Page 1

PARTS AND OPERATION MANUAL

MQ POWER

DCA-150SSJU

DCA-150SSJU2

TM

WHISPERWATT

GENERATOR

© COPYRIGHT 2001, MULTIQUIP INC.

Parts List No. M3870300254

Revision #3 (09/07/01)

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-835-2551

FAX: 310-537-3927 FAX: 310-638-8046

E-mail:mq@multiquip.com • www:multiquip.com

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT:

Page 2

PAGE 2 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800/427-1244 or 310/537-3700

FAX: 800/672-7877 or 310/637-3284

SERVICE DEPARTMENT

800/835-2551 or 310/537-3700

FAX: 310/638-8046

WARRANTY DEPARTMENT

800/835-2551 or 310/537-3700

FAX: 310/638-8046

MAIN

800/421-1244 or 310/537-3700

FAX: 310 - 537-3927

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 3

Page 4

TABLE OF CONTENTS

Here's How To Get Help ............................................... 3

Table Of Contents ........................................................ 4

Parts Ordering Procedures .......................................... 5

Rules for Safe Operation .......................................... 6-9

Towing Rules for Safe Operation ............................... 10

Trailer Safety Guidelines ............................................ 11

Trailer Specifications ............................................ 12-13

Trailer Braking System ......................................... 14-15

Trailer Tires & Suspension .................................... 16-17

Trailer Wire Diagram ................................................... 18

Trailer Electric Brake Troubleshooting ........................ 19

Trailer Hydraulic Brake Troubleshooting ..................... 20

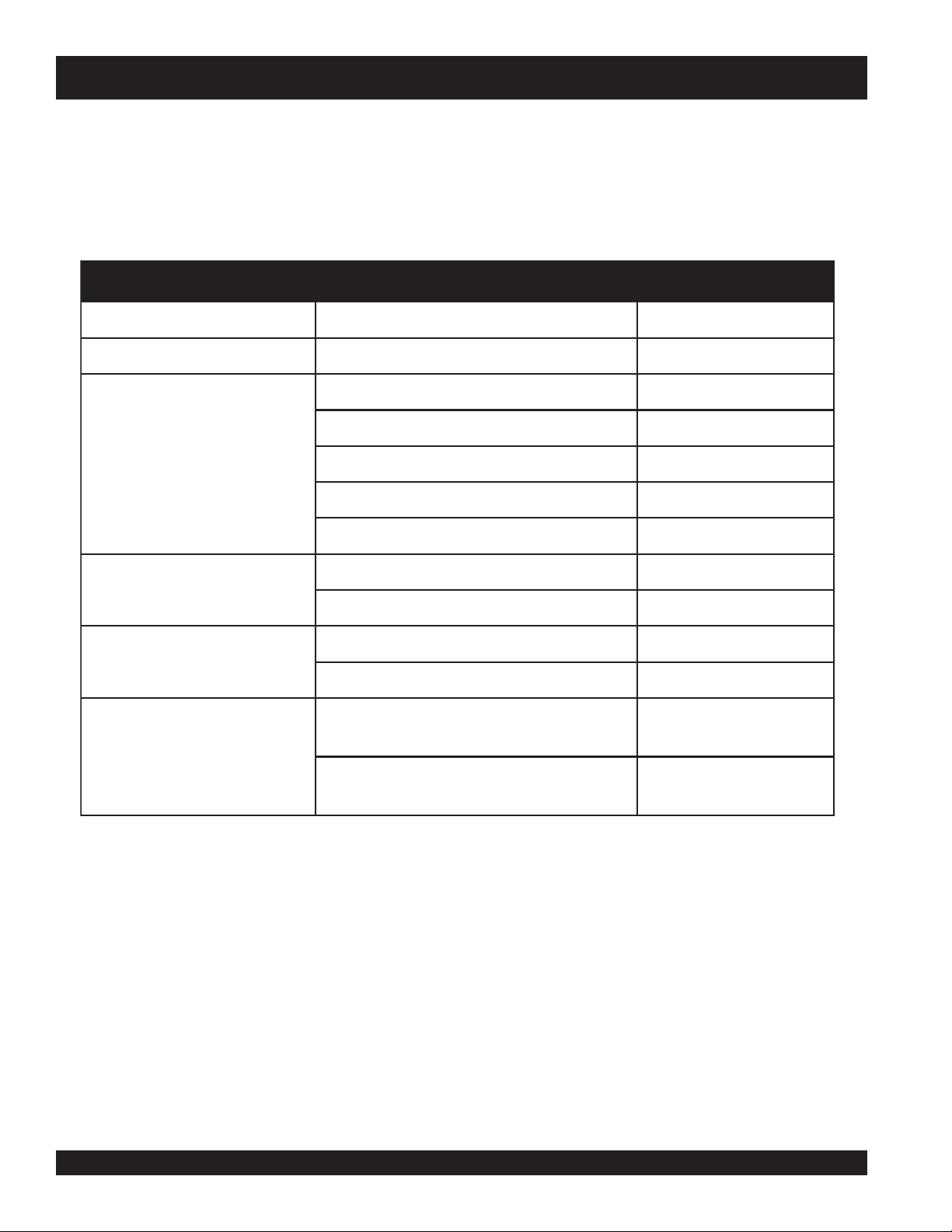

Operation and Safety Decals ................................ 21-22

DCA-150SSJU Specifications ................................... 23

MQPower DCA-150SSJUMQPower DCA-150SSJU

MQPower DCA-150SSJU

MQPower DCA-150SSJUMQPower DCA-150SSJU

AC GeneratorAC Generator

AC Generator

AC GeneratorAC Generator

General Information ................................................... 24

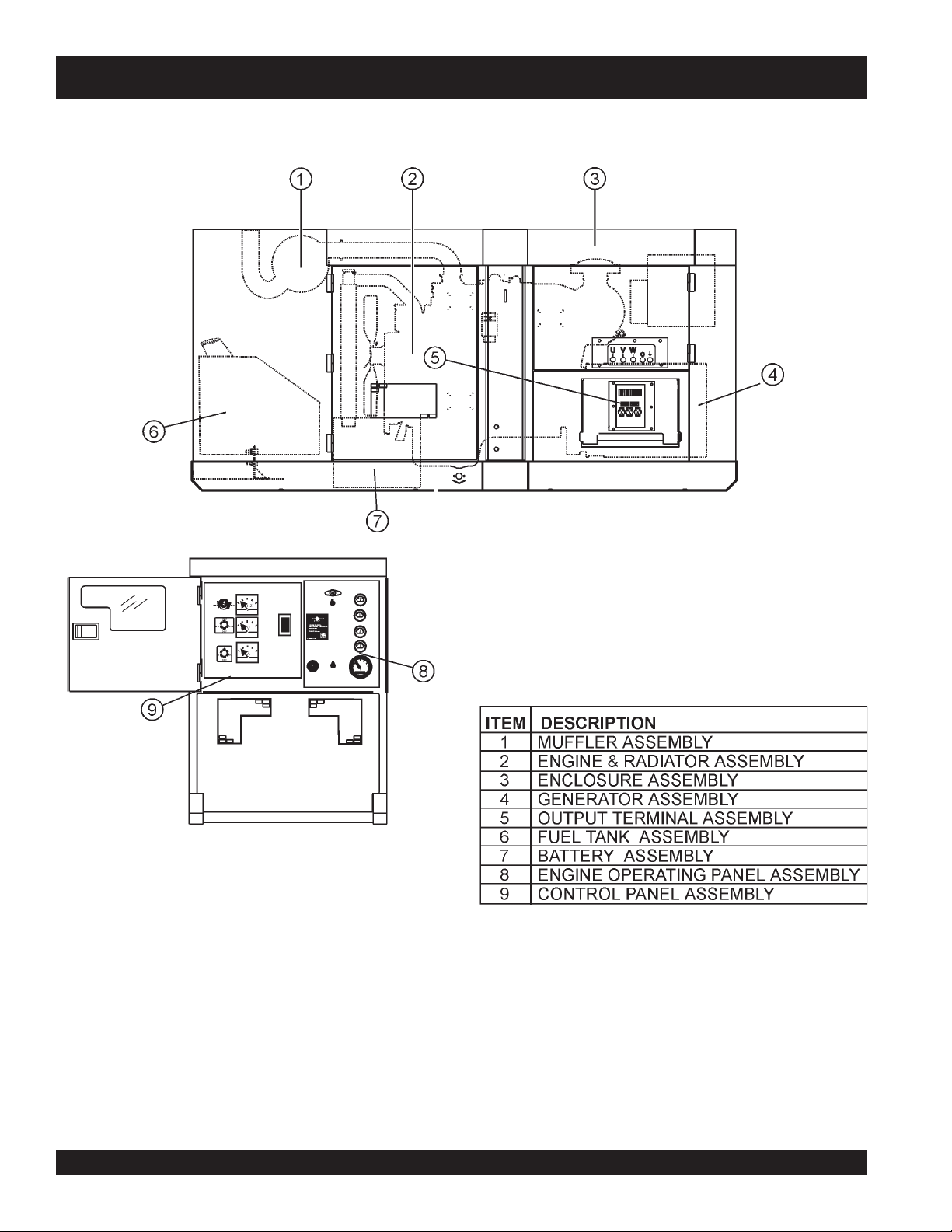

Major Components .................................................... 26

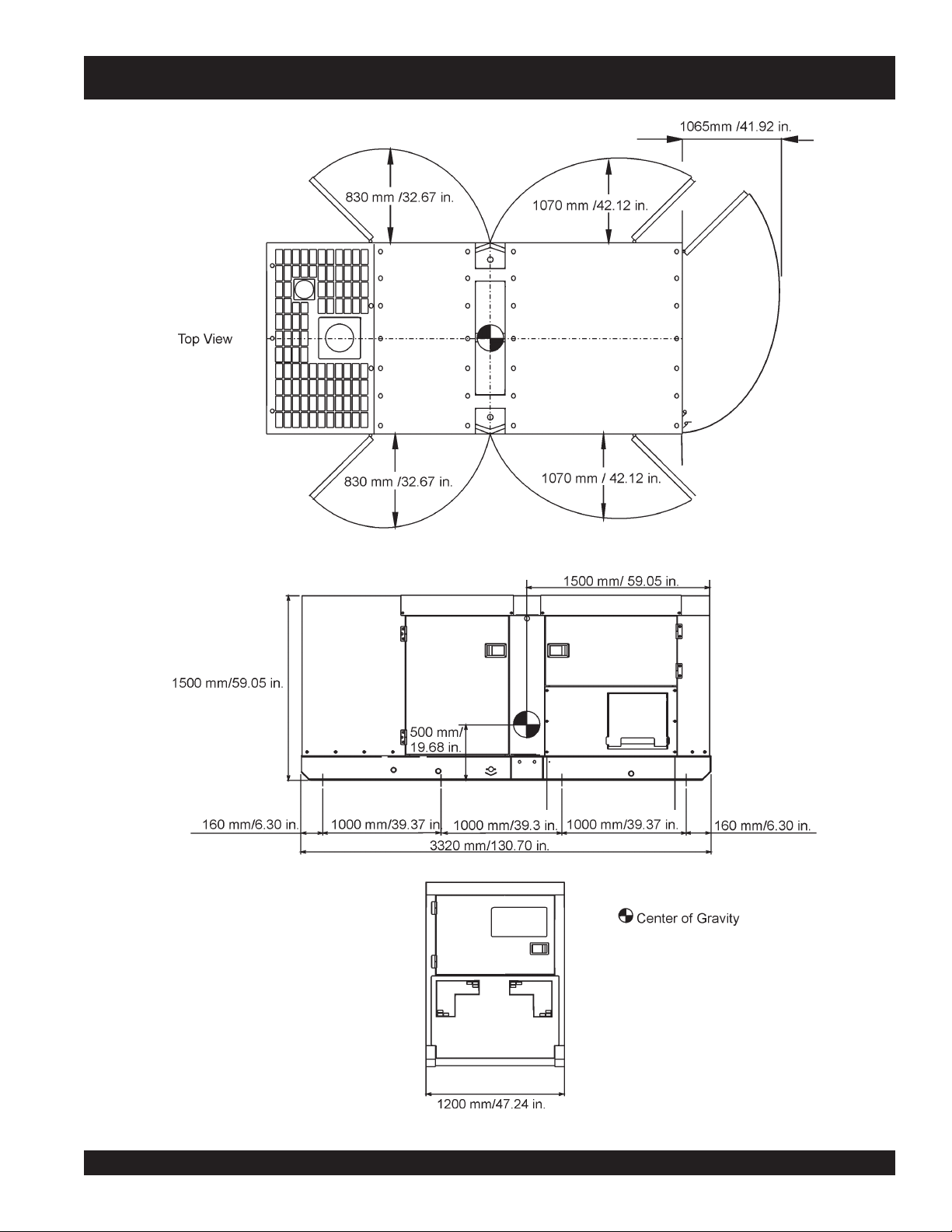

Dimensions ................................................................ 27

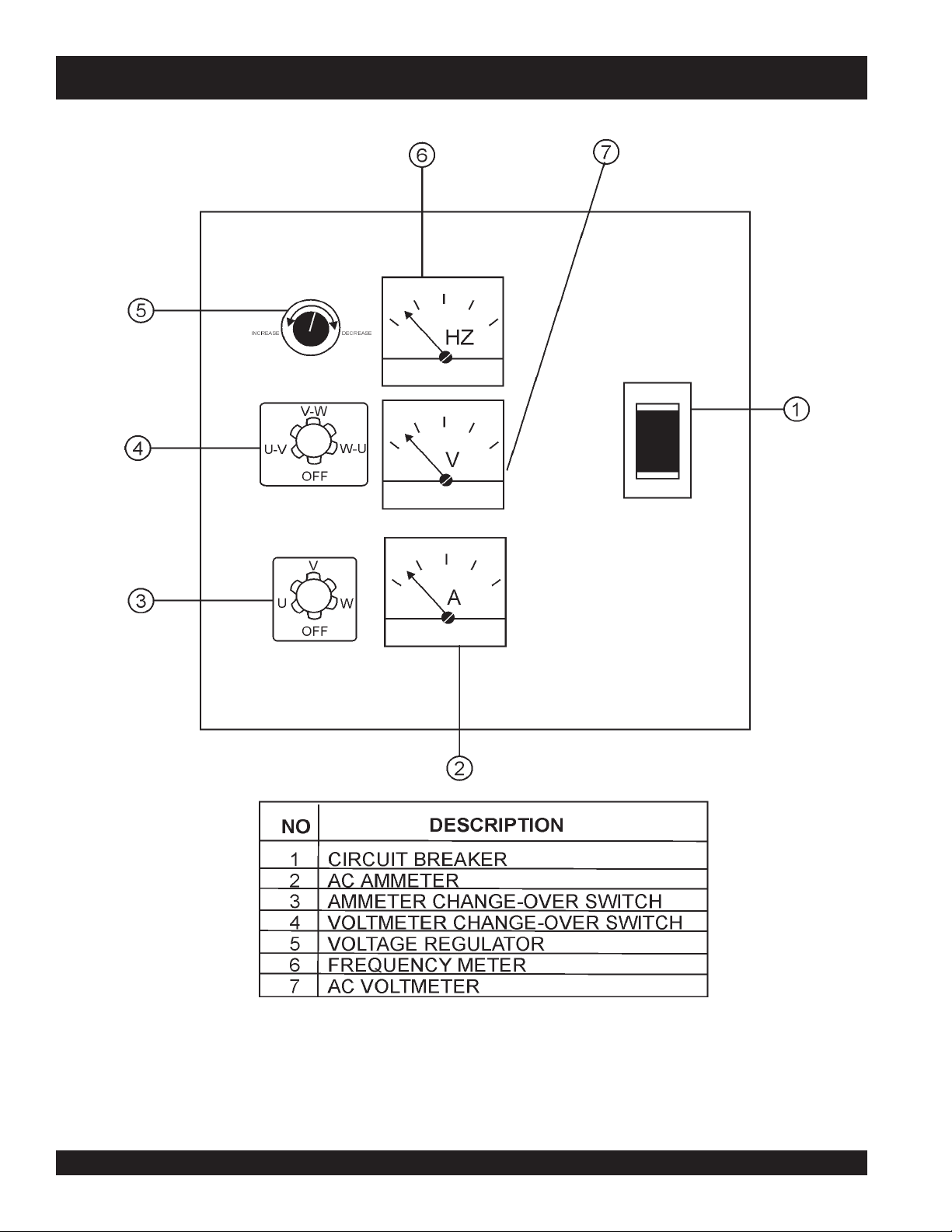

Control Panel Descriptions ................................... 28-29

Engine Operating Panel Description-

Engine Controller .................................................. 30-31

Engine Operating Panel Description-Ignition......... 32-33

Output Terminal Panel Descriptions ...................... 34-41

Installation ............................................................ 42-43

Pre Setup ............................................................. 44-47

Load Application ........................................................ 48

Generator Start-Up W/Key .................................... 49-51

Start-Up-Engine Controller/Manual ....................... 52-53

Start-Up Engine Controller/Auto ................................ 54

Generator Shut-Down Procedure ............................... 55

Maintenance ......................................................... 56-57

Engine Troubleshooting ......................................... 58-59

Engine Controller Troubleshooting .............................. 60

Generator Wiring Diagram .......................................... 61

Engine Wiring Diagrams ....................................... 62-63

Explanation of Code in Remarks Column .................. 64

Suggested Spare Parts ............................................. 65

Generator Assembly ............................................. 66-67

Control Box Assembly ........................................... 68-71

Engine & Radiator Assembly ................................. 72-77

Engine Operating Panel Assembly ........................ 78-81

Output Terminal Assembly ..................................... 82-83

Battery Assembly .................................................. 84-85

Muffler Assembly .................................................. 86-87

Fuel Tank Assembly .............................................. 88-89

Enclosure Assembly ............................................. 90-93

Rubber Seal Assembly .......................................... 94-95

Name Plate And Decals ........................................ 96-97

Terms and Condition of Sale — Parts ....................... 98

NOTE

Specification and part number

are subject to change without

notice.

PAGE 4 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 5

PARTS ORDERING PROCEDURES

■■

■ Dealer account number

■■

■■

■ Dealer name and address

■■

■■

■ Shipping address (if different than billing address)

■■

■■

■ Return fax number

■■

■■

■ Applicable model number

■■

■■

■ Quantity, part number and description of each part

■■

■■

■ Specify preferred method of shipment:

■■

UPS Ground

•

UPS Second Day or Third Day*

•

UPS Next Day*

•

Federal Express Priority One (please provide us with your Federal

•

Express account number)*

Airborne Express*

•

Truck or parcel post

•

*Normally shipped the same day the order is received, if prior to 2PM west coast time.

Earn Extra Discounts when

you order by FAX!

All parts orders which include complete part numbers

and are received by fax qualify for the following extra

discounts:

Number of

line items ordered Additional Discount

1-9 items 3%

10+ items** 5%

Get special freight allowances

when you order 10 or more

line items via FAX!**

■■

■

UPS Ground Service at no charge for freight

■■

■■

■

PS Third Day Service at one-half of actual freight cost

■■

No other allowances on freight shipped by any other carrier.

**Common nuts, bolts and washers (all items under $1.00 list price)

do not count towards the 10+ line items.

Extra Fax DiscountExtra Fax Discount

Extra Fax Discount

Extra Fax DiscountExtra Fax Discount

for Domestic USAfor Domestic USA

for Domestic USA

for Domestic USAfor Domestic USA

Dealers OnlyDealers Only

Dealers Only

Dealers OnlyDealers Only

UPS

Special

For faxed orders only

Now! Direct TOLL-FREE access

to our Parts Department!

Toll-free nationwide:

800-421-1244

Toll-free FAX:

*DISCOUNTS ARE SUBJECT TO CHANGE*

Fax order discount and UPS special programs revised June 1, 1995

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 5

800/6-PARTS-7 • 800-672-7877

Page 6

RULES FOR SAFE OPERATION

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

Failure to follow instructions in this manual

may lead to serious injury or even death!

This equipment is to be operated by

trained and qualified personnel only! This

equipment is for industrial use only.

The following safety guidelines should always be used when

operating the DCA-150SSJU portable generator:

GENERAL SAFETY

■

DO NOT operate or service this equipment before

reading this entire manual.

■

This equipment should not be operated by

persons under 18 years of age.

■

NEVER operate this equipment without proper

protective clothing, shatterproof glasses,

steel-toed boots and other protective devices

required by the job.

■

NEVER touch the hot exhaust

manifold, muffler or cylinder. Allow

these parts to cool before servicing

engine or generator.

■

High Temperatures – Allow the engine to cool before

adding fuel or performing service and maintenance

functions. Contact with

burns.

■

The engine of this generator requires an adequate free

flow of cooling air. Never operate the generator in any

enclosed or narrow area where free flow of the air is

restricted. If the air flow is restricted it will cause serious

damage to the generator or engine and may cause injury

to people. The generator engine gives off DEADLY carbon

monoxide gas.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

hot

components can cause serious

:

■

NEVER operate this equipment when not feeling

well due to fatigue, illness or taking medicine.

■

NEVER operate this equipment under the

influence or drugs or alcohol.

■

NEVER use accessories or attachments,

which are not recommended by MQ Power for this

equipment. Damage to the equipment and/or injury to user

may result.

■

Manufacturer does not assume responsibility for any

accident due to equipment modifications.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

Always check the machine for loosened threads or bolts

before starting.

■

■

Always refuel in a well-ventilated area,

away from sparks and open flames.

■

Always use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it to

cool. DO NOT smoke around or near the

machine. Fire or explosion could result

from fuel vapors, or if fuel is spilled on a

hot engine.

NEVER operate the generator in an explosive atmosphere

or near combustible materials. An explosion or fire could

result causing severe

Topping-off to filler port is dangerous, as it tends to spill

fuel.

bodily harm or even death.

PAGE 6 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 7

RULES FOR SAFE OPERATION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

■

Backfeed to a utility system can cause electrocution

and.or property damage. Do not connect to any

building's electrical system except through an approved

device or after building main switch is opened.

:

NEVER touch output terminals during

operation. This is extremely dangerous.

Always stop the machine when contact with

the output terminals.

:

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Radiator

1. Radiator Cap - Removing the radiator cap while the

2. Coolant Drain Plug - Removing the coolant drain plug

3. Engine Oil Drain Plug - Removing the engine oil drain

:

DO NOT touch or open any of the below

mentioned components while the

generator is running. Always allow

sufficient time for the engine and generator

to cool before performing maintenance.

engine is hot will result in high pressurized, boiling water

to gush out of the radiator, causing severe scalding to

any persons in the general area of the generator.

while the engine is hot will result in hot coolant to gush

out of the coolant drain plug, therefore causing severe

scalding to any persons in the general area of the

generator.

plug while the engine is hot will result in hot oil to gush

out of the oil drain plug, therefore causing severe

scalding to any persons in the general area of the

generator.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

:

Never use damaged or worn cables when

connecting power tools or equipment to the

generator. Make sure power connecting

cables are securely connected to the

generator’s output terminals, insufficient

tightening of the terminal connections may

cause damage to the generator and

electrical shock.

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 7

Page 8

RULES FOR SAFE OPERATION

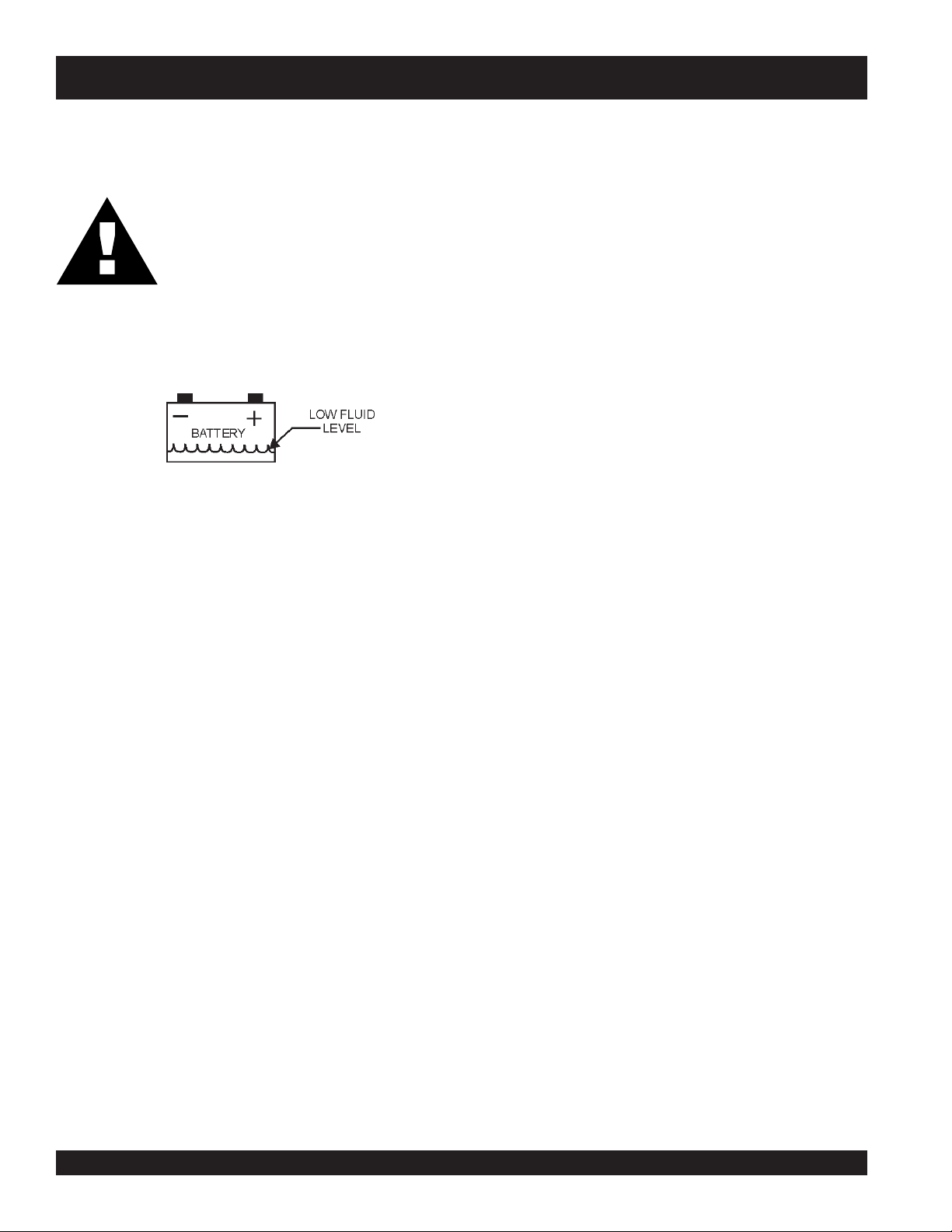

Battery

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

injury to the eyes and skin. To avoid eye irritation, always

wear safety glasses. Use well insulated gloves when picking

up the battery. Use the following guidelines when handling

the battery:

1. DO NOT drop the battery. There is the possibility of risk

that the battery may explode.

2. DO NOT expose the battery to open flames, sparks,

cigarettes etc. The battery contains combustible gases

and liquids. If these gases and liquids come in contact

with a flame or spark, an explosion could occur.

3. Always keep the battery charged. If the battery is not

charged a buildup of combustible gas will occur.

4. Always keep battery charging and booster cables in good

working condition. Repair or replace all worn cables.

5. Always recharge the battery in an open air environment,

to avoid risk of a dangerous concentration of combustible

gases.

6. In case the battery liquid (dilute sulfuric acid) comes in

contact with

immediately with plenty of water.

:

■

Never over fill the battery with water above

the upper limit.

The battery contains acids that can cause

clothing or skin

, rinse skin or clothing

■

NEVER Run engine without air filter. Severe engine

damage may occur.

■

Always service air cleaner frequently to prevent carburetor

malfunction.

■

Always disconnect the battery before performing service

on the generator.

■

Always be sure the operator is familiar with proper safety

precautions and operations techniques before using

generator.

■

Always store equipment properly when not in use.

Equipment should be stored in a clean, dry location out of

the reach of children.

■

DO NOT leave the generator running in the manual mode

unattended.

■

DO NOT allow unauthorized people to operate this

equipment.

■

Always read, understand, and follow procedures in

Operator’s Manual before attempting to operate equipment.

■

Refer to the

engine technical questions or information.

Loading and Unloading (Crane)

■

Before lifting, make sure the generator's lifting hook is

secure and that there is no apparent damage to the

generator itself (loose screws, nuts and bolts). If any

part is loose or damaged, please take corrective action

before lifting.

■

Always drain fuel prior to lifting.

■

Always make sure crane or lifting device has been

properly secured to the hook of guard frame on generator.

■

NEVER lift the machine while the engine is running.

John Deere Engine Owner's Manual

for

■

7. In case the battery liquid (dilute sulfuric acid) comes in

contact with your eyes, rinse eyes immediately with

plenty of water, then contact the nearest doctor or hospital,

and seek medical attention.

PAGE 8 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Use adequate lifting cable (wire or rope) of sufficient

strength.

■

When lifting the generator, always use the balanced

center-point suspension hook and lift straight upwards.

■

NEVER allow any person or animal to stand underneath

the machine while lifting.

■

When loading the generator on a truck, be sure to use

the front and back frame bars as a means to secure the

generator during transport.

Page 9

Transporting

■

Always shutdown engine before transporting.

■

Tighten fuel tank cap securely.

■

Drain fuel when transporting generator over long distances

or bad roads.

■

Always tie-down the generator during transportation by

securing the generator.

■

If generator is mounted on a trailer, make sure trailer

complies with all local and state safety transportation

laws. See page 10 for basic towing procedures.

Emergencies

■

Always know the location of the nearest

and

first aid kit

Also know the phone numbers of the nearest

doctor

and

Maintenance Safety

■

NEVER lubricate components or attempt service on a

running machine.

. Know the location of the nearest telephone.

fire department

.

fire extinguisher

ambulance

,

RULES FOR SAFE OPERATION

■

Always allow the machine a proper amount of time to

cool before servicing.

■

Keep the machinery in proper running condition.

■

Fix damage to the machine immediately and always

replace broken parts.

■

Dispose of hazardous waste properly. Examples of

potentially hazardous waste are used motor oil, coolant,

fuel, and fuel filters.

■

DO NOT use plastic containers to dispose of hazardous

waste.

■

DO NOT pour waste, oil, coolant or fuel directly onto the

ground, down a drain or into any water source

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 9

Page 10

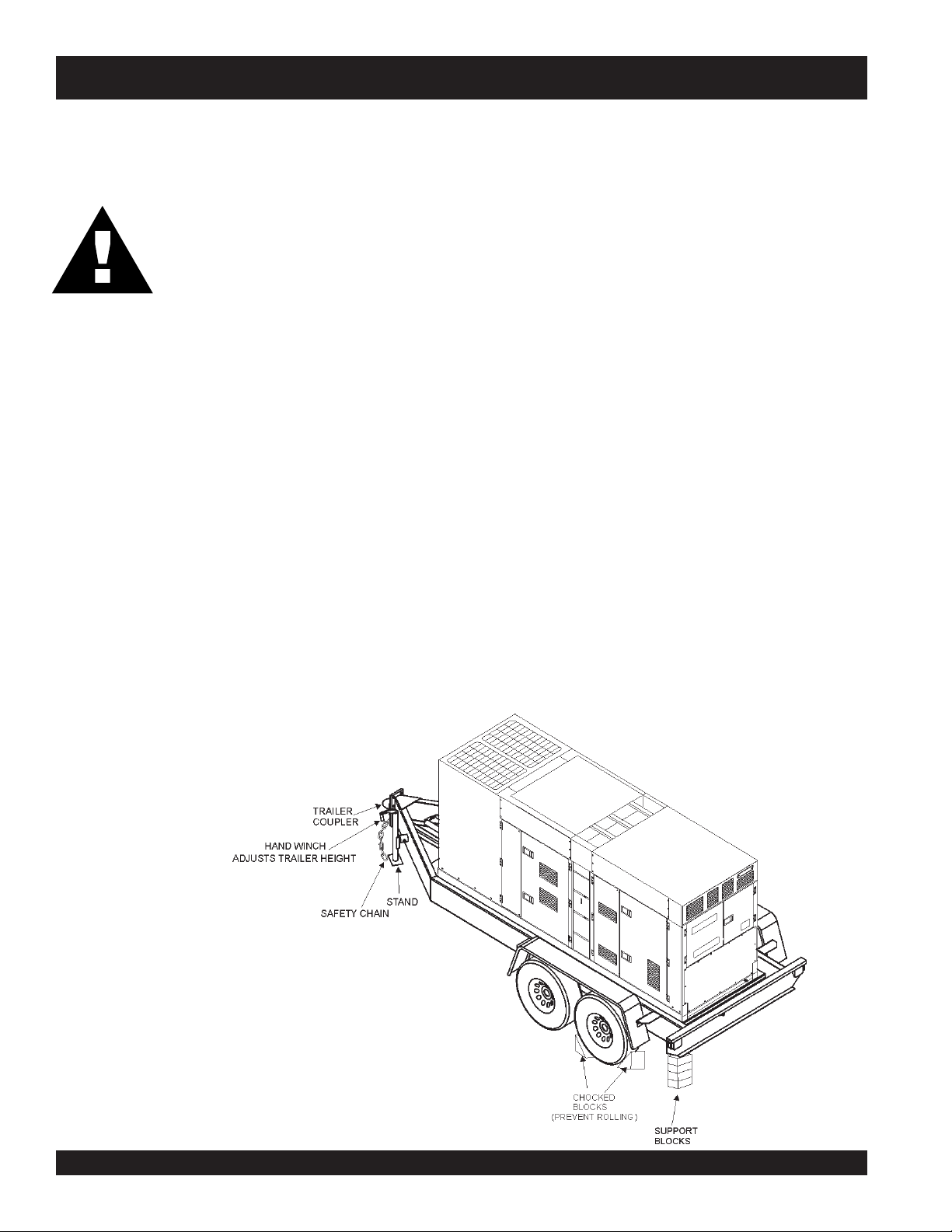

DCA-150SSJU — TOWING RULES FOR SAFE OPERATION

Towing Safety Precautions

CAUTION :CAUTION :

CAUTION :

CAUTION :CAUTION :

Check with your county or state safety

towing regulations department before towing

your generator.

To reduce the possibility of an accident

while transporting the generator on public roads, always

make sure the trailer (Figure 1) that supports the generator

and the towing vehicle are in good operating condition and

both units are mechanically sound.

The following list of suggestions should be used when towing

your generator:

■

Make sure the hitch and coupling of the towing vehicle

are rated equal to, or greater than the trailer "gross vehicle

weight rating" (GVWR).

■

ALWAYS inspect the hitch and coupling for wear. NEVER

tow a trailer with defective hitches, couplings, chains

etc.

■

Check the tire air pressure on both towing vehicle and

trailer. Also check the tire tread wear on both vehicles.

■

ALWAYS make sure the vehicle and trailer directional,

backup, brake, and trailer lights are connected and

working properly.

■

The maximum speed for highway towing is 45 MPH

unless posted otherwise. Recommended off-road towing

is not to exceed 10 MPH or less depending on type of

terrain.

■

Place

rolling, while parked.

■

Place

prevent tipping, while parked.

■

Use the trailer’s hand winch to adjust the height of the

trailer, then insert locking pin to lock wheel stand in place,

while parked.

■

Avoid sudden stops and starts. This can cause skidding,

or jackknifing. Smooth, gradual starts and stops will

improve gas milage.

■

Avoid sharp turns to prevent rolling.

■

Remove wheel stand when transporting.

■

DO NOT transport generator with fuel in tank.

chocked blocks

support blocks

underneath wheel to prevent

underneath the trailer’s bumper to

■

ALWAYS make sure the trailer is equipped with a "Safety

Chain".

■

ALWAYS attach trailer’s safety chain to bumper of towing

vehicle.

Figure 1. Generator with Trailer

PAGE 10 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 11

DCA-150SSJU — TRAILER-SAFETY GUIDELINES

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

ALWAYS make sure the trailer is in good

operating condition. Check the tires for

proper inflation and wear. Also check the

wheel lug nuts for proper tightness.

Explanation of Chart:

This section is intended to provide the user with trailer service and maintenance information. The service and maintenance guidelines referenced in this section apply a wide

range of trailers. Remember periodic inspection of the trailer

will ensure safe towing of the equipment and will prevent

damage to the equipment and personal injury.

It is the purpose of this section to cover the major maintenance components of the trailer. The following trailer components will be discussed in this section:

Brakes

Tires

Lug Nut Torquing

Suspension

Electrical

Brake Troubleshooting Tables

Use the following definitions while reading Table 1.

1. Fuel Cell - Provides an adequate amount of fuel for

the equipment in use. Fuel cells must be empty when

transporting equipment.

2. Braking System - System employed in stopping the

trailer. Typical braking systems are electric, surge, hydraulic, hydraulic-surge and air.

7. Coupler - Type of hitch used on the trailer for towing.

8. Tire Size - Indicates the diameter of the tire in inches

(10,12,14, etc.), and the width in millimeters

(175,185,205, etc.). The tire diameter must match the

diameter of the tire rim.

9. Tire Ply - The tire ply (layers) number is rated in letters;

2-ply,4-ply,6-ply, etc.

10. Wheel Hub - The wheel hub is connected to the trailer’s

axle.

11. Tire Rim - Tires are mounted on a tire rim. The tire rim

must match the size of the tire.

12. Lug Nuts - Used to secure the wheel to the wheel hub.

Always use a torque wrench to tighten down the lug

nuts. See Table 4 and Figure 5 for lug nut tightening and

sequence.

13. Axle - Indicates the maximum weight the axle can support in pounds, and the diameter of the axle expressed

in inches (see Table 3 on page 17). Please not that

some trailers have a double axle. This will be shown as

2-6000 lbs., meaning two axles with a total weight capacity of 6000 pounds.

14. Suspension - Protects the trailer chassis from shock

transmitted through the wheels. Types of suspension

used are leaf, Q-flex, and air ride.

15. Electrical - Electrical connectors (looms) are provided

with the trailer so the brake lights and turn signals can

be connected to the towing vehicle. See page 16 for

proper wiring connections.

16. Application - Indicates which units can be employed

on a particular trailer.

3. GVWR- Gross Vehicle Weight Rating (GVWR), is the

maximum number of pounds the trailer can carry, including the fuel cell (empty).

4. Frame Length - This measurement is from the ball

hitch to the rear bumper (reflector).

5. Frame Width - This measurement is from fender to

fender.

6. Jack Stand - Trailer support device with maximum

pound requirement from the tongue of the trailer.

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 11

Page 12

DCA-150SSJU — TRAILER-SPECIFICATIONS

snoitacificepS.1elbaT

LEDOM NOITACILPPA LEUF

LLEC

W01-RLRT ,522WDS

01-RLRT ,21GLT,01ACD

FX01-RLRT ,21-GLT,01ACD

W522-RLRT ,SREDLEW

004WLB-RLRT 004-WLBONCIRTCELESBL0072"451TSAM/W

X05-RLRT 52-ACDONONSBL0072"421"55.BL008

FX05-RLRT 52-ACDLAG14ONSBL0072"421"55.BL008

W07-RLRT 07,06-,54-ACDONEGRUSSBL0007"681"77.BL0002

X07-RLRT 07,06-,54-ACDTPOEGRUSSBL0007"831"66.BL00

FX07-RLRT 07,06-,54-ACDLAG35EGRUSSBL0007"831"66.BL0002

FX001-RLRT 521,001-ACDLAG051EGRUSCILUARDY

521/58-RLRT ,001,58-ACD

FX051-RLRT 08

FX022-RLRT 022-ACDLAG052EGRUSCILUARDYHSBL00041"222"38.BL

FX003-RLRT 003-ACDLAG052EGRUSCILUARDYHSBL00081"832"38.BL0005

FX004-RLRT 004-ACDLAG053CIRTCELESB

FX006-RLRT 008,006-ACDLAG055RIASBL00003"483"69.BL0005

XS008-RLRT 008,006-ACDLAG0

003WLT,052WGS

51-ACD

003-WLT,51ACD

S0007AD

S

521

1,051-ACDLAG002EGRUSCILUARDYHSBL06111"402"48.BL0005

ONONSBL0091"69"05.BL008

ONONSBL0091"69"05.BL00

LAG25ONSBL0091"69"05.BL008

ONONSBL0022"58"24.BL008

HSBL0007"091"67.BL0002

LAG541CILUARDYHSBL00001"681"77.BL0002

55RIASBL00003"483"69.BL0005

EKARB

METSYS

RWVG EMARF

HTGNEL

"421O/W

L00081"832"38.BL0005

EMARF

HTDIW

"55

)LLAT"87(

KCAJ

DNATS

LEEHWTLITLLUF

8

02

LEEHWTLITLLUF

LEEHWTLITLLUF

LEEHWTLITLLUF

008

.BL

LEEHWTLITLLUF

LEEHWTLITLLUF

WTLITLLUF

LEEH

DAPTALF

DAPTALF

DAPTALF

DAPTALF

DAPTALF

DAPTALF

0005

DAPTALF

DAPTALF

DAPTALF

DAPTALF

DAPTALF

PAGE 12 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 13

DCA-150SSJU — TRAILER-SPECIFICATIONS

)t'noC(snoitacificepS.1elbaT

LEDOM RELPUOC SERIT SLEEHW ELXA SBUH NOISNEPSUS LACIRTCELE

W01-RLRT SSALCLLAB"2

01-RLRT SSALCLLAB"2

FX01-RLRT SSALCLLAB"2

W522-RLRT SSALCLLAB"2

WLB-RLRT

004

X05-RLRT SSALCLLAB"2CRL31-87B"05.4X"31.sbl0053

FX05-RLRT SSALCLLAB"2CRL31-87B"05.4X"31.sbl0053

W07-RLRT SSALCLLAB"2

X07-RLRT SSALCLLAB"2

FX07-RLRT SSALCLLAB"2

FX001-RLRT 6/5-2ELBATSUJDA

521/58-RLRT 6/5-2ELBATSUJDA

FX051-RLRT EYE

FX022-RLRT EYE"3

FX003-RLRT EYE"3

FX004-RLRT EYE"3

FX006-RLRT LEEHWHT5H5.7

RA008-RLRT LEEHWHT5H5.71R57/512TS

ELBATSUJDA2

ELBATSUJDA2

ELBATSUJDA2

ELBATSUJDA2

SSALCLLAB"2

SUJDA2

ELBAT

LBATSUJDA"3

E

ELBATSUJDA"3

ELBATSUJDA"3

EYE"3TPO

EYE"3TPO

LLAB"3E61-057

ELBATSUJDA

ELBATSUJDA

ELBATSUJDA

C31-571"05.4X"312X2#0022GUL5FAEL3/WMOOLERIW4

C31-571"5.4X"312X2#0022GUL5FAEL3TALFELOP4

C31-571"5.4X"312X2#0022GUL5FAEL3T

B31-571"5.4X312X2#0022GUL5XELFQTALFELOP4

C31-571"5.4X312X2#0022GUL5FAEL3TALFELOP4

"8/3-2

"8/3-2

C41-502

)4(SAIB

C41-502

4(SAIB

)

C41-502

)4(SAIB

C51-502

)4(SAIB

D51R57/522TS

)4(LAIDAR

)4(SAIB

E61R58/532TS

)4(LAIDAR

E61R58/532TS

)6(LAIDAR

E61R58/532TS

)6(LAIDAR

1R57/512TS

)8(LAIDAR

)8(LAIDAR

"5X"41.sbl0053

"5X"41sbl0053

"5X"41.sbl0053

"5.5X"41sbl0053

"6x"41sbl0006-)2(GUL6FAEL7MOOLERIW4

"7X"61sbl0006-)2(GUL8FAEL7MOOLERIW4

"7X"6

1sbl0007-)2(GUL8XELFQMOOLERIW4

"7X"61sbl0006-)2(GUL8XELFQMOOLERI

"7X"61.sbl0007-)3(GUL8XELFQMOOLERIW4

"7X"61sbl00001-)3(GUL8FAEL7MOOLERIW6

"7X"61sbl00

"3

"3

"3

"3

001-)3(GUL8EDIR-RIAMOOLERIW6

GUL5FAEL4REBBU

GUL5FAEL4REBBURELOP4

GUL5FAEL5REBBURELOP4

GUL5FAEL5REBBURELOP4

GUL5FAEL5REBBURELOP4

GUL5FAEL5MOOLERI

TALFELOP4

ALFELOP4

RELOP4

TALF

TALF

TALF

TALF

TALF

W4

W4

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 13

Page 14

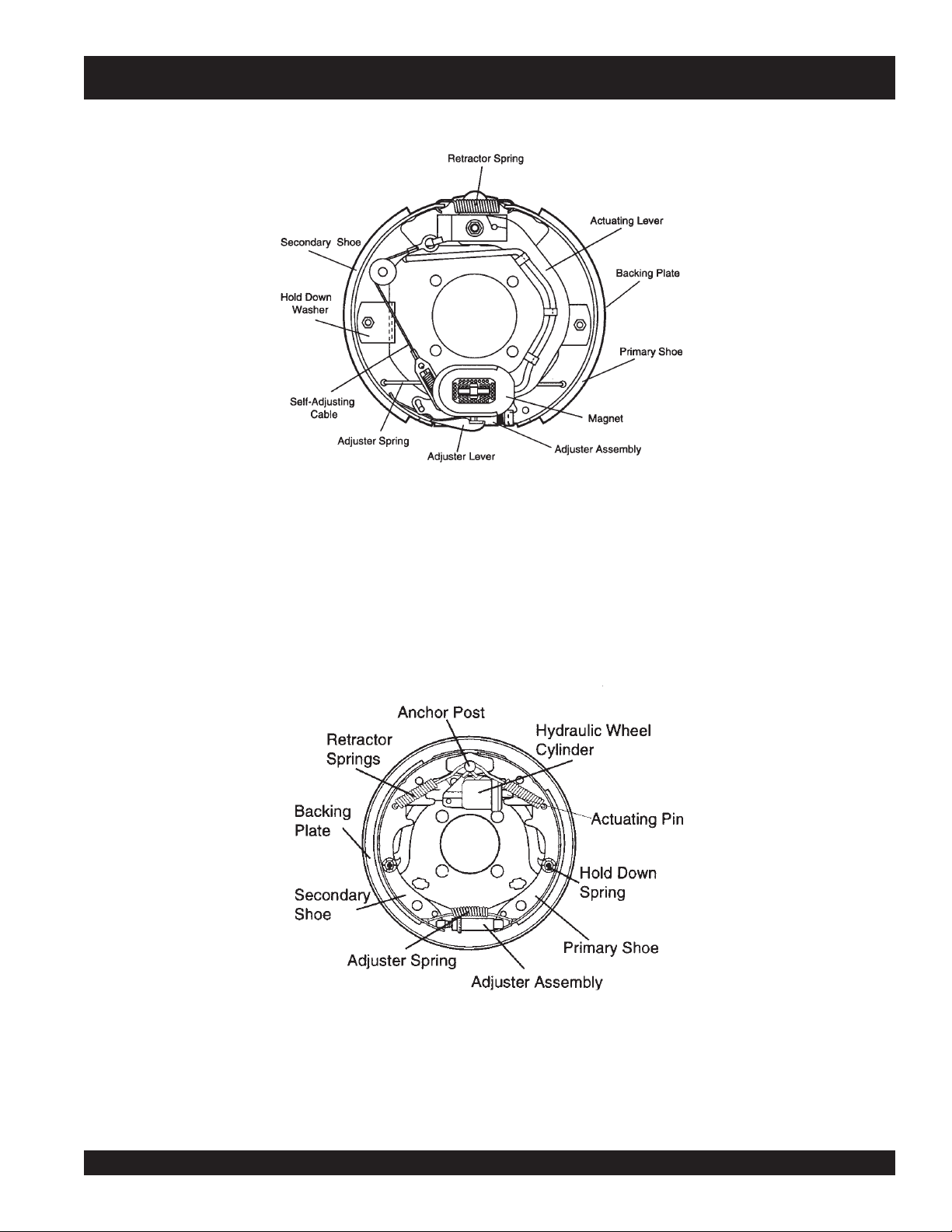

DCA-150SSJU — TRAILER BRAKING SYSTEM

Brakes

If your trailer has a braking system, the brakes should be

inspected the first 200 miles of operation. This will allow

the brake shoes and drums to seat properly. After the first

200 mile interval, inspect the brakes every 3,000 miles. If

driving over rough terrain, inspect the brakes more

frequently.

Electric Brakes

Electrically actuated brakes (Figure 2) are similar to

hydraulic brakes. The basic difference is that hydraulic

brakes are actuated by an electromagnet.

Listed below are some of the advantages that electric

brakes have over hydraulic brakes:

An electric brake system can be manually adjusted to

provide the corrected braking capability for varying road

and load conditions.

An electric brake system can be modulated to provide

more or less braking force, thus easing the brake load

on the towing vehicle.

An electric brake system has very little lag time between

the time the vehicle’s brakes are actuated and the

trailer’s brakes are actuated.

An electric brake system can provide an independent

emergency brake system.

Road testing is necessary in order to properly synchronize

the towing vehicle’s braking to the trailer’s braking. Brake

lockup, grabbiness, or harshness is due to lack of

synchronization between the tow vehicle and the trailer

being towed or under-adjusted brakes.

Before any brake synchronizations adjustments can be

made, the trailer brakes should be burnished-in by applying

the brakes 20-30 times with approximately a 20 m.p.h.

decrease in speed, e.g. 40 m.p.h. to 20 m.p.h.. Allow ample

time for brakes to cool between application. This allows

the brake shoes to slightly be seated into the brake drum

surface.

Figure 2 displays the major electric brake components that

will require inspection and maintenance. Please inspect

these components as required. Refer to Table 5 for electric

brake troubleshooting guidelines.

Electric Brake Adjustment

1. Place the trailer on jack stands. Make sure the jack

stands are placed on secure level ground.

2. Check the wheel and drum for free rotation.

3. Remove the adjusting hole cover from the adjusting

slot at the bottom brake backing plate.

4. With a screwdriver or standard adjusting tool, rotate

the star wheel of the adjuster assembly to expand the

brake shoes.

5. Adjust the brake shoes outward until the pressure of

the lining against the wheel drum makes the wheel

difficult to turn.

6. Rotate the star wheel in the opposite direction until the

wheel rotates freely with slight lining drag.

7. Replace the adjusting hole cover and lower the trailer

to the ground.

8. Repeat steps 1 through 6 on the remaining brakes.

PAGE 14 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 15

DCA-150SSJU — TRAILER BRAKING SYSTEM

Figure 2. Electrical Brake Components

Hydraulic/Air/Surge Brakes

Hydraulic brakes (Figure 3) should not require any special

attention with the exception of routine maintenance such

as shoe and lining replacement. These brakes can be

adjusted in the same manner as electric brakes. Brake

lines should be periodically checked for cracks, kinks, or

blockage.

Figure 3 below displays the major hydraulic/air/surge brake

components that will require inspection and maintenance.

Inspect these components as required using steps 1

through 6 as referenced in the electric brake adjustments

section. Reference Table 6 for hydraulic brake

troubleshooting guidelines.

Figure 3. Hydraulic Brake Components

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 15

Page 16

DCA-150SSJU — TRAILER TIRES & SUSPENSION

Tires/Wheels/Lug Nuts

Tires and wheels are a very important and critical

components of the trailer. When specifying or replacing

the trailer wheels it is important the wheels, tires, and axle

are properly matched.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

DO NOT attempt to repair or modify a

wheel. DO NOT install an inner tube to

correct a leak through the rim. If the

rim is cracked, the air pressure in the

inner tube may cause pieces of the rim

to explode (break off) with great force and cause serious

eye or bodily injury.

Suspension

The leaf suspension springs and associated components

Tire Wear/Inflation

Tire inflation pressure is the most important factor in

preserving tire life. Pressure should be checked cold before

operation. DO NOT bleed air from tires when they are hot.

Check inflation pressure weekly to insure the maximum

tire life and to prevent premature tread wear.

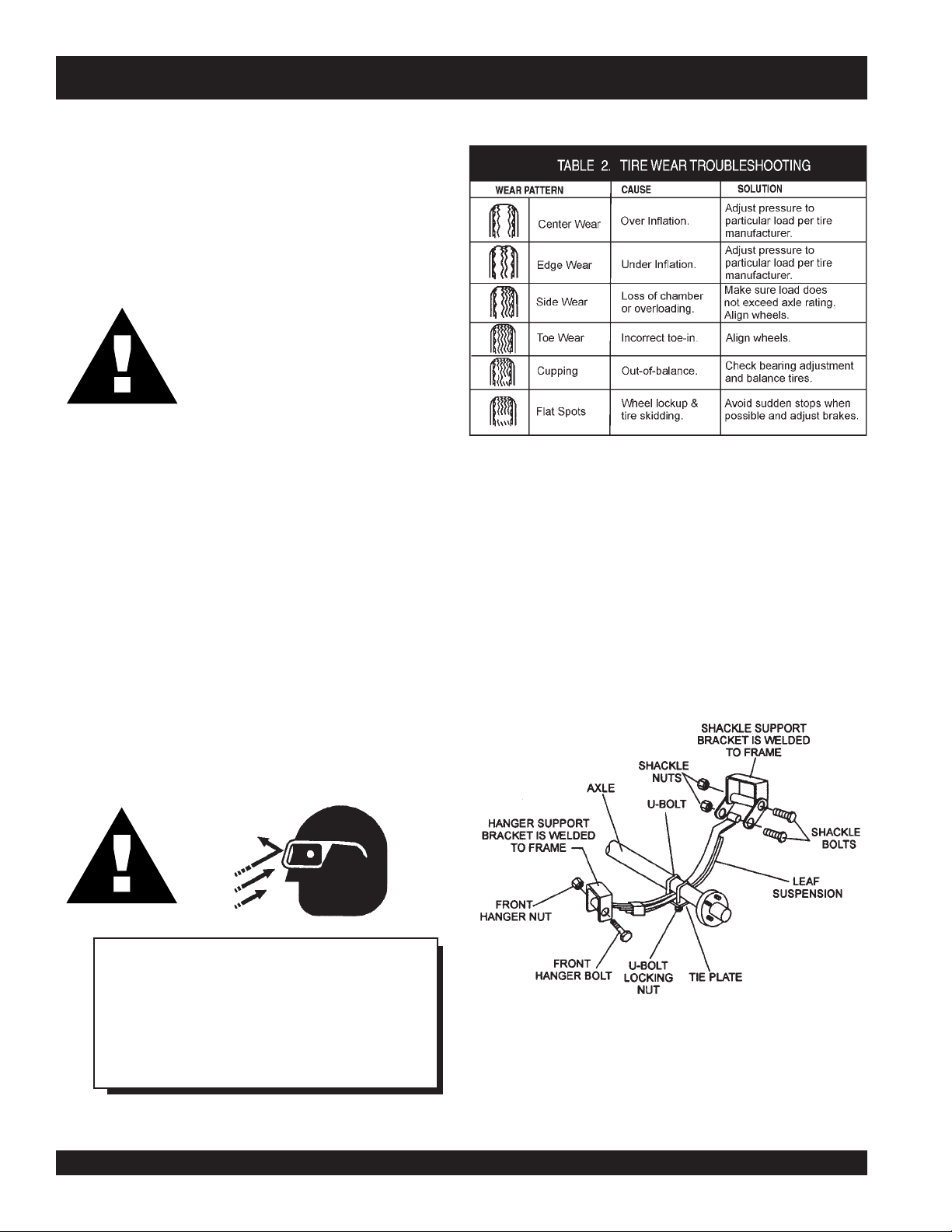

Table 2 (Tire Wear Troubleshooting) will help pinpoint the

causes and solutions of tire wear problems.

(Figure 4) should be visually inspected every 6,000 miles

for signs of excessive wear, elongation of bolt holes, and

loosening of fasteners. Replace all damaged parts

(suspension) immediately. Torqued suspension components

as detailed in Table 3.

CAUTION:CAUTION:

CAUTION:

CAUTION:CAUTION:

NOTE

ALWAYS wear safety glasses when removing

or installing force fitted parts. Failure to

comply may result in serious injury.

PAGE 16 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Figure 4. Suspension Components

Page 17

metI ).sbL-.tF(euqroT

TLOB-U"8/353-XAM03-NIM

TLOB-U"61/706-XAM54-NIM

TLOB-U"2/106-XAM54-NIM

DCA-150SSJU — TRAILER TIRES & SUSPENSION

stnemeriuqeReuqroTnoisnepsuS.3elbaT

SHACKLE BOLT

SPRING EYE BOLT

SHOULDER TYPE

SHACKLE BOLT

SNUG FIT ONLY.PARTS MUST ROTATE FREELY

LOCKING NUTS OR COTTER PINS ARE PROVIDED TO

-

RETAIN NUT

BOLT ASSEMBLY

.

05-XAM03-NIM

.

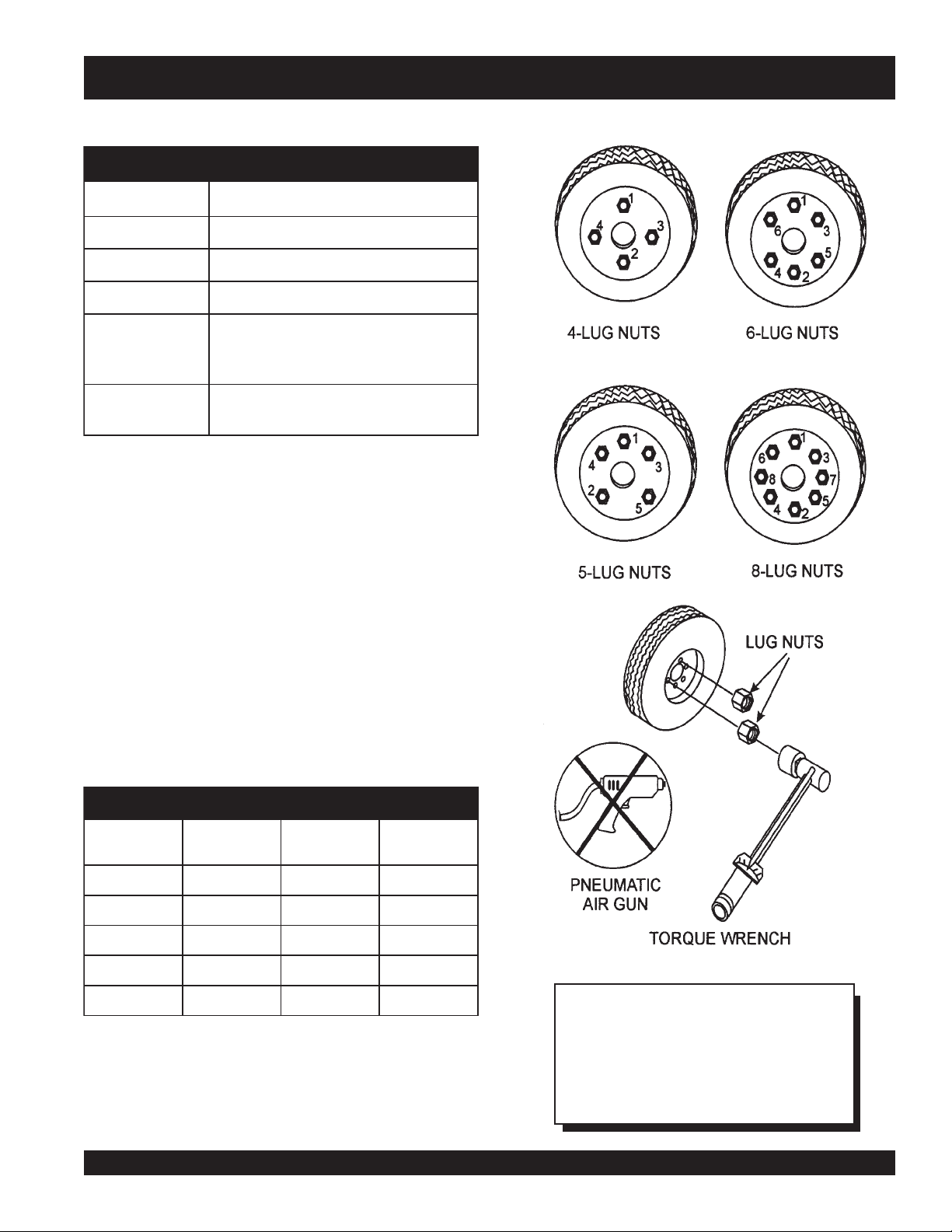

Lug Nut Torque Requirements

It is extremely important to apply and maintain proper wheel

mounting torque on the trailer. Be sure to use only the

fasteners matched to the cone angle of the wheel. Proper

procedure for attachment of the wheels is as follows:

1. Start all wheel lug nuts by hand.

2. Torque all lug nuts in sequence. See Figure 5. DO

NOT torque the wheel lug nuts all the way down. Tighten

each lug nut in 3 separate passes as defined by Table

4.

3. After first road use, retorque all lug nuts in sequence.

Check all wheel lug nuts periodically for continued safe

operation.

stnemeriuqeReuqroTeriT.4elbaT

eziSleehWssaPtsriF

SBL-TF

"2152-0204-5356-05

"3152-0204-5356-05

"4152-0206-05021-09

5152-0206-05021-09

"

"6152-0206-05021-09

ssaPdnoceS

SBL-TF

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 17

ssaPdrihT

SBL-TF

Figure 5. Lug Nut Tightening Sequence

NOTE

NEVER use an pneumatic air gun to

tighten wheel lug nuts.

Page 18

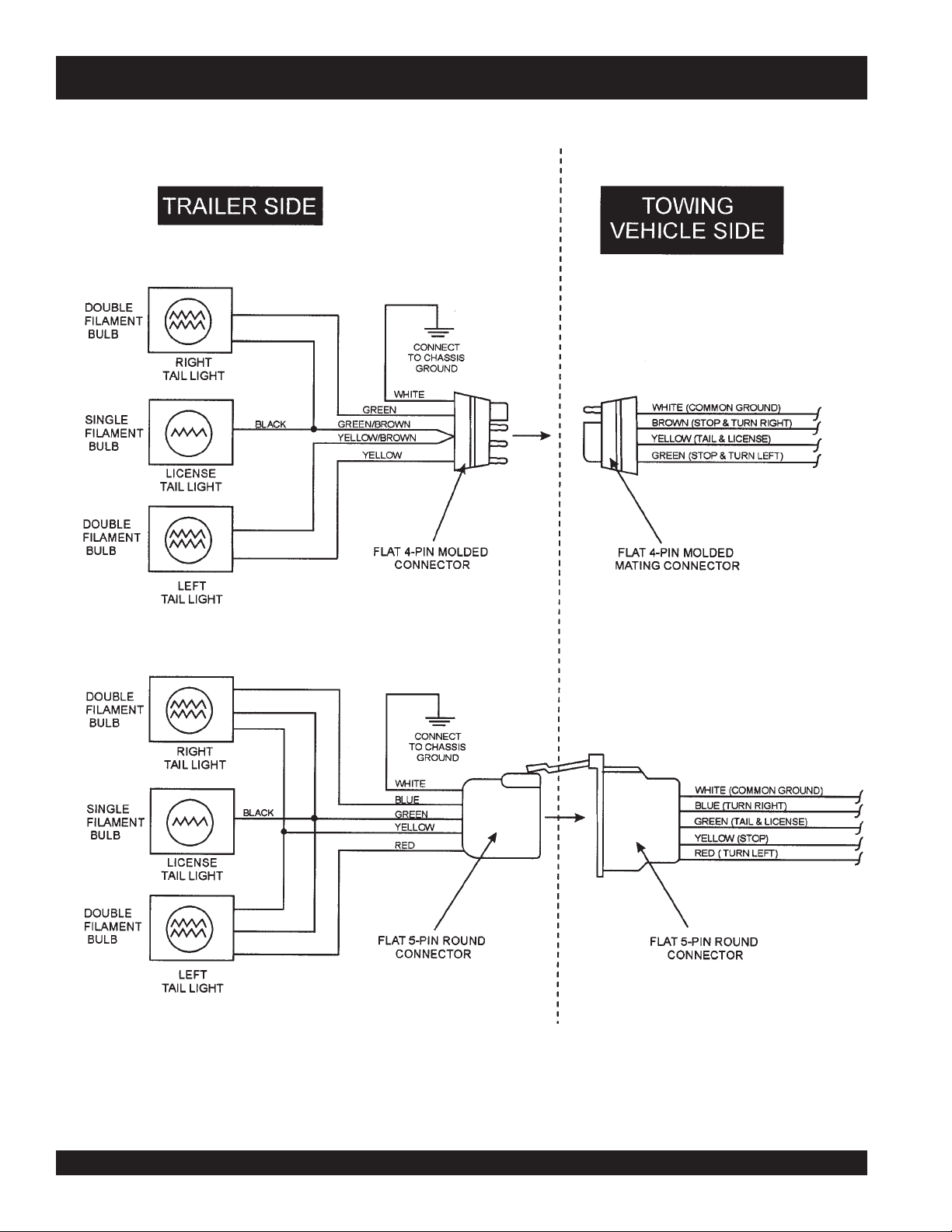

DCA-150SSJU — TRAILER WIRING DIAGRAM

NOTE:

LIGHTS ARE ORIENTED FROM THE DRIVER’S SEAT

PAGE 18 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 19

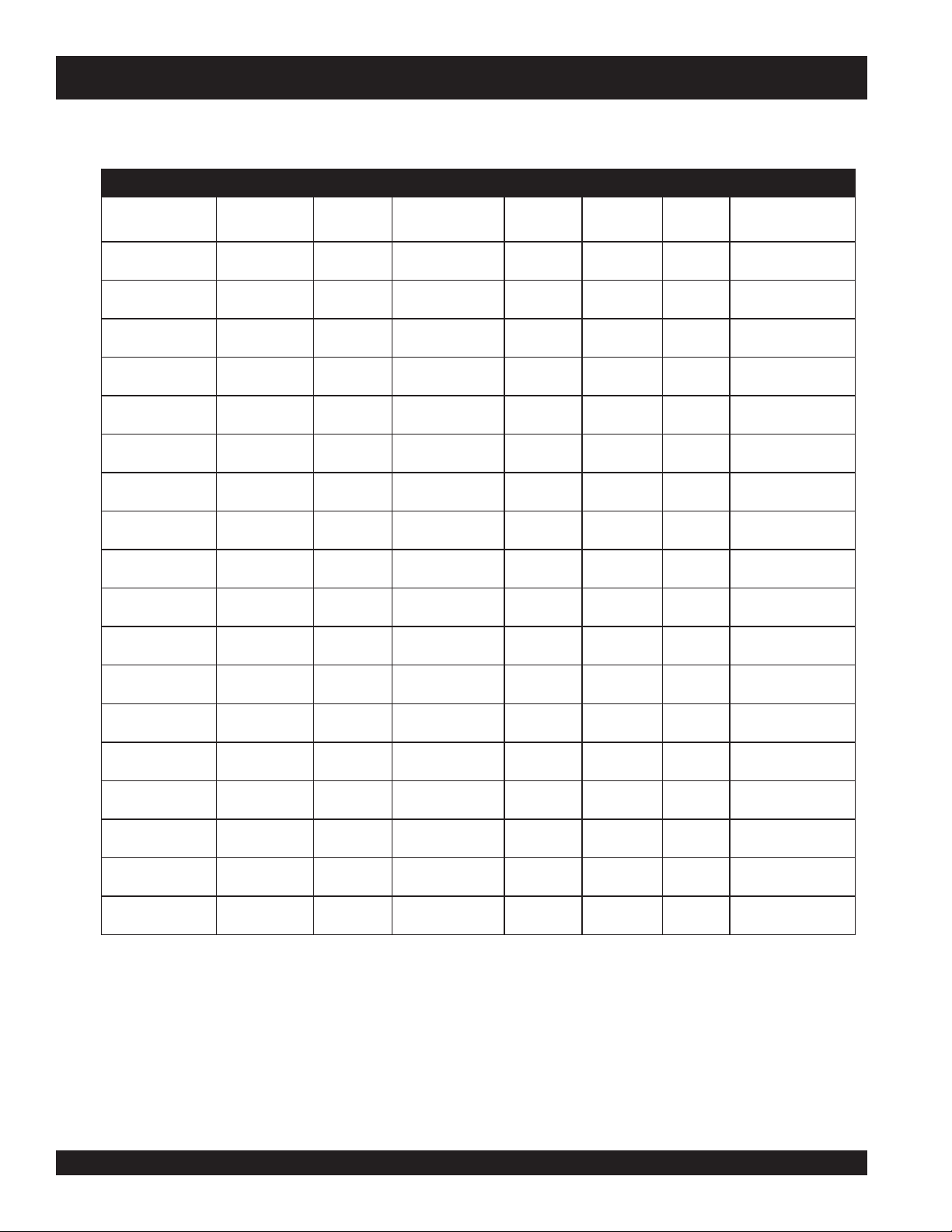

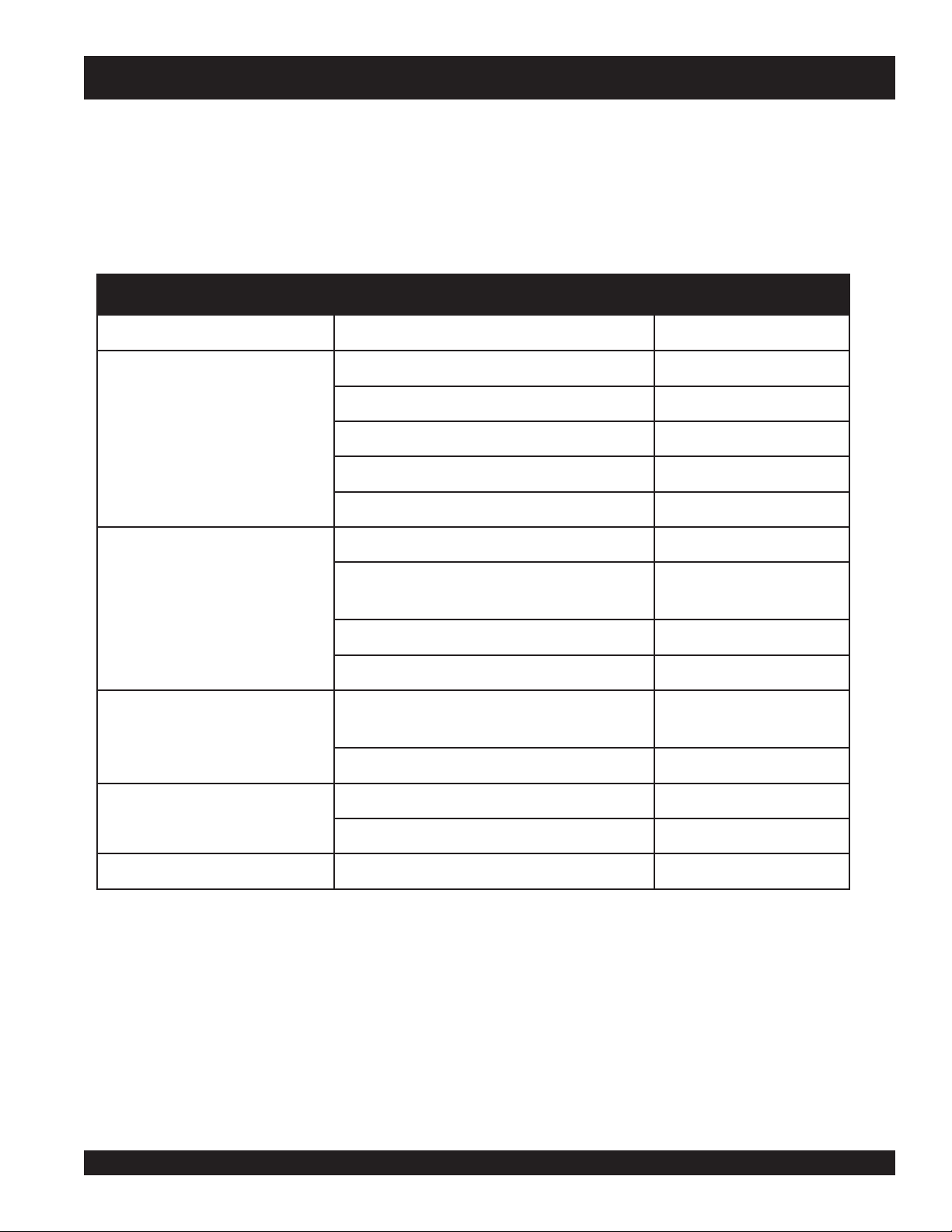

DCA-150SSJU — TRAILER-BRAKE TROUBLESHOOTING

gnitoohselbuorTekarBcirtcelE.5elbaT

motpmyS esuaCelbissoP noituloS

tnettimretnIrosekarBoN

sekarB

sekarBrosekarBkaeW

ediSenOotlluP

gnikcoLrotneb,esoolstnenopmocekarB

sekarB

sekarBysioN?de

?seriwnekorbrostiucricnepoynA.tcerrocdnadniF

?stiucrictrohsynA.tcerr

?rellortnocytluaF.tcerrocdnatseT

?snoitcennocesoolynA.riaperdnadniF

?eruceseriwdnuorG.erucesdnadn

?sgninilrostengamnolioroesaerG.ecalperronaelC

?dedorrocsnoitcennoCtcerr

?devoorgroderocssmurdekarB.ecalperroenihcaM

?dezinorhcnyssekarB.tcerroC

?nekorb

?dnuor-fo-tuosmurdekarB.ecalpeR

tacirbulmetsyS.etacirbuL

ocdnadniF

iF

ocdnanaelC

.noisorrocfoesuac

.stnenopmocecalpeR

?tcerrocstnenopmocekarB.tcerrocdnaecalpeR

sekarBgniggarD?detsujdaleehwehtfosgnira

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 19

eB.tsujdA

Page 20

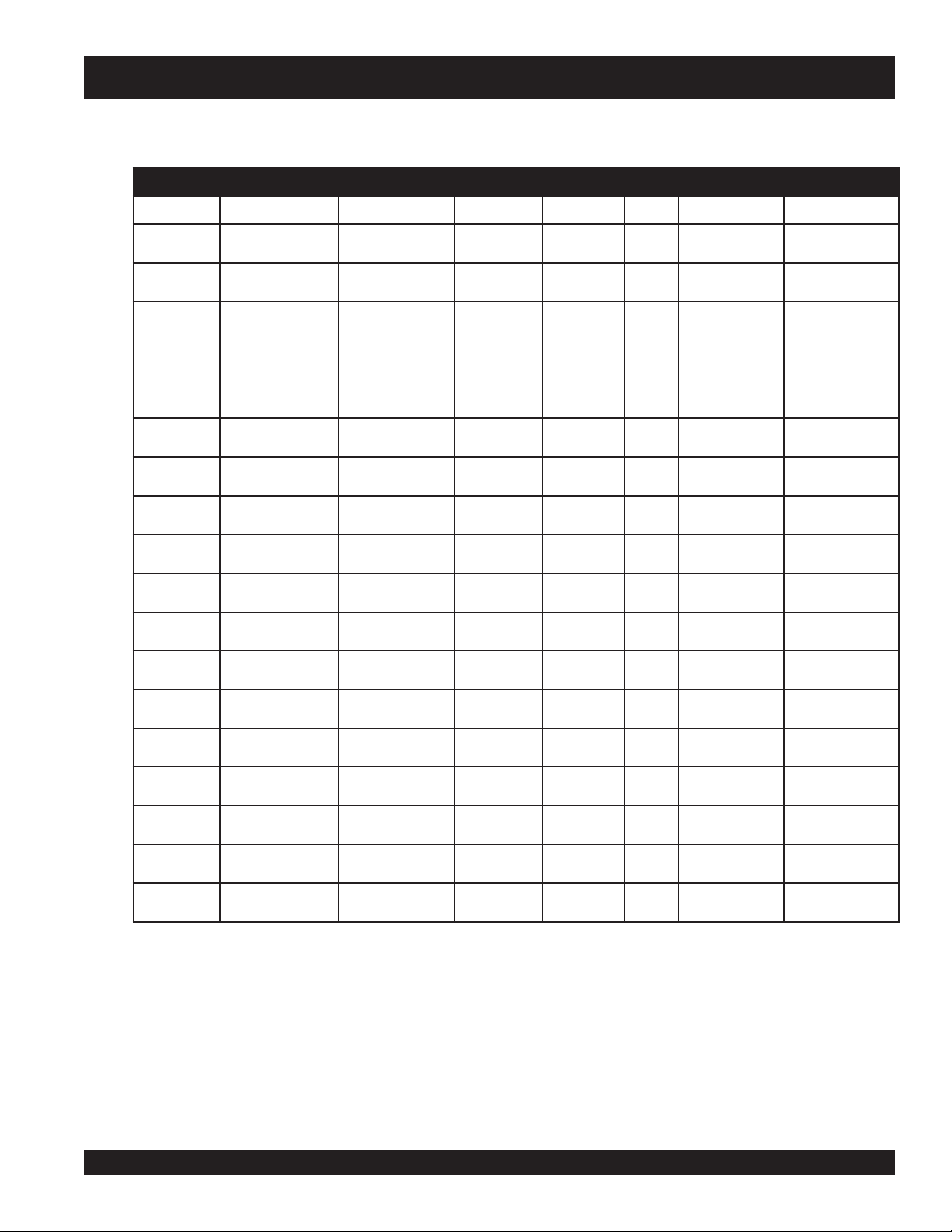

DCA-150SSJU — TRAILER-BRAKE TROUBLESHOOTING

gnitoohselbuorTekarBciluardyH.6elbaT

motpmyS esuaCelbissoP noituloS

sekarBoN?deknikronekorbenilekarB.ecalperroriapeR

otlluPsekarBrosekarBkaeW

ediSenO

sekarBgnikcoL?nekorbrotneb,esoolstnenopmocekarB.stnenopmocecalpeR

sekarBysioN?detacirbulmetsyS.etacirbuL

sekarBgniggarDthgirnirotcerrocssenkcihtgninilekarB

rB.ecalperrohsinrubeR

erusserperiT.yllauqeseritllaetalfnI

w

?dezalggninileka

?dedaolrevoreliarT.thgiewtcerroC

?devoorgroderocssmurdekarB.ecalperroenihcaM

?tcerroc

?elxaemasehtnodehctamnuseriT.serithctaM

?dnuor-fo-tuosmurdekarB.ecalpeR

?

tcerrocstnenopmocekarB.tcerrocdnaecalpeR

?noitisopgnor

?diulftcerrocrodiulfekarbhguonEstraprebburecalpeR

dnaseohswenllatsnI

.sgninil

.diulf4todhtiwllif

PAGE 20 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 21

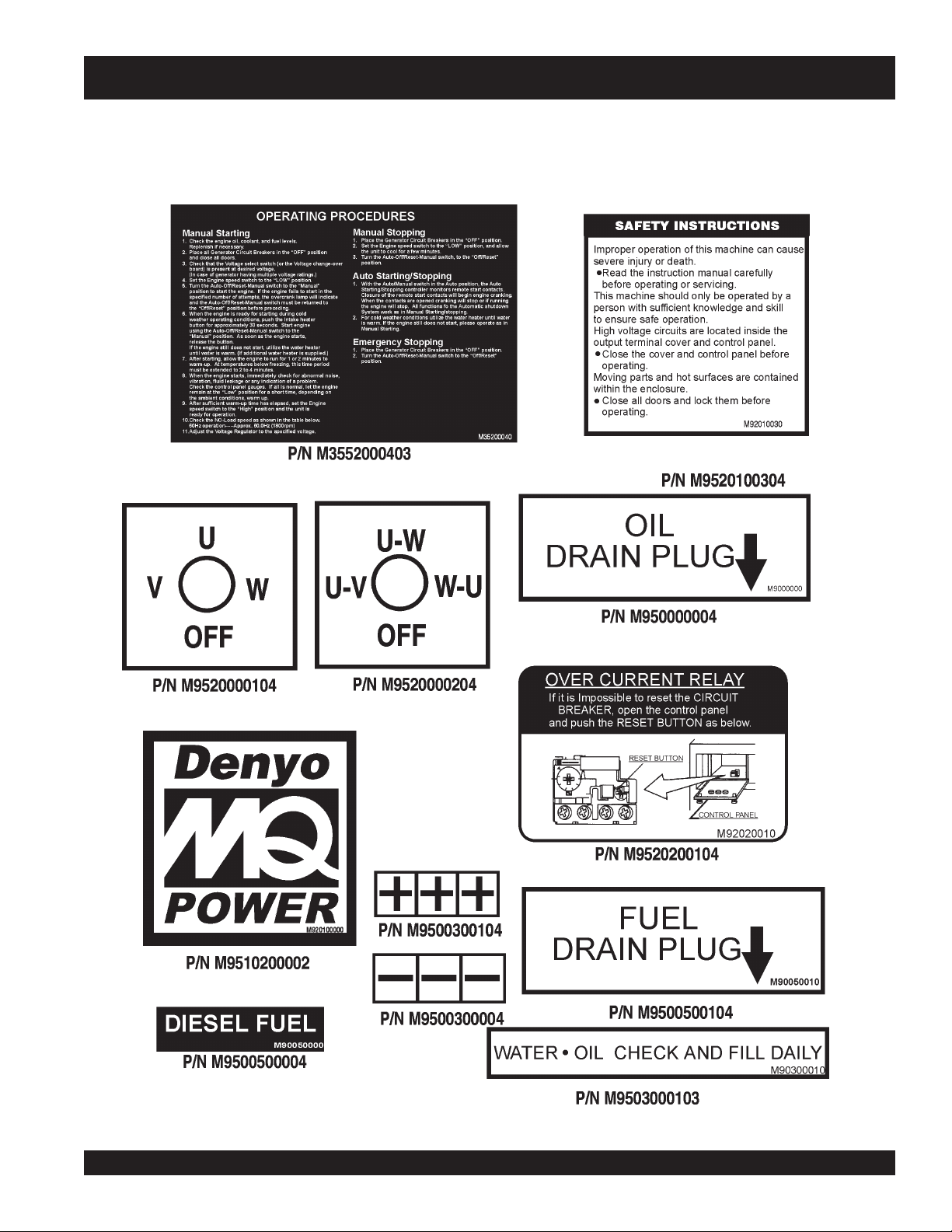

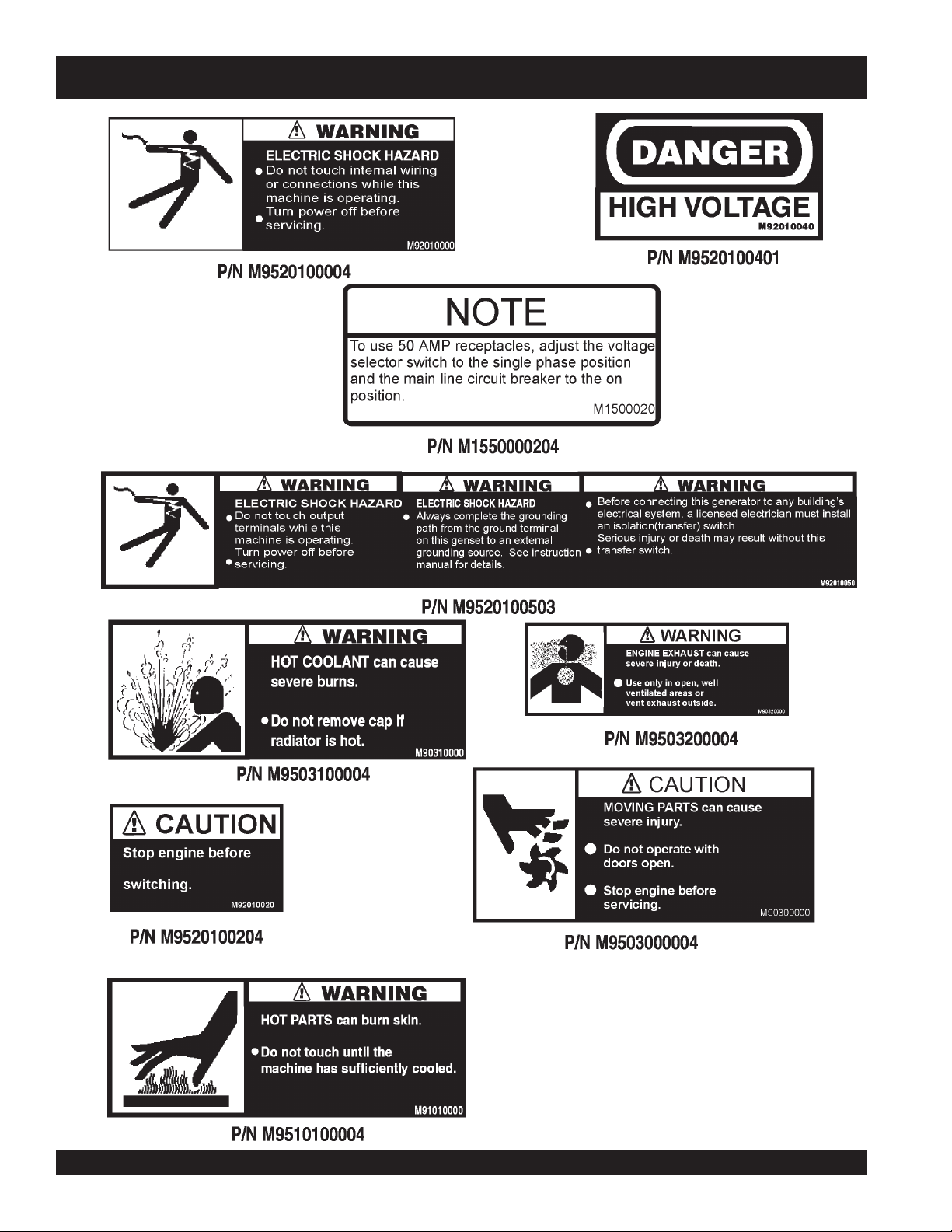

DCA-150SSJU — GENERATOR DECALS

The DCA-150SSJU generator is equipped with a number of safety decals. These decals are provided for operator safety

and maintenance information. The illustration below and on the preceding pages show the decals as they appear on the

machine. Should any of these decals become unreadable, replacements can be obtained from your dealer.

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 21

Page 22

DCA-150SSJU — GENERATOR DECALS

PAGE 22 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 23

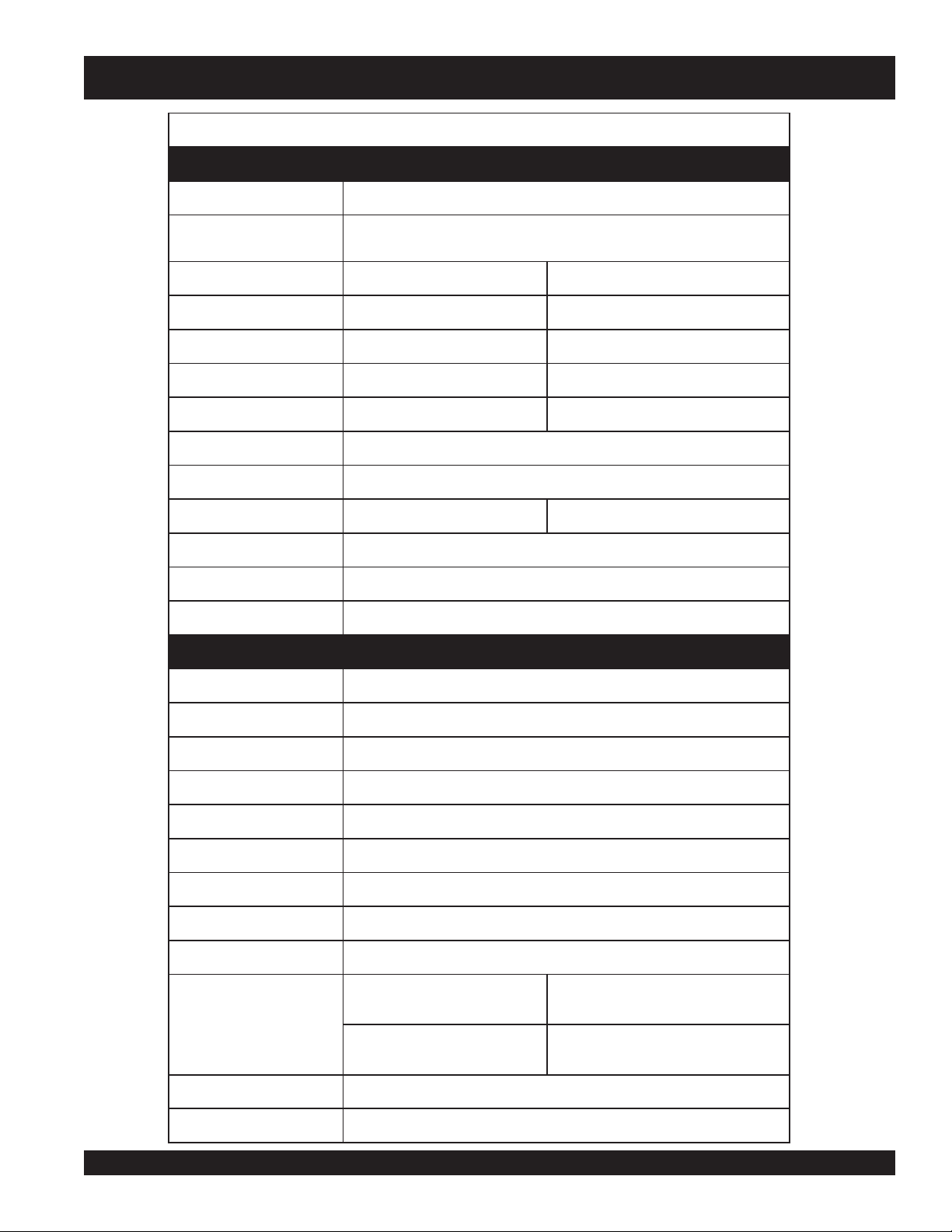

DCA-150SSJU — SPECIFICATIONS

ledoMUJSS051-ACD

snoitacificepS.7elbaT

snoitacificepSrotareneG

epyT

mrA

esahP3 elgniS

egatloVV084roV0

deepSmpr0081

egatloVV021

tuptuO)2xWK4.2(WK8.4

noitcennoCeruta

tuptuOybdnatS)WK231(AVK561WK69

tuptuOemirP)WK021(AVK051WK78

42V021/042

ycneuqerFzH06

rotcaFrewoP8.01

rewoPCA.xuAzH06,esahPelgniS

lartueNhtiwratSgaZgiZ

rotarenegsuonorhcnys

epytdetcetorpnepo,detalitnevfles,dleifgnivloveR

snoitacificepSenignE

ledoM100FT1806EREEDNHOJ

epyTdegrahc-obrut,noitcejnitcerid,delooc-retaw,elcyc-4

srednilyCfo.oNsrednilyc6

eko

rtSxeroB)mm921xmm611(.ni80.5x.ni75.4

tuptuOdetaRmpr0081/PH091

tnemecalpsiD)cc0018(.ni.uc494

gnitratScirtcelE

yticapaCtnalooC)sretil13(.lag2.8

yticapaCliOebuL)sretil23(.lag5.8

tarh/)L7.63(.lag7.9 lluf

aol

d

noitpmusnoCleuF

yrettaB1xHA522-V21

leuFle

tarh/)L02(.lag3.5 2/1

daol

tarh/)L3.82(.lag5.7 daol4/3

tarh/)L2.31(.lag5.3 daol4/1

uFleseiD2#

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 23

Page 24

DCA-150SSJU — GENERAL INFORMATION

DCA-150SSJU FAMILIARIZATION

Generator

The MQ Power Model DCA-150SSJU is a 120 kW

that is designed as a high quality portable (requires a trailer

for transport) power source for telecom sites, lighting

facilities, power tools, submersible pumps and other

industrial and construction machinery.

Engine Control Panel

The “Engine Control Panel” is provided with the following:

z

Tachometer

z

Water Temperature Gauge

z

Oil Pressure Gauge

z

Charging Ammeter Gauge

z

Engine Speed Switch

z

Auto/On/Off Engine Controller(if applicable)

z

Pre-Heat Button

z

Pre-Heat Lamp

z

Key Ignition starter

z

Fuel Gauge

z

Panel Light

z

Panel Light Switch

Generator Control Box

The “Generator Control Box” is provided with the following:

z

Output Voltage Adjustment Knob

z

Frequency Meter (Hz)

z

AC Ammeter (Amps)

z

AC Voltmeter (Volts)

z

Ammeter Change-Over Switch

z

Voltmeter Change-Over Switch

z

Main Circuit Breaker 400 amps

z

Over-Current Relay

z

Voltage Selector Switch

Output Terminal Panel

The “Output Terminal Panel” is provided with the following:

z

Three 240 output receptacles, 50 amp

z

Two 120V output receptacles, 20 amp

z

3 Circuit Breakers 240V @50 amps

z

2 GFCI Circuit Breakers 120V@ 20amps

generator

Open Delta Excitation System

The DCA-150SSJU generator is equipped with the state of

the art "

system consist of an electrically independent winding wound

among stationary windings of the AC output section.

There are four leads: A, B, C and D. During light loads, the

power to the

from the leads parallel connections of B&C. When loads

increase, the AVR switches and accepts power from leads

A&D. The output of leads A&D increase proportionally with

load. This of adding the voltages to each phase provides

better voltage response during heavy loads.

The connections of the AVR to the AC output windings are

for sensing only. No power is required from these windings.

The open-delta design provides virtually unlimited excitation

current, offering maximum motor starting capabilities. The

excitation does not have a "

according the demands of the required load.

Engine

The DCA-150SSJU is powered by a 4 cycle, water cooled,

turbocharged John Deere 6081TF001 diesel

engine is designed to meet every performance requirement

for the generator. Reference Table 7, page 23 for engine

specifications.

In keeping with MQ Power's policy of constantly improving

its products, the specifications quoted herein are subject to

change without prior notice.

The basic controls and indicators for the DCA-150SSJU

generator are addressed on the following pages.

Electronic Governor System

The electronic governor system is made up of two parts, an

electronic controller that monitors frequency variation as the

load increases and decreases and an electronic actuator

that controls the engine throttle. The frequency is regulated

at ±0.25 to help protect sensitive equipment.Engine

Open-Delta

" excitation system. The open delta

Automatic Voltage Regulator

fixed ceiling

(AVR) is supplied

" and responds

engine. This

PAGE 24 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 25

NOTE PAGE

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 25

Page 26

DCA-150SSJU

___

MAJOR COMPONENTS

Figure 6. Major Components

PAGE 26 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 27

DCA-150SSJU — DIMENSIONS

Figure 7. Dimensions

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 27

Page 28

DCA-150SSJU — CONTROL PANEL

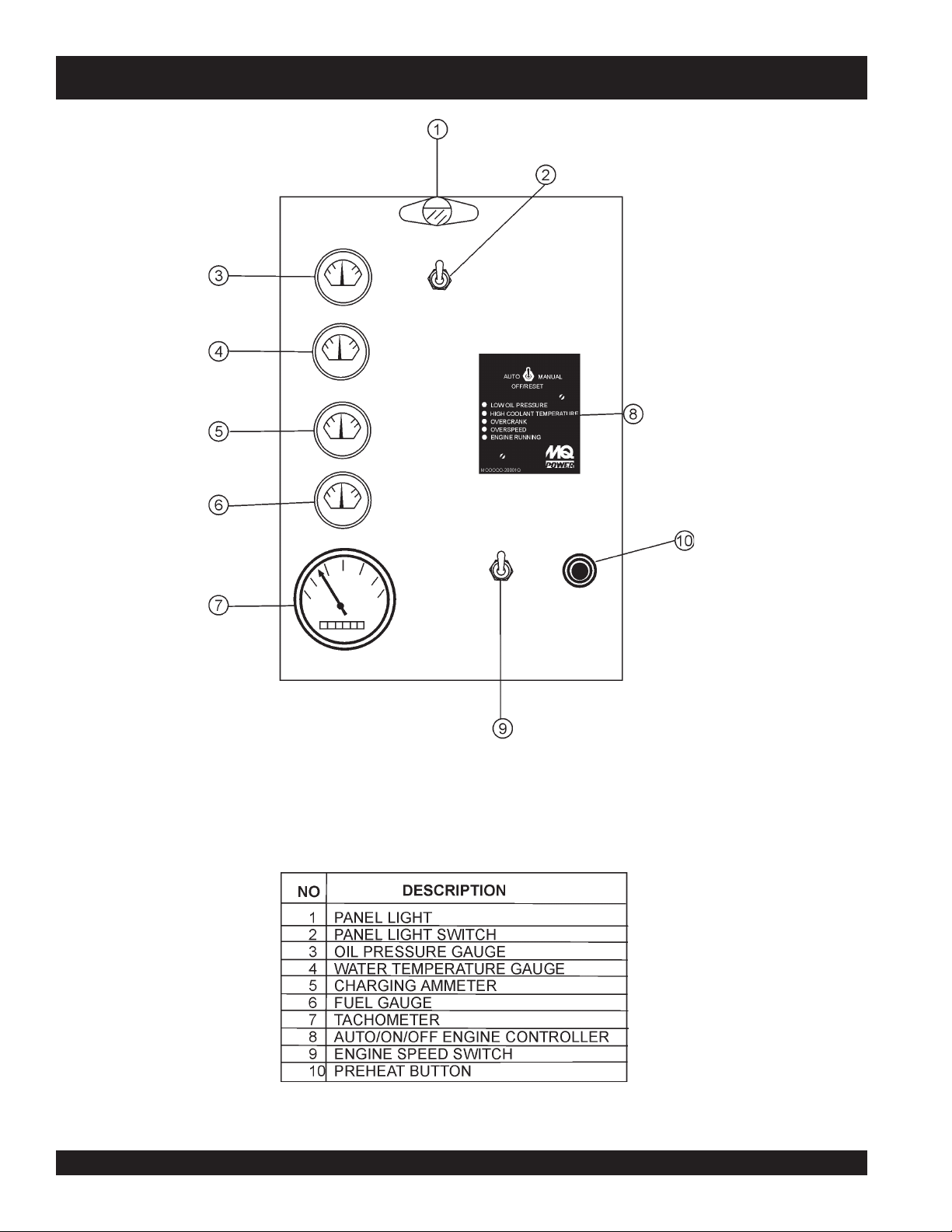

Figure 8. Control Panel

PAGE 28 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 29

DCA-150SSJU — CONTROL PANEL

The definitions below describe the controls and functions of

the DCA-150SSJU "

1. Main Circuit Breaker – This three-pole, 400 amp main

breaker is provided to protect the UVW voltage output

terminals from overload.

2. AC Ammeter – Indicates the amount of current the

load is drawing from the generator.

3. Ammeter Change-Over Switch – This switch allows

the AC ammeter to indicate the current flowing to the

load connected to any phase of the output terminals, or

to be switched off.

4. Voltmeter Change-Over Switch – This switch allows

the AC Voltmeter to indicate phase to phase voltage

between any two phases of the output terminals, or to

be switched off.

5. Voltage Regulator Control – Allows adjustment of the

generator’s output voltage.

Control Panel

" (Figure 8).

6. Frequency Meter – Indicates the output frequency in

hertz (Hz). Normally 63Hz. with a calibration difference

of +0.5% with the mechanical governor or +0.25% with

the electronic governor.

7. AC Voltmeter – Indicates the single phase output

voltage present at the UVW terminals.

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 29

Page 30

DCA-150SSJU — ENGINE OPERATING PANEL

S/N 7600091~

Figure 9. Engine Operating Panel

PAGE 30 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 31

DCA-150SSJU — ENGINE OPERATING PANEL (With Engine Controller)

The definitions below describe the controls and functions of

the DCA-150SSJU "

Number greater than7600090 (Figure 9).

1. Panel light - Normally used in dark places or at night.

When activated, panel will luminate. When the generator

is not in use, turn the panel light switch to the ‘OFF’

position.

2. Panel light switch- When activated, will turn on panel

light.

3. Oil Pressure Gauge – During normal operation this

gauge be should read 42 to 71 psi. When starting the

generator the oil pressure may read slightly higher, but

after the engine warms up the oil pressure should return

within that range.

4. Water Temperature Gauge – During normal operation

this gauge be should read 165

5. Charging Ammeter Gauge – Indicates the current

being supplied by the engine’s alternator which provides

current for generator’s control circuits and battery

charging system.

Engine Operating Panel

o

-203oF.

" with Serial

using variable resistive values from the oil pressure

sending unit. This is considered a

C. High Coolant Temperature – Indicates the engine

temperature has exceeded 215°F. The engine

temperature is detected using variable resistive values

from the temperature sending unit. This is considered a

major

D. Overcrank Shutdown – Indicates the unit has

attempted to be started a pre- programmed number of

times, and has failed to start. The number of cycles

and duration are programmable. It is pre-set at 3 cycles

with a 10 second duration. This is considered a

fault.

E. Overspeed Shutdown – Indicates that the engine is

running at an unsafe speed. This is considered a

fault.

F. Engine Running – Indicates that engine is running

at a safe operating speed.

9. Throttle Handle - This handle controls the speed of

the engine (low or high).

fault.

major

fault.

major

major

6. Fuel Gauge - Indicates amount of diesel fuel available.

7. Tachometer – Indicates engine speed in RPM’s for 60

Hz operation. This meter should indicate 1800 RPM’s

when the rated load is applied. In addition a built in hour

meter will record the number of operational hours that

the generator has been in use.

8. Auto Start Controller – This controller will indicated

with LEDs that an engine fault has been detected. When

a fault has been detected the controller will evaluate

the fault will shutdown the generator if it may be

damaging to the engine.

A. Off/Manual/Auto Switch – This switch controls the

running of the generator. If this switch is left in the "OFF"

position, the generator will not run. When this switch is

set to the

immediately.

If the generator is to be connected to a building's AC

power source via a transfer switch (isolation), place the

switch in the

will monitor the AC line output from the building's power

source.

manual

auto

position, the generator will start

position. In this position the generator

10. Pre-Heat Button – This is to pre-heat the engine under

extreme cold conditions.

B. Low Oil Pressure – Indicates the engine pressure

has fallen below 15 psi. The oil pressure is detected

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 31

Page 32

DCA-150SSJU — ENGINE OPERATING PANEL

UP TO S/N760090

Figure 10. Engine Operating Panel

PAGE 32 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 33

DCA-150SSJU — ENGINE OPERATING PANEL (With Key Switch)

The definitions below describe the controls and functions of

the DCA-150SSJU "

10).

1. Panel light - Normally used in dark places or at night.

When activated, panel will luminate. When the generator

is not in use, turn the panel light switch to the ‘OFF’

position.

2. Panel light switch- When activated, will turn on control

panel light.

3. Oil Pressure Gauge – During normal operation this

gauge be should read between 42 to 71 psi. When

starting the generator the oil pressure may read slightly

higher, but after the engine warms up the oil pressure

should return within the normal range.

4. Water Temperature Gauge – During normal operation

this gauge be should read between 165o to 203o F.

5. Charging Ammeter Gauge – Indicates the current

being supplied by the engine’s alternator which provides

current for generator’s control circuits and battery

charging system.

Engine Operating Panel

" (Figure

6. Fuel Gauge - Indicates amount of diesel fuel available.

7. Tachometer – Indicates engine speed in RPM’s for 60

Hz operation. This meter should indicate 1800 RPM’s

when the rated load is applied. In addition a built in hour

meter will record the number of operational hours that

the generator has been in use.

8. Ignition Switch - This switch is used to turn on or off

the engine with a key.

9. Throttle Handle - This handle controls the speed of

the engine (low or high).

10. Pre-Heat Button – This is to pre-heat the engine under

extreme cold conditions.

11. Water Temperature Indicator - This light indicates the

water temperature is too high and will shut down the

engine.

12. Oil Pressure Indicator - This light indicates the oil

pressure is either too high or too low and will shut down

the engine.

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 33

Page 34

DCA-150SSJU — OUTPUT TERMINAL PANEL OVERVIEW

OUTPUT TERMINAL PANEL FAMILIARIZATION

Output Terminal Panel

The “Output Terminal Panel” is provided with the following:

z

Three 240 output receptacles, 50 amp

z

Two 120V output receptacles, 20 amp

z

3 Circuit Breakers 240V @50 amps

z

2 GFCI Circuit Breakers 120V@ 20amps

Output Terminal Panel

The Output Control Panel (See Figure 14) is located on the

right hand side (left from control panel) of the generator.

The UVW lugs are protected by a face plate cover that can

be secured in the close position by a pad lock. (See Figure

11).

FIGURE 11. Output Terminal Cover

120 Volt Receptacle

Two GFCI Duplex Nema 5-20R (120V, 20 Amp) receptacle

is provided on the output terminal. This receptacle can be

used anytime the generator is in operation. The receptacle

is controlled by the circuit breaker located on the control

panel.

Connecting Load

Loads can be connected to the generator by the UVW Lugs or

the convenience receptacles. (See Figure 13). Make sure to

read the operation manual before attempting to connect a load

to the generator.

Circuit Breakers

To protect the generator from an overload, a 3-pole, 400 amp,

main

circuit breaker is provided to protect the UVW output

terminals from overload. In addition two single-pole, 20 amp

GFCI

circuit breakers are provided to protect the GFCI

receptacles from overload. Three 50 amp

have also been provided to protect the load side of the

generator from overload. Make sure to switch

breakers to the "OFF" position prior to starting the engine.

Maximum Output

The entire load connected to the UVW Lugs, all four slots in the

duplex receptacles, and the must not exceed 132 kW in

standby or 120 kW in prime output.

FIGURE 13. Connecting Load

load

circuit breakers

ALL

circuit

Pressing the reset button resets the receptacle after being

tripped. Pressing the "Test Button" (See Figure 12) in the

center of this receptacle will check the GFCI function. The

receptacle should be tested at least once a month.

FIGURE 12. GFCI Test Button

PAGE 34 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Twist Lock Dual Voltage Receptacles - To use these

receptacles, place the voltage selector switch in the single

phase 240/120 voltage position and adjust the output

voltage to 240 volts with the voltage regulator on the

Control Panel. Place the voltmeter change-over switch to

the U-W position and the ammeter change-over switch to

the U or W to read the output.

Page 35

DCA-150SSJU — OUTPUT TERMINAL PANEL OVERVIEW

NOTE

Legs O and Ground are

considered Bonded Grounds.

FIGURE 14. Output Terminal Panel

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 35

Page 36

DCA-150SSJU — OUTPUT TERMINAL PANEL OVERVIEW

Output Terminal Panel Available Voltages

A wide range of voltages are available to supply load to

many different applications. Voltages may be selected by

using the voltage selector switch and how you hookup

Maximum Amps

The following table show the maximum amps the entire

generator can provide. Do not exceed the maximum amps

listed. (See Table 9)

your hard wire connection to the generator. To obtain some

of the voltages listed, fine adjustment with the Voltage

Regulator on the control panel is necessary. See the table

below (Table 8) for a list of available voltages the generator

is able to supply.

ELBALIAVASEGATLOV.8ELBAT

EGATLOVESAHP3

)ELBAHCTIWS(

ESAHPELGNIS

)ELBAHCTIWS(

TLOV802TLOV022TLOV042TLOV614TLOV044TLOV084

TLOV021TLOV721TLOV

931TLOV042TLOV452TLOV772

Voltage Selector Switch

The voltage selector switch is located above the UVWO

Hard Wire Hookup Panel. It has been provided for ease of

voltage selection.

CAUTION :

:ledoMUJSS051ACD

detaR

egatloV

esahPelgniS

tloV021

esahPelgniS

tloV042

esahPeerhT

tloV042

esahPeerhT

tloV084

spmAmumixaM.9elbaT

spmAmumixaM

)eriw4(spma3.333

)eriw4(spma7.661

spma163

spma081

NEVER switch Voltage Selector Switch

position while the engine is engaged.

Receptacle Use

When the UVWO terminals are providing power, the

receptacle power available decrease. Do not exceed

receptacle power available listed on Table 10.

Voltage Selector Switch Locking Button

The voltage selector switch has a locking button to protect

the generator and generator load from being switched while

the engine is running. To lock the Voltage Selector Switch,

press in the red button located on the Voltage Selector

Switch, and use a pad lock to hold it into this position.

Over Current Relay

An over current relay is connected to the circuit breaker.

In an over current situation, both the circuit breaker and

the over current relay may trip. If the circuit breaker can

not be reset, the reset button on the over current relay

must be pressed. The over current relay is located in the

control box.

esUelcatpeceR.01elbaT

elcatpeceR

esUnirewoP

rewoP

elbaliavA

V021/042

V084/042

esahP-3

AVKWKWK

051780

6418.582.1

2416.484.2

esahPelgniS

tsiwTro

9636SCkcoL

ICFG

xelpuD

AMEN

V021R02-5

8314.386.3

3312.288.4

PAGE 36 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 37

DCA-150SSJU — OUTPUT TERMINAL PANEL OVERVIEW

How to read the output terminal gauges.

The gauges and knobs on the control panel DO NOT effect

the generator output in any fashion. They are there to

simply help the operator observe how much power is being

supplied produced at the UVWO legs.

When the voltage selector switch is in the 240/120V

position (see Figure 15), place the AC Voltmeter Changeover switch to the W-U position and the AC ammeter

Change-over Switch to the U or W position to read the

output on the selected leg.

FIGURE 18. AC Ammeter

Change-over Switch

(Reading the U leg on the

output terminal panel)

FIGURE 19. AC Ammeter

(Amp reading on U lug)

NOTE

FIGURE 15. Voltage Selector Switch 240/120V Single Phase

Position

FIGURE 16. AC Voltmeter

Change-over switch

(Reading the W-U leg on

the output terminal panel)

FIGURE 17. AC Voltmeter

Gauge

(Volt reading on W-U Lug)

When using plural single phase

voltages, make sure to balance

the load on each of the single

phase legs.

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 37

Page 38

DCA-150SSJU — OUTPUT TERMINAL PANEL OVERVIEW

240/120V Hard Wire Hookup

The output terminal panel, when suppling single phase 120

volts, will provide three legs available with 333.3 amps each

on three different circuits. (See Figure 21 below.) The

voltage selector switch must be set at the single phase 240/

120V position. (See Figure 20 below.)

The output terminal panel, when suppling single phase 240

volts, will provide one leg only with 166.7 amps available.

(See Figure 21 below.) The voltage selector switch must be

set at the single phase 240/120V position. (See Figure 20

below.)

480/240V Hard Wire Hookup

The output terminal panel, when suppling three phase 240

volts, will provide one circuit available at 361 amps with any

two wires plus the ground. (See Figure 23 below.) The voltage

selector switch must be set at the three phase 480/277V

position. (See Figure 22 below.)

The output terminal panel, when suppling 3 phase 480 volts,

will provide one circuit available at 180 amps available with

all three wires plus ground. (See Figure 23 below.) The

voltage selector switch must be set at the three phase 480/

277V position. (See Figure 22 below.)

FIGURE 20. Voltage Selector Switch 240/120V Single Phase

Position

FIGURE 21. Hard Wire Hookup at 240/120V Position

FIGURE 22. Voltage Selector Switch 480/277V Three Phase

Position

FIGURE 23. Hard Wire Hookup at 480/240V Position

PAGE 38 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 39

DCA-150SSJU — OUTPUT TERMINAL PANEL OVERVIEW

Voltage Selector Switch- 3 Phase 480/277V Position

The following are additional voltages available when the

voltage selector switch is in the 3 phase 480/277V

position. (See Figure 24 below.)

Single Phase: 480V, 440V, or 416 Volt

The following connection, with the voltage selector switch

locked into the 3 phase 480/277V position (See Figure 27),

can offer SINGLE PHASE power at 480V, 440V, or 416V.

After hooking up the hard wires to the lugs as shown in

Figure 27 below, 480V will be the voltage with the Voltage

Regulator Knob turned toward maximum. 440 volt will be

reached when the Voltage Regulator Knob is turned down,

and 416 volt when the Voltage Regulator Knob is toward

the lowest setting (See Figure 25).

FIGURE 25. Voltage

Regulator Knob

FIGURE 24. Voltage Selector Switch 480/277V Single Phase

Position

FIGURE 27. Hard Wire Hookup for Single Phase 480V, 440V,

or 416V

Single Phase: 277V, 254V, or 240V

3 Phase, 480V, 440V, or 416 Volt

The following connection, with the voltage selector switch

locked into the 3 phase 480/277V position (See Figure 24),

can offer THREE PHASE power at 480V, 440V, or 416V.

After hooking up the hard wires to the lugs as shown in

Figure 26 below, 480V will be the voltage with the Voltage

Regulator Knob turned toward maximum. 440 volt will be

reached when the Voltage Regulator Knob is turned down,

and 416 volt when the Voltage Regulator Knob is toward

The following connection, with the voltage selector switch

locked into the 3 phase 480/277V position (See Figure 28),

can offer SINGLE PHASE power at 277V, 254V, or 240V.

After hooking up the hard wires to the lugs as shown in

Figure 28 below, 277V will be the voltage with the Voltage

Regulator Knob turned toward maximum. 254 volt will be

reached when the Voltage Regulator Knob is turned down,

and 240 volt when the Voltage Regulator Knob is toward

the lowest setting (See Figure 25).

the lowest setting (See Figure 25).

FIGURE 26. Hard Wire Hookup for Three Phase 480V, 440V,

or 416V

FIGURE 28. Hard Wire Hookup for Single Phase 277V, 254V,

or 240V

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 39

Page 40

DCA-150SSJU — OUTPUT TERMINAL PANEL OVERVIEW

Voltage Selector Switch- 3 Phase 240/139V Position

The following are additional voltages available when the

voltage selector switch is in the 3 phase 240/139V

position. (See Figure 29 below.)

Single Phase: 240V, 220V, or 208 Volt

The following connection, with the voltage selector switch

locked into the 3 phase 240/139V position (See Figure 32),

can offer SINGLE PHASE power at 240V, 220V, or 208V.

After hooking up the hard wires to the lugs as shown in

Figure 32 below, 240V will be the voltage with the Voltage

Regulator Knob turned toward maximum. 220 volt will be

reached when the Voltage Regulator Knob is turned down,

and 208 volt when the Voltage Regulator Knob is toward

the lowest setting (See Figure 30).

FIGURE 30. Voltage

Regulator Knob located

on the control panel

FIGURE 32. Hard Wire Hookup for Single Phase 240V, 220V,

FIGURE 29. Voltage Selector Switch 240/139V Three Phase

Position

or 208V

Single Phase: 139V, 127V, or 120V

3 Phase, 240V, 220V, or 208 Volt

The following connection, with the voltage selector switch

locked into the 3 phase 240/139V position (See Figure 29),

can offer THREE PHASE power at 240V, 220V, or 208V.

After hooking up the hard wires to the lugs as shown in

Figure 31 below, 240V will be the voltage with the Voltage

Regulator Knob turned toward maximum. 220 volt will be

reached when the Voltage Regulator Knob is turned down,

and 208 volt when the Voltage Regulator Knob is toward

The following connection, with the voltage selector switch

locked into the 3 phase 240/139V position (See Figure 33),

can offer SINGLE PHASE power at 139V, 127V, or 120V.

After hooking up the hard wires to the lugs as shown in

Figure 33 below, 139V will be the voltage with the Voltage

Regulator Knob turned toward maximum. 127 volt will be

reached when the Voltage Regulator Knob is turned down,

and 120 volt when the Voltage Regulator Knob is toward

the lowest setting (See Figure 30).

the lowest setting (See Figure 30).

FIGURE 31. Hard Wire Hookup for Three Phase 240V, 220V,

or 208V

FIGURE 33. Hard Wire Hookup for Single Phase 139V, 127V,

or 120V

PAGE 40 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 41

DCA-150SSJU — OUTPUT TERMINAL PANEL OVERVIEW

Voltage Selector Switch- Single Phase 240/120V

Position

The following are additional voltages available when the

voltage selector switch is in the single phase 240/120V

position. (See Figure 34 below.)

Single Phase: 120 Volt

The following connection, with the voltage selector switch

locked into the single phase 240/120V position (See

Figure 34), will offer SINGLE PHASE power at 120V. After

hooking up the hard wires to the lugs as shown in Figure

37 below, use the Voltage Regulator Knob to fine tune to

120V. (See Figure 35).

FIGURE 35. Voltage

Regulator Knob located

on the control panel

FIGURE 34. Voltage Selector Switch 240/120V Single Phase

Position

FIGURE 37. Hard Wire Hookup for Single Phase, 120 volt

Single Phase, 240 Volt

The following connection, with the voltage selector switch

locked into the single phase 240/120V position (See

Figure 34), will offer SINGLE PHASE power at 240V. After

hooking up the hard wires to the lugs as shown in Figure

36 below, use the Voltage Regulator Knob to fine tune to

240V. (See Figure 35).

FIGURE 36. Hard Wire Hookup for Single Phase 240 volt

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 41

Page 42

DCA-150SSJU — INSTALLATION

Outdoor Installation

Install the generator in a location where it will not be exposed

to rain or sunshine. Make sure the generator is on secure

level ground so that it cannot slide or shift around. Also

install the generator in a manner so that the exhaust will not

be discharged in the direction of nearby homes.

The installation site must be relatively free from moisture

and dust. All electrical equipment should be protected from

excessive moisture. Failure to do will result in deterioration

of the insulation and will result in short circuits and grounding.

Foreign materials such as dust, sand, lint and abrasive

materials have a tendency to cause excessive wear to

engine and alternator parts.

CAUTION :CAUTION :

CAUTION :

CAUTION :CAUTION :

Pay close attention to ventilation when

operating the generator inside tunnels and

caves. The engine exhaust contains

noxious elements. Engine exhaust must

be routed to a ventilated area.

Indoor Installation

Exhaust gases from diesel engines are extremely poisonous.

Whenever an engine is installed indoors the exhaust fumes

must be vented to the outside. The engine should be installed

at least two feet from any outside wall. Using an exhaust

pipe which is too long or too small can cause excessive

back pressure which will cause the engine to heat

excessively and possibly burn the valves.

Mounting

The generator must be mounted on a solid foundation (such

as concrete) and set firmly on the foundation to isolate

vibration of the generator when it is running. The generator

must set at least 6 inches above the floor or grade level (in

accordance to NFPA 110, Chapter 5-4.1). DO NOT remove

the metal skids on the bottom of the generator. They are to

resist damage to the bottom of the generator and to maintain

alignment.

CAUTION CAUTION

CAUTION

CAUTION CAUTION

Generator Grounding

To guard against electrical shock and possible damage to

the equipment, it is important to provide a good EARTH

ground.

Article 250 (Grounding) of the National Electrical Code (NEC)

provides guide lines for proper grounding and specifies that

the cable ground shall be connected to the grounding system

of the building as close to the point of cable entry as

practical.

NEC articles 250-64(b) and 250-66 set the following

grounding requirements:

1. Use one of the following wire types to connect the

generator to earth ground.

a. Copper - 10 AWG (5.3 mm2) or larger.

b. Aluminum - 8 AWG (8.4 mm2) or larger.

2. When grounding the generator (Figure 38) connect the

ground cable between the lock washer and the nut on

the generator and tighten the nut fully. Connect the other

end of the ground cable to earth ground.

3. NEC article 250-52(c) specifies that the earth ground

rod should be buried a minimum of 8 ft. into the ground.

When connecting the generator to any buildings

electrical system ALWAYS consult with a licensed

electrician.

:

An electric shock may happen when

vibrators are used. Pay close attention to

handling when operating vibrators and

always use rubber boots and gloves to

insulate the body from electrical shock.

NOTE

PAGE 42 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 43

DCA-150SSJU — INSTALLATION

CAUTION CAUTION

CAUTION

CAUTION CAUTION

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 43

Figure 38. Typical Generator Grounding Application

:

Always check Local, State, and Federal

laws before grounding generator set.

Page 44

DCA-150SSJU — PRE-SETUP

General Inspection Prior to Operation

The DCA-150SSJU generator has been thoroughly inspected

and accepted prior to shipment from the factory. However,

be sure to check for damaged parts or components, or loose

nuts and bolts, which could have occurred in transit.

Extension Cable

When electric power is to be provided to various tools or

loads at some distance from the generator, extension

cords are normally used. Cables should be sized to allow

for distance in length and amperage so that the voltage

drop between the generator and point of use (load) is held

to a minimum. Use the Cable Selection Guide (Table 11)

as a guide for selecting proper cable size.

Circuit Breakers

To protect the generator from an overload, a 3-pole, 400 amp,

main

circuit breaker is provided to protect the UVW output

terminals from overload. In addition two single-pole, 20 amp

GFCI

circuit breakers are provided to protect the GFCI

receptacles from overload. Three 50 amp

have also been provided to protect the load side of the

generator from overload. Make sure to switch

breakers to the "OFF" position prior to starting the engine.

load

circuit breakers

ALL

circuit

NOTE

ALWAYS consult with a licensed

electrician for correct extension

cord wire size.

PAGE 44 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 45

DCA-150SSJU — PRE-SETUP

Lubrication Oil

Fill the engine crankcase with lubricating oil through the filler

hole, but do not overfill. Make sure the generator is level.

With the dipstick inserted all the way, but without being screw

into the filler hole, verify that the oil level is maintained

between the two notches (Figure 39) on the dipstick. See

Fuel

Fill the fuel tank with clean and fresh

fill the tank beyond capacity.

Pay attention to the fuel tank capacity when replenishing

fuel. Refer to the fuel tank capacity listed on page 23,

Specification Table 7.

Table 12 for proper selection of engine oil.

The fuel tank cap must be closed tightly after filling. Handle

fuel in a safety container. If the container does not have a

spout, use a funnel. Wipe up any spilled fuel immediately.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Coolant

Use only drinkable tap water. If hard water or water with

many impurities is used, the inside of the engine and radiator

may become coated with deposits and cooling efficiency

will be reduced.

Figure 39. Engine Oil Dipstick

An anticorrosion additive added to the water will help prevent

When checking the engine oil, be sure to check if the oil is

clean and viscous. If the oil is not clean, drain the oil by

deposits and corrosion in the cooling system. See the engine

manual for further details.

removing the oil drain plug, and refill with the specified amount

of oil as outlined in the John Deere Engine Owner's

Manual.

diesel fuel.

DO NOT

:

Never fill the fuel tank while the engine is

running or in the dark. Diesel spillage on a

hot engine can cause a fire or explosion.

If diesel spillage occurs, wipe up the spilled

diesel completely to prevent fire hazards.

liOrotoMdednemmoceR.21elbaT

erutarepmeT

egnaR

o

22

o

05(

o

68

o

03(

DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 45

o

8-~F

F

o

51-~C

)C

o

22-~F

F

o

03-~C

)C

o

F

22-woleB

o

51-(

)C

liOepyT

04-w51EAS

03-W5EAS

03-W0EAS

Page 46

DCA-150SSJU — PRE-SETUP

CAUTION :CAUTION :

CAUTION :

CAUTION :CAUTION :

When adding coolant or antifreeze to the

radiator, do not remove the radiator cap

until the unit has completely cooled.

Day-to-day addition of coolant is done from the reserve tank.

When adding coolant to the radiator, DO NOT remove the

radiator cap until the unit has completely cooled. See Table

13 for engine, radiator, and reserve tank coolant capacities.

Make sure the coolant level in the reserve tank is always

between the "H" and the "L" markings.

yticapaCtnalooC.31elbaT

rotaidaRdnaenignE)sretiL14(.laG9.01

knaTevreseR)sretiL9.11(strauQ2

Cleaning the Radiator

The engine may overheat if the radiator fins become

overloaded with dust or debris. Periodically clean the radiator

fins with compressed air. Cleaning inside the machine is

dangerous, so clean only with the engine turned off and the

battery disconnected.

Air Cleaner

Periodic cleaning/replacement is necessary. Inspect it in

accordance with the John Deere Engine Owner's Manual.

Fan Belt Tension

A slack fan belt may contribute to overheating, or to

insufficient charging of the battery. Inspect the fan belt for

damage and wear and adjust it in accordance with the John

Deere Engine Owner's Manual.

The fan belt tension is proper if the fan belt bends 7 to 10

mm (Figure 40) when depressed with the thumb as shown

below.

Operation in Freezing Weather

When operating in freezing weather, be certain the proper

amount of antifreeze (Table 14) has been added.

serutarepmeTgnitarepOezeerF-itnA.41elbaT

tnioPgnizeerFtnioPgnilioB

%loV

ezeerF-itnA

C°F°C°F°

0442-21-601222

0573-43-80

NOTE

When the antifreeze is mixed with

water, the antifreeze mixing ratio must

be less than 50%.

1622

Figure 40. Fan Belt Tension

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Battery

This unit is of negative ground DO NOT connect in reverse.

Always maintain battery fluid level between the specified

marks. Battery life will be shortened, if the fluid level is not

properly maintained. Add only distilled water when

replenishment is necessary.

Check to see whether the battery cables are loose. Poor

contact may result in poor starting or malfunctions. Always

keep the terminals firmly tightened. Coating the terminals

with a thin film of grease will help inhibit corrosion.

:

Never place hands near the belts or fan while

the generator set is running.

PAGE 46 — DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01)

Page 47

DCA-150SSJU — PRE-SETUP

Battery Cable Installation

ALWAYS be sure the battery cables (Figure 41) are properly

connected to the battery terminals as shown below. The

RED

cable is connected to the positive terminal of the battery,

and the BLACK cable is connected to the negative terminal

of the battery.

Figure 41. Battery Connections

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Before connecting battery do the following:

:

If the battery cable is connected

incorrectly, electrical damage to the

generator will occur. Pay close attention

to the polarity of the battery when

connecting the battery.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Wiring

Inspect the entire generator for bad or worn electrical wiring

or connections. If any wiring or connections are exposed

(insulation missing) replace wiring immediately.

Piping and Hose Connection

Inspect all piping, oil hose, and fuel hose connections for

wear and tightness. Tighten all hose clamps and check hoses

for leaks.

If any hose (fuel or oil) lines are defective replace them

immediately.

Ether Canister Operation (During Cold Conditions)

To bleed the ether, crank the engine for at least two

revolutions, then momentarily depress the starting aid button

while the engine is cranking. If the engine does not start,

repeat the cranking process using only short bursts of ether