Page 1

BLADE TOWER

2 Valve Root Beer Dispenser

INSTALLATION & SERVICE GUIDE

Part Number 020001448

Notice: DO NOT throw this manual away.

This manual contains important information

regarding this product.

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

April 01, 2008 REV0

Keep this manual at the dispenser location.

Page 2

FOREWORD

Manitowoc Beverage Equipment (MBE) developed this manual as a reference guide for the owner/

operator, service agent, and installer of this equipment. Please read this manual before installation

or operation of the machine. A qualified service technician should perform installation and startup of this equipment, consult the

If you cannot correct the service problem, call your MBE Service Agent or Distributor. Always have your model and

serial number available when you call.

Your Service Agent___________________________________________________________________

Service Agent Telephone Number ______________________________________________________

Your Local MBE Distributor ___________________________________________________________

Distributor Telephone Number _________________________________________________________

Model Number ______________________________________________________________________

Serial Number _______________________________________________________________________

Installation Date _____________________________________________________________________

Troubleshooting Guide

within this manual for service assistance.

UNPACKING AND INSPECTION

Note: The unit was thoroughly inspected before leaving the factory. Any damage or irregularities should

be noted at the time of delivery.

WARRANTY INFORMATION

Consult your local MBE Distributor for terms and conditions of your warranty. Your warranty specifically

excludes all beverage valve brixing, general adjustments, cleaning, accessories and related servicing.

Your warranty card must be returned to Manitowoc Beverage Equipment to activate the warranty on this

equipment. If a warranty card is not returned, the warranty period can begin when the equipment leaves

the MBE factory.

No equipment may be returned to Manitowoc Beverage Equipment without a written Return Merchandise

Authorization (RMA). Equipment returned without an RMA will be refused at MBE’s dock and returned to

the sender at the sender’s expense.

Please contact your local MBE distributor for return procedures.

Page 3

TABLE OF CONTENTS

FOREWORD ........................................................................................................ 2

UNPACKING AND INSPECTION......................................................................... 2

WARRANTY INFORMATION ............................................................................... 2

SAFETY ............................................................................................................... 5

IMPORTANT SAFETY INSTRUCTIONS ........................................................................... 5

CARBON DIOXIDE WARNING ......................................................................................... 5

QUALIFIED SERVICE PERSONNEL ................................................................................ 5

SHIPPING, STORAGE, AND RELOCATION ..................................................................... 5

ADDITIONAL WARNINGS ................................................................................................ 5

INSTALLATION .................................................................................................... 6

UNIT INSPECTION ........................................................................................................... 6

PRE-INSTALLATION CHECK LIST .................................................................................. 6

STARTING YOUR BEVERAGE SYSTEM AND DISPENSER ............................................ 6

SPECIFICATIONS ............................................................................................................ 6

BLADE TOWER DIMENSIONS ........................................................................................ 7

COUNTER TOP FOOTPRINT ........................................................................................... 7

UNIT INSTALLATION ....................................................................................................... 8

BASIC B-I-B SYSTEM & PRESSURES ............................................................................ 8

DRAINAGE OPTIONS ...................................................................................................... 9

PLUMBING DIAGRAM LOCATION .................................................................................. 9

SINGLE TOWER PLUMBING ......................................................................................... 10

DUAL TOWER PLUMBING ............................................................................................ 10

TRIPLE TOWER PLUMBING ..........................................................................................11

BRIXING PROCEDURE ................................................................................................... 11

SYRUP DELIVERY SYSTEM .......................................................................................... 12

BACK ROOM PACKAGE ............................................................................................... 12

RACKING ....................................................................................................................... 13

B-I-B ............................................................................................................................... 13

PUMPS ........................................................................................................................... 13

AUTO BAG SELECTORS............................................................................................... 13

Page 4

TABLE OF CONTENTS

USER MAINTENANCE ...................................................................................... 13

PREVENTATIVE MAINTENANCE .................................................................................. 13

WINTERIZATION ............................................................................................................ 13

CO2 HANDLING ............................................................................................................. 13

HOW TO DISASSEMBLE TOWER COMPONENTS ....................................................... 14

CLEANING EQUIPMENT AND SUPPLIES ..................................................................... 14

CLEANING & SANITIZING THE DISPENSING VALVES & PRODUCT LINES ............... 14

MAINTENANCE SCHEDULE ......................................................................................... 15

NIGHTLY SHUTDOWN PROCEDURE ............................................................................ 15

CLEANING AND SANITIZING PROCEDURE ................................................................. 16

BEVERAGE SYSTEM CLEANING ................................................................................. 16

BAG-IN-BOX SYSTEM ................................................................................................... 17

TROUBLESHOOTING ....................................................................................... 18

DRINKS .......................................................................................................................... 18

Page 5

Installation and Service Manual

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual. Learn how to operate the A&W Tower unit

properly. Do not allow anyone to operate the unit without proper training and keep it in proper

working condition. Unauthorized modifications to the A&W Tower may impair function and/or

safety and affect the life of the unit.

CARBON DIOXIDE WARNING

DANGER: Carbon Dioxide (CO2) displaces oxygen. Exposure to a high concentration of CO2 gas

causes tremors, which are followed rapidly by loss of consciousness and suffocation. If a CO2 gas leak

is suspected, particularly in a small area, immediately ventilate the area before repairing the leak. CO

lines and pumps should not be installed in an enclosed space. An enclosed space can be a cooler or

small room or closet. This may include convenience stores with glass door self serve coolers. If you

suspect CO2 may build up in an area, venting of the B-I-B pumps and / or CO2 monitors should be utilized.

QUALIFIED SERVICE PERSONNEL

WARNING: Only trained and certified electrical and plumbing technicians should service this unit.

All wiring and plumbing must conform to national and local codes.

2

SHIPPING, STORAGE, AND RELOCATION

CAUTION: Before shipping, storing, or relocating this unit, syrup systems must be sanitized. After

sanitizing, all liquids (sanitizing solution and water) must be purged from the unit. A freezing environment causes residual sanitizing solution or water remaining inside the unit to freeze, resulting

in damage to internal components.

ADDITIONAL WARNINGS

Installation and start-up of this equipment should be done by a qualified service technician. Operation,

maintenance, and cleaning information in this manual are provided for the user/operator of the equipment.

Save these instructions.

5

Page 6

INSTALLATION

Installation and Service Manual

Included with each Blade Tower should be one (1) installation kit (020001441) and if multiple towers are being

installed a tee kit (020001411) is included with each additional tower. Listed below are the contents of each kit;

020001441- KIT INSTL 2 VLV RB BLADE TOWER

Item Description Quantity

00861302 SPLICER 1/4 X 3/8 BARB SS 2

020001403 UBEND BARB 1/2 X 1/2 X 28 1/4 1

11.3-505R CLAMP STEPLESS SS 4

15514500 CLAMP STEPLESS SS 14.5MM 2

18.5-706R CLAMP STEPLESS SS 2

020001448 MAN A AND W BLADE TOWER 1

0901803 WASHER FLAT #10 ZINC 4

020002097 SCR 10-24 X 2 SS 4

00850812 NUT HEX 10-24 SS 4

5006594 WASHER STAR #10 SS 4

Thoroughly inspect the unit upon delivery. Immediately report any damage that occurred during transportation to

the delivery carrier. Request a written inspection report from a claims inspector to document any necessary claim.

UNIT INSPECTION

020001411- KIT CONDUIT TEE 4 LINE

Item Description Quantity

00854996 ELL 1/2 X 1/2 BARB SS 2

5009851 TEE 3/8 BARB 2

15514500 CLAMP STEPLESS SS 14.5MM 6

18.5-706R CLAMP STEPLESS SS 4

1900315 BAG 9X12 CLR ZIPLOCK 1

5029545 TAPE 3IN X 60FT BLK 1

PRE-INSTALLATION CHECK LIST

When installing any system, first make sure the major components are available. Generally the major components

necessary for an installation are:

Pre-mix system:

CO

regulator set

2

Product connectors for tank

Gas connectors for tank

Beverage dispenser

Beverage tubing

CO

tank

2

Beverage tanks

Stepless (Oetiker) clamps

Chain for CO

Double Check:

tank

2

B-I-B System:

B-I-B connectors

B-I-B regulator set

B-I-B rack

B-I-B syrup boxes

Also consider the location of the following items before installation:

Water line

Drain

Power outlet

Heating and air conditioning ducts

Do you have enough space to install the dispenser?

Is the counter top level?

Can the counter top support the weight of the

tower?

STARTING YOUR BEVERAGE SYSTEM AND DISPENSER

Upon completion of the beverage dispenser and / or system installation, all tubing, dispenser, and system components must be cleaned and sanitized prior to use.

NOTE: At installation equipment, dispensers, and tubing

get moved through many environments, dirt, dust, chases,

insulation, drywall, etc. It is an important procedure and

best practice to address cleaning to deliver the best quality

drink to your customer.

Clean and sanitize the water and syrup circuits according

to instructions provided in this manual. Clean and sanitize

the dispenser components according to instructions provided in this manual. Seal the unit to the counter top. Consult and use local health codes if a discrepancy occurs

between this manual and your local health codes.

SPECIFICATIONS

Blade Tower has a stainless steel cabinet standard. Beverage valves, tubing connections, valves are top serviceable.

The tower drains through either an existing counter top drain or the optional drain for this unit. Optimum ambient

conditions for Blade Tower operation is between 500F and 950F.

6

Page 7

.750

1.750

Counter Top Weight

INSTALLATION

BLADE TOWER DIMENSIONS

11.86

9.68

3.00

17.30

10.75

5.00

3.29

7.39

Installation and Service Manual

25 Lbs (11.34 Kgs)

4.88

COUNTER TOP FOOTPRINT

COUNTER TOP AREA

CAUTION:

be braced to support the dispenser counter top weight plus ice storage capacity and weight of icemaker, if applicable.

Cutting the counter top may decrease its strength. Counter should

7

Page 8

Installation and Service Manual

INSTALLATION

UNIT INSTALLATION

1. Using the footprint cut holes in the desired counter

top location(s). If installing the optional flush mount

drain cut the hole for the drain(s) at this time also.

Repeat this step for each tower being installed if

this is a two or three tower system.

Use an existing drain or the optional flush mount drain as

Illustrated above (See Drain Options).

NOTE: The minimum to maximum ambient tempera-

ture that the unit should be installed and operated at is 40 degrees F to 105 degrees F (4.44

C to 40.56 C)

2. Place the tower(s) in the desired location(s). Each

tower must be placed and operated in a horizontal

(level) position.

3. Run the beverage lines and water lines; make sure to

install the water connections to the proper inlets. If

installing more than one tower connect the tee tower

kit at this time, 1 per additional tower installed.

(

See the Plumbing Section)

4. If installing the optional flush mount drain plumb for

drain(s) and insulate at this time.

5. Turn water supply on to the dispenser. Water pressure should be between 40 and 55 psi with the carbonator pump running. If not in between those pressures, proper measures must be taken to regulate

them to correct settings.

6. Once water is supplied to unit air needs to be purged

from the carbonator tank. Do so by lifting the pressure

relief valve tab on the carbonator tank until water

comes out of the relief valve.

7. Check water and beverage lines for leaks, if there

are no leaks fasten the tower to the counter top

using the bolts included in the installation kit and

seal to the counter top using a silastic sealant such

as Dow Corning RTV 731 or equivalent on the base

bottom edges.

8. Meet all local code requirements.

9. Brix beverage valves. (See the Brixing Section)

10. Attach tower top riser.

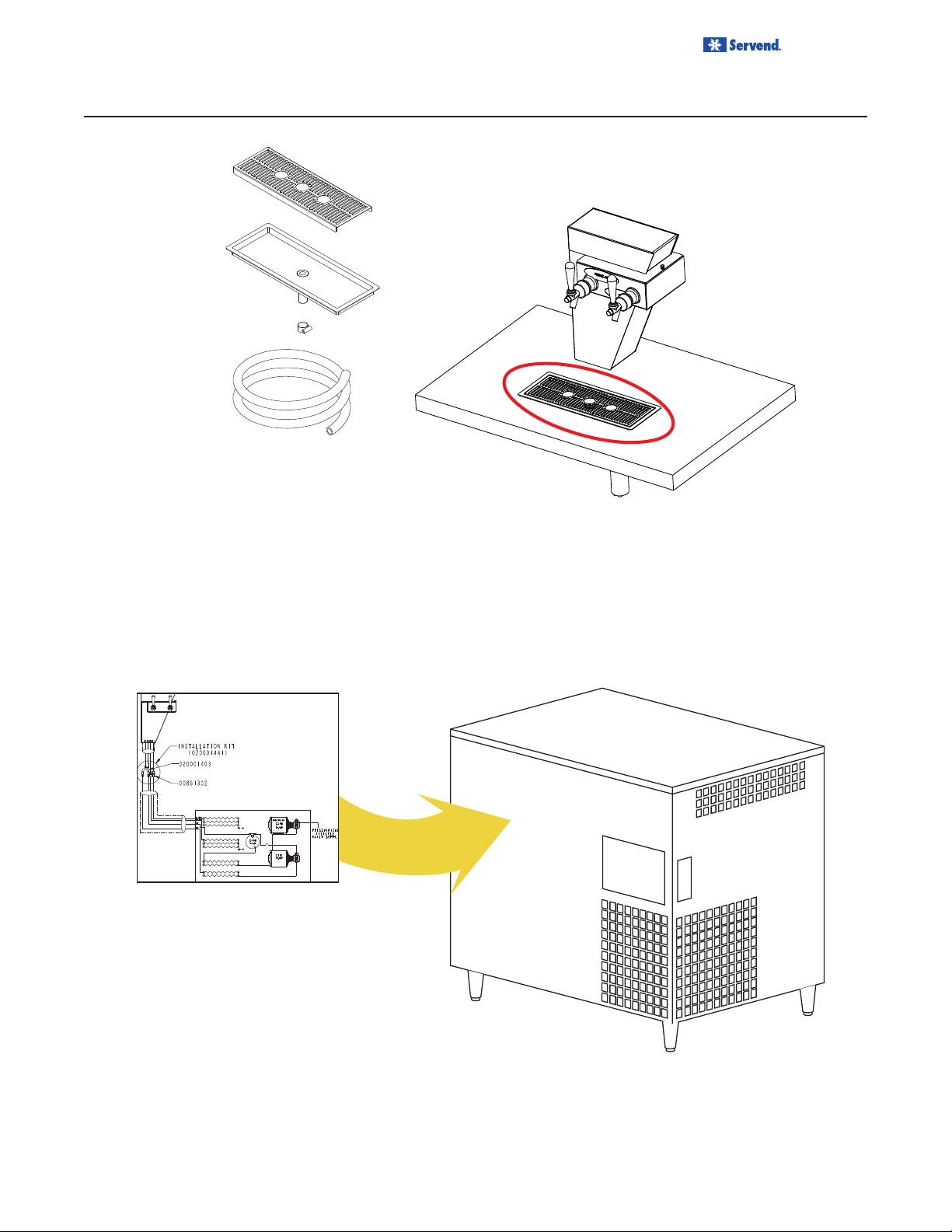

BASIC B-I-B SYSTEM & PRESSURES

Typical A&W

Blade Tower Rootbeer

Dispensing System (BIB)

SYRUP

SYRUP

CARBONATED WATER

1

Tap Water

Multiplex

1. Incoming tap water - should be at a minimum dy-

namic pressure of 40 psi and maximum static pres-

sure of 80 psi. (measured at inlet to pump).

2. BIB pressure gauge set for 35-40 psi or according to

your line run.

CARBONATED WATER

CO

2

NOTE:

This is a simplified schematic to

show the basic operation of the

SYRUP

SYRUP

beverage system.

Countertop

BIB

Syrup Pump

2

Bag-In-Box

Syrup

Carton

Blade Tower Valves

SYRUP

SYRUP

3

1800

Cylinder

2

CO

90

60

CO

2

CO

2

3. CO2 supply regulator should be set between 26-30 psi.

NOTE: If incoming water pressure is under 40 psi, a wa-

ter booster is recommended. If incoming water

pressure is over 80 psi, a water regulating valve

is required.

8

Page 9

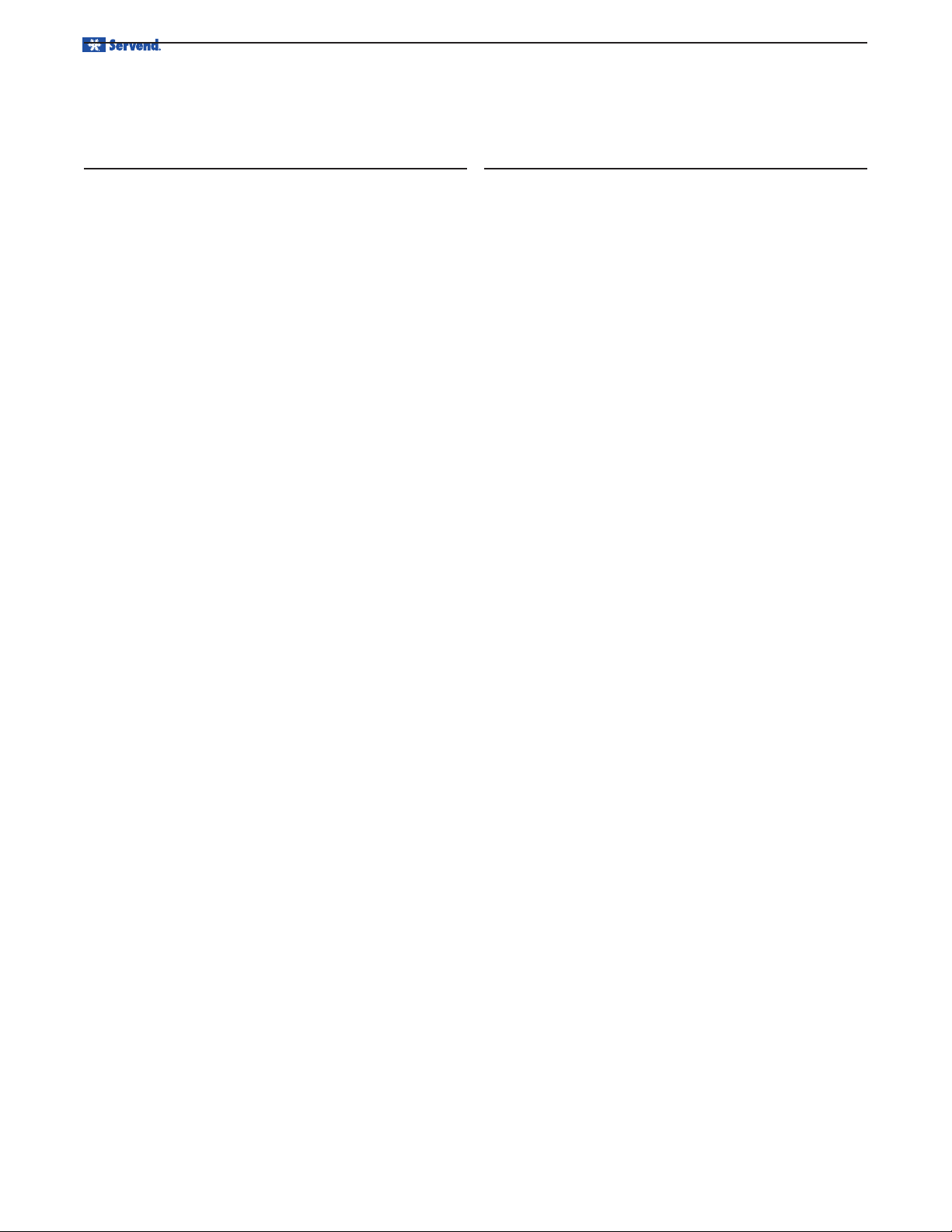

DRAINAGE OPTIONS

Flush Mount Drain - 020001388

Installation and Service Manual

INSTALLATION

The Blade Tower can be set up to use an existing drain or an optional drain can be ordered for use with the tower.

The illustration below shows the optional flush mount drain setup (Part Number 020001388). If using the optional

flush mount drain be sure to plumb according to local codes.

PLUMBING DIAGRAM LOCATION

A plumbing diagram for the A&W rootbeer system can be found on the remote refrigeration unit or see the

Plumbing Section for the plumbing diagram that fits your installation.

9

Page 10

Installation and Service Manual

INSTALLATION

SINGLE TOWER PLUMBING

DUAL TOWER PLUMBING

10

Page 11

INSTALLATION

TRIPLE TOWER PLUMBING

Installation and Service Manual

BRIXING PROCEDURE

NOTE: This tower consists of two valves combined as one with a mixer block, mixer tube and mixer. One Pre-ME

valve (CMBEGKER) and one Flomatic 424 Flow Control Base

Set water flow rate first:

1. Turn off syrup shut-off at post-mix (424) valve block.

2. Use stop watch to time the dispense of soda water

only.

3. Dispense for 5 seconds.

4. Record volume in a volume cup or ratio cup.

Water Shut-off

Syrup Shut-off

Water Flow Rate

Adjustment

Syrup Flow Rate

Adjustment

5. Adjust the water flow rate as needed until 10 ounces

of water is measured in a 5 second (2 oz/sec) dispense.

Set the syrup flow rate:

1. Adjust the ratio (brix) of water to syrup (4.75:1) or 12.3

to 12.7 brix)

2. Turn on syrup shut-off and turn off the water shut-off.

3. Use a stop watch to time the dispense of syrup only.

4. Dispense for 5 seconds.

5. Record volume in a volume cup or ratio cup.

6. Adjust syrup flow rate as needed until 2 ounces of

syrup is measured in a 5 second dispense.

7. Use a refractometer if possible to get final brix ratio of

12.3 to 12.7. You will have to rely on volume adjustment above for diet products.

11

Page 12

Installation and Service Manual

OPERATION

SYRUP DELIVERY SYSTEM

Your syrup location can vary depending on the volume of beverages served and ease of accessibility. Your beverage system may set in a back storage room or under the counter of the dispenser. Configurations are almost

limitless. Check the temperatures expected for the storage location. Adverse temperatures can affect the storage

and quality of beverage products. It is recommended the temperature of storage location should not fall below 40

F or rise above 90o F.

BACK ROOM PACKAGE

o

1. Incoming tap water - should be at a minimum dynamic pressure of 40 psi and maximum static pressure of 55 psi.

2. Carbonator Water pump motor - Powers the water

pump. The water pump motor is part of the carbonator pump deck.

3. Carbonator Water pump - Pumps tap water into the

carbonator tank. The water pump is part of the carbonator. The incoming water for the carbonator must

be first ran through the pump before connecting to

the proper cold plate inlet.

4. Internal/External Carbonator tank - Combines CO

gas and tap water to form carbonated water. The “carbonator” is the carbonator tank, water pump and water pump motor.

5. CO2 cylinder - Holds highly pressurized carbon dioxide (CO2). The CO2 cylinder is a steel or aluminum

cylinder tank. CO2 gas flows through the primary pressure regulator.

12

6. BIB pressure gauge - Set for a minimum of 60 psi.

Indicates CO2 pressure going to B-I-B pumps.

7. Primary pressure regulator - Lowers the CO2 gas

pressure, to 100 psi, so the CO2 gas will be at the

proper pressure to enter the carbonator regulator.

8. Lowered outgoing pressure - Set for 75 psi. Gauge

indicated lowered outgoing pressure from the CO2 cylinder after being routed through the primary pressure

regulator at 100 psi..

9. Secondary pressure regulator - Lowers the CO2 gas

pressure before the CO2 gas flows to the syrup pump.

CO2 pressure, activates the syrup pump.

2

10. Syrup pump - Draws syrup out of the bag-in-box

syrup package. Syrup flows through the syrup lines

to the dispenser for chilling, then dispensing. There

is a syrup pump for each bag-in-box syrup system.

11. Bag-In-Box syrup cartons - Box which contains a

plastic bag, filled with syrup.

Page 13

Installation and Service Manual

OPERATION

RACKING

Regardless if you are working on pre-mix or post-mix (B-I-B or Figal) system, a place will be designated for placement

of the product. A rack (or shelf) system affords systematic placement and complete usage of the beverage paid for. The

B-I-B rack allows the boxes to lay properly for syrup dispersal. Please check with your B-I-B syrup supplier. Some boxes

must be slightly tilted down, while others may be in virtually any position. The Figal tank rack keeps the newer and full

tanks organized at one end of the beverage line with the partial tanks at the other.

B-I-B

The Bag-In-Box system refers to a plastic disposable bag. The B-I-B normally contains 5 gallons of syrup, however

some locations offer 2 1/2 or 3 gallon B-I-B units. This plastic bag is then held inside a cardboard or other container. BI-B systems are for post-mix applications only.

PUMPS

The syrup in a B-I-B system is delivered to the beverage system through gas operated pumps. These pumps extract the

syrup out of the bags forcing the syrup throughout the system.

AUTO BAG SELECTORS

These are used on higher volume B-I-B systems where two or more bags of the same product are connected to one

pump and one system. An auto bag selector is essentially a valve that automatically changes from one bag (or series of

bags) to another bag (or series of bags) of syrup as the bags empty, allowing a constant flow of product.

USER MAINTENANCE

PREVENTATIVE MAINTENANCE

Preventative maintenance is a vital part of keeping your Servend dispenser in top condition. Following the guidelines

below will assist you in continued trouble free operation of your unit. Contact MBE at 1-800-367-4233 for more

information about our ProActive Maintenance Program.

1. Conduct the daily and nightly recommended maintenance of the machine.

2. Perform the monthly recommended maintenance of

the machine.

WINTERIZATION

Servend equipment is rated for indoor use only. This

equipment will not operate in sub-freezing temperatures.

In a situation when temperatures drop below freezing

the equipment must be turned off immediately and properly winterized. Contact the manufacturer for winterization processes.

CO2 HANDLING

Breathing high

concentrations of carbon

dioxide gas can cause

tremors, followed by loss

of consciousness and

suffocation

Route CO

CO2 DISPLACES OXYGEN

All CO2 tanks must be chained and/or affixed to a permanent

post or wall. Changing of or recharging tanks should be

done by a trained individual. Contents of the tanks are

stored at an extreme high pressure and can cause physical

damage if not handled properly.

vent tube

2

outside or to an

3. Perform periodic maintenance and sanitizing of beverage system.

5. Do not allow the dispenser to sit for prolonged periods

of non use.

NOTE: The minimum to maximum ambient temperature

that the unit should be installed and operated at is 40 degrees F to 105 degrees F (4.44 C to 40.56 C).

DANGER: Carbon Dioxide (CO2) displaces oxygen. Expo-

sure to a high concentration of CO2 gas causes tremors,

which are followed rapidly by loss of consciousness and

suffocation. If a CO2 gas leak is suspected, particularly in a

small area, immediately ventilate the area before repairing

the leak. CO2 lines and pumps should not be installed in an

enclosed space. An enclosed space can be a cooler or

small room or closet. This may include convenience stores

with glass door self serve coolers. If you suspect CO2 may

build up in an area, venting of the B-I-B pumps and / or CO

monitors should be utilized.

2

13

Page 14

Installation and Service Manual

USER MAINTENANCE

HOW TO DISASSEMBLE TOWER COMPONENTS

Note: This tower consists of two (2) valves combined as one (1) with a mixer block, mixer tube, and mixer. One

pre-mix valve (CMBECKER) and one (1) Flomatic 424 flow control base.

1

Tower & Valve Disassembly:

1. Remove tower housing cover by removing the

thumb screw on the side.

2. Turn OFF both shut-off valves on the flow control

base and remove pressure by pulling the dispense

handle to the ON position.

Water Shut-off

Water Flow Rate

Adjustment

Mixer Block

Latch Pin

Syrup Shut-off

Syrup Flow

Rate Adjustment

Flow Control

Base Latch Pin

CLEANING EQUIPMENT AND SUPPLIES

• Recommended cleaner: Any caustic-base (low

sudsing, non-perfumed, easily rinsed) detergent solution which provides a minimum 2% sodium hydroxide. The solution should be prepared in accordance

with the manufacturer's instructions. Solution temperature should be between 90°F (32°C) to 110°F (43°C).

Temperatures in excess of this can cause internal damage to the dispensing valve components.

• Recommended sanitizer: Any sanitizer which provided a minimum of 100 parts per million (100 milligrams per liter) of available chlorine. Solution temperature should be between 90°F (32°C) to 110°F

(43°C). Temperatures in excess of this can cause internal damage to the dispensing valve components.

3. Remove the latch pin on the mixer block by pulling

straight up.

4. Unscrew the inside flange nut on the pre-mix valve.

5. Remove the pre-mix valve and mixer tube out the

front of the tower.

6. Remove the 424 flow control base by lifting up on

its latch pin.

To reassemble follow these steps in reverse order.

• Two five gallon (figals) syrup tanks and fittings,

cleaned and sanitized (one for cleaner; one for

sanitizer).

• Containers for cleaner and sanitizer solutions

• Clean, non-abrasive cloths

• Bucket

• Small Brush

• Extra Nozzles

• Extra Jumpers

CLEANING & SANITIZING THE DISPENSING VALVES & PRODUCT LINES

All cleaning must meet your local health department regulations. The following cleaning instructions are

provided as a guide.

CAUTION: Use only warm soapy water to clean the exterior of the dispensing tower. Do not

use solvents or other cleaning agents

14

.

Page 15

Installation and Service Manual

USER MAINTENANCE

MAINTENANCE SCHEDULE

Everyday Dispensing Valves For the pre-mix dispensing valve, run carbonated water

ONLY through the valve and dispense nozzle for 10

seconds. Turn syrup shut OFF, and block the dispense

nozzle base with a clean new napkin. Dispense carbonated water only for a few seconds to fully fill the dispense

nozzle. Then unblock the dispense nozzle and flow

carbonated water for 10 seconds. Wipe external nozzle

surfaces with carbonated water, then turn syrup shut off,

ON. Clean other nearby surfaces with carbonated water or

cleaning solution.

Everyday Drip pan and drain hose Wash with mild detergent. Rinse with clean water.

Everyday Quick disconnects Wash with mild detergent. Rinse with potable water.

Weekly Outside, dispenser cabinet Wash with clean water and mild detergent. Wipe dry.

Every 3 months Syrup circuits Sanitize each syrup circuit. See ”Cleaning and Sanitizing

Procedure“.

Every 3 months Water bath Drain, melt ice and clean using detergent and brush; rinse

with potable water. Do not use water over 140°F (60°C).

Every 6 months Condenser Vacuum fins or use soft bristle brush (scrub brush).

Every 6 months Air purifier filter (if equipped) Replace.

NIGHTLY SHUTDOWN PROCEDURE

It is recommended that the following steps are followed to keep your Blade Tower clean and running properly;

1 Remove tower top piece to gain access to the

valves.

2 Turn the syrup shut off valve to the OFF position on

all valves (2 valves per tower).

3 Dispense carbonated water for 10 seconds from all

valves.

4 Leave valves off overnight and turn back on in the

morning for use.

15

Page 16

Installation and Service Manual

USER MAINTENANCE

CLEANING AND SANITIZING PROCEDURE

Note: Cleaning and sanitizing is not required for potable water circuits. Potable water lines should remain con-

nected and operational during the cleaning and sanitizing procedures for syrup circuits.

Caution: It is required that the Carbonated Water Lines should remain connected and operational during cleaning and sanitizing of the syrup circuits. Sanitizing of the valve without the

Carbonated Water side operation may leave bacteria in the nozzle, diffuser, and syrup tube.

CLEANING THE DISPENSING VALVES

1. Disconnect each syrup container from its product line,

tank connector, or bag-in-box connector. Remove

product from the lines by purging with clean warm

tap water until syrup has been fully purged from the

product lines and valves.

2. Clean all lines and fittings with cleaning solution and

rinse with clean, room temperature water to remove

all traces of residual product.

3. For the A&W pre-mix valve, clean dispense nozzle in

place with sanitizing solution and nozzle brush, up to

internal shut off port.

Caution: Do not allow cleaning and sanitizing solutions to remain in syrup systems longer than

recommended contact time. Exceeding contact time will result in damage to valve components.

PRESSURIZING THE PRODUCT LINES

1. For 15 seconds turn dispensing valve “on”, “off”,

and then immediately “on” again for 15 cycles.

2. Allow the valve to remain flowing for 3 minutes.

3. Repeat pulsing and flowing the valves again until all

cleaning solution has been used.

4. Flush the cleaning solution from the lines with clean

water after a minimum of 3 minutes, by pulsing the

valves as described above.

5. Attach each valve product line to the pressure tank

containing the sanitizing solution or place the bag-inbox connector in sanitizing solution. Remove branch

port cover on bag-in-box connector to allow suction

of sanitizing solution. Be sure all connections are

cleaned and sanitized before connecting to each product line.

BEVERAGE SYSTEM CLEANING

CLEANING THE PRODUCT LINES

1. To clean each valve product line, attach the valve

product lines to the pressure tank containing the

cleaning solution or place the bag-in-box connector

in cleaning solution. Remove branch port cover on

bag-in-box connector to allow suction of cleaning

solution. Make sure each line is completely filled.

Pressurize the lines by pulsing the valves.

6. Pressurize and fill the lines with sanitizing solution.

Make sure lines are completely filled. Allow the sanitizing solution to flow through each valve while activating the valves for 15 cycles (as described in “Pressurizing the product lines”).

a. Leave valves “off” and allow to stand pressur-

ized for 30 minutes.

b. Activate the valves for two (2) cycles (as de-

scribed in “Pressurizing the product lines”). Flush

remaining sanitizer continuously through the

valves.

7. Reconnect the syrup containers to their respective

circuits. Prepare the unit for operation.

8. Draw drinks to refill lines and flush the sanitizing

solution from the dispenser. Taste the beverage to

verify that there is no off-taste (chlorine).

Sanitize the beverage system at initial start-up as well as regularly scheduled cleaning. The drain pan must be in

place under soda valves, to carry away detergent and sanitizing agents that will be flushed through valves.

16

Page 17

Installation and Service Manual

USER MAINTENANCE

BAG-IN-BOX SYSTEM

The procedure below is for the sanitation of one syrup circuit at a time. Repeat to sanitize additional circuits.

You will need the following items to clean and sanitize

the Bag-in-Box (BIB) beverage system:

• Three (3) clean buckets

• Plastic brush or soft cloth

• Mild detergent

• Unscented bleach (5% Na CL O) or

Commercial sanitizer

• Bag-In-Box bag connector

1. Prepare the following in the buckets:

• Bucket 1 - warm to hot tap water for rinsing.

• Bucket 2 - mild detergent and warm to hot water.

• Bucket 3 - mix a solution of unscented bleach

(5% Na CL O) or commercial sanitizer and warm

to hot water. Mixture should supply 100 PPM available chlorine (1/4 oz. bleach to 1 gallon water).

2. Disconnect the “syrup-line side” of the bag-in-box

connector.

3. Rinse connector with warm tap water.

4. Connect syrup connector to BIB connector and im-

merse both into Bucket 1. A “bag-side” connector

can be created by cutting the connector from an

empty disposable syrup bag.

5. Draw rinse water through system until clean water

is dispensed. Most beverage valves allow the syrup

side to be manually activated by depressing the

syrup pallet.

6. Connect Bucket 2 to system.

7. Draw detergent solution through system until solu-

tion is dispensed.

8. Repeat steps 2-7 until all syrup circuits contain de-

tergent solution.

9. Allow detergent solution to remain in the system for

5 minutes.

10. Connect Bucket 3 to system.

11. Draw sanitizing solution through system until solu-

tion is dispensed.

12. Repeat step 11 until all syrup circuits contain sani-

tizer solution.

13. Allow sanitizer solution to remain in system for 15

minutes.

14.Remove nozzles and diffusers from beverage

valves.

15. Scrub nozzles, diffusers and all removable valve

parts (except electrical parts) with a plastic brush

or a soft cloth and the detergent solution.

17

Page 18

Installation and Service Manual

CONDITION INVESTIGATION CHECK CORRECTION

TROUBLESHOOTING

DRINKS

Water only dispensing No pressure Regulator(s) out of

adjustment

Out of CO

2

Defective regulator(s) Check/repair/replace regulator(s)

CO

line pinched, kinke d or

2

obstructed

Syrup and CO

dispensing

only

2

Carbonator No power Check power supply. Plug in

Water supply Make sure water is turned "on"

Defective carbonator Check/repair/replace carbonator

Syrup and plain water

only dispensing

No pressure Out of CO

HP regulator out of

2

adjustment

Defective HP regulator Check/repair/replace HP regulator

CO

line pinched, kinke d or

2

obstructed

One valve wi ll not

dispense anything

Is there power to the

val ve?

Broken wire or loose

connection

Bad microswitch Replace microswitch

Beverage dispensed

is too sweet

Is the ratio (brix) of

the drink correct?

Flow control out of

adjustment

Insufficient soda flow due to

low carbonator pressure

Low CO

leaks

pressure due to

2

Obstruction in the water or

soda line

Beverage is not sweet

enough

Is the ratio (brix) of

the drink correct?

Flow control out of

adjustment

Soda flow too high Reset CO

Obstruction in syrup line Clean out the syrup line

Drinks are foaming Are system

Over carbonation Check CO

pressures correct?

Dirty lines/valves Clean/sanitize entire system

Check/adjust regulator(s)

Install fresh tank

Check/repair/replace CO2 line

carbonator or reset breaker.

Replace water filter

Check/clean/replace pump strainer

Check/clean/repair water check

valve

Check for frozen water li ne.

Internal Carbonator unit only.

pump, motor, electrode or liquid

level control.

Install fresh tank

Adjust HP regulator to the proper

setti ng

Check/repair/replaceCO2 line

Replace/repair wire or connector

Adjust the flow control

Adjust CO

tank

pressure or change the

2

Repair CO2 leaks

Clean out the lines

Adjust the flow control

pressure or replace

regulator if necessary

pressure or replace regulator if

2

supply. Reset

2

necessary

18

Page 19

TROUBLESHOOTING

Installation and Service Manual

CONDITION

Water Only Dispensing

Syrup and CO2 only

Dispensing

One Valve will not

dispense anything

Beverage Dispense is

too sweet

Drinks are Foaming

Drink Stratification

too great

INVESTIGATION

No Pressure

Carbonator

Pre-Mix Valve

(CMBecker)

Post-Mix Valve

(Flomatic 424)

Are system

pressures correct

Visually verify Soda

Water and Syrup flowing

at the same time in

mixer block, when

initially dispensing

CHECK

BNB Fittings Clogged

Tank Fittings Clogged

No Power

Check Liquid Level

Control Board

For Clogging

For Mechanical

For Clogging

For Mechanical

Syrup Push Pressure

Check Valves in Water

and Product Lines.

If soda water check

valve is bad, Syrup will

overcome soda water

when first dispensing

product. If syrup check

valve is bad, soda water

will overcome syrup flow

when first dispensing

product

CORRECTION

Clean and Sanitize

Clean and Sanitize

Check Power Supply

Replace Control

Clean and Sanitize

Replace if Necessary

Clean and Sanitize

Replace parts or entire

valve if necessary

Adjust to 30-40 PSI per

Tower Manual. Lower

equals less foaming.

Too low will limit flow

volume.

Replace check valve(s)

19

Page 20

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

020001448 April 01, 2008 REV0

Loading...

Loading...