Page 1

AD-600

Installation Guide

Page 2

Installation Guide

AD-600

General Information

The main panels of the AD-600 are made of polypropylene and are 2.36”(6 CM) in height. Cable trench

caps are made of steel. Quick and easy installation is a strong advantage of the ConnectFloor systems.

AD-600 compromises one of the most unique, cost effective, and easily installed low-profile floors on

the market. No special tools are required. Professional quality installation can be achieved by flooring

installers such as those for carpet tiles and PVC tiles; or carpenters, handymen, and even amateurs.

Installation Time

The following estimates do not include material preparation and handling time.

For open space:

Trained installer: 900-1200 sq. feet (80-110 sq. meters) per man-day.

Newly trained or amateur: 600-800 sq. feet (55 – 75 sq. meters) per man-day.

Small rooms and irregular floor plans: may call for 20 to 30 percent more installation time. Good

preparation and job site planning are very influential to installation costs.

Recommended Tools Application

Electric Drill & Driver Perimeter & wall finish

Chalk line Marking straight line for large rooms

Pencils General Markings

Steel rule Measuring

Cutting Knife Cut UniPanel into Sub-Panels

Scroll saw Cut Wall Rail, Edge Rail at corners

Tape measures Measuring

1. Before installation

The following Instructions should be read before installation:

a. ConnectFloor systems are for in-door use only.

b. Modular carpet is the standard finish flooring for the AD-600 (3’X3’ carpet tiles are recommended).

c. Condition: UniPanel (AD-611) and adhesive should be conditioned at room temperature, not lower

than 40°F(5°C).

d. Floor Preparation: Sub-Floor must be free of grease, oil, wax, and moisture or any other foreign

material. All holes, cracks, and depressions should be filled with floor patching compound.

e. Sub-floor of the job site should be generally level. Elevation variation shall be no more than 3/8”(1

CM) within 3.3 feet (1 meter).

1

Page 3

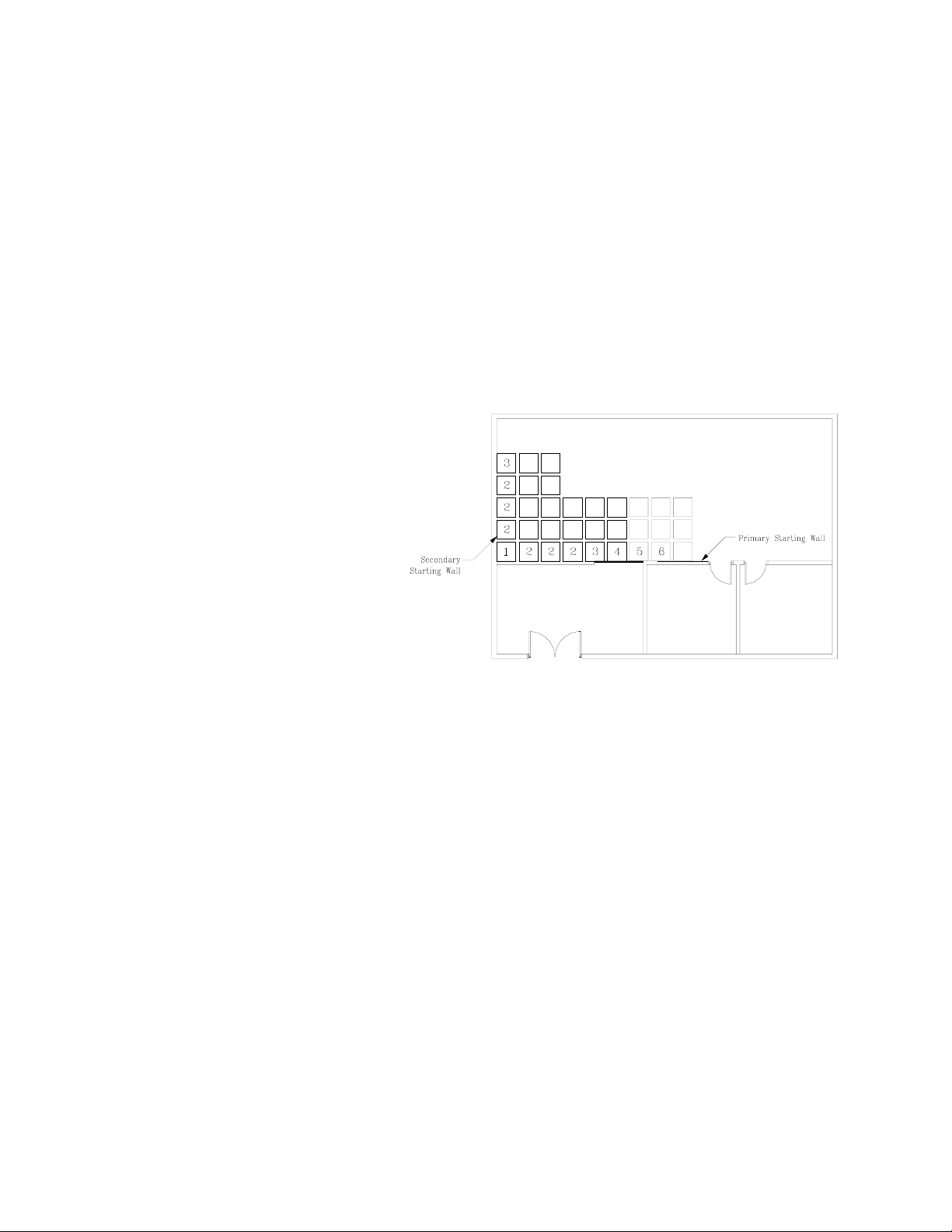

2. Starting Line – laying instructions

To maximize usage of full panels at the borders, it is recommended that you select the longest walls

or the entrance wall as starting point.

Note: Properly selecting the starting line is important. It saves labor time and materials.

Other factors that may affect choice of the starting line include: door, ramp, entry wall, other

long walls and so on.

General Office Example – (Drawing D605)

Use the longer wall as the primary starting wall. Starting from the corner, test sequence

no. 1 and no. 2 UniPanels along both walls, connected by half-Connector. If extension is not

obstructed, move on to

sequence no. 3. Be aware that

any two walls might not be

perfectly perpendicular to each

other. If the second wall is at an

angle less than 90° to the

primary starting wall, the first

UniPanel laid will need to be

strategically offset from both

walls to allow for extension of

UniPanels in both directions.

The resulting gaps to both

walls will then

with appropriate accessories. If

the gaps are greater than 1/5”(5

mm) in width, Edge Rail should work well.

Lay out entire floor with complete UniPanels until the remaining walls cannot allow

complete UniPanels up against them. Cutting or trimming pieces will be required for the

remaining walls to finish the UniPanel matrix. There will also be removal of some panels

that have been laid down to apply the ramping required at the entranceways. In figure

D605A, note that in cases where doors swing inside the room their must be a 25 sq. ft.

entrance area to maintain ADA compliancy. The actual ramping area can easily be added by

removing one UniPanel in front of the door plus an additional half of a UniPanel to account

for the length of the ramps.

be filled up

D605A

D605

2

Page 4

3. Installation

a. Apply Sound Attenuation Blanket. Spray adhesive, duct tape, or 3M adhesive tape may be used

to hold down the sound blanket to the sub floor.

b. Old carpet or resilient floor to substitute Sound Attenuation Blanket: For retrofit installation over

existing commercial rated low-pile carpet, carpet tile, PVC tile and sheet vinyl, step a and b may be

omitted. Depending on the old floor covering, Sound Attenuation Blanket may also be skipped.

However, application over thick foam-backed or cut pile carpet is not recommended.

c. Starting along the wall with half-size Base Connector:

First, use a knife or snap on a straight edge to cut Base Connector into halves.

Position original perimeter side of half-Connectors

against the wall surface, allowing a uniform

+/- .08”(2 mm) offset. Along the starting line,

connect corner feet of the first row

UniPanels. (Drawing D608)

D608

d.

Repeat installation with full size Base Connectors: Starting from the second row, use full Base

Connectors to UniPanels consecutively. No tool is needed. Extension of the Connectors and

UniPanels is simple and straightforward.

e. Cable Trench: Base Connectors connect UniPanels at their corner feet as shown, setting the panels

apart by a standard 3.54”(9 CM) gap. This automatically allows for a two-way uniform-width 3.54”

3

Page 5

grid of cable trench every 23.62”(60 CM) on center. (Drawing D609)

Accessible Cable Trench - Clearance: 2.24”(57 mm)

Width: 3.54”(90 mm)

To assemble a module of 23.63” X 23.63”(60 cm X 60 cm) coverage requires:

1 UniPanel + 1 Central Cap + 1 Base Connector + 4 Flank Caps

D609

f.

UniPanel: The main component of AD-

600 system is the UniPanel, which is a

composite panel of structurally

independent Sub-Panels. The 20.06” X

20.06”(510mm x 510mm) UniPanel

consists of 16 SubPanels each standing

on 4 integral pedestals. The SubPanels

are pre-connected by a .08”(2mm)

uniform joint line on all sides to form the

16-square UniPanels. This feature

provides maximum built-in flexibility for

the panels to easily accommodate either

any variance there might be in sub-floor

elevation--as the joints are not rigid. Or,

when encountering other architectural

elements such as walls and doorways, the

Panels can “break off” any of the

SubPanels to conform to floor area

constraints. (Drawing D610)

D610

g.

Central Cap and Flank Cap: Central Caps are to be installed at the intersection of Cable Trenches,

and Flank Caps alongside UniPanels over the Cable Trenches. There is no need of tools of any kind.

The trenches remain fully accessible--Caps can be simply lift up by hand, and re-place after cable

4

Page 6

installation or service. (Drawing D609)

Note: This ease eliminates frequent coordination conflicts between trades. Instead of the

contractors converging on job sites attempting to achieve opposite results (caps on/caps off, cables

down/ cables up), the electrical contractor can route and lay the cables after the installation of

ConnectFloor is completed. Carpeting is done when both trades are gone from the job site.

h. Ramp without Ramp Rail: The nominal width of

the Ramp part (AD-625) is 4”(10CM). Plan Ramp

installation according to width of the ramp area—this

often corresponds to the opening of the adjacent

doorway, or as required by applicable Building

Codes. Use full ramp sections and then use the Free

Standing Edge, to take up the residual space and

provide a finish edge to the triangular sides of the

ramp as well as carpeting. Use tape of sufficient

width to tape down top and bottom of Ramp.

Carpeted over, there is no visual transition between

ramps and carpet. (Drawing D612)

D612

i.

Free Standing (Skirting) Edge: It is a strip of

aluminum extrusion shaped like a letter “F” crosssection-wise, with the top channel to receive the edge

of carpeting. There is also a luminous strip on the

top of the edge that provides a luminous strip that

remains illuminated for about 6 minutes. Cut strips to

required length, drill holes on top flange as needed

and secure to UniPanels by flat-head screws. The

vertical flange provides a finished edge to the

exposed sides of ConnectFloor. (Drawing D614).

D614

j. Finish Wall / Perimeter: Various ConnectFloor

accessories are designed to “round out” UniPanel

installation by successively taking up the residual

space after installation of the last full UniPanels or

SubPanels along the finish wall. The wall may be

finished by the accessories or by cutting the

UniPanel to run +/-.08” from the wall. The optional

accessories that can be used are located under

Section 4 – Optional Trim Accessories.

k. Finish Wall of irregular shapes: Irregular perimeter spaces may be filled up by using a

combination of Wall Rail, Edge Rail and Corner Rail units. The most flexible installation is

5

Page 7

facilitated by using sections of Wall Rail cut to length with a scroll saw and set down perpendicular

to the edge of the last irregularly laid ConnectFloor part. The sections’ varying lengths are carefully

measured so that they will fill up the entire space between the wall and the ConnectFloor that is

already installed.

l. End Caps are used to trim and finish the ConnectFloor installation along the walls. Since

UniPanels there on the first row are laid on Half Connectors, a kind of “partial cap” is needed to

cap off the gap at the end of cable trenches running into the wall—hence the End Cap. (Drawing

D611).

5. Finish Floor Covering: Commercial-rated modular carpet is the standard floor covering to be used

over ConnectFloor systems. In general office area, apply adhesive in grid pattern; while for heavy traffic

areas such as entrance or aisle, apply adhesive generously throughout. Press the carpet tile down firmly.

If acceptable by the flooring manufacturer’s specifications, 1” wide or wider double-sticky tape of

sufficient viscidity may be substituted. Install as provided by the specifications.

6. Interior Partitions: Semi-permanent interior partitions can be erected on top of ConnectFloor AD-

600. They may be built directly on top of ConnectFloor’s surface, or over finished flooring such as

carpet tiles. To secure

on top of ConnectFloor, pre-drill from

partition’s floor track through UniPanel of

ConnectFloor, then, fasten with blunt tipped

screws through the pre-drilled hole to avoid

damage to cables underneath. “Ram setting”

floor track to UniPanels is not recommended.

Partitions thus installed will not interrupt the

distribution of cables and wires underneath

(Drawing D615).

partition’s floor track

D615

4. Optional Trim Accessories

6

Page 8

These following pieces of trim may be used in cases where the edge of the flooring does not butt

completely up against the wall. The UniPanels, as mentioned in previous sections, can also be cut to

meet up against the wall to finish the flooring matrix.

(1) When the residual space is less than 2.36”(6 cm) in width: Use Edge Rail (AD-623). Fasten Edge

Rail through the pre-punched holes at both ends to the UniPanel or SubPanels with type-s or flat-head

screws (Drawing D611).

(2) When the residual space is a width of 2.36”- 5.11”(6 cm ~ 13 cm): Use Wall Rail (AD-630) as a

spacer. First butt the Wall Rail directly against the last UniPanel or SubPanels. Then, as described in step

(1), fasten Edge Rail to take up the remaining gap (Drawing D611).

(3) Distance between 5.11”- 8.66”(13 cm ~ 22 cm): Use a row of SubPanels (1/4 of UniPanel) as a

spacer. Butt the SubPanels against the last UniPanels. Connect the SubPanels by Half-Connector at

trench. Then, fill the balance by single use or combined use of Edge Rail and/or Wall Rail to finish the

remaining gap (Drawing D611).

(4) The final space left in the corner after use of the last Edge Rail: Use Corner Rail (AD-629), which

has short segments that can be broken off, and each segment has a pre-punched hole to allow fastening to

adjoining parts. (Drawing D611)

Ramp Rail: When installing ramp with Ramp Rail, cut Rail to length then insert between Ramp section

and first UniPanels as shown. Pre-drill holes as needed on both the flat flange and the sloped flange, then

secure it with flat-head screws to both the adjacent UniPanels and the Ramp sections. Carpet tile edges

are tucked into the channels on top of the Rail. This provides easy rigidity and a finished look. The

visible aluminum strip also serves as a ready reminder of the sloping (Drawing D612).

Edge Trimmers are used to trim and finish the ConnectFloor installation along the walls. They are set

down on the small recessed “shelf” –on all four sides of the UniPanels designed to receive Flank Caps—

along the starting wall to bring up the finished floor to a uniform elevation. In most cases, this edge trim

is not used in typical installations. (Drawing D611).

D611

D611

(Single or Double)

7

Page 9

E-Mail: engsupport@multilinkbroadband.com

Web: www.multilinkbroadband.com

580 Ternes Avenue P.O. Box 955

Elyria, OH 44035

Phone: 440.366.6966

Fax: 440.366.6802

24 Hour Voice Messaging

Worldwide Distribution

8

Loading...

Loading...