Page 1

G SERIES CUBER

INSTALLATION & SERVICE GUIDE

Part Number 5006772

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

Printed in The United States of America

5006772 Revision June 19, 2003

Page 2

Installation and Service Manual

WARRANTY POLICY

SerVend retains the right to refuse payment for the following conditions. Premium labor rates, holidays, overtime,

travel time, flat service call charge, mileage or material charges.

SerVend will not pay for:

Corrections to your installation, to instruct you how to care for your equipment, maintenance, leveling, or cleaning.

Replacement of fuses, circuit breakers, building wiring or plumbing to accommodate installation of this equipment.

Repairs to this equipment when used in a non-approved installation, or removal of equipment for repairs. Repairs

due to improper installation or correcting original installation. Repairs due to transportation or mishandling.

Adjustments to SerVend equipment.

Repairs when accessibility of equipment is hindered by ambient conditions. Repairs to parts or systems caused by

unauthorized modifications. Return service calls for the same problem. Any claim submitted with improper, inaccurate or illegible labor forms.

Damage due to failure of electrical supply, water supply, or improper ventilation around the product. Damages due

to fire, flooding or freezing. Damage and/or defects attributed to the use of any non factory accessory or components, including but not limited to filters, reclaimers, remote condensers, or any other devices attached to SerVend

equipment. Labor or part claim for components proven at our facilities not to be defective. Repairs or replacement

of damaged components. Labor claims (including diagnostic) submitted over the times allowed in our current labor

time chart.

The other of the warranted equipment is responsible for any transportation costs for replacement components.

SerVend will pay for:

Replacement parts and designated labor hours to repair defects in material and workmanship during the warranty

period. Service provided by an authorized SerVend service company.

Please see your dealer for a copy of the detailed SerVend warranty for your equipment.

PURCHASED PARTS WARRANTY

Following the expiration of SerVend’s standard cuber and dispenser warranty, replacement purchased (from SerVend)

parts are covered by the parts warranty. Any replacement part purchased by the owner of the SerVend equipment

shall be warranted for a period of ninety (90) days from date of purchase, or proof of installation of said purchased

part(s)

Following the expiration of SerVend extended parts warranties (compressor or evaporator), any purchased (from

SerVend) part is covered by the parts warranty. These components (compressor or evaporator) are covered for a

period of one (1) year from date of purchase or proof of installation of said purchased part(s).

The owner of the equipment will be required to pay for any labor to replace these defective parts. The owner shall

also be responsible for transportation costs to obtain and return any defective parts.

The purchased parts policy shall cover any part or component supplied as a standard original equipment part is

covered under this warranty.

5006772

Revision June 19, 2003

3

Page 3

Installation and Service Manual

FREIGHT CLAIM LOSS OR DAMAGE

The delivery freight company, distributor or dealer is responsible for loss or damage to your merchandise. All claims

must be filed with the party that delivers your merchandise.

Check the number of containers delivered against the number shown on your receipt. If the total is not correct, have

the driver note the shortage on your receipt. Check all cartons for visible damage, open and check the contents of any

carton in question before the driver leaves. Be sure the driver notes the type and degree of damage on your receipt.

All damaged merchandise must be inspected within 15 days of delivery. Please notify your carrier immediately.

If concealed damage is found when merchandise is unpacked, place the packing material with the merchandise and

request an inspection from the delivering carrier. File your claim for loss or damage at once. Delays in filing will only

hinder achieving a satisfactory resolution to your claim.

SAFETY INSTRUCTIONS

Installation and start-up of this equipment should be done by a qualified service technician. Operation, maintenance, and cleaning information in this manual are provided for the user/operator of the equipment.

REFRIGERANT LEAK AND REPLACEMENT POLICY

In any instance where there is a partial charge of R-404A refrigerant in a SerVend ice maker or a compressor

electrical burn out, SerVend requires the following:

Recover and properly dispose of any remaining refrigerant charge in the machine. After all repairs are made to the system,

replace the refrigerant with a weighed in charge (listed on the serial name plate) of new virgin refrigerant. This policy also

applies to any machine having a compressor replacement with an electrical burn out.

RE-USE OF CURRENT REFRIGERANT

In any instance where a component in a SerVend ice maker is replaced, the following is policy.

Properly recover the refrigerant charge from the system. Replace the component in question. Check the system

for refrigerant leaks using dry nitrogen. Replace the original refrigerant back to the machine. This will apply with all

component changes EXCEPT a compressor electrical burn out. In the event of a compressor burn out refer to the

refrigerant leak policy above.

REPLACEMENT OF FILTER DRIERS

In regards to filter driers on SerVend R-404A equipment, the following is SerVend policy.

Whenever entering a refrigerant system on a SerVend ice maker always replace the filter drier. The replacement

filter drier must be of one size larger than the original equipment filter drier, according to the replacement chart

found in the specification section of this manual. When making any repair to the sealed system under warranty, the

filter drier is considered a part of the repair to the system, and SerVend driers MUST be used.

If the filter drier is not replaced or SerVend parts are not used in the repair, all warranties are voided.

4

Revision June 19, 2003

5006772

Page 4

Installation and Service Manual

TABLE OF CONTENTS

WARRANTY POLICY .......................................................................................... 3

PURCHASED PARTS WARRANTY ...................................................................................... 3

FREIGHT CLAIM LOSS OR DAMAGE .................................................................................. 4

SAFETY INSTRUCTIONS .....................................................................................................4

REFRIGERANT LEAK AND REPLACEMENT POLICY ......................................................... 4

RE-USE OF CURRENT REFRIGERANT ............................................................................... 4

REPLACEMENT OF FILTER DRIERS ...................................................................................4

SERVEND CUBER MODEL NUMBERING SYSTEM.......................................... 8

SERVEND SERIAL NUMBER SYSTEM ............................................................. 9

ICE MACHINE INSTALLATION INSTRUCTIONS ............................................. 10

STORAGE BIN .................................................................................................................... 10

ICE DROP ZONE................................................................................................................. 10

CUBER WITH ICE DISPENSER .......................................................................................... 11

LOCATION OF REMOTE CONDENSER ............................................................................. 11

ASSEMBLY OF THE REMOTE CONDENSER .................................................................... 11

INSTALLATION OF THE REMOTE TUBING ....................................................................... 11

PLUMBING LINES AND CONNECTIONS ........................................................................... 12

DRAINS .............................................................................................................................. 12

ELECTRICAL CONNECTIONS SELF CONTAINED ............................................................ 12

ELECTRICAL CONNECTIONS REMOTE CONDENSER: ................................................... 13

ADJUSTMENT OF THE WATER LEVEL ............................................................................. 13

ADJUSTMENT OF THE WATER CURTAIN ......................................................................... 13

STACKING KITS ................................................................................................ 14

INSTALLATION INSTRUCTIONS ........................................................................................ 14

INSTALLATION CHECK LIST ............................................................................................. 14

START UP PROCEDURE SELF CONTAINED.....................................................................15

REMOTE START UP PROCEDURE .................................................................................... 15

ICE MAKER CLEANING PROCEDURE: .......................................................... 16

SANITIZE CYCLE: .............................................................................................................. 16

4 RELAY CIRCUIT BOARD (SERIES 007 MICROCHIP) ................................. 16

SEQUENCE OF OPERATION ............................................................................................. 16

4 RELAY CIRCUIT BOARD (SERIES 008 MICROCHIP) .................................. 17

SEQUENCE OF OPERATION ............................................................................................. 17

4 RELAY CIRCUIT BOARD COMPONENTS ....................................................................... 17

5006772

Revision June 19, 2003

5

Page 5

Installation and Service Manual

TABLE OF CONTENTS

4 RELAY CIRCUIT BOARD ............................................................................... 18

CHECKING THE CIRCUIT BOARD ..................................................................................... 18

COMPRESSOR & START COMPONENTS ...................................................... 19

COMPRESSOR CONTACTOR ............................................................................................ 20

CHECKING THE CONTACTOR ........................................................................................... 20

EVAPORATOR .................................................................................................................... 20

FAN CYCLE CONTROL ...................................................................................................... 20

FLOAT VALVE..................................................................................................................... 20

HALL SWITCH .................................................................................................................... 20

HEAD PRESSURE CONTROL VALVE ................................................................................ 21

HIGH PRESSURE CUT OUT ............................................................................................... 21

HOT GAS VALVE ................................................................................................................21

ICE CAPACITY .................................................................................................. 22

ICE CAPACITY CHECK PROCEDURE ............................................................................... 22

ICE THICKNESS CONTROL DIAGNOSIS ........................................................................... 22

CHECK PROCEDURE ........................................................................................................ 22

CHECKING THE THERMISTOR ....................................................................... 23

ICE THICKNESS CONTROL REPLACEMENT .................................................................... 24

ICE THICKNESS CONTROL ADJUSTMENT ...................................................................... 24

SAFETY THERM-O-DISC .................................................................................................... 24

CHECKING THE THERM-O-DISC ....................................................................................... 25

THERMOSTATIC EXPANSION VALVE ................................................................................25

CHECKING THE EXPANSION VALVE ................................................................................ 25

WATER PUMP .................................................................................................................... 25

DISASSEMBLY OF A SERVEND WATER PUMP ................................................................ 26

WATER REGULATING VALVE .......................................................................... 26

SYSTEM EVACUATION .................................................................................... 27

SELF CONTAINED SYSTEM ACCESS POINTS ................................................................. 27

REMOTE REFRIGERATION SYSTEM ACCESS POINTS ................................................... 28

CHARGING THE SYSTEM ................................................................................ 29

CLEANING UP A CONTAMINATION SYSTEM .................................................................... 29

6

Revision June 19, 2003

5006772

Page 6

Installation and Service Manual

TABLE OF CONTENTS

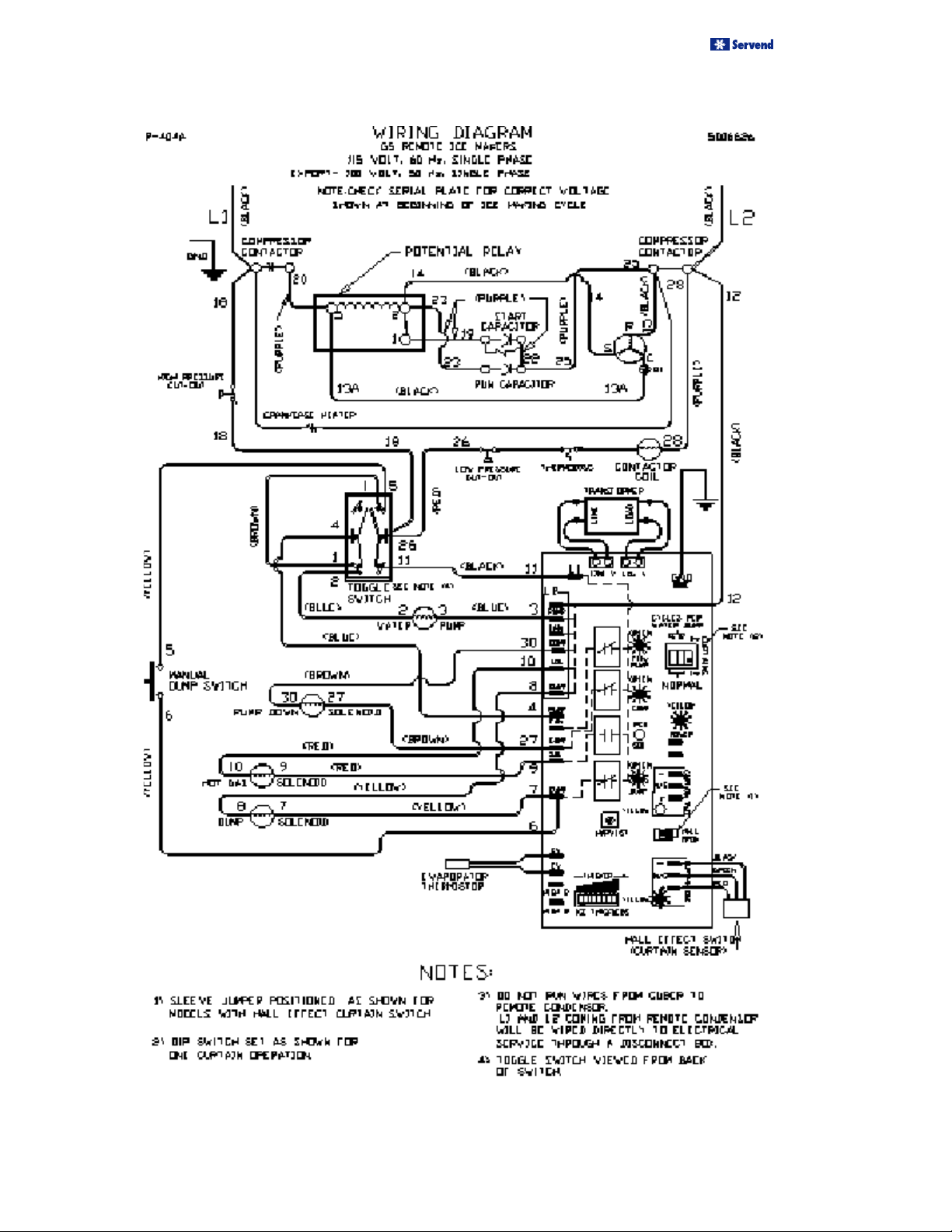

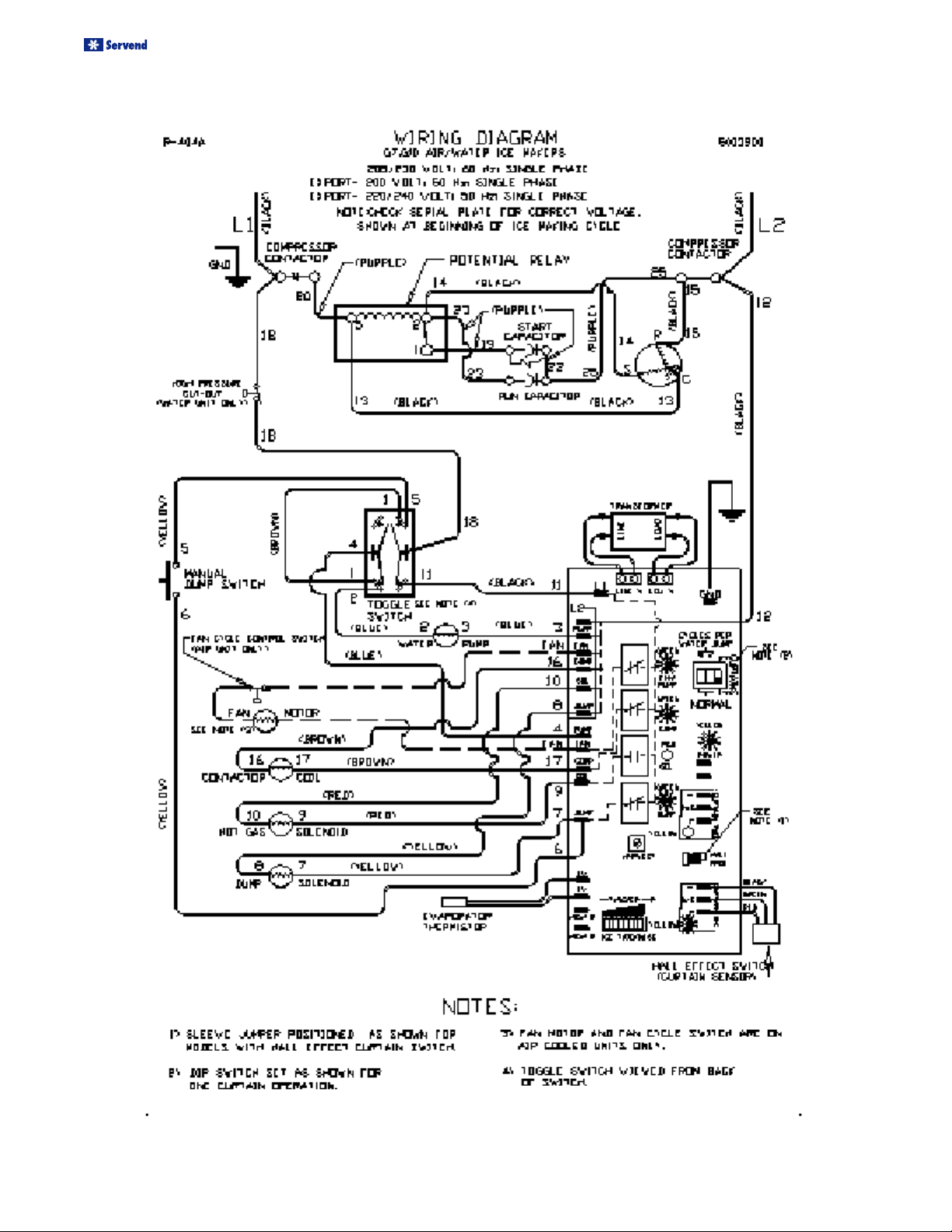

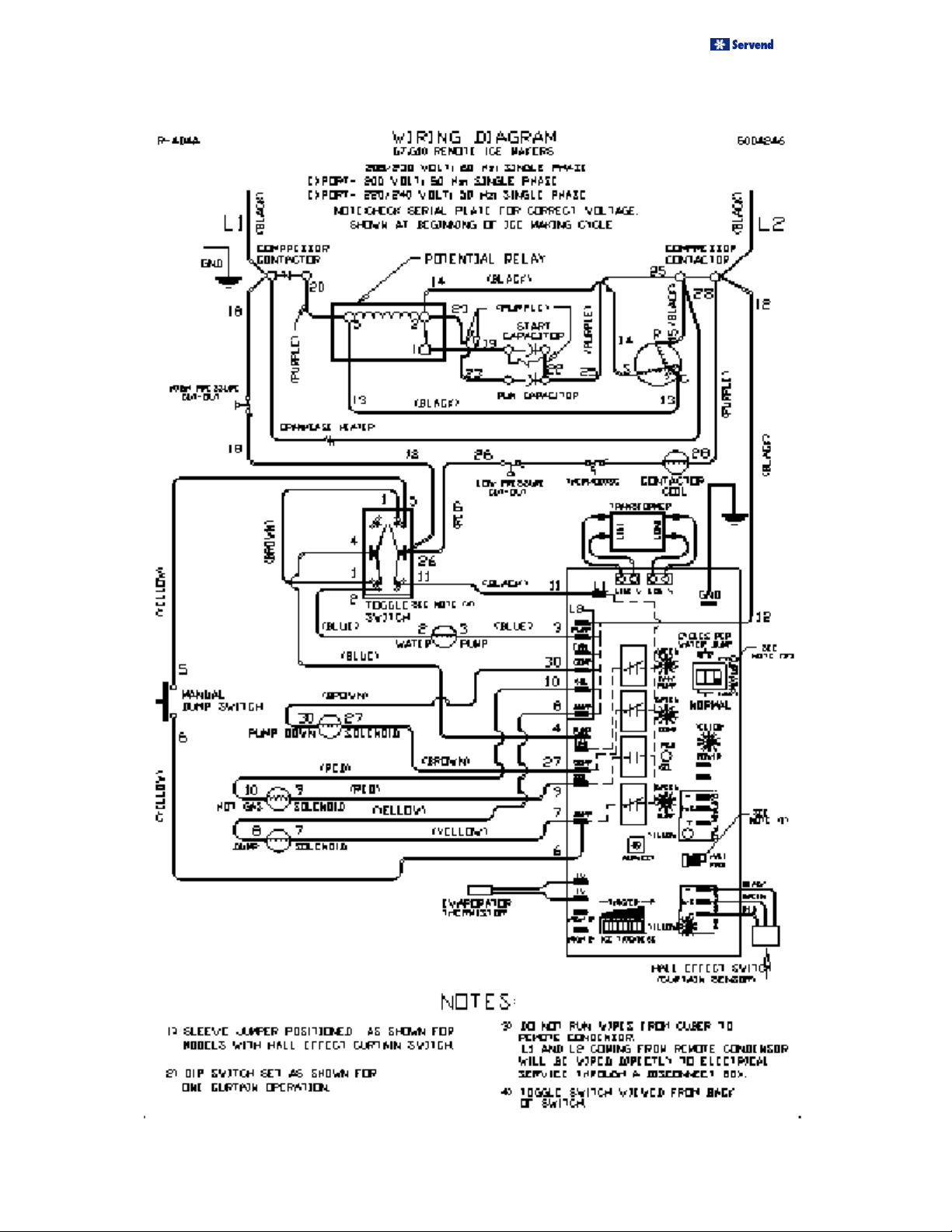

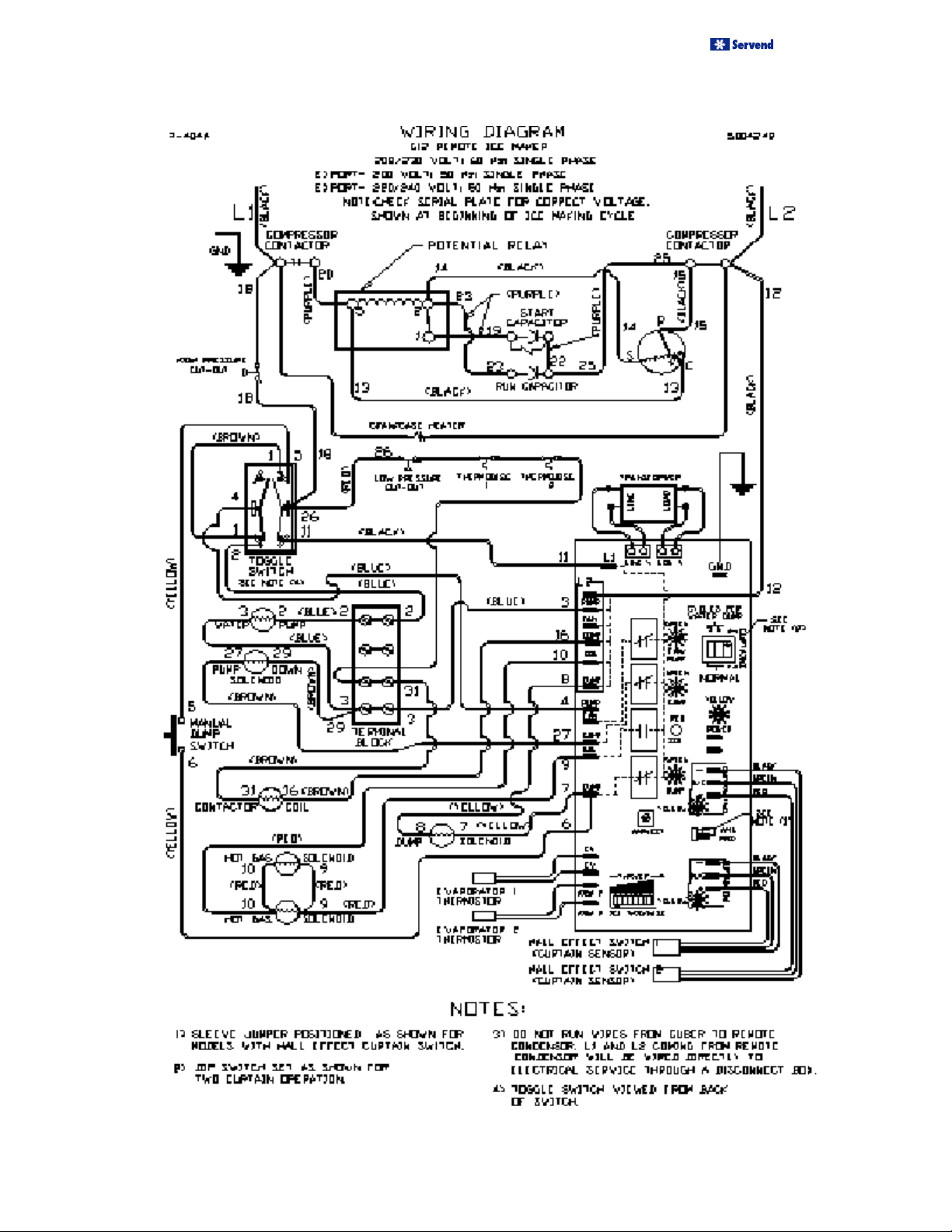

WIRING DIAGRAMS ......................................................................................... 30

SPECIFICATIONS ............................................................................................. 39

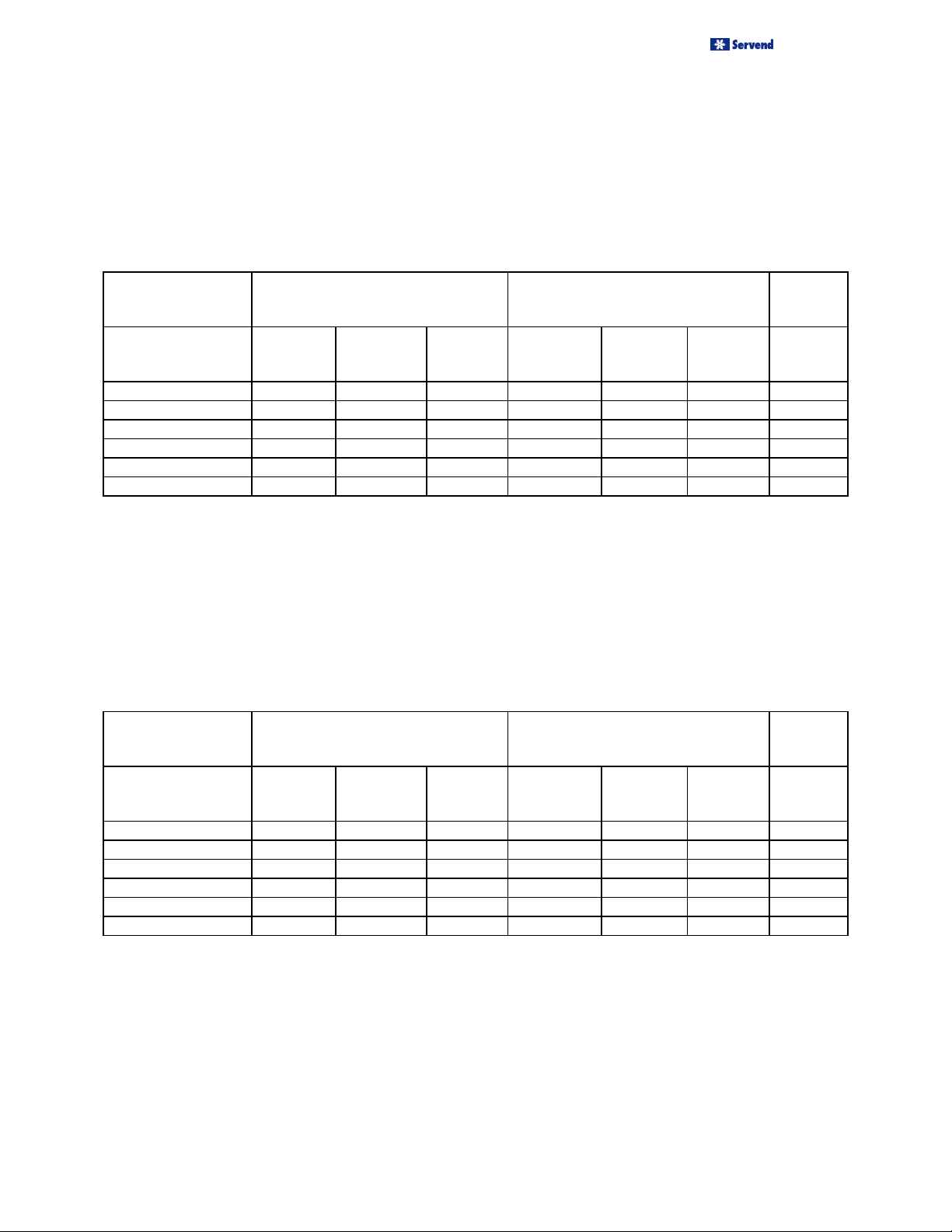

DATA PER ARI STANDARDS & WATER CONSUMPTION ..................................................39

OPERATING LIMITS ........................................................................................................... 39

PRESSURE - TEMPERATURE CHART FOR R-404A ......................................................... 40

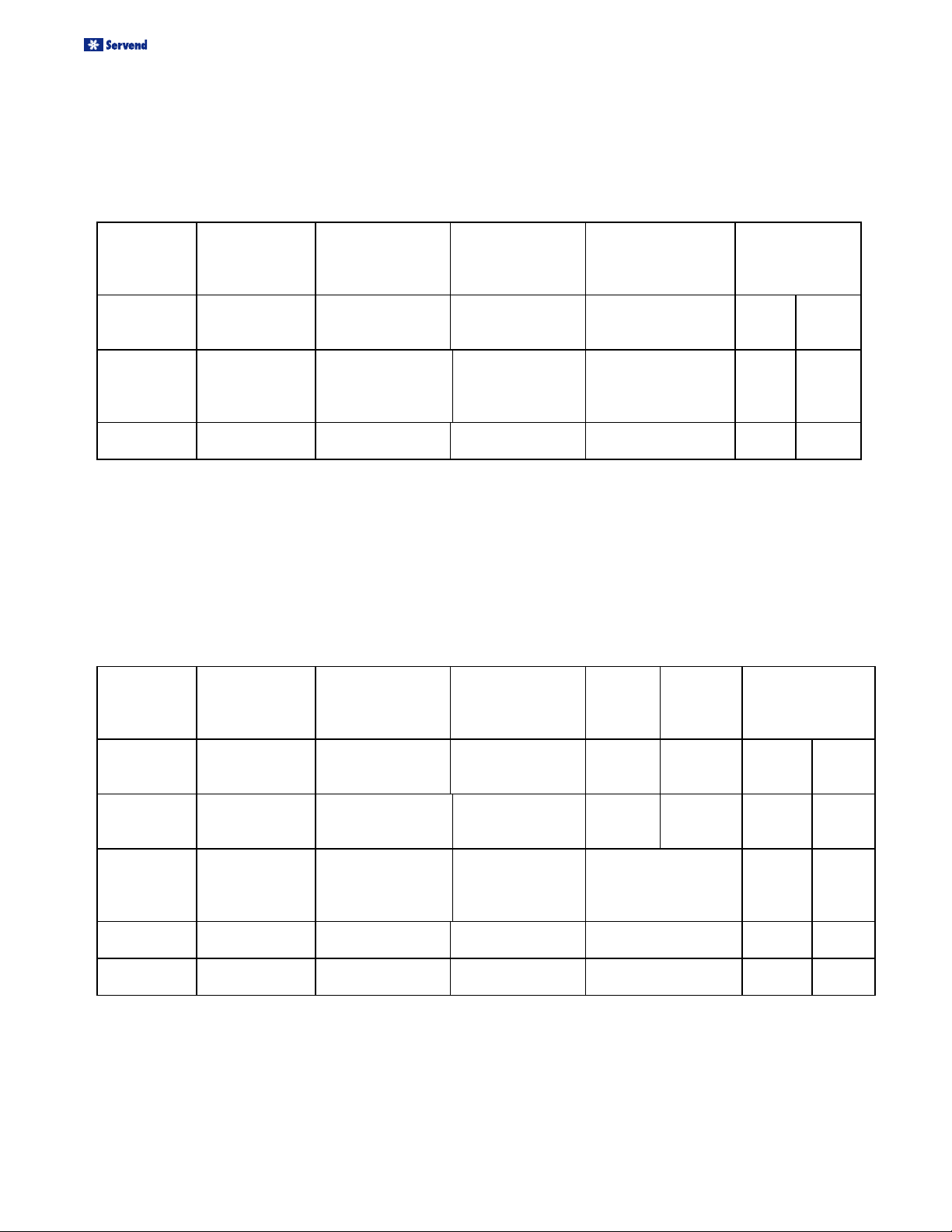

G2 SPECIFICATIONS ......................................................................................................... 43

G4 SPECIFICATIONS ......................................................................................................... 44

G5 SPECIFICATIONS ......................................................................................................... 45

G7 SPECIFICATIONS ......................................................................................................... 46

G10 SPECIFICATIONS ........................................................................................................ 47

G12 SPECIFICATIONS ........................................................................................................ 48

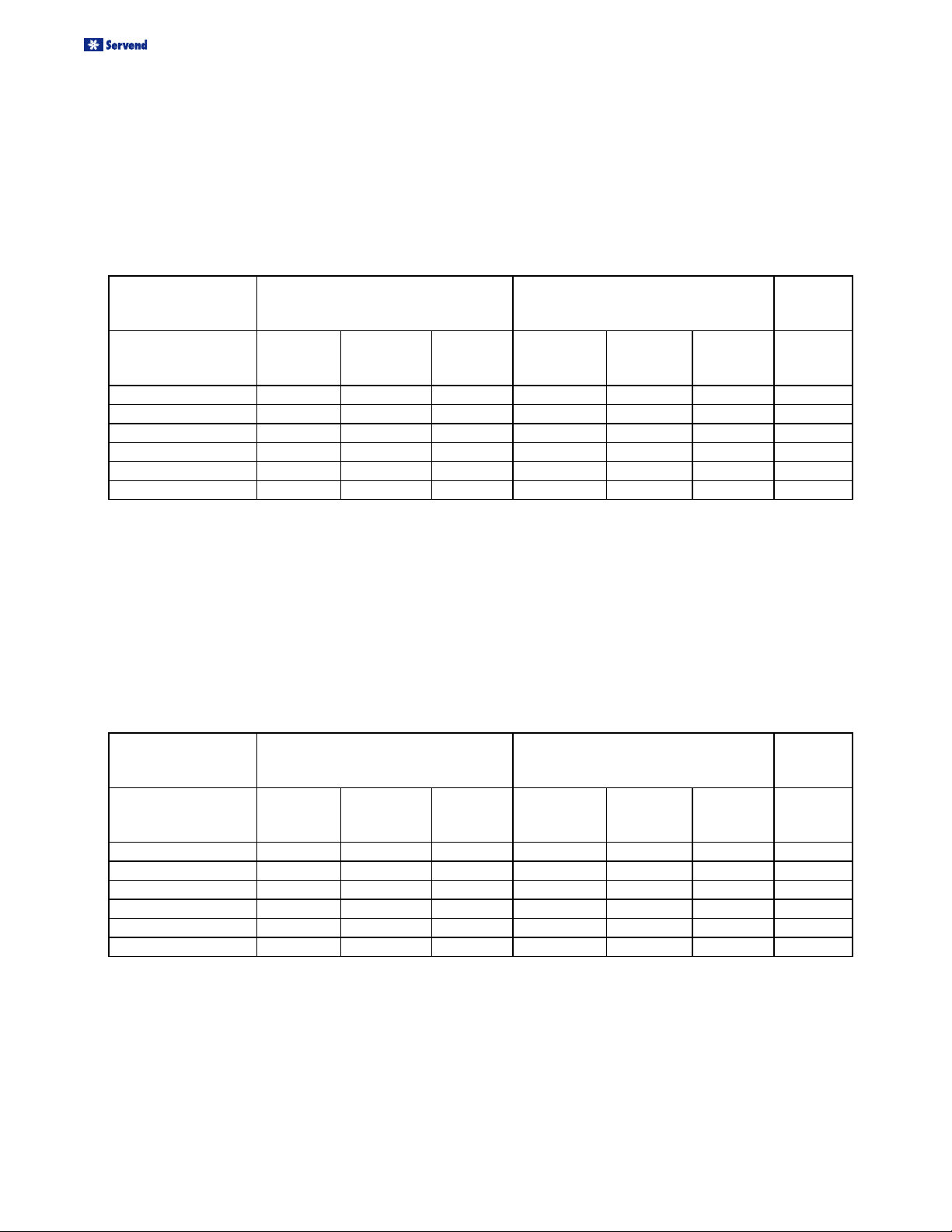

"KG" CONDENSER SPECIFICATIONS .............................................................................. 49

COMPRESSOR SPECIFICATIONS ..................................................................................... 50

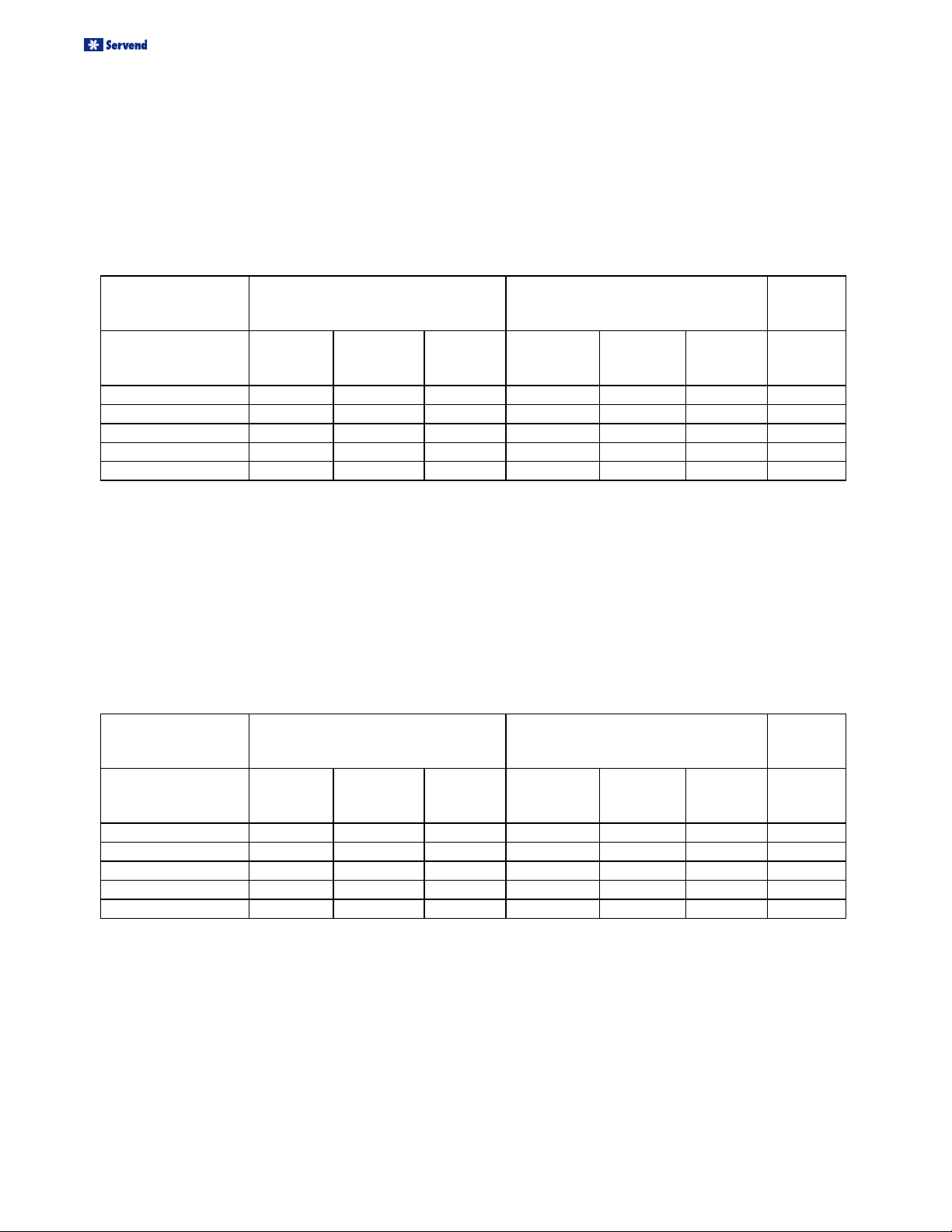

MODEL G-2 A ..................................................................................................................... 55

MODEL G-2 W .................................................................................................................... 56

MODEL G-4 A ..................................................................................................................... 57

MODEL G-4 W .................................................................................................................... 58

MODEL G-5 A ..................................................................................................................... 59

MODEL G-5 W .................................................................................................................... 60

MODEL G-7 A ..................................................................................................................... 61

MODEL G-7 W .................................................................................................................... 62

MODEL G-7 R ..................................................................................................................... 63

MODEL G-10 A ................................................................................................................... 64

MODEL G-10 W .................................................................................................................. 65

MODEL G-10 R ................................................................................................................... 66

MODEL G-12 A ................................................................................................................... 67

MODEL G-12 W .................................................................................................................. 68

MODEL G-12 R ................................................................................................................... 69

5006772

Revision June 19, 2003

7

Page 7

Installation and Service Manual

SERVEND CUBER MODEL NUMBERING SYSTEM

Example:

MODEL - G 7 A M A S - A

(1) (2) (3) (4) (5) (6) (7)

(1) Series of the machine

C = R-502 refrigerant - 30” or 48” wide cuber

S = R-502 refrigerant - 22” wide cuber

B = Ice Storage Bin

G = R-404A ice machines - all widths

(2) Nominal Capacity per 24 hours in 100 pounds

i.e. 7 = 700 pounds

(3) Type of Condenser

A = Air Cooled

W = Water Cooled

R = Remote Cooled

(4) Size of Cuber

M = Mini Cube (3/8” x 7/8” x 7/8”)

F = Full Cuber (7/8” x 7/8” x 7/8”)

J = Jumbo Cube (7/8” x 7/8” x 1 1/2”)

(5) Electric Code

VOLTS CYCLE PHASE

A = 208/230 60 1

B= 115 60 1

C = 208/230;200/220 60/50 1

D = 220/240 50 1

G = 208/230 60 3

(6) S = Stainless Steel Panels (blank) = Painted Panels

(7) Generation Code

A, B, C, etc.

8

Revision June 19, 2003

5006772

Page 8

Installation and Service Manual

SERVEND SERIAL NUMBER SYSTEM

Effective August 12, 1991 all SerVend dispensers, cubers and bins manufactured by SerVend International have a

new serial numbering system.

SAMPLE

94 H G 01 0001

Year Month Product Major Change Unit

Manufactured Code Code S/N

The above serial number is defined as:

Hotel dispenser built in August, 1994 - 1st unit built under major code #1

MONTH MANUFACTURED PRODUCT CODE

January A A = K Seried (obsolete)

FebruaryB B = KD Seried (obsolete)

March C C = M Series

April D D = MD Series

May E E = B Series

June F F = H Series

July G G = Cubers

August H H = Bins

September J J = Drop-In

October K 7 = Remote Condensers

November L

December M

Alphabet codes will not use the letter “I” to prevent confusion with the number “1”.

Unit Serial number will roll back to 0001 at the beginning of each new year and/or with each major change code.

MAJOR CHANGE CODE IS AN ENGINEERING TRACKING CODE FOR SERVEND USE. A major change code of

‘XX’ identifies an engineering field test unit.

5006772

Revision June 19, 2003

9

Page 9

Installation and Service Manual

ICE MACHINE INSTALLATION

INSTRUCTIONS

To assure maximum efficiency and performance from

your new SerVend equipment, we recommend the installation and start up be performed by SerVend Contracted Service Company.

For best performance, select a location away from all

heat sources such as ovens, direct sunlight, etc.. Avoid

placing air cooled models in kitchens whenever possible

as grease, flour or other airborne particles will collect on

the condenser and fan blade. This will require increased

maintenance and will reduce efficiency.

Discuss the best location with your SerVend Contracted

Service Company representative. Always allow 15 cm

(6”) clearance around the ice maker for air circulation.

This includes the top, back, and both sides. Restricted

air circulation will affect the maintenance free life of your

ice maker and its efficiency.

Your ice maker will perform at optimum efficiency in an

approximate 210 C (700 F) room with 100 C (500 F) water.

Increased air or water temperatures will decrease performance. Never operate your machine with ambient

temperatures below 100 C (500 F) or above 380 C (100

F). If the ice maker is located in an unheated are, it

must be protected from freezing temperatures or shut

down and winterized.

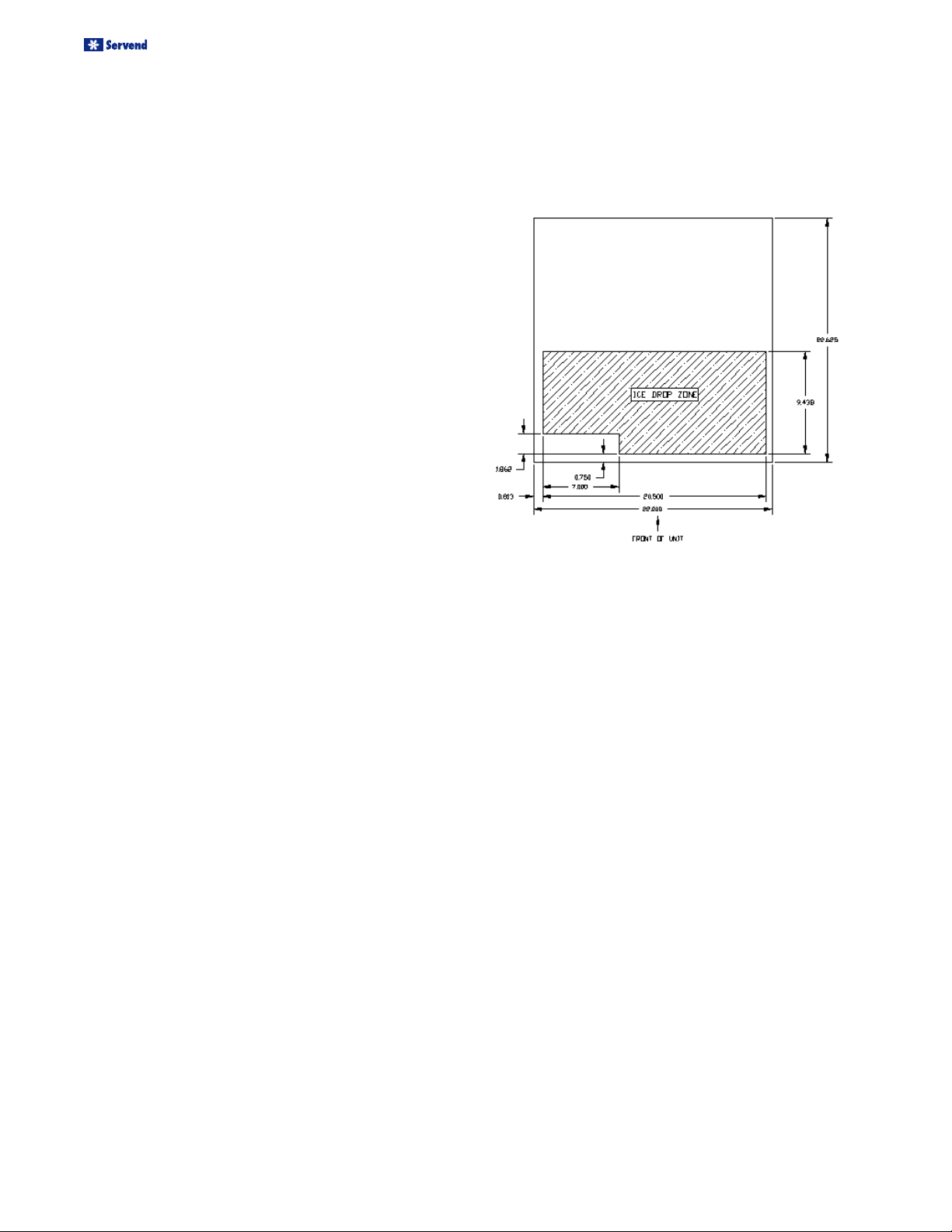

ICE DROP ZONE

If this installation of a SerVend ice maker is on a different manufacture bin or other storage device, the opening to allow the ice to fall into that device is as indicated

on the following drawings:

0

STORAGE BIN

Remove the sides and top from the ice storage bin. Lay

the flattened carton on the floor. Place the bin on its

back on the corrugated carton to prevent scratching.

Screw the legs into the bin bottom. Set the bin on its

legs. Move the bin to its final location, level the bin by

screwing the feet either up or down. Remove the carton

from the ice maker and place the ice maker on the bin.

Align the machine with the bin back and sides. Remove

the internal packing from the ice maker.

Level the ice maker head. Remove the water curtain

and place a torpedo level on the face of the evaporator.

With the level held against the lower edge of the metal

evaporator, level the unit left to right. Accomplish this

adjustment by the bin legs. Place the level in the vertical position on the face of the evaporator. Level the

machine from front to back (evaporator plumb). This is

critical to have the EVAPORATOR level and plumb.

10

Revision June 19, 2003

5006772

Page 10

Installation and Service Manual

CUBER WITH ICE DISPENSER

Install the dispenser according to the instructions provided.

Remove the carton from the ice maker and place the ice

maker on the dispenser. Align the machine with the dispenser

front. Secure the unit with earthquake brackets if provided.

Remove the internal packing from the ice maker.

Level the ice maker head. Remove the water curtain and

place a torpedo level on the face of the evaporator. With

the level held against the lower edge of the metal evaporator, level the unit left to right. This is done by the utilization of shims between the ice maker head and the dispenser. Place the level in the vertical position on the face

of the evaporator. Level the machine from front to back

(evaporator plumb).

IT IS CRITICAL TO HAVE THE EVAPORATOR PLUMB

AND LEVEL.

Install the ice deflector baffle in the evaporator space behind the front panel. Remove the front panel from the cuber. Remove the bottom screw from the component box

cover. Slide the ice deflector between the left side panel

and enclosure and between the component box cover and

enclosure. Slide slot and notch in ice deflector over the

front channel. Install the screw in the component box

cover. Replace the front panel on the cuber. Refer to the

drawing on previous page.

DO NOT INSTALL A REMOTE MACHINE WITH

LONGER LINES WITHOUT WRITTEN PERMISSION

FROM THE FACTORY. INSTALLATION WITH LONGER

LINES WILL VOID YOUR WARRANTY.

In using longer line lengths, you can starve the compressor of oil. Longer lines can also provide a very high

pressure drop in the tubing.

When placing the remote condenser, keep in mind the

maximum height and drop from the ice maker head. The

condenser cannot be placed over 10 m (35 ft.) above

the head. The condenser cannot be placed more than 5

m (15 ft.) below the head.

NOTE: HEIGHT + LENGTH SHOULD NOT

EXCEED 50 FEET.

ASSEMBLY OF THE REMOTE

CONDENSER

Select an area for the condenser that is well ventilated.

The condenser must be located away from the discharge

of other condensers and ventilators.

Unpack the condenser assembly at the final location.

Turn the condenser upside down. This eases further

assembly.

INSTALLATION INSTRUCTION REMOTE CONDENSER:

Follow the standard installation instructions for the remote condenser head. These instructions are listed previously in this section of this manual. Do not power the

ice maker unit before the remote system installation is

complete

INSTALLATION OF A SERVEND REMOTE ICE MAKER

WITH A NON-SERVEND CONDENSER CAN VOID ALL

FACTORY WARRANTIES.

LOCATION OF REMOTE CONDENSER

The placement of the remote condenser is very important. Place the condenser where the air flow through the

condenser will be unobstructed. The intake to the condenser must have a minimum clearance of 1 m (3 ft.) to

the closest object. The discharge minimum clearance

must be 3 m (9 ft.). The maximum remote tubing line

length is 15 m (50 ft.).

Assemble the four legs to the base panel. Place the leg

gussets on the legs and attach the support brackets. Use

the diagrams included for additional guidance. Turn condenser upright and place in proper position.

Using the mounting holes in the base of the leg gussets, secure the condenser to the mounting surface. Remember to

properly seal all roof and wall penetrations.

INSTALLATION OF THE REMOTE

TUBING

Unpack the pre-charged tubing from the carton. Carefully unroll the tubing. BE SURE YOU DO NOT KINK

THE TUBING. Position the tubing in its proper location.

Do not connect any of the tubing ends at this time.

When making a roof penetration, proceed as follows:

Cut a 10 cm (4in.) hole in the roof. Seal around the line

set at the hole with appropriate sealant. Place a roof

flange over the tubing penetration, sealing again.

5006772

Revision June 19, 2003

11

Page 11

Installation and Service Manual

INSTALLATION OF THE REMOTE TUBING

Decide if the tubing is of the proper length. A service

loop is advisable behind the ice maker head. If you must

coil the tubing, you need to shorten the length as described below. Servend has line sets available in 6 m

(20 ft.), 10 m (35 ft.), and 15 m (50 ft.). To ease service,

SerVend has placed access ports on each end of both

tubes.

You may need to lengthen the remote tubing (maximum

total length of 15 m - 50 ft.) Evacuate the charge in the

tubing. Cut the lines and insert the needed length. The

size of the condenser incoming line is 1/2” and the remote discharge line is 5/16”. These are O.D. refrigeration

tubing size. Solder the sections together and evacuate

the tubing. You man add one or two ounces of refrigerant

to act as a holding charge.

You may need to shorten the line length. Evacuate the

charge in the tubing. Cut the lines and remove the excess length. Solder the sections together and evacuate

the tubing. You may add one or two ounces of refrigerant to act as a holding charge.

detrimental to the components of the machine and can

not be ingested by some of your customers. The incoming water pressure must not exceed 8.4 kg/cm

and not lower than 1.4 kg/cm2 (20 psi). Water supply lines

to the water cooled condenser should include a standpipe

for the prevention of “water hammer.” Locate shut off

valves in all water supply lines. It is impossible to connect

a water cooled condenser to a recirculation system or

cooling tower. However, you must maintain a minimum of

.7 kg/cm

when operational.

2

(10 psi) pressure drop across the condenser

2

(120 psi)

DRAINS

To ensure trouble free drainage, vent the cuber and bin

drains to the atmosphere at the cabinet. Each of the

drains should have a 25 cm (10”) standing vent pipe to

the atmosphere. This allows oxygen to enter the drain,

slowing the formation of algae in the drain. Venting also

relieves back pressure on the drains allowing faster and

easier water removal. Drain lines require a drop of 6

mm (1/4”) per 30 cm (1”) line length. Lines should end

over an open, trapped, vented drain.

Working at one end, apply refrigeration oil to the threads

of the connectors (both male and female).

Hand thread the fittings onto the machine. Using two

wrenches, tighten the fitting an additional 1/8 turn. DO

NOT TURN MORE THAN 1/4 TURN.

Working at the other end, apply refrigeration oil to the

threads of the connectors (both male and female). Hand

thread the fittings onto the machine. Using two wrenches,

tighten the fitting an additional 1/8 turn. DO NOT TURN

MORE THAN 1/4 TURN.

When the fittings are attached to the machines, the line

seals are broken. Removal of the tubing will discharge

the operating charge of the machine.

PLUMBING LINES AND CONNECTIONS

All plumbing (water and drain) connections must conform

to local and national codes. Please refer to diagrams

concerning the locations of all connections.

To prevent water condensation, insulate all water and drain

lines.

It may be necessary to connect the potable water supply

to a water treatment system. Contact your local SerVend

Contracted Service Company for the proper size required.

DO NOT connect this or any commercial ice maker to a

water softener using salt. The salt can precipitate out of

the water during the freeze cycle. The salt water can be

ELECTRICAL CONNECTIONS SELF

CONTAINED

All supply wiring and connections must conform to national and local codes. Properly size wiring and electrical protection devices to the nameplate specifications.

Connect the cuber to a separate location between the

cuber and the protection device. You must ground the

cuber by the control box ground screw provided or a

proper conduit connection. See wiring connection diagram on this page.

12

Revision June 19, 2003

5006772

Page 12

Installation and Service Manual

ELECTRICAL CONNECTIONS

REMOTE CONDENSER:

Connection of the remote ice making head is accomplished similar to that found in the installation section of

this manual. Please refer to the self contained installation instructions previously established in this manual.

The power supply for the remote condenser is routed to

the condenser separately, not through the ice maker

head. Obtain the proper voltage from the vicinity of the

condenser. A manual disconnect should be installed in

the electric line. You may connect electric from the power

distribution panel direct to the condenser.

DO NOT RUN THE POWER WIRES FROM THE

ICE MAKER HEAD TO THE REMOTE

CONDENSER.

Route the power supply wires to the condenser junction

box. Connect the wires to the proper wires. Properly

ground the condenser.

The fan motor of a remote condenser is independently

controlled. This is accomplished through the use of a

fan cycle switch inside the condenser. The fan will energize at approximately 17.5 kg/cm2 (250 PSI) and will turn

off at 13 kg/cm2 (185 PSI).

EXAMPLE OF WATER LEVEL MARK:

With the water level set, turn only the water pump

on. This will circulate the water throughout the system. Check to assure the float returns the water

level to the proper water level mark and shuts off.

ADJUSTMENT OF THE WATER

CURTAIN

The water curtain acts as a shield to prevent the

water being circulated across the evaporator from

going into the ice bin. With the water curtain missing the float must allow additional make up water to

the machine.

Before making any adjustments be sure the ice

maker evaporator is level and plumb.

The water pan should rest on the plastic holding

blocks. See drawing on previous page.

Please follow all local codes when installing any equipment.

ADJUSTMENT OF THE WATER

LEVEL

Each water pan has a water level mark molded into it.

The water mark is the crease in the water pan about one

half way up the front of the water pan. The proper water

level is achieved when the water in the water pan is at

this water level mark on the pan. This should be checked

when the float has just filled the pan and closed off the

supply of water to the pan.

Adjust the float by loosening the screw on the float bracket.

This will allow you to rise or lower the float assembly.

Adjust the water curtain to a maximum clearance of

3 mm (1/8”) above the water pan. Adjust the curtain

as close to the evaporator as possible. Adjustments

to the curtain are attainable through the plates holding the curtain pins. Loosen the two screws on each

of the curtain plates. This will allow the plate to adjust up and down, forward and back.

The water curtain should not touch and yet clear the

Hall switch by a maximum of 1.5 mm (1/16”). This

adjustment is accomplished in two ways. First the

curtain should have little lateral (left to right) movement. If the curtain moves laterally more than 1.5

mm (1/16”) the addition of a curtain shim behind the

curtain plate is necessary. If the curtain moves less

than 1.5 mm (1/16”) with more than 1/5 mm (1/16”)

clearance or touching the Hall switch you must adjust the position of the switch. To adjust the Hall

switch, loosen the lock nuts on the body of the switch,

allowing proper placement of the switch.

5006772

Revision June 19, 2003

13

Page 13

Installation and Service Manual

STACKING KITS

Stacking allows more ice production in the same foot print

size. All G5 and larger SerVend ice makers are stackable

with the same physical size ice maker. When ordering a

stacking kit for your machine, always order by using the

model number of the bottom ice maker.

EXAMPLE You have a G-7 ice maker installed and wish to

add additional capacity. You can then order a

K7-SK stacking kit for the lower machine. Then

you could place either another G-7 on top, or

install a G-9 machine on top.

INSTALLATION INSTRUCTIONS

Install the bottom ice maker on the bin according to the

ice maker installation instructions.

Remove front panel, top cover, component box cover

and left side cover of the bottom ice maker.

On air cooled units ONLY:

Remove the right side and back panels.

Install support bracket (item #3) as shown in Figure

1of the instructional diagram. Replace the back

panel at this time.

Replace left side panel, inserting a gasket between panel

and bottom flange as shown in Figure 1 of the instructional

diagram.

After start up procedures have been completed, replace any

panels removed.

INSTALLATION CHECK LIST

• Is the cuber evaporator level and plumb?

• Are electric connections complete?

• Is the proper voltage supply provided? Check the

nameplate and verify before turning power on to the

machine.

• Turn power on to the machine.

• Has the water inlet pressure been checked? Is it

within guidelines?

• Are water filters installed?

• Are water shut off valves open?

• Are the drain connections made properly? Is the bin

drain separate from the ice maker drain?

• When used, is the water cooled condenser drained

separately?

• Are the cuber and bin drains vented at the rear of the

equipment with an open stand pipe?

• Are all drain lines vented at the floor?

• Are the drain lines insulated and sloped to the open

floor drains?

On air cooled units, place the air condenser baffle on

bottom unit as shown in Figure 2 of the instructional diagram.

Install stacking kit top panel (item #1) as shown in Figure 2 of the instructional diagram.

Before installing the second unit and inserting stacking

kit ice chute, start the bottom unit per start up procedures. Allow at least four complete cycles of the bottom

unit.

Replace front panel and component box cover.

Install second unit on top of bottom unit following the

instructional diagram.

Make sure each unit is connected to a separate fused circuit.

Install the ice chute (item #2) in the bottom unit as shown in

Figure 3 of the instructional diagram. Hook the down-turned

flange on top of ice chute into the upturned flange on stacking

kit top panel.

Use two #8-32 x 1 inch SS screws and ESNA nuts to attach the

ice chute to the bottom of the bottom unit and to attached the

bottom unit to the top unit.

Start the top unit per start up procedures. Allow the top unit

to complete at least four cycles.

• Is there 15 cm (6”) clearance around the cuber for

ventilation?

• Is the cuber installed in ambient temperatures with a minimum of 100 C (500 F) or above 380 C (1000 F)?

WARNING! If the air temperature drops below 100 C

(500 F) the unit must be shut down.

• Is the water temperature maintained between 70 C

(450 F) and 320 C (900 F)?

WARNING! If the water temperature drops below 5

C (400 F) the unit must be shut down.

• Does the water curtain move freely?

• Is the water level set properly in the water pan?

• Is the water pan seated properly on the plastic support blocks?

• Is the ice maker and the bin sanitized?

• Is the air cooled baffle installed, if necessary, to prevent condenser air recirculation?

• If the ice maker is being installed with an ice dispenser, is the ice deflector installed?

0

14

Revision June 19, 2003

5006772

Page 14

Installation and Service Manual

START UP PROCEDURE SELF

CONTAINED

Open the potable water valve to the machine. Allow water

to fill the water pan. Check the water level in the pan.

The water level should be up to the water level mark in

the water pan with the float “at rest”. Adjust the water

level if necessary.

Apply power to the machine. Turn the toggle switch to

the pump position. Check the water flow across the top

evaporator extrusion. The water flow should be even

across the top. If the water “creeks” across the top with

streams and dry spots, clean the top extrusion with a

SCOTCH BRITE

rough up the extrusion with any abrasion material.

With the water pump on in the pump position, check the

dump valve. Depress the manual dump switch and hold.

This should clean out most of the water in the water pan

while allowing the float to refill the pan. When releasing

the purge switch, the flow of water through the purge

valve should cease.

Place the toggle switch in the off position to allow the

water to refill the water pan.

TM

pad or CLEAN shop cloth. Do not

wedge above the switch case for thicker or thinner bridge.

The switch is on if the top is pushed in.

For future service on this equipment, place your phone

number on the front or side panel of the machine.

Before leaving, be sure the owner understands the ice

maker operation and the value of preventative maintenance.

REMOTE START UP PROCEDURE

Remove the left side panel from the ice maker.

Locate the receiver tank. Remove the service valve stem

cap from both receiver tank valves. Open the receiver

valves fully (backseat) to allow the refrigerant to flow

throughout the system.

Leak check the remote tubing connections. This would include both fittings at the ice maker and the condenser.

Replace the side panels of the ice maker.

Follow the start up procedure as outlined at the top of

this page.

Place the toggle switch in the ice position. The compressor, condenser fan (if air cooled), and water pump

will operate. Depress the manual harvest switch. The

water pump and fan motor will stop. The harvest solenoid will open. Swing the water curtain open and hold

for a maximum of thirty (30) seconds. The compressor

will stop. Release the water curtain. The machine will

restart in the ice making mode.

There is a minimum freeze time built into the circuit board.

This minimum time is not in effect on an initial freeze

cycle of the machine.

For optimum life and performance of the ice maker, the

bridge should be a minimum of 3 mm ( 1/8”) to a recommended thickness of 5 mm (3/16”) in the center of the

sheet of ice.

Allow the ice maker to make two (2) complete sheets of

ice before making any bridge thickness adjustments.

Make these adjustments with the machine in the off position.

Adjustment to the bridge thickness is done at the circuit

board. On the bottom (front) of the board in the control

box is a set of 8 DIP switches. To have a thicker bridge,

turn the next (right) switch “on”. To have a thinner bridge,

turn the next (left) switch “off”. It is acceptable to have

all of the switches either on or off. Follow the indicator

When power is applied to the remote machine, the compressor may operate for a short time. This is the normal pump

down cycle. The unit may do this periodically.

DOES THE OWNER/OPERATOR KNOW?

• The location of the electrical disconnect switch and

water shut off valves?

• How to start, clean, sanitize, and shut down the ice

machine?

• How the bin full operation works?

• Proper method for cleaning the air cooled condenser

and fan blade?

• Use and location of the high pressure reset, if

equipped?

• How to inspect the distributor tube and water system for mineral deposits?

• How to identify when the water filter needs to be

changed?

Who to contact for service?

5006772

Revision June 19, 2003

15

Page 15

Installation and Service Manual

ICE MAKER CLEANING

PROCEDURE:

The use of non approved ice machine cleaners is expressly forbidden and will void your warranty. The approved ice machine cleaners are:

Calgon (Green) Nickel Safe Cleaner

Lime-A-Way Ice Machine Cleaner

WARNING: When using any cleaning fluids or chemicals,

always wear rubber gloves and eye protection.

Turn the selector switch to the off position. Remove all

ice from the storage bin.

SANITIZE CYCLE:

Turn the toggle switch to the pump position. Push the purge

switch allowing the water in the water pan to drain out.

Allow the water to refill the pan and check the water level.

Adjust the water level if required.

Add 7cl. (1/4 oz.) unscented laundry bleach (5.25% Cl

Na O concentration) mixed to yield 200 PPM of available chlorine to the water pan. Allow the pump to circulate the solution for five (5) minutes.

ALTERNATE: You may use the commercial ice ma-

chine sanitizer following the directions on the container.

Push the purge switch to remove this solution from the

machine.

Wipe all surface areas of the bin and ice contact areas

with a solution of 28 ml (1 oz.) liquid laundry bleach per

gallon water. You may use a commercial sanitizer mixed

according to package directions.

Turn the toggle switch to the ice position. Discard the

first batch of ice.

4 RELAY CIRCUIT BOARD

(SERIES 007 MICROCHIP)

Pour 4 oz. of approved cleaner in the water pan. Turn the

toggle switch to the pump position. Allow this solution to

circulate over the evaporator for 10 minutes.

While the solution is running in the machine, take some

of the solution on a rag to wipe the inside of the machine

and the water curtain.

Clean the air cooled condenser and fan blade of all dirt.

Push the purge switch and hold. When the solution in

the water pan has been flushed out release the purge

switch. Allow the water to refill the pan.

Circulate this refill water over the evaporator for three

(3) minutes. Then repeat pushing of the purge switch

and hold. When the solution in the water pan has been

flushed out release the purge switch. Allow the water to

refill the pan.

Turn the toggle switch to the ice position. Discard the

first batch of ice.

SEQUENCE OF OPERATION

Place the toggle switch in the ice making mode. The power

LED and the LED(s) by the curtain terminal connections will be

illuminated. You will also energize 3 of the 4 relays on the board.

These are indicated by the illumination of green LED lights along

the side of each rely. Activated will be the dump solenoid, compressor contactor, water pump and fan motor, or water pump

and pump down solenoid on remote units. The dump solenoid

relay will be energized for six (6) seconds at the beginning of

the freeze cycle. At the end of the dump cycle the water pump

and dump valve will stop for eight (8) seconds. At the end of this

time period the water pump will resume.

As the ice builds on the evaporator a bridge is built from one

cube to the next. At the bottom of the evaporator this bridge

begins to roll over the lower extrusion. As the thickness of

the ice builds, the temperature of the ice decreases. On this

lower extrusion is located the SerVend ice thickness control.

This control senses the temperature of the ice. When the ice

temperature reaches a specific point as determined by adjustments on the circuit board, the control indicates the

machine should enter the harvest mode. This harvest mode

is initiated at any time after the first eight (8) minutes of operation. This delay prevents premature harvest.

16

Revision June 19, 2003

5006772

Page 16

Installation and Service Manual

SEQUENCE OF OPERATION

During the harvest mode of operation two relays should

be energized. These relays control the compressor

(green LED) and the hot gas solenoid (red LED). This

mode allows the hot gas to flow directly from the compressor tot the evaporator. This will warm up the evaporator allowing the sheet of ice to slide off.

As each falls from the evaporator it will push the curtain

away from the evaporator. As the curtain moves, the

target on the curtain will move out of range of the electronic sensing Hall switch. If the ice holds the curtain

target out of the range of the Hall switch, the machine

will shut down. This acts as a bin full indicator. When

the curtain returns to the closed position, the machine

will return to the freeze mode. As the curtain moves

away from the evaporator the machine will remain in the

harvest mode for 30 seconds or until the curtain resets

against the evaporator, whichever is first. If the machine

remains in the harvest mode, the circuit board will restart the unit in freeze at the end of nine (9) minutes.

Removal of the water curtain(s) can cause the machine

to not operate. If the machine is in the freeze mode, and

the water curtain is taken off, when the machine is to

enter the harvest mode the machine will stop operation.

The cuber can be placed in the harvest mode at anytime. Be sure the water curtain is in place. With the

toggle switch in the ICE mode, gently press the harvest

switch located on the circuit board. This will immediately enter the machine in the harvest mode. If the machine is manually placed in the harvest mode, the minimum freeze time for the next cycle only, is not applicable.

4 RELAY CIRCUIT BOARD

(SERIES 008 MICROCHIP)

SEQUENCE OF OPERATION

This programing version is the same as the 007 chip

except for the following:

The water dump cycle is moved to the end of the freeze

cycle. This chip energizes the valve for 30 seconds. This

will also allow the water to refill the water pan while a

harvest cycle is in progress.

4 RELAY CIRCUIT BOARD

COMPONENTS

The top relay (with green LED) controls the water pump

on all machines. This relay also controls the condenser

fan motors on an air cooled self contained ice maker.

The second relay (with green LED) from the top controls

the compressor contactor on self contained machines.

On a remote cooled machine, this contactor controls the

pump down solenoid.

The third relay (with red LED) from the top controls the

operation of the hot gas solenoid valve.

The fourth (bottom) relay (with green LED) controls the

operation of the water dump solenoid valve.

The EV terminals on the circuit board just below the fourth

relay are for the ice thickness control. This controls the

thickness of the ice on all machines. On all equipment

this works as a high temperature safety. On a dual evaporator machine, the control is connected to the left (facing

the machine) evaporator.

The terminals marked HI TEMP in the lower left corner

are used on a dual evaporator machine only. The ice

thickness control from the right evaporator connects to

this terminal. This controls the high temperature safety

of this evaporator only. This has nothing to do with the

thickness of the ice.

Approximately one half way up the right side of the circuit

board is a bank of three DIP switches. The left and center

switch control how often the water dump valve operates.

With both of the switches in the down (1) position the dump

valve operates at the beginning of each freeze cycle. With

the left switch in the up (3) position and the center switch

down (1) the machine will dump water at the beginning of

every 3rd freeze cycle. With the left switch down (1) and

the center switch up (5) the dump solenoid will operate at

the beginning of every 5th freeze cycle.

Please remember, the less the water is dumped, the more

mineral build up on the evaporators.

The right switch of this three switch bank tells the board

how many evaporators are in this machine. The switch

should be placed at the one (1) or two (2) position corresponding to the number of evaporators in your machine.

5006772

Revision June 19, 2003

17

Page 17

Installation and Service Manual

4 RELAY CIRCUIT BOARD

COMPONENTS

Just below the 3 DIP switch case is a yellow LED. This is

the POWER light. Whenever power is applied to the

machine with the toggle switch to the ICE position, this

light will be on. If the machine is off due to a bin full situation, this light will still be illuminated.

If the power light is flashing, this is giving you a warning.

A flashing light indicates that any of the following conditions may apply:

• High temperature cut out

• Curtain switch set incorrectly one curtain with two

thermistors attached or two curtains with one thermistor attached

• Missing ice thickness control

• Mis-wired ice thickness control

• Shorted ice thickness control

• Open ice thickness control

To restart the machine, investigate the reason for the flashing light and subsequent shut down. Correct the cause of

the shut down. Turn the toggle switch to the off position

for 5 seconds. Turn the toggle switch to the ICE position.

The machine should restart.

In the lower right corner of the board are two sets of three

spade terminals. The curtain/Hall switch(s) attach to these

terminals. If you are working on a machine with a single

evaporator, your Hall switch connects to the bottom set of

terminals marked “CURTAIN ONE”. If you are working on

a dual evaporator machine, the left Hall switch connects to

the terminals marked “CURTAIN ONE”. The right Hall switch

will then connect to the terminals marked “CURTAIN TWO”.

Between the sets of curtain terminals is a set of three

prongs with a sleeve jumper. Be sure this jumper is covering the top and middle prongs. This is the setting for

the Hall switch used on your equipment. If the jumper is

missing or on the bottom and middle terminals, the machine will not work or may work in harvest cycle when it

should be freezing and freezing when it should be harvesting.

At the bottom of the circuit board in the center is a bank

of 8 DIP switches. These switches control the thickness

of the ice. Above the switch bank is a wedge giving a

visual indicator of the direction to move the switches.

The top of the switch pushed down indicates that switch

is energized. Turn switches on or off in succession from

left to right. Do not skip switches in this bank.

Slightly to the left of the ice thickness DIP switches is a

small potentiometer. This is a very coarse thickness adjustment. Do not move this adjustment more than one (1)

graduation at a time. To increase thickness with this potentiometer, turn the control clockwise. To decrease thickness,

turn this control counterclockwise.

4 RELAY CIRCUIT BOARD

CHECKING THE CIRCUIT BOARD

There are only two checks you must make in the field on

this board.

1. If the LED along side the relay is energized the relay

should be energized. With your meter in parallel to the

component you are testing you should observe voltage.

If there is no voltage, the relay (board) is defective.

2. If you are experiencing bin control problems and have

tested the Hall switch to be good, take a voltage test.

Remove the Hall switch leads from the + (positive) and

the - (negative) terminals. With the toggle switch in the

ICE position and your meter set to D.C. volts, place the

leads on the corresponding terminals. Your voltage reading should be from 12 to 24 volts D.C.. If you have any

other voltage reading check the transformer load side. If

the voltage is the same as found at the circuit board,

verify the incoming voltage to the transformer is correct.

If the transformer is putting out the correct voltage,

change the circuit board. If the transformer is putting out

the wrong voltage with correct line voltage, change the

transformer. Transformer actual voltage should read AC

voltage.

To the left of the jumper mentioned above is a manual harvest switch. By depressing this switch one time the machine can go immediately into harvest. This will happen if

the toggle switch is to the ICE position, the curtain is in

place and the power light is steady on.

18

Revision June 19, 2003

5006772

Page 18

Installation and Service Manual

COMPRESSOR & START

COMPONENTS

When compressors fail to start or run properly, normally it is

a result of an external failure. You should not rule out electric

voltage, start, or run component failure.

Check for the proper voltage. Low or not voltage will require you to trace the electric wiring to determine where

the electric failure has occurred. Correct any discrepancy you may find. The lowest voltage should be no

lower than 95% of the ice maker name plate voltage of a

dual voltage machine. A single voltage machine should

be no lower than 90% of the name plate voltage. High

voltage is 10% greater than the name plate voltage.

A defective capacitor or relay may prevent the compressor from starting. If the compressor attempts to start or

hums check the start components.

The potential relay contacts are normally closed. These

contacts are opened by the counter electromotive force from

the compressor at approximately 80% of the operating

speed. When the contacts open this removes the start

capacitor from the circuit. The start and run winding with

the run capacitor remain in the circuit. If this relay fails to

open in during operation you should check the holding coil

for continuity.

To check the compressor for ground, use your ohm meter.

Place one lead on a good compressor case ground. The

copper suction line tubing works very well for this. Place

the other lead in sequence on the common, start, and run

terminals. If you obtain any reading of a circuit through the

case, the windings are shorted to ground. The compressor must be replaced.

If the overload protector on the compressor trips, you

should check the following items. The voltage at the compressor terminals should be no less than 95% of the ice

maker name plate voltage of your particular machine.

Check the ambient operating temperatures, be sure you

have not exceeded the ambient limits of 380 C (1000 F).

Check the condenser for high head pressure conditions.

Tripping can also be caused by defective capacitors or

start relay.

Compressors used in the R-40A machines use polyol ester oil (POE). This oil is very susceptible to moisture contamination. An open compressor or can of oil can become

saturated with moisture within 15 minutes. Please reduce

the open refrigerant system time. Current accepted POE

oils are:

Mobil # EAL 22 CC-package AK ICI # RL 184

The current relay contacts are normally open. As the compressor starts, the high current draw produces a magnetic

field. This magnetic field draws the relay armature in. The

contacts for the start circuit will then close. If the coil on the

relay is open, the relay will not operate.

If a capacitor shows any sign of leaking or damage, replace it.

When checking capacitors, a capacitor tester must be

used. Remove the resistor (if any) from the terminals.

Attach the tester to the capacitor. If you use an ohm

meter to test capacitors, you can check only of an open,

shorted, or grounded capacitor.

The resistance testing of compressor windings must be

accomplished without wires or components attached. Using an ohm meter, obtain a reading of the compressor windings. Place one lead on the common (C) terminal. Place

the second lead on the start (S) and run (R) terminal in

succession. Compare your readings with those from the

compressor manufacturer.

CAUTION: POE oils are caustic to the skin. Always

wear gloves and goggles when working with the

refrigeration system.

Any defective compressor returned to SerVend must be

stubbed with copper tube and soldered closed.

5006772

Revision June 19, 2003

19

Page 19

Installation and Service Manual

COMPRESSOR CONTACTOR

The contactor serves as the power supply switch for the

compressor circuit. Voltage to the coil of the contactor is

supplied by the control board relay on self contained

models.

Caution: On 230 volt models, the contactor breaks only

one power leg. The ice maker is still “live”.

Remote models are wired through controls outside the

control board. The coil receives power through the low

pressure cut out and therm-o-disc(s).

CHECKING THE CONTACTOR

The top terminals of the contactor should always have line

voltage present. The lower two terminals must have the

same line voltage when the contactor is energized. If the

lower terminals have a different voltage when the contactor

is energized, replace the contactor. To check the contactor

coil, you may either ohm check the coil with the coil supply

wires removed or check for power to the coil with your meter

leads in parallel to the coil.

EVAPORATOR

The ice is made on a nickel-coated copper evaporator plate.

This plate has the refrigerant serpentine coil attached to

the back of the plate. As the water cascades over the evaporator, check the distribution tube at the top of the evaporator. The water must flow from the tube with the holes in the

appropriate direction.

CHECKING THE FAN CYCLE CONTROL

Install a high side gauge to the high side service valve. Do

not attach the gauge to the receiver valve. Operate the system and observe the pressures with the fan cycling. If the

cycling pressures vary greater than + 10% of the previously

mentioned pressures, replace the contorl. This control is non

adjustable.

FLOAT VALVE

The water level in the water pan is controlled by use of a float

valve. This valve modulates to allow a sufficient volume of

make up water into the pan for production into ice.

Adjustment of the valve is accomplished by the valve bracket.

This bracket has two screws. Loosen the screws to move

the float and bracket up or down to raise or lower the amount

of water in the pan.

Located within the float valve is a flow control washer. This

washer prevents high water pressure from interfering with

the operation of the float valve. At pressures below 1.4 Kg/

cm2 (20 PSI) to 3.9 Kg/cm2 (55 PSI) the flow control washer

is inactive. The flow washer begins to hold back the water

pressure from the float valve from 3.9 Kg/cm2 (55 PSI) to

8.4 Kg/cm2 (120 PSI). At pressures above 8.4 Kg/cm2 (120

PSI) the flow control washer will not control the incoming

water pressure, you must use a water pressure regulating

valve.

HALL SWITCH

The Hall switch operates in conjunction with a magnetic target on the side of the water curtain. This has two functions on

the SerVend machine.

The Hall switch serves as a bin full control. When the bin fills

up the curtain is held away from the face of the evaporator

and out of the range of the Hall switch. As ice is removed from

the bin, the curtain will fall back toward the evaporator. This

will again put the target within range of the Hall switch and the

machine will restart.

FAN CYCLE CONTROL

This is a high slide pressure control that cycles the condenser

fan motor off at approximately 13 kg/cm2 (180 PSI) and will

engage at 17.5 kg/cm2 (250 PSI). It’s purpose is to maintain

a minimum head pressure for operation in low ambient conditions.

The fan cycle control is used on all remote condensers. It

is also installed in the left fan of a dual evaporator self contained air cooled machine. Also on the G9 air cooled self

contained units.

20

This switch also acts as a harvest termination control. As

the ice falls off the evaporator, the curtain swings out taking

the target out of the switch range. The ice will then fall into

the bin allowing the curtain to immediately fall back against

the evaporator. At that time, the target will return to the Hall

switch range. This will put the machine directly from harvest into freeze.

5006772

Revision June 19, 2003

Page 20

Installation and Service Manual

CHECKING THE HALL SWITCH

Turn the toggle switch to the ICE position. With the curtain

in the closed position against the evaporator check the LED

on the circuit board. This is the LED at the curtain switch

terminals on the circuit board. The corresponding curtain

position LED should be on. With the LED on, pull the curtain away from the evaporator. The LED should go off.

Release the curtain, allowing it to fall against the evaporator. The LED should go on. If the LED operates in this

manner, the switch is good. If the LED does not operate

this way, and voltage is correct according to the section

checking the circuit board on page IV-14, change the switch.

HEAD PRESSURE CONTROL VALVE

The head pressure control used on SerVend remote ice

makers is a modulating control. This control maintains

the proper head pressure in the remote condenser. At

outdoor temperatures above 20o C (70o F) the refrigerant

will flow from the compressor tot the valve. The valve

then moves the flow to the condenser onto the receiver.

At outdoor temperatures below 21o C (70o F) the refrigerant flow is from the compressor tot the valve. The

valve then mixes the discharge line and the condenser

line. The resultant mixture is sent tot he receiver. This

“by-pass” mode supplements the condenser pressures

and is used to maintain proper operating head pressure.

CHECKING THE HEAD PRESSURE CONTROL

Install a gauge at the receiver tank. With outdoor temperatures below 21o C (70o F) receiver pressures will be 13 kg/

cm2 (180 PSI) to 17 kg/cm2 (240 PSI) + 3%.

A head pressure control that stays in by-pass may be the

result of a system that is short of refrigerant. Before replacing the head pressure control, check the fan cycling

control. If it is not cycling, add refrigerant in 1 kg (2 lb.)

increments up to 2 kg (4 lb.). Allow the machine several

minutes to “balance” between additions. If the addition of

refrigerant corrects the valve problems, locate and repair a

refrigerant leak.

REPLACEMENT OF A HEAD PRESSURE VALVE

Always snap off the stub line at the dome before using a

torch to heat the lines for removal. When installing the

new valve, be sure the dome area is covered with ample

heat sink before applying heat to the valve stubs.

HIGH PRESSURE CUT OUT

Al SerVend water cooled, remote condenser, and G2 air

products contain a high pressure cut out. The function of

this switch is to turn the ice maker off in the event of excessive pressure developing in the high pressure side of

the refrigeration system. This switch will open the power

circuit to the circuit board at 35.2 kg/cm

is a manual reset control located beside the power toggle

seitch. To reset this control, push the red button in.

In the event the high pressure control shuts down the

machine, find the reason for this shut down. Correct any

necessary problems then restart the machine.

2

(500 PSI). This

HOT GAS VALVE

SerVend employs a hot gas defrost method of harvesting

the ice. When the ice reaches the proper temperature,

the ice sensing control initiates the board to open the hot

gas bypass valve. This electrically operated solenoid valve

will allow hot discharge refrigerant gas leaving the compressor to return to the inlet of the evaporator. The flow of

liquid refrigerant from the expansion valve will then cease.

The hot refrigerant warms the evaporator therefore allowing the ice to melt and slide off the evaporator.

If the hot gas valve fails to open, check the electric power

supply to the coil of the valve. This power supply is supplied

to the coil from the circuit board. The power should be

checked in parallel and should be present when the red LED

is energized. If there is power to the coil without the coil

operating, remove the wire leads from the coil of the valve.

Place your continuity meter on the coil terminals. You should

have continuity at these terminals. If there is no continuity,

replace the coil.

If the coil is energized but the valve still fails to operate, you

may have a sticking valve that needs to be replaced.

A leaking valve can cause excessive freeze times, uneven

bridge thickness, high suction pressures, etc.. A leaking

hot gas valve is difficult to troubleshoot. Several methods

to determine if this valve is leaking in the closed mode are

as follows:

1. The hand temperature method. Place you hand on the

outlet of the valve. The outlet line of the valve should feel

ambient temperature or a little cooler.

2. The use of an electronic sight glass. This can be beneficial

in the detection of a leaking valve. Install the probes on the

outlet line of the valve, several inches apart. If there is a

small leak in the valve, the instrument should detect hot

gas condensing due to the pressure drop and cooler temperatures of the evaporator section.

5006772

Revision June 19, 2003

3. Use of a pinch off tool. By closing the line between the hot

gas valve and the evaporator, you will be able to determine

if the valve is leaking.

21

Page 21

Installation and Service Manual

ICE CAPACITY

The ice manufacturing capacity of any maker is affected by

many operating conditions. These conditions include, but are

not limited to, water and air temperatures, electric and ocation

of equipment, etc.. We have included in the operating specifications section typical production capabilities for SerVend

ice makers at specific conditions.

All printed capacity ratings are laboratory readings. If you are

working with a 50 Hz. unit cycle time will increase 12% while

capacity will decrease approximately 12%.

ICE CAPACITY CHECK PROCEDURE

Of paramount importance in checking the ice produciton of

any machine is the collection of accurate data.

Measure the ambient air temperature 5 cm (2”) from the

condenser fins if air cooled. If not air cooled, measure air

temperature 5 cm (2”) from either the right or left side panel

about one half way from the front to the back of the unit.

The incoming water temperature should be measured in the

water stream at the inlet of the float valve. Be sure your

thermometer does not read the water pan temperature.

CHECK PROCEDURE

1. Clear the evaporator of any ice. This can be done with

the use of the manual harvest switch on the circuit baord.

2. Place the machine in the ice mode. Allow the unit to

make one sheet of ice.

3. At the end of a normal freeze time, manually harvest the

ice.

4. Observe the sheet of ice. Is the bridge thickenss even

from top to bottom? Is the bridge thinner at the top of the

sheet than at the bottom?

5. If your sheet of ice is thinner at the top than at the bottom,

your machine is probably suffering from a water loss or a

refrigeration problem. Please refer to the appropriate sections for help.

6. If your ice has an even bridge from top to bottom, proceed

with the OHM meter check.

7. Remove the control wires from the EV terminals on the

circuit board. Do not remove the control from the evaporator extrusion. In a dual evaporator machine, only the left

ice thickness control (connected to the EV terminals) determines the thickness of the ice.

Allow the machine to make one sheet of ice. Catch this

sheet and weigh it. During produciton, time the complete

cycle. Production time includes the freeze and harvest times

added together.

With this information the calculation can be made.

1440 (number of minutes in a day) + total cycle time X

weight of one sheet of ice X number of evaporators - ice

produciton.

ICE THICKNESS CONTROL

DIAGNOSIS

Before replacing a potential ice thickness control, please

check the following:

1. Are the wire leads to the circuit board secure and tight?

2. Is the tip of the control mounted to the front of the plastic extrusion? The tip of the thermistor should not be

recessed into the thermistor hole.

3. Is there a glob of sealant over the tip of the control? A

very slight film is OK. If the tip of the control has an

overabundance of silicone, it can act as an insulator to

the ice.

8. If the ice sensing control is “open” or “shorted”, the power

light on the circuit board will flash. The machine will not

operate, replace the control.

9. Attach your ohm meter to the ends of the wires. Your meter

should be capable of reading 5,000 to 40,000 ohms accurately.

10. At room temperature, with no ice on the evaporator,

your control should read ABOUT 10,000 to 15,000 OHM

resistance.

11. Place an ice cube on the tip of the control. You should

obtain a reading about 25,000 to 36,000 ohms. You may

hold in the contactor for the compressor to freeze the evaporator rather than hold ice on the tip. Do not hold the contactor

in for more than two minutes. Flood back to the compressor may occur with damage to the compressor.

These readings are approximate. Do not be concerned if

your readings are slightly different.

If your control responds comparable to the above readings,

this control is good. If your control does not respond, replace this ice sensing contorl.

4. After the cachine seats for 24 hours is the first sheet of

ice OK? Does each succeeding sheet of ice get thinner? This could be a sealing problem with water in the

sensor well.

22

Revision June 19, 2003

5006772

Page 22

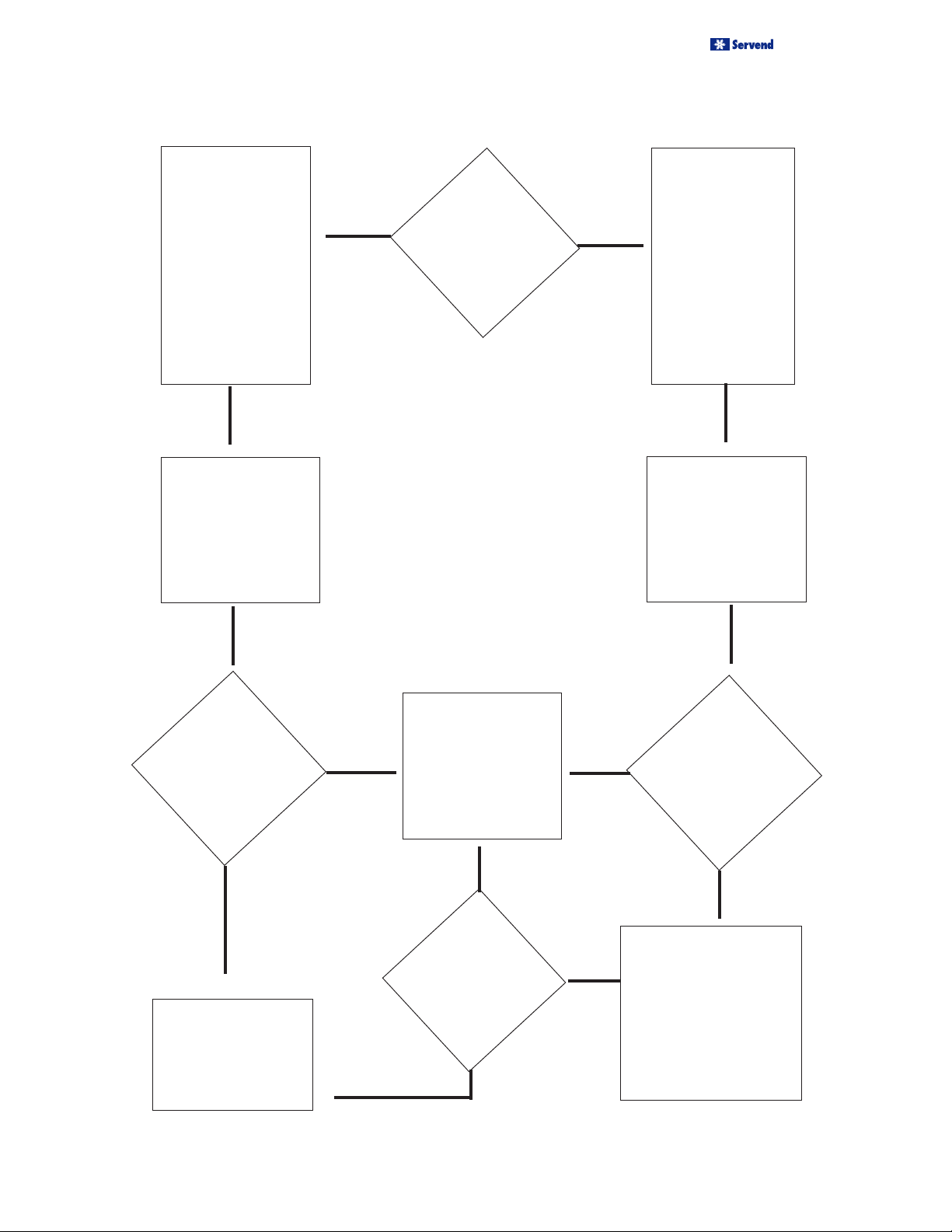

CHECKING THE THERMISTOR

Installation and Service Manual

Remove the

thermistor

wires from

the circuit

board. DO

NOT remove

the

thermistor

<

Attach your ohm

meter leads to the

thermistor

<

YES

Is there ice

on the

evaporator?

NO

Remove the thermistor wires from

the circuit board.

<

Do NOT remove

the thermistor

<

Attach your ohm

meter leads to the

thermistor wires

<

Is

ohm

reading

32,000 ohms

or greater?

YES

<

Thermistor is good.

DO NOT replace!

<

NO

Thermistor is defective. Replace

the control

<

<

NO

Is ohm reading 32,000

ohms or greater?

YES

<

<

ohm

NO

reading

between 10,000 to

15,000 ohms?

YES

Place machine into

freeze mode. Allow

unit to make 1/8”

bridge thick ice.

<

Is

<

5006772

Revision June 19, 2003

23

Page 23

Installation and Service Manual

ICE THICKNESS CONTROL

REPLACEMENT

1. Shut off water and electric supply to the ice maker.

2. Remove the float valve and the water pan from the machine. Remove the side panel from the control box side

of the machine.

3. Use a 1.5 mm (1/16”) punch to push the control out of the

extrusion. Clean the old silcone out of the hole.

4. Remove the old control from the machine. Thread the

new control through the machine from the complressor

compartment. Push the control tip through the enclosure

toward the evaporator.

5. When routing the new control wires to the cifcuit board,

be sure the wires do not touch any hot gas lines. Attach

the lead wires to the circuit board in the appropriate positions. There is no polarity in the wires of the ice thickness

control.

6. Using GE RTV-108 silicone, fill the hole with silicone. This

silicone is available from your local SerVend distributor.

7. Immediately after filling the hole with silicone, place your

thumb over the front of the hole for the ice sensing control.

Push the new control into the hole from behind the evaporator. This will allow the silicone to encompas the outside

of the control jacket. Continue to push the control into the

hole until the control hits the stop at the front of the hole.

Never make a sharp bend with the control nor allow the

wire to loop behind the evaporator. This can produce internal damage to the control.

ICE THICKNESS CONTROL

ADJUSTMENT

Adjustment to the bridge thickness on a new start-up

must only be done AFTER the machine has made one

sheet of ice. Make subsequent adjustments after each

sheet of ice.

Adjustment to the bridge thickness is done at the circuit

board. On the bottom (front) of the board in the control

box is a set of 8 DIP switches. To have a thicker bridge,

turn the next (right) switch “on”. To have a thinner bridge,

turn the next (left) switch “off”. It is acceptable to have all

of the switches either on or off. Follow the indicator

wedge above the switch case for thicker or thinner bridge.

The switch is on if the top of the switch is down.

If further adjustment is necessary, you may adjust the

potentiometer. Locate this “pot” left of the 8 DIP switch