Multicoat IFC STUCCO SHEET User Manual

Insulated Concrete Form

DESCRIPTION AND USE

The Multicoat Insulated Concrete Form (ICF)

TUCCO SYSTEM is specifically designed to

S

create a hard durable weather resistant,

rack resistant and impact resistant stucco

c

finish to ICF block. This system provides an

economically lightweight and attractive finish

to all makes and styles of ICF Block.

ADVANTAGES

●

Flexible

●

Stain Resistant

●

Excellent Resistance to Freeze Thaw

●

Water Resistant

●

Excellent Crack Resistance

●

Abrasion and Impact Resistant

●

Super Adhesion

●

Non Chalking

●

Wide Variety of Colors

ICF STUCCO SYSTEM

Stucco System.

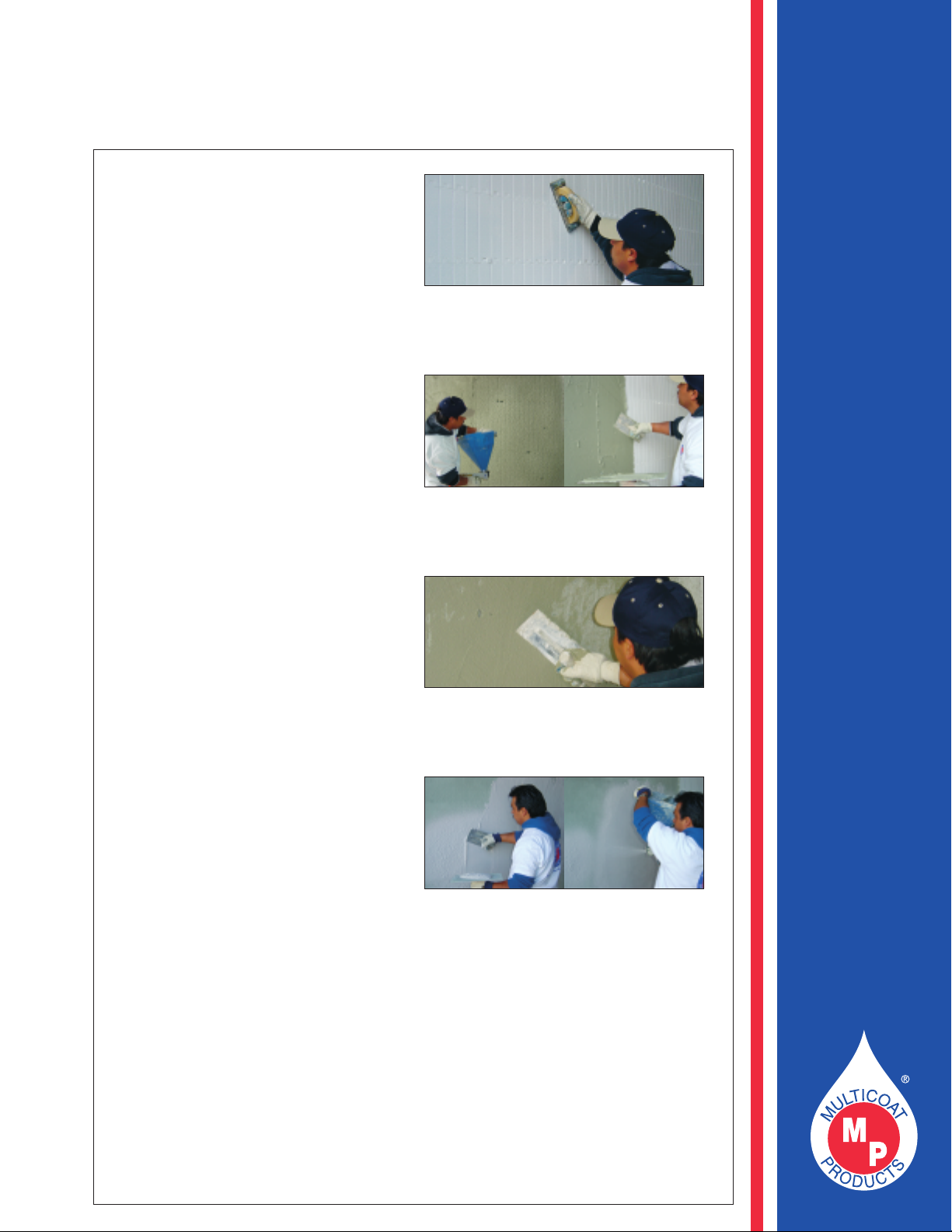

RASP FOAM BLOCKS TO REMOVE OXIDATION AND

TO LEVEL SURFACE

SPRAY OR TROWEL BASE COAT ONTO ICF BLOCK

SURFACE PREPARATIONS

Remove any dirt, oxidation or other foreign

materials from ICF Block surface prior to

application or coating. Repair any large

holes or divots in substrate before application of first coat..

APPLICATION

MULTICOAT ICF STUCCO SYSTEM incorporates a base coat of SCRATCH KOTE,

KRETE KOTE or MULTI-BASE and a finish

coat of MULTI-TEX STUCCO MIX applied

over properly prepared ICF Block.

The base coat is field mixed with potable

(clean) water to desired consistency and

applied to sur

perse all lumps and thor

cles. Use margin trowel to clear vessel walls.

Embed and trowel Fiberglass Mesh into the

base coat. Cure a minimum of 12 hours

e proceeding, longer in cold weather

befor

An additional base coat may be necessary

to cover Fiberglass Mesh.

Finish coat of MUL

applied onto base coat and textured to

desired finish.

face. Mix vigor

TI-TEX STUCCO is

ously to dis

oughly wet all parti-

-

.

IMMEDIATELY EMBED FIBERGLASS MESH INTO

BASE COAT & TROWEL

APPLY MULTI-TEX STUCCO FINISH & TEXTURE TO

DESIRED FINISH

COVERAGE

Each 65 lb bag of

KOTE or

60-120 sq. ft.

Coverage may var

MULTI-BASE will cover approximately

KRETE KOTE, SCRA

y due to substrate conditions.

TCH

Each 5 gallon pail of MUL

finish coat will cover appr

Coverages will vary depending on porosity of

substrate, texture of base coat, and desired

finish textur

e.

TI-TEX STUCCO mix

ox. 60-125 sq. ft.

LIMITATIONS

Do not apply when substrate temperature is below 50°F or

above 100°F; if ambient temperature is below 50°F and

alling; or over 100°F and expected to rise; or if precipitation

f

is expected within a 24-hour period.

PACKAGING AND STORAGE

ASE COAT – SCRATCH KOTE/KRETE KOTEor MULTI-BASE is

B

urnished in 65 lb bags.

f

STUCCO FINISH – MULTI-TEX STUCCO furnished in 65 lb - 5

gallon pails, Ready-to-Use.

FIBERGLASS MESH – (20 x 10 Leno weave, 4.5 oz per sq. yard,

hickness .0135".) 475 sq. ft. rolls 38" wide.

t

Store in dry area at 40-90°F.

Shelf life is approximately 24 months in unopened bags and

approximately 18 months in unopened pails.

WARRANTY

Materials are guaranteed with respect to uniformity and quality

ithin manufacturers’ specifications. Seller makes no other

w

arranty, expressed or implied, regarding the use of its products.

w

ince use of the product is beyond Seller’s control, the Buyer

S

assumes all risks of use. Seller’s sole obligation shall be to

replace material if found to be defective. Seller shall not be

liable for any damage, injury, loss, direct or consequential,

resulting from use of its products.

TEST DATA: ICF STUCCO SYSTEM

The ICF STUCCO SYSTEM complies with Federal Specification TT.C-55b for “Coating, Textured for Interior and Exterior Masonry

Surfaces.”

STUCCO MIX

TEST METHOD RESULTS

1. Weatherometer. . . . . . . . . . . . . . . . . . . . . . . . . . . ASTM G-23 . . . . . . . . . . . . . . . . . . . . . . . . . 2000 hours – Passed

2. Moisture Resistance. . . . . . . . . . . . . . . . . . . . . . . ASTM D2247 . . . . . . . . . . . . . . . . . . . . . No blistering or cracking

3. Freeze-Thaw . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section vi d EIFS criteria . . . . . . . . . . . . . . . No change – Passed

4. Abrasion Test (Falling Sand) . . . . . . . . . . . . . . . . ASTM DE-968-A . . . . . . . . . . . . Initial wear started at 3200 liters

5. Fungus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mil-Std 810-B (method 508) . . . . . . . . . . . . . . . . . . . . . . . Passed

6. Moisture Vapor Transmission . . . . . . . . . . . . . . . . ASTM E-96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.56 Perms

BASE COAT

1. Weatherometer. . . . . . . . . . . . . . . . . . . . . . . . . . . ASTM G23 . . . . . . . . . . . . . . . . . . . . . . . . . 2000 hours – Passed

2. Compressive Strength . . . . . . . . . . . . . . . . . . . . ASTM C109 . . . . . . . . . . . . . 45 Days air cured. . . . . . . 2595 psi

3. Tensile Strength . . . . . . . . . . . . . . . . . . . . . . . . . . ASTM C190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 457 psi

4. Bond Strength (Flatwise Tension) . . . . . . . . . . . . ASTM C297 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225 psi

5. Abrasion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ASTM 1242A . . . . . . . . . . . . . 1000cyc-1000gms . . . . 39 mil loss

6. Salt Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ASTM B117 . . . . . . . . . . . . . . . . . . . . . . . . . . 300 hours – Passed

ater Vapor Transmission . . . . . . . . . . . . . . . . . . ASTM E96A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.26 Perms

W

7.

8. 50-Cycle Freeze Thaw . . . . . . . . . . . . . . . . . . . . ASTM C67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Passed

9. Flexural Strength . . . . . . . . . . . . . . . . . . . . . . . . . ASTM D790 . . . . . . . . . . . . . . . . . . Modulus of Rupture – 770psi

Impact Resistance . . . . . . . . . . . . . . . . . . . . . . . MIL-D-3134F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Passed

10.

11. Flame Spread . . . . . . . . . . . . . . . . . . . . . . . . . . . ASTM E84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class A

MULTICOAT®CORPORATION

West Coast

Toll Free: (877) 685-8426

(949) 888-7100 F

Website: www.multicoat.com

E-mail: info@m

ax (949) 888-2555

ulticoat.com

MULTICOAT®PRODUCTS, INC.

East Coast

Toll Free: (800) 660-6729

(304) 586-0616 F

Website: www.multicoat.com

o@m

E-mail:

inf

ax (304) 586-0620

ulticoat.com

Available Through:

MC0406

The Coating of the Future…Today

Loading...

Loading...