Multi-Fittings Solvent Weld PVC DWV, Blue Brute, Trench Tough Plus, Cycle Tough Installation Manual

Installation

Guide

www.multifittings.com

Trench Tough Plus

TM

Blue Brute

®

Cycle Tough

®

Ultra-Rib

®

Solvent Weld PVC DWV

Multi Fittings Corp. maintains a policy of

ongoing product improvement. This may result

in modification of features or specifications

without notice.

This booklet is meant as a general installation

guide for Trench Tough Plus

TM

, Blue Brute®,

Cycle Tough

®

, Ultra-Rib®and Solvent Weld &

PVC DWV fittings. For specific needs or

applications, please contact your local supplier

or one of our customer service offices.

Multi Fittings Installation Guide

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

MULTI FITTINGS MEET THESE STANDARDS . . . . . .6

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Pressure Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Gasketed Sewer Fittings . . . . . . . . . . . . . . . . . . . . . . . .6

PVC DWV Fittings - Solvent Weld . . . . . . . . . . . . . . . . .7

SDR35 Sewer Fittings - Solvent Weld . . . . . . . . . . . . . .7

RECEIVING AND HANDLING FITTING SHIPMENTS .8

Before Accepting the Shipment . . . . . . . . . . . . . . . . . . .8

Storage at the Job Site . . . . . . . . . . . . . . . . . . . . . . . . .8

Extremely Cold Weather . . . . . . . . . . . . . . . . . . . . . . . .9

Prolonged Outdoor Storage . . . . . . . . . . . . . . . . . . . . . .9

UNDERGROUND BURIAL OF FITTINGS . . . . . . . . .10

Trench Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Excavating and Preparing the Trench . . . . . . . . . . . . .10

Flotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

The Bottom of the Trench . . . . . . . . . . . . . . . . . . . . . . .11

Lowering the Fittings into the Trench . . . . . . . . . . . . . .11

1

HAUNCHING & BACKFILLING . . . . . . . . . . . . . . . . .12

Initial Backfill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Final Backfill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Compacting the Backfill . . . . . . . . . . . . . . . . . . . . . . . .13

Embedment Materials . . . . . . . . . . . . . . . . . . . . . . . . .14

Selection of Embedment Materials . . . . . . . . . . . . . . .15

2

GASKETED PVC PRESSURE FITTINGS

PREPARING FOR ASSEMBLY . . . . . . . . . . . . . . . . . .16

Preparing the Spigot . . . . . . . . . . . . . . . . . . . . . . . . . .17

Assembling the Joint . . . . . . . . . . . . . . . . . . . . . . . . . .18

CURVATURE IN THE PIPELINE SYSTEM . . . . . . . . .20

Using Blue Brute or Cycle Tough Fittings . . . . . . . . . .20

Deflecting the Fitting Joint . . . . . . . . . . . . . . . . . . . . . .21

OUTSIDE DIAMETER CONSIDERATIONS . . . . . . . .22

Blue Brute Fittings Cast Iron Outside Diameter (CIOD) .22

Blue Brute Dimensional Data . . . . . . . . . . . . . . . . . . . .23

Cycle Tough IPS Fittings Outside Diameter . . . . . . . . .27

Cycle Tough Engineered Joint . . . . . . . . . . . . . . . . . . .27

Cycle Tough Dimensional Data . . . . . . . . . . . . . . . . . .29

FABRICATED PVC PRESSURE FITTINGS . . . . . . . .36

Fabricated Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Butt Fusion Fabricated Fittings . . . . . . . . . . . . . . . . . .37

Butt Weld Fabricated Fittings . . . . . . . . . . . . . . . . . . . .37

Multi Fittings Installation Guide

RESISTING THRUST AT PRESSURE FITTINGS &

VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Bearing Strength of Undisturbed Soils . . . . . . . . . . . . .39

Resisting Thrust in Very Poor Soils . . . . . . . . . . . . . . .40

Resisting Vertical Thrust . . . . . . . . . . . . . . . . . . . . . . .41

Holding Pipe and Fittings to Steep Slopes . . . . . . . . .42

Mechanical Thrust Restraints for Fittings . . . . . . . . . . .42

FLANGED JOINTS . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Service Connections . . . . . . . . . . . . . . . . . . . . . . . . . .43

Tapped Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

THE PIPELINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Leakage and Pressure Tests . . . . . . . . . . . . . . . . . . . .44

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Multi Fittings Installation Guide

TRENCH TOUGH PLUS AND ULTRA-RIB GASKETED

SEWER FITTINGS

STARTING THE JOB . . . . . . . . . . . . . . . . . . . . . . . . . .47

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Line and Grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Assembly of Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Curved Sewers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Field Cut Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Manhole Connections . . . . . . . . . . . . . . . . . . . . . . . . .51

Service Connections . . . . . . . . . . . . . . . . . . . . . . . . . .52

Sewer Laterals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Riser Problems Demand Special Attention . . . . . . . . .55

Backfilling and Tamping . . . . . . . . . . . . . . . . . . . . . . . .56

Tamping Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . .57

TESTING OF SEWERS . . . . . . . . . . . . . . . . . . . . . . . .58

Joint Tightness Testing . . . . . . . . . . . . . . . . . . . . . . . . .58

Deflection Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Videos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Shallow Burial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

3

SOLVENT WELD SEWER AND DWV FITTINGS

SOLVENT CEMENTING . . . . . . . . . . . . . . . . . . . . . . .65

Basic Principles of Solvent Cementing . . . . . . . . . . . .65

SOLVENT CEMENTING INSTRUCTIONS . . . . . . . . .67

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Storage Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Cold Weather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Initial Set Time Schedule . . . . . . . . . . . . . . . . . . . . . . .72

Joint Cure Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . .73

4

APPENDICES

APPENDIX I:

Dimensions of Cycle Tough Pressure Pipes

with IPS OD’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

APPENDIX II:

Dimensions of Blue Brute and

Centurion Pressure Pipes with CIOD’s . . . . . . . . . . . .76

APPENDIX III:

Percent % Deflection of Blue Brute Pipe and

Blue Brute C907 Fittings . . . . . . . . . . . . . . . . . . . . . . .77

APPENDIX IV:

Percent % Deflection for Centurion Pipe and

Fabricated Blue Brute s C900 Fittings . . . . . . . . . . . . .78

APPENDIX V:

Percent % Deflection for Cycle Tough Pipe and

Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

APPENDIX VI:

Percent % Deflection for Trench Tough Plus SDR35

and Trench Tough Plus SDR26 Heavy Wall Fittings . .80

APPENDIX VII:

Pipe Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Multi Fittings Installation Guide

APPENDIX VIII:

Lubricant Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Multi Fittings Installation Guide

INTRODUCTION

5

This booklet will meet the needs of fitting installers looking

for general recommendations on how to install Blue

®

Brute

, Cycle Tough®, Trench Tough PlusTMgasketed

sewer, Ultra-Rib

®

, Solvent Weld sewer and PVC DWV

fittings. Out-of-the-ordinary conditions not covered here

should be referred to the Engineer or his inspectors to

provide on-site solutions. In such cases Multi's advice is

always available. Our objective is to encourage the use of

methods that lead to a professional installation that will

ensure the maximum service life for our fittings.

The Engineer who designs the pipe and fitting system will

determine how it should be installed. It is not our intention

that the Guide should assume that responsibility unless

the Engineer so directs the installer.

This booklet sets out the preferred methods of installation

based on Multi's experience and on a number of published

reports from other industry sources. Users will find additional

helpful advice published by the Uni-Bell PVC Pipe

Association and available from Multi on request.

Readers are invited to order a copy of the "Uni-Bell

Handbook of PVC Pipe - Design and Construction". This

comprehensive reference manual, with over 400 pages,

covers all aspects of

design and installation

for PVC pipe and

fittings. Call Uni-Bell at

(972) 243-3902

to order.

Introduction

6

Multi Fittings Installation Guide

MULTI FITTINGS MEETS THESE STANDARDS

The list below identifies some industry standards in use

today regarding manufacturing, quality control and proper

installation of PVC sewer pipe and fittings.

ABBREVIATIONS

Introduction

CSA Canadian Standards Association

ASTM American Society for Testing and Materials

UNI-B Uni-Bell PVC Pipe Association

AASHTO American Association of State Highway and

Transportation Officials

AWWA American Water Works Association

NSF National Sanitation Foundation

PRESSURE FITTINGS

CSA B137.2 PVC Injection Molded Gasketed Fittings

for Pressure Applications

CSA B137.3 Large Diameter Fabricated PVC Pressure

Fittings

AWWA C900 Polyvinyl Chloride (PVC) Fabricated

Fittings 10" through 12"

AWWA C907 Polyvinyl Chloride (PVC) Injection Molded

Pressure Fittings for water - 4" through 12"

AWWA C905 Polyvinyl Chloride (PVC) Fabricated

Fittings, 14" through 48"

AWWA C605 Underground Installation of Polyvinyl

Chloride (PVC) Pressure Pipe

ASTM D2241 Polyvinyl Chloride (PVC) Pressure Rated

Pipe (SDR Series)

GASKETED SEWER FITTINGS

CSA B182.1 Plastic Drain and Sewer Pipe and Fittings

CSA B182.2 PVC Sewer Pipe and Fittings

CSA B182.4 Profile (Ribbed) PVC Sewer Pipe and

Fittings

CSA B182.11 Recommended Practice for the Installation

of Thermoplastic Drain, Storm & Sewer

Pipe and Fittings

ASTM D2321 Underground Installation of Flexible

Thermoplastic Sewer Pipe

Multi Fittings Installation Guide

ASTM D3034 Type PSM Polyvinyl Chloride (PVC) Sewer

Pipe and Fittings

ASTM D3212 Joints for Drain and Sewer Plastic Pipes

Using Flexible Elastomeric Seals

ASTM F477 Elastomeric Seals for Joining Plastic Pipes

ASTM F679 Polyvinyl Chloride (PVC) Large Diameter

Plastic Gravity Sewer

ASTM F794 Polyvinyl Chloride (PVC) Ribbed Gravity

Sewer Pipe and Fittings

ASTM F913 Thermoplastic Elastomeric Seals

(Gaskets) for Joining Plastic Pipe

ASTM F1336 Polyvinyl Chloride (PVC) Gasketed Sewer

Fittings

UNI-B-6 Recommended Practice for Low-Pressure

Air Testing of Installed Sewer Pipe

UNI-PUB-6 Installation Guide for PVC Sewer Pipe

UNI-TR-1 Deflection: The Pipe/Soil Mechanism

UNI-TR-6 PVC Force Main Design

AASHTO M278 Class PS46 Polyvinyl Chloride (PVC)

Piping Systems for Subsurface Drainage

of Transportation Facilities

AASHTO M304Polyvinyl Chloride (PVC) Ribbed Drain

Pipe and Fittings Based on Controlled

Inside Diameter

7

Introduction

PVC DWV FITTINGS - SOLVENT WELD

NSF 14 Plastic Piping Systems Components &

Related Materials

ASTM F1866 PVC Plastic Schedule 40 Drainage and

DWV Fabricated Fittings

ASTM D2665 Polyvinyl Chloride (PVC) Plastic Drain

Waste and Vent Pipe and Fittings

SDR35 SEWER FITTINGS - SOLVENT WELD

CSA B182.1 Plastic Drain and Sewer Pipe and Fittings

CSA B182.2 PVC Sewer Pipe and Fittings

ASTM D3034 Type PSM Polyvinyl Chloride (PVC) Sewer

Pipe and Fittings

ASTM D2729 Polyvinyl Chloride (PVC) Sewer Pipe and

Fittings

8

Multi Fittings Installation Guide

RECEIVING AND HANDLING

FITTING SHIPMENTS

BEFORE ACCEPTING THE SHIPMENT

Our fittings are manufactured to a number of standards,

Introduction

none of which are more demanding than Multi's own

Standard Product Specifications. Quality Control

inspection of the products before they leave our plants

ensures that only the highest quality products are

shipped. Damage to the fittings, or shortages, are

possible and must be checked before the shipment is

received and signed for by the contractor.

1. The contractor should inspect each fitting as it is

unloaded.

2. Check the quantity shipped against the tally sheet.

The contractor must note any shortages on the

trucker's bill of lading.

3. Carefully note any sign of damage to the fittings in

the form of cracks, chips or other damage.

4. DO NOT THROW AWAY ANY DAMAGED MATERIAL.

Mark it carefully for further inspection by the carrier

or their representative.

5. Re-order any fittings that are needed to make up for

missing or damaged fittings.

6. Notify the carrier immediately and enter a claim for

damaged or missing parts in accordance with their

instructions.

STORAGE AT THE JOB SITE

The preferred method of storage at the job site is in boxes

or crates as shipped.

Multi Fittings Installation Guide

EXTREMELY COLD WEATHER

9

Although PVC fittings have very good impact resistance,

they offer slightly reduced impact resistance at very low

temperatures (below freezing). Do not allow the fittings to

fall or be thrown off the truck or into the trench.

PROLONGED OUTDOOR STORAGE

Prolonged exposure of PVC fittings to the direct rays of

the sun will not damage the fittings. However, some mild

discoloration may take place in the form of a milky film on

the exposed surfaces. This change in color merely

indicates that there has been a harmless chemical

transformation at the surface of the fitting. Physical

properties such as pipe stiffness and tensile strength are

unaffected by surface discoloration. However, a small

reduction in impact strength could occur at the discolored

surfaces. These are of a very small order and will not

affect a proper field installation. Multi Fittings products that

are exposed to sunlight will still exceed all of the impact

requirements of the standards.

Discoloration of the fittings can be avoided by shading

them from the direct rays of the sun. This can be

accomplished by covering the fittings with an opaque

material such as canvas. If the fittings are covered, always

allow for the circulation of air through the fittings to avoid

heat buildup in hot summer weather. Do not store the

fittings in plastic bags in warm climates for long periods of

time. Make sure that the fittings are not stored close to

sources of heat such as boilers, steam lines, engine

exhaust outlets, etc. If the fitting will be installed in an

exposed application, the fitting can be protected by

painting with a water based “latex paint” only.

Introduction

10

Multi Fittings Installation Guide

UNDERGROUND BURIAL OF

FITTINGS

TRENCH PREPARATION

SAFETY

Introduction

Trenches can be dangerous places. The contractor is

responsible for ensuring that all applicable regulations

have been observed and that the protection of the

workers and the general public is provided.

EXCAVATING AND PREPARING THE TRENCH

The drawings and bid documents will specify the correct

line and grade to be established by the trenching

operation. Aside from these engineering considerations

good bedding practices make sense for all types of pipe

and fittings, including PVC.

The width of the top of the trench will be determined by

local conditions. But at the “fitting zone” the trench width

should be kept to a practical minimum.

The general rule is that the maximum width at the top of

the fitting should not be more than the outside diameter of

the fitting plus 24". If trench width cannot be controlled

and will exceed the minimum then compacted backfill

must be provided for a distance of 2-1/2 fitting diameters

to either side of the fitting or to the trench wall. This is

applicable for fitting sizes up to 10". For larger sizes the

compacted haunching material should be placed one

fitting diameter or 24" (whichever is greater), to either side

of the fitting. The placement of the backfill under the fitting

haunches is important. For this reason you need enough

room at the sides of the fitting to slice the material under

the haunch and compact it. The minimum distance

required is 8" on either side of the fitting.

Keep the three basic operations close together: digging,

pipe and fitting laying and backfilling. The shortest

practical stretch of open trench reduces the possibility of

problems associated with water, frozen ground, impact

damage, flotation and traffic.

Multi Fittings Installation Guide

11

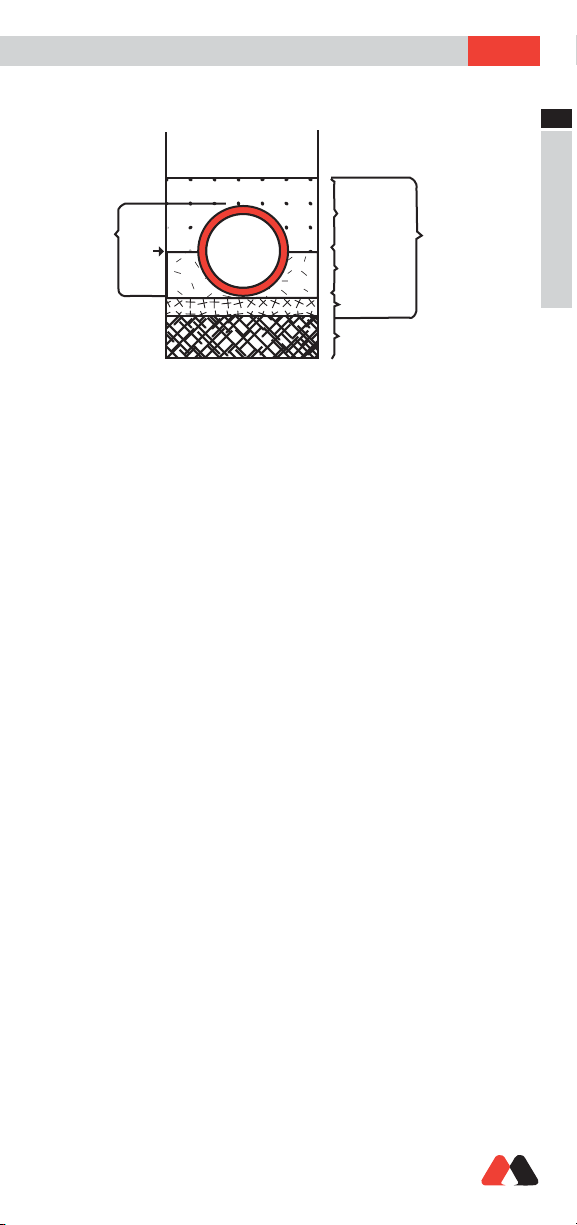

Initial

Fitting

Zone

e

glin

rin

p

S

g

ittin

of F

Backfill

Haunching

Bedding

6 in.

Foundation

(may not be required)

ent

bedm

Pipeline Em

FLOTATION

Where the fitting is in a flooded condition and it is not

possible to remove standing water from the trench, the

fitting should be held at grade with a minimum backfill

cover of twice the fitting diameter.

THE BOTTOM OF THE TRENCH

The objective of bedding is to provide a continuous

support for the fitting at the required line and grade.

Frozen material should not be used to support or bed the

fitting. At least 4" of bedding material should be placed

under the fitting if rocky conditions exist. The bedding may

or may not be compacted, but in any event the projecting

bells of the fitting should be properly relieved in the trench

bottom so that the entire fitting is evenly supported by the

bedding. Where the trench bottom is unstable (organic

material, or "quick" sand or similar material), the trench

bottom should be over-excavated and brought back to

grade with an approved material.

Introduction

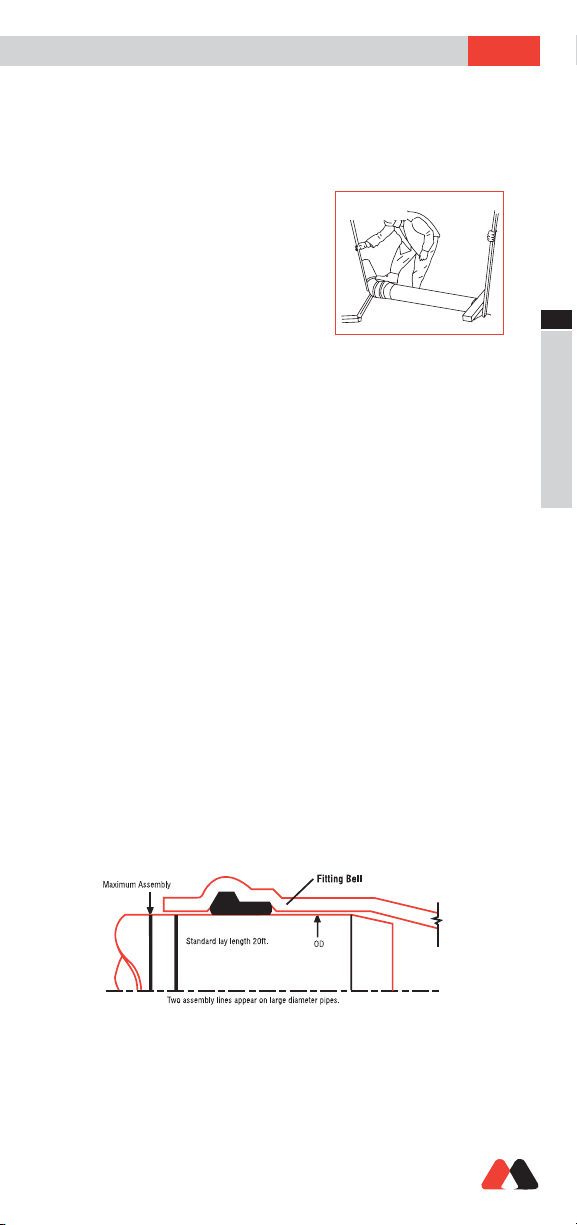

LOWERING THE FITTINGS INTO THE TRENCH

Place the fittings into the trench by hand, using ropes and

skids or slings on the backhoe bucket. Do not throw the

fittings into the trench. At this point the fittings are in a

good position for final inspection. Ensure there are no

damaged materials before assembly begins.

12

Multi Fittings Installation Guide

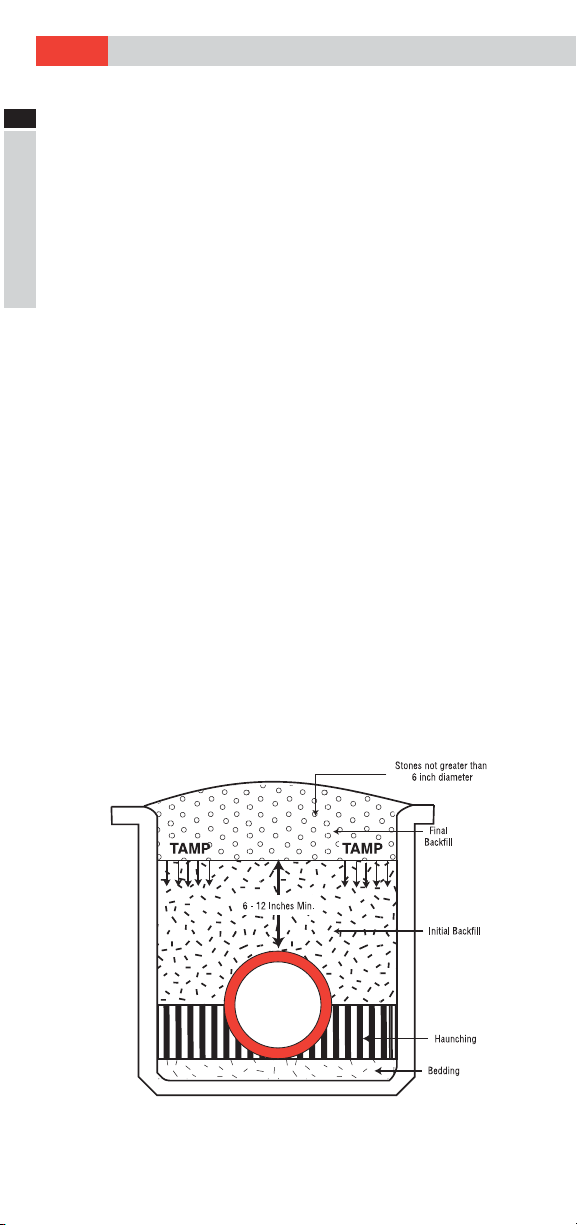

HAUNCHING & BACKFILLING

The material placed to the sides of the fitting from the

bedding to about the springline (center line) is intended to

help the fitting support the vertical loads. It is frequently a

material with sizes not larger than 1-1/2".

Introduction

INITIAL BACKFILL

The material placed over the fitting itself to a height of 6"

to 12" above the top of the fitting is the initial backfill. The

maximum size of stone in the initial backfill, where not

specified, should be 1-1/2". Where it is not otherwise

specified, the initial backfill may consist of the native

material in the trench provided it is free from large stones,

not frozen, and free of debris or other organic materials.

The purpose of the initial backfill is to protect the fitting

and the pipeline from the final backfill.

FINAL BACKFILL

The material placed over the initial backfill to the top of the

trench is the final backfill. If not otherwise specified, the

final backfill material may contain boulders up to 6" in

diameter and may consist of native material.

Multi Fittings Installation Guide

COMPACTING THE BACKFILL

13

Compact the haunching, initial backfill and final backfill in

accordance with the job drawings. Observe the following

precautions.

1. When a "self-compacting" material is used, such as

crushed stone, ensure that the material does not arch

or bridge beneath the haunch of the fitting. Remove

such voids with the tip of a spade.

2. When compacting the material underneath and at

either side of the fitting, do not allow the tool or the

machine to strike the fitting.

3. When compaction in excess of 85% standard proctor

density is required in the haunching area, ensure

that the compacting effort does not dislodge the

pipeline from the correct grade. If the compacting

effort dislodges the fitting, re-lay the fitting to the

correct grade.

PVC pressure fittings (DR14, DR18 and DR25) may

be buried with as little as 12" of cover and be

subjected to H-20 traffic loading. A minimum soil

stiffness of E’ = 1,000 psi is recommended in the

fitting zone of the trench for these conditions and this

type of fitting.

Introduction

PVC gasketed sewer fittings, with a minimum pipe

stiffness of 46 psi (DR35), may be buried with as little

as 12" of cover and be subjected to H-20 traffic

loading. A minimum soil stiffness of E’ = 1,000 psi is

recommended in the fitting zone of the trench for

these conditions.

For pressure or gasketed sewer fittings with a

minimum pipe stiffness less than 46 psi (DR41 and

DR51) a minimum cover of 24" is required with a

minimum soil stiffness of E’ = 1,000 psi.

4. It is not necessary to compact the initial backfill

directly over the top of the fitting for the sake of the

fitting's structural strength. However, it may be

necessary for the sake of roadway integrity.

14

5. A matrix of embedment materials can be successfully

Introduction

Multi Fittings Installation Guide

used with PVC fittings. Consult the table found in

Appendices III, IV or V on pages 77 - 79 for the

expected deflection given a particular embedment

material, compacted to a certain density. As can be

seen in this chart, at normal depths under 16' of

cover, compaction effort is used strictly to prevent

trench settlement.

EMBEDMENT MATERIALS

Some general rules about all soils to be used in a buried

pipeline trench include that they must be free of sharp

objects, sticks, large clumps, frozen material, organic

materials and boulders.

Most of the soil commonly found can be classified into

one of the following categories, which are referenced from

ASTM D2487.

Class 1

Angular, 1/4" - 1-1/2" graded stone, including a number of

fill materials such as coral, slag, cinders, crushed stone

or crushed shells.

Class 2

Coarse sands and gravels with a maximum particle size

of 1-1/2", including various graded sands and gravels

containing small percentages of fines, generally granular

and non-cohesive.

Class 3

Fine sand and clayey gravels, including fine sands, sandclay mixtures and gravel-clay mixtures.

Class 4

Silt, silty clays and clays including inorganic clays and

silts of medium to high plasticity and liquids limits.

Class 5

Includes organic soils such as frozen earth, debris and

other foreign materials. These materials are not

recommended for use in the bedding, haunch or initial

backfill zones.

Note: The performance of a flexible conduit does not

depend only on the class of embedment materials used,

but more importantly on the density achieved in

compaction of the haunching material.

Multi Fittings Installation Guide

SELECTION OF EMBEDMENT MATERIALS

15

Soil to be used in the pipe zone should be capable of

maintaining the specified soil density. For example, if a

coarse material such as Class 1 is used for bedding the

pipe, it should also be used in the haunch zone to the

springline of the pipe. Otherwise, side support may be

lost due to migration of the Class 2, 3 or 4 materials into

the bedding.

When selecting the embedment materials, ensure that

native soil migration from the trench walls cannot occur.

A well-graded compacted granular material will prevent

this condition from occurring. In trenches subject to

inundation, the granular material should be compacted to

a minimum of 85% Standard Proctor Density.

Introduction

16

Multi Fittings Installation Guide

GASKETED PVC PRESSURE FITTINGS

PREPARING FOR ASSEMBLY

All Multi PVC gasketed pressure fittings are prepared for

assembly as follows:

Keep both the spigot of

the pipe and the bell of

the fitting clean. It is

good practice to lay the

pipeline with the bells

forward so that the

assembly operation will

consist of pushing the

spigot into the bell. This

Pressure Fittings

will minimize the

possibility of contaminating the surfaces with foreign

material. All assemblies should be concentric.

Use an approved lubricant for all gasketed fittings. Apply

an NSF approved lubricant with pressure fittings used

with potable water. The use of substitute lubricants that

are not NSF approved may damage the gaskets and

should not be used.

Before inserting the spigot into the sealing gasket of the

fitting, make sure that the gasket is clean and that the

groove is free of any debris or dirt.

Multi Fittings Installation Guide

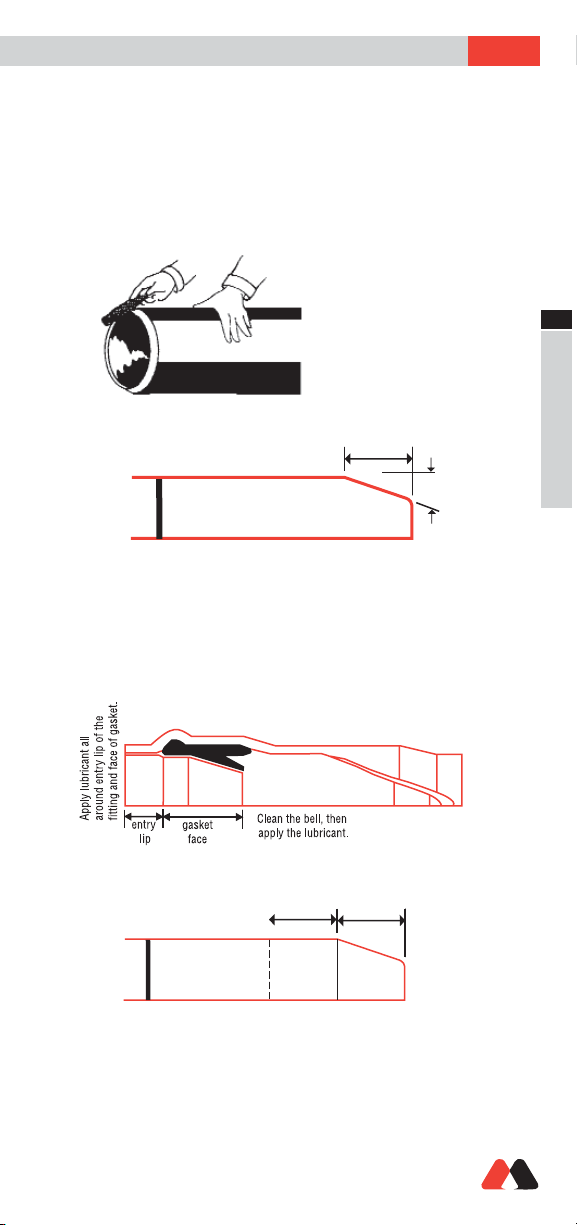

PREPARING THE SPIGOT

Pipe is generally shipped with a chamfer on the end of

the spigot. If there is no chamfer, follow the example of a

factory made spigot and machine a suitable chamfer for

easy insertion into the gasketed fittings.

From the chamfer using a

beveling tool, hand rasp or

disk cutter.

1 1/2"

Chamfer

15˚

Assembly

Line

Apply a thin coating of lubricant (about 1/32" thick,

equivalent to a brushed coating) using a glove, a rag, or a

paint brush. The area to be covered is as follows:

17

Pressure Fittings

Assembly

Line

1 1/2"

Lube Depth

Apply lubricant all around the

spigot chamfer plus

1 1/2" back.

1 1/2"

Chamfer

*For proper lubricant usage refer to page 84.

18

Multi Fittings Installation Guide

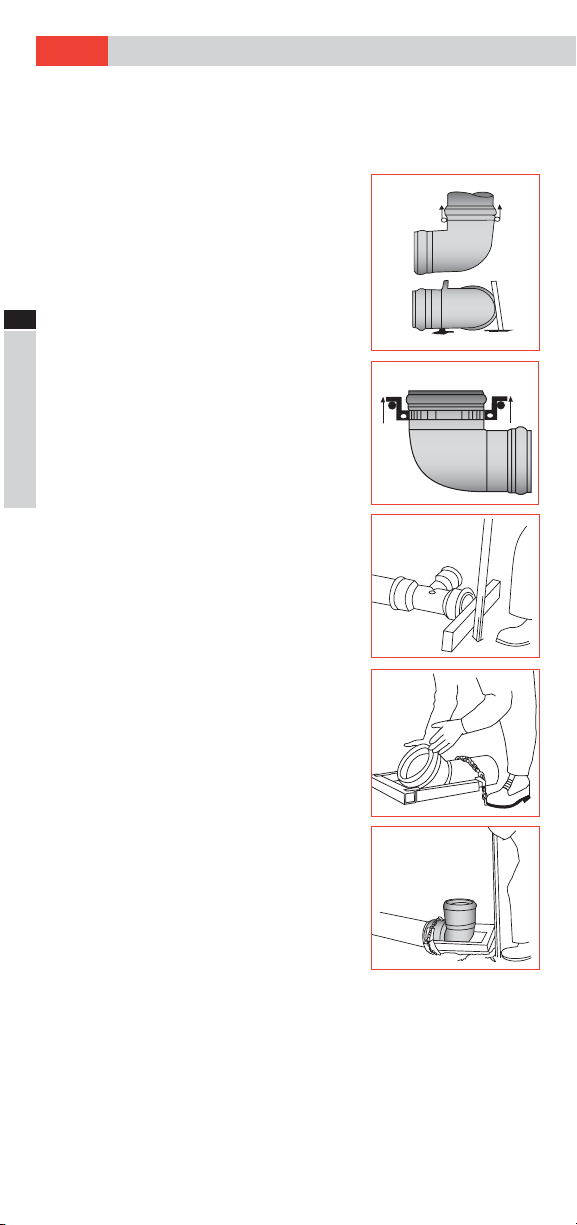

ASSEMBLING THE JOINT

Assemble the joint with a come-along and chain or use

one of the methods illustrated below.

The correct insertion depth in fitting

bells differs from the correct

insertion depth for pipe bells.

Factory-applied assembly lines on

pipe spigots should be ignored when

assembled to fittings. Special

assembly lines may be marked on

pipe ends by measuring the depth

of the fitting bell.

Successful assemblies of fittings

have been made by forming a

Pressure Fittings

scissors grip on the

leading bell with two implanted

crowbars. See Figure 1.

Assembly using two crowbars is

made easier when a special collar

is attached to the bell behind the

gasket race. Two projections at

either side of the collar allow a

more substantial grip in the bell.

See Figure 2.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

When assembling in-line bell

fittings such as couplings and

tees, a crowbar and a 2 x 4 are all

that’s needed. See Figure 3.

For deflection fittings such as 45°

elbows an assembly jig should be

used to transfer the assembly

effort to the bell being assembled

rather than directly to the edge of

the trailing bell. The jig illustrated

is typical. See Figure 4.

The hinged “clamshell” of the assembly jig is opened and

positioned behind the gasket race of the bell as shown in

Figure 4. The two halves are pulled tightly together with

the chain and fixed by looping a link of the chain through

the slot in the hinged arm. The fitting can then be levered

home. If the clamshell tends to ride over the gasket race,

Fig. 5

Multi Fittings Installation Guide

Multi Fittings Installation Guide

stop the operation and retighten the chain. If the trailing bell

faces the wrong direction after assembly, immediately

rotate it by hand to the correct position. See Figure 5.

19

19

Adjoining lengths of pipe can be

Fig. 6

assembled in the usual way with

suitable support for the fitting when it

is not fixed in position by backfills.

See Figure 6.

FOR SIZES OVER 12 INCHES

Keeping the pipe spigot out of the dirt, position it so that

the chamfer is resting against the gasket in the bell of the

fitting. Push the spigot into the bell so that the assembly

line on the spigot is even with the edge of the bell. If there

are two assembly lines the edge of the bell should line up

between the two lines.

The assembly effort can be delivered by hand in small

diameters with the aid of a twist as the spigot enters the

bell of the fitting, or by using a bar and block. Other

assembly methods include lever pullers, hydraulic jacks,

and for large diameter pipe and fittings the IPEX Sure

Joint Puller or a backhoe bucket.

Where mechanical means are used, the assembly effort

should not be applied directly to the edge of the fitting. A

two by four or a plank should be placed between the

backhoe bucket and the edge of the fitting. The use of a

backhoe bucket has the disadvantage that the backhoe

operator is unable to see clearly when the assembly is

complete. A helper should be located near the assembly

to signal when the insertion is complete.

Pressure Fittings

OVER-ASSEMBLY OF THE JOINT COULD DAMAGE THE FITTING. ALWAYS

MAKE SURE THAT PREVIOUSLY ASSEMBLED JOINTS REMAIN UNDISTURBED.

If resistance is felt to the assembly it may mean that the

sealing gasket has somehow become dislodged. If so, the

joint should be disassembled, cleaned, and reconstructed

in accordance with the methods given above.

20

20

Multi Fittings Installation Guide

Multi Fittings Installation Guide

CURVATURE IN THE PIPELINE

SYSTEM

There are two common methods used to achieve

changes in direction with Multi pressure fittings. They are

1) using Blue Brute or Cycle Tough fittings and 2)

deflecting the joint.

A. USING BLUE BRUTE OR CYCLE TOUGH

FITTINGS

Changes in direction in a pipeline can also be achieved

by using PVC fittings. Multi offers standard 90°, 45°,

22½° and 11¼° bends. (Special radius bends are

available upon request.) Multi also offers 5° CIOD

sweeps in DR18 up to 16". The sweeps are bell x spigot

Pressure Fittings

as illustrated below.

The cut lengths and radii are as follows:

Size Cut Length Radius

(in) (in) (ft)

636 36

836 36

10 42 43

12 48 46

14 60 59

16 72 69

Multi Fittings Installation Guide

Multi Fittings Installation Guide

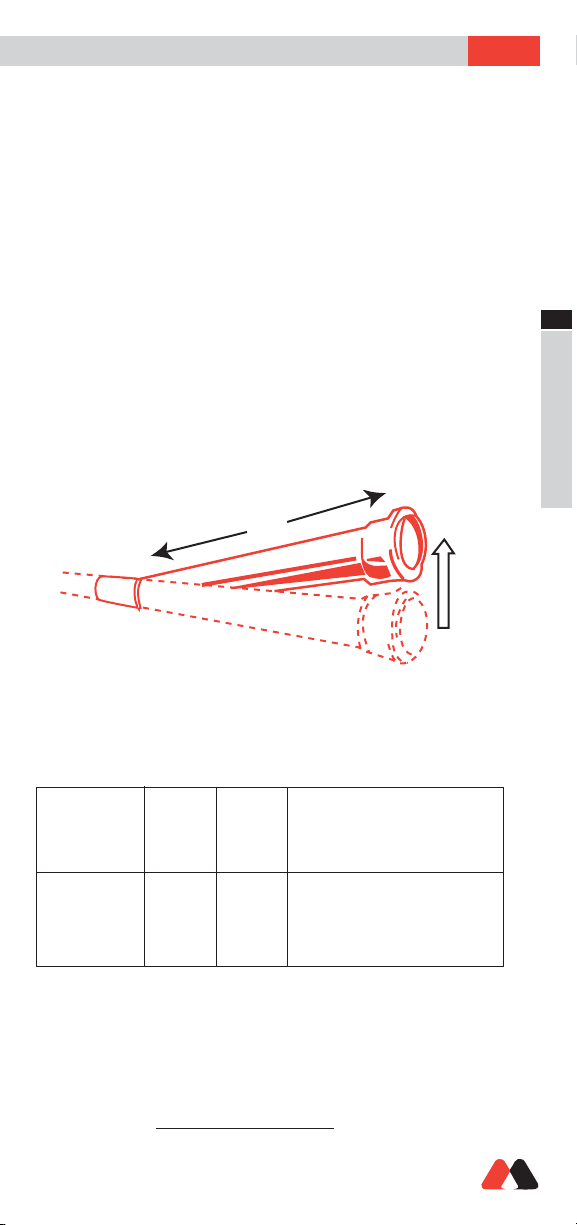

B. DEFLECTING THE FITTING JOINT

The close tolerances of Multi Fitting joints limit the amount

of unstressed deflection that can be taken by offsetting a

straight length of pipe. Injection Molded Blue Brute and

Cycle Tough fittings offer a 1° change in direction at each

bell. The procedure is as follows:

1. Make a concentric assembly, but push the spigot into

the bell of the fitting only to a point about 1/2" short of

the measured fitting bell depth. This incomplete

assembly permits more movement of the end of the

pipe at the bottom of the bell of the fitting.

2. Shift the loose bell end of the assembled length by

not more than the following recommended maximum

offsets. Use only manual effort.

t

f

0

2

21

21

Pressure Fittings

Offset

MAXIMUM RECOMMENDED OFFSETS, TO ACHIEVE

MINIMUM CURVE RADIUS BY DEFLECTING A

STRAIGHT LENGTH OF 20 FT. PIPE AT A FITTING

JOINT (FOR ALL DIMENSION RATIOS)

PIPE MAX ANGLE RESULTING RADIUS OF

SIZE OFFSET AT ONE CURVATURE USING

inches inches BELL 20 FOOT LENGTHS

Molded

PVC Fittings 4 1°** 1146 ft**

(all sizes)

** At each fitting bell. Bell by bell configurations such as

Tee's and Couplings offer a total of 2° deflection per fitting.

Note: If shorter lengths of pipe are used, the above offset

values must be multiplied by:

4" x length of pipe (in feet)

20

22

22

Multi Fittings Installation Guide

Multi Fittings Installation Guide

OUTSIDE DIAMETER

CONSIDERATIONS

Multi pressure fittings are available in two different outside

diameter dimensions in most nominal sizes. These are

Cast Iron (CIOD) and Iron Pipe Size (IPS) Outside

Diameters. The dimensions for these two different outside

diameters are shown in the Appendix on pages 75 and 76.

BLUE BRUTE®FITTINGS

CAST IRON OUTSIDE DIAMETER (CIOD)

These are the fittings normally associated with the

American Water Works Association Standards C900,

C905 and C907. Multi offers sizes of 4", 6", 8", 10" and

Pressure Fittings

12" with CIOD's in Class 100 (DR25), Class 150 (DR18)

and Class 200 (DR14). Also available are fitting sizes 14"

through 48" with CIOD's in PR 80 (DR51), PR100

(DR41), PR125 (DR32.5 to 42"), PR165 (DR25 to 36")

and PR235 (DR18, to 24" only). All CIOD PVC Pressure

Fittings by Multi are third party certified to CSA B137.3.

Multi Blue Brute PVC injection molded fittings are

available for cast iron O.D. pipe in sizes 4" through 12".

Direct assembly of CIOD pipes to these fittings should be

made following the principles given in the previous

sections. These fittings are supplied with the sealing

gasket inserted in the bells. Special transition gaskets

allow IPS O.D. pipe to also be used with Multi Blue Brute

fittings. Injection molded Cycle Tough PVC fittings are

also available for IPS O.D. pipes. Sealing gaskets supplied

for these fittings are not interchangeable with the gaskets

supplied for other pipes and fittings.

Note: Factory-made assembly lines on the pipe do not

indicate correct assembly to fittings.

Multi Fittings Installation Guide

BLUE BRUTE DIMENSIONAL DATA

Below are the exterior dimensions for each of the molded

Blue Brute fittings available from Multi.

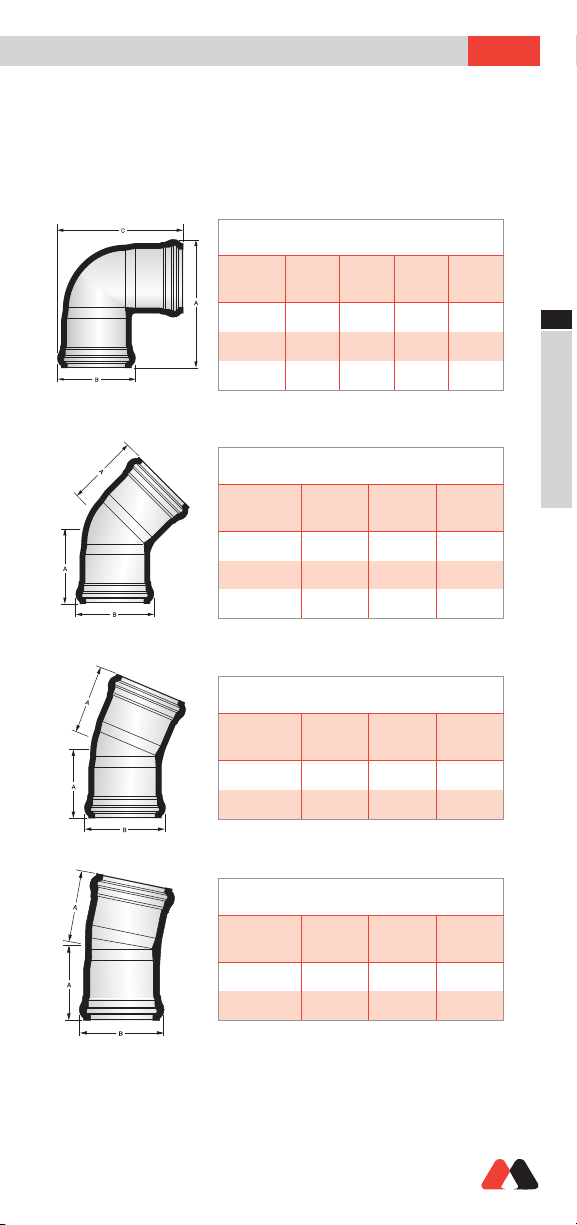

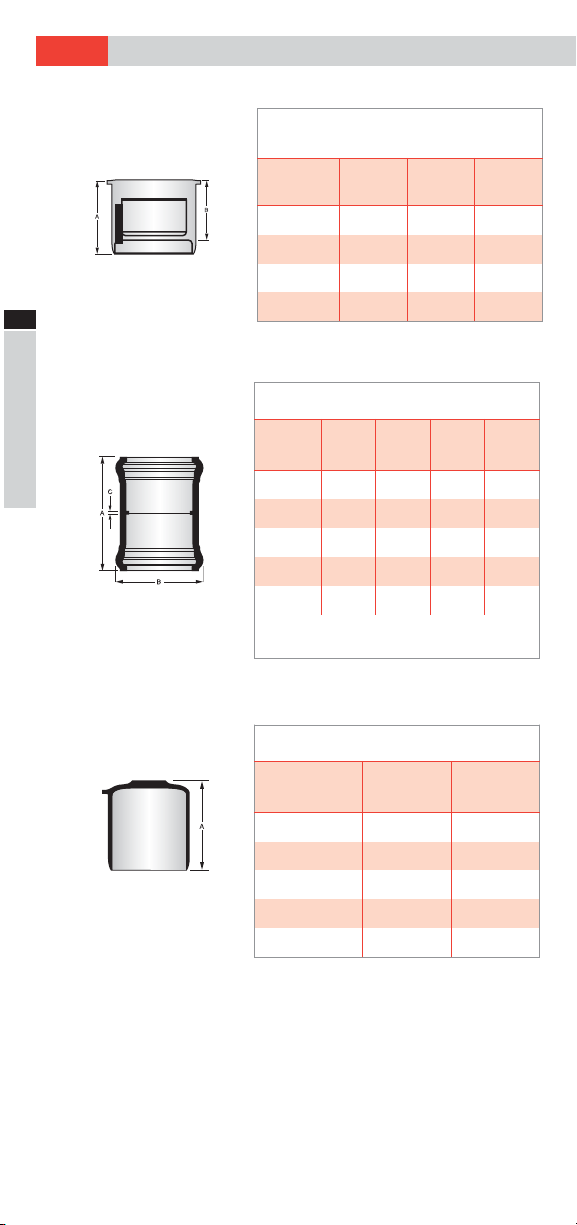

90° ELBOW

Nominal

Size (in)A(in)B(in)C(in)

4 10.14 6.25 10.14 4.7

6 13.90 8.88 13.90 15.1

8 16.90 11.36 16.90 28.0

Wt./

(lbs)

45° ELBOW

Nominal

Size (in)A(in)

4 5.63 6.27 4.1

6 7.56 8.80 11.1

8 8.80 11.30 20.3

B

(in)

Wt./

(lbs)

23

Pressure Fittings

22½° ELBOW

Nominal

Size (in)A(in)

6 6.82 8.84 10.3

8 7.90 11.30 19.2

B

(in)

11½° ELBOW

Nominal

Size (in)A(in)

6 6.45 8.84 10.0

8 7.48 11.30 18.0

B

(in)

Wt./

(lbs)

Wt./

(lbs)

24

Pressure Fittings

Multi Fittings Installation Guide

REDUCING ADAPTER

SPIGOT x BELL

Nominal

Size (in)A(in)

6 x 4 5.8 4.3 7.5

8 x 6 12.5 5.5 9.4

10 x 8 7.3 5.8 11.3

12 x 10 10.1 6.5 19.8

B

(in)

COUPLING

Nominal

Size (in)A(in)B(in)C(in)

4 8.18 6.27 0.25 3.4

6 12.11 8.88 0.25 8.2

8 13.58 11.35 0.25 22.0

10 18.12 14.30 0.50 43.3

12 19.40 17.30 0.50 65.9

(available without center stop as a

repair coupling)

Wt./

(lbs)

Wt./

(lbs)

PLUG

Nominal Size

(in)

4 5.9 1.3

6 7.0 3.8

8 8.1 7.3

10 9.0 12.4

12 9.8 19.5

A

(in)

Wt./

(lbs)

Multi Fittings Installation Guide

Multi Fittings Installation Guide

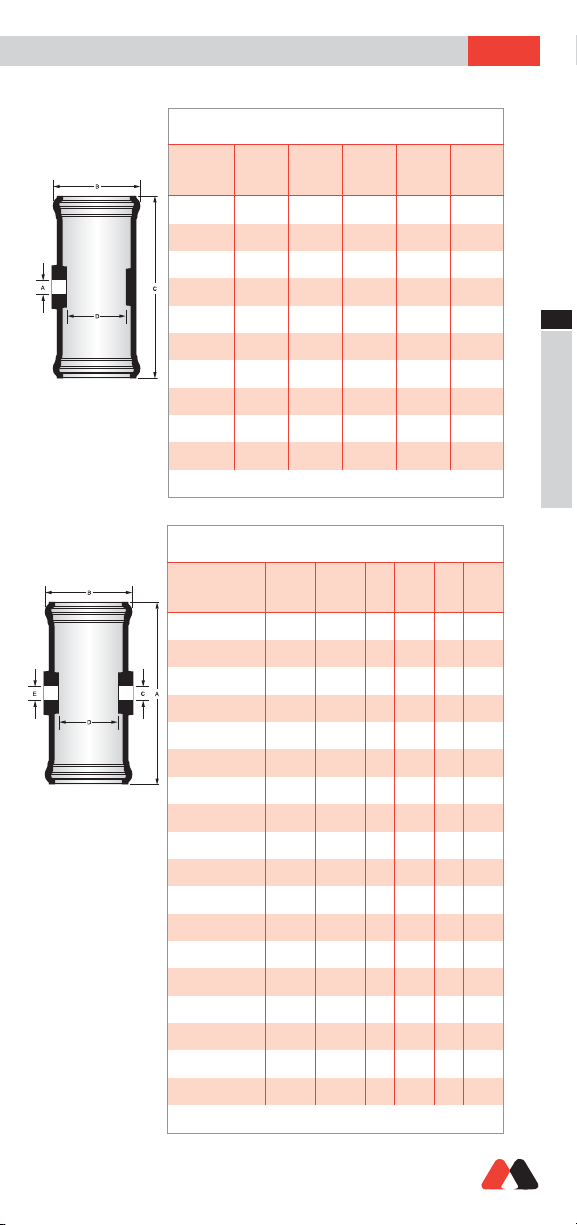

SINGLE TAPPED COUPLING

Nominal

Size (in)A(in)B(in)C(in)D(in)

4 x 4 x 3/4 6.27 10.20 4.43 4.0

4 x 4 x 1 6.27 10.20 4.43 4.0

6 x 6 x 3/4 8.74 14.38 6.06 10.6

6 x 6 x 1 8.74 14.38 6.06 10.6

6 x 6 x 1-1/2 8.74 14.38 6.06 10.6

6 x 6 x 2 8.74 14.38 6.06 10.6

8 x 8 x 3/4 11.30 15.00 7.91 17.3

8 x 8 x 1 11.30 15.00 7.91 17.3

8 x 8 x 1-1/2 11.30 15.00 7.91 17.3

8 x 8 x 2 11.30 15.00 7.91 17.3

Note: 3/4" Taps to 2", Taps: AWWA Thread

DOUBLE TAPPED COUPLING

Nominal Size

(in)

6 x 6 x 3/4

6 x 6 x 1 x 3/4 14.38 8.74 1 6.06 3/4 10.5

6 x 6 x 1 x 1 14.38 8.74 1 6.06 1 10.5

6 x 6 x 11/4 x 3/4 14.38 8.74 11/4 6.06 3/4 10.5

6 x 6 x 11/4 x 1 14.38 8.74 11/4 6.06 1 10.5

6 x 6 x 11/2 x 3/4 14.38 8.74 11/2 6.06 3/4 10.5

6 x 6 x 11/2 x 1 14.38 8.74 11/2 6.06 1 10.5

6 x 6 x 2 x 3/4 14.38 8.74 2 6.06 3/4 10.5

6 x 6 x 2 x 1 14.38 8.74 2 6.06 1 10.5

8 x 8 x 3/

8 x 8 x 1 x 3/415.00 11.30 1 7.91 3/4 17.0

8 x 8 x 1 x 1 15.00 11.30 1 7.91 1 17.0

8 x 8 x 11/4 x 3/4 15.00 11.30 11/4 7.91 3/4 17.0

8 x 8 x 11/4 x 1 15.00 11.30 11/4 7.91 1 17.0

8 x 8 x 11/2 x 3/4 15.00 11.30 11/2 7.91 3/4 17.0

8 x 8 x 11/2 x 1 15.00 11.30 11/2 7.91 1 17.0

8 x 8 x 2 x 3/4 15.00 11.30 2 7.91 3/4 17.0

8 x 8 x 2 x 1 15.00 11.30 2 7.91 1 17.0

Note: 3/4" Taps to 2", Taps: AWWA Thread

A

(in)B(in)C(in)D(in)E(in)

3

x

/4 14.38 8.74 3/4 6.06 3/4 10.5

3

4 x

/415.00 11.30 3/4 7.91 3/4 17.0

Wt./

(lbs)

Wt./

(lbs)

25

25

Pressure Fittings

Loading...

Loading...