Installation, Servicing & User Instructions

THESE INSTRUCTIONS TO BE LEFT WITH THE USER

Manufactured By:

Multiglow Fires

Canterbury Road,

St. Nicholas-at-Wade,

Nr. Canterbury,

Kent CT7 0PQ

Telephone: 01843 847575

Fax: 01843 848300

Email: sales@multiglow.com

Web: www.multiglow.com

IM006.2 (12th April 2010)

Fuori Firebox

Decorative fuel effect appliances

for use with Natural Gas

Copyright:

This manual is copyrighted by Multiglow Fires © 2009.

No part of this document may be reproduced in any form or by any means, without the

express written permission of Multiglow Fires.

Warranty:

Multiglow Fires takes pride in using and supplying high quality materials and parts.

However, should any defect in either the workmanship or the materials used become

apparent within one year of purchase, Multiglow Fires will replace or repair the item, free

of charge, at a time that is convenient to you, our valued customer.

In order to ensure your safety, warranty claims must be made through the retailer from

whom the product was purchased.

Under UK law, the purchaser’s contract of sale is with the retailer. As such, Multiglow Fires

cannot enter into discussions with the purchaser until the retailer has inspected any

claim and validated it.

Multiglow Fires reserve the right to make a charge for any service call or to refuse service

when a defect is due to incorrect use or installation.

Page i

Table of Contents

GENERAL INFORMATION........................................................................................1

1. Conformity .................................................................................................... 2

2. General Notes ............................................................................................... 3

2.1. Flue Specifications .................................................................................... 4

2.2. Ventilation Requirements........................................................................... 4

3. Important Notes ............................................................................................ 4

4. Technical Data............................................................................................... 5

4.1. Technical Data Common to all Models......................................................... 5

4.2. Model Specific Technical Data .................................................................... 5

INSTALLATION INSTRUCTIONS.............................................................................6

5. Installation Procedure .................................................................................... 7

5.1. Contents Checklist .................................................................................... 7

5.2. Flue Requirements.................................................................................... 7

5.3. Room Ventilation ...................................................................................... 8

5.4. Appliance Location.................................................................................... 8

5.5. Hearths ................................................................................................... 8

5.6. Hole-In-The-Wall Installations.................................................................... 8

5.7. Installation of the Appliance ...................................................................... 8

5.7.1. Remote Control (GV60)........................................................................ 9

5.7.2. Wall Switch Control (GV60) ................................................................ 10

5.8. Commissioning the Fire ........................................................................... 11

5.9. Fuel Bed Installation ............................................................................... 11

6. Function Checks .......................................................................................... 12

6.1. Lighting the Pilot and Main Burner............................................................ 12

6.2. Checking the Reference Pressure ............................................................. 12

6.3. Checking for Spillage............................................................................... 12

7. Commissioning ............................................................................................ 13

8. Final Check & Customer Briefing ................................................................... 14

9. Servicing..................................................................................................... 15

9.1. Parts List ............................................................................................... 15

9.2. General Maintenance .............................................................................. 15

9.3. Renewing Pilot Burner/Ignition Unit.......................................................... 15

9.4. Renewing Flame Failure Control Valve ...................................................... 17

USER INSTRUCTIONS ...........................................................................................18

10. Fuel Bed Layouts ......................................................................................... 19

10.1. Pumice Base Layer.................................................................................. 19

10.2. Fuori 400 - Pebble Layout........................................................................ 20

10.3. Fuori 400 - Driftwood Layout ................................................................... 21

10.4. Fuori 550 - Pebble Layout........................................................................ 22

10.5. Fuori 550 - Driftwood Layout ................................................................... 23

10.6. Fuori 700 - Pebble Layout........................................................................ 24

10.7. Fuori 700 - Driftwood Layout ................................................................... 25

11. Control Systems........................................................................................... 26

11.1. Identification.......................................................................................... 26

Page ii

11.2. Remote Control (GV60) ........................................................................... 27

11.3. Wall Switch Control (GV60)...................................................................... 28

11.4. Remote Control Handset Battery Replacement .......................................... 28

11.5. Remote Control Receiver Unit Battery Replacement ................................... 28

TROUBLESHOOTING .............................................................................................29

12. General Troubleshooting .............................................................................. 30

13. Appendix 1 – GV60 Installation Instruction..................................................... 31

Page 1

GENERAL INFORMATION

Page 2

1. Conformity

Because Multiglow Fires believe in the use of modern technology and materials, they

reserve the rights to modify or change the layout and controls of their burner trays, at

anytime, whilst still complying with current specifications.

Therefore these ‘instructions’ are a general guide only and are not specifically in

compliance with the shape or size of your appliance. These units must be installed in line

with current ‘GAS SAFETY (INSTALLATION AND USE) REGULATION’ applicable to the

country of use.

Warning

Only use the approved refractories supplied with this appliance.

NOTE: For the safe and efficient operation of this appliance, it must be installed inline

with current British Standard (BS 5871: PART 3) or the equivalent standard for

the country of use and take into account the local and national building

regulations or bye-laws where necessary.

NOTE: This appliance has been designed for use with NATURAL GAS only. Prior to

installation, ensure that the distribution conditions (identification of the type of

gas and pressure) and the adjustment of the appliance are compatible.

NOTE: The white fibre blanket should not be removed from the burner tray.

NOTE: Multiglow Fires will NOT accept any liability or responsibility for an appliance that

has been installed outside the technical data specified in this manual and is not in

agreement with the above statements.

Page 3

2. General Notes

The MULTIGLOW FUORI FIREBOX is a Decorative Fuel Effect (D.F.E.) primary aerated gas

fire, designed to comply with BS EN 509:2000 and is intended for decorative use only. It

has been designed to operate on NG gas only and must be fitted on a non-combustible

hearth in a standard builders opening, with a chimney in compliance and satisfying the

requirements of BS 5871 – Part 3.

This appliance conforms to the relevant Safety Standards but during use, there are naked

flames and parts of the casing become hot.

Warning

If the appliance is fitted with a permanent guard (to BS 6778), no part of

the guard should be permanently removed so that access to the flame is

minimized, as it does not give full protection for young children, the

elderly or the infirm.

This appliance is not fitted with an integral guard. In normal use

consideration may be given to the use of a guard conforming to BS 6678

or BS 6539 such that the access to the flame is minimised and for the

protection of young children, the elderly or the infirm.

NOTE: The larger of the units manufactured have gas of 33,000 BTU. Therefore, it is

essential that the gas supply pipework be of a size that will allow for the correct

flow rate (see TECHNICAL DATA for required information). Ideally, the 8mm

connection pipe to the burner should be as short as possible and the maximum

length should not be greater than 1m. Also ensure that the isolating tap does not

have a reduced bore.

RCF Advice:

This product may use components containing Refractory Ceramic Fibres (RCF), which are

main-made vitreous silicate fibres. Excessive exposure to the fine dust of this material

may cause irritation to eyes, skin and respiratory tract.

Therefore during installation and servicing we recommend that you use a HEPA filtered

vacuum cleaner to remove any dust and soot accumulated in and around the fire before

and after working on the fire, to ensure that the release of fibres from these RCF articles is

kept to a minimum.

You should follow the normal hygiene rules of not smoking, eating or drinking in the work

area.

When replacing components containing Refractory Ceramic Fibres (RCF), we recommend

that the replaced items are not broken up, but are sealed within heavy duty polythene

bags, clearly labelled as RCF waste and may be disposed of in suitably licensed landfill

sites.

It should be noted that exposure to the fibres is unlikely in normal use.

Page 4

2.1. Flue Specifications

The appliance has been tested and approved with a flue of 7” (177.8mm) diameter and 5”

(127.0mm) diameter. Please review the technical specifications in Section 4.2 Model

Specific Technical Data for full details of applicable flue diameters and lengths for each

model.

2.2. Ventilation Requirements

Sizes 400 and 550 are rated below 7kW, therefore no vent is required if the flue flow for

the clearance of the products of combustion is correct. However, if spillage is detected

using the method defined for spillage test, then additional ventilation may be required.

All other appliance sizes (7kW or over) will require purpose provided ventilation in the

room where the appliance is located, in accordance to the rules in force.

All ventilation must comply with the rules in force for the country in which the appliance is

fitted.

3. Important Notes

1) Do not cover ventilation holes in top grille with fuel bed.

2) The chimney should be regularly checked to ensure that all products of combustion are

entering the flue and there is no excessive build up of soot.

3) Regularly inspect the purpose provided ventilation to check that it is free from

obstruction.

4) This appliance is fitted with an oxygen depletion system which shuts off the gas supply

if the oxygen level in the room is depleted, which is caused a blocked or obstructed

chimney.

5) If for any reason the fire shuts itself down, attempt to relight the appliance by using

the startup procedure described in Section 11 - Control Systems.

6) If the oxygen depletion system continues to operate (and repeatedly shuts the

appliance off) following several restarts, call in a properly qualified installation

engineer.

7) There are no user replaceable parts, except the 4 high quality AA batteries, which can

be changed by the end user.

Page 5

4. Technical Data

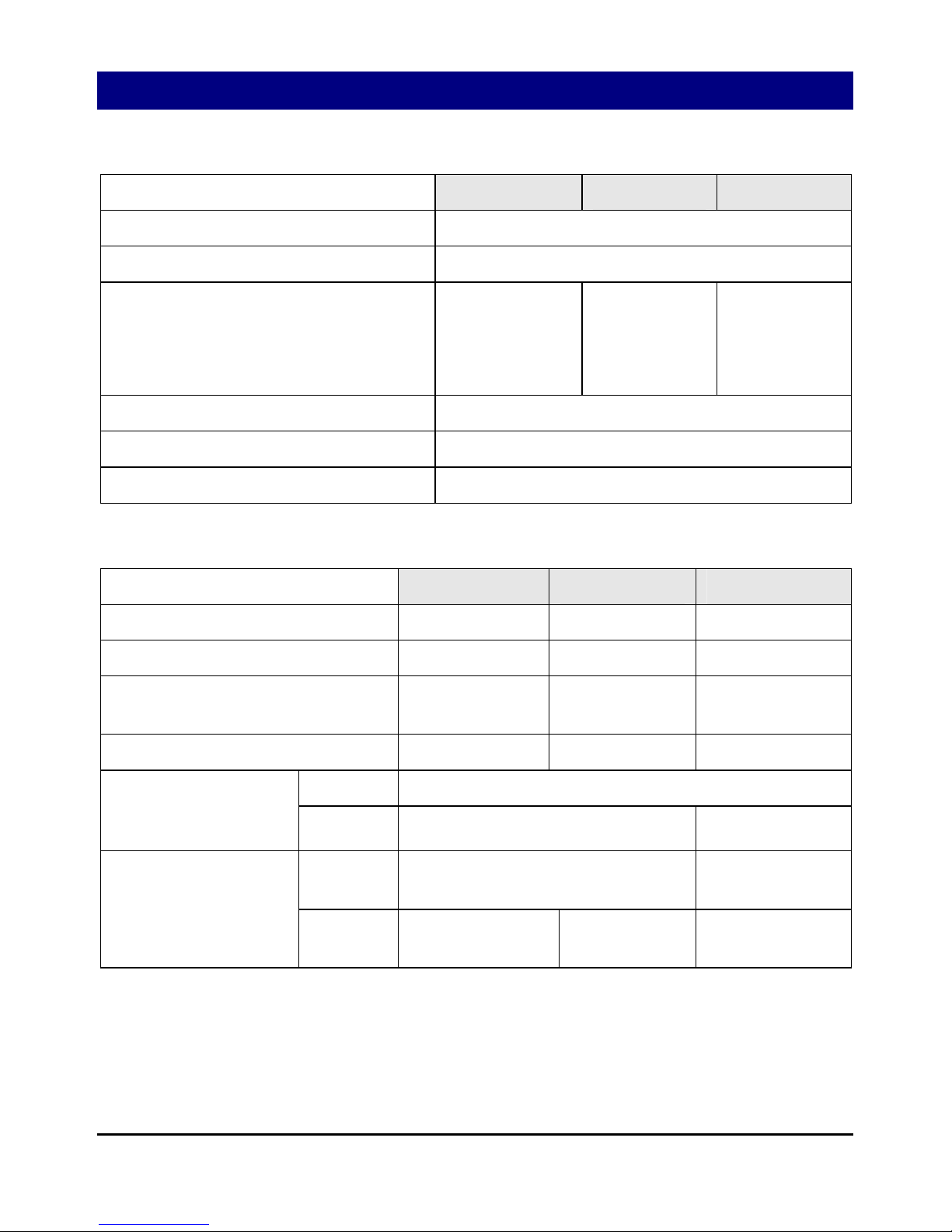

4.1. Technical Data Common to all Models

Gas Category I2H I

2E

I

2E+

Gas Type G20

Inlet Pressure 20mbar

Countries of Destination

AT, CH, CZ, DK, EE,

ES, FI, GB, GR, HR,

IE, IT, LT, LV, NO,

P

T, RO, SE, SI, SK,

TR

DE, LU, PL

BE, FR

OxyPilot SIT NG 9039

Gas Valve Mertik Maxitrol GV60

Inlet Connection 8mm

4.2. Model Specific Technical Data

Size/Model 400mm 550mm 700mm

Nominal Input (Gross) 5.0 kW 6.95kW 9.80kW

Nominal Gas Flow Rate 0.476 (m3/h) 0.662 (m3/h) 0.933 (m3/h)

Injector Marking/Size

1x Bray 82/520

1x Bray

82/520

1x Bray 82/750

Mass of Appliance 7.5kg 9kg 10.5kg

Class 1 3.0 metres / 177.8mm (7”) Minimum Flue

Height/

Diameter

Class 2 3.0 metres / 127.0mm (5”) n/a

Class 1 580mm W x 580mm H

870mm W x

455mm H

Maximum Opening

Size for Min. Flue

Height/Diameter

Class 2

580mm W x

470mm H

580mm W x

375mm H

n/a

Note: Other combinations of Builder’s opening sizes are acceptable, provided that the

minimum flue diameter/height are not less than those stated above and the

products of combustion clear following a smoke test after 10 minutes running

from cold.

Page 6

INSTALLATION INSTRUCTIONS

Page 7

5. Installation Procedure

5.1. Contents Checklist

1 x Fuori Fire Box

1 x Pumice Burner

1 x Receiver Pack

1 x Set Ceramic Set (driftwood or pebbles)*

1 x Inlet nut & Olive

4 x AA Batteries

1 x 9V Battery

*The Fuori Firebox can be supplied and used with or without driftwood or pebble ceramics,

depending on customer’s requirements.

IMPORTANT: Before installation, ensure that the local distribution conditions (identification

of gas type and pressure) and the adjustment of the appliance are compatible.

5.2. Flue Requirements

Ensure that the builders opening, flue and hearth are constructed from non-combustible

materials, and conform to National Regulations.

The Fuori 400 & 550 Firebox appliances require a minimum flue diameter of 125mm (or

equivalent area) and are used with the opening sizes as specified in the Technical Data

section.

The Fuori 700 Firebox requires a minimum flue diameter of 175mm (or equivalent area)

and is used with the opening size dimensions as specified in the Technical Data section.

The chimney should be swept before appliance is installed and a flue flow test, as

described below, in accordance with national regulations should be carried out.

Flue Flow Test - Apply smoke match/pellet to the flue opening at hearth level and observe

smoke. If there is a definite flow in to the flue continue with installation. If not preheat

the flue for approximately 10 minutes and re-test. If there is still no flow the flue may

need attention.

SEEK EXPERT ADVICE

Any flue damper plates or flue restrictors must be removed, or fixed permanently in the

fully open position.

It is important to ensure that only one appliance is connected to the chimney and it is

structurally sound, so that combustion products DO NOT enter any part of the building.

The chimney must be continuous from inlet to termination

Page 8

5.3. Room Ventilation

The room ventilation must be in accordance with national regulations. If in any doubt

about any ventilation requirements seek expert advice.

5.4. Appliance Location

The Fuori Fireboxes can be mounted on a hearth, shelf mounted or flush mounted for

hole-in-the wall applications. The builder’s opening must be constructed of noncombustible material

5.5. Hearths

Multiglow Fires recommends that a hearth is fitted which conforms to national regulations.

It must be constructed of be non-combustible material and minimum of 12mm thick and

must project 150mm either side of the burner and at least 300mm in front of the burner.

The hearth should not be less than 50mm above floor level. A fender of at least 50mm

height will satisfy the requirements of the installation regulations (refer to BS5871: Part 2).

5.6. Hole-In-The-Wall Installations

If a hearth is not fitted, the fire must be installed so that the burner or incandescent

material will be at least 225mm above the floor (refer to Document J of the Building

Regulations).

5.7. Installation of the Appliance

IMPORTANT NOTES

An isolation valve must be fitted adjacent to the appliance which, when closed, allows

the complete burner and control assembly to be disconnected for maintenance or

repair in accordance with national regulations.

Dirt and debris in the gas system can block the valve and injectors, any fault caused

by this are not covered by the guarantee

Do not use any jointing compound on compression fittings as it can get into the

control valve and cause it to fail and void the guarantee.

The appliance has been set and tested at the factory; however the Connections may

have been disturbed in transit or storage. Check that all gas connections are sound

before installation.

In certain wind conditions downdraughts can be caused, which will affect the

chimney’s performance. It is recommended that a chimney cowl is fitted that suitable

for Decorative Fuel Effect Appliances (D.F.E’s), which conforms to national regulations.

This appliance is not fitted with an integral guard. In normal use, consideration may

be given to the use of a guard that conforms to National Regulations so that access to

the naked flame is minimized.

Page 9

It is recommended that a guard be fitted to provide protection for children, the

elderly, or infirm. BS 8423-2002.

This appliance is intended for decorative purposes.

Use only parts supplied by Multiglow Fires if any replacements are required

Having ensured that the appliance application is correct and flue requirements,

ventilation and the gas supply (pressure and type) are correct, proceed with the

installation as described below.

For Wall switch control models, the wall switch may be fitted into an appropriately

sized flush or surface mounted box. Wiring may then be run to where the receiver

unit is located within the Fuori firebox.

For Mains operated receiver models locate the transformer in a suitable position

(this must not be under the fire) where it can be wired into the mains electric supply

and the low voltage lead connected to the receiver which is located within the Fuori

firebox. Transformers must be connected to the mains supply in accordance to the

rules in force.

1) Place the Fuori Firebox, with the pilot at the rear, and remove top grille.

2) Pass the gas supply pipe through the hole in the bottom of burner and connect it to

the test point elbow on the inlet at the right hand side, ensure restrictor screw in the

test point is fully open.

3) Carry out a gas soundness test in accordance with national installation regulations.

4) Use the test point on the isolator to check that the gas supply pressure is at the

correct working pressure of 20mbar with the burner operating at full rate.

5.7.1. Remote Control (GV60)

1) The GV60 remote control comes pre-wired. When installing make sure that the

ignition cable and infra-red sensor cable are kept apart by a minimum of 20mm.

2) If using battery operated receiver: Insert 4 x 1.5v AA high quality Alkaline,

Lithium or Nickel oxy hydroxide batteries into the receiver.

3) If using mains operated receiver: Ensure that there are no batteries in the

receiver unit, and then connect the transformer lead into the power inlet socket of the

receiver.

Warning

Using the mains transformer whilst batteries are installed in the receiver

unit may cause damage to both the batteries and the receiver.

4) Place the receiver unit into position.

5) Insert and connect 1 x 9v alkaline battery into the handset.

Page 10

Warning

The free air circulation below the burner must be such that the

temperature of any electrical or electronic component does not exceed 600

centigrade.

NOTE: In line with the best engineering codes and practices, it is essential that the

electrical wiring is protected from accidental damage. It is advised that the

flexible cables are placed in a plastic tube or sheath especially where the wiring

must pass through a wall or behind a fireplace surround. All wiring situated

below the burner should be placed so that the maximum clearance is obtained

from any potential hotspots.

5.7.2. Wall Switch Control (GV60)

1) The GV60 remote control receiver unit comes pre-wired. When installing make sure

that the ignition cable and infra-red sensor cable are kept apart by a minimum of

20mm.

2) If using battery operated receiver: Insert 4 x 1.5v AA high quality Alkaline,

Lithium or Nickel oxy hydroxide batteries into the receiver.

3) If using mains operated receiver: Ensure that there are no batteries in the

receiver unit, and then connect the transformer lead into the power inlet socket of the

receiver.

Warning

Using the mains transformer whilst batteries are installed in the receiver

unit may cause damage to both the batteries and the receiver.

4) Connect the lead from the wall switch into the receiver.

5) Place the receiver unit into position.

6) If the handset is also required, insert and connect 1 x 9v alkaline battery into the

handset.

Warning

The free air circulation below the burner must be such that the

temperature of any electrical or electronic component does not exceed 600

centigrade.

NOTE: In line with the best engineering codes and practices, it is essential that the

electrical wiring is protected from accidental damage. It is advised that the

flexible cables are placed in a plastic tube or sheath especially where the wiring

must pass through a wall or behind a fireplace surround. All wiring situated

below the burner should be placed so that the maximum clearance is obtained

from any potential hotspots.

Page 11

5.8. Commissioning the Fire

IMPORTANT: CHECK FOR SPILLAGE

A SPILLAGE CHECK MUST BE MADE BEFORE THE INSTALLED APPLIANCE IS

HANDED OVER TO THE CUSTOMER

This test is to be carried out with the appliance completely installed and all doors and

windows closed in the room in which the appliance is fitted. Test for spillage as described

in the procedure below:

1) Light the fire and set the control to maximum and leave for five (5) minutes.

2) After five (5) minutes, light a smoke match and position flush with fireplace opening, a

minimum of 50mm (2”) from side and a maximum of 50mm (2”) from top.

3) If the installation is satisfactory, smoke is drawn into the chimney and out of the

room. If this does not happen then leave alight for a further ten (10) minutes and recheck.

4) If smoke is still not drawn up the chimney, turn off, disconnect the appliance and seek

expert advice.

NOTE: If there are extractor fans in the room or adjacent rooms, these must be running

at full speed with all interconnecting doors left open.

Warning

If the fire goes out under normal operation and continues to go out after

relighting, spillage has occurred and the flue should be checked.

Warning

This appliance is fitted with an Oxygen Depletion System, which is

incorporated into the pilot ignition unit. Therefore it is important that it

must not be adjusted or put out of operation by the installer and must be

replaced with a complete unit of original manufacture in the event of

renewal.

5.9. Fuel Bed Installation

Refer to the appropriate section within Section 10 in the Users Instructions, starting

on Page 19 to lay out the fuel bed.

Page 12

6. Function Checks

6.1. Lighting the Pilot and Main Burner

1) Turn on gas supply, purge the gas line and check all gas joints for gas soundness.

Using the instructions in Section 11 for the appropriate control system:

2) Ignite the pilot (if applicable).

3) Light the main burner and leave on high for 10 minutes.

4) Set the burner back to the low position, where the flames should remain alight.

5) Turn the burner back to the pilot only position (if applicable).

6) Turn the burner/pilot off and ensure the pilot extinguishes.

6.2. Checking the Reference Pressure

The appliance is preset to the given heat input for the inlet pressure on the Data Plate. No

further adjustment should be necessary. However, the burner can be checked by fitting a

pressure gauge at the Test Point accessible to the left of the control valve. The pressure

should be checked with the appliance alight and the control set at ‘HIGH’ after checking

pressure, turn off appliance, remove pressure gauge, replace test point seal and check gas

soundness.

6.3. Checking for Spillage

A SPILLAGE CHECK MUST BE MADE BEFORE THE INSTALLED APPLIANCE IS HANDED

OVER TO THE CUSTOMER.

This test is to be carried out with the appliance fully fitted and front grate in

position.

a) Close all doors and windows of the room in which the appliance is fitted

b) Light the fire and set control to maximum and leave for five minutes.

After five minutes light a smoke match and position flush with fireplace opening, a

minimum of 50mm (2”) from side and a maximum of 50mm (2”) from top.

The installation is satisfactory if the smoke is drawn into the chimney and out of the room.

If this does not happen then leave alight for a further (10) minutes and check again

Warning

If smoke is still not drawn into the chimney, turn off and disconnect the

appliance and seek expert advice.

Page 13

Warning

If fire goes out under normal operation and continues to go out after

relighting, has occurred and the flue should be checked.

Warning

a) The oxypilot system shall not be adjusted by the installer.

b) The oxypilot spillage monitoring system shall not be put out of

operation.

c) When the oxypilot system is damaged or any of its parts exchanged

only original Manufacturer’s parts shall be used.

7. Commissioning

1) Check that the flue is adequate.

2) Ensure installation is gas tight.

3) Purge the installation.

4) Check the ignition system works correctly.

5) All controls operate correctly and freely.

6) Ensure that the burner pressure and gas rate are correct.

7) Any flame supervision devices operate in the correct time.

8) Carry out a spillage test on the appliance.

9) Clean area and ensure customer knows how to operate the appliance.

10) Complete the following section for final checks and handover to the customer.

Page 14

8. Final Check & Customer Briefing

1) Instruct the customer on the full operation of the appliance.

2) Recommend to the customer that a competent person should service the appliance

annually.

3) Recommend to the customer that on a yearly basis the flue should be swept to ensure

that all products of combustion are entering the flue or canopy and that there is no

excessive build up of soot and that rubbish should not be burnt on the fire or the fuel

bed be disturbed.

4) Instruct the customer that the pilot and flame sensing device fitted to this fire, also

acts as an atmospheric sensing device which shuts off the appliance if the evacuation

of the products of the combustion is interrupted.

5) Inform the customer that if the fire shuts off to restart the main burner as detailed in

Section 11. If the appliance fails to relight or repeatedly cuts off, then do not use

and inform a qualified person.

6) The customer should be warned not to throw rubbish onto or otherwise disturb the

fuel bed.

7) Where it is necessary to remove the refractories (fuel effect) for cleaning purposes,

this must be done using a soft brush (do not use a vacuum cleaner). When replacing

the refractories, this must be done as per the layouts in these instructions. Under no

circumstances should the layout be changed or more refractories added or taken off.

8) Hand over these Instructions to the Customer.

Page 15

9. Servicing

9.1. Parts List

Description Part No Quantity

Oxypilot

NG 9039 1

GV 60 Control Valve

GV 60 M1 1

Receiver

G6R-RIA 1

Batteries

AA 4

Batteries

PP3 1

All servicing of this appliance is to be carried out by a competent person.

Turn off gas supply before commencing any servicing always test for gas soundness and

spillage after refitting the appliance

9.2. General Maintenance

At yearly intervals turn off and allow to cool down. Check all fuel, pilot burner/ignition

unit, for soot or debris deposits. These can cause imperfect flame appearance and should

be removed by lightly vacuuming. Replace all misplaced coals/logs and relight.

NOTE: On the failure of either the pilot burner/ignition unit, or main control valve, have

repairs carried out by a competent person.

9.3. Renewing Pilot Burner/Ignition Unit

1) Isolate the gas supply.

2) Remove all ceramics and remove slotted vent plate surrounding the burner and store

in a safe place.

3) Lift out the burner noting the front face and store in a safe place.

4) Undo and remove the thermocouple nut from the interrupter block in the rear of the

control valve.

5) Disconnect and remove the piezo ignition wiring from the ignition electrode.

6) Undo and remove the 4mm gas supply pipe from the bottom of the pilot burner.

7) Undo the two screws holding pilot bracket in place.

Page 16

8) Undo and remove 2x4mm locating nuts/screws on the pilot/ignition unit. Remove the

unit.

9) Replace with new unit and reassemble in reverse order.

Figure 1 - Pilot Burner & Ignition Unit (9039)

Pilot Burner

Ignition Electrode

Piezo Lead

Connection

Thermocouple

4mm Copper

Tube Connection

Page 17

9.4. Renewing Flame Failure Control Valve

1) Proceed as items 1 through 5 of Section 9.3 above.

2) Remove the two wires from the interrupter block noting their position and unscrew

and remove the interrupter block.

3) With reference to Figure 2 undo and remove the ‘gas inlet’ pipe, the ‘gas outlet to

burner’ pipe and the pilot feed pipe.

4) Undo and remove the two pozi pan screws that hold the body of the main valve.

5) Using a new valve, reverse the procedure and re-fit the parts.

Valve - gas inlet

Valve - gas outlet to

burner

Interrupter block

Thermocouple

nut

Pilot feed pipe

Figure 2 - GV60

Page 18

USER INSTRUCTIONS

Page 19

10. Fuel Bed Layouts

Warning

The layout and quantity of the material contained in the fuel bed should

not be changed for any of the ceramic layouts contained within these

instructions.

Note: For all ceramic layouts, it is important to not compact the pumice during the

levelling process.

10.1. Pumice Base Layer

Spread the pumice evenly over the top of the burner until level with the top edge.

Figure 3 – Pumice Base Layer

Page 20

10.2. Fuori 400 - Pebble Layout

Spread the pumice evenly over the top of the burner until level with the top edge, and lay

the pebbles as shown in the photographs below. There should be a total of 21 pebbles.

Figure 4 – Fuori 400 Pebble Bottom Layer

Figure 5 - Fuori 400 Pebble Top Layer

Page 21

10.3. Fuori 400 - Driftwood Layout

Spread the pumice evenly over the top of the burner until level with the top edge, and lay

the driftwood as shown in the photographs below. There should be a total of 7 driftwood

pieces.

Figure 6 - Fuori 400 Driftwood Bottom Layer

Figure 7 - Fuori 400 Driftwood Top Layer

Page 22

10.4. Fuori 550 - Pebble Layout

Spread the pumice evenly over the top of the burner until level with the top edge, and lay

the pebbles as shown in the photographs below. There should be a total of 37 pebbles.

Figure 8 - Fuori 550 Pebble Bottom Layer

Figure 9 - Fuori 550 Pebble Top Layer

Page 23

10.5. Fuori 550 - Driftwood Layout

Spread the pumice evenly over the top of the burner until level with the top edge, and lay

the driftwood as shown in the photographs below. There should be a total of 8 driftwood

pieces.

Figure 10 - Fuori 550 Driftwood Bottom Layer

Figure 11 - Fuori 550 Driftwood Top Layer

Page 24

10.6. Fuori 700 - Pebble Layout

Spread the pumice evenly over the top of the burner until level with the top edge, and lay

the pebbles as shown in the photographs below. There should be a total of 48 pebbles.

Figure 12 – Fuori 700 Pebble Layout Bottom Layer

Figure 13 - Fuori 700 Pebble Layout Top Layer

Page 25

10.7. Fuori 700 - Driftwood Layout

Spread the pumice evenly over the top of the burner until level with the top edge, and lay

the driftwood as shown in the photographs below. There should be a total of 10 driftwood

pieces

Figure 14 - Fuori 700 Driftwood Bottom Layer

Figure 15 - Fuori 700 Driftwood Top Layer

Page 26

11. Control Systems

Warning

If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call the National Gas Emergency Service on 0800 111 999.

11.1. Identification

Depending on the specification of your appliance, it will be supplied with a number of

possible control methods. Please identify your control from the details below, and then

refer to the appropriate following section.

Figure 16 - Remote Control

(GV60)

Figure 17 - Wall Switch

Control

Page 27

11.2. Remote Control (GV60)

Figure 18 – GV60 Valve Controls

Figure 19 - GV60 Remote Control Handset

1) Ensure that the ON/OFF switch on the control valve is ON.

2) Press both the bottom left hand button on the handset and the UP button at the same

time (both buttons are linked with an arrow) until a beep is heard, which indicates the

start sequence has begun, then release the buttons.

3) At this point further beeps indicate that the ignition process is in progress, after which

point the burner will move to the high rate and the burner will cross-light from the

pilot.

4) Adjust the gas rate/flame height by using either the up or down buttons on the

remote control.

5) To leave the burner in standby, continue to press the down arrow button until the

main burner extinguishes, leaving the pilot on.

6) To turn off both the main burner and pilot, press the OFF button.

NOTE: Should the fire be extinguished intentionally or unintentionally, do not attempt to

relight it for at least 3 minutes.

Page 28

11.3. Wall Switch Control (GV60)

Figure 20 – Wall Switch Control

1) Ensure that the ON/OFF switch on the control valve is ON.

2) Press and hold the ON-OFF button until a beep is heard, which indicates the start

sequence has begun, then release the buttons.

3) At this point further beeps indicate that the ignition process is in progress, after which

point the burner will move to the high rate and the burner will cross-light from the

pilot.

4) Adjust the gas rate/flame height by using either the up or down buttons on the

control.

5) To leave the burner in standby, continue to press the down arrow button until the

main burner extinguishes, leaving the pilot on.

6) To turn off both the main burner and pilot, press the ON-OFF button.

NOTE: Should the fire be extinguished intentionally or unintentionally, do not attempt to

relight it for at least 3 minutes.

11.4. Remote Control Handset Battery Replacement

1) Remove the battery cover from the rear of the handset, by pressing down at the top

of the battery cover and sliding downwards.

2) Remove and unclip the old battery and replace with a new PP3 9v battery.

3) Replace the cover.

11.5. Remote Control Receiver Unit Battery

Replacement

1) For remote control models that use a battery powered receiver unit:

2) Pull out the receiver unit from its location (normally under the fire).

3) Remove the battery cover.

4) Remove the existing batteries and replace with 4 x AA batteries. For the GV60 it is

recommended that high quality Alkaline, Lithium or Nickel oxy hydroxide are used

Page 29

TROUBLESHOOTING

Page 30

12. General Troubleshooting

No Spark

1) Ignition lead has become detached from electrode;

2) Pilot is damaged, or too far away from electrode, or too close;

3) Electrode is damaged and needs to be replaced;

4) Soot or debris on the pilot assembly and shorting spark;

5) Faulty ignition lead.

Sparking But Will Not Light

1) Check that gas isolator is open and gas is present;

2) Valve inlet has become blocked with debris;

3) Pilot injector is blocked.

Pilot Flame Shortens or Goes Out When Main Burner Is Opened

1) This indicates insufficient gas pressure to the appliance. Check for obstruction.

2) Check that there are no tight bends or kinks in the supply pipe and that it is capable

of supplying the required volume of gas.

3) Check pressure setting.

Pilot Goes Out At Regular Intervals

1) Check thermocouple is not loose. DO NOT OVER TIGHTEN

2) Thermocouple is damaged and needs replacing.

3) Faulty magnetic coil in valve – replace gas valve.

Blue Flame

1) It will take about 20 minutes for the fire to reach its working temperature, after this

time most of the blue flame should have gone.

2) Continuous blue flame can also be caused by poor pebble or wood arrangement, or

excessive up draught of the flue. Seek advice from your supplier.

3) Low gas pressure from the gas meter will also cause blue flame, check gas pressure.

Poor Flame Picture

1) Check gas pressure.

2) Ensure there are no obstructions in the gas supply.

3)

Re-lay the pebbles or wood as shown in the relevant drawing.

Page 31

13. Appendix 1 – GV60 Installation Instruction

Page 32

Page 33

Page 34

Page 35

0558

Manufactured By:

Multiglow Fires

Canterbury Road,

St. Nicholas-at-Wade,

Nr. Canterbury,

Kent CT7 0PQ

Telephone: 01843 847575

Fax: 01843 848300

Email: sales@multiglow.com

Web: www.multiglow.com

Loading...

Loading...