Page 1

DIS185SSI4F Air Compressor

Hose Reel Kit Installation Instructions

The following instructions are intended to assist the user in the installation of the hose reel kit for use on the

DIS185SSI4F air compressor. Please read all installation instructions before installing the kit.

REQUIRED TOOLS

Power drill with 13/64", 11/32", and 3/4" drill bits

Metric/SAE ratchet set

Metric/SAE socket set

Wire cutters/strippers

1/2" thread sealant tape

Scriber or equivalent tool

PARTS

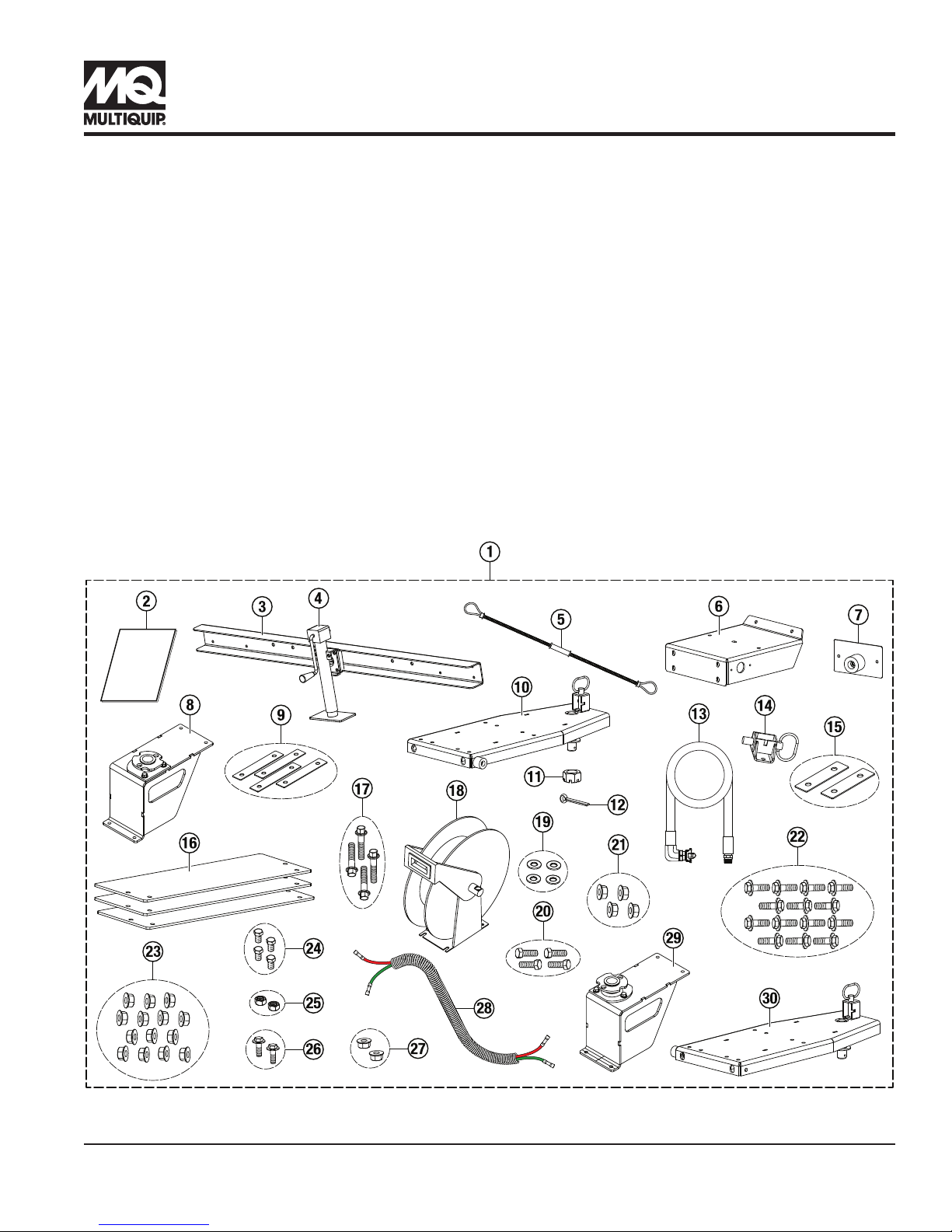

Verify that all parts are accounted for. See Figure 1 and Table 1.

INSTRUCTIONS

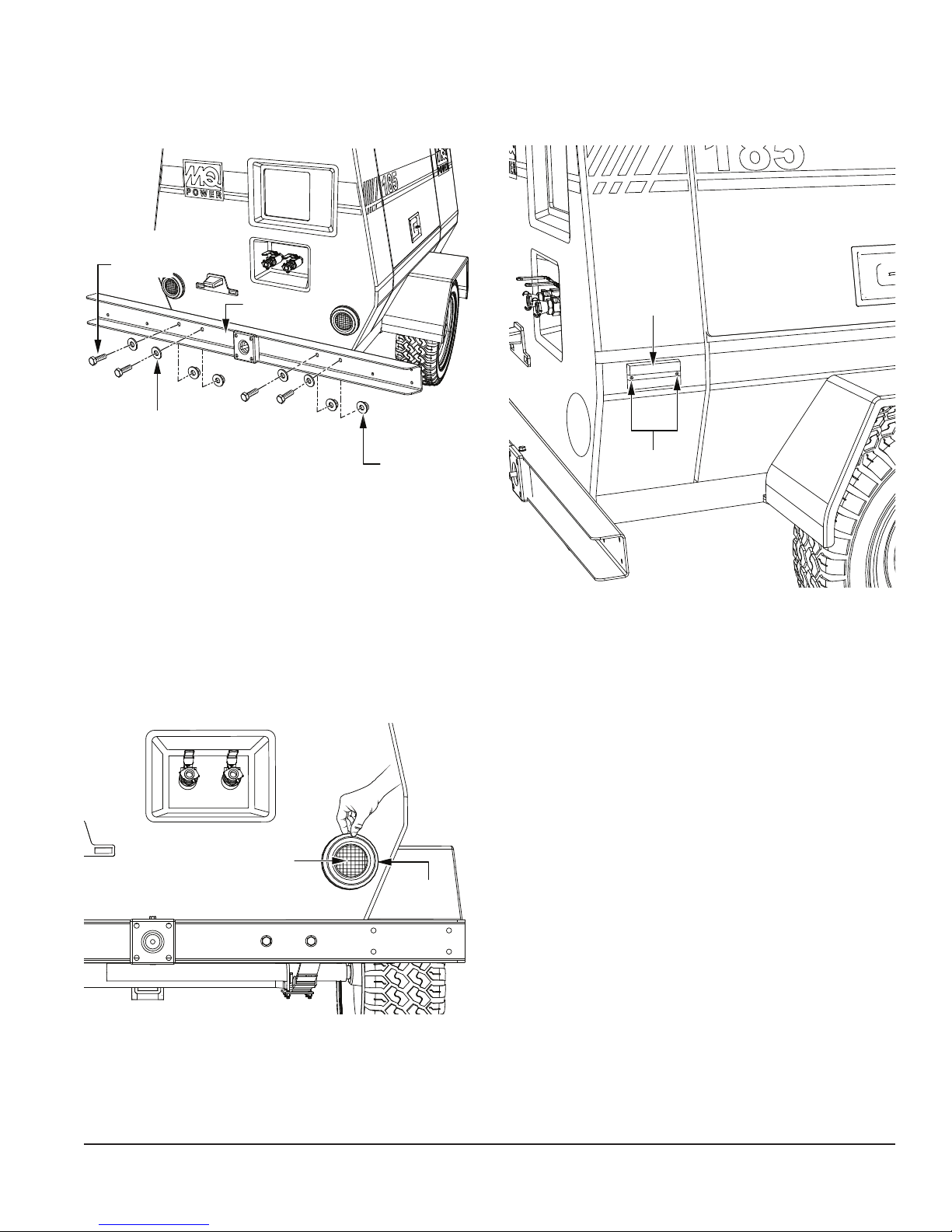

Figure 1. DIS185SSI4F Hose Reel Installation Kit

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 1

Page 2

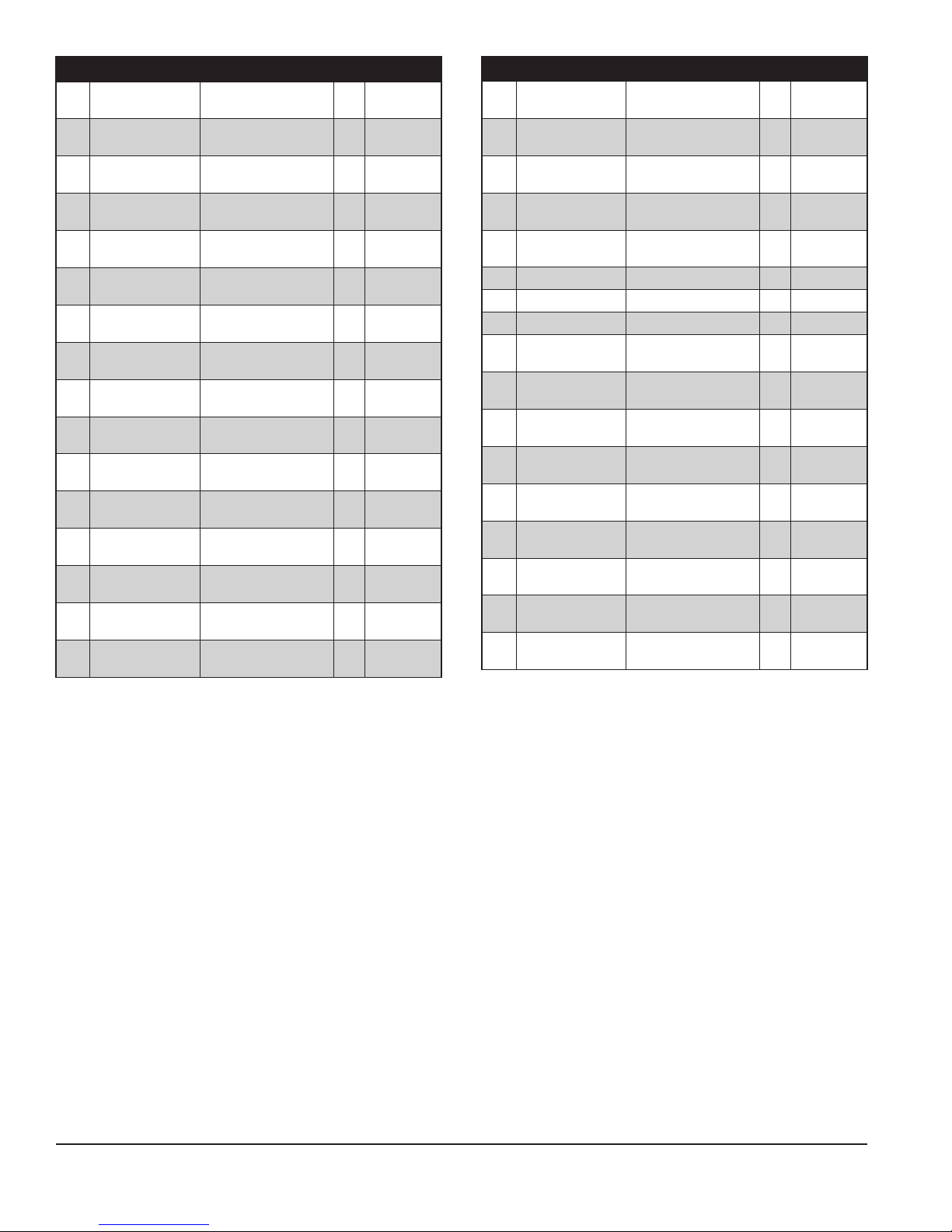

Table 1. DIS185SSI4F Hose Reel Installation Kit

Item

No.

1 MQPSINGLEREEL50

1 MQPDUALREEL50

2 EE60468

3 59269

4 29479

5 59274

6 59234 Plate, Pivot Base Mt 1

7 59267

8 59272

9 59286

10 59275

11 EM968481 Nut, Hex Slotted, 1-14 1

12 38709 Pin, Cotter 3/16 × 2" 1

13 59265 Hose Assembly 1

14 59251 Lock Pin Assembly 1

Part No. Description Qty. Remarks

Reel Kit Assembly, DIS185

50', Right

Reel Kit Assembly, DIS185

Dual 50'

Work Instruction, Reel Kit,

DIS185SSI4F

Bumper Assembly,

Hose Reel Kit

Jack, Sidewind 10"

Bolt-On, .5 Pin, Foot

Safety Cable Hose Whip

1/8 × 20"

Bump Stop Assembly,

Rear

Pivot Base Assembly,

Right

Shim, Pivot Plate Mt,

.075 Thk

Reel Mount Assembly,

Right

1

1

1

1

1

1

1

1

4

1

Includes

items 2–28

Includes

items 2–30

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

Table 1. DIS185SSI4F Hose Reel Installation Kit (Continued)

Item

No.

15 59289 Shim, Lock Latch 2

16 59290

17 42346

18 59263

19 0447 Washer, Flat SAE, 1/2" 4

20 5218 Bolt, HHC, 1/2-13 × 1-1/2" 4

21 26328 Nut, HFS, 1/2"-13 4

22 1023

23 21781 Nut, HFS, 3/8"-16 14

24 28922-083

25 32664 Nut, Hex, M4 2

26 36720

27 49071 Nut, HFS, 5/16"-18 2

28 59291

29 59273 Pivot Base Assembly, Left 1

30 59276 Reel Mount Assembly, Left 1

Part No. Description Qty. Remarks

Double qty.

for dual kit

Plate, Tongue Ballast,

DIS185

Bolt, HHFS,

M8-1.25 × 40 mm

Reel, 3/4" × 50',

Spring Return

Hex Flange Bolt

3/8-16 × 1-1/4"

Screw, HHC,

M4-0.7 × 12 mm

Screw, HHFS,

5/16-18 × 3/4" Gr5

2-Wire Extension

Harness, Split Loom

2

4

1

14

4

2

1

Qty. of 3 in

dual kit

Includes

items 19–20

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

Double qty.

for dual kit

For dual kit

only

For dual kit

only

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 2

Page 3

WORK SAFELY!

PREPARATION

Only a qualified service technician with proper training

should perform this installation. Follow all shop safety rules

when performing this installation.

AIR COMPRESSOR SAFETY

DANGER

NEVER operate the equipment in an

explosive atmosphere or near combustible

materials. An explosion or fire could result,

causing severe bodily harm or even death.

WARNING

NEVER disconnect any emergency or safety devices.

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of

these devices will void all warranties.

CAUTION

NEVER lubricate components or attempt service on a

running machine.

1. Make sure the air compressor is turned OFF and the

engine is cool.

2. Place the air compressor in an area free of dirt and

debris. Make sure it is on secure level ground with

chock blocks underneath each wheel to prevent it

from rolling.

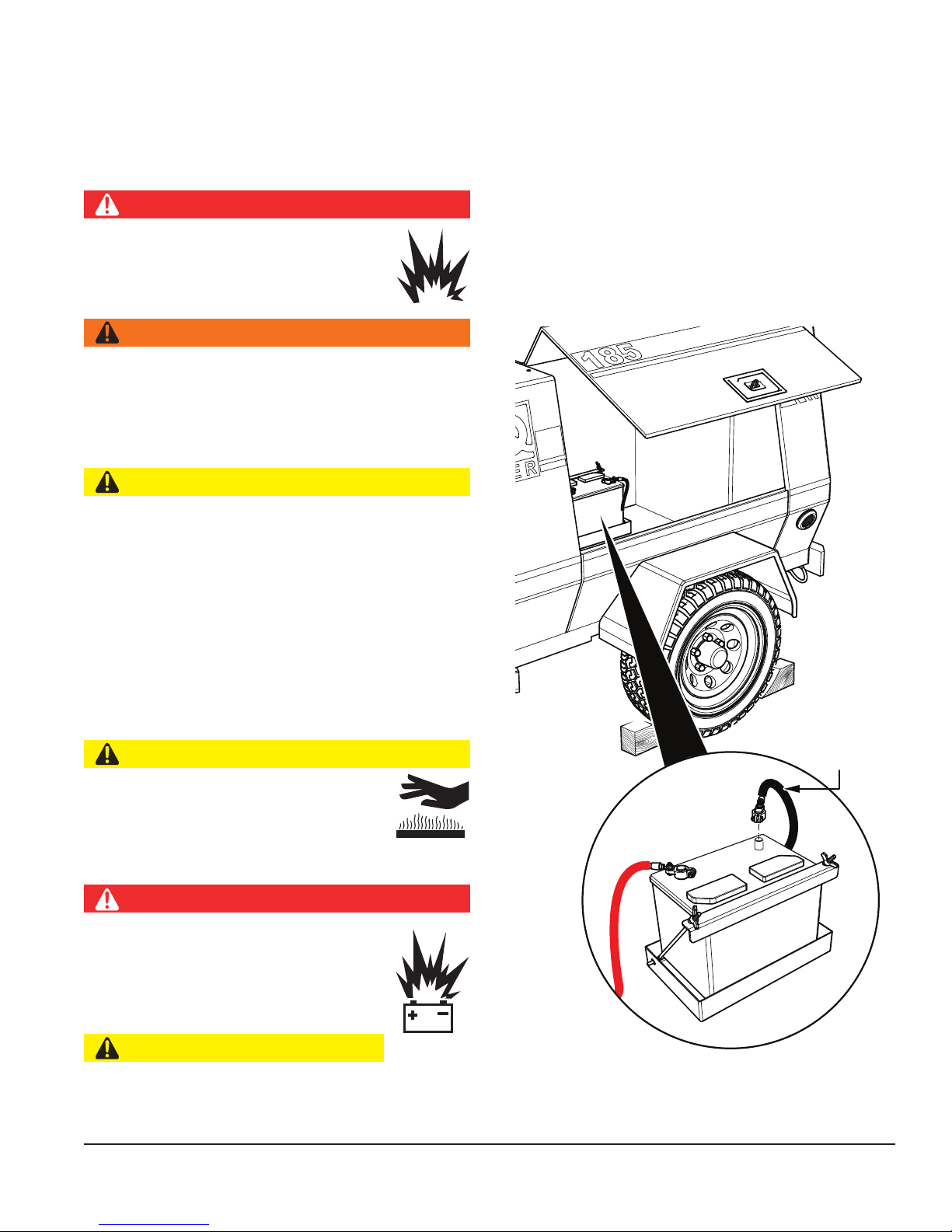

BATTERY DISCONNECTION

1. Open the battery-side cabinet door to access the

battery (Figure 2).

CABINET DOOR

Fuels, fluids, coolants, lubricants, and battery electrolyte

used in the air compressor are typical of the industry.

Care should be taken to avoid accidental ingestions and/

or skin contact.

Make sure the air pressure reads zero before performing

any maintenance.

ENGINE SAFETY

CAUTION

NEVER touch the hot exhaust manifold,

muffler or cylinder. Allow these parts to cool

before servicing the equipment.

BATTERY SAFETY

DANGER

DO NOT expose the battery to open flames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases or liquids come into contact with a

flame or spark, an explosion could occur.

NEGATIVE

(BLACK)

CAUTION

ALWAYS disconnect the NEGATIVE battery terminal

before performing service on the generator.

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 3

Figure 2. Battery Cable Disconnection

2. Disconnect the negative cable (BLACK) from the

negative (−) terminal on the battery. See Figure 2.

Page 4

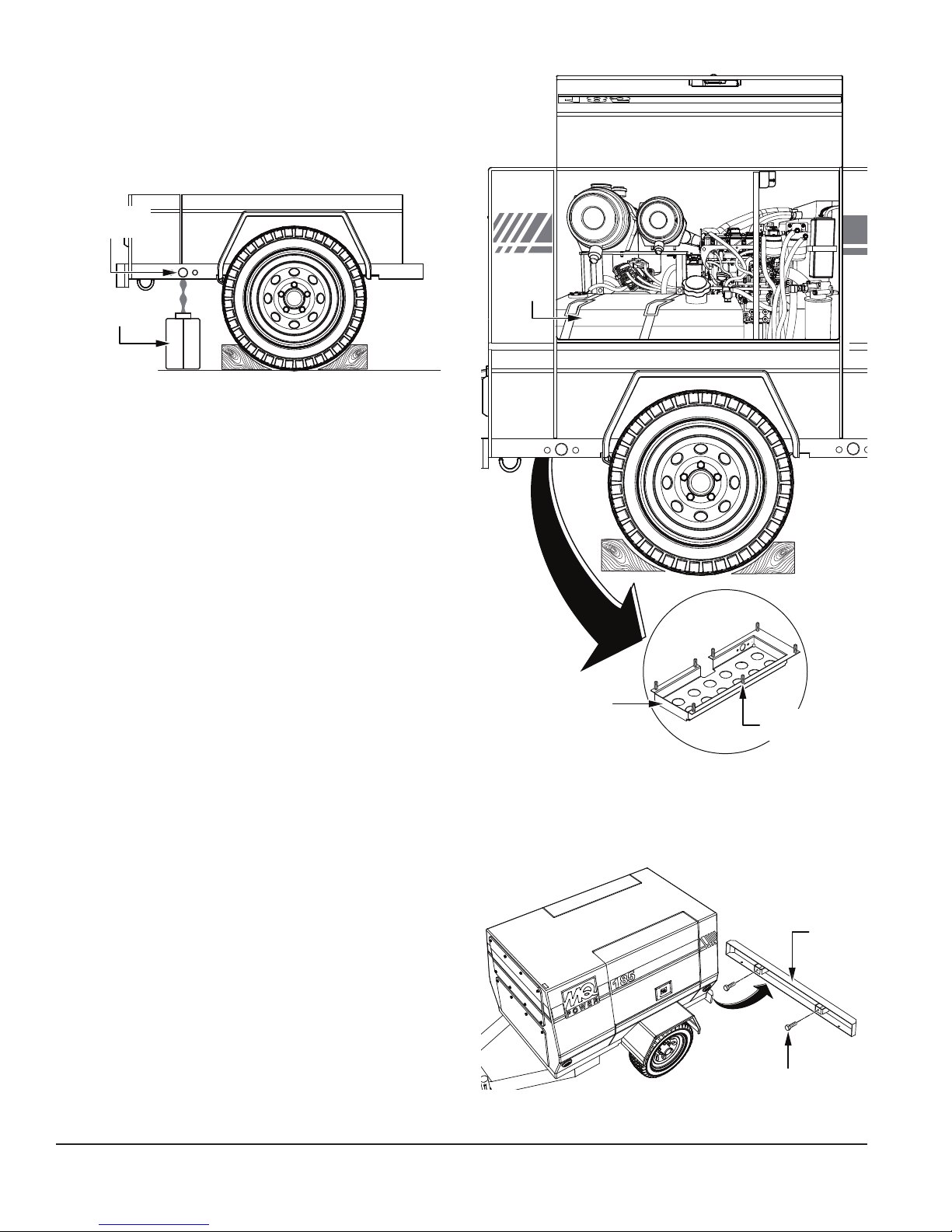

DRAINING THE FUEL TANK

If there is fuel in the fuel tank, it must be drained before

performing this installation.

1. Prepare a container (Figure 3) into which to drain the

fuel.

FUEL TANK

DRAIN BOLT

CONTAINER

Figure 3. Draining the Fuel Tank

2. The fuel drain bolt (Figure 3) is located on the fuel

tank side of the air compressor at the rear of the trailer

frame. Loosen the bolt to allow any fuel inside the tank

to drain into the container. Retighten the fuel drain bolt

when finished.

FUEL

TANK

NEW BUMPER INSTALLATION

1. The fuel tank base cover (Figure 4) must be loosened

to allow access to the bumper hardware. Loosen the

seven hex head bolts securing the fuel tank base

cover to the frame. DO NOT remove the bolts nor the

cover itself.

FUEL TANK

BASE COVER

Figure 4. Fuel Tank Base Cover

LOOSEN

BOLTS

2. Remove and discard the two hex head bolts securing

the existing rear bumper (Figure 5) to the chassis.

Discard the rear bumper.

REAR

BUMPER

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 4

HEX HEAD BOLT

Figure 5. Rear Bumper Removal

Page 5

3. Secure the new bumper (P/N 59269) to the chassis

P/N 26328

with the four 1/2-13 × 1-1/2" hex head bolts (P/N 5218),

flat washers (P/N 0447), and 1/2"-13 flange nuts

(P/N 26328). See Figure 6.

1/2-13 × 1-1/2"

HEX HEAD BOLT

P/N 5218

BUMPER

P/N 59269

FLAT WASHER

P/N 0447

1/2"-13

FLANGE NUT

2. On the fuel tank side of the air compressor, remove

the two bolts securing the rear side marker lens

(Figure 8) to the frame. Set the lens and foam backing

aside and discard the bolts.

SIDE MARKER

LENS

REMOVE

TWO BOLTS

Figure 6. Bumper Installation

WIRING EXTENSION INSTALLATION

To install the wiring for this kit, the tail light on the fuel tank

side of the air compressor must be removed.

1. Remove by hand the rubber seal securing the tail light

(Figure 7) on the fuel tank side of the air compressor.

Disconnect the tail light and set it and the rubber seal

aside.

TAIL LIGHT

RUBBER

SEAL

Figure 8. Side Marker Lens Removal

Figure 7. Tail Light Removal

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 5

Page 6

3. Cut the two wires extending from the side marker light

GREEN WIRE

bulb socket as shown in Figure 9. Set the light bulb

socket assembly aside for later.

5. The wiring extension harness (P/N 59291) contains

a red wire and a green wire. There are butt splice

connectors crimped onto each end of both wires. See

Figure 10.

EXTENSION

HARNESS

P/N 59291

STRIP

INSULATION 1/4"

CUT TWO

WIRES HERE

6"

SIDE MARKER

LIGHT BULB

BUTT SPLICE

CONNECTOR

RED WIRE

Figure 10. Wiring Extension Harness

6. Insert the end of one of the stripped wires into one

of the extension harness butt splice connectors

(Figure 11) and crimp.

STRIPPED

WIRES

BUTT SPLICE

CONNECTORS

EXTENSION

HARNESS

P/N 59291

SOCKET

Figure 9. Side Marker Light Disconnection

4. Strip the insulation back 1/4-inch (6 mm) from the end

of the remaining wires to expose the conductors. See

Figure 9.

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 6

Figure 11. Wire Splicing

7. Insert the end of the other stripped wire into the

remaining butt splice connector on the same end of

the extension harness (P/N 59291) and crimp. See

Figure 11.

8. Push the spliced wiring extension harness (P/N 59291)

inside the cabinet through the side marker hole.

9. If installing the dual hose reel kit (P/N MQPDUALREEL50),

repeat steps #2–8 on the battery side of the air

compressor. DO NOT remove the battery-side

tail light! The battery-side electrical wiring can be

accessed by opening the cabinet door.

Page 7

BUMPER STOP INSTALLATION

PIVOT BASE INSTALLATION

1. On the fuel tank side of the air compressor, secure

the bumper stop (P/N 59267) to the frame where

the rear marker light was removed earlier with

two M4-0.7 × 12 mm screws (P/N 28922-083). See

Figure 12.

1. On the fuel tank side of the air compressor, drill a

3/4-inch hole into the side of the rear frame as shown

in Figure 13.

BUMPER STOP

P/N 59267

M4-0.7 × 12 mm

SCREW

P/N 28922-083

Figure 12. Bumper Stop Installation

2. If installing the dual hose reel kit (P/N MQPDUALREEL50),

repeat step #1 on the battery side of the air compressor.

REAR BUMPER

P/N 59269

1-3/4"

2-1/2"

Figure 13. Drill Wiring Harness Hole

DRILL HOLE

3/4" DIAMETER

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 7

Page 8

1. Secure the pivot base plate (P/N 59234) to the end of

PIVOT BASE

P/N 59234

RIGHT

P/N 21781

the bumper (P/N 59269) with four 3/8-16 × 1-1/4" hex

flange bolts (P/N 1023) and four 3/8"-16 hex flange

nuts (P/N 21781). See Figure 14.

PLATE

BUMPER

P/N 59269

P/N 59234

FENDER

3/8"-16

HEX FLANGE NUT

P/N 21781

3/8-16 × 1-1/4"

HEX FLANGE BOLT

P/N 1023

PIVOT BASE

PLATE

3/8"-16

3/8-16 × 1-1/4"

HEX FLANGE BOLT

P/N 1023

HEX FLANGE NUT

P/N 21781

Figure 14. Pivot Base Plate Installation

2. Using the pivot base plate (P/N 59234) as a guide, drill

two 13/32-inch holes into the fender. See Figure 15.

FENDER

DRILL TWO

13/32" HOLES

PIVOT BASE

PLATE

P/N 59234

Figure 16. Secure Pivot Base Plate to Fender

4. Secure the right pivot base (P/N 59272) to the pivot

base plate (P/N 59234) with two 3/8-16 × 1-1/4" hex

flange bolts (P/N 1023) and two 3/8"-16 hex flange

nuts (P/N 21781). Place pivot plate shims (P/N 59286)

between the pivot base plate and pivot base as needed

to keep the top of the base level with the top of the

fender. See Figure 17.

PIVOT BASE

P/N 59272

3/8-16 × 1-1/4"

HEX FLANGE BOLT

P/N 1023

SHIM

P/N 59286

Figure 15. Drill Pivot Base Plate Holes

3. Insert two 3/8-16 × 1-1/4" hex flange bolts (P/N 1023)

through the new holes in the fender with two 3/8"-16

hex flange nuts (P/N 21781), and tighten securely.

See Figure 16.

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 8

3/8"-16 HEX

FLANGE NUT

PIVOT BASE

PLATE

P/N 59234

Figure 17. Pivot Base Installation

Page 9

5. Using the pivot base (P/N 59272) as a guide, drill two

13/32-inch holes into the top of the fender as shown

in Figure 18.

FENDER

PIVOT BASE

P/N 59272

DRILL TWO

13/32" HOLES

SIDE MARKER INSTALLATION

1. Strip the insulation back 1/4-inch (6 mm) from the

ends of the wires extending from the back of the side

marker light bulb socket to expose the conductors.

See Figure 20.

SIDE MARKER

STRIP

INSULATION 1/4"

SOCKET

LIGHT BULB

Figure 18. Drill Pivot Base Holes

6. Insert two 3/8-16 × 1-1/4" hex flange bolts (P/N 1023)

through the new holes in the fender with two 3/8"-16

hex flange nuts (P/N 21781), and tighten securely.

See Figure 19.

3/8-16 × 1-1/4"

HEX FLANGE BOLT

P/N 1023

FENDER

3/8"-16 HEX

FLANGE NUT

P/N 21781

Figure 20. Strip Side Marker Wires

Figure 19. Secure Pivot Base to Fender

7. If installing the dual hose reel kit (P/N MQPDUALREEL50),

repeat steps #1–6 with the left pivot base (P/N 59273)

on the battery side of the air compressor.

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 9

Page 10

2. From inside the frame, insert the spliced wiring

PIVOT BASE

P/N 28922-083

RIGHT REEL

extension harness (P/N 59291) through the newly

drilled 3/4-inch hole in the frame so that it extends out

of the pivot base plate hole as shown in Figure 21.

SIDE MARKER

LIGHT BULB

PLATE

P/N 59234

FOAM

BACKING

EXTENSION

HARNESS

P/N 59291

PIVOT BASE

PLATE

SIDE MARKER

BUTT SPLICE

CONNECTORS

LIGHT

Figure 21. Side Marker Wiring Connection

3. Insert the stripped end of one of the side marker wires

into one of the extension harness butt splice connectors

(Figure 21) and crimp.

4. Insert the stripped end of the remaining side marker

wire into the remaining extension harness butt splice

connector (Figure 21) and crimp.

5. Place the side marker light bulb socket into the

hole in the pivot base plate (P/N 59234). Secure

the side marker lens and foam backing to the

pivot base plate with two M4-0.7 × 12 mm screws

(P/N 28922-083) and two M4 hex nuts (P/N 32664)

See Figure 22.

M4 HEX NUT

P/N 32664

SIDE MARKER

LENS

M4-0.7 × 12 mm

SCREW

Figure 22. Side Marker Installation

6. Reinstall the tail light and rubber seal on the fuel tank

side of the air compressor.

7. If installing the dual hose reel kit (P/N MQPDUALREEL50),

repeat steps #1–5 on the battery side of the air

compressor.

HOSE REEL INSTALLATION

1. Insert the right reel mount (P/N 59275) into the pivot

base (P/N 59272) as shown in Figure 23.

MOUNT

P/N 59275

PIVOT BASE

P/N 59272

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 10

Figure 23. Reel Mount Installation

Page 11

2. Secure the right reel mount (P/N 59275) to the

pivot base (P/N 59272) with the slotted hex nut

(P/N EM968481) and 3/16 × 2" cotter pin (P/N 38709)

as shown in Figure 24. Bend the cotter pin tines to

lock it in place.

RIGHT REEL

MOUNT

P/N 59275

PIVOT BASE

P/N 59272

MARK AND DRILL

TWO 11/32" HOLES

ALIGN PIN

WITH HOLE

IN REEL

MOUNT

FENDER

9/16"

REEL MOUNT

LOCK LATCH

P/N 59251

RIGHT

REEL MOUNT

P/N 59275

SLOTTED

HEX NUT

P/N EM968481

COTTER PIN

P/N 38709

Figure 24. Secure Reel Mount to Pivot Base

3. Place the reel mount lock latch (P/N 59251) onto the

fender 9/16-inch from the end of the right reel mount

(P/N 59275). Align the pin in the center of the reel

mount lock latch with the hole in the reel mount. See

Figure 25.

Figure 25. Drill Reel Mount Lock Latch Holes

4. Make sure the reel mount (P/N 59275) swings out freely

without hitting the reel mount lock latch (P/N 59251),

then mark the two lock latch hole positions on the right

fender with a scriber or equivalent tool. See Figure 25.

5. Drill two 11/32-inch holes into the top of the fender

(Figure 25).

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 11

Page 12

6. Secure the reel mount lock latch (P/N 59251) to

5/16-18 × 3/4"

the fender with the two 5/16-18 × 3/4" hex flange

bolts (P/N 36720) and two 5/16"-18 hex flange nuts

(P/N 49071). Place lock latch shims (P/N 59289)

between the reel mount lock latch and fender as

needed to keep the lock latch pin lined up with the hole

in the right reel mount (P/N 59275). See Figure 26.

8. If installing the dual hose reel kit (P/N MQPDUALREEL50),

repeat steps #1–7 with the left reel mount (P/N 59276)

on the battery side of the unit.

9. Each hose reel (P/N 59263) includes a 3/4" swivel

fitting. On the fuel tank side of the air compressor,

place 1/2" thread sealant tape onto the male threads

of the hose reel swivel fitting. See Figure 28.

HEX FLANGE BOLT

P/N 36720

FENDER

5/16"-18 HEX

FLANGE NUT

P/N 49071

REEL MOUNT

LOCK LATCH

P/N 59251

LOCK

LATCH SHIM

P/N 59289

Figure 26. Reel Mount Lock Latch Installation

7. Secure the hose reel (P/N 59263) to the right reel

mount (P/N 59275) with four 3/8-16 × 1-1/4" hex flange

bolts (P/N 1023) and four 3/8"-16 hex flange nuts

(P/N 21781). See Figure 27.

FUEL TANK

SIDE

PLACE 1/2" THREAD

SEALANT TAPE

ON MALE THREADS

HOSE REEL

P/N 59263

SWIVEL

FITTING

Figure 28. Swivel Fitting Installation

(Fuel Tank Side)

3/8-16 × 1-1/4"

HEX FLANGE BOLT

P/N 1023

3/8"-16

HEX FLANGE NUT

P/N 21781

Figure 27. Hose Reel Installation

RIGHT REEL

MOUNT

P/N 59275

HOSE REEL

P/N 59263

10. Insert the swivel fitting into the opening on the hose

reel (P/N 59263) on the fuel tank side of the air

compressor, and tighten it securely (Figure 28).

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 12

Page 13

11. If installing the dual hose reel kit (P/N MQPDUALREEL50),

remove the hex plug on the hose reel (P/N 59263) on

the battery side of the air compressor. See Figure 29.

HEX PLUG

13. Place 1/2" thread sealant tape onto the threads of the

battery-side hose reel swivel fitting (Figure 31). Insert

the swivel fitting into the opening on the battery-side

hose reel (P/N 59263) and tighten it securely.

PLACE 1/2" THREAD

SEALANT TAPE

ON MALE THREADS

HOSE REEL

P/N 59263

BATTERY

SIDE

Figure 29. Hex Plug Removal (Battery Side)

12. Place 1/2" thread sealant tape onto the threads of

the hex plug (Figure 30). Insert the hex plug into the

opening on the opposite side of the battery-side hose

reel (P/N 59263), and tighten it securely.

PLACE 1/2" THREAD

SEALANT TAPE

ON THREADS

HOSE REEL

P/N 59263

SWIVEL

FITTING

HOSE REEL

P/N 59263

Figure 31. Swivel Fitting Installation

(Battery Side)

BATTERY

SIDE

Figure 30. Hex Plug Installation

(Battery Side)

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 13

HEX PLUG

BATTERY

SIDE

Page 14

HOSE INSTALLATION

RIGHT AIR

1. Place 1/2" thread sealant tape onto the straight fitting

on the hose (P/N 59265). See Figure 32.

PLACE 1/2" THREAD

SEALANT TAPE

ON STRAIGHT FITTING

HOSE REEL

P/N 59263

4. Loop the other end of the safety cable (P/N 59274)

onto the 90-degree fitting end of the hose (P/N 59265).

See Figure 33.

5. Connect the 90-degree fitting on the hose (P/N 59265)

to the right air output valve at the rear of the air

compressor. See Figure 33.

6. If installing the dual hose reel kit (P/N MQPDUALREEL50),

repeat steps #1–5 on the battery side of the unit.

JACK INSTALLATION

Secure the jack (P/N 29479) to the bumper (P/N 59269)

with the included lock nut and spacer. See Figure 34.

BUMPER

P/N 59269

HOSE

P/N 59265

SWIVEL

FITTING

FUEL TANK

SIDE

Figure 32. Connect Hose to Reel

2. On the fuel tank side of the air compressor, connect

the straight fitting on the hose (P/N 59265) to the

swivel fitting on the hose reel (P/N 59263), and tighten

securely. See Figure 32.

3. Loop one end of the safety cable (P/N 59274) onto the

right air output valve at the rear of the air compressor.

See Figure 33.

OUTPUT VALVE

JACK

P/N 29479

SPACER

LOCK NUT

Figure 34. Jack Installation

SAFETY CABLE

P/N 59274

P/N 59265

Figure 33. Connect Hose to Output Valve

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 14

90º FITTING

HOSE

Page 15

BALLAST INSTALLATION

1. To open the storage compartment at the front of the

air compressor, turn the storage compartment door

thumb screws counterclockwise and open the door

(Figure 35).

M8 × 40 mm

BOLT

P/N 42346

TOOL TRAY

TOOL TRAY

DISCARD

BOLTS

RETAIN

WASHERS

STORAGE

COMPARTMENT

DOOR

THUMB

SCREWS (2)

Figure 35. Tool Tray Removal

2. Remove the four bolts, lock washers, and flat washers

securing the tool tray inside the storage compartment

(Figure 35). Set the tool tray and washers aside, and

discard the bolts.

EXISTING

BALLAST

PLATE

P/N 59290

Figure 36. Ballast Plate Installation

EXISTING

WASHER

LOCK

WASHER

FLAT

4. Place the tool tray on top of the ballast plates

(P/N 59290), and secure the tray and plates to the

inside of the storage compartment with the four

M8 × 40 mm bolts (P/N 42346) and the four lock

washers and flat washers that were removed earlier.

See Figure 36.

POST INSTALLATION

1. Tighten the seven hex head bolts securing the fuel tank

base cover to the frame.

2. Make sure all fasteners are tightened securely.

3. Reconnect the negative cable (BLACK) to the negative

(−) terminal on the battery.

3. If installing the single hose reel kit

4. Refill the fuel tank with diesel fuel.

(P/N MQPSINGLEREEL50), place two ballast plates

(P/N 59290) inside the storage compartment as

shown in Figure 36. If installing the dual hose reel kit

(P/N MQPDUALREEL50), place three ballast plates

inside the storage compartment.

DIS185SSI4F AIR COMPRESSOR — HOSE REEL INSTALLATION INSTRUCTIONS P/N EE60468 — REV. #0 (04/16/18) — PAGE 15

Page 16

HERE’S HOW TO GET HELP

© COPYRIGHT 2017, MULTIQUIP INC.

Multiquip Inc

the MQ logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or altered without written permission. All other trademarks are the property

of their respective owners and used with permission.

The information and specifi cations included in this publication were in effect at the time of approval for printing. Illustrations, descriptions, references and technical data contained in

this document are for guidance only and may not be considered as binding. Multiquip Inc. reserves the right to discontinue or change specifi cations, design or the information published

in this publication at any time without notice and without incurring any obligations.

DIS185SSI4F Air Compressor

Hose Reel Kit Installation Instructions

PLEASE HAVE THE MODEL AND SERIAL

NUMBER ON-HAND WHEN CALLING

UNITED STATES

Multiquip Corporate Offi ce MQ Parts Department

18910 Wilmington Ave.

Carson, CA 90746

Contact : mq@multiquip.com

Service Department Warranty Department

800-421-1244

310-537-3700

Technical Assistance

800-478-1244 Fax: 310-943-2238

CANADA

Multiquip Multiquip (UK) Limited Head Offi ce

4110 Industriel Boul.

Laval, Quebec, Canada H7L 6V3

Contact : infocanada@multiquip.com

Tel. (800) 421-1244

Fax (310) 537-3927

Tel: (450) 625-2244

Tel: (877) 963-4411

Fax: (450) 625-8664

800-427-1244

310-537-3700

800-421-1244

310-537-3700

UNITED KINGDOM

Unit 2, Northpoint Industrial Estate,

Globe Lane,

Dukinfi eld, Cheshire SK16 4UJ

Contact : sales@multiquip.co.uk

Fax: 800-672-7877

Fax: 310-943-2249

Tel: 0161 339 2223

Fax: 0161 339 3226

and

Your Local Dealer is:

Loading...

Loading...