealer

net price of less than $5.00.

d. Special order items.

e. Electrical components.

f. Paint, chemicals, and lubricants.

g. Decals and paper products.

h. Items purchased in kits.

received that is not acceptable.

days from notification, pending

instructions. If a reply is not received

within 5 days, the material will be returned

to the sender at his expense.

dealer net price at time of the original

purchase, less a 15% restocking charge.

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

purchases only.

Prices are subject to change without prior

notice. Price changes are effective on a specific

date and all orders received on or after that date

will be billed at the revised price. Rebates for

price declines and added charges for price

increases will not be made for stock on hand at

the time of any price change.

Multiquip reserves the right to quote and sell

direct to Government agencies, and to Original

Equipment Manufacturer accounts who use

our products as integral parts of their own

products.

SPECIAL EXPEDITING SERVICE

A $20.00 to $50.00 surcharge will be added to

the invoice for special handling including bus

shipments, insured parcel post or in cases

where Multiquip must personally deliver the

parts to the carrier.

LIMITATIONS OF SELLER’S LIABILITY

Multiquip shall not be liable here under for

damages in excess of the purchase price of the

item with respect to which damages are claimed,

and in no event shall Multiquip be liable for loss

of profit or good will or for any other special,

consequential or incidental damages.

LIMITATION OF WARRANTIES

No warranties, express or implied, are made in

connection with the sale of parts or trade

accessories nor as to any engine not

manufactured by Multiquip. Such warranties

made in connection with the sale of new,

complete units are made exclusively by a

statement of warranty packaged with such

units, and Multiquip neither assumes not

authorizes any person to assume for it any

other obligation or liability whatever in

connection with the sale of its products. A part

from such written statement of warranty, there

are no warranties, express, implied or statutory,

which extend beyond the description of the

products on the face hereof.

PAGE 56 — DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01)

Page 57

NOTE PAGE

DS-SERIES DUOSCREED — PARTS & OPERATION MANUAL — REV. #0 (09/19/01) — PAGE 57

Page 58

PARTS AND OPERATION MANUAL

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-537-4259

E-mail:mq@multiquip.com • www:multiquip.com

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT:

Loading...

Loading...