Page 1

SII-017

A

B

C

D

8/09

Parts & Service Communicator

Subject: Carbonation T est Procedures

SCOPE

The following tests will provide data that shows carbonation levels of a given soda product. Varying from test procedures will

greatly affect the results of the test. It is important to read through the procedure s and understan d how to use the test

equipment before testing. The unit being tested should be clean a nd installed according to manufacturer s specifications along

with all installed components.

The test equipment should be in calibration and clean. The carbonation tester will malfunction if not cleaned after use. Hot tap

water can be used to rinse inside of carbonation tester and glass jar for cleaning. When clea ning carbonation tester, do not

allow pressure gauge to be submerged in wate r . The temperature sensing devices should be tested in an ice bath to check for

calibration before testing.

ACTION

Equipment Required

A. TERRISS CONSOLIDA TED INDUSTRIES, INC. Carb onation

Tester, Fountain Cup. Part# T-03-567 http ://terriss.com/

B. Thermometer – Needs to read in graduations of 1 degree or less.

C. Ice Bath – Used to check thermometer and for chilling

carbonation tester while performing test.

D. 24 oz. Paper Cups – A new cup should be used for each sample

taken from test unit. Cups should be waxed lined.

E. Test unit.

T est Prep aratio n

1. Insure test equipment is calibrated and clean.

2. Prepare an ice bath large enough for both halves of carbonation teste r

to fit in.

3. Check unit installation and unit setup. Make sure it complies

manufacturers specifications. This would include checking BIB

pressure, CO

4. Once the unit has been installed, unit should be allowed to operate

under normal conditions for approximately 2 hours before testing. This

should eliminate any air in the plumbing that might have been

introduced during installation. This time may vary de pending on usage

and air in plumbing.

2 pressure and water pressure going to unit.

Manitowoc Beverage Systems Sellersburg, 2100 Future Drive, Sellersburg, IN 47172, Tel: 812-246-7000, www.manitowocbeverage.com

Page 2

Carbonation Test Procedures SII-017 8/09

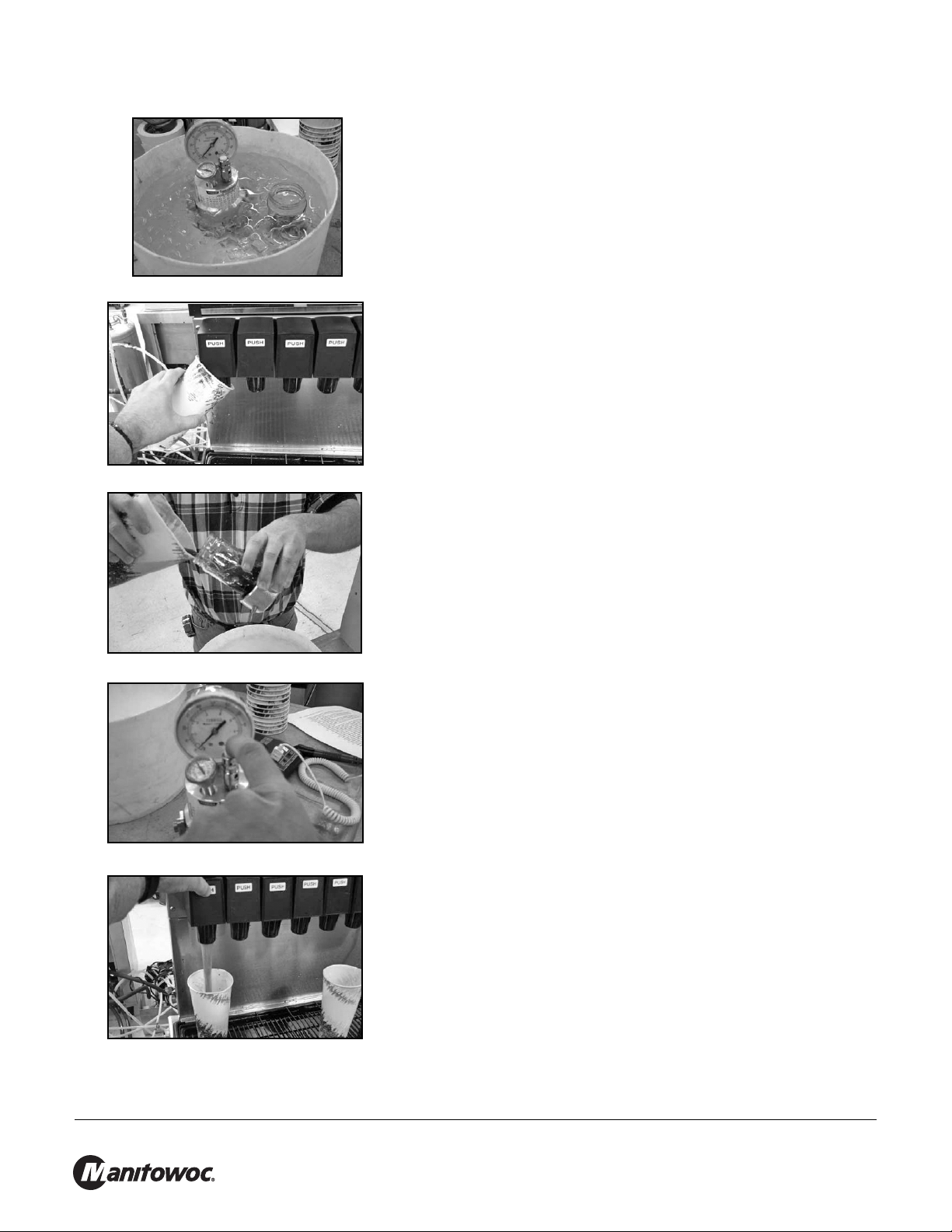

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Tilted Cup At Valve Test

1. Chill carbonation tester by placing both halves in an ice bath. Chill

tester all the way to the top but do not allow gauge to be submerged.

See Fig. 1.

2. Draw 5 – 12oz. Drinks from the valve to be tested in 60-second

intervals. This will prepare the unit chilling all components to a

consistent temperature. Measure temperature each draw with

thermometer and record.

3. Tilt a 24 oz. W axed lined p aper cup undernea th and against nozzle of

valve to be tested. While dispensing soda it should flow down the

inside of cup. See Fig. 2. Dispense until cup is half full. Once flow has

started do not stop until cup is at desired level.

4. Remove glass jar from ice bath. Slowly and carefully pour the contents

into the glass jar allowing soda to flow consistently down the inside.

See Fig. 3. Fill the glass jar till overflowing.

5. Assembly other half of tester carefully together and clamp the tester

closed. This should be down with no sudden movements, as this will

cause CO

2 to escape from the soda prematurely.

6. Burp the tester . This is done by mom entarily depressing the button on

top the pressure relief valve. See Fig. 4. Watch the pressure gauge

while doing this, it should drop to 0 PSI.

7. Shake the tester vigorously for 20 seconds. Read an d record both

pressure gauge and dial thermometer.

8. Determine the carbonation level by using the carbonation chart

provided. Record this value.

9. Take a minimum of 10 readings. A verage all 10 r eadings to represent

the carbonation level. Be sure to agitate ice every other draw. All

recorded data should be put on Form CCT. Remember to clean all test

equipment when finished.

Cup On Grid Without Ice T est

1. Chill carbonation tester by placing both halves in an ice bath. Chill

tester all the way to the top but do not allow gauge to be submerged.

See Fig. 1.

2. Draw 5 – 12oz. Drinks from the valve to be tested in 60-second

intervals. This will prepare the unit chilling all components to a

consistent temperature. Measure temperature each draw with

thermometer and record.

3. Place a 24 oz. Waxed lined pa per cup underneath valve on the grid.

While dispensing soda it should flow into center of cup. See Fig. 5.

Dispense until foam is level with top of cup. Once flow has started do

not stop until cup is at desired level. Measure height of foam and

record.

4. Remove glass jar from ice bath. Slowly and carefully pour the contents

into the glass jar allowing soda to flow consistently down the inside.

See Fig. 3. Fill the glass jar till overflowing.

Manitowoc Foodservice Sellersburg, 2100 Future Drive, Sellersburg, IN 47172, Tel: 812-246-7000, www.manitowocbeverage.com

Page 3

Carbonation Test Procedures SII-017 8/09

Figure 6

5. Assembly other half of tester carefully together and clamp the tester closed.

This should be down with no sudden movements, as this will cause CO

escape from the soda prematurely.

6. Burp the tester. Th is is done by momentarily dep ressing the button on top the

pressure relief valve. See Fig. 4. W atch the pressur e gauge while doing this, it

should drop to 0 PSI.

7. Shake the tester vigorously for 20 seconds. Read and record both pressure

gauge and dial thermometer .

8. Determine the carbonation level by using the carbonation chart provid ed.

Record this value.

9. Take a minimum of 10 readings. Average all 10 readings to represent the

carbonation level. Be sure to agitate ice every othe r draw. All recorded data

should be put on Form CCT. Remember to clean all test equipment when

finished.

Cup On Grid With Ice Test

1. Chill carbonation tester by placing both halves in an ice bath. Chill tester all the

way to the top but do not allow gauge to be submerged. See Fig. 1.

2. Draw 5 – 12oz. Drinks from the valve to be tested in 60-second intervals. This

will prepare the unit chilling all components to a consistent temperature.

Measure temperature each draw with thermometer and record.

3. Place a 24 oz. Waxed lined paper cup with 1/3 full of ice underneath va lve on

the grid. While dispensing soda it should flow into center of cup. See Fig. 5.

Dispense until foam is level with top of cup. Once flow has started do not stop

until cup is at desired level. Measure height of foam and record.

2 to

4. Remove glass jar from ice bath. Slowly and carefully pour the contents into the

glass jar allowing soda to flow consistently down the inside. Pinch the top of

the cup to stop any ice from spilling into jar . See Fig. 6. Fill the glass jar till

overflowing.

5. Assembly other half of tester carefully together and clamp the tester closed.

This should be down with no sudden movements, as this will cause CO2 to

escape from the soda prematurely.

6. Burp the tester. Th is is done by momentarily dep ressing the button on top the

pressure relief valve. See Fig. 4. W atch the pressur e gauge while doing this, it

should drop to 0 PSI.

7. Shake the tester vigorously for 20 seconds. Read and record both pressure

gauge and dial thermometer .

8. Determine the carbonation level by using the carbonation chart provid ed.

Record this value.

9. Take a minimum of 10 readings. Average all 10 readings to represent the

carbonation level. Be sure to agitate ice every othe r draw. All recorded data

should be put on Form CCT. Remember to clean all test equipment when

finished.

Manitowoc Foodservice Sellersburg, 2100 Future Drive, Sellersburg, IN 47172, Tel: 812-246-7000, www.manitowocbeverage.com

Page 4

Carbonation Test Procedures SII-017 8/09

CARBONA TION CHART

VOLUMES OF CO

2

VOLUMES OF CO2

FURTHER ACTIONS

Contact Manitowoc Beverage Systems Service Sellersburg Indiana if you have any questions or concerns: 800-3 67-0427.

Manitowoc Foodservice Sellersburg, 2100 Future Drive, Sellersburg, IN 47172, Tel: 812-246-7000, www.manitowocbeverage.com

Loading...

Loading...