Page 1

ICE MACHINE

SERVICE MANUAL

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

5005979 07-20-07 REV 0

Page 2

Installation and Service Manual

FOREWORD

Manitowoc Beverage Equipment (MBE) developed this manual as a reference guide for the owner/

operator , service agent, and installer of this equipment. Please read this manual before installation

or operation of the machine. A qualified service technician should perform installation and startup of this equipment, consult the Troubleshooting Guide within this manual for service assistance.

If you cannot correct the service problem, call your MBE Service Agent or Distributor. Always have your model and

serial number available when you call.

Your Service Agent___________________________________________________________________

Service Agent Telephone Number ______________________________________________________

Your Local MBE Distributor ___________________________________________________________

Distributor Telephone Number _________________________________________________________

Model Number ______________________________________________________________________

Serial Number _______________________________________________________________________

Installation Date _____________________________________________________________________

UNPACKING AND INSPECTION

Note: The unit was thoroughly inspected before leaving the factory. Any damage or irregularities should

be noted at the time of delivery.

WARRANTY INFORMATION

Consult your local MBE Distributor for terms and conditions of your warranty. Your warranty specifically

excludes all beverage valve brixing, general adjustments, cleaning, accessories and related servicing.

Your warranty card must be returned to Manitowoc Beverage Equipment to activate the warranty on this

equipment. If a warranty card is not returned, the warranty period can begin when the equipment leaves

the MBE factory .

No equipment may be returned to Manitowoc Beverage Equipment without a written Return Materials

Authorization (RMA). Equipment returned without an RMA will be refused at MBE’ s dock and returned to

the sender at the sender’s expense.

Please contact your local MBE distributor for return procedures.

3

Page 3

Installation and Service Manual

FOREWORD ........................................................................................................ 3

UNP ACKING AND INSPECTION......................................................................... 3

WARRANTY INFORMATION ............................................................................... 3

SAFETY ...............................................................................................................6

IMPORT ANT SAFETY INSTRUCTIONS ........................................................................... 6

CARBON DIOXIDE WARNING......................................................................................... 6

QUALIFIED SERVICE PERSONNEL................................................................................ 6

SHIPPING, STORAGE, AND RELOCATION ..................................................................... 6

ADDITIONAL WARNINGS................................................................................................ 6

GROUNDING INSTRUCTIONS ........................................................................................ 7

WARRANTY INFORMATION...............................................................................8

SERVEND MODEL NUMBERING SYSTEM ..................................................................... 8

SERVEND INTERNATIONAL SERVICE POLICY AND PROCEDURE.............................. 9

INSTALLATION.................................................................................................. 10

ICE MACHINE INSTALLATION INSTRUCTIONS ........................................................... 10

TABLE OF CONTENTS

SIPHON VENT.................................................................................................................11

DUMP VALVE................................................................................................................. 12

ADJUSTING PROPER WATER LEVEL .......................................................................... 15

WATER CURTAIN ADJUSTMENT.................................................................................. 18

ST ACKING KITS............................................................................................................. 19

ICE MAKER CLEANING PROCEDURE ......................................................................... 20

REMOTE CONDENSER INSTALLATION INSTRUCTIONS ............................................ 21

REMOTE CONDENSER INSTALLATION GUIDELINES...................................22

REMOTE CONDENSERS MAXIMUM LOCA TION DISTANCE ....................................... 22

COMPONENT DIAGNOSTICS .......................................................................... 23

DECISION TREE BEFORE REPLACING A THERMIST OR ............................................ 25

DIAGNOSIS OF SERVEND CUBER THERMISTOR ....................................................... 26

FLOWCHART................................................................................................................. 27

SAFETY THERMO-DISC / F AN CYCLE CONTROL ....................................................... 29

HEAD PRESSURE CONTROL VALVE ........................................................................... 30

HOT GAS V ALVE / COMPRESSOR CONTACTOR / CHECK PROCEDURE.................. 31

COMPRESSOR AND STARTING COMPONENTS CHECK OUT PROCEDURE ............ 32

TOTAL ICE CAPACITY / ICE PRODUCTION CHECK..................................................... 33

4

Page 4

Installation and Service Manual

TABLE OF CONTENTS

3 RELAY CIRCUIT BOARD SEQUENCE OF OPERATION /

ADJUSTING BRIDGE THICKNESS / 3 RELAY CIRCUIT BOARD.................................. 36

3 RELAY CIRCUIT BOARD PROXIMITY SWITCH CHECK PROCEDURE..................... 37

PROXIMITY SWITCH VOLTAGE CHECK....................................................................... 38

4 RELAY CIRCUIT BOARD SEQUENCE OF OPERATION ............................................ 39

ADJUSTING BRIDGE THICKNESS................................................................................ 42

HALL SWITCH CHECK PROCEDURE 4 RELAY CIRCUIT BOARD............................... 43

TROUBLESHOOTING ....................................................................................... 44

PROBLEM ANALYSIS GUIDE - 3 RELAY BOARD......................................................... 44

EV ACUA TION AND CHARGING ....................................................................... 50

SYSTEM EVACUATION AND CHARGING / ALL REMOTE SYSTEMS DISCHARGE,

EVACUATION & RECHARGING PROCEDURES........................................................... 50

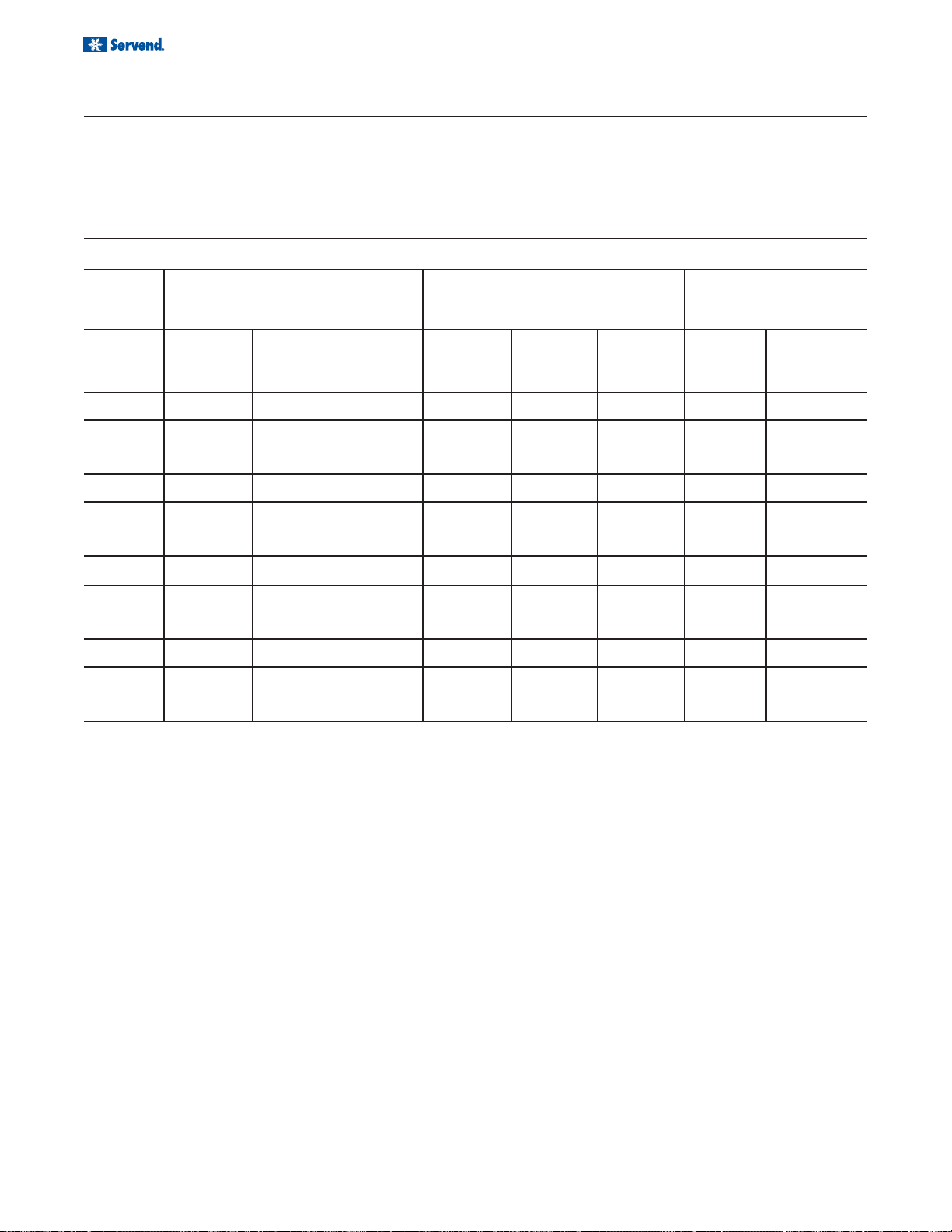

OPERATING SPECS AND CHARACTERISTICS.............................................. 52

DATA PER ARI STANDARDS......................................................................................... 52

AIR MODEL SPECIFICATIONS ...................................................................................... 53

WATER MODEL SPECIFICATIONS................................................................................ 55

REMOTE MODEL SPECIFICATIONS ............................................................................. 57

COMPRESSOR SPECIFICATIONS ................................................................................ 58

AVERAGE OPERATING CHARCTERISTICS ................................................................. 61

WIRING DIAGRAMS.......................................................................................... 71

INDEX.................................................................................................................83

5

Page 5

Installation and Service Manual

SAFETY

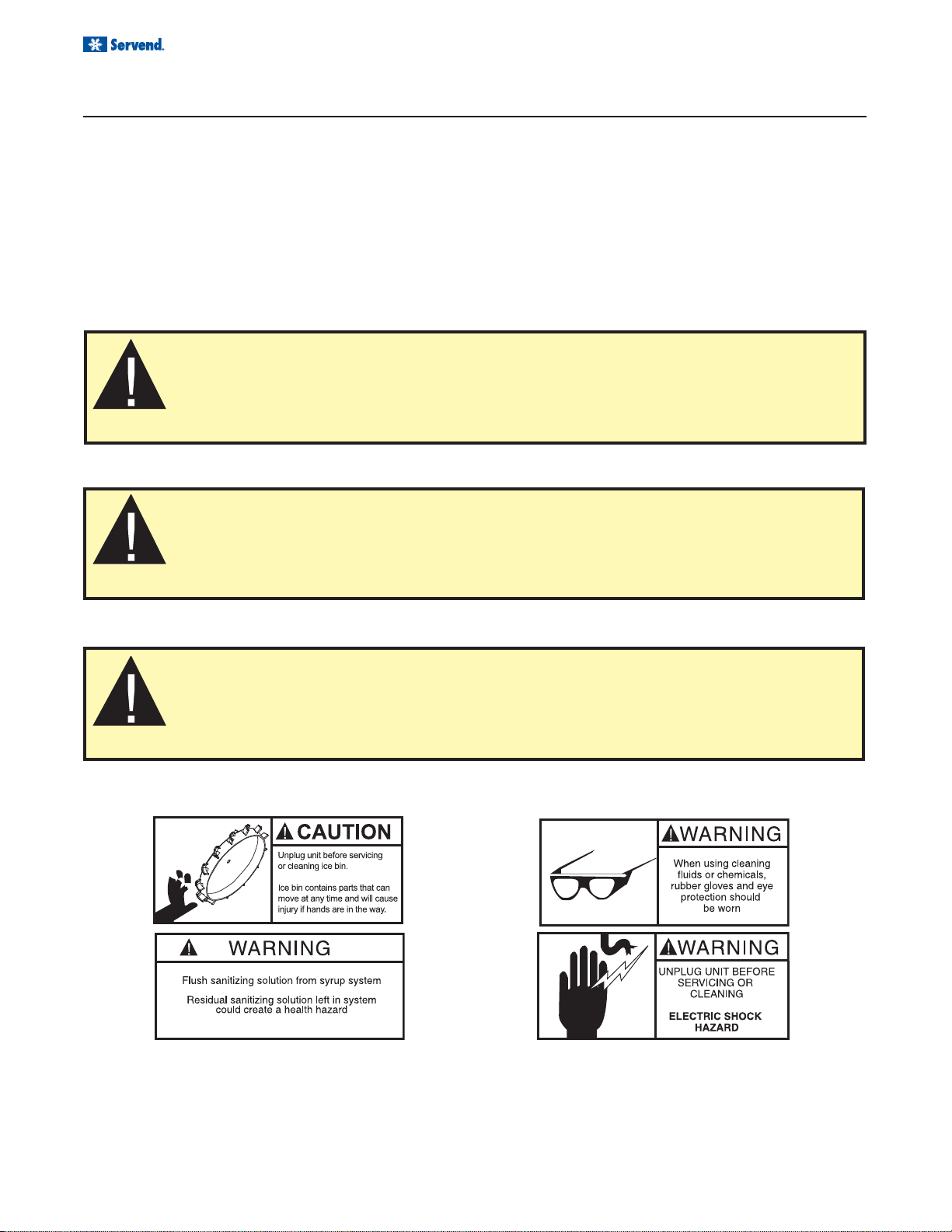

IMPORTANT SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual. Learn how to operate the SV unit properly . Do

not allow anyone to operate the unit without proper training and keep it in proper working condition. Unauthorized modifications to the SV may impair function and/or safety and affect the life of

the unit.

CARBON DIOXIDE WARNING

DANGER: Carbon Dioxide (CO2) displaces oxygen. Exposure to a high concentration of CO2 gas

causes tremors, which are followed rapidly by loss of consciousness and suffocation. If a CO2 gas leak

is suspected, particularly in a small area, immediately ventilate the area before repairing the leak. CO

lines and pumps should not be installed in an enclosed space. An enclosed space can be a cooler or

small room or closet. This may include convenience stores with glass door self serve coolers. If you

suspect CO2 may build up in an area, venting of the B-I-B pumps and / or CO2 monitors should be utilized.

QUALIFIED SERVICE PERSONNEL

WARNING: Only trained and certified electrical and plumbing technicians should service this unit.

All wiring and plumbing must conform to national and local codes.

2

SHIPPING, STORAGE, AND RELOCATION

CAUTION: Before shipping, storing, or relocating this unit, syrup systems must be sanitized. After

sanitizing, all liquids (sanitizing solution and water) must be purged from the unit. A freezing environment causes residual sanitizing solution or water remaining inside the unit to freeze, resulting

in damage to internal components.

ADDITIONAL WARNINGS

Installation and start-up of this equipment should be done by a qualified service technician. Operation,

maintenance, and cleaning information in this manual are provided for the user/operator of the equipment.

Save these instructions.

6

Page 6

Installation and Service Manual

SAFETY

GROUNDING INSTRUCTIONS

WARNING: Risk of electrical shock. Connect to a properly grounded outlet only.

This appliance must be grounded. In the event of malfunction or breakdown, grounding provides

a path of least resistance for electric current to reduce the risk of electric shock. This appliance is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER – Improper connection of the equipment-grounding conductor can result in a risk of

electric shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment grounding conductor. If rep air or replacement of the cord or plug

is necessary , do not connect the equipment-grounding conductor to a live terminal. Check with a

qualified electrician or serviceman if the grounding instructions are not completely understood, or

if in doubt as to whether the appliance is properly grounded. Do not modify the plug provided with

the appliance – if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

WARNING – When using electric appliances, basic precautions should always be followed, including the following:

a)Read all the instructions before using the appliance.

b)To reduce he risk of injury, close supervision is necessary when an appliance is used

near children.

c)Do not contact moving parts.

d)Only use attachments recommended or sold by the manufacturer.

e)Do not use outdoors.

f) For a cord-connected appliance, the following shall be included:

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Unplug from outlet when not in use and before servicing or cleaning.

• Do not operate any appliance with a damaged cord or plug, or after the appliance

malfunctions or is dropped or damaged in any manner. Return appliance to the

nearest authorized service facility for examination, repair , or electrical or mechanical

adjustment.

g)For a permanently connected appliance – Turn the power switch to the of f position when

the appliance is not in use and before servicing or cleaning.

h)For an appliance with a replaceable lamp – always unplug before replacing the lamp.

Replace the bulb with the same type.

i) For a grounded appliance – Connect to a properly grounded outlet only . See Grounding

Instructions.

SAVE THESE INSTRUCTIONS

7

Page 7

Installation and Service Manual

Example:

MODEL- C 7 - A M A S - A A

(1) (2) (3) (4) (5) (6) (7) (8)

(1) Series of the machine

C = 30" or 48" wide cuber

S = 22" wide cuber

B = Ice Storage Bin

(2) Nominal Capacity per twenty four hours in one hundred pounds

I.E. 7 = Seven Hundred Pounds

(3) Type of Condenser

A = Air Cooled

W = Water Cooled

R = Remote Cooled

(4) Size of Cube

M = Mini Cube (3/8" x 7/8" x 7/8")

F = Full Cube (7/8" x 7/8" x 7/8")

J = Jumbo Cube (7/8" x 7/8" x 1 1/2")

WARRANTY INFORMATION

SERVEND MODEL NUMBERING SYSTEM

(5) Electric Code

Volts Cycle Phase

A = 208/230; 200 60; 50 1

B = 115 60 1

C = 208/230; 200 60; 50 1

D = 220/240 50 1

F = 208/230 60 1

G = 208/230 60 3

H = 220/240 50 3

(6) S = Stainless Steel Panels

(Blank) = Painted Panels

P = Painted Panels

(7) Generation Code

A, B, C, etc.....

(8) Unit Configuration

A = Standard Machine

Any Other Letter = Special Machine, call factory for parts or service information.

8

Page 8

Installation and Service Manual

SAMPLE:

91 H F 01 0001

Year Month Product Major Change Unit

Manufactured Manufactured Code Code S/N

WARRANTY INFORMATION

SERVEND INTERNATIONAL SERVICE POLICY AND PROCEDURE

DATE ISSUED: AUGUST 12, 1991

DATE EFFECTIVE: AUGUST 12, 1991

NEW SERIAL NUMBER FORMAT

DATE REVISED: MAY 1, 1993

Effective AUGUST 12.1991 all Servend dispensers, cubers and bins manufactured by Servend International will

have new serial number format.

The above serial number is defined as:

Hotel dispenser built in August, 1991 1st unit built under major code #1

Month Manufactured: Product Code:

January A A = K Series (obsolete)

February B B = KD Series (obsolete)

March C C = M Series

April D D = MD Series

May E E = B Series

June F F = H Series

July G G = Cubers

August H H = Bins

September J J = Drop-ins

October K 7 = Remote Condensers

November L

December M

** Alphabet codes will not use the letter "I" to prevent confusion with the number "1".

** Unit serial number will roll back to 0001 at the beginning of each new year and/or with each major

change code.

MAJOR CHANGE CODE IS AN ENGINEERING TRACKING CODE FOR SERVEND USE.

9

Page 9

Installation and Service Manual

INSTALLATION

ICE MACHINE INSTALLATION INSTRUCTIONS

Freight Claim Loss or Damage:

1. The delivery freight company, distributor or

dealer is responsible for loss or damage to your merchandise. All claims must be filed with the p arty that delivers your merchandise.

2. Check the number of containers delivered

against the number shown on your receipt. If the total is

not correct, have the driver note the shortage on your

receipt.

3. Check all cartons for visible damage, open and

check the contents of any carton in question before the

driver leaves. Be sure the driver notes the type and degree fo damage on your receipt. All damaged merchandise must be inspected within 15 days of delivery , notify

your carrier immediately.

4. If concealed damage is found when merchandise in unpacked, place the packing material with the

merchandise and request an inspection from the delivering carrier.

5. File your claims for loss or damage at once.

Delays in filing will only hinder achieving a satisfactory

resolution to your claim.

Installation:

We recommend that installation and start-up be performed by the Dealer Professionals where your ice maker

was purchased.

Your ice maker will perform at optimum efficiency in

a approximate 70

ter. Increased air or water temperatures will decrease

performance. Never operate your machine in rooms with

temperatures below 50oF (10oC) or above 100oF (38oC).

If the ice maker is located in an unheated area, it

must be protected from freezing temperatures or shut

down and winterized.

Set-up of the Storage Bin and Cuber:

1. Remove the bin from the shipping carton. Using

the carton for protection against scratching, place the

bin on its back.

2. Screw the bin legs (enclosed inside the bin) into

the bottom of the ice bin.

3. Place the bin upright in the permanent position.

4. Remove the carton from the ice maker and place

the ice maker on the bin. Align the ice maker with the bin

back. Install stabilizing bolts through the lower front channel of the ice maker and into the header plate of the bin.

These bolts are packed in the plastic bag located in the

water pan of the ice maker.

5. Remove the ice maker internal packing. Level

the ice maker with a torpedo level on the face of the

evaporator. The evaporator MUST be plumb vertically

and level horizontally left to right. Level the machine by

screwing the feet of the bin either up or down.

o

F (21.1oC) room with 50oF (10oC) wa-

Location:

For best performance, select a location away from

all heat sources, such as radiators, ovens, refrigeration

equipment, direct sunlight, etc.

Avoid placing air cooled models in kitchens whenever possible as grease, flour or other airborn particles

will collect on the condenser and fan blade, requiring

increased preventative maintenance and will reduce efficiency.

Discuss the best location with your Dealer Professional. Allow a minimum of 6" (15.24cm) clearance

around the ice maker for air circulation (both sides, top,

and black). Restricted air circulation will affect the maintenance-free life or your ice maker and its effeciency.

10

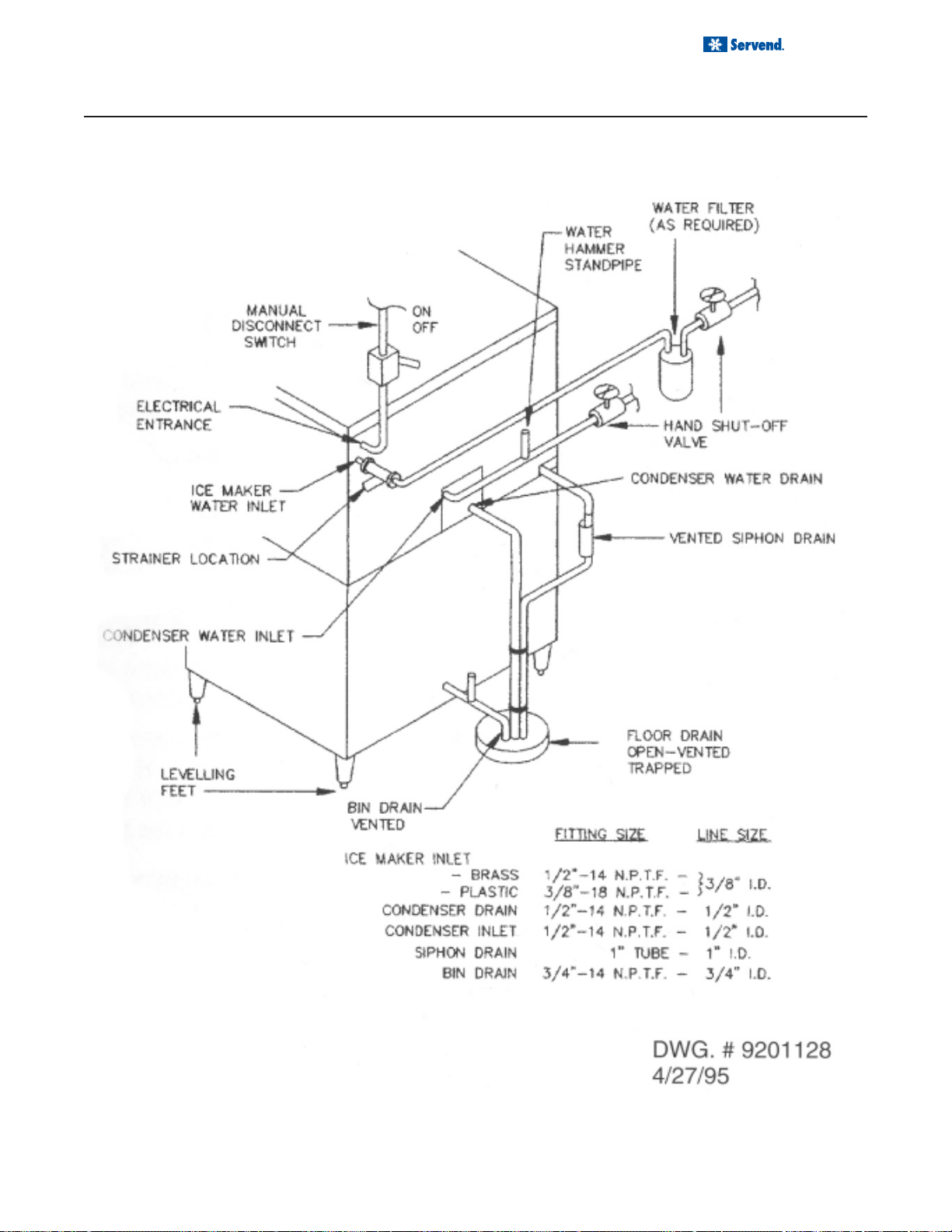

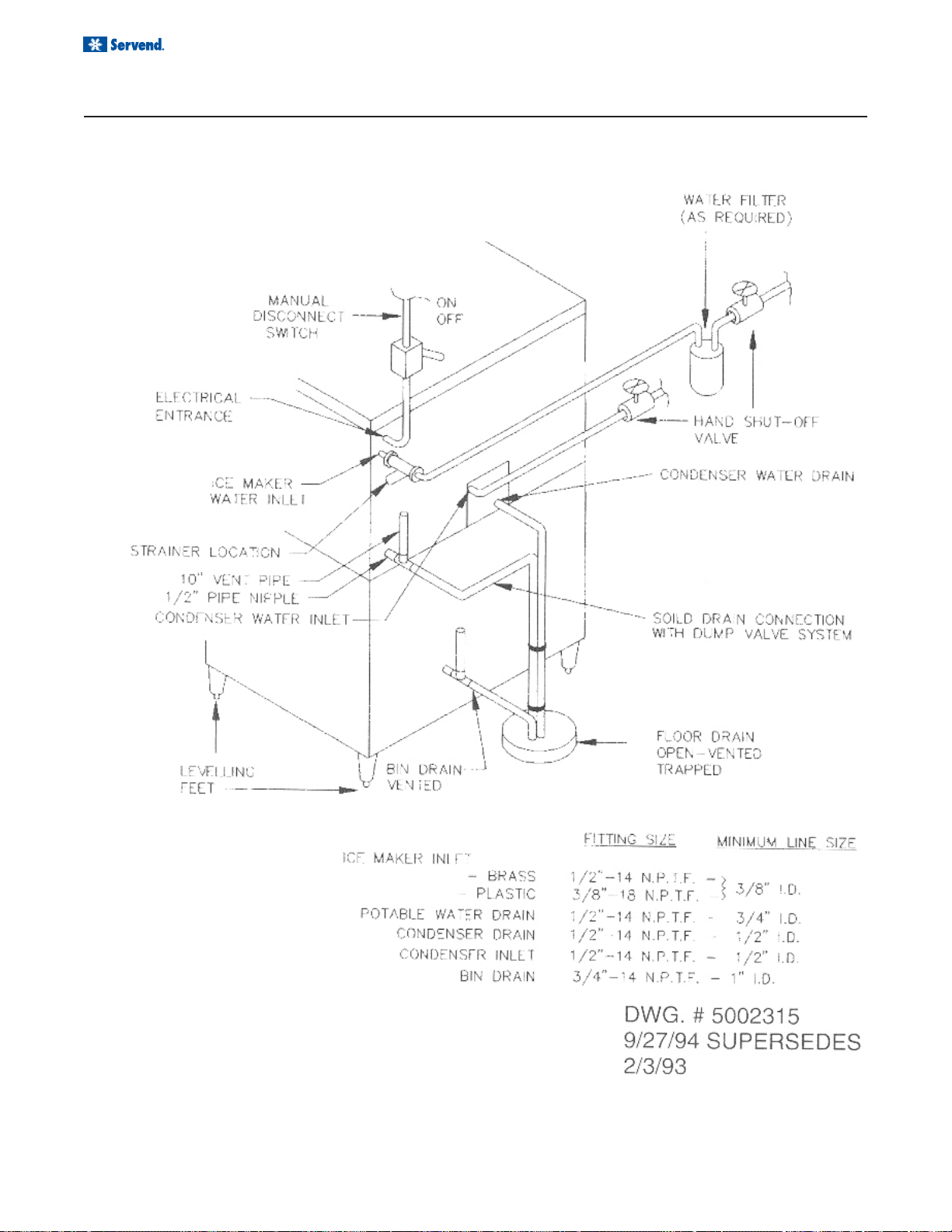

Plumbing Lines and Connections:

All plumbing (water and drain) connnections must

conform to local and national codes.

To prevent condensation, insulate all water supply

and drain lines. Insulating water lines will increase efficiency as well.

Page 10

INSTALLATION

SIPHON VENT

Installation and Service Manual

11

Page 11

Installation and Service Manual

INSTALLATION

DUMP VALVE

12

Page 12

INSTALLATION

Installation and Service Manual

Shut off valves should be loacted in the water supply lines for ice maker and condenser (water cooled

units). The water inlet strainer must be installed in the

ice maker water supply (see diagram on water curtain

and/or rear of machine). Water supply to water cooled

condensers should include a standpipe for the prevention of "water hammer".

It may be necessary to connect water supply to a

water treatment system. Consult your local Servend

Dealer or Distributor for proper size required. Water treatment may pay for itself through reduced maintenance,

higher efficiency, quality of ice, and longer equipment

life.

NOTE: Water cooled unit s connected to recirculation systems or cooling towers etc., must maintain

a minimum of 10 psi pressure drop across the condenser when operational.

Drains:

To ensure trouble-free drainage, vent cuber and bin

drains to the atmosphere at the cabinet (see sketch).

Drain lines from the cabinet require 1/4" (6mm) drop

per foot (30cm) fo run. Lines should terminate over an

open trapped and vented floor drain.

Installation Check List:

1. Has cuber evaporator been leveled?

2. Are electrical connections complete per name-

plate specifications? Is manual disconnect "ON"?

3. Check water and drain connections:

A) Has water inlet pressure been checked?

B) Are water shut-off valves open?

C) Is water strainer installed?

D) Is bin drain tube assembled to bin?

E) When used, is the water cooled condenser

drained seperately?

F) Are drain lines vented?

G) Are drain lines insulated and sloped to floor

drain?

4. Is there 6" (15.24cm) clearance at cuber sides,

back, top for air circulation?

5. Is the cuber installed where ambient tempera-

tures will not be bleow 50oF (10oC) or above 100oF

(38oC)? Will incoming water temperature be maintained

between 45oF (7oC) and 90oF (32oC)? If air temerature

drops below 50oF (10oC) shut unit down! Disconnect all

water lines to prevent freeze up of unit.

Electrical:

All supply wiring and connections must conform to

the national and local engineering codes. Size wiring and

fuse per nameplate specification. Connect the cuber to

a seperately fused circuit. Conduit must be connected

to the electrical control box inside the cuber, not the rear

panel on a "C" Series machine. Place a manual disconnect in a convenient location between the cuber and fuse

box. The cuber must be grounded by the control box

ground screw or conduit connection.

6. Does water curtain move freely?

7. Check float valve and adjust water level as required. Be certain water pan is seated on its support

block.

8. Has storage bin and cuber been sanitized?

Air deflection baffles are available for all air cooled

equipment. The baffles attach to the side and rear to

prevent air from recirculating through the condenser.

Sart-Up Procedure Siphon System:

13

Page 13

Installation and Service Manual

INSTALLATION

Sart-Up Procedure Siphon System:

1. Place the ON/OFF switch in the water pump

position. Only the water pump will start. Permit the sump

to fill and the float to shut off. Check for continuous and

even water flow over top plastic extrusion and evaporator. Is water flowing from all water distribution tube holes?

Check water level in siphon tube.

2. Place switch in "off" position. Water should fill

the sump and pan tube starting a siphoning action. The

siphon should drain the sump then stop flowing. In not,

lower the water level to approximately 3/8" (.95cm) below the siphon clip.

3. Place switch in the ice position, the compressor,

condenser fan motor (if air cooled) and water pump and

fan motor will stop and the harvest solenoid will open.

Swing the water curtain open and hold for a maximum of

15 seconds, the compressor will stop. Release the water curtain and the compressor, fan motor and water

pump will start, initiating a new ice making cycle.

4. For optimum life performance of the ice maker,

the bridge should be a minimum of 1/8" (.32cm) to a

maximum of 3/16" (.475cm) in the center of the ice sheet.

Permit the ice maker to drop two (2) complete sheets of

ice before making any bridge adjustment.

5. Ice bridge adjustment:

A.If ice size requires adjustment, use fine adjustment only .

4. Place the switch in the ice position. The compressor, condenser fan (if air cooled), and water pump

will operate. Depress the manual harvest switch, the

water pump and fan motor will stop and the harvest solenoid will open. Swing the water curtain open and hold

for a maximum of thirty (30) seconds. The compressor

will then stop. Release the water curtain. The water pump

and compressor fan (if air cooled) will start in the ice

making cycle.

5. For optimum life and performance fo the ice

maker, the bridge should be minimum of 1/8" (.32cm) to

a maximum of 3/16" (.475cm) in the center of the ice

sheet. Permit the ice maker to drop two (2) complet

sheets of ice before making any bridge adjustment.

6. To adjust the bridge thickness of the ice sheet,

go to the bottom of the circuit board. There is a bank of

eight (8) DIP switches. To make the bridge thicker, turn

the next switch to the "on" position. To make the bridge

thinner, turn the next switch to the "off" position.

7. If you have any difficulty in the operation of this

machine, please call your local Servend service company or dirstributor.

Owner/Operator:

Before leaving, be sure the owner/operator understands the ice maker operation and the value of preventative maintenance.

Purge Valve System:

1. Open water valve to machine and allow the water pan to fill with water through the float valve. Check

the water level in the water pan - adjust if required to

have water level equal to the crease in the side of the

pan.

2. Engage electric to the machine. Turn the water

pump to the "on" position. Check for continuous and even

water flow over the top plastic extrusion and evaporator.

Is the water flowing from all holes in the distribution tube?

If the water seems to "creek" at the top extrusion without

having a slow sheet fo water cascading over the top extrusion, clean the top extrusion with Scotch Brite pad or

terry cloth.

3. With the toggle switch in the pump postion, check

the dump valve. Depress the manual dump switch and

hold. This should clean out most of the water in the water pan while allowing the float to refill the pan.

14

Does the owner know:

1. Location of the electrical disconnect switch and

water shut-off valves?

2. How to start, shut down, clean and sanitize?

3. Bin full operation?

4. Proper method of cleaning condenser and fan

blade?

5. To inspect distribution tubes and evaporator for

mineral deposits.

6. How to identify when water filter needs replac-

ing?

7. Who to contact for product information or service? We suggest placing the organization's name and

phone number on the front panel.

8. Use and location of high pressure reset on water cooled equipment?

Page 14

INSTALLATION

ADJUSTING PROPER WATER LEVEL

Installation and Service Manual

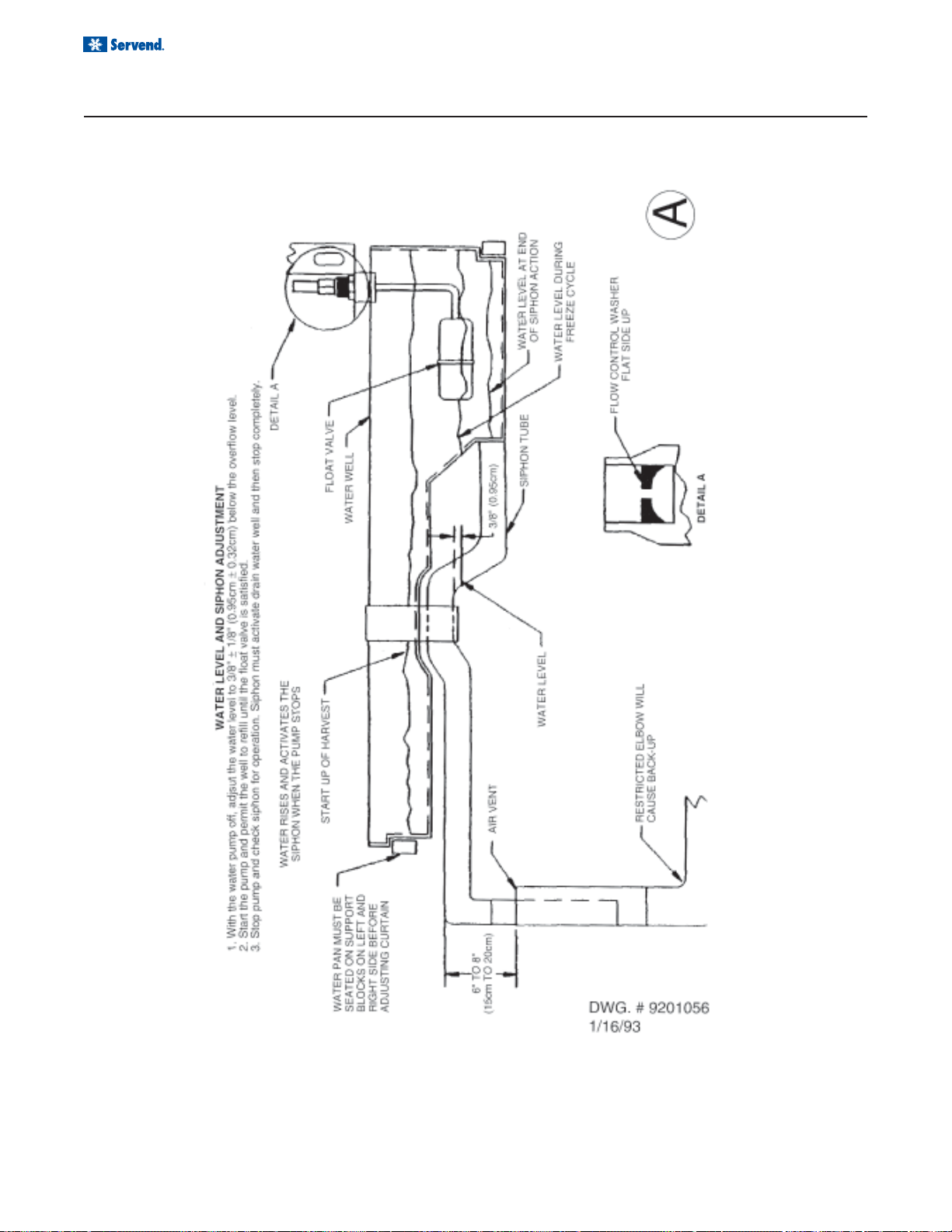

Siphon System:

A) Be sure water pan is properly seated on its sup-

port blocks.

B) Adjust float by releasing the bracket screws to

raise, or lower, float assembly.

C) W ater level should be set 3/8" (.95cm) below the

bottom of siphon hose clip.

D) With water level set, turn pump on to circulate

the water. Be sure the float will return water level to original setting and stops inlet water.

E) Turn water pump off. The machine should now

siphon, the siphon action stops and the float returns the

water level to original settings.

F) The flow washer in the float assembly (detail A)

will control water pressure from 55/120 PSI (3.79/8.27

Bars) to eliminate float chatter. In low water areas 20

PSI (1.37 Bars) and less, remove the flow washer.

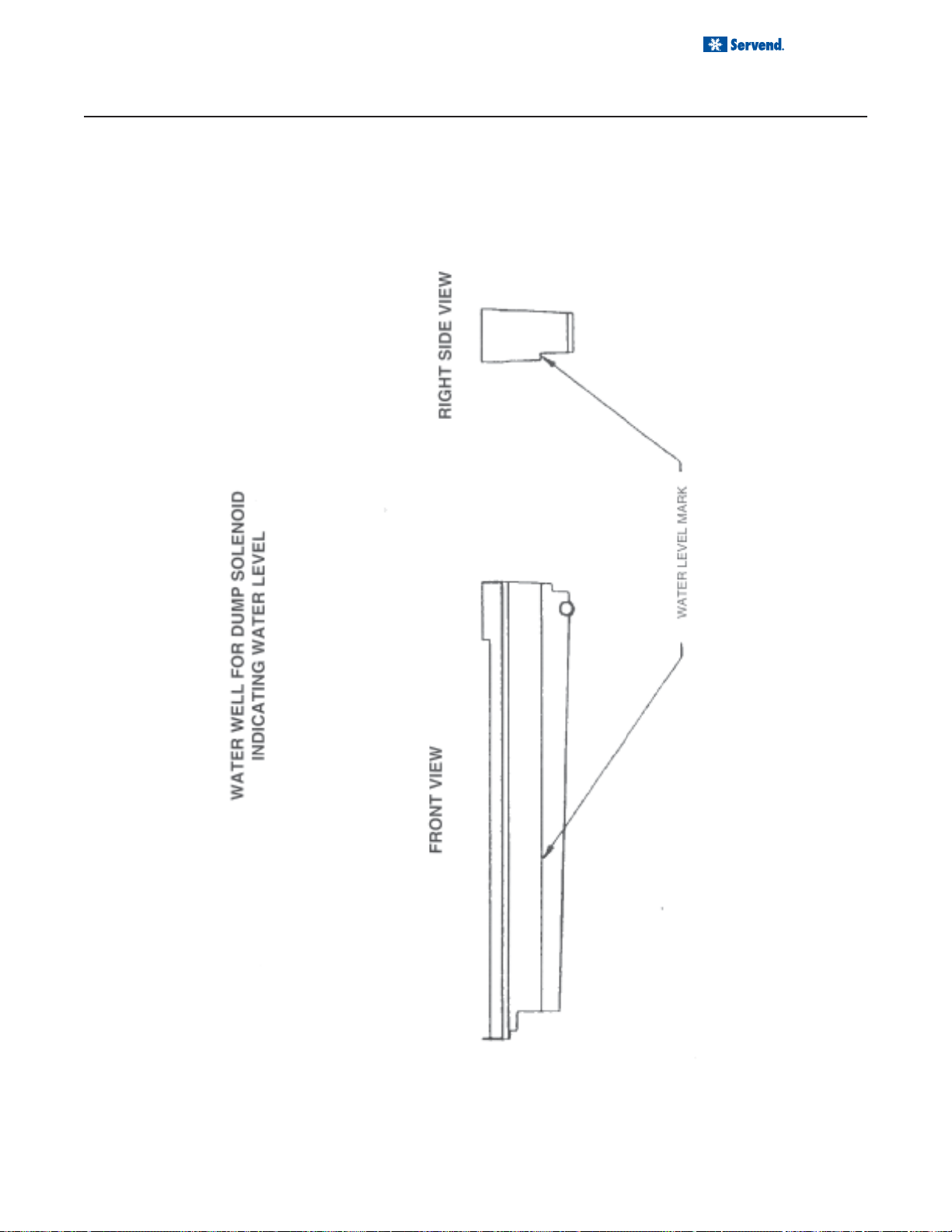

Dump System:

A) Adjust float by disengaging the bracket screws

to raise, or lower, float assembly.

B) Water level to be set at water level mark on wa-

ter pan (see diagram).

C) With water level set, turn water pump ON to circulate the water. Examine to be sure the float will return

water level to original setting and stops inlet water.

D) Depress and hold the manual dump switch (white

button by toggle switch) - allow dump action to empty

water pan. This is a momentary switch - you must hold it

depressed to complete manual dump cycle.

E) Release the manual dump switch - float should

return water to original level.

15

Page 15

Installation and Service Manual

INSTALLATION

16

Page 16

INSTALLATION

Installation and Service Manual

17

Page 17

Installation and Service Manual

INSTALLATION

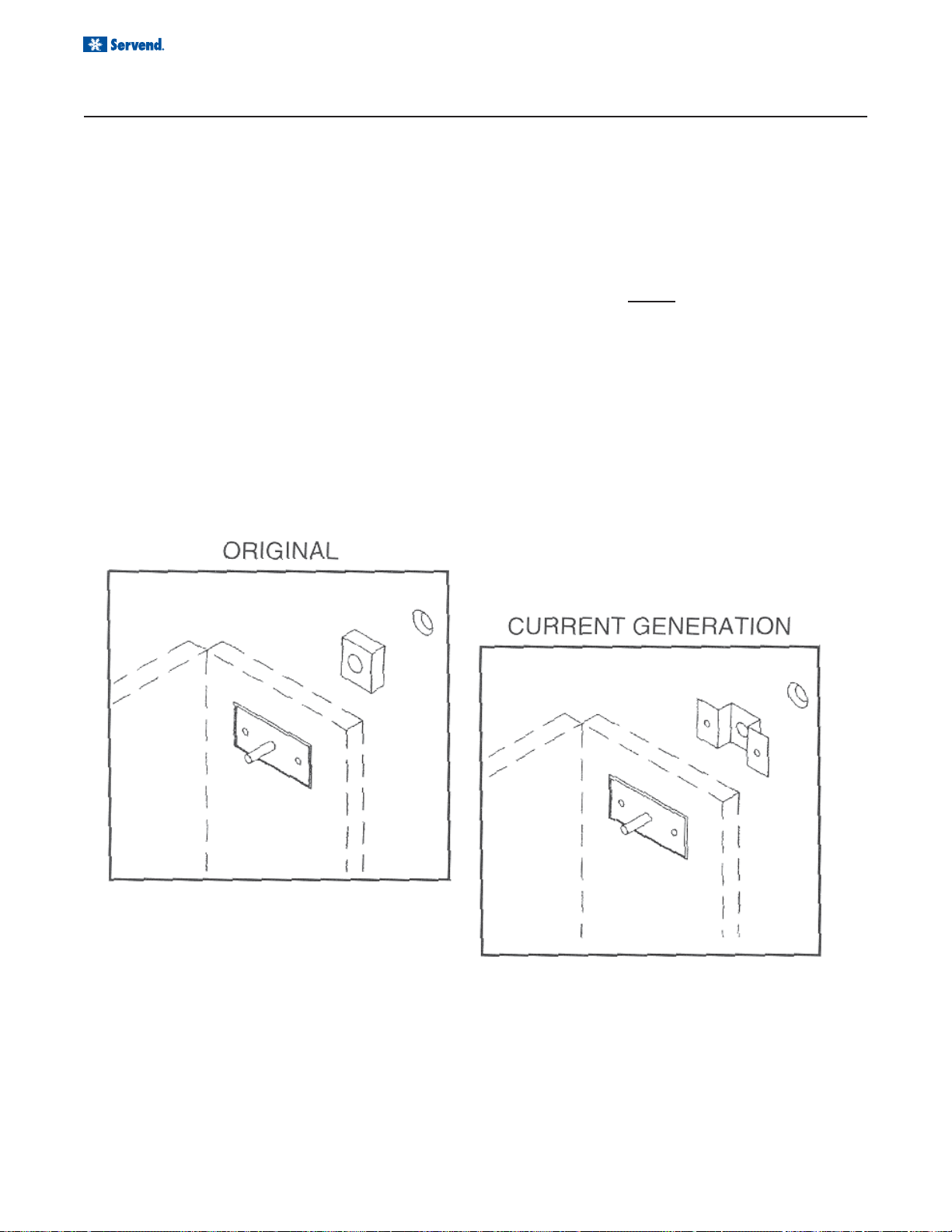

WATER CURTAIN ADJUSTMENT

The water curtain acts as a shield to prevent the

water circulated across the evaporator from teh splashing into the bin, resulting in additional make up water

being required.

T o adjust, the screws holding the curtain bracket and

pin assembly must be loosened, left and right side. The

bracket assembly will allow the curtain to be adjusted

5/16" (8mm) up or down and front to rear. the bottom

edge of the curtain should be set to clear the water pan

by a maximum of 1/8" (.32cm). Normal adjustment, front

to rear, would be to adjust the curtain in as far as possible.

Adjustment must also observe side to side travel of

curtain. Any side to side movement of 1/16" (.16cm) or

greater must be shimmed out as this would create erratic operation of proximity and/or Hall switch.

NOTE: Be certain water pan is properly seated on

it's support blocks

before adjusting water curtain.

18

Page 18

INSTALLATION

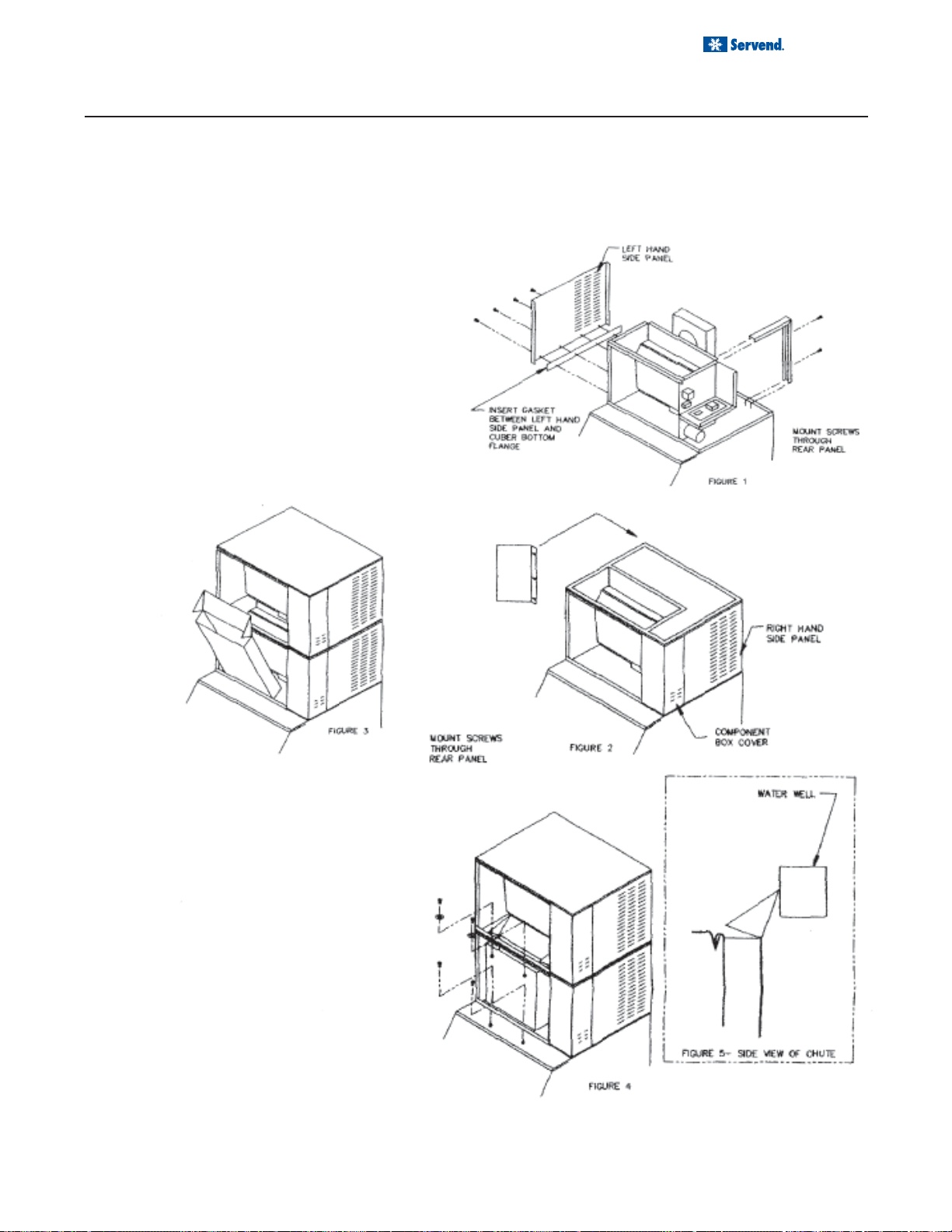

STACKING KITS

The Servend "C" series ice machines are stackable

to double their capacity . When ordering stacking kits, the

bottom unit determines the kit required. Any Servend ice

machines of the same width. Dual evaporator ice machines will only stack with dual evaporator ice machines.

EXAMPLE: You have a C-7 installed and wish to add

a C-9 for additional ice capacity . Y ou would order the

K4SK (for the C-7)

Installation and Service Manual

19

Page 19

Installation and Service Manual

INSTALLATION

ICE MAKER CLEANING PROCEDURE

WARNING: When using cleaing fluids or any chemicals, rubber gloves and eye protection should be worn.

Approved Ice Machine Cleaners:

Lime-A-Way or Calgon Nickel Safe (green color only)

Caution: Before attempting any cleaning of the ice machine, the ice in the bin or dispenser must be removed.

Prep-Clean:

Using full strength ice machine cleaner on a section

of coarse surface material (terry cloth) wipe down the

inside walls of the food zone, wipe out the water pan,

wipe off the water curtain and evaporator plastic extrusions. Should the water distribution tube be heavily

scaled, remove and soak in full strength ice machine

cleaner while prep-cleaning.

Clean the water system and evaporator:

1. Place toggle switch to pump position to circulate cleaner through water system and across evaporator.

2). Pour 4 ounces of approved cleaner into water

pan. (4 ounces (1 13.39g) is proper amount for all Servend

ice machines).

3). Float will bring in additional water during circulation to produce proper cleaning ratio of 4 ounce cleaner

to 1/2 gallon (1.89Liters) of water.

4. Place toggle switch in pump position. Allow

cleaning solution to circulate for 10 to 15 minutes maximum.

5. Turn toggle switch to OFF position - this will allow cleaning solution to siphon out of machine. On later

production models (with manual dump switch), do not

turn toggle switch off.

NOTE: A) Ice machine should only be cleaned when

required. Do not clean by a timed schedule of every

60 days, or etc.

B) Required cleaning of more than twice (2)

per year may require water treatment. Contact your

local Servend distributor.

Sanitize Cycle:

1. Check water level to be at mark on water pan - if

required, adjust float to maintain proper level.

2. Add 1/4 ounce (7.08g) unscented laundry bleach

(5.25% CI NaO concentration) to water contained in the

water pan in order to yield 200 PPM available chlorine.

Allow the pump to circulate this solution for 5 minutes

(or use a commercial ice machine sanitizer following the

directions on the container).

3. Depress the manual dump switch to drain the

water pan.

4. To sanitize the bin surface and other cont act areas - use 1 ounce of liquid bleach per gallon of water

and wipe all surface areas with the solution.

5. Place toggle switch in ice position. Discard the

first batch of ice produced.

6. Should you ever have any questions on teh

proper procedure, please call you local distributor.

Depress the manual dump switch and hold until

cleaner is dumped from system.

6. Fresh water will refill water pan - allow this fresh

water to recirculate for approximately 5 minutes to rinse

water system. Repeat step #5 twice (2 times).

7. After second rinse cycle, place toggle switch in

ice position. Allow product to produce one (1) slab of ice

- discard ice.

8. Cleaning cycle is now complete - return ice machine to normal operation.

20

Page 20

Installation and Service Manual

REMOTE CONDENSER INSTALLATION GUIDELINES

REMOTE CONDENSER INSTALLATION INSTRUCTIONS

1. Follow the standard installation supplied with

cuber. Do not connect cuber into power source until the

remote condenser and line set installation is complete.

2. Assembly of remote condensers:

A) Assemble four (4) legs to base panel. Place

leg gussets on legs. Att ach support bracket from

base panel to legs.

B) Locate the remote condenser in a well ventilated area on the roof away from other condenser

discharge air flow.

C) Using the four (4) mounting holes provided

to secure the remote to the roof. Seal over heads

of bolt or fasteners with tar or pitch to prevent

entrance of moisture.

NOTE: Consult your local distributor for other

applications.

Installing a Servend remote cuber with other than

Servend condenser will void cuber warranty .

3. Each condenser and cuber is connected with two

(2) *pre-charged lines.

A) The pre-charged lines are ordered separately

from the condenser to suit each individual application.

mote condenser then using the proper sized

wrench, tighten unitl fittings bottom out, then turn

an additional 1/8" but DO NOT TURN MORE

THAN 1/4.

NOTE: Once the refrigerant lines are connected, the

seal is broken in the fittings. If the lines are

removed or loosened from the cuber or remote condenser, the refrigerant charge will

be discharged to the atmosphere. DISCHARGING OF ANY REFRIGERANT TO THE

ATMOSPHERE IS IN VIOLATION OF THE

CLEAN AIR ACT OF JULY 1992.

5. Remote condenser electrical hook-up:

A) Connect remote condenser to power source

(208/230 V AC, 60HZ). A disconnect switch must

be used.

B) Make sure the electrical connection follows

all local and national codes.

NOTE: A) Never wire condenser into cuber section.

The condenser is an independent electrical

connection.

B) Fan motor will not start until pressure rises

to 250 PSIG (16.55 Bars) closing fan cycling

switch.

B) The pre-charged line lengths are 20 feet

(6.096 meters), 35 feet (10.66 meters), and 50

feet (15.24 meters).

*(Pre-Charged is defined as a vapor holding

charge - not a portion of the system charge).

4. Installation of line kits

A) Remove the tubing from the carton. Carefully

uncoil the lines so the tubing doesn't become

kindled.

NOTE: Excess tubing should be cut from the tube

sets

before connections are made at con-

denser and ice maker.

B) The refrigerant o-ring fittings on the cuber and

remote condenser are to be lubricated with REFRIGERANT OIL BEFORE CONNECTING.

C) Charge ports are provided on each end of

line sets. Line sets are non-directional and fittings match either cuber or condenser.

D) Carefully thread (by hand) the female line fittings to the male fittings on the cuber and re-

6) Finishing cuber section:

A) Remove left hand side panel of cuber.

B) Turn service valves on receiver tank to open

position (fully extended) releasing refrigerant to

the balance of the system.

C) Leak check line connections at cuber and condenser.

D) Replace side panel of cuber.

E) Connect cuber to power source.

F) Make sure electrical connections follow all

local and national codes.

7) Start Up:

A) Use standard procedures from cuber instal-

lation instruction.

B) Af ter the cuber is running, check the remote con-

denser and verify that condenser fan is running.

NOTE: Fan may cycle off during harvest cycle, this

would be normal

21

Page 21

Installation and Service Manual

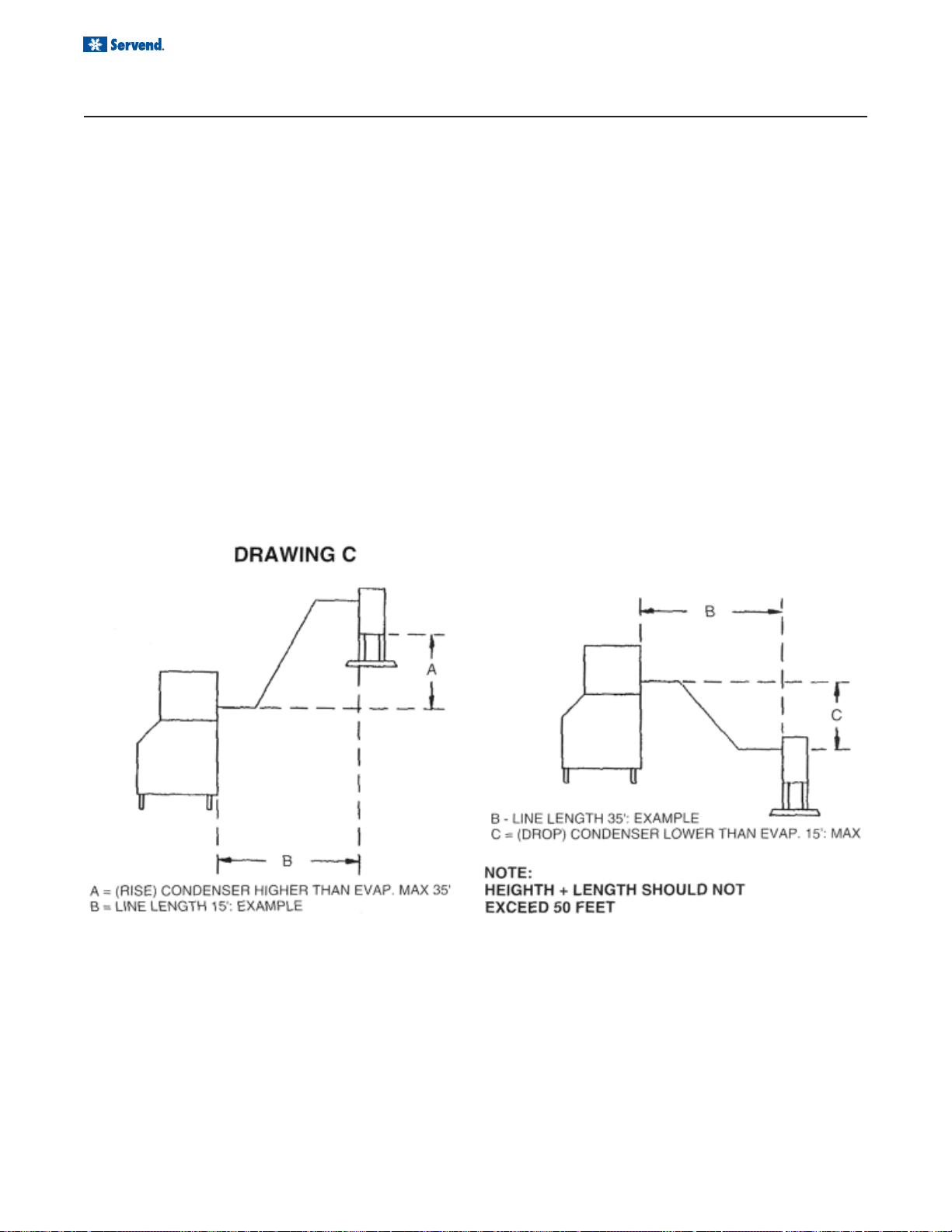

REMOTE CONDENSER INSTALLATION GUIDELINES

REMOTE CONDENSERS MAXIMUM LOCATION DISTANCE

(REFRENCES DRAWING C)

Remote condenser installations consist of vertical

and horizontal distances to the condenser that, when

combined, must fit within approved guidelines.

CONDENSER MAXIMUM HEIGHT:

This should never exceed 35 feet (10.66 meters).

TOTAL MAXIMUM LINE LENGTH:

This should never exceed 50 feet (15.24 meters)

total. The pressure drop, due to the refrigerant flowing

through the lines and condenser, will exceed the design

limits of the head pressure control.

CONDENSER MAXIMUM DROP:

The condenser should never be positioned more than

15 feet (4.57 meters) below the ice machine. the liquid

refrigerant pushed from the condenser up to the ice

machine will contribute to an overall pressure drop.

22

Page 22

COMPONENT DIAGNOSTICS

ICE MACHINE CHECKLIST

Installation and Service Manual

PROBLEM

1. ERRATIC SIPHON ACTION:

O Water level not correct

O Water pan not seated on blocks

O Float leaking through

O Algae build-up in siphon

O Siphon tube to copper vent tube too short or

kinked at rear of cabinet. Siphon not istalled

on vertical.

O Too small or restricted drain line for copper

vent tube.

O High water pressure.

PROBLEM

2. PUMP CAVITATING (PULLING AIR), or pump

air locked:

CORRECTIVE ACTION

Adjust.

Reseat water pan.

A) If float is not round bulb style, replace with

#9200377.

B) If float is round bulb style, clean.

Pour 1/4 cup household bleach through siphon.

Plastic siphon tube must be 6" (15cm) to 8" (20cm)

out rear of cabinet, if not, replace tube - if tube is

kinked, reform or replace.

Increase drain size and/or remove any restrictions.

Is flow washer installed correctly? If yes, install water pressure regulator.

CORRECTIVE ACTION

O Low water pressure

O Water supply line too small

O Water discharge from float directed at pump

pick-up tube

O Pump to distributor tube has air lock

O Water level set too low

O High water pressure agitating water

20 PSI (1.37 Bars) or lower remove flow washer

3/8" (.32cm) minimum water supply

Raise shelf area of float bracket 2o

Tube too long and has raise at distribution tube.

Shorten tube - be certain tube does not prevent water curtain operation

Adjust

Is flow washer installed correctly?

23

Page 23

Installation and Service Manual

COMPONENT DIAGNOSTICS

ICE MACHINE CHECKLIST (CONTINUED)

PROBLEM

3. POOR ICE FILL ON EVAPORATOR:

O Float or dump valve leaking through

O Water pan not seated or out of level

O Water curtain out of adjustment allowing wa-

ter to splash into bin and/or curtain freezing

to evaporator changing flow and freeze pattern over thermistor

O Water flow too fast over evaporator

O Water distributor tube not centered

O No control of water flow over evaporator (too

fast)

CORRECTIVE ACTION

Replace, or clean, as required.

Reseat pan on blocks. Level ice machine.

Adjust curtain brackets for proper alignment. Curtain brackets are adjustable 3/8" (9.5mm) up down/

front to back. Curtain should be set to just clear top

edge of water pan.

Check position of water distribution tube. The tube

should be spraying toward lower back of extrusion.

Be certain required sealing of evaporator upper extrusion area is done.

Water Distribution tube must be centered over top

extrusion of evaporator.

Check inner tube of water distribution to be 180o

from outer tube. Check restriction plug in water system.

PROBLEM

4. ICE BRIDGE NOT CORRECT:

O Slow harvest

A) Excessive meltage of bridge and cubes

B) Machine not level

O Control board out of adjustment

O Thermistor incorrectly mounted

O Thermistor sealant defective

O Defective thermistor

CORRECTIVE ACTION

Mineral contamination - clean evaporator

Re-Level ice machine.

See adjusting bridge thickness for your style of circuit board.

Follow procedure to remount thermistor

Follow procedure to remount thermistor

Replace thermistor

24

Page 24

Installation and Service Manual

COMPONENT DIAGNOSTICS

DECISION TREE BEFORE REPLACING A THERMISTOR

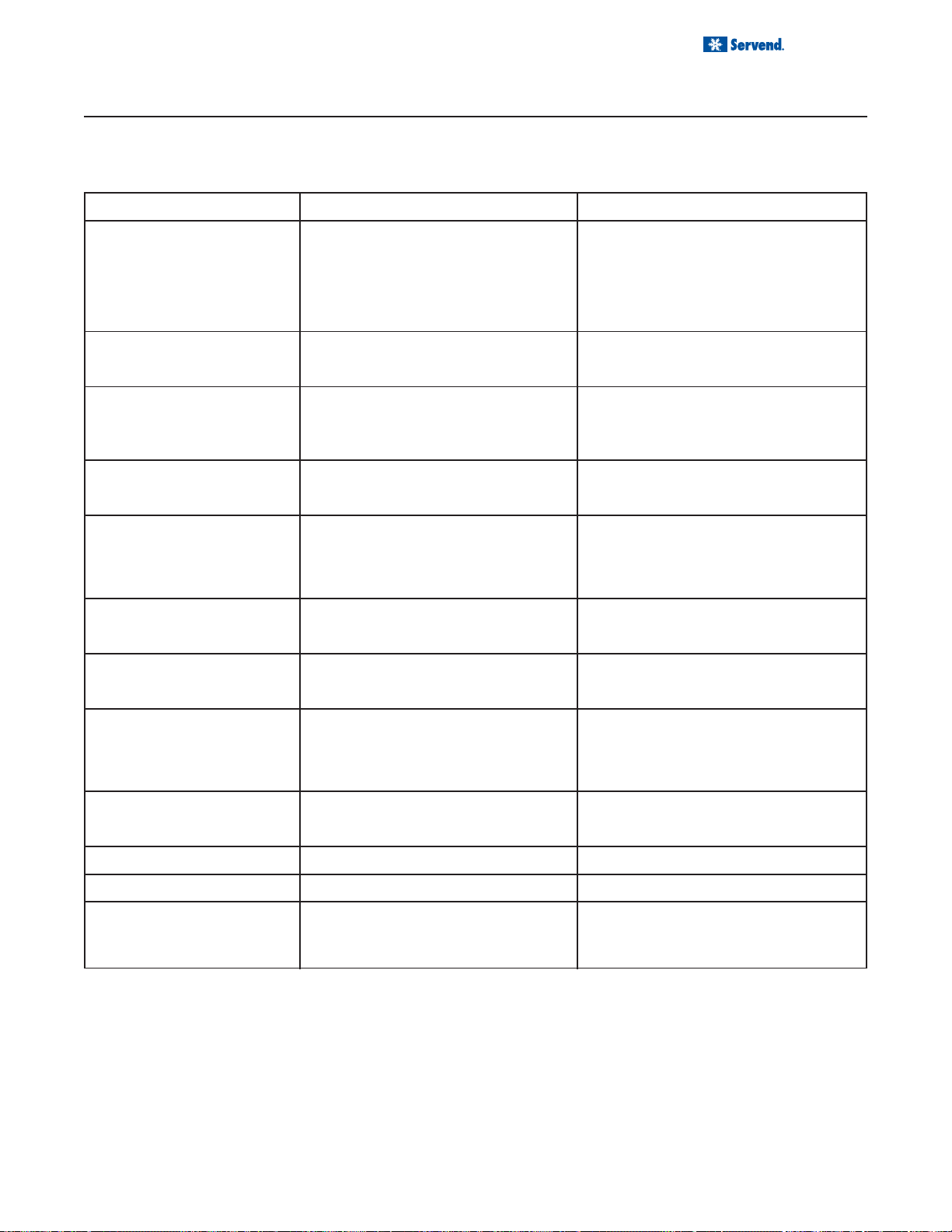

SERVICE SYMPTOM COMMON MISDIAGNOSIS ACTUAL DIAGNOSIS

1.Eratic bridge thickness Replace thermistor Dirty evaporator

Dirty water system

Exposed TXV bulb

Flooding TXV

2.Freezes for 2-3 minutes Replace thermistor Slushing

then goes into harvest Ice bridge too thin

3. Ice frozen to the curtain Replace thermistor Hall switch lost target area and

made a second batch of ice

Flooding TXV

4. Ice not filling completely Replace thermistor Poor water flow

before going into harvest

5. No ice Replace thermistor Water cavitation

Premature harvest

Ice freezing to evaporator

6. Premature harvest with Replace thermistor Pump cavitation

no water flow or harvest

7. Thick ice at the bottom with Replace thermistor Conintuous syphoning of water from

thin ice at the top of the slab machine

8. Thick ice on bottom of Replace thermistor Starving expansion valve

evaporator with no ice on Flooding expansion valve

the top

9. Very thick ice bridge Replace thermistor Dirty condenser

Low refrigerant charge

10. Will not harvest ice Replace thermistor Dirty condenser

11.Will not go into harvest Replace thermistor Hall/proximity switch out of alignment

12. Will not go into harvest Replace thermistor Water dripping into bin

Ambient air entering into bin

25

Page 25

Installation and Service Manual

DIAGNOSIS OF SERVEND CUBER THERMISTOR

COMPONENT DIAGNOSTICS

Erratic Operation (Bridge Thickness Erratic):

1. Check thermistor mounting:

A) Are the wire leads to the circuit board secure?

B) Is the tip of the control flush or protrude 1/64"

(.4mm) beyond the lower evaporator extrusion?

If correctly mounted, you may feel a slight bump.

C) Is there a heavy film of sealant over the tip of the

control? A very slight film is OK. If the tip of the control

looks a milky color, the silicone is too thick.

D) Af ter the machine sets for 24 hours is the first

sheet of ice OK? Does each succeeding sheet

of ice get thinner? This could be a sealing problem with water in the sensor well.

2. Bridge thickness gets progressively thinner each cycle:

A) Thermistor not properly sealed in lower evapo-

rator molding or thermistor set too far back into

molding.

B) To Reseal:

1. Remove water pan

2. Reach up in back of evaporator and

grasp thermistor leads and remove thermistor. Use a 1/16" punch to push thermistor out.

3. Remove dried silicone adhesive from

thermistor and clean out opening in

evaporator molding.

4. If replacing a plastic sleeve thermistor

with a metal jacket thermistor hole will

have to be reamed to 1 1/64" (.43cm). Do

not use a power drill.

5. Force G.E. RTV-108* silicone adhesive into front opening of evaporator

molding filling the hole until silicone

come out the back. Place thumb or finger over opening and reinsert thermistor

from rear of opening pushing toward the

front of the evaporator modling (this will

force silicone around the thermistor as

you push thermistor forward giving a

positive seal). Allow thermistor to be

flush or protrude approximately 1/64"

(.4mm) beyond face of evaporator molding with ample amount of silicone

ahesive. (1/64" equals a very slight

bump).

6. The G. E. RTV-108 silicone will set,

tack-free, in aproximately 15 minutes. Do

not allow water to contact silicone

until it is tack free.

*This is the only silicone recommended for proper

sealing of thermistor by Servend International (part

#5000881, or purchase locally.

Check Procedure:

1. Clear the evaporator of any ice. This can be done

with the use of the manual harvest switch on the circuit board.

2. Place the machine in the ice mode. Allow the

unit to make one sheet of ice.

3. At the end of a regular freeze time, manually har-

vest the ice.

4. Observe the sheet of ice. Is the bridge thickness

even from the top to bottom? Is the bridge thinner at the

top than at the bottom?

5. If your sheet of ice is thinner at the top than at

the bottom, your machine is suffering from a water loss

or refrigeration problem.

6. If you ice has an even bridge from top to bottom,

proceed with the OHM meter check.

7. Remove the control wires from the EV terminals

on the circuit board. In a dual evaporator machine, only

the left control (connected to the EV terminals) determines the thickness of the ice.

8. Attach you OHM meter to the ends of the wires.

Do not remove the control from the evaporator extrusion. Your meter should be capable of reading 5,000 to

40,000 OHMs accurately.

9. At room temerature, your control should read

ABOUT 10,000 to 15,000 OHM resistance.

10. Place an ice cube on the tip of the control. You

should obtain a reading in the range of 25,000 to 36,000

OHMs.

1 1. These readings are approximate. Do not be con-

cerned if your reading are slightly different.

12. If your control responds comparable to the above

readings, this control is good. If your control does not

respond, replace the control.

13. If you are working with a 4 relay circuit board

and the ice sensing control is "open" or "shorted", the

power light on the circuit board will flash. The machine

will not operate.

26

Page 26

COMPONENT DIAGNOSTICS

NOTE: THE RESISTANCE

CHANGE IS NOT

INSTANTANEOUS!!

There may be a delayed response

to temperature change opposite of

the evaporator temperature.

Installation and Service Manual

FLOWCHART

BEGIN

Remove thermistor leads

from circuit board. Con-

nect OHM meter to

thermistor.

Place thumb on tip

of thermistor.

Does OHM reading

decrease to 7,000 to

10,000 OHMs?

Apply ice to

thermistor tip.

Does OHM reading

increase to 25,000 to

36,000 OHMs?

Yes

Thermistor OK.

NO

Replace

Thermistor

NO

Replace

Thermistor

END

27

Page 27

Installation and Service Manual

COMPONENT DIAGNOSTICS

Product Operation:

If the thermistor is "open" the cuber will start in the

harvest, or hot gas cycle, on a 3 relay board:

1. Adjusting the potentiometers ("pot") will not put

the cuber into a freeze mode.

2. Proximity switch will trip control board red light

off and on with water curtain movement, but,

product will remain in harvest mode when curtain closes.

If the thermistor is "shorted" the cuber will remain in

the freeze cycle on a 3 relay board.

If thermistor passes flowchart test the thermistor is

OK - do not replace; check thermistor mounting and Erratic Operation Troubleshooting Guide for bridge thickness.

NOTE: BEFORE REPLACING THERMISTOR PLEASE

TEST USING CHECK PROCEDURE OR

FLOWCHART.

New generation circuit board (4 relays, remote

mounted transformer) - the power on light (LED) will flash

if there is a warning mode in the thermistor circuit.

NOTE: EV thermistor - Controls bridge thickness,

provides hi-temp safety cut-out on single

evaporator units and the left evaporator on

dual evaporator models.

High 2 thermistor - Dual evaporator models

only - right evaporator thermistor provides

high temperature safety shut-down.

ICE THICKNESS CONTROL REPLACEMENT

1. Shut off water and electric supply to the ice

maker.

2. Remove the float valve and water pan from the

machine. Remove the side panel from the control box side of the machine.

3. Use a 1/16" punch or allen wrench to push the

control out of the extrusion. Clean the old silicone out of the hole.

board in the appropriate positions. There is no

polarity in the wires of the ice thickness control.

6. If your old control has a plastic jacket, you must

redrill the control hole. Use a 5mm (11/64") drill

bit for this purpose. Use the drill bit by hand to

enlarge the hole to fit the metal jacketed control.

7. Using GE RTV -108 clear silicone only fill the hole

with silicone. This silicone is available from your

local Servend Distributor.

8. Immediately after filling the hole with silicone,

place your thumb over the front of the hole for

ice sensing control. Push the new control into

the hole from behind the evaporator. This will

allow the silicone to encompass outside the

contrl jacket. Continue to push the control into

the hole until you can feel the conrol hitting your

thumb. Never make a sharp bend with the control or allow the wire to loop behind the evaporator. this can produce internal damage to the control.

9. The ice thickness control should be flush or protrude through the hole 1/64" (.4mm). You may

feel a slight bump.

10. With your thumb still over the opening, wipe your

thumb sideways over and off the control. This

will allow a very slight silicone seal to remain on

the control tip.

11. Reinstall the side panel, water pan, float valve

and restore all utilities to the machine.

12. W ait for 15 minutes before allowing water to run

over the evaporator. This will allow the silicone

to dry tack free.

13. Check the water level in the water pan. turn the

machine to the ICE position.

14. Allow the machine to make one batch of ice. You

may check this sheet for proper bridge thickness.

If adjustment is necessary , please follow the procedure for your particular machine.

4. Remove the old control from the machine.

Thread the new control through the machine from

the compressor compartment. Push the control

tip through the enclosure to the evaporator.

5. When routing the new control wires to the circuit

board be sure the wires do not touch any hot

gas lines. Attach the lead wires to the circuit

28

Page 28

Installation and Service Manual

COMPONENT DIAGNOSTICS

SAFETY THERMO-DISC / FAN CYCLE CONTROL

Ice Thickness Control Adjustment

1. Adjustment to the bridge thickness is done at the

circuit board. On the bottom (front) of the board

you will find either two round black potentiometers

or a set of 8 DIP switches. Please follow the instructions below for the particular type of board

you have. For optimum ice production and harvest, it is recommended that a 5mm (3/16") bridge

thickness be obtained. In any event, you must not

have a bridge thickness less than 3mm (1/8").

2. TO ADJUST A BOARD WITH TWO POTENTIOMETERS (3 RELAY):

If the machine had been running properly prior to

failure of the thermistor, run the machine through

one complete cycle without making any adjustment

in the bridge thickness. If further adjustment is

necessary, adjust the FINE (right) potentiometer

first. Turn the dial to a higher number for a thinner

bridge thickness. Turn the dial to a lower number

for a thicker bridge thickness. Always wait for one

complete cycle after making any adjustment before readjusting the machine. If further adjustment

is necessary beyond that obatinalbe with the fine

adjustment, you may utilize that COARSE (left)

potentiometer. This dial should only be moved one

marked graduation at a time. One mark is equivalent to about 3/4 turn of the fine dial. The coarse

dial should be moved one mark then fine tuned

with the fine dial.

3. TO ADJUST A BOARD WITH 8 DIP SWITHCES

(4 RELAY)

If the machine had been running properly prior

to failure of the thermistor, tun the machine

through one complete cycle without making any

adjustment in the bridge thickness. If further

adjustment is necessary, adjust the DIP

swithces. To have a thicker bridge, turn the next

(right) switch "on". To have a thinner bridge, turn

the next (left) switch "off". It is acceptable to have

all the switches either on or off. Follow the wedge

above the switch case for thicker or thinner

bridge. To turn the swithc "on" push the top of

the swithc down. If further adjustment is necessary, you may adjust the potentiometer . This "pot"

is located to the left of the 8 DIP switch case.

Remember this is a coarse adjustment. Move

this pot no more than one (1) graduation at a

time. You will then have to adjust the DIP

switches for proper thickness.

SAFETY THERMO-DISC

The thermo-disc is a safety control located on the

evaporator inlet for 3 relay siphon systems. This disc is

insulated to prevent ambient air from effecting the operation. The disc is non-adjustable and set to open at 120

49oC (closes at 95oF/35oC) evaporator inlet line temperature. The disc prevents the cuber from over heating if the

product should remain in a hot gas harvest cycle for any

reason.

On a remote cuber, a thermo-disc(s) is wired in series

with the compressor contactor. The thermo-disc will provide a second high temperature safety cut-out device to

protect the ice maker during the pump down cycle when

the circuit board and thermistor does not control the unit.

To Check the Safety Thermo-Disc

Disconnect the thermo-disc RED leads from the machine. With an OHM meter check for continuity - if ther is

none, replace the disc if temperature of disk is below 90oF

(32oC).

Should thermo-disc be open becuase of hi-temp safety

cut-out, you may reclose the disc by manually holding the

contactor closed to run the compressor and cool the evaporator inlet line to be certain the thermo-disc will reclose. Do

not hold the contactor in for more than 30 seconds.

FAN CYCLE CONTROL

This is a high side pressure control that cycles the condenser fan motor off at approximately 180 PSI (12.4Bars)

and on at 250 PSI (17.2Bars). Its purpose is to maintain a

minimum head pressure for proper operation in low ambient conditions.

Remote systems and dual evaporator models utilize

fan cycle controls.

To check:

Install a high side gauge to the hi-side service valve.

DO NOT attach to the receiver valves. Operate the system

and observe the pressures the fan motor cycles. If the cycling pressure is more than +/- 10% out of the control range,

replace the control - it is nonadjustable.

NOTE: CONCAVED SIDE OF BLADE IS FACING FAN

MOTOR ON ALL AIR COOLED SERVEND

CUBERS AND REMOTE CONDENSERS.

o

F/

29

Page 29

Installation and Service Manual

COMPONENT DIAGNOSTICS

HEAD PRESSURE CONTROL VALVE

(REMOTE CONDENSERS ONLY)

A modulating control to maintain proper receiver

operating pressure for correct defrost. At outdoor temperatures above 70oF (21.1oC) the refrigerant flow is from

the condenser to receiver. At temperatures below 70oF

(21.1oC) the valve will enter a "by-pass mode" and the

refrigerant flow will be from discharge line to receiver

allowing the compressor discharge vapor to increase the

receiver pressure by "by-passing" the condenser. The

head pressure control is designed to only operate in bypass at temperatures below 70oF (21.1oC).

Check Procedure

Install gauge at receiver and monitor pressure. With

temperature below 70oF (21.1oC) receiver pressure will

be 200 PSI (13.7Bars) to 240 PSI (16.55Bars) +/- 5 PSI

(.34Bars).

A head pressure control that stays in by-pass may

be the result of a system that is short of refrigerant. Before replacing the head pressure control, check fan cycling control. If it is not cycling, add refrigerant in 2 pound

(1Kg) increments and allow product to run 10/15 minutes to determine operation. Do not exceed 4 pounds

(2Kg) total during this test. If the addition of refrigerant

corrects head master operation you must now locate the

leak, correct, and properly recharge the system.

CAUTION: When removing a head pressure control,

always snap off the stub line at the dome BEFORE

using a torch to heat lines to remove. When reinstalling be sure the dome area has ample heat-sink

BEFORE applying heat to valve.

High Pressure Cut-Out

All Servend water cooled and remote condenser

products contain a high pressure cut-out. The function

of this switch is to turn the ice maker off in the event of

excessive pressure developing in the high pressure side

of the refrigerant system. This switch will open the power

circuit to the circuit board at 450 PSI (31Bars) pressure

on current units. It is a manual reset control located beside the power toggle switch. To reset this control, push

in the red button.

In the event this control shuts down the machine,

please find teh reason for this shut down. Correct any

necessary problems before restarting the machine.

Water Regulating Valve

THE WATER REGULATING VALVE IS USED ON

WATER COOLED CUBERS ONLY...The valve is

mounted in the condenser water line. Its function is to

maintain the proper operating head pressure by controlling the amount of water flow through the condenser.

The valve is adjustable and factory set to maintain condenser discharge water at 105o/108oF (39o/42oC). Setting the water regulating valve to maintain dishcarge

water temperature eliminates the need to enter the sealed

refrigerant system. Water temperaute should be taken

as close to the condenser discharge as possible. This

water temperature will equate to operating head pressures of approximately 230/240 PSI (15.86/16.55 Bars).

Should adjustment be required, the valve has an

adjustment stem on the top. After allowing the cuber to

operate for 6 minutes into the ice making cycle to balance the system, turning the adjusting stem CW will increase the discharge water temperature and CCW will

decrease the discharge water temperature.

The water regulating valve must close off condenser

water flow completely during hot gas "harvest" cycle. If

the valve fails to close during the harvest mode, the condenser will continue to condense the hot gas needed for

the harvest cycle and produce long harvest times.

Leaking water regulating valve are normally the result of scale build-up on the valve diaphragm and the

valve should be flushed, not replaced. T o flush the valve,

open the adjusting stem full open CCW (or force the valve

spring up with a screw driver) open and close the water

supply to the condenser resulting in the flush action.

Should this not correct the problem replacing the valve

diaphragms can be done without entering the sealed refrigeration system.

Damage to the water regulating valve may also be

caused by water hammer. W ater hammer will result from

condenser inlet and drain lines being reversed or defective valve stops in the supply line. Proper installation of

water cooled equipment should always include a antiwater hammer standpipe or expansion tank in the supply inlet water line as close to the cuber as possible.

30

Page 30

Installation and Service Manual

COMPONENT DIAGNOSTICS

HOT GAS VALVE / COMPRESSOR CONTACTOR / CHECK PROCEDURE

Hot Gas Valve

Servend employs a hot gas defrost harvest method.

When the ice reaches the proper temperature, the ice

sensing thermistor initiates the board to open the hot

gas bypass valve. This electrically operated solenoid

valve will then allow hot discharge refrigerant gas as it

leaves the compressor to return to the inlet of the evaporator. The flow of liquid refrigerant out of the expansion

valve will then cease. The hot refrigerant warms the

evaporator therefore allowing the ice to melt and slide

off of the evaporator.

If the hot gas fails to open, check the electric power

supply to the coil of the valve. This power supply comes

to the coil from the circuit board and should be energized when the red LED is energized. If the coil is

envergized but the valve still fails to operate, you have a

sticking valve that needs to be replaced.

A leaking valve can cause excessive freeze times,

uneven bridge thickness, high suction pressures, etc.

A leaking hot gas valve is difficult to troubleshoot.

Several methods to determine if this valve is leaking in

the closed mode is as follows:

The hand temperature method - Place your hand

on the outlet line of the valve. The outlet line of the

valve should feel ambient temperature or a little

cooler.

Compressor Contactor

CAUTION: 230 VOLT MODELS - CONTACTOR

BREAKS ONE POWER LEG ONLY - ICE MAKER IS

STILL LIVE (HOT).

The contactor serves as the voltage supply switch

for the compressor circuit. Voltage to the coil of the

contactor is supplied by the control board relay on selfcontained models (see diagrams). Remote models are

wired directly across the supply line from the toggle

switch. The coil receives power through the low pressure cut-out and thermo-disc.

Check Procedure (Single Phase)

Top two (2) screws of contactor should always have

line voltage supply present. The lower two (2) screws

should have line voltage when the contactor closes.

The contactor coil must receive line voltage from teh

control board relay . If the coil will not close the contactor:

A) Check the coil with an OHM meter for continuity.

B) *Check for proper voltage supplied to coil.

*NOTE:High impedance digit al meter may show voltage from the control board, but that voltage may not

carry a current load. Test light 25W or higher or a

low impedance dial type meter should be used when

testing output voltage from control board.

The use of an electronic sight glass - Can be ben-

eficial in the leak detection. Install the probes on the

oulet line of the valve, several inches apart. If there

is a small leak in the valve, the instument should

detect hot gas condensing due to the pressure drop

and cooler temperatures of the evaporator section.

Another leak detection method for the hot gas

valve is the use of a pinch off tool - By closing the

line between the hot gas valve and the evaporator,

you should be able to determine if the valve was

slightly leaking through.

31

Page 31

Installation and Service Manual

COMPONENT DIAGNOSTICS

COMPRESSOR AND STARTING COMPONENTS CHECK OUT PROCEDURE

When compressors fail to start or run properly, it is

normally the external electrical supply or start components

that are defective. The over-load protector , start and/or run

capacitor, relay, control board, safety controls, etc:

1. With machine in ice position and contactor closed,

check voltage at compressor terminals. NO voltage will require a back check from compressor to

determine where the voltage supply is interrupted.

Correct as required. The load voltage, while compressor is trying to start, should not be less than

95% of rating required for product.

Line voltage and line size effect life expectancy of

electrical components, compressor, motor coils,

etc. Line voltage should be maintained at 95% of

lowest rated voltage.

NOTE: For 50 HZ application on dual rated 50/60 mod-

els, load voltage, while compressor is starting

must not be less than 95% of 50 HZ rating.

NOTE: Poor line quality voltage will cause many er-

ratic electrical problems. Every electrical product, ice machine, dispenser, walk-in, reach-in,

air conditioner, etc. requires proper power supply to operate. Be certain your voltage check is

load voltage, not line.

2. A defective capacitor or relay may prevent the

compressor from starting. If the compressor attempts to start, but in unable to do so, or if the

compressor hums or trips out on the over-load

protector, check:

Relay - Potential type, contacts normally closed.

Contacts open by C.E.M.F. from compressor at

approximately 80% of operating speed removing start capacitor from circuit. Both start and run

winding and run capacitor remain in circuit.

Capacitors - Any capacitor found to be bulging,

leaking or damaged should be replaced.

CAUTION: Before removing leads for testing purposes, short across capacitor with a 10K OHM resistor to discharge capacitor if capacitor does not

have bleed resistor installed.

A quick check is to replace suspected capacitors with a

known good capacitor. Be sure specified cap acities are used.

If capacitor analyzer is not available, an OHM meter

may be used to check start capacitors for short, or open,

circuits. Set the OHM meter to its highest scale and connect prods to capacitor terminals.

A) With a good capacitor , the indicator should first move

to zero (0) and then gradually increase to infinity .

B) If ther is no movement of the OHM meter indica-

tor, an open circuit is indicated.

C) If the OHM meter indicator moves to zero (0)

and remains there, or on low resistance reading, a short circuit is indicated.

D) Remember this check does not determine that

capacitor will deliver the MFD/UFD rating required, only detects shorted or open plates.

E) Capacitors that show any sign of leakage of elec-

trolyte, or damage of can, should be replaced.

DO NOT TEST!

CAUTION: Turn power off. Before removing supply

leads to compressor, short across both capacitor

terminals to discharge capacitors.

1. Using an OHM meter check for continuity from

terminals C to R, and C to S. If the compressor

is hot, wait one (1) hour for compressor to cool

and recheck. the internal over-load protector can

cause a lack of continuity. If continuity cannot

be established through all motor windings, the

compressor must be replaced.

2. Check compressor for ground by means of a

continuity check between terminals C, R and S

to the compressor shell or copper refrigeration

line (be sure to scrape metal surface clean to

get good contact). Continuity present, the compressor windings are grounded and the compressor must be replaced.

If compressor starts, but trips, repeatedly on the over-

load protector, check:

Operating pressures should be within limitations of

normal operating conditions.

Check the amperage drawn while the compressor is

operating. Under normal operating condintions, the continuous amperage drawn will seldom exceed 100% of

compressor nameplate amperage and should never exceed 120% of nameplate amperage. High amperage can

be caused by: Low Voltage, Undersized Lines, High

Head Pressure, High Suction Pressure, Defective

Running Capacitors or Starting Relay, Compressor

Mechanical Damage.

32

Page 32

Installation and Service Manual

COMPONENT DIAGNOSTICS

TOTAL ICE CAPACITY / ICE PRODUCTION CHECK

Thermostatic Expansion Valve(s)

The following suggestions are made with the under-

standing that:

A) The condenser and fan blade are clean and have

proper operating conditions.

B) Water supply to the product is correct and water

flow over the evaporator is correct.

C) System charge is correct.

D) TXV bulb is properly located and secured to the

line and correctly insulated.

E) Hot gas valve(s) not leaking through.

F) Discharge pressure OK.

Starving Valve - Product Symptoms:

1. Suction pressure lower than normal for the op-

erating conditions.

2. Ice production lower than normal and/or none.

3. Ice pattern on evaporator (if any) thin at top and

thick at bottom.

Flooding Valve - Product Symptoms:

1. Ice production lower than normal or none.

2. Suction pressure stabilizes at higher than nor-

mal and does not continue to modulate and de-

cline (may start to slowly rise).

Total Ice Capacity

Ice capacity of any ice maker is affected by many

operating conditions, such as water and air temperatures

and location factors. Please review the capacity tables

in this manual for average 24 hour capacity under various conditions. All printed capacity ratings are +/- 10%

except 50 HZ units.

50 HZ units cycle time will increase by approximately

12% and capacity will decrease by approximately 17%.

Ice Production Check

Take air temperature, if air-cooled condenser, at the

inlet of condenser, 2" from condenser fins.

Incoming water temperature at the outlet of the float valve.

Cycle time (CT) = Freeze time + harvest time, in minutes.

1440 divided by CT = number cycles per 24 hours.

Weight of ice from one cycle in pounds.

EXAMPLE:

Weight x cycles/day = total production/24 hours

Compare your known facts to the production tables

found in the product service manual.

3. Ice pattern will be very thick from top to bottom

of evaporator - unit may not enter harvest.

4. Frost on the suction line is normal on medium

temperature refrigeration equipment. Frost extending onto the compressor shell may not be a

problem. Before checking the sealed system,

check external conditions such as spacing

around poor ventilation, dirty condenser, etc.

CAUTION:

A) On models with the expansion valve bulb clamped to

a vertical section of the suction line - capillary tube

should point upward. This is done to eliminate the

possibility of contaminates from plugging capillary

tube. DO NOT RELOCA TE THE BULB.

B) Superheat settings and bulb charges are designed

specifically for Servend ice makers, and vary by model

and refrigerant used. Be sure to replace expansion

valves by part number and with Servend parts only.

33

Page 33

Installation and Service Manual

SHARP CORNERS

DETAIL "A"

COMPONENT DIAGNOSTICS

ACCEPTABLE ICE

JUMBO CUBE

SHARP CORNERS,

PARALLEL SIDES

ON CUBES

BRIDGE 1/8"

TO 3/16"

BRIDGE WILL VARY

FROM TOP TO BOTTOM

TYP. ALL SIZES

SHARP CORNERS

BRIDGE 1/8"

TO 3/16"

DETAIL "A"

EVENLY SPACED

DETAIL "A"

EVENLY SPACED

FULL CUBE

FRONT VIEW

FRONT VIEW

TOP VIEW

SHARP CORNERS,

PARALLEL SIDES

ON CUBES

TOP VIEW

SHARP CORNERS

BRIDGE 1/8"

TO 3/16"

34

DETAIL "A"

EVENLY SPACED

MINI CUBE

FRONT VIEW

AIR POCKETS

RANDOMLY SCATTERED

AT BACK OF MINI

CUBE ONLY

SHARP CORNERS,

PARALLEL SIDES

ON CUBES

TOP VIEW

Page 34

COMPONENT DIAGNOSTICS

Installation and Service Manual

LONG HARVEST OR

UNIT NOT LEVEL

SEE DETAIL "A"

COMPLETE SLAB OF ICE

LONG HARVEST OR

UNIT NOT LEVEL

BRIDGE OUTSIDE

RANGE OF

1/8" TO 3/16"

BRIDGE OUTSIDE

RANGE OF

1/8" TO 3/16"

HOLLOW CUBES

UNACCEPTABLE ICE

JUMBO CUBE

DETAIL "A"

FULL CUBE

POOR WATER DISTRIBUTION

UNEVEN TRACKING

OVER EXTRUSION

TYP. ALL SIZES

TOP VIEW

HOUNDS TOOTH

IF WHITE ICE OR POOR DISTRIBUTION

OCCURS DUE TO SLUSH, TEST

AFTER EXCESSIVE SLUSH CLEARS

TYP. ALL SIZES

TOP VIEW

HOLLOW CUBES

LONG HARVEST OR

UNIT NOT LEVEL

BRIDGE OUTSIDE

RANGE OF

1/8" TO 3/16"

HOLLOW CUBES

DETAIL "A"

DETAIL "A"

UNEVEN TRACKING

HOUNDS TOOTH

MINI CUBE

TOP VIEW

HOUNDS TOOTH

UNEVEN TRACKING

BITE MARKS GREATER

THAN 1/8" ON MINI CUBE ONLY

35

Page 35

Installation and Service Manual

3 RELAY CIRCUIT BOARD SEQUENCE OF OPERATION /

ADJUSTING BRIDGE THICKNESS / 3 RELAY CIRCUIT BOARD

COMPONENT DIAGNOSTICS

3 Relay Circuit Board Sequence Of Operation

When the toggle switch is placed in the ice mode,

the control board activates the water pump, condenser

fan motor (on air cooled units), the compressor contactor .

The water pump circulates the water supply across

the evaporator. The refrigeration system chills the evaporator removing removing the heat from the water and ice

is formed. This process continues until the ice rolls over

the evaporator bottom extrusion covering the thermistor

sensing tip. At approximate 26oF (-3.3oC) ice temperature the thermistor signals to the control board to start

the harvest mode.

The control board shuts down the water pump, condenser fan (on air cooled units) and activates the hot

gas valve for the harvest mode. When the water pump

stops, the water in circulation returns the water pan increasing the water level and creates the siphon action.

The siphon action cleans the water pan. The float assembly allows fresh water to fill the water pan for the

next cycle.

With the hot gas valve open the evaporator warms

up to allow the ice to move off the evaporator. The ice

travle forces the water curtain to open. The opening of

the water curtain interrupts the proximity switch circuit,

closing the hot gas valve. The ice falls into the storage

bin, the curtain closes activating the proximity switch and

the next refrigeration cycle begins. This operation is repeated until the ice drop during harvest can not clear the

water curtain. The curtain being held open for approximately 15 seconds causes the proximity switch to indicate a full bin, the curtain will close and the ice machine

will start in a refrigeration mode. The cycle(s) are repeated until the bin is once again full and the water curtain opens allowing the proximity switch to shut down

the ice machine operation.

Adjusting Bridge Thickness

For optimum ice production and maximum cube

seperation, the ice connecting the individual cubes

should be a minimum of 1/8" (.32cm) thick at the center

of the ice waffle.

CUBES

BRIDGE 1/8"

(0.32 cm)

3 Relay Circuit Board

These five (5) steps must be followed in proper sequence:

1. Set fine "pot" to 50

2. Set coarse "pot" to 50

3. Allow cuber to build ice until bridge appears to

be correct thickness (1/8" to 3/16" (.32 to .49cm)

thick

4. With water curtain in place, slowly advance (towards 100) coarse "pot" until harvest mode begins - allow the ice to harvest and check bridge

thickness to be 1/8" to 3/16" (.32 to .49cm) thick.

5. Additional adjustments to be made with fine "pot"

turning 1/2 to 1 division at a time until 1/8" to 3/

16" (.32 to .49cm) bridge is achieved. The lower

the number, the thicker the bridge.

NOTE: Too thin of a bridge (less than 1/8" (.32cm)

will cause harvest problems.

36

NOTE: Never judge the thickness from the first batch

of ice produced - the first cycle is a machine

balance cycle. Always wait for the second

cycle before making any adjustments.

Page 36

Installation and Service Manual

COMPONENT DIAGNOSTICS

3 RELAY CIRCUIT BOARD PROXIMITY SWITCH CHECK PROCEDURE