Page 1

Soda Systems & SuperChil™

Refrigeration Units

Technician’s

Handbook

This manual is updated as new information and models

are released. Visit our website for the latest manual.

America’s Quality Choice in Refrigeration

Part Number STH12 9/10

www.manitowocfsg.com

Page 2

Page 3

Safety Notices

!

Warning

!

Caution

Important

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this handbook.

Disregarding the notices may lead to serious injury

and/or damage to the equipment.

Throughout this handbook, you will see the following

types of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Ca ution box alerts you to a situation in

which you could damage the equipment. Be sure

to read the Caution statement before proceeding,

and work carefully.

Procedural Notices

As you work on Manitowoc equipment, be sure to read

the procedural notices in this handbook. These notices

supply helpful information which may assist you as

you work.

Throughout this handbook, you will see the following

types of procedural notices:

Text in an Important box provides you with

information that may help you perform a

procedure more efficiently. Disregarding this

information will not cause damage or injury, but it

may slow you down as you work.

NOTE: T ext set off as a Note provides you with simple,

but useful, extra information about the procedure you

are performing.

Page 4

Read These Before Proceeding:

!

Caution

Important

! Warning

We reserve the right to make product

improvements at any time. S pecifications and

design are subject to change without notice.

Proper installation, care and maintenance are

essential for maximum performance and troublefree operation of your Manitowoc equipment. If

you encounter problems not covered by this

handbook, do not proceed, contact Manitowoc

Foodservice Group. We will be happy to provide

assistance.

Routine adjustments and maintenance

procedures outlined in this handbook are not

covered by the warranty.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

Page 5

Table of Contents

General Information

Model Numbers . . . . . . . . . . . . . . . . . . . . .9

How to Read a Model Number . . . . . . . . .10

Accessories . . . . . . . . . . . . . . . . . . . . . . .10

Special Applications . . . . . . . . . . . . . . . .11

Model/Serial Number Location . . . . . . . .11

Warranty Information . . . . . . . . . . . . . . . .11

Installation

Pre-installation Checklist . . . . . . . . . . . . .13

Top Mounted Ice Maker Installations . . . 15

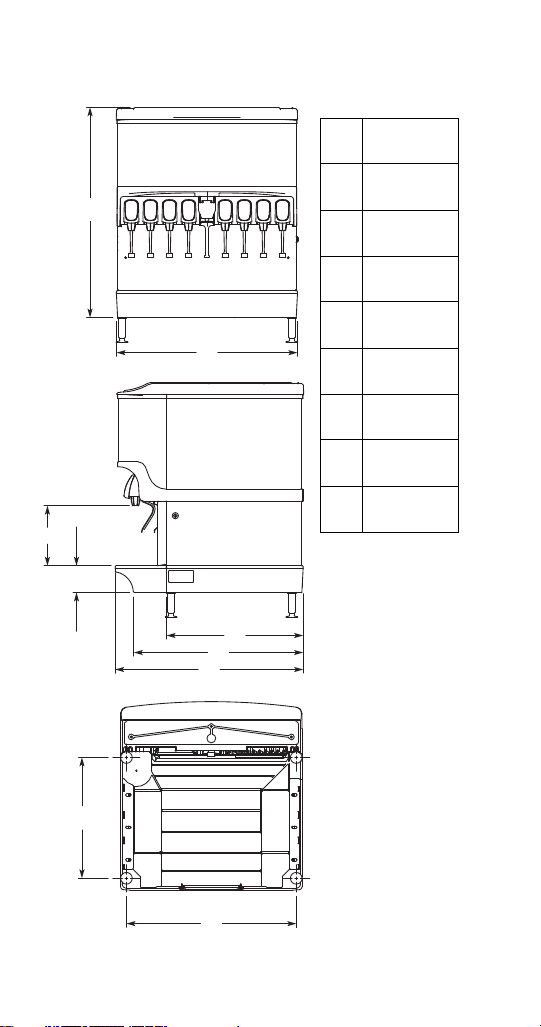

S250-M Dimensions . . . . . . . . . . . . . . . . .16

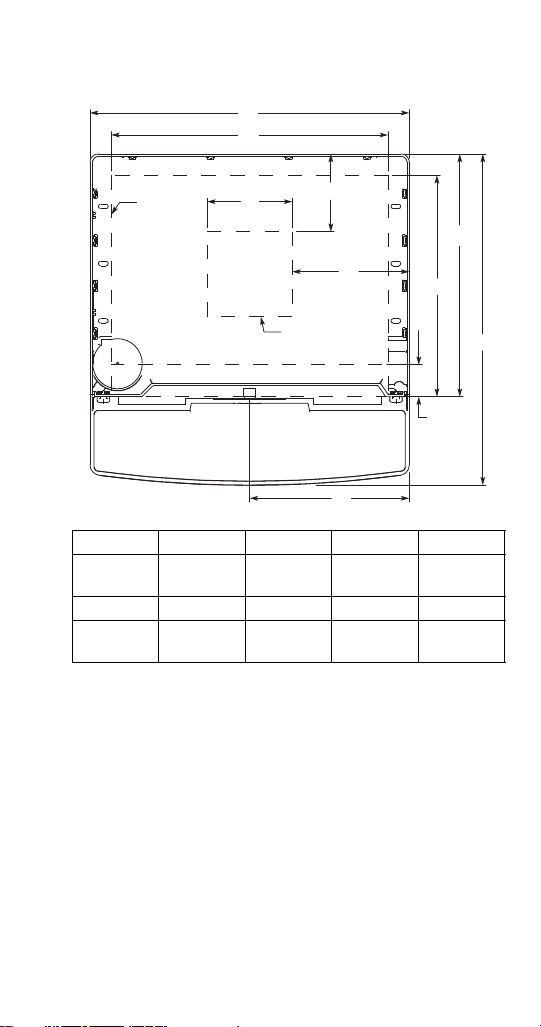

MII-250 Dimensions . . . . . . . . . . . . . . . . .18

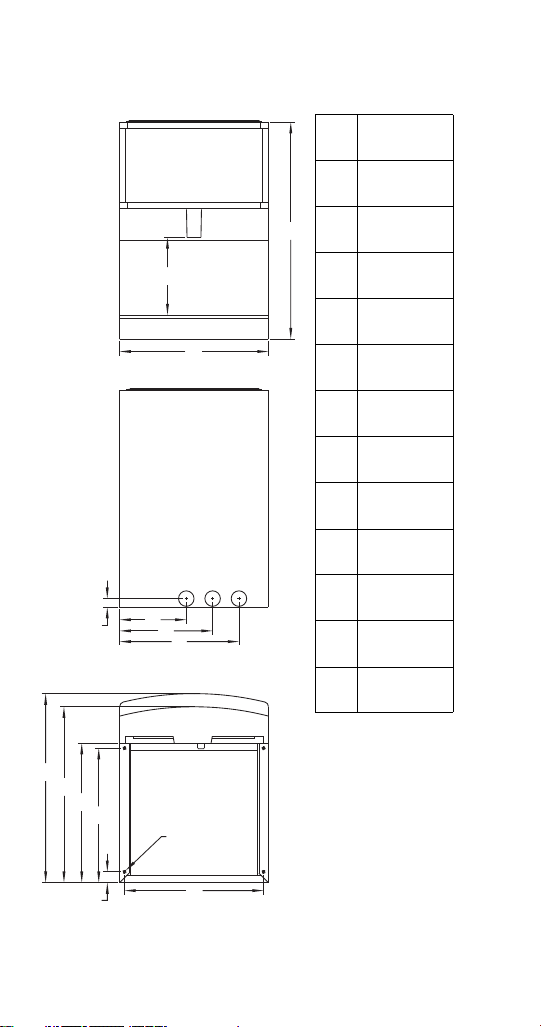

MII-302 Dimensions . . . . . . . . . . . . . . . . .20

MII-250 Installation Kit . . . . . . . . . . . . . . .22

MII-302 Installation Kit . . . . . . . . . . . . . . .23

Refrigeration Units . . . . . . . . . . . . . . . . . .25

Safe Installation Dos and Don’ts . . . . . . .28

Location Requirements . . . . . . . . . . . . . .30

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . .34

Plumbing/Water Supply . . . . . . . . . . . . . .38

Preparing Ice Bank – Non-ERC . . . . . . . .39

Preparing Ice Bank with ERC . . . . . . . . .41

Component Identification

Typical System . . . . . . . . . . . . . . . . . . . . .43

Connections . . . . . . . . . . . . . . . . . . . . . . .44

Maintenance

Maintenance Schedule . . . . . . . . . . . . . . .49

Cleaning and Sanitizing the Dispensing

Valves and Product Lines . . . . . . . . . . . .54

Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . .58

Shipping, Storage and Relocation . . . . . 62

Operation

How the Multiplex Works . . . . . . . . . . . . .63

Differences Between the TS & SS Units .64

Equipment Setup Procedure (Non-ERC) 71

Part Number STH12 9/10 5

Page 6

Start-up (Non-ERC) . . . . . . . . . . . . . . . . . 72

Sequence of Operation (Non-ERC) . . . . 74

Start-up (with ERC) . . . . . . . . . . . . . . . . . 76

Sequence of Operation (with ERC) . . . . 78

Equipment Setup Procedure (with ERC) 82

Equipment Close Procedure — All Units 84

Troubleshooting

Electronic Refrigeration Control (ERC) Model

Error Codes . . . . . . . . . . . . . . . . . . . . . . . 87

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Problem Cross-reference Guide . . . . . . . 100

Gas System . . . . . . . . . . . . . . . . . . . 101

CO

2

Carbonated Water System . . . . . . . . . . . 104

Circulating System . . . . . . . . . . . . . . . . . 111

Compressed Air System . . . . . . . . . . . . . 112

Dispensing Valve and Tower . . . . . . . . . 114

Electrical System . . . . . . . . . . . . . . . . . . . 119

Refrigeration System . . . . . . . . . . . . . . . . 120

Syrup System . . . . . . . . . . . . . . . . . . . . . . 123

Water Booster System . . . . . . . . . . . . . . 125

Water Filter System . . . . . . . . . . . . . . . . . 127

When the Brix is OFF . . . . . . . . . . . . . . . 128

Component Check Procedures

Test Procedures: MPC 64A Timer/Selection

Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Dual Transformers . . . . . . . . . . . . . . . . . 133

New MPC84A Portion Control Board . . . 134

MOVs Field Testing . . . . . . . . . . . . . . . . . 140

Test Procedures: MPC84C Timer/Selection

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Back-flow Preventer Maintenance . . . . . 144

Head Pressure Control Valve . . . . . . . . . 145

Charging Multiplex Remote Refrigeration

Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Compressor & Remote Condenser . . . . 148

Agitator Condenser . . . . . . . . . . . . . . . . . 149

Carbonation System A or B . . . . . . . . . . 150

Circulation System A or B . . . . . . . . . . . 151

ERC Control Board, Keypad & Display . 152

Programming / Auto Set . . . . . . . . . . . . . 153

6 Part Number STH12 9/10

Page 7

ERC Component (Output) Connector Layout

154

ERC Sensor (Input) Connector Layout .154

Component Specifications

Refrigeration Unit Specifications . . . . . . 155

S-250M Specifications . . . . . . . . . . . . . . .156

MII-302 Specifications . . . . . . . . . . . . . . .156

Charts

Refrigerant Charge . . . . . . . . . . . . . . . . . .157

Operating Pressures . . . . . . . . . . . . . . . .161

McDonald’s Models History . . . . . . . . . . .163

Sustained Draw Curve Chart s . . . . . . . . .164

Diagrams

Wiring Diagrams . . . . . . . . . . . . . . . . . . . .167

Soda Wiring Diagrams . . . . . . . . . . . . . . .185

Super-Chil Wiring Diagrams . . . . . . . . . .200

Circuit Schematics . . . . . . . . . . . . . . . . . .212

Ice/Beverage Units Diagrams . . . . . . . . .231

Part Number STH12 9/10 7

Page 8

8 Part Number STH12 9/10

This Page Intentionally Left Blan k

Page 9

General Information

Model Numbers

This manual covers the following models:

(A) Air Cooled (W) Water Cooled (R) Remote Cooled

2803A04 2803W04 2803R04

2803AX04 2803WX04 2803RX04

2803A04 2803W04 2803R04

11MA04 11MW04 11MR04

11MAX04 11MAW04 11MRX04

11MA04 11MW04 11MR04

42MA04 42MW04 42MR04

42MAX04T 42MWX04T 42MRX04T

44MA04 44MW04 44MR04

44MAX04T 44MWX04T 44MRX04T

44EAX04T 44EWX04T 44ERX04T

50MA04 50MW04 50MR04

50MAX04 50MWX04 50MRX04

50MA04Q/T 50MW04Q/T 50MR04Q/T

SC180A SC180W SC180R

SC180AX SC180WX SC180RX

SC340A SC340W SC340R

SC340AX SC340WX SC340RX

SC1000A SC1000W SC1000R

SC1000AX SC1000WX SC1000RX

SC2000A SC2000W SC2000R

SC2000AX SC2000WX SC2000RX

Ice/Beverage Dispensers

MII-302 S-250M

Part Number STH12 9/10 9

Page 10

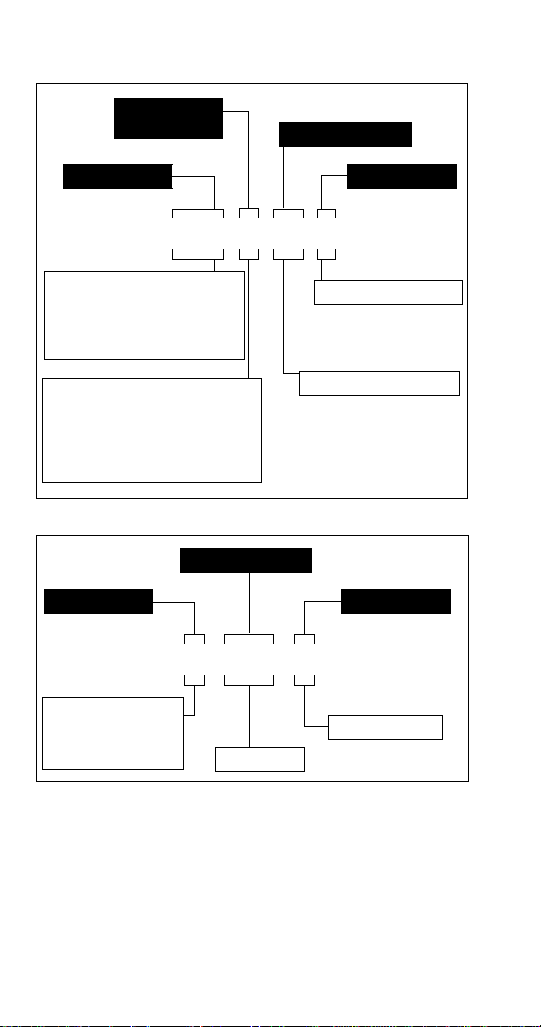

How to Read a Model Number

Special Configuration

04 - R404a refrigerant

Model Prefix

Model Suffix

Model Base

11M A 04 x

A - Air-cooled

AX - Air-cooled, international

R - Remote

RX - Remote, international

W - Water-cooled

WX - Water-cooled, international

Condenser

Type

2803 & SC180 - 1/3 hp

11M & SC340 - 1/2 hp

44M, 42M & SC1000 - 1 hp

44E - 1 hp, TUV Approved

50M & SC2000 - 2.2 hp

S - Ice/Beverage

Dispenser

MII - Ice/Beverage

Dispenser

M - Multiplex

Ice Capacity

Model Prefix Model Suffix

Model Base

S–250–M

ICE/BEVERAGE MODEL NUMBERS

Accessories

Depending on store type and location, various optional

equipment (such as CO

booster kit, etc.) may be added to this system. Install

and connect any optional equipment in the desired

location according to the installation instructions

provided with these kits/equipment.

10 Part Number STH12 9/10

Panel, water filter kit, water

2

Page 11

Special Applications

!

Warning

!

Warning

ATTENTION: MARINE INSTALLATIONS

This unit is for use on vessels over 66 ft (20 m) in

length. This unit must not be installed in the engine

space of a gasoline-powered ship.

NOTE: This unit must be secured to the vessel during

installation. Models with part numbers beginning with

the letters TS are NOT marine listed.

OUTDOOR APPLICATIONS

TS Multiplex Beverage Recirculating units are

approved and listed by Underwriters Laboratories

(UL). However they are not UL approved for weather

exposure applications. These units must be installed in

areas where adequate protection from the elements is

provided, all other models are ETL listed.

Personal Injury Potential

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

Model/Serial Number Location

These numbers are required when requesting

information from your local Manitowoc Distributor,

service representative, or Manitowoc Foodservice.

The model and serial number are listed on the

OWNER WARRANTY REGISTRATION CARD. They

are also listed on the MODEL/SERIAL NUMBER

DECAL affixed to the unit.

Warranty Information

Consult your local distributor for terms and conditions

of your warranty. Your warranty specifically excludes

all beverage valve brixing, general adjustments,

cleaning, accessories and related servicing.

Part Number STH12 9/10 11

Page 12

Your warranty card must be returned to activate the

warranty on this equipment. If a warranty card is not

returned, the warranty period can begin when the

equipment leaves the factory.

No equipment may be returned without a written

Return Materials Authorization (RMA). Equipment

returned without an RMA will be refused at the dock

and returned to the sender at the sender’s expense.

Please contact your local distributor for return

procedures.

12 Part Number STH12 9/10

Page 13

Installation

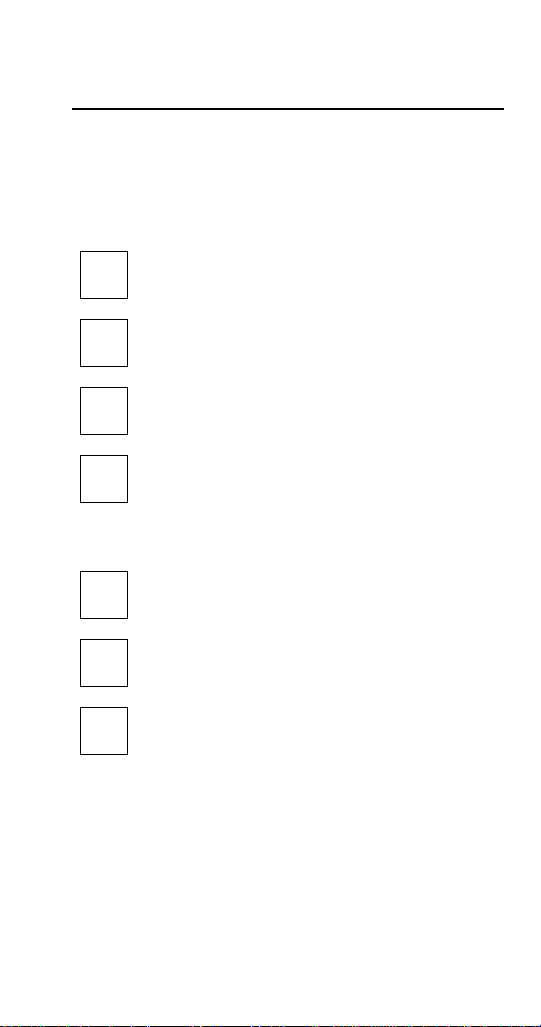

Pre-installation Checklist

When installing any system, first make sure the major

components are available. Generally the major

components necessary for an installation are:

B-I-B System also:

B-I-B connectors

B-I-B regulator set

B-I-B rack

B-I-B syrup boxes

Bulk Syrup System also:

Syrup connectors for Bulk tank

Gas connectors for Bulk tank

Bulk syrup tanks

Part Number STH12 9/10 13

Page 14

Post Mix System:

CO2 regulator set

Beverage dispenser

Beverage tubing

CO

tank

2

Carbonator

Stepless (Oetiker) clamps

Chain for CO

tank

2

Double Check:

Do you have enough space to install the

dispenser or a dispenser and top mounted

cuber?

Does top mounted cuber (if utilized) have a

minimum of 6 inches (15.3 cm) clearance on

all sides?

Is the countertop level?

Can the countertop support the weight of the

dispenser, or the dispenser/cuber

combination plus the weight of the stored

ice?

14 Part Number STH12 9/10

Page 15

Also consider the location of the following items before installa tio n:

Water line

Drain

Power outlet

Heating and air conditioning ducts

Top Mounted Ice Maker Installations

Location — Avoid placing the dispenser

and/or ice machine near heat sources such

as radiators, ovens, refrigeration equipment

and direct sunlight.

Clearances — Six inch (15.2 cm) clearance

on all sides of the icemaker is needed.

Front of icemaker to be flush with front of

dispenser — The front of the icemaker must

be flush with the front of the dispenser. When

the icemaker is flush with the front of the

dispenser, some icemakers may overhang at

the back of the dispenser.

Drains — A separate drain line is required

for the ice machine, in addition to a drain line

for the ice/beverage dispenser.

Dispensers require an adapter kit to install

some top-mounted icemakers. Contact your

local distributor for the correct adapter kit.

Part Number STH12 9/10 15

Page 16

S250-M Dimensions

I

H

B

A

E

F

G

D

C

A

39.81"

(101.1 cm)

B

30.00"

(76.2 cm)

C

9.94"

(25.2 cm)

D

4.44"

(11.3 cm)

E

22.63"

(57.5 cm)

F

28.00"

(71.1 cm)

G

31.13"

(79.1 cm)

H

20.00"

(50.8 cm)

I

27.44"

(69.7 cm)

16 Part Number STH12 9/10

Page 17

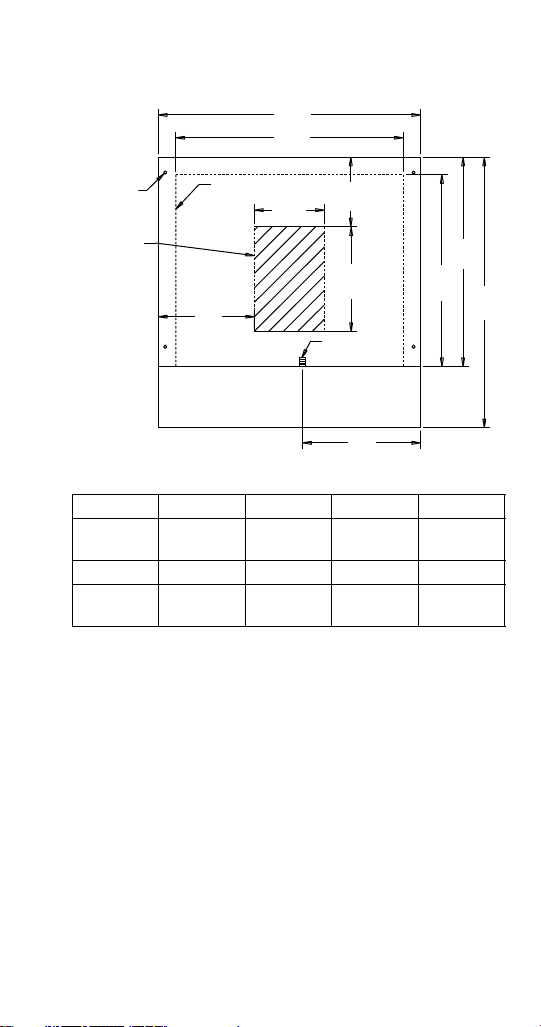

S250-M FOOTPRINT

A

B

D

C

E

G

I

J

H

F

Minimum Area

for Cutout

Maximum

Area for

Cutout

ABCDE

30.00"

(76.2 cm)

FGHI J

15.00"

(38.1 cm)

26.00"

(66.0 cm)

20.81"

(52.8 cm)

8.00"

(20.3 cm)

3.00"

(7.6 cm)

7.30"

(18.5 cm)

22.81"

(57.9 cm)

11.00"

(27.9 cm)

31.13"

(79.1 cm)

Part Number STH12 9/10 17

Page 18

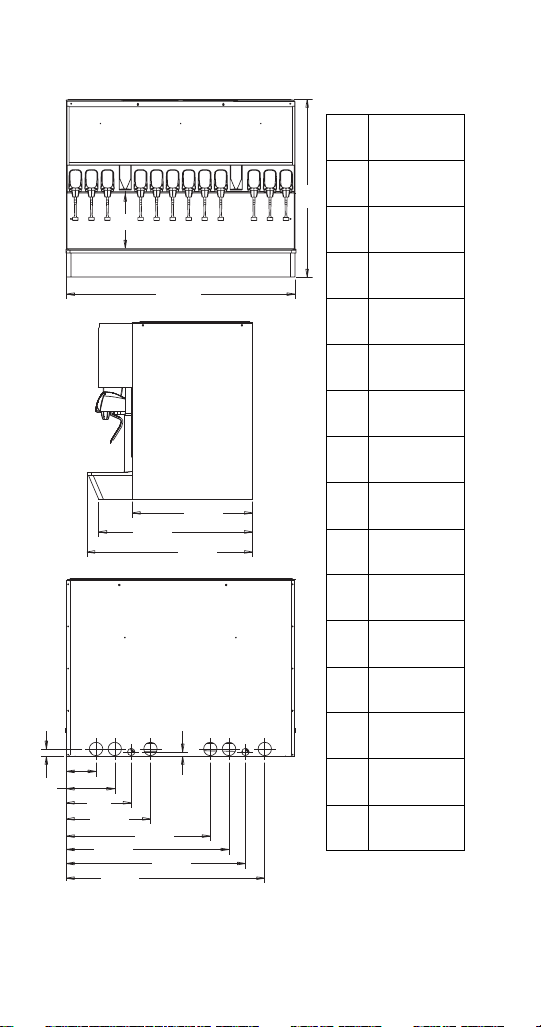

MII-250 Dimensions

A

A

39.00"

(99.1 cm)

B

12.50"

(31.8 cm)

C

30.00"

(76.2 cm)

D

1.50"

(3.8 cm)

E

9.94"

(25.2 cm)

F

13.50"

(34.3 cm)

G

20.00"

(50.8 cm)

H

30.50"

(77.5 cm)

K

28.38"

(72.1 cm)

L

22.50"

(57.2 cm)

M

21.69"

(55.1 cm)

N

1.75"

(4.4 cm)

P

28.44"

(72.2 cm)

Front View

Back View

Bottom View

3/8"-16

Thread

Mounting

Holes for

optional

legs

B

C

M

E

F

G

D

H

K

L

P

N

18 Part Number STH12 9/10

Page 19

MII-250 FOOTPRINT

A

B

C

Maximum Area

for Cutout

D

F

E

3/4" NPT

Fitting

Drainpan

G

H

I

J

3/8"-16

Thread

Mounting

Holes for

Optional

Legs

Minimum

area for

Cutout:

Install

conduit to

the back of

opening to

allow

forward

movement

for service

of flex

manifold.

ABCDE

30.00"

(76.2 cm)

FGHI J

12.00"

(30.5 cm)

26.00"

(66.0 cm)

13.50"

(34.3)

8.00"

(20.3 cm)

22.00"

(55.9cm)

8.00"

(20.3 cm)

24.00"

(61.0 cm)

11.00"

(27.9 cm)

31.00"

(78.7 cm)

Part Number STH12 9/10 19

Page 20

MII-302 Dimensions

A

33.25"

(84.5 cm)

B

12.50"

(31.8 cm)

C

42.75"

(108.6 cm)

D

1.38"

(3.5 cm)

E

5.59"

(14.2 cm)

F

9.10"

(23.1 cm)

G

12.16"

(30.9 cm)

H

31.00"

(78.7)

J

15.78"

(40.1 cm)

K

28.78"

(73.1 cm)

L

22.50"

(57.2 cm)

M

0.82"

(2.1 cm)

N

26.97"

(68.5 cm)

O

30.47"

(77.4 cm)

P

33.75"

(85.7 cm)

Q

37.16"

(94.4 cm)

B

C

L

K

H

D

E

F

G

J

O

Q

M

N

P

A

20 Part Number STH12 9/10

Page 21

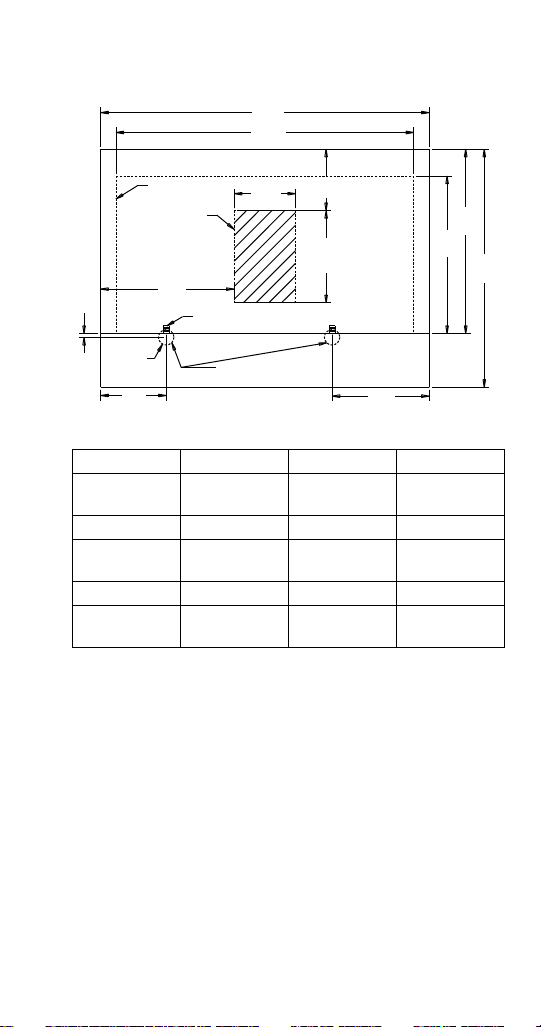

MII-302 FOOTPRINT

A

B

C

Maximum Area

for Cutout

D

F

E

3/4" NPT Fitting

Drainpan

H

I

J

K

Minimum area

for Cutout: Install

conduit to the back of

opening to allow forward

movement for service of

flex manifold.

Cutouts for Extended

Splash Panel Drain Tube

G

0.50

(1.3)

ABCD

42.75"

(108.6 cm)

EFGH

17.38"

(44.1 cm)

IJK

20.50"

(52.1 cm)

38.75"

(98.4 cm)

12.00"

(30.5 cm)

24.00"

(61.0 cm)

8.00"

(20.3 cm)

8.54"

(21.7 cm)

31.00"

(78.7 cm)

8.00"

(20.3 cm)

12.63"

(32.1 cm)

Part Number STH12 9/10 21

Page 22

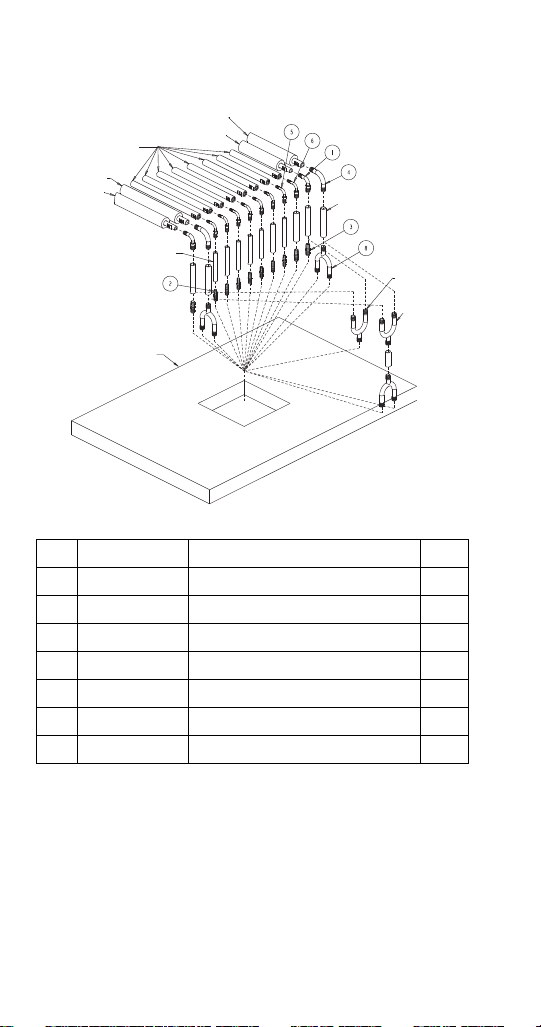

MII-250 Installation Kit

Carb Water to

Left Manifold

Plain Water to

Left Manifold

Syrup Tubes

to Valves

Carb Water to

Right Manifold

Plain Water to

Right Manifold

3/8" ID Tubing

from Conduit (7X)

1/2" ID Tubing

from Conduit (5X)

Use Only for

One Conduit

Plain Water

Line

Use Only for

Two Conduit

Carb Water

Line

Countertop

To Conduit

No. Part Number Description Qty.

1 00854998 Ell 1/2 x 3/8 Barb SS 2

2 00861304 Splicer 3/8 x 3/8 Barb 7

3 00861306 Splicer 1/2 x 1/2 Barb 3

4 5018595 Splicer Elbow SS 1/2 x 1/2 2

5 5030996 Elbow 1/4 x 3/8 Barb SS 7

6 5030997 Elbow 1/4 x 1/2 Barb SS 1

7 5030998 U-bend 1/2 x 1/2 WI - 1/2 Stem 3

22 Part Number STH12 9/10

Page 23

Carb Water to

Left Manifold

Plain Water to

Left Manifold

Syrup Tubes

to

Valves

Carb Water

to Right

Manifold

Plain Water

to Right

Manifold

3/8" ID Tubing

from Conduit (7X)

1/2" ID Tubing

from Conduit (9X)

Use Only

for One

Conduit

Plain

Water

Line

Use Only

for Two

Conduit

Carb

Water

Line

Countertop

To Conduit

MII-302 Installation Kit

No. Part Number Description Qty.

1 00854998 Ell 1/2 x 3/8 Barb SS 2

2 00861304 Splicer 3/8 x 3/8 Barb 6

3 00861306 Splicer 1/2 x 1/2 Barb 6

4 5011751 Fitting 3/8" Y Barb 1

5 5018595 Splicer Elbow SS 1/2 x 1/2 2

6 5030996 Elbow 1/4 x 3/8 Barb SS 8

7 5030997 Elbow 1/4 x 1/2 Barb SS 4

8 5030998 U-bend 1/2 x 1/2 WI - 1/2 Stem 3

WATER AND SYRUP LINES

This kit facilitates connecting the unit to a 12-16 line

conduit, with one or two carbonated water recirculating

systems, and one or two plain water supply lines, and

maximum 8 syrup product lines.

The unit is shipped with connecting lines terminating

under the unit. It will be necessary to make a 90° turn

Part Number STH12 9/10 23

Page 24

down through the counter top, to connect to the

conduit. It will also be necessary to fully insulate this

new added section before passing through the counter

top, or before hooking to main conduit.

CARB WATER LINES

• Unit has two carb water lines, one for each flex

manifold.

• Use 2 @ 1/2" x 1/2" elbow and 6-12" of 1/2"

conduit tubing to make connection bend from unit

down through hole in counter top, to mate with

conduit.

• Conduit with only two circulating carb water lines.

• Use two @ 1/2" barb U-bend adapters (invert one)

to connect the two carb circulating lines from

conduit to the two carb water lines from the unit.

Use short 1/2" conduit line to connect the two

U-bends as shown (item #8).

• Conduit with four, two sets of recirculating carb

water lines.

• Use two @ 1/2" barb U-bend adapters, to connect

each set of circulating conduit lines to each carb

water line from unit as shown (8).

PLAIN WATER LINES

• Unit has two plain water lines, one for each flex

manifold.

• Use two @ 3/8" x 1/2" elbows and 6-12" of 1/2"

conduit tubing to make connection bend from unit

down through hole in counter top, to mate with

conduit.

• Conduit with only one plain water line.

• Use one @ 1/2" U-bend adapter, to connect the

two plain water lines to one plain water line from

conduit (item #3).

• Conduit has two plain water lines.

• Use two @ 1/2" straight adapters to connect each

plain water line from unit to each plain water line

from conduit as shown (3).

24 Part Number STH12 9/10

Page 25

SYRUP LINES

• Unit has eight syrup lines.

• Use seven @ 1/4 x 3/8" and one @ 1/4 x 1/2"

elbows and proper size conduit tubing to make

connection bend from unit down through hole in

counter top, to mate with conduit.

• FULLY INSULATE (no air gaps) and finish with

tape wrap, all these connections from unit, through

90° bend connection and down close to straight

conduit connection. Locate unit properly on

counter, and secure to counter . Finish connections

to conduit with 3/8" x 3/8" and 1/2" x 1/2" straight

barb connectors, and U-bend adapters, as

needed.

• FULLY INSULATE and finish with tape wrap all

these connections to the conduit.

Refrigeration Units

• Refrigeration units require stand or 6" (15.2 cm)

legs. Refrigeration unit cannot be placed directly

on floor.

• Conduit can be run through floor or ceiling chase.

• Syrup supply can be located on stand or adjacent

to refrigeration unit.

CLEARANCES

Control Side (Right) 18" (45.7 cm)

Tower Connection Side (Left) 12" (30.5 cm)

Back Side 6" (15.2 cm)

Ceiling 18" (45.7 cm)

Part Number STH12 9/10 25

Page 26

REMOTE CONDENSER LINESET REQUIREMENTS

Important

Important

If you have a MAC Multi-Pass condenser please

add three (3) pounds additional charge.

If you exceed the 100ft line set length add

.72oz/ft of line set run (one way) for every foot

over 100ft, to the UNIT charge

1. Both the discharge and liquid remote condensing

lines must be kept to a minimum distance for

maximum performance. All Multiplex systems are

capacity rated to 100 ft (30.5 m) tubing distance

between the compressor and condenser. If you

have another brand condenser, please add

additional charge for the condenser (example: up

to three (3) pounds for a MAC condenser).

2. Any vertical ri se 25 ft (7.62 m) or greater must

have a manufactured or installed trap (bend), in

the discharge refrigeration line from the

compressor to the remote condenser. A trap is

necessary for every additional 25 ft (7.62 m)

vertical rise. When excessive vertical rise exists,

this trap allows oil to reach the condenser and

return to the compressor.

26 Part Number STH12 9/10

Page 27

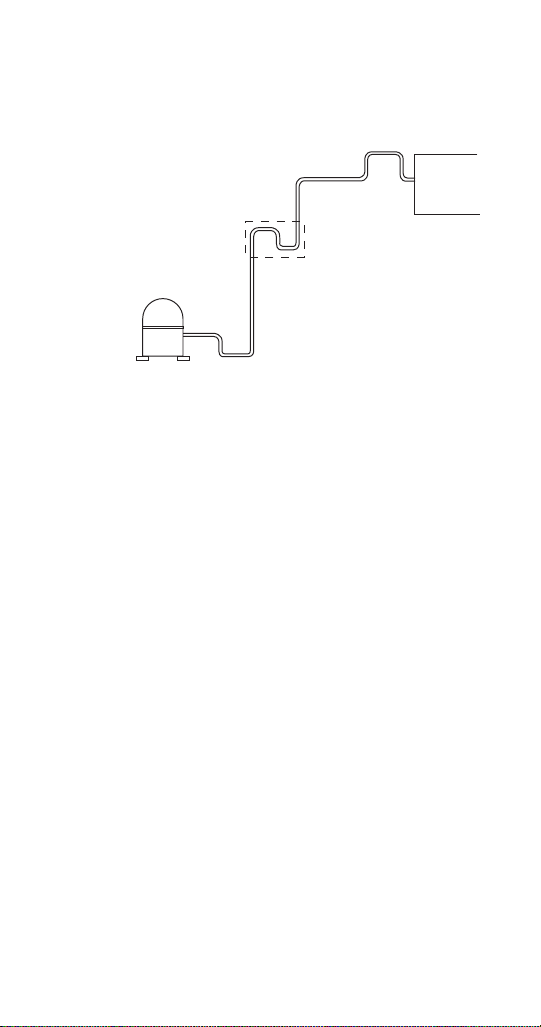

3. The easiest method to create a trap is to bend the

To the

Condenser

Discharge Line Trap Every

25 Vertical ft. (7.62 m)

3 ft (.9 m) (minimum) of Discharge

Line Trap at the Compressor

Compressor

3" (7.6 cm) x 6" (15.2 cm)

Maximum Trap Area

Discharge Line

Condenser Trap

tubing (smoothly , no kinks) into the trap form.

4. The trap(s) must be of minimum height of 3"

(7.6 cm) and a width of 6" (15.2 cm) to minimize oil

accumulation. The traps can also be bent out of the

refrigeration tubing. Carefully bend the tubing down

12", and then sweep the tubing back up.

5. It is critical that the remote condensing line size

specifications for the specific model be

maintained. The specifications are 1/2" discharge

and 3/8" liquid lines.

Part Number STH12 9/10 27

Page 28

Safe Installation Dos and Don’ts

! Warning

!

Warning

! Warning

Read the following warnings before beginning an

installation. Failure to do so may result in

possible death or serious injury.

• Adhere to all National and Local Plumbing

and Electrical Safety Codes.

• Turn OFF incoming electrical service

switches when servicing, installing, or

repairing equipment.

DO NOT throw or drop a CO

•

Secure the cylinder(s) in an upright position

with a chain.

DO NOT store CO

•

above 125°F (51.7°C) near furnaces, radiator

cylinders in temperature

2

or sources of heat.

cylinder.

2

DO NOT connect the CO

the product container. Doing so will result in an

cylinder(s) directly to

2

explosion causing possible death or injury. It is best

to connect the CO

cylinder(s) to a regulator(s).

2

Carbon Dioxide (CO2) displaces oxygen. Exposure

to a high concentration of CO

which are followed rapidly by loss of consciousness

and suffocation. If a CO

particularly in a small area, immediately ventilate the

area before repairing the leak. CO

must not be installed in an enclosed space. An

gas causes tremors,

2

gas leak is suspected,

2

lines and pumps

2

enclosed space can be a cooler or small room or

closet. This may include convenience stores with

glass door self serve coolers. If you suspect CO

may build up in an area, venting of the BIB pumps

and/or CO

28 Part Number STH12 9/10

monitors must be utilized.

2

2

Page 29

• DO check that all flare fittings are tight. This check

must be performed with a wrench to ensure a

quality seal.

• DO inspect pressure on regulators before starting

up equipment.

• DO protect eyes when working around

refrigerants.

• DO use caution when handling metal surface

edges of all equipment.

• DO handle CO

Secure cylinders properly against abrasion.

• DO store CO

• DO NOT exhaust CO

into an enclosed area, including all types of walk-in

cylinders and gauges with care.

2

cylinder(s) in well ventilated areas.

2

gas (example: syrup pump)

2

coolers, cellars, and closets.

• DO NOT release CO

gas from old cylinder.

2

• DO NOT touch refrigeration lines inside units;

some may exceed temperatures of 200°F

(93.3°C).

NOTE: All utility connections and fixtures must be

sized, installed, and maintained in accordance with

Federal, State, and Local codes.

Part Number STH12 9/10 29

Page 30

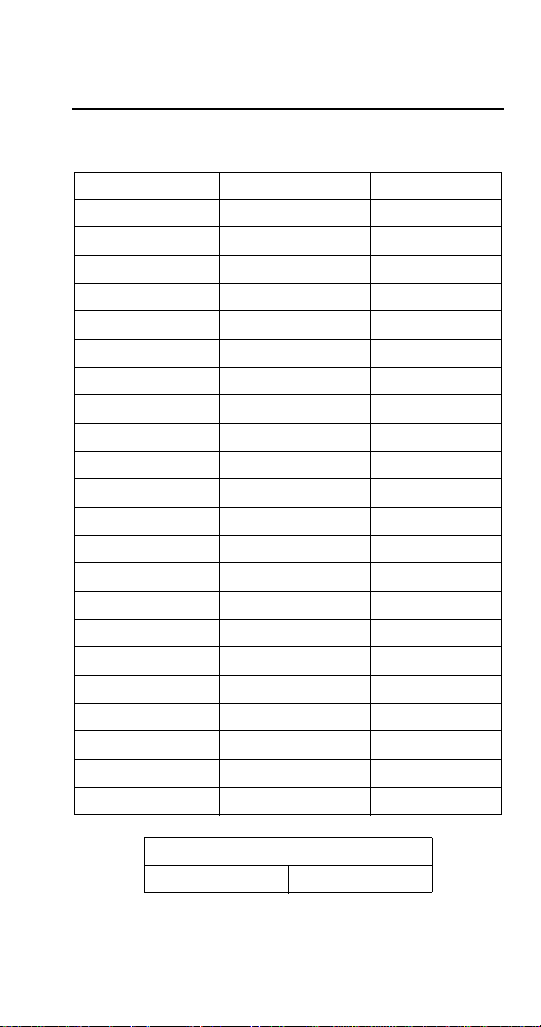

Location Requirements

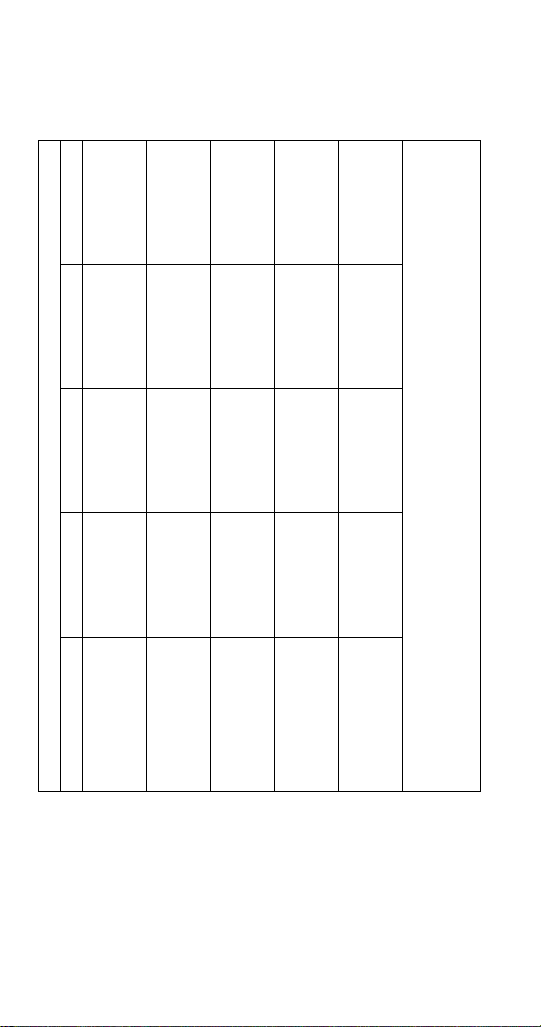

Number of Dispensing Stations

Business Level* 1 2 3 4

Up to 6 gal / 3 L

of syrup/day or

280 drinks/day

(2,000 gal/yr)

Model 2803

40 ft / 12 m

Maximum

Conduit Length

Model 11M

100 ft / 30 m

Maximum

Conduit Length

Model 44M

250 ft / 80 m

Maximum

Conduit Length

Model 44M

250 ft / 80 m

Maximum

Conduit Length

Up to 12 gal / 45 L

of syrup/day or

560 drinks/day

(4,000 gal/year)

Model 11M

100 ft / 30 m

Maximum

Conduit Length

Model 11M

100 ft / 30 m

Maximum

Conduit Length

Model 44M

250 ft / 80 m

Maximum

Conduit Length

Model 44M

250 ft / 80 m

Maximum

Conduit Length

Up to 21 gal / 79 L

of syrup/day or

980 drinks/day

(7,500 gal/yr)

Model 44M

250 ft / 80 m

Maximum

Conduit Length

Model 44M

250 ft / 80 m

Maximum

Conduit Length

Model 44M

250 ft / 80 m

Maximum

Conduit Length

Model 44M

250 ft / 80 m

Maximum

Conduit Length

Up to 32 gal / 121 L

of syrup/day or

1400 drinks/day

(11,500 gal/yr)

Model 44M

250 ft / 80 m

Maximum

Conduit Length

Model 44M

250 ft / 80 m

Maximum

Conduit Length

Model 50M

350 ft / 107 m

Maximum

Conduit Length

Model 50M

350 ft / 107 m

Maximum

Conduit Length

Up to 42 gal / 159 L

of syrup/day or

2000 drinks/day

(15,000 gal/yr)

Model 50M

350 ft / 107 m

Maximum

Conduit Length

Model 50M

350 ft / 107 m

Maximum

Conduit Length

Model 50M

350 ft / 107 m

Maximum

Conduit Length

Model 50M

350 ft / 107 m

Maximum

Conduit Length

* Care must be taken when selecting the proper refrigeration unit. Above selections are for 75°F

(24°C) conditions, 16 ounce (470 ml) drinks, and average business cycles. Other factors such as

lunch or dinner peak periods, large drinks, or high ambient conditions may require the next larger

size unit. Contact your Manitowoc Company Author ized Distributor or Manitowoc Bever age Systems

(MBS) for more information.

SODA REFRIGERATION UNIT “QUICK-PICK” SELECTION CHART

30 Part Number STH12 9/10

Page 31

Select a location for the refrigeration unit that meets

the requirements of the building plans, local codes,

and personnel. The unit must be positioned for free

airflow as well as for future service. The following

minimum requirements must be met:

• 100 GPH (379 LTR/hr) potable water supply

Models 2803/11/38; 200 GPH (757 L TR/hr) potable

water supply Models 44/50

• Beverage quality CO

with a minimum 3/8" (.96 cm) line

gas (bulk or bottled supply)

2

• One Bag-In-Box (BIB) container of each post mix

syrup flavor.

NOTE: Refer to nameplate on side of refrigeration unit

for voltage and amperage specifications. Make all

electrical connections at the junction box located at the

top rear of unit. Optional equipment may require

additional power supplies.

NOTE: Potable water connections to the equipment

must comply with local plumbing code requirements,

particularly the back-flow prevention requirements.

PLUMBING REQUIREMENTS – GENERAL

Incoming water supply must be provided before

installation of the refrigeration unit and must comply

with local plumbing requirements.

1. A minimum 1" (2.54 cm) water supply line with a

manual shut-off valve must be plumbed at least

6 ft (183 cm) from the unit. The incoming water

supply pressure must not exceed 70 psi static

(4.8 bar) and be no less than 40 psi (2.8 bar)

dynamic. If supply water pressure is greater than

70 psi (5 bar), a water regulator will be required.

2. Locate the drain hose, bracket, and two screws

provided in the installation kit. Attach the drain

hose to the water bath overflow tube located on

the bottom of the refrigeration unit.

Part Number STH12 9/10 31

Page 32

3. Connect the water manifold supply line, located

Screw

Drain Hose

Bottom

of Unit

Bracket

on the bulkhead panel in the motor compartment

to the main water supply. The main water supply

shut-off valve must remain in the OFF position. If

a water filter is to be installed, connect the line to

the outlet fitting of the filter. Plumb according to

applicable plumbing codes.

Drain Hose Connection

4. When a water coole d conde nser is installed, a

copper supply line (not supplied with unit) must be

plumbed to the 3/8" (.965 cm) male flare fitting

installed in the water shut-off assembly. The

shut-off must be placed in the OFF position. A

copper drain line (not supplied) is to be connected

to the outlet fitting of the water cooled condenser

and routed to the floor drain.

32 Part Number STH12 9/10

Page 33

WATER SUPPLY

1. Use the built in fill valv e that is already plumbed

into the unit.

2. An appropriate floor drain is required within 6 ft

(2 m) of the unit.

3. Potable water connections to the equipment must

comply with the basic plumbing code of the

Building Officials and Code Administrators

International, Inc. (BOCA) and the Food Service

Sanitation Manual of the Food and Drug

Administration. Verify local plumbing code

requirements.

Part Number STH12 9/10 33

Page 34

Electrical

! Warning

GENERAL

All wiring must conform to local, state and

national codes.

MINIMUM CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select

the wire size of the electrical supply. (Minimum circuit

ampacity is not the unit’s running amp load.) The wire

size (or gauge) is also dependent upon location,

materials used, length of run, etc., so it must be

determined by a qualified electrician.

ELECTRICAL REQUIREMENTS

Refer to unit’s Model/Serial Plate for

voltage/amperage specifications.

34 Part Number STH12 9/10

Page 35

SPECIFICATIONS

* Only the model 50M with SS part numbers have 120V components, the TS does not.

Model Volt/Cycle/Phase

Minimum

Circuit Amps

Breaker Compressor

2803 &

SC180

120/60/1

230/50/1

20.3

9.0

25A

16A

1/3 hp

.46 kW

11M &

SC340

120/60/1

230/50/1

21.5

10.7

30A

16A

1/2 hp

.97 kW

44M,

42M &

SC1000

208-230/60/1

230/50/1

20.6

20.6

30A

25A

1 hp

1.9 kW

50M 120* /208-230/60/3

230/400/50/3

25.2

11.6

30A

20A

2.2 hp

2.0 kW

SC2000 208-230/60/3

230/400/50/3

25.2

11.6

20A

15A

2.2 hp

2.0 kW

Part Number STH12 9/10 35

Page 36

GROUNDING INSTRUCTIONS

! Warning

!

Warning

The unit must be grounded in accordance with

national and local electrical codes.

This appliance must be grounded. In the event of

malfunction or breakdown, grounding provides a path

of least resistance for electric current to reduce the risk

of electric shock.

NOTE: The refrigeration units are not equipped with a

cord.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

The conductor with insulation having an outer

surface that is green with or without yellow stripes

is the equipment grounding conductor. If repair or

replacement of the cord or plug is necessary, do

not connect the equipment-grounding conductor

to a live terminal. Check with a qualified

electrician or serviceman if the grounding

instructions are not completely understood, or if

in doubt as to whether the appliance is properly

grounded. Do not modify the plug provided with

the appliance — if it will not fit the outlet, have a

proper outlet installed by a qualified electrician.

36 Part Number STH12 9/10

Page 37

!

Warning

When using electric appliances, basic

precautions must always be followed, including

the following:

a. Read all the instructions before using the

appliance.

b. T o reduce the risk of injury , close supervision

is necessary when an appliance is used near

children.

c. Do not contact moving parts.

d. Only use attachments recommended or sold

by the manufacturer.

e. Do not use outdoors.

f. For a cord-connected appliance, the

following shall be included:

• Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

• Unplug from outlet when not in use and

before servicing or cleaning.

• Do not operate any appliance with a

damaged cord or plug, or after the

appliance malfunctions or is dropped or

damaged in any manner. Contact the

nearest authorized service facility for

examination, repair, or electrical or

mechanical adjustment.

g. For a permanently connected appliance —

Turn the power switch to the off position

when the appliance is not in use and before

servicing or cleaning.

h. For an appliance with a replaceable lamp —

Always unplug before replacing the lamp.

Replace the bulb with the same type.

i. For a grounded appliance — Connect to a

properly grounded outlet only. See

Grounding Instructions.

Part Number STH12 9/10 37

Page 38

Plumbing/Water Supply

PLUMBING POTABLE WATER

Model

2803 &

SC180

11M &

SC340

44M,

42M &

SC1000

50M 40 – 70 psig

SC2000 40 – 70 psig

Required

Water

Pressure

40 – 70 psig

(2.8 – 4.9 bar)

40 – 70 psig

(2.8 – 4.9 bar)

40 – 70 psig

(2.8 – 4.9 bar)

(2.8 – 4.9 bar)

(2.8 – 4.9 bar)

A 1" (2.54 cm) ID copper inlet water line equipped with

a 3/4" (1.905 cm) FPT adapter with shut-off must be

supplied by plumber at rear of equipment. Appropriate

floor drains must be provided within 6 ft (183 cm) of

each unit installed.

NOTE: The carbonator in this unit is provided with a

dual check valve type back-flow preventer, which

conforms to ASSE 1032. The Model 50M & 44M

vented backflow preventer conforms to ASSE 1022.

Potable water connections to the equipment must

comply with the basic plumbing code of the Building

Officials and Code Administrators International, Inc.

(BOCA) and the Food Service Sanitation Manual of

the Food and Drug Administration. Verify local

plumbing code requirements.

Drain

Connections

3/4" ID

within 6 ft (2 m)

3/4" ID

within 6 ft (2 m)

3/4" ID

within 6 ft (2 m)

3/4" ID

within 6 ft (2 m)

3/4" ID

within 6 ft (2 m)

Water

Supply

3/8" ID

EVA Line

3/8" ID

EVA Line

1/2" ID

EVA Line

1/2" ID

EVA Line

1/2" ID

EVA Line

38 Part Number STH12 9/10

Page 39

Preparing Ice Bank – Non-ERC

Drain Tube

Overflow

Tube

Wate r Bath

Tank

Tab

Clamp

BUILDING AN ICE BANK

1. At this time, fill the unit water bath tank to the top,

or within 1/2" (1.3 cm) of the top minimum, of the

overflow tube. Use a garden hose or another

water supply to do this.

NOTE: A manual fill valve is incorporated into the

water circuit to the carbonator tank. This valve can be

used to manually add water lost for any reason. Do not

leave this valve ON constantly, only use it for filling and

topping off. The water bath must be drained, flushed,

and refilled every six months.

2. Turn ON the switch labeled “Refrigeration”. Allow

unit to run for about 15 minutes before proceeding

to step 3.

3. Turn ON the switch labeled “Agitator”.

NOTE: Turn this switch OFF to perform any operations

in the water bath area.

With water bath water temperature of 65°F (18°C), ice

will begin to form on the evaporator coils in

approximately 2 hours. The unit will build a full ice

bank in approximately 4 to 6 hours (depending on

ambient water temperature).

4. Before turning on the carbonator or circulator

switch, verify that the pump box assembly has

been mounted and connected to the unit and the

appropriate syrup and water has been supplied.

Part Number STH12 9/10 39

Page 40

5. Turn on the main water supply to the booster

Important

assembly. Verify the booster is plugged in and

that the accumulator tank valve is open. (If the

system has an optional “Out-of-Syrup” device,

verify that it is unplugged.)

6. Verify the pump is running. Place the valve on the

right side of the pump box in the purge position

until all air bubbles have passed through the line.

Turn the valve back to “dispense”. Plug the

Out-of-Syrup device power cord into an

appropriate wall outlet at this time (if supplied).

NOTE: Verify that the pump box holding tank is full

before proceeding.

7. Turn on the circulator and carbonator switches.

The carbonator must run for approximately 1 to 3

minutes and shut off. The circulator must run

continuously. Verify that water is returning to the

water bath through the return bulk head fitting.

Wait until a thin layer of ice has begun to form on

the evaporator before proceeding any further.

8. Go to the tower(s) and brix th e valves. Using a

syrup separator and volume cup, adjust the flow

rate of the carbonated water to two fluid ounces

per second. Then, using the separator and a brix

cup, adjust the syrup flow rate for a ratio of

carbonated water to syrup.

40 Part Number STH12 9/10

Page 41

Preparing Ice Bank with ERC

Drain Tube

Overflow

Tube

Wate r Bath

Tank

Tab

Clamp

BUILDING AN ICE BANK

1. At this time, fill the unit water bath tank to the top,

or within 1/2" (1.3 cm) of the top minimum, of the

overflow tube. Use a garden hose or another

water supply to do this.

NOTE: A manual fill valve is incorporated into the

water circuit to the carbonator tank. This valve can be

used to manually add water lost for any reason. Do not

leave this valve ON constantly, only use it for filling and

topping off. The water bath must be drained, flushed,

and refilled every six months.

2. Main power to unit must be on. Power delay of 30

seconds occurs when power applied. “Pd30”

3. Press COMP/AGIT switch on keypad display.

4. Agitator will come on immediately and

compressor delay will start. “Cd99” will count from

180 to 0.

NOTE: Turn this switch OFF to perform any operations

in the water bath area.

With water bath water temperature of 65°F (18°C), ice

will begin to form on the evaporator coils in

approximately 2 hours. The unit will build a full ice

bank in approximately 4 to 6 hours (depending on

ambient water temperature).

Part Number STH12 9/10 41

Page 42

5. Turn on the main water supply to the booster

Important

assembly. Verify the booster is plugged in and

that the accumulator tank valve is open. (If the

system has an optional “Out-of-Syrup” device,

verify that it is unplugged.)

6. Verify the pump is running. Place the valve on the

right side of the pump box in the purge position

until all air bubbles have passed through the line.

Turn the valve back to “dispense”. Plug the

Out-of-Syrup device power cord into an

appropriate wall outlet at this time (if supplied).

NOTE: Verify that the pump box holding tank is full

before proceeding.

7. Turn on the circulator and carbonator. The

carbonator must run for approximately 1 to 3

minutes and shut off. The circulator must run

continuously. Verify that water is returning to the

water bath through the return bulk head fitting.

Wait until a thin layer of ice has begun to form on

the evaporator before proceeding any further.

8. Go to the tower(s) and brix th e valves. Using a

syrup separator and volume cup, adjust the flow

rate of the carbonated water to two fluid ounces

per second. Then, using the separator and a brix

cup, adjust the syrup flow rate for a ratio of

carbonated water to syrup to 5 to 1.

42 Part Number STH12 9/10

Page 43

Typical System

Conduit (In Wall)

6 Valve

Soda

Tower

8 Valve

Soda

Tower

Water Booster

Air

Compressor

Conduit

CO

2

Panel

Multiplex

Refrigeration

Unit

CO

2

Tank

Bag-In-Box

(BIB)

Syrup

BIB

Rack

Water

Filters

BIB Pumps

Component Identification

Part Number STH12 9/10 43

Page 44

Connections

John Guest Fittings

Drain Hose

Control Switches

1/4" Plastic

CO

2

Line from

Carbonator

Right Hand

Opening for

Conduit Supply

Lines

MODEL 2803 CONNECTIONS

44 Part Number STH12 9/10

Page 45

MODEL 11M CONNECTIONS

John Guest Fittings

Drain Hose

Control Switches

Opening for

Conduit Supply

Lines

Part Number STH12 9/10 45

Page 46

MODEL 42, 44, & 50M CONNECTIONS

John Guest Fittings

Drain Hose

Control

Switches

(Non-ERC)

Opening for

Conduit Supply

Lines

ERC Controls

46 Part Number STH12 9/10

Page 47

ERC CONTROL BOARD OUTPUT CONNENCTIONS

CR

L

L/N

EARTH

AGITATIOR CIRC

CARB A CARB B CIRC A

PLUG THIS PIN

Part Number STH12 9/10 47

Page 48

ERC CONTROL BOARD INPUT CONNENCTIONS

HIGH PROBE

LOW PROBE

GND

GND

HIGH PROBE

LOW PROBE

HIGH PROBE

LOW PROBE

CO2 TS TD TW TB TA WL ICE CA A CA B

12 11 10 9 8 7 6 5 4 3 2 1

HPCO WATER

COM

+5V DC

OUTPUT

COM

+5V DC

GND

LEVEL PROBE

CIRC A TEMP

CIRC B TEMP

WATER BATH TEMP

DISCHARGE TEMP

SUCTION TEMP

OUTPUT

HPCO SWITCH

48 Part Number STH12 9/10

Page 49

Maintenance

Maintenance Schedule

This section provides a list of periodic maintenance

tasks and the scheduled frequency required to ensure

the proper operation of your Multiplex dispensing

equipment. To ensure quality beverages, prevent

downtime, and reduce costs, these tasks must be

performed as indicated.

PERIODIC MAINTENANCE FOR SOFT DRINK EQUIPMENT (LISTED BY MAJOR COMPONENTS)

Dispensing stations

Daily (365 times per year)

• Take te mperature of finished drinks. Pour off the

first and take the temperature of the second drink.

The proper temperature of drinks must be 38°F

(4°C) or less.

• Remove nozzles and diffusers from each

dispensing valve. Clean with soap and warm water

(not hot). Rinse with carbonated water and

reinstall.

• Flush all dispenser drains. Pour hot water down

drains at closing.

Beverage conduits

Every 4 months (3 times per year)

• Inspect beverage conduits for damage. Re-

insulate and seal any uninsulated areas.

• Inspect floor chases and seal any open chase

ends.

Air compressor

Monthly (12 times per year)

• Drain condensate water from air compressor tank.

Every 4 months (3 times per year)

• Inspect air compressor filter and repl ace if

clogged. Air filter must be replaced every 6

months.

Part Number STH12 9/10 49

Page 50

• Inspect air compressor to verify cut-in at 70 psi

(4.8 bar) and cut-out at 90 psi (6.3 bar). Adjust

pressure switch if necessary.

• Inspect system for air leaks and repair as required.

Refrigeration unit

Every 4 months (3 times per year)

• Clean the refrigeration unit air-cooled condenser

using a vacuum cleaner. If equipped with watercooled condenser, verify the water discharge

temperature is at 105°F (41°C). Adjust water

modulating valve if necessary.

• Inspect water bath to verify water level is at the top

of stand pipe. If below, add water and repair water

makeup device. If excessive amount of water is

flowing over stand pipe, locate leak within bath and

repair.

• Inspect ice bank within the water bath to verify

proper size ice bank and clarity. Look for uniform,

2" to 4" thick ice bank.

• Drain, clean, and refill water bath.

• Inspect agitator motor and ensure proper

operation.

• Inspect the circulating motor/pump assembly.

Clean strainer and oil motor.

• Inspect the carbonating motor/pump assembly.

Clean strainer and oil motor.

• Inspect entire system for leaks and repair as

required.

Water filters

Every 4 months (3 times per year)

• Verify that incoming water pressure is not less than

40 psi (2.8 bar) or greater than 60 psi (4.1 bar). If

equipped with a water regulator, verify proper

setting of 55 psi (3.8 bar). Adjust if necessary.

• If pressure is low, inspect water filter cartridges to

ensure they are able to supply adequate water

pressure under normal system flow. Replace if

unable to provide minimum 20 psi (1.4 bar) under

load.

50 Part Number STH12 9/10

Page 51

Syrup supply

Daily (365 times per year)

• Clean general area of syrup hookup with soap and

warm water. Rinse off all soap.

Every 4 months (3 times per year)

• Inspect syrup lines for proper flavor identification

labels. Replace labels if necessary.

• Disconnect syrup containers. Clean connector with

soap and warm water. Rinse with plain water and

reconnect to syrup containers.

CO2 gas supply

Every 4 months (3 times per year)

• Inspect pressure setting at CO

regulator. Verify proper 90 psi (6.3 bar) pressure

high pressure

2

setting. Adjust if necessary.

• Inspect pressure setting at syrup pressure

regulators. Verify propter pressure setting. Adjust if

necessary.

• Inspect system for CO

leaks, repair as required.

2

PERIODIC MAINTENANCE FOR SOFT DRINK EQUIPMENT (LISTED BY SCHEDULED FREQUENCY)

Daily (365 times per year)

• Take te mperature of finished drinks. Pour off the

first and take the temperature of the second drink.

The proper temperature of drinks must be 38°F

(4°C) or less.

• Remove nozzles and diffusers from each

dispensing valve. Clean with soap and warm water

(not hot). Rinse with carbonated water and

reinstall.

• Flush all dispenser drains. Pour hot water down

drains at closing.

• Clean general area of syrup hookup with soap and

warm water. Rinse off all soap.

Every 4 months (3 times per year)

• Using Brix cup and syrup separator, check for

proper carbonated water flows (standard flow: 5

oz. in 4 seconds, fast flow: 10 oz. in 4 seconds)

Part Number STH12 9/10 51

Page 52

and syrup to water ratios at each dispensing

station. Adjust as required.

• Inspect beverage conduits for damage. Reinsulate and seal any uninsulated areas.

• Inspect floor chases and seal any open chase

ends.

• Inspect air compressor filter and repl ace if

clogged. Air filter must be replaced every 6

months.

• Inspect air compressor to verify cut-in at 70 psi

(4.8 bar) and cut-out at 90 psi (6.3 bar). Adjust

pressure switch if necessary.

• Inspect system for air leaks and repair as required.

• Clean the refrigeration unit air-cooled condenser

using a vacuum cleaner. If equipped with watercooled condenser, verify the water discharge

temperature is at 105°F (41°C). Adjust water

modulating valve if necessary.

• Inspect water bath to verify water level is at the top

of stand pipe. If below, add water and repair water

makeup device. If excessive amount of water is

flowing over stand pipe, locate leak within bath and

repair.

• Inspect ice bank within the water bath to verify

proper size ice bank and clarity. Look for uniform,

2" to 4" thick ice bank.

• Drain, clean, and refill water bath.

• Inspect agitator motor and ensure proper

operation.

• Inspect the circulating motor/pump assembly.

Clean strainer and oil motor.

• Inspect the carbonating motor/pump assembly.

Clean strainer and oil motor.

• Inspect entire system for leaks and repair as

required.

• Verify that incoming water pressure is not less than

40 psi (2.8 bar) or greater than 60 psi (4.1 bar). If

equipped with a water regulator, verify proper

setting of 55 psi (3.8 bar). Adjust if necessary.

52 Part Number STH12 9/10

Page 53

• If pressure is low, inspect water filter cartridges to

ensure they are able to supply adequate water

pressure under normal system flow. Replace if

unable to provide minimum 40 psi (1.4 bar) under

load.

• Inspect syrup lines for proper flavor identification

labels. Replace labels if necessary.

• Disconnect syrup containers. Clean connector with

soap and warm water. Rinse with plain water and

reconnect to syrup containers.

• Inspect pressure setting at CO

regulator. Verify proper 90 psi (6.3 bar) pressure

high pressure

2

setting. Adjust if necessary.

• Inspect pressure setting at syrup pressure

regulators. Verify propter pressure setting. Adjust if

necessary.

• Inspect system for CO

leaks. Repair as required.

2

Part Number STH12 9/10 53

Page 54

Cleaning and Sanitizing the Dispensing Valves and Product Lines

MAINTENANCE SCHEDULE

Every day

Dispensing

valves

Drip pan and

drain hose

Quick

disconnects

Weekly

Outside,

dispenser

cabinet

Every 3 months

Syrup

circuits

Water bath Drain, melt ice and clean using

Every 6 months

Condenser Vacuum fins or use soft bristle brush

Air purifier

filter (if

equipped)

Remove nozzles and diffusers and

soak in mild detergent cleaning

solution. Scrub parts with small bristle

brush taking care to clean small

crevices and O-ring grooves. Turn

OFF power to dispensing valves.

Scrub exterior surfaces, including

bottom splash area and actuator

lever, with cleaning solution.

Reassemble diffusers and nozzles.

Wipe dry exterior surfaces before

turning ON power.

Wash with mild detergent. Rinse with

clean water.

Wash with mild detergent. Rinse with

potable water.

Wash with clean water and mild

detergent. Wipe dry.

Sanitize each syrup circuit. See

“Cleaning and Sanitizing Procedure”.

detergent and brush; rinse with

potable water. Do not use water over

140°F (60°C).

(scrub brush).

Replace.

54 Part Number STH12 9/10

Page 55

CLEANING EQUIPMENT AND SUPPLIES

• Recommended cleaner: Any caustic-base (low

sudsing, non-perfumed, easily rinsed) detergent

solution which provides a minimum 2% sodium

hydroxide. The solution must be prepared in

accordance with the manufacturer’s instructions.

Solution temperature must be between 90°F

(32°C) and 110°F (43°C). Temperatures in excess

of this can cause internal damage to the

dispensing valve components.

• Recommended sanitizer: Any sanitizer which

provides a minimum of 120 parts per million

(120 milligrams per liter) of available chlorine.

Solution temperature must be between 90°F

(32°C) and 110°F (43°C). Temperatures in excess

of this can cause internal damage to the

dispensing valve components.

• Two five gallon (figals) syrup tanks and fittings,

cleaned and sanitized (one for cleaner; one for

sanitizer)

• Containers for cleaner and sanitizer solutions

• Clean, non-abrasive cloths

• Buckets

• Small Brush

• Extra Nozzles

• Extra Jumpers

Part Number STH12 9/10 55

Page 56

CLEANING AND SANITIZING PROCEDURE

!

Caution

NOTE: Cleaning and sanitizing is not required for

potable water circuits. Potable water lines must remain

connected and operational during the cleaning and

sanitizing procedures for syrup circuits.

It is required that the Carbonated Water Lines

remain connected and operational during

cleaning and sanitizing of the syrup circuits.

Sanitizing of the valve without the Carbonated

Water side operation may leave bacteria in the

nozzle, diffuser, and syrup tube.

Cleaning and dispensing valves

1. Disconnect each syrup container from its product

line. Remove product from the lines by purging

with clean warm tap water until syrup has been

fully purged from the product lines and valves.

2. Clean all lines and fittings with cleaning solution

and rinse with clean, room temperature water to

remove all traces of residual product.

Cleaning the product lines

1. To clean each valve product line, attach the valve

product lines to the pressure tank containing the

cleaning solution. Make sure each line is

completely filled. Pressurize the lines by pulsing

the valves.

Pressurizing the product lines

A. For 15 seconds turn dispensing valve ON,

OFF, and then immediately ON again for 15

cycles.

B. Allow the valve to remain flowing for 3

minutes.

C. Repeat pulsing and flowing the valves again

until all cleaning solution has been used.

56 Part Number STH12 9/10

Page 57

!

Caution

Do not allow cleaning and sanitizing solutions to

remain in syrup systems longer than

recommended contact time. Exceeding contact

time will result in damage to valve components.

2. Flush the cleaning solution from the lines with

clean water after a minimum of 3 minutes, by

pulsing the valves as described above.

3. Remove the nozzles and the diffuser assemblies

from the valves. Clean with cleaning solution.

Agitate the assemblies to ensure assemblies are

clean. Place them in a container of sanitizing

solution for 15 minutes. Wearing sanitary gloves,

remove the nozzles and diffuser assemblies from

the sanitizing solution. Drain each until dry and

reassemble to the valves.

4. Attach each valve product line to the pressure

tank containing the sanitizing solution. Be sure all

connections are cleaned and sanitized before

connecting to each product line.

5. Pressurize and fill the lines with sanitizing

solution. Make sure lines are completely filled,

Allow the sanitizing solution to flow through each

valve while activating the valves for 15 cycles.

A. Leave valves OFF and allow to stand

pressurized for 30 minutes.

B. Activate the valves for two (2) cycles. Flush

remaining sanitizer continuously through the

valves.

6. Reconnect the syrup containers to their

respective circuits. Prepare the unit for operation.

7. Draw drinks to refill lin es and flush the sanitizing

solution from the dispenser. Taste the beverage to

verify that there is no off-taste (chlorine).

Part Number STH12 9/10 57

Page 58

Sanitizing

! Warning

! Warning

BEVERAGE SYSTEM CLEANING

Flush sanitizing solution from syrup system.

Residual sanitizing solution left in system could

create a health hazard.

When using cleaning fluids or chemicals, rubber

gloves and eye protection must be worn.

Sanitize the beverage system at initial start-up as well

as regularly scheduled cleaning. The drain pan must

be in place under soda valves, to carry away detergent

and sanitizing agents that will be flushed through

valves.

BAG-IN-BOX SYSTEM SANITATION

The procedure below is for the sanitation of one

syrup circuit at a time. Repeat to sanitize

additional circuits.

You will need the following items to clean and sanitize

the Bag-in-Box (BIB) beverage system:

• Three (3) clean buckets

• Plastic brush or soft cloth

• Mild detergent

• Unscented bleach (5% Na CL O) or

Commercial sanitizer

• Bag-In-Box bag connector

1. Prepare the following in the buckets:

• Bucket 1 — warm to hot tap water for rinsing.

• Bucket 2 — mild detergent and warm to hot

water.

58 Part Number STH12 9/10

Page 59

• Bucket 3 — mix a solution of unscented

Bag

side

connector

bleach (5% Na CL O) or commercial sanitizer

and warm to hot water. Mixture should supply

100 PPM available chlorine (1/4 oz. bleach to

1 gallon water).

2. Disconnect the “syrup-line side” of the BIB

connector.

3. Rinse connector with warm tap water.

Part Number STH12 9/10 59

Page 60

4. Connect syrup connector to BIB connector and

immerse both into Bucket 1. A “bag-side”

connector can be created by cutting the connector

from an empty disposable syrup bag.

5. Draw rinse water through system until clean water

is dispensed. Most beverage valves allow the

syrup side to be manually activated by depressing

the syrup pallet.

6. Connect Bucket 2 to system.

7. Draw detergent solution through system until

solution is dispensed.

8. Repeat steps 2-7 until all syrup circuits contain

detergent solution.

9. Allow detergent solution to remain in the system

for 5 minutes.

10. Connect Bucket 3 to system.

11. Draw sanitizing solution through system until

solution is dispensed.

12. Repeat step 11 until all syrup circuits contain

sanitizer solution.

13. Allow sanitizer solution to remain in system for 15

minutes.

14. Remove nozzles and di ffusers from beverage

valves.

15. Scrub nozzles, diffusers and all removable valve

parts (except electrical parts) with a plastic brush

or a soft cloth and the detergent solution.

16. Soak nozzles, diffusers and removable valve

parts (except electrical parts) in sanitizer for 15

minutes.

17. Replace nozzles, diffusers and valve parts.

18. Connect Bucket 1 to system.

19. Draw rinse water throug h system until no

presence of sanitizer is detected.

20. Attach syrup connectors to BIBs.

21. Draw syrup through system until only syrup is

dispensed.

22. Discard first 2 drinks.

60 Part Number STH12 9/10

Page 61

FIGAL BEVERAGE SYSTEM

1. Prepare the following in three clean Figal tanks:

• Rinse tank - fill with room temperature tap

water.

• Detergent tank - mix approved beverage

system cleaner with warm water as directed.

• Sanitizing tank - mix a solution of un sce nted

bleach (5% Na CL O) or commercial sanitizer

and warm to hot water. Mixture should supply

100 PPM available chlorine (1/4 oz. bleach to

1 gallon water).

2. Disconnect all product and water lines from

product tanks and remove carbonator.

3. Locate the Figal syrup tank for the circuit to be

sanitized. Remove both quick disconnects from

the Figal syrup tank. Rinse quick disconnects in

tap water.

4. Connect rinse tank to the syrup line. Draw clean

rinse water through the valve until syrup is flushed

from the system.

5. Connect detergent tank to the syrup line and draw

detergent through the valve for two minutes.

Then, allow remaining detergent to stay in the

system for five minutes.

6. Connect rinse tank to the syrup line. Draw clean

rinse water through the valve until detergent is

flushed from the system.

7. Remove valve nozzle and diffuser as shown in

Daily Cleaning instructions. Using a plastic brush

or a soft cloth and warm water, scrub the nozzle,

diffuser, bottom of the dispensing valve and cup

lever, if applicable.

8. Place removable valve parts (EXCEPT solenoids)

in sanitizing solution for 15 minutes.

9. Replace valve diffuser and nozzle on the

beverage valve.

10. Connect sanitizer tank to the syrup line and draw

sanitizer through the valve for two minutes. Allow

sanitizer to remain in the system for a minimum of

15 minutes.

Part Number STH12 9/10 61

Page 62

11. Reconnect syrup and carbonated water lines.

!

Caution

12. Draw syrup through the lines to rinse the system.

Discard drinks until at least two cups of

satisfactory tasting beverage are dispensed

through the valve.

Shipping, Storage and Relocation

Before shipping, storing, or relocating this unit,

syrup systems must be sanitized. After sanitizing,

all liquids (sanitizing solution and water) must be

purged from the unit. A freezing environment

causes residual sanitizing solution or water

remaining inside the unit to freeze, resulting in

damage to internal components.

62 Part Number STH12 9/10

Page 63

Operation

How the Multiplex Works

Model 2803 — a 1/3 HP refrigeration unit that will provide

pre-mix carbonated beverages and chilled carbonated water

for up to 6 gal (3 L) of syrup/day or 280 drinks/day (2,000 gal/yr)

with a 40 ft (12 m) maximum conduit length. This is a remote

refrigeration unit that derives its peak draw capacity from the

reserve ice bank produced from a capillary tube refrigeration

system. This system is controlled to cycle ON and OFF by the

operation of the ice bank control. The sensing bulb that controls

the ice bank is located on an adjustable bracket in the water

bath.

Model 11M — a 1/2 HP refrigeration unit that will provide

premix carbonated beverages and chilled carbonated water for

up to 12 gal (45 L) of syrup/day or 560 drinks/day (4,000

gal/year) with a 100 ft (30 m) maximum conduit length. This is

a remote refrigeration unit that derives its peak draw capacity

from the reserve ice bank produced from a capillary tube

refrigeration system. This system is controlled to cycle ON and

OFF by the operation of the ice bank control. The sensing bulb

that controls the ice bank is located on an adjustable bracket in

the water bath.

Model 42M — a 1 HP refrigeration unit that will provi de pre-mix

carbonated beverages and chilled carbonated water for up to

50 gal (190 L) of syrup/day or 3,060 drinks/day (18,200 gal/yr)

with a 250 ft (80 m) maximum conduit length. This refrigeration

unit is a remote refrigeration unit that derives its peak capacity

from the reserve ice bank produced from a TXV system. This

system is controlled to cycle ON and OFF by the operation of

the ice control. The sensing probe that controls the ice bank, is

located on an adjustable bracket in the water bath.

Model 44M — a 1 HP refrigeration unit that will provi de pre-mix

carbonated beverages and chilled carbonated water for up to

50 gal (190 L) of syrup/day or 3,060 drinks/day (18,200 gal/yr)

with a 250 ft (80 m) maximum conduit length. This refrigeration

unit is a remote refrigeration unit that derives its peak capacity

from the reserve ice bank produced from a TXV system. This

system is controlled to cycle ON and OFF by the operation of

the ice control. The sensing probe that controls the ice bank, is

located on an adjustable bracket in the water bath.

Part Number STH12 9/10 63

Page 64

Model 50M — a 2.2 HP Pre-mix refrigeration unit that will

• The TS uses common components from Manitowoc Ice makers

to assist in product and parts availability.

provide pre-mix carbonated beverages and chilled carbonated

water for up to 42 gal (159 L) of syrup/day or 2,000 drinks/day

(15,000 gal/yr) with a 350 ft (107 m) maximum conduit length.

This refrigeration unit is a remote refrigeration unit that derives

its peak capacity from the reserve ice bank produced by the

operation of the compressor. This system is controlled to cycle

ON and OFF by the operation of the ice bank control. The

sensing bulb that controls the ice bank is located on an

adjustable bracket in the water bath.

Differences Between the TS & SS Units

Multiplex soda and water chillers may have three

different series numbers. Starting in 2007 some no

longer begin with an “SS”; they now begin with a “TS”.

Starting in 2008, units with ERC (Electronic

Refrigeration Controls) end with an “E”. The following

shows you how to tell the difference between the TS

version and the SS.

64 Part Number STH12 9/10

Page 65

• The TS compressor is mounted with bolts instead of studs.

• TS remote and water-cooled back panel connections

are offset to protect fittings.

Part Number STH12 9/10 65

Page 66

WATER MANIFOLD TS

• TS air-cooled condenser comes standard with a filter.

Two Stainless Steel log style

manifolds

• One regulated supply for

carbonator pumps.

• One unregulated supply for

non-carb drinks and water

bath fill.

Other Connections

• Connections are made in the

water bath compartment.

• Separate plain water manifold

eliminates need to plug off

during installation.

66 Part Number STH12 9/10

Page 67

ELECTRICAL TS

• Electrical compartment has been moved up on the unit to eliminate

water intrusion potential from the pump compartment.

• All components are now 208/230V. This eliminates the need for a

neutral wire.

• New unit has service connections in the electrical compartment.

Allows more room to work and more reliable connection.

• Pump protection switch has been moved to the pump

compartment to eliminate potential leak point in electrical

compartment.

Part Number STH12 9/10 67

Page 68

WATER BATH ACCESS SS

• Has a round hole in the front and back panels with

no edge trim to protect lines.

• End panel has two ovals in the rear of the panel with

edge trim to help protect conduit lines.

• All panels have large oval access holes with interchangeable

covers.

• Front panel has 3 hole cover for water and CO

2

line routing.

• Back panel has solid cover.

• End panel has one open cover and one solid cover.

• Open cover provides wide ledge for conduit line protection.

WATER BATH ACCESS TS

68 Part Number STH12 9/10

Page 69

SERVICE ACCESS SS

• Front panel was solid and did not allow easy access for service.

• Switch panel was mounted flush to end panel.

SERVICE ACCESS TS

• Front panel is split to allow front access to the compressor

compartment.

• Switches are recessed and the edge has trim panel to protect

fingers from sheet metal edges.

Part Number STH12 9/10 69

Page 70

SERVICE ACCESS TS WITH ERC

LED Display

Service Switch

Program

Switch

SER

PGM

CIRC

B

COMP/

AGIT

CARB A CARB B CIRC A CIRC B

• Service Switch — (SER) switch, press to send ID on power line

network.

• Wink Function — LED flashes “Ion” to indicate wink function. Press

program switch (PGM) to disable wink function.

70 Part Number STH12 9/10

Page 71

Equipment Setup Procedure (Non-ERC)

1. Ensure that all valve nozzles are attached to the

valves.

2. Observe pressure of CO2 high pressure tank of

500 psi (34 bar) or more, or bulk CO

150 psi or more. Primary regulator set at 90 psi

(6 bar) and the secondary regulator set at 35 psi

(2.4 bar).

3. Observe the contro l panel to verify that al l

pressure gauges are set at correct operating

pressures.

4. Check the syrup tanks to make sure a sufficient

number of tanks are connected in series to satisfy

business volume.

5. Clean syrup inlet and outlet quick disconnects at

the same time tanks are replaced. Rinse

disconnects in clean potable water.

tank of

2

Part Number STH12 9/10 71

Page 72

Start-up (Non-ERC)

1. Fill the refrigeration unit water bath tank with

water to within 1/2" (1.27 cm) of the top of the

overflow tube.

2. Open the manual water shut-off valve to the water

cooled condenser (if applicable).

3. Turn ON the rocker switch labeled “Refrigeration”

to begin building an ice bank.

4. Turn ON the rocker switch labeled “Agitator”.

NOTE: On TS units 3 & 4 are combined into 1 switch.

5. Ice will begin to form on the evaporator coils in

approximately 2 hours.

6. The refrigeration unit will build an ice bank in

approximately 4 to 6 hours.

7. If optional CO

installed on the refrigeration unit, refer to the

installation instructions for operation and testing

the circuits for leaks.

8. The carbona tion circuits “A” and “B,” as well as

the syrup circuits must be checked for leaks and

possible cross circuits before turning ON the

water supply to carbonator pumps.

9. Turn on main water supply. Set incoming

regulator to 55 psi on the CO

Model 11M root beer system’s internal regulator

(must be lower than CO2 supply pressure). Once

water is supplied to the unit, air needs to be

purged from the carbonator tank. Do so by lifting

press relief valve tab until water comes out of

relief valve.

10. Turn on main CO

90 – 100 psi. For the Model 11 Root Beer system,

set regulator initially to 26 psi; it can be raised

incrementally to 30 psi if there is excessive

foaming.

11. Set bag-in-box syrup tank push pressure CO

regulator to 65 – 70 psi. For the Model 11 Root

Beer system, set push pressure CO

35 – 40 psi.

/Water Control Panel has been

2

panel; 25 psi for the

2

supply. Set regulator initially to

2

regulator to

2

2

72 Part Number STH12 9/10

Page 73

PLACING THE CARBONATION SYSTEM IN OPERATION

1. Open the CO

bulk tank. Adjust the CO

(6.2 bar).

gas supply valve at CO2 tanks or

2

pressure to 90 psi

2

2. Open relief valve on top of the carbonator tank for

4 seconds to bleed off air in tank.

3. Turn ON the water supply to unit.

4. Turn ON the switch labeled “Carbonator Pump”.

Allow carbonator to run and cycle OFF.

5. Activate all valves until a smooth, continuous flow

of carbonated water and non-carbonated water

appear at the valves.

6. Turn ON switch labeled “Circulator”.

7. Allow at least 1 hou r before proceeding to

calibration instructions. You may complete the

sanitizing instructions during this period.

Part Number STH12 9/10 73

Page 74

Sequence of Operation (Non-ERC)

PRE-MIX REFRIGERATION UNIT

Ice Bank Is Required

1. Check water bath for full ice bank.

2. The stabilized water bath operating temperature

must be maintained at 33°F (0.6°C) to 35°F

(1.7°C).

The following is a sequence of operations for the

Multiplex Pre-mix Beverage equipment.

1. Once a drink is dispensed, the following will

occur:

A. For a Syrup Tank System, the Pre-mix syrup

is manually mixed at the store. Pre-mix