Page 1

INSTALLATION INSTRUCTIONS

464, 424 & 324 POST-MIX VALVES

The Flomatic valves are available in manual, electric,

portion control and automatic fill mo dels. All Flomatic

valves share the same mounting and fl ow control char acteristics. The 324 valves are also compati ble with

the 300-Q mounting block. Those instructions are not

included here.

MOUNTING BLOCK

Prior to installation determine which mounting block

you need. The Flomatic mounting block kit 500784 2

has inlet “O” rings sized for both inlet port sizes

(located at the rear of the block) port. Sized at 0.380

inches is compatible with most c urrent mounting block

inlet fittings.

INSTALLATION / REPLACEMENT

Be sure to relieve system pressure prior to beginning

work. When replacing most other brand valves with

the Flomatic valve, remove the existing mounting

block and install the appropriate Flomatic mount ing

block. This is an easy first ste p – just align the four bolt

holes and mount. The Flomatic mounting blocks have

a positive shut off and mounting system to prevent

accidental removal while the system is pressurized.

The valve cannot be removed unless the shut -off

valves are in the closed po sition (arrows poin ted

across the service line).

The hole pattern for most current valves will have key

slots for the product supply lines. Some older valve

mountings may require the use of the “S” clip 2 to hold

the product supply lines in place (av ail able as an

option).

Part Number 5027981 8/10

Page 2

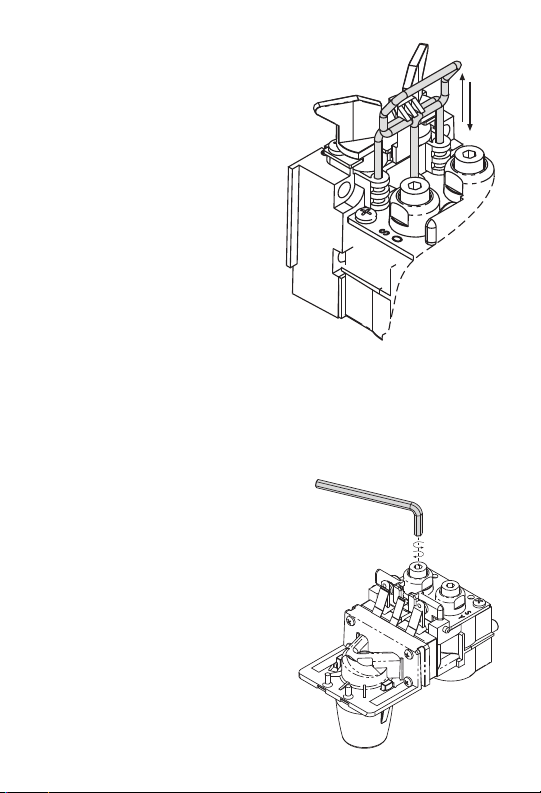

Remove the valv e cove r

and align the valve stems

with the mounting block.

Engage the valve and

depress the latch pin. Do

not force the latch pin

down or you may bend

the latch pin. If you are

having difficulty , simply

re-engage the valve and

try again. Be sure the

valve base is completely

seated against the mounting block. Open the shutoff valves by turning 1/4

turn (arrows pointed

toward the service line) to

engage system pressure.

FLOW CONTROL & BRIX

T wo simple adjustments are all you need to brix the

Flomatic valves. You will need a Flomatic S tube syrup

separator, 5/32 inch hex wrench, w atch and brix cup .

Place the S-tube syrup separator over the syrup diffuser and you are ready to

begin. You need not

remove the nozzle. Clockwise movement of the brix

nut adjustment screw

increases the flow rate and

vice versa. Restri ct the flow

by withdrawing the brix nut

adjustment screw as far as

it will go (turn counterclock wise). At this point the flow

will be at a minimum.

The 424 or 324 ceramic

flow controls can be

adjusted from 1.5 oz. /sec.

to 3.0 oz. /sec. T urn the

2 Part Number 5027981 8/10

Page 3

soda brix nut adjustment screw five full turns clockwise and the flow rate should be close to 2.5 oz/sec.

You will need to fine tune from there. F or fast flow ,

continue adjusting the valv e until you get 7.5 oz. of

soda in 3 seconds. Once the soda flow rate is set, then

establish the syrup ratio in exactly the sam e way.

The 464GP ceramic flow controls can be adjusted from

2.0 oz./sec. to 4.0 oz./sec. Turn the soda brix nut

adjustment screw five full turns clockwise and the flow

rate should be close to 3.0 oz./sec. You will need to

fine tune from there. For fast flow, continue adjust ing

the valve until you get 9.0 oz. Of soda in 3 seconds.

Once the soda flow rate is set, then establish the sy rup

ratio in exactly the same wa y.

Most brix cups are calibrated for a sta ndard brix r atio.

Adjust the syrup flow with movement of the adjusting

screw until the desired ratio is established. Some Flomatic valves are equipped with a flow washer on the

water side instead of flow controls. In that case, it is

not necessary to set the flow rate. Simply se t the

syrup ratio and you are done.

Flomatic juice valves may combine with a flow washer

on the water side. The syrup side may be manufactured

with a flow control or metering screw. The metering

screw turns clockwise to close and counter clockwise to

open. The screw does not have a stop; be sure not

to withdraw completely when under pressure.

SYNCHRONIZATION

When converting a manual 424 valve to electric solenoid operation, the actuators need to be removed prior

to installing the yoked armature soleno id coil. The

actuators are the white pivots that engage the pallet

stem.

Synchronization should only be nece ssary when converting an electric to manual v alv e, in which case y ou

may be adding the actuators. The soda a djustment

screw needs to be adjusted until it is snug (not tight ).

If too tight, the valve will remain open and leak. Set

Part Number 5027981 8/10 3

Page 4

the soda side first and then follow with the syrup actuator. The syrup actuator needs to be tightened until

snug and then backed off 1/4 turn. These settings will

allow for proper synchronization of the soda an d syrup

on a manual valve.

WATER / SODA ONLY

Installation of a Flomatic Add-A-Lever is easy. If you

have the pallet actuators as described above, simply

remove the valve cover and place the Add- A- Lever

(with the side attachment removed) on the end of the

pivot pin. Replace the cover and it will be firmly held in

place to provide soda only when desired. If y ou hav e

the electric operated val ve without the ac tuators, the

side attachment of the Add-A -Lever i s placed thro ugh

the pivot pin to push against the pallet stem.The lever

portion of the Add-A-Lever is placed on the end of the

pivot pin. Replace the valve cov er and the Add-A-Lever

will be held in place.

PORTION CONTROL

The Flomatic portion control electronics are contained

with the cover and can be factory or field instal led.

When installing in the field, simply order the portion

control conversion kit to upgrade an electric valve to

full portion control.

The portion control module is designed to simpl ify

installation for the service technician. No more wasted

product trying to set the time though tr ial and error.

The board can be programmed with the first pour.

The “Stop/Fill” button does just that; it serves as a

top-off button and cancels any of the timed portions if

the operator needs to abort th e pour. If the board has

never been programmed, the only button that will be

responsive is the “Stop/Fill” button. Cup siz es are preprogrammed at the factory: 1 sec. = small, 2 sec.=

medium, 3 sec. = large, 4 sec. = extra large. These

timed portions are helpful in setting flow rate; i.e., 7 ½

oz. soda in 3 seconds.

4 Part Number 5027981 8/10

Page 5

There are four cup sizes:

424/324 Portion Contr ol

T ouch Pad

464 Portion Control

T ouch P ad

small, medium, large and

Hidden Switch

extra large. Each cup size

needs to be programmed

separately . Set the flow

rate first and then brix the

STOP

FILL

valve. By doing so, yo u will

be sure to set times that

match your desired flow

rate. Once the v alve is

brixed, you can replace the

valve cover because the

times (cup sizes) are all set

from the front switch pad.

The switch pad has a hidden “program” switch

which needs to be held

down to keep the module in program mode.

Setting the times or programming is a two

handed operation: push

and hold the program

STOP

FILL

Hidden Switch

switch with one finger

while dispensing the cup

size you wish to program

with another. Once the drink is full, simply release the

cup size button to end the pour cy cle and then let go of

the program switch. Repeat the process for each cup

size and you are finished.

The module will remember one top-off cy cle automa tically if the foam height requires a top-off to complete

the pour. To program a top-off cycle, simply begin programming as described above. Once the foam crests

the top of the cup, PAUSE by removing your finger

from the cup size button. Do not release the progr am

button or it will think you’re done. Pause lo ng enough

for the foam to settle, and then continue your pour

with your finger on the same cup size button until the

Part Number 5027981 8/10 5

Page 6

cup is full. The portion control module will remember

the sequence “pour – pause – pour” just as it was executed. If you program the top-off feature, be sure to

train the operators so they do not pull a drink before

the cycle is complete. The portion control modu le will

finish the pour whether a cup is there or not.

AUTOMATIC FILL VALVE

The Flomatic Automatic Fill valv e can be used to dispense both carbonated and noncarbonated products.

The valve is factory set for carbonated products where

a delayed top-off is standard, and the wire-lead plug

should be attached to pins 1 and 2 (those furthest to

the left). If your installation uses noncarbonated products requiring no top-off, yo u will need to adjust the

position of the lever wire-lead plug on the electro nics.

For noncarbonated products, the wire-lead plug should

be attached to pins 2 and 3 (those furthest to the

right), as shown in the photo. The Auto matic Fill v alve

requires no sensitivity adjustments. The valve automatically delays top-off if more foam is present after

the initial pour, and performs a top-off more quickly if

less foam is present.

CLEANING

Under normal operating conditions, periodic cleaning is

minimal but necessary. Remove the nozzle and so da

diffuser . Using w arm water and a mild detergent, clean

each part with a brush. Once finished, rinse well an d

reassemble. If you wish to soak the no zzle and diffusers, soak them only is soda water, never use bleach.

Brush lever slot with w arm wat er to prev ent syrup

build-up and sticking. Wipe cover and panel with a

clean cloth and you are finished. Nothing more need

be done unless you experienced a problem. Regular

servicing and cleaning of the complete beverage system is advised to maintain proper functioning of the

equipment. Be sure to follow instructions provid ed by

the manufacturer .

6 Part Number 5027981 8/10

Page 7

TROUBLE SHOOTING

Occasionally, the v alve will not perform as desired.

Here are some helpful hints:

BRIX: Reset the flow rate and r e-brix the valve.

Look for foreign matter in the adjustment

screws, flow controls or pallet seats.

Sometimes if a system is not flushed

completely at startup, foreign particles,

etc. will be introduced into the system.

BUZZING: Make sure the plungers in the older style

double coil solenoid are properly aligned.

Do not lubricate the plungers with anything other than a “dry” product, e.g. , silicone spray.

LEAKS: Check for damaged or improperly fitted

O-rings. The slightest piece of hair, dust,

etc., on the sealing surface may contri bute to a leak. When in doubt, replace an

O-ring. Be sure you have the correct Oring and fitting combination for the

respective mounting block.

Part Number 5027981 8/10 7

Page 8

Manitowoc Beverage Systems

Manitowoc Beverage Systems

guarantees all Flomatic products free from

defects in material and workmanship under

normal use and service for two years from

date of purchase. If defective, Manitowoc

Beverage Systems will, at its sole

discretion, repair or replace the defective

item at no charge.

FLOMATIC WARRANTY

2100 Future Drive

Sellersburg, IN 47172-1868 USA

TOLL -F REE: (800) 367-4233

TEL: (812) 246-7000 FAX: (812) 24 6-9922

Visit us online at: www.ma nitowocfsg.com

© 2010 Manitowoc

Continuing product improvements may neces-

sitate change of specifications without notice.

Part Number 5027981 8/10

Loading...

Loading...