Page 1

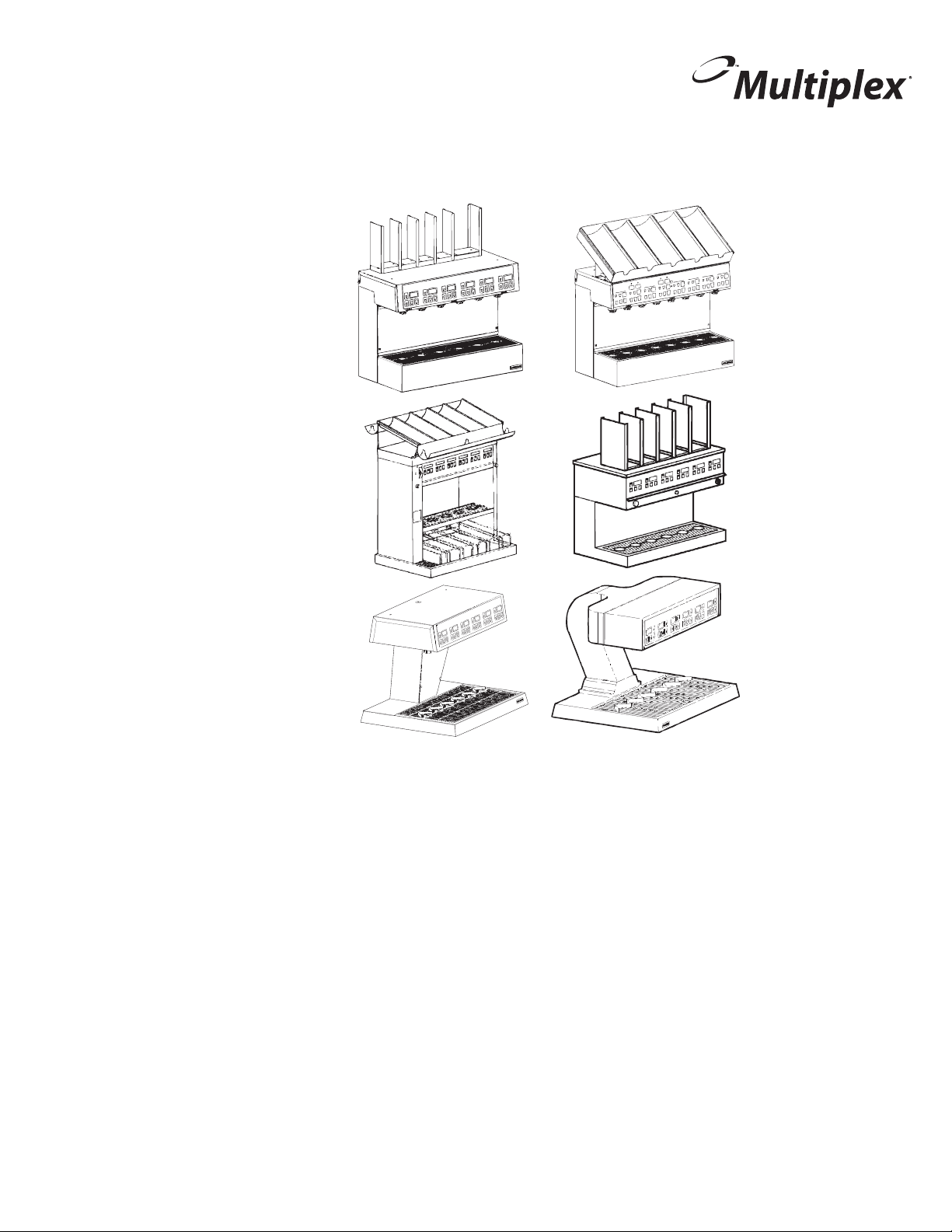

Soda Dispensing Towers

Installation, Use & Care Manual

This manual is updated as new information and models are released.

Visit our website for the latest manual. www.manitowocfsg.com

America’s Quality Choice in Refrigeration

Part Number 020002777 10/11

Page 2

Safety Notices

!

Warning

!

Caution

Important

!

Caution

Important

!

Warning

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this manual.

Disregarding the notices may lead to serious injury and/

or damage to the equipment.

Throughout this manual, you will see the following types

of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Caution box alerts you to a situation in

which you could damage the equip ment. Be sure to

read the Caution statement before proceeding, and

work carefully.

Procedural Notices

As you work on Manitowoc equipment, be sure to read

the procedural notices in this manual. These notices

supply helpful information which may assist you as you

work.

Throughout this manual, you will see the following types

of procedural notices:

Read These Before Proceeding:

Proper installation, care and maintenance are

essential for maximum performance and trouble-free

operation of your Manitowoc equipment. Read and

understand this manual. It contains valuable care

and maintenance information. If you encounter

problems not covered by this manual, do not

proceed, contact Manitowoc. We will be happy to

provide assistance.

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

NOTE: SAVE THESE INSTRUCTIONS.

Text in an Important box provides you with

information that may help you perform a procedure

more efficiently. Disregarding this information will not

cause damage or injury, but it may slow you down as

you work.

NOTE: Text set off as a Note provides you with simple,

but useful, extra information about th e pr oce dur e yo u

are performing.

We reserve the right to make product improvements at any time.

Specifications and design are subject to change without notice.

Page 3

We reserve the right to make product improvements at any time.

THIS PAGE INTENTIONALLY LEFT BLANK

Specifications and design are subject to change without notice.

Page 4

We reserve the right to make product improvements at any time.

Specifications and design are subject to change without notice.

Page 5

Section 1

General Information

Section 2

Installation

Table of Contents

Read This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Model Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Attention: Marine Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Outdoor Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Serial Plate Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

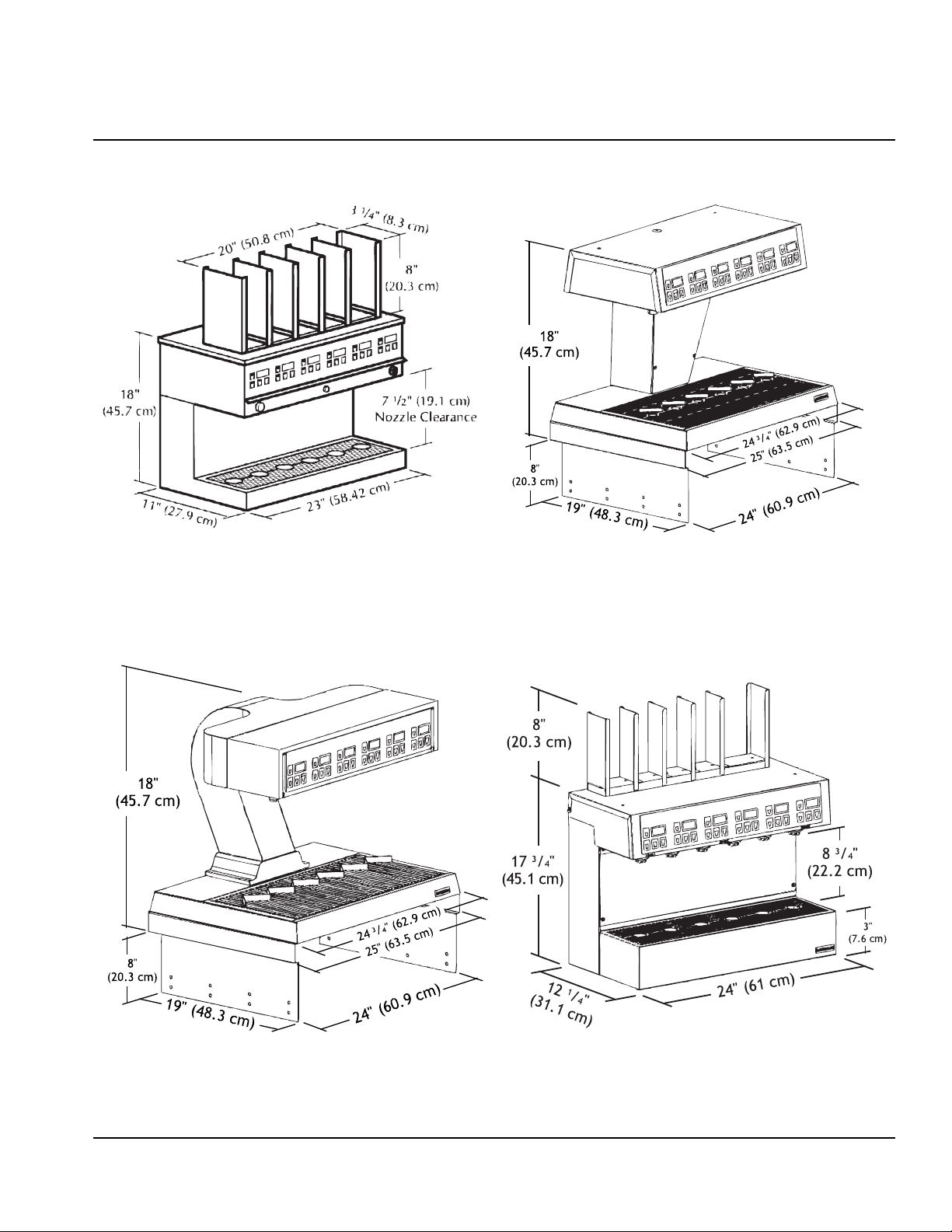

Dimensions and Clearances — All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Model 116 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Model 126 (V-Style) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Model 136 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Model 126 (S-Style) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

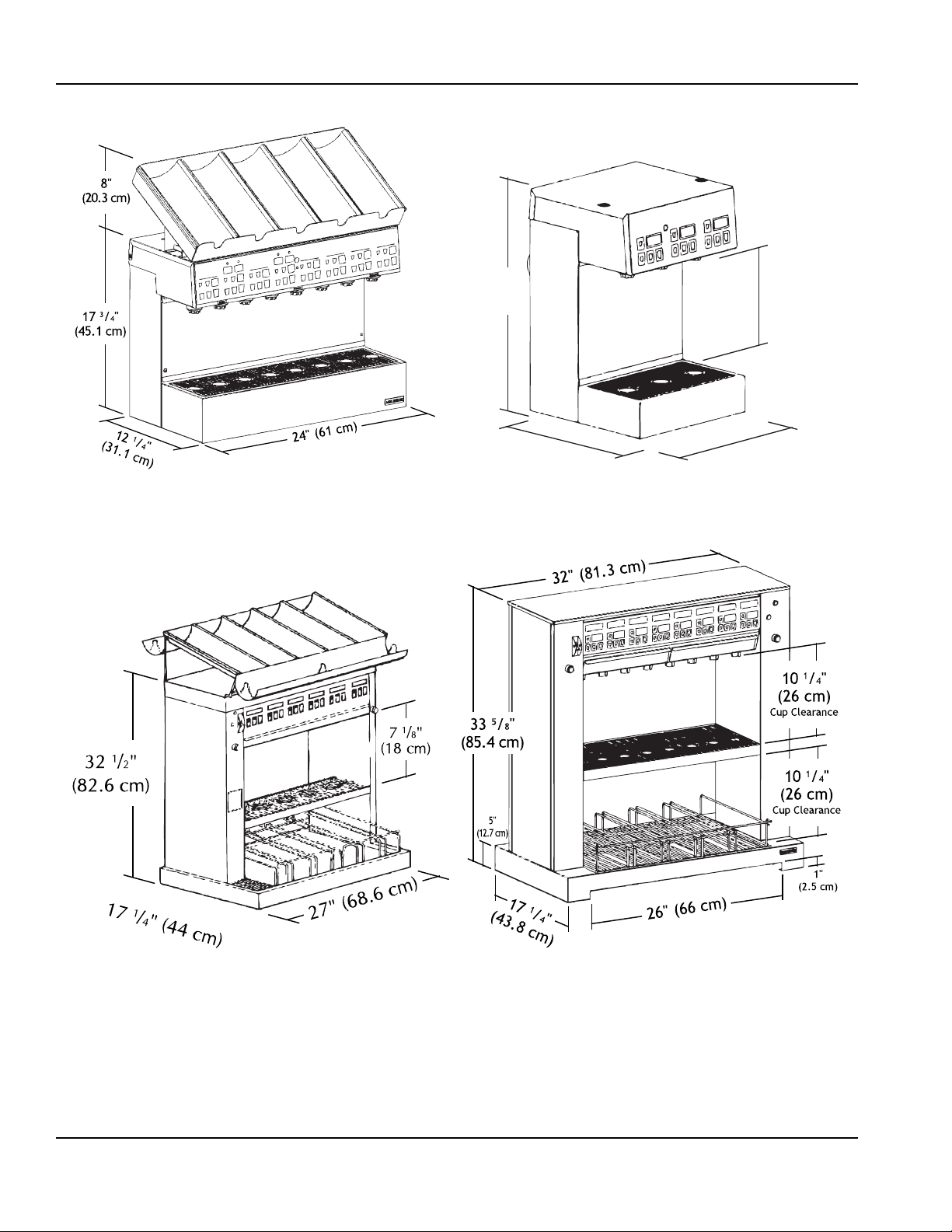

Model 138 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Model 143 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Model 158 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Model 156 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

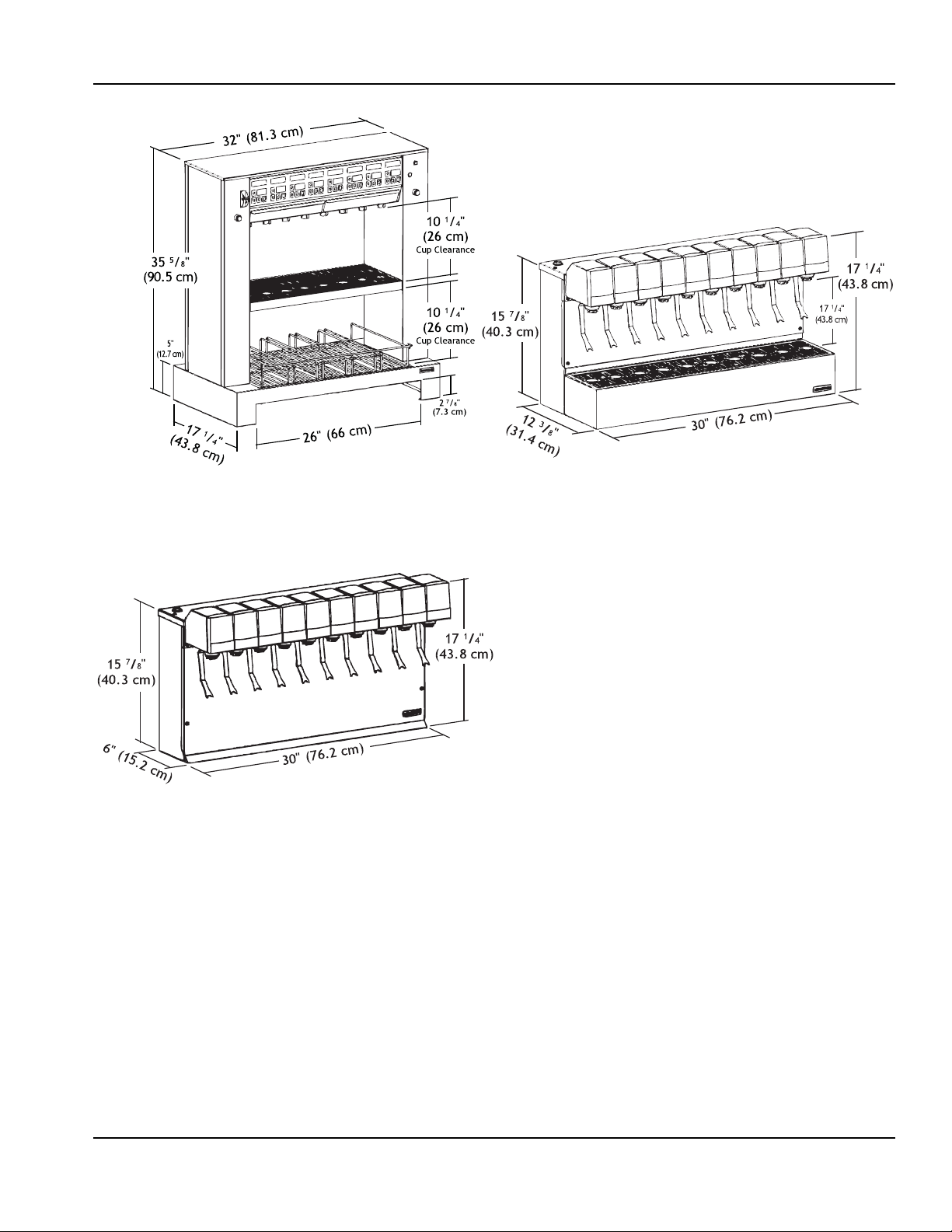

Model 158 (High Cup Clearance) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Model 1310 (With Drain Pan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Model 1310 (No Drain Pan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

FootPrints - All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Model 116 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Model 126 (V & S-Style Towers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Model 136 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Model 138 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Model 143 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Model 156 (Left Hand Pass-Thru) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Model 156 (Right Hand Pass-Thru) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Model 158 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Model 1310 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Safe Installation Dos and Don’ts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Part Number 020002777 10/11 i

Page 6

Table of Contents (continued)

Location Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Location of the Dispensing Tower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Kitchen Equipment Installer Representative Responsibilities . . . . . . . . . . . 2-10

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Installer Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Minimum Circuit Ampacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Making the Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Grounding Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Mounting The Dispensing Tower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Secured By Bolting To The Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Secured With Mounting Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Plumbing – General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Connecting The Syrup And Water Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

How to Insulate all the Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Section 3

Operation

Calibration of the Dispensing Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Set The Flow (Water Flow Rate Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Set The Ratio (Water To Syrup Mixture) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Set The Volume (Drink Portion Sizes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Program modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Program Mode CAL No. 1 (total volume) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Program Mode CAL No. 2 (incremental) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Program Mode CAL No. 3 (Water/Soda) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Top-off program mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Test And Sanitation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Instructions For Dual Flavor Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Entering Water/soda Programming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Equipment Setup and Close Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Equipment Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Equipment Close Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

ii Part Number 020002777 10/11

Page 7

Section 4

Maintenance

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Cleaning Equipment and Supplie s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Sanitizing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Shipping, Storage and Relocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Section 5

Before Calling for Service

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Table of Contents (continued)

Periodic Maintenance Listed By Major Components . . . . . . . . . . . . . . . . . 4-1

Periodic Maintenance Listed By Scheduled Frequency . . . . . . . . . . . . . . . 4-2

Cleaning & Sanitizing The Dispensing Valves And Product Lines . . . . . . . 4-3

Beverage System Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Bag-In-Box System Sanitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figal Beverage System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

No syrup or insufficient syrup in finished drink . . . . . . . . . . . . . . . . . . . . . . 5-1

No carbonated water or insufficient carbonated water in finished drink . . . 5-2

No water or insufficient water in finished drinks . . . . . . . . . . . . . . . . . . . . . 5-2

Part Number 020002777 10/11

iii

Page 8

Table of Contents (continued)

THIS PAGE INTENTIONALLY LEFT BLANK

iv Part Number 020002777 10/11

Page 9

Section 1

!

Warning

General Information

Read This Manual

Manitowoc Food Service developed this manual as a

reference guide for the owner/operator and installer of

this equipment. Please read this manual before

installation or operation of the machine. A qualified

service technician must perform installation and start-up

of this equipment, consult Section 5 within this manual

for service assistance.

If you cannot correct the service problem, call your

Manitowoc Beverage Equipment (MBE) Service Agent

or Distributor. Always have your model and serial

number available when you call.

Your Service Agent ____________________________

Service Agent Telephone Number_________________

Your Local MBE Distributor ______________________

Distributor Telephone Number ____________________

Model Number _______________________________

Serial Number ________________________________

Installation Date ______________________________

Unit Inspection

Thoroughly inspect the unit upon delivery. Immediately

report any damage that occurred during transpo rtation to

the delivery carrier. Request a written inspection report

from a claims inspector to document any nece ssa ry

claim.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

Model Numbers

This manual covers the following models:

Soda Tower Models

1 16, 126CNK. 126ENK, 126LNK, 126LDP, 126LDPX,

136, 136PDP, 136PDPX, 138CDA, 136LDAX,

136EDLVX, 136LDLX, 138EDSX, 138EDSX, 138DS,

138LDAX, 138CDAL, 138PDLX, 138PDP , 138PDPX,

136FDL, 136FDP , 136FDS, 136EDL, 136FDL, 136FDP ,

136FDS, 136LDAL, 136LDL, 138FDL, 138FDP ,

138FDS, 138EDL, 138FDL, 138FDP , 138FDS,

138LDAL, 138LDL, EDA, FDA, LDA, 143LDAX,

143EDA, 143EDAX, 146, 146 Quad Control, 156,

156PDP, 156PDPX, 156EDL, 156EDRA, 156FDAX,

Pass-Thru, Quad Control, 156 Pass-Thru, 158FDLHX,

158LDLHX, 158PDPLH, 158PDPLHX, 158LDLHX,

1310EDC, 1310ENS, 1310LVD, 1310PDL, 1310PDP,

1510EDLH, 1510LDLHX

Part Number 020002777 10/11 1-1

Page 10

General Information Section 1

!

Warning

ATTENTION: MARINE INSTALLATIONS

This unit is for use on vessels over 66 ft (20 m) in

length. This unit must not be installed in the engine

space of a gasoline-powered ship.

NOTE: This unit must be secured to the vessel during

installation.

OUTDOOR APPLICATIONS

TS Multiplex Beverage Recirculating units are approved

and listed by Underwriters Laboratories (UL). However

they are not UL approved for weather exposure

applications. These units must be installed in areas

where adequate protection from the ele m en ts is

provided, all other models are ETL listed.

Serial Plate Location

Warranty Information

Consult your local MBE Distributor for terms and

conditions of your warranty. Your warranty specifically

excludes all beverage valve brixing, general

adjustments, cleaning, accessories and related

servicing.

Your warranty card must be returned to MBE to activate

the warranty on this equipment. If a warranty card is not

returned, the warranty period can begin when the

equipment leaves the MBE factory.

No equipment may be returned to MBE without a written

Return Materials Authorization (RMA). Equipment

returned without an RMA will be refused at MBE’s dock

and returned to the sender at the sender’s expense.

Please contact your local MBE distributor for return

procedures.

1-2

Part Number 020002777 10/11

Page 11

Section 2

MODEL 116

MODEL 126 (V-STYLE)

MODEL 136

MODEL 126 (S-STYLE)

Installation

DIMENSIONS AND CLEARANCES — ALL MODELS

Part Number 020002777 10/11 2-1

Page 12

Installation Section 2

MODEL 138

MODEL 143

MODEL 158

MODEL 156

8" (20.3 cm)

cup clearance for

18 3/8"

(46.7 cm)

12

3

/

8

" (31.4 cm)

12" (30.5 cm)

3" tall drain pan

9 1/2" (24.1 cm)

cup clearance for

1

1

/2" tall drain pan

P.N. 00914300

2-2

Part Number 020002777 10/11

Page 13

Section 2 Installation

MODEL 158 (HIGH CUP CLEARANCE)

MODEL 1310 (WITH DRAIN PAN)

MODEL 1310 (NO DRAIN PAN)

Part Number 020002777 10/11 2-3

Page 14

Installation Section 2

MODEL 116

MODEL 126 (V & S-STYLE TOWERS)

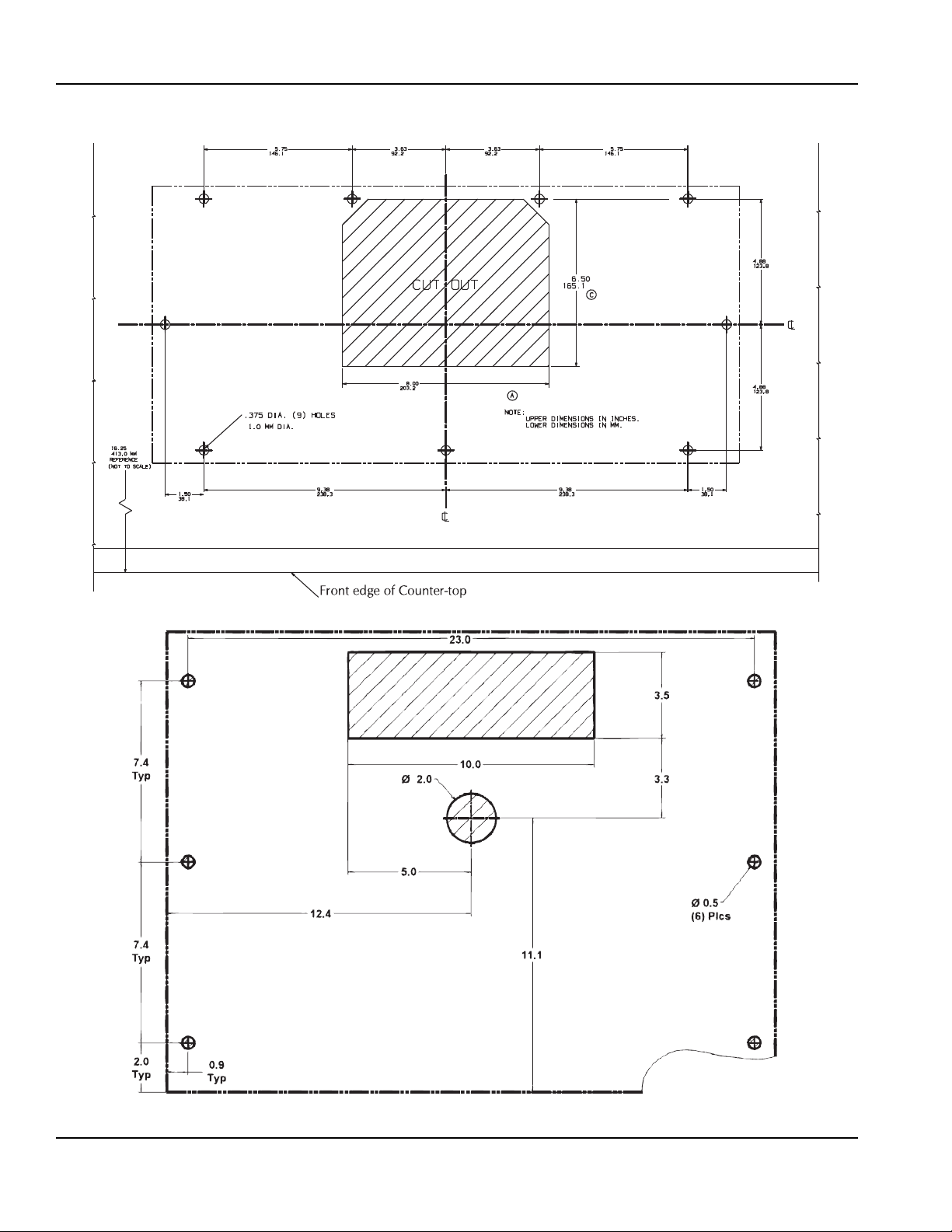

FOOTPRINTS - ALL MODELS

2-4

Part Number 020002777 10/11

Page 15

Section 2 Installation

MODEL 136

MODEL 138

Part Number 020002777 10/11 2-5

Page 16

Installation Section 2

MODEL 143

2-6

Part Number 020002777 10/11

Page 17

Section 2 Installation

MODEL 156 (LEFT HAND PASS-THRU)

MODEL 156 (RIGHT HAND PASS-THRU)

Part Number 020002777 10/11 2-7

Page 18

Installation Section 2

MODEL 158

2-8

Part Number 020002777 10/11

Page 19

Section 2 Installation

MODEL 1310

Part Number 020002777 10/11 2-9

Page 20

Installation Section 2

!

Warning

!

Warning

Safe Installation Dos and Don’ts

Read the following warnings before beginning an

installation. Failure to do so may result in possible

death or serious injury.

• DO adhere to all National and Local Plumbing and

Electrical Safety Codes.

• DO turn OFF incoming electrical service switches

when servicing, installing, or repairing equipment.

• DO check that all flare fittings are tight. This check

must be performed with a wrench to ensur e a quality

seal.

• DO inspect pressure on regulators before starting up

equipment.

• DO protect eyes when working around refrigerants.

• DO use caution when handling metal surface edges

of all equipment.

• DO handle CO

Secure cylinders properly against abrasion.

• DO store CO

• DO NOT exhaust CO

into an enclosed area, including all types of walk-in

coolers, cellars, and closets.

• DO NOT throw or drop a CO

cylinder(s) in an upright position with a chain.

• DO NOT connect the CO

product container. Doing so will result in an explosion

causing possible death or injury. It is best to connect

the CO

cylinder(s) to a regulator(s).

2

• DO NOT store CO

125°F (51.7°C) near furnaces, radiator or sources of

heat.

• DO NOT release CO

• DO NOT touch refrigeration lines inside units; some

may exceed temperatures of 200°F (9 3. 3° C) .

NOTICE: All utility connections and fixtures must be

sized, installed, and maintained in accordance with

Federal, State, and Local codes.

cylinders and gauges with care.

2

cylinder(s) in well ventilated areas.

2

gas (example: syrup pump)

2

cylinder. Secure the

2

cylinder(s) directly to the

2

cylinders in temperature above

2

gas from old cylinder.

2

Location Requirements

LOCATION OF THE DISPENSING TOWER

1. Determine the location where the Multiplex

Dispensing Tower will be installed.

2. Locate the mounting template provided with the

tower installation kit.

3. Using the mounting template as a guide, punch out

the required holes in the counter top.

RATINGS

NOTE: Refer to nameplate on side of unit for voltage

and amperage specifications. Optional equipment may

require additional power supplies.

Carbon Dioxide (CO2) displaces oxygen. Exposure

to a high concentration of CO

which are followed rapidly by loss of consciousness

and suffocation. If a CO

particularly in a small area, immediately ventilate the

area before repairing the leak. CO

must not be installed in an enclosed space. An

enclosed space can be a cooler or small room or

closet. This may include convenience stores with

glass door self serve coolers. If you suspect CO

may build up in an area, venting o f the BIB pumps

and/or CO

monitors must be utilized.

2

KITCHEN EQUIPMENT INSTALLER REPRESENTATIVE RESPONSIBILITIES

Prior to scheduling Multiplex Equipment installer,

the following steps listed below must be completed:

1. Usable floor sewer drain.

2. Refer to electrical requirement chart for your model.

3. Usable potable water.

4. CO

Gas (bulk or bottled supply); minimum 3/8" line.

2

5. One 5 gallon (19 L) container or Bag-In-Box

container of each post mix syrup flavor.

6. A 120 VAC, 3-wire, 1 Phase, 60 Hz dual wall

receptacle for optional electrical equipment

(domestic only).

NOTE: Do not schedule the authorized Multiplex

Equipment Installer until all of the above have been

completed. It will only result in charge-backs to you for

the unnecessary trips.

gas causes tremors,

2

gas leak is suspected,

2

lines and pumps

2

2

2-10

Part Number 020002777 10/11

Page 21

Section 2 Installation

Important

Important

!

Warning

REQUIREMENTS

• Conduit can be run through floor or ceiling chase.

• 60°F (15.6°C) minimum and 105°F (40.5°C)

maximum operating ambient conditions.

• For indoor installation only.

• Syrup supply can be located on stand or adjacent to

refrigeration unit.

Installer Instructions

The remainder of these instructions is to be

completed by an authorized Multiplex Installer.

These equipment instructions are intended to assist

qualified personnel in the unpacking, locating and the

initial operation of the Multiplex Beverage Equipment

and/or Post Mix Refrigeration Unit.

This publication must be saved for future reference.

Read instructions before attempting installation.

Electrical

GENERAL

All wiring must conform to local, state and national

codes.

MINIMUM CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select the

wire size of the electrical supply. (Minimum circuit

ampacity is not the beverage/ice machine’ s running amp

load.) The wire size (or gauge) is also dependent upon

location, materials used, length of run, etc., so it must be

determined by a qualified electrician.

ELECTRICAL REQUIREMENTS

Refer to Machine Model/Serial Plate for

voltage/amperage specifications.

ELECTRICAL SPECIFICATIONS

ALL TOWERS

PREPARATION

The Multiplex Beverage Equipment Soda Tower is preassembled in the factory and requires min im um

installation.

For future reference or to be used when ordering parts,

record the Model Number, Serial Number, Part Numbers

of Unit, Condenser (if remote), Towers, etc., and Date of

Installation on the inside of this Manual. Leave manual

on site in a safe place. Do not discard manual.

Ambient Location Requirement

This equipment is rated for indoor use only. It will not

operate in sub-freezing temperature. In a situation when

temperatures drop below freezing, the equipment must

be turned off immediately and properly winterized.

Contact the manufacturer for winterization process.

120 or 220VAC primary

24 VAC secondary

50/60Hz

MAKING THE ELECTRICAL CONNECTIONS

1. Locate the low voltage transformer and position it

below the tower in a shielded and protected area. Use

the screws provided to secure the transformer to the

cabinet.

2. Route the transformer cords up to the rear of the

dispensing tower and plug into the cords in the rear of

the tower.

3. Connect the transformer power supply cord to an

appropriate wall outlet. Do Not turn "on" the power

switch at this time.

Part Number 020002777 10/11 2-11

Page 22

Installation Section 2

!

Warning

!

Warning

!

Warning

GROUNDING INSTRUCTIONS

When using electric appliances, basic precautions

The beverage/ice machine must be grounded in

accordance with national and local electrical codes.

This appliance must be grounded. In the event of

malfunction or breakdown, grounding provides a path of

least resistance for electric current to reduce the risk of

electric shock. This appliance is equipped with a cord

having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into an

appropriate outlet that is properly inst alled and grounded

in accordance with all local codes and ordinances.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment grounding conductor. If repair or

replacement of the cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal. Check with a qualified electrician or

serviceman if the grounding instructions are not

completely understood, or if in doubt as to whether

the appliance is properly grounded. Do not modify

the plug provided with the appliance — if it will not fit

the outlet, have a proper outlet installed by a

qualified electrician.

must always be followed, including the following:

a. Read all the instructions before using the

appliance.

b. To reduce the risk of injury, close supervision is

necessary when an appliance is used near

children.

c. Do not contact moving parts.

d. Only use attachments recommended or sold by

the manufacturer.

e. Do not use outdoors.

f. For a cord-connected appliance, the following

shall be included:

• Do not unplug by pulling on cord. To unplug,

grasp the plug, not the cord.

• Unplug from outlet when not in use and

before servicing or cleaning.

• Do not operate any appliance with a

damaged cord or plug, or after the appliance

malfunctions or is dropped or damaged in any

manner. Contact the nearest authorized

service facility for examination, repair, or

electrical or mechanical adjustment.

g. For a permanently connected appliance — Turn

the power switch to the off position when the

appliance is not in use and before servicing or

cleaning.

h. For an appliance with a replaceable lamp —

Always unplug before replacing the lamp.

Replace the bulb with the same type.

2-12

i. For a grounded appliance — Connect to a

properly grounded outlet only. See Grounding

Instructions.

Part Number 020002777 10/11

Page 23

Section 2 Installation

FIGURE 1

Mounting The Dispensing Tower

SECURED BY BOLTING TO THE COUNTER

1. Locate the drain pan and mounting screws. Mount the

dispensing tower onto the counter.

2. Locate the rubber drain hose and clamp. Attach it to the

drain pan fitting.

3. Apply a bead of plumber's putty to the bottom of the tower.

4. Position the tower on the counter. Route the drain line,

electrical cord and product tubes through the opening in

the counter. Pull the tower backwards into position. V erify

that the drain pan is secure.

5. Remove the access panel. Locate the 1/4" 20 mounting

screws, flat washers, lock washers and nuts supplied in the

installation kit. Mount the tower via the slots inside the

tower.

SECURED WITH MOUNTING CLAMPS

View "A"

Dispensing Tower

Counter Top

Internal

Tooth

Washer

View "B"

Flat Counter

Dispensing

Tower

Counter Top

Internal

Tooth

Washer

1

/4"-20 Hex

Head

Screw

Angle

Bracket

1

/4"-20

Hex Head

Screw

Angle

Bracket

Pre-formed Counter-Top

1. Position the tower on the counter-top in it's final location.

2. Locate the rubber drain hose and clamp. Attach it to the

drain pan fitting.

3. Locate the angle mounting clamps, the 1/4"-20 x 1" Hex

Head screws, and the internal tooth washers supplied with

tower installation kit.

4. Secure the tower to the counter top with angle mounting

clamps, screws, and washers provided in kit. (see figure 1)

NOTE: If the tower is to be mounted to a flat counter top

as in Figure 1 View B, it will be necessary to seal the

edge of the tower to the counter top with R.T.V. sealant.

5. Route the beverage conduit up to the stainless steel Barb

Stem Adaptors at the base of the dispensing tower . If the

lines of the conduit are of different lengths, always connect

the shortest line first. Use two (2) tab clamps at every

connection.

Part Number 020002777 10/11 2-13

Page 24

Installation Section 2

Plumbing – General

CONNECTING THE SYRUP AND WATER LINES

Model 138CDA or 138CDAX

1. Locate the Barb-stem splicers and tab-clamps in the

installation kit.

NOTE: The Installation Kit provides syrup connections

for 1/2 or 3/8 ID conduits. The circulating carbonated

Water Lines are supplied with 1 /2 Barbs only. Determine

the conduit size prior to the attaching Barb systems.

2. Attach the 1/4" Barb of the 1/4" x 1/2" or 1/4" x 3/8"

Barb splicer to the Syrup Lines in the tower labeled

#1, #2, #4, #5, #6, #7, and #8. clamp in place with

tab clamp.

3. Attach the four (4) 1/2" x 1/2" Barb splicers to the

tower lines labeled "AF or AR" and "BF or BR".

Clamp in place with tab clamp (refer to "Note"

below).

4. Route the beverage conduit up to the tower. If the

lines of the conduit are different lengths, always

connect the shortest line first. Use two (2) tab

clamps per connection.

5. Using the plumbing diagram (located in this manual)

as a guide for steps 5 through 7 attach the tower

Syrup Lines labeled #1, #2, #3, #4, #5, #6, #7 and

#8 to the corresponding numbered or colored line of

the conduit. Clamp in place.

Model 136EDA, 136EDAX, 138EDA, or 138EDAX

1. Locate the Barb stem splicers and tab clamps in the

installation kit.

NOTE: The Installation Kit provides syrup connections for

1/2 or 3/8 ID conduits. The circulating carbonated W ater

lines are supplied with 1/2 Barbs only . Determine the conduit

size prior to the attaching Barb systems.

2. Attach the 1/4" Barb of the 1/4" x 1/2" or 1/4" x 3/8" Barb

splicer to the Syrup Lines in the tower labeled #1, #2,

#3, #4, #5, and #6. Clamp in place with tab clamp.

3. Attach the two (2) 1/2" x 1/2" Barb splicers to the tower

lines labeled "AF or AR". Clamp in place with tab clamp.

4. Route the beverage conduit up to the tower. If the lines

of the conduit are different lengths, always connect the

shortest line first. Use (2) tab clamp s per connection .

5. Using the Plumbing diagram (in this manual) as a guide

for steps 5 through 7, attach the tower Syrup Lines

labeled #1, #2, #3, #4, #5, and #6 to the corresponding

numbered or colored line of the conduit. Clamp in place.

6. Connect the plain water supply to the line labeled "WF

or WR". Clamp with tab clamp.

7. Attach the Carbonated Water Line to the line labeled

"AF or AR". Clamp in place

6. Connect the plain water supply to the line labeled

"WF or WR". clamp with tab clamp.

7. Attach the Carbonated Water Line to the line labeled

"AF or AR" and "BF or BR". Clamp in place.

NOTE: If a Single Circuit is used, run "AF or AR" In and

"AF or AR" Out to "BF or BR" In. Route "BF or BR" back

to conduit.

2-14

Part Number 020002777 10/11

Page 25

Section 2 Installation

Model 136FDA, 136FDAX, 138FDA, or 138FDAX

1. Locate the Barb stem splicers and tab clamps in the

installation kit.

NOTE: The Installation Kit provides syrup connections

for 1/2 or 3/8 ID conduits. The circulating carbonat ed

Water lines are supplied with 1/2 Barbs only. Determine

the conduit size prior to the attaching Barb systems.

2. Attach the 1/4" Barb of the 1/4" x 1/2" or 1/4" x 3/8"

Barb splicer to the Syrup Lines in the tower labeled

#1, #2, #3, #4, #5, and #6. Clamp in place with tab

clamp.

3. Attach the two (2) 1/2" x 1/2" Barb splicers to the

tower lines labeled "AF or AR". Clamp in place with

tab clamp.

4. Route the beverage conduit up to the tower. If the

lines of the conduit are different lengths, always

connect the shortest line first. Use (2) tab clamps

per connection.

5. Using the Plumbing diagram (in this manual) as a

guide for steps 5 through 7, attach the tower Syrup

Lines labeled #1, #2, #3, #4, #5, and #6 to the

corresponding numbered or colored line of the

conduit. Clamp in place.

6. Connect the plain water supply to the line labeled

"WF or WR". Clamp in place.

7. Attach the Carbonated Water Line to the line labeled

"AF or AR". Clamp in place Water Supply

Model 136LDA, 136LDAX, 138LDA, or 138LDAX

1. Locate the Barb-stem splicers and tab-clamp s in the

installation kit.

NOTE: The Installation Kit provides syrup connections

for 1/2 or 3/8 ID conduits. The circulating carbonate d

Water Lines are supplied with 1/2 Barbs only. Determine

the conduit size prior to the attaching Barb systems.

2. Attach the 1/4" Barb of the 1/4" x 1/2" or 1/4" x 3/8"

Barb splicer to the Syrup Lines in the tower labeled

#1, #2, #4, #5, #6, #7, and #8. clamp in place with

tab clamp.

3. Attach the four (4) 1/2" x 1/2" Barb splicers to the

tower lines labeled "AF or AR" and "BF or BR".

Clamp in place with tab clamp (refer to "Note"

below).

4. Route the beverage conduit up to the tower. If the

lines of the conduit are different lengths, always

connect the shortest line first. Use two (2) tab

clamps per connection.

5. Using the plumbing diagram (located in this manual)

as a guide for steps 5 through 7 attach the tower

Syrup Lines labeled #1, #2, #3, #4, #5, #6, #7 and

#8 to the corresponding numbered or colore d line of

the conduit. Clamp in place.

6. Connect the plain water supply to the line labeled

"WF or WR". clamp with tab clamp.

7. Attach the Carbonated Water Line to the line labeled

"AF or AR" and "BF or BR". Clamp in place.

NOTE: If a Single Circuit is used, run "AF or AR" In and

"AF or AR" Out to "BF or BR" In. Route "BF or BR" back

to conduit.

Part Number 020002777 10/11 2-15

Page 26

Installation Section 2

Model 138EDA2

1. Locate the Barb-stem splicers and tab-clamps in the

installation kit.

NOTE: The Installation Kit provides syrup connections

for 1/2 or 3/8 ID conduits. The circulating carbonated

Water Lines are supplied with 1 /2 Barbs only. Determine

the conduit size prior to the attaching Barb systems.

2. Attach the 1/4" Barb of the 1/4" x 1/2" or 1/4" x 3/8"

Barb splicer to the Syrup Lines in the tower labeled

#1, #2, #4, #5, #6, #7, and #8. clamp in place with

tab clamp.

3. Attach the four (4) 1/2" x 1/2" Barb splicers to the

tower lines labeled "AF or AR" and "BF or BR".

Clamp in place with tab clamp (refer to "Note"

below).

4. Route the beverage conduit up to the tower. If the

lines of the conduit are different lengths, always

connect the shortest line first. Use two (2) tab

clamps per connection.

5. Using the plumbing diagram (located in this manual)

as a guide for steps 5 through 7 attach the tower

Syrup Lines labeled #1, #2, #3, #4, #5, #6, #7 and

#8 to the corresponding numbered or colored line of

the conduit. Clamp in place.

Model 115, & 116

1. Locate the Barb-stem splicers and tab-clamps in th e

installation kit.

NOTE: The Installation Kit provides syrup connections

for 1/2 or 3/8 ID conduits. The circulating carbonate d

Water Lines are supplied with 1/2 Barbs only. Determine

the conduit size prior to the attaching Barb systems.

2. Attach Barb splicer to the syrup lines labeled #1, #2,

#3, #4, and #5 ("6" and "W" if it is a six (6) valve

tower). Clamp in place with ta clamps. Attach the

two (2) 1/2 x 1/2 Barb splicers to the lines labeled #7

Carbonated Water and #8 Carbonated Water then

clamp in place.

3. Attach the syrup lines labeled #1, #2, #3, #4, #5, and

#6 (for six (6) valve towers application only) to the

corresponding numbered or colored lines of the

conduit. Clamp in place using two (2) clamps each.

4. Connect the plain water line (labeled "W") to the

plain water supply and clamp in place (for six (6)

valve tower application only).

5. Attach the Carbonated Water line to the line labeled

#7 Carbonated Water and #8 Carbonated Water,

then clamp in place.

6. Connect the plain water supply to the line labeled

"WF or WR". clamp with tab clamp.

7. Attach the Carbonated Water Line to the line labeled

"AF or AR" and "BF or BR". Clamp in place.

NOTE: If a Single Circuit is used, run "AF or AR" In and

"AF or AR" Out to "BF or BR" In. Route "BF or BR" back

to conduit.

2-16

Part Number 020002777 10/11

Page 27

Section 2 Installation

Model 156, 158, & 1510

1. Route the Beverage Cond uit up to the stainless

steel Barb St em Adaptors at the base of the tower. If

the lines of the conduit are of different lengths,

always connect the shortest line first. Use two (2)

tab clamps at every connection.

NOTE: The Model 158 and 1510 Pass-Thru towers have

two (2) internal Carbonated Water Circuits. Use the

Carbonated Water lines #8, and #9 to connect to the

lines labeled "xF or xR" and "A". Connect the

Carbonated Water Lines labeled #7 an d #10 to th e line s

labeled "xF or xR" and "B". If the refrigeration unit has

only one (1) Carbonated Water Circuit, these lines must

be connected together.

2. Attach the syrup lines labeled "1" through "6", "1"

through "8", or "1" through "10" to the corresponding

numbered Barb fittings of the tower. Use two (2) tab

clamps per connection.

3. Attach the Non-carbonated Water Line (labeled "W")

of the beverage conduit to the Barb Stem of the

tower labeled "W". Use two (2) tab clamps.

Model 126LDP

1. Route the beverage conduit up to the base of the

tower. If the lines of the conduit are different lengths,

always connect the shortest line first. Use two (2)

Tab Clamps at every connection.

NOTE: The Multiplex Model 126 Front Draw Dispensing

Tower has only one internal carbonated water circuit.

2. Attach the six (6) Syrup Lines labeled 1, 2, 3, 4, 5,

and 6 to the corresponding numbered Barb Fittings

of the tower . Use two (2) t ab clamp s per co nnection.

If conduit has non-numbered colored tubing, use the

"Conduit Number to Color Reference Chart" listed in

these instructions.

3. Attach the Plain Water line (labeled "W") of the

beverage conduit to the Barb System of the tower

labeled "W". Use two (2) tab clamps. If six (6)

Carbonated Water Valves are required, use 1/4" tee

provided to connect the carbonated line to "W" line.

Part Number 020002777 10/11 2-17

Page 28

Installation Section 2

Model 1310

1. Locate the Barb stem splicers and tab clamps in the

install kit.

NOTE: The Installation Kit provides syrup connections

for the 1/2 or 3/8 ID conduit. The circulating carbonated

water lines are supplied with 1/2 barbs only. Determine

the conduit size prior to the attaching barb systems.

2. Attach barb splicer to the syrup lines labeled #1, #2,

#3, #4, #5, #6, #7, #8, #9 and #10 and clamp in

place. Attach two (2) 1/2 x 1/2 barb splicers to the

lines labeled #7 Carbonated Water and #8

Carbonated Water and clamp in place. Attach one

(1) 1/2 x 1/2 barb splicer to the line labeled "W" and

clamp in place.

3. Attach the syrup lines labeled #1, #2, #3, #4, #5, #6,

#7, #8, #9 and #10 to the corresponding number or

color lines of the conduit. Clamp in place.

4. Connect the plain water line labeled "W" to the plain

water supply and clamp in place.

5. Attach the Carbonated water line to the line labeled

#7 Carbonated Water and #8 Carbonated Water,

then clamp in place.

Model 143

1. Route the beverage conduit up to the stainless steel

barb stem adaptors at the base of the dispensing

tower. If the line s of the conduit are dif ferent lengths,

always connect the shortest line first. Use two (2)

tab clamps at every connection.

2. Attach the three (3) syrup lines labeled #1, #2, and

#3 to the corresponding numbered barb fittings of

the dispensing tower. Use two (2) tab clamps per

connection.

3. Attach the Carbonated Water line labeled "xF or xR"

of the beverage conduit to the barb stem of the

tower labeled "xF or xR". Use two (2) tab clamps.

How to Insulate all the Connections

NOTE: Make sure all exposed Carbonated Water, Plain

Water, and Syrup Lines are well insulated.

1. To insulate use conduit sections, aluminum foil and

tape.

2. Cut the conduit sections to fit snugly over the

exposed lines and fittings.

3. After all the lines are properly insulated, wrap tightly

with tape to assure air tightness. This will prevent

condensation from forming on the lines and prevent

dripping.

2-18

Part Number 020002777 10/11

Page 29

Section 3

Important

Portion Control Keyboard Layout

Six (6) Valve Tower Keyboard

Eight (8) Valve Tower Keyboard

FIGURE 2

Operation

Calibration of the Dispensing Valves

SET THE FLOW (WATER FLOW RATE ONLY)

For Electronic Volumetric Valves use OEM valve

manual (skip this section).

Check that the Primary CO

or Bulk CO

Pressure Regulator for sugar-based syrup must be

adjusted to 60 psi (4 bar). The Low Pressure Regulator for

sugar-free syrup must be adjusted to 14-16 psi (0.9-

1.1 bar).

1. Turn “off” the syrup at the dispensing valve by

2. Check the Water Shut-off (if applicable). It should be

NOTE: The Syrup and Water Shut-off (if equipped) are

not to be used as an alternate for flow controls. They are

to be used only for shutting “on” or “off” the syrup and/or

the water supply.

2 Regulator is adjusted properly. The Medium

turning the Syrup Shut-off (located on the valve

mounting block). If there is no syrup shut-off, use a

Syrup Separator.

in the full “open” position.

2 Tank High Pressure Regulator

3. Place a Volume Cup with 10 oz (295.7 ml)

measurement line, under valve to be adjusted. If

using Syrup Separator, place Volume Cup under

water side of separator only.

4. To adjust the water flow rate (if necessary), turn the

adjusting screw clockwise to increase. Turn the

adjusting screw counterclockwise to decrease the

flow of water.

A. Press CAL pad three (3) times in less than 3

seconds to enter Calibrate Mode. Calibrate lamp

will light. (Omit this step if already in Calibration

Mode).

B. Press STOP-FILL pad of valve to adjusted once

to cause 4 second pour into V olume Cup.

5. Repeat 4 second dispense (STOP-FILL pad) and

water flow adjustment until volume is correct.

6. Open Syrup Shut-off or remove Syrup Separator (if

applicable).

7. Repeat this procedure (steps 1 through 6 above) for

each valve.

8. Press CAL button once to exit Calibrate Mode.

Calibrate lamp will go “off”.

Part Number 020002777 10/11 3-1

Page 30

Operation Section 3

SET THE RATIO (WATER T O SYRUP MIXTURE)

1. Remove valve nozzle by turning the nozzle and pulling

down.

2. Place Syrup Separator on valve to be adjusted. Actuate

the valve manually (pad, lever) until both syrup and water

flow out of the syrup/water separator .

3. Position the proper ratio cup under the Syrup Separator .

Manually Actuate the valve pad or lever valve (pad,

lever). Dispense until at least 3/4 of the ratio cup is filled.

Both products should fill to the same level.

4. T o adjust the syrup flow (if levels are not equal), turn the

syrup flow control adjusting screw clockwise to increase.

Turn the syrup flow control adjusting screw

counterclockwise to decrease the flow of syrup.

NOTE: Do not adjust the water flow during this procedure.

5. After syrup is adjusted, remove the Syrup Separator and

replace the valve nozzle.

6. Repeat this procedure (steps 1 through 5 above) for the

remaining valves.

For Special Dual Flavor Dispensing V alves

NOTE: The Syrup Separator is not used on second flavor.

1. Make sure first flavor (keypad and LED to left) is selected

when testing Ratio as above.

2. Make sure second flavor (keypad and LED to right) is

selected when testing Ratio as follows. Leave original

nozzle on.

3. Rotate proper Ratio Cup 90o so it catches the second

flavor syrup from tube just back of nozzle on bottom of

valve.

4. Dispense until at least 3/4 of the ratio cup is filled. Both

products should fill to the same level.

5. Adjust Syrup flow as necessary as stated above (step 4

under "Hot to set the Ratio (water to syrup mixture)".

SET THE VOLUME (DRINK PORTION SIZES)

1. T o enter the Portion Control Calibrate Mode, press CAL

pad three (3) times in less than 3 seconds. The calibrate

lamp will illuminate.

2. Use Volume Cup with finished drink marking lines, or use

correct size sample cup with desired volume of ice.

3. Press and hold respective SIZE pad until product gets

close to proper finished drink mark, or until close to top of

sample cup.

4. Release SIZE pad before reaching final mark or before

foam exceeds final mark. Press SIZE pad again

momentarily , as many times as is necessary (letting foam

settle), to get to the correct finished drink mark.

5. Repeat steps 2 through 4 above for all sizes and all

stations (products) needing calibration. Be sure to use the

correct Volume Cup finished drink marking line, or correct

sample cup size and ice amount, for each size pad.

NOTE: If you fill above the final mark or need to "start over" for

any reason, you must exit the Calibrate Mode and then reenter the Calibrate Mode to resume.

6. Exit Calibrate Mode by pressing CAL pad once. Calibrate

light will go out. All changes will be permanently saved.

RUN MODE

Size Buttons

Press any size button (0, 1, 2, 3, or 4) on any station to

dispense product for that station for pre-programmed time for

that respective size.

STOP-FILL Buttons

If no dispense is in progress, press any STOP-FILL button to

manually dispense from the station. If portion dispense is in

progress, press the STOP-FILL button to manually cancel.

Portion Control Water/Soda dispensing

Press either the WATER or the SODA b utton momentarily.

Now press any size button on the respective station (within

2 seconds maximum). Portion dispense will continue

automatically for that size only .

Optional Dual Flavor Keyboard

NOTE: Station No. 2 and No. 4 have Dual Flavors.

1. Press the flavor button and its associated LED will come

“on”.

2. Press any size button to dispense this flavor and size. If the

required flavor button LED is already “on”, press the size

button desired.

NOTE: The left LED flavor is the default on both stations.

3-2

Part Number 020002777 10/11

Page 31

Section 3 Operation

Program modes

PROGRAM MODE CAL NO. 1 (TOTAL VOLUME)

To enter the Calibrate No. 1 mode, simultaneously press

the CAL button and the Size 1 button (1) on any station.

You may also press the CAL button three times within

three seconds. The CAL light will come “on” constantly.

Volume Sizing

NOTE: Use a Calibration Cup (or an appropriate size

cup with the proper amount of ice).

1. Press the respective size button for that cup (0, 1, 2,

3, or 4) at that station.

2. Fill the cup with product to the correct level.

NOTE: This same size button may be started and

stopped as many times as desired to acquire the correct

level while letting the drink settle. All times for the same

station and size are additive in the program session.

3. Repeat volume sizing procedure for all sizes and

stations needing programming.

Flow Rate Calibration

In the Calibrate No. 1 Mode, press any STOP-FILL

button one (1) time. That respective valve will flow for

exactly 4 seconds allowing for checking or adjusting the

valve flow rate.

One Station Sets All

Immediately after entering the Calibrate No. 1 Mode,

press any STOP-FILL button two (2) times in less than

1 second. The CAL light will flash constantly, 2 ti mes per

second. Now all volumes on that station programmed in

this session, will copy to all other stations when exiting.

Exiting the Program Mode, CAL No. 1

To exit, press the CAL button one (1) time turning “off”

the CAL light. All volume changes made during this

session will be permanently stored.

PROGRAM MODE CAL NO. 2 (INCREMENTAL)

To enter Calibrate No. 2 Mode, simult aneously press the

CAL button and the Size 2 button (2) on any station. The

CAL light will flash constantly, one (1) time per second.

Volume incrementing/decrementing

1. Press the size button (0, 1, 2, 3, or 4) on the specific

station that needs a small increment of time

adjustment. The CAL light will come “on” constantly

indicating this size/station time is selected.

2. To increase time, press the Size 4 button () at this

time. Each press of the Size 4 button () will increase

total selected size stored time by 0.1 seconds. The

CAL light will go “off” every time button is pressed.

Example: 10 presses = 1 second.

3. To decrease time, press the Size 1 button () at this

time. Each press of the Size 1 button () will decrease

total selected size stored time by 0.1 seconds. The

CAL light will go “off” every time button is pressed.

4. Press STOP-FILL button on this station to

temporarily save new time for this size this station.

The CAL light will resume flashing.

5. Repeat procedure 1 through 5 for any other size or

station needing incremental time programming

Exiting the Program Mode, CAL No. 2

To exit, press the CAL button one (1) time turning “off”

the flashing CAL light. All incremental volume changes

made during this session will be permanently stored.

PROGRAM MODE CAL NO. 3 (WATER/SODA)

NOTE: This is set at the factory to station number 2

(water) and 4 (soda). This may have to be reset in the

field if someone inadvertently changes location, or if the

location must change stations.

T o enter water/soda programming mode, simultaneously

press the CAL button and SIZE 3 button () on any station

(refer to figure above). The CAL light will come “on”

constantly.

1. Before changing the water/soda pour stations, you

must make sure the correct WATER and SODA

solenoids (from the stations to be programmed ) ar e

wired correctly to J9 and J10 respectively.

2. Pressing SIZE 1 button on any station, will set the

special WA TER solenoid driver J10 to come ON with

all dispenses of THIS station, as well as the W ATER

button dispensing water from this station.

An automatic 2 second pour of water solenoid from this

station will occur, to verify setting.

3. Pressing SIZE 4 button on any specific station, will

set the special SODA solenoid driver J9 to come ON

with all dispenses of this station, as well as the

SODA button dispensing soda water from this

station.

An automatic 2 second pour of water solenoid from this

station will occur, to verify setting.

Exiting the programming mode, CAL No. 3.

To exit, press the CAL button one (1) time turning “off”

the CAL light. All water/soda changes made during this

session will be permanently stored.

Part Number 020002777 10/11 3-3

Page 32

Operation Section 3

TOP-OFF PROGRAM MODE

Top-Off Program Mode

To enter the top-off program mode, simultaneously

press CAL button and the Size 4 button () on any station.

You may also press the CAL button five times within

three seconds. The CAL light will flash five (5) times and

then remain “on”.

Enabling / Disabling the individual station Top-off

Enabling the individual station top-off allows every size

dispensed on this station to pour all the volume

programmed in two (2) pours with a 3 second delay

between pours. Disabling the individual station top-off

allows every size dispensed on this station to pour all the

volume programmed in one pour.

1. Press the STOP-FILL button on the station desired

to change the top-off mode.

2. The CAL light will immediately flash five (5) times to

indicate the top-off mode has been toggled. If the

respective station was disabled for top-off, then it will

toggle to enable for top-off. If the respective station

was enabled for top-off, then it will toggle to disable

for top-off.

Exiting the Top-off Program Mode

To exit the Top-off Program Mode, press the CAL button

one (1) time turning “off” the CAL light. All station top-off

mode changes made during this session will be

permanently stored.

TEST AND SANITATION MODE

1. With the power “off”, press the CAL button and turn

power “on” simultaneously.

2. Release the CAL button. The portion control board

will sequence each station for 4 seconds starting

with the left most (station No. 1).

3. Check that each LED on the Portion Control board

comes “on” sequentially and all valve solenoids

come “on”.

NOTE: If the drain can support more than one (1) valve

pouring at a time, press the STOP-FILL button on the

station number for the number of valves flowing

simultaneously.

Example: At station number 3, press the STOP-FILL

button. Three (3) valves will flow simultaneously.

NOTE: If the LED light does not come “on” for any

station(s), the Portion Control board is bad. If the LED

light comes “on” but the valve does not come “on”, check

wiring and valve solenoids.

INSTRUCTIONS FOR DUAL FLAVOR STATIONS

NOTE: Station No. 2 and 4 have Dual Flavors

1. Press the flavor and it's associated LED will come

"on"

2. Press any size button to dispense this flavor and

size. If the required flavor button LED is already

"on", press the size button desired.

NOTE: The left LED flavor is the default on both stations.

ENTERING WATER/SODA PROGRAMMING MODE

To enter wate r/soda programming mode, press and hold

the CAL button SIZE 3 buttons. The CAL light will come

ON instantly.

Pressing SIZE 1 button on any station, will set the

special WATER solenoid driver J10 to come ON with all

dispenses of THIS station, as well as water button

dispensing from this station. An automatic 2 second pour

of water from this station will occur, to verify setting.

Pressing SIZE 4 button on any specific station, will set

the special SODA solenoid driver J9 to come on. An

automatic 2 second pour of water from this station will

occur to verify setting.

Y ou must also make sure the correct WATER and SODA

solenoids (from the stations you just programmed) are

wired correctly to J9 and J10 respectively.

Equipment Setup and Close Procedure

EQUIPMENT SETUP PROCEDURE

1. Ensure that all valve nozzles are attached to the valves.

2. Observe pressure of CO

(34 bar) or more, or bulk CO

Primary regulator set at 90 psi (6 bar) and the secondary

regulator set at 35 psi (2.4 bar).

3. Observe the control panel to verify that all pressure

gauges are set at correct operating pressures.

4. Check the syrup tanks to make sure a sufficient number

of tanks are connected in series to satisfy business

volume.

5. Clean syrup inlet and outlet quick disconnects at the

same time tanks are replaced. Rinse disconnects in clean

potable water .

EQUIPMENT CLOSE PROCEDURE

1. Clean the underside of the dispensing tower around the

nozzle area with a clean damp towel.

2. Pour at least 60 oz (1.8 liters) of warm water down the

drain openings.

high pressure tank of 500 psi

2

tank of 150 psi or more.

2

3-4

Part Number 020002777 10/11

Page 33

Section 4

Maintenance

Maintenance Schedule

This section provides a list of periodic maintenance

tasks and the scheduled frequency required to ensu re

the proper operation of your Multiplex dispensing

equipment. To ensure quality beverages, prevent

downtime, and reduce costs, these tasks must be

performed as indicated.

PERIODIC MAINTENANCE LISTED BY MAJOR COMPONENTS

Dispensing stations

Daily (365 times per year)

• Take temperature of finished drinks. Pour off the first

and take the temperature of the second drink. The

proper temperature of drinks must be 40°F (4°C) or

less.

• Remove nozzles and diffusers from each dispensing

valve. Clean with soap and warm water (not hot).

Rinse with carbonated water and reinstall.

• Flush all dispenser drains. Pour hot water down

drains at closing.

Beverage conduits

Every 4 months (3 times per year)

• Inspect beverage conduits for damage. Re-insulate

and seal any un-insulated areas.

• Inspect floor chases and seal any open chase ends.

Air compressor

Monthly (12 times per year)

• Drain condensate water from air compressor tank.

Every 4 months (3 times per year)

• Inspect air compressor filter and replace if clogged.

Air filter must be replaced every 6 months.

• Inspect air compressor to verify cut-in at 70 psi (4.8

bar) and cut-out at 90 psi (6.3 bar). Adjust pressure

switch if necessary.

• Inspect system for air leaks and repair as required.

Refrigeration unit

Every 4 months (3 times per year)

• • Clean the refrigeration unit air-cooled condenser

using a vacuum cleaner. If equipped with watercooled condenser, verify the water discharge

temperature is at 105°F (41°C). Adjust water

modulating valve if necessary.

• Inspect water bath to verify water level is at the top of

stand pipe. If below, add water and repair water

makeup device. If excessive amount of water is

flowing over stand pipe, locate leak within bath and

repair.

• Inspect ice bank within the water bath to verify proper

size ice bank and clarity. Look for uniform, 2" to 4"

thick ice bank.

• Drain, clean, and refill water bath.

• Inspect agitator motor and ensure proper operation.

• Inspect the circulating motor/pump assembly. Clean

strainer and oil motor.

• Inspect the carbonating motor/pump assembly.

Clean strainer and oil motor.

• Inspect entire system for leaks and repair as

required.

Water filters

Every 4 months (3 times per year)

• Verify that incom ing water pressure is not less than

40 psi (2.8 bar) or greater than 60 psi (4.1 bar). If

equipped with a water regulator , verify proper setting

of 55 psi (3.8 bar). Adjust if necessary.

• If pressure is low, inspect water filter cartridges to

ensure they are able to supply adequate water

pressure under normal system flow. Replace if

unable to provide minimum 20 psi (1.4 bar) under

load.

Syrup supply

Daily (365 times per year)

• Clean general area of syrup hookup with soap and

warm water. Rinse off all soap.

Every 4 months (3 times per year)

• Inspect syrup lines for proper flavor identification

labels. Replace labels if necessary .

• Disconnect syrup containers. Clean connector with

soap and warm water. Rinse with plain water and

reconnect to syrup containers.

CO

2 gas supply

Every 4 months (3 times per year)

• Inspect pressure setting at CO

regulator. Verify proper 90 psi (6.3 bar) pressure

setting. Adjust if necessary.

2 high pressure

Part Number 020002777 10/11 4-1

Page 34

Maintenance Section 4

• Inspect pressure setting at syrup pressure regulators.

Verify propter pressure setting. Adjust if necessary.

• Inspect system for CO

2 leaks, repair as required.

PERIODIC MAINTENANCE LISTED BY SCHEDULED FREQUENCY

Daily (365 times per year)

• T ake temperature of finishe d drinks. Pour off the fir st and

take the temperature of the second drink. The prope r

temperature of drinks must be 40°F (4°C) or less.

• Remove nozzles and diffusers from each dispensing

valve. Clean with soap and warm water (not hot).

Rinse with carbonated water and reinstall.

• Flush all dispenser drains. Pour hot water down

drains at closing.

• Clean general area of syrup hookup with soap and

warm water. Rinse off all soap.

Every 4 months (3 times per year)

• Using Brix cup and syrup separator , check for proper

carbonated water flows (standard flow: 5 oz. in 4

seconds, fast flow: 10 oz. in 4 seconds) and syrup to

water ratios at each dispensing station. Adjust as

required.

• Inspect beverage conduits for damage. Re-insulate

and seal any un-insulated areas.

• Inspect floor chases and seal any open chase ends.

• Inspect air compressor filter and replace if clogged.

Air filter must be replaced every 6 months.

• Inspect the circulating motor/pump assembly. Clean

strainer and oil motor.

• Inspect the carbonating motor/pump assembly.

Clean strainer and oil motor.

• Inspect entire system for leaks and repair as

required.

• Verify that incom ing water pressure is not less than

40 psi (2.8 bar) or greater than 60 psi (4.1 bar). If

equipped with a water regulator , verify proper setting

of 55 psi (3.8 bar). Adjust if necessary. If pressure is

low, inspect water filter cartridges to ensure they are

able to supply adequate water pressure under

normal system flow. Replace if unable to provide

minimum 20 psi (1.4 bar) under load.

• Inspect syrup lines for proper flavor identification

labels. Replace labels if necessary.

• Disconnect syrup containers. Clean connector with

soap and warm water. Rinse with plain water and

reconnect to syrup containers.

• Inspect pressure setting at CO

2 high pressure

regulator. Verify proper 90 psi (6.3 bar) pressure

setting. Adjust if necessary.

• Inspect pressure setting at syrup pressure

regulators. Ver ify propter pressure setting. Adjust if

necessary.

• Inspect system for CO

2 leaks. Repair as required.

• Inspect air compressor to verify cut-in at 70 psi (4.8

bar) and cut-out at 90 psi (6.3 bar). Adjust pressure

switch if necessary.

• Inspect system for air leaks and repair as required.

• Clean the refrigeration unit air-cooled condenser

using a vacuum cleaner. If equipped with watercooled condenser, verify the water discharge

temperature is at 105°F (41°C). Adjust water

modulating valve if necessary.

• Inspect water bath to verify water level is at the top of

stand pipe. If below, add water and repair water

makeup device. If excessive amount of water is

flowing over stand pipe, locate leak within bath and

repair.

• Inspect ice bank within the water bath to verify proper

size ice bank and clarity. Look for uniform, 2" to 4"

thick ice bank.

• Drain, clean, and refill water bath.

• Inspect agitator motor and ensure proper operation.

4-2

Part Number 020002777 10/11

Page 35

Section 4 Maintenance

CLEANING & SANITIZING THE DISPENSING VALVES AND PRODUCT LINES

Maintenance Schedule

Every day

Dispensing

valves

Drip pan and

drain hose

Quick

disconnects

Weekly

Outside,

dispenser

cabinet

Every 3 months

Syrup

circuits

Water bath Drain, melt ice and clean using

Every 6 months

Condenser Vacuum fins or use soft bristle brush

Air purifier

filter (if

equipped)

Remove nozzles and diffusers and

soak in mild detergent cleaning

solution. Scrub parts with small bristle

brush taking care to clean small

crevices and O-ring grooves. Turn

OFF power to dispensing valves.

Scrub exterior surfaces, including

bottom splash area and actuator

lever, with cleaning solution.

Reassemble diffusers and nozzles.

Wipe dry exterior surfaces before

turning ON power.

Wash with mild detergent. Rinse with

clean water.

Wash with mild detergent. Rinse with

potable water.

Wash with clean water and mild

detergent. Wipe dry.

Sanitize each syrup circuit. See

“Maintenance”.

detergent and brush; rinse with

potable water. Do not use water over

140°F (60°C).

(scrub brush).

Replace.

Cleaning Equipment and Supplies

• Recommended cleaner: Any caustic-base (low sudsing,

non-perfumed, easily rinsed) detergent solution which

provides a minimum 2% sodium hydroxide. The solution

must be prepared in accordance with the manufacturer’s

instructions. Solution temperature must be between 90°F

(32°C) and 110°F (43°C). Temperatures in excess of this

can cause internal damage to the dispensing valve

components.

• Recommended sanitizer: Any sanitizer which provides a

minimum of 120 parts per million (120 milligrams per liter)

of available chlorine. Solution temperature must be

between 90°F (32°C) and 110°F (43°C). Temperatures in

excess of this can cause internal damage to the dispensing

valve components.

• Two five gallon (figals) syrup tanks and fittings, cleaned

and sanitized (one for cleaner; one for sanitizer)

• Containers for cleaner and sanitizer solutions

• Clean, non-abrasive cloths

• Buckets

• Small Brush

• Extra Nozzles

• Extra Jumpers

Part Number 020002777 10/11 4-3

Page 36

Maintenance Section 4

!

Warning

!

Warning

Bag

side

connector

Sanitizing

BEVERAGE SYSTEM CLEANING

Flush sanitizing solution from syrup system.

Residual sanitizing solution left in system could

create a health hazard.

2. Disconnect the “syrup-line side” of the BIB

When using cleaning fluids or chemicals, rubber

gloves and eye protection must be worn .

Sanitize the beverage system at initial start-up as well as

regularly scheduled cleaning. The drain pan must be in

place under soda valves, to carry away detergent and

sanitizing agents that will be flushed through valves.

BAG-IN-BOX SYSTEM SANITATION

connector.

The procedure below is for the sanitation of one

syrup circuit at a time. Repeat to sanitize additional

circuits.

You will need the following items to clean and sanitize

the Bag-in-Box (BIB) beverage system:

• Three (3) clean buckets

• Plastic brush or soft cloth

• Mild detergent

• Unscented bleach (5% Na CL O) or

Commercial sanitizer

• Bag-In-Box bag connector

1. Prepare the following in the buckets:

• Bucket 1 — warm to hot tap water for rinsing.

• Bucket 2 — mild detergent and warm to hot

water.

• Bucket 3 — mix a solution of unscented bleach

(5% Na CL O) or commercial sanitizer and warm to

hot water. Mixture should supply 100 PPM

available chlorine (1/4 oz. bleach to 1 gallon water).

3. Rinse connector with warm tap water.

4. Connect syrup connector to BIB connector and

immerse both into Bucket 1. A “bag-side” connector

can be created by cutting the connector from an

empty disposable syrup bag.

4-4

Part Number 020002777 10/11

Page 37

Section 4 Maintenance

5. Draw rinse water through system until clean water is

dispensed. Most beverage valves allow the syrup

side to be manually activated by depressing the

syrup pallet.

6. Connect Bucket 2 to system.

7. Draw detergent solution through system until

solution is dispensed.

8. Repeat steps 2-7 until all syrup circuits contain

detergent solution.

9. Allow detergent solution to remain in the system for

5 minutes.

10. Connect Bucket 3 to system.

11. Draw sanitizing solution through system until

solution is dispensed.

12. Repeat step 11 until all syrup circuits contain

sanitizer solution.

13. Allow sanitizer solution to remain in system for 15

minutes.

14. Remove nozzles and diffusers from beverage

valves.

15. Scrub nozzles, diffusers and all removable valve

parts (except electrical parts) with a plastic brush or

a soft cloth and the detergent solution.

16. Soak nozzles, diffusers and removable valve parts

(except electrical parts) in sanitizer for 15 minutes.

17. Replace nozzles, diffusers and valve parts.

18. Connect Bucket 1 to system.

19. Draw rinse water through system until no presence

of sanitizer is detected.

20. Attach syrup connectors to BIBs.

21. Draw syrup through system until only syrup is

dispensed.

22. Discard first 2 drinks.

FIGAL BEVERAGE SYSTEM

1. Prepare the following in three clean Figal tanks:

• Rinse tank - fill with room temperature tap water.

• Detergent tank - mix approved beverage system

cleaner with warm water as directed.

• Sanitizing tank - mix a solution of unscented

bleach (5% Na CL O) or commercial sanitizer and

warm to hot water. Mixture should supply 100 PPM

available chlorine (1/4 oz. bleach to 1 gallon water).

2. Disconnect all product and water lines from product

tanks and remove carbonator.

3. Locate the Figal syrup tank for the circuit to be

sanitized. Remove both quick disconnects from the

Figal syrup tank. Rinse quick disconnects in tap water.

4. Connect rinse tank to the syrup line. Draw clean rinse

water through the valve until syrup is flushed from the

system.

5. Connect detergent tank to the syrup line and draw

detergent through the valve for two minutes. Then,

allow remaining detergent to stay in the system for

five minutes.

6. Connect rinse tank to the syrup line. Draw clean rinse

water through the valve until detergent is flushed from

the system.

7. Remove valve nozzle and diffuser as shown in Daily

Cleaning instructions. Using a plastic brush or a so ft

cloth and warm water , scrub the nozzle, dif fuser , bottom

of the dispensing valve and cup lever , if applicable.

8. Place removable valve part s (EXCEPT sole noids) in

sanitizing solution for 15 minutes.

9. Replace valve diffuser and nozzle on the beverage valve.

10. Connect sanitizer tank to the syrup line and draw sanitizer

through the valve for two minutes. Allow sanitizer to

remain in the system for a minimum of 15 minutes.

1 1. Reconnect syrup and carbonated water lines.

12. Draw syrup through the lines to rinse the system.

Discard drinks until at least two cups of satisfactory

tasting beverage are dispensed through the valve.

Part Number 020002777 10/11 4-5

Page 38

Maintenance Section 4

!

Caution

Shipping, Storage and Relocation

Before shipping, storing, or relocating this unit, syrup

systems must be sanitized. After sanitizing, all

liquids (sanitizing solution and water) must be

purged from the unit. A freezing environment causes

residual sanitizing solution or water remaining inside

the unit to freeze, resulting in damage to internal

components.

4-6

Part Number 020002777 10/11

Page 39

Checklist

!

Warning

Section 5

Before Calling for Service

If a problem arises during operation of your post mix

soda refrigeration unit, follow the checklist below before

calling service. Routine adjustments and maintenance

procedures are not covered by the warranty.

Problem Possible Cause To Correct

All corresponding valves dispensing no

syrup.

No syrup at only one dispensing valve. Syrup Shut-off V alve closed or partially

Malfunction of syrup system. Refer to Troubleshooting “Section 8: Syrup

closed.

Mounting Block restricted. Remove Dispensing valve from Mounting

Only trained and certified electrical and plumbing

technicians must service this unit. All wiring and

plumbing must conform to national and local codes.

System” under No syrup or insufficient syrup

in finished drink.

Remove top cover from Dispensing valve or

T ower. Locate Syrup Shut-off Valve on right

hand side of Dispensing valve. Verify shut-off

is turned fully open.

Block. Place cup over Syrup outlet on

Mounting Block and carefully open Syrup

Shut-off V alve. If little or no syrup is present,

Mounting Block is restricted. Remove and

clean mounting block. Replace if necessary.

NO SYRUP OR INSUFFICIENT SYRUP IN FINISHED DRINK

No carbonated water at half or all dispensing

valves.

Flow Control our of adjustment or inoperative. Readjust Flow Control to proper Brix. If no

response, clean Syrup Flow Control. Replace

if necessary.

Valve Port restricted. Clean Syrup valve Port Assembly.

Seat swollen. Replace Syrup Seat.

Solenoid Coil defective. Replace Syrup Solenoid Coil.

Malfunction of Carbonated Water System. Refer to Troubleshooting “Section 2:

Carbonated Water System” under No

carbonated water at any of the dispensing

valves.

Part Number 020002777 10/11 5-1

Page 40

Before Calling for Service Section 5

Problem Possible Cause To Correct

NO CARBONATED WATER OR INSUFFICIENT CARBONATED WATER IN FINISHED DRINK

No Carbonated Water only at one dispensing

valve.

NO WATER OR INSUFFICIENT WATER IN FINISHED DRINKS

All valves dispensing noncarbonated

drinks no water.

Problem occurs at only one dispensing

valve.

Too much Syrup, Carbonated Water or

Water in finished drink. Problem occurs

at only one dispensing valve.

Too much syrup in finished drink. All

valves dispensing same flavor-too much

syrup.

Too much water in finish e d dri n k. Al l

valves dispensing noncarbonated drink

too much water.

Syrup or Carbonated Water or Water

dripping from Nozzle.

Carbonated water Shut-off Valve closed or

partially closed.

Mounting Block restricted. Place cup over Carbonated Water outlet on

Flow Control our of adjustment or inoperative. Readjust Flow Control to proper Brix (5 oz in

Valve Port restricted. Clean Carbonated Water valve Port

Seat swollen. Replace Carbonated Water Seat.

Solenoid Coil defective. Replace Carbonated Water Solenoid Coil.

Carbonated Water Switch defective (black). Replaced Carbonated Water Switch.

Water Shut-off Valve closed or partially

closed.

Syrup, carbonated water, or noncarbonated