Page 1

Instructions

MULTIPLEX Modellsport GmbH & Co.KG • Westliche Gewerbestraße 1 • Bretten • Germany

© MULTIPLEX 2014 • Printed in Germany

www.multiplex-rc.de

Page 2

Page 3

1. Contents

1. Contents 1

2. Introduction 5

2.1. The ROYAL SX philosophy ...................... 6

2.2. Arrangement of the instructions ............. 6

3. Safety Notes 7

3.1. General safety notes ................................. 8

3.2. Range checking ......................................... 9

4. Liability / Compensation 10

5. Guarantee 10

6. CE Conformity Declaration 10

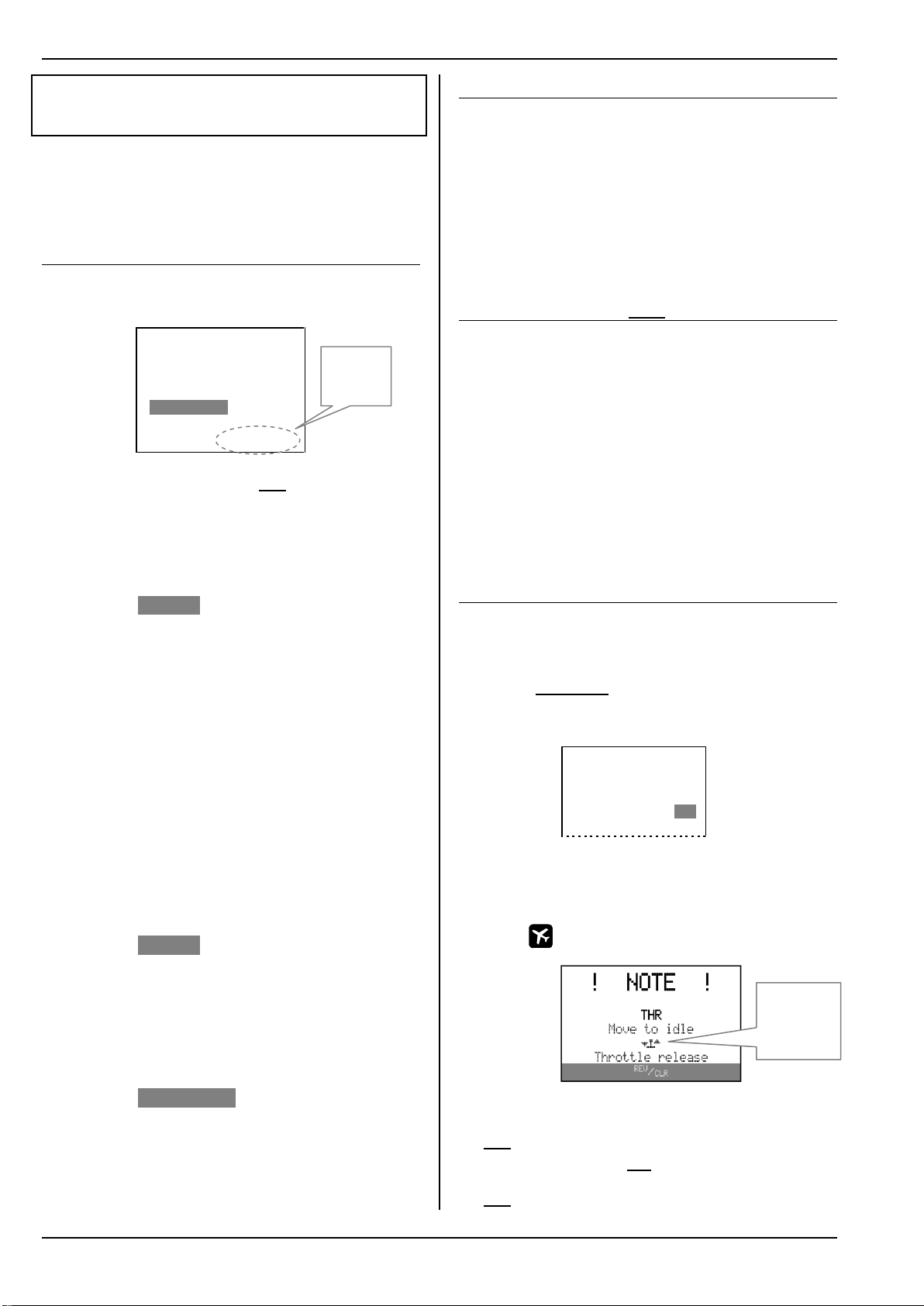

10. Switching on, using the transmitter 22

10.1. Switching on for the first time ................ 22

10.2. Switching on “normally” ......................... 22

10.2.1. Normal OpartionsFehler! Textmarke nicht definiert.

10.2.2. RF module excl. Scanner installed 22

10.3. Switching the transmitter on with throttle-

check active............................................. 22

10.3.1. Throttle-check for fixed-wing models 22

10.3.2. 23

10.3.2. Throttle-check for model helicopters 23

10.4. Binding Procedure................................... 23

10.5. Range Checking ....................................... 23

10.6. Fast Response ON/OFF .......................... 24

10.7. The Status displays ................................. 24

10.7.1. Status display 1 (standard) 24

10.7.2. Status display 2 (flight phases) 24

10.7.3. Status display 3 (timers) 25

10.7.4. Status display 4 (system information) 25

7. Specification 11

8. The Transmitter Battery 11

8.1. Safety Notes ............................................. 11

8.2. Charging the transmitter battery ........... 11

8.3. The correct method of charging ............ 12

8.4. ROYAL SX battery management ............ 12

8.4.1. Self-discharge 12

8.4.2. Unchanged features 13

8.4.3. This is important 13

8.5. Terms used in battery charging ............. 13

8.5.1. Normal charging … 13

8.5.2. Fast charging … 13

8.5.3. Trickle charging … 14

8.6. Replacing the transmitter battery .......... 14

8.7. Transmitter battery care and storage .... 14

8.8. Recycling ................................................. 14

9. The Transmitter 15

9.1. Front face of the transmitter .................. 15

9.2. Rear face of the transmitter ................... 16

9.3. Interior of the transmitter ....................... 16

9.4. Mechanical details ................................... 17

9.4.1. Opening / closing the transmitter case 17

9.4.2. Removing / installing the RF module 17

9.4.3. Ideal Transmitter Aarial Orientation When Using the

Transmitter 18

9.4.4. Replacing the transmitter battery 18

9.4.5. Disabling the stick centring spring, activating the

ratchet / friction system 19

9.4.6. Adjusting the “hardness” of the sticks 19

9.4.7. Swivelling the stick units 19

9.4.8. Adjusting / replacing the stick tops 19

9.5. Plastic stick top with three buttons:

installation and functions ...................... 20

9.6. Digital trims .............................................. 20

9.6.1. General information 20

9.6.2. Advantages of digital trims 21

9.6.3. The cruciform digital trims 21

9.6.4. On-screen trim display 21

11. The “ROYAL SX” philosophy 25

11.1. Operating the ROYAL SX ........................ 25

11.1.1. Using the keypad 25

11.1.2. Using buttons when operating a model 26

The............................................................. 26

11.2. ROYAL SX menu structure ..................... 26

11.3. What do the sticks, sliders and switches

do? Or: Global assignments (lists) ....... 27

11.3.1. What does “Assignment” mean? 27

11.3.2. What are transmitter controls? 27

11.3.3. What are switches? 27

11.3.4. Why “global” assignments? 27

11.3.5. Which assignment lists are available? 28

11.3.6. How are the assignment lists arranged? 28

11.3.7. How are the assignment lists used? 28

11.3.8. Summary: “Global assignments” 29

11.4. Global mixer definitions .......................... 29

11.4.1. Why “global” mixer definitions? 29

11.4.2. Which global mixers are available? 29

11.4.3. Mixer names with a “+” suffix 29

11.4.4. How are the free mixers used in fixed-wing model

aircraft? 29

11.4.5. How are mixers used in helicopters? 30

11.4.6. Summary of the “free mixers” 30

11.5. Model templates ....................................... 30

11.5.1. Why are model templates needed? 30

11.5.2. What do the model templates contain? 30

11.5.3. Which model templates are available? 30

11.6. Servo configuration ................................. 30

11.7. Servo calibration ...................................... 31

11.7.1. What can be calibrated? 31

11.7.2. How is the calibration carried out? 31

11.7.3. Allocation - what’s that? 31

12. Setting up a fixed-wing model 32

12.1. The method in principle .......................... 32

12.2. Setting up the new model in the

transmitter ............................................... 32

12.2.1. Menu I, call up New model 32

12.2.2. Which model memory will be used? 32

12.2.3. Selecting the Template 32

19.11.2008 1

Page 4

ROYAL SX

12.2.4. Selecting the servo configuration (servo conf.)32

12.2.5. Selecting the stick mode 33

12.2.6. Selecting the Assignment 33

12.2.7. Confirming with OK 33

12.2.8. Entering the model name 34

Preparing the controls / switches .......... 34

12.3. 34

12.3.1. Selecting / changing the idle position for spoiler /

throttle 34

12.3.2. Changing the switch ON position 35

12.4. Preparing servos ..................................... 35

12.4.1. Checking / changing the servo assignment 35

12.4.2. Checking / changing the direction of servo rotation36

12.4.3. Calibrating servos = setting the centre and

maximum travels 36

12.5. Adjusting ailerons, and activating landing

aid (Mixer AILERON+) .............................. 37

12.6. Differential aileron travel ........................ 38

12.6.1. Activating differential 38

12.6.2. Setting the differential value 38

12.7. Adjusting elevator, activating elevator

mixers (Mixer ELEVATR+) ........................ 39

12.7.1. Spoiler to elevator = Spoiler compen-sation

(Spoiler input to ELEVATR+ mixer) 39

12.7.2. Throttle to elevator = Throttle compen-sation (Thr

-Tr input to ELEVATR+ mixer) 39

12.8. Activating inboard flaps (camber-

changing flaps) (Mixer FLAP+) ............... 39

Activating the Spoiler input in the mixer FLAP+

( 40

12.8.1. Butterfly) 40

12.8.2. Activating the Flap input in the mixer FLAP+

(camber-changing flaps) 40

12.8.3. Activating the Aileron input in the FLAP+ mixer

(aileron support by the inboard (camber-changing)

flaps) 40

12.8.4. Activating the Elevator-Tr (Ele -Tr) input in the

FLAP+ mixer (snap-flap) 41

12.9. V-tail models ............................................ 41

12.9.1. Assigning V-tail servos 41

12.9.2. Activating the mixer V-TAIL+ 41

12.9.3. 41

12.9.3. Checking / changing the direction of servo rotation41

12.9.4. Adjusting the remaining inputs 42

Working with flight phases ................. 42

12.10. 42

12.10.1. What is the purpose of switching between different

flight phases? 42

12.10.2. Default settings in the menu Flight phase 42

12.10.3. Assigning flight phase switches 42

12.10.4. Locking / unlocking flight phases 42

12.10.5. Copying flight phases 43

12.10.6. Changing flight phase names 43

12.10.7. Setting a transition time 43

12.11. Supplementary functions ....................... 44

12.11.1. D/R and Expo 44

12.11.2. Activating Combi-Switch 44

12.11.3. Motor run timer 44

13. Setting up a model helicopter 45

13.1. The method in principle .......................... 45

13.2. Setting up a New model in the transmitter45

13.2.1. Menu I, call up New model 45

13.2.2. Which model memory will be used? 45

13.2.3. Selecting the template 45

13.2.4. Selecting the servo config(uration) 45

13.2.5. Selecting the stick Mode 46

13.2.6. Selecting the Assignment 46

13.2.7. Confirming with OK 46

13.2.8. Entering the model name 47

13.3. Preparing the controls / switches .......... 47

13.3.1. Checking / changing control settings for idle /

collective pitch min. and throttle limiter min. 47

13.3.2. Changing the switch ON positions and / or the

switch assignment 48

13.4. Checking / changing the servo

Assignment .............................................. 48

13.5. Checking / adjusting the main rotor ...... 49

13.5.1. Checking / changing the direction of rotation of the

rotor head servos 49

13.5.2. Calibrating servos = setting the centre and

maximum travels 49

13.6. Checking / adjusting the tail rotor .......... 50

13.6.1. Checking / changing the direction of rotation of the

tail rotor servo 50

13.6.2. The TAIL mixer 50

Basic 51

13.6.3. Offset value 51

13.6.4. Collective pitch to tail (Revo-Mix) 51

13.6.5. Mixer Zero point 51

13.6.6. Differential yaw (rudder) travel 51

13.7. Gyro ........................................................... 51

13.7.1. Parameter Type of Gyro 52

13.7.2. Adjusting gyro suppression 52

13.8 ............................................................ 53

13.8. Throttle, and associated functions ........ 53

13.8.1. What is the meaning of the terms Limiter, Curve,

Throttle Min., Trim, DTC and Throttle cut? 53

13.8.2. Throttle for electric helicopters 54

13.8.3. Throttle for I.C. powered helicopters 54

13.9. Setting the collective pitch curve ........... 55

13.10. Working with Flight phases .................. 55

13.10.1. What is the purpose of switching between different

flight phases? 55

13.10.2. Default settings in the menu Flight phase 55

13.10.3. Assigning flight phase switches 56

13.10.4. Locking / unlocking flight phases 56

13.10.5. Copying flight phases 56

13.10.6. Changing flight phase names 56

13.10.7. Setting a transition time 57

14. Main menu ¡Setup 58

14.1. Menu Transmitter .................................. 58

If the screen area is not sufficient to display all the sub-menus,

this is indicated by means of arrows ( or ) at

the left-hand edge of the screen. In this case you

can access the start or end of the list by scrolling up

or down using the UP / DOWN buttons ( / ) or

one of the two 3-D digi-adjusters. 58

14.1.1. Parameter Sound 58

14.1.2. Parameter group Safety 58

14.1.3. Parameter group Battery 58

2

Page 5

Manual

14.1.4. Parameter group Display 59

Menu ......................................................... 59

14.2. Mixer def. .............................................. 59

14.2.1. Defining a free mixer 59

14.2.2. Method of working and options for the mixer inputs59

14.2.3. Making mixer inputs switchable 61

14.3. Menu: Assignment .................................. 61

14.3.1. Sub-menu Assign.Controls 61

14.3.2. Sub-menu Assign.Switches 62

(Proportional) transmitter controls as switches: 62

14.3.3. Special case Extra Sw. 62

14.4. Menu Training ....................................... 63

14.4.1. The ROYAL SX as Teacher transmitter 63

14.4.2. The ROYAL SX as Pupil transmitter 64

14.5. Menu User ................................................ 65

14.5.1. Parameter PIN (access code) 65

14.5.2. Parameter Language 65

Parameter Name 65

14.5.3. 65

15. Main menu ¢Control 66

15.1. Menu Control ................................. 66

15.2. Menu Control ................................. 67

15.3. Menu ¢TriggerPoint .......... 68

15.4. Control menu screen layout ................... 68

15.4.1. Parameter Trim 68

15.4.2. Parameter Step (Trim increment) 68

15.4.3. Parameter Mode (throttle trim) 69

15.4.4. Parameter D/R (Dual-Rate) 69

15.4.5. Parameter Trvl (Travel) 69

15.4.6. Parameter Expo 69

15.4.7. Parameter Fixed Value 69

15.4.8. Parameter Time 70

15.4.9. Parameter Limit 70

15.4.10. Parameter Collect. P1 ... P5 (Coll. pitch curve)70

15.4.11. Parameter Throttle P1 ... P5 (Throttle curve)70

15.4.12. Parameter Throttle Min. (idle, throttle limiter) 71

Main menu 72

16. £Mixer 72

16.1. Menu Mixer Fixed-wing models . 72

16.1.1. Combi-Sw. (Combi-Switch) 72

16.1.2. Ail.Diff. (aileron differential) 72

16.1.3. Controls Mix (transmitter control mixer) 73

16.1.4. Setting up free mixers 73

16.2.4. Rotor head (swashplate mixer) 76

17. Main menu Servo K 78

17.1. Menu Calibrate ...................................... 78

17.1.1. Sub-menus for individual servos 78

17.1.2. The procedure for calibrating a servo 79

17.2. Menu Assignment .................................... 79

17.2.1. ROYAL SX 16 only: Special features relating to

servo 11 and / or servo 12 (PPM modulation) 80

17.2.2. Non-MULTIPLEX receivers with ten channels 81

17.3. Menu Monitor .......................................... 81

Menu: Test run ........................................ 81

17.4. 81

18. Main menu Timer A 81

18.1. Slot, Sum and Interval timers: display

and reset .................................................. 81

18.2. Menu ¥Timer, Model for flight time per

season / session ..................................... 82

18.2.1. Summary Timer Model 82

18.3. Menu ¥Timer, µSlot ............................ 82

18.3.1. Example: monitoring the slot time (time limit) 82

Summary: Timer 1 µSlot 83

18.3.2. 83

18.4. Menu ¥Timer, ´Sum .............................. 83

18.4.1. Example: recording motor run time 83

18.4.2. Summary Timer 2 ´Sum 83

18.5. Menu ¥Timer, ¶¶Interval ................... 84

Example 84

18.5.1. : Monitoring motor run time per climb 84

18.5.2. Summary Timer 3 ¶¶Interval 84

18.6. Total transmitter operating time ............ 84

19. Main menu Memo I 85

19.1. Selecting a model memory ..................... 85

19.2. Copying a model memory ....................... 85

19.3. Erasing model memories ........................ 86

19.4. Managing Flight phases ....................... 86

19.4.1. Selecting flight phase names 86

19.4.2. Locking / unlocking flight phases 87

19.4.3. Copying flight phases 87

Setting the flight phase transition time 87

19.4.4. 87

19.5. Checking / changing the Properties of

the current model memory .................... 87

19.5.1. What is displayed? 87

19.5.2. What can be changed? 87

19.6. Setting up a New model ............................ 87

19.7. Menu: Modulation .................................. 88

20. Special facilities 89

16.2. Menu: Mixer Helicopters ............ 74

16.2.1. Comp. Mixer (compensation mixer) 74

16.2.2. Gyro (Gyro mixer) 75

16.2.3. TAIL (tail rotor mixer) 75

a. Basic Offset value 76

b. Collective pitch to tail (Revo-Mix) 76

c. Mixer Zero point 76

d. Differential yaw (rudder) travel 76

3

20.1. Using the 3-D digi-adjuster to alter

settings in flight ...................................... 89

20.2. PC data back-up / updating .................... 90

Using a flight ............................................ 91

20.3. simulator ................................................... 91

20.4. Error messages ........................................ 91

20.5. Accessories .............................................. 91

Page 6

ROYAL SX

20.5.1. Trainer lead 91

20.5.2. Aluminium stick top with switch or button installation and functions 91

a. Installing the stick tops 91

b. Using the stick switches 92

c. Connecting the stick button 92

d. Connecting a stick switch or second stick button 92

e. Using the second stick button 93

20.5.3. Retro-fitting switches K and / or P 93

Two-position switch 94

20.5.4. Additional accessories, replacement parts 94

21. Model templates in detail 94

21.1. Fixed-wing model aircraft ....................... 94

21.1.1. BASIC model template 95

21.1.2. ACRO model template 96

21.1.3. HOTLINER model template 97

21.1.4. DELTA model template 99

21.1.5. GLIDER model template 100

21.1.6. 4 FLAPS model template 101

21.2. Model helicopters .................................. 104

21.2.1. HELImech model template 104

21.2.2. HELIccpm model template 104

21.3. Servo configurations ............................. 105

22. Appendix: “global” lists 107

22.1. Global transmitter control and switch

assignments .......................................... 107

22.2. Pre-set mixers ........................................ 108

23. Care and maintenance 109

24. Disposal 109

25. Advice and Service 109

4

Page 7

Manual

2. Introduction

We are delighted that you have decided to purchase

the MULTIPLEX ROYAL SX radio control system.

The ROYAL SX is the result of a consistent programme

of development through the ROYAL series. The new

ROYAL SX retains many familiar and proven features

from the ROYALevo in combination with new features

suggested and requested by our large circle of users.

Transmission

M-LINK is a transmission system designed by

MULTIPLEX. It operates on the 2.4 GHz ISM band,

and exploits modern FHSS technology (FHSS = Frequency Hopping Spread Spectrum).

Automatic RF channel management:

With this system it is no longer necessary for the operator to select the RF channel manually (plug-in crystals, Synthesizer). 2.4 GHz Spread Spectrum systems

automatically divide up the frequency spectrum, and

this eliminates the need for conventional frequency

monitoring. Same-channel interference (as is possible

on the 35, 40 … MHz band) is virtually impossible.

The first time the system is used you just have to

carry out a simple binding procedure to link the transmitter to the receiver. From this moment on the receiver only responds to the signals from your specific

transmitter.

FHSS technology:

The transmitter and receiver jump from channel to

channel every few milliseconds, maintaining the same

rhythm; the data is transmitted during a fraction of this

period. The resultant brief period of channel occupation minimises signal conflicts, and suppresses interference. Even if data packets are lost on particular

channels, the constant high-speed hopping to the next

channel makes any interruptions unnoticeable to the

pilot.

Good data security / transmission security:

The enormous bandwidth available on 2.4 GHz makes

it possible to transmit much greater quantities of data

than is possible, for example on the 35 MHz band

(bandwidth on 2.4 GHz = 83.5 MHz; on 35 MHz =

1 MHz). Digital modulation in conjunction with sophisticated error-checking in the receiver guarantee outstanding data quality.

Good resistance to interference:

Typical interference sources in the model, such as

electric motors, and electronic devices such as speed

controllers, petrol engine ignition systems etc., have

an interference spectrum whose maximum frequency

is significantly below the 2.4 GHz range. It is virtually

impossible for 2.4 GHz systems to suffer interference

from such sources, and this provides a further improvement in security.

Fast, accurate transmission:

MULTIPLEX M-LINK is a digital transmission system

offering a maximum of sixteen servo channels with a

resolution of 12 bits (3872 steps). Background noise

has no effect on servo signal accuracy right up to the

limits of range. Resolution, centring precision and with

it general accuracy of control are at a con-stant high

level up to the effective limits of range. M-LINK’s digital encoding allows both HOLD and FAIL-SAFE to operate very accurately. The standard servo pulse rate

of 21 ms (16-channel mode) can be reduced to 14 ms

(12-channel mode - Fast Response) in the case of the

ROYALevo, ROYAL SX and ROYAL SX M-LINK

transmitter types.

Feedback capability / Telemetry:

The 2.4 GHz ISM band offers the possibility of transmitting data from the model back to the transmitter. If

you use a telemetry-capable receiver, the actual voltage of the receiver power supply is displayed on the

transmitter’s integral screen. If the voltage falls below

the set minimum value, an audible signal warns you

that the battery is almost flat. It is also possible to

have additional telemetry data from the model displayed on the screen, provided that appropriate sensors are installed in the model; these parameters include motor current, battery voltage, temperature, …).

Short transmitter aerial:

The short 2.4 GHz transmitter aerial is robust and

easy to handle, and it does not impinge on the pilot’s

field of vision.

Operation

Digital trim system

easily accessible cruciform trim buttons, trims specific to each flight phase, clearly arranged graphic

on-screen trim display, audible support, variable

trim increments

Voltage display and battery monitor with variable

warning threshold (battery voltage) and audible

alarm

Battery management system

Transmitter battery monitor with display of residual

charge in mAh, plus calculated display of remaining operating time in hours

Servo monitor

with graphic or numerical display, for checking

model settings

Code lock PIN (4-digit) for securing the transmitter

against unauthorised data access

Hardware

Modern, ergonomically efficient case design with

ultra-precise, individually variable, swivelling ballraced stick units for use hand-held or in a tray

Graphics-capable folding screen (132 x 64 pixels)

with variable contrast

Modern FLASH processor technology; simple up-

date via the Internet when new software versions

become available

MULTIPLEX multi-function socket fitted as stan-

dard: acts as charge socket, Trainer mode interface, PC interface (PC update, data back-up, flight

simulator)

Selective Trainer mode operations

facilities provided as standard; unique QuickSelect control assignment

5

Page 8

ROYAL SX

ROYAL SX

9

16

Channels

9

16

Model memories

28

36

Timers for total transmitter operating time and

model operating time (model-specific)

Programming

Clearly designed, efficiently structured menus for

simple programming

Optional keypad or two 3-D digi-adjusters for pro-

gramming

Clear text menu system, screen texts can be dis-

played in various national languages

Model-specific settings

Flight phase switching

With up to four flight phases for fixed-wing models

and helicopters, variable transition time

Dual-Rate and Expo, variable for each flight phase

separately

Five-point servo adjustment

Servo travel right / left, centre and two intermediate

adjustment points allow compensation for linkage

inaccuracies and mechanical travel discrepancies

Three timers (slot, sum, interval)

With variable alarm time and audible alarm

Separate timer for the model’s total operating time

Convenient model memory management

Unrestricted model names, up to sixteen characters, copy and erase functions

Comprehensive set-up and mixer facilities for

fixed-wing model aircraft and helicopters

Eight model templates cater for many different

model types and help to minimise the programming effort required

Differences between transmitter versions:

We are confident that you will rapidly learn to appreciate

your ROYAL

familiarise yourself with its facilities. These operating

instructions are intended to guide you through this

process. The system will give your endless hours of

pleasure in our mutual and fascinating hobby of model

sport.

pro

once you have taken a little time to

Yours - the MULTIPLEX team

2.1. The ROYAL SX philosophy

At the design stage of the ROYAL SX we placed particular emphasis on high-level user-friendliness, flexibility and maximum standardisation.

The user-friendly aspect results from the clearly arranged menu structure, the informative and well laidout menus and the large number of useful “little

touches” which make it easier to program and use the

transmitter.

The transmitter’s flexibility is due to a combination of

two features: the large number of facilities which are

pre-defined and ready to use, and the ability to vary

almost all of them exactly as you wish. Transmitter

controls (sticks, sliders and switches) and servos can

be assigned without restriction, and the pre-defined

mixers can be modified in any way you like.

You can create your own “standard” by fine-tuning the

pre-defined mixers and assignment lists to suit your

personal preferences and applications.

Standardisation makes it easier and more intuitive to

program the transmitter. Pre-defined model templates,

mixers and assignment lists ensure that you can set

up a new model memory with just a few buttonpresses, and it is then ready for immediate use.

Chapter “11. The ROYAL SX philosophy” describes

the background to the system and related facilities,

and is intended to help you understand the way the

transmitter works. It is therefore particularly important

to read this section.

2.2. Arrangement of the instructions

In addition to other subjects, Part 1 (Chapters 1. to

10.) contains important information on the subject of

safety !. This section also includes all the informa-

tion you need concerning the transmitter’s hardware.

Essential reading!

Part 2 (Chapter 11.) concentrates on the HOW and

WHY of the ROYAL SX’s wide-ranging software func-

tions. This background information makes it much

easier to understand the sequence of operations

when programming the transmitter.

Part 3 and Part 4 describe step by step how to pro-

gram a fixed-wing model aircraft and a model heli-

copter.

First the basic functions (aileron, elevator, rudder,

throttle / collective pitch, roll, pitch, yaw) are “brought

into play”.

After this the text explains the essential steps required

to expand and refine the model’s functions.

Part 5 contains a detailed description of all the

menus, the model templates, the default transmitter

control settings, the switch assignments and much

more.

6

Page 9

Manual

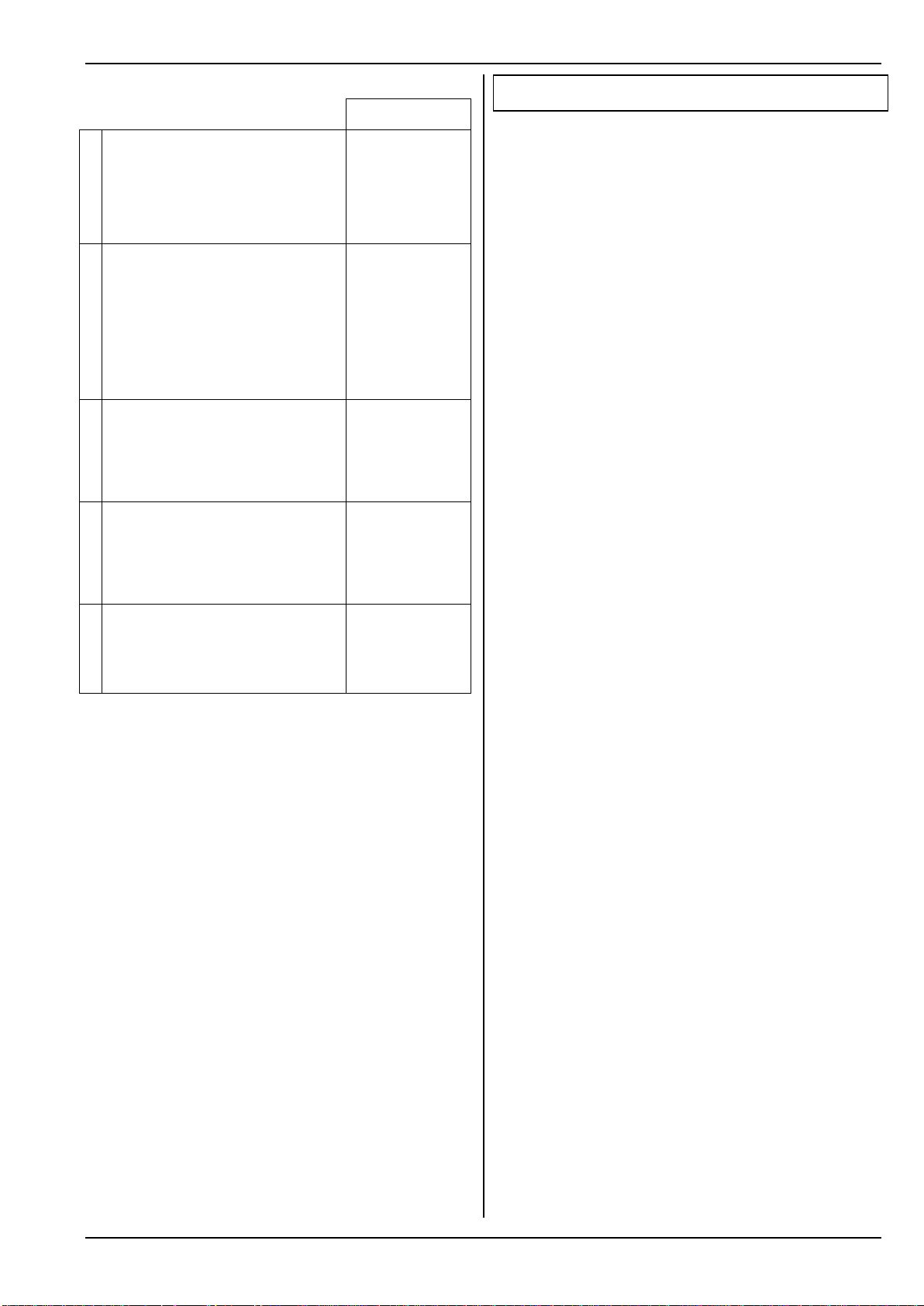

Chapter

Part 1

Introduction

Safety notes

Specification

Notes on the transmitter battery

Transmitter hardware

Switching on for the first time

2.

3.

7.

8.

9.

10.

!

!

Part 2

The “ROYAL SX” philosophy

Buttons and 3-D digi-adjusters ...

... when programming

... when operating the model

... when switching on

Global assignments

Global mixers

Model templates

11.

Part 3

Programming a fixed-wing model

Preparing the transmitter

Preparing the model

Setting up the basic functions

Supplementary functions

12.

Part 4

Programming a model helicopter

Preparing the transmitter

Preparing the model

Setting up the basic functions

Supplementary functions

13.

Part 5

Reference

All the menus in detail

Trainer mode operations

Overviews

14. - 19.

14.4. + 20.6.3.

21. + 22.

Arrangement of the instructions

3. Safety Notes

! These operating instructions are an integral

part of the product, and contain important information and safety notes. Please store them

in a safe place, and be sure to pass them on

to the new owner if you ever dispose of the

product.

! Observe the safety notes!

Read the instructions carefully!

Do not switch the system on until you have

studied these operating instructions and the

safety notes which follow (either included in

the instructions, or supplied separately).

! Warning!

Radio-controlled models are not playthings in

the usual sense of the term. The construction,

the installation of the RC system and the

method of operating the models require technical expertise, care and responsible, safetyconscious behaviour. Errors and neglect can

result in serious damage or injury. However,

since we as manufacturers have no means of

ensuring that you build and operate your

models competently, all we can do is express-

ly point out these hazards. We deny all liability.

A model which goes out of control, for what-

ever reason, can cause severe personal injury

and serious damage to property. It is fundamentally essential that you take out suitable insurance to cover this risk.

This character indicates chapters which are

!

safety-related. It is essential to read and observe

these sections!

7

! Under no circumstances is it permissible to

carry out technical modifications to your radio control system. Use genuine MULTIPLEX

accessories and replacement parts exclusively; this applies in particular to the

transmitter battery, aerial, expansion units,

additional hardware items, …).

! If you operate the transmitter in conjunction

with products made by other manufacturers,

it is up to you to ensure that they are of good

quality and work properly. Every time you set

up a new or modified chain of products, you

must ensure that all the functions work properly, and carry out a range check before flying

the model. Do not be tempted to fly the model

if something is not in order: first seek out the

problem and eliminate it.

! Have your radio control equipment (especially

transmitters and receivers) checked at regular

intervals (every two or three years) by an

authorised MULTIPLEX Service Centre.

! Operate your transmitter only within the per-

missible temperature range ( 7.). Please

note that condensation can form inside the

transmitter if it is subjected to a rapid change

of temperature (e.g. warm car, cold flying

field). Damp has an adverse effect on the operation of the transmitter and any other electronic items.

Page 10

ROYAL SX

If damp is present in any electrical device,

cease operations immediately, disconnect the

power source, and allow the unit to dry out

thoroughly, preferably with the case open.

This may take several days. After this, carry

out a thorough check of its operation. If you

have the slightest doubt, send the device to

an authorised MULTIPLEX Service Centre for

checking.

! This radio control system may only be oper-

ated legally on particular channels / transmitter frequencies, which vary from country to

country. In some regions official formalities

have to be completed before the system can

be used. Please read the notes included with

the system.

! Always program a new model at home in

peace, and check all functions carefully. Make

sure you are familiar with the methods of

programming and using the transmitter before you operate your model outdoors.

! Always keep to the correct sequence when

switching on and off, as this avoids the possibility of the power system switching itself

on unexpectedly: this can be a serious hazard:

1. When switching on:

first switch transmitter ON,

then switch receiver ON,

then connect flight / drive battery

or switch power system ON.

2. When switching off:

first disconnect flight / drive battery

or switch power system OFF,

then switch receiver OFF,

then switch transmitter OFF.

3.1. General safety notes

Build your model carefully:

Install and adjust all control surface linkages in

such a way that the surfaces move smoothly and

freely, and are not stalled at maximum travel. Don’t

limit servo travels at the transmitter; it is always

better to adjust the system mechanically, i.e. the

horns, levers and pushrods. Avoid lost motion

(sloppy linkages). These measures are essential in

order to minimise the load on the servos. This in

turn allows them to perform at their best, and they

will also last longer and operate more reliably.

Provide effective protection from vibration to the

receiver, battery, servos and other RC and electronic components (danger of electronic component failure!). Read and observe the advice included in the appropriate operating instructions.

Of course, this also includes the avoidance of

vibration in the first place: balance propellers and

rotor blades before use, and replace them at any

sign of damage. Install I.C. engines on vibrationabsorbing mounts, and replace motors, engines

and motor parts which are damaged or do not run

true.

Do not place leads under tension or kink them;

protect them from rotating parts.

Avoid unnecessarily long or superfluous servo ex-

tension leads. Leads longer than about 30 to 50

cm should be fitted with separation filters (ferrite

ring # 8 5131 or separation filter lead # 8 5035),

and must be of adequate conductor cross-section

(voltage loss). We recommend at least 0.3 mm2.

Do not shorten or coil up the receiver aerial. Never

deploy the aerial parallel to conductive parts such

as metal pushrods, or inside fuselages with a

shielding effect (made of or reinforced with carbon

fibre, metallic painted finish). Do not lay the aerial

on electrically conductive model components.

Whip aerials are recommended for large-scale

model aircraft. Read the instructions supplied

with your receiver!

Ensure that the receiver power supply is of ade-

quate capacity. For servos up to about 40 Ncm

torque you can estimate the required battery ca-

pacity using the following formula:

Capacity [mAh] > Servo count x 200 mAh

If in doubt, always use the next larger size of bat-

tery unless weight or space make this impossible.

Moving parts made of conductive materials (e.g.

metal linkage components or pushrods) must not

be allowed to touch each other. They produce

metal-to-metal “noise” interference which has an

adverse effect on radio reception.

Interference caused by static charge and powerful

electrical or electro-magnetic fields should be

avoided by suitable suppression measures (e.g.

suppress brushed electric motors with suitable ca-

pacitors, fit petrol engines with shielded sparkplug

connectors, suppress ignition leads and ignition

units), and keep such items well away from the RC

system, the receiver aerial, wiring and batteries.

Maintain an adequate distance between high-

current cables (e.g. electric power system leads)

and all the receiving system components. In par-

ticular, the leads between brushless electric mo-

tors and their speed controllers should be kept as

short as possible (guideline: max. 10 to 15 cm).

The receiver can be shielded from interference

generated by speed controllers by the use of sup-

pressor filters (ferrite ring # 8 5146 or suppressor

filter lead # 8 5057).

Check your model at regular intervals:

Ensure that control surfaces and their linkages

move freely, smoothly, and without lost motion.

Ensure that pushrods, other linkages, hinges etc.

are stiff enough, and are in perfect condition.

Carry out a visual check for fractures, cracks, pos-

sible shear points etc. on the model itself, and in its

components such as the RC and power systems.

Check that all electrical leads and connectors are

in perfect condition, and are making sound contact.

8

Page 11

Manual

It is essential to examine the airborne power sup-

ply and its wiring at regular intervals. This includes

the switch harness, and the external condition of

the battery.

Regular maintenance also covers the battery

gular maintenance also covers the battery (conditioning by repeated charge / discharge cycles), and

regular checks of the voltage curve and capacity.

This requires the use of a battery charger and a

charge process which is suitable for the type of

battery in use.

Pre-flight checks:

Charge the transmitter, receiver and flight batteries

carefully, and ensure that they are in good condition

during pre-flight checks and between flights.

At the flying field your first job is to check with the

other modellers present whether your own channel /

transmitter frequency is free. If there is a flight director or site warden, be sure to register with that

person, and make sure you understand the type of

frequency control in use.

Only then switch ON!

Ignore this, and you risk a “channel clash” (two

transmitters on the same frequency)!

Carry out a range check with the transmitter aerial

fitted, but collapsed. ( 3.2.).

Ensure that the correct model memory is active.

Check the function and effect of all primary and

secondary control systems.

! If you discover anything doubtful: do not fly!

Locate the fault, eliminate it, then check again.

When operating the model:

If you have never flown a radio-controlled model, it

is really essential initially to ask an experienced

model pilot for help. A Trainer (buddy-box) system

is ideal for the first steps in learning to fly.

Models should only be operated at suitable sites.

Never fly or drive over or towards spectators.

Do not carry out any high-risk flying or driving ma-

noeuvres.

It is tempting to over-estimate your own ability and

skill. Don’t do it: keep within your limits.

If you detect any sign of a problem or interference,

land or cease operations immediately.

Caution: static electrical charges!

In extremely dry air (in mountainous terrain, in a

mountain bowl, close to weather fronts) static

charges tend to build up in the transmitter and / or

the pilot. The discharge takes the form of static

sparking, which can endanger the pilot, and cause

interference or damage to the transmitter.

Counter-measures:

Cease operations as quickly as possible, and walk

a little way down the mountain in order to find a

less exposed location.

Keep at least 2 m away from mobile phones!

We recommend that you stand at least 2 m away

from mobile telephones when operating your model, as the high output of these devices may cause

interference to your transmitter or RF module. In

general terms we recommend that you switch off

mobile phones and any other equipment which

could affect the concentration of pilots.

ESD notes for electronic sub-assemblies:

The sub-assemblies of radio control transmitters (main circuit board, RF module,

Channel-Check module, Scanner module)

are fitted with electrostatically sensitive

components. These parts can be destroyed or their

useful life shortened if static discharges take place

(potential equalisation through electro-static discharge) when the sub-assembly is touched.

The following protective measures are essential if you

have to handle electrostatically sensitive subassemblies:

Before fitting or removing such assemblies, equal-

ise the potential difference between yourself and

your environment (e.g. by touching a heating radiator).

If necessary, open the main device and touch it

over a large area, in order to equalise the potential

relative to the base unit.

Do not remove the sub-assembly from the conduc-

tive anti-static bag until you have equalised the potential. Avoid touching electronic components or

solder pads directly. Hold the sub-assembly by the

edges of the circuit board only.

Once removed from the basic device, the sub-as-

sembly should only be stored in the conductive

anti-static bag in which it was delivered. Never allow the sub-assembly to make direct contact with a

conventional, non-ESD compatible container made

of foam, Styrofoam or other plastic.

3.2. Range checking

Regular range checks are very important - even when

using a 2.4 GHz system - in order to ensure reliable

operation of the radio control system, and to give you

a chance to detect sources of interference in good

time. This applies in particular:

Before the use of new or changed components, or

existing components in a new or modified arrangement.

Before re-using radio control system components

which were previously involved in a crash or a hard

landing.

If you have encountered problems on a previous

flight.

9

Page 12

ROYAL SX

Important:

Always ask a second person to help you with your

range check, so that one of you can secure and observe the model.

If possible, carry out the range check when no other

trans-mitters are operating.

Preparations, carrying out the range check:

1. Select “Range check” mode on the transmitter:

Hold button F on the transmitter pressed

in.

Switch the transmitter ON.

Release button F:

The red LED on the transmitter now glows

constantly, and the message “RANGE!”

flashes on the transmitter’s screen in all

the status displays with the exception of

status display 4.

2. Switch the M-LINK receiver ON.

3. Carry out the range check as described in the op-

erating instructions supplied with your M-LINK receiver.

4. When the range check is completed, switch the

M-LINK transmitter OFF, and then ON again, in

order to switch back to full range.

! Caution: selecting “Range check” mode re-

duces the transmitter’s output power. The trans-

mitter emits an audible signal every ten seconds

or so to warn you of this. Never attempt to fly a

model with the transmitter set to reduced output

(Range check mode)!

4. Liability / Compensation

Radio-controlled models are not playthings in the

usual sense of the term. The construction, the installation of the RC system and the method of operating

the models require technical expertise, care and responsible, safety-conscious behaviour. Errors and

oversights, not to mention deliberate negligence, can

result in serious damage or injury. You, as operator of

the model, are fundamentally responsible for the hazards presented by your model. This liability is not accepted by the manufacturer. The same applies to accidents caused by uncontrollable interference or outside intervention. As operator of the model, you therefore are assumed to have an enhanced obligation of

care.

Since we as manufacturers have no means of ensuring that you build, operate and maintain your models

and radio control equipment competently, all we can

do is expressly point out these hazards. We deny all

liability.

MULTIPLEX Modellsport GmbH & Co.KG accepts no

liability for loss, damages or costs which are incurred

due to the improper use and operation of the product,

or are connected in any way with such activity.

Whatever legal argument is employed, the liability of

MULTIPLEX is limited to the invoice value of those

MULTIPLEX products which were directly involved in

the event which caused the damage. This clause is

valid unless deemed invalid in a court of law. It no

longer applies if liability is accepted due to statutory

regulation on account of deliberate or gross negligence.

Moreover MULTIPLEX Modellsport GmbH & Co.KG

does not guarantee that the documents which accompany the radio control components are complete or

correct in every respect.

Please read the relevant information sheets

included in the transmitter documentation!

5. Guarantee

We guarantee our products in accordance with the

currently valid legal requirements. If you wish to make

a claim under guarantee, please contact the dealer

from whom you purchased the equipment.

The guarantee does not cover malfunctions which are

caused by the following:

- improper usage, incorrect connections, reversed

polarity,

- maintenance carried out incorrectly, carried out

late, not carried out at all, or carried out by a nonauthorised body,

- the use of accessories other than genuine

MULTIPLEX items,

- modifications or repairs not carried out by

MULTIPLEX or an authorised MULTIPLEX Service

Centre,

- accidental or deliberate damage,

- defects due to normal wear and tear,

- operation of the equipment outside the specification,

or in conjunction with equipment made by other

manufacturers.

Please read the relevant information sheets

included in the transmitter documentation.

6. CE Conformity Declaration

ROYAL SX systems have been assessed in accordance with European harmonised directives.

You are therefore the owner of a product whose design and construction satisfy the protective aims of the

European Community for the safe operation of equipment.

A detailed Conformity Declaration is available on our

Internet site www.multiplex-rc.de from the DOWNLOADS

area under PRODUCT INFORMATION.

If necessary you can also request a copy of the conformity declaration from us.

MULTIPLEX Modellsport GmbH & Co.KG

Kundendienst / Customer Service

Westliche Gewerbestraße 1

D-75015 Bretten-Gölshausen

Germany

10

Page 13

Manual

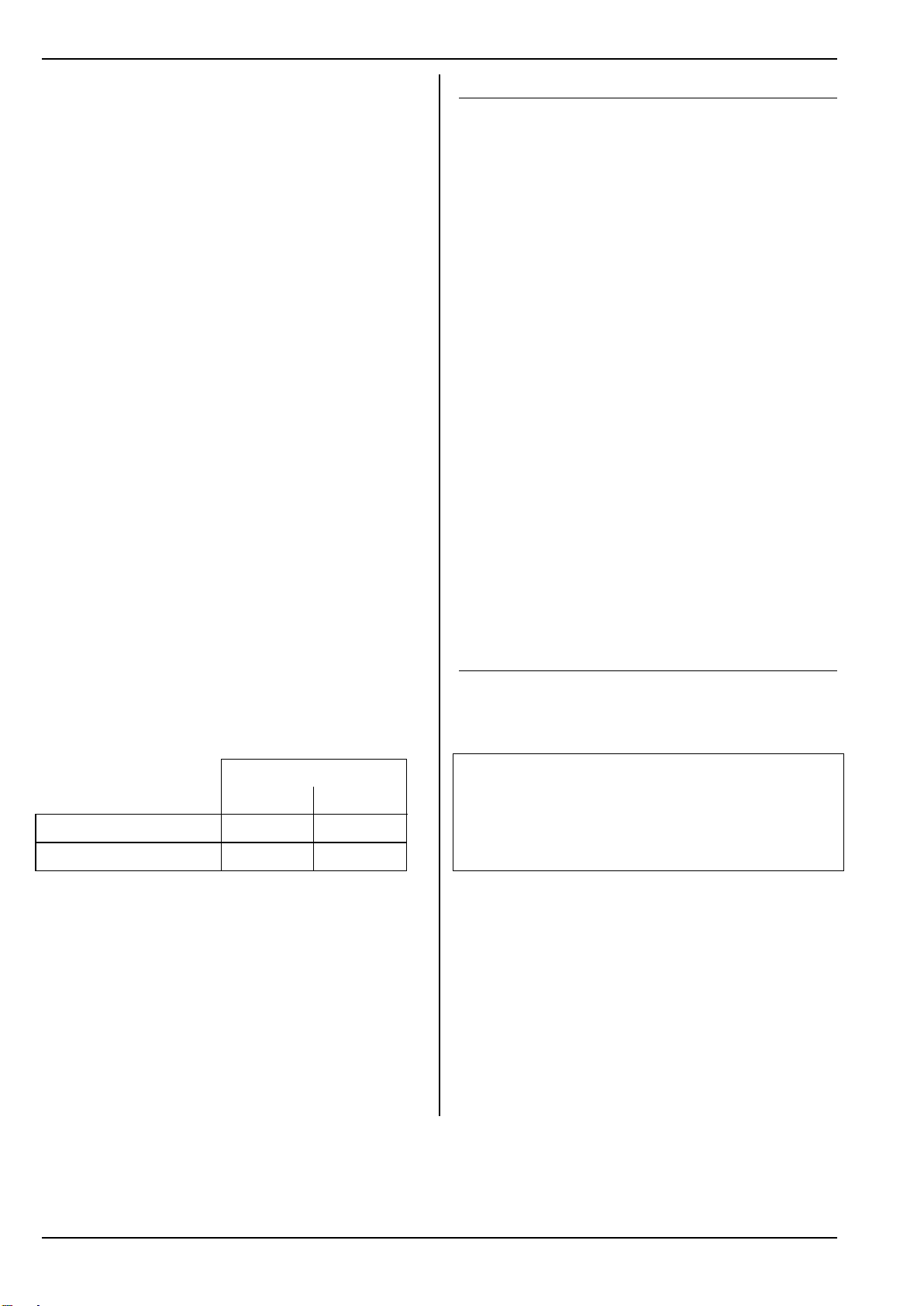

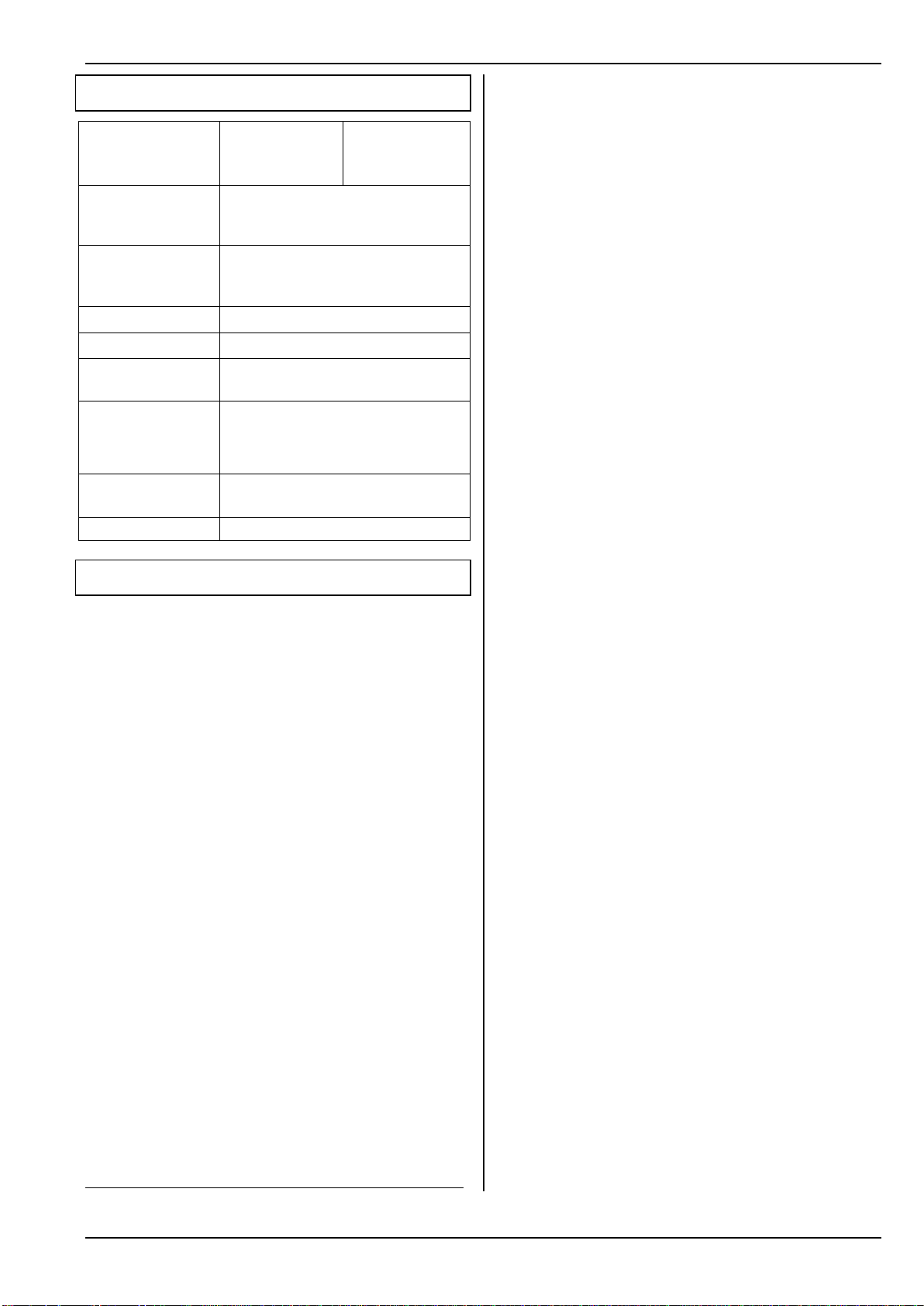

ROYAL SX

Model Memories

Channels

9

28

9

16

36

16

Frequency range

2.4000 GHz … 2.4835 GHz

Restricted frequency range:

2.4000 GHz … 2.4540 GHz

Transmission type

2.4 GHz FHSS M-LINK system

Frequency Hopping Spread Spectrum

MULTIPLEX-LINK

Transmission power

100 mW EIRP

Power supply

7.2 V, 6 AA cells

Charge current

max. 1.4 A (fast charge)

210 mA (normal charge)

Temperature range

Operation

Storage

Battery Charging

- 15 °C to + 55 °C

- 20 °C to + 60 °C

0 °C to + 40 °C

Dimensions

(L x W x H)

approx. 220 x 270 x 60 mm

Weight

approx. 900 g

7. Specification

8. The Transmitter Battery

The ROYAL SX is powered by a high-quality rechargeable PERMABATT+ battery consisting of six

AA-size NiMH (Nickel-Metal-Hydride) cells.

Features of the PERMABATT+ transmitter battery:

Capacity 2100 mAh

(approx. eight hours’ operation possible).

Self-discharge rate around 25% per year

(no recharging required even when stored for long

periods).

Fast-charge capable, max. 1.4 A

The pack must only be charged using a charger

with automatic cut-off: Delta-Peak cut-off at < 5 mV

per cell.

Normal charge at 210 mA

(corresponding to 1/10 C, charge for sixteen hours).

Integral over-current fuse, self-resetting

The battery is ready for use again approx. 1 s after

the excessive current is eliminated.

Avoid deep-discharging the battery (< 5.4 V).

If the transmitter or transmitter battery is to be

stored for a long period (several days), avoid temperatures above 30°C (brief maximum 55°C).

! The transmitter battery is responsible for the power

supply to the transmitter, and plays an important

role in operational security. For this reason it is essential to heed our recommendations regarding

charging and storing the rechargeable battery.

! The transmitter is fitted with a self-resetting fuse

which protects the battery and the transmitter from

short-circuit, reversed polarity and excessive currents. The transmitter electronics feature no additional fuse!

For this reason it is absolutely essential to use

genuine MULTIPLEX transmitter batteries in this

transmitter!

! Additional safety notes:

Batteries are not playthings, and must always be

stored well out of the reach of children.

Check that the battery is in perfect condition before

every flying session. Damaged or defective batteries must not be re-used. Dispose of them in the

authorised manner / recycling centre ( 8.8.).

Do not heat, incinerate, open or short-circuit re-

chargeable batteries, do not charge or discharge

them at excessive currents, do not overcharge

them, and do not charge with reversed polarity.

Place the transmitter or battery on a heat-resistant,

non-inflammable and non-conductive surface for

charging, and do not leave it on charge unsupervised.

Do not modify the battery pack in any way. Never

solder or weld directly to the cells.

Mis-handling the battery incurs a risk of combus-

tion, explosion, corrosion and burning.

Suitable extinguishing agents: water, CO2, sand.

Escaped electrolyte is corrosive!

Do not allow electrolyte to contact your skin or eyes.

In an emergency rinse the affected area with copious quantities of water, and call for medical assistance immediately.

Note:

Like many other technical components, rechargeable

batteries are the subject of constant development. For

this reason we reserve the right to alter the specification of the battery pack installed as standard, in order to keep abreast of technical developments.

8.1. Safety Notes

11

Page 14

ROYAL SX

8.2. Charging the transmitter battery

Never connect the transmitter to a battery

!

charger without a battery in the transmitter!

High voltages may be present at the charge out puts of battery chargers if no battery is connected.

These voltages can easily damage the transmitter.

Timer-controlled fast-charging, automatic cur-

!

rent setting systems and REFLEX charging

must not be used with this battery!

Fast-charge at max. 1.4 A!

!

This also applies if you remove the battery

from the transmitter for charging.

Important when fast-charging:

!

The battery charger must be suitable for NiMH

cells!

Delta-Peak cut-off sensitivity < 5 mV / cell

Charging using mains or 12 V chargers:

!

It is safe to leave the battery in the transmitter for

recharging. The charger should be connected

using the multi-function socket on the underside

of the transmitter ( 9.2.). Use genuine MULTIPLEX

charge leads (e.g. transmitter charge lead with

banana plugs # 8 6020). Please refer to the cur rent MULTIPLEX main catalogue for information

concerning other charge leads and battery char gers.

8.3. The correct method of charging

a. Switch the transmitter OFF.

b. Select a charger suitable for NiMH batteries,

switch it on and connect the charge lead to it.

c. Check correct polarity:

red plug = positive terminal (+)

blue / black plug = negative terminal (-)

Connecting the transmitter battery with reversed polarity may wreck the battery

(overheating, escape of corrosive electrolyte, cell

burst)!

d. Connect the charge lead to the transmitter

(back panel, CHARGE ( 9.2.)).

e. Select the charge current (max. 1.4 A).

If you are using an automatic fast-charger,

!

select the current manually!

f. If the battery becomes hot whilst on charge, to the

point where you can no longer touch the pack, interrupt the charge process immediately.

g. When the charge process is complete, first discon-

nect the transmitter / battery from the charger, and

then the charger from the power source.

h. When the charge process is complete, check the

charge quantity calculated by the battery management circuit, and correct it if necessary ( 8.4.3. a.).

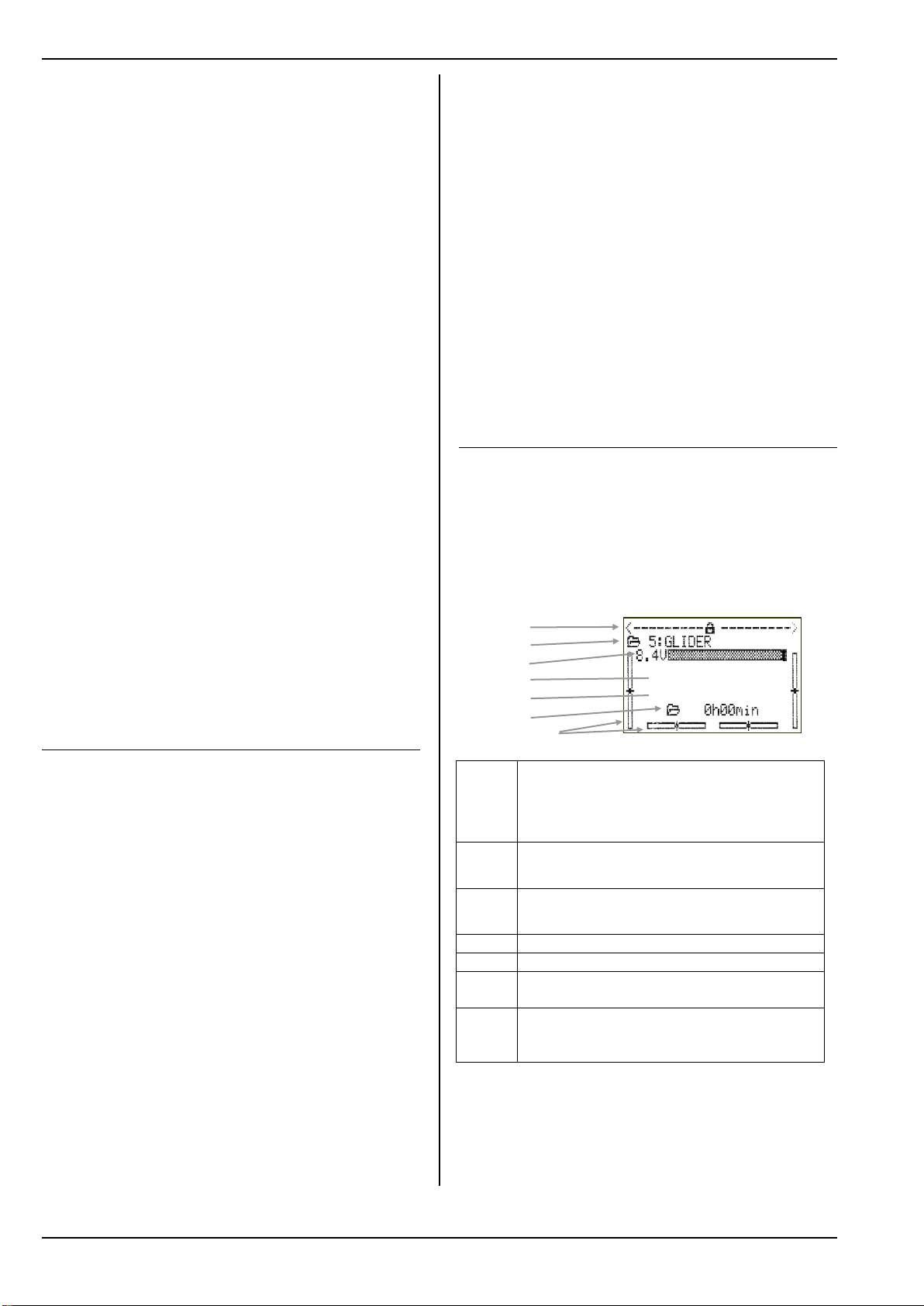

8.4. ROYAL SX battery management

The term “battery management” means that the transmitter measures the current when the unit is in use

and when the battery is on charge. From this data the

software calculates the actual state of charge of the

battery, and displays it on-screen in Status display 4

( Fig. 8.4.1.) and in the main menu ¡Setup under

Transmitter ( Fig. 8.4.2.).

When the RF module is operating (LED flashes red)

the expected residual operating time is calculated

and displayed in Status display 4. This indicates how

long the transmitter should be able to operate if the

current drain remains the same:

ROYAL SX16 3.46 DE/EN

M-LINK

Batt. voltage 8.20V

Battery charge 1998mAh

Remaining time 7.7h

Operating time 12.4h

Fig. 8.4.1.: Status display 4

8.4.1. Self-discharge

When the transmitter is stored, the system also takes

into account the battery’s rate of self-discharge, and

corrects the available battery charge quantity accordingly.

The ROYAL SX uses transmitter batteries of the type

PERMABATT+. The new manufacturing process used

for these batteries has reduced the rate of selfdischarge to around 0.07% per day (approx. 25% selfdischarge annually). The self-discharge rate of conventional NiMH batteries is around 1.5% per day.

For this reason the menu ¡Setup, Transmitter includes the menu point SlfDsCharge (self-discharge):

¡Transmitter

©

Battery

Alarm 7.10V

Capacity 2100mAh

Charge 1900mAh

SlfDsCharge low

Display

ª Contrast 0

Fig. 8.4.1.1.: Menu: Setup, Transmitter

In this menu point it is possible to switch the self-discharge rate between “low” (approx. 25% per year)

and “normal” (approx. 1.5 % per day). The factory default setting is “low”.

12

Page 15

Manual

Battery management only provides supple-

!

mentary information!

Battery charge and residual time represent additional

information relating to the condition of the transmitter

battery, and are intended to provide additional security

when handling the transmitter. However, major discrepancies may occur due to production tolerances,

battery ageing and the effects of battery maintenance.

In any case the system only works properly if the capacity and battery charge quantity ( 8.4.3.a.) are set

correctly when the battery is initially charged.

8.4.2. Unchanged features

Voltage display:

Virtually all modern transmitters display the actual battery voltage as a numerical value and / or in graphic

form (bar graph).

Battery alarm:

If the battery voltage falls below a certain minimum

value, the transmitter emits an audible alarm. On

many transmitters the alarm threshold is variable.

As you would expect, the ROYAL SX also includes

these two functions (Setting the alarm threshold

( 14.1.3.)).

8.4.3. This is important

To ensure that the battery management function displays values which are as close to “the truth” as possible, it is essential to observe the following points:

a. Correcting the battery capacity

The battery management function assumes that

the transmitter is fitted with a battery of 2100 mAh

capacity. When the transmitter battery has been

conditioned (more than five charge / discharge cycles) you can correct any discrepancy from the

nominal capacity as follows:

Menu: LSetup, Transmitter,

Parameter: Battery Capacity.

At this point you can set the value determined by

the battery charger (in increments of 50 mAh).

When the battery voltage falls below 6.5 V,

!

the available charge quantity is set to 0 mAh.

b. Correcting the available battery charge quantity

If you fit a new transmitter battery, or charge it di-

rectly (i.e. not via the socket on the back panel),

then the available battery charge quantity must be

corrected manually:

Menu: LSetup, Transmitter,

Parameter: Battery charge.

If the battery voltage is above 8.6 V when

!

the transmitter is switched on, the battery

charge quantity is set to the value which is set

for battery capacity in the menu ¡Setup,

Transmitter.

If the battery voltage falls below 6.5 V, the

!

available charge quantity is set to 0 mAh.

c. Charge the battery via the charge socket!

The battery management system can only

calculate the available charge quantity if you recharge the battery via the charge socket.

d. Normal charging at constant current (210 mA)

If you leave the battery connected to the charger

for longer than the period calculated according to

the formula in Section 8.5.1, the battery management system still displays the charge quantity

which you have set as the capacity in the menu

¡Setup, Transmitter.

8.5. Terms used in battery charging

Full capacity and potential performance ...

… are achieved by NiMH batteries only after several

charge / discharge cycles (~5 cycles). The initial charge /

discharge cycles should be carried out at 0.1 C (210

mA). Don’t fast-charge the battery until you have first

conditioned the pack in this way.

Charging at 1 C ...

... feeds 100% of the battery’s nominal capacity into

the pack in one hour in the form of charged-in energy.

For a battery of 2000 mAh capacity a current of

2000 mA is required to achieve this. If this current is

used for charging, we speak of a 1 C charge. This current value is found by simply taking the nominal capacity in mAh (or Ah), and omitting the “h” (hours).

8.5.1. Normal charging …

... means that the battery is charged at a current

within the range 0.05 C and 0.2 C. For a 2000 mAh

pack, for example, this means a charge rate of 100

mA to 400 mA.

To ensure that a rechargeable battery really is fully

charged, it is necessary to feed more than 100% of its

nominal capacity into the pack. The amount of the additional charge is defined by the charge factor.

The charge time for a flat battery is calculated as follows:

Capacity [mAh]

Charge time [h] = ------------------------------ Charge current [mA]

Note the charge factor for normal charging!

!

For PERMABATT+ type batteries of 2100 mAh the

charge factor is 1.6. Using a charge current of 210 mA

(1/10 C) a flat battery must therefore be charged for

sixteen hours if it is to be charged fully.

8.5.2. Fast charging …

... means that the battery is charged at a current in the

range 0.5 C to 1 C.

Observe the maximum charge current!

!

For PERMABATT+ type batteries of 2100 mAh the

maximum approved fast-charge current is 1.4 A.

In this case the charge time is determined by the fastcharger’s automatic cut-off circuit.

charge factor

*

13

Page 16

ROYAL SX

8.5.3. Trickle charging …

... means that the battery is charged at a current within

the range 0.03 C to 0.05 C.

Observe the maximum trickle charge current!

!

For PERMABATT+ type batteries of 2100 mAh capacity we recommend a trickle charge current of 20

mA to 100 mA. At a trickle charge rate of max. 105

mA the battery can safely be left connected to the

charger for up to a year.

Many automatic battery chargers switch to a trickle

charge current when the main charge process is terminated. If this is the case, we recommend that you

switch off the trickle charge no later than 24 hours after the charge process is complete.

8.6. Replacing the transmitter battery

If you replace the transmitter battery by a pack other

than a genuine MULTIPLEX battery, please note the

following:

Maximum current via the charge socket: 2 A!

!

Be sure to follow the charging instructions

!

provided by the battery manufacturer!

Set the self-discharge rate to suit the battery

!

type you are using! ( 8.4., Fig. 8.4.2.).

8.7. Transmitter battery care and storage

NiMH batteries should always be stored fully charged.

This avoids the danger of deep-discharging.

Store NiMH batteries at temperatures in the range 0°C

to 30°C, in dry conditions, away from direct sunshine.

Top up (recharge) unused NiMH batteries every six to

twelve months. This compensates for the selfdischarge effect, and avoids the danger of the cells

becoming deep-discharged.

Batteries which have been stored for a long period

should be conditioned (multiple charge / discharge cycles). Note that the usable capacity of such batteries

may diminish after a long period of storage.

8.8. Recycling

Do not dispose of exhausted rechargeable batteries in

the ordinary domestic waste. Take your old packs to a

suitable recycling centre. Make sure the batteries are

completely discharged beforehand, and insulate the

terminals to avoid the danger of short-circuit.

14

Page 17

Manual

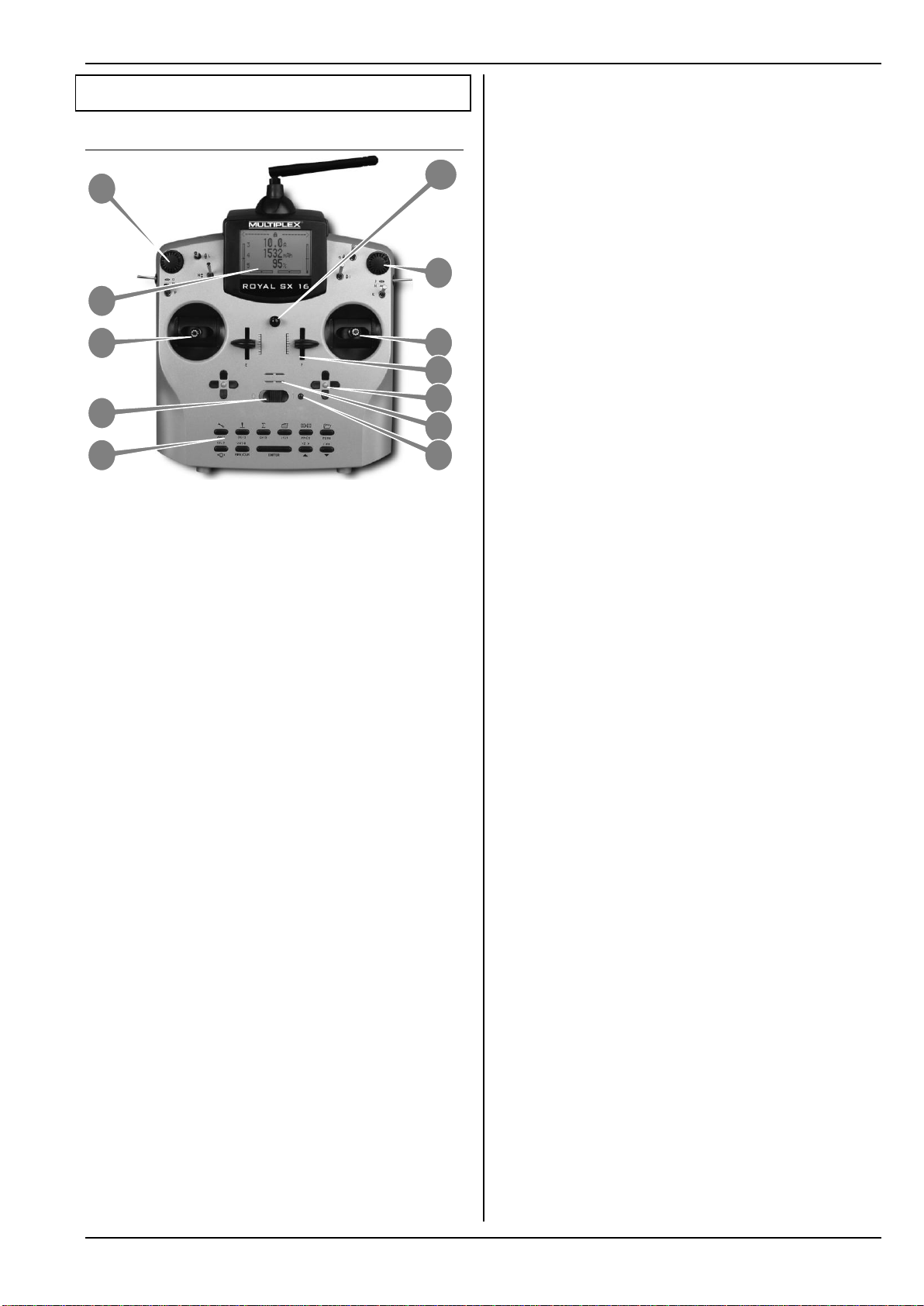

1 9 8 1 7 6 2

10

9

3

4

5

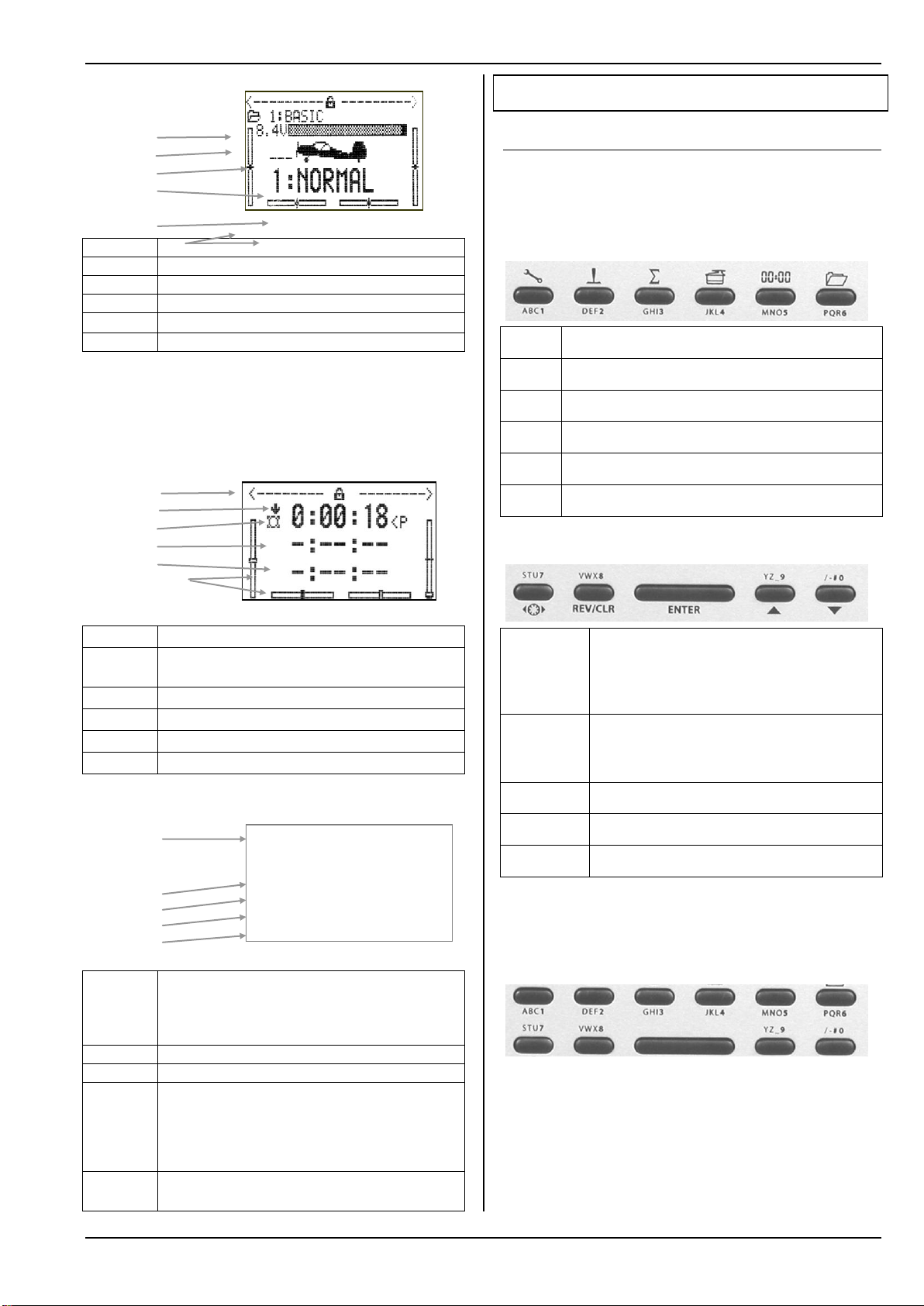

9. The Transmitter

9.1. Front face of the transmitter

Fig. 9.1.1.: Front face of transmitter

(Switches K and P retro-fitted; not included as standard.)

The front face of the transmitter features the following

elements:

Two extremely accurate, ballraced stick units for

controlling the four primary axes. Stick ratchet for

throttle / spoiler can be activated right or left. Both

stick units can be swivelled to suit the pilot’s ergonomic preferences ( 9.4.7.). The stick tops rotate

and are infinitely variable in length; various types of

stick top are available.

With the exception of the “ENTER” button, all the buttons have a dual function for text input. Text is entered

in a similar way to mobile telephones ( 11.1.1.c.).

OFF / ON switch (“O” / “1”).

The screen is a modern, UV-stable, non-reflective

graphic LCD unit (132 x 64 dots) featuring variable

contrast ( 14.1.4.). The screen can be hinged

through around 40° to optimise the viewing angle.

Two 3-D digi-adjusters are used for program-

ming and set-up tasks. They are fitted as standard,

and are permanently installed. For programming, both

adjusters work in parallel with the “ENTER” button and

the “” (UP) / “” (DOWN) buttons. When using the

transmitter it is possible to allocate many different settings / parameters to the 3-D digi-adjusters, enabling

the pilot to adjust the settings quickly and easily while

the model is in the air ( 20.1.).

Neckstrap lug for attaching a support strap (e.g.

# 8 5161 or # 8 5646).

All the remaining control elements ...

… (switches / buttons “G” to “O”, apart from installa-

tion wells “K” and “P” ( 20.6.6.)), are installed as

standard in easily accessible locations. They cannot

be altered or interchanged.

The switch and button designations are neutral (“G”,

“H”, “I”, ... “O”, “P”) and are only intended for identification purposes, as they can be assigned to any

channel and / or switched function (transmitter control

or switch) ( 14.3.).

Two permanently installed proportional controls

(sliders “E” and “F”) with centre detent; available for

use with freely assignable channel functions and / or

switched functions.

Two cruciform trim groups below the stick units

for digital trimming of the primary control axes. They

consist of pairs of buttons for left / right and up / down.

Audible sounder (piezo beeper).

When the transmitter is switched on, the RF sta-

tus indicator / LED (red LED) indicates whether an

RF (Radio Frequency) signal is being transmitted:

LED glows constantly

no RF transmission

LED flashes every two seconds

RF being transmitted

The LED is controlled by the current drain of the RF

module. If the RF module is not drawing the corresponding current, or is not installed, the constantly

glowing LED warns you that an RF signal is not being

transmitted.

Keypad consisting of eleven buttons in two rows.

The six buttons in the top row provide fast, direct access to the six main menus (direct menu access buttons). The five buttons in the second row are used for

programming the transmitter.

15

Page 18

ROYAL SX

3 2 3 1 4 2 1

9.2. Rear face of the transmitter

Fig. 9.2.1.: Rear face of the transmitter

Two sliding latches (marked “OPEN”) provide a

fast, easy method of opening and closing the transmitter, e.g. for changing the RF module ( 9.4.2).

The robust carry handle provides a safe method

of carrying the transmitter, and also protects the rear

face when you set the transmitter down.

As is usual with MULTIPLEX, the ROYAL SX is

also fitted with a MULTIPLEX multi-function socket

installed as standard (marked “CHARGE”). It is used

as:

charge socket for the transmitter ( 8.2.)

socket for Trainer operations

( 14.4.1. and 14.4.2.)

PC interface for backing-up model data

( 20.2.)

PC interface for updating the transmitter

( 20.2.)

PC interface for flight simulators

( 20.3.)

interface for a ‘closed-loop’ receiver connection

(without RF transmission) for programming and adjustment work using a Diagnosis lead ( 20.2.).

The TORX

in clips in the transmitter’s back panel, is used for

various tasks such as adjusting the stick ratchet, friction and centring spring force, swivelling the stick

units, and for installing supplementary switches in the

installation wells “K” and “P”.

screwdriver (size T6), which resides

9.3. Interior of the transmitter

Fig. 9.3.1.: The interior of the transmitter

The transmitter battery fitted as standard con-

sists of six environmentally friendly, high-capacity AAsize NiMH (Nickel-Metal-Hydride) cells. For safety

reasons the individual cells are permanently interconnected and protected by a heat-shrink sleeve.

! Use genuine replacement batteries only!

Always heed the charging instructions!

( 8.2. and 8.3.)

The transmitter battery is fitted with a thermal fuse

which protects the battery - and above all the transmitter - from short-circuit, reversed polarity and excessive currents. The transmitter does not feature

a separate fuse. For this reason it is essential to

use genuine MULTIPLEX transmitter batteries designed for this transmitter.

RF module (Radio Frequency module). The RF

module is simply plugged into the main circuit board,

and can easily be changed if you wish.

Only RF modules of this type may be fitted to

!

the ROYAL SX!

Fig. 9.2.2.: TORX screwdriver in the transmitter back panel

16

Page 19

9.4. Mechanical details

OPEN

CLOSE

9.4.1. Opening / closing the transmitter case

! Switch the transmitter OFF before opening the

case (short-circuit hazard)!

Opening the transmitter case:

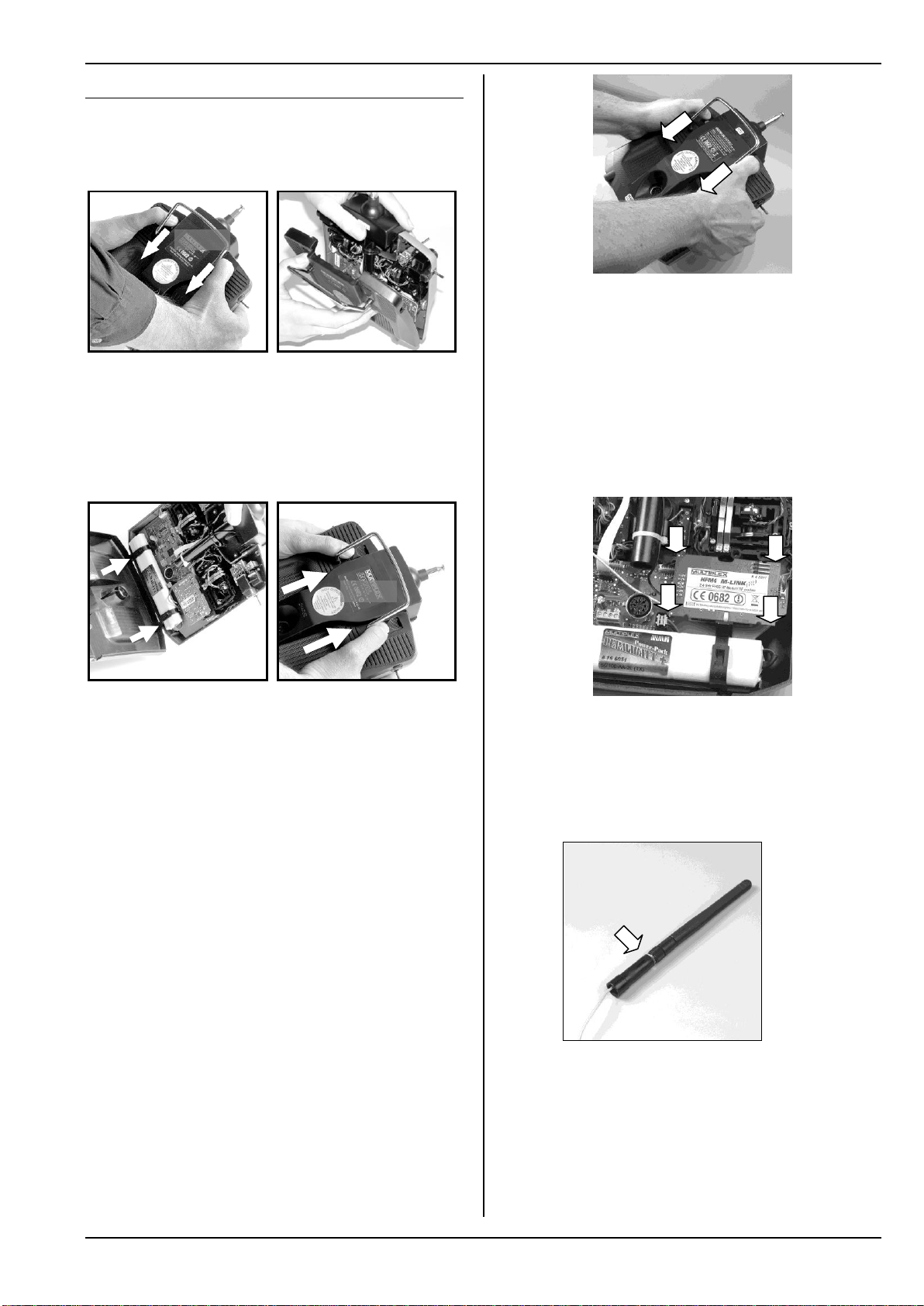

Fig. 9.4.1.1. Fig. 9.4.1.2.

a. Hold the transmitter in both hands, and push the

rear-mounted sliding latches down with both

thumbs (towards “OPEN”) ( Fig. 9.4.1.1.).

b. Carefully remove the rear case panel

( Fig. 9.4.1.2.).

Closing the transmitter case:

Manual

2. Carefully remove the back cover of the transmitter

case.

Plug in the HFM4 M-LINK 2.4 GHz RF module

1. Remove the HFM4 M-LINK 2.4 GHz RF module from

the protective anti-static bag, and hold it as described

above.

2. Carefully insert the RF module using steady pressure.

Ensure that the module is fitted on the correct pins,

and is inserted “squarely”, i.e. not canted over:

Fig. 9.4.1.3. Fig. 9.4.1.4.

c. Carefully stand the case at an angle on its rear edge,

and engage the two retaining lugs on the back panel

in their recesses

(arrows in Fig. 9.4.1.3.).

d. Carefully close the back panel ( Fig. 9.4.1.4.).

! Ensure that no wires are trapped, and that the

transmitter aerial has not slipped out of its guide

tube. It should be possible to fit the case back

easily, without using force.

e. Push the sliding latches up as far as they will go

(opposite direction to “OPEN”).

9.4.2. Removing / installing the RF module

The following section describes the method of

installing the HFM4 M-LINK 2.4 GHz RF module in a

transmitter of the ROYALevo, ROYAL SX or ROYAL

SX M-LINK type.

Open the transmitter case

! Switch the transmitter OFF before opening the

case (short-circuit hazard)!

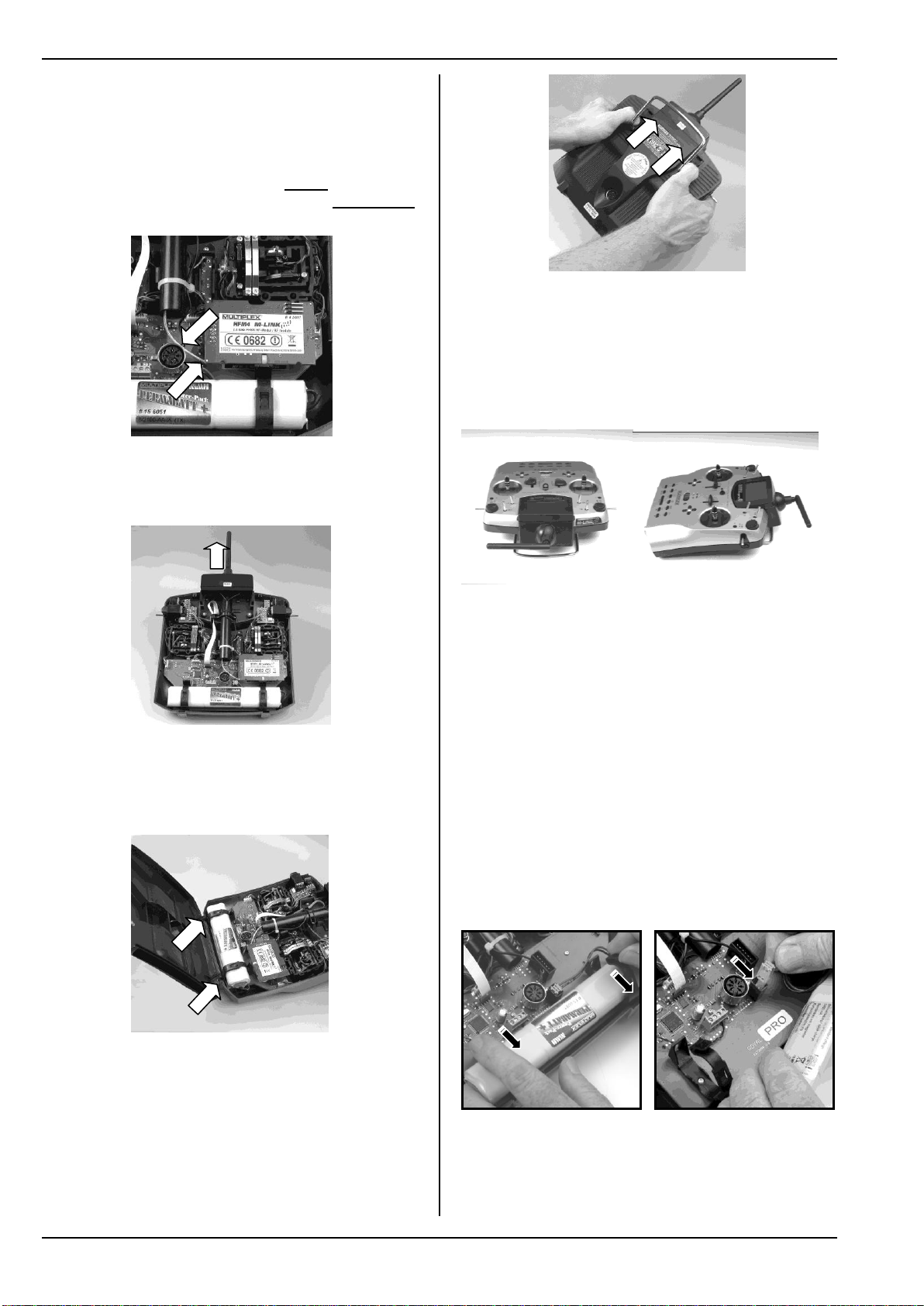

1. Hold the transmitter in both hands, locate the sliding latches, and push both of them down using

your thumbs (in the direction marked “OPEN”):

Fit the 2.4 GHz aerial unit

1. Screw the 2.4 GHz aerial to the aerial base:

Hold the aerial by the knurled section.

Check that the resultant screwed joint is firm, to

ensure that the aerial cannot possibly come

loose in use, e.g. when swivelled in the installed

state:

! Note: avoid using excessive force, and keep

the parts correctly aligned when screwing them

together.

2. Set the prepared 2.4 GHz aerial unit straight (not at

an angle), then carefully slide it into the aerial

guide sleeve from the bottom end.

! Caution: the swivel base on the top face of

the transmitter must lie parallel with the aerial

guide sleeve during this stage. If you ignore

17

Page 20

ROYAL SX

this and hold the aerial at an angle, the wiper

contacts in the aerial guide sleeve could be

damaged.

3. Deploy the connecting lead from the RF module

and the aerial unit inside the transmitter:

The connecting lead must pass under the HFM4

M-LINK 2.4 GHz RF module and also to one side

of the MULTIPLEX multi-function socket:

4. Pull the 2.4 GHz aerial unit upwards out of the

aerial guide sleeve to the point where the aerial

joint is visible; you will feel a distinct mechanical

resistance at this point:

9.4.3. Ideal Transmitter Aarial Orientation When

Using the Transmitter

When installed, the 2.4 GHz transmitter aerial can be

rotated to either side and swivelled upwards.

Before using the transmitter, the aerial should be angled approximately at right-angles at the swivel joint,

then swivelled either to left or right in the horizontal

plane (see illustrations):

Close the transmitter case

1. Carefully offer up the case back panel to the

transmitter, inserting the retaining lugs at the bottom edge, and ensure that both lugs engage properly (arrows in the picture below):

2. Carefully close the transmitter back panel:

Ensure that no cables are trapped or jammed. It

should be possible to fold the case back into position without requiring force.

1. Push the sliders up as far as they will go (away

from the “OPEN” marking):

For applications where the model is not operated directly above or below the transmitter, the optimum aerial orientation is vertically upwards; this applies in

particular to model cars and boats.

! Important:

Never point the aerial directly at the model. For

physical reasons the signal radiated from the aerial is

at its weakest in an imaginary line extending straight out

from the aerial.

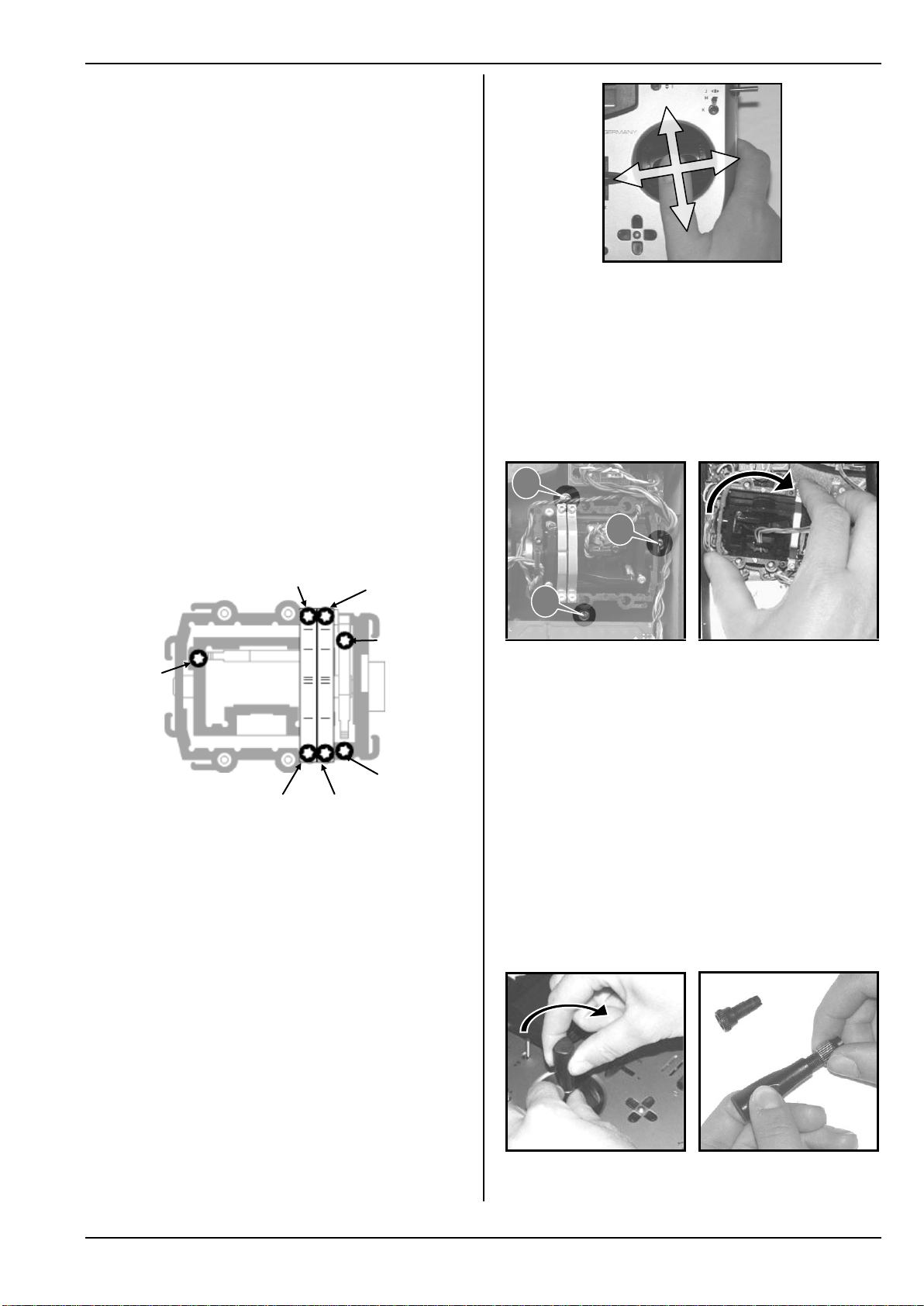

9.4.4. Replacing the transmitter battery

a. Switch the transmitter OFF!

b. Locate the snap-catches of the two plastic battery

retainers, pull both of them back in the direction of

the battery, then fold them up ( Fig. 9.4.4.1.).

c. Remove the battery and withdraw the battery con-

nector and lead from the socket on the main circuit

board ( Fig. 9.4.4.2.).

Fig. 9.4.4.1. Fig. 9.4.4.2.

Opening / closing the retainers Connecting the battery

When installing the battery ensure that the connecting

lead is neatly deployed, so that it cannot become trapped

when you close the transmitter back.

18

Page 21

Note:

(4) "Hardness"

centring force

right / left

(4) "Hardness"

centring force

forward / back

(1) Disable

neutralising action

(3) Strength of friction / ratchet

(2) Spring for

friction or ratchet

1 2 3

No model data is lost when you swap batteries.

9.4.5. Disabling the stick centring spring, activating the ratchet / friction system

ROYAL SX transmitters are supplied as standard with

self-centring sticks. The springs for use with a ratchet

or friction system are already fitted to both stick units,

and can be activated quickly and easily as follows:

Switch the transmitter OFF and open the case.

a. Locate the TORX screwdriver on the inside of the

transmitter back panel, and use it to tighten (turn

clockwise) the TORX screw on the appropriate

(please check!) neutralising lever (1) to the point

where the stick centring action is completely disabled. Don’t screw it in too far! On no account

remove the neutralising lever and centring

spring!

b. The screws (2) hold the springs, while the screws

(3) adjust the hardness of the ratchet / friction action: the further you tighten the screw, the harder

the ratchet or friction.

If you wish, you can set a superimposed ratchet / friction action by activating both springs on one stick.

This is simply a matter of personal preference.

Manual

Fig. 9.4.7.1.

a. Using the T6 TORX screwdriver (located in clips in

the transmitter back cover) ( Fig. 9.4.7.2.),

loosen the three TORX screws which retain the

appropriate stick unit until the unit can be swivelled.

b. Rotate the stick unit to the angle which seems

most natural to you ( Fig. 9.4.7.3.), then tighten

the TORX screws again. Don’t over-tighten them,

or you might strip the threads in the plastic.

Fig. 9.4.5.1.: Adjuster screws on the stick unit

9.4.6. Adjusting the “hardness” of the sticks

This term applies to the centring force of the neutralising spring on any one stick axis.

The ROYAL SX allows you to adjust the “hardness”

for each of the four stick axes separately. The picture

above shows how adjustments are made. The stick

axes become “harder” when you tighten the screws (4)

(turn them clockwise).

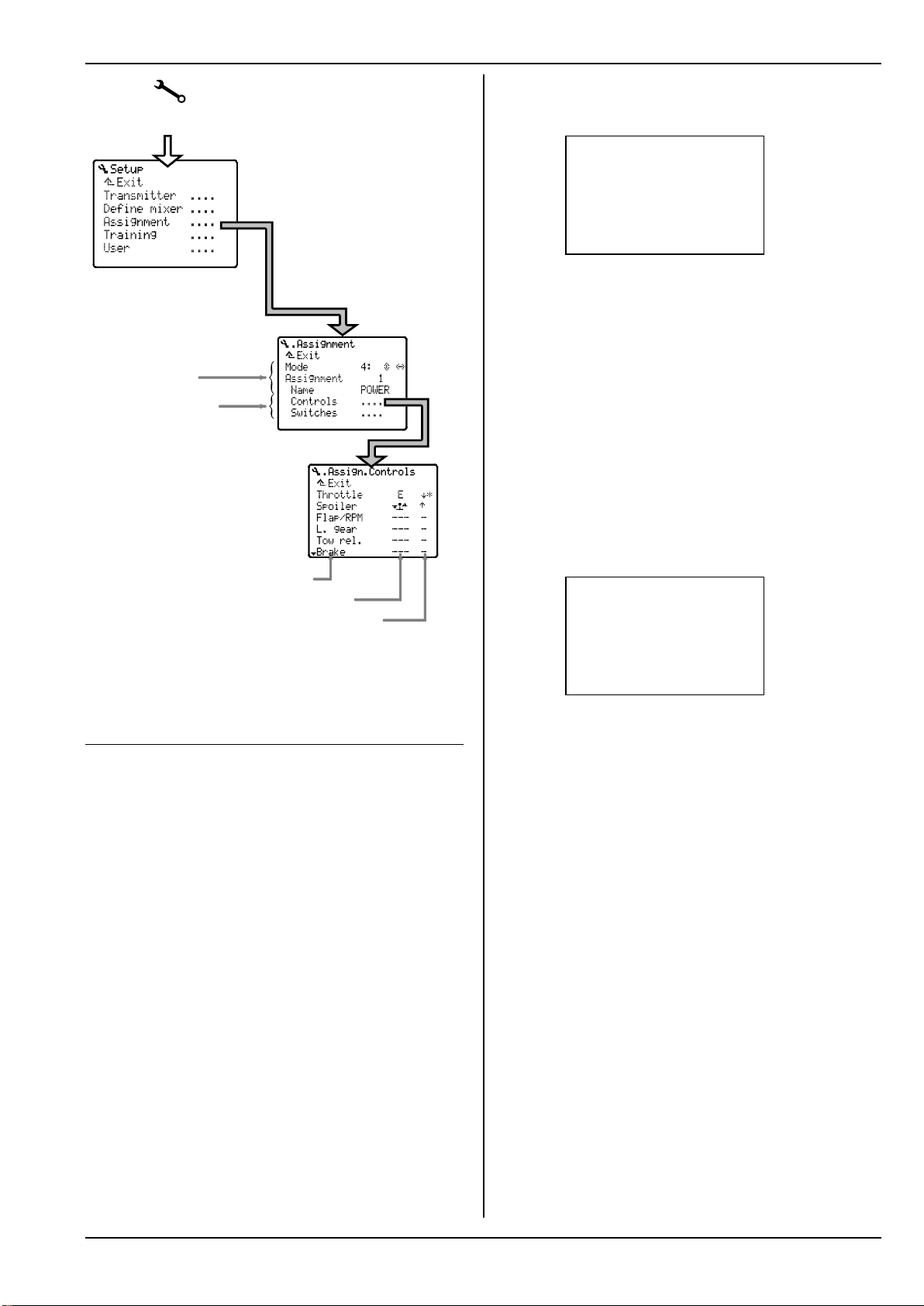

9.4.7. Swivelling the stick units

A unique feature of the ROYAL SX is that its stick

units can be swivelled to improve the ergonomics of

the transmitter. This is particularly advantageous if

you operate the transmitter hand-held, and use your

thumbs to control short sticks. In this case the “natural

working axis” is not exactly horizontal and vertical

relative to the transmitter, but at a more or less pronounced angle. Both stick units of the ROYAL SX can

be swivelled to any angle up to about 15° from the

nominal position.

Fig. 9.4.7.2. Fig. 9.4.7.3.

9.4.8. Adjusting / replacing the stick tops

The ROYAL SX is supplied as standard with three

pairs of stick tops of different lengths. They are easily

changed, rotated and adjusted in length:

a. Place the transmitter on a flat surface.

b. Hold the stick top in one hand, and loosen the

locking nut by turning it clockwise with your other

hand ( Fig. 9.4.8.1.).

The stick shaft is smooth, so the stick top can now be

rotated or adjusted in length. If you wish to change the

stick tops, unscrew the locking nuts and use them to

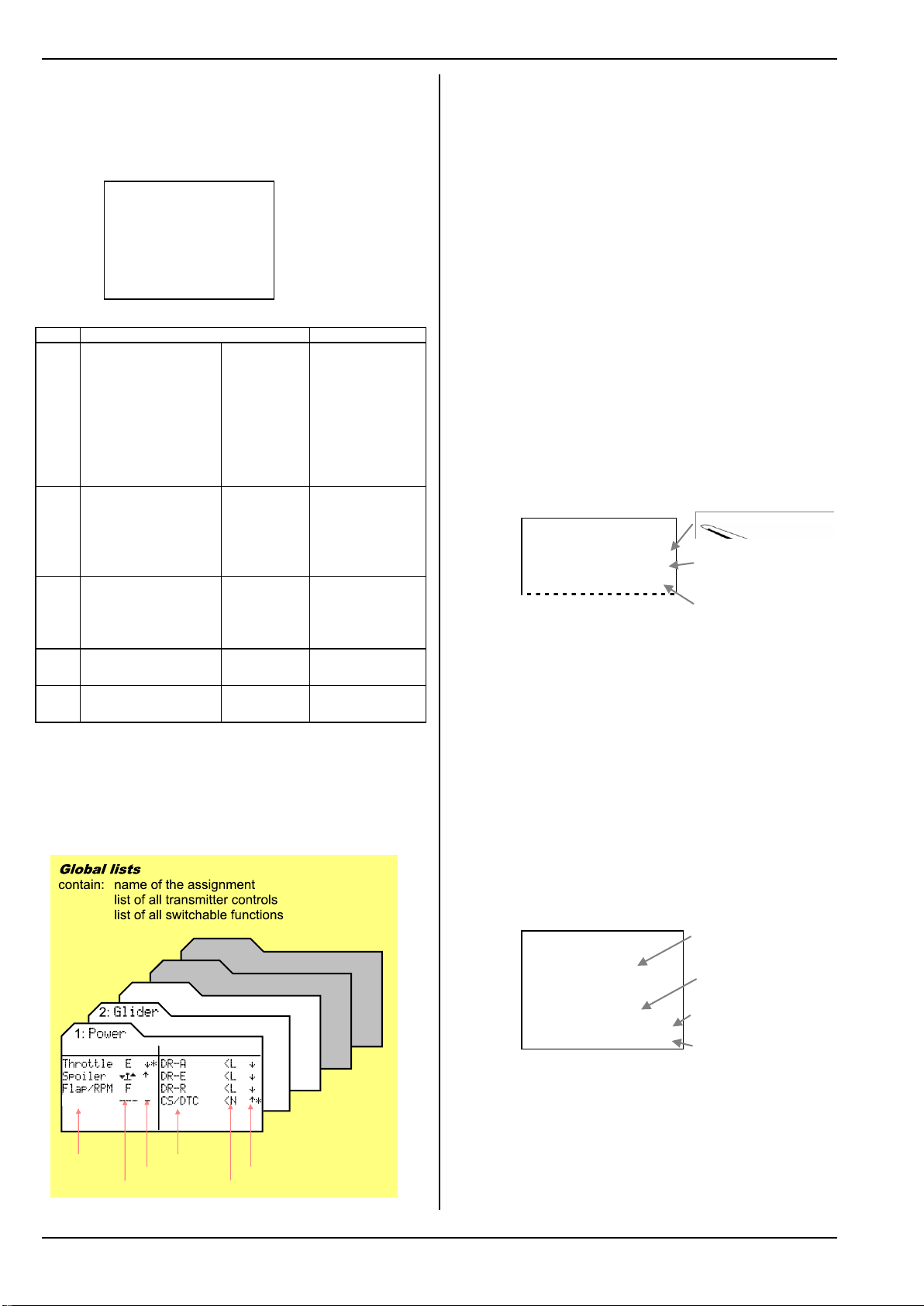

secure the alternative items ( Fig. 9.4.8.2.).