Page 1

Flomatic

Beverage Valves

Technician’s

Handbook

This manual is updated as new information and models

are released. Visit our website for the latest manual.

America’s Quality Choice in Refrigeration

Part Number STH15 9/10

www.manitowocfsg.com

Page 2

Page 3

Safety Notices

!

Warning

!

Caution

Important

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this handbook.

Disregarding the notices may lead to serious injury

and/or damage to the equipment.

Throughout this handbook, you will see the following

types of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Ca ution box alerts you to a situation in

which you could damage the equipment. Be sure

to read the Caution statement before proceeding,

and work carefully.

Procedural Notices

As you work on Manitowoc equipment, be sure to read

the procedural notices in this handbook. These notices

supply helpful information which may assist you as

you work.

Throughout this handbook, you will see the following

types of procedural notices:

Text in an Important box provides you with

information that may help you perform a

procedure more efficiently. Disregarding this

information will not cause damage or injury, but it

may slow you down as you work.

NOTE: T ext set off as a Note provides you with simple,

but useful, extra information about the procedure you

are performing.

Page 4

Read These Before Proceeding:

!

Caution

Important

! Warning

We reserve the right to make product

improvements at any time. S pecifications and

design are subject to change without notice.

Proper installation, care and maintenance are

essential for maximum performance and troublefree operation of your Manitowoc equipment. If

you encounter problems not covered by this

handbook, do not proceed, contact Manitowoc

Foodservice Group. We will be happy to provide

assistance.

Routine adjustments and maintenance

procedures outlined in this handbook are not

covered by the warranty.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

Page 5

Table of Contents

General Information

Model Numbers . . . . . . . . . . . . . . . . . . . . .7

How to Read a Model Number . . . . . . . . .8

Model/Serial Number Location . . . . . . . .8

Accessories . . . . . . . . . . . . . . . . . . . . . . .8

Special Applications . . . . . . . . . . . . . . . .12

Warranty Information . . . . . . . . . . . . . . . .12

Installation

Pre-installation Checklist . . . . . . . . . . . . .13

324, 424 & 464 Valves . . . . . . . . . . . . . . .13

Component Identification

Valve Types . . . . . . . . . . . . . . . . . . . . . . . .19

Levers . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Maintenance

Maintenance Schedule . . . . . . . . . . . . . . .23

Cleaning and Sanitizing the Dispensing

Valves and Product Lines . . . . . . . . . . . .25

Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . .28

Setting the Brix . . . . . . . . . . . . . . . . . . . . .32

Operation

Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . .33

Automatic Fill Valve . . . . . . . . . . . . . . . . .34

Troubleshooting

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . .35

Carbonated Water System . . . . . . . . . . . .37

Circulating System . . . . . . . . . . . . . . . . . .44

Dispensing Valve . . . . . . . . . . . . . . . . . . .45

When the Brix is OFF . . . . . . . . . . . . . . . .50

Component Check Procedures

RATIO . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

BUZZING . . . . . . . . . . . . . . . . . . . . . . . . . .53

LEAKS . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Every 6 months (2 times per year) . . . . . 53

Part Number STH15 9/10 5

Page 6

Component Specifications

Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . 57

424 Specifications . . . . . . . . . . . . . . . . . . 57

464 Specifications . . . . . . . . . . . . . . . . . . 58

Product Viscosity . . . . . . . . . . . . . . . . . . 58

6 Part Number STH15 9/10

Page 7

General Information

Model Numbers

This manual covers the following models:

424 464-GP

(Back Block) 380-Q (Back Block)

372-Q

Tower

Part Number STH15 9/10 7

Page 8

How to Read a Model Number

GP - Global Performance

HF - High Flow

464

454

424

324

202

Model Suffix

Model Base

464–GP

VALVE MODEL NUMBERS

With all models, mounting and ratio control are the same.

All Flomatic valves are identified by a Model Number,

Serial Number, a manufacture month and year on the

underside of the flow control base. These numbers are a

helpful reference before beginning any valve service.

Model/Serial Number Location

This number is required when requesting information

from your local distributor. All Flomatic valves are

identified by a Model Number, Serial Number, a

manufacture month and year on the underside of the flow

control base. These numbers are a helpful reference

before beginning any valve service

Accessories

Manitowoc Foodservice developed this manual as a

reference guide for the service agent and installer of

fountain equipment.

Fountain dispensing is the serving of a beverage (soft

drink, tea, or juice, etc.) from a dispenser that will chill

the product to an acceptable serving temperature for

the consumer.

The beverage, delivery system and dispenser can be

postmix or premix. The system may be an elaborate

system with most of the components in the back of the

store and the dispenser in the front. Fountain systems

could be a simple system with the complete system

under the counter where the dispenser is located.

Our goal is that this manual will remove some of the

confusion, and mystery of beverage dispensing

equipment while providing a general overview of

service to the equipment.

8 Part Number STH15 9/10

Page 9

VALVES

Most Flomatic valves are available in sanitary push

lever, push button,automatic fill lever, and portion

control models.

Replacement

Flomatic created a kit (5007842) to replace both the 372-Q

or 380-Q Flomatic mounting blocks. All Flomatic mounting

blocks are identical in appearance, except for the part

numbers shown on the front recess of the block. The 380Q has inlet ports sized at 0.380 in. The 372-Q inlet ports

are sized at 0.372 in.

WHAT IS CARBONATION

Carbonation is the process of mixing carbon dioxide gas

into a liquid (water). The resulting liquid is called soda

water or carbonated water . The carbon dioxide gas is the

bubbles you see when a carbonated beverage (like soda)

is dispensed.

Most cola, lemon-lime products, etc. are carbonated.

Normally teas, juices, etc. are noncarbonated.

Some beverage technicians refer to noncarbonated water

as sweet water.

WATER CHARACTERISTICS

Water makes up over 80% of the typical finished

beverage. The quality of this primary ingredient is of

utmost importance. You should use regular cold tap water,

not water that has been through a water sof tener,

conditioner, etc. Any of f taste or color should be treated by

proper water filtration.

Part Number STH15 9/10 9

Page 10

WATER FILTERS

It is recommended that proper water filters treat the water

supply for the beverages. There are two basic filters

commonly in use.

1. Pre-filter, or sand filter . This filter re moves any foreign

matter from the water down to 25 microns in size.

2. Carbon or activated charcoal filter is also used. This

filter will reduce chlorine and other chemicals, offtaste and odor . Some of the higher quality filters may

reduce organic compounds (bacteria) in the water.

Do not use a filter containing any typ e of phosphate on the

beverage system. Phosphate as used for scale reduction

will cause the beverage to loose its carbonation and

become “flat” quickly .

WATER PRESSURES

Dynamic (flowing) water pressures to most

carbonators should be a minimum of 40 PSI. Water

pressure to dispensers for noncarbonated beverages

should be a minimum of 60 pounds. These pressures

are minimum operating pressures, not static pressure.

SYRUP BASICS

Your concentrated syrup containers should be stored

in a cool dry location that is easily accessible. Any

extremes in temperature can wreak havoc with the

quality of the product. For best results, the syrup

should be maintained in an environment between 40

and 90 degrees.

PREMIX

Premix fountain dispensing consists of a container

(figal) of beverage ready for dispensing, beverage

delivery system, carbon dioxide (CO

2) propellant,

beverage cooling system, and dispenser. We shall

discuss each component of this type of system within

the context of this manual.

The major advantage of a premix system over most

other types is its flexibility . This flexibility is the ability to

go anywhere. Many premix systems will operate

without electric power or separate water supply.

10 Part Number STH15 9/10

Page 11

POSTMIX

Postmix fountain dispensing consists of either a tank

(called a Figal) or a box (called a Bag-in-Box) of

beverage syrup. The postmix system will also include

the carbonator, fresh water supply, carbon dioxide

(CO

2) supply, syrup delivery system, beverage cooling

system, and dispenser. We shall discuss each

component of this type of system within the context of

this manual.

The major advantage of the postmix system over most

other systems is the very low cost of delivering a high

quality, fresh beverage to the consumer utilizing less floor

and storage space for the quantity of beverages served.

PIPING

The fountain system is connected together by a series

of tubing or hoses. This tubing is called beverage tube

or hose and is commonly available in 1/4”, 3/8”, and 1/

2” inside diameters. Beverage hose is a flexible, highpressure hose. This hose is capable of withstanding

system pressures in excess of 100 PSI. The beverage

hose may be an individual line or assembled with

many lines of hose bundled together.

The beverage tubing or hose is attached to the various

components of the system with barbed stems, nuts,

tees, etc. The tubing is held onto the fittings with small

tube clamps called stepless (Oetiker®) clamps. When

attaching the tubing and fitting to a “flared” fitting, the

use of a flare washer is required.

Several different type of tubing are available for the

beverage industry. If there is any possibility of the

tubing laying in a damp environment, the use of nonpermeable tubing should be used. Tubing is also

available as a single tube or bundled together. Single

tube is available as non-permeable plastic or stainless

steel. Bundled tube is available as plastic only.

Part Number STH15 9/10 11

Page 12

Special Applications

!

Warning

OUTDOOR APPLICATIONS

Flomatic Valves are approved and listed by

Underwriters Laboratories (UL). However they are not

UL approved for weather exposure applications.

These units must be installed in areas where adequate

protection from the elements is provided, all other

models are ETL listed.

Personal Injury Potential

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

Warranty Information

Consult your local distributor for terms and conditions

of your warranty. Your warranty specifically excludes

all beverage valve brixing, general adjustments,

cleaning, accessories and related servicing.

No equipment may be returned without a written

Return Materials Authorization (RMA). Equipment

returned without an RMA will be refused at the dock

and returned to the sender at the sender’s expense.

Please contact your local distributor for return

procedures.

12 Part Number STH15 9/10

Page 13

Installation

Important

Pre-installation Checklist

When installing any system, first make sure the

following has been done:

Relieve the system pressure before

removing or repairing the mounting block.

Determine which mounting block you need.

324, 424 & 464 Valves

These valves are available in manual, electric, portion

control and automatic fill models. All of these Flomatic

valves share the same mounting and flow control

characteristics. The 324 valves are also compatible

with the 300-Q mounting block.

Flomatic created a kit (5007842) to replace both the

372-Q or 380-Q Flomatic mounting blocks. All

Flomatic mounting blocks are identical in appearance,

except for the part numbers shown on the front recess

of the block. The 380-Q has inlet ports sized at 0.380

in. The 372-Q inlet ports are sized at 0.372 in. Select

the appropriate mounting option and install the

mounting block. Wet the inlet O-rings with water to

ease installation; do not use Vaseline®. Align the four

bolt holes and mount

.

Be sure to relieve the system pressure before

removing or repairing the mounting block.

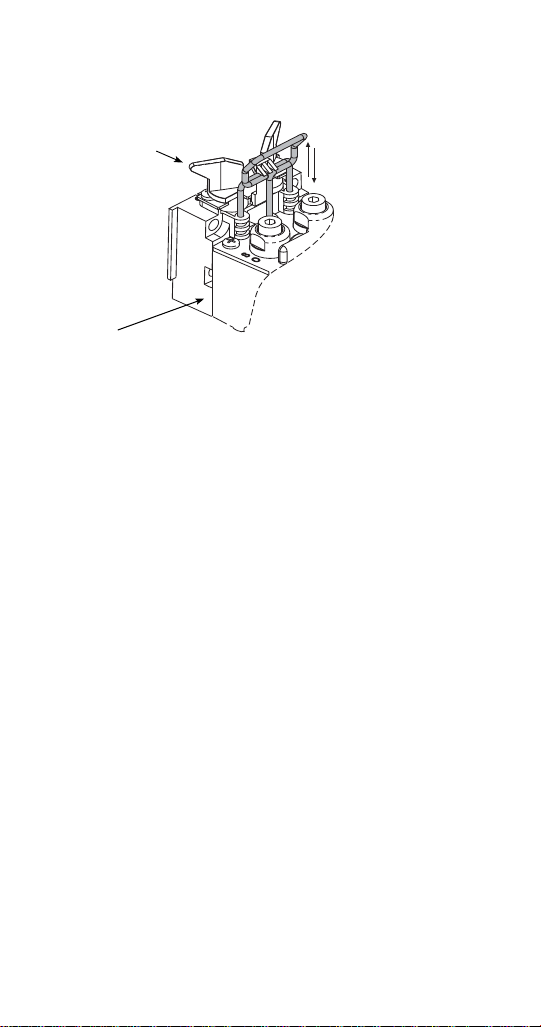

Remove the valve cover and align the valve stems

with the mounting block. Independent positive

shut-offs and the locking system prevent removal

while the system is pressurized. The valve cannot be

removed unless the shut-off valves are closed (arrows

pointed across service line).

Part Number STH15 9/10 13

Page 14

The mounting hole pattern typically has key slots to

Valve should seat securely

Shut-off closed

secure the product supply lines. If no key slots are

present, use the “S” clip option.

Engage the valve and depress the latch pin. Do not

force or you could bend the pin. If you have difficulty,

remount the valve and try again. Be sure the valve

base is completely seated against the block. Open the

shut-off valves by turning 1/4 turn (arrows pointed

toward service line) to engage system pressure.

INSTALL ADD-A-LEVER FOR “SODA ONLY”

The Flomatic Add-a-Lever is a two-piece assembly

which mounts on the pivot pin. Remove the cover,

partially withdraw the pivot pin to allow mounting,

reinsert the pin then replace the cover.

CONVERT TO PORTION CONTROL

Flomatic portion control electronics are contained in

the cover and can be factory or field installed. When

installing in the field, the 5031015 Conversion Kit for

the 464-GP makes it easy to add portion control.

The portion control module is designed to simplify

installation. The board can be programmed with the

first pour.

The “Stop/Fill” button serves as a top-off button and

cancels any of the timed portions if you need to abort

the pour.

14 Part Number STH15 9/10

Page 15

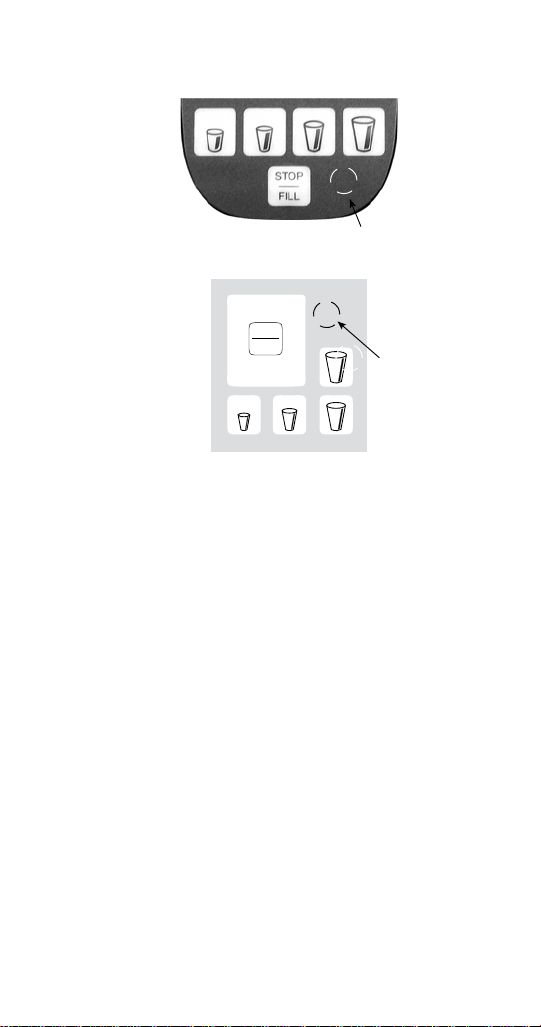

Hidden Program Switch

464 Portion Controls

STOP

Hidden Program

Switch

424 Portion Controls

FILL

Each cup size must be programmed separately. Cup

sizes are preprogrammed at the factory:

1 second = small

2 second = medium

3 second = large

4 second = x-large.

Set the flow rate first, brix the valve, and then set the

cup sizes to match your desired flow rate. Once the

valve is brixed, replace the valve cover and set the

times (cup sizes) from the front switch pad.

The switch pad has a hidden “program” switch that

must be held down to keep the module in program

mode. Setting the times or programming is a

two-handed operation; push and hold the program

switch with one finger while dispensing the cup size

you wish to program with another. Once the drink is

full, simply release the cup size button to end the pour

cycle and then let go of the program switch. Repeat

the process for each cup size.

Part Number STH15 9/10 15

Page 16

The module will remember one top-off cycle

Pivot Pin

Cover

automatically if the foam height requires it to complete

the pour. To program a top-off cycle, begin

programming as described above. Once the foam

crests the top of the cup, PAUSE by removing your

finger from the cup size button. Do not release the

program button. Pause long enough for the foam to

settle, and then continue the pour with your finger on

the same cup size button until the cup is full. The

module will remember the sequence “pour - pause pour” as it was executed.

If you program the top-off feature, be sure to train the

operators so they do not pull a drink before the cycle is

complete. The portion control module will finish the

pour whether a cup is there or not.

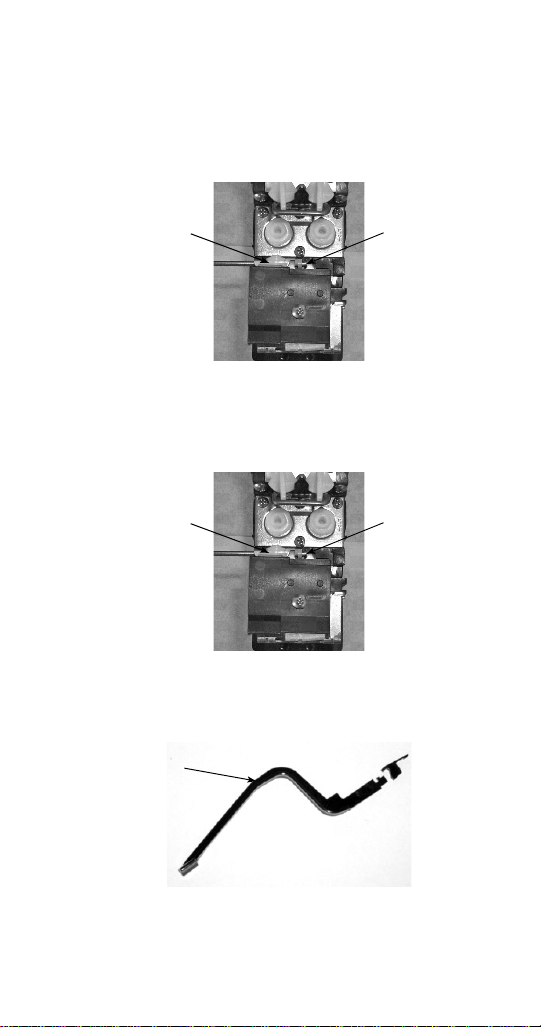

TO CONVERT PUSH BUTTON TO SANITARY LEVER OPERATION

Flomatic Valve W ith Pallet Actu ators

1. Remove the valve cover from the valve.

2. Slide pivot pin far enough to one side to remove

the actuator spacer bushing from between the two

actuator assemblies.

16 Part Number STH15 9/10

Page 17

3. Slide the pivot pin back into place. Make sure both

Actuator Spacer

Bushing

Actuator Assembly

Actuator Spacer

Bushing

Actuator Assembly

Sanitary Lever

actuator assemblies are mounted correctly on the

pivot pin. The “fingers” of the solenoid armature must

be located on the back side of the actuators. When

the armature pulls into the solenoid, these “fingers”

will pull the actuators and open the pallets.

4. Slide sanitary lever from the bottom up into the

flow control base. The notch on the sanitary lever

will be on the top of the lever facing toward the

back of the valve. Hook the notch near the top of

the lever over the pivot pin.

5. Snap the electric retainer cap onto the sanitary

lever. Make sure it is tight. The retainer cap has a

top “arm” extension that is the back portion of the

retainer.

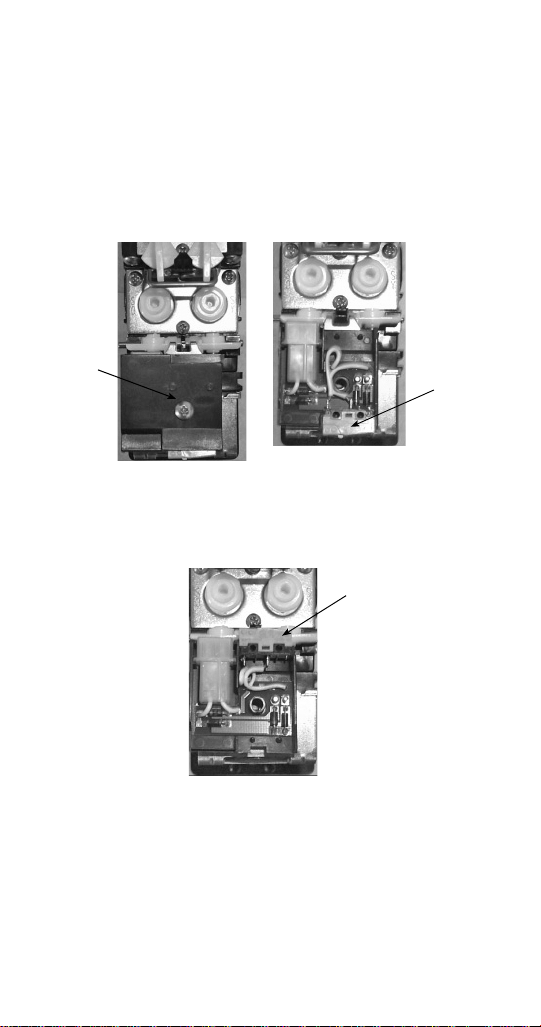

6. Remove the screw from the convertible switch

housing cover.

Part Number STH15 9/10 17

Page 18

7. The switch cover snaps together with a top and

Convertible

switch

housing

screw

Switch

Switch

bottom half. Unsnap the top cover. Downward

pressure on the bottom half of the assembly while

unsnapping the sides of the switch assembly

makes the job easier. If you accidentally pull the

entire switch assembly off the solenoid, you must

put it back one piece at a time. Gently lift the

micro switch from the two pins in the front of the

convertible switch housing base.

8. Being careful not to break any wires, flip the micro

switch on its back. Install the switch on the two

pins at the rear of the lower switch base. Make

sure the button on the switch lines up with the

retainer cap arm.

9. Snap the switch housing cover onto the base and

re-install the screw. Tighten the screw snug.

10. Install a push lever cover or place a flavor label

over the entire front of the valve cover.

18 Part Number STH15 9/10

Page 19

Component Identification

Push Button

Portion Control

Automatic Fill

Sanitary Push Lever

Universal Electrical

Connection

Field

Conversion

Switch

Solenoid Plunger

Diffuser

Nozzle

Mounting Block Lever

Wire Keeper

Mounting Block

Ratio Control

Torsional Pallet

Spring

24-volt AC

Solenoid

Valve Types

464-GP POST-MIX

Parts

Part Number STH15 9/10 19

Page 20

424 POST-MIX

Push Button

Portion Control

Automatic Fill

Sanitary Push Lever

Universal Electrical

Connection

Field

Conversion

Switch

1 Piece

Diffuser

Mounting Block Lever

Wire Keeper

Mounting

Block

Ratio Control

24-volt AC

Solenoid

Soft Pour

Clear Nozzle

Parts

20 Part Number STH15 9/10

Page 21

Levers

1 2 3 4 5

6 7

1. Automatic Fill Lever (Walrus) Part # 516-10. This lever

is used on current production Automatic Fill valves.

2. Automatic Fill Lever Part # 516-08. This Stainless Steel

auto fill lever was used on the 424-A30, 454-A30, and

464-A30 valves.

3. Lever Molded Sanitary Part # 516-09. This Lever is

currently used on 424 sanitary lever valves and on 464GP sanitary lever valves. This lever was also used on

454 and 464 valves.

4. Lever Stainless Steel Sanitary Part # 516-06. This lever

was used on early production 424 and 454 sanitary

lever valves, and can also be used on current

produ cti on s ani tar y le ver val ves whe n th e

application requires a stainless steel lever.

5. Euro Lever Part # 516-07. This lever is used in the

European market for Flomatic valves and on Flomatic

202 water valves.

6. Lever Black (Dove Tail) Part # 516-01. This was the

standard lever used on 424, and 454 valves prior to the

sanitary lever. Until August 15, 2001 this lever was

produced for 202 water valves. This lever has been

replaced by Part# 516-07.

NOTE: See technical bulletin TB-FL03-01.

7. M4 Lever Sanitary Part # 516-04. This valve is used on

the 424-612-M4-1521 Juice Valve.

8. Not Shown Powder coated Stainless Steel Sanitary

Lever Part # 516-06-B. Used on 202-FN-SLB-B valves.

This lever is the same as # 4 (516-06) but it has a black

powder coat finnish.

Part Number STH15 9/10 21

Page 22

22 Part Number STH15 9/10

This Page Intentionally Left Blan k

Page 23

Maintenance

!

Caution

!

Warning

! Warning

Maintenance Schedule

This section provides a list of periodic maintenance tasks

and the scheduled frequency required to ensure the

proper operation of your dispensing equipment. To ensure

quality beverages, prevent downtime, and reduce costs,

these tasks must be performed as indicated.

All cleaning must meet your local health department

regulations. The following cleaning instructions are

provided as a guide.

Use only warm soapy water to clean the exterior of the

valve. Do not use solvents or other cleaning agents.

Electric Shock Hazard

Unplug unit before servicing or cleaning.

Rubber gloves and eye protection should be worn.

PERIODIC MAINTENANCE

Dispensing Stations

• Take te mperature of finished drinks. Pour off the

first and take the temperature of the second drink.

The proper temperature of drinks must be 40°F

(4°C) or less.

• Remove nozzles and diffusers from each

dispensing valve.

Part Number STH15 9/10 23

Page 24

• Clean with soap and warm water (not hot). Rinse with

Important

carbonated water and reinstall.

If you wish to soak the nozzle and diffusers, soak them

ONL Y

in soda water , NEVER use bleach.

• Brush lever slot with warm water to prevent syrup

build-up and sticking. Wipe cover and panel with a

clean cloth and you are finished. Nothing more

needs to be done unless you experience a problem.

• If refurbishing a piece of equipment, remove the

solenoid from the valve. Once removed, the entire

valve can be submerged in warm water for cleaning.

• Flush all dispenser drains. Pour warm water down

drains at closing.

Daily

• Take temperature of finished drinks. Pour off the

first and take the temperature of the second drink.

The proper temperature of drinks must be 40°F

(4°C) or less.

• Remove nozzles and diffusers from each

dispensing valve. Clean with soap and warm water

(not hot). Rinse with carbonated water and

reinstall.

• Clean general area of syrup hookup with soap and

warm water. Rinse off all soap.

24 Part Number STH15 9/10

Page 25

Cleaning and Sanitizing the Dispensing Valves and Product Lines

MAINTENANCE SCHEDULE

Every day

Dispensing valves

Drip pan and drain hose

Quick disconnects

Weekly

Outside, dispenser cabinet

Every 3 months

Syrup circuits

CLEANING EQUIPMENT AND SUPPLIES

• Recommended cleaner: Any caustic-base (low

sudsing, non-perfumed, easily rinsed) detergent

solution which provides a minimum 2% sodium

hydroxide. The solution must be prepared in

accordance with the manufacturer’s instructions.

Solution temperature must be between 90°F

(32°C) and 110°F (43°C). Temperatures in excess

of this can cause internal damage to the

dispensing valve components.

• Recommended sanitizer: Any sanitizer which

provides a minimum of 120 parts per million

(120 milligrams per liter) of available chlorine.

Solution temperature must be between 90°F

(32°C) and 110°F (43°C). Temperatures in excess

of this can cause internal damage to the

dispensing valve components.

• Two five gallon (figals) syrup tanks and fittings,

cleaned and sanitized (one for cleaner; one for

sanitizer)

• Containers for cleaner and sanitizer solutions

• Clean, non-abrasive cloths

• Buckets

• Small Brush

• Extra Nozzles

Part Number STH15 9/10 25

Page 26

CLEANING AND SANITIZING PROCEDURE

!

Caution

NOTE: Cleaning and sanitizing is not required for

potable water circuits. Potable water lines must remain

connected and operational during the cleaning and

sanitizing procedures for syrup circuits.

It is required that the Carbonated Water Lines

remain connected and operational during

cleaning and sanitizing of the syrup circuits.

Sanitizing of the valve without the Carbonated

Water side operation may leave bacteria in the

nozzle, diffuser, and syrup tube.

Cleaning and dispensing valves

1. Disconnect each syrup container from its product

line. Remove product from the lines by purging

with clean warm tap water until syrup has been

fully purged from the product lines and valves.

2. Clean all lines and fittings with cleaning solution

and rinse with clean, room temperature water to

remove all traces of residual product.

Cleaning the product lines

1. To clean each valve product line, attach the valve

product lines to the pressure tank containing the

cleaning solution. Make sure each line is

completely filled. Pressurize the lines by pulsing

the valves.

Pressurizing the product lines

A. For 15 seconds turn dispensing valve ON,

OFF, and then immediately ON again for 15

cycles.

B. Allow the valve to remain flowing for 3

minutes.

C. Repeat pulsing and flowing the valves again

until all cleaning solution has been used.

26 Part Number STH15 9/10

Page 27

!

Caution

Do not allow cleaning and sanitizing solutions to

remain in syrup systems longer than

recommended contact time. Exceeding contact

time will result in damage to valve components.

2. Remove the nozzles and the diffuser assemblies

from the valves. Clean with cleaning solution.

Agitate the assemblies to ensure assemblies are

clean. Place them in a container of sanitizing

solution for 15 minutes. Wearing sanitary gloves,

remove the nozzles and diffuser assemblies from

the sanitizing solution. Drain each until dry and

reassemble to the valves.

3. Flush the cleaning solution from the lines with

sanitizer after a minimum of 3 minutes, by pulsing

the valves as described above.

4. Attach each valve product line to the pressure

tank containing the sanitizing solution. Be sure all

connections are cleaned and sanitized before

connecting to each product line.

5. Pressurize and fill the lines with sanitizing

solution. Make sure lines are completely filled,

Allow the sanitizing solution to flow through each

valve while activating the valves for 15 cycles.

A. Leave valves OFF and allow to stand

pressurized for 30 minutes.

B. Activate the valves for two (2) cycles. Flush

remaining sanitizer continuously through the

valves.

6. Reconnect the syrup containers to their

respective circuits. Prepare the unit for operation.

7. Draw drinks to refill lines and flush the sanitizing

solution from the dispenser. Taste the beverage to

verify that there is no off-taste (chlorine).

Part Number STH15 9/10 27

Page 28

Sanitizing

! Warning

! Warning

BEVERAGE SYSTEM CLEANING

Flush sanitizing solution from syrup system.

Residual sanitizing solution left in system could

create a health hazard.

When using cleaning fluids or chemicals, rubber

gloves and eye protection must be worn.

Sanitize the beverage system at initial start-up as well

as regularly scheduled cleaning. The drain pan must

be in place under soda valves, to carry away detergent

and sanitizing agents that will be flushed through

valves.

BAG-IN-BOX SYSTEM SANITATION

The procedure below is for the sanitation of one

syrup circuit at a time. Repeat to sanitize

additional circuits.

You will need the following items to clean and sanitize

the Bag-in-Box (BIB) beverage system:

• Three (3) clean buckets

• Plastic brush or soft cloth

• Mild detergent

• Unscented bleach (5% Na CL O) or

Commercial sanitizer

• Bag-In-Box bag connector

1. Prepare the following in the buckets:

• Bucket 1 — warm to hot tap water for rinsing.

• Bucket 2 — mild detergent and warm to hot

water.

28 Part Number STH15 9/10

Page 29

• Bucket 3 — mix a solution of unscented

Bag

side

connector

bleach (5% Na CL O) or commercial sanitizer

and warm to hot water. Mixture should supply

100 PPM available chlorine (1/4 oz. bleach to

1 gallon water).

2. Disconnect the “syrup-line side” of the BIB

connector.

3. Rinse connector with warm tap water.

Part Number STH15 9/10 29

Page 30

4. Connect syrup connector to BIB connector and

immerse both into Bucket 1. A “bag-side”

connector can be created by cutting the connector

from an empty disposable syrup bag.

5. Draw rinse water through system until clean water

is dispensed. Most beverage valves allow the

syrup side to be manually activated by depressing

the syrup pallet.

6. Connect Bucket 2 to system.

7. Draw detergent solution through system until

solution is dispensed.

8. Repeat steps 2-7 until all syrup circuits contain

detergent solution.

9. Allow detergent solution to remain in the system

for 5 minutes.

10. Connect Bucket 3 to system.

11. Draw sanitizing solution through system until

solution is dispensed.

12. Repeat step 11 until all syrup circuits contain

sanitizer solution.

13. Allow sanitizer solution to remain in system for 15

minutes.

14. Remove nozzles and diffusers from beverage

valves.

15. Scrub nozzles, diffusers and all removable valve

parts (except electrical parts) with a plastic brush

or a soft cloth and the detergent solution.

16. Soak nozzles, diffusers and removable valve

parts (except electrical parts) in sanitizer for 15

minutes.

17. Replace nozzles, diffusers and valve parts.

18. Connect Bucket 1 to system.

19. Draw rinse water through system until no

presence of sanitizer is detected.

20. Attach syrup connectors to BIBs.

21. Draw syrup through system until only syrup is

dispensed.

22. Discard first 2 drinks.

30 Part Number STH15 9/10

Page 31

FIGAL BEVERAGE SYSTEM

1. Prepare the following in three clean Figal tanks:

• Rinse tank - fill with room temperature tap water .

• Detergent tank - mix approved beverage system

cleaner with warm water as directed.

• Sanitizing ta nk - mix a solution of unscented bleach

(5% Na CL O) or commercial sanitizer and warm to

hot water. Mixture should supply 100 PPM available

chlorine (1/4 oz. bleach to 1 gallon water).

2. Disconnect all product and water lines from product

tanks and remove carbonator .

3. Locate the Figal syrup tank for the circuit to be sanitized.

Remove both quick disconnects from the Figal syrup

tank. Rinse quick disconnects in tap water .

4. Connect rinse tank to the syrup line. Draw clean rinse

water through the valve until syrup is flushed from the

system.

5. Connect detergent tank to the syrup line and draw

detergent through the valve for two minutes. Then, allow

remaining detergent to stay in the system for five

minutes.

6. Connect rinse tank to the syrup line. Draw clean rinse

water through the valve until detergent is flushed from the

system.

7. Remove valve nozzle and diffuser as shown in Daily

Cleaning instructions. Using a plastic brush or a soft cloth

and warm water, scrub the nozzle, diffuser , bottom of the

dispensing valve and cup lever, if applicable.

8. Place removable valve parts (EXCEPT solenoids) in

sanitizing solution for 15 minutes.

9. Replace valve diffuser and nozzle on the beverage valve.

10. Connect sanitizer tank to the syrup line and draw

sanitizer through the valve for two minutes. Allow

sanitizer to remain in the system for a minimum of 15

minutes.

11. Reconnect syrup and carbonated water lines.

12. Draw syrup through the lines to rinse the system. Discard

drinks until at least two cups of satisfactory tasting

beverage are dispensed through the valve.

Part Number STH15 9/10 31

Page 32

Setting the Brix

5 oz. 1 oz.

RATIO

RATIO

4 oz.

1 oz.

RATIO

RATIO

FLOMATIC BRIX CUP INSTRUCTIONS

OZ CC

CCOZ

225

200

175

150

125

100

75

50

50

RATIO

The Flomatic Brix Cup provides scale graduation on

both the soda and syrup compartments. It is sized

such that with a normal 5:1 product, the syrup and

soda will be at the same level.

With each side of the cup graduated in ounces (or

cc’s), you can easily proportion a range of products

from 2:1 through 11:1.

45

8

7

40

6

35

11:1

30

1

5

25

4.75

20

4

3

15

11:1

2

10

5

1

5:1

RATIO

5:1

Set the soda flow rate first, then brix or adjust syrup to

the desired ratio. If you want 4:1, adjust the syrup flowrate to have filled to the 1 oz. mark when you have

delivered 4 oz. of soda.

8 oz.

1 oz.

RATIO

RATIO

The diagram represents 4:1 and 8:1 but the cup will

easily accommodate products from 2:1 to 11:1

32 Part Number STH15 9/10

Page 33

Operation

5/32 Allen Wrench Flow Controls

Flow Rate

To simplify installation, the soda flow rate is optimized

for cold carb operation and is preset at the factory:

3.125 oz./second soda water flow rate is standard for

the 464-GP. Should field conditions require adjusting

the flow rate, clockwise movement of the adjustment

screw increases the flow rate and vice versa. Ceramic

flow controls can be adjusted from 2 oz./second to 4.0

oz./second total flow rate on the GP valve.

RATIO CONTROL

You will need a syrup separator, hex wrench (5/32

Allen), and brix cup. Place the Flomatic S-tube syrup

separator (part no.1089-00) over the syrup diffuser.

You need not remove the nozzle.

Most brix cups are calibrated for the standard 5:1 ratio.

Adjust the syrup flow by moving the adjusting screw

until the desired ratio is established.

Part Number STH15 9/10 33

Page 34

Automatic Fill Valve

1

2

3

The Automatic Fill valve can be used to dispense both

carbonated and noncarbonated products. The valve is

factory set for carbonated products where a delayed

top-off is standard, and the wire-lead plug should be

attached to pins 1 and 2 (those furthest to the left). If

your installation uses noncarbonated products

requiring no top-off, you will need to adjust the position

of the lever wire-lead plug on the electronics. For

noncarbonated products, the wire-lead plug should be

attached to pins 2 and 3 (those furthest to the right), as

shown in the photo.

The Automatic Fill valve requires no sensitivity

adjustments. The valve automatically delays top-off if

more foam is present after the initial pour, and

performs a top-off more quickly if less foam is present.

34 Part Number STH15 9/10

Page 35

Troubleshooting

!

Warning

Checklist

If a problem arises during operation of your Flomatic

Valve, follow the checklist below. Routine adjustments

and maintenance procedures are not covered by the

warranty.

Only trained and certified beverage technicians

must service this unit. All wiring and plumbing

must conform to national and local codes.

Problem Possible Cause To Correct

Water only

dispensing:

No pressure

Syrup and CO2 only

dispensing:

Carbonator

Syrup and plain

water only

dispensing: No

pressure

One valve will not

dispense anything:

Is there power to

the valve?

Regulator(s) out of

adjustment

Out of CO

Defective regulator(s) Check/repair/replace

CO2 line pinched,

kinked, or obstructed

Defective carbonator Check/repair/replace carbonator

HP regulator out of

CO

kinked, or obstructed

Broken wire or loose

Bad microswitch Replace microswitch.

2

No power Check power supply. Plug in

Water supply Make sure water is turned ON.

Out of CO

2

adjustment

Defective HP

regulator

line pinched,

2

connection

Check/adjust regulator(s).

Install fresh tank.

regulator(s).

Check/repair/replace CO2 line.

carbonator or reset breaker.

Replace water filter.

Check/clean/replace pump

strainer.

Check/clean/repair water check

Internal Carbonator unit only.

pump, motor, electrode or liquid

Adjust HP regulator to the proper

Check/repair/replace CO2 line.

Replace/repair wire or connector.

valve.

Check for frozen water line.

level control.

Install fresh tank.

setting.

Check/repair/replace HP

regulator.

Part Number STH15 9/10 35

Page 36

Problem Possible Cause To Correct

Beverage

dispensed is too

sweet:

Is the ratio (brix) of

the drink correct?

Beverage is not

sweet enough:

Is the ratio (brix) of

the drink correct?

Drinks are foaming:

Are system

pressures correct?

Flow control out of

adjustment

Insufficient soda flow

due to low carbonator

pressure

Low CO2 pressure

due to leaks

Obstruction in the

water or soda line

Flow control out of

adjustment

Soda flow too high Reset CO2 pressure or replace

Obstruction in syrup

line

Over carbonation Check CO2 supply. Reset

Dirty lines/valves Clean/sanitize entire system.

Adjust the flow control.

Adjust CO2 pressure or change

Repair CO2 leaks.

Clean out the lines.

Adjust the flow control.

regulator if necessary.

Clean out the syrup line.

pressure or replace regulator is

the tank.

necessary.

36 Part Number STH15 9/10

Page 37

Carbonated Water System

Qualifier

Malfunctioning of

Refrigeration

System.

Malfunctioning of

Circulating System.

Beverages at

dispensing tower

are below 40°F

(5°C).

Probable

Cause

Flat drinks

Beverages at

dispensing

tower are above

40°F (5°C).

CO2 supply

exhausted.

Primary CO2

Regulator out of

adjustment or

inoperative.

Water Regulator

incorrectly

adjusted or

inoperative.

Improper water

treatment.

Carbonator

Pump worn

(Brass pump).

Pressure Relief

Valve is leaking.

Corrective Action

Refer to Troubleshooting

“Refrigeration System” under Warm

Refer to Troubleshooting “Circulating

minimum of 500 psi (35 kg/cm2) on

Primary Pressure Regulator Gauge

marked 0-2000 psi. Switch to full t ank

Ensure CO2 Shut-off Valves to

Carbonators are both in the ON

position. Refer to Troubleshooting

“CO2 Gas System” under Flat drinks.

Verify CO2 Primary Regulators are set

at 90 psi (6.3 kg/cm2). Adjust if

necessary if Regulator will not stay in

Verify Filtered Water Pressure Gauge

registers 55 psi (3.9 kg/cm2), if higher

than 55 psi, flooding of Carbonator will

occur. To adjust, loosen Locknut, turn

Adjustment Screw clockwise to

decrease. If regulator will not respond

to adjustments, replace regulator.

Verify By-pass handle is in the “filter

operating” position. Ensure Filter

Cartridge is still effective, if necessary

Troubleshooting “Water Filter System”

Dispense Carbonated Water while

listening for carbonator pump and

motor to cycle ON at Refrigeration

Unit. Pumps should operated between

6 to 12 seconds before cycling OFF. If

operating time exceeds 30 seconds

carbonator pump is worn, replace

Remove top cover from Remote

Carbonated Water until carbonator

Pumps and Motor cycle ON. Observe

Pressure Relief Valves on carbonator

Tank. If water is observed escaping

from either, replace leaking Relief

Note: Do not confuse the Water Bath

Make-up valve for the carbonator T ank

drinks.

System” under Warm drinks.

Verify CO2 T ank pr essu re is a

if necessary.

adjustment replace Regulator.

increase, counterclockwise to

replace Cartridge. Refer to

Pump.

Refrigeration Unit. Dispense

valve.

Relief valves.

Part Number STH15 9/10 37

Page 38

Qualifier

Beverages at

Dispensing Tower

are below 40°F

(5°C). (continued)

Probable

Cause

Back Flow

Preventer.

Double Check

valve (water)

stuck open.

Corrective Action

Remove top cover from Remote

Refrigeration Unit. Use a soap

solution around Back Flow Preventer.

If bubbles appear at Vent Hole or

underside of Back Flow Preventer,

clean or replace Back Flow Preventer

and corresponding Water Check valve

carbonator Tank.

With top cover from Remote

Refrigeration Unit removed and

carbonator Pump Switch and Water

turned OFF, loosen water supply line

at inlet side of Double Check valve

Assembly. If CO2 gas escapes from

Check valve, it must be cleaned or

replaced.

38 Part Number STH15 9/10

Page 39

Qualifier

No carbonated water at any of the dispensing valves

No CO2 gas or

water present at

dispensing valves.

CO2 gas is present

at dispensing

valves but no water.

Probable

Cause

Malfunction of

Refrigeration

System.

Malfunction of

Circulating

System.

No power to

carbonator.

Water supply

restricted to

carbonator

pump.

Water Filter

restricted.

Water Inlet

strainer

clogged.

Liquid Level

Control

defective.

Electrode

Assembly

defective.

Refer to Troubleshooting “Circulating

System” under No carbonated water

Verify toggle switch for Carbonator is

in the ON position and Main Power

should register 55 psi (3.9 kg/cm2). To

decrease. If regulator will not respond

Examine Water Shut-off Valve(s) to

Carbonator and ensure they are in the

Strainer in carbonator Pump (Brass),

Shut OFF Main Power Supply unit.

Remove electrical Access Panel from

unit. Locate liquid level control. Using

a pair of insulated needle nose pliers,

carefully remove the white wire from

the terminal marked “H” and th e black

wire from the terminal marked “L” on

Position safely to side. Turn ON Main

carbonator pump and motor do not

Level Control is defecti v e . Rep l ac e.

If Liquid Level Control is operating,

test the Electrode Assembly, refer to

Probable Cause “Liquid Level Cont rol

Defective”. Verify wire leads are dry

and that they are not touching. If not,

Corrective Action

Refer to Troubleshooting

“Refrigeration System” under No

carbonated water at any of the

dispensing valves (freeze up).

at any of the dispensing valves.

Supply is ON.

Verify water to unit by observing

Filtered Water Pressure Gauge. It

adjust, loosen Locknut, turn

Adjustment Screw clockwise to

increase, counterclockwise to

to adjustments, replace regulator.

ON position.

Place Filter By-pass Valve into the

Filter By-pass position. Replace

Cartridge Filter. Reposition valve

handle to “operating” position.

Remove Filter Screen from Inlet

flush with water to clean and

reassemble.

Push Toggle Switch for carbonator

and circulator to the OFF position.

the Liquid Level Control Board.

Power Supply. Push carbonator

Switch to the ON position. If

cycle ON immediately, that Liquid

replace Electrode.

Part Number STH15 9/10 39

Page 40

Qualifier

No carbonated water at any of the dispensing valves (continued)

CO2 gas is present

at Dispensing

Valves but no

water. (continued)

Probable

Cause

Carbonator

Pump worn

(Brass pump).

Motor defective. If Motor will not operate, verify voltage

Carbonator

Pump frozen.

Corrective Action

Dispense Carbonated Water while

listening for carbonator pump and

motor to cycle ON at Refrigeration

Unit. Pumps should operate between

6 to 12 seconds before cycling OFF. If

operating time exceeds 30seconds,

carbonator Pumps is worn, replace

across Motor T erminals with voltmeter .

If voltage reads 110 to 120 VAC, the

Motor or Pump is defective. Loosen

the Coupling Clamp with a flat-blade

screwdriver and disengage Pump

from Motor. If Motor still will not

operate with Pump disengaged, Motor

Loosen the Coupling Clamp with a

flat-blade screwdriver and disengage

Pump from Motor. By hand, turn the

Coupling Key in back of Pump. If

pump shaft will not spin freely, Pump

is defective and must be replaced.

Pump.

is defective. Replace.

40 Part Number STH15 9/10

Page 41

Qualifier

Carbonator pump and motor will not cycle OFF (possibly noisy pump)

Little or no

carbonated water at

dispensing valve.

Probable

Cause

Primary CO2

Regulator

adjusted at

extremely high

pressure.

Water supply to

Carbonator

Pump shut-off

or restricted.

Water Filter

restricted.

Back Flow

Preventer or

Double Check

Valve.

Carbonator

Pump worn.

Coupling Key

defective.

Corrective Action

Verify CO2 Primary Regulators are set

at 90 psi (6.3 kg/cm2). Adjust if

necessary. If regulator will not stay in

adjustment, replace regulator.

Verify water to unit by observing

Filtered Water Pressure Gauge. It

should register 55 psi (3.9 kg/cm2).

Examine Water Shut-off Valves to

carbonator and ensure they are in the

ON position. Examine Pump Strainer

for restriction. Clean if necessary.

Place Filter By-pass valve into the

“Filter By-pass” position. If carbonator

pump and motor immediately cycle

OFF, Filter Cartridge is restricted.

Replace Cartridge.

Examine Filter Water Pressure

Gauge. If it registers 90 psi (6.3

kg/cm2) CO2 gas is passing from the

carbonator tank and through the Back

Flow Preventer or Double Check

Valve, preven ting wa ter fr om enter ing

pump. Clean or replace Back Flow

Preventer/Double Check Valve.

Remove top cover from Remote

Refrigeration Unit. Locate Toggle

Relief Valve on Carbonator Tank and

lift lever to allow CO2 gas to escape

from Tank for 30 seconds. If during

this time Carbonator Pump cycles

OFF, pump is worn and should be

Loosen the Coupling Clamp with a

flat-blade screwdriver and disengage

Pump from Motor. Examine Coupling

Key in Pump. If defective, replace.

replaced.

Part Number STH15 9/10 41

Page 42

Qualifier

Carbonator pump and motor will not cycle OFF (possibly noisy pump)

Carbonated water

at dispensing valve.

Peculiar taste in

carbonated water

only.

Probable

Cause

(continued)

Liquid Level

Control

defective.

Electrode

defective.

Water filter

contaminated.

Back Flow

Preventer Va lve

leaking or

Double Check

Valve leaking.

Carbonated

water flowing

through

materials other

than plastic or

stainless.

Corrective Action

Shut OFF main power supply to unit

and push Toggle Switch for

Carbonator and Circulator to the OFF

position. Remove Electrical Access

Panel from Refrigeration Unit and

locate Liquid Level Control. Strip a

1-1/2" (3.8 cm) piece of solid strand

wire of insulation to use as a jumper.

Turn main power supply unit ON to

unit. With a pair of insulated pliers,

jump across Terminals marked “G, H

and L” on Liquid Level Control.

Simultaneously, while pushing

corresponding Toggle Switch to

“carbonator” to the ON position. If

carbonator pump and motor continue

to operate after Liquid Level Control

Jumper Wire is in place, Liquid Level

Control is defective, replace.

Examine wire leads to ensure no

breaks in connections. Remove and

clean Electrode with find sand paper

operation of carbonator Motor. Refer

Refer to Troubleshooti ng “Water Filter

Push Toggle Switch for carbonator to

the OFF position. Turn Water Shut-off

Remote Refrigeration Unit. Carefully

side of the carbonator pump. If water

Trace carbonated water flow through

system. Ensure no foreign materials

are present. Replace non-acceptable

and reinstall.

Note: Reversing Electrode Wire

Leads on either electrode o r Liquid

Level Control will cause erratic

to Wiring Diagram.

System” under Peculiar taste.

Valve to carbonator to the OFF

position. Remove tope cover from

disconnect water line on the outlet

or CO2 is observed continually

escaping from line, Back Flow

Preventer/Double Check Valve is

leaking. Disassemble, clean, and

replace if necessary.

Caution: Carbonated water must

never be allowed to flow through

materials other than plastic or

stainless steel. (Copper, zinc or

galvanized material is

non-acceptable.)

material if found.

42 Part Number STH15 9/10

Page 43

Qualifier

Carbonator pump and motor will not cycle OFF (possibly noisy pump)

Carbon particles in

furnished drink.

Carbonator Motor

cycles ON and OFF

in short cycles.

Probable

Cause

(continued)

Malfunction of

Water Filter.

Defective

Carbonator

Pump.

Defective

Circulating

Pump.

Electrode

Assembly

incorrectly wired

or defective.

Corrective Action

Refer to Troubleshootin g “Water Filter

System” under Carbon particles in

finished drinks.

Remove top cover from Refrigeration

Unit. Loosen Coupling Clamp with a

flat-blade screwdriver and disengage

pump from motor. Turn the Coupling

Key by hand, in back of pump. If pump

shaft does not turn freely and/or

Carbon is found in pump, carbon

veins are defective. Replace pump.

Refer to Troubleshooting “Circulating

System” under Carbon particles in

finished drinks.

Examine wiring diagram found on

Refrigeration Unit. Verify Electrode

wiring leads are on proper terminal s of

both Electrode and Liquid Level

Control. If problem still occurs, replace

electrode.

Part Number STH15 9/10 43

Page 44

Circulating System

Qualifier

Drinks warm

throughout the day ,

warm all the time.

Drinks warm during

periods of low

demand, much

colder during

periods of high

demand.

Carbon Particles in

finished drink.

No CO2 gas or

water present at

dispensing valve.

gas is present

CO

2

at dispensing

valves but no

carbonated water.

Probable

Cause

Warm drinks

Malfunction of

Refrigeration

System.

No power to

Circulating

Motor.

Motor defective. Using a flat-blade screwdriver, loosen

Circulating

Pump defective

(stainless steel).

Malfunction of

Water Filter.

Malfunction of

Carbonated

Water System.

Circulating

Pump defective

(Stainless

Steel).

Malfunction of

Refrigeration

System.

Particles

obstructing flow

through

Circulating

Circuit (In-line

Strainer).

Malfunction of

Carbonating

System.

Corrective Action

Refer to Troubleshooting

“Refrigeration System” under Warm

drinks (carbonated water

temperature over 40°F [5°C]).

Verify Switch to Circulating Motor is in

the ON position and Main Power

Supply is ON.

the Coupling Clamp and diseng age

Pump from Motor. If Motor will not

operate, verify voltage across Motor

Terminal with voltmeter. If voltage

reads from 110 to 120 VAC, the Motor

is defective and should be replaced.

Dispense approximately 1 gallon of

carbonated water at dispensing

valves. If temperature of carbonated

water drops, Circulating pump is not

operating. Examine Coupling Key

found between Pump and Motor

Shaft. If coupling key is defective,

replace. If key is operational,

Circulating pump is defective, replace.

Refer to Troubleshooti ng “Water Filter

System” under Carbon particles in

finished drinks.

Refer to Troubleshooting “Carbonated

Water System” under Carbon

particles in finished drinks.

Remove top cover from Refrigeration

Unit. Loosen Coupling Clamp with a

flat-blade screwdriver and disengage

Pump from Motor. Turn Pump shaft

with screwdriver. If Pump does not

turn freely and/or carbon is found in

Pump, carbon veins in pump are

defective. Replace Circulating Pump.

Refer to Troubleshooting

“Refrigeration System” under No

carbonated water at dispensing

valve (freeze up).

Remove top cover from Remote

Refrigeration. Push toggle switch to

carbonator and circulator to the OFF

position. Lift lever on Toggle Relief

valve at top of carbonator Tank until

pressure is completely released.

Remove In-line Strainer Screen. Flush

with clean water and reassemble.

If CO2 gas is present at the

Dispensing Valves and there is no

water, the problem is in the

Carbonated Water System. Refer to

Troubleshooting “Carbonated Water

System”.

44 Part Number STH15 9/10

Page 45

Dispensing Valve

Qualifier

All corresponding

valves dispensing

no syrup.

No syrup at only

one dispensing

valve.

No syrup or insufficient syrup in finished drink

No carbonated

water at half or all

dispensing valves.

Probable

Cause

Malfunction of

syrup system.

Syrup Shut-off

Valve closed or

partially closed.

Mounting Block

restricted.

Flow Control

our of

adjustment or

inoperative.

Valve Po rt

restricted.

Seat swollen. Replace Syrup Seat.

Solenoid Coil

defective.

Malfunction of

Carbonated

Water System.

Corrective Action

Refer to Troubleshooting “Syrup

System” under No syrup or

insufficient syrup in finished drink.

Remove top cover from Dispensing

valve or Tower. Locate Syrup S hut -of f

Valve on right hand side of Dispensing

valve. Verify shut-off is turned fully

Remove Dispensing valve from

Mounting Block. Place cup over Syrup

outlet on Mounting Block and car efully

open Syrup Shut-off Valve. If little or

no syrup is present, Mounting Block is

restricted. Remove and clean

mounting block. Replace if necessary.

Readjust Flow Control to proper Brix.

If no response, clean Syrup Flow

Control. Replace if necessary.

Clean Syrup valve Port Assembly.

Replace Syrup Solenoid Coil.

Refer to Troubleshooting “Carbonated

Water System” under No carbonated

water at any of the dispensing

open.

valves.

Part Number STH15 9/10 45

Page 46

Qualifier

No carbonated water or insufficient carbonated water in finished drink

No Carbonated

Water only at one

dispensing valve.

Probable

Cause

Carbonated

water Shut-off

Valve closed or

partially closed.

Mounting Block

restricted.

Flow Control

our of

adjustment or

inoperative.

Valve Po rt

restricted.

Seat swollen. Replace Carbonated Water Seat.

Solenoid Coil

defective.

Carbonated

Water Switch

defective

(black).

Corrective Action

Remove top cover from Dispensing

valve or Tower. Locate Carbonated

Water Shut-off Valve on left hand side

of Dispensing valve. Verify Shut-off

Valve is turned fully open.

Remove Dispensing valve from

Mounting Block. Place cup over

Carbonated Water ou tlet on Moun ting

Block and carefully open Carbonated

Water Shut-off Valve. If little or no

Carbonated Water is present,

Mounting Block is restricted. Remove

and clean mounting block. Replace if

Readjust Flow Control to proper Brix

(5 oz in 4 seconds Stand ar d val ve,

10 oz in 4 seconds Fast Flow valve). If

no response, clean Carbonated W ater

Flow Control. Replace if necessary.

Clean Carbonated Water valve Port

Replace Carbonated Wa t er Solenoid

Replaced Carbonated Water Switch.

necessary.

Assembly.

Coil.

46 Part Number STH15 9/10

Page 47

Qualifier

No water or insufficient water in finished drinks

All valves

dispensing

noncarbonated

drinks no water.

Problem occurs at

only one dispensing

valve.

T oo mu ch Sy r up,

Carbonated Water

or Water in finished

drink. Problem

occurs at only one

dispensing valve.

Too much syrup in

finished drink. All

valves dispensing

same flavor-too

much syrup.

Too much water in

finished drink. All

valves dispensing

noncarbonated

drink too much

water.

Syrup or

Carbonated Water

or Water dripping

from Nozzle.

Valves will not

activate when

Selection Panel

pressed. Problem

occurs at two (2) or

three (3)

consecutive Va lves

on one (1) tower.

Probable

Cause

Water Shut-off

Valve closed or

partially closed.

Syrup,

carbonated

water, or

noncarbonated

water flow

control out of

adjustment or

inoperative.

Malfunction of

syrup system.

Malfunction of

water Booster

system.

Valve port

scarred.

Armature Spring

or Retaining

Ring broken.

Seat scarred or

obstructed.

Transformer

inoperative.

Dispensing

tower’s ON and

OFF Toggle

defective.

Corrective Action

Refer to Troubleshooting “Water

Booster System” under Low or No

Water Pressure at Noncarbonated

dispensing valve in the dispensing

Readjust appropriate Flow Control. If

Water Flow rates: (5 oz in 4 seconds

Standard valve, 10 oz in 4 seconds

Water Assembly. Examine valve Port

Water Assembly. Examine Armature,

Spring and Retainer Ring. If damaged,

scarred, replace. If foreign material is

have solid connections. Switch low

supplying power to left and right hand

side of Tower. If Valves operate and

the other three do not, T r an sfor m er is

valves still do not operate, the ON and

Beverages.

Refer to this section on No

carbonated water at only one

valve.

Flow Control does not respond to

adjustment, clean Flow Control.

Replace if necessary. Carbonated

Fast Flow valve).

Refer to Troubleshooting “Syrup

System” under Drinks too sweet.

Refer to Troubleshooting “Water

Booster System” under Qualifier:

Pump and motor cycles ON and

OFF excessively.

Disassemble appropriate Syrup or

for scars or nicks. Replace if

necessary.

Disassemble appropriate Syrup or

replace.

Disassemble appropriate Syrup or

Water Assembly. Examine Seat, if

found in Assembly, remove,

reassemble.

Verify wire leads from Transformer

voltage lead from Transformer

defective. Replace.

If after switching Leads, the three

OFF Toggle Switch is defective.

Part Number STH15 9/10 47

Page 48

Qualifier

No water or insufficient water in finished drinks (continued)

Problem occurs at

all valves on one

(1) dispensing

tower.

Problem occurs at

only one (1)

dispensing valve.

Valve will not shut

OFF.

Probable

Cause

No power to

transformer or

transformer

defective.

Dispensing

tower’s ON and

OFF is Switch

defective.

Poor connection

on valve Wire

Harness.

Portion Control

Timer

inoperative.

Selection

Switch

inoperative.

Poor connection

at Contact Clips

on Selection

Panel (with

Portion Control

Timer).

Moisture on

Portion Control

Timer or

Contact Clips.

Portion Control

Timer

Adjustment

Screw turned

beyond control

limit.

Portion Control

Timer defective.

Selection Panel

defective.

Corrective Action

Verify power with a voltmeter at wall

outlet. Verify power acr oss low voltage

leads on transformer. If 24 volts are

present ON and OFF Toggle Switch is

defective. Replace.

Verify Main Power Supply and power

at Transformer Leads repl ace ON and

OFF Switch if operative.

Trace wiring on defective valve and

reconnect any loose wires. Clean and

reconnect any corroded connections.

Replace the problem valve Portion

Control Timer with a known Operative

Timer. If valve then operates, Portion

Control Timer was def ective. Replace.

Replace defective Portion Control

Timer with operative Timer. If Va lves

still will not activate, Selection Panel is

defective. Replace Selection Switch.

Examine Contact Clips on Selection

Panel and ensure proper contact

between Portion Control Timer and

Contact Clips.

Remove top cover from Dispensing

Tower. Remove all moisture from

Portion Control Timer and Contacts.

Turn Portion Control Adjustment

Screws on defective valve

counterclockwise 10 complete turns. If

valve shuts off when selection is

pressed, readjust for proper portions.

Note: Several revolutions may be

necessary to bring control back into

Verify above probables are not the

problem. Push ON/OFF Switch for

Dispensing T ower to the OFF position.

If valve ceases to dispense when

pushed to ON position, Portion

Control Timer is defective. Replace.

Push ON/OF Switch for dispensing

tower to the OFF position. If valve

ceases and then continues to

dispense when switch is pushed in

ON position, Selection Panel is

defective. Replace.

range.

48 Part Number STH15 9/10

Page 49

Qualifier

No water or insufficient water in finished drinks (continued)

Foaming of finished

products.

Unit totally

inoperative; all

electrical switches

in the ON position.

Probable

Cause

Nozzles, Syrup

Tube Diffusers

dirty.

Warm drinks. Refer to Troubleshooting

Incorrect

pressure on

syrup.

Change-over

Valve Medium

or Low Pressure

is in the wrong

position.

Air or CO2 gas

in syrup line.

Flake ice. Only cube ice should be used for

Improper

adjustment of

valve.

Power failure,

all power to

system is OFF,

or Fuse/Circuit

Breaker is

“open”.

Corrective Action

Remove and clean Nozzle

Assemblies and reassemble.

“Refrigeration System” under Warm

Verify pressure supplied to sugar base

products is at 60 psi (4.2 kg/cm2).

Adjust Medium Pressure Regulator if

necessary. V eri fy pressure supplied to

diet product is at 15 psi (1.1 kg/cm2).

Adjust Low Pressure Regulator if

Note: Ensure the Low Pressure

Supply Line has not mistakenly been

switched for a Medium Pressure

Supply Line on the diet tank.

Verify valve Medium to Low Pressure

is in the Low Pressure position for diet

Replace empty Syrup Tank. Dispense

Syrup from valve until consistent flow

is achieved and product stabilizes. If

evidence of air is still entering line,

replace Liquid Disconnect which is

allowing air to be drawn into syrup

carbonated beverages.

Ensure carbonated water flow is

properly set (5 oz. in 4 seconds

standard valve, 10 oz in 4seconds

Fast Flow valve). Ensure Brix is

properly set. Adjust as necessary.

Check Circuit Breaker. Reset.

Examine Time Delay, replace if

drinks.

necessary.

products.

supply.

necessary.

Part Number STH15 9/10 49

Page 50

When the Brix is OFF

70 psi (4.8 bar) ON

90 psi (6.2 bar) OFF

Maximum Efficiency

55 psi (3.8 bar)

Service

Filters

90 psi (6.2 bar) to 105 psi (7.2 bar)

Below 39°F (3.9°C)

Air Compressor

Filtered Water Pressure

CO

High Pressure at CO2 Tank

2

Drink Temperatu re

50 Part Number STH15 9/10

Page 51

Bag-In-Box Usage

60 psi (4.1 bar)

Medium Syrup

Pressure

60 psi (4.1 bar)

Medium Syrup

Pressure

15 psi (1.0 bar)

Low Syrup

Pressure

65 psi (4.5 bar) ON

85 psi (5.9 bar) OFF

Syrup Tank Usage

Pressurized Filtered Water Pressure (Water Booster)

Part Number STH15 9/10 51

Page 52

WHEN USING A MULTIPLEX REFRIGERATION UNIT

Problem

Drink too warm. Refrigeration

Not enough

carbonation.

Product foaming. Dirty or sanitizer

No syrup

dispensed.

No carbonated

water dispensed.

Product has an off

taste.

Probable

Cause

switch OFF.

Condenser dirty. Have condenser cleaned.

Condenser

obstructed.

Circulator

switch OFF.

CO2 Shut-off

Valve OFF.

CO2 cylinder

empty.

soaked.

Warm drinks. See “Drink too warm” under Problem

Empty syrup

container.

Air Compressor

is OFF.

Change-over

valve centered.

Carbonator

turned OFF.

Water supply

turned OFF.

Dirty nozzles. Clean or replace nozzles.

Out of date

syrup.

Saturated water

filters.

Remove any objects blocking the air

Turn ON circulator switch and allow

Note: If service is required, you can

continue to dispense cold drinks by

completing following this procedure.

1. Turn OFF the compressor switch

and agitator switch.

2. Drain the water from the water

bath. Reinstall the grey plastic

over-flow pipe.

3. Fill water bath with ice from the ice

machine.

4. Monitor frequently. Refill as

needed.

Switch over to a new cylinder and

dispense carbonated water until

Position switch totally on either air or

Solution

Turn ON refrigeration switch.

flow in or out of the unit.

time for drinks to cool.

Open Shut-off Valve.

carbonation returns.

Clean or replace nozzles.

above.

Replace syrup container.

Turn ON and plug-in the Air

Compressor.

CO2.

Turn ON carbonator switch.

Turn ON water to the system.

Replace with fresh syrup.

Replace water filters.

52 Part Number STH15 9/10

Page 53

Component Check Procedures

RATIO

• Look for foreign matter in the adjustment screw s,

flow controls or pallet seats. If a system is not

flushed completely at start-up, foreign particles

may be introduced into the system. Reset the flow

rate and readjust the syrup ratio.

BUZZING

• Do not lubricate the plungers. If contaminated,

simply wash with hot water, dry and reinstall.

LEAKS

• Check for damaged or improperly fitted O-rings.

The slightest piece of hair, dust, etc., on the

sealing surface may contribute to a leak. When in

doubt, replace an O-ring. Be sure you have the

correct O-ring and fitting combination for the

respective mounting plate.

Every 6 months (2 times per year)

• Using Brix cup and syrup separator, check for

proper carbonated water flows (standard flow: 5

oz. in 4 seconds, fast flow: 10 oz. in 4 seconds)

and syrup to water ratios at each dispensing

station. Adjust as required.

• Inspect beverage conduits for damage. Reinsulate and seal any uninsulated areas.

• Inspect floor chases and seal any open chase

ends.

• Inspect air compressor to verify cut-in at 70 psi

(4.8 bar) and cut-out at 90 psi (6.3 bar). Adjust

pressure switch if necessary.

• Inspect system for air leaks and repair as required.

• Verify that incoming water pressure is not less than

40 psi (2.8 bar) or greater than 60 psi (4.1 bar). If

equipped with a water regulator, verify proper

setting of 55 psi (3.8 bar). Adjust if necessary.

Part Number STH15 9/10 53

Page 54

• If pressure is low, inspect water filter cartridges to

ensure they are able to supply adequate water

pressure under normal system flow. Re place if unable

to provide minimum 20 psi (1.4 bar) under load.

• Inspect syrup lines for proper flavor identification

labels. Replace labels if necessary.

• Disconnect syrup containers. Clean connector with

soap and warm water. Rinse with plain water and

reconnect to syrup containers.

• Inspect pressure setting at CO

regulator. Verify proper 90 psi (6.2 bar) to 105 psi

high pressure

2

(7.2 bar) pressure setting. Adjust if necessary.

• Inspect pressure setting at syrup pressure

regulators. Verify propter pressure setting. Adjust if

necessary.

• Inspect system for CO

leaks. Repair as required.

2

WATER FILTERS

• Verify that incoming water pressure is not less than 40

psi (2.8 bar) or greater than 60 psi (4.1 bar). If

equipped with a water regulator , verify proper setti ng

of 55 psi (3.8 bar). Adjust if necessary .

• If pressure is low, inspect water filter cartridges to

ensure they are able to supply adequate water

pressure under normal system flow. Re place if unable

to provide minimum 40 psi (1.4 bar) under load.

SYRUP SUPPLY

• Clean general area of syrup hookup with soap and

warm water. Rinse off all soap.

• Inspect syrup lines for proper flavor identification

labels. Replace labels if necessary.

• Disconnect syrup containers. Clean connector with

soap and warm water. Rinse with plain water and

reconnect to syrup containers.

54 Part Number STH15 9/10

Page 55

CO2 GAS SUPPLY

• Inspect pressure setting at CO

regulator. Verify proper 90 psi (6.3 bar) to 105 psi

high pressure

2

(7.2 bar) pressure setting. Adjust if necessary.

• Inspect pressure setting at syrup pressure

regulators. Verify propter pressure setting. Adjust if

necessary.

• Inspect system for CO

leaks, repair as required.

2

BEVERAGE CONDUITS

• Inspect beverage conduits for damage. Reinsulate and seal any uninsulated areas.

• Inspect floor chases and seal any open chase

ends.

Part Number STH15 9/10 55

Page 56

56 Part Number STH15 9/10

This Page Intentionally Left Blan k

Page 57

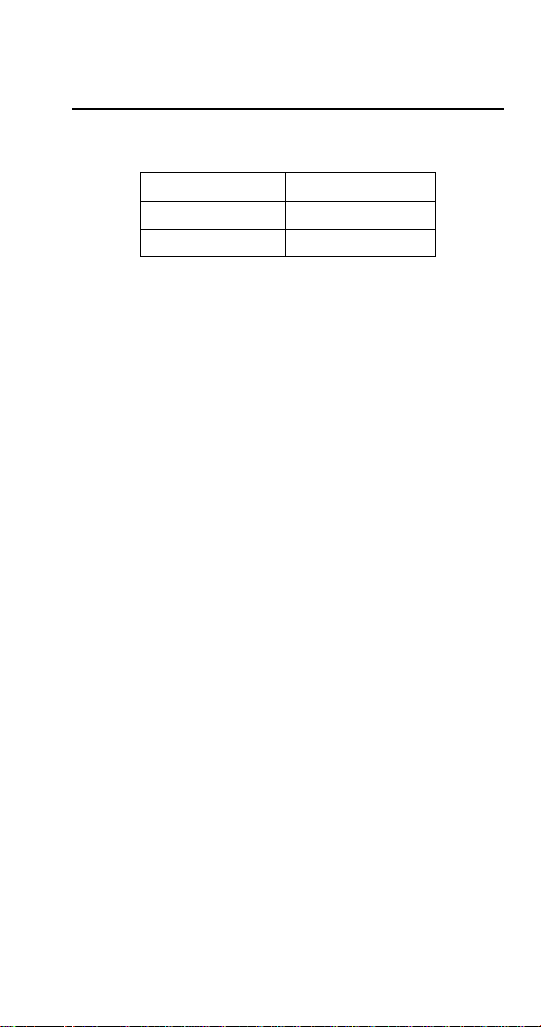

Component Specifications

Flow Rates

Model Flow Rate

424 1-1/2 to 3 oz./sec Post-Mix

464 2 to 4 oz./sec Post-Mix

424 Specifications

Type

Dimensions 2 1/2"W x 5

Model

Number

Mounting

Blocks

Options Add-a-

Sanitary

Push Lever

5/8"D x 9"H

63.5 x

142.9 x

228.6 (mm)

424-CF-

E36-1521

380-Q or

372-Q

Lever; field

conversion

options

available for

push button

and portion

control

manual

option

available

Push Button

2 1/2"W x 5

5/8"D x 51/

8"H

63.5 x 142.9

x 130.2

(mm)

424-CF-

S36-1525

380-Q or

372-Q

Add-a-Lever;

field

conversion

options

available for

push button

and portion

control

Portion

Control

2 1/2"W x 5

5/8"D x 51/

8"H

63.5 x 142.9

x 130.2

(mm)

424-CF-

P36-1500

380-Q or

372-Q

Add-aLever; field

conversion

options

available for

push button

and portion

control

Type of

Valve

Automatic

Fill Lever

2 1/2"W x 5

5/8"D x 123/

63.5 x 142.9

424-CF-

A36-1521

380-Q or

Lever; field

conversion