Page 1

Roboinject Manual

Page 2

Information in this document is subject to change without notice.

No part of this document may be reproduced or transmitted without the express written

permission of Multi Channel Systems MCS GmbH.

While every precaution has been taken in the preparation of this document, the publisher

and the author assume no responsibility for errors or omissions, or for damages resulting

from the use of information contained in this document or from the use of programs and

source code that may accompany it. In no event shall the publisher and the author be liable

for any loss of profit or any other commercial damage caused or alleged to have been caused

directly or indirectly by this document.

© 2013 Multi Channel Systems MCS GmbH. All rights reserved.

Printed: 19. 07. 2013

Multi Channel Systems

MCS GmbH

Aspenhaustraße 21

72770 Reutlingen

Germany

Fon +49-71 21-90 92 5 - 0

Fax +49-71 21-90 92 5 -11

info@multichannelsystems.com

www.multichannelsystems.com

Microsoft and Windows are registered trademarks of Microsoft Corporation.

Products that are referred to in this document may be either trademarks and / or

registered trademarks of their respective holders and should be noted as such.

The publisher and the author make no claim to these trademark.

Page 3

Table of Contents

Introduction 1

About this Manual 1

Important Information and Instructions 3

Important Safety Advice 3

High Voltage 3

Requirements for the Installation 3

Compressed Air Supply 4

Handling of the Carrier 4

Handling of the Injector Mount ( = z-Axis) 4

Handling of Injection Needles 4

Regular Backups 4

System File Modifications 5

Guarantee and Liability 5

Operator's Obligations 5

Roboinject 7

Welcome to the Roboinject 7

First Use of the Roboinject 9

Installing the Roboinject 12

Installing the Roboinject Software 14

Roboinject Software 15

Main Menu 16

Toolbar 29

Control View 35

Tube View 40

Well Plate View 42

Injection 47

About Injection with the Roboinject 47

Strategies for a Successful Injection 48

Preparations for Injection 50

Setting Up the Well Plate 52

Inserting or Changing the Well Plate 52

Selecting Oocytes for Injection 57

Changing the Well Plate and Loading the Needle 58

Alignment 60

Starting the Injection 63

Saving the Well Plate 65

iii

Page 4

Roboinject Manual

Troubleshooting 67

Troubleshooting 67

Clogged Injection Needle 68

Error Messages 70

Appendix 71

Technical Support 71

Service and Maintenance 72

Cleaning the x/y Table 72

Replacing the Plunger 72

Contact Information 73

Ordering Information 74

About Preparation of Xenopus Oocytes 76

Materials 76

Chemicals 77

Oocyte Removal 78

Collagenase Digestion and Defolliculation 78

Selecting Good Oocytes 79

Plating Oocytes 80

Technical Specifications 81

Index 83

iv

Page 5

1 Introduction

1.1 About this Manual

This manual comprises all important information about the first installation of the Roboinject

hardware and software and about the daily work with the Roboinject. It is assumed that you

already have a basic understanding of technical and software terms. Thus, no special skills are

required to read this manual.

If you are using the Roboinject for the first time, please read the "Important Safety Advice"

before installing the hardware and software. Please see chapter "First Use of the Roboinject",

where you will find important information about the installation of hardware and software.

The printed manual and online help are basically the same, so it is up to you which one you will

use. The help offers you the advantage of scrolling through the text in a non-linear fashion,

picking up all information you need, especially if you use the index and the search function.

If you are going to read larger text passages, however, you may prefer the printed manual.

The device and the software are part of an ongoing developmental process. Please understand

that the provided documentation is not always up to date. The latest information can be found

in the Roboinject help. Check also the Multi Channel Systems MCS GmbH web site

(www.multichannelsystems.com) for downloading up-to-date manuals.

1

Page 6

Page 7

2 Important Information and Instructions

2.1 Important Safety Advice

Warning: Make sure to read the following advice prior to installations of the Roboinject.

If you do not fulfill all requirements stated below, this may lead to malfunctions, breakage,

or even fatal injuries. Obey always the rules of local regulations and laws. Only qualified

personnel should be allowed to perform laboratory work. Work according to good laboratory

practice to obtain best results and to minimize risks.

The product has been built to the state of the art and in accordance with recognized safety

engineering rules. The device may only

be used for its intended purpose;

be used when in a perfect condition.

Improper use could lead to serious, even fatal injuries to the user or third parties and damage

to the device itself or other material damage. Malfunctions which could impair safety should

be rectified immediately.

2.1.1 High Voltage

Electrical cords must be properly laid and installed. The length and quality of the cords must

be in accordance with local provisions.

Only qualified technicians may work on the electrical system. It is essential that the accident

prevention regulations and those of the employers' liability associations are observed.

Each time before starting up, make sure that the mains supply agrees with the specifications

of the product.

Check the power cord for damage each time the site is changed. Damaged power cords should

be replaced immediately and may never be reused.

Check the leads for damage. Damaged leads should be replaced immediately and may never

be reused.

Liquids may cause short circuits or other damage. Keep the power supply and the power cords

always dry. Do not handle it with wet hands.

2.1.2 Requirements for the Installation

The Roboinject weighs more than 23 kg. Always grip it tightly and do not carry it alone,

but with the aid of another person.

The movement of the well plate carrier can lead to vibrations of the workbench on which the

Roboinject is set up. Therefore, the Roboinject must be set up on a rigid, vibration-free base.

The base must also be sufficiently solid to carry the weight of the device.

The Roboinject should be operated only in an air conditioned room. A room temperature of

20° C (or less) is recommended. Make sure that the device is not subject to direct sunlight.

It may overheat.

If the air cannot circulate freely around the external power supply, the device may overheat.

Do not shield the power supply by laying anything on top of it.

The external power supply unit is only for use with the Roboinject. Do not connect it to any

other instrument.

3

Page 8

Roboinject Manual

2.1.3 Compressed Air Supply

Even small amounts of water in the compressed air can lead to a corrosion of the carrier.

Other contaminations can also result in malfunctions. Use only compressed air fulfilling

the following standards.

The air must be absolutely free of water, oil, and any particles.

When air is compressed, the humidity in the air is concentrated into a smaller area, frequently

condensing inside the air hoses. Use a water separator to remove water from the air. The

provided water separator is not suitable to establish the necessary conditions; it serves only

as a control device. If you regularly observe an accumulation of water in the provided water

separator, the compressed air does not fulfill the required standards.

Warning: Water in the system leads to corrosion and destroys the device!

This is extremely important!

Use a filter with 5 μm pores or smaller to remove any particles from the air.

Set the external air pressure at least to 5 bar, the maximum pressure of 10 bar must not be

exceeded. Adjust the provided pressure regulator to 3 bar, too high or too low pressure can

lead to malfunction and can severely damage the device. Check the pressure at the end of the

pressure line, directly before it is lead into the Roboinject. The Roboinject needs a minimum

flow rate of 20 l/min.

Do not use other compressed air hoses than those provided, that is, ID 4 mm OD 6 mm from

compressor to water separator, and ID 2.5 OD 4 mm from water separator to the Roboinject.

The use of other hoses could lead to a decrease of pressure.

2.1.4 Handling of the Carrier

Do not try to lift the carrier off the x/y table. You may move the carrier carefully sideways

by hand if necessary but not during operation. For cleaning or alignment purposes use the

appropriate software control, please read chapter "Maintenance" and "Alignment".

If it happens that any liquid spills over the x/y table, please remove it as soon as possible

in order to prevent a corrosion of the carrier.

2.1.5 Handling of the Injector Mount ( = z-Axis)

Do not move the z-axis by hand. Breakage may occur. Always use the software controls

to move an axis up and down, please see chapter “Manual Mode".

Change the injection needle with great care. The injection needle is sharp and may lead

to injuries. Stay at a safe distance during operation and protect your eyes. Especially take

care not to move your hands in the range of the z-axis.

2.1.6 Handling of Injection Needles

The injection needles are sharp and break easily. Always handle them with care.

In rare cases, a needle may splinter when inserting the plunger into the needle and fitting it.

Stay at a safe distance and protect your eyes.

Dispose the used injection needles into an appropriate container.

2.1.7 Regular Backups

You (or the administrator) should perform backups of the Roboinject plate files (*.rpf files) and

template files (*.rit files) at regular intervals and to appropriate media for preventing data loss.

Data loss may be caused by power failure, system and software errors.

4

Page 9

Important Information and Instructions

2.1.8 System File Modifications

If you remove or edit text of an initialization ("ini") or configuration ("cfg") file, the software may

cause severe problems. These files relate to hardware functions. A modification of these files may

lead to malfunctions or even severe damage of the hardware. Always keep a copy of the original

files. Only advanced users should modify program files like these. This warning message applies to

all initialization and configuration file modifications.

2.2 Guarantee and Liability

The general conditions of sale and delivery of Multi Channel Systems MCS GmbH always apply.

The operator will receive these no later than on conclusion of the contract.

Multi Channel Systems MCS GmbH makes no guarantee as to the accuracy of any and all tests

and data generated by the use of the device or the software. It is up to the users to use good

laboratory practice to establish the validity of their findings.

Guarantee and liability claims in the event of injury or material damage are excluded when

they are the result of one of the following.

Improper use of the device.

Improper installation, commissioning, operation or maintenance of the device.

Operating the device when the safety and protective devices are defective and/or inoperable.

Non-observance of the instructions in the manual with regard to transport, storage, installation,

commissioning, operation or maintenance of the device.

Unauthorized structural alterations to the device.

Unauthorized modifications to the system settings.

Inadequate monitoring of device components subject to wear.

Improperly executed and unauthorized repairs.

Unauthorized opening of the device or its components.

Catastrophic events due to the effect of foreign bodies or acts of God.

2.3 Operator's Obligations

The operator is obliged to allow only persons to work on the device, who

are familiar with the safety at work and accident prevention regulations and have been

instructed how to use the device;

are professionally qualified or have specialist knowledge and training and have received

instruction in the use of the device;

have read and understood the chapter on safety and the warning instructions in this manual

and confirmed this with their signature.

It must be monitored at regular intervals that the operating personnel are working safely.

Personnel still undergoing training may only work on the device under the supervision

of an experienced person.

5

Page 10

Page 11

3 Roboinject

3.1 Welcome to the Roboinject

The Roboinject is a fully-automated all-in-one solution for injection of cDNA, mRNA and other

compounds into Xenopus oocytes in standard 96 well plates. It is also suited for automated

injection of other cells or organisms in standard (96, 384) as well as customized well plates.

Main features:

Compact and functional design, works fully computer controlled.

Easy handling - neither special skills nor special equipment required.

Maintenance-free system.

Extremely simple and stable mounting of injection capillaries.

Injection is performed by a positive displacement motorized unit which is capable

of repetitively dispensing precisely 1 to 100 nl per cell or organism.

Reproducible and defined cell impalement depth.

Automated sample uptake of up to eight different RNAs, DNAs or compounds

per well plate from industry standard 0.5 ml reaction tubes.

Automated and effective needle rinsing before uptake of new samples.

Injection of up to four different samples per cell.

Full documentation of all injection parameters.

Compatibility with the Roboocyte when using 96 well plates.

7

Page 12

Roboinject Manual

Operation summary:

Instead of having a vast amount of different pull down menus, there is one clearly structured

menu bar and also a toolbar presenting commonly used commands. Therefore, you will quickly

become familiar with the Roboinject.

The first step is to set up your "virtual" well plate according to your "real" well plate.

Enter a unique ID for the plate and / or assign a file name. The virtual well plate is then visualized

in a X x Y grid (for example, 12 x 8 for a standard 96 well plate) as the real one, and therefore

it is easy to overview and to handle.

Define up to eight different injection samples and select the respective velocity of injection.

Enter the respective sample volume.

Finally, assign the different injection samples to a selection of wells, rows or columns. To allow

maximal flexibility, you can inject up to four samples per cell - even on different days - and assign

injection depth and injection volume for every cell independently.

Fill the injection needle with mineral oil and lock it to the injector's luer connector.

Start the injection sequence by mouse click. The "Injection Wizard" will open and guide you

through a quick and easy alignment procedure. Finally, you start the injection and it will proceed

automatically until finished or interrupted by the user.

Information about the plate and the current state of all wells is displayed and updated online on

the screen.

You may save the well plate and load it later on the Roboocyte to proceed with your experiment.

8

Page 13

3.2 First Use of the Roboinject

This section contains important information about the general concept of the Roboinject and

the setup of the system. Please read the "Important Safety Advice" in the introduction prior to

installing the Roboinject hardware and software.

The Roboinject Hardware

The Roboinject is compatible with standard lab equipment and can be easily integrated

in your working environment. Software controls for all settings replace any knobs on the device.

The Roboinject is straightforward and easy to operate; handling does not require special skills or

special equipment.

Roboinject

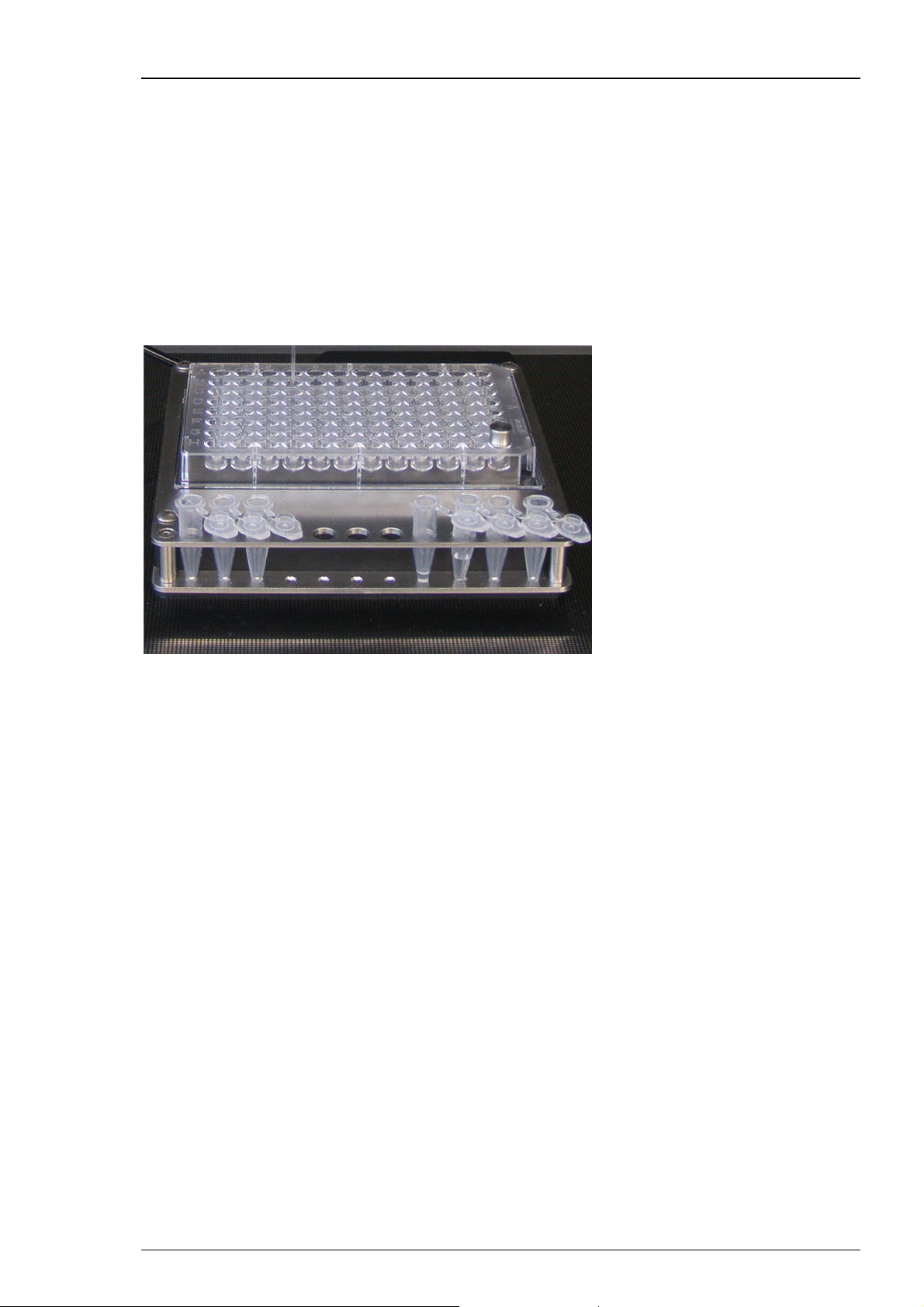

The well plate carrier, powered by linear motors, hovers smoothly and noise free on a cushion

of compressed air above the magnetic x/y table. The carrier operates at a resolution of 20 μm.

The complete system does not require maintenance other than occasional cleaning of the steel

plate. The well plate carrier can hold up to eight industry standard 0.5 ml reaction tubes serving

as sample reservoirs.

9

Page 14

Roboinject Manual

The vertically moving injector mount (z-axis), holding the injection device, is designed

specifically for the demand of high stability, speed and precision. It moves at a resolution

of 20 μm; position and speed are software controlled.

The injection device is composed of a linear motor driving a steel plunger which fits precisely

in the provided injection capillaries. The oil gap between the inner glass wall and the plunger

surface serves for a perfect leak tightness and makes additional gaskets dispensable.

Prepulled borosilicate glass micropipettes are provided by Multi Channel Systems MCS GmbH,

but custom injection needles may also be used. Mounting of injection capillaries is extremely fast

and simple by using luer fittings. There are no additional gaskets susceptible to leakage rendering

the injection device durable and maintenance free.

10

Page 15

Roboinject

Injection and cultivation of Xenopus oocytes is performed using disposable standard 96 well

plates, which are commercially available from several providers. Please see chapter "Ordering

Information" in the Appendix. The oocytes are plated into the wells in a couple of minutes and

can be kept for several days. They quickly settle within the cone-shaped wells and adhere to the

well bottom after a few hours. The oocytes do not have to leave the plate anymore; you can easily

transfer the oocytes from the incubator to the Roboinject and back again.

A quick alignment process guarantees that the oocytes are injected precisely. The cDNA or mRNA

or other compounds to be injected are aspirated into the injection pipette by upward movement

of the plunger and then pushed into either the nucleus or the cytoplasm by downward movement

of the plunger.

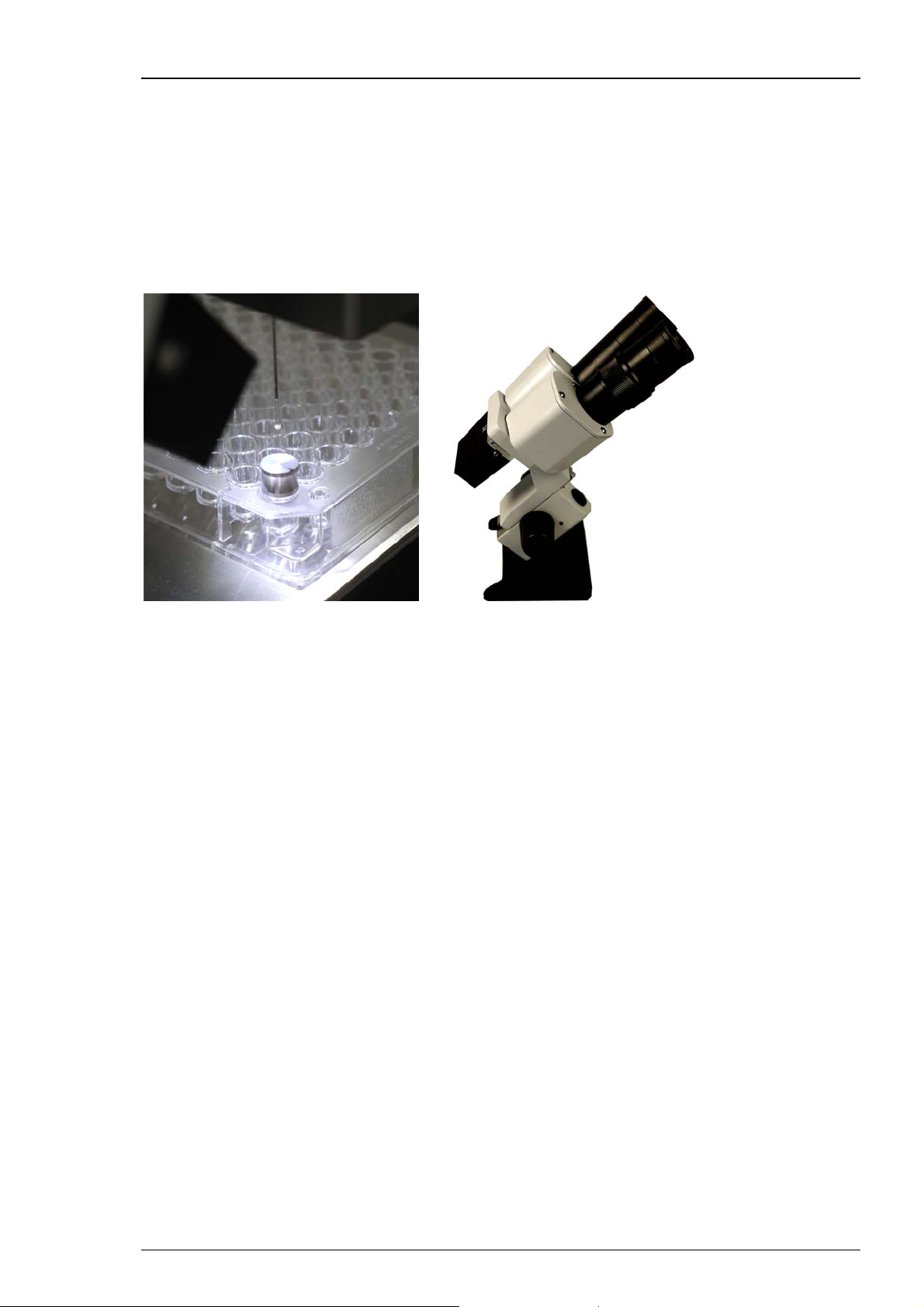

The provided microscope is mandatory for the alignment process. Place the microscope

in a position onto the x/y table which allows to focus on the alignment device plugged

in well H12 of the well plate. Please read chapter “Alignment” for detailed information.

11

Page 16

Roboinject Manual

3.3 Installing the Roboinject

Setting Up the Roboinject

1. Place the Roboinject on a rigid, stable, and vibration-free base in an air conditioned room.

2. Provide a power supply in the immediate vicinity of the installation site.

3. Provide a compressed air supply in the immediate vicinity of the installation site.

4. Place the computer and its accessories next to it.

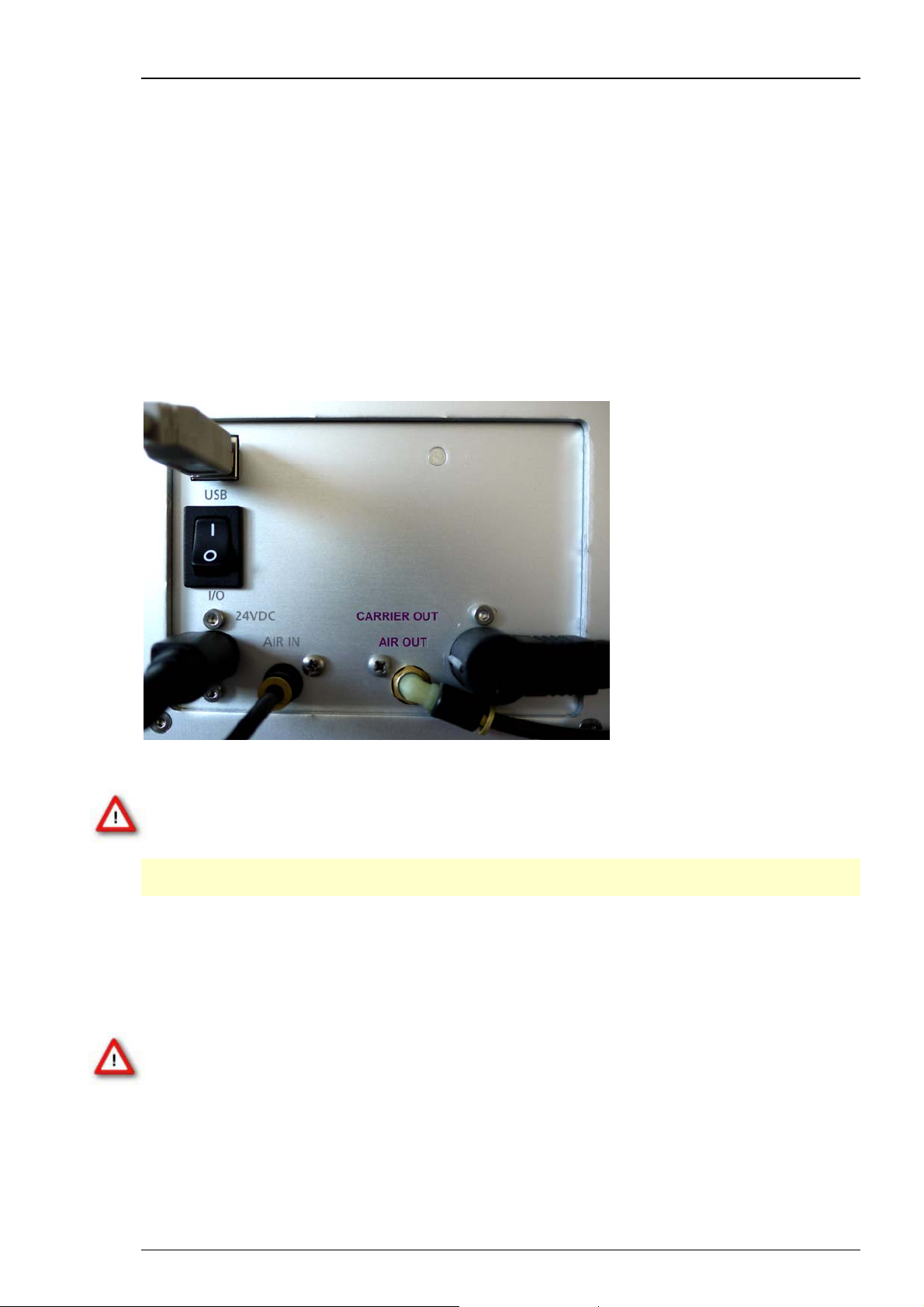

Connecting the Roboinject

The following illustration shows the rear panel of the Roboinject.

Connect all cables as described below.

Warning: Carefully lay and secure the cords. Remember that someone could easily trip over

a loose cable.

Note: All electrical connections are clearly marked, and the plug coding prevents confusion.

The cords should be plugged in without the use of excessive force.

Connecting the carrier

Plug the carrier connector into the according socket located on the Roboinject's rear panel,

labelled with "CARRIER OUT".

Warning: Confusion of the compressed air's inlet and outlet may destroy the device.

Have a close look at the preceding picture of the Roboinject's rear panel and take care

to connect the lines properly. The air hose connecting the Roboinject with the well plate

carrier is close to the electrical connection between them.

12

Page 17

Roboinject

Connecting the Roboinject to the pressure line

1. Connect one end of the provided compressed air hose (ID 2.5 mm, OD 4 mm) to the water

separator.

2. Connect the other end to the compressed air inlet on the Roboinject's rear panel, labelled

with "AIR IN".

3. Connect the other provided compressed air hose (ID 4 mm, OD 6 mm) to the provided water

separator.

4. Make sure that the pressure line is closed. Connect the free end of the provided compressed

air hose (ID 4 mm, OD 6 mm) to the pressure line, labelled with "AIR OUT".

5. Open the pressure line and apply a pressure of 3 bar with the provided pressure regulator.

Warning: Make sure that the compressed air used fulfills all requirements for working with

the Roboinject. Otherwise, use of an improper compressed air could result in physical harm

to the hardware. Especially, check that the compressed air is absolutely free of water, oil,

and any particles. Refer to the chapter "Important Safety Advice" for more information.

Connecting the Roboinject to the computer

1. Connect the Roboinject by the provided USB cable, labelled with "USB".

2. Connect the Roboinject to the power line.

3. Finally, plug the power cord into the AC power line input, labelled with “24 VDC”.

4. Switch the Roboinject on or off via “I/O” toggle switch.

Warning: If the air cannot circulate freely around the external power supply, the device

may overheat. Do not shield the power supply by laying anything on top of it. Make sure

it is not exposed to direct sunlight.

13

Page 18

Roboinject Manual

3.4 Installing the Roboinject Software

System requirements

Software: One of the following Microsoft Windows ® operating systems is required:

Microsoft Windows 7, Vista or XP (English versions supported with the NT file system).

Other language versions may lead to software errors.

Hardware: An USB 2.0 High Speed serial bus must be provided for the communication

between the Roboinject and the computer. Additional 1 GB RAM working memory

is strongly recommended.

Recommended operating system settings

The following automatic services of the Windows operating system interfere with the data

storage on the hard disk and can lead to severe performance limits. These routines were

designed for use on office computers, but are not very useful for a data acquisition computer.

Turn off “Windows System Restore”.

Turn off automatic “Windows Update”.

Deselect “Windows Indexing Service” for all local disks.

Turn off “Optimize hard disk when idle” (automatic disk fragmentation).

It is also not recommended to run any applications in the background when using the Roboinject.

Remove all applications from the Autostart folder.

Please check the system requirements before you install the software. MCS cannot guarantee

that the software works properly if these requirements are not fulfilled.

Important: Please make sure that you have full control over your computer as an administrator.

Otherwise, it is possible that the installed software does not work properly.

Installing the Roboinject Software with computer connected

Power up the connected computer and wait until it is ready.

1. Double-click Setup.exe on the installation volume. The installation assistant will open

and guide you through the installation procedure.

2. Follow the instructions of the installation assistant. The Roboinject software and all necessary

drivers will be installed on your computer.

14

Page 19

3.5 Roboinject Software

Starting the Roboinject

Press the main switch on the back of the Roboinject for switching on the Roboinject.

The Roboinject is starting now. After a few seconds the Roboinject is ready for use.

Starting the Roboinject Software

You may use the computer and the software offline that is, the Roboinject is switched off or not

connected to the computer, to review already injected plates or define new injection protocols.

You can switch from offline to online mode, when the Roboinject is switched on later. However,

if you start the software to operate the Roboinject, the easiest way is to start the Roboinject first

and then start the software.

Each time you start the Roboinject software the well plate carrier and the injection mount will

automatically move to a reference point, that means to the "home" position. These movements

do not use any software command.

The factory preset default values have been extensively tested with RNA and DNA injection of

Xenopus oocytes and should work in most circumstances. Therefore, it is advisable to use the

default values for the first injections with Xenopus oocytes.

Roboinject

1. Double-click the Roboinject icon

- OR -

Select Roboinject from the "Start" menu to start the Roboinject software.

2. When you start the Roboinject software for the very first time, the file dialog box appears

for setting the directories for the plate files and template files. You can either accept the

predefined directories or select directories according to your personal preferences.

If the Roboinject is offline indicated by a red status lamp below the Roboinject logo,

switch the Roboinject on and wait until the status lamp turns green.

on the desktop.

15

Page 20

Roboinject Manual

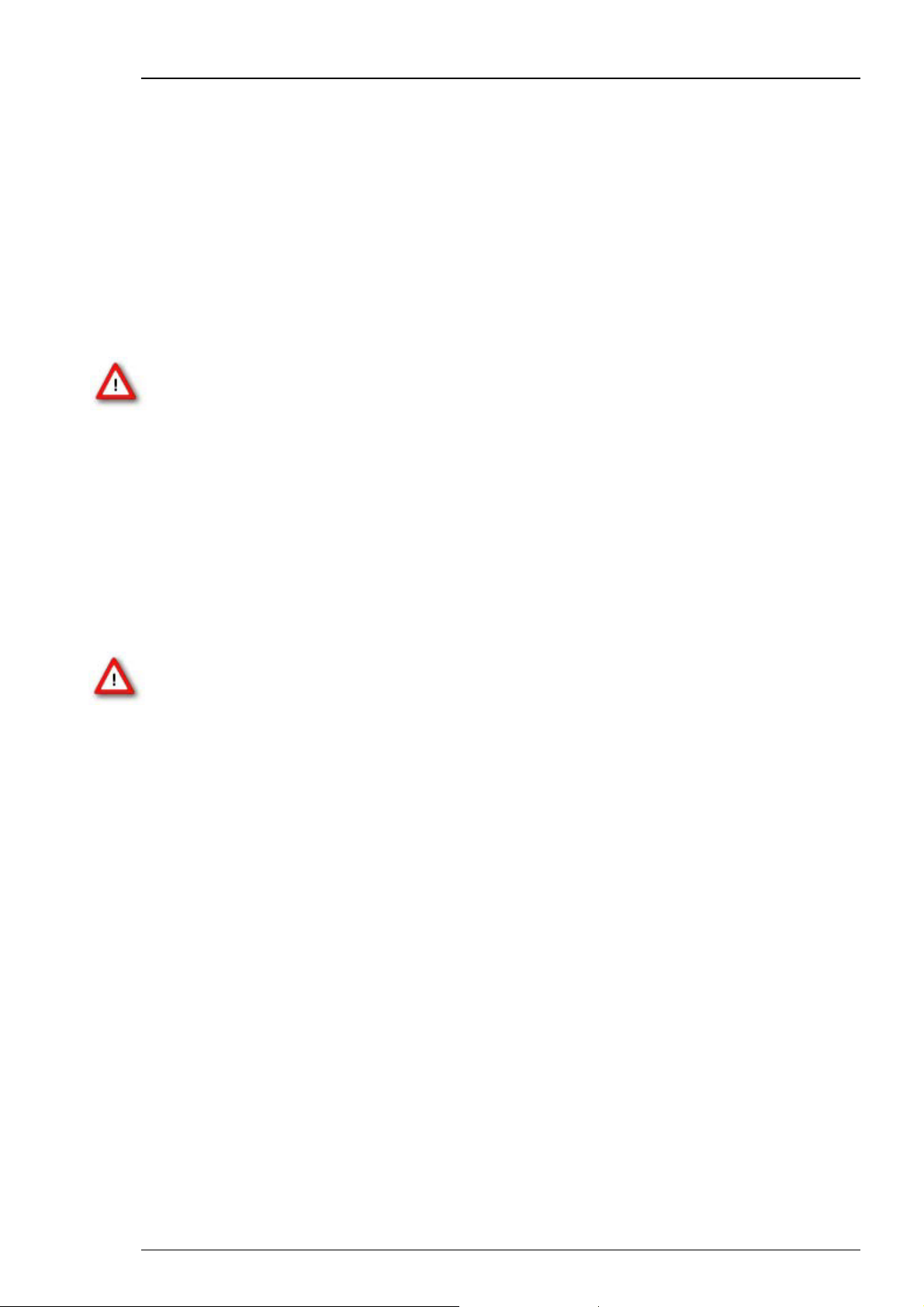

The Roboinject main window opens.

16

Page 21

3.6 Main Menu

For maximum flexibility all relevant parameters for the injection can be changed by the user

via main menu.

Note: The preset default values have been extensively tested with RNA and DNA injection of

Xenopus oocytes and should work in most circumstances. Therefore, it is advisable to use the

default values for the first injections with Xenopus oocytes.

File

Roboinject

Menu for creating new files, opening existing files, and for saving them. Menu for opening

and saving templates, and for closing the program.

The option "Export to Roboocyte1" is a feature for exporting plates to the Roboocyte1 device

from Multi Channel Systems MCS GmbH.

Well plate files, created and saved with Roboinject software, can be transferred to the data base

of Roboocyte1 software. The corresponding well plates, injected with the Roboinject device can

be processed with the Roboocyte1 device. The feature is available only for owners of Roboocyte1

devices (Clamp Amplifier A and Clamp Amplifier B) and together with Roboinject software

version 1.1.0 which includes a firmware update. It is not possible to export plates to other devices.

17

Page 22

Roboinject Manual

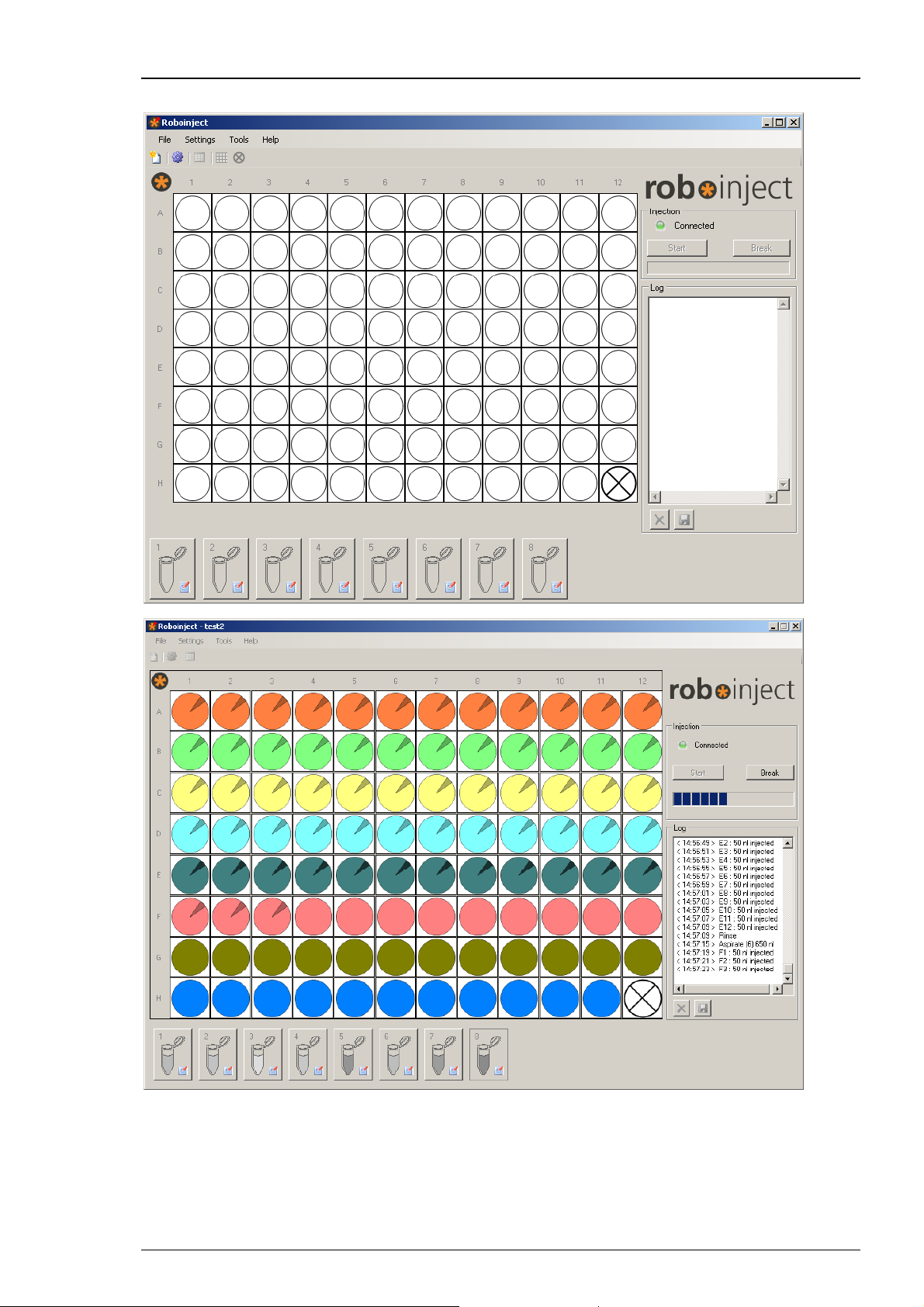

Click "New" in "File" menu. The following "Plate Info" dialog opens.

Please give an appropriate file name in "Plate ID". The type of the well plate can be defined

from the "Plate Type" drop down menu. If you want to set the selected plate type as default,

please enable the check box "Set As Default". You can type in notes concerning the actual

experiment into the "Comment" text box. All information will be stored in the plate info (*.rpf)

file, and displayed in the report sheet.

If you want that the plate ID is automatically counted up when creating a new file, please enable

the check box “Auto increment plate ID” in “General” tab of the “Options” dialog in main menu

“Settings”.

Click "OK" to enter additional dialogs, or to start the injection.

If you want to inject the same plate again or review previously injected cells, open the appropriate

well plate file.

18

Page 23

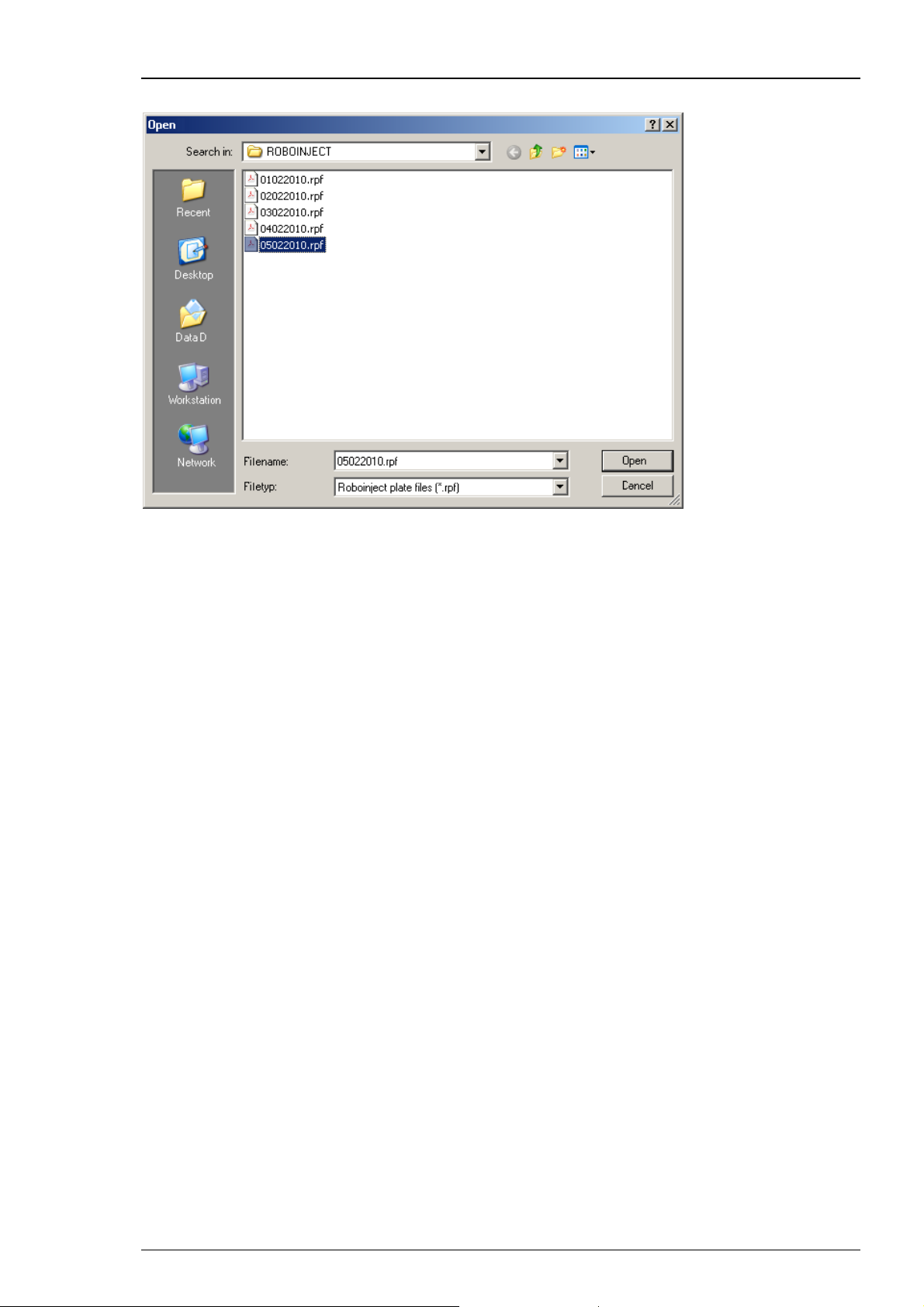

Click "Open" in "File" menu. The "Open" dialog box appears.

Roboinject

Browse your folders and select the Roboinject plate info file (*.rpf) you want to open.

Click "Open". The main window now shows the state of the already saved plate.

Click "Save" to save a Roboinject plate info (*.rpf) file. It will be stored in the selected

"Plate Info" directory.

Click "Save Template" and "Open Template" to open and save a template (*.rit) file.

It will be stored in the selected "Template" directory, respectively.

Click "Exit" to close the Roboinject software program.

19

Page 24

Roboinject Manual

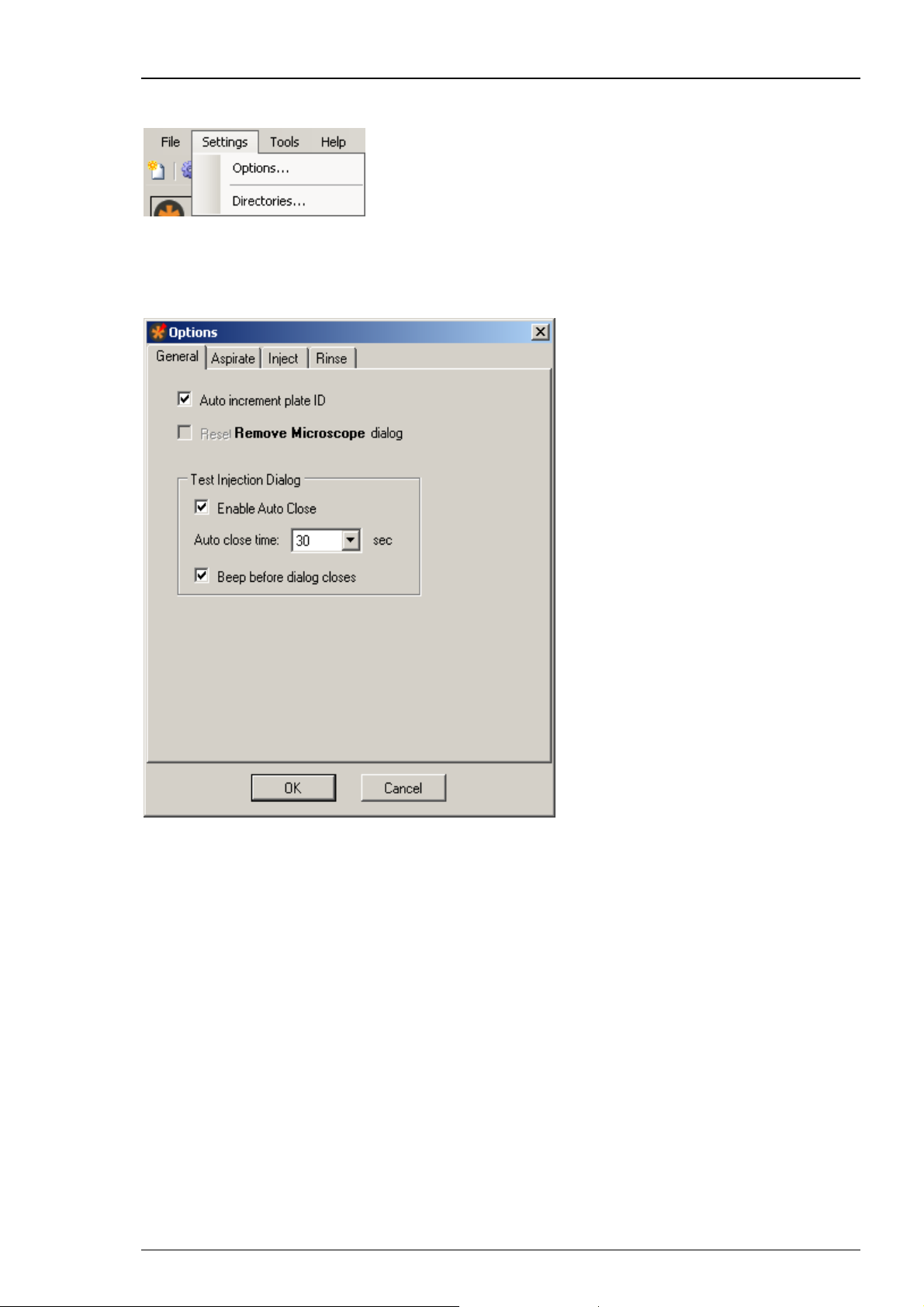

Settings

Menu for setting options and for defining directories.

Click "Options" in main menu "Settings". The "Options" dialog has four tabs.

Click "General" tab.

The dialog allows general settings concerning two general software features,

and the "Test Injection Dialog" in particular.

Enable the check box "Auto increment plate ID", if you want that the plate ID

is automatically counted up when creating a new file.

Enable the check box "Reset / Remove Microscope dialog" if you want to see

the “Remove Microscope” dialog after alignment again.

The “Test Injection” dialog appears immediately before the injection run of each sample

if selected in the "Sample Information" dialog. This allows the user to execute a test

injection before starting the injection run or to stop the injection run completely.

With regard to the "Test Injection Dialog" you can select or deselect the two check boxes

"Enable Auto Close" and "Beep before dialog closes". Additionally you can choose

the time span for displaying the "Test Injection Dialog" from the drop down menu.

The "Auto close time" varies from 30 to 180 seconds.

20

Page 25

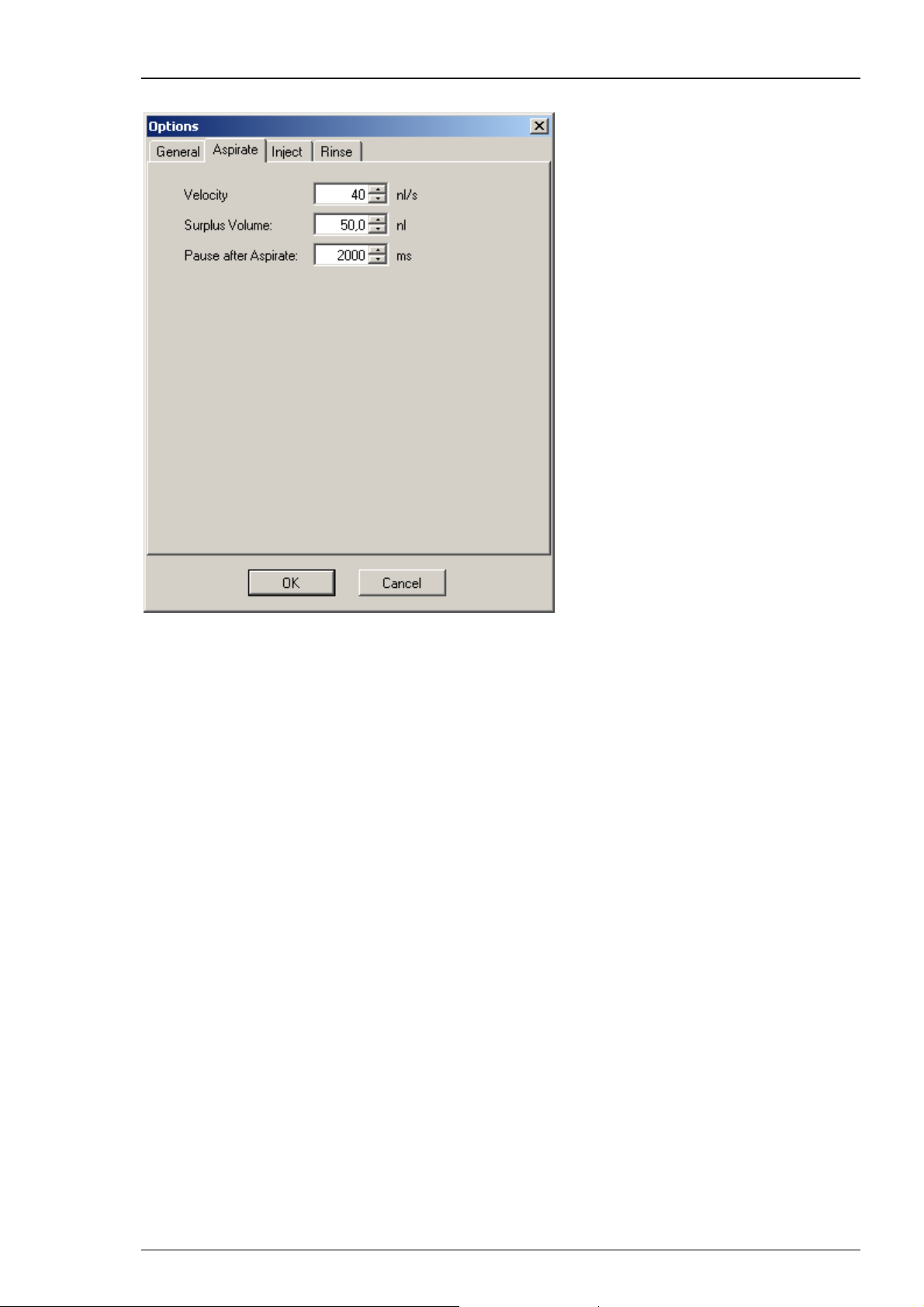

Click "Aspirate" tab.

Roboinject

This dialog allows to define the aspiration of compound from the reservoir tubes.

The parameters are the “Velocity” of aspiration in nl/s, the “Surplus Volume” in nl,

and the “Pause after Aspirate” in ms.

“Velocity”: The aspiration velocity for a given compound depends on its viscosity. Samples

with high viscosity should be aspirated slower than samples with low viscosity. This prevents

the accumulation of negative pressure inside of the injection needle leading to the formation

of air bubbles inside of the capillary.

“Surplus Volume”: In order to prevent the injection of minute volumes of mineral oil -

the needle was filled with first - with the last injection, you can define a "Surplus Volume".

The volume will be aspirated additionally to the injection volume, defined in the "Injection" tab.

Values of 50 nl are recommended.

"Pause after Aspirate": You can define a time period during which the injection needle stays

in the compound after aspirating the RNA, DNA or other compounds, before the injector mount

moves upward. This feature minimizes the risk of sucking air into the needle tip. A time span of

2000 ms is recommended.

21

Page 26

Roboinject Manual

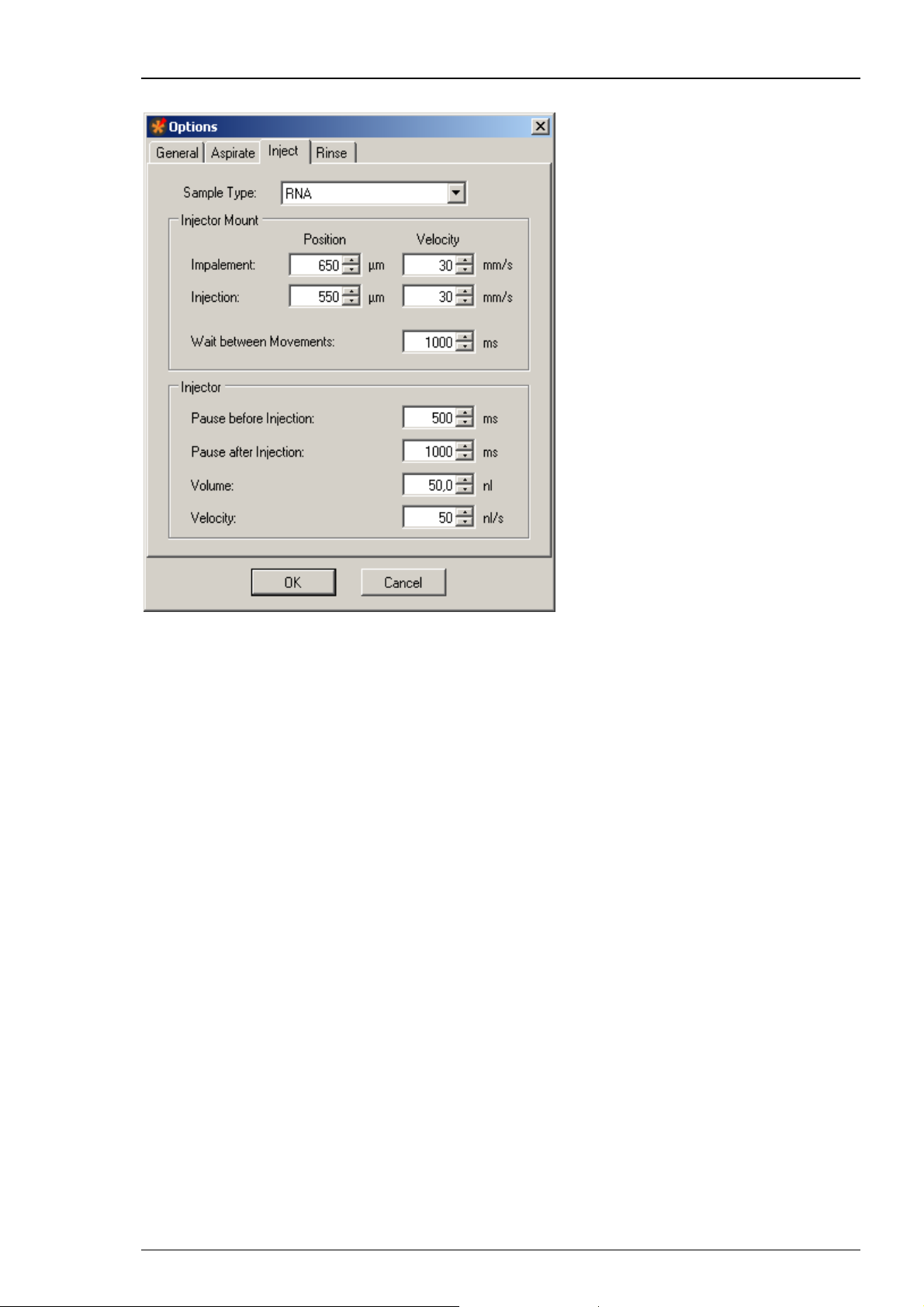

Click "Inject" tab.

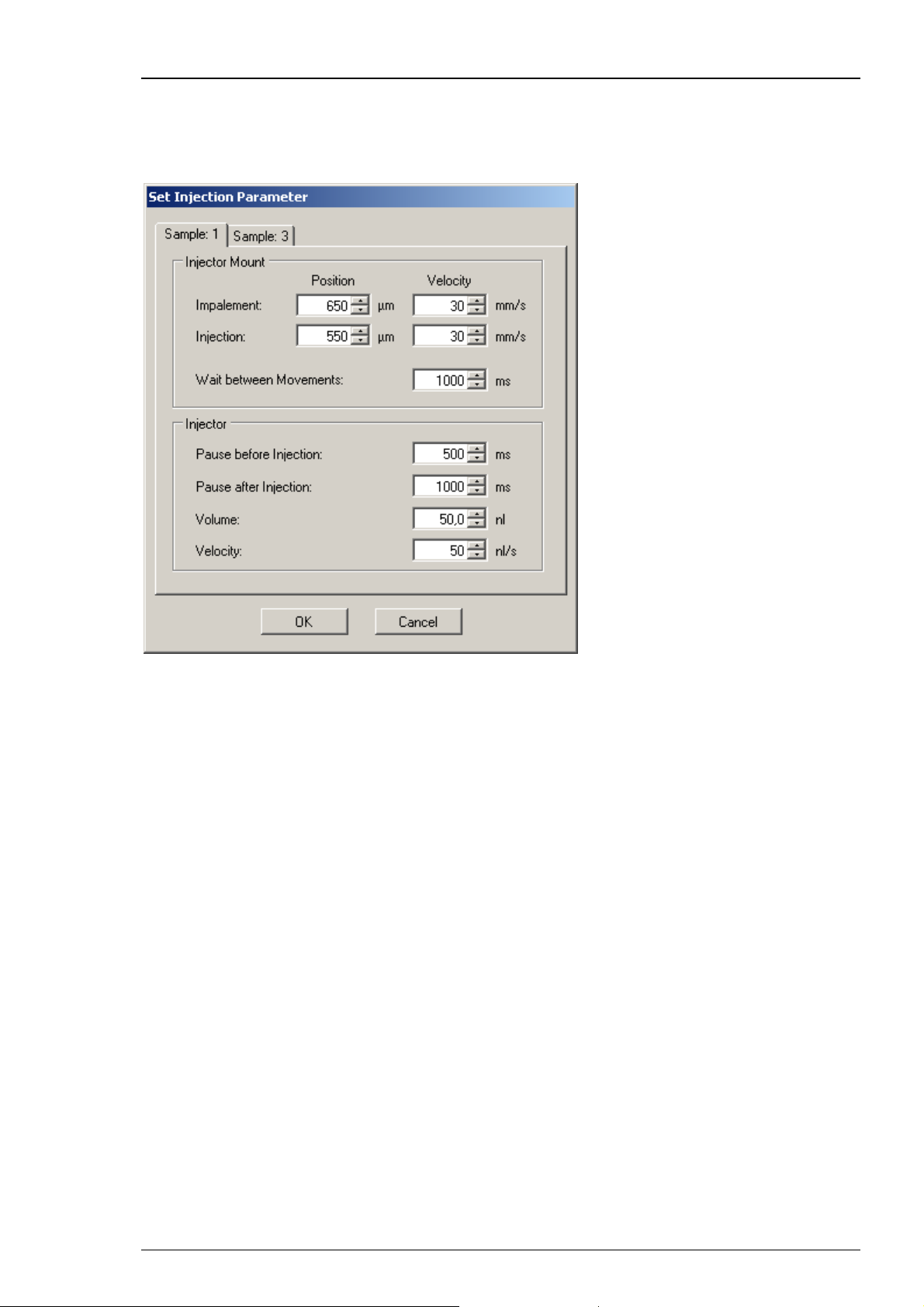

The dialog allows to define parameters concerning the “Injector Mount” (z-axis) and the

“Injector” device itself. The settings are attributed to the different "Sample Types" such

as RNA, DNA or others.

“Sample Type”: Define the type of compound to which you want to assign the setting

parameters from the drop down menu.

“Injector Mount = z- Axis”:

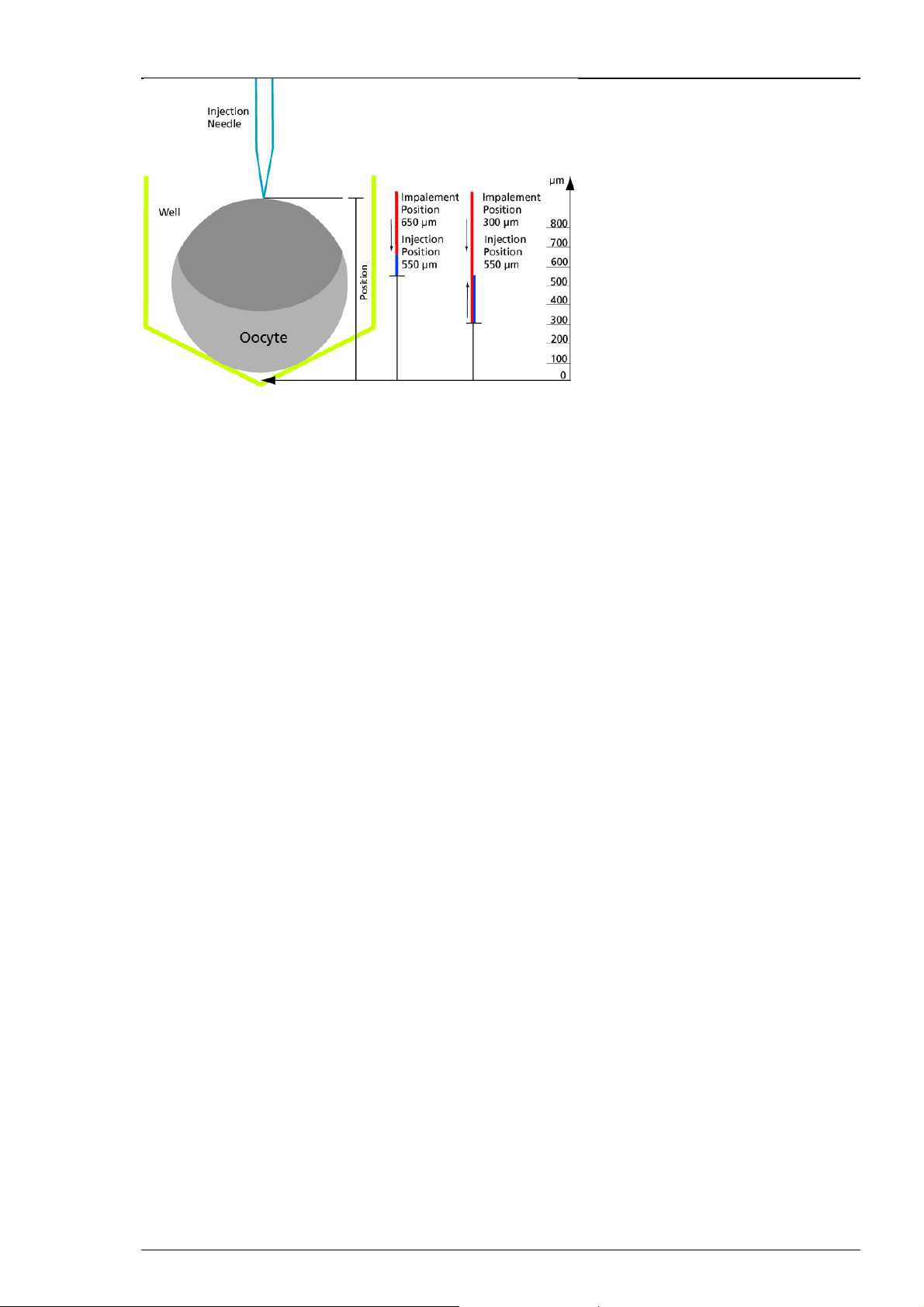

You can separate the impalement process of the injection needle into an oocyte or another cell

in two phases. This is especially useful, for example, when working with "soft" oocytes. If the

first movement (for example, to 650 μm above well bottom) only pushes down the cell without

penetrating the vitelline layer and membrane, a second movement (for example, to 550 μm

above well bottom) will most likely lead to a successful impalement. Please see the picture.

Please define the parameters of the first step, called “Impalement Position”. Please note that

the value in micrometer refers to the distance between the tip of the needle and the well bottom.

Define the “Velocity” of impalement in mm/s. The default value of 30 mm/s was intensively

tested with oocytes and will work in most of the cases.

Please define the parameters of the second step, called “Injection Position”. Define the position

of the injection in μm from the up-down control. Please note that the value in micrometer refers

to the distance between the tip of the needle and the well bottom in relation to the bottom of

the well. Define the “Velocity” of injection in mm/s. Again, the default of 30 mm/s will work with

most oocytes.

22

Page 27

Roboinject

Example on the picture: The bottom of the well is value zero, the reference value. If you define,

for example an impalement position of 650 μm, the injector mount will move down until its

position is 650 μm above the bottom of the well. If you additionally define an injection position

of 550 μm, the injector mount will move down again until its position is 550 μm above the bottom

of the well.

If you define, for example an impalement position of 300 μm, the injector mount will move down

until its position is 300 μm above the bottom of the well. If you additionally define an injection

position of 550 μm, the injector mount will move up until its position is 550 μm above the bottom

of the well.

The “Wait between Movements” in ms as well as the "Pauses before and after Injection"

can be adjusted to user preferences.

“Injector”

The injection interval is terminated by the time frame before injection "Pause before

Injection", and the time frame after injection "Pause after Injection", both measured in ms.

The default values for the wait times before and after injection (500 ms and 2000 ms, respectively)

have been tested with oocytes and RNA injections.

You have to define the injection “Volume” in nl, and the “Velocity” in nl/s from the up-down

controls. The respective default values (50 nl and 70 nl/s) have been tested with oocytes and

should work in most cases.

23

Page 28

Roboinject Manual

Adjusting the Injection Parameters for each Well separate

It is possible to adjust the settings for the injection for each single well separate. Click with

the right mouse button onto a well in the virtual well plate, and the following dialog appears.

Now you can adjust the injection parameters for this specific well and for each sample separate.

If the oocyte in the specific well should be injected with different samples, you can adjust

the injection parameters for each sample separately. Please click the "Sample" tabs.

24

Page 29

Click "Rinse" tab.

Roboinject

Rinsing the injection needle between the injection of different samples is mandatory for

preventing cross-contamination. In principal, you can reuse an injection needle as long as

it is not clogged or broken. Nevertheless, MCS does not recommend to reuse the needle

longer than one day after the last injection.

Define the number of "Repeats", the "Rinse Volume" in nl, and the "Velocity" in nl/s

from the up-down controls to avoid contamination when working with different compounds.

Volumes of 1000 nl and three repeats guarantee the absolute purity for each injected sample.

Click "Directories" in main menu "Settings". The "Set Directories" dialog opens.

Templates: Please browse through your folders, and define the directory you want to store

your template files with the extension "*.nit".

Plate Info: Please browse through your folders, and define the directory you want to store

your plate info files with the extension "*.rpf".

The "Log" file with the extension "*.log" is a file you can save by users command from

the "Log File" window. Please browse through your folders, and define the directory you

want to store the log files.

25

Page 30

Roboinject Manual

Tools

Menu for manual mode and for creating a report sheet. The option "Set Plate to Manually

Injected" offers the possibility to document information about a well plate, loaded with manually

injected oocytes which will be processed with the Roboocyte1 device. Please see below.

About software controlled manual manipulation of the Roboinject, please read the next chapter

"Toolbar" "Open Manual Mode Dialog".

Click "Show Report".

The report sheet displays all important information about the selected well plate: Plate ID,

plate file destination, report date, plate date, plate type and notes written in the comment.

When injection run has finished you find additionally the definition of the samples,

and the well plate. The log file is displayed.

26

Page 31

Roboinject

Click "Set Plate to Manually Injected".

When you are using the Roboocyte1 device from Multi Channel System MCS GmbH and you

decide to inject manually, or if you performed manual injection with Roboinject for other reasons,

you can define the oocytes of a well plate as "injected" with this function.

Click "File" menu “New” to create a new plate. Fill in the respective information about the well

plate, created and injected in Roboocyte1.

Define the samples which were used for injection in Roboocyte1 device.

Define the respective wells in the plate view.

Right-click on each well to document the information about the injection of the cells in the “Set

Injection Parameter” dialog. After that click the option “Set Plate to Manually Injected”, and the

wells - already injected in Roboocyte1 - are marked as injected with black arrows. After doing so,

please save the file. Then you can create and print a report about a well plate, which can not be

created in Roboocyte1 software. The feature is available only for owners of Roboocyte1 devices

(Clamp Amplifier A and Clamp Amplifier B) together with Roboinject software version 1.1.0 which

includes a firmware update.

27

Page 32

Roboinject Manual

Help

The menu offers the use of the Roboinject online help, and shows the "About Roboinject" dialog.

Click “Roboinject Help” to start the online help.

Click "About".

The dialog displays the actual used version of Roboinject software, and hardware information.

Note: Please keep in mind that these information are essential in case of support!

28

Page 33

3.7 Toolbar

Roboinject

Click the "New File" icon

The "Plate Info" dialog opens. Please read the description in chapter "File" of the main menu.

.

Click the "Open Manual Mode Dialog" icon

.

29

Page 34

Roboinject Manual

The "Manual Mode" dialog opens. The dialog is divided in five sections: Global, Plate Carrier,

Air Pressure, Injector Mount and Injector. That means, you are able to influence each part of the

device manually via software controls. The commands inside the sections refer to the plate carrier,

the injector mount (= z-axis) and the injector (= plunger) only. The "General" section refers to the

complete device. The "Air Pressure" check is for measuring the air pressure in the pressure line of

the Roboinject device.

Warning: The "Manual Mode" gives you the chance to test the Roboinject device and all its

parts separately. Since all kind of movements are allowed, you can easily destroy almost any

part of the Roboinject by executing movements at the wrong time. Please always doublecheck before executing any command, whether this command could be harmful to the

Roboinject.

Examples:

Moving the carrier when the injection needle is inside of an well will destroy the needle.

Moving the z-axis to "Tube" position when the carrier is at any well position will destroy

the needle and bend the plunger.

Moving the carrier when the z-axis is at "Tube" position will destroy the injector device

and bend the plunger.

Please handle with great care!

Global Section

Click "Reference" to perform reference movements of carrier, injector mount (z-axis),

and injection plunger.

Click "Coarse Position" to initialize the manual carrier and z-axis alignment after installation of

the injection needle. The z-axis will move to a position 3 mm above the last z-alignment position,

and the carrier will move to the last x/y-alignment position. (If the last alignment was right,

this will be exactly below the position of the injection needle).

Click "Change Plate" for changing the well plate. The carrier will move to a position at which

you can easily access the well plate or the reservoir reaction tubes.

Click "Home" for moving the carrier and the z-axis in home position (X = 0, Y = 0, Z = 0).

Click "Set Alignment" for setting the actual position of carrier and z-axis at the alignment

position. Before doing so, please insert the alignment tool in well H12 when using a 96 well plate.

Click "Change Needle" for installing, changing or removing the injection needle in the injection

mount. The carrier will move to its home position (or stay there), and the z-axis will move down

to allow you an easy access to the luer connector for the injection needle.

30

Page 35

Plate Carrier Section

Click "Reference". The carrier performs its reference movement in x/y direction.

If the carrier does not move, please check all cable connections.

Roboinject

Warning: Perform the alignment procedure before using any of the following commands.

Please double-check whether the z-axis is in "Home" position whenever carrier movements

are elicited. Otherwise there is the risk of severe damage to the injector.

Click "Home" for moving the carrier in home position. The home position is defined as the

backmost right corner of the x/y table when looking on the front panel of the Roboinject

(X = 0, Y= 0).

Select a "Well" from the drop down menu. Select well A1, for example, and click "Well".

The carrier will move until well A1 is exactly underneath the injector axis.

Select a "Tube" from the drop down menu. Select tube 1, for example, and click "Tube".

The carrier will move until tube 1 is exactly underneath the injector axis.

Select "Rinse 1", "Rinse 2" or "Waste". This will move the carrier to the tubes serving as rinse

and waste station, respectively.

Click "Air Cushion", and select "Slow" or "Fast" movement. Use the arrow buttons

to move the carrier stepwise in 30 μm steps (slow) or continuously (fast) to any desired position.

The X and Y values show the actual position relative to the home position (X = 0, Y = 0).

The air cushion pressure is only present when the carrier receives a movement command from the

software. Therefore, never touch the carrier or try to move the carrier manually when it performs

software controlled movements. There is only one exception during alignment of the carrier to

the grid of the table manually. For this purpose, switch on the air cushion pressure by clicking "Air

Cushion" in “Manual Mode”. In this mode it is possible to move the carrier safely by hand as long

as the "Air Cushion" button is active. Please see chapter "Alignment of the Well Plate Carrier".

Warning: Remove the injection needle before manually moving the carrier. Otherwise there

is the risk of severe injury and damage of the injector.

31

Page 36

Roboinject Manual

Air Pressure Section

Check the air pressure. It should be set to a minimum value of 3000 hPA,

and should never exceed a value of 4 bar.

Injector Mount = z-Axis Section

Click "Reference". The z-axis will perform its reference movement and will stop in home position.

The depicted Z value is 0 μm.

Click "Home" to move the z-axis into home position. The home position for the z-axis is defined

as the position when the injection device is at its topmost position. The depicted Z value is 0 μm.

Click "Tube". The z-axis moves to a position from where a sample can be taken up from one of

the reservoir tubes.

Warning: Never try to move the z-axis to any tube position before moving the carrier

to the respective tube. Otherwise there is the risk of severe damage of the injector.

Click "Impalement". Select the "Depth" of impalement from the drop down menu.

Select "Rinse 1", "Rinse 2" or "Waste". The actual position of the z-axis will be displayed

in "Z = x μm".

Use the arrow buttons to move the z-axis stepwise in 20 μm "Slow" or 200 μm "Fast" steps

up and down. The "Z" value shows the actual position of the z-axis in μm relative to the home

position (Z = 0).

32

Page 37

Roboinject

Injector = Plunger Section

Click "Reference". The plunger will perform its reference movement and will stop in home

position.

Click "Home" to move the injection plunger inside the z-axis into home position. The home

position is defined as the topmost position.

Click "Replace" to start the needle installation or needle changing.

Click "Empty" to move the injector plunger continuously from the topmost position into the

injection needle to extrude the oil filling of a new injection needle.

Click "Aspirate" to move the injector plunger upwards for aspirating the volume in nl selected

from the up-down control beside the button. Be sure to immerse the tip of the needle into the

medium you want to aspirate to avoid the suction of air into the needle.

Note: You cannot aspirate more "volume" than it has been ejected before by the command

"Empty".

Click "Inject" to move the plunger stepwise from top to bottom, for injecting the volumes

selected from the up-down control beside. It is possible to inject volumes from 1 to 100 nl.

Changing the Injection Needle

Click on the

icon to open the "Manual Mode" dialog.

Use the injector section to test the functionality of the injector with installed injection needle to

test the injector under more realistic conditions or to do injections manually. Click "Home" and

wait until the plunger arrived at its topmost home position. Click "Replace" in “Injector Section”

of “Manual Mode” if there is an used needle installed, and remove it carefully. Be sure not to

bend the plunger wire.

Fill a fresh injection needle completely and air-bubble free with mineral oil. Install the needle by

inserting the plunger wire end slowly into the capillary. Lock the luer connector tightly but not

with excessive force.

33

Page 38

Roboinject Manual

Alignment of the Well Plate Carrier

The well plate carrier hovers over the magnetic x/y table. For a smooth and proper movement,

it is crucial that the table is kept dry and clean, and the carrier is properly aligned on the table.

Clean the x/y table with a soft tissue and pure alcohol.

Click on the

icon to open the "Manual Mode" dialog.

Activate the air cushion by clicking on the "Air Cushion" button. Now it is possible to move

the carrier carefully by hand. Switch the Roboinject off for cleaning the x/y table and the carrier.

After cleaning, switch the Roboinject on. Activate the air cushion again to align the carrier

precisely to the grid on the x/y table by hand. The air cushion will be automatically deactivated

when you close the "Manual Mode" dialog.

Important: A manual movement of the carrier is possible only if the Roboinject is switched

on and the air cushion is present. Please make sure that the compressed air pressure is sufficient

(minimum 3 bar).

Warning: Do not use aqueous solutions and / or cleaning agents for cleaning the magnetic

x/y table. Otherwise, the carrier and / or the x/y table can be damaged. Please make always

sure that the carrier is aligned to the grid of the table. Otherwise, a correct movement of

the carrier is not possible.

Click "Show Report" icon

.

Please see chapter "Tools", "Show Report" of the main menu.

Click "Clear Plate" icon

.

The "Clear Plate" button sets back all wells which are already assigned to a sample

to the original, non-selected status. The deselected (crossed out) wells will remain.

Click "Void Well" icon

.

The icon is for selecting or deselecting wells in the virtual well plate. If you activate the button

"Void Well" you can select and deselect single wells or rows and columns. The deselected wells

are crossed out, and will not be injected.

34

Page 39

3.8 Control View

Roboinject

The "Control View" on the right side of the main window of the Roboinject software is divided

into two smaller windows: "Injection" and "Log" file.

In the "Injection" window the status LED indicates the status of the device. Green color indicates

a valid connection between Roboinject and computer, red color indicates no connection.

The "Start" and "Break" buttons start and interrupt the injection process. The status bar below

the buttons displays the injection proceeding during the injection run.

In the "Log" file window the injection process is documented.

35

Page 40

Roboinject Manual

"Injection" Window

After completing the definition of the injection protocol the "Start Injection Wizard" proceeds

with the final preparations for the injection.

Via "Start" and "Break" buttons you start and stop the injection manually. The status bar under

the buttons will show the processing of the injection.

Click the "Start" button. The "Preparation" dialog of the "Start Injection Wizard" appears.

Air pressure: Please check the air pressure, the minimum has to be 3 bar = 3000 hPa.

Check the connection status: A green LED indicates a sufficient air pressure.

Plate Carrier: Click "Change Plate". This command will move the carrier to an easily accessible

position. Please remove the old well plate from the carrier if necessary, Take a well plate from

the type you specified in the "Plate Info" dialog box. Place the plate onto the carrier and press

it against the springs in the lower middle and lower right corner of the carrier. Then put the rest

of the plate down onto the carrier. The well plate position is correct when there is no play

between the well plate bottom and the carrier surface at all edges and when the well plate

has full contact to the left and upper side of the carrier holding frame.

Place the reservoir tubes according to their appearance in the virtual well plate in the respective

mounting holes. Do not use excessive force. Also place the rinse tubes and the waste tube at their

designated positions.

Click "Home" for moving the well plate carrier into the home position.

Injector Mount: Please mount an injection needle. Click "Change Needle". Enable the check box

"Reset Needle Coarse Position" to initialize the manual z-axis alignment after installation of

the injection needle, if the needle length has changed.

Put the alignment device (with crosshairs) into well H12. Please read chapter “Alignment”.

36

Page 41

Click "Next". The "Alignment" dialog of the "Start Injection Wizard" appears.

Roboinject

Plate Carrier: It is possible to move the plate carrier stepwise with the arrow buttons

in x- and y- direction on the table. The actual position of the carrier in relation to the home

position (X = 0 μm, Y = 0 μm) is displayed.

Use the arrow buttons to move the carrier stepwise in 30 μm steps (slow) or continuously (fast)

to any desired position. The X and Y values show the actual position relative to the home position

(X = 0, Y = 0).

Injector Mount: It is possible to move the injector mount stepwise with the arrow buttons

in z- direction on the plunger. The actual position of the carrier in relation to the home position

(Z = 0 μm) is displayed.

After proper alignment in x, y, and z- direction click "Finish".

The "Remove Microscope" dialog appears.

Please enable the check box if you do not want to see this dialog again. You can display

the dialog again when selecting the check box "Reset Remove Microscope dialog"

in the "General" tab of the options dialog.

Click "OK" and a sequence of movements are performed. First, the carrier moves to "waste"

position and the oil is extruded into the waste container. Then, the carrier moves to the first

defined sample tube and the necessary volume is taken up. Finally, the test injection dialog opens

if "Test Injection" was selected in the "Sample Information" dialog of the respective sample.

37

Page 42

Roboinject Manual

The "Test Injection" dialog appears immediately before starting the injection process

of the selected sample.

This dialog gives the user the possibility to check the transmissibility of the tip opening of the

injection needle. The defined sample volume will be injected into air. Before doing so, please

place the microscope on the x/y table in a way that you can clearly see the needle tip.

Multi Channel Systems MCS GmbH recommends up to two test injections for checking the

transmissibility of the tip opening. The additional volume for two test injections is aspirated

automatically in addition to the injection volume necessary for all injections of the respective

compound. The default test injection volume is half of the injection volume. If you have defined

different injection volumes for a respective compound, it is half of the largest injection volume.

If you do more than two test injections, the missing volume is automatically taken up during

the injection process.

Click the button "Inject" to perform the test injection the volume of which is displayed

in the up-down control window.

The "Sample" window displays important sample parameters. In the "Auto close" window

the time in seconds is counted down before this dialog is automatically closed.

Click "Continue" to start the injection process.

Click "Halt Time" if you need more time, for example, to check the tip opening by doing

test injections.

Click "Break" to stop the test injection and the general injection process, for example,

if the injection needle is broken or clogged.

The "Injection Halt" dialog appears.

38

Page 43

To control the ongoing injection process you can choose between three possibilities:

Click "Continue" to continue with injection process.

Click "Cancel" to stop the injection process. The carrier and the injection mount will

automatically move to home position.

Click "Stop" to stop the injection process without any movement of carrier or z-axis.

This is useful in case of severe malfunctions which could possibly lead to damages

if further movements would be performed.

After a successful injection process the Roboinject software displays

the "Injection Finished" dialog.

Roboinject

Click "OK" to continue with the same well plate, or remove the plate and click "OK".

"Log File" Window

The log file is displayed in the "Log File" window. The "Log" file documents the injection

process. To save the log file, click the "Save Log"

"*.log". To delete the log file, please click the icon "Clear Log"

icon. The log file has the extension

.. If you save the log file,

the "Save As" dialog will open. Please browse through your folders, and define the directory

you want to store the log file.

39

Page 44

Roboinject Manual

3.9 Tube View

In the "Tube View" you control the definition and selection of the samples. You can use

the eight reservoir tubes for eight different samples.

Click onto the symbol

The "Sample Information" dialog opens.

of a "Edit Sample" icon.

This dialog allows the definition of the respective injection samples inside of the 0.5 ml

micro reaction tubes.

Note: The sequence of injection is always from left sample (No 1) to right sample (No 8).

Please keep this in mind if the injection sequence of samples is of importance for you.

Enter an ID and / or a name which univocally identifies your sample in the "ID" and "Name"

window.

Select the type of sample RNA, DNA or Other in "Sample Type", and its "Concentration".

Important: The minimal volume which always has to remain in the tube reservoir is 1 μl.

For example, if you need 4 μl sample volume for your injection run, please make sure that

you start with at least 5 μl. This is because the injection needle keeps always a safe distance

to the tube bottom to avoid uptake of contaminants and clogging.

Enable the check box "Test Injection". The "Test Injection" dialog will appear before

the injection process of a sample is started. Please see chapter "Test Injection" dialog.

Type notes concerning the actual experiment into the "Comment" text box, for example,

the type of the sample when selecting "Others". The comments are saved in the "Plate Info"

file and shown in the report sheet.

40

Page 45

Roboinject

Click the "Set Injection" button for setting injection parameters for that sample. Ignore the

button for keeping the default settings.

Click "OK" to complete the settings for this sample. Click "Clear" if you want to restart with

default values, and "Cancel" if you want to go back to the main window without changes.

Repeat the settings in "Sample Information" of other tubes until all samples you want to inject

are defined.

Note: The sequence of injection is always from left sample (No 1) to right sample (No 8). Please

keep this in mind if the injection sequence of samples is important for your injection process.

Click "Set Injection". The "Set Injection" dialog opens. The parameters are also available

in the "Inject" tab of the "Option" dialog in main menu "Settings". Please read chapter

"Inject" tab of the "Options" dialog in "Settings" menu.

After finishing the settings in the “Sample Information” dialog the tube icons appear colored,

according to their content for a good discrimination between the compounds.

41

Page 46

Roboinject Manual

3.10 Well Plate View

This prominent "Well Plate View" shows a 96 well plate. When using a 384 well plate,

this view is automatically adapted.

Click the "Void Well" icon

well. To select or deselect complete rows or columns, click onto a letter on the left side to mark

a horizontal row, or onto a digit on top to mark a column. Deselected wells are crossed out,

and will not be injected. The well H12 is deselected by default. It is used for the alignment tool,

please read chapter "Alignment" for more information.

. To select or deselect a single well, please click onto the respective

42

Page 47

Roboinject

Click the "Clear Plate" icon to set back all wells to the original, non-selected status.

The deselected (crossed out) wells will remain.

43

Page 48

Roboinject Manual

Defining the Samples

After setting up the "Sample Information” dialog, the samples of the tubes are fixed. To define

which well should be injected with which sample, please click onto the tube icon first, and then

onto the well icon. The color of the well will immediately change into the symbol color of the

sample of the selected tube. Choose another tube to assign one or several wells to that tube

sample respectively. It is possible to assign any well to any sample. Use the letters and digits

to correlate horizontal rows and vertical columns to the samples. Use the Roboinject icon

to select and deselect the sample of the complete well plate.

44

Page 49

Roboinject

Defining the Number of Injections into a single Oocyte

In some experiments it is necessary to inject more than one compound into a single oocyte.

The Roboinject program gives the possibility for up to four injections into the same oocyte.

To define the well for several injections, please click onto the tube icon first, and after that

onto the well. The color of the well will immediately change into the symbolic color of the

sample of the selected tube.

Select a second tube icon, and click onto the same well again. One half of the color of the well

will immediately change into the color of the second sample.

Select a third tube icon, and click onto the same well again. One third of the color of the well

will immediately change into the color of the third sample. Select a fourth tube icon, and click

onto the same well again. One quarter of the color of the well will immediately change into

the color of the fourth sample.

Click "Clear Plate" to set back all wells to the origin, non-colored status. The deselected

(crossed out) wells will remain. After successful injection the wells (or sections of the well)

will be marked with an arrow.

45

Page 50

Page 51

4 Injection

4.1 About Injection with the Roboinject

Manual injection is often a limiting factor in high-throughput screens. The Roboinject injects

Xenopus oocytes and other large cells or small embryos in a fully automated way.

For example, injection and cultivation of Xenopus oocytes are performed using disposable

standard 96 well plates, which are commercially available from several providers. The oocytes are

plated into the wells in a couple of minutes and can be kept there for several days. They quickly

settle within the cone-shaped wells and adhere to the well bottom after a few hours. The oocytes

do not have to leave the plate anymore; you can easily transfer the oocytes from the incubator to

the Roboinject and back again. For other cells or organisms custom-designed well plates can be

easily adapted.

The cDNA, mRNA or compound to be injected is automatically taken up into the injection needle

and then pushed into either the nucleus or the cytoplasm by the positive displacement method.

Using positive displacement has the advantage that the injected volume is always as pre-selected.

Importantly, it is independent of the viscosity of the samples or the opening diameter of the

injection needle. Another advantage of positive displacement based injectors when compared

to air-pressure driven system is, that there is no need of tedious volume calibrations.

The overall expression rate you can achieve with the Roboinject is by no means worse than success

rate with manual RNA injection of Xenopus oocytes and can reach close to 100 percent. Of course,

the success rate depends on the receptor type and oocyte performance.

47

Page 52

Roboinject Manual

4.2 Strategies for a Successful Injection

Multi Channel Systems provides injection pipettes with an inner diameter exactly matching the

plunger wire. The provided injection pipettes are glued to luer-fittings and therefore ready to use.

If you nevertheless decide to fabricate your own injection pipettes you should keep in mind that

you can only use the capillaries listed in the chapter "Ordering Information" in the Appendix.

Other capillaries will not work properly.

The Roboinject software allows to define the impalement and injection position for each sample

separately during the well selection process. The "Impalement Position" and the "Injection

Position" in the main "Set Injection" window denotes the distance of the needle tip to the well

bottom (zero value). This means, for example, that for an oocyte with a diameter of 1.2 mm an

impalement or injection position of 650 μm would correspond to an oocyte impalement depth

of 550 μm (1200 μm - 650 μm = 550) Please read chapter "Inject" tab of "Option" dialog in

"Settings" menu.

Changing and loading the injection needle

Click

or install a new needle. "Change Needle" will move the plunger and carrier in home position

and move the z-axis a bit down for better access to the luer connector for the needle.

Use a fine pipette tip, for example, a microloader tip filled with mineral oil. Insert the fine tip into

the injection needle as close as possible to the needle tip. Fill the injection needle completely and

air-bubble free with oil. The remaining air in the tip region will be cleared automatically later on.

Insert the plunger wire carefully into the needle end, move it slowly up and close the luer lock.

Part of the oil will drop out of the needle tip. Remove it with a soft tissue from the table.

Be careful not to break the glass capillary.

to start the “Manual Mode” dialog. Use the "Change Needle" command to change

48

Page 53

Injection

Xenopus oocytes

The impalement and injection distances for cDNA are preset to 300 μm and 550 μm, respectively.

(from the bottom of the well = 0 value).

These distances have been shown as the optimum values for DNA injection. The overall expression

rate you can achieve by this method is 80 percent of the oocytes. You can define your own

impalement and injection depth, but MCS recommends using the default values in order to

achieve the best expression rate.

You may wonder why the injection needle is placed so deeply for cDNA injections while the

nucleus is known to be located near the animal pole. As it seems, the nucleus is pressed down

by the injection needle until the pressure is sufficient for the needle to penetrate the membrane

of the nucleus.

Messenger RNA is injected into the cytoplasm. Generally, it is not important where in the

cytoplasm the RNA is released. The default impalement and injection distances for mRNA

are 650 μm and 550 μm, respectively. These are safe values even for smaller oocytes.

Running a test for nuclear injection with a dye

To demonstrate the precision of the injection and to practice the general handling, you may

consider running a test injection with the dye "Trypan Blue", which stains proteins unspecifically,

before you start to inject your constructs. Injected oocytes are then torn open with forceps, thus

releasing the complete, stained nucleus.

1. Dissolve Trypan Blue in distilled water. The solution should appear bright blue.

2. Remove any particles with a 0.22 μm syringe filter or something similar.

Continue with the next chapter "Preparations for Injection". You can use this dye solution

to mimic cDNA. If you have successfully performed the test or if you prefer to start your first

experiment under real conditions, you can right away start to use your cDNA or mRNA.

You may consider the test injection again if you observe any troubles.

The following pictures show injected oocytes. In the left picture, the penetration site of the

needle is clearly visible in the middle of the animal pole. The right picture shows an opened

oocyte. Only the nucleus is stained, showing that the nucleic membrane is still intact and

therefore impermeable for the dye.

49

Page 54

Roboinject Manual

4.3 Preparations for Injection

Generally, you can use cDNA or mRNA concentrations and injection volumes as described in

the literature or as applicable for your experiment. In the following, typical cDNA or mRNA

concentrations and recommended treatment of the sample are described. Please follow this

advice if you are new in operating the Roboinject or if you have observed trouble with the

injection process.

You will also need the provided stereo microscope and alignment device (with crosshairs)

for the alignment of the injection needle. Please read chapter "Alignment".

Note: The cDNA or mRNA sample has to be very clean and pure to obtain good results.

Any particles, dirt, dust, and so on could clog the needle. Please check the sample for protein

contaminations, cellular debris, residues of the extraction kit, or a high salt content.

Checking the oocyte quality

You need oocytes plated in standard 96 well plates. You should only use oocytes of a very high

quality and of uniform size. Make sure that all oocytes are positioned with the animal pole (dark

side) up, when you want to inject cDNA into the nucleus. The oocytes will have adhered to the

well bottom after about 2 to 3 hours. Do not use the cells before. Best results have been obtained

if oocytes have been incubated over night before use. See also "Preparation of Xenopus Oocytes"

in the Appendix.

cDNA / mRNA Concentration and storage

Depending on the efficiency of protein expression, about 10 to 50 ng of cDNA (about 250

to 2500 ng of mRNA) is sufficient to maximally express the desired receptor in all 96 oocytes.

Much lower amounts might be appropriate if you need a reduced expression level,

for example for electrophysiological recording of ion channels.

A typical cDNA sample has a concentration of 10 to 50 ng/μl, a typical mRNA sample

has a concentration of about 50 to 500 ng/μl.

DNA or RNA should be stored in sterile, nuclease-free 0.5 ml or 1.5 ml Eppendorf tubes

(or similar reaction tubes) at -80 °C.

Highly concentrated stock solutions should be diluted with nuclease-free water before use.

Do not use saline solutions because salt crystals may form during injection and may cause

the needle to clog.

50

Page 55

Injection

Preparing the sample for injection

1. Take the sample out of the freezer at least 10 minutes before the injection.

2. Let it stand at room temperature until the sample is completely thawed.

3. Mix the sample thoroughly, for example, by vortexing for a short moment,

or manually by striking the side of the tube with a finger.

4. Spin the sample in an Eppendorf centrifuge (or a similar centrifuge) at full speed (>10000 g)

for 5 minutes immediately before the injection for sedimentation of any remaining particles

that might clog the needle.

Filling and placing of the reaction tubes

3. Please use the provided reaction tubes as sample reservoirs.

4. Fill the respective reservoir tubes (position 1 to 8) always with a sample volume that is 1 μl

more than needed for the injection of all selected oocytes. The needle tip will not go down

to the very well bottom but will always stop at a safety distance. This avoids breakage and

contamination of the tip.

5. Fill the two rinsing reservoirs (position 9 and 10) with at least 200 μl of nucleotidase-free

water.

6. The waste reservoir (position 11) can be kept empty, it will be used for oil removal only.

7. Place the tubes centered into the mounting holes. Bend the tube caps in a way that they

are perpendicular to the tube. The tube caps should be positioned that they are facing

away from the plate.

51

Page 56

Roboinject Manual

4.4 Setting Up the Well Plate

4.4.1 Inserting or Changing the Well Plate

Click the icon to open the “Manual Mode” dialog. Select “Change Plate” in the “Global”

section to move the carrier into home position. Remove the used well plate if necessary. Place the

type of well plate which is defined in the “Plate Info” dialog in correct orientation on the carrier.

Place the well plate onto the carrier and press its side against the springs in the lower middle and

lower right corner of the carrier. Then put the rest of the plate down onto the carrier. The well

plate position is correct when there is no play between the well plate bottom and the carrier

surface at all edges and when the well plate has full contact to the left and upper side of the

carrier holding frame.

Important: The well plate should be immovably fixed on the carrier, otherwise the injection will

not be successful!

52

Page 57

Creating a new file

Injection

1. Click "New File" icon

either on the toolbar or on the "File" menu.

The "Plate Info" dialog box opens.

2. Type in the "Plate ID", select the "Plate Type", and all information ("Comment")

you want to associate with this well plate, for example the oocyte batch, name of

the operator, and so on.

3. Click "OK" when you are finished. The "Save As" dialog box is displayed.

The plate ID is also the suggested file name.

4. When opening the directory you can choose another file and / or rename the file, if necessary.

Right-click on the file name, and choose “Rename”. All characters are allowed in the file name,

except the following: slash mark (/), backslash (\), colon (:), asterisk (*), question mark (?),

quotation mark (“), less than (<), greater than (>), and vertical bar ( | ).

If you try to use one of these characters the following error message appears:

53

Page 58

Roboinject Manual

Opening a previously saved file

1. If you want to inject the same plate again or review previously injected cells,

open the appropriate well plate file.

2. Click "Open" on the "File" menu. The "Open" dialog box appears.

3. Select the Roboinject file (*.rpf) you want to open.

4. Click "Open". The well plate window now shows the status of the already saved plate;

and the Roboinject header shows the name of the actually opened file.

Defining the Injection Samples

1. The next step after creating a new file and well plate is the definition of the respective

injection samples inside of the 0.5 ml micro reaction tubes.

2. Click on the symbol

of one of the sample reservoir tubes to open the “Sample

Information” dialog box. Please read also chapter "Sample Information" dialog.

Note: The sequence of injection is always from left sample to right sample. Please

keep this in mind if the injection sequence of samples is of importance for you.

54

Page 59

Injection

Enter an ID and / or a name which univocal identifies your sample. Select the type of “Sample”

and its “Concentration”.

Note: The minimal volume which always has to remain in the tube reservoir is 1 μl. For example,

if you need 4 μl sample volume for your injection run, please make sure that you start with at

least 5 μl. This is because the injection needle keeps always a safety distance to the tube bottom

to avoid uptake of contaminants and plugging.

Click the button "Set Injection" for changing injection parameters. The "Set Injection" dialog

opens. Please read also chapter "Inject" tab of "Options" dialog in main menu "Settings".

Ignore the "Set Injection" button for keeping the default settings.

55

Page 60

Roboinject Manual

Enable the check box "Test Injection" if you want to use this feature. Write a comment

in the "Comment" text box.

Click "OK" if you finished the settings of the sample, "Clear" if you want to restart with

default values and "Cancel" if you want to go back to the main window without changes.

Repeat the steps above until all samples you want to inject are defined.

Adjusting the Injection Parameters for each Well separate

It is possible to adjust the settings for the injection for each single well separate.

Click with the right mouse button onto a well in the virtual well plate, and the following

dialog appears. Now you can adjust the injection parameters for this specific well.

If the oocyte in the specific well should be injected with different samples, you can adjust

the injection parameters for each sample separately in the respective "Sample" tabs.

56

Page 61

4.5 Selecting Oocytes for Injection

The next step after definition of the injection samples is the allocation of the sample(s)

to the respective wells.

Injection

Click the "Void Well" icon

will be crossed out. Click the "Clear" icon

non-selected status.

First, please select an injection sample.

to exclude certain wells from injection. The deselected wells

to set back the virtual well plate to the origin,

To assign a sample to a well, please click onto the colored tube on the icon first, and after that

on the well, you want to assign to the sample. The color of the well immediately changes to the

symbol color of the sample tube.

Click on the row letters A to H to assign single rows or on the column numbers 1 to 12 to assign

single columns.

If you want to select all wells, click on the Roboinject icon

virtual well plate.