Page 1

MFT 102/103hsm Labeler

Operator Manual

Document No. 3906330

Document Revision 0D

Multifeeder Technology

4821 White Bear Parkway

St. Paul, MN 55110

651-407-3100 ww w.multifeeder.com

Page 2

This page is intentionally blank.

Page 3

This page is intentionally blank.

Page 4

Table of Contents

Introduction 6

Icon Definitions 6

Viewing Electronic Manual 8

Viewing Printed Manual 9

Safety 10

Personal Safety Warnings 10

Machine Precautions 11

Hazard Warnings 12

Hazard Warnings - Cutout 13

Terminology 14

Main Body and Power Unwind 14

Rewind Assembly Options 16

Vacuum Take Up Rewind 16

Power Take Up Rewind 16

Vacuum Take Up Rewind Configuration 17

Power Take Up Rewind Configuration 17

Peel Plate Assembly 18

Typical Media 18

Labeler Control Box - Exterior 20

Labeler Control Box - Interior 22

Keypad Detailed 24

Setup 26

Sequence of Operation 26

Labeler Control Box Power Up 28

Labeler Thread Pattern 30

General Labeler Thread Pattern 30

Power Unwind Media Sensor Box 32

With Power Unwind and Vacuum Take Up 34

With Power Unwind and Power Take Up 36

Standard Product Sensor Setup 38

Standard Product Sensor Setup - Continued 40

Standard Product Sensor Setup - Continued 42

Label Stop Position 44

Label Stop Position - Continued 46

Labeler Speed Adjustment 48

Page 5

Labeler Basic Menu - Settings Menu 50

Labeler Basic Menu - Settings Menu (continued) 52

Non-Standard Product Sensor Setup 54

Non-Standard Product Sensor Setup - Continued 56

Non-Standard Product Sensor Setup - Continued 58

Label Product Sensor Advanced Calibration 60

Label Product Sensor Advanced Calibration - Continued 62

Label Product Sensor Advanced Calibration - Continued 64

Label Product Sensor Advanced Calibration - Continued 66

Ready-to-Run Checklist 70

Notes 71

Maintenance 72

Preventative Maintenance 72

Daily 72

Weekly 72

Semi-Annually 72

Annually 72

Maintenance Log 73

Control Box External Connections 74

Control Box Intercommunication Wiring 75

Product Dimensions 76

MFT 102hsm 76

MFT 103hsm 76

Spare Parts 77

Terms and Conditions 78

Page 6

TerminologySafetyIntroduction

Maintenance

Terms/ConditionsSetup

Introduction

Below is a description of the sections contained in the manual. You may also navigate to a specic

section in the electronic version of this manual by clicking on one of the section tabs above.

Safety - The Safety section outlines the general safety precautions you should use when operating

your MFT equipment.

Terminology - The Terminology section describes the main components of your MFT equipment and

introduces you to terminology used later in the manual.

Setup - The Setup section provides instructions for basis setup the MFT equipment.

Maintenance - The Maintenance section describes the basic maintenance necessary to ensure

optimal performance of your MFT equipment.

Terms and Conditions - Multifeeder Standard Terms and Conditions.

Icon Definitions

Caution - This icon is used to alert you to very important safety instructions.

Tip - This icon is used to alert you to helpful information or operational tips.

Important - This icon is used to alert you to important information.

[ 6 ]

Page 7

TerminologySafetyIntroduction

Maintenance

Terms/ConditionsSetup

Congratulations on the purchase of your new equipment from Multifeeder Technology, Inc. This

document is designed to provide you with the information about the basic set operation of the MFT

equipment.

This manual may not illustrate optional equipment purchased with your unit or units. Multifeeder

Technology (MFT) designed this equipment to be used by operators with basic knowledge of machine

functions. In order for your MFT equipment to operate as intended, the equipment must be properly

installed and basic maintenance must be performed at regular intervals. Compromised performance

and unsafe operation may result from unauthorized modication. Unauthorized modications of any

kind will void the product warranty and are strongly discouraged. This equipment requires operation by

properly trained personnel in accordance with all the applicable, operation and maintenance manuals

using approved product and procedures.

Technical phone support is available by calling (651) 407-3100 Monday - Friday, 8 am to 5 PM (CST).

Please have direct access to your MFT system when you call.

[ 7 ]

Page 8

Viewing Electronic Manual

TerminologySafetyIntroduction

Maintenance

Terms/ConditionsSetup

As viewed on a typical monitor.

When viewing this manual electronically. It is best viewed with Adobe Reader® version 9.0 or later.

Adobe Reader® version 9.0 version allows the for full display and inter activity features of this manual.

Furthermore, set the display settings to view to “Two-Up” and “Show Cover Page During Two-Up”.

That ensure the manual will be displayed as intended.

[ 8 ]

Page 9

11

1 Base Feeder

2 Base Feeder Pressure Roller

3 Tipping Feeder

4 Tipping Feeder Pressure Roller

5 Shingling Conveyor

6 Height Adjustable Stand

7 Glue System Tank

8

9

10 Glue System Control Box

11

12 Shingling Conveyor Control Box

Terms/ConditionsSetup

Maintenance

SafetyIntroduction Terminology

Viewing Printed Manual

TerminologySafetyIntroduction

Maintenance

Terms/ConditionsSetup

Terminology

System Overview

6 7

SafetyIntroduction Terminology

2 31 4 5

119 10 12

8

10

Maintenance

Terms/ConditionsSetup

When printing this manual, print in color and two sided. This allows the printed pages to be placed into

a three ring binder as illustrated above with the graphics on the left and the denitions on the right.

Illustration Page Denition Page

[ 9 ]

Page 10

TerminologyIntroduction Safety

Maintenance

Terms/ConditionsSetup

Safety

Personal Safety Warnings

All equipment from Multifeeder Technology is designed with safety in mind. However, in

order to ensure your safety and the safety of others around you, common sense must

always be used when using this machine. Please read the all of the manuals provided

carefully before operating any of your MFT equipment.

• Do not install or use your MFT equipment without rst reading each of the individual

component manuals completely prior to operation.

• Use proper lifting techniques when removing MFT equipment and associated components

from the shipping box.

• Always power down equipment before making any adjustment or clearing jams.

• Never use a knife or sharp instrument to make an adjustment to the MFT equipment, or to

clean or clear jams on the MFT equipment.

• The MFT equipment may be unplugged in an emergency.

• Be aware that air cylinder (if equipped) may actuate during power up and power down

sequences.

• Be aware the MFT could cycle unexpectedly if the MFT equipment is not placed into a safe

mode.

• Make sure loose jewelry, clothing, long hair, neckties, etc., are properly secured before you

operate the MFT equipment.

• Always power down the MFT equipment and disconnect the power cord before working with

any of the MFT equipment’s electrical components or when performing maintenance tasks.

• This machine operates on mains voltage. Contact with this voltage may lead to serious injury,

or death.

• Do not use the MFT equipment, make mechanical adjustments, or perform maintenance

tasks while under the inuence of drugs or alcohol.

[

10

]

Page 11

Terms/ConditionsSetup

Machine Precautions

All equipment from Multifeeder Technology is designed with safety in mind. However, in

order to ensure your safety and the safety of others around you, common sense must

always be used when using this machine. Please read this section of the manual carefully

before operating your MFT equipment.

TerminologyIntroduction Safety

Maintenance

• Do not install or use your MFT equipment without rst reading each of the individual

component manuals completely prior to operation.

• Always power down the MFT equipment and disconnect the power cord before working with

any of the MFT equipment’s electrical components or when performing maintenance tasks.

• Use proper lifting techniques when removing MFT equipment and related components from

the shipping box.

• Make sure the MFT equipment is securely mounted before enabling the motor. The machine

may also be unplugged in an emergency.

• Use only fuses of the correct type, voltage, and current ratings. (5 x 20mm, 10A, 250V).

• Do not stack items on the machine even when it is not in use.

• Always power down equipment before making any adjustment or clearing jams.

• Perform regular maintenance on your MFT equipment. Failure to do so may result in

damage to the machine or machine operators.

• Maintenance tasks should be performed according to the methods described in this manual

by properly trained personnel.

• This system is intended to operate within the following environmental range: Temperature

10-35˚C (50-95˚F), the recommended relative humidity range of 30% to 60% with 80%

maximum, non-condensing.

• This machine should be operated in a well lit area.

• This machine should not be operated around loose cords.

• This machine should not be operated around loose tools or objects such as screw drivers,

pliers, paper clips, or anything that may accidentally interfere with normal operation.

[

11

]

Page 12

Hazard Warnings

TerminologyIntroduction Safety

Maintenance

Terms/ConditionsSetup

Read and understand the entire manual

before operating the equipment.

Use common sense when operating the

equipment.

Do not operate the equipment while

distracted.

This equipment is intended to be

operated by trained and qualified

personnel.

Make sure loose jewelry, clothing, long

hair, neckties, etc., are properly secured

before you operate the MFT equipment.

This machine operates on mains

voltage. Contact with this voltage may

lead to serious injury, or death.

[

]

12

Page 13

TerminologyIntroduction Safety

Maintenance

Terms/ConditionsSetup

Hazard Warnings - Cutout

Print this page separately to cutout the hazard warning illustrations and afx it to the equipment as required.

[

13

]

Page 14

SafetyIntroduction Terminology

Terminology

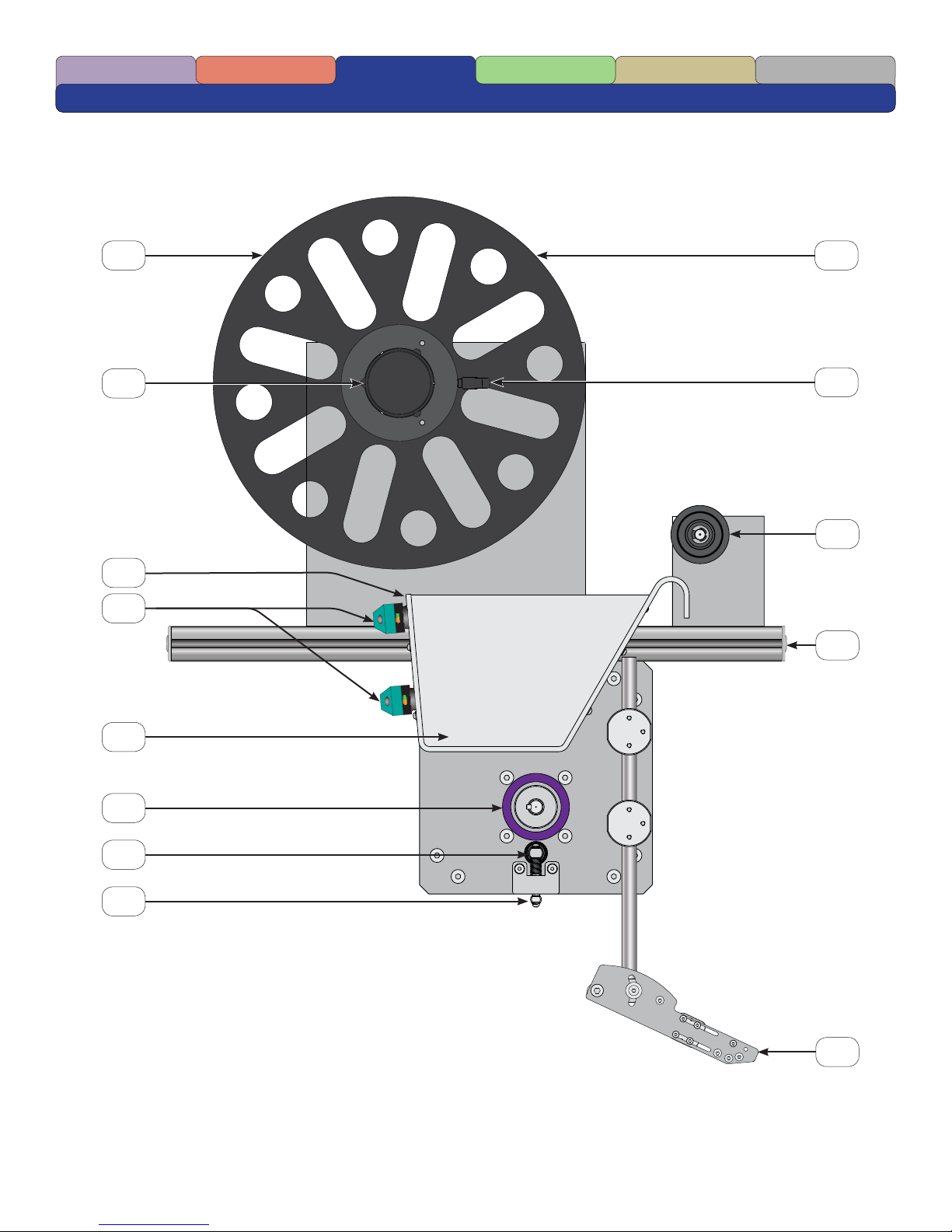

Main Body and Power Unwind

1 9

Maintenance

Terms/ConditionsSetup

2

3

4

5

6

10

11

12

7

8

[

14

13

]

Page 15

SafetyIntroduction Terminology

Maintenance

1 Power Unwind Media Back Plate

2 Power Unwind Hub

3 Power Unwind Media Sensor Box

4 Power Unwind Media Sensor

5 Power Unwind Media Sensor Box Label Width Adjustment Plate

6 Main Drive Roller

7 Main Drive Pinch Roller

8 Main Drive Pinch Roller Pull Down Bar

Terms/ConditionsSetup

9 Power Unwind Media Front Plate

10 Power Unwind Media Front Plate Locking Lever

11 Media Guide Roller

12 Main Mounting Bar

13 Peel Plate Assembly

[

15

]

Page 16

SafetyIntroduction Terminology

Rewind Assembly Options

Vacuum Take Up Rewind

1

Maintenance

Terms/ConditionsSetup

2

3

Power Take Up Rewind

1

4

5

6

4

7

2

3

[

16

5

8

6

]

Page 17

SafetyIntroduction Terminology

Maintenance

Terms/ConditionsSetup

Vacuum Take Up Rewind Power Take Up Rewind

1 Vacuum Take Up Mount 1 Power Take Up Rewind Hub Back Plate

2 Vacuum Take Up Device 2 Power Take Up Rewind Hub

3 Vacuum Take Up Device Pipe 3 Power Take Up Rewind Dancer Arm

4 Vacuum Take Up Device Mounting Bracket 4 Power Take Up Rewind Main Housing

5 Vacuum Take Up Device Entry Cap 5 Power Take Up Rewind Upper Idler Roller

6 Vacuum Take Up Device Entrance 6 Power Take Up Rewind Lower Idler Roller

7 Upper Rewind Dancer Arm Sensor

(Shown behind dancer arm cutaway)

8 Lower Rewind Dancer Arm Sensor

Vacuum Take Up Rewind Configuration Power Take Up Rewind Configuration

[

17

]

Page 18

Peel Plate Assembly

1

2

SafetyIntroduction Terminology

Maintenance

Terms/ConditionsSetup

3

4

5

6

Typical Media

7

8

1

2 3 4

[

18

]

Page 19

SafetyIntroduction Terminology

Peel Plate Assembly

1 Peel Plate Mounting Rods

2 Peel Plate Media Guide Roller with Adjustable Guide Rings

3 Product (Label) Sensor Pair Mounting Rod

4 Upper Product (Label) Sensor

5 Lower Product (Label) Sensor

6 Product (Label) Sensor Pair Mounting Rod Adjustment Slot

7 Peel Plate

Maintenance

Terms/ConditionsSetup

8 Peel Edge

Typical Media

1 Media

2 Liner

3 Label

4 Gap

[

19

]

Page 20

SafetyIntroduction Terminology

Labeler Control Box - Exterior

2

1

Maintenance

RESET

Terms/ConditionsSetup

3

4

2

[

20

5

]

Page 21

SafetyIntroduction Terminology

Maintenance

Terms/ConditionsSetup

1 Mounting Tabs - Used to mount the Control Box to the production line.

2 Motor Connection - Connects the Control Box to the labeler motors.

3 Primary Keypad - Allows operator to access and adjust labeler settings.

4 System Reset Button - Allows the operator to reset the labelers interlock system.

5 Cover Cam Latch - Used to latch the cover closed.

[

21

]

Page 22

SafetyIntroduction Terminology

Labeler Control Box - Interior

1

Maintenance

RESET

Terms/ConditionsSetup

2

3

[

22

]

Page 23

SafetyIntroduction Terminology

Maintenance

Terms/ConditionsSetup

The interior of the control box houses all of the electronics required to operate the labeler.

Labeling systems with a vacuum take-away will contain 2 servo-drive controllers while a system

with a powered rewind will contain 3 servo-drive controllers. See page 15 for conguration examples.

1 Primary Keypad - Allows operator to access and adjust the labeler’s main drive settings.

2 Powered Unwind Keypad - Allows operator to access and adjust the labeler’s powered unwind

settings.

3 Powered Rewind Keypad - Allows operator to access and adjust the labeler’s powered rewind

settings.

[

23

]

Page 24

Keypad Detailed

SafetyIntroduction Terminology

14

Maintenance

Terms/ConditionsSetup

1

2

4 1186 7

3 105 12

9

13

[

24

]

Page 25

SafetyIntroduction Terminology

Maintenance

Terms/ConditionsSetup

1 On/Off Key - Used before/after turning on the Main On/Off Switch.

2 Auto On/Off Key - Used to enable or disable the automatic application cycle startup.

3 Menu Key - Used to enter and navigate the menu system.

4 Numeric Keys - Used to enter values in various menu settings.

5 Enter Key - Used to enter value changes in various menu settings.

6 Clear/Cancel Key - Used to clear or cancel values entered in various menu settings and stop

certain function of the feeder.

7 Stop Motor Key - Used to stop or de-energies the drive motor.

8 Change Speed Key - Used to change the dispense speed.

9 Set Product Thickness- Used during media setup.

10 Cycle Start Key - Used to start the application cycle.

11 Jog To Clear Key - Used to feed the label to the end of the peel plate.

12 Jog Key - Used to jog or feed the media or label . The drive continuously feed while this key is

pressed.

13 Display - Used to display functions and menu setting.

14 Function Keys - Used to display certain functions and menu settings.

[

25

]

Page 26

SafetyIntroduction Terminology Setup

Setup

Sequence of Operation

Maintenance

Terms/Conditions

4

3

2

1

[

26

]

Page 27

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

1 The Labeler receives a signal to begin the application cycle.

2 The Main Drive Roller engages and moves the label until the Product (Label) Sensor is triggered

by the gap.

3 The Power Unwind Media Sensor is triggered as the media is used up and triggers the Power

Unwind to supply additional media into the Power Unwind Media Box.

4 The Rewind Dancer Arm Sensor on the Power Rewind is triggered and takes up the slack in the

liner as it develops during the application.

[

27

]

Page 28

J3-Low Product

J4-RS 232

Remote Keypad

SafetyIntroduction Terminology Setup

Labeler Control Box Power Up

Action Displayed

Maintenance

Terms/Conditions

1

2

=

=

STATUS: OFF

PRESS ON TO ENABLE EQUIPMENT

MODE: XXXXXXXXX MODE

F1 - TECHNICIAN F2 - FACTORY

MODE: ADVANCED TIPPING MODE AUTO OFF

STATUS: READY PRODUCT COUNT 1

PROGRAM NUMBER 1

[

28

]

Page 29

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

Be curtain that you have read and understand ALL of the Safety Section before powering

up or setting up any Multifeeder Equipment.

1 Turn on the main Power Switch and wait until you see illustrated screen is displayed.

2 Press the On Key to complete the Power On Sequence.

[

29

]

Page 30

SafetyIntroduction Terminology Setup

Labeler Thread Pattern

General Labeler Thread Pattern

Maintenance

Terms/Conditions

1

3

6

2

4

5

[

30

]

Page 31

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

1 Place the roll of labels onto the Power Unwind Hub such that the label exits the top of the roll in

the direction of the Peel Plate.

2 Form a loop within the Power Unwind Media Sensor Box.

3 Thread the media around the Media Guide Roller.

4 Thread the media around the Peel Plate Media Guide Roller and between the Upper and Lower

Product (Label) Sensor Pair.

5 Thread the media over the Peel Plate and around the Peel Edge removing any labels from the

liner after the Peel Edge as illustrated by the dashed line.

6 Thread the liner under the Main Drive Pinch Roller and then between the Main Drive Pinch Roller

and the Main Drive Roller Using the Main Drive Pinch Roller Pull Down Bar. Continue threading

the liner around the Main Drive Roller and to the rewind device. Note: Alternative thread pattern is

available if required.

Common Thread Pattern Alternative Thread Pattern

[

31

]

Page 32

SafetyIntroduction Terminology Setup

Power Unwind Media Sensor Box

1

Maintenance

Terms/Conditions

2

[

32

]

Page 33

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

1 Verify the Power Unwind Media Sensor is properly positioned to trigger with the media being

applied.

2 Use the 4 screws to adjust the Power Unwind Media Sensor Box Label Width Adjustment Plate to

control the side-to-side movement of the media.

[

33

]

Page 34

SafetyIntroduction Terminology Setup

With Power Unwind and Vacuum Take Up

Maintenance

1

Terms/Conditions

7

3

2

6

[

34

4

5

]

Page 35

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

1 Place the roll of labels onto the Power Unwind Hub such that the label exits the top of the roll in

the direction of the Peel Plate.

2 Form a loop within the Power Unwind Media Sensor Box.

3 Thread the media around the Media Guide Roller.

4 Thread the media around the Peel Plate Media Guide Roller and between the Upper Product

(Label) Sensor Pair.

5 Thread the media over the Peel Plate and around the Peel Edge removing any labels from the

liner after the Peel Edge as illustrated by the dashed line.

6 Thread the liner under the Main Drive Pinch Roller and then between the Main Drive Pinch Roller

and the Main Drive Roller Using the Main Drive Pinch Roller Pull Down Bar. Continue threading

the liner around the Main Drive Roller and to the rewind device.

7 Place a length of liner material into the Vacuum Take Up Device Entrance. The length will vary

depending on the characteristics of the Liner.

Common Thread Pattern Alternative Thread Pattern

[

35

]

Page 36

SafetyIntroduction Terminology Setup

With Power Unwind and Power Take Up

Maintenance

1

Terms/Conditions

10

3

2

9

6

8

7

[

36

4

5

]

Page 37

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

1 Place the roll of labels onto the Power Unwind Hub such that the label exits the top of the roll in

the direction of the Peel Plate.

2 Form a loop within the Power Unwind Media Sensor Box.

3 Thread the media around the Media Guide Roller.

4 Thread the media around the Peel Plate Media Guide Roller and between the Upper Product

(Label) Sensor Pair.

5 Thread the media over the Peel Plate and around the Peel Edge removing any labels from the

liner after the Peel Edge as illustrated by the dashed line.

6 Thread the liner under the Main Drive Pinch Roller and then between the Main Drive Pinch Roller

and the Main Drive Roller Using the Main Drive Pinch Roller Pull Down Bar. Continue threading

the liner around the Main Drive Roller and to the rewind device.

7 Thread the liner underneath the Power Take Up Rewind Lower Idler Roller.

8 Thread the label around the Power Take Up Rewind Dancer Arm.

9 Thread the label around the Power Take Up Rewind Upper Idler Roller.

10 Wrap the liner several times around Power Take Up Rewind Hub.

Common Thread Pattern Alternative Thread Pattern

[

37

]

Page 38

SafetyIntroduction Terminology Setup

Standard Product Sensor Setup

1

Maintenance

Terms/Conditions

2

Sensor Safe Area

[

38

]

Page 39

.

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

In normal operation, the label product sensor can be setup by positioning the last 5 mm of the trailing

SET PROD

edge of the label below the product sensor and then pressing the

key. If however, the labeler

THICKNESS

product sensor has been moved and becomes seriously out of adjustment, the following setup

instructions will restore the labeler product sensor to normal operation:

1 When required use an 1.5mm allen wrench to align the emitter and receiver as illustrated.

2 Position the labeler product sensor within the safe sensor area that is 5mm from any edge of the

label.

Continue on the next page.

[

39

]

Page 40

SafetyIntroduction Terminology Setup

Standard Product Sensor Setup - Continued

Action Displayed

Maintenance

Terms/Conditions

2

3

=

=

MAIN 1/2 : MENU KEY FOR NEXT

1. SETTINGS 4. REPORTS

2. PROGRAMS 5. IDENTIFICATION

3. SETUP 6. DIAGNOSTICS

SYSTEM DIAGNOSTICS 1/4 : MENU FOR NEXT

1.STACK LIGHT 4.PSTART/LOW-P INPUT

2.PRODUCT SENSOR 5.LOW PRODUCT OUTPUT

3.LINE SPEED ENC 6.AUTO ON OUTPUT

[

40

]

Page 41

MENU

6

SafetyIntroduction Terminology Setup

Continue from previous page.

3

From the READY screen on the controller, press the

4

Press the

key to select DIAGNOSTICS.

Continue on the next page.

key.

Maintenance

Terms/Conditions

[

41

]

Page 42

SafetyIntroduction Terminology Setup

Standard Product Sensor Setup - Continued

Action Displayed

Maintenance

Terms/Conditions

4

6

=

SYSTEM DIAGNOSTICS ITEM 2 OF 24

PRODUCT SENSOR

1-4 SELECTED(0):1=XXX,2=XXX,3=XXX,4=XXX

5

7

=

8

MODE: ADVANCED TIPPING LABELER

STATUS : READY PRODUCT COUNT 1

PROGRAM NUMBER

=

CHECKING PRODUCT THICKNESS

PLEASE WAIT...

[

]

42

Page 43

2

.

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

Continued from previous page.

4

Press the

key to select PRODUCT SENSOR.

5 Sensor drive #3 should ideally be between 90-110.

6 If the labeler has not been feeding correctly and sensor drive #3 is not between these values you

should loosen the top half of the product sensor and move it until the values fall between 90-110.

When the numbers are in range tighten the top half of the sensor drive to lock it in place.

CLEAR

7

Press the

CANCEL

key until you return to the READY screen.

8

Press the

your settings.

SET PROD

key. The labeler product sensor is now ready. It is recommended that you save

THICKNESS

Note - For alternate or non-standard sensor setup go to page 50.

[

43

]

Page 44

Label Stop Position

1

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

2

3

Label Stop Position

Action Displayed

MAIN 1/2 : MENU KEY FOR NEXT

1. SETTINGS 4. REPORTS

=

=

2. PROGRAMS 5. IDENTIFICATION

3. SETUP 6. DIAGNOSTICS

PRODUCT LENGTH (M-F3), DEFAULT: 210

RANGE: 5-1500 mm

CURRENT: 150 NEW: 150

[

44

]

Page 45

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

The Label Stop Position is where the label stops with respect to the Peel Edge after an application

cycle. However certain applications may require adjusting the Label Stop Position. Follow the

instructions below to adjust the Label Stop Position as required.

1 The Stop Position is the where the label stops after the completion of an application cycle.

2

From the READY screen on the controller, press the

3

Press the key to select SETTINGS.

Continue on the next page.

Note - Follow the rules below to ensure proper label feeding when adjusting the Label Stop

Position.

MENU

key.

• Never use a minimum product length longer than the length of the label.

• Never use a minimum product length that makes the label stop past the sensor. If this happens,

then instead move the sensor down-stream so the product stops under the sensor.

• This distance and location are dependent on:

• Length of label

• Speed of labeler

• Deceleration value for motor

• Desired stop position of the label on peel plate

[

45

]

Page 46

SafetyIntroduction Terminology Setup

Label Stop Position - Continued

Action Displayed

Maintenance

Terms/Conditions

4

10X

5

6

=

=

MIN PRODUCT LENGTH (M-F3), DEFAULT: 0

RANGE: 0-1000 mm

CURRENT: 0 NEW: 0

MODE: ADVANCED TIPPING LABELER

STATUS : READY PRODUCT COUNT 1

PROGRAM NUMBER

[

46

]

Page 47

MENU

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

Continued from previous page.

4

Press the

key 10 times to navigate to the Minimum Product Length screen and enter the new

value.

CLEAR

5

Press the

CANCEL

key until you return to the READY screen.

6 Some applications may require the repositioning of the Product (Label) Sensors. Do this by

loosening the bolts on the Product (Label) Sensor Pair Mounting Rod and repositioning as

required.

[

47

]

Page 48

SafetyIntroduction Terminology Setup

Labeler Speed Adjustment

Action Displayed

Maintenance

Terms/Conditions

1

2

3

4

=

=

MACHINE SPEED (M-F30, DEFAULT: 50

RANGE: 1-140 MPM

CURRENT: 50 NEW: 50

+

NEW VALUE OF 92

SUCCESSFULLY STORED

MODE: ADVANCED TIPPING LABELER

STATUS : READY PRODUCT COUNT 1

=

PROGRAM NUMBER

[

48

]

Page 49

SafetyIntroduction Terminology Setup

Maintenance

1 Press the Change Speed Key.

2 Enter the desired Machine Speed value by using the Number Keys.

3 Press the Enter Key. The screen will briey display:

Terms/Conditions

NEW VALUE OF

[

the entered value

]

SUCCESSFULLY STORED

After three (3) seconds the screen will return to the Machine Speed setting screen.

CLEAR

4

Press the

CANCEL

key until you return to the READY screen.

If you keyed an incorrect value, press the Clear Cancel Key to re-enter the value.

[

49

]

Page 50

SafetyIntroduction Terminology Setup

=

Labeler Basic Menu - Settings Menu

Action Displayed

Maintenance

Terms/Conditions

1

2

3

=

=

=

MAIN 1/2 : MENU KEY FOR NEXT

1. SETTINGS 4. REPORTS

2. PROGRAMS 5. IDENTIFICATION

3. SETUP 6. DIAGNOSTICS

PRODUCT LENGTH (M-F3), DEFAULT: 210

RANGE: 5-1500 mm

CURRENT: 210 NEW: 210

MAX JOG SPEED (S), DEFAULT: 20

RANGE: 1-100

CURRENT: 20 NEW: 20

4

=

5

SIGNAL DELAY (M-F3), DEFAULT: 0

RANGE: 0-30000

CURRENT: 0 NEW: 0

SIGNAL PERIOD (M-F3), DEFAULT: 0

RANGE: 0-10000

CURRENT: 0 NEW: 0

[

50

]

Page 51

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

Basic menu setting allow the operator control over common adjustments required for basic setup.

More advanced menu settings are available through the password protected Technicians Menu. Press

the key from the ready screen to access the operator available settings illustrated on the previous

page.

1

Press the key from the ready screen to access the sub-menu.

2

Press the key from the sub-menu to access the settings screen and the Product Length

setting. This setting allows the operator to adjust the Product (Label) Length the labeler looks for

when feeding a label.

3

Press the from the previous screen to enter the Max Jog Speed setting. This setting

allows the operator to adjust the speed the labeler jogs a label when the key or the is

pressed.

4

Press the from the previous screen to enter the Signal Delay setting. This setting allows the

operator to adjust when the labeler begins applying the label. In effect the position of the label on

the product it is applied to.

5

Press the from the previous screen to enter the Signal Period setting. This setting allows

the operator to adjust how many start signal are ignored before triggering an application cycle.

For example, with the value set to 0, no start signals are ignored and every start signal triggers

an application cycle by the labeler. With a value of 21, 21 start signals are require to trigger an

application cycle.

Continue on the next page.

[

51

]

Page 52

SafetyIntroduction Terminology Setup

Labeler Basic Menu - Settings Menu (continued)

Action Displayed

Maintenance

Terms/Conditions

6

7

=

=

NO PRODUCT LIMIT (M-F3), DEFAULT: 240

RANGE: 15-255

CURRENT: 240 NEW: 240

PRODUCT SEPARATION(0.1 mm units) (M-F3)

RANGE: 1-1000, DEFAULT: 5

CURRENT: 5 NEW: 5

[

52

]

Page 53

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

Continued from previous page.

6

Press the from the previous screen to enter the No Product Limit setting. This setting allows

the operator to adjust the value the Product (Label) Sensor uses to determine when a label gap is

detected. See page 58.

7

Press the from the previous screen to enter the Product Separation setting. This setting

allows the operator to adjust the Label Gap settings for non-standard labels.

Continue on the next page.

[

53

]

Page 54

SafetyIntroduction Terminology Setup

Non-Standard Product Sensor Setup

1

Maintenance

Terms/Conditions

2

3

J3

Action Displayed

MAIN 1/2 : MENU KEY FOR NEXT

1. SETTINGS 4. REPORTS

=

=

2. PROGRAMS 5. IDENTIFICATION

3. SETUP 6. DIAGNOSTICS

MAIN 2/2 : MENU KEY FOR NEXT

1. DEMO MODE 4. LANGUAGE

2. TECHNICIAN

3. FACTORY

[

54

]

Page 55

MENU

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

The Multifeeder Technology high speed labeling system allows the use of non standard product or

label sensors to meet specic application requirements. Follow the instructions below to connect

and enable the non standard product or label sensor. Follow the instructions specic to the sensor to

ensure the sensor function properly in your application.

1 Connect the non Standard Sensor to J3.

2 Navigate to the Advanced Sensor settings. From the READY screen on the controller, press the

key.

3

Press the to navigate to the Main 2/2 screen.

Continue on the next page.

[

55

]

Page 56

SafetyIntroduction Terminology Setup

Non-Standard Product Sensor Setup - Continued

Action Displayed

4

ENTERING TECHNICIAN SETTINGS MENU

Maintenance

Terms/Conditions

5

Enter

[ ]

Password

6

7

=

=

=

TYPE PASSWORD TO CONTINUE [ ]

TECHNICIAN 1/4 : MENU KEY FOR NEXT

1. MOTOR 4. ADVANCED SETTINGS

2. FEEDING 5. DIGITAL I/O

3. DEBOUNCE 6. WIZARDS

DIGITAL I/O 1/4 : MENU KEY FOR NEXT

1. STANDARD I/O SIGNALS

2. DUPLICATE SIGNALS

3. PRODUCT SENSOR

NO PRODUCT LIMIT (M-F3), DEFAULT: 240

RANGE: 15-255

=

8

=

CURRENT: 240 NEW: 240

ADVANCED PRODUCT SENSOR (S), DEFAULT: 0

RANGE: 0=OFF, 1-9=PORT

CURRENT: 0 NEW: 0

3X

[

56

]

Page 57

SafetyIntroduction Terminology Setup

Maintenance

Continued from previous page.

4 Enter the Technician Level password. (See Note)

5 Entering the Technician Level password displays the Technician 1/4 screen.

6

Press the key to navigate to the Digital I/O screen.

7

Press the key to enter the Product Sensor menu options.

Terms/Conditions

8

Press the

MENU

key 3 times to navigate to the Advanced Product Sensor setting.

Note - The password is disclosed during the install and training or available by contacting the

Multifeeder Technology service department at (651) 407-3100 during normal business hours in

the central time zone.

[

57

]

Page 58

SafetyIntroduction Terminology Setup

Non-Standard Product Sensor Setup - Continued

Action Displayed

Maintenance

Terms/Conditions

9

10

=

=

ADVANCED PRODUCT SENSOR (S), DEFAULT: 0

RANGE: 0=OFF, 1-9=PORT

CURRENT: 9 NEW: 9

MODE: ADVANCED TIPPING LABELER

STATUS : READY PRODUCT COUNT 1

PROGRAM NUMBER

[

58

]

Page 59

SafetyIntroduction Terminology Setup

Maintenance

Continued from previous page.

9

Press the key to set J3 as the input port for the non standard product sensor.

CLEAR

10

Press the

CANCEL

key until you return to the READY screen.

Terms/Conditions

[

59

]

Page 60

SafetyIntroduction Terminology Setup

Label Product Sensor Advanced Calibration

Maintenance

Terms/Conditions

1

2

Labels and Sensor

Side View

Sensor Prole

1

3

4

2

6

255

7

5

[

60

0

]

Page 61

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

The label or product sensor is calibrated at the factory and will function without adjustment for the

majority of applications. However certain applications may require adjusting sensor parameters to

achieve maximum performance. Follow the instructions below to calibrate the sensor as required.

1 This illustration shows the sensor, label and liner relationship as viewed from the side. The sensor

components consist of an upper emitter 1 and a lower receiver 2. The sensor is calibrated to

detect the gap or space 3 between labels on the liner 4.

2 This illustration shows the sensor prole. The sensor prole is a graphic representation of what

the sensor “sees” as the media passes through it. The wavy line 5 is the sensor value when

the sensor is seeing the label and liner and the spike 6 is the sensor value when the label sees

the label gap or liner only. The graph 7 represents numerical values of what the sensor might

see. The values range from 0 to 255. Where 0 is a completely opaque material and 255 is a

completely transparent material.

A software algorithm is used to determine the actual value required to indicate wether the sensor is

seeing a label or gap. In some applications this value may need to be adjusted manually. Follow the

instructions on the following pages to determine and set the Sensor No Product Value.

Continue on the next page.

[

61

]

Page 62

SafetyIntroduction Terminology Setup

Label Product Sensor Advanced Calibration - Continued

3

Maintenance

Terms/Conditions

Action Displayed

4

=

5

=

MAIN 1/2 : MENU KEY FOR NEXT

1. SETTINGS 4. REPORTS

2. PROGRAMS 5. IDENTIFICATION

3. SETUP 6. DIAGNOSTICS

SYSTEM DIAGNOSTICS 1/4 : MENU FOR NEXT

1.STACK LIGHT 4.PSTART/LOW-P INPUT

2.PRODUCT SENSOR 5.LOW PRODUCT OUTPUT

3.LINE SPEED ENC 6.AUTO ON OUTPUT

[

62

]

Page 63

6

SafetyIntroduction Terminology Setup

Continued from previous page.

3 Remove any labels from the liner as illustrated.

Maintenance

Terms/Conditions

4

From the READY screen on the controller, press the

5

Press the

key to select DIAGNOSTICS.

Continue on the next page.

MENU

key.

[

63

]

Page 64

SafetyIntroduction Terminology Setup

Label Product Sensor Advanced Calibration - Continued

Action Displayed

Maintenance

Terms/Conditions

6

=

Value=(255–(Drive 3 Value))x(.25)+(Drive 3 Value)

8

SYSTEM DIAGNOSTICS ITEM 2 OF 24

PRODUCT SENSOR

1-4 SELECTED(0):1=255,2=255,3=102,4=36

7

Example:

9

=

MODE: ADVANCED TIPPING LABELER

STATUS : READY PRODUCT COUNT 1

PROGRAM NUMBER

[

64

]

Page 65

2

SafetyIntroduction Terminology Setup

Maintenance

Continued from previous page.

6

Press the

key to select PRODUCT SENSOR.

7 Note the value of #3, referred to as “Drive 3”. In this example a value of 102.

8 Enter the value into the No Product Sensor Value formula as illustrated.

CLEAR

9

Press the

CANCEL

key until you return to the READY screen.

Continue on the next page.

Terms/Conditions

[

65

]

Page 66

SafetyIntroduction Terminology Setup

Label Product Sensor Advanced Calibration - Continued

Action Displayed

Maintenance

Terms/Conditions

10

11

12

=

=

=

MAIN 1/2 : MENU KEY FOR NEXT

1. SETTINGS 4. REPORTS

2. PROGRAMS 5. IDENTIFICATION

3. SETUP 6. DIAGNOSTICS

MAIN 2/2 : MENU KEY FOR NEXT

1. DEMO MODE 4. LANGUAGE

2. TECHNICIAN

3. FACTORY

ENTERING TECHNICIAN SETTINGS MENU

TYPE PASSWORD TO CONTINUE [ ]

13

Enter

[ ]

Password

14

=

=

TECHNICIAN 1/4 : MENU KEY FOR NEXT

1. MOTOR 4. ADVANCED SETTINGS

2. FEEDING 5. DIGITAL I/O

3. DEBOUNCE 6. WIZARDS

DIGITAL I/O 1/4 : MENU KEY FOR NEXT

1. STANDARD I/O SIGNALS

2. DUPLICATE SIGNALS

3. PRODUCT SENSOR

[

66

]

Page 67

MENU

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

Continued from previous page.

The following instructions guide you through navigating and entering the No Product Sensor

Value determined from the previous page.

10

From the READY screen on the controller, press the

11

Press the key to navigate to the Main 2/2 screen.

12

Enter the Technician Level password. (See Note) Press the key.

key.

13 Entering the Technician Level password displays the Technician 1/4 screen.

14

Press the key to navigate to the Digital I/O screen.

Continue on the next page.

Note - The password is disclosed during the install and training or available by contacting the

Multifeeder Technology service department at (651) 407-3100 during normal business hours in

the central time zone.

[

67

]

Page 68

SafetyIntroduction Terminology Setup

Action Displayed

Maintenance

Terms/Conditions

15

16

=

=

NO PRODUCT LIMIT (M-F3), DEFAULT: 240

RANGE: 15-255

CURRENT: 240 NEW: 140

MODE: ADVANCED TIPPING LABELER

STATUS : READY PRODUCT COUNT 1

PROGRAM NUMBER

[

68

]

Page 69

SafetyIntroduction Terminology Setup

15 Use the keypad to enter the value calculated from page 60.

CLEAR

16

Press the

CANCEL

key until you return to the READY screen.

Maintenance

Terms/Conditions

[

69

]

Page 70

SafetyIntroduction Terminology Setup

Ready-to-Run Checklist

□ Verify the media is loaded and labels are removed

from the liner after the Peel Plate.

□ Verify the media is properly triggering the Power

Unwind Media Sensor and the Power Unwind Media

Sensor Box Label Width Adjustment Plate is position

properly.

Maintenance

Terms/Conditions

□ Verify the Product (Label) Sensor is properly adjusted

by pressing the several times verifying the label

stops consistently along the Peel Edge.

□ Verify the operation of the rewind. Turn on

the pneumatics for the Vacuum Take Up Rewind

conguration (if required) or set the Control Box to Auto

On for the Powered Take Up conguration.

□ Set the control box to Auto On and press Cycle Start

to activated for the Labeler.

Sensor Safe Area

RESET

[

70

]

Page 71

Notes

SafetyIntroduction Terminology Setup

Maintenance

Terms/Conditions

[

71

]

Page 72

Maintenance

Terms/ConditionsTerminologySafetyIntroduction Setup

Maintenance

Preventative Maintenance

Proper operation of your Multifeeder equipment is dependent on a regularly

preventative maintenance scheduled and inspection program. The generic

scheduled outlined in this section may need to be adjusted to your specific

application and environmental conditions.

Warnings

• Before any maintenance tasks are performed, the power must be disconnected from the Feeder.

• Use only a 50% isopropyl alcohol and water solution unless otherwise noted. Other cleaning

agents may damage the material.

• Isopropyl alcohol is very ammable! Use only in an open area away from any source of ignition,

including open ame or sparks.

• Be certain that the belts are completely dry before operating equipment. Damp belts may slip or

track incorrectly causing injury or damage to the equipment.

• ONLY USE CLEAN DRY AIR IF PNEUMATIC AIR IS REQUIRED FOR YOUR APPLICATION.

Daily

• Clean any debris from the equipment with a clean cloth dampened with the alcohol/water

solution.

• Visually inspect the rollers and guides for damage or unusual wear.

• Visually inspect the machine for loose screws, bolts, and adjustment knobs.

Weekly

• Inspect the photo optic sensors with clean lint free cloth dampened with the alcohol/water

solution if necessary.

• Inspect any belt pulleys for looseness and tighten if necessary. With the power cable

disconnected the pulleys may be rotated manually.

• Remove any adhesive buildup.

Semi-Annually

• Open the side covers and remove any accumulated debris if necessary.

Annually

• Inspect all belts, bearings and timing belts for wear and replace if necessary.

[

72

]

Page 73

Maintenance

Terms/ConditionsTerminologySafetyIntroduction Setup

Maintenance Log

Date Type Comments Initials

10-10-05 Weekly Cleaned glue built up on peel plate idler roller. DM

[

73

]

Page 74

J4 - RS232/Remote Keypad

Control Box External Connections

Maintenance

Terms/ConditionsTerminologySafetyIntroduction Setup

J24 - Motion Stop J22 - Signal Light

J10 - RS485

J7 - Descrete I/O

Lower Unwind Sensor

J24 J22

J23

J10

J7

J6

J25

J6 - Product Sensor

J25 - RS232

Lower Rewind Sensor

Vacuum Rewind

Upper Unwind Sensor

J1 - Start Sensor

Main

Encoder

Main

Motor

Unwind

Encoder

Unwind

Motor

J1 J2

Rewind

Encoder

Rewind

Motor

Upper Rewind Sensor

J2 - APL Interface

J3 - Low Product

Module

[

74

J4

J3

Power Entry

]

Page 75

Control Box Intercommunication Wiring

Upper Sensor Rewind

Lower Sensor Rewind

Maintenance

Upper Sensor Unwind

Lower Sensor Unwind

Terms/ConditionsTerminologySafetyIntroduction Setup

J6

1 2 3

Optional/Non-Standard

4

J3

Label Sensor

1

2

3

4

Standard Label Sensor

Labeler Drive Labeler Unwind

Labeler Rewind

[

75

]

Page 76

Product Dimensions

MFT 102hsm

Maintenance

Terms/ConditionsTerminologySafetyIntroduction Setup

MFT 103hsm

[

76

]

Page 77

Spare Parts

Part # Part Description

4598108 HSL Drive Roller Assembly

7105301 Motor 800W 950 With Plugs

1002600 Bearing 174012

1710109 R-W EKL020B 19x16 Mod

1528200 Sleeve Bearing 081210

4503600 Drive Roller Idler Block

1395301 HSL Drive Traction idler

Maintenance

Terms/ConditionsTerminologySafetyIntroduction Setup

1522400 Roller Sleeve 7/8 16Id

1155900 Timing Belt 15X59

1055600 Timing Pulley 051534 16 Keyed

1055700 Timing Pulley 051534 16 Mod.

1554200 Thrust Washer GTM 1630-015

3003000 5/8 Needle Roller Bearing

1002600 Ball Bearing 174012

For Use with Power Rewind Only

3091801 Compression Spring Lc042G 085

1712100 Spring Retaining

To order spare parts:

Send fax to 651-407-3199 with part numbers and pricing on company P.O, or Call 651-407-3100.

We do require a faxed company P.O. before shipment. Please indicate on P.O. the date you need the

parts delivered. We ship all orders UPS Ground unless specied on your purchase order.

[

77

]

Page 78

TerminologySafetyIntroduction Terms/Conditions

Setup

Maintenance

Terms and Conditions

MULTIFEEDER TECHNOLOGY, INC. (MFT) TERMS AND CONDITIONS

ALL SALES ARE SUBJECT TO THE FOLLOWING TERMS AND CONDITIONS.

1. Definitions.

1.1 “Accessory Products” mean spare parts purchased, at Buyer’s option, to enhance the System or replace components within the

System.

1.2 “Agreement” means this Sale Agreement.

1.3 “Buyer” means the person or entity that enters into this Agreement for the design and for manufacture of the System, subsystem accessory

products, or related services and/or Buyer’s assigns, successor’s agents and transferees.

1.4 “Default Specifications” means the MFT Default Specifications set forth in Exhibit A, attached hereto, which set forth the default functional

and technical performance criteria for the System.

1.5 “Final Product Throughput” means the end-product as fully processed by the MFT System.

1.6 “MFT” means Multifeeder Technology, Inc.

1.7 The “Operation and Maintenance Manual” means the operative and instruction guide supplied by Seller to Buyer, which addresses one or

several of the devices, components or Subsystems within the System.

1.8 “Order” means Buyer’s order in the form of Seller’s Proposal, signed by Buyer and delivered to Seller.

1.9 “Order Acknowledgement Form” means the written form Seller sends to Buyer indicating that Seller is in receipt of Buyer’s

Or der.

1.10 “Parties” means the Buyer and Multifeeder Technology, Inc.

1.11 “Product Samples” mean Buyer-supplied components and/or material to be fed through and/or processed by the System to create a Final

Product Throughput.

1.12 “Product Schedule” means the actions undertaken by MFT to design and build the System over a period of time.

1.13 “Production Schedule Date” means the date upon which production is scheduled for completion.

1.14 “Proposal” means Seller’s written description of the System and/or Accessory Products

1.15 “Quote” means the price quote for the System and/or Accessory Products.

1.16 “Seller” means Multifeeder Technology Inc.

1.17 “Shipment Date” means the estimated date upon which MFT anticipates shipment of the System from the MFT facility.

1.18 “Specifications” means the functional and technical per formance criteria for the System, as agreed-to by the Parties.

1.19 “Subsystem” means any smaller MFT-designed system that constitutes a component of the overall System.

1.20 “System” means the custom-designed product manufactured by Seller according to the Specifications, which may or may not include various

other Subsystems.

[

78

]

Page 79

TerminologySafetyIntroduction Terms/Conditions

1.21 “System Manual” means the operative and instruction guide supplied to Buyer by Seller with the shipment of the System, which addresses the

overall System, and may or may not address each separate device, component or Subsystem within the System

2. The System.

2.1 Purchase and Supply. Seller will sell the System and/or Accessory Products to Buyer under the terms and conditions set forth in this

Agreement.

2.2 Spec ifications . The System will be manu factured by Seller ac cording to the Spe cificatio ns. The Proposal wil l include a Quote for ea ch component

of the System. If the Buyer does not provide specif ications prior to the Quotation process, the Default Specifications will apply. All specif ications

supplied by Buyer are subject to (a) MFT’s written approval and (b) signature by a MFT-authorized representative.

2.3 Pa cking. Unless o therwise s pecified i n this Agreement or B uyer’s Order, the System and /or all Access ory Produc ts are to be packed and i dentified

in accordance with customary industry practice. Seller shall mark each container with necessary lifting, loading and shipping information,

including the applicable purchase order number, date of shipment, and the name and address of Seller and Buyer.

3. Assent to Terms and Conditions of Agreement. Unless otherwise indicated, Seller’s Proposal will expire thirty (30) days following the date the

Proposal is transmitted to Buyer. Seller’s Proposal is not binding upon Seller until Buyer’s Order is accepted in writing by Seller on an Order

Acknowledgement Form. Buyer’s Order must be submitted within the time frames provided herein.

Setup

Maintenance

4. Price, Price Adjustment & Additional Charges.

4.1 Price. The purchase price for the System will be set forth in the Quote. The pricing of Accessory Products is subject to change from time to

time.

4.2 Price Adjustment. The purchase price in the Quote may be increased to reflect increases in the cost of materials or labor, if:

4.2.1 Shipment of the System is scheduled for a date that is more than three (3) months after the date of Buyer’s Order;

4.2.2 Shipment of the System is delayed by Buyer to a date that is more than three (3) months after the date of Buyer’s Order; or

4.2.3 Shipment of the System is accelerated due to an accelerated Production Schedule Date.

4.3 Delivery, Risk of Loss and Title. The System will be delivered f.o.b. Seller’s Minnesota facility. Buyer will pay all packaging, handling and

freight to Buyer’s destination. Risk of loss or damage to the System passes to Buyer at the time of delivery to the carrier. Seller will purchase

shipping insurance at Buyer’s request and at Buyer’s expense. Transfer of title is not deemed to occur until payment in full has been

received by Seller. Shipment dates are Seller’s best estimate of when product(s) will be shipped or delivered, but the Shipment Date is not

guaranteed.

4.4 Ta xes. Buyer will pay all duties and taxes including sales, use, property, excise, value added and gross receipts taxes levied on the System

or Accessory Products. Seller will not collect an otherwise applicable tax if Buyer’s purchase is exempt from Seller’s collection of such tax

and a valid tax exemption certificate is furnished by Buyer to Seller.

4.5 Cancellation of Orders. Following Seller’s acceptance of Buyer’s Order, the Order can be cancelled only with Seller’s written consent. A

minimum cancellation charge of 35% of the purchase price of the System or Accessory Products will be assessed and will var y according to

the date on which the cancellation occurs in the Production Schedule, the quantity of work and materials that are salvageable, the degree to

which the System is custom-designed, and other factors in MFT’s sole discretion.

4.6 Additional Charges. Additional work completed or time consumed by reason of Buyer’s alterations or delays caused by Buyer, will be charged

to Buyer at Seller’s current price for work or material at the time of such alterations, changes, or delays.

[

79

]

Page 80

TerminologySafetyIntroduction Terms/Conditions

5. Payment.

5.1 Payment of Purchase Price. If Seller approves Buyer for credit, the payment schedule is (a) 55% of the purchase price in certified or other

currently available funds within five (5) days following acceptance of Buyer’s Order; (b) no later than ten (10) days before Buyer’s requested

shipment date (i) 35% of the purchase price in certified funds; and (ii) the remaining balance by Buyer’s delivery of an irrevocable letter of

credit or some other MFT-approved payment alternative, drawn on a U.S. bank in an amount equal to the remaining balance due for the benefit

of Seller or Seller’s agent. The letter of credit and/or its equivalent must be drawn on a financial institution and in form reasonably acceptable

to Seller, must be in U.S. dollars, and will expire no earlier than 60 days after the requested shipment date. Under no circumstances will

Seller be liable to Buyer for delays in shipment caused by Buyer’s delay in payment. If Seller does not approve Buyer for credit, payment will

be disbursed to Seller within five (5) days following acceptance of Buyer’s Order by certified or other currently available funds or by Buyer’s

delivery of an irrevocable letter of credit or some other MFT-approved payment alternative, drawn on a U.S. bank in an amount equal to the

full amount of the purchase price. The letter of credit and/or its equivalent shall provide for interim draws in accordance with the schedule

referenced in the preceding paragraph, be drawn on a financial institution and in form reasonably acceptable to Seller, in U.S. dollars, and will

expire no earlier than 60 days after the requested shipment date. Buyer authorizes Seller to review any and all necessary credit reports and

information to assess whether Seller will extend credit to Buyer.

5.2 Invoicing for Ongoing Services and/or Accessory Products. Seller will invoice Buyer for any ongoing services or Accessory Products

purchased separately from Buyer’s Order for the System. Invoices will reference purchase order number, item number and description of

product(s) and/or service(s), unit price of products and/or service(s), total amounts due, and the due date. Invoices shall be due and payable

within thirty (30) days after the date of invoice. Payments will be applied to oldest invoices first. Overdue invoices will accrue interest at a rate

equal to the lesser of 18% per annum or the maximum rate allowable by law.

Setup

Maintenance

5.3 Non-payment of Amounts Due. Seller hereby retains a security interest in the System or Accessory Products for any portion of the purchase

price thereof unpaid by Buyer. Seller is authorized to perfect its security interest. In addition, if payment in full is not made within sixty (60)

days following delivery of the System, or within 60 days of the invoice date for any and all additional charges accrued by Buyer, whichever

applies, Seller may at its sole discretion, activate the control software installed in the System that will disable the System from functioning.

Upon receipt of full payment, Seller will reactivate the System.

6. Performance of System and Product Samples.

6.1 Acceptance Criteria of System Performance. The acceptance testing shall be conducted in two (2) phases, as set forth below:

6.1.1 Phase One Acceptance Testing. Prior to shipping the equipment from the Multifeeder Technology, Inc. facility to the place of delivery, MFT

will conduct a system performance test mutually-agreed upon with the Buyer and reduced to a writing signed by both Parties. Buyer may,

at its option, witness the Phase One Acceptance Test in person or by electronic means supplied by MFT. If the Parties do not agree upon

an a specific test, the Parties agree that MFT will conduct a 30-minute test demonstrating 90% uptime, after excluding any lost time or lost

production due to Nonconforming Product Samples (defined in section 3.3 of Exhibit A and all related subsections) or other factors out of

MFT’s control. MFT reserves the right to restart or continue the test until completed, or to abbreviate the test by discounting lost time or lost

production due to Nonconforming Product Samples or other factors out of MFT’s control. It is Buyer’s responsibility to supply an adequate

amount of acceptable quality test product pursuant to ¶ 6.2 below. MFT bears no responsibility if Buyer fails to provide Product Samples to

MFT.

6.1.2 Phase Two Acceptance Testing. After completion of delivery of the System, assembly, and training at the place-of-delivery, MFT personnel

will conduct a second test to confirm the System’s performance (“Phase Two Acceptance Testing”). The Phase Two Acceptance Testing will

be conducted using the same Product Samples and performance criteria specified for the Phase One Testing. If the Phase One performance

criteria are met during the Phase Two Acceptance Testing, the Parties agree that the System shall be deemed accepted.

6.2 Acceptance of All Other Goods. For any other goods that are not subject to paragraphs 6.1.1 – 6.1.2, Buyer will have ten (10) days after receipt

to reject nonconforming goods before such goods are deemed accepted by Buyer.

[

80

]

Page 81

TerminologySafetyIntroduction Terms/Conditions

6.3 Product Samples. Seller requires Buyer to supply Product Samples to MFT prior to MFT’s submission of a Proposal to Buyer, and in sufficient

quantities to (a) evaluate Product Samples for consistency in structure and form, and (b) design the System Specifications to process the

Product Samples provided. The projected System performance, as presented in the Proposal, is valid only for Product Samples provided to

Seller prior to the date of the Proposal. Buyer must also supply to Seller actual Product Samples to the same specification as those provided

prior to the MFT Proposal, so that MFT may conduct Acceptance Testing of the System, as set forth above in paragraphs 6.1.1-6.1.2. MFT will

estimate and advise Buyer of the quantity of Product Samples MFT requires. If not otherwise specified by MFT, MFT requires a stack of each

Product Sample, approximately 25 inches high, for testing any System that is composed of feeders. If automatic product loaders are to be

tested, a minimum of 5,000 samples are required. Product Samples should be shipped at Buyer’s cost to Seller no later than ten (10) days after

Seller’s acceptance of Buyer’s Order. Product Samples will not be returned. Seller does not guarantee feeding performance of any specific

product unless an exact Product Sample has been tested before delivery of the System to Buyer. LIMITED WARRANTY AND LIMITATION

OF LIABILITY To activate the warranty, Buyer must sign and return to MFT (a) the Proposal and (b) fully completed warranty registration

cards, which Buyer will receive with the System. Seller warrants to Buyer, for a period of one year from the date of delivery of the System to

Buyer or for 2000 operating hours, whichever occurs first, that the System or Accessory Product(s) will be free from defects in material and

workmanship. An extension of this Limited Warranty is available for an additional charge. OTHER THAN THE FOREGOING, NO WARR ANTY

OR GUARANTEE, WHETHER STATUTORY, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY AS TO MERCHANTABILITY OR

FITNESS FOR ANY PURPOSE IS MADE. THE EXPRESS WARRANTY SET FORTH HEREIN SHALL BE THE SOLE AND EXCLUSIVE

REMEDY BY THE BUYER HEREUNDER FOR ANY SYSTEM OR ACCESSORY PRODUCTS DELIVERED TO THE BUYER WHICH ARE

FOUND TO BE DEFECTIVE IN ANY MANNER, WHETHER SUCH REMEDIES BE IN CONTRACT, TORT, STRICT LIABILITY, OR BY

LAW. OTHER THAN AS SET FORTH HEREIN, SELLER SHALL UNDER NO CIRCUMSTANCE BE DIRECTLY OR INDIRECTLY LIABLE

FOR ANY LOSS OR DAMAGE HOWSOEVER ARISING FROM SUCH MERCHANDISE, INCLUDING LOST USE, LOST PRODUCT, LOST

REVENUE, LOST PROFITS, COST OF CAPITAL, OR SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES. If during the warranty

period, the System or an Accessory Product fails to meet the Specifications, Buyer shall notify in writing of the specific nature of the failure and

all-pertinent observations related to the failure. Seller does not represent or warrant that Systems or Accessory Products sold by it complies

with OSHA or any like state, local, or national law or regulation, and the cost of modification and responsibility for such compliance is imposed

upon Buyer. Equipment must be used in a non-condensing, low-humidity, dry environment, unless explicitly exempted by MFT in writing. THE

TOTAL CUMULATIVE LIABILITY OF SELLER TO BUYER FOR ANY CLAIM OF ANY KIND, FOR ANY LOSS OR DAMAGE WHATSOEVER

ARISING OUT OF, CONNECTED WITH OR RESULTING FROM THE SALE OR SERVICING OF THE PRODUCTS HEREIN, SHALL NOT

EXCEED THE PURCHASE PRICE OF THE SYSTEM OR ACCESSORY PRODUCT. BUYER AGREES TO INDEMNIFY, DEFEND AND

HOLD HARMLESS SELLER FROM ALL CLAIMS ARISING IN WHOLE OR IN PART ON ACCOUNT OF IMPROPER USE, ABUSE, MISUSE,

USE NOT IN ACCORDANCE WITH SELLER’S RECOMMENDATIONS SET FORTH IN THE OPERATION, MAINTENANCE AND SYSTEM

MANUALS SUPPLIED BY SELLER, OR BUYER’S FAILURE TO PERFORM UNDER THIS AGREEMENT. Warranty coverage excludes cost

of delivery to and from Seller’s Minnesota facility. All units that the customer wishes to have repaired under warranty shall be accompanied

by a MFT issued Returned Material Authorization (RMA) and must be sent to Multifeeder at Buyer’s expense. A service fee of $500.00 will be

charged for products sent to Seller for warranty repair, which are found to comply with the Specifications. Seller reserves the right to suspend

any and all warranties if the Buyer has a delinquent account. The System and Accessory Products are sensitive. To qualify for the warranty

set forth in this Agreement, the System and Accessory Products warranted must be repaired by knowledgeable and specially trained MFT

personnel only. Accordingly, warranty coverage will be void in its entirety upon any sign or evidence of (a) opening the System or field service

conducted by individuals other than Seller’s authorized personnel, (b) tampering or any kind of misuse of the System including Buyer’s use

of belts, Stripper Wheels or other parts not supplied by Seller, or (c) abuse of the System or Accessory Products. Non-warranty work will be

completed according to Seller’s standard rates and charges in effect at the time.

Setup

Maintenance

7. Confidentiality. Buyer acknowledges that Seller’s technology is confidential and agrees not to disclose or utilize for its own commercial benefit

any technology that Buyer learns through the purchase or use of the Systems and/or Accessory Products. In no manner does this Agreement

imply or authorize any form of technology license to Buyer for any portion of Seller’s technology except for Buyer’s use of the System and

Accessory Products for their intended purpose.

81[ 81

]

Page 82

TerminologySafetyIntroduction Terms/Conditions

8. Export Controls. Buyer agrees that it will not, without obtaining prior authorization from the U.S. Department of Commerce:

(i) export or re-export, directly or indirectly, any technical data or products (as defined by the U.S. Export Administration Regulations) received

by Buyer under this Agreement to destinations restricted or prohibited by U.S. law;

(ii) disclose such technical data to destinations restricted or prohibited by U.S. law; or

(iii) expor t or re-export, directly or indirectly, any direct product resulting from the technical data received by Buyer to destinations restricted or

prohibited by U.S. law. Buyer hereby agrees to indemnify, defend and hold harmless Seller for any export, re-export or disclosure in violation

of U.S. law that results directly or indirectly from Buyer’s actions.

10. Patents. Seller warrants that it has utilized reasonable efforts to ensure that the System and/or Accessory Products do not infringe on any

patented technology belonging to any other person or entity. If infringement is found and Buyer’s use of the System, Subsystem and/or

Accessory Products is restricted, Seller will, at its option, either (a) redesign the System, Subsystem, and/or Accessory Products to avoid the

infringement; (b) seek a license to allow the current technology to be utilized by Seller; or (c) allow Buyer to return the System, Subsystem and/

or Accessory Products for a full refund.

11. Choice of Law.

Setup

Maintenance

11.1 Governing Law. The laws of the State of Minnesota, United States of America and any applicable Federal laws of the United States of

America, as from time to time amended and in effect, govern all matters arising out of or relating to this Agreement, including without limitation

its validity, interpretation, construction, performance (including the details of performance), and enforcement. The Parties agree that any

applicable conflict of law provision that results in the application of the laws of a foreign jurisdiction shall be disregarded. Buyer and Seller

expressly agree that neither this Agreement, nor any ancillary agreement, undertaking, or performance that may be promised, performed, or

executed to implement this Agreement will not be subject to or interpreted by the United Nations Convention on Contracts for International

Sale of Goods.

11.2 Foreign Corrupt Practices Act of 1977. Buyer is subject to the laws and regulations of the Foreign Corrupt Practices Act of 1977 (FCPA), Title

15 United States Code Service section 78dd-1 and its progeny.

11. 3 Prohibition on Flowdown Provisions. In no event will this Agreement be subject to any other contract which would subject Seller to any

additional terms and conditions or liability. Buyer bears all liability for all other contracts to which Buyer is subject.

12. Forum Selection Clause. Buyer and Seller agree that all disputes, claims, controversies and disagreements relating to or arising out of this

Agreement are subject to the exclusive jurisdiction and venue of the state and federal courts of Minnesota, of the United States of America.

Buyer waives any objections to jurisdiction or venue in any proceeding before any such court in Minnesota and hereby submits to the exclusive

jurisdiction of any such court in Minnesota. Buyer and Seller agree that the exclusive choice of forum set forth in this section does not prohibit

the enforcement of any judgment obtained in that forum or any other forum.

13. Miscellaneous.

13 .1 Governing Language. The English language of this Agreement shall govern and control any translations of the Agreement into any other

language. Documents furnished by Buyer to Seller under the terms of this Agreement shall be furnished in English or accompanied by an

English translation. Seller will not be held responsible for errors or misunderstandings that may occur due to omissions or translations to

another language. Seller reserves the right to correct all errors.

13.2 Assignment. This Agreement shall be binding upon and shall inure to the benefit of Buyer and Seller and their respective successors and

assigns, provided, however, that Buyer may not assign its rights or delegate its duties under this Agreement without Seller’s prior written

consent, which may be granted or withheld at Seller’s sole discretion. Buyer and its assignees and/or transferees of the System and/or

Accessory Products, including all associated proprietar y and intellectual property rights, agree to the terms and conditions of the Agreement.

Buyer agrees to indemnify, defend and hold harmless Seller for any claim or loss or damage suffered as a result of any assignee or transferee

failing to abide by these terms and conditions.

[

82

]

Page 83

TerminologySafetyIntroduction Terms/Conditions

13.3 Counterparts. This Agreement may be executed in multiple identical counterparts, all of which taken together constitute a single

agreement.

13.4 Entire Agreement. This Agreement and any exhibits attached hereto, including Multifeeder Technology, Inc. General System Default

Specifications (Exhibit A), constitute the entire agreement and understanding between Buyer and Seller. All prior written or oral agreements,

undertakings, promises, warranties, or covenants relating to any subject matter not expressly set forth within this Agreement are hereby

superseded.

13.5 Amendments and Waivers. No inconsistent, additional or modified terms or conditions, including price, will apply unless specifically agreed to

in a writing signed by Buyer and Seller. No waiver of any provision or condition shall be valid unless set forth in a writing signed by the waiving

party.

13.6 Force Majeure. Whether foreseen or unforeseen, Seller will not be liable for any failure, defect in performance, delay in the performance of

orders or in the deliver y of goods, or for any damages arising from events beyond Seller’s reasonable control, including without limitation, acts

of Buyer, acts of God, accidents, fires, floods, acts of insurrection or war, governmental interference, embargo, delays by the shipper, strikes,

labor disturbances, unavailability or shortage of supplies or raw materials, unforeseen absence of transportation capabilities or rescheduled,

postponed or cancelled transportation arrangements, changes due to export controls or the ability to obtain an export license, or any other

like cause.

Setup

Maintenance

13.7 Limit of Time to Bring Action. No actions or arbitrations arising out of this Agreement may be brought by Buyer more than eighteen (18) months

after the occurrence of the event giving rise to such action or arbitration.

13.8 Attorneys Fees. Seller will be entitled to recover reasonable attorneys’ fees and costs in any proceeding to enforce payment from

Buyer.

13.9 Buyer’s right to use all of Seller’s products, systems and materials are conditioned upon Buyer’s acceptance of these Terms and

Conditions.

EXHIBIT A: MULTIFEEDER TECHNOLOGY, INC.

GENERAL SYSTEM DEFAULT SPECIFICATIONS

1.0 SCOPE. The scope of these Default Specifications is to define the equipment configuration and performance requirements for the Custom

Multifeeder Technology, Inc. System (hereinafter “System”). All definitions set forth under the MFT Terms and Conditions apply to these

Default Specifications.

2.0 APPLICABLE DOCUMENTS.

National Electric Code 1993

3.0 DEFAULT SPECIFICATIONS. The System shall be configured as specified herein (the “Default Specifications”), unless more specifically

defined in the applicable Proposal. To the extent that any of the Default Specifications specified here are varied by the Proposal submitted

to Buyer, for the purposes of creating custom-designed product-specific or application-specific requirements, those specifications that are

specially varied will apply. Other than to the extent specifically varied in the Proposal, the Default Specifications apply.

3.1 POWER REQUIREMENTS. Each Subsystem will have 110 VAC +/-10%, 50/60 HZ or 208 VAC +/- 10% 50/60 HZ single phase power

available on a circuit capable of delivering 15 amps minimum per feed station. The power will be clean and free from power surges or power

outages. The power, fusing, wiring and disconnects will be in accordance with the applicable requirements of the National Electrical Code,

as updated.

[

83

]

Page 84

TerminologySafetyIntroduction Terms/Conditions

3.2 ENVIRONMENTAL REQUIREMENTS.

3.2.1 TEMPERATURE REQUIREMENTS. The System will be maintained and operated in a location where the temperature range is maintained

between 10 to 35 degrees Celsius (50 to 95 degrees Fahrenheit).

3.2.2 HUMIDITY REQUIREMENTS. The System will be maintained and operated in a non-condensing, dry location with a relative humidity range

of 40 to 80%.

3.3 PRODUCT SAMPLE REQUIREMENTS. This System is a customized high technology system that depends upon strict quality standards

and uniformity of Product Samples handled in order to achieve strict quality standards and uniformity of Final Product Throughput. By way

of example and without limitation, the Product Samples to be fed and/or processed by the System will be uniform and free of defects, such

as bent corners, dog ears, warpage, tears, bends, folds, debris, contamination, any other nonconforming factor that affects feeding and/or

secondary processing, or any other nonconforming Product Sample Tolerances as defined below. Product Samples that do not fall within the

Product Sample Tolerances set forth below or within the Proposal will be deemed “Nonconforming Product Samples.”

3.3.1 PRODUCT SAMPLE TOLERANCES.