CLASSIC II

QUATTRO

DECORATIVE FUEL EFFECT APPLIANCES FOR USE WITH

NATURAL GAS

IIN

INSTALLATION, SERVICING & USER

INSTRUCTIONS

THESE INSTRUCTIONS MUST BE LEFT WITH THE USER

MANUFACTURED BY:

MULTIGLOW FIRES

Canterbury Road, St. Nicholas-At- Wade.

Kent. CT7 0PQ

MULTIGLOW

FIRES

2

INDEX

SECTION 1. CONFORMITY AND GENERAL NOTES (INSTALLER)

SECTION 2. TECHNICAL DATA (INSTALLER)

SECTION 3. INSTALLATION PARAMETERS (INSTALLER)

SECTION 4. PRE-INSTALLATION CHECK (INSTALLER)

SECTION 5. INSTALLATION (INSTALLER)

SECTION 6. REMOTE CONTROL (INSTALLER & END USER)

SECTION 7. FUNCTION CHECKS & COMMISSIONING

(INSTALLER)

SECTION 8. FINAL CHECKS & CUSTOMER BRIEFING

(INSTALLER)

SECTION 9. SERVICING (SERVICE ENGINEER &END USER)

SECTION 10. END USER INSTRUCTIONS

SECTION 11. BURNER INSTALLATION RECORD AND

WARRANTY INFORMATION

MULTIGLOW

FIRES

3

PLEASE READ THESE INSTRUCTIONS FULLY

BEFORE COMMISSIONING OR USE

CONFORMITY & GENERAL NOTES

SECTION 1

Because Multiglow Fires believe in the use of modern technology and materials, they reserve the

rights to modify or change the layout and controls of their burner trays, at any time, whilst still

complying with current specifications.

Therefore these ‘Instructions’ are a general guide only and not specifically in compliance with the

shape or size of your appliance. These units must be installed in line with the current ‘GAS

SAFETY (INSTALLATION AND USE) REGULATION’ applicable to the country of use.

NOTE:

For the safe and efficient operation of this appliance, it must be installed inline with

the current British Standard (BS 5871:PART 3) or the equivalent standard for the country of use

and take into account the

Local and national building regulations or bylaws where necessary.

NOTE:

This appliance has been designed for use on NATURAL GAS only. Prior to

installation, ensure that the distribution conditions (identification of the type of gas and pressure)

and the adjustment of the appliance are compatible.

NOTE:

THE WHITE FIBRE BLANKET SHOULD NOT BE REMOVED FROM THE BURNER

TRAY.

NOTE:

Multiglow Fires will not accept any liability or responsibility for a appliance that has

been installed outside of the technical data specified in this manual and is not in agreement with

the above statements.

The MUTIGLOW CLASSIC II is a Decorative Fuel Effect (D.F.E.) primary aerated gas fire

designed to comply with BS EN 509:2000 and is intended for decorative use only. It has been

designed to operate on Natural Gas (N.G.) only and must be fitted on a non-combustible hearth in

a standard builders opening, with a class 1 chimney in compliance and satisfying the

requirements of BS 5871- PART 3. The appliance has been tested and approved with a flue of 7”

(178mm) diameter and having a minimum effective height of 10ft. (3mtrs.)

The MULTIGLOW CLASSIC II conforms to the relevant Safety Standards but during use there

are naked flames and parts of the casing become hot. A suitable guard to (BS.6539 fireguards for

4

use with solid fuel appliances) is therefore recommended where the young, elderly or infirm are

concerned.

NOTE:

The larger of the units manufactured have gas consumption similar to that of a small

boiler (i.e.50000 BTU). Therefore, it is essential that the gas supply pipe work be of a size that will

allow for the correct flow rate (See TECHNICAL DATA for required information). Ideally the 8mm

connection pipe to the burner should be as short as possible and the maximum length should not

be greater than 1mtr. Also ensure that the isolating tap does not have a reduced bore.

NOTE:

The Box used with this appliance will become hot during use. Care should be taken

when operating the controls.

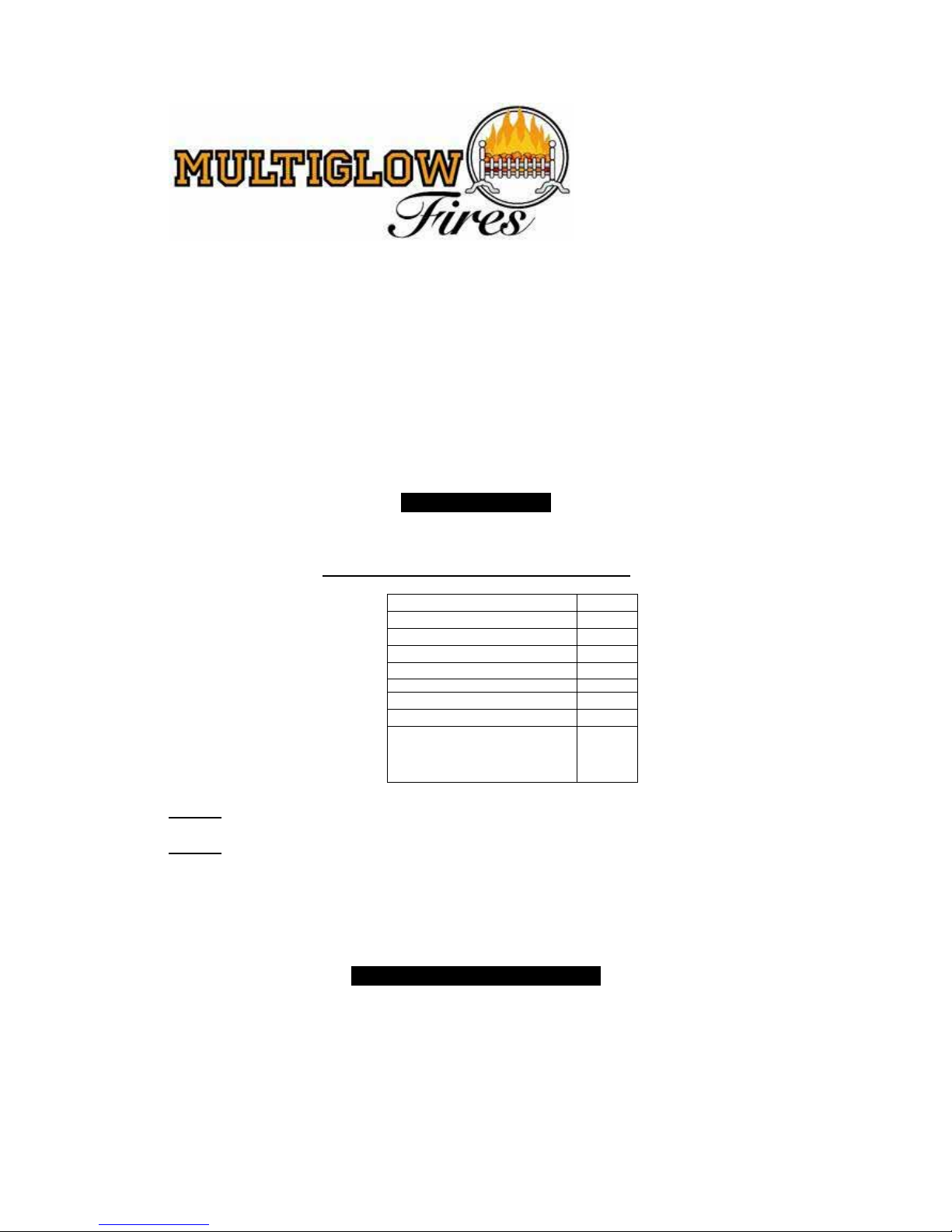

SECTION 2

TECHNICAL DATA

GAS TYPE G20 at 20

mbar

CATEGORIES I2H

HEAT INPUT (GROSS kW )

6.95

FLOW RATE (m3/h)

0.65

WORKING ‘’P’’ (mbar)

20

BURNER TEST ‘’P’’(mbar)

9.3

REMOTE VALVE

GV60

PILOT OXY DEPLETION DEVICE

OP9039

ONE I NJECTOR

16/650

APPLIANCE MASS (kg)

6.0

DATA LABEL AFFIXED

TO BURNER TRAY

NOTE:

This size is rated below 7kw, therefore no vent is required if flue flow for the clearance

of the products of combustion is correct.

NOTE:

This appliance is to be used with a class 1 flue (7” diameter).

INSTALLATION PARAMETERS

SECTION 3 – REGULATIONS AND CODE OF PRACTICE

3.1 In your own interest and safety it is law that all gas appliances are installed by a

competent person, in accordance with the current Gas Safety (Installation and Use)

5

Regulations applicable to the country of use. In addition, the installation must be carried

out in-accordance with the relevant and current local and national specifications and

building regulations.

3.2 The fireplace surround, hearth and builders opening shall be of non-combustible material.

Hearth and clearance dimensions must comply with the requirements of BS 5071 part 3.

WARNING:This appliance must not be fitted in any room where steam is present (e.g.

bathroom).

3.3 The minimum clearance height above fireplace opening for a combustible shelf (having a

depth of 150mm (6”) is 200mm (8”), add 12mm (½”) for each additional 25mm (1”) depth

of shelf.

WARNING:Please note that soft wall coverings may become discoloured when close to a

heating appliance – this should be born in mind.

3.4 The minimum flue opening is 178mm (7”) diameter 250dq. Cm. (38½ sq. inches) and a

minimum effective height 3m (10ft). Provided that the flue, which is to serve this

appliance, satisfies the requirements of BS 5871:Part 3 then a terminal in-line fan

satisfying BS 5440: Part 1 may be used to improve flue draught.

WARNING: The flue must NOT be shared with any other appliance.

3.5 All chimney dampers or restrictions should be removed or permanently fixed in the open

position.

WARNING:If the fireplace has previously been used with a solid fuel the flue should be

swept clean prior to installation.

3.6 The room in which the appliance is to be fitted must have permanent air vent with a

minimum effective area of 100cm. Sq. (15½ sq. inches) and be accessible to the outside

air, unless specifically stated otherwise by the manufacturer.

NOTE:Vent should be checked on a regular basis to ensure that there is no obstruction.

PRE-INSTALLATION CHECK

SECTION 4

FLUE SOUNDNESS

4.1 Using a smoke bomb, carry out a flue flow test to check the effectiveness of the flue and

ensure that there is no leakage into another part of the premises (including any loft) or, as

appropriate, other adjoining premises.

NOTE:Although a smoke pellet produces a large amount of smoke, the volume is small

compared with the volume of the combustion products from an appliance. Clearance of

smoke from a pellet is, therefore, no guarantee that the products of combustion from the

appliance will clear. This must be tested after the installation is completed by carrying

out a spillage test

WARNING:Smoke coming out of other than the correct terminal, or a down-draught or

no-flow condition, indicates as unsatisfactory flue. The flue may need attention – seek

expert advice.

VENTILATION

4.2 In line with 3.7 above, make sure that the room or space where the appliance is located

is adequately ventilated and that the means of ventilation is suitable.

6

NOTE:The size and type of ventilation should take into account any other gas appliance

that may be fitted in the room or space

.

GAS SOUNDNESS

4.3

“An isolation valve, or valves, has to be fitted adjacent to the

appliance, which when closed allows the complete burner and

control assembly to be disconnected for

maintenance or repair in accordance with national regulations”

COMPATIBILITY

4.4Before commencing installation, check that the local distribution conditions (identification of

type of gas and pressure) and the adjustment of the appliance are compatible.

.

SECTION 5- INSTALLATION

A P PLIA N C E LO C ATIO N

The fire must be fitted on a flat non combustible base

Also a non combustible hearth or physical barrier

should be placed in front of the fire opening where

relevant.

This appliance is not fitted with an integral guard. In normal use

consideration may be given to the use of a fire guard, which conforms to

BS6539,such that accessibility to the naked flame produced by the

appliance is minimised.

It may not be desirable with a hole in the wall situation

to include a hearth with the appliance installation.

Building Regulation Approved Document J currently

states:-

A Appliances should be placed on a hearth unless:

They are installed so that every part of any flame

or incandescent material will be at least 225mm

Above the floor

Or

B. The manufacturers instructions state that a

Hearth is not required

Multiglow Fires recommend that a hearth or

physical barrier is installed with this appliance

7

However should you decide not to follow the

recommendation and do not fit a hearth or

barrier or decide to remove one or both.

Then consideration as to the safety of the

occupants of the room should be given.

CONTENTS CHECKLIST

1. Box

2. Four Part Frame (attached to box)

3. Fixing Screws

4. Burner Shelf

5. Burner

6. Refractories

7. 1 x Receiver pack (Inc batteries)

8. 1x Burner Control Unit

9. 1x Nut and Olive for 8mm Inlet Pipe

1x 1½ meter 8mm Copper Pipe

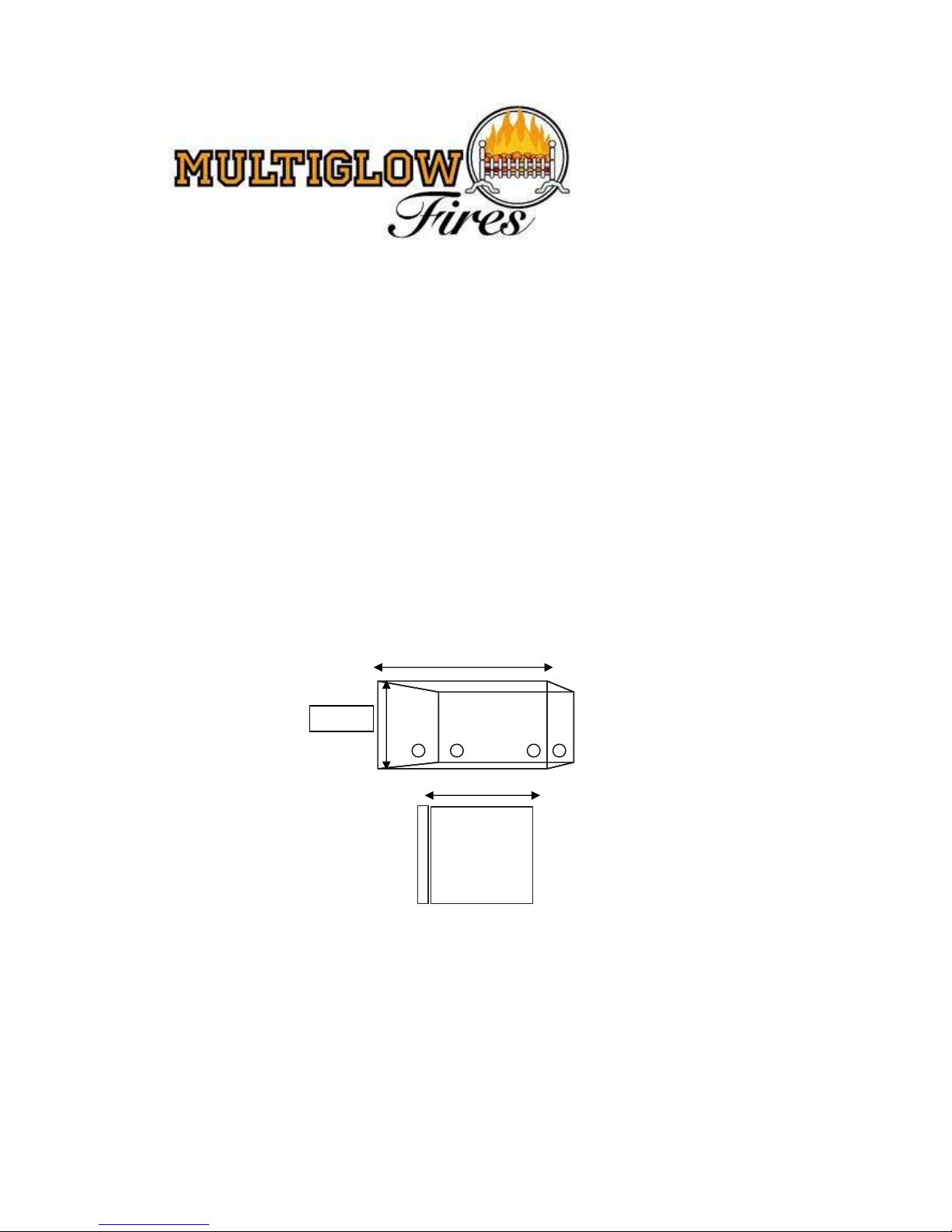

Preparing the Fireplace Opening

1. Create an opening for the box using

the dimensions shown.

2. Shown are the actual box dimensions when creating

the hole for the box allow 2-5mm extra for a good fit.

600mm

330mm

3. The base of the opening must be flat and level.

4. Route the gas supply feed inside the fireplace

opening and provision made for it to enter the

box through one of the four slots either at the

back of the box or at either side.

5.Remove the four pieces of frame by unscrewing

the screws, see next page.

400m

8

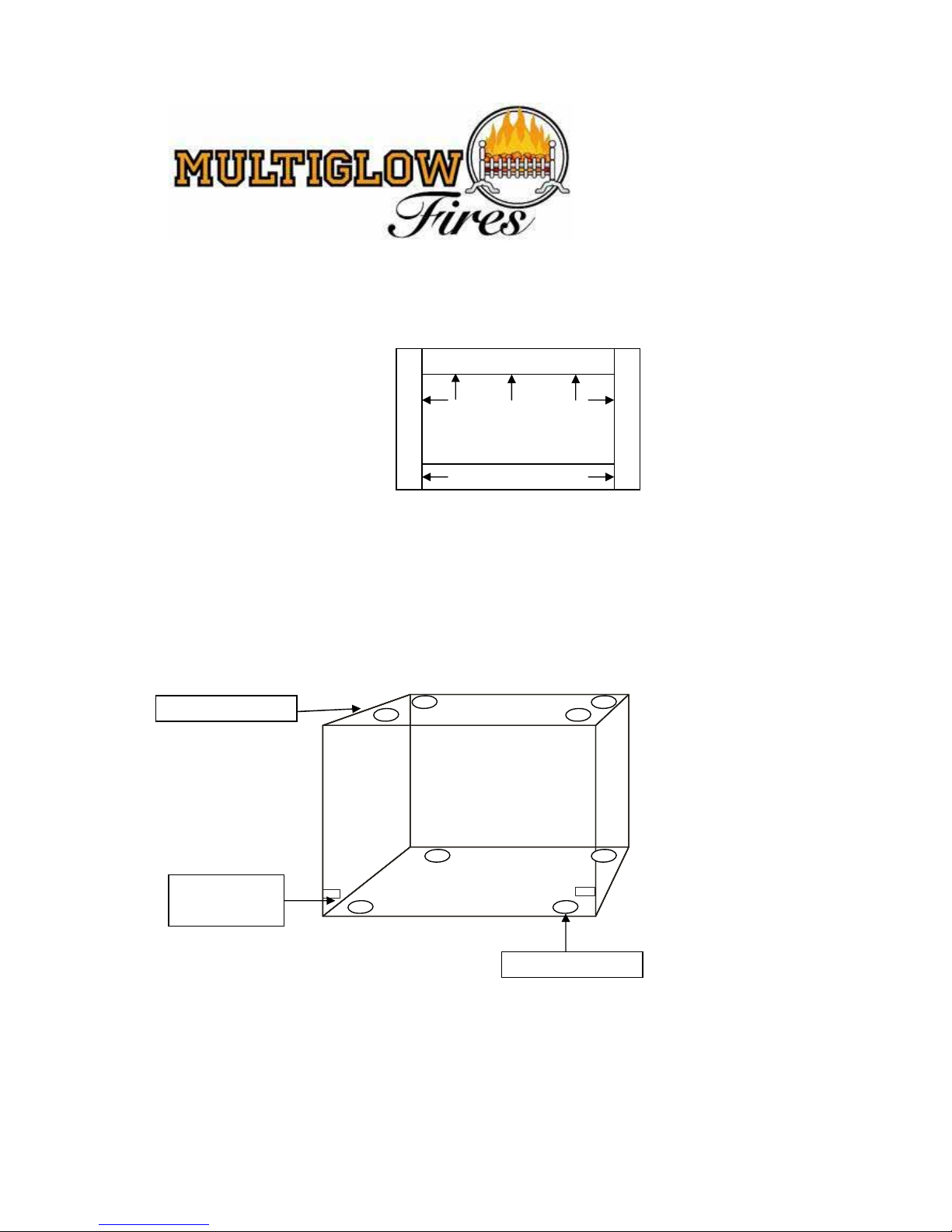

6. Place the box centrally into the opening.

7. Whilst holding the box in place, mark

the appropriate holes in the base and

roof of the box.

8. Remove the box, drill and plug the respective

positions.

9. Replace box and fix with screws supplied.

10. Place burner shelf in the box sliding front

legs onto locating pins.

11. Prepare the gas supply pipe for final fixing

12. Fit burner in burner shelf.

13. Fit the four piece frame back onto the box

ensuring the bottom flap opens and closes without

LOCATING

PIN

FIXING HOLES

FIXING HOLES

9

too much force.

14. Purge the gas supply pipe work to remove air and debris BEFORE connection of the fire.

The 8mm pipe should be used to connect valve to an isolating tap, which must be

adjacent to the appliance (so that when tap is closed appliance is totally isolated). NOTE

Soft soldered joints should not be used beneath the burner tray.

WARNING: Flexible pipe must not be used .

15. Turn on gas supply and check for gas soundness. (Tests should be carried out in

accordance with current Gas Safety Regulations).

16. Place refractories on burner as shown

PEBBLE AND DRIFTWOOD LAYOUT

TOTAL = 16 PEBBLES, 1 LARGE, 1 MED LARGE, 8 MED OF DRIFTWOOD

UNDER NO CIRCUMSTANCES MUST YOU CHANGE THE

THE LAYOUT OR QUANTITY OF REFRACTORIES

LAYER 1 LAYER 2

1 X LARGE PIECE OF DRIFTWOOD 1 X MED/LARGE PIECE OF

3 X ROW OF 6 PEBBLES DRIFTWOOD

LAYER 3 LAYER 4

4 X MED PIECES OF DRIFTWOOD 4 X MED PIECES OF DRIFTWOOD

1 X SMALL PIECE OF DRIFTWOOD

10

11

12

13

14

15

16

17

18

19

20

Check that the valve and remote control are all functioning properly. If there is a problem

double check the trouble shooting guide in section 6.

REFERENCE PRESSURE

7.0 The appliance is pre-set to the given heat input for the inlet pressure given on the

Data Plate. No further adjustment should be necessary. However, the burner can be

checked by fitting a pressure gauge at the Test Point accessible to the left of the Control

Valve. The pressure should be checked with the appliance alight and the control set at

‘High’. After checking pressure, turn off appliance, remove Pressure Gauge, replace Test

Point Seal and check gas soundness.

CHECK FOR SPILLAGE

IMPORTANT: A SPILLAGE CHECK MUST BE MADE BEFORE THE INSTALLED

APPLIANCE IS HANDED OVER TO THE CUSTOMER.

This test is to be carried out with the appliance fully fitted and front flap in position.

Close all doors and windows of the room in which the appliance is fitted.

Light the fire and set the control to maximum and leave for five (5) minutes.

After five (5) minutes, light a smoke match and position flush with fireplace opening, a minimum

of 50mm (2”) from side and a maximum of 50mm (2”) from top.

The installation is satisfactory if the smoke is drawn into the chimney and out of the room.

If this does not happen then leave alight for a further ten (10) minutes and check again.

WARNING:If smoke is still not drawn up the chimney, turn off and disconnect the

appliance and seek expert advice.

WARNING:If the fire goes out under normal operation and continues to go out after

relighting, spillage has occurred and the flue should be checked.

This appliance is fitted with a pre-set Oxygen Depletion System incorporated into the Pilot Ignition

Unit. Therefore this system must not be adjusted or put out of operation and must be replaced

with a complete unit of original manufacture in the event of renewal.

SECTION 8. FINAL CHECK & CUSTOMER BRIEFING

8.0 Instruct the customer on the full operation of the appliance.

8.1 Recommend to the customer that a competent person should service the appliance annually.

8.2 Recommend to the customer that on a yearly basis the flue should be swept and that rubbish

should not be thrown or burnt on the fire or fuel bed disturbed.

SECTION 7. FUNCTION CHECKS &

COMMISSIONING

21

8.3 Instruct the customer that the pilot and flame-sensing device fitted to this fire also acts as an

atmospheric sensing device, which shuts off the appliance if the evacuation of the products of

the combustion is interrupted.

If the fire shuts off, restart the main burner as stated in section 6. If the appliance fails to

relight or repeatedly cuts off, then do not use and inform a qualified person.

8.4 Inform customer of end users instructions Sections 10& 11 of this manual.

8.5 Hand over these User instructions to the customer.

SECTION 9. SERVICING

SPARES LIST

FIG. N

O.

DESCRIPTION

PART No.

QTY.

1

PILOT BURNER & IGNITION UNIT

9039

1

SEC 6

CONTROL VALVE

GV 60

1

SEC 6

RECEIVER PACK

G6R PISOA5AS10

1

SEC 6

4 X AA ALKALINE BATTERIES 1 X 9 VOLT BATTERY

ENERGIZER

4, 1

Fig 1.

All servicing of this appliance is to be carried out by a competent person.

22

Turn off gas supply before commencing any servicing. Always check for gas soundness and

spillage after refitting the appliance.

9.1 GENERAL MAINTENANCE

At yearly intervals, turn off and allow to cool down. Check all refractories, pilot

burner/ignition unit, for soot or debris deposits. Theses can cause imperfect flame

appearance and should be removed by brushing with a soft brush (DO NOT USE A

VACUUM CLEANER). Replace all misplaced pebbles/driftwood as per layout (see page

9) and relight.

NOTE:On the failure of either the pilot burner/ignition unit, or main control valve, have

repairs carried out by a competent person.

9.2 RENEWING PILOT BURNER/IGNITION UNIT (Fig.1)

9.2.1 Isolate gas supply.

9.2.2 Remove all refractories– store in a safe place.

9.2.3 Disconnect main 8mm gas supply pipe from control valve (See section 6)

9.2.4 Remove appliance from tray.

9.2.5 Undo and remove thermocouple nut from the rear of the control valve.

9.2.6 Disconnect and remove piezo ignition wiring from ignition electrode (Fig.1 (2))

9.2.7 Undo and remove the 4mm

gas

supply pipe from the bottom of the pilot burner (Fig.1 (5) )

9.2.8 Undo and remove 2x 4mm locating nuts/screws on pilot/ignition unit. Remove unit.

9.2.9 Replace with a new unit and reassemble in reverse order.

10.0 For safe operation of this appliance which includes lighting and shut-down procedures,

including instructions in the event of remote breakdown (manual ignition) please refer to

section 6 of this manual.

10.1 The chimney shall be swept regularly to ensure that all products of combustion

are entering the flue, and that there is no excessive build up of soot.

10.2 Any debris from any source or any soot shall require removal; this must be done

by using a soft brush (DO NOT USE A VACUUM CLEANER).

10.3 THE USER IS WARNED NOT TO THROW RUBBISH ON OR OTHERWISE

DISTURB THE FUEL BED.

10.4 WHERE IT IS NECESSARY TO REMOVE THE REFRACTORIES FOR

CLEANING PURPOSES,THIS MUST BE DONE USING A SOFT BRUSH (DO NOT

USE A VACUUM CLEANER).WHEN REPLACING THE REFRACTORIES THIS

MUST BE DONE AS PER LAYOUT SHOWN ON NEXT PAGE,UNDER NO

CICUMSTANCES SHOULD THE LAYOUT BE CHANGED OR MORE

REFRACTORIES ADDED OR TAKEN OFF.

SECTION 10. END USER

INSTRUCTIONS

23

FIG 1, LAYER 1 FIG 2, LAYER 2

1 X LARGE PIECE OF DRIFTWOOD 1 X MED/LARGE PIECE OF

3 X ROW OF 6 PEBBLES DRIFTWOOD

FIG 3, LAYER 3 FIG 4, LAYER 4

4 X MED PIECES OF DRIFTWOOD 4 X MED PIECES OF DRIFTWOOD

1 X SMALL PIECE OF DRIFTWOOD

FIG 1

FIG 3

FIG 4

FIG 2

24

PLEASE FILL IN INFORMATION BELOW FOR FUTURE REFERENCE INFORMATION CAN BE FOUND ON THE DATA PLATE

SERIAL NO

WARRANTY INFORMATION

If within the period of one year of purchase there is the unlikely

occurrence of defect in either materials or workmanship Multiglow

will arrange to repair or replace the item free of charge.

All warranty claims must be made through the retailer that this appliance

was purchased through.

Multiglow are not able to discuss with the purchaser any claim until

the retailer has inspected a claim and deemed it valid this being due

to the fact that the purchaser's contract of sale is with the retailer.

When a defect is due to installation error or misuse Multiglow reserve the

right to refuse service or make the appropriate charge for any warranty

call.

DATE

MODEL

MODEL

SERIAL NUMBER

INSTALLER

INSTALLATION DATE

25

Loading...

Loading...