Page 1

Operating Instructions for RX-5 M-LINK /

RX-7 M-LINK 2.4 GHz receivers

Page 11

Instructions for RX-5/7 M-LINK 2.4 GHz receivers # 985 5312 LA 30.09.2014 • Errors and omissions excepted! •

MULTIPLEX

! These operating instructions are an integral part

of the product, and contain important information

and safety notes. Please store them in a safe place,

where you can find them at any time, and pass

them on to the new owner if you sell the receiver.

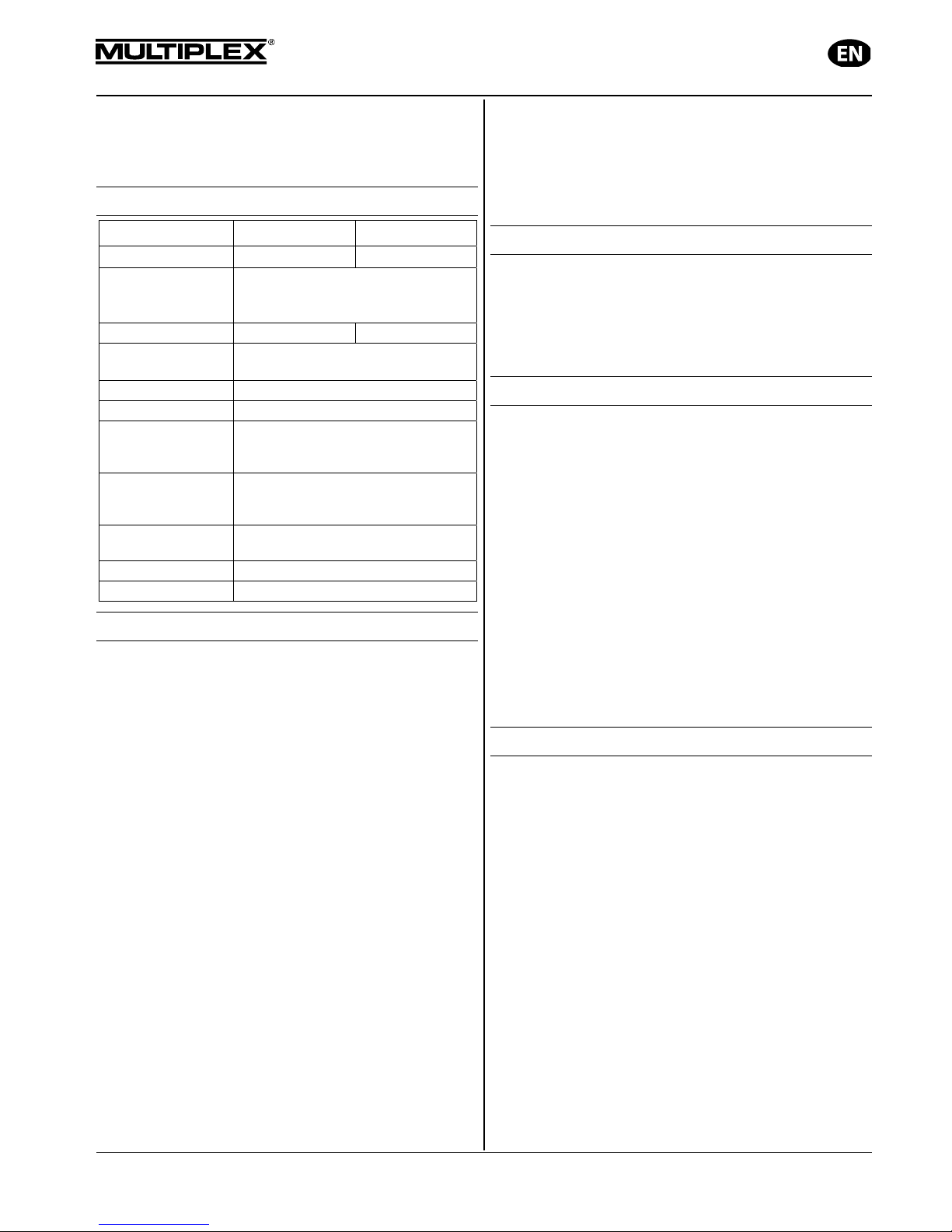

1. SPECIFICATION

RX-5 M-LINK

RX-7 M-LINK

Order No.

# 5 5817 # 5 5818

Reception system

2.4 GHz FHSS M-LINK

Frequency Hopping Spread Spectrum

MULTIPLEX-LINK

Servo channel count

5 7

Servo frame rate

Fast Response: 14 ms

Standard: 21 ms

Signal resolution

12-bit, 3872 steps

Current drain

Approx. 45 mA (excl. servos)

Aerial length

Total: approx. 20 cm,

of which feed cable approx. 17 cm and

active aerial section approx. 3 cm

Operating voltage

3.5 V … 9.0 V

4 - 6 NiCd / NiMH (NiXX) cells

2S LiPo / LiIo (LiXX)

Operating

temperature range

- 20 °C … + 55 °C

Weight

13 g

Dimensions

Approx. 54.0 x 22.5 x 11.5 mm

2. SPECIAL FEATURES

High-quality 5-channel / 7-channel receivers assembled

using the latest SMT methods, exploiting MULTIPLEX

2.4 GHz M-LINK technology.

Supplementary signal pre-amplification:

For maximum sensitivity and great range.

In-line connectors arranged on the front and back:

Ultra-compact dimensions: suitable for models with very little

internal space.

HOLD / FAIL-SAFE function.

Integral SET button and LED:

For binding, FAIL-SAFE programming, RESET and

displaying operating status information.

Telemetry / feedback channel capability:

Receiver battery voltage and connection quality

= standard features.

Integral sensor interface for connecting external sensor

modules via MSB (MULTIPLEX Sensor Bus).

Prepared for two-receiver operation:

Diversity lead (# 8 5070) required.

Prepared for serial servo output:

Servo outputs as sum signal – SRXL-MULTIPLEX.

The receiver’s first twelve channels are carried by a threecord lead (# 8 5070) via the receiver’s B/D socket, e.g. for

power supply / servo management systems, or for flybarless

systems in model helicopters.

Prepared for selecting one sensor address as “priority

address”:

The selected sensor value is updated at a faster rate than all

the other sensor values.

Integral error counter / data logger:

For voltage and signal errors.

Compatible with the MULTImate (# 8 2094).

Integral PC interface:

Carry out updates and adjustment using the MULTIPLEX

Launcher PC program in conjunction with the UNI USB PC

lead (# 8 5149).

3. SAFETY NOTES

! Please read the instructions before using the receiver.

! Use the receiver only for the intended applications

( 4.).

! Ensure the power supply is of adequate capacity ( 6.).

! Observe the installation notes ( 13.).

! Carry out regular range checks ( 14.).

4. APPLICATIONS

The RX-5 M-LINK and RX-7 M-LINK 2.4 GHz receivers (abbr eviated to RX-5/7 M-LINK in this document) are radio control

receivers intended exclusively for use in model sport. It is

prohibited to employ them for other purposes such as full -size

(people-carrying) vehicles or industrial installations.

Typical applications for RX-5 M-LINK and RX-7 M-LINK receivers:

Gliders and electric gliders up to about 2.50 m wingspan

Small to medium-sized RC helicopters with rotor diameters

up to about 1 m

Model aircraft with electric and I.C. power systems and

wingspans up to about 1.60 m

RC model cars

RC model boats

RX-5/7 M-LINK 2.4 GHz receivers can only be operated in

conjunction with transmitters which utilise MULTIPLEX MLINK transmission technology.

5. POWER SUPPLY

RX-5/7-DR M-LINK

receivers work within a broad range of voltages from 3.5 V … 9.0 V, i.e. they can be used with receiver

batteries consisting of four to six NiXX cells or 2S LiPo / 2S LiIo

(LiXX).

! Note: if you intend to use a five-cell or six-cell NiXX b attery,

or a 2S LiPo or 2S LiIo pack, it is essential to check that all the

servos, gyros and other components connected to the system

are approved for use with this higher operating voltage.

! Note: ensure that the power supply is adequate

A power supply system in good condition a nd of adequat e capacity for the specific application plays an indispens able role in the

safe operation of any model:

Use only high-quality receiver batteries of adequate capacity.

Balance and maintain them carefully, and charge them fully.

Ensure that all cables are of adequate conductor cross-

section. Keep all wiring as short as possible, and use the

absolute minimum of plug / socket connections.

Use high-quality switch harnesses exclusively.

Brief collapses in the power supply voltage (lasting a few

milli-seconds) have no adverse effect on the receiver. Longer

voltage collapses to below 3.5 V may cause a receiver r eset,

resulting in a brief interruption in reception. This may be due

to a receiver battery which is almost flat, too weak or

Page 2

Operating Instructions for RX-5 M-LINK /

RX-7 M-LINK 2.4 GHz receivers

Page 12

Instructions for RX-5/7 M-LINK 2.4 GHz receivers # 985 5312 LA 30.09.2014 • Errors and omissions excepted! •

MULTIPLEX

defective, cables of inadequate cross-section, poor-quality

connectors or an overloaded or defective BEC system.

6. RECEIVER CONNECTIONS

This receiver employs the UNI connector system, which is compatible with the connector systems used by most radio control

manufacturers (e.g. HiTEC, robbe/Futaba, Graupner/JR).

The receiver sockets are marked as follows:

1, 2, 3 … 5

(… 7)

Servo sockets, channels 1, 2, 3 … 5 (… 7).

Alternatively: receiver battery socket.

B

In the case of the RX-5 M-LINK:

Receiver battery socket

(can also be connected to servo sockets 1 … 5).

Duplicated for extra security: twice the conductor

cross-section, twice the number of contacts.

B/D

Receiver battery socket

(can also be connected to servo sockets 1 … 5

(… 7)).

Duplicated for extra security: twice the conductor

cross-section, twice the number of contacts.

Socket for PC or Diversity lead, for the serial

servo output lead (SRXL-MULTIPLEX), and for

the MULTImate.

S

Socket for external sensor module.

! When connecting the receiver battery, servos, speed

controllers, sensors ... it is essential to insert the connector

the correct way round. With other makes of component

always check the pin assignment (see symbols on the

receiver)!

7. FIRST USE, FUNCTIONS

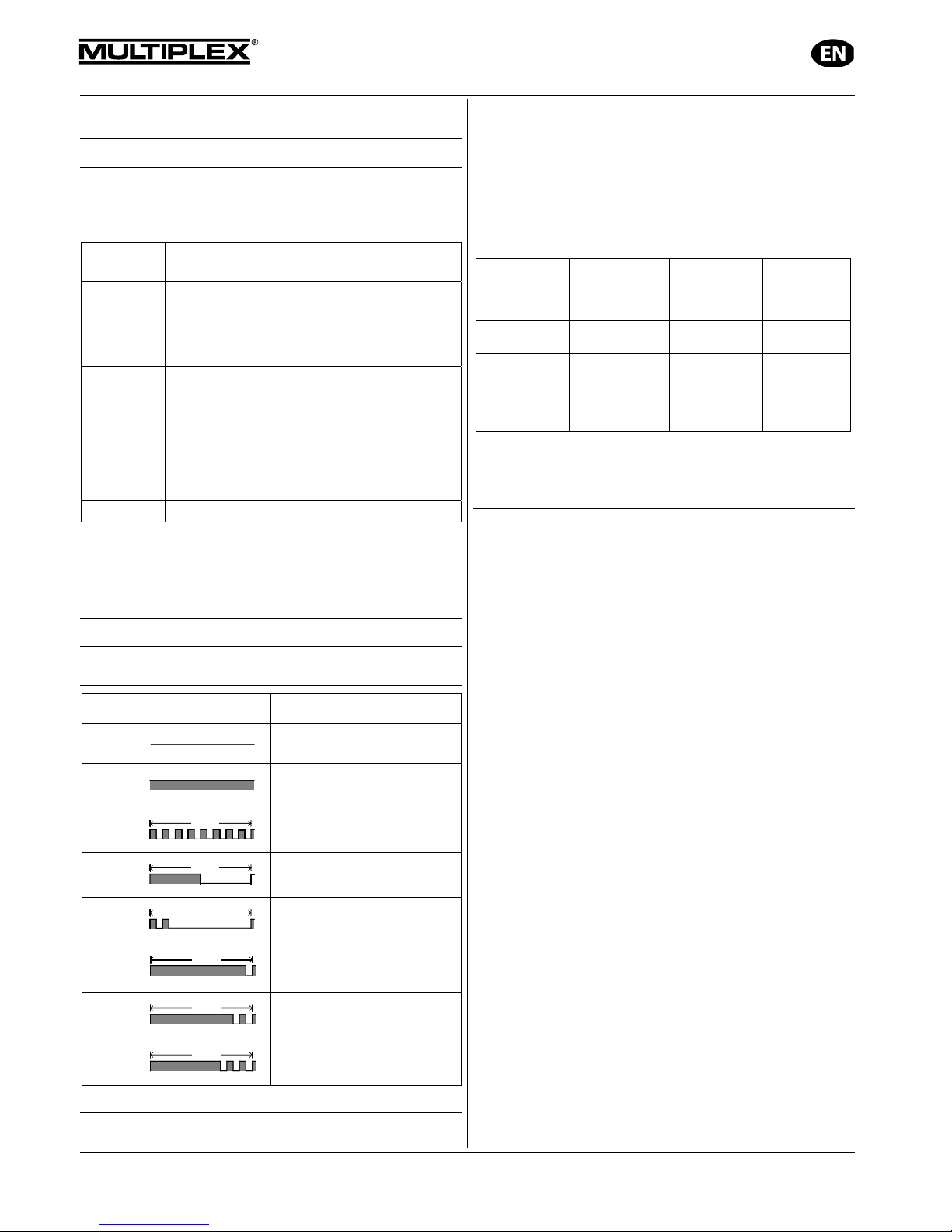

LED Codes

LED code Description

LED Code 0

LED OFF

Battery voltage too low

LED Code 1

LED ON

No reception

LED Code 2

1,6 sec

Binding procedure in progress

1,6 sec

LED Code 3

Normal receiving operation,

no errors

1,6 sec

LED Code 5

Confirmation signal

1 – 19 errors

20 – 49 errors

>= 50 errors

The functions of the SET button

Pressing the SET button on the top of the receiver when

switching on initiates the binding process.

In receive mode, the SET button can be used to trigger two additional functions. The function selected depends on the length of

the button-press:

1.

Save error counter or FAIL-SAFE settings

Press the SET button for 0.5 to 1 second.

2.

RESET receiver to factory default settings

Press the SET button for longer than ten seconds.

While the SET button is pressed, the LED indicates the length of

the button-press with time markers:

Press SET

button constantly for

< 2

seconds

2 to 10

seconds

> 10

seconds

LED

OFF ON OFF

Purpose

Save error

counter /

FAIL-SAFE

settings

RESET

to default

settings

!

Note:

When the Save process is complete, the LED flashes in confirmation (LED code 5).

Binding

The receiver must be set up to match the transmitter before the

system can work. This process is known as “binding”.

! Note:

The signal output to the servo sockets is switched off during the

binding procedure. This means that the servos are “soft”, and do

not move, while the motor connected to a modern electronic

speed controller remains OFF due to the lack of a signal. Ne vertheless, it is important to secure the model and keep well clear

of the power system.

The binding process is necessary in the following cases:

The first time the receiver is used.

After a receiver RESET.

After the transmitter setting for “Fast Response” has been

changed. For more information on this please refer to the

operating instructions supplied with your M-LINK transmitter

or M-LINK RF module.

After the transmitter setting for the transmitted frequency

range has been changed. For more information on this

please refer to the operating instructions supplied with your

transmitter or M-LINK RF module (“France mode”).

If the receiver is to be operated in conjunction with a different

M-LINK transmitter.

Sequence of the binding procedure

1. The first step is always to set the transmitter and receiver to

Binding mode:

Move the transmitter and the receiver aerial very close to

each other.

Switch the transmitter ON in binding mode.

(see the operating instructions supplied with your M-LINK

transmitter or M-LINK RF module).

Switch the RX-5/7 M-LINK receiver ON in binding mode:

Use a pointed object to press and hold the SET button

on the top of the receiver.

Switch the receiver ON, or connect the battery:

LED Code 6

1,6 sec

LED Code 7

1,6 sec

LED Code 8

1,6 sec

Page 3

Operating Instructions for RX-5 M-LINK /

RX-7 M-LINK 2.4 GHz receivers

Page 13

Instructions for RX-5/7 M-LINK 2.4 GHz receivers # 985 5312 LA 30.09.2014 • Errors and omissions excepted! •

MULTIPLEX

The binding procedure runs, the receiver LED

flashes at high frequency

(LED code 2).

Now release the SET button.

!

Note:

the binding process starts automatically when

the receiver is used for the first time, and after a RESET even if you have not pressed the SET button.

2. Once the transmitter and rec eiver are bound to each other,

both switch automatically to normal operation:

The LED on the receiver flashes slowly

(LED code 3).

! Note: in most cases the binding process only takes a few

seconds.

Binding: locating and correcting faults

Fault:

During the binding process the receiver LED continues to flash

at a high rate after several seconds.

Cause:

No M-LINK signal of adequate strength detected.

Remedy:

Reduce the distance between your transmitter and the

receiver aerial.

Ensure that your transmitter is switched ON in binding mode.

Repeat the binding procedure.

Switching the receiver ON and OFF

in normal operations

Sequence of switching ON and OFF

To switch the M-LINK RC system ON, please use this

procedure:

1. Switch the transmitter ON.

2. Switch the receiver ON.

The receiver LED flashes slowly and evenly

(LED code ):

An M-LINK signal is being received,

the RC system is ready for use.

To switch the M-LINK RC system OFF, please use this

procedure:

1. Switch the receiver OFF.

2. Now switch the transmitter OFF.

Locating and correcting faults when switching ON

Fault:

The receiver LED lights up constantly when switched on (LED

code 1 ), but does not flash.

Cause:

No M-LINK signal detected.

Remedy:

Is the transmitter switched on?

Is the transmitter generating an M-LINK signal?

Are the transmitter and receiver bound to each other?

Have you carried out a receiver RESET?

Have you made changes to the setting for “Fast Response”

or “France mode” ?

Error:

The receiver LED stays off after switching on

(LED code 0).

Cause:

The operating voltage (battery voltage) is too low.

Remedy:

Recharge the receiver battery or drive / flight battery.

HOLD and FAIL-SAFE

If no signal is picked up, or if the received data is corrupt, the

last valid information is passed on to the servos in order to

bridge the signal loss (HOLD mode).

If interference should occur and FAIL-SAFE has been invoked,

the servos (...) run to a previously defined position at the end of

the HOLD period. FAIL-SAFE mode ends as soon as error-free

signals are picked up again.

The factory default setting for the HOLD period is 0.75 seconds.

This period can be adjusted to meet personal requirements

using the

MULTImate

or the PC program

MULTIPLEX

Launcher

.

FAIL-SAFE is switched OFF in the receiver’s default state (as

delivered), and after a RESET. FAIL-SAFE is activated using the

SET button on the receiver, or - in the case of certain transmitters - “by radio”.

If you wish to disable FAIL-SAFE again, the receiver must be

reset to the default state (RESET). After a RESET you must

repeat the binding procedure!

! Note: always activate FAIL-SAFE!

For safety reasons we recommend that you always activate

FAIL-SAFE, and ensure that the selected FAIL-SAFE settings

will cause the model to take up as safe an attitude as possible

(e.g. motor idle / electric motor OFF, control surfaces neutral,

landing flaps deployed, tow-release open, …).

Selecting the FAIL-SAFE settings:

1. The receiver LED must not display any errors

(LED code 3).

If it does: switch the receiver OFF, then ON again.

2 Use your transmitter to move all the servos (and the speed

controller) to your preferred FAIL-SAFE positions. Press the

SET button briefly (0.5 to 1 second). The FAIL-SAFE positions are now stored for all servo channels, and the LED

flashes the confirmation signal (LED code 5).

Testing the FAIL-SAFE positions:

Move the sticks to positions other than the FAIL-SAFE settings,

and then switch the transmitter OFF: the servos should go into

HOLD mode briefly (0.75 seconds), and then move to the FAILSAFE positions which you previously selected.

The FAIL-SAFE positions must always be checked and updated

when necessary, e.g. when you install the receiver in a new

model.

! Checking the FAIL-SAFE function:

For testing the FAIL-SAFE function only, the receiver can be

operated with the transmitter switched off. Caution: if the FAILSAFE settings are incorrect, the motor could burst into life: injury

hazard!

After sixteen seconds in FAIL-SAFE mode no further signals are

sent to the servos (default setting; this period can be altered

using the

MULTImate

or the

MULTIPLEX Launcher

.

Analogue servos and some digital servos (see instructions) then

become “soft”, to avoid them being stalled. Modern speed controllers switch themselves off. However, some digital servos

remain “hard” and maintain their last position.

The FAIL-SAFE function can be activated and disabled servo by

servo using the

MULTImate

or the

MULTIPLEX Launcher

.

Example: throttle only to Idle / OFF, all other servos = HOLD.

RESET to factory default settings

The receiver settings can be reset to the factory default settings.

If you do this, all the settings you have entered, such as bindi ng

information, FAIL-SAFE settings ... are lost permanently.

Page 4

Operating Instructions for RX-5 M-LINK /

RX-7 M-LINK 2.4 GHz receivers

Page 14

Instructions for RX-5/7 M-LINK 2.4 GHz receivers # 985 5312 LA 30.09.2014 • Errors and omissions excepted! •

MULTIPLEX

Hold the SET button pressed in for at least ten seconds (as a

guide, the LED goes out when you press the button, comes on

again after two seconds, then off again after ten seconds).

When the RESET has been carried out, the LED displays the

confirmation signal (LED code 5), and the receiver switches to

binding mode.

!

Note:

it is not possible to carry out a RESET if the receiver is

in binding mode (LED flashing at high frequency).

Overview of the factory default settings and variable

set-up values

Parameter Default setting Set-up value can

be altered using

the MULTImate* or

MULTIPLEX

Launcher*

Low voltage

(error counter)

4.5 V Yes

HOLD period

0.75 seconds Yes

FAIL-SAFE period

16 seconds Yes

FAIL-SAFE

Off Can be activated

channel by channel

Receiver name

Internal ID Max. 12 characters

Address for receiver

battery voltage

0

Yes

Address for

connection quality

1 Yes

Two-receiver mode

On Yes

Servo outputs as

sum signal

= SRXL-MULTIPLEX

(serial servo output /

digital servo data)

Off Yes

One sensor address

as “Priority address”

= Address with Prio 1

Off Yes

* Refer to Chapter (

9.

) here.

Error counter

The receiver features two error counters: for low voltage and

signal errors.

The receiver LED indicates the sum of the seconds during which

errors were detected.

If errors are indicated, they can be saved (stored) after the

landing using the SET button, and read out again later (

9.

).

1.

Operating voltage errors

Examples: flat or faulty battery, inadequate cable crosssection, etc.

The counter registers voltage collapses below the threshold

of 4.5 V (threshold can be altered using the

MULTImate

or

the

MULTIPLEX Launcher

(

9.

)).

2.

Signal errors

The count contains instances of interference to the M-LINK

signal packet. For example, this could indicate problems in

the power supply, a defective aerial, etc.

Signal errors are recorded in virtually every flight. In most

cases the pilot does not notice them, but they are still picked

up by the extremely sensitive error counter.

After a few flights, and regular analysis of the error counter, you

will gain the experience required to render the error counter

genuinely helpful, enabling you to detect changes in good time,

and to locate indications of possible causes of interference.

!

Protracted voltage collapses below 3.5 V cause the receiver

to re-boot. If this occurs, the values for both error counters are

lost permanently.

!

If you press the SET button for the purpose of saving the

error count, the stored information is retained until the next time

you save the error count.

8. TELEMETRY / FEEDBACK CAPABILITY

The telemetry-capable

RX-5 M-LINK

and

RX-7 M-LINK

2.4 GHz

receivers offer a means of transmitting data from the model back

to the transmitter.

When these receivers are employed, the telemetric values for

“receiver battery voltage” and “connection quality” are transmitted

directly, i.e. they require no additional external sensors.

The receivers can also be used in conjunction with up to sixteen

external M-LINK sensors, which are connected to the “S” socket.

In this way a very wide variety of telemetry data can be “sent

back” to the pilot.

!

Note:

The possible methods of indicating telemetry data by visual

and / or audible means vary according to the M-LINK transmitter or RF module in use.

Examples of external M-LINK sensors are as follows:

Voltage sensor (# 8 5400).

Temperature sensor (# 8 5402).

Current sensor:

150 A (# 8 5405) or

35 A ((# 8 5403) or (8 5404)).

Rev count sensor:

Optical (# 8 5414) or magnetic (# 8 5415).

Vario / altitude sensor (# 8 5416).

GPS (# 8 5417).

For more information on connecting and operating the various

sensor types and their features (measurement range, addressing, warning threshold settings, display facilities for minimum,

average or maximum values, in some cases activation of a

second m easu rem ent channel, ...) please refer to the instructions

supplied with the sensors and / or the MULTImate.

9. MULTIMATE AND

MULTIPLEX LAUNCHER PC PROGRAM

All MULTIPLEX M-LINK receivers are based on modern microcontrollers (FLASH technology). In the case of most M-LINK

receiver types (see the operating instructions supplied with your

receiver) it is also possible to connect the unit to the MULTImate

(# 8 2094) and / or to a PC or notebook computer using t he PC

connecting lead (# 8 5149); the PC program MULTIPLEX

Launcher can then be used.

The MULTIPLEX Launcher PC program is available as a free

download from the MULTIPLEX website (www.multiplex-rc.de).

This program, and the MULTImate (V1.50 or higher), opens up

Page 5

Operating Instructions for RX-5 M-LINK /

RX-7 M-LINK 2.4 GHz receivers

Page 15

Instructions for RX-5/7 M-LINK 2.4 GHz receivers # 985 5312 LA 30.09.2014 • Errors and omissions excepted! •

MULTIPLEX

the following facilities:

Availability of expanded receiver options, such as freely

variable HOLD and FAIL-SAFE period, individual FAIL-SAFE

settings can be activated and adjusted channel by channel,

…

Error counter / error memory read-out:

The error count can be read out separately for signal error s

and operating voltage errors.

Unrestricted sensor address assignment for the receiver

battery voltage and for connection quality (0 - 15).

Receiver name assignment (max. 12 characters).

Switching the following options on and off: “Two-receiver

mode” ( 11.) and serial servo output (dig ital servo data /

SRXL-MULTIPLEX) ( 12.).

Setting one sensor address as “priority address”:

The selected sensor value is updated at a higher rate than all

the other sensor values ( 13.).

The MULTIPLEX Launcher also allows:

Firmware updates:

Keep your receiver up-to-date at all times.

!

Note:

We recommend that you update your MULTImate or the MULTIPLEX Launcher at regular intervals to ensure that you can

exploit all the current features of your receiver and the connected components generally.

10. TWO-RECEIVER MODE

What is known as “two-receiver mode” is possible with the

MULTIPLEX RX-5 M-LINK and RX-7 M-LINK 2.4 GHz M-LINK

receivers:

In this mode two M-LINK receivers are inter-connected using a

Diversity lead (# 8 5070).

With this arrangement a total of two or even three receive circuits operate in parallel:

The two or three receive circuits incorporated in the two receiver

cases pick up and analyse the signals (“double diversity” or

“triple diversity”). This type of diversity can also be described as

“two-receiver mode”.

Since the orientation of the two or three receiver aerials is

different, this arrangement provides a further improvement in

receive performance, since it minimises directional aerial effects.

This means that at least one receiver aerial has a “good view” of

the transmitter regardless of the model’s attitude. Two-receiver

mode therefore provides a wider safety margin.

!

Tip:

you can also inter-connect different types of M-LINK

receiver, provided that they are capable of two-receiver mode

(e.g. 1 x

RX-16-DR pro M-LINK

and 1 x

RX-5 M-LINK

).

Information concerning suitability for two-receiver mode can be

found in the operating instructi ons provided with the various

M-LINK receivers.

This is the procedure for re-activating two-receiver mod e:

!

Note:

M-LINK receivers are set to two-receiver mode by default. For

this reason you can skip steps 1. – 3. and go directly to step 4.

1. Re-activating using the MULTImate:

At the menu point “4-7 B/D output“ / “4-7 Ausgabe B/D“

(= output B/D) select the following option:

“MPX 2-Receiver“ / “MPX 2-Empfänger“

(= MPX Two-receiver mode).

Select the menu point:

“4-10 Send data“ / “4-10 Dat. senden“ (= Send data)

and hold the 3-D digi-adjuster pressed in:

the MULTImate displays the following:

“please wait…“ / “bitte warten…“ (= please wait).

Release the 3-D digi-adjuster:

When the send process is complete, the screen

displays “--> OK!“ (= complete!).

Disconnect the receiver, switch off the MULTImate.

2. Re-activating using the MULTIPLEX Launcher:

At “More settings Options…“ / “Weitere Einstellungen

Optionen…“ (= More settings Options) select the

following menu point:

“MULTIPLEX Two-Receiver-Mode“ / “MULTIPLEX ZweiEmpfänger-Betrieb“

(= MULTIPLEX two-receiver mode).

Click on the “Accept“ / “Übernehmen“ button

(= Accept).

Click on the “Send data“ / “Daten senden“ button

(= Send data).

Click on the “Close“ / “Beenden“ button

(= Finish).

Close MULTIPLEX Launcher, disconnect the receiver.

3. You may need to carry out the steps described under 1. or 2.

on the second M-LINK receiver in order to activate tworeceiver mode.

4. Inter-connect the two M-LINK receivers by the B/D sockets

using the three-cord Diversity lead (# 8 5070). Please refer to

the operating instruction supplied with the Diversity lead.

! Take care to connect the lead correctly, i.e. the connectors must be correctly orientated, and the pin assig nment must be compatible (see symbols on the receiver)!

11. SERIAL SERVO OUTPUT –

SRXL-MULTIPLEX

RX-5/7 M-LINK receivers offer the facility to use the servo outputs as a sum signal (serial servo output = SRXL-MULTIPLEX):

The receiver’s first twelve channels are carried by a three-core

lead (# 8 5070) via the receiver’s B/D socket.

Applications:

Power supply / servo management systems, or

Flybarless systems on model helicopters.

!

Note:

SRXL-MULTIPLEX is switched off by default on M-LINK recei-

vers, and can be activated using the MULTIPLEX MULTImate

or the MULTIPLEX Launcher PC program in conjunction with

the UNI USB PC lead (# 8 5149).

This is the procedure for activating serial servo output:

1. Activating using the MULTImate:

At the menu point “4-7 B/D output“ / “4-7 Ausgabe B/D“

(= Output B/D) select the following option:

“Digit. Servodata“ / “Dig. Servodaten“

(= Digital servo data).

Select the menu point:

“4-10 Send data“ / “4-10 Dat. senden“ (= Send data)

and hold the 3-D digi-adjuster pressed in:

The MULTImate screen displays:

“please wait…“ / “bitte warten…“ (= please wait).

Release the 3-D digi-adjuster:

Page 6

Operating Instructions for RX-5 M-LINK /

RX-7 M-LINK 2.4 GHz receivers

Page 16

Instructions for RX-5/7 M-LINK 2.4 GHz receivers # 985 5312 LA 30.09.2014 • Errors and omissions excepted! •

MULTIPLEX

When the Send process is complete, the screen

displays “--> OK!“ (= complete!).

Disconnect the receiver, switch off the MULTImate.

2. Activating using the MULTIPLEX Launcher:

At “More settings Options“ / “Weitere Einstellungen

Optionen…“ (= More settings Options) select the

following menu point:

“Digital servodata“ / “Digitale Servodaten“

(= Digital servo data).

Click on the “Accept“ / „Übernehmen“ button

(= Accept).

Click on the „Send data“ / “Daten senden“ button

(= Send data).

Click on the “Close“ / “Beenden“ button

(= Finish).

Close MULTIPLEX Launcher, disconnect the receiver.

3. Connect the three-core lea d (# 8 5070) to the receiver’s B/D

socket.

4. Connect the lead to the power supply / servo management

system, or to the flybarless system (see the operating

instructions supplied with these devices).

! Take care to connect the lead correctly, i.e. the connectors must be correctly orientated, and - especially

when using non-MULTIPLEX products - the pin assignment must be compatible. Be sure to check the symbols

on the M-LINK receiver, and on the non-MULTIPLEX

product if present. Refer to the operating instructions of

the non-MULTIPLEX device, and ask the manufacturer if

you are in any doubt!

12. SELECTING ONE SENSOR ADDRESS AS

“PRIORITY ADDRESS”

The telemetry-capable RX-5/7 M-LINK receivers permit the user

to define any one of the sensor addresses (0 … 15) as a “priority

address”:

This one selected sensor value is then updated at a higher rate

than all the other sensor values.

Typical application: “Vario”:

The audio output for climb and descent, and the associated onscreen display, are updated more frequently than the other

sensor values, and are therefore generated without delay.

!

Note:

The “Priority address” optio n is switched off by defa ult on M-LINK

receivers, and can be activated using the MULTIPLEX MULTI-

mate or the MULTIPLEX Launcher PC program in conjunction

with the UNI USB PC lead (# 8 5149).

This is the procedure for activating the priority address:

1. Activating using the MULTImate:

At the menu point “4-6 Sensor addr.“ / “4-6 Sensoradr.“

(= Sensor address) select the option:

“4-6 Prio address“ / “4-6 Prio Adresse“

(= Priority address).

Hold the 3-D digi-adjuster pressed in:

The MULTImate displays: “L 0“.

Release the 3-D digi-adjuster.

Press the 3-D digi-adjuster briefly, and select the priority

address (0 … 15).

Press the 3-D digi-adjuster briefly.

Switch to the menu:

“4-6 Go back …to RX M-LINK“ /

“4-6 Zurück …zu RX M-LINK“

(= back … to RX M-LINK)

and confirm by pressing the 3-D digi-adjuster.

Select the menu point:

“4-10 Send data“ / “4-10 Dat. senden“

(= Send data)

and hold the 3-D digi-adjuster pressed in:

The MULTImate displays:

“please wait…“ / “bitte warten…“ (= please wait).

Release the 3-D digi-adjuster:

When the Send process is complete, the screen

displays “--> OK!“ (= complete!).

Disconnect the receiver, switch off the MULTImate.

2. Activating using the MULTIPLEX Launcher:

At “Sensor addresses“ / “Sensorparameter“

(= Sensor address) auswählen:

“Address w/prio 1:“ / “Adresse mit Prio 1:“

(= Address with priority 1).

Select the “Address“ / “Adresse“ (= Address) check-box,

and enter the desired address (0 … 15).

Click on the “Accept“ / “Übernehmen“ button

(= Accept).

Click on the “Send data“ / “Daten senden“ button

(= Send data).

Click on the “Close“ / “Beenden“ button

(= Finish).

Close the MULTIPLEX Launcher, disconnect the

receiver.

This is the procedure for disabling the priority address:

1. Disabling using the MULTImate:

At the menu point “4-6 Sensor addr.“ / “4-6 Sensoradr.“

(= Sensor address) select the option:

“4-6 Prio address“ / “4-6 Prio Adresse“

(= Priority address).

!

Note:

The second line of the screen displays the selected

priority address.

Hold the 3-D digi-adjuster pressed in:

The screen entry in the second line changes to:

“L off“ / “L aus“ (= L off).

Switch to the menu:

“4-6 Go back …to RX M-LINK“ /

“4-6 Zurück …zu RX M-LINK“

(= back … to RX M-LINK)

and confirm by pressing the 3-D digi-adjuster.

Select the menu point:

“4-10 Send data“ / “4-10 Dat. senden“

(= Send data)

and hold the 3-D digi-adjuster pressed in:

The MULTImate displays:

“please wait…“ / “bitte warten…“ (= please wait).

Release the 3-D digi-adjuster:

When the Send process is complete, the screen

displays “--> OK!“ (= complete!).

Disconnect the receiver, switch off the MULTImate.

2. Disabling using the MULTIPLEX Launcher:

At “Sensor addresses“ / “Sensorparameter“

(= Sensor parameters) auswählen:

“Address w/prio 1:“ / “Adresse mit Prio 1:“

(= Address with priority 1).

Clear (erase) the tick in the “Address“ / “Adresse“ check-

box (= Address).

Page 7

Operating Instructions for RX-5 M-LINK /

RX-7 M-LINK 2.4 GHz receivers

Page 17

Instructions for RX-5/7 M-LINK 2.4 GHz receivers # 985 5312 LA 30.09.2014 • Errors and omissions excepted! •

MULTIPLEX

Click on the “Accept“ / “Übernehmen“ button

(= Accept).

Click on the “Send data“ / “Daten senden“ button

(= Send data).

Click on the “Close“ / “Beenden“ button

(= Finish).

Close the MULTIPLEX Launcher, disconnect the

receiver.

13. INSTALLATION NOTES

Protect your receiver from vibration, especially in models

powered b y an internal-combustion engine (e.g. pack it loosely

in foam).

Locate the receiver at least 150 mm away from electric mo-

tors, petrol engine ignition systems and any other electronic

components such as speed controllers for electric motors and

drive batteries. Keep the aerial away from these components.

Install the receiver in the model in such a way that the aerial

is as far away as possible from all conductive materials.

If your model’s fuselage consists of conductive materials (e.g.

carbon fibre), then the aerial must be installed in such a way

that the active part of the aerial (the final 30 mm) is located

outside the model.

Do not deploy the receiver aerial inside or on model com-

ponents which are laminated or reinforced with electrically

conductive materials (metal foil, carbon fibre, metallic paints

etc.), as they have a shielding effect.

Do not shorten or extend the aerial or the aerial feed cable.

Never attempt to replace or repair the aerial or aerial cable!

Do not deploy the aerial parallel to servo leads, high-current

cables or electrically conductive parts (e.g. pushrods).

Keep to the recommended installed arrangements (

20.

,

sketches A - C)!

High-current cables, e.g. those attached to the speed con-

troller, motor and flight battery, should be kept as short as

possible.

If you are using a diode-based battery backer, always install a

PeakFilter (

# 8 5180

).

Reception quality can be optimised by fitting a special ferrite

ring (

# 8 5146

) or suppressor filter lead (

# 8 5057

) in the speed

controller cable. It is also advisable to fit effective suppressors

to conventional (brushed) electric motors (not brushless types)

(e.g. use the suppressor set

# 8 5020).

14. RANGE CHECKING

Regular range checks are very important - even when using a

2.4 GHz system - in order to ensure reliable operation of the

radio control system, and to enable you to detect sources of

interference in good time. This applies in particular:

Before the use of new or changed components, or existing

components in a new or modified arrangement.

Before re-using radi o control system components which were

previously involved in a crash or a hard landing.

If you have encountered problems on a previous flight.

Important:

Always ask a second person to help you with your range

check, so that one of you can secure and observe the model.

If possible, carry out the range check when no other trans-

mitters are operating.

Carrying out the range check:

1. Select “range-check mode” on your transmitter (see the

operating instructions supplied with the transmitter or RF

module).

There must be line-of-sight connection between the transmitter and receiver aerials (i.e. the model) during the range

check.

Keep the transmitter and the model about one metre above

ground during the range check.

2. When checked with reduced transmitter power, the range of the

RX-5/7 M-LINK receiver must be 40 metres. You have reached

the range limit when the servos start to move jerkily.

If your transmitter features an automatic servo test facility,

we recommend that you activate it for one control function

(e.g. rudder). This sets up a steady movement of the servo,

and enables you to detect the limit of range clearly.

Important:

Carry out the first range check with the motor switched off. Turn

the model into all attitudes, and attempt to optimise reception by

changing the position of the two aerials.

For the second range check, run the motor at varying speeds

and check that the effective ra nge is not significantly reduce d. If

there is a marked reduction, locate and eliminate the cause of

the interference (caused by the motor, the arrangement of the

receiving system and power supply, vibration, etc.).

15. EXCHANGING THE AERIALS

If you require longer or shorter aerial feed cables, please contact

the MULTIPLEX Service Department or any MULTIPLEX Service Centre, as they stock cables of different lengths, and will

gladly quote an individual price for modifying your receiver to

professional standards.

! Caution: never attempt to exchange the aerial yourself!

Changing the aerial to a professional standard requires

special tools as well as appropriate expertise. Ignoring this

warning may have an adverse effect on the receiver’s

reception quality.

! Cau tion: if the active part of the aerial (the final 30 mm)

should be damaged, the aerial must be replaced by the

MULTIPLEX Service Department or a MULTIPLEX Service

Centre; this also applies if the aerial feed cable is damaged.

16. CE CONFORMITY DECLARATION

This device has been assessed and approved in

accordance with European harmonised directives.

This means that you possess a product whose design and

construction fulfil the protective aims of the European Community designed to ensure the safe operation of equipment.

The detailed CE conformity declaration can be downloaded in

the form of a PDF file from the Internet under www.multiplexrc.de. It is located in the DOWNLOADS area under PRODUKTINFOS.

Page 8

Operating Instructions for RX-5 M-LINK /

RX-7 M-LINK 2.4 GHz receivers

Page 18

Instructions for RX-5/7 M-LINK 2.4 GHz receivers # 985 5312 LA 30.09.2014 • Errors and omissions excepted! •

MULTIPLEX

17. FCC WARNING STATEMENTS

This device complies with part 15 of the FFC rules. Operation is

subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

NOTE: The grantee is not responsible for any changes or

modifications not expressly approved by the party responsible

for compliance. Such modifications could void the user´s

authority to operate the equipment.

18. IC WARNING STATEMENTS

This device complies with Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions:

(1) this device may not cause interference, and (2) this device

must accept any interference, including interference that may

cause undesired operation of the device.

19. DISPOSAL NOTES

Electrical equipment marked with the cancelled waste

bin symbol must not be discarded in the standard

household waste; instead it should be taken to a

suitable specialist disposal system.

In the countries of the EU (European Union) electrical

equipment must not be discarded via the normal

domestic refuse system (WEEE - Waste of Electrical and

Electronic Equipment, Directive 2002/96/EG). You can take

unwanted equipment to your nearest local authority waste

collection point or recycling centre. There the equipment will be

disposed of correctly and at no cost to you.

By returning your unwanted equipment you can make an

important contribution to the protection of the environment!

20. GUARANTEE / LIABILITY EXCLUSION

The company MULTIPLEX Modellsport GmbH & Co.KG accepts

no liability of any kind for loss, damage or costs which are due to

the incorrect use and operation of this product, or which are

connected with such operation in any way. Unless the law

expressly states otherwise, the liability on the part of MULTIPLEX Modellsport GmbH & Co.KG to pay damages, regardless

of the legal argument employed, is limited to the invoic e value of

those products supplied by MULTIPLEX Modellsport GmbH &

Co.KG which were directly involved in the event in which the

damage occurred. This does not apply if liability is incurred

according to statutory law on account of intentional or gross

negligence.

We guarantee our products in accordance with the currently

valid statutory regulations. If you wish to make a claim under

guarantee, your initial course of action should always be to

contact the dealer from whom you purchased the equipment.

The guarantee does not cover faults and malfunctions which are

caused by the following:

Incorrect or incompetent use

Maintenance carried out incorrectly, belatedly or not at all, or

not carried out by an authorised Service Centre

Incorrect connections

The use of accessories other than genuine MULTIPLEX

items

Modifications or repairs which were not carried out by

MULTIPLEX or by an authorised MULTIPLEX Service

Centre

Accidental or intentional damage

Defects due to normal wear and tear

Operation of the unit outside the limits stated in the

Specification

Operation of the unit in conjunction with equipment made by

other manufacturers.

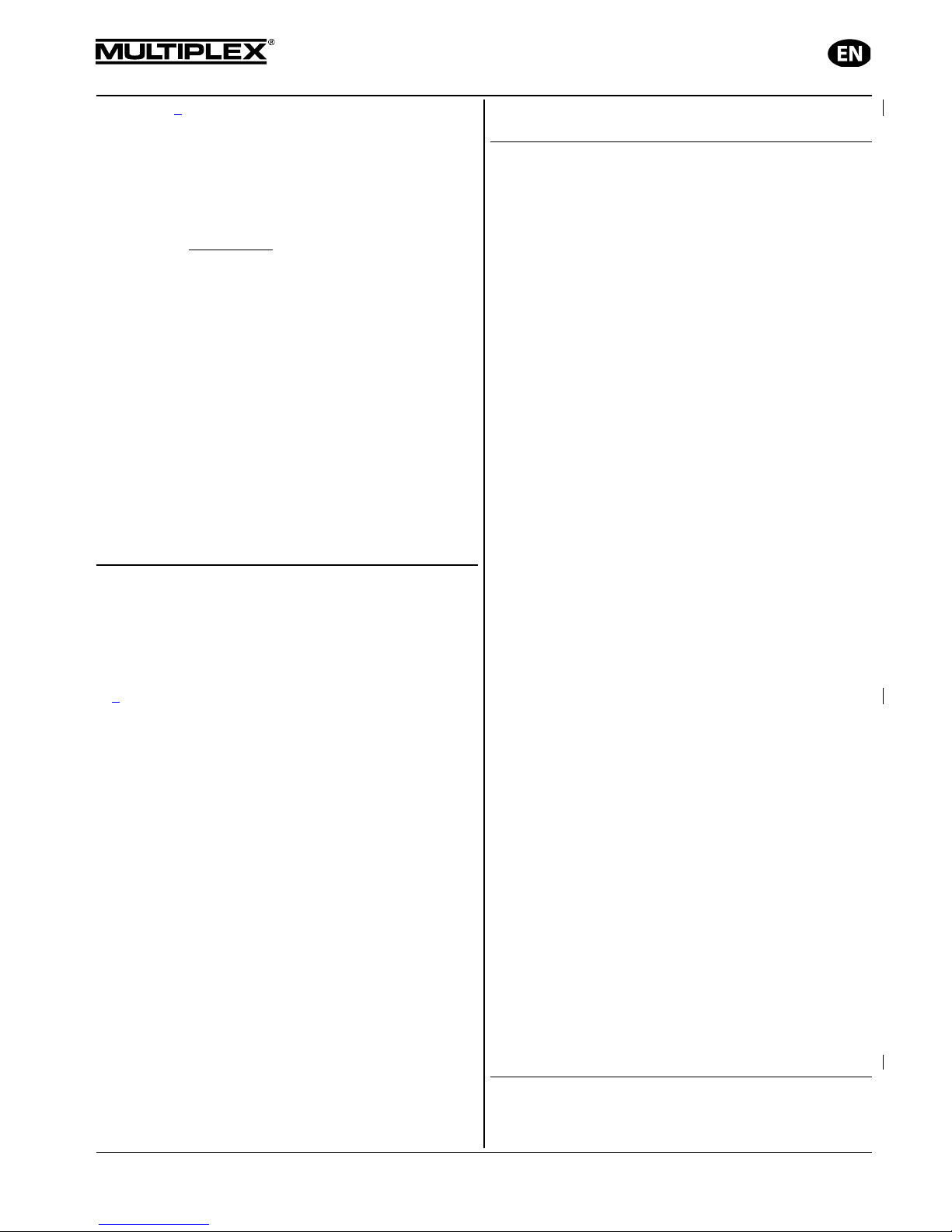

21. RECOMMENDED INSTALLATIONS

*Max. = As far as possible

A

B

Max.*

Max.

*

C

Loading...

Loading...