Page 1

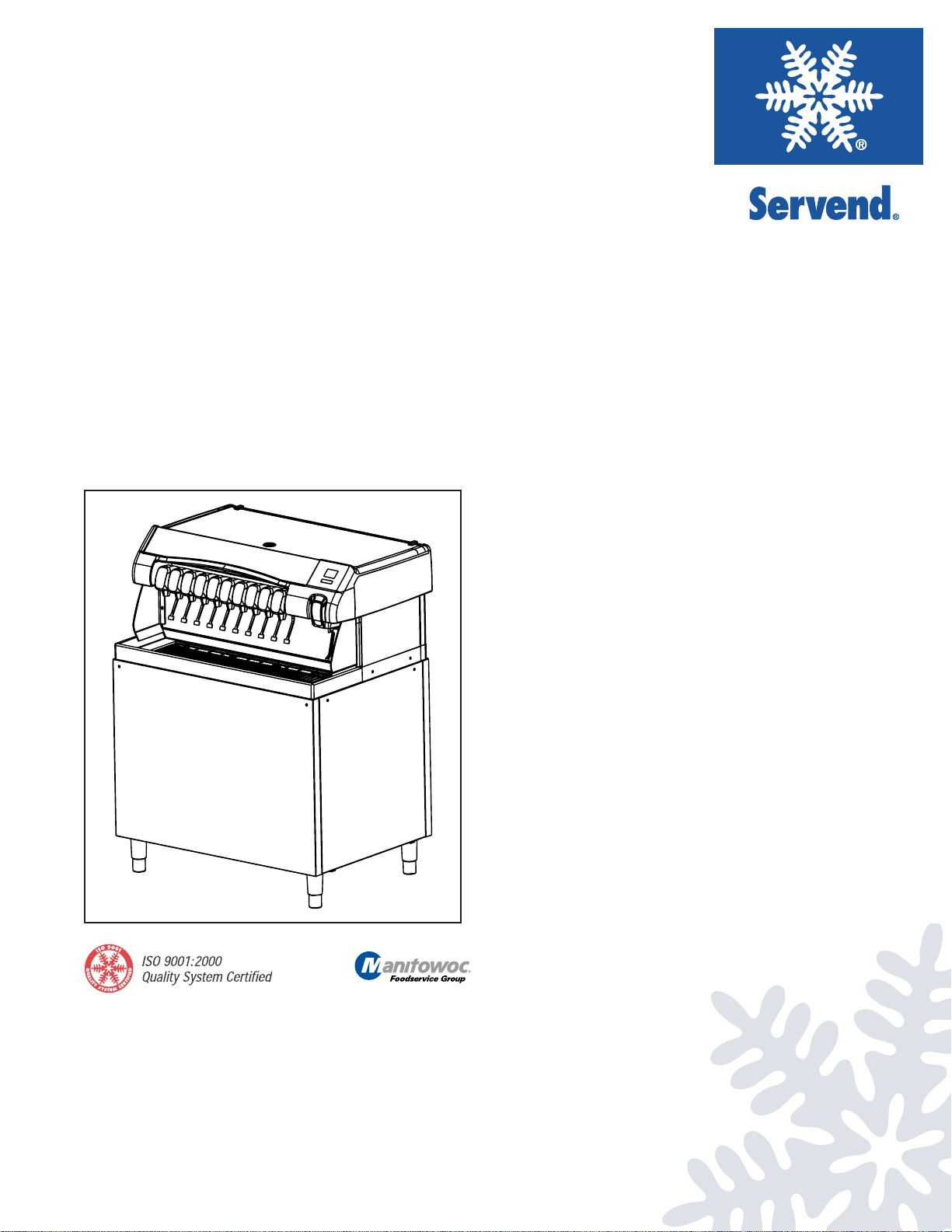

LP-3

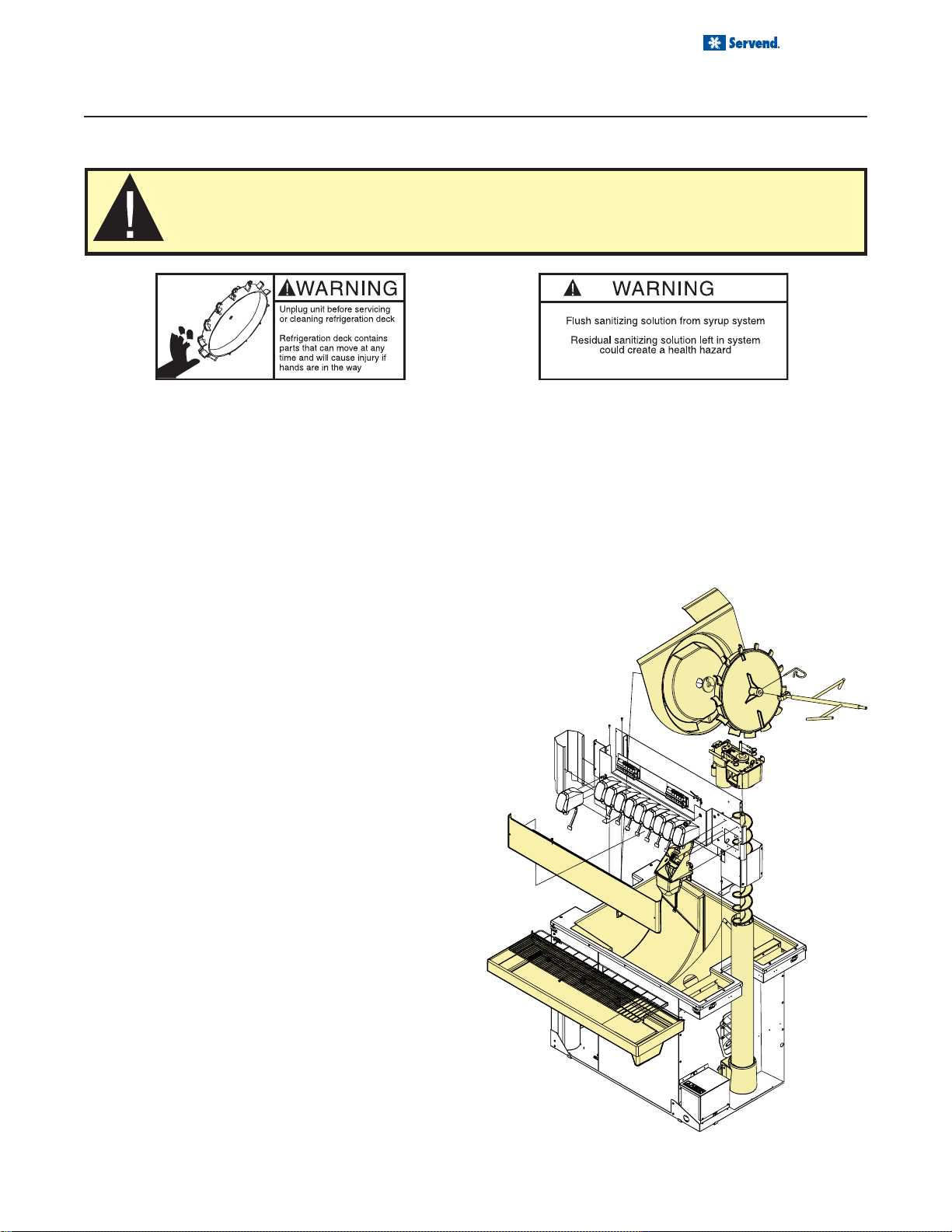

Beverage/Ice Dispenser

INSTALLATION & SERVICE GUIDE

Part Number 5027727

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

May 17, 2007 REV5

Page 2

Page 3

FOREWORD

Manitowoc Beverage Equipment (MBE) developed this manual as a reference guide for the owner/

operator, service agent, and installer of this equipment. Please read this manual before installation

or operation of the machine. A qualified service technician should perform installation and startup of this equipment, consult the

If you cannot correct the service problem, call your MBE Service Agent or Distributor. Always have your model and

serial number available when you call.

Your Service Agent___________________________________________________________________

Service Agent Telephone Number ______________________________________________________

Your Local MBE Distributor ___________________________________________________________

Distributor Telephone Number _________________________________________________________

Model Number ______________________________________________________________________

Serial Number _______________________________________________________________________

Installation Date _____________________________________________________________________

Troubleshooting Guide

within this manual for service assistance.

UNPACKING AND INSPECTION

Note: The unit was thoroughly inspected before leaving the factory. Any damage or irregularities should

be noted at the time of delivery.

WARRANTY INFORMATION

This LP-3 ice and beverage dispenser may contain an integral ice maker. Any ice maker contained within

this dispenser is warranted by the manufacturer of the ice maker (Manitowoc Ice, Inc.) as a separate

entity. Consult your local MBE Distributor for terms and conditions of your warranties. Your dispenser

warranty specifically excludes all beverage valve brixing, general adjustments, cleaning, accessories and

related servicing.

Your warranty card must be returned to Manitowoc Beverage Equipment to activate the warranty on this

equipment. If a warranty card is not returned, the warranty period can begin when the equipment leaves

the MBE factory.

No equipment may be returned to Manitowoc Beverage Equipment without a written Return Goods

Authorization (RGA). Equipment returned without an RGA will be refused at MBE’s Receiving Department

and returned to the sender at the sender’s expense.

Please contact your local MBE distributor for return procedures.

Page 4

TABLE OF CONTENTS

FOREWORD ........................................................................................................ 3

UNPACKING AND INSPECTION......................................................................... 3

WARRANTY INFORMATION ............................................................................... 3

SAFETY ............................................................................................................... 6

IMPORTANT SAFETY INSTRUCTIONS ........................................................................... 6

CARBON DIOXIDE WARNING ......................................................................................... 6

QUALIFIED SERVICE PERSONNEL ................................................................................ 6

SHIPPING, STORAGE, AND RELOCATION ..................................................................... 6

INSTALLATION WARNING .............................................................................................. 6

ADDITIONAL WARNINGS ................................................................................................ 6

GROUNDING IN STRUCTIONS ........................................................................................ 7

PRE-INSTALLATION CHECK LIST .................................................................................. 8

UNIT INSTALLATION ....................................................................................................... 9

ICEMAKER REQUIREMENTS ........................................................................................ 10

COLD CARB AND AMBIENT SYSTEM PRESSURES .................................................... 10

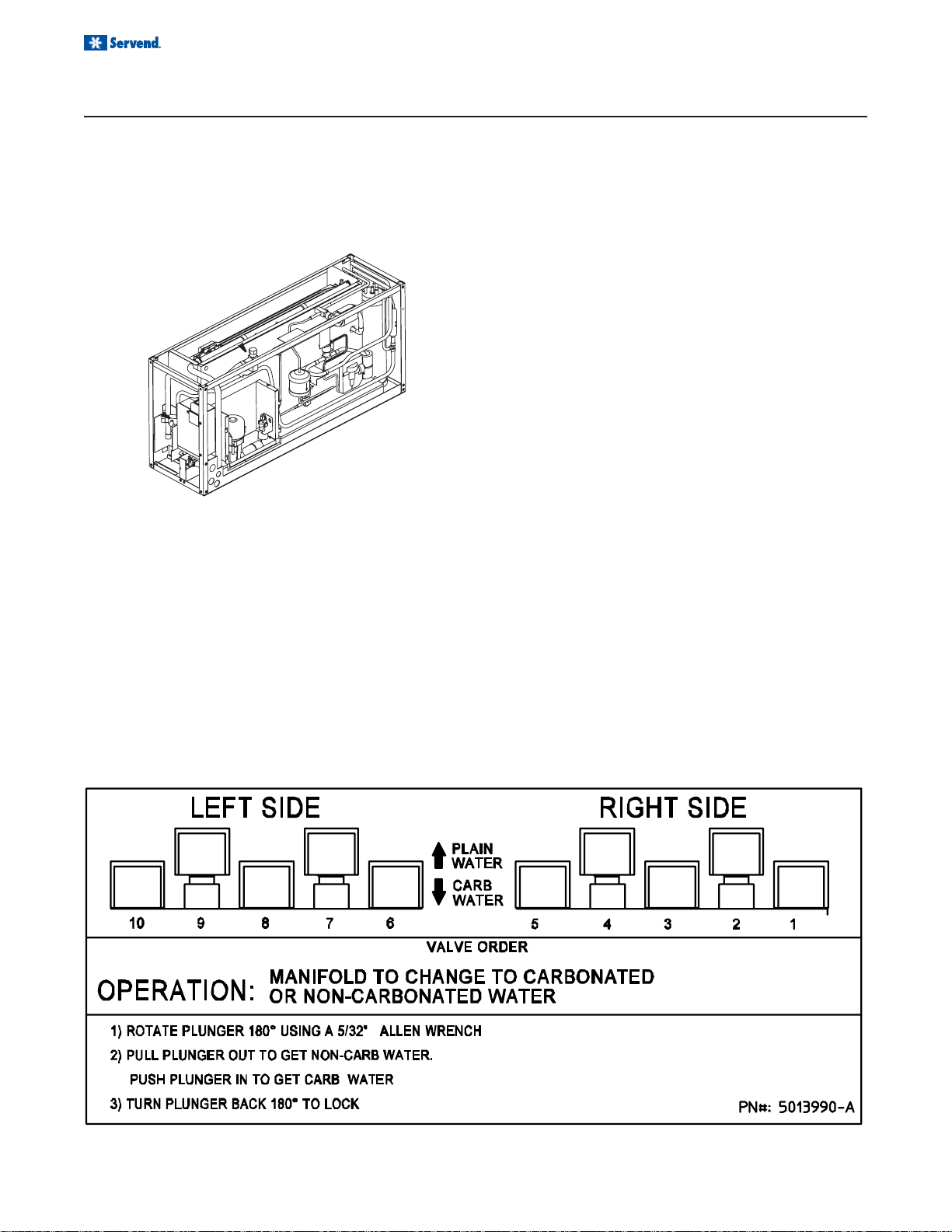

CARBONATED/NON-CARBONATED CONVERSION INSTRUCTIONS ......................... 10

DRAINS ...........................................................................................................................11

PURGE TUBE ROUTING ............................................................................................... 12

RECOMMENDED PLUMBING ........................................................................................ 13

OPERATION ...................................................................................................... 14

UNIT INSPECTION ......................................................................................................... 14

SERIAL TAGS ................................................................................................................ 14

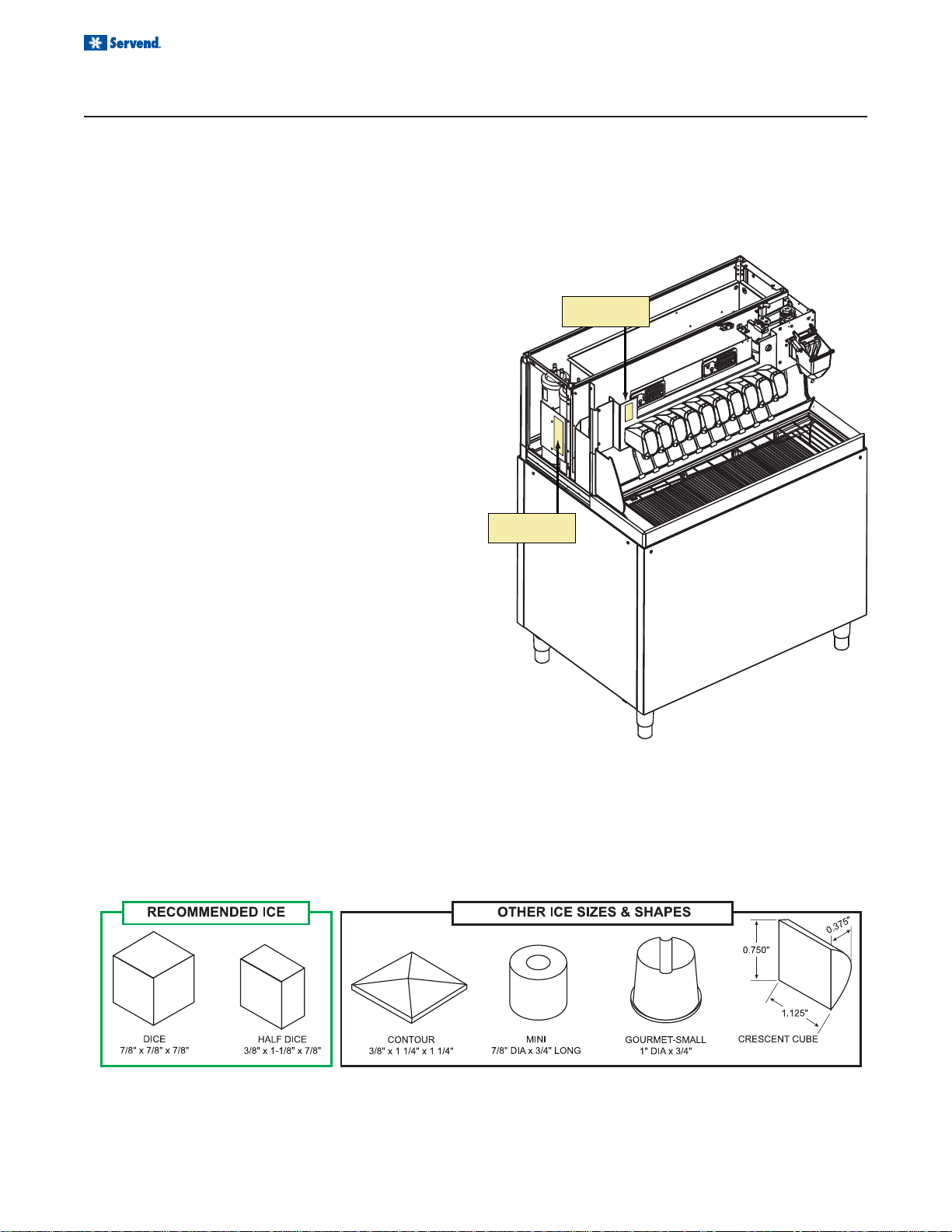

ICE RECOMMENDED FOR DISPENSING ...................................................................... 14

EQUIPMENT ................................................................................................................... 15

ICE STORAGE AND DISPENSING................................................................................. 16

ICE AGITATION .............................................................................................................. 16

ROCKING CHUTE ICE DISPENSING ............................................................................. 16

ICE AUGER .................................................................................................................... 16

COLD PLATE BEVERAGE COOLING ............................................................................ 16

BEVERAGE VALVES ..................................................................................................... 16

SPECIFICATIONS .......................................................................................................... 17

B-I-B ............................................................................................................................... 18

PUMPS ........................................................................................................................... 18

AUTO BAG SELECTORS............................................................................................... 18

BACK ROOM PACKAGE ............................................................................................... 19

CARBONATION ............................................................................................................. 20

INTERNAL CARBONATION ........................................................................................... 20

Page 5

TABLE OF CONTENTS

USER MAINTENANCE ...................................................................................... 21

HOW TO DISASSEMBLE FOR CLEANING OR MAINTENANCE .................................. 21

DAILY CLEANING .......................................................................................................... 22

MONTHLY CLEANING ................................................................................................... 23

CLEANING AND SANITIZING OF THE DISPENSER ..................................................... 23

BEVERAGE SYSTEM CLEANING ................................................................................. 24

BAG-IN-BOX SYSTEM ................................................................................................... 24

PREVENTATIVE MAINTENANCE .................................................................................. 25

EXPLODED VIEWS, PARTS & DIAGRAMS ..................................................... 26

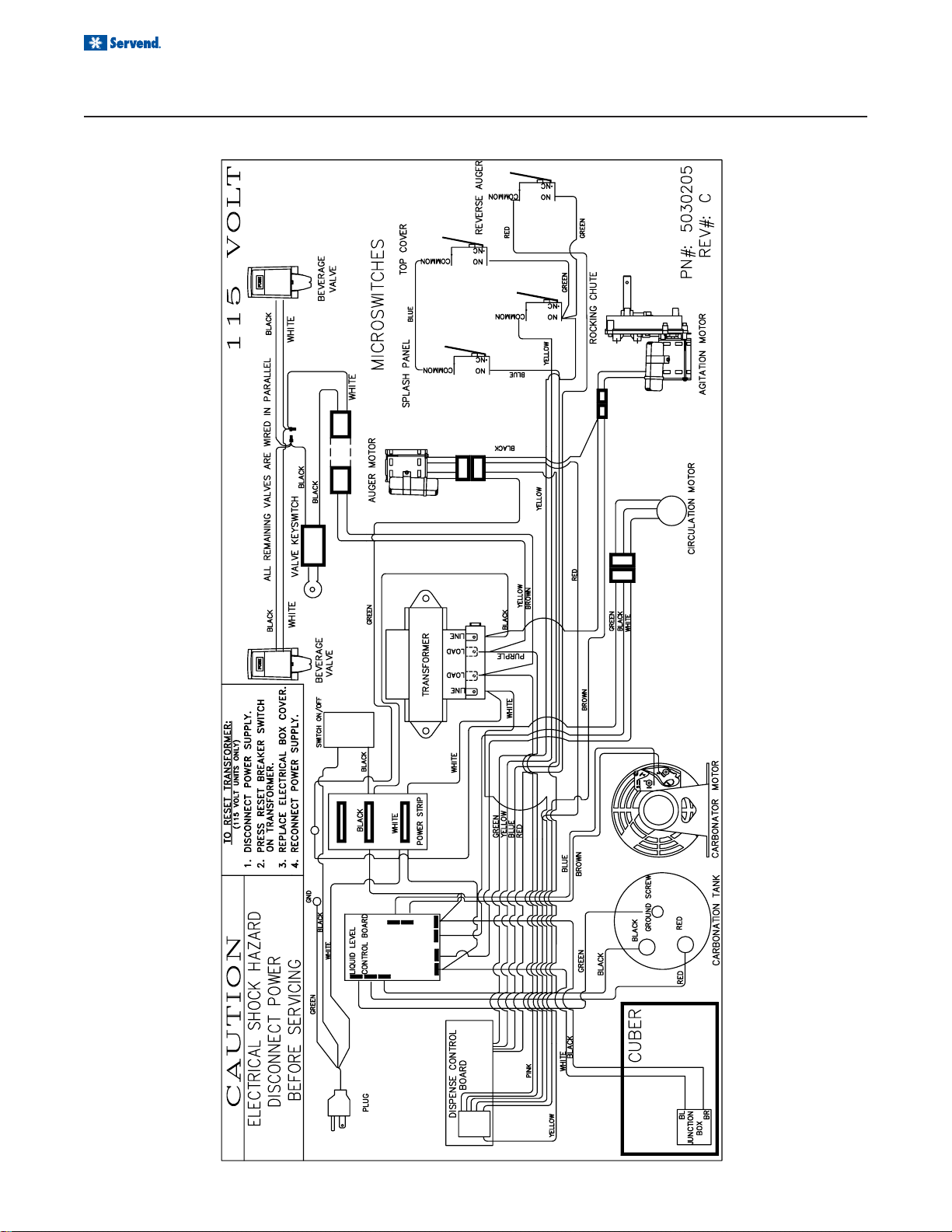

115V WIRING DIAGRAM ................................................................................................ 26

COVERS & PANELS ...................................................................................................... 27

SPLASH PANEL, DRAINPAN & CUBER ........................................................................ 28

PANELS & LID BONNET ................................................................................................ 29

AUGER, AGITATION & DRAIN ....................................................................................... 30

LEGS, CARB TANK & ELECTRIC BOX ......................................................................... 31

AUGER DRIVE, VALVE MOUNT, ROCKING CHUTE, PUMP ......................................... 32

120V AUGER DRIVE ...................................................................................................... 33

120V CUBER .................................................................................................................. 34

RIGHT SIDE BONNET COVER ...................................................................................... 34

LEFT SIDE BONNET COVER ......................................................................................... 34

120V CARB PUMP & TANK ASSEMBLY ....................................................................... 35

AUGER & ROCKING CHUTE ......................................................................................... 36

VALVE MOUNT CAP & AGITATOR MOTOR .................................................................. 37

AUGER TRANSITION & 120V ELECTRIC BOX ............................................................. 38

BIN ................................................................................................................................. 39

MANITOWOC® SU1024YC ICEMAKER ........................................................... 40

CONTROL BOX & EVAPORATOR COMPARTMENT ..................................................... 40

REFRIGERATION COMPARTMENT .............................................................................. 41

CVD1075 CONDENSING UNIT ...................................................................................... 43

CVD1075 CONDENSING UNIT PANELS ....................................................................... 44

TROUBLESHOOTING ....................................................................................... 45

INDEX................................................................................................................. 50

Page 6

Installation and Service Manual

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual. Learn how to operate the SV unit properly. Do not

allow anyone to operate the unit without proper training and keep it in proper working condition.

Unauthorized modifications to the SV may impair function and/or safety and affect the life of the unit.

CARBON DIOXIDE WARNING

DANGER: Carbon Dioxide (CO2) displaces oxygen. Exposure to a high concentration of CO2 gas

causes tremors, which are followed rapidly by loss of consciousness and suffocation. If a CO

is suspected, particularly in a small area, immediately ventilate the area before repairing the leak. CO

lines and pumps should not be installed in an enclosed space. An enclosed space can be a cooler or

small room or closet. This may include convenience stores with glass door self serve coolers. If you

suspect CO2 may build up in an area, venting of the B-I-B pumps and / or CO2 monitors should be utilized.

QUALIFIED SERVICE PERSONNEL

WARNING: Only trained and certified electrical and plumbing technicians should service this unit.

All wiring and plumbing must conform to national and local codes.

gas leak

2

2

SHIPPING, STORAGE, AND RELOCATION

CAUTION: Before shipping, storing, or relocating this unit, syrup systems must be sanitized. After

sanitizing, all liquids (sanitizing solution and water) must be purged from the unit. A freezing environment causes residual sanitizing solution or water remaining inside the unit to freeze, resulting

in damage to internal components.

INSTALLATION WARNING

WARNING: The splash panel must remain in place for installation because the splash panel pro-

vides structural integrity to the unit. Do not remove the splash panel until after the unit is installed.

ADDITIONAL WARNINGS

Installation and start-up of this equipment should be done by a qualified service technician. Operation,

maintenance, and cleaning information in this manual are provided for the user/operator of the equipment.

Save these instructions.

6

Page 7

Installation and Service Manual

SAFETY

GROUNDING IN STRUCTIONS

WARNING: Risk of electrical shock. Connect to a properly grounded outlet only.

This appliance must be grounded. In the event of malfunction or breakdown, grounding provides

a path of least resistance for electric current to reduce the risk of electric shock. This appliance is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER – Improper connection of the equipment-grounding conductor can result in a risk of

electric shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment grounding conductor. If repair or replacement of the cord or plug

is necessary, do not connect the equipment-grounding conductor to a live terminal. Check with a

qualified electrician or serviceman if the grounding instructions are not completely understood, or

if in doubt as to whether the appliance is properly grounded. Do not modify the plug provided with

the appliance – if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

WARNING – When using electric appliances, basic precautions should always be followed, including the following:

a) Read all the instructions before using the appliance.

b) To reduce he risk of injury, close supervision is necessary when an appliance is used

near children.

c) Do not contact moving parts.

d) Only use attachments recommended or sold by the manufacturer.

e) Do not use outdoors.

f) For a cord-connected appliance, the following shall be included:

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Unplug from outlet when not in use and before servicing or cleaning.

• Do not operate any appliance with a damaged cord or plug, or after the appliance

malfunctions or is dropped or damaged in any manner. Return appliance to the

nearest authorized service facility for examination, repair, or electrical or mechanical

adjustment.

g) For a permanently connected appliance – Turn the power switch to the off position

when the appliance is not in use and before servicing or cleaning.

h) For an appliance with a replaceable lamp – always unplug before replacing the lamp.

Replace the bulb with the same type.

i) For a grounded appliance – Connect to a properly grounded outlet only. See Grounding

Instructions.

SAVE THESE INSTRUCTIONS

7

Page 8

Installation and Service Manual

INSTALLATION

PRE-INSTALLATION CHECK LIST

When installing any system, first make sure the major components are available. Generally the major components

necessary for an installation are:

Post mix system:

CO

regulator set

2

Beverage dispenser

Beverage tubing

CO

tank

2

Carbonator

Stepless (Oetiker) clamps

Chain for CO

tank

2

B-I-B System also:

B-I-B connectors

B-I-B regulator set

B-I-B rack

B-I-B syrup boxes

Also consider the location of the following items before

installation:

Water line

Drain

Power outlet

Heating and air conditioning ducts

Before you begin the installation, please check to be sure you can achieve a proper installation. Things to look for

include, but are not limited to:

If being installed in a counter, be sure you have

a flat, level counter top.

Is there enough space for the LP-3? You will

need to have at least a 36” deep countertop to

do a proper installation.

How about under the counter? Is there room for

the LP-3 with drain underneath and beverage

tubing coming from the rear of the unit along

with the electricity necessary? It is suggested

that you have at least 18” of open space to the

right and left of the unit for an easy installation.

If being installed in a counter are there any

braces or support structures in the counter top

that could be cut and damaged?

Avoid direct sunlight or close heating / air con-

ditioning ducts.

Is a proper drain available? The LP-3 has four

3/4" drains and two 1/4" purge drain.

If installed in a cabinet the side, rear, and front

panels should be left off for service ability.

8

Page 9

Installation and Service Manual

INSTALLATION

UNIT INSTALLATION

The LP-3 is shipped in a heavy duty corrugated carton with a wooden pallet. Inspect the unit for freight damage. If

any damage is noticed, stop immediately and contact your delivering freight company. You must file a freight claim

for your equipment. Failure to do so can void any claims. Manitowoc Beverage Equipment is not responsible for

any freight damage.

To properly install the LP-3, Use these guidelines:

• Meet all local code requirements.

• Have a receptacle with the proper voltage at the

installation site for connection to the LP-3. A standard 120V grounded outlet is needed for the dispenser. If the unit is equipped with an ice maker,

the condensing unit will need 208/230v wherever

the condenser is mounted.

• Completely unpack the LP-3, removing all padding

and shipping retainers.

• Route the beverage tubing from the syrup racks to

the location of the LP-3. Make sure to leave some

slack in each of the syrup lines in case the unit needs

to be pulled out some for service work or cleaning.

• Make all beverage connections, if necessary, at the

syrup racks.

• If installing in a counter mark the counter top with

the appropriate cut out opening.

• Check that the cut out location is approved by the

owner before any cuts are made in the counter top.

• Compare the marked cut out with the dispenser

chest size. Be sure you are going to make the proper

hole size.

• Cut the marked opening in the counter top.

• If installing in a cabinet it is recommended you permanently remove the lower panels for easier service access.

• Install the legs or casters provided to the unit. Fol-

low the instructions on the cabinet to install.

Water Connections

There are three water connections, one on the right for

the icemaker and two located on the bottom left side of

the unit that feeds all the valves for both non-carbonated and carbonated water drinks.

for exact routing

must be at least 40 psi and no more than 55 psi. Proper

measures must be taken if the water pressure is under

or over the operating specifications. Water for the carbonated drinks connect at the brass carbonator pump

inlet. Water for the non-carbonated drinks connects to

the inline check valve on the inlet to the cold plate.

). The incoming dynamic water pressure

(

See Plumbing diagram

CO

2

Connect the CO2 supply line. This connection is also located at the bottom left side of the unit and is already

connected to the carbonator. The regulator for the carbonator should be set at 75 psi.

Syrup Connections

Make all syrup connections. These connections are located on the bottom left side of the unit. There are ten

connections. Refer to the plumbing diagram for proper

valve selection.

Turn the power switch to on at the electrical box located

at the bottom right side of the unit.

9

Page 10

Installation and Service Manual

INSTALLATION

ICEMAKER REQUIREMENTS

The LP-3 may be equipped with a Manitowoc® SU1024YC icemaker. Refer to the Manitowoc® Ice/Beverage Series

QuietQube® Ice Machines with CVD® Technology Installation, Use and Care Manual for additional information. See

also the "MANITOWOC® SU1024YC ICEMAKER" section in this manual for exploded views and parts lists.

NOTE: To turn the SU1024YC ice maker on and off and put in clean mode you need to access the toggle switch.

1. To access the toggle switch for the ice maker lift

and turn the latch at the front of the lid

(see the Covers and Panels section item 5).

2. Using the latch and rubber handle, lift the lid off

3. The toggle switch is located on the back right corner. Switch forward for ON, center for OFF and back

for CLEAN.

COLD CARB AND AMBIENT SYSTEM PRESSURES

1. Incoming tap water should be at a minimum pressure of 40 psi and a maximum of 55 psi with carbonator pump operating (measured at inlet to pump).

2. BIB pressure gauge set for 60 psi or according to

the legnth of the line run.

CONVERSION INSTRUCTIONS

3. Carbonator Pressure gauge (Use Preset Regulator):

• Cold Carbonation set for 75 psi.

NOTE: If incoming water pressure is under 40 psi, a

water booster is required. If incoming water pressure is

over 55 psi, a water regulating valve is required.

CARBONATED/NON-CARBONATED

10

Page 11

A

D

H

G

D

FIGURE 1

Installation and Service Manual

INSTALLATION

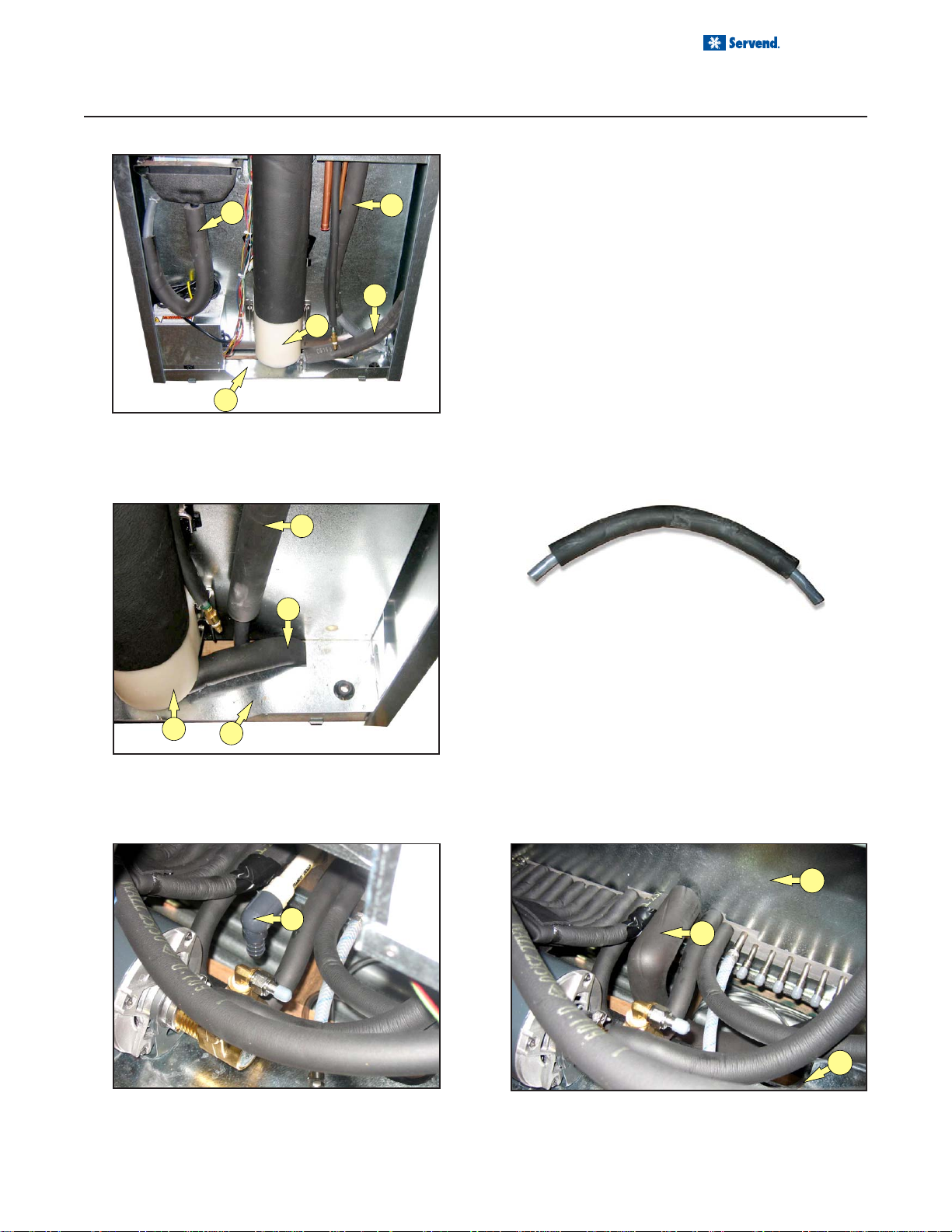

DRAINS

Right Side of unit as shipped:

1. During installation all drains on right side of the unit

B

C

E

must be properly routed.

2. Remove right side lower panel to access the drain

pan (A), icemaker (B) and auger (C) drains.

(see figure 1)

3. Route drain pan drain (A) through cut-out in baseplate (D) and follow all national plumbing codes.

4. Route Icemaker drain (B) through cut-out in baseplate (D) and follow all national plumbing codes.

(see figure 2)

5. Pull the insulation covering the auger drain (C) over

the clamp and fittings on the auger base (E).

6. Route auger drain (C) through cut-out in baseplate

(D) and follow all national plumbing codes.

Drain Kit:

B

FIGURE 3

C

1. Attach Drain Kit (figure 3) to barbed gray drain elbow (F). Use worm gear clamp that is provided to

secure the hose to the barb.

2. Route the drain hose through the opening in the

LP-3 base plate (D). Follow all local & national

E

D

FIGURE 2

plumbing codes.(see figure 5)

3. Pull the insulation (G) on the drain kit over the gray

drain elbow and the CPVC drain fitting until it is flush

with the stainless steel side panel (H).

F

FIGURE 4 FIGURE 5

11

Page 12

Installation and Service Manual

Pressure

Relief Valve

INSTALLATION

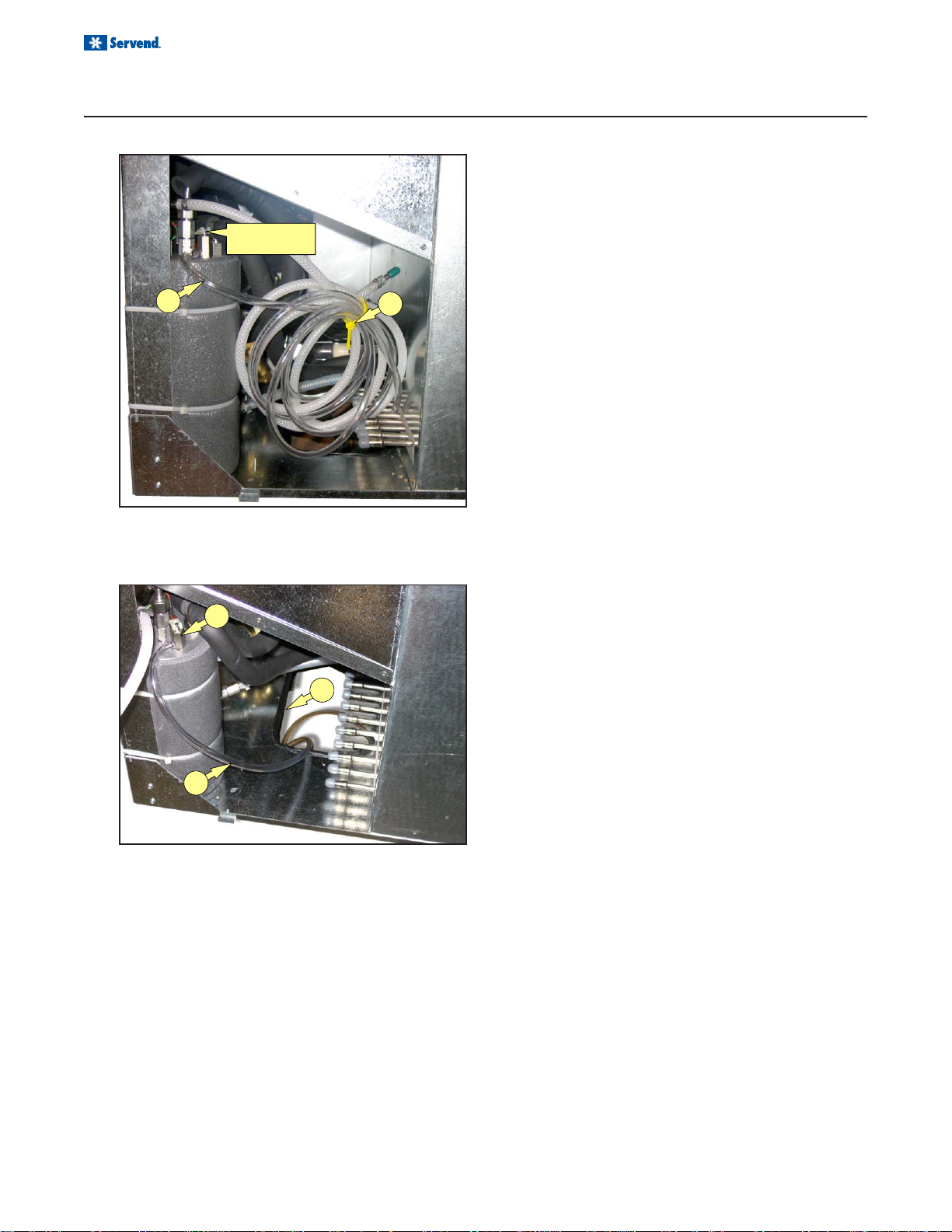

PURGE TUBE ROUTING

1. During installation of the LP-3 the carbonator tank

purge tube (A) must be properly routed to a drain.

The carbonator tank purge tube (A) may be accessed by removing the front panel of the LP-3. Clip

the tie strap (B) and uncoil the purge tube (A).

(see figure 1)

A

D

B

2. Route the carbonator tank purge tube (A) to the

opening beneath the ice bin drain elbow (C). Be

sure not to collapse or kink the carbonator tank

purge tube (A) during routing from the unit to the

drain. The purge tube (A) is connected to the pressure relief valve (D) on the carbonator tank and must

be routed to a drain.

(see figure 2)

FIGURE 1

3. Strap the carbonator tank purge tube to the drain

hose and route to a drain. Follow all local and national plumbing codes when routing the carbonator

tank purge tube to the drain.

C

12

A

FIGURE 2

Page 13

Installation and Service Manual

INSTALLATION

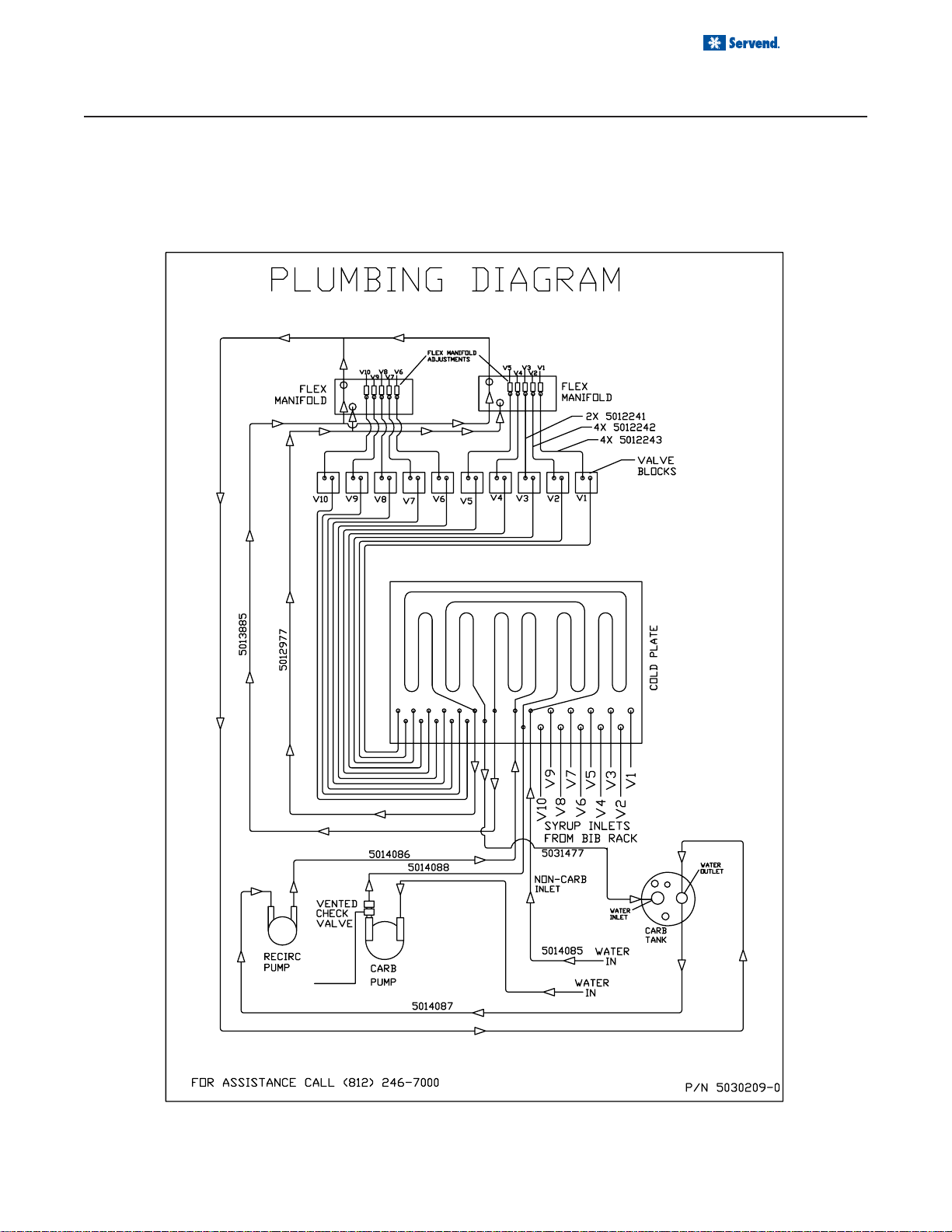

RECOMMENDED PLUMBING

The plumbing diagram is printed on a white vinyl label, normally located above the inlet tubes for syrup and water,

it can be accessed by removing the splash panel of the dispenser. The plumbing diagram label explains which inlet

coldplate fittings supply which dispenser valves and water manifolds.

NOTE: Valves are read from right to left.

A check valve must be installed in the water supply line 3 feet from the noncarbonated water connection

“PW”. Contact factory if not installed.

13

Page 14

Installation and Service Manual

OPERATION

UNIT INSPECTION

Thoroughly inspect the unit upon delivery. Immediately report any damage that occurred during transportation to

the delivery carrier. Request a written inspection report from a claims inspector to document any necessary claim.

SERIAL TAGS

At the time of installation both the LP-3 (ice and drink dispenser) and the SU1024-YC (ice maker) serial numbers

must be recorded.

LP-3

SERIAL TAG

The LP-3 serial number may be found by removing the

valve cover. The serial tag is located to the left of the left

hand Flexible Manifold above the #10 dispensing valve.

The SU1024-YC serial number may be found by removing the Left Side Plastic Cap. The serial tag is located on

the galvanized panel that protects the Receiver.

ICEMAKER

SERIAL TAG

ICE RECOMMENDED FOR DISPENSING

Servend dispensers are designed to dispense hard, cube ice up to one-inch square. The ice shapes and sizes

listed above are recommended for dispensing. Warm “Super Cooled” Ice Before Dispensing “Super Cooled”

ice is not recommended for dispensing. “Super cooled” ice is ice that has been stored in freezers below 32oF.

Should it be necessary to temporarily use “super cooled” ice, allow the ice to warm at room temperature for 25

to 30 minutes before placing the ice in the dispenser.

Dispensing compressed flake “nugget” ice in Servend dispensers takes special handling. Most dispensers require

special bin components plus a universal ice management kit. Contact MBE regarding details for your particular

installation.

14

Page 15

OPERATION

EQUIPMENT

Installation and Service Manual

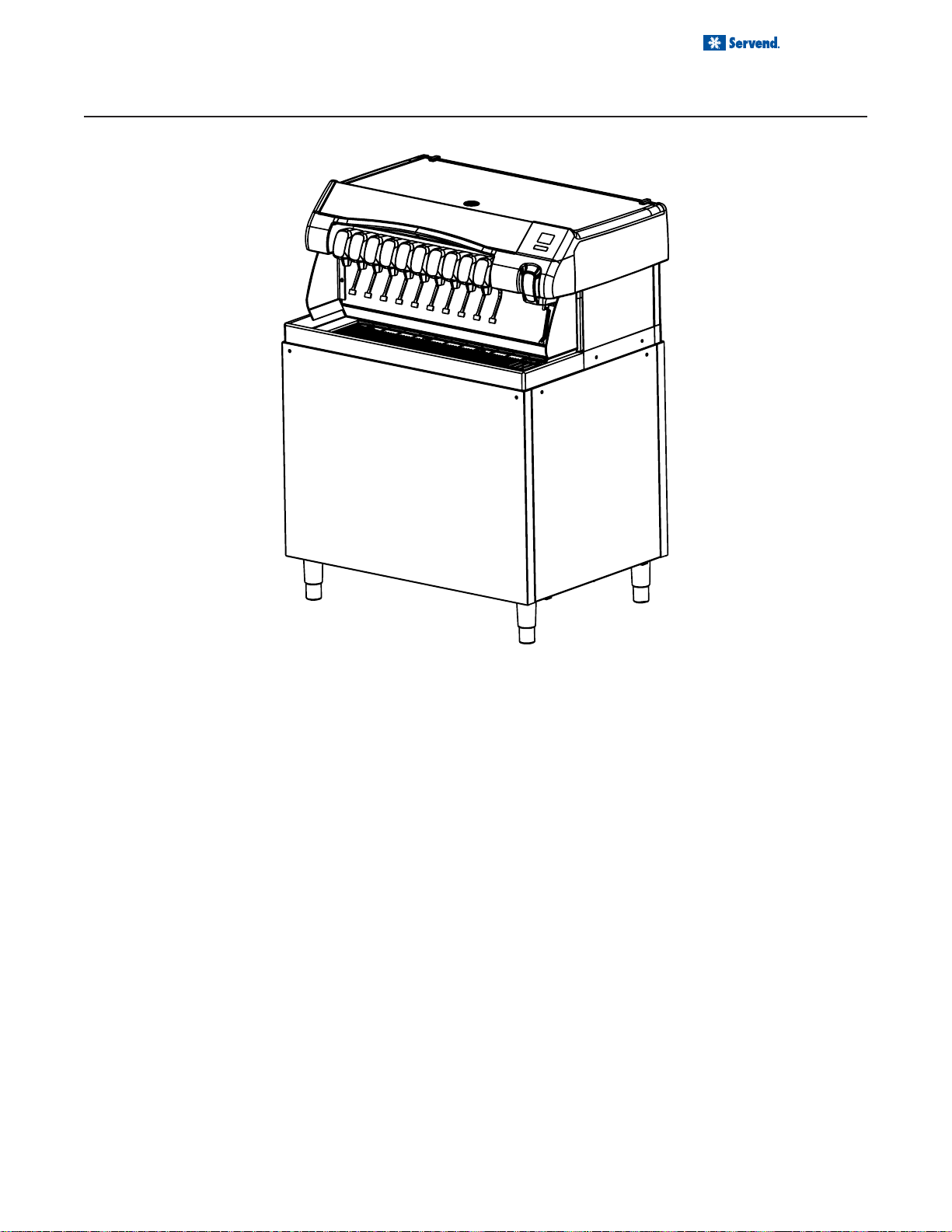

The LP-3 is a 10 flavor ice and beverage dispenser, with

the ice storage bin located below the counter top level. A

drink tower extends 19” above the counter top level. The

LP-3 is designed to fit into a 42.5” wide by 30.38” deep

space, and can be counter mounted (like a conventional

drop-in unit), or arranged as a stand alone with cosmetic

stainless panels.

Within the 19” drink tower is an optional 1000 lb/day remote ice cube maker, especially designed by Manitowoc

for this application.

Beverage cooling is accomplished by means of a cold

plate positioned below the storage bin, and the unit can

include an internally mounted or externally mounted carbonator system. In order to allow any valve to dispense

carbonated or non-carbonated beverages, two Servend

Flex Manifolds are incorporated into the tower.

Ice is dispensed from the storage bin by means of the paddle

wheel into an auger which raises the ice to the top of the

tower where it is dispensed by means of a rocking chute.

The drink tower is enclosed by 5 panels, one on each

side and back, as well as a splash panel in front below

the valves, and a top panel. Safety switches will disable

the ice dispensing circuit when either the top panel or

the splash panel are removed. The drive motors for agitation and auger ice lifting are mounted using locking pins,

and thus can be removed for maintenance and cleaning

without tools. Access is provided for in place cleaning of

the ice maker. The ice maker water valve, water pan, curtain, and water pump can all be removed for service and

cleaning without removing the ice maker itself.

®

The LP-3 can be built in either a left hand or right hand ice

dispense arrangement. In the right hand configuration water/syrup lines from the BIB pumps are brought in to the

unit at the lower left, drains, electrical and refrigerant lines

on the right.

Drain hoses are provided for the waste water from the

cuber, spillage and melt water from the drain pan, and

melt water from the storage bin and auger. A water supply line is necessary for the ice maker and beverage system, each connecting to a 3/8” ID. beverage tube.

15

Page 16

Installation and Service Manual

OPERATION

ICE STORAGE AND DISPENSING

Ice is stored in the dispenser’s bin. Ice below the stainless steel bin liner is used to cool the aluminum cold plate, at

the bottom of the ice dispenser bin. Ice above the stainless steel bin liner is dispensed into the customer’s cup.

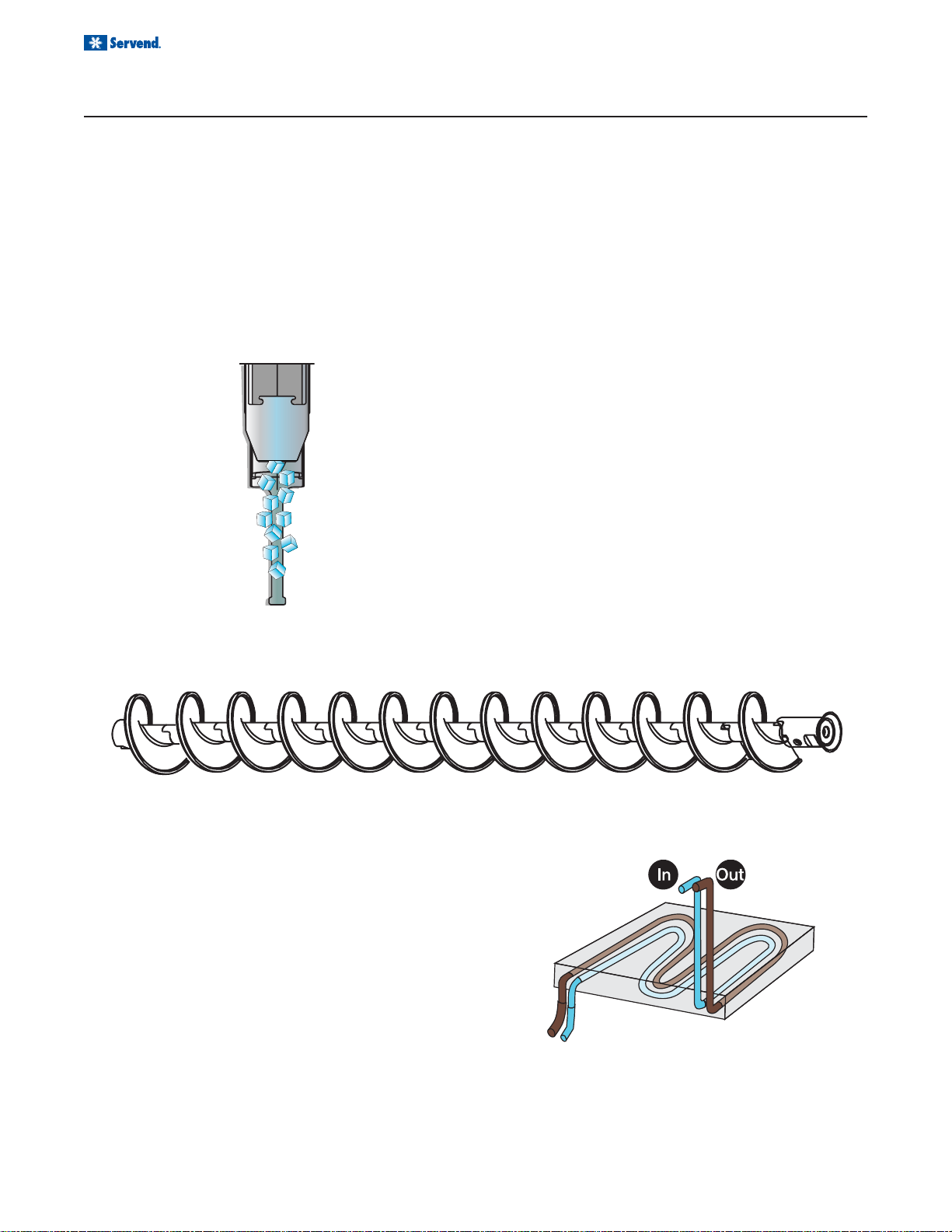

Ice is transported from the bin to the ice dispense point by the paddle wheel and vertical auger. The injection

molded paddle wheel has paddles which push the ice into a vertical auger that carries it to the dispense point.

ICE AGITATION

The paddle wheel and auger carry ice. Periodic agitation is standard on the LP-3. During periodic agitation, the

paddle wheel, auger and agitator turn for approximately three seconds every hour. The door lock prevents ice from

being dispensed during the agitation cycle.

ROCKING CHUTE ICE DISPENSING

As the customer presses the rocking chute, the arm at

the top left rear of the chute pushes upward on the door

lock. The door opens until it contacts the stops in the

mounting brackets. The plastic arm on the ice chute also

activates the lever of the ice dispensing switch. When

activated, the micro switch starts the gear motor and

auger motor. The gear motor turns the paddle wheel and

agitator bar, the auger motor turns the auger.

ICE AUGER

Ice is pushed into the auger by the paddlewheel. The auger lifts the ice from the bottom of the bin to the ice

dispense point at the rocking chute.

COLD PLATE BEVERAGE COOLING

A cold plate is a block of aluminum with serpentine stainless steel tubes molded inside the aluminum block. The

cold plate is approximately the same length and width

as the bottom of the dispenser bin. Ice sits on top of the

cold plate and cools the cold plate.

The stainless steel tubes inside the cold plate carry carbonated water (soda water), noncarbonated water (plain

water) and syrup to the beverage valves. While flowing

through the stainless steel tubes in the cold plate, water

and syrup are chilled to serving temperature.

BEVERAGE VALVES

Post-mix beverage valves are designed to precisely meter the flow of both water and syrup to obtain the proper

mixing ratio. The syrup and soda water components of the post-mix beverage are mixed as they leave the beverage valve.

16

Page 17

OPERATION

SPECIFICATIONS

Installation and Service Manual

Dimensions 44.4" X 31.1" X 57.3" (including top cover)

Weight 570 lbs (with ice 870 lbs)

Electrical Requirements 110 vac 60 hz 4 amps max.

Water 45 to 55 psi at 3 gpm

Ice Machine Options: Offered with 1000 lbs/day CVD model SU1024Y with remote

condenser

Drain Four 3/4" drain hoses to be routed to a floor drain

Syrups

Standard with Equipment: Internal carbonation or ambient carbonation for commercial

Options: With or without ice maker, right or left ice dispenser.

Listing/Approvals: UL and NSF

5

/16 barb connections for 10 flavors

applications.

17

Page 18

Installation and Service Manual

OPERATION

SPECIFICATIONS

B-I-B

The Bag-In-Box system refers to a plastic disposable bag. The B-I-B normally contains 5 gallons of syrup, however

some locations offer 2 1/2 or 3 gallon B-I-B units. This plastic bag is then held inside a cardboard or other container.

B-I-B systems are for post-mix applications only.

PUMPS

The syrup in a B-I-B system is delivered to the beverage system through gas operated pumps. These pumps

extract the syrup out of the bags forcing the syrup throughout the system.

AUTO BAG SELECTORS

These are used on higher volume B-I-B systems where two or more bags of the same product are connected to

one pump and one system. An auto bag selector is essentially a valve that automatically changes from one bag (or

series of bags) to another bag (or series of bags) of syrup as the bags empty, allowing a constant flow of product.

18

Page 19

Installation and Service Manual

OPERATION

Your syrup location can vary depending on the volume of beverages served and ease of accessibility. Your beverage system may set in a back storage room. Configurations are almost limitless. Check the temperatures expected

for the storage location. Adverse temperatures can affect the storage and quality of beverage products. It is recommended the temperature of storage location should not fall below 40o F or rise above 90o F.

BACK ROOM PACKAGE

1. Incoming tap water - should be at a minimum dy-

namic pressure of 40 psi and maximum of 55 psi.

2. Carbonator Water pump motor - Powers the water

pump. The water pump motor is part of the carbonator

pump deck.

3. Carbonator Water pump - Pumps tap water into the

carbonator tank. The water pump is part of the

carbonator. The incoming water for the carbonator

must be first ran through the pump before connecting

to the proper cold plate inlet.

4. Internal/External Carbonator tank - Combines CO

gas and tap water to form carbonated water. The “carbonator” is the carbonator tank, water pump and water pump motor.

5. CO2 cylinder - Holds highly pressurized carbon dioxide (CO2). The CO2 cylinder is a steel or aluminum

cylinder tank. CO2 gas flows through the primary pressure regulator.

6. BIB pressure gauge - Set for a minimum of 60 psi.

Indicates CO2 pressure going to B-I-B pumps.

7. Primary pressure regulator - Lowers the CO2 gas

pressure, to 75 psi, so the CO2 gas will be at the proper

pressure to enter the carbonator regulator.

8. Secondary pressure regulator - Lowers the CO2 gas

pressure before the CO2 gas flows to the syrup pump.

CO2 pressure, activates the syrup pump.

9. Syrup pump - Draws syrup out of the bag-in-box

syrup package. Syrup flows through the syrup lines

to the dispenser for chilling, then dispensing. There

2

is a syrup pump for each bag-in-box syrup system.

10. Bag-In-Box syrup cartons - Box which contains a

plastic bag, filled with syrup. Usually, six bag-in-box

cartons are placed on a rack.

19

Page 20

Installation and Service Manual

OPERATION

CARBONATION

The purpose of the carbonator is to take regular tap water at street water pressure (minimum 40 PSI dynamic or

flowing pressure) 3/8” water line, and increase the water to beverage system pressure (usually 75 PSI). This water

is then combined with the CO2 gas. Chilling the mixture before dispensing will assist in locking the carbon dioxide

into the water. After dispensing, the CO2 may be unlocked from the liquid. The CO2 will gradually leave the liquid

due to pressure and temperature changes.

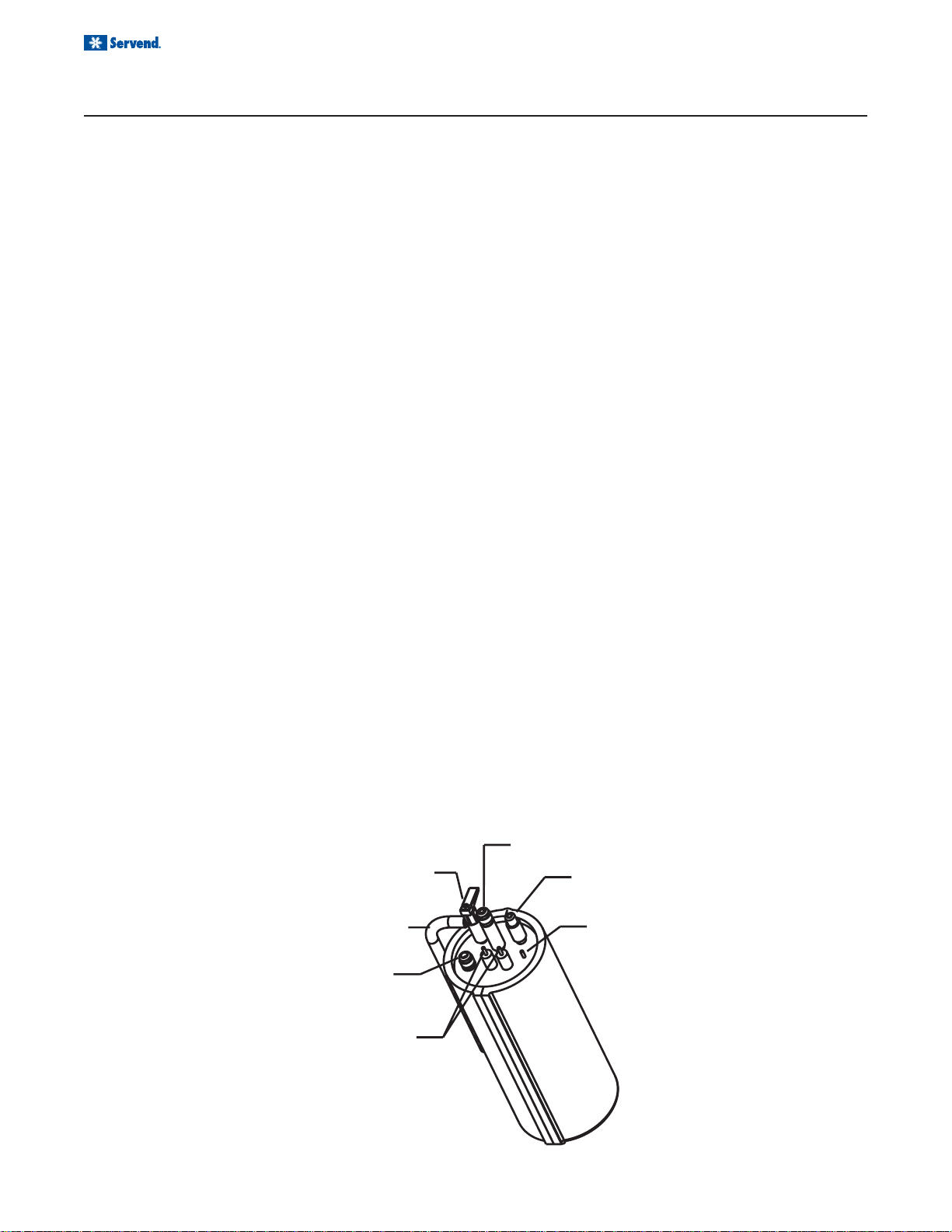

Components

The components of the carbonator are: water pump, an

electric motor to operate the pump, carbonator tank

where the water & CO2 mix, and a water level control.

Operation

Carbon Dioxide (CO2) leaves the storage tank and arrives at the carbonator tank through the gas inlet. Water

supply enters the carbonator pump inlet at regular street

water line pressure (minimum 40 PSI dynamic or flowing pressure). The water pump increases the pressure

of the water, which allows the water to flow into the carbonator tank. The CO2 and the water mix together in the

carbonator to produce the carbonated water that is then

sent to the tank soda dispenser.

The agitation of the water & CO2 together in the tank

under high pressure creates the carbonated water. The

quality of carbonation (percent of CO2 mixed in the water) increases as the water temperature decreases and

exposure time increases.

The water level in the carbonator tank is controlled by a

water level control in the tank. This control turns the pump

motor off and on to maintain a preset level of liquid in the

tank. The water level control is two conductivity probes

wired to a liquid level control board.

INTERNAL CARBONATION

The carbonator tank has two inlets and one outlet connection, as well as a relief valve and two conductivity

probes. The water inlet is topped by a 3/8" male flared

fitting. The carbonator will be pre-plumbed as it leaves

the factory. If the carbonator needs to be serviced or if

the fittings need to be replaced, make sure a nylon

washer is used inside each inlet fitting to prevent leaks.

The conductivity probes are used to control the level of

water inside the carbonator tank. The red probe, or the

“high” probe, is the shorter of the two. When the level

of the water reaches the bottom of the red probe, the

pump shuts off. The pump starts when the water level

inside the tank goes below the bottom tip of the of the

black or "low" probe. Both probes are wired to the elec-

Pressure

Relief

Purge

Tube

Carbonated

water Outlet

tronic liquid level control, which is a circuit board

mounted inside the electrical box that activates the

pump and motor. Removing the cover of the electrical

box will grant access to the circuit board. As the control

receives a signal from the conductivity probes, it activates the pump motor, which will pump water into the

carbonator until the water reaches the high probe.

The pump is a standard 125 GPH brass rotary vane

pump. The flared fittings accept the same swivel/barb

connectors used on the carbonator water connections.

Also, water enters the pump from the water source on

the side that has the strainer.

Water

Inlet

CO

2

Inlet

Ground

20

Electronic

Probes

Page 21

Installation and Service Manual

USER MAINTENANCE

HOW TO DISASSEMBLE FOR CLEANING OR MAINTENANCE

1. Disconnect electrical power to the unit.

2. Remove thumb screws holding plastic splash

guards and stainless splash panel.

3. Remove grid and drainpan.

4. Release the plastic latches on the back of either

side of the lid assembly. (see Detail A)

5. Slide the lid assembly forward and lift to remove.

6. Remove the plastic side panel assemblies.

7. Remove all ice from the ice storage bin.

8. Rotate the agitator arm so the paddle wheel pin

handle is pointing up, toward the ceiling.

9. Loosen the hand-removable paddle wheel pin from

the agitator by twisting counter clockwise until it

snaps from the agitator bar.

10. Then remove the paddle wheel pin from the hole in

the agitator. Push the agitator bar toward the back

of the unit until the agitator is free of the paddle

wheel hub and remove the agitator.

11. Remove the bin liner.

12. Remove horizontal tower cover brace then remove

the auger motor assembly by pulling the 7 pins holding it in place, disconnecting the 2 sets of insulated

quick slides to the motor, and lifting the assembly

straight up and out of the unit.

13. Lift the auger and auger tube up and out of the unit.

14. Remove the auger transition by pulling the 2 pins

holding it in place.

15. Remove the ice chute assembly and spout.

CLEANING CHECKLIST

• Check CO

the primary regulator gauge will point to a shaded area

that reads “Low CO2” or “Change CO2 Cylinder.”

supply. If CO2 supply is low, an arrow on

2

• Check syrup supply.

• Clean drain pan, grid, and splash panel.

• Clean the valve nozzles and diffusers.

21

Page 22

Installation and Service Manual

USER MAINTENANCE

DAILY CLEANING

CAUTION: Use only warm soapy water to clean the exterior of the tower. Do not use solvents or

other cleaning agents

drain pan can eventually crack the drain pan, especially if the drain pan is cold or still contains ice.

All cleaning must meet your local health department regulations. The following cleaning instructions are

. Do not pour hot coffee into the drain pan. Pouring hot coffee down the

provided as a guide.

Clean the exterior, nozzles and diffusers:

1. Turn off the key switch located on either right or left

side of the unit.

2. Lift the grid and remove it from the drain pan.

3. Using mild soap, warm water and a clean cloth, wipe

the drain pan and splash panel. Then, rinse with clean,

warm water. Allow plenty of warm (not hot) water to

run down the drain of the drain pan, to remove syrup

residue that can clog the drain opening.

4. Wash the grid, then rinse with clean water. Place

the grid back in the drain pan.

5. Wash all exterior surfaces of the unit with warm

water and a clean cloth. Wipe again with a clean,

dry cloth.

Clean the dispensing valves:

6. Remove nozzles and diffusers from beverage

valves.

7. Rinse nozzle and diffuser with warm, clean water.

8. Clean nozzles and diffusers with soapy water and

a soft bristle brush.

9. Clean the underside of the beverage valves with

warm, soapy water. Rinse with clean damp towel.

10. Replace nozzles and diffusers on valves.

11. Turn on the key switch.

22

Page 23

Installation and Service Manual

USER MAINTENANCE

MONTHLY CLEANING

Scheduled cleaning must be in compliance with local health codes. This cleaning schedule is a

recommendation. Follow cleaning and sanitizing instructions found in the Manitowoc manual to

clean and sanitize the icemaker. The LP-3 drainpan and splash panel must be removed before

cleaning the icemaker.

CLEANING AND SANITIZING OF THE DISPENSER

Note: Sanitize the dispenser at initial start-up in addition to monthly sanitizing.

Mix a solution of mild, nonabrasive detergent to clean the dispenser bin and components. Using a clean cloth or a

soft bristle brush, clean the following dispenser parts:

• Cold plate

• Ice storage bin, including the

• Agitator

• Agitator Pin

• Bin liner & support

• Drainpan support bracket

• Auger

• Auger tube

• Auger transition

• Ice chute outer bracket

• Ice chute

• Ice chute door

• Ice chute lock

• Ice chute spout

• Paddle wheel

• Paddle wheel bushing

• Paddle wheel area

Rinse all parts in clean, running water. Mix a sanitizing

solution of ¼ ounce liquid, unscented laundry bleach

(5.25% Cl Na O concentration) for each gallon of water,

to supply 100 PPM of available chlorine. Using this solution and a clean cloth or soft bristle brush, clean the

dispenser parts listed above. Allow parts to air-dry then

reassemble.

23

Page 24

Installation and Service Manual

USER MAINTENANCE

BEVERAGE SYSTEM CLEANING

Sanitize the beverage system at initial start-up as well as during regularly scheduled cleaning. The drain pan must

be in place under soda valves, to carry away detergent and sanitizing agents that will be flushed through valves.

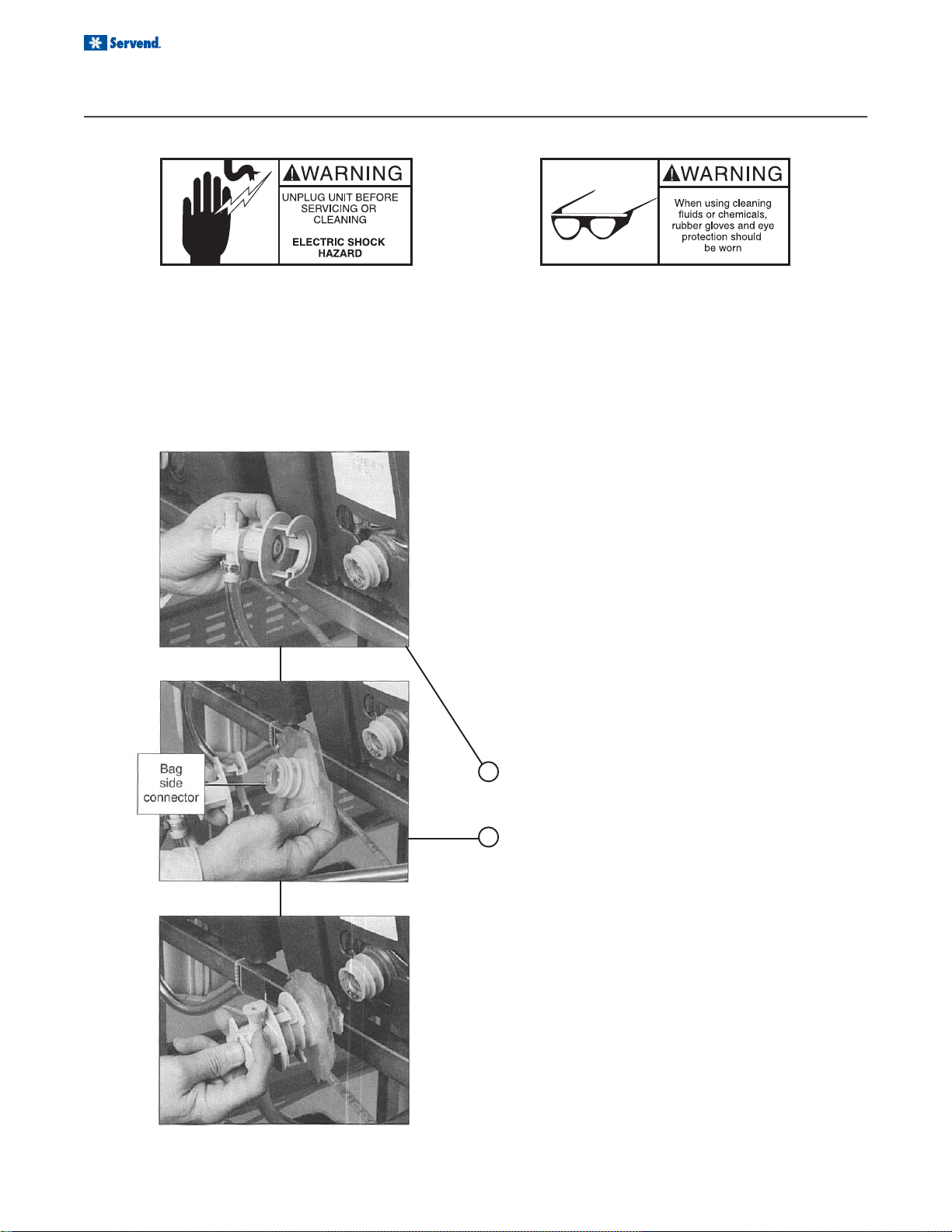

BAG-IN-BOX SYSTEM

The procedure below is for the sanitation of one syrup circuit at a time. Repeat to sanitize additional circuits.

You will need the following items to clean and sanitize

the Bag-in-Box (BIB) beverage system:

• Three (3) clean buckets

• Plastic brush or soft cloth

• Mild detergent

• Unscented bleach (5% Na CL O) or

Commercial sanitizer

• Bag-In-Box bag connector

1. Prepare the following in the buckets:

• Bucket 1 - warm to hot tap water for rinsing.

• Bucket 2 - mild detergent and warm to hot water.

• Bucket 3 - mix a solution of unscented bleach

(5% Na CL O) or commercial sanitizer and warm

to hot water. Mixture should supply 100 PPM available chlorine (1/4 oz. bleach to 1 gallon water).

2. Disconnect the “syrup-line side” of the bag-in-box

connector.

3. Rinse connector with warm tap water.

4. Connect syrup connector to BIB connector and immerse both into Bucket 1. A “bag-side” connector

can be created by cutting the connector from an

empty disposable syrup bag.

5. Draw rinse water through system until clean water

is dispensed. Most beverage valves allow the syrup

side to be manually activated by depressing the

syrup pallet.

6. Connect Bucket 2 to system.

7. Draw detergent solution through system until solution is dispensed.

8. Repeat steps 2-7 until all syrup circuits contain detergent solution.

9. Allow detergent solution to remain in the system for

5 minutes.

24

Page 25

USER MAINTENANCE

BAG-IN-BOX SYSTEM

Installation and Service Manual

10. Connect Bucket 3 to system.

11. Draw sanitizing solution through system until solution is dispensed.

12. Repeat step 11 until all syrup circuits contain sanitizer solution.

13. Allow sanitizer solution to remain in system for 15

minutes.

14. Remove nozzles and diffusers from beverage valves.

15. Scrub nozzles, diffusers and all removable valve

parts (except electrical parts) with a plastic brush

or a soft cloth and the detergent solution.

16. Soak nozzles, diffusers and removable valve parts

(except electrical parts) in sanitizer for 15 minutes.

17. Replace nozzles, diffusers and valve parts.

18. Connect Bucket 1 to system.

19. Draw rinse water through system until no presence

of sanitizer is detected.

20. Attach syrup connectors to BIB’s.

21. Draw syrup through system until only syrup is dispensed.

22. Discard first 2 drinks.

PREVENTATIVE MAINTENANCE

Preventative maintenance is a vital part of keeping your dispenser in top condition. Following the guidelines below

will assist you in continued trouble free operation of your unit.

1. Conduct daily maintenance of the machine.

2. Perform monthly maintenance of the machine.

3. Perform periodic maintenance and sanitizing of beverage system.

4. Do not overfill the dispenser bin with ice.

5. Do not allow the dispenser to sit for prolonged periods of non use with ice in the bin.

6. Most ice dispenser service problems are caused by

low usage of the ice dispenser.

7. Do not allow ice to remain in the bin more than a day

in order to prevent ice from freezing together and/or

stagnant ice.

Possible excess ice storage reasons:

• Storage capacity exceeds daily requirements.

• Low demand during the off season.

• Dispenser oversized with future growth in mind.

Lower ice storage to meet one day’s needs. If you manually fill ice, fill only with the appropriate amount of ice. Fill

the dispenser with fresh ice each morning. Do not fill the

dispenser at night just before shut down. Ice cubes can

freeze together if not dispensed.

Contact MBE at 1-800-367-4233 for more information

about our ProActive Maintenance Program.

25

Page 26

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

115V WIRING DIAGRAM

26

Page 27

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

COVERS & PANELS

NO Part# Description

1 5029883 CABINET GALV

2 020000214 RH COVER ASSM

3 020000215 LH COVER ASSM

4 020000216 LID ASSM

27

Page 28

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

SPLASH PANEL, DRAINPAN & CUBER

28

No. Part Number Description

1 5012090 GRID

2 5012238 DRAINPAN RH

3 5012311 CUBER 120V

Page 29

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

PANELS & LID BONNET

NO Part Number Description

1 000000246 LABEL LOGO SNOWFLAKE

2 00850809 NUT # 4-40 HEX BRASS

3 0901001 SCR #8X1/2" SS PH TR HD

4 5000888 CLIP PUSH ON

5 5031260 LENS

6 5031525 GROMMET FINGER

7 5031550 LABEL LOGO SERVEND

8 5031590 LABEL ICE

NO Part Number Description

9 020000141 COVER FRONT

10 020000144 TRIM, TOWER

11 020000145 TRIM, TOWER LOGO

12 020000207 BSHG BONNET ANGLED

13 020000213 LID, SS TOWER RH

14 020001321 SPACER, LATCH

15 020001323 LATCH PLAS

16 020001328 SCR 4-40 X 1/2

29

Page 30

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

AUGER, AGITATION & DRAIN

30

Page 31

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

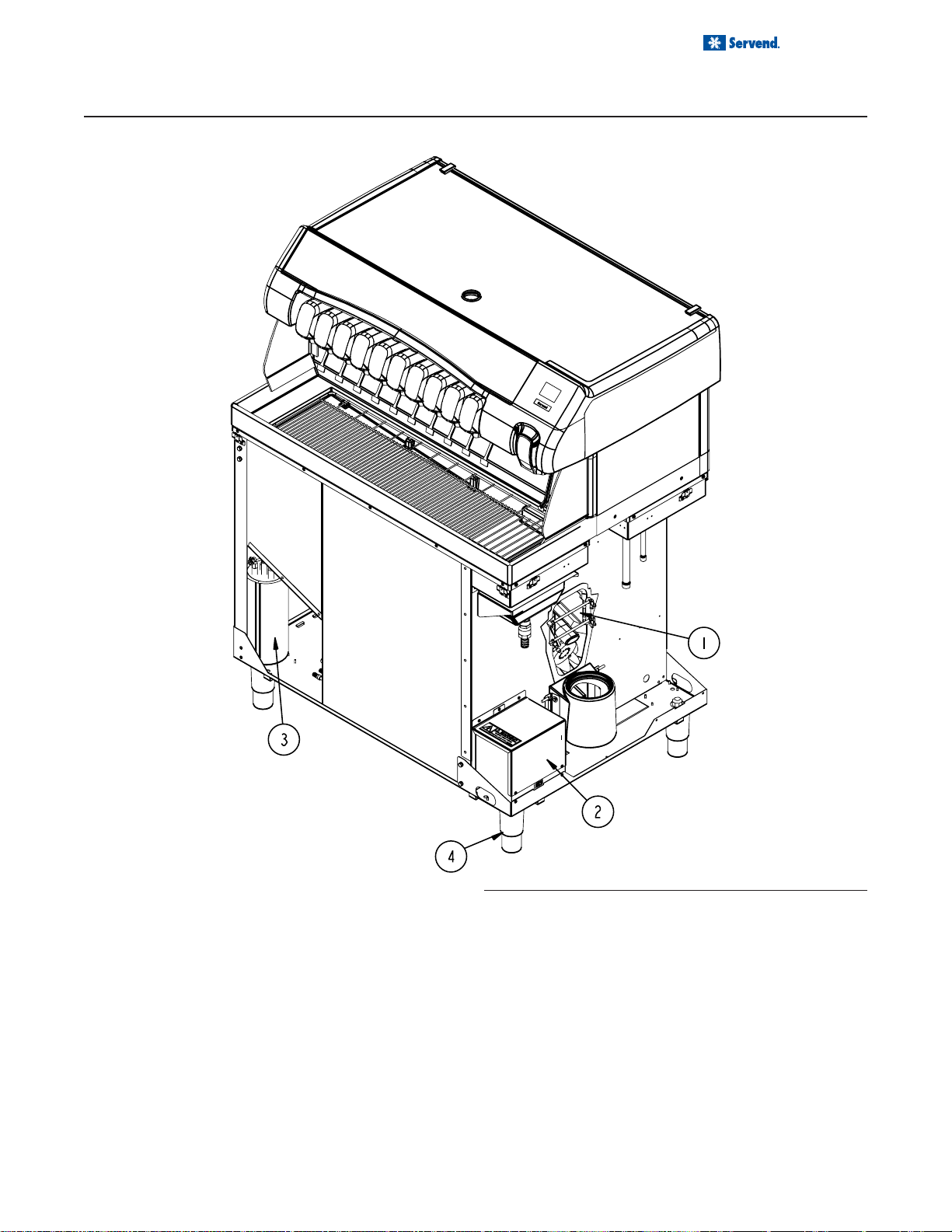

LEGS, CARB TANK & ELECTRIC BOX

No Part Number Description

1 5029874 MNT MOTOR 120V

2 5029876 ELEC 120/60

3 5029887 TANK CARB

4 5030236 LEG

31

Page 32

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

AUGER DRIVE, VALVE MOUNT, ROCKING CHUTE, PUMP

NO. Part Number Description

1 5029884 BOM BASE

2 5029872 CAP VLV MNT RH

3 5028889 AREA RH PADDLEWHEEL

4 5029888 PUMP CARB 120V

5 5014007 PUMP RECIRC 120V

6 5012308 AUGER DRIVE 120V

7 5012326 CHUTE ROCKING

32

NO. Part Number Description

8 5012615 VLV FLO 464HF SL GP COVER

9 5000220 KEYSWITCH

10 020001299 BRKT SAFETY SWITCH

11 100703 MICROSWITCH

12 0900901 SCR 6-32 X 1" SS PH RHMS

13 0902101 NUT 6-32 HEX SS

Page 33

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

120V AUGER DRIVE

33

Page 34

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

120V CUBER

NO. Part # Description

1 5031580 CUBER BRAZED EXT

2 5029830 BRACE RT SIDE PANEL

3 5029832 BRACE LFT SIDE PANEL

4 5029831 BRACE BACK PANEL

5 5011940 SCREW 8-32 X 1/2

6 5012891 WRAP BACK

7 5012933 TRIM EVAPORATOR WRAP BACK1

8 5012281 SCREW 8-32 X 1/4 ES FORM 7

9 0901001 SCR #8X1/2" SS PH TR HD A4

10 0900240 CLIP TINN C191728Z4

11 5031078 SPACER ICEMAKER

12 5012892 WRAP RIGHT

13 5012893 WRAP LEFT

14 5012934 TRIM EVAPORATOR WRAP SIDE2

15 5029806 RIVNUT 10-32

16 020001298 BRKT REAR PANEL SUP

17 020000226 WRAP BACK

18 020001323 Latch Plas

19 020001322 SCREW #4 X 1/2 SELF TAP 4

RIGHT SIDE BONNET COVER LEFT SIDE BONNET COVER

NO Part # Description

1 0901001 SCR #8X1/2" SS PH TR HD A

2 0901803 WASHER FLAT #10 ZINC

3 020000142 CAP TOWER END

4 020000212 SUPPORT BONNET SIDE

NO Part # Description

1 0901001 SCR #8X1/2" SS PH TR HD A

2 0901803 WASHER FLAT #10 ZINC

3 020000143 CAP TOWER END

4 020000212 SUPPORT BONNET SIDE

34

Page 35

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

120V CARB PUMP & TANK ASSEMBLY

No. Part Number Description

1 1701110 NUT 3/8"X9/16" SWIVEL FITTING

2 1701115 Washer 3/8" Black Nylon

3 1701301 CLAMP OTR 1/2" 13.3-706R

4 5009025 FITTING SWIVEL 3/8" BARB

5 5009613 PUMP HEAD CARB 125 GPH

6 5009983 FITTING 3/8X3/8 NPT ELBOW

7 5010781 FITTING 3/8 BARB SW/ELBOW

8 5028931 MOTOR CARB PUMP 115V

9 5031042 VALVE CHK VENTED 3/8" NPT X 3/8" FLARE

10 5030533 TUBE CARB TANK PURGE

35

Page 36

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

AUGER & ROCKING CHUTE

36

Page 37

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

VALVE MOUNT CAP & AGITATOR MOTOR

37

Page 38

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

AUGER TRANSITION & 120V ELECTRIC BOX

38

Page 39

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

BIN

39

Page 40

Installation and Service Manual

9

9

MANITOWOC® SU1024YC ICEMAKER

CONTROL BOX & EVAPORATOR COMPARTMENT

5

6

7

1, 2

10

9

8

SV3000

DESCRIPTION PART NUMBER

1 Control Board (for use with all voltages) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-2782-3

27 amp Fuse Mounted on Control Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-1100-3

3 Wiring Harness Control Box (Not shown)

a. 115V/60 Hz/1 ph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0077-3

b. 208-230V/60 Hz/1 ph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0077-3

c. 230V/50 Hz/1 ph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0077-3

4 Wiring Harn ess From Control Box (Not shown)

a. 115V/60 Hz/1 ph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0112-3

b. 208-230V/60 Hz/1 ph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0112-3

c. 230V/50 Hz/1 ph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0112-3

5 Toggle Swit ch (Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-0134-3

a. Toggle Switch With Wiring Harness Attached. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0113-3

b. Mounting Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-0056-3

Miscellane ous Screws, Support s, etc.

6 Control Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604739-1

7 Control Box Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-0116-3

8 Control Board Mounting Supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43-0225-3

9 Screw, #10-24 x .50 Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52-0216-

10 Screw, 10 x 24 x .50 Phillips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52-0209-

12

1

6

13

2

7

14

5

11

3, 8

DESCRIPTION PART NUMBER

9

10

4

1 Evaporator Assembly Half Dice Cube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-0096-3

2 Ice Thickness Control Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-2781-3

3 Magnetic Bin Switch (Mounted to Evaporator). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-0148-3

4 Water Trough. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-0468-3

5 Water Curtain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-0944-3

6 Water Distribution Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43-0322-3

7 Vinyl Tubing Water Distribution Tube to Water Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-0412-3

Miscellaneous Bracket s, Screws, etc.

8 Water Curtain Magnet With Attachment Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-2802-3

9 Quarter Turn Fastener Male (Water Trough and Water Pump Mounting) . . . . . . . . . . . . . . . . . . . . . . 50-0045-3

10 Quarter Turn Fastener Receptacle Female (Water Trough and Water Pump Mounting). . . . . . . . . . . 56-5085-3

11 Screw 10 x 24 x .75 with washer Evaporator Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52-0218-9

12 Screw, #8-32 x .63 Water Distribution Tube Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-0001-3

13 Evaporator Top Molding and Gasket Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-2801-3

14 Water Curtain Pin Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-2856-3

Refer to Cross Reference Guide

40

PT370

Page 41

MANITOWOC® SU1024YC ICEMAKER

REFRIGERATION COMPARTMENT

8

2

3

Installation and Service Manual

5

6

18

14

19

16

1

11

17

13

4

14

12

10

9

7

41

Page 42

Installation and Service Manual

MANITOWOC® SU1024YC ICEMAKER

REFRIGERATION COMPARTMENT

DESCRIPTION PART NUMBER

1 Water Dump Valve

a. Dump Valve Assembly without Electrical Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-0520-3

b. 115V/60 Hz Coil Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-0521-3

c. 208/230V 50/60 Hz Coil Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-0522-3

d. Dump Valve Rebuild Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-0501-3

2 Manual Shut -off Valve Suct ion Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83-7301-3

a. Valve Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83-7327-3

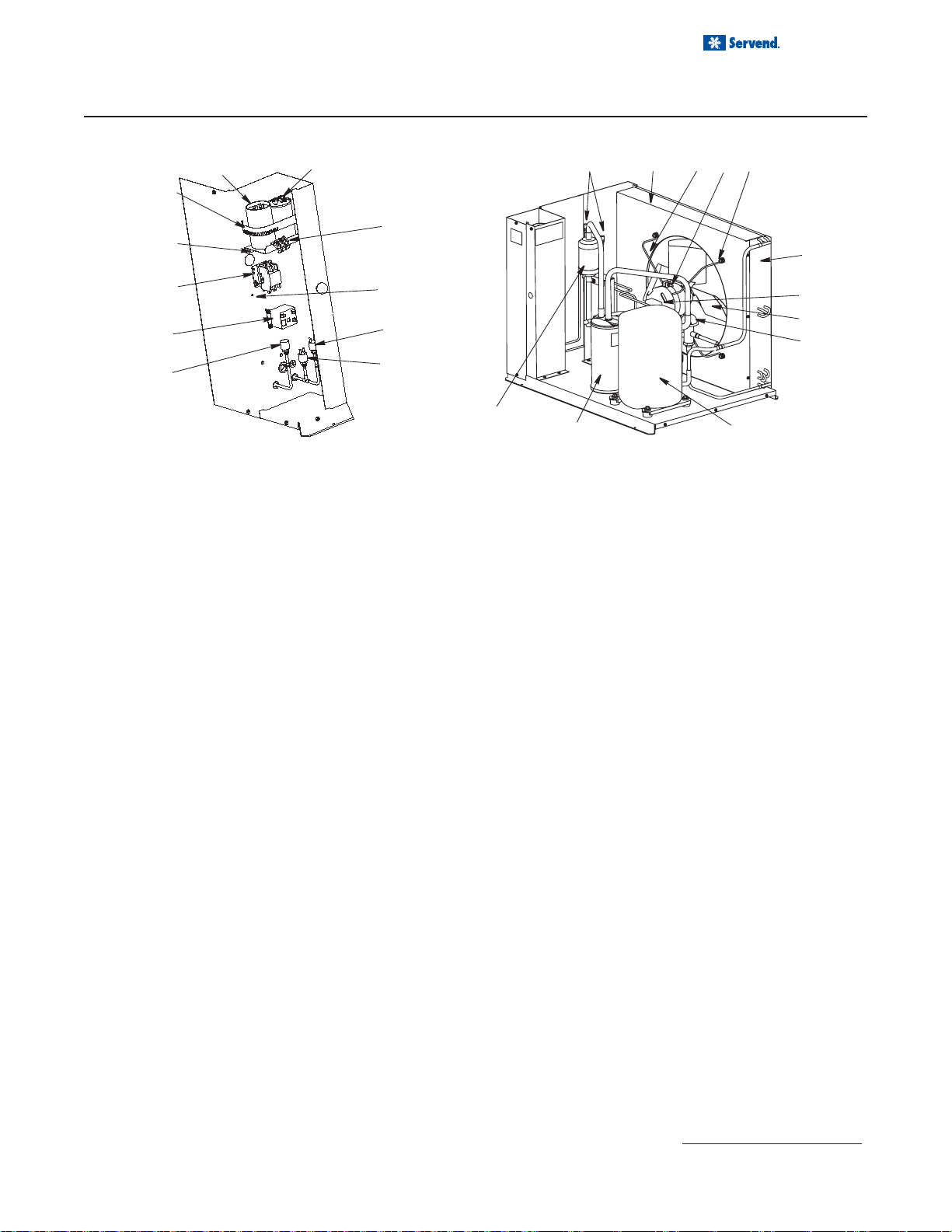

3 Manual Shut -off Valve Liquid Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83-7300-3

a. Valve Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83-7302-3

4 Receiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-5058-3

a. Equalizer Tube (Connects The Receivers). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-0154-3

5 Check Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83-7315-9

6 Expansion V alve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-0022-3

a. Expansion Valve Body Insulation Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-0080-3

b. Expansion Valve Bulb Insulation Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-0092-3

7 Cool Vapor Valve

a. Solenoid Valve Including 115V/60 Hz Electrical Coil (Danfoss) . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-3005-1

b. 115V/60 Hz Electrical Coil only Danfoss. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0176-3

c. 115V/60 Hz Electrical Coil only Alco. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-0436-3

d. Solenoid Valve Including 208/230V 50/60 Hz Electrical Coil (Danfoss) . . . . . . . . . . . . . . . . . . . . . 76-3011-1

e. 208/230V 50/60 Hz Electrical Coil Only Danfoss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0177-3

f. 208/230V 50/60 Hz Electrical Coil Only Alco . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-0448-3

8 Receiver Serv ice Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83-7316-9

a. Valve Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56-5075-3

9 Liqu id Line Solenoid V alve

a. Liquid Line Solenoid Valve Including 115V/60 Hz Coil (Danfoss). . . . . . . . . . . . . . . . . . . . . . . . . . 76-3001-1

b. 115V/60 Hz Coil Only Danfoss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0176-3

c. 115V/60 Hz Coil Only Alco . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-0436-3

d. Liquid Line Solenoid Valve Including 208/230V 50/60 Hz Electrical Coil (Danfoss) . . . . . . . . . . . . 76-3007-1

e. 208/230V 50/60 Hz Coil Only Danfoss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0177-3

f. 208/230V 50/60 Hz Coil Only Alco . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-0448-3

10 Liquid Line Drier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89-3027-3

11 Float Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83-6904-9

a. Compression Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56-5072-9

12 Water Pump

a. 115V/60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-2552-3

b. 220V/50 Hz/1 ph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-8027-9

c. Water Pump Electrical Lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-7810-3

13 Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Miscellaneous Brackets, Screws, etc.

14 Side Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604721-1

15 Clamp, Expansion Valve Bulb (Not shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-0081-3

a. Copper Expansion Valve Bulb Clamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-0050-3

16 Float Valve Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604728-1

17 Thumbscrew. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-0512-3

18 Pump Chimney Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-0117-3

19 Pump Chimney Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-0118-3

. . . . . . . . . . 82-5061-3

42

Refer to Cross Reference Guide

Page 43

Installation and Service Manual

3

3

3

3

3

3

3

3

9

9

9

MANITOWOC® SU1024YC ICEMAKER

CVD1075 CONDENSING UNIT

13

22

21

14

23

3

16

17 18

19

4

12

11

10

24

8

9

PT1286A

5

6

7

15

2

1

PT1284

DESCRIPTION P ART NUMBER

1 Compressor

a. 208-230V/60 Hz/1 ph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-0002-

b. 208-230V/60 Hz/3 ph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-0003-

c. 208-230V/50 Hz/1 ph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-0004-

2 Suction Accumulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89-0058-3

3 Access Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83-7325-3

4 Air-Cooled Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88-5139-3

5 Fan Motor

a. 208-230V/60 Hz/1 ph (or 3 ph) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-1315-3

b. 208-230V/50 Hz/1 ph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-1318-3

6 Fan Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-1623-3

7 Head Pressure Control Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83-6810-3

8 Fan Cycling Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0126-

9 High Pressure Cut Out Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0124-

10 Low Pressure Cut Out Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-5546-3

11 Start Relay 50-60 Hz/1 Ph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85-0457-3

12 Contactor 50-60 Hz/1 Ph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-1035-3

a. 60 Hz/3 Ph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-0116-3

13 Start Capacitor 60 Hz/1 Ph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85-0385-

a. 50 Hz/1 Ph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85-0582-3

14 Run Capacitor 60 Hz/1 Ph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85-0497-

a. 50 Hz/1 Ph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85-0540-3

15 Filter, Suction Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-5054-

Miscellaneous Brackets, Screws, etc.

16 Fan Shroud. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603449-1

17 Fan Motor Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-0669-3

18 Fan Motor Mounting Screw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-3358-

a. Fan Motor Mounting Lockwasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-4511-9

b. Fan Motor Mounting Hexnut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 -2952-9

19 Fan Bracket Mounting Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-3358-

a. Fan Bracket Mounting Lockwasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-4511-9

b. Fan Bracket Mounting Flatwasher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55-7305-9

c. Fan Bracket Mounting Rubber Wellnut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54-2955-9

20 Screw, #10-24 x .50 (Used For Panel Attachment - Not shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52-0206-9

21 Capacitor Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603498-1

22 Capacitor Mounting Strap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 602160-1

23 Terminal Block (50 Hz Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-1125-3

24 Ground Screw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52-0216-

Refer to Cross Reference Guide

43

Page 44

Installation and Service Manual

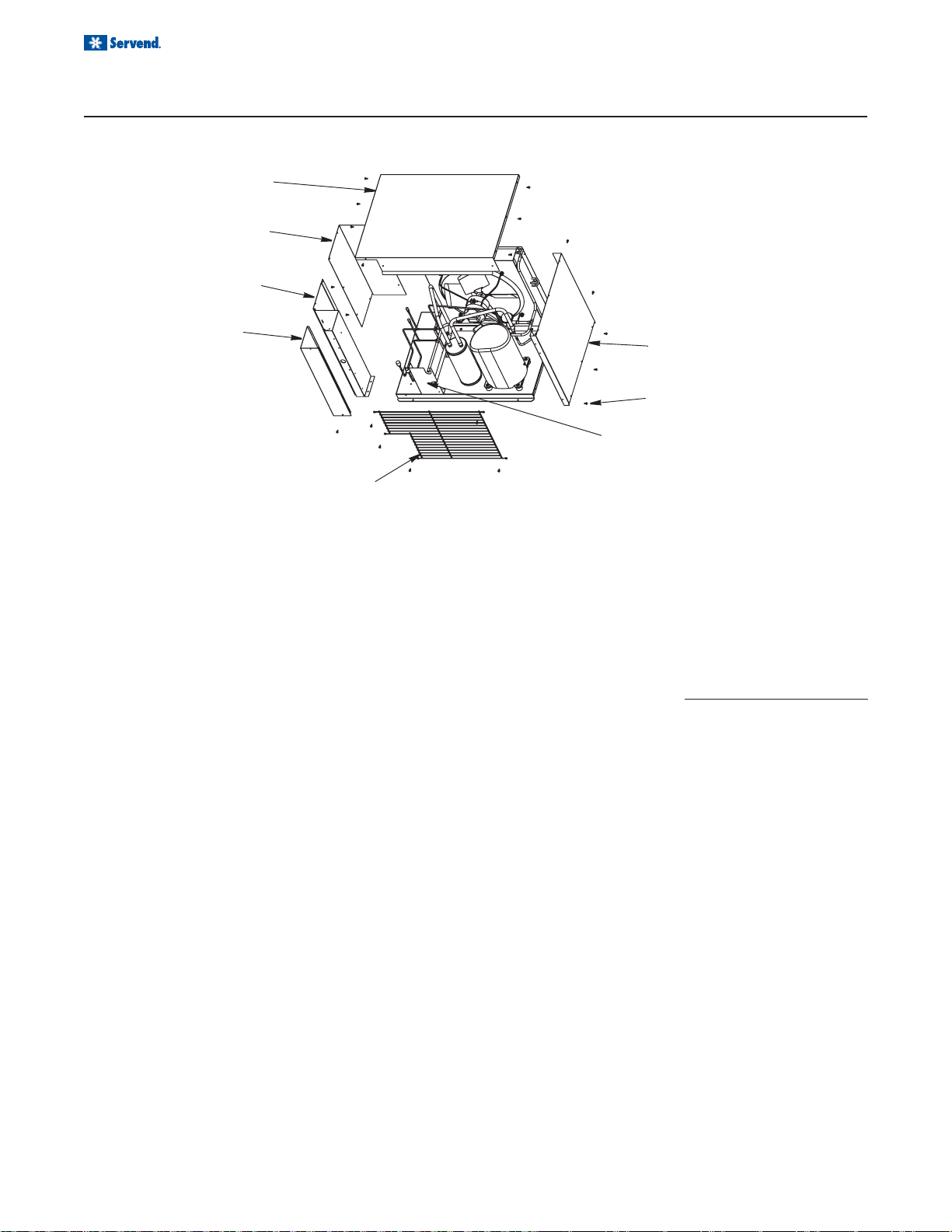

MANITOWOC® SU1024YC ICEMAKER

CVD1075 CONDENSING UNIT PANELS

5

4

3

2

1

6

8

7

PT1287

DESCRIPTION PART NUMBER

1 Condenser Fan Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-0689-3

2 Control Box Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603477-1

3 Control Box Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603707-1

4 Left Side Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603729-1

5 Cover Top. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603475-1

6 Right Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603470-1

7 Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604226-1

Miscellaneous Brackets, Screws, etc.

8 Screw, #10-24 x .50 Hex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52-0206-9

Refer to Cross Reference Guide

44

Page 45

Installation and Service Manual

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Pump will not run but

tank appears to be

always full.

Pump will not run but

tank level appears to

be below start level.

Pump motor does not

shut off.

Black and/or red probe shorted

Problem with motor or motor wiring

Problem with Liquid Level Control

Board.

Common Lead (Green) shorted out to

Red wire (High Probe)

Common Lead (Green) shorted out to

Black wire (Low Probe)

Problem with Liquid Level Control

Board

Probe Harness Connection may be

open.

Water may not be reaching top probe

in carb tank.

Remove probes and bend straight or replace with new

probe(s)

Check line voltage first. Check AC voltage across

load terminals on Liquid Level Control. If voltage is

120 plus or minus 10%, replace motor or motor wiring.

Check line voltage first. If AC voltage across load

terminals is not 120 plus or minus 10%, replace the

Liquid Level Control Board.

Verify Green and Red wires are not touching.

Verify Green and Black wires are not touching.

Short the "H & L" terminals on the Liquid Level Control

Board. If motor does not shut off, replace Liquid Level

Control Board.

Verify connections are good or replace the wiring

harness.

Verify tank is not filled with CO

valve up and letting air escape until water comes out.

or air by pulling relief

2

Pump motor

intermittent

High Lead (Red) open or not

connected.

Common lead (Green) open or not

connected.

Problem with probe or probe harness.

Problem with motor or motor wiring.

Verify Red lead wire is connected from tank to unit.

Verify Green lead wire is connected from tank to unit.

Check motor and motor wires by removing red and

black wires from the Liquid Level Control Board. If

okay, short "H & L" terminal on Liquid Level Control

Board. If motor stays off, verify probes and bend

straight or replace. Verify with meter.

Measure AC voltage across load terminals on Liquid

Level Control Board. If line voltage is 120 plus or

minus 10% replace motor or motor wiring.

45

Page 46

Installation and Service Manual

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Pump motor intermittent Problem with Liquid Level Control

Board.

Pump motor starts and

stops, short cycles, as soon

as water level drops below

Red (High) probe.

Pump motor starts and

stops, short cycles, as soon

as water level drops below

Black (Low) probe.

Pump short cycles from

below high probe to just

above high probe - Low

probe has no effect.

Black (Low) Lead wire is open or

disconnected.

Red and Black Leads are switched with

each other.

Red and Green Leads are switched with

each other.

Black and Green Leads are switched

with each other.

Check li ne voltage first. If AC voltage across

load terminals on Liquid Level Control Board is

not 120 plus or minus 10%, replace the Liquid

Level Contorl board.

Verify connections and continuity of black wire

from Liquid Level Control Board to Probes on

Carb Tank.

Verify Red Lead is going to Red probe and

Balck Lead is going to Black probe.

Verify Red Lead is going to Red Probe and

Green Lead is going to Ground Screw on tank

Verify Black Lead is going to Black Probe and

Green Lead is going to Ground Screw on tank.

46

Page 47

Installation and Service Manual

47

Page 48

Installation and Service Manual

48

Page 49

Installation and Service Manual

49

Page 50

INDEX

A

agitation ........................... 15, 16

agitation cycle ......................... 16

Agitator Motor ......................... 37

Ambient ................................... 10

Auger ........................ 21, 30, 36

Auger Drive ............................. 33

auger motor ............................ 21

Auger Transition............... 23, 38

Auger tube ....................... 21, 23

Auto Bag Selectors ................. 18

B

B-I-B connectors ....................... 8

Back Room Package .............. 19

Bag-In-Box .......... 18, 19, 24, 25

Beverage Cooling ................... 16

Beverage System ................... 24

beverage tube ......................... 15