Page 1

BEVERAGE CONDUIT

Multiplex System Conduit

INSTALLATION INSTRUCTION MANUAL

Part Number EI211017

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

May 04, 2007 REV2

Page 2

Page 3

FOREWORD

Manitowoc Beverage Equipment (MBE) developed this manual as a reference guide for the owner/

operator, service agent, and installer of this equipment. Please read this manual before installation

or operation of the machine.

If you cannot correct the service problem, call your MBE Service Agent or Distributor. Always have your model and

serial number available when you call.

Your Service Agent___________________________________________________________________

Service Agent Telephone Number ______________________________________________________

Your Local MBE Distributor ___________________________________________________________

Distributor Telephone Number _________________________________________________________

Model Number ______________________________________________________________________

Serial Number _______________________________________________________________________

Installation Date _____________________________________________________________________

UNPACKING AND INSPECTION

Carefully inspect the conduit immediately upon unpacking. Inspect conduit for any damages that may have occurred during shipping.Before installing conduit, be sure conduit is proper length for installation, contains the correct number of lines for connection, and all lines are proper diameter.

WARRANTY INFORMATION

Consult your local MBE Distributor for terms and conditions of your warranty. Your warranty specifically

excludes all beverage valve brixing, general adjustments, cleaning, accessories and related servicing.

Your warranty card must be returned to Manitowoc Beverage Equipment to activate the warranty on this

equipment. If a warranty card is not returned, the warranty period can begin when the equipment leaves

the MBE factory.

No equipment may be returned to Manitowoc Beverage Equipment without a written Return Goods

Authorization (RGA). Equipment returned without an RGA will be refused at MBE’s dock and returned to

the sender at the sender’s expense.

Please contact your local MBE distributor for return procedures.

Page 4

TABLE OF CONTENTS

FOREWORD ........................................................................................................ 3

UNPACKING AND INSPECTION......................................................................... 3

WARRANTY INFORMATION ............................................................................... 3

ADDITIONAL WARNINGS ................................................................................................ 5

SAFETY ............................................................................................................... 5

INFORMATION ................................................................................................................. 5

CARBON DIOXIDE WARNING ......................................................................................... 5

QUALIFIED SERVICE PERSONNEL ................................................................................ 5

FLAME AND SMOKE RATING ......................................................................................... 6

SPECIFICATION COMPLIANCE ...................................................................................... 6

SHIPPING, STORAGE, AND RELOCATION ..................................................................... 7

PRE-INSTALLATION ........................................................................................... 8

REQUIRED TOOLS .......................................................................................................... 8

UNPACKING AND INSPECTING ...................................................................................... 8

ROUTING MULTIPLEX CONDUIT ....................................................................... 8

FLOOR CHASES .............................................................................................................. 8

SEALING INSTRUCTIONS ............................................................................................... 9

OVERHEAD INSTALLATION ............................................................................................ 9

BASEMENT CONSTRUCTION ....................................................................................... 10

HOW TO CONNECT THE MULTIPLEX CONDUIT .......................................................... 10

CONDUIT IDENTIFICATION CHART ...............................................................................11

COLOR AND NUMBER CODING ....................................................................................11

TEEING INTO THE MULTIPLEX CONDUIT ON SODA SYSTEMS ................................. 13

CONDUIT KIT ................................................................................................................. 15

BEERMASTER BEER CONDUIT ...................................................................... 16

INTRODUCTION ............................................................................................................. 16

FLOOR CHASES ............................................................................................................ 16

PULLING CONDUIT THROUGH FLOOR CHASE .......................................................... 16

FLOOR CHASES ............................................................................................................ 17

OVERHEAD INSTALLATION .......................................................................................... 17

BASEMENT CONSTRUCTION ....................................................................................... 18

CONNECTING BEER CONDUIT .................................................................................... 18

CONDUIT KIT ................................................................................................................. 19

KIT CONTENTS .............................................................................................................. 19

INSTALLING THE CONDUIT KIT ................................................................................... 21

BEER RESTRICTOR LINES ........................................................................................... 22

INDEX................................................................................................................. 23

Page 5

Installation and Service Manual

SAFETY

INFORMATION

Carefully read all safety messages in this manual. Learn how to operate the equipment properly.

Do not allow anyone to operate the unit without proper training and keep it in proper working

condition. Unauthorized modifications to the equipment may impair function and/or safety and

affect the life of the unit.

CARBON DIOXIDE WARNING

WARNING: Carbon Dioxide (CO2) displaces oxygen. Exposure to a high concentration of CO2 gas

causes tremors, which are followed rapidly by loss of consciousness and suffocation. If a CO

is suspected, particularly in a small area, immediately ventilate the area before repairing the leak. CO

lines and pumps should not be installed in an enclosed space. An enclosed space can be a cooler or

small room or closet. This may include convenience stores with glass door self serve coolers. If you

suspect CO2 may build up in an area, venting of the B-I-B pumps and / or CO2 monitors should be utilized.

QUALIFIED SERVICE PERSONNEL

CAUTION: Only trained and certified electrical and plumbing technicians should service this unit.

All wiring and plumbing must conform to national and local codes.

gas leak

2

2

ADDITIONAL WARNINGS

Installation of this equipment should be done by a qualified service technician. Operation, maintenance,

and cleaning information in this manual are provided for the user/operator of the equipment.

Breathing high

concentrations of carbon

dioxide gas can cause

tremors, followed by loss

of consciousness and

suffocation

Route CO

CO2 DISPLACES OXYGEN

vent tube

2

outside or to an

unconfined area

5

Page 6

Installation and Service Manual

SAFETY

Caution: To Avoid Serious Injury

Important: Read the following warnings before beginning an installation. Failure to do so may result in possible

death or serious injury.

DO Adhere to all National and Local Plumbing and Electrical Safety Codes.

DO Turn “off” incoming electrical service switches when servicing, installing, or repairing equipment.

DO Check that all flare fittings are tight. This check should be performed with a wrench to ensure a quality seal.

DO Inspect pressure on Regulators before starting up equipment.

DO Protect eyes when working around refrigerants.

DO Use caution when handling metal surface edges of all equipment.

DO Handle CO

DO Store CO2 cylinder(s) in well ventilated areas.

DO NOT Exhaust CO2 gas (example: beer pump) into an enclosed area, including all types of walk in coolers,

DO NOT Throw or drop a CO2 cylinder. Secure the cylinder(s) in an upright position with a chain.

DO NOT Connect the CO2 cylinder(s) directly to the product container. Doing so will result in an explosion

DO NOT Store CO2 cylinders in temperature above 125°F (51.7°C) near furnaces, radiator or sources of heat.

DO NOT Release CO2 gas from old cylinder.

DO NOT Touch Refrigeration lines inside units, some may exceed temperatures of 200°F (93.3°C).

Notice: All utility connections and fixtures shall be

sized, installed and maintained in accordance with

Federal, State, and Local codes.

cylinders and gauges with care. Secure cylinders properly against abrasion.

2

cellars, and closets.

causing possible death or injury. Best to connect the CO2 cylinder(s) to a regulator(s).

FLAME AND SMOKE RATING

INSUL-TUBE® Pipe Insulation in wall thickness of 1" (25 mm) and below has a flame spread rating of 25 or less

and a smoke development rating of 50 or less as tested by ASTM E 84 Method of Testing entitled: Surface Burning

Characteristics of Building Materials. Duct/Plenum Applications INSUL-TUBE® is acceptable for duct/plenum

applications, meeting requirements of NFPA 90A.

Numerical flammability ratings alone may not define the performance of products under actual fire conditions. They

are provided only for use in the selection of products to meet limits specified, when compared to a known standard.

SPECIFICATION COMPLIANCE

ASTM C 534 Type 1 (Tubing)

ASTM D 1056-00-2C1

ASTM C 1534-02

New York City MEA 186-86-M Vol. IV

USDA Requirements

UL 94-5V Flammability Classification (Recognition No.

E147665)

ASTM E 84 1" 25/50-tested according to UL 723 and

NFPA 255

Complies with requirements of CAN/ULC S102-M88

6

NFPA No. 101 Class A Rating

Meets requirements of NFPA 90A Sect. 2.3.3 for

Supplementary Materials for Air Distribution Systems.

Meets requirements of ASTM C 411 (Tested Method of

Hot Surface Performance of High Temperature Thermal

Insulation).

Meets requirements of UL 181 sections 11.0 and 16.0

(Mold Growth/Air Erosion)

MIL-P-15280, For T (Tubing)

Page 7

Installation and Service Manual

SAFETY

SHIPPING, STORAGE, AND RELOCATION

CAUTION: Before shipping, storing, or relocating this unit, syrup systems must be sanitized. After

sanitizing, all liquids (sanitizing solution and water) must be purged from the unit. A freezing environment causes residual sanitizing solution or water remaining inside the unit to freeze, resulting

in damage to internal components.

Store conduit in 60°F (15.5°C) to 80°F (16.6°C) environment.

Keep in a cool, dry location.

Do not expose to direct sunlight.

Do not store conduit outside the original carton.

Do not store conduit for more than one year.

Do not store anything directly on top of conduit.

Do not store in an enclosed location with high aromatic compounds.

Conduit warranty is 2 years from date of manufacture as printed on the conduit.

If you have any questions or concerns, please contact the MBE Service Department at 800-3674233 or service@servend.com

7

Page 8

Installation and Service Manual

PRE-INSTALLATION

REQUIRED TOOLS

• Steel Fish Tape

• Length of Rope

• Duct Tape

UNPACKING AND INSPECTING

Carefully inspect the conduit immediately upon unpacking. Inspect conduit for any damages that may have occurred during shipping.

ROUTING MULTIPLEX CONDUIT

FLOOR CHASES

FIGURE 1

• Approved Tubing Cutters

• Razor Blade Knife

• Tab Clamp Pliers

Before installing conduit, be sure conduit is proper length

for installation, contains the correct number of lines for

connection, and all lines are proper diameter.

Before pulling Multiplex conduit through a floor chase, ensure the floor chase contains the following:

• 8" Minimum PVC Conduit

• Wide Sweep Elbows with a minimum 2 ft

(61 cm) radius

Pulling Conduit Through Floor Chase

1. Determine the most convenient way of routing conduit, starting at the end which offers adequate room

for installation. The conduit installation process requires the assistance of two (2) qualified personnel.

2. Locate steel fish tape and route through chase opening. Route fish tape through entire chase until it appears at opposite end.

3. Locate an appropriate length of rope and tie to end

of fish tape (end that was routed through chase in

step 2). Approximately 2 ft (61 cm) from steel fish

tape/rope connection, secure a swab to rope (use

mop heads or bundle of rags for swab).

4. Pull end of fish tape from starting point through chase

with rope and swab. The swab will sweep clean any

construction materials, moisture, or debris that may

exist in floor chase.

• Chase openings should extend 6" (15.2 cm)

above floor

• Chase must be clean and dry, no foreign materials

Caution: All objects and moisture must be removed from

floor chase before conduit can be routed. It may be necessary to repeat this process to ensure floor chase is clean.

5. After floor chase has been cleaned, remove steel

fish tape and swab from rope. Locate bundle of Multiplex conduit and unspool conduit to allow unrestricted feed during installation process.

6. Locate rope through chase opening and connect to

proper end of Multiplex conduit.

Note: Multiplex conduit is designed to be pulled

through a chase in the direction of arrows printed on

conduit

(refer to figure 2)

.

8

Page 9

Installation and Service Manual

ROUTING MULTIPLEX CONDUIT

ROUTING MULTIPLEX CONDUIT

7. After rope has been connected, tape end of conduit, including rope, and form conduit end to a point.

Tape will ensure that no contaminants enter conduit

tubes during installation.

8. Place pointed end of Multiplex conduit through chase

opening. While one person pushes the conduit

through chase, another person should be pulling

conduit through chase with rope on opposite end.

FIGURE 2

SEALING INSTRUCTIONS

Aerosol foam is to be used to fill the openings between the conduit insulation and the inside diameter of the floor

chases. The purpose is to provide an air tight seal at the floor level to prevent foreign matter from entering the chases.

Note: Please read the manufacturer’s instructions carefully.

9. Once conduit has been routed through chase, pull

enough conduit through openings to ensure an adequate supply at each end of chase for connections.

1. If the opening is too deep, insert a section of the

excess conduit insulation in the opening prior to using

the foam insulation.

2. Make sure all exposed carbonated water and syrup

lines are well insulated: towers to conduit; conduit

junctions, remote unit to conduit; drive thru junction.

Note: A little extra time spent doing a professional job

initially will eliminate a call back in several days to make

corrections.

OVERHEAD INSTALLATION

3. Use aluminum foil (if used), and tape, packed in the

inner pack carton to insulate these connections.

4. Cut the conduit sections to fit like a glove over the

exposed lines and fittings.

Warning: Do not inject foam material directly on the

connections where the tubing connects to the barb

fittings.

FIGURE 3

1. Determine the correct location for routing Multiplex

conduit. Be sure to avoid heat ducts, hoods, grills,

or any sharp objects that may exist above drop ceiling tile.

2. Unspool Multiplex conduit to allow unrestricted feed.

3. Conduit hangers should be spaced no more than 6

ft centers

Once conduit has been routed, ensure an adequate supply of conduit is provided at each end to make all connections

(refer to figure 3)

4. Route conduit above ceiling tiles and connect to ceiling and/or pipes using the appropriate conduit hangers. Be sure conduit is suspended above ceiling tiles.

Concern should be given when determining appropriate method of hanging conduit securely. Hangers must not crush or pinch insulation. This will reduce cooling efficiency.

9

Page 10

Installation and Service Manual

ROUTING MULTIPLEX CONDUIT

BASEMENT CONSTRUCTION

FIGURE 4

1. Unspool Multiplex conduit to allow unrestricted feed

during installation process.

2. Route the conduit up basement wall and secure

with appropriate conduit hangers.

Caution: Don't crush or pinch conduit insulation with hangers.

3. Conduit hangers should be spaced no more than 6

ft centers

Once conduit has been routed, ensure an adequate supply of conduit is on hand to make all connections.

4. Route conduit above ceiling tiles and connect to ceiling and/or pipes using the appropriate conduit hangers. Be sure conduit is suspended above ceiling tiles.

Concern should be given when determining appropriate method of hanging conduit securely. Hangers must not crush or pinch insulation. This will reduce cooling efficiency.

HOW TO CONNECT THE MULTIPLEX CONDUIT

Caution: Only an approved cutting tool should be

used to cut polyethylene tubing. Use a new blade so

that the tubing will not be crushed when cutting.

FIGURE 5

All Multiplex conduit syrup lines, carbonated water lines,

and the plain water line are coded for quick identification

and easy installation.

1. Locate the lines of Multiplex conduit routed at refrigeration unit and dispensing tower.

2. Using an approved razor knife, cut Multiplex conduit insulation by slicing along top side while peeling insulation back at the same time.

3. For soda systems, connect each syrup line, carbonated water line, and plain water line to the appropriate stainless steel coil in refrigeration unit.

For Glycol systems, connect to bulkhead fittings.

Note: Conduit lines should be long enough to allow

adequate work space when servicing equipment.

FIGURE 6

Note: Stainless steel cooling coils in our refrigeration units may contain either barb fittings or John Guest

fittings, depending on model. Before connecting conduit, identify whether the conduit is thick wall or thin wall

tubing (see illustration). Thick wall tubing should only be used with barb stem fittings. John Guest fittings can

only be used with thin wall tubing

10

Page 11

Installation and Service Manual

ROUTING MULTIPLEX CONDUIT

CONDUIT IDENTIFICATION CHART

When suspending Multiplex conduit with conduit hangers, the maximum allowable distance between hangers is 6

ft (1.82 m).

If ambient temperature of the conduit location is 90ºF (32.2ºC) or above, double insulated conduit must be utilized.

COLOR AND NUMBER CODING

I.D. Size of Tub e / Hose Number Color Suggested Use Tab Clamp Size

1/4" Tube S1 White Syrup 10.5

S2 Black

S3 Orange

S4 Red

S5 Blue

S6 Green

S7 Purple

S8 Brown

S9 Pink

S10 Ye llow

S11 White

S12 Black

S13 Orange

S14 Red

S15 Blue

S16 Green

11

Page 12

Installation and Service Manual

ROUTING MULTIPLEX CONDUIT

COLOR AND NUMBER CODING

I.D. S iz e of Tub e / H ose Number Color Suggested Use Tab Clamp Size

3/8" Tube AF Red Water / Glycol 13.8

½" Tube VS1 Orange High Viscous Syrup 17.0

½" H ose AF Blue Water / Glycol 18.5

Product suggestions for conduit tubing

AR Red

BF Blue

BR Blue

S1 White Syrup / Beer 13.8

S2 Black

S3 Orange

S4 Red

S5 Blue

S6 Green

S7 Purple

S8 Brown

S9 Pink

S10 Yellow

S11 White

S12 Black

S13 Orange

S14 Red

S15 Blue

S16 Green

VS2 Natural

VS3 Green

VS4 White

VS5 Black

VS6 Red

VS7 Blue

VS8 Purple

VS9 Brown

VS10 Pink

VS11 Yellow

VS12 Purple

AR Blue

BF Yellow

BR Yellow

WF Black

WR Black

Current conduit tubing is PTE lined. Therefore it is no longer necessary to make sure pungent flavors are used with

specific tubing. Keeping with that process, when connecting conduit to syrup boxes and valves, the best flavor/

tubing selection would be to utilize line number S1 for valve number 1, S2 for valve number 2, etc.

12

Page 13

ROUTING MULTIPLEX CONDUIT

ROUTING MULTIPLEX CONDUIT

Barb Stem Fittings

1. Moisten barbed fittings with warm water.

2. Connect appropriate lines to barbed fittings and secure with two (2) tab clamps. Tab clamps should

be staggered when connecting

(refer to figure 7)

.

Installation and Service Manual

2. Once the end of each line has been cut, lubricate

with water and insert line into John Guest Fitting.

Be sure the tubing is inserted firmly through O-ring

in John Guest fitting.

3. Connect each syrup line, carbonated water line, and

plain water line to the appropriate connection in dispensing tower. Secure with two (2) tab clamps. If

tower has barbs, a John Guest adapter stem should

be used when connecting to a conduit with John

Guest Fittings.

FIGURE 7

John Guest Fittings

1. Before inserting appropriate conduit lines to John

Guest fittings, ensure that the end of each line is

cut square at a 90° angle.

TEEING INTO THE MULTIPLEX CONDUIT ON SODA SYSTEMS

1. Locate the section in main conduit where tee connections are to be made. Measure a 12" (30.5 cm)

area in the designated section.

2. Using a razor knife, cut a “X” pattern in designated

section as shown in figure 8. Peel back the ends of

foam insulation and identify each syrup line and

water line located in conduit. Be careful not to cut

lines inside conduit. Even a small “nick” will result

in leaks.

FIGURE 9

Note: Connections in dispensing towers may contain

either barb stem fittings or John Guest fittings. See

previous section for proper instruction.

FIGURE 10

4. Locate the section of tee conduit. Using a razor

knife, slice foam insulation in a straight line on top

side of conduit. Pull back foam insulation and locate each syrup line

(refer to figure 11)

.

FIGURE 8

3. Using a tubing cutter, cut each syrup line (one [1]

line at a time) in main conduit. Locate barbed tees

in conduit tee kit, connect to each syrup and water

line. Secure with two tab clamps

(refer to figure 10)

.

FIGURE 11

13

Page 14

Installation and Service Manual

TEEING INTO THE MULTIPLEX CONDUIT ON SODA SYSTEMS

ROUTING MULTIPLEX CONDUIT

5. Connect each syrup line in a tee conduit to the appropriate barbed tee connected to the syrup lines

in the main conduit. Secure with two (2) tab clamps

(refer to figure 10)

sponding to the main conduit markings.

6. Locate carbonated water lines in main conduit and

cut using tubing cutter. Locate barbed “Ell” fitting

provided in kit and connect to carbonated water

lines

(refer to figure 12)

7. Connect the carbonated water lines in tee conduit

to the appropriate barbed ells connected to carbonated water lines in main conduit. Secure with

two tab clamps

Note: The number of carbonated water lines will vary

depending on the model of the refrigeration unit.

. Be sure to tee line markings corre-

.

FIGURE 12

(refer to figure 13)

.

8. Pull the sliced sections of foam insulation back over

openings where connections were made. Using

cloth tape, tape over openings and seal air tight.

9. After ensuring there are no leaks at conduit connections, wrap foam insulation tape around the

sliced sections and insulate the Multiplex conduit

completely. This is very important to prevent condensation and loss efficiency.

10. Seal each chase opening by spraying foam insulation into each end of chase opening. This will reduce risk of contamination of conduit in chase.

14

FIGURE 13

Page 15

ROUTING MULTIPLEX CONDUIT

CONDUIT KIT

FIGURE 14

Installation and Service Manual

FIGURE 15

FIGURE 16

15

Page 16

Installation and Service Manual

BEERMASTER BEER CONDUIT

INTRODUCTION

The following instructions will provide information for installing Multiplex/Multiplex Beer Conduit with your Beermaster

System. Areas which will be covered include routing the conduit for different bar set-ups, connecting the conduit at

the Beermaster Glycol Chiller, connecting the conduit at the beer cooler, and connecting the conduit at the dispensing stations.

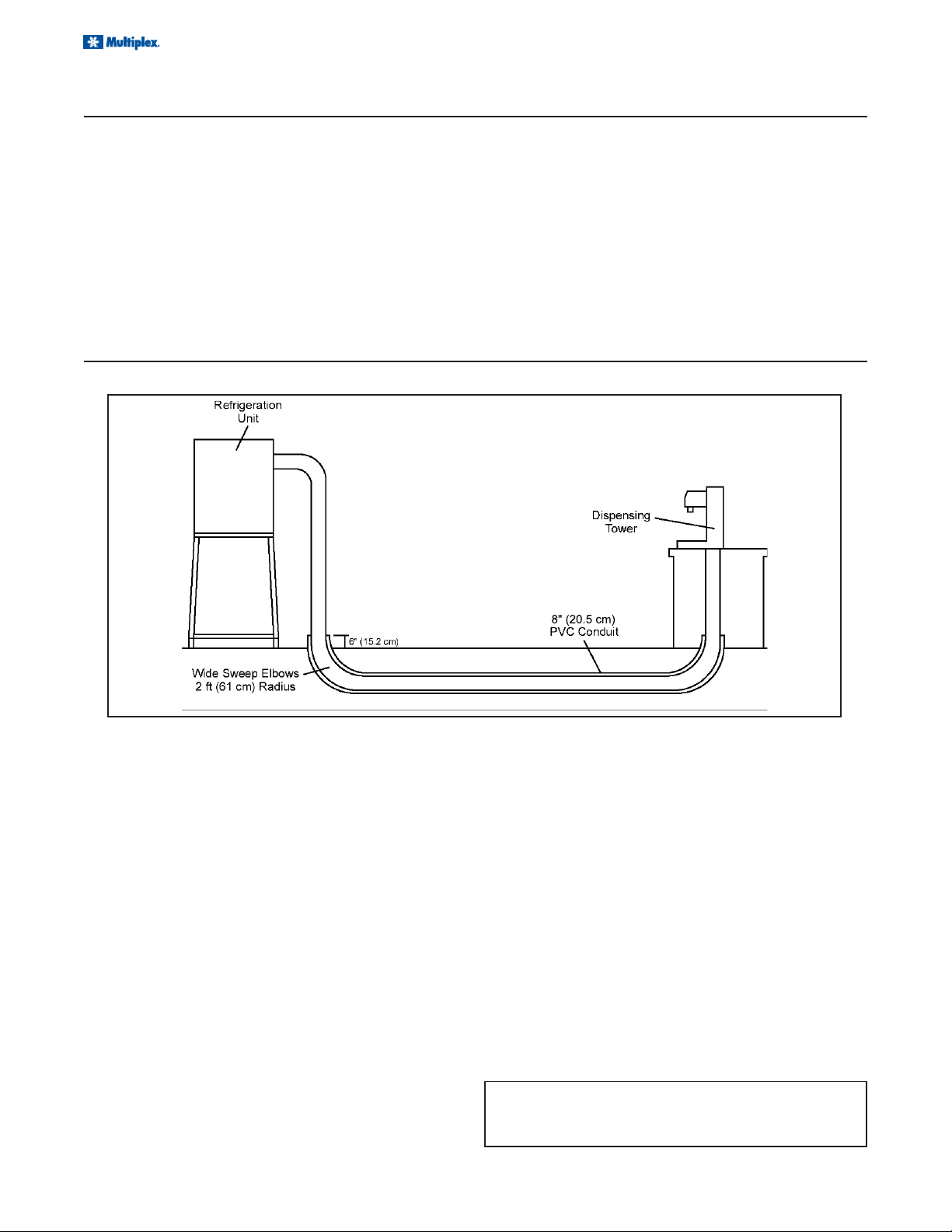

FLOOR CHASES

Before pulling beer conduit through a floor chase, ensure the floor chase contains the following

(see Figure 1)

• 6" (minimum) PVC conduit chase

• Wide sweep elbows (2 ft radius)

• Chase openings should extend 6" above floor

• Chase must be clean and dry–no foreign materials

FIGURE 1

Pulling conduit through floor chase

1. Determine the most convenient way of routing conduit, starting at the end which offers adequate room

for installation. The conduit installation process requires the assistance of at least two (2) qualified

personnel.

2. Route the steel fish tape through chase opening.

Push fish tape through entire chase until it appears

at opposite end.

3. Locate an appropriate length of rope and tie to end

of fish tape (end which was routed through chase

in step 2). Approximately 2 ft from steel fish tape/

rope connection, secure a swab to rope (use mop

heads or a bundle of rags for swab).

16

4. Pull end of fish tape from starting point through

chase with rope and swab. The swab will clean

any construction materials, moisture, or debris that

may exist in floor chase. Continue to swab the

chase until the swab exits the chase clean and dry.

5. After floor chase has been cleaned, remove steel

fish tape and swab from rope. Locate bundle of

beer conduit and unspool conduit to allow unrestricted feed during installation process.

6. Locate rope through floor chase opening and connect to proper end of beer conduit.

Note: The beer conduit is designed to be pulled

through floor chase in the direction of arrows printed

on conduit.

Page 17

BEERMASTER BEER CONDUIT

FLOOR CHASES

FIGURE 2

7. After rope has been connected, tape end of conduit, including rope, and form conduit end to a point

(see Figure 2)

enter conduit tubes during installation.

. Tape will ensure that no contaminants

OVERHEAD INSTALLATION

Installation and Service Manual

8. Place pointed end of the conduit through chase

opening. While one person pushes the conduit

through chase, another person should be pulling

the conduit through the chase with rope at the opposite end.

9. Once the conduit has been routed through the

chase, pull enough conduit through the openings

to ensure an adequate supply at each end of the

chase for connections.

Refer to Figure 3 for the following:

1. Determine the correct location for routing the beer

conduit. Be sure to avoid heat ducts, hoods, grills,

or any sharp objects that may exist above drop ceiling tile.

2. Unspool the beer conduit to allow unrestricted feed.

3. Route the conduit above ceiling tiles and connect

to ceiling and/or pipes using the appropriate conduit hangers. Be sure the conduit is suspended

FIGURE 3

above ceiling tiles, not lying on the tiles. Care should

be taken when determining appropriate method of

handing conduit securely. Hangers must not crush

or pinch insulation. This will reduce cooling efficiency.

4. Once the conduit has been routed, ensure an adequate supply of conduit is provided at each end

to make all connections.

17

Page 18

Installation and Service Manual

BEERMASTER BEER CONDUIT

BASEMENT CONSTRUCTION

FIGURE 4

Refer to Figure 4 for the following:

1. Unspool the beer conduit to allow unrestricted feed

during installation process.

2. Route the conduit up basement wall and secure

with appropriate conduit hangers.

3. After routing the conduit up the basement wall, route

conduit overhead on the basement ceiling. Con-

nect to the basement ceiling using appropriate conduit hangers.

4. Once the conduit has been routed, ensure an adequate supply of conduit is on hand to make all

connections.

CONNECTING BEER CONDUIT

Before connecting the beer conduit at the walk-in beer cooler and beer towers, ensure an adequate length of

conduit is being supplied to make proper connections.

CAUTION: Only an approved cutting tool should be used to cut polyethylene tubing. The cutting tool should

contain a razor sharp cutting blade so that the tubing will not be crushed when cutting. A razor blade knife

or butterfly tubing cutter is sufficient (

Glycol Chiller.

FIGURE 5

see Figure 5

). Multiplex packs a butterfly cutter with each Beermaster

1. Locate the lines of the beer conduit routed to the

Beermaster Glycol Chiller.

2. Using an approved cutting tool, cut the beer conduit insulation along the top side while peeling insulation back at the same time.

Note: Glycol circuit is a pair of lines; one blue and

one red. The blue line is the discharge or supply line.

The red line is the return line.

18

Page 19

BEERMASTER BEER CONDUIT

CONNECTING BEER CONDUIT

FIGURE 5

Installation and Service Manual

3. Locate the return glycol supply lines of the beer

conduit and connect to the corresponding John

Guest fitting on the Beermaster Glycol Chiller.

4. Locate the discharge glycol supply lines of the beer

conduit and connect to the corresponding John

Guest fitting on the Beermaster Glycol Chiller.

5. Locate the glycol lines in the main conduit. Connect the glycol lines of the beer unit to walk-in cooler

conduit to the glycol lines of the main beer conduit.

6. Locate the beer and glycol supply lines at the dispensing station. Connect each beer line, incoming

glycol line, and outgoing glycol line to the appropriate John Guest fitting at the dispensing station.

CONDUIT KIT

General

The following instructions will cover installation procedures required for properly connecting each component of

the Beermaster system. These instructions also contain the necessary information required for; calculating restrictor

line length, required regulator operating pressures and start up procedures. It is recommended that before proceeding with these instructions you ensure that each of the following items have been properly installed. Items

listed in suggested order of installation:

1. Glycol Chiller Unit,

2. Dispensing Towers,

3. Secondary Regulator Kits,

4. Beer Conduit,

Once the above items have been installed the following instructions can be completed.

Note: Your system may not include each item.

5. High Pressure CO2 Regulator Kit,

6. Blender Kit or Beer Pumps

7. Air Compressor Kit, (optional)

8. Low CO2 Alarm Kit.

Kit contents

Four (4) and Seven (7) line conduit kits

• Three (3) Return bends

• Eight (8) Elbows

• 29 Unions

• Five (5) Tail pieces

• Five (5) Beer nuts

• One (1) 60 ft of PVC tape

• One (1) 60 ft of foil

• One (1) Spanner wrench

10 and 14 line conduit kits

• Four (4) Return bends

• 15 Elbows

• 42 Unions

• Eight (8) Tail pieces

• Eight (8) Beer nuts

• One (1) 60 ft of PVC tape

• One (1) 60 ft of foil

• One (1) Spanner wrench

19

Page 20

Installation and Service Manual

BEERMASTER BEER CONDUIT

CONDUIT KIT

FIGURE 6

FIGURE 7

FIGURE 8

20

Page 21

Installation and Service Manual

BEERMASTER BEER CONDUIT

INSTALLING THE CONDUIT KIT

Connections preview

Review Figures 6, 7 and 8 to determine which best illustrates your particular installation. Consider the following

while examining the drawings:

Beer conduits have been designed to achieve the proper

cooling of each encased beer line. In order to function

properly, you must follow these guidelines:

To insure colder dispensing temperatures, glycol should flow directly to the dispensing towers before returning to

the remote Glycol Chiller Unit. After examining the drawings determine the desired glycol circuit to be achieved and

illustrate on paper for referral. Do the same for the assignment of the beer supply lines.

Up to eight (8) line conduit:

• six (6) beer maximum, one (1) glycol circuit (two [2] lines)

Ten (10) and over line conduit:

• two (2) glycol circuits (four [4] lines)

Connecting the glycol chiller to the walk-in cooler or

main beer conduit

1. Route the glycol conduit(s) from the Beermaster

Glycol Chiller to the point of connection on the main

beverage conduit(s). This connection could be done

in the walk-in cooler or at any desired location along

the length of the main beer conduits.

2. Identify the proper glycol lines within the glycol

conduit(s) at the Beermaster Glycol Chiller, cut to

length and insert into the appropriate John Guest

bulkhead fitting(s) found on the side panel of the

Beermaster Glycol Chiller (see Figure 9).

Connecting main beer conduit at walk-in cooler

1. At the top of each beer wall bracket fitting, found

on the dual secondary regulator, secure a Beer Nut,

John Guest adapting tail piece, washer, and 1/2"

John Guest union (see Figure 10).

2. Identify the appropriate beer lines to be connected

to each of the wall bracket fittings, cut to length

and insert into the proper John Guest 1/2" connector (see Figure 10).

FIGURE 9

3. At the walk-in end of the conduit(s), peel back the

insulation from the beer conduit and identify the

appropriate glycol circuit and lines to be connected

(blue and red). Cut glycol lines and secure to the

appropriate elbow or union connections that are

best suited for connection with the beer conduit.

FIGURE 10

Connecting beer conduit to the tower

Glycol lines in

1. Peel the insulation back from the end of the beer

conduit to expose all lines. Locate the appropriate

glycol circuit lines, cut to length and attach a 1/2"

John Guest union to each line (see Figure 11).

2. Attach the opposite end of each 1/2" John Guest

unions to the 1/2" adaptors located at the base of

the dispensing tower (see Figure 11).

21

Page 22

Installation and Service Manual

BEERMASTER BEER CONDUIT

INSTALLING THE CONDUIT KIT

FIGURE 11

Note: If conduit contains more than one glycol circuit it will be necessary to attach U-bends for each of the

additional circuits. Use a 1/2" U-bend quick connect fitting or the U-bend can be built by attaching two (2)

1/2" John Guest elbows to one another by means of a 2" length of 1/2" tubing.

BEER RESTRICTOR LINES

1. Cut each restrictor line to the calculated length and

carefully insert the 3/16" Barb x 1/2" John Guest

adaptor and clamp securely with the adjustable

clamps provided (see Figure 11).

2. Identify the beer line to be connected to each of

the appropriate restrictor line, cut the beer lines to

length and attach a 1/2" John Guest Union to each.

Neatly wrap the excess restrictor line securely

around the glycol supply lines to ensure good heat

exchange. Connect the adaptor from each restrictor

to the 1/2" connector of each of the appropriate

beer lines.

Connecting main beer conduit to branch beer conduit

1. At the required point of connection carefully split

open and fold back the insulation on the main beer

conduit and identify the correct set of glycol lines

(circuit) to connect to the branch beer conduit. Cut

the glycol line(s) and attach the appropriate 1/2"

elbow or union connections that are best suited to

connecting with the main beer conduit

(see Figure 12).

2. Peel the insulation back from the end of the branch

beer conduit to expose all lines. Locate the glycol

circuit lines, cut to length and insert each line into

the open end of the previously attached 1/2" con-

nectors at the main beer conduit (see Figure 12).

3. Locate the appropriate beer line(s) in the main beer

conduit to be connected to the branch conduit. Cut

desired beer line(s) long so that they can be pulled

back and then routed in a smooth curve into the

branch conduit. Attach appropriate beer line(s) from

main beer conduit to beer line(s) in branch beer

conduit with 1/2" John Guest Union(s).

Caution: To avoid agitation use only straight unions when

splicing beer lines.

22

FIGURE 12

Page 23

INDEX

B

Basement ................................ 18

beer cooler .............................. 18

Beer nuts................................. 19

branch ..................................... 22

brixing ....................................... 3

C

Carbon Dioxide ......................... 5

CAUTION ............................. 4, 6

chase ...................................... 16

Cleaning .................................... 3

CO2 ...................................... 4, 6

CO2 monitors ............................ 4

Conduit................ 16, 17, 18, 19

conduit chase .......................... 16

Conduit Kit ... 15, 19, 20, 21, 22

Connecting ................ 18, 19, 22

construction ............................ 18

cooler ...................................... 18

D

distributor .................................. 3

E

Elbows .................................... 19

Electrical Safety Codes ............. 6

F

Floor chases .................... 16, 17

FOREWORD ............................ 3

G

Glycol ...................................... 21

I

Information ................................ 5

INSPECTION ............................ 3

installation ............................... 17

Installation Date ........................ 3

Introduction ............................. 16

L

lines ......................................... 21

M

MBE .......................................... 3

Model Number .......................... 3

modifications ............................. 5

O

Operation .................................. 5

Overhead ................................ 17

P

Plumbing ................................... 6

PVC ......................................... 16

PVC tape ................................. 19

Q

Qualified Service Personnel ..... 5

R

restrictor line ........................... 22

Return bends .......................... 19

return procedures ..................... 3

S

SAFETY ........................... 5, 6, 7

sanitizing ................................... 7

Serial Number ........................... 3

Service Personnel ..................... 5

Spanner wrench ...................... 19

sweep ...................................... 16

T

Tail pieces ............................... 19

tower ....................................... 21

towers ..................................... 18

U

UNPACKING ............................. 3

W

walk-in .............................. 18, 21

WARNING ................................. 4

Warning ..................................... 5

WARRANTY INFORMATION ... 3

Page 24

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

EI211017 May 04, 2007 REV2

Loading...

Loading...