Page 1

PPS2 Peristaltic Perfusion System

Manual

Page 2

Information in this document is subject to change without notice.

No part of this document may be reproduced or transmitted without the express

written permission of Multi Channel Systems MCS GmbH.

While every precaution has been taken in the preparation of this document,

the publisher and the author assume no responsibility for errors or omissions,

or for damages resulting from the use of information contained in this document

or from the use of programs and source code that may accompany it. In no event shall

the publisher and the author be liable for any loss of profit or any other commercial

damage caused or alleged to have been caused directly or indirectly by this document.

© 2013 Multi Channel Systems MCS GmbH. All rights reserved.

Printed: 13.05.2013

Multi Channel Systems

MCS GmbH

Aspenhaustrasse 21

72770 Reutlingen

Germany

Fon +49-7121-9 09 25- 0

Fax +49-7121-9 09 25-11

info@multichannelsystems.com

www.multichannelsystems.com

Products that are referred to in this document may be either trademarks and /

or registered trademarks of their respective holders and should be noted as such.

The publisher and the author make no claim to these trademarks.

Page 3

Table of Contents

1 Important Information and Instructions 2

1.1 Operator's Obligations 2

1.2 Guarantee and Liability 2

1.3 Important Safety Advice 3

2 Installation and Operation 4

2.1 Welcome to the PPS2 Peristaltic Perfusion System 4

2.2 Setting Up and Connecting the PPS2 Pump 5

2.2.1 Use of Droplet Isolators 6

2.3 Control Options 9

2.3.1 Operation of the Perfusion Peristaltic Pump with PPS2

Software 9

2.3.2 Operation of the Perfusion Peristaltic Pump via PPS2

Touch Screen 14

2.4 Cleaning and Maintenance 16

PPS2 Manual

3 Application Example: MEA2100-System 17

3.1 Setup 17

3.2 Perfusion and Noise 18

4 Appendix 19

4.1 Technical Specifications 19

4.2 Ordering Information 20

4.2.1 Scope of Delivery 20

4.2.2 Replacement 20

4.2.3 Data Sheet 21

4.3 Contact Information 22

1

Page 4

Peristaltic Pump Manual

1 Important Information and Instructions

1.1 Operator's Obligations

The operator is obliged to allow only persons to work on the device, who

are familiar with the safety at work and accident prevention regulations and have been

instructed how to use the device;

are professionally qualified or have specialist knowledge and training and have received

instruction in the use of the device;

have read and understood the chapter on safety and the warning instructions in this manual

and confirmed this with their signature.

It must be monitored at regular intervals that the operating personnel are working safely.

Personnel still undergoing training may only work on the device under the supervision

of an experienced person.

1.2 Guarantee and Liability

The General conditions of sale and delivery of Multi Channel System MCS GmbH always apply.

The operator will receive these no later than on conclusion of the contract.

Guarantee and liability claims in the event of injury or material damage are excluded

when they are the result of one of the following.

Improper use of the device.

Improper installation, commissioning, operation or maintenance of the device.

Operating the device when the safety and protective devices are defective and / or inoperable.

Non-observance of the instructions in the manual with regard to transport, storage,

installation, commissioning, operation or maintenance of the device.

Unauthorized structural alterations to the device.

Unauthorized modifications to the system settings.

Inadequate monitoring of device components subject to wear.

Improperly executed and unauthorized repairs.

Unauthorized opening of the device or its components.

Catastrophic events due to the effect of foreign bodies or Acts of God.

2

Page 5

PPS2 Manual

1.3 Important Safety Advice

Warning: Make sure to read the following advice prior to install or to use the device

and the software. If you do not fulfill all requirements stated below, this may lead

to malfunctions or breakage of connected hardware, or even fatal injuries.

Warning: Obey always the rules of local regulations and laws. Only qualified personnel

should be allowed to perform laboratory work. Work according to good laboratory practice

to obtain best results and to minimize risks.

Warning: Be very careful with the rotating parts of the pump! Do not clamp something

in between neither long hair nor a cravat, for example.

The product has been built to the state of the art and in accordance with recognized safety

engineering rules. The device may only

be used for its intended purpose;

be used when in a perfect condition.

Improper use could lead to serious, even fatal injuries to the user or third parties and damage

to the device itself or other material damage.

Warning: The device and the software are not intended for medical uses and must not

be used on humans.

Malfunctions which could impair safety should be rectified immediately.

Requirements for the installation and operation

Do not use the PPS2 peristaltic pump for perfusion with flammable or aggressive

(corrosive) liquids.

Do not store flammable materials nearby during operation.

Check in regular intervals that the PPS2 pump does not overheat.

3

Page 6

Peristaltic Pump Manual

2 Installation and Operation

2.1 Welcome to the PPS2 Peristaltic Perfusion System

The peristaltic pump PPS2 with software control is developed for the perfusion of

biological samples. The pumps are driven by stepper motors providing a very long lifetime

without maintenance. The durable brushless motors are extremely reliable, show very

constant rotation speed, are vibration free and have low electromagnetic emission. These

characteristics make the PPS2-System an ideal choice for electrophysiological experiments.

The device consists of two independent peristaltic pumps, one perfusion (inlet) pump

for delivering perfusion solution to the sample, and one waste (outlet) pump to remove

dispensable solution. The droplet isolator chambers avoid pulsation artifacts and allow

optical fluid control.

If you need more than two channels you can connect several PPS2-Systems in serial.

Each pump can still be controlled separately.

The flow rate of the pumps vary between 0 to 30 ml/minute. Other flow rates are available

on demand, please contact MCS.

The PPS2 is a highly flexible system which can be controlled in different ways:

The pump velocity and the flow rate can be controlled from a connected computer

via USB connection and the included software PPS2.

In future versions it will be possible to control the PPS2 with the LTP-Director software

from Multi Channel Systems MCS GmbH. Please see chapter “Software Control”.

Additional analog and digital inputs allow to operate the PPS2 pump via external

inputs, for example from a stimulus generator STG.

It is also possible to operate the pump without software control, via touch screen

on top of the device.

4

Page 7

2.2 Setting Up and Connecting the PPS2 Pump

Warning: Do not start the perfusion until you have double-checked that the perfusion lines

are set up properly and that the inflow and outflow rate are matching. Spilled liquid may

irreversibly damage electronic instruments.

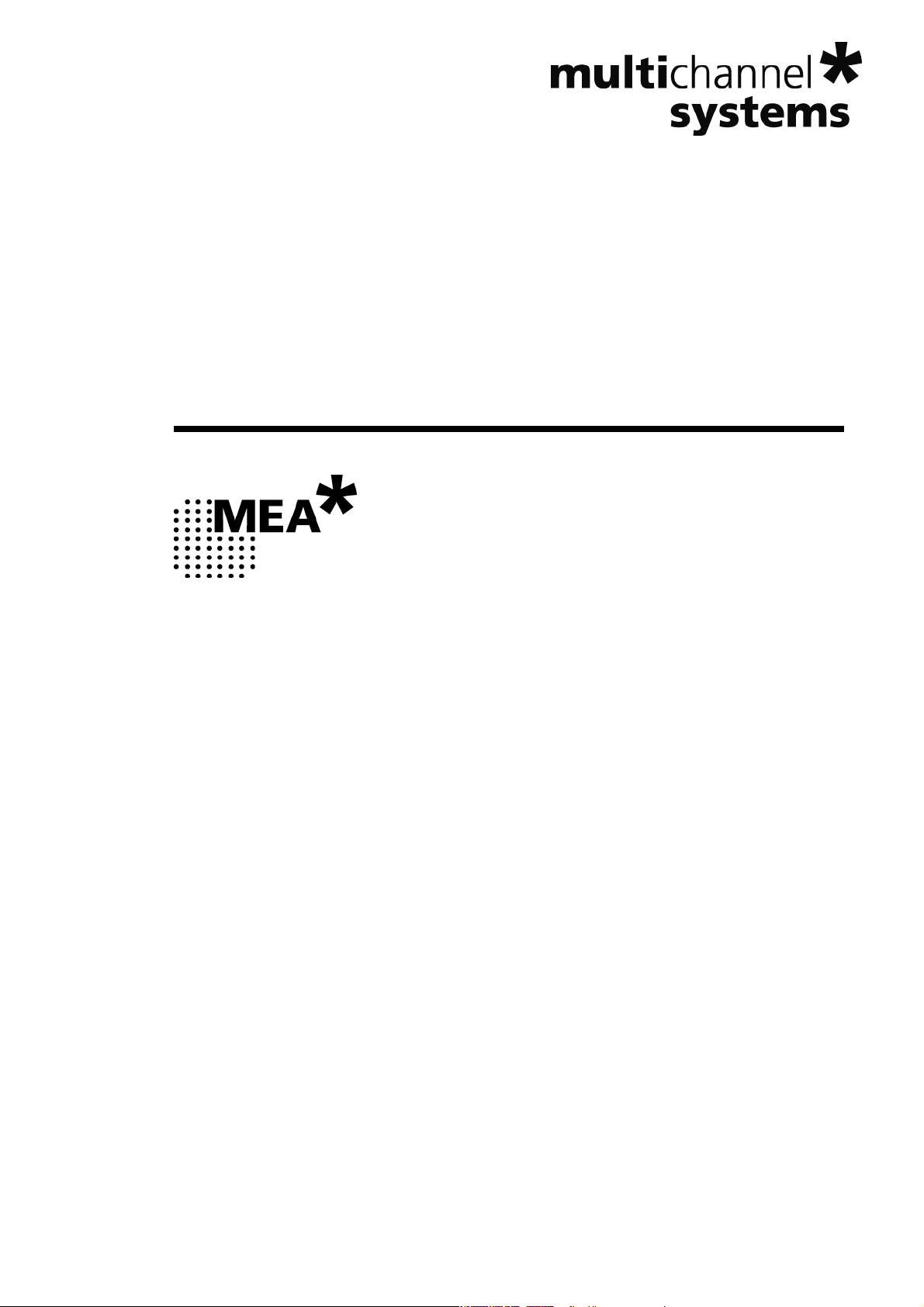

The PPS2 consists of two independent peristaltic pumps, which both are rotating

counterclockwise. The left one is intended for perfusion inlet, the right one for perfusion

outlet. It is of course also possible to use both pumps as independent perfusion inlet pumps,

and to use for example a vacuum pump for suction. This manual will focus on the intended

function as inlet and outlet pumps. Each pump cycle contains a droplet isolator. The outlet

pump is additionally equipped with a bubble detector.

Connecting the Tube Set

The following tubes are used:

Identical Pharmed ® BPT (Saint–Gobain) tubes with an inner diameter of 1.65 mm

and an outer diameter of 3.35 mm around the pump revolver and for the connection

between outlet droplet isolator chamber and outlet pump, where the sensor of the

bubble detector is located.

PPS2 Manual

A PVC tube with larger inner diameter is used for the tube to the waste bottle.

Silicon tubing is used for all other connections.

The specified tubing must be used for the pump revolvers to ensure that the volumes set

in the software are correct. Other tubing can be used for all other connections as well.

Sets of ten tubes for replacement are available from Multi Channel Systems (For example:

PPRT1.65-10 tubes: Pharmed ® BPT, ID: 1.65 mm, OD: 3.35 mm). Additionally you can order

a replacement set for all fluidic components PPS2-Set-F. Please see section “Ordering

Information” in the Appendix.

5

Page 8

Peristaltic Pump Manual

For connecting or changing the tubes, please open the screw and remove the bracket of the

pump revolver. Insert the provided tube and fix it with the luer tube connectors in the denoted

way. To remount the bracket, take care to insert the bar of the bracket into the corresponding

socket on the pump housing. Fix the screw firmly.

If you do not need the droplet isolator, please use the circlet and connect the heads

of the tube with a luer adapter.

2.2.1 Use of Droplet Isolators

The droplet isolators can be used to disrupt the direct liquid column from the pump to the

sample. This can help to remove low frequency noise originating from the pulsation of the

pump head. On the other hand, the droplet isolators make the flow speed inaccurate, and

cause a continued flow even after the pump is stopped. If the flow rate is high (approximate

> 6 – 8 ml/min) the droplet isolators will fill up over time and might even overflow.

The suggested procedure is to start working without the droplet isolators, and use them only

in case unacceptable fluctuations caused by the pump occur in the recordings which can not

be removed otherwise, for example by using a 10 Hz high pass filter.

6

Page 9

PPS2 Manual

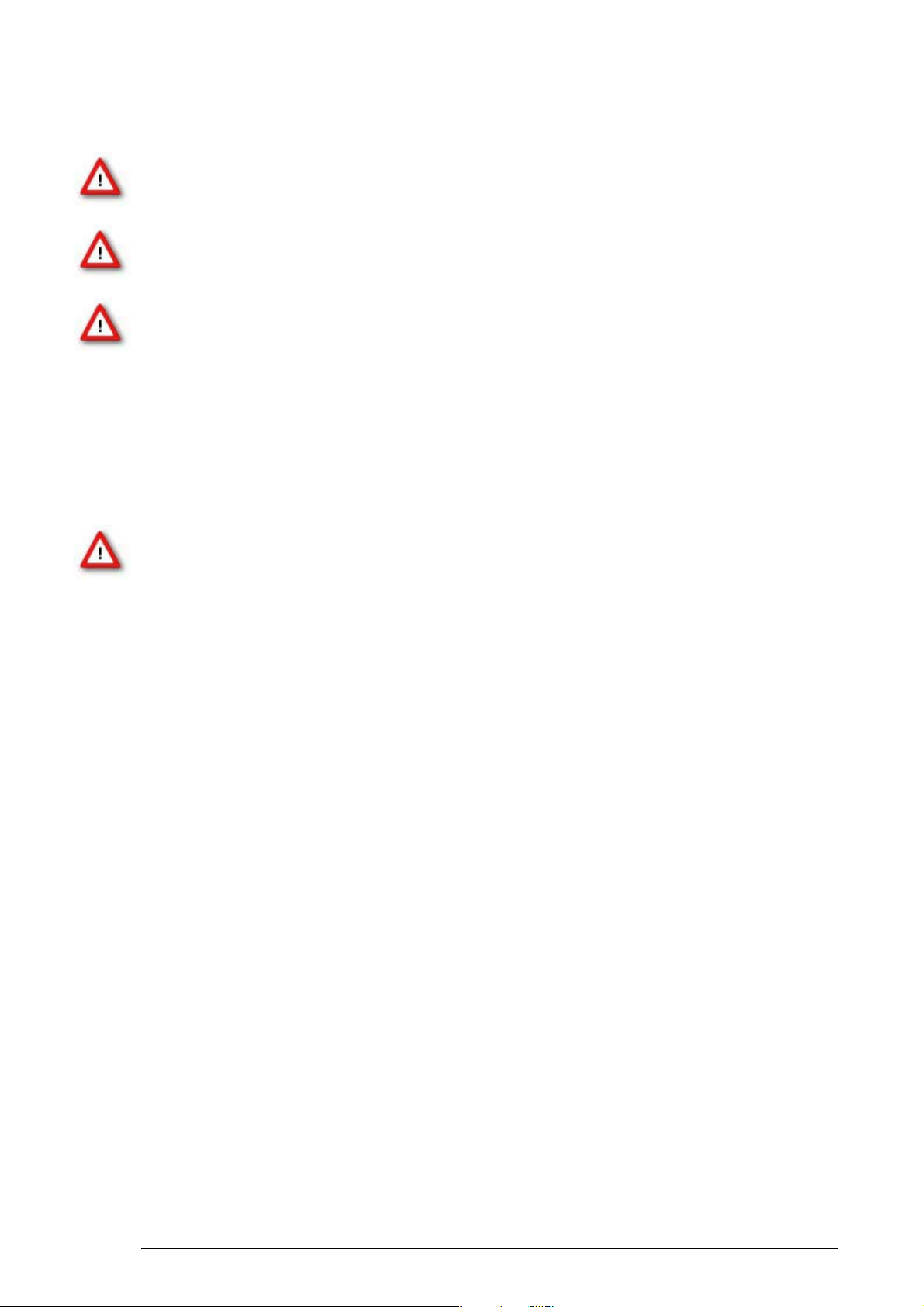

Complete Setup

The left pump of the PPS2 is intended for perfusion inlet, the right one for perfusion outlet.

Please connect all tubing and droplet isolators as indicated on the following image. Take

care to use the short Pharmed ® BPT tube between outlet pump and droplet isolator.

Warning: The droplet isolators remove pulsation artifacts, but also cause a continuing

flow even some time after the pumps are stopped. To avoid flooding, please use hose

clamps to stop the flow. Do not forget to open the clamps when you restart the pump.

7

Page 10

Peristaltic Pump Manual

Bubble Detector

The bubble detector connected to the outlet detects the amount of bubbles in the outlet tube.

A low number of bubbles can indicate that the perfusion outlet cycle is not working properly,

so the bubble detector can be used as an alarm system to prevent flooding of the recording

equipment.

The sensor of the bubble detector is on the left side of the LED, the short Pharmed ® BPT tube

has to be guided through the bubble detector as shown on the picture. The LED indicates the

fluid flow: The LED is constantly on without tube, when the fluid flow is not correct it flashes

fast, with correct flow the LED flashes slow. Please pay attention to the LED. See also chapter

“Software”.

Rear Panel

1. Connect the PPS2 pump with the provided power supply cable to the power supply.

2. Connect the PPS2 pump with an USB cable (type A – B) to an USB 2.0 port.

3. If necessary, connect the ground connector to the ground of your recording system.

4. Use the “I/O” switch to switch the PPS2 on and off.

As additional means to control the PPS2, inputs for analog or digital (TTL) signals are provided.

These inputs can be used to start / stop the pump and control the pump speed by external

signals.

It is possible to connect several PPS2 devices via USB hub to one computer to be controlled

by the same software. In future versions the MCS Bus interface can be used to connect several

PPS2 devices in series, also controlled by the same software application.

8

Page 11

2.3 Control Options

The PPS2 perfusion system can be controlled via USB connection by the provided software

PPS2. In future versions it will be possible to control the PPS2 also with the LTP-Director

software from Multi Channel Systems MCS GmbH. The device can also be controlled

independently from a computer connection via touch screen.

2.3.1 Operation of the Perfusion Peristaltic Pump with PPS2 Software

PPS2 Manual

PPS2 software is running on Microsoft Windows ® systems Windows XP or higher.

About

Click the “About” button to see the software version. Free software updates will be available

on the MCS web site. Please check http://www.multichannelsystems.com/downloads/software.

9

Page 12

Peristaltic Pump Manual

Main Window of PPS2 Software

Manual Control Mode

When using more than one PPS2-System, connected via USB cable, one main window tab

page will be available for each PPS2 connected. The tab slider will show the serial number

of the deices. The pumps can be operated independently from each other. Only the “Stop”

button will affect all connected pumps, all other control functions are independent.

The intended use for the PPS2-System is the perfusion of a biological sample on a MEA and

the aspiration of the waste solution. To avoid flooding of the amplifier, the flow rate of the

outlet must always be higher than the flow rate of the inlet. Select the check box “Fixed

Speed Ratio Waste to Perfusion” in %. Via slider or up-down box you can choose the

relation between the velocity of the waste and the perfusion pump. If the “Fixed Speed Ratio”

function is active, both pump speeds will remain at the same relative relation, and only the

control slider for the perfusion pump is active.

The green color of the buttons above the “On” and “Off” buttons indicate that the respective

pump is running. Additionally the speed symbol is rotating.

10

Page 13

PPS2 Manual

Click the button “More” to display further information. At the moment, the default

“Analog Range” of the analog input and the internal “Supply Voltage” is noted.

For using both pumps independently, deactivate the check box “Fixed Speed Ratio”.

With the two sliders, the speed of the left Perfusion (inlet tube) pump, and the right

Waste (outlet tube) pump can be controlled. The unit is milliliter per minute, the maximum

is 30 ml/min for the inlet and 30 ml/min for the drain, if no relation between both parameters

is selected. Alternatively, type the desired value into the text box below the slider or click

the up-down box. The resolution is 100 μl/min. Click the button “On” to start the pump of

your choice and the button above will turn to green. Click “Off” to stop the pump and the

button above turns to grey. It is possible to change the velocity via slider or by writing into

the window while the pump is running. Clicking the button “Fast” sets the pump speed to

maximum as long as the button is pressed. The yellow color indicates the “Fast” mode.

This feature can be used for rinsing the tubes, for example.

The Peristaltic Perfusion PPS2-System has three different operation modes via software and

the additional possibility to control the device without computer connection via touch screen.

Please see chapter “Operation of the Perfusion Peristaltic Pump via PPS2 Touch Screen”.

11

Page 14

Peristaltic Pump Manual

Stop

The “On” and “Off” buttons will affect one pump of the PPS2. The “Stop” button will always

stop both pumps. If several pumps are connected with a serial cable, all connected pumps will

be stopped.

Bubble Detector

The bubble detector can be used as an alarm system to prevent flooding of the recording

equipment. A light barrier detects the changes of fluid to air in the outlet tube and measures

whether this event takes place at least once every ten seconds or not. More than one bubble

per 10 seconds is considered okay, less is considered as an indicator that the fluid flow in the

outlet is too low. The LED is constantly on without tube, when the fluid flow is not correct it

flashes fast, with correct flow the LED flashes slowly.

Select the check box “Use Bubble Detector” to use the function of the bubble detector.

The detector is only active while the pump is running and the “Bubbles” button turns to

green “Startup”.

When fluid flow in the outlet tube is too low or too high, the bubble detector stops the

inlet perfusion pump automatically. The waste pump runs continuously to prevent overflow.

The button turns to red “No”.

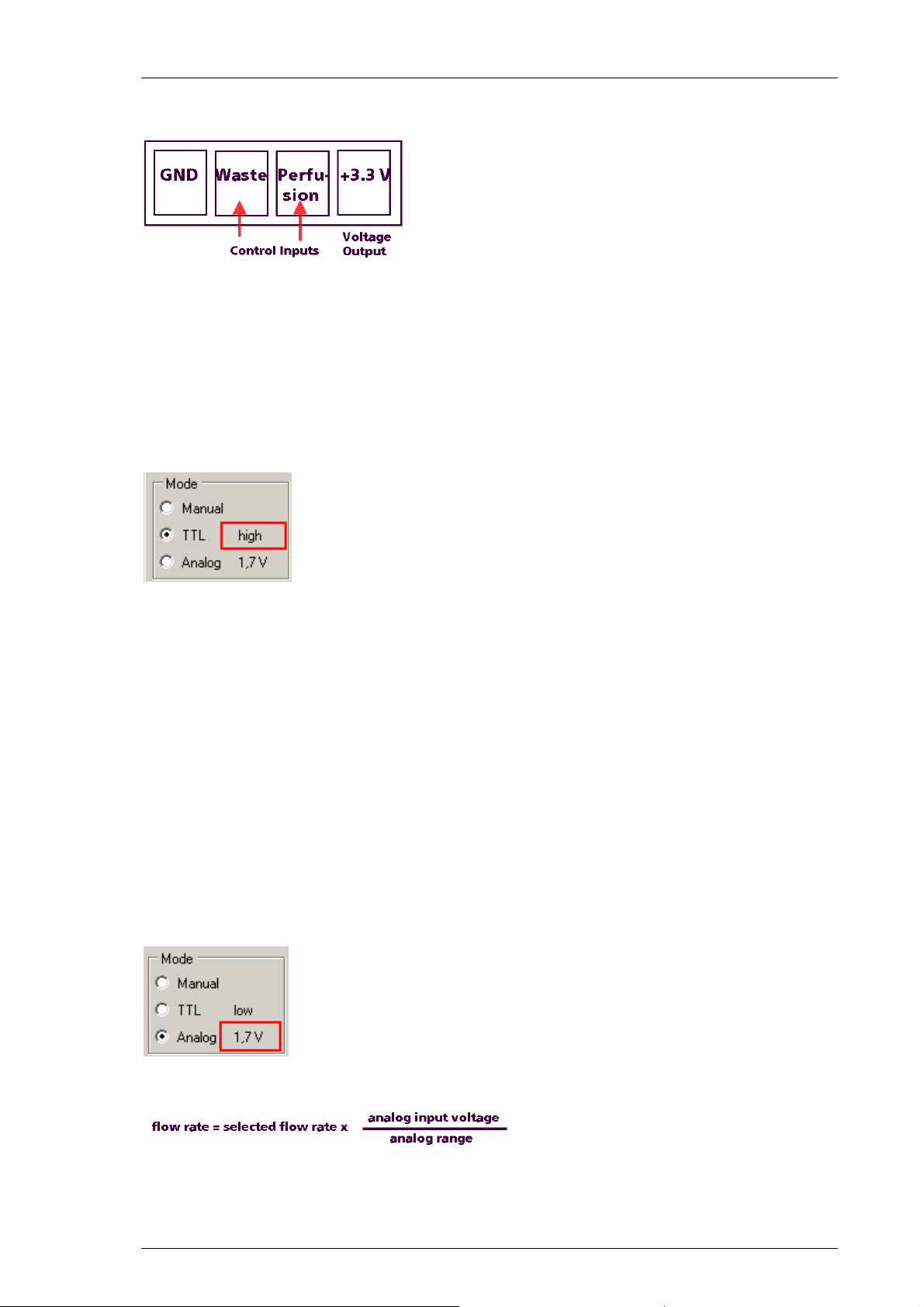

External Control: Digital (TTL) and Analog Mode

External control via analog input or digital TTL input allows the same functions as the manual

mode or the controlling via touch screen without software. You can use different modes for

each pump.

The pump speed is still selected in PPS2 software, and the pump status has to be “On”,

as the state of the external input and the pump state are in an logical AND relation:

Digital Mode: The digital input must be “high” AND the pump must be “On” to start

the pump.

Analog Mode: The analog input must be > 0.0 V AND the pump must be “On” to start

the pump.

12

Page 15

PPS2 Manual

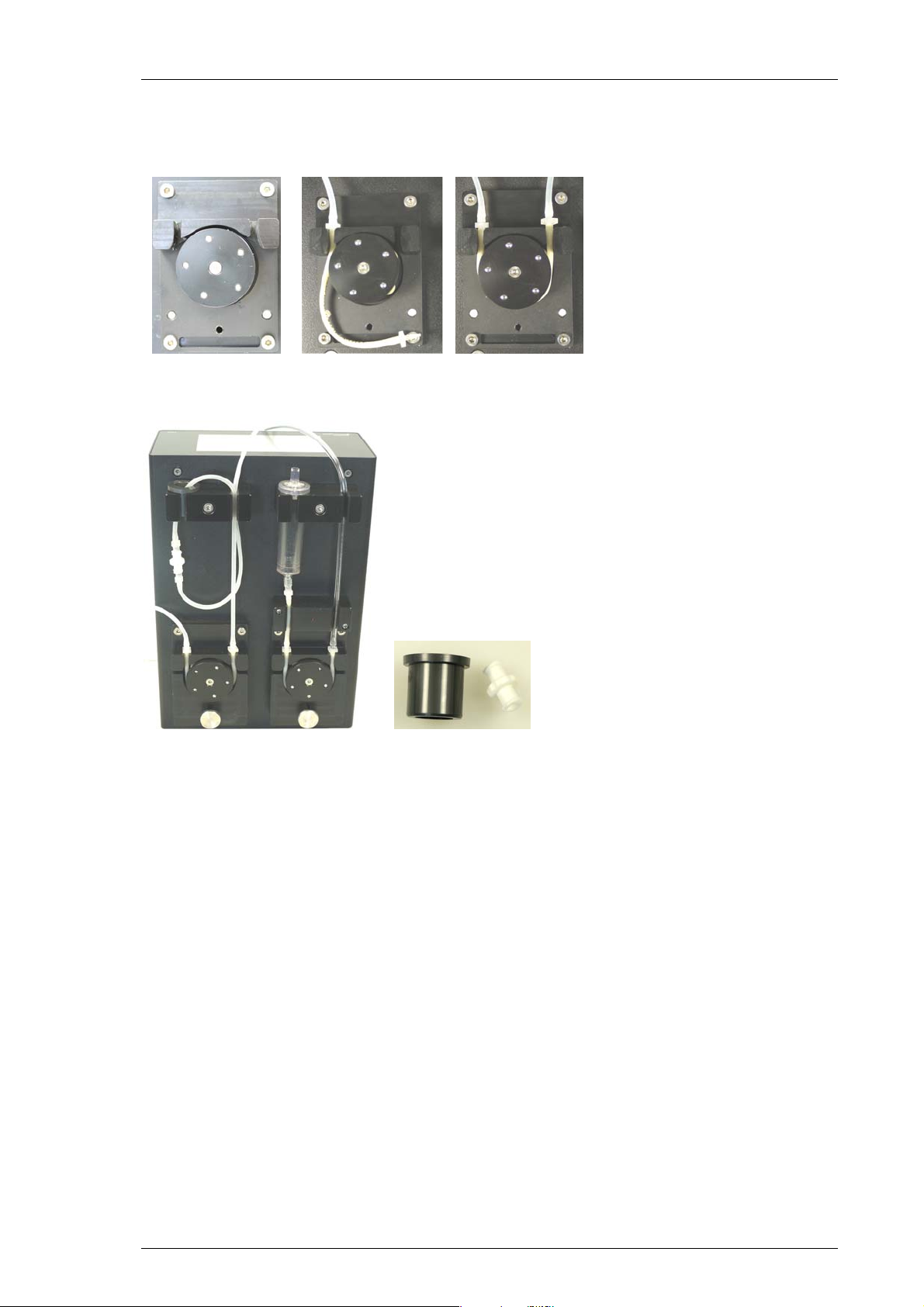

When looking directly to the rear panel of the PPS2 the pin layout of the digital and analog

inputs are as shown on the picture.

Connect either a TTL or an analog output device to the respective inputs and select the

desired control mode in the PPS2 software. In sum (digital and analog input), the maximum

load current for the voltage output (+3.3 V) is 100 mA.

Digital Control

Connect, for example a stimulation generator STG4000, to the “Ground” and “Control

Input(s)” of the digital input on the rear panel. The “Voltage Output” is not needed.

The status of the TTL inputs are displayed in the “Mode” window. If nothing is connected

to the TTL inputs the status is low.

TTL input low ( +0.4 V) pump off.

TTL input high ( +1.5 V ) pump on.

As long as the status of the TTL input is high, the respective pump will run at the speed

selected in PPS2 software. The maximum voltage for the TTL input is +5.5 V.

Analog Control

With the analog control, it is possible not only to start and stop the pump by an external

device, but also the pump speed. Connect an adjustable voltage source, for example a

potentiometer to the “Ground” and “Control Input(s)” of the analog input on the rear panel.

The pin layout of the analog input is the same as for the digital input when looking directly

to the rear panel of the PPS2. If nothing is connected to the analog inputs the status is 0.0 V.

The maximum voltage for the analog input is +10.3 V.

The current voltage level on the analog inputs is displayed in the “Mode” window. The analog

range is by default +5.0 V, as stated in the dialog “More”.

The resulting fluid flow of the pumps can be calculated by the following equation:

Example:

Selected flow rate 5ml/min x (analog input voltage 10 V / analog range 5 V)=10 ml/min.

13

Page 16

Peristaltic Pump Manual

2.3.2 Operation of the Perfusion Peristaltic Pump via PPS2 Touch Screen

Alternatively it is possible to operate the peristaltic pump without software control, via touch

screen on top of the device. The touch screen provides the same control functions of the PPS2

which are available via software. The pumps can be operated independently from each other

or in a fixed ratio. The “Stop” button will always affect both pumps. The touch screen has

three windows, Configuration, Main and Speed.

Configuration Window of PPS2 Touch Screen

Please open the “Configuration” window first because settings done here influence

the settings in the “Main Window” and the “Speed Window”.

Select the check box “Fixed Speed Ratio”. Via up and down arrows you can choose the

relation between the velocity of the waste and the perfusion pump. If the “Fixed Speed

Ratio” function is active, both pump speeds will remain at the same relative relation.

For example 150 % to make sure that the waste pump runs faster than the perfusion pump.

Define a ratio below 100 % and the perfusion pump will run faster than the waste pump.

Note: If the waste perfusion pump is used for the suction of “waste” do not use a ratio below

100 %, this will result in flooding of the connected device!

Bubble Detector

The bubble detector connected to the waste pump tube detects insufficient flow in the waste

tube. This can be an indicator for a problem with the perfusion. A light barrier detects the

changes of fluid to air in the outlet tube and measures whether this event takes place at least

once every ten seconds or not. More than one bubble per 10 seconds is considered okay, less

is considered as an indicator that the fluid flow in the outlet is too low. The LED is constantly

on without tube, when the fluid flow is not correct it flashes fast, with correct flow the LED

flashes slowly. When the bubble detector detects too low fluid flow in the outlet tube, the

inlet perfusion pumps will be stopped automatically. The waste pump runs continuously to

prevent overflow.

Select “Use Bubble Detector” to switch the bubble detector on. This option influences the

“Main Window”. The indicator “Bubbles” is only visible in the main window when the check

box is selected here.

Main Window of PPS2 Touch Screen

In the “Main Window” you can start and stop the pumps separately. The “Fast” mode is,

for example for rinsing the tubes, the pump runs fast as long as the “Fast” button is pressed.

The color of the button above indicates whether a pump is running or not.

14

Page 17

PPS2 Manual

The pictures shows the “Main Window” of the touch screen. The “On” and “Off” buttons

are connected for the operation of both pumps. The grey color of the upper buttons indicate

that no pump is running at the moment, the green color indicates running pumps.

Select the check box “Use Bubble Detector” in “Configuration” to switch the bubble

detector on and the “Bubbles” indicator will be visible in the “Main window”.

In the left picture of the “Main Window” no tube is connected to the bubble detector.

In the right picture no pump is running and therefore no bubbles are detected by the

bubble detector.

“Main Window” when both pumps are running and the bubble detector detects bubbles.

Speed Window of PPS2 Touch Screen

The up down arrows in the “Speed Window” are responsible for controlling the fluid flow.

In the “Speed Window” on the left picture, the speeds of the perfusion and waste peristaltic

pump are independent adjustable with the up down arrows under “Perfusion” and “Waste".

When both pumps are coupled because a “Fixed Speed Ratio” is selected, you control the

speeds of both pumps together via up down arrows under “Perfusion” as shown on the right

picture.

15

Page 18

Peristaltic Pump Manual

2.4 Cleaning and Maintenance

To clean the peristaltic pump system after use, flush all tubes with distilled water for a few

minutes and then quickly with 70 % Ethanol (EtOH). Suck the tubes dry. Disconnect all tube

connectors and unscrew the caps of the compound or waste bottle. Empty the bottles and

wash them out. Take care not to mistake the tubing when reconnecting.

Warning: Make sure no liquid is sucked into the pump revolvers! This can lead to irreversible

damage. Empty the bottle after each experiment. Avoid remaining liquid in the bottle and

tubing, this can result in contamination.

16

Page 19

PPS2 Manual

3 Application Example: MEA2100-System

The peristaltic perfusion PPS2-System consists of two peristaltic pumps. In this application

example, one is connected to a reservoir for ringer solution and pumps solution through

a perfusion heating PH01 to a MEA recording chamber inside a MEA2100 headstage.

The PH01 is connected to a temperature controller TC01/02 and heats the solution to a set

value. A cannula is connected to the second pump, which removes the ringer from the MEA

chamber and pumps it into a waste bottle. PH01 and cannula are positioned by magnetic

perfusion holders MPH. The MPHs connect both perfusion in- and outlet to the ground

of the recording system, via the metal plate in the front of the MEA2100 recording system.

3.1 Setup

1. Provide a power supply in the immediate vicinity of the installation site.

2. Place all devices on a stable and dry surface, where the air can circulate freely and the devices

are not exposed to direct sunlight. Take care not to position the PPS2 and fluid reservoirs

directly above the recording system, to prevent damage by accidentally spilled liquid.

3. Set up the computer with installed PPS2 program and connect the PPS2 with an USB cable.

4. Set up the MEA2100 system as described in the respective manual.

5. Connect the PH01 via tube to the inlet (left) peristaltic pump of the PPS2 and the bottle

with ringer solution.

6. Connect the outlet tube to the outlet (right) peristaltic pump and the waste bottle.

7. Add a hose clamp to the inlet and the outlet tube each.

8. Connect the ground of the PPS2 to the ground on the interface board of the MEA2100,

if necessary.

17

Page 20

Peristaltic Pump Manual

3.2 Perfusion and Noise

Low frequency fluctuations in electrophysiological measurements can be caused by the

perfusion. Shortly switch off the pump to see whether the fluctuations disappear if the pump

is off. 50 Hz noise can also be caused by the perfusion, but is independent of the pump running

or not. Perfusion in and out should contain a piece of metal that can be connected to the

amplifiers ground to remove 50 Hz noise. The easiest way is to use a bend cannula for suction.

In the setup described above, both perfusion in- and outlet are already grounded via the MPHs.

The opening of the cannula should be positioned in a way that it always sucks air and liquid at

the same time, possibly resulting in a constant slurping noise. This prevents the fluid level from

going up and down, which also causes noise. See a suggested perfusion setup below.

Warning: The droplet isolators remove pulsation artifacts, but also cause a continuing flow

even some time after the pumps are stopped. To avoid flooding, please use hose clamps to

stop the flow. Do not forget to open the clamps when you restart the pump.

If you experience low frequency noise from the perfusion, try to optimize the suction as

described above. Additionally, the droplet isolator chambers of the PPS2 interrupt the fluid

flow between pump and recording chamber, and thereby minimize the influence of the pump

head movement on the recordings.

50 Hz noise can be caused by the perfusion of by external noise sources. Remove perfusion in

and out from the bath. If the noise persists, check for external noise sources, like microscope

lamp, power supplies close by and so on. If the noise is caused by the perfusion, check the

grounding of the perfusion in and out. If the magnetic perfusion holders (MPH) from MCS

are used, make sure that there is an electrical contact between PH01, suction cannula, and

the metal plate in front of the MEA2100.

Perfusion Cannula PH01 with Magnetic Perfusion Holder MPH

All MEA amplifiers can be equipped with a magnetic stainless steel plate on top to enable

the use of magnets as perfusion holders. The magnetic perfusion holders MPH also connect

any attached metal cannula directly to the ground of the MEA recording system. The metal

ball holding the cannula allows an accurate positioning of the perfusion tips and a quick and

easy detachment of the perfusion by removing the ball from the magnetic base, if necessary.

The perfusion cannula PH01 with heating element and sensor and a temperature controller

TC01 or TC02 is able to heat the perfusion solution with an accuracy of 0.1 °C to any

temperature from room temperature up to a maximum of 50 °C.

18

Page 21

4 Appendix

4.1 Technical Specifications

PPS2 Manual

General Information

Operating temperature 10 °C to 40 °C

Storage temperature 10 °C to 50 °C

Dimensions (H x W x D) 235 x 160 x 110 mm

Weight 3.6 kg

Number of perfusion pump inlets 1

Number of perfusion pump outlets 1

Maximum perfusion rate inlet 30 ml per minute

Maximum perfusion rate outlet 30 ml per minute

Bubble detector optical fluid flow control

Analog and Digital Input

Maximal voltage of the digital input + 5.5 V

Maximal voltage of the analog input + 10.3 V

Maximal load current ( +3.3 V output) 100 mA

Power Supply

Type SPU63-108

Voltage range @ frequency 100 to 240 VAC @ 47 to 63 Hz

Power consumption 10 W

Software Control

Connection to the computer USB 2.0 High Speed (cable type A – B)

Operating system Microsoft Windows ® 7, Vista or XP with NTFS,

English and German version

19

Page 22

Peristaltic Pump Manual

4.2 Ordering Information

4.2.1 Scope of Delivery

1 PPS2 main device

1 PPS2 CD (Software and Manual)

1 PPS2 power supply (SPU63-108)

1 power cord, country-specific

1 USB 2.0 cable (A – B)

1 PPRT1.65-10

Fluidic: 3 hose clamps, 2 luer adaptors, 2 circlets

Electrical accessories: 1 grounding cable, 1 alligator clip, 2 A/D input connectors

Fluidic devices: 2 PPS2-Set-F

Optionally

1 MCS Bus cable

4.2.2 Replacement

Peristaltic Pump PPS2 Replacement Tube Set

PPRT1.65-10: Unit of 10 peristaltic pump tubes: Pharmed ® BPT (Saint–Gobain),

(ID = 1.65 mm, OD = 3.35 mm, L = 90 mm)

Peristaltic Pump PPS2 Replacement Complete Fluidic

PPS2-Set-F: Set of complete fluidic device components for the PPS2

1 supply tube (Silicon L =1000 mm)

1 interconnection tube (Silicon L = 210 mm)

1 detector tube (Pharmed ® BPT L = 45 mm)

1 waste tube (PVC L = 1000 mm)

2 sample tube (Silicon L = 1000 mm)

2 drip chamber bodies with cover

20

Page 23

Peristaltic Pump PPS2 Replacement Fluidic Accessories

PPS2-Set-FA: Fluidic accessories

3 hose clamps

2 luer adapter

2 circlets

Peristaltic Pump PPS2 Replacement Electrical Accessories

PPS2-Set-EA: Electrical accessories

1 alligator clip

1 grounding cable

2 D / A input connectors

4.2.3 Data Sheet

PPS2 Manual

21

Page 24

Page 25

Page 26

Peristaltic Pump Manual

4.3 Contact Information

Local retailer

Please see the list of official MCS distributors on the MCS web site.

User forum

The Multi Channel Systems MCS GmbH User Forum provides the opportunity

for you to exchange your experience or thoughts with other users worldwide.

Mailing list

If you have subscribed to the Mailing List, you will be automatically informed about

new software releases, upcoming events, and other news on the product line.

You can subscribe to the list on the contact form of the MCS web site.

www.multichannelsystems.com

22

Loading...

Loading...