Page 1

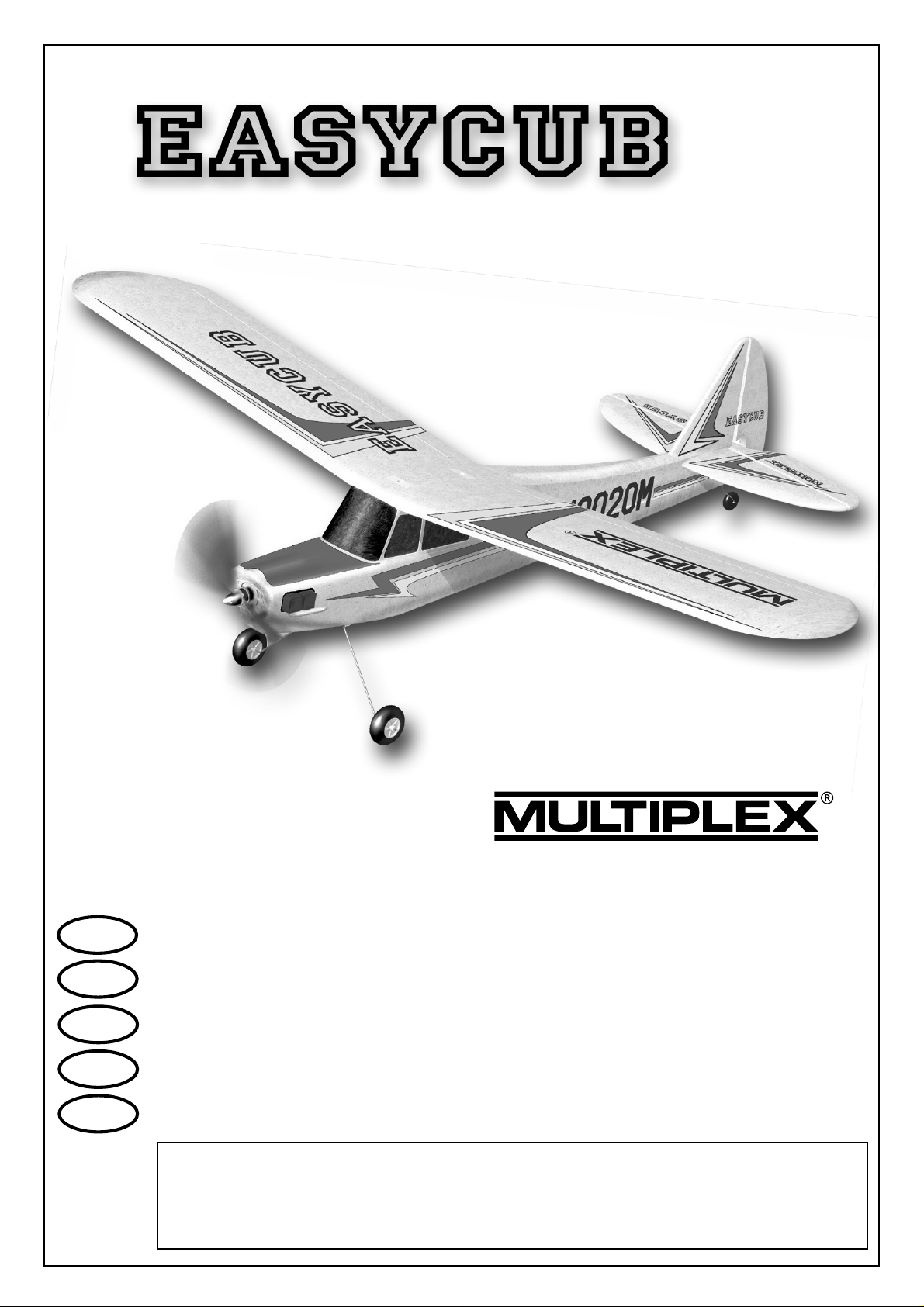

Baukasten / kit # 21 4235

D

F

GB

I

E

© Copyright by MULTIPLEX 2008 Version 1.0

Bauanleitung 3 ... 9

Notice de construction 10 ... 16

Building instr uctions 17 ... 27

Instruzioni di montaggio 28 ... 34

Instrucciones de montaje 35 ... 41

Ersatzteile

Replacement parts

Pièces de rechanges

Parti di ricambio

Repuestos

42 ... 43

1

Page 2

D

Sicherheitshinweise

Prüfen Sie vor jedem Start den festen Sitz des Motors und der Luf tschraube - insbesondere nach dem Transport, härteren Landungen

sowie Abstürzen. Prüfen Sie ebenfalls vor jedem S tart den festen Sitz und die richtige Position der T ragflächen auf dem Rumpf.

Akku erst einstecken, wenn Ihr Sender eingeschaltet ist und Sie sicher sind, daß das Bedienelement für die Motorsteuerung auf "AUS"

steht.

Im startbereiten Zustand nicht in den Bereich der Luftschraube greifen.

Vorsicht in der Luf tschraubendrehebene - auch Zuschauer zur Seite bitten!

Zwischen den Flügen die Motortemperatur durch vorsichtige Fingerprobe prüfen und

vor einem Neustart den Motor ausreichend abkühlen lassen. Die Temperatur ist richtig, wenn Sie den Motor problemlos berühren

können. Insbesondere bei hohen Außentemperaturen kann dieses bis zu 15 Minuten dauern.

Denken Sie immer daran: Niemals auf Personen und Tiere zufliegen.

F

Conseils de sécurité

Avant chaque décollage, vérifiez la fixation du moteur et de l'hélice, notamment après le transport, après les atterrissages violents et

après un “Crash”. Vérifiez également, avant chaque décollage la fixation ainsi que le positionnement de l’aile par rapport au fuselage.

Ne branchez l’accu de propulsion que si vous êtes sûr que votre émetteur est allumé et que l’élément de commande moteur est en

position “ARRET”.

Ne mettez pas vos doigts dans l’hélice! Attention à la mise en marche, demandez également aux spect ateurs de reculer.

Entre deux vols, vérifiez en posant un doigt dessus, la température du moteur, laissezle refroidir suffisamment avant le prochain

décollage. La température est correcte si vous pouvez maintenir votre doigt ou votre main sur le moteur. Le temps de refroidissement

peut varier jusqu’à 15 minutes s’il fait particulièrement chaud.

Pensez-y toujours: ne volez jamais vers ou au-dessus des personnes ou des animaux.

GB

E

Safety notes

Before every flight check that the motor and propeller are in place and secure - especially after transporting the model, and after hard

landings and crashes. Check also that the wing is correctly located and firmly secured on the fuselage before each flight.

Don’t plug in the battery until you have switched on the transmitter, and you are sure that the motor control on the transmitter is set to

“OFF”.

When the model is switched on, ready to fly , take care not to touch the propeller . Keep well clear of the propeller disc too, and ask

spectators to stay back.

Allow the motor to cool down after each flight. You can check this by carefully touching the motor case with your finger. The

temperature is correct when you can hold your finger on the case without any problem. On hot days this may take up to 15 minutes.

Please keep in mind at all times: don’t fly towards people or animals.

I

Note di sicurezza

Prima di ogni decollo controllare che il motore e la eliche siano fissati stabilmente - specialmente dopo il trasporto, atterraggi duri e se il

modello è precipitato. Controllare prima del decollo anche il fissaggio e la posizione corretta delle ali sulla fusoliera.

Collegare la batteria solo quando la radio è inserita ed il comando del motore è sicuramente in posizione ”SPENTO”.

Prima del decollo non avvicinarsi al campo di rotazione della eliche. Attenzione alla eliche in movimento - pregare che eventuali spettatori

si portino alla dovuta distanza di sicurezza!

Tra un volo e l’altro controllare cautamente con le dita la temperatura del motore e farli raffreddare sufficientemente prima di ogni nuovo

decollo. La temperatura è giusta se si possono toccare senza problemi. Specialmente con una temperatura esterna alta questo può

durare fino a 15 minuti.

Fare attenzione: Non volare mai nella direzione di persone ed animali.

Advertencias de seguridad

Compruebe antes de cada despegue que el motor y la hélice estén fuertemente sujetados, sobretodo después de haberlo transportado,

de aterrizajes más fuertes así como después de una caída. Compruebe igualmente antes de cada despegue que las alas estén bien

sujetas y bien colocadas en el fuselaje.

Conectar la batería, cuando la emisora esté encendida y Usted esté seguro que el elemento de mando para el motor esté en ”OFF”.

No meter la mano en la zona inmediata a la hélice cuando el avión esté a punto de despegar. ¡Cuidado con la zona de la hélice! ¡Pedir a

los espectadores que se aparten!

Entre los vuelos hay que comprobar cuidadosamente la temperatura del motor con el dedo y dejar que el motor se enfríe antes de volver

a despegar. La temperatura es correcta, si puede tocar el motor sin problemas. Sobretodo en el caso de temperaturas del ambiente muy

altas, esto puede tardar unos 15 minutos.

Recuerde: No volar nunca hacía personas o animales.

2

Page 3

GB

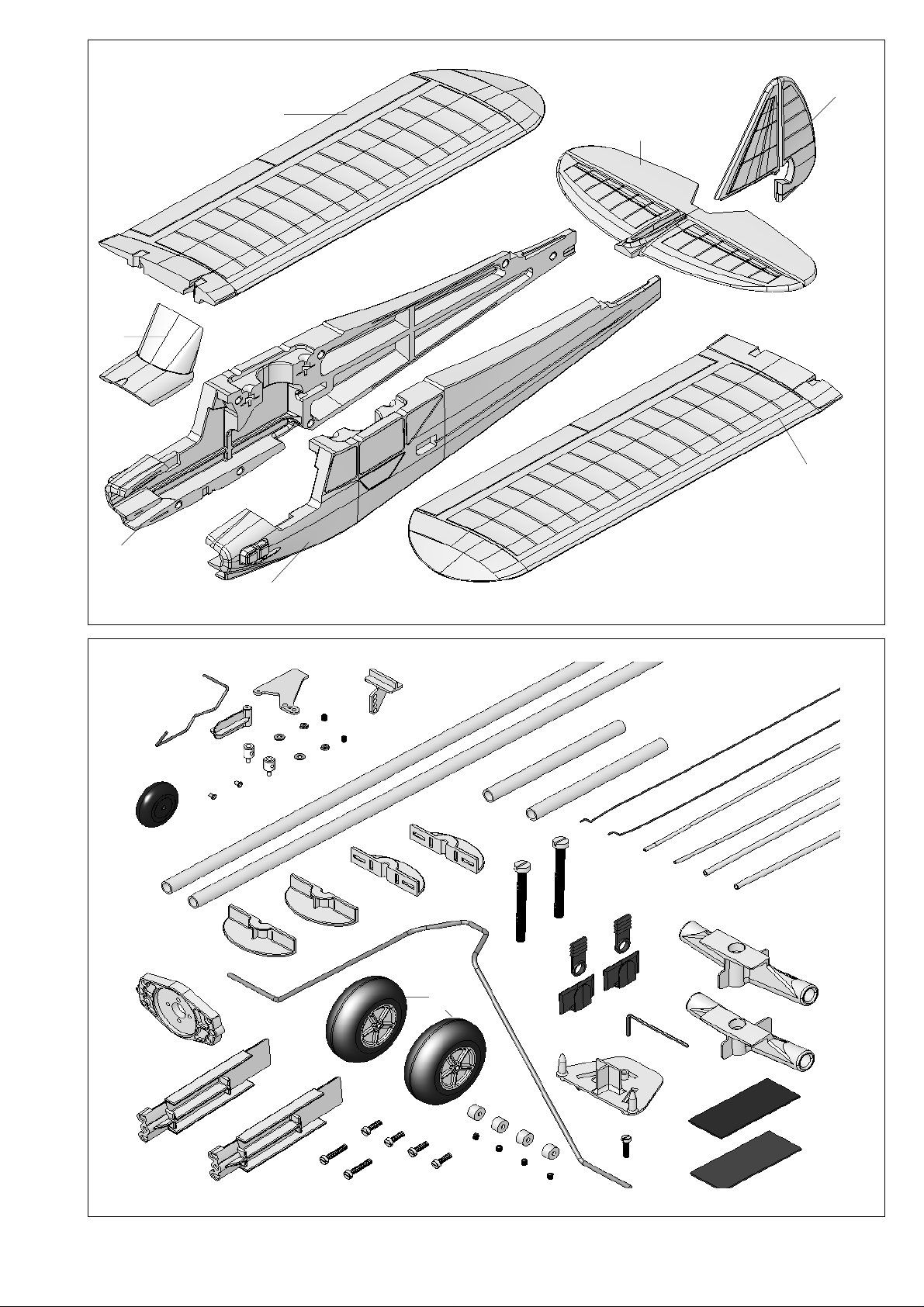

Examine your kit carefully!

MULTIPLEX model kit s are subject to const ant quality checks throughout the production process, and we sincerely hope that you

are completely satisfied with the contents of your kit. However, we do ask you to check all the parts (referring to the Parts List)

before you start construction, as we cannot exchange components which you have already modified. If you find any part is not

acceptable, we will readily correct or exchange it once we have examined it. Just send the component to our Model Department;

please be sure to include the purchase receipt and a brief description of the fault.

We are constantly working on improving our models, and for this reason we must reserve the right to change the kit contents in

terms of shape or dimensions of parts, technology, materials and fittings, without prior notification. Please understand that we

cannot entertain claims against us if the kit contents do not agree in every respect with the instructions and the illustrations.

Caution!

Radio-controlled models, and especially model aircraft, are by no means playthings. Building and operating them safely

requires a certain level of technical competence and manual skill, together with discipline and a responsible attitude at the

flying field. Errors and carelessness in building and flying the model can result in serious personal injury and damage to

property. Since we, as manufacturers, have no control over the construction, maintenance and operation of our product s,

we are obliged to take this opportunity to point out these hazards and to emphasise your personal responsibility .

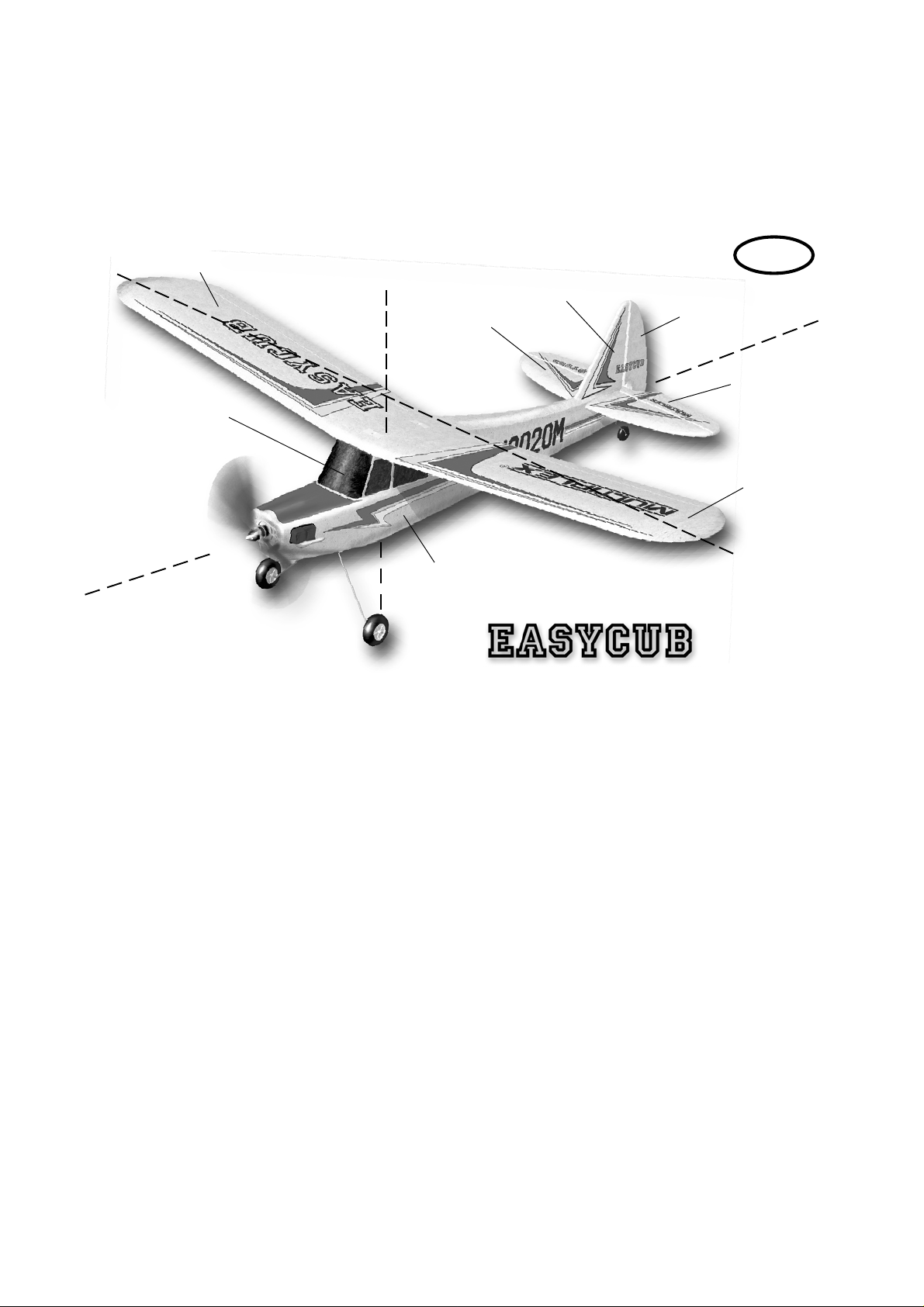

Additional items required for the EasyCub:

Airborne radio control components:

MULTIPLEX RX-7-Synth IPD receiver 35 MHz A band Order No. 5 5880

alternatively: 40 / 41 MHz band Order No. 5 5882

or MULTIPLEX RX-6-Synth light 35 MHz A / B-band Order No. 5 5876

2 x MULTIPLEX T iny S servo elevator, rudder Order No. 6 5121

or 2 x MULTIPLEX T iny MG servo elevator, rudder Order No. 6 5122

# 21 4235

Power set:

MULTIPLEX EasyCub power set Order No. 33 2637

Motor: Himax C 2816-1220; speed controller: BL 27 II; 10 x 5” propeller, propeller driver

Flight battery:

MULTIPLEX Li-Batt eco 2/1-2000 flight battery Order No. 15 7230

or MULTIPLEX Li-Batt BX 2/1-2100 flight battery Order No. 15 7130

Tools:

Scissors, balsa knife, combination pliers, screwdriver.

Specification:

Wingspan: 1400 mm

Fuselage length: 980 mm

All-up weight with Li-Batt BX 2/1-2100 approx.: 850 g

Wing area: 36.5 dm²

Wing loading (FAI) approx.: 23 g/dm²

RC functions: Rudder, elevator, throttle

Note: please remove the illustration pages from the centre of the instructions.

Important note

This model is not made of styrofoam™, and it is not possible to glue the material using white glue, polyurethane or

epoxy; these adhesives only produce a superficial bond which simply gives way when stressed. Please use mediumviscosity cyano-acrylate glue exclusively, preferably our Zacki-ELAPOR®, # 59 2727 - the cyano glue optimised

specifically for ELAPOR® particle foam.

If you use Zacki-ELAPOR® you will find that you do not need cyano kicker or activator for most joints. However, if you

wish to use a different adhesive, and are therefore obliged to use kicker / activator spray, we recommend that you

apply the material in the open air to avoid health problems.

Please take care when working with any type of cyano-acrylate (“cyano”, “CA”) adhesive, as they can cure in

seconds. Don’t allow the glue to contact your fingers or any other part of your body. Always wear goggles to protect

your eyes!

Keep out of the reach of children!

17

Page 4

1. Before assembling the model

Please check the contents of your kit before you start working

on it.

You will find Figs. 1 + 2 and the Parts List helpful here.

2. The fuselage

The first step is to glue the canopy latches 22 and the motor

mounts 37 to both fuselage shells.

Fig. 3

3. Installing the servos

Trial-fit the “rudder” and “elevator” servos in the fuselage shells

3 + 4, and secure them with a drop of glue at each mounting

lug. Fix the servo leads in place with paper masking tape so

that the leads and plugs cannot cause damage, and do not

get in the way when the fuselage shells are joined

subsequently.

Fig. 4

4. Control snakes

Prepare the snakes 54 / 56 and 55 / 57 as follows: cut the outer

and inner sleeves to length if necessary, and slip the steel

pushrods 52 / 53 into them. Connect the pre-formed end of the

pushrods to the servos, position the snakes carefully and glue

them to the fuselage. Note that the pre-formed pushrod ends

should be connected to the innermost holes in the servo output

levers. Lay the fuselage shells down flat when gluing the

snakes in place, otherwise there is a chance of distorting the

fuselage.

Figs. 4 - 6

5. Preparing the wing screw supports

Snap the wing screw support components 33 + 34 together

and glue the joints; use a pair of flat-nose pliers to join them if

necessary . Glue the prepared wing screw supports in the righthand fuselage shell as shown.

Fig. 7

6. Joining the fuselage shells

Join the fuselage shells 3 / 4 “dry” (without glue) initially, and

check that everything fits properly before gluing the shells

together permanently. Check that the fuselage is perfectly

straight before allowing the glue to set hard.

Fig. 7

end over at 90° as close to part 35 as possible, as shown in

Fig. 10.

Glue the rudder horn 35 in the rudder, but apply cyano to the

underside only. Allow the glue to set hard, then cut a slot about

1.5 mm deep for the tailwheel unit above the horn.

Wipe away excess adhesive if necessary. Position the wire

tailwheel unit 76 over the horn 35, align the parts and glue

them together using plenty of cyano. Allow the glue to cure,

then attach the swivel pushrod connector to the horn. Secure

the retaining nut with a drop of paint or glue. Fig. 11

Fit the tailwheel 77 on the axle: first push one metal wheel

retainer sleeve 78 on the wire, then the wheel, followed by the

second retainer sleeve. Secure each sleeve 78 with a drop of

cyano.

Fig. 12

10. Gluing the fin to the fuselage

Trial-fit the prepared fin in the slots in the fuselage and tailplane,

and glue it in place.

Fig. 13

11. Main undercarriage

Prepare the main undercarriage 70 as follows:

Fit socket-head grubscrews 73 in the four wheel collets 72,

and secure the wheels 71 on the undercarriage by fitting a

collet on each side of each wheel. Check that the wheels rotate

freely, then tighten the grubscrews. Fig. 15

The plastic undercarriage bracket 74 can now be installed in

the fuselage: first press it into position, then apply glue all

round it. Fig. 14

Allow the undercarriage 70 to snap into position in the bracket,

then fit the retainer screw 75 to secure it.

Fig. 15

12. The wings

The wing panels 6 / 7 should not be glued together!

Trial-fit the wing spars 50 / 51 and the spar holders 30 / 31 as

shown in the illustration.

7. Preparing the pushrod connector

Fit the swivel pushrod connector 25 for the elevator 8 in the

outer hole in the elevator horn 24, and secure it with the washer 26 and the nut 27. Caution: be sure to fit the connector on

the correct side of the horn (see illustration). Tighten the nut

carefully: the pushrod connector must swivel smoothly, but

without undue slop. Apply a tiny drop of cyano or paint to the

threads (on the point of a pin) to prevent the nut working loose.

Fit the socket-head grubscrew 28 on the allen key 29, and use

it to fit the screw loosely in the pushrod connector 25. Glue the

horn 24 in the elevator 8 with the row of holes facing forward.

Fig. 8

8. Gluing the tailplane to the fuselage

Place the tailplane on the fuselage and check that it can be

positioned and aligned correctly; carry out any minor trimming

required. Glue the tailplane to the fuselage and hold it in

position while the adhesive hardens.

Fig. 9

9. Fin and tailwheel

Fit the wire tailwheel unit 76 through the glue-fitting tailwheel

bush 36, then through the glue-fitting rudder horn 35. Bend the

18

Note: the front spar holder 30 is taller than the rear holder 31.

When you are sure that everything fits properly, glue the spars

50 / 51 and the spar holders 30 / 31 in the right-hand wing

panel only. Fig. 16

Now insert the second pair of spars in the free end of the spar

holders (do not use glue!). Slide the left wing onto the spars

and holders and check that they fit correctly. Apply glue to the

spar channel in the left wing and position it accurately on the

spars. Fig. 17

If you have done everything correctly, you will now be able to

part the wing panels in the centre once the glue has set hard.

13. Trial assembly

The wings are held on the fuselage using the plastic screws

32. The locating blocks moulded into the underside of the

wing prevents the wing slipping off the fuselage or out of

position.

Fig. 18

14. Power set:

The model is designed to be fitted with the MULTIPLEX

Page 5

EasyCub Power Set, Order No. 33 2637.

The set consists of a Himax C 2816-1220 motor, a BL 27/II

speed controller, a 10 x 5” propeller and a propeller driver.

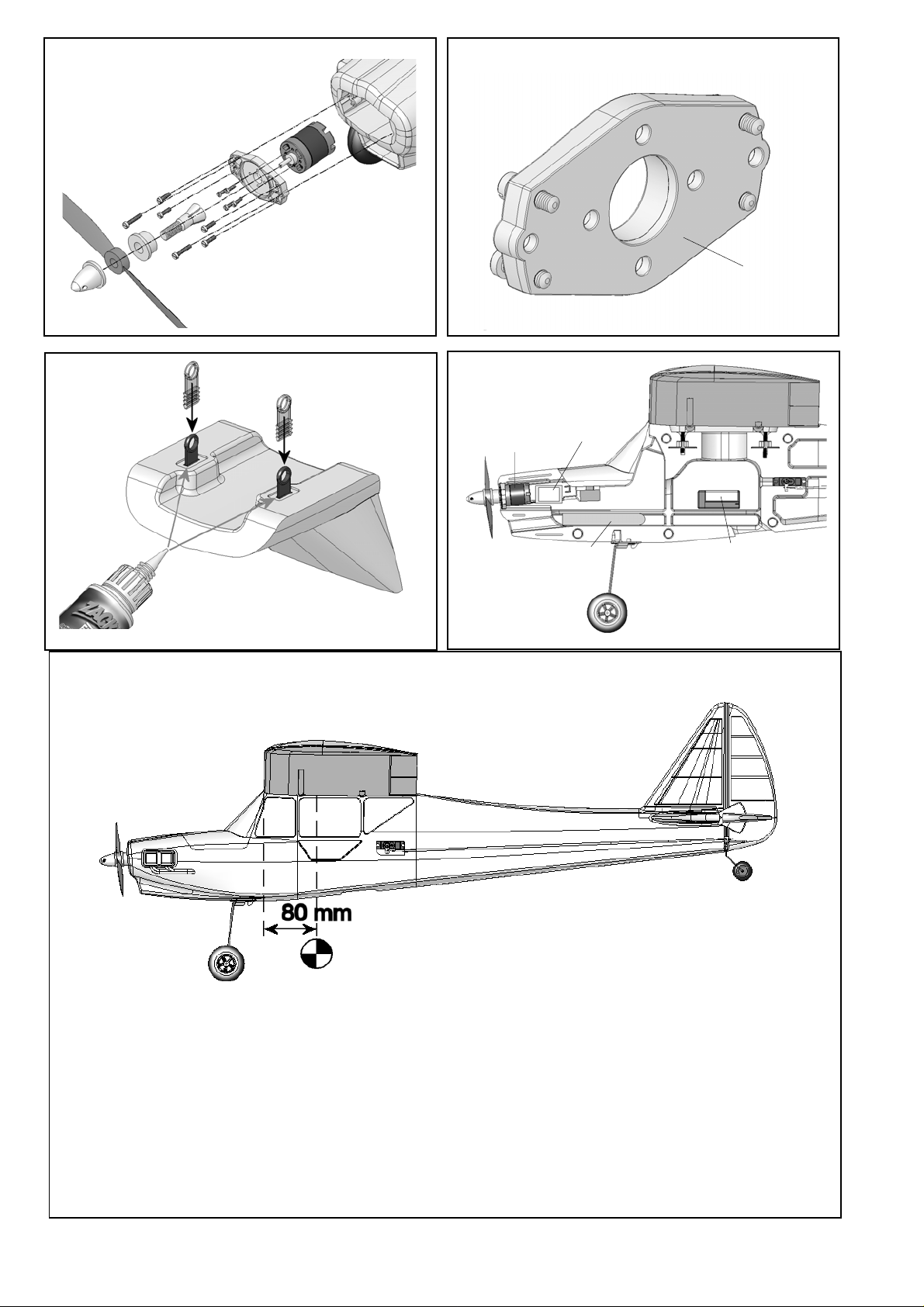

15. Attaching the motor bulkhead to the motor mount

The motor sidethrust and downthrust can be adjusted using

the motor mounts 37 and the motor bulkhead 38. Fitting the

four adjustor screws 39 flush installs the mount asymmetrically,

giving maximum sidethrust and no downthrust. The basic

position for the EasyCub is set as follows (note that we are

looking at the rear (!) of the motor bulkhead). Fig. 20

Upper left adjustor screw 1 mm = approx. two

turns

Upper right adjustor screw 1 mm = approx. two

turns

Lower left adjustor screw 1 mm = approx. two

turns

Lower right adjustor screw 1 mm = approx. two

turns

The screws should project by the values stated above. The

settings may require fine-tuning during the test-flying

programme.

16. Installing the motor

Attach the motor to the motor bulkhead 38 using the retaining

screws included in the power set. Install the motor as shown

in Fig. 19.

17. Installing the canopy latch tongues

The canopy 5 is first slid into the fuselage towards the wing,

and only then folded down at the front. Temporarily insert the

two latch tongues 23 in the canopy, and position them as

shown in the illustration. Apply high-viscosity (thick) cyano to

the textured surfaces, then fit the latch tongues into the slots in

the canopy. Place the canopy on the fuselage, and allow the

latch tongues to engage in the latches 22. Check immediately

that the canopy is correctly aligned with the fuselage. Wait for

about one minute, then carefully open the canopy again. If

necessary, apply more glue to the latch tongues to reinforce

the joints.

Fig. 21

the wrong direction, swap over any two of the motor connections

- never swap over the battery connections.

Caution: there is a serious risk of injury in the area around

the propeller!

19. Deploying the aerial on the underside of the fuselage

The wire receiver aerial should be routed through a hole in the

underside of the fuselage and deployed towards the tail.

You will need to pierce a hole in the fuselage from the outside

before threading the aerial through it from the inside. Tape the

aerial to the fuselage. If the aerial is longer than the fuselage,

simply allow the excess length to trail freely.

20. Setting the control surface travels

The control surface travels must be set correctly in order to

obtain a balanced control response from the model.

Elevator travels:

up (stick back towards you) 15 mm

down (stick away from you) 12 mm

Rudder travel to left and right: 15 mm each way

Note that the stated travels are measured at the widest point of

the control surface.

21. Gilding the lily - applying the decals

The kit is supplied with a multi-colour decal sheet 2. Cut out

the individual name placards and emblems and apply them to

the model in the position shown in the kit box illustration, or in

an arrangement which you find pleasing. The decals cannot

be re-positioned once applied, so place them carefully!

22. Balancing

Like any other aircraft, the EasyCub must be balanced at a

particular point in order to achieve stable flying characteristics.

Assemble your model ready to fly, and install the flight battery.

The Centre of Gravity (CG) should be at a position 80 mm aft

of the root leading edge, i.e. at the fuselage sides. Mark this

point on both sides of the fuselage.

18. Installing the flight battery and receiver

The space for the flight battery is under the canopy, extending

back under the wing saddle. The battery is held in place using

the Velcro tape 20 / 21.

The speed controller fits on the fuselage side on one side of

the battery. The receiver should be installed below the wing

saddle, again using the Velcro tape 20 / 21.

Fig. 22

If the controller is connected to the motor, do not connect

the battery to the speed controller without first switching

the transmitter on and ensuring that the throttle control is at

the “OFF” position.

Connect the servo leads to the receiver. Switch the transmitter

on, connect the flight battery (installed in the model) to the

speed controller, and connect the speed controller to the

receiver.

Now switch the motor on briefly by advancing the throttle stick,

and check that the propeller spins in the correct direction. When

test-running the motor be sure to hold the model securely, and

remove all loose, light objects before and behind the model

before the propeller does the job for you. If the motor rotates in

Support the model at this position on two fingertips, and it

should balance level. If not, you can move the flight battery

forward or aft to correct the balance point. Once the correct

position is found, mark the location of the flight pack inside the

model to ensure that it is always replaced in the same position.

The CG location is not critical - 10 mm forward or aft of the

stated position presents no problems.

Fig. 23

23. Preparing for the first flight

For the first flight wait for a day with as little breeze as possible.

The early evening is often a good time.

Be sure to carry out a range check before the first flight!

Just before the flight, charge up the transmitter battery and the

flight pack using the recommended procedures. Ensure that

“your” channel is not already in use

transmitter.

Ask your assistant to walk away from the model, holding the

transmitter. The transmitter aerial should be fitted but

completely collapsed.

Your assistant should operate one of the functions constantly

before you switch on the

19

Page 6

while you watch the servos. The non-controlled servo should

stay motionless up to a range of about 60 m, while the controlled

one should follow the stick movements smoothly and without

any delay. Please note that this check can only give reliable

results if the radio band is clear of interference, and if no other

radio control transmitters are in use - even on different channels.

If the range check is successful, repeat it with the motor running.

There should only be a very slight reduction in effective radio

range with the motor turning.

If you are not sure about anything, please don’t risk a flight.

Send the whole system (including battery, switch harness and

servos) to the Service Department of your RC system

manufacturer and ask them to check it.

fuselage level. Use the controls to hold the model in a steady,

gentle climb - remember to keep the rate of ascent shallow

and the airspeed high!

Allow the aeroplane to climb to a safe height, then adjust the

trims on the transmitter until it flies in a perfectly straight line

“hands off”.

While the model is still at a safe altitude, throttle back and try

out the controls on the glide. Carry out a “dry run” landing

approach at a safe height so that you are prepared for the real

landing when the battery runs flat.

Don’t try any tight turns at first, and especially not on the landing

approach at low altitude. It is always better to land safely at

some distance from you, than to force the model back to your

feet and risk a heavy landing.

The first flight ...

The EasyCub should always be launched exactly into any wind.

If you are a beginner to model flying we strongly recommend

that you ask an experienced model pilot to help you for the

first few flights.

24. T aking off from a hard strip

If you have access to a hard landing strip, a ground take-off is

the safest option.

Apply full up-elevator initially (to keep the tail down) and

accelerate gradually, using the rudder to keep the model on a

straight track.

Apply full-throttle to continue accelerating, gradually returning

the elevator stick to neutral. The tail will now rise; when the

model reaches flying speed apply gentle but deliberate upelevator to lift off. Allow the aeroplane to climb at a steady, fairly

shallow angle, taking care to keep the airspeed up!

From a closely mown grass strip a ground take-off works just

like on a hard strip, but the ground-roll will be longer. If you do

not have access to a runway of any kind, a hand-launch works

fine.

Caution: if your assistant is an experienced hand-launcher

then you can be confident of success; if not, watch out!

25. Hand-launching

Please don’t try unpowered test-glides with this model - the

result is invariably a damaged airframe. The EasyCub should

always be hand-launched with the motor running at full-throttle,

and always pointing directly into wind.

Ask an experienced modeller to hand-launch your aircraft for

you: he should run forward for two or three paces, then give the

machine a powerful straight launch, with the wings and

26. Safety

Safety is the First Commandment when flying any model

aircraft. Third party insurance should be considered a basic

essential. If you join a model club suitable cover will usually be

available through the organisation. It is your personal

responsibility to ensure that your insurance is adequate.

Make it your job to keep your models and your radio control

system in perfect order at all times. Check the correct charging

procedure for the batteries you are using. Make use of all sensible safety systems and precautions which are advised for

your system. An excellent source of practical accessories is

the MULTIPLEX main cat alogue, as our product s are designed

and manufactured exclusively by practising modellers for other

practising modellers.

Always fly with a responsible attitude. You may think that flying

low over other people’s heads is proof of your piloting skill;

others know better. The real expert does not need to prove

himself in such childish ways. Let other pilots know that this is

what you think too. Always fly in such a way that you do not

endanger yourself or others. Bear in mind that even the best

RC system in the world is subject to outside interference. No

matter how many years of accident-free flying you have under

your belt, you have no idea what will happen in the next minute.

We - the MULTIPLEX team - hope you have many hours of

pleasure building and flying your new model.

MULTIPLEX Modellsport GmbH & Co. KG

Product development and maintenance

20

Klaus Michler

Page 7

9

6

5

8

7

4

77

50

76

36

78

3

35

24

51

28

27

26

25

32

34

23

33

71

70

22

29

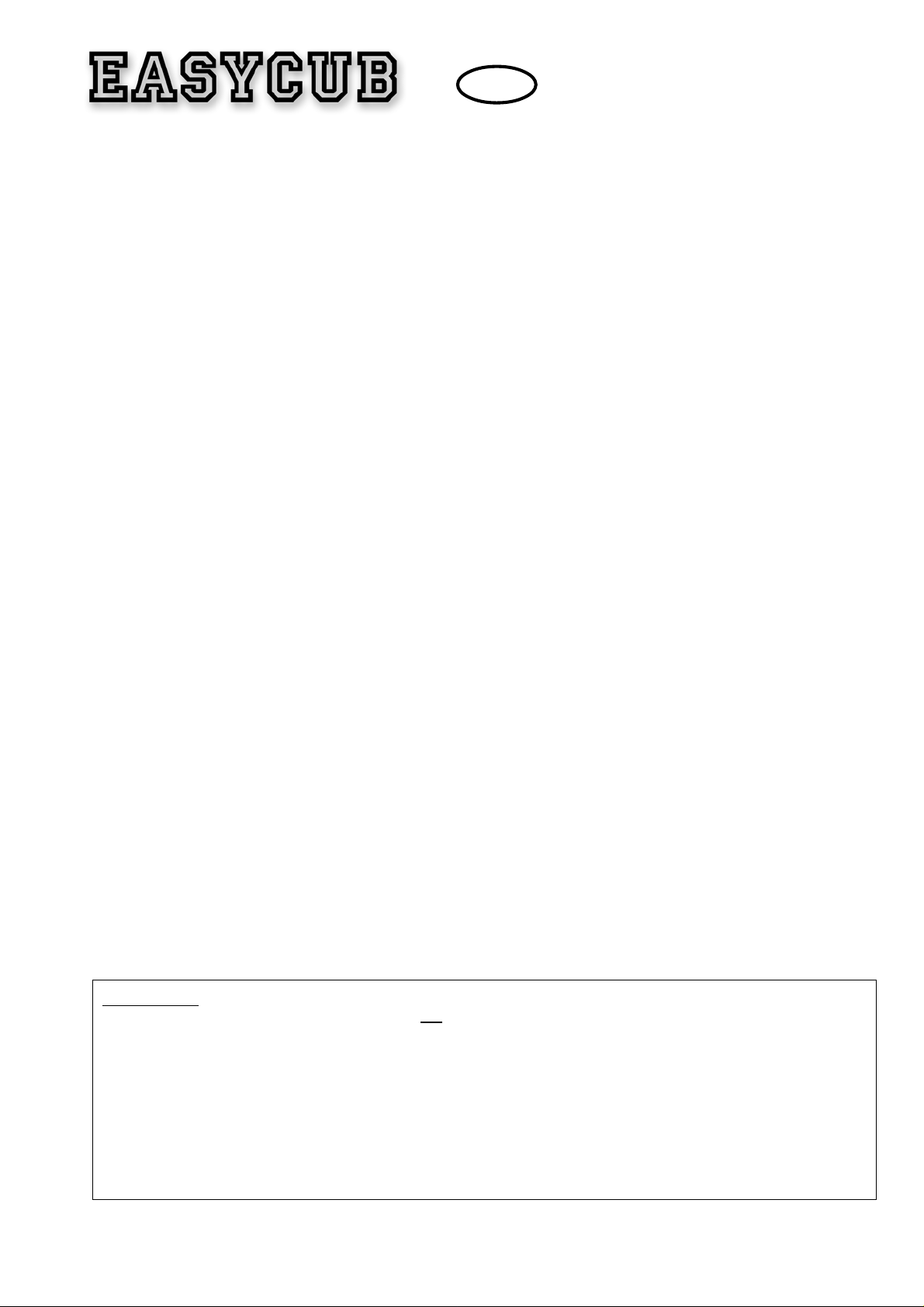

Abb. 1

52

53

56

57

54

55

30

38

37

2x 40

4x 39

4x72

4x73

75

74

31

3x 20

3x 21

Abb. 2

21

Page 8

22

4

54 56 52

37

Abb. 3

4

52

4

56

54

Abb. 4

3

53 57 55

2x 33/34

Abb. 5

4

3

27 26 24 25 28

Abb. 6

8

Abb. 7

Abb.8

8

22

4

35

36

3

Abb. 9

76

Abb.10

Page 9

4

28

25

35

36

78

78

26

27

76

Abb. 11

9

8

Abb. 13

77

74

3

4

76

Abb. 12

Abb. 14

72

71

Abb. 15

50

51

73

70

75

50

7

32

7

6

51

Abb. 16

30

31

Abb. 17

6

Abb. 18

23

Page 10

Antriebsatz / Powerset # 33 2637

38

23

Abb. 19

5

Abb. 21

Motor

ESC

Akku

Abb. 20

RX

Abb. 22

24

Abb. 23

Page 11

EasyCub Parts List

Part No. Description Material Dimensions

No. off

1 1 Building instructions Paper, 80 g/m² A4

2 1 Decal set Printed adhesive film 500 x 700 mm

3 1 L.H. fuselage shell Moulded Elapor foam Ready made

4 1 R.H. fuselage shell Moulded Elapor foam Ready made

5 1 Canopy Moulded Elapor foam Ready made

6 1 L.H. wing panel Moulded Elapor foam Ready made

7 1 R.H. wing panel Moulded Elapor foam Ready made

8 1 Tailplane Moulded Elapor foam Ready made

9 1 Fin Moulded Elapor foam Ready made

70 1 Main undercarriage unit Spring steel 2.5 mm Ø, ready made

Small items

20 3 Velcro tape, “mushroom” Plastic 25 x 60 mm

21 3 Velcro tape, “felt” Plastic 25 x 60 mm

22 2 Canopy latch Inj. moulded plastic Ready made

23 2 Canopy latch tongue Inj. moulded plastic Ready made

24 1 Glue-fitting control surface horn Inj. moulded plastic Ready made

25 2 Swivel pushrod connector Metal Ready made, 6 mm Ø

26 2 Washer Metal M2

27 2 Nut Metal M2

28 2 Socket-head grubscrew Metal M3 x 3 mm

29 1 Allen key Metal 1.5 mm A/F

30 1 Front spar holder, “tall” Inj. moulded plastic Ready made

31 1 Rear spar holder, “low”` Inj. moulded plastic Ready made

32 2 Screw Inj. moulded plastic M5 x 50 mm

33 2 Wing screw support, part A Inj. moulded plastic Ready made, M5

34 2 Wing screw support, part B Inj. moulded plastic Ready made, M5

35 1 Glue-fitting horn, tailskid Inj. moulded plastic Ready made

36 1 Glue-fitting tailskid bush Inj. moulded plastic Ready made

37 2 Motor mount Inj. moulded plastic Ready made

38 1 Motor bulkhead Inj. moulded plastic Ready made

39 4 Motor bulkhead adjustor screw Metal M3 x 10 mm

40 2 Motor bulkhead mounting screw Metal M3 x 16 mm

Wire and rod

50 2 Tubular wing spar GRP tube 8 Ø x 6 Ø x 400 mm

51 2 Tubular wing spar GRP tube 8 Ø x 6 Ø x 100 mm

52 2 Pre-formed elevator pushrod Metal 0.8 Ø x 510 mm

53 2 Pre-formed rudder pushrod Metal 0.8 Ø x 510 mm

54 1 Elevator snake outer sleeve Plastic 3 Ø x 2 Ø x 480 mm

55 1 Rudder snake outer sleeve Plastic 3 Ø x 2 Ø x 480 mm

56 1 Elevator snake inner sleeve Plastic 2 Ø x 1 Ø x 500 mm

57 1 Rudder snake inner sleeve Plastic 2 Ø x 1 Ø x 500 mm

Undercarriage set

71 2 Lightweight main wheel Plastic 53 Ø

72 4 Wheel collet Metal 2.7 Ø x 8 Ø x 5 mm

73 4 Socket-head grubscrew Metal M3 x 3 mm

74 1 Undercarriage bracket Plastic Ready made

75 1 Undercarriage retainer screw Metal M3 x 12 mm

76 1 Tailwheel unit Metal 1.3 mm Ø

77 1 Lightweight tailwheel Foam rubber 26 mm Ø

78 2 Tailwheel retainer sleeve Tubular rivet 2 Ø x 0.2 x 3 mm

25

Page 12

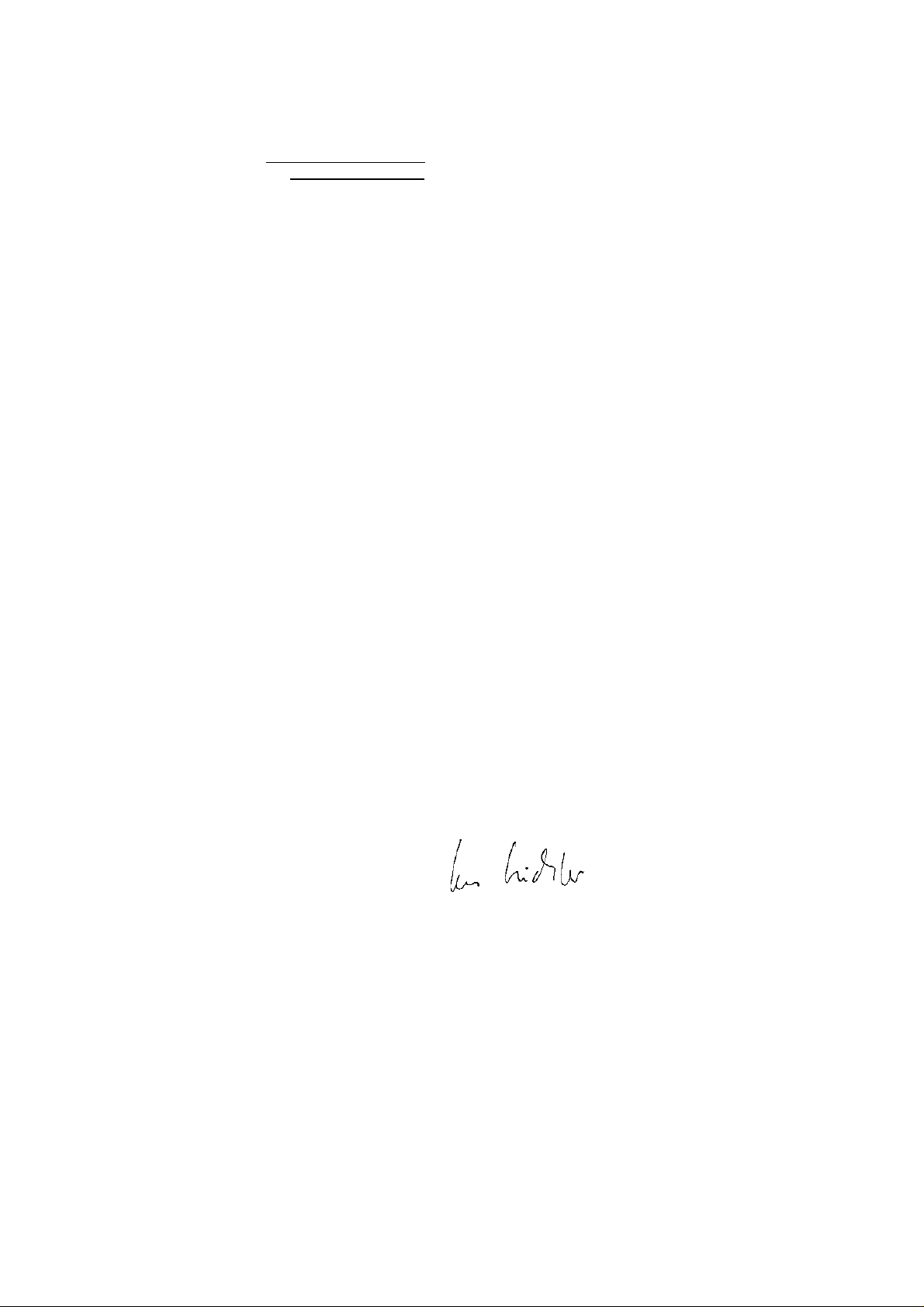

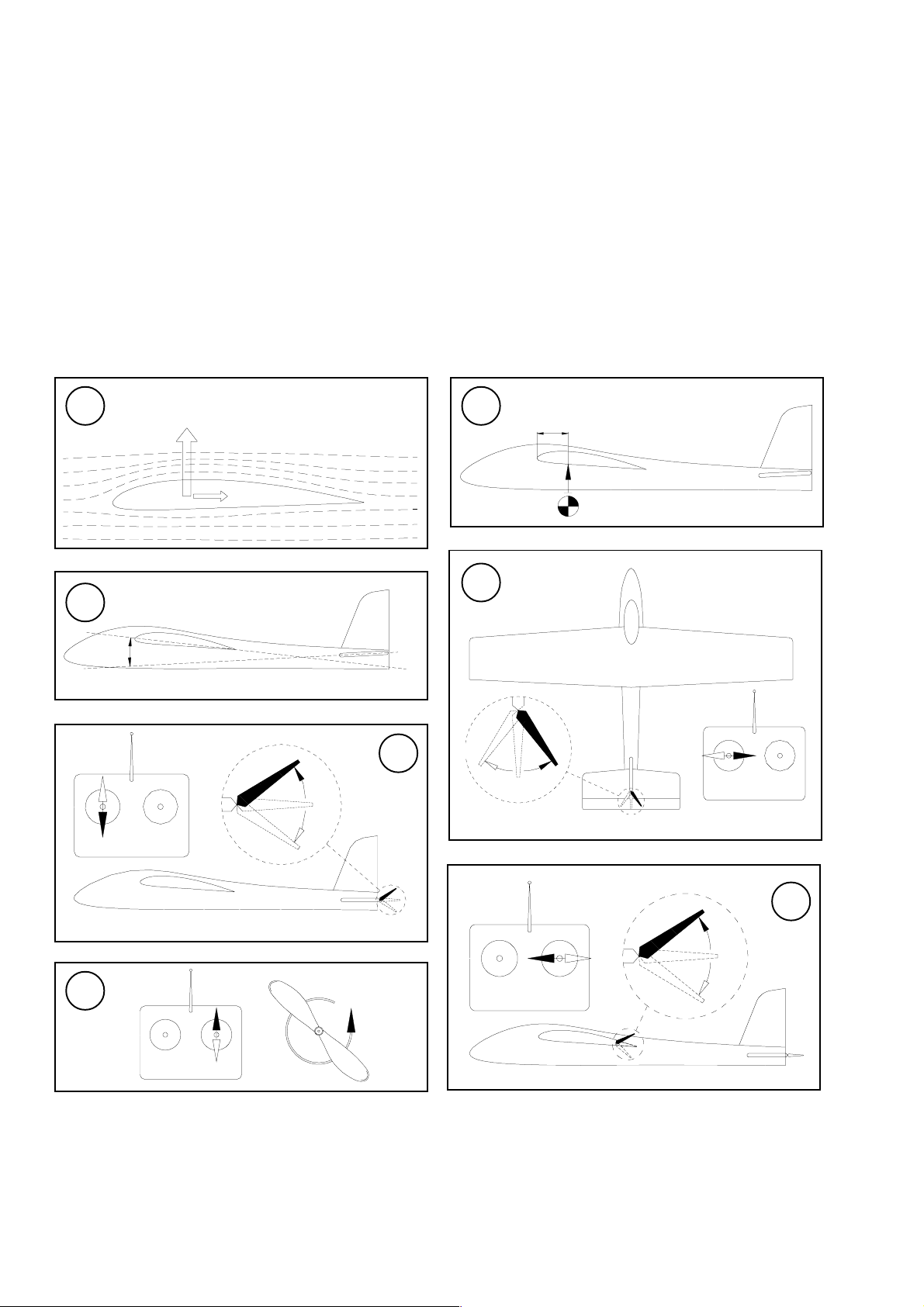

The basics of flying - using a model aircraft as an example

Any aircraft - full-size or model - can be controlled around three primary axes: the vertical (yaw) axis, the lateral (pitch) axis and the

longitudinal (roll) axis. Operating the elevator produces a change in the model’s flight attitude around the lateral axis (nose up

or down). External influences such as air turbulence constantly tend to divert the model from its intended flight path, and it is the

pilot’s job to control the model actively in such a way that it flies where he or she wants it to. The aircraft’s altitude is controlled

using the power system (motor and propeller). In our models the rotational speed of the propeller is usually controlled

proportionally by means of an electronic speed controller. Although applying up-elevator will make the model climb, it is important

to understand that it will also make it slow down, i.e. the aircraft will only continue to climb until its airspeed falls to the minimum

flying speed (stall speed). Opening the throttle (increasing power) will enable the model to continue climbing, i.e. the power of

the motor dictates the maximum climb angle.

Right wing

Vertical (yaw)

axis

Canopy

Longitudinal (roll)

axis

The wing section

The wing features a cambered cross-section (known as an

airfoil) which affects the air as it passes through it: within a

given space of time, the air flowing over the wing has to cover

a longer distance than the air flowing under the wing. This

generates a low-pressure area on the top surface of the wing

which tends to create lift, holding or raising the aircraft in the

air. Fig. A

The Centre of Gravity

If your Mentor is to fly safely and stably it must balance at the

correct point - just like every other aircraft. It is absolutely essential to set the correct CG (balance point) before you fly the

model for the first time.

The stated CG position is measured from the root leading

edge of the wing (on either side of the fuselage). Support the

model on your fingertips at these points, and it should balance

level. Even better: use the MPX CG gauge, # 69 3054. Fig. B

If necessary, adjust the position of the flight battery until this is

the case. If you still cannot set the balance point correctly, add

ballast (lead, plasticene, modelling clay) to the nose or tail to

correct it. If ballast is needed, fix it very securely. If the model is

tail-heavy, the ballast must be fixed in the fuselage nose. If it is

nose-heavy, the ballast is fixed at the tail end of the fuselage.

The longitudinal dihedral (difference between the wing and

tailplane incidence) is also important. Provided that you attach

the wing and tailplane to the fuselage exactly as described in

these instructions, this parameter will automatically be correct.

If both these settings - centre of gravity and longitudinal dihedral

- are correct, you will have no problems flying the model, and

the test-flying process will be straightforward. Fig. C

GB

Fin

Tailplane

Fuselage

Control surfaces, control surface travels

The model will only be able to offer safe, accurate flying

characteristics if the control surfaces move freely, deflect in the

correct directions, and move to the appropriate angles. The

control surface travels stated in the building instructions have

been established as a result of practical flight testing, and we

strongly recommend that you keep to them - at least initially.

You may wish to adjust them later to suit your style of flying,

and this is a straightforward procedure.

Transmitter control function arrangement s

The transmitter is fitted with two primary sticks which control

the servos in the model; the servos in turn move the control

surfaces. The arrangement of the control functions shown here

corresponds to Mode A, but other stick modes are possible.

The transmitter is used to operate the control surfaces as

follows:

The rudder (left / right) Fig. D

The elevator (up / down) Fig. E

The ailerons (left / right) Fig. F

The throttle (motor off / on) Fig. G

The throttle (motor control) stick must stay in the set position

by itself, i.e. it must not be self-centring. For this reason the

throttle stick is usually set up with a ratchet. If your transmitter

is not set up in this way, please read the operating instructions

supplied with the RC set to find out how to set up the throttle

ratchet.

Rudder

Elevator

Left wing

Lateral (pitch)

axis

26

Page 13

Grundlagen am Beispiel eines Flugmodells

Basic information relating to model aircraft

Bases du pilotage d’un modèle réduit

ozioni fondamentali

Principios básicos tomando como ejemplo un avión

A

C

Auftriebskraft

α

E

B

D

X

34

F

G

Page 14

Ersatzteile (bitte bei Ihrem Fachhändler bestellen)

Replacement parts (please order from your model shop)

Pièces de rechanges (S.V.P. à ne commander que chez votre revendeur)

Parti di ricambio (da ordinare presso il rivenditore)

Repuestos (por favor, diríjase a su distribuidor)

# 22 4139

Tragflächen

Wing panels

Ailes

Ali

Alas

# 22 4140

Leitwerkssatz

Tail set

Kit de stabilisateurs

Piani di coda

Kit de empenajes

# 22 4137

Rumpfhälften + Bowdenzüge

Fuselage shells + snakes

Moitié de fuselage + tringlerie

Semigusci fusoliera + bowden

Fuselaje + transmisiones bowden

# 22 4138

Kabinenhaube

Canopy

Verrière

Capottina

Cabina

42

Page 15

Ersatzteile (bitte bei Ihrem Fachhändler bestellen)

Replacement parts (please order from your model shop)

Pièces de rechanges (S.V.P. à ne commander que chez votre revendeur)

Parti di ricambio (da ordinare presso il rivenditore)

Repuestos (por favor, diríjase a su distribuidor)

# 72 3130

CFK Holmrohr

CFRP Wing joiner

Tube en fibre de carbo

tubo carbonio

Tubo Fibra de vidrio

# 72 4519

Dekorbogen

Decal sheet

Planche de décoration

Decals

Lámina decorativa

# 22 4141

Kleinteilesatz

Small items set

Petit nécessaire

Minuteria

Piezas pequeñas

# 22 4142

Hauptfahrwerk

Main undercarriage

Train d’atterrissage principal

carrello principale

Tren principal

43

Page 16

MUL TIPLEX Modellsport GmbH & Co.KG Westliche Gewerbestrasse1 D-75015 Bretten-Gölshausen www .multiplex-rc.de

44

Loading...

Loading...