Multicoat MULTI-TEXR User Manual

The Patented; Durable, Fire Retardant,

Weather Resistant Exterior Stucco System.

DESCRIPTION AND USE

The MULTICOAT MULTI-TEX STUCCO SYSTEM

consists of a high build flexible acrylic

mulsion applied to a special non-combustible,

e

lightweight, autoclaved, cementitious smoothprimed fibercement siding. It forms a cost-effective, durable weather-resistant exterior stucco

finished (primed) wall, installed on wood or steel

frame, residential or commercial structures.

ADVANTAGES

l

Replaces Shear Panel

l

Flexible

l

High Impact and Abrasion Resistance

l

Resists Moistur

of Fungus and Mildew

l

Resistant to Salt Spray

Most Chemicals

l

UV Resistant

l

Easy to Install

l

Multiple Finishes - Smooth - Medium - Coarse

l

Multiple Color Choice

l

Waterbase Stucco Emulsion Environmentally Safe

e Penetration and Formation

, Freeze/Thaw, and

SEE TEST DATA

PROPERLY ATTACH PRIMED FIBERCEMENT BOARD

TO STRUCTURE (LEAVE MIN. 1/8" GAP BETWEEN

PANELS)

CAULK ALL JOINTS WITH POLYURETHANE CAULK

(ALLOW TO CURE)

MULTI-TEX

®

STUCCO SYSTEM

SURFACE PREPARATION

Smooth primed fibercement siding must be

structurally sound, and surface must be free

from grease, oil, paint, dirt, dust, sealers,

laitence, and other foreign materials that may

PREVENT PROPER BONDING. Proper

expansion joints should be installed according

to applicable local building codes or structural

engineer

every 16 feet when wall has no openings.)

NOTE: A mositure barrier or house wrap may

be necessar

local building codes or str

. (Recommended: Approximately

y in some applications. Check

uctural engineer

.

APPLICATION

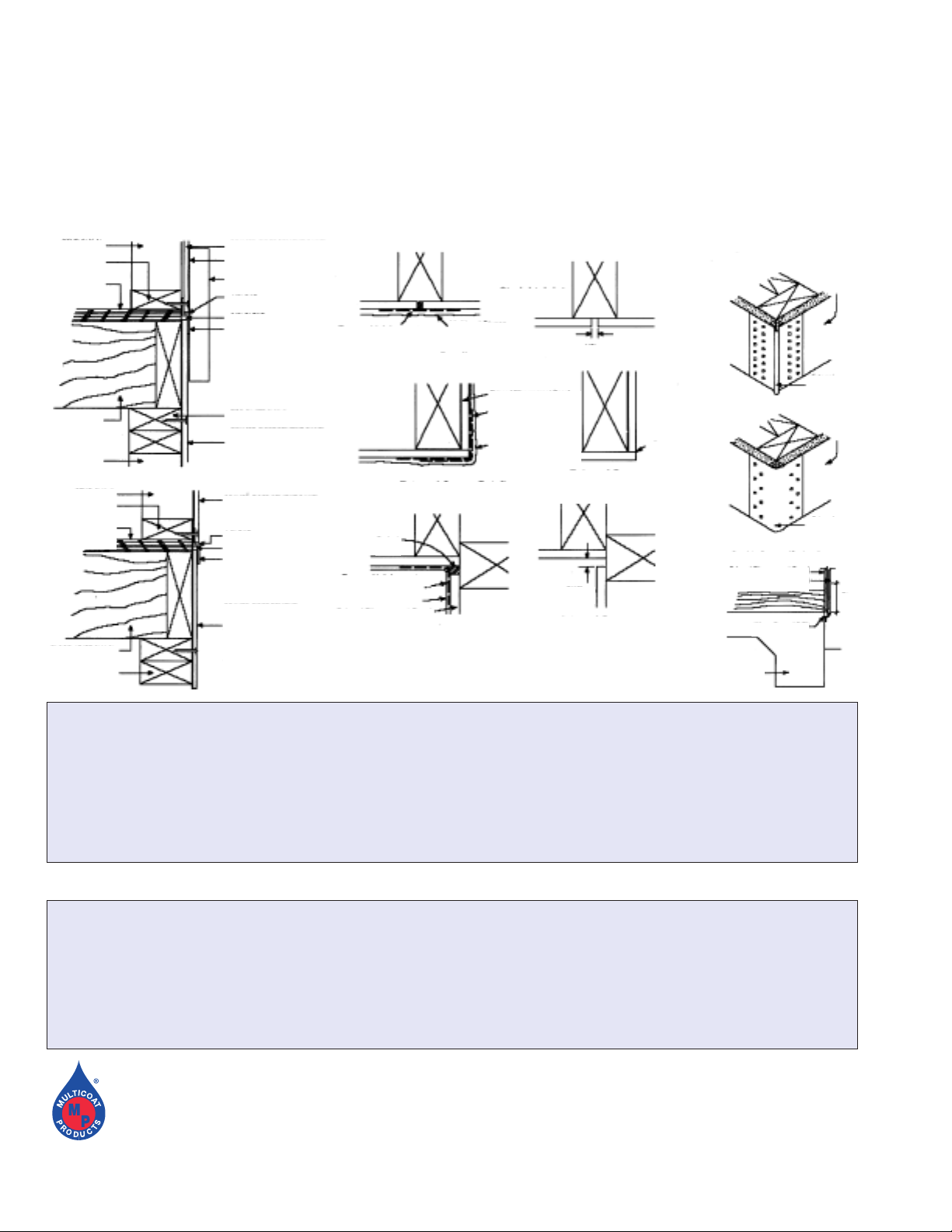

STEP 1: Install smooth primed fiber

siding on existing structure using galvanized

nails (wood) or self-tapping ceramic coated

screws (steel), 6” centers. All panel edges shall

be supported by framing, per manufacturer’s

instructions. Leave minimum 1/8” space

between panels (refer to diagrams). Caulk all

joints with polyurethane caulk. Allow caulk to

thoroughly cur

dampened sponge.

STEP 2: Tape all caulked joints with Multicoat

elastomeric 3” joint tape. Use 6” tape on all

corners (refer to diagrams).

STEP 3: Apply a skim coat of smooth stucco

over all joints and cor

apply Multicoat STUCCO MIX dir

board with trowel or sprayer, and finish to

desired texture.

U.S. Patent No. 5,732,520/6,516,580

e.Clean wall boar

ners, allow to dr

cement

d with water

. Then

y

ectly to wall

APPLY MULTICOAT ELASTOMERIC JOINT TAPE TO

CORNERS AND JOINTS

Y SMOOTH TO CORNERS AND JOINTS. THEN

APPL

APPLY STUCCO MIX TO DESIRED TEXTURE

NOTE: Smooth texture requires a minimum

two coats, troweled finish. See COVERAGE.

(Additional coat(s) may be necessary to

properly hide joints.)

COVERA

Stucco Textures - Each 5-gallon pail of

STUCCO MIX will cover approximately

80-125 sq. ft., depending on textur

Smooth Texture - Each 5-gallon pail of

STUCCO MIX will cover approximately 150175 sq. ft., two coats.

(All coverages may var

application methods.)

GE

e.

y depending on

APPLICATION LIMITATIONS

o not apply if wall board surface temperature is below 50°F, or

D

ver 100°F. Do not apply if ambient temperature is less than 50°F

o

and falling, over 100°F and rising, or if precipitation or extreme

high humidity is expected within a 12-hour period.

PACKAGING AND STORAGE

SMOOTH PRIMED FIBERCEMENT SIDING

2 ft. Lengths

1

STANDARD THICKNESS - 5/16” – Special Order 7/16”

MULTICOAT STUCCO MIX - 5-Gal. Pails

S

TUD 2' X 4'

B

OTTOM PLATE

2' X 4'

FLOORING

FLOOR JOIST

2

' X 6'

S

TUD 2' X 4'

S

TUD 2' X 4'

B

OTTOM PLATE

2

' X 4'

FLOORING

F

LOOR JOIST 2' X 6'

TE 2' X 4'

TOP PLA

Thicknesses: 1/4", 5/16" & 7/16"

Installed Weight:

1/4" thick 1.9 lbs/sq.ft.

5/16" thick 2.4 lbs/sq.ft.

7/16" thick 3.3 lbs/sq.ft.

Density: 86 lbs/cu.ft.

Bending Strength:

Transversal: 2,000 psi

Longitudinal: 2,500 psi

P

RIMED FIBERCEMENT PANEL

ADHESIVE

FOAM OR MIX PANEL

A

TTACHED OR GLUED

TO TOP SHEET ONLY

1/8" GAP

3

/8" CLEAR

HORIZONTAL

E

XPANSION

J

OINT REVEAL

T

OP PLATE 2' X 4'

P

RIMED FIBERCEMENT PANEL

NAILED TO TOP

PLATE, FLOATING

ON JOIST AND FLOOR

PRIMED FIBERCEMENT P

SMOOTH

1

.8" GAP

3

/8" CLEAR

AL

HORIZONT

EXPANSION

JOINT REVEAL

PRIMED FIBERCEMENT

P

ANEL

N

AILED TO

T

OP PLATE,

F

TING

LOA

ON JOIST

A

ND FLOOR

- 4’ wide x 8, 9, 10 or

Tape and joining system

y coating applicator

b

traight Joint Detail

S

xternal Corner Detail

ANEL

Tape and joining system

by coating applicator

Multicoat Stucco Mix

Primed Fibercement Panel

E

Sealant

Internal Corner Detail

TEST DATA –CEMENTITIOUS WALL BOARD

ICC/ES Report #5139 SBCCI Report #9556

MULTICOAT ELASTOMERIC JOINT TAPE - 3” & 6” widths 100 ft. rolls

POLYURETHANE CAULK - Tubes

Store at 40 –90°F. Shelf life is approximately 24 months in

unopened pails.

WARRANTY

Materials are guaranteed with respect to uniformity and quality

within manufacturers’ specifications. Seller makes no other

arranty, expressed or implied, regarding the use of its products.

w

Since use of the products is beyond seller’s control, the buyer

ssumes all risks of use. Seller’s sole obligation shall be to replace

a

material if found to be defective. Seller shall not be liable for any

oss, direct or consequential, resulting from use of its products.

l

Outside Corner (Optional)

Straight Joint

P

rimed Fibercement Panel

Multicoat Stucco

Mix over Primed

Fibercement Panel

P

rimed Fibercement Panel

R

einforcing tape

M

ulticoat

Stucco Mix

Thermal Resistance: R=0.17

Shrinking: Ambient to oven-dry: 0.06%

Swelling of Thickness

(after 7 days of full saturation): 0.2%

Flame Spread: 0

Smoke Density: 0

Wind Pressures:

alues:

V

Shear

1/8" gap

External Corner

Primed Fibercement Panel

3/16" gap

Internal Corner

Primed Fibercement Panel

e

dges

ner (Optional)

Outside Cor

cement Panel

Primed Fiber

oundation

F

eep Screed 3/8"

W

F

inish

P

rimed

xternal

E

Corner

Bead

Primed

Fibercement

External

Bullnose

Corner Bead

F

ibercement

P

2'

P

anel

anel

TEST DATA –STUCCO MIX

TEST TYPE TEST METHOD RESULTS

2000 Hour Weatherometer . . . . . . .ASTM G-23 No marked evidence of surface cracking, blistering, flaking, chalking,

crazing or any other deleterious ef

fects obser

Moisture Resistance . . . . . . . . . . . .ASTM D2247 No blistering or cracking of surface

Freeze-Thaw . . . . . . . . . . . . . . . . . .Section VI D of acceptance No change in color, no cracks, no crazing, no delamination

criteria for EIFS

Abrasion Test (Falling Sand) . . . . . .ASTM DE968 Method A Initial wear started at 3200 liters

Fungus . . . . . . . . . . . . . . . . . . . . . .Mil-Std-810B (Method 508) Passed

Moisture Vapor Transmission . . . . .ASTM E96 4.56 Perms, the coating is not a vapor barrier

MC0406

MULTICOAT®CORPORATION

West Coast

Toll Free: (877) 685-8426

(949) 888-7100 F

ax (949) 888-2555

Website: www.multicoat.com

E-mail: info@m

ulticoat.com

The Coating of the Future…Today

MULTICOAT®PRODUCTS, INC.

East Coast

Toll Free: (800) 660-6729

(304) 586-0616 F

Website: www.multicoat.com

o@m

inf

E-mail:

ax (304) 586-0620

ulticoat.com

ved

Available Through:

Loading...

Loading...