Multicam Systems Pty A2MC Installation And Training Manual

A2MC Machine

Installation and

Training

Documentation

Revised 9 February, 2017© Multicam Systems Pty Ltd

All rights reserved. No part of this document may be reproduce or transmitted in any form or

by any means, electronic, mechanical, photocopying, recording, or otherwise, without prior

written permission of Multicam Systems Pty Ltd.

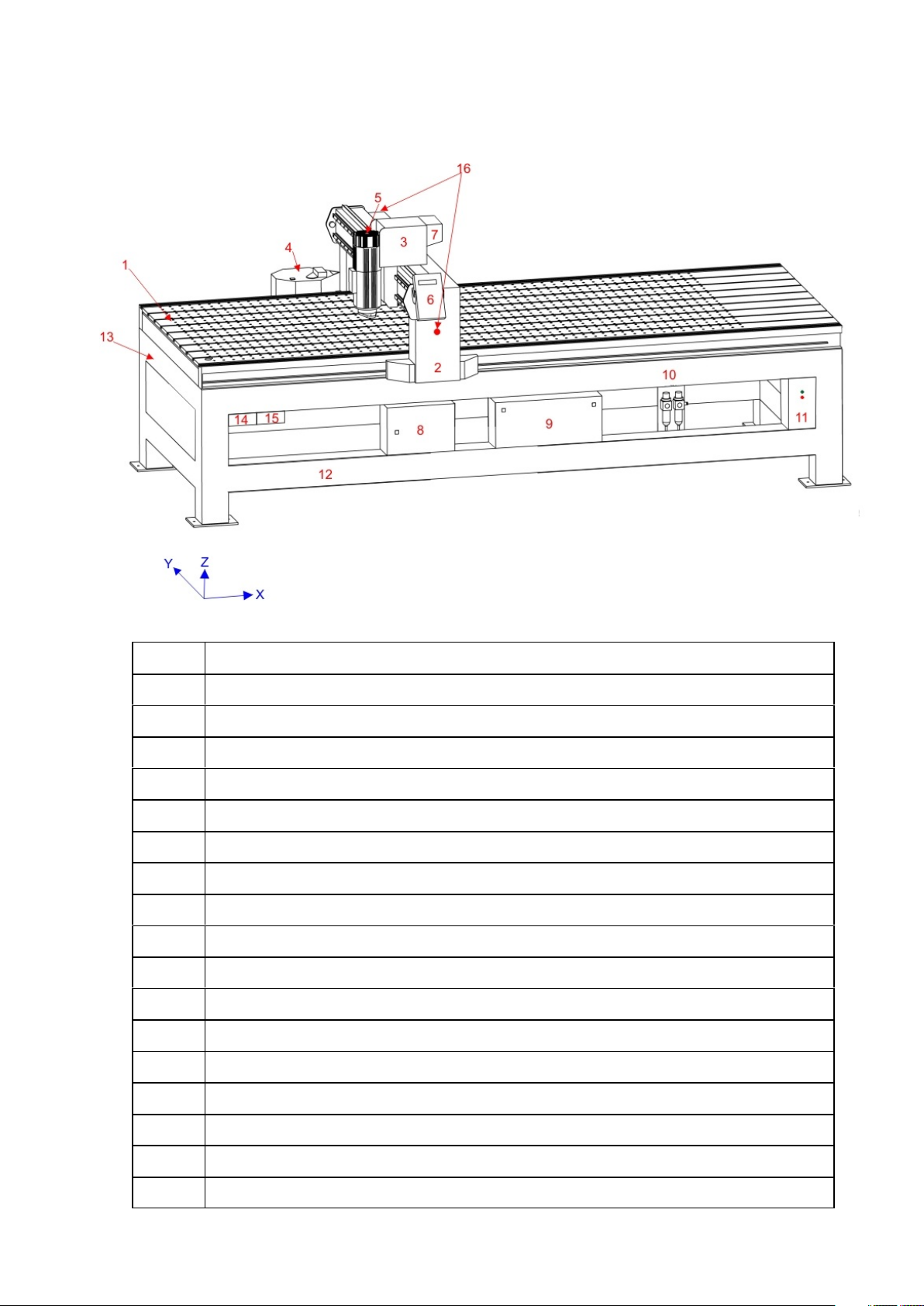

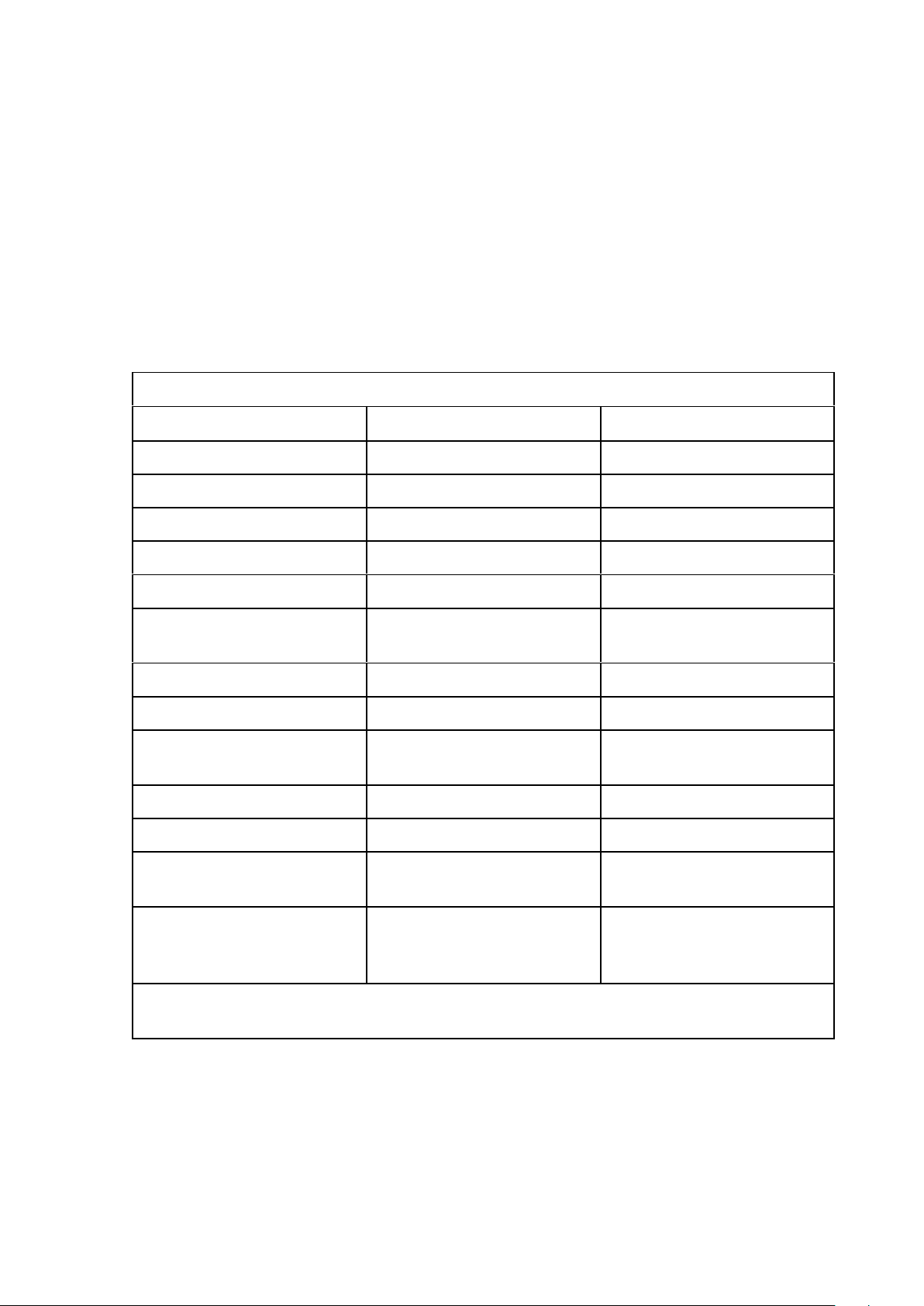

Machine Component Identification

The following diagram and table indicates the location of major components of the machine. There

may be variations depending on individual size, configuration and options fitted.

Item Description Items marked * are optional and may not be present on all machines

1 Machine bed. Aluminium vacuum hold down table or t-slot table

2 Travelling steel gantry. Contains X axis drives

3 Machine head. Contains Y and Z axis drives

4 Travelling rotary tool changer*

5 Location of cutting spindle/s*, knife head/s*, camera*

5 Location of Air assist head attachment*

6 Operator’s sub console unit

7 Mist sprayer attachment*

8 Inverter enclosure - Danger High Voltage

9 A2MC controller enclosure - Danger High Voltage

10 Micro air filter inlet and distribution

11 Power Box Master On/Off control for machine - Danger High Voltage

12 Machine frame

13 Linear tool changer*

14 Machine air supply, tool change and vacuum pressure gauges*

15 Additional switches for dust collectors, vacuum pumps, other ancillary devices*

16

Emergency stop buttons, operator’s and off side of gantry

HEALTH AND SAFETY

WARNING

Machine must only be operated by

persons trained and accredited by

Multicam Systems

General Safety And Machine Specifications

This manual and the safety guidelines contained within it are designed to enable the user to

obtain the best performance from the machine over a long lifetime and to ensure the safety

of the operator. Each person who will operate the equipment, perform a service or

maintenance, or supervise its use must read the safety instructions in this manual. Please

read it carefully before using or working on the machine.

The machine is a 3-axis router designed to cut and shape a variety of materials using either

vacuum or manual clamping. The correct method of using these mechanisms is covered

elsewhere in the users manual.

Ensure that you have read and understood the operational and health and safety sections of

the manual before beginning to use the machine.

The machine has been designed and constructed to prevent the build-up of electrostatic

charges during operation.

The machine is not intended for use in an explosive environment.

ALWAYS CONSULT SEPARATE MANUALS FOR ANCILLARY

DEVICES SUCH AS MIST SPRAYER ATTACHMENTS, OSCILLATING

TANGENTIAL KNIFE HEADS AND GANG DRILL HEADS FOR SAFE

OPERATION.

Placement of the Machine and machine attachments

The machine must be placed with consideration given to the following;

• The actual floor space required by the machine and associated accessories and

attachments.

• Adequate free air flow around vacuum pumps to reduce the risk of overheating.

• How you intend to move material to and from the cutting surface.

• OH&S requirements in relation to safe work practices. Refer to AS4024 & AS1473 for

specific details in regards to placement of machinery. We recommend a minimum of

1meter of space around the machine. The amount of space left behind a machine,

especially when placed in close proximity to a wall, must be sufficient so that workers,

and our technicians can have safe and unobstructed access to allow for service and

maintenance.

General Requirements

Noise Emission

The noise level produced by the machine will be dependant on;

• the material being cut

• ancillary devices being used (knife heads, drill heads etc)

• attachments to the machine (vacuum pumps, dust collectors, air compressors etc)

• the individual workplace environment.

The appropriate health and safety regulations must be consulted when considering the location

of the machine in the workplace, any sound-proofing or acoustic enclosure to be erected, or the

provision of personal protective equipment (PPE) in the form of hearing protection.

A noise survey and specific risk assessments should be undertaken by a competent person in

each workplace and for each work situation and material being cut, but in general the noise

levels produced by the machine may be found to be in the region of the following readings:

Equivalent continuous A-weighted sound pressure level, LAEQ above 90dB (A) when machining

aluminium.

Equivalent continuous A-weighted sound pressure level, LAEQ above 90dB (A) when machining

medium density fibreboard (MDF).

There is not normally any impulsive noise from the machine.

It is recommended that precautions are taken against injury to machine operators and others

from long-term exposure to noise, either by:

• enclosing the machine in an acoustic enclosure or booth fitted with closing doors

• requiring the operator, and other persons working or having cause to be nearby, to wear

a suitable form of hearing protection.

Suitable mandatory hearing protection signs should be displayed on or adjacent to the acoustic

enclosure or in the zone where the machine is located. The wearing of adequate protective

equipment should be enforced.

Operating Temperatures

The machines are designed to be operated between temperatures of -5oC and +40oC.

During operation machine components such as spindles, vacuum pumps and cutting tools will

become hot. Care must me exercised when coming in to contact with these or any other items

likely to become affected by heat.

Vacuum Pumps:

Vacuum pumps expel hot air at high velocity. Adequate provision must be made to allow

for the safe and unrestricted expulsion of the exhaust air. DO NOT

• block the exhaust manifold

• place objects in close proximity to the exhaust air

• place vacuum pumps in confined spaces

• touch the surface of the vacuum pump as it will become hot during operation

resulting in burns and scalding

Materials Suitable for Cutting

The machine is designed to cut, engrave and form a wide range of materials, as detailed below:

• Plastics - all plastics can be cut, including the 'hard' plastics such as polycarbonate.

• Woods - the majority of wood-based materials can be readily cut, including MDF,

plywood and other composite boards.

Note. When cutting some types of hard wood, e.g. mahogany, jarrah etc an appropriate

form of jigging will need to be considered.

• Metals - aluminium, brass and other soft metals can be readily cut. The hard metals

such as stainless steel can be cut, but due care must be taken regarding the depth of

cut, feed rate and cutter used. If in doubt, consult an appropriate person or the

manufacturers agent or machine supplier.

Other hard materials, such as carbides, should not be cut on the machine due to the risk

of damaging the machine or endangering the operator.

Note. When cutting metals a suitable lubricant should be used. Flammable fluids such

as Methylated spirit must not be used.

• Foams - all foam-based materials, such as sign foam, can be readily cut.

• Cardboard, rubber and insulation materials - most of these products can be cut using

an oscillating knife head

• Composites and Laminates - some composites and laminates, such as fibreglass, can

be cut. Please contact the manufacturers agent or machine supplier for more

information.

Dust Extraction

Dust may be produced during machining operations and this may introduce a risk of fire or

exposure of the operator to a hazardous substance. A suitable form of local exhaust ventilation

(LEV) must be fitted to the machine to remove machining dust. Outlets for extraction hoses are

fitted to the dust pickup head supplied with the machine. The hose must be firmly secured to the

fitting.

Note. Always ensure that the extraction system is clear of obstructions and is in correct working

order before using the machine. On dust extraction systems with manual cleaning devices follow

the manufacturers recommendation for regular cleaning. Filters should be cleaned daily.

Mist Dispensing Systems

Mist dispensing systems, such as Trico and UNIST cooling/lubrication systems, are designed

to assist in the cutting of ferrous and non-ferrous materials by delivering a fine mist of fluid under

controlled pressure. Only use recommended fluids in these devices. Flammable fluids such as

Methylated spirit must not be used and will cause damage to the devices. The use of nonrecommended fluids in mist sprayers will void manufacturers warranty.

Corrosion

Some of the components of the machine may be subject to corrosion in unfavourable conditions.

The machine should be used in a dry, moisture free atmosphere and should not be exposed to

water-based fluids or lubricants. The machine should not be exposed to acidic or alkaline

substances and it should be maintained in accordance with the servicing schedule.

General Safety Rules

WARNING

Machine must only be operated by

persons trained and accredited by

Multicam Systems

It is essential that these instructions are made available to the machine operators. It is also

important to hand them on if the machine is sold or given to another user.

The machine should only be used by a suitably trained operator. Other personnel within the

organisation should be aware of the methods to stop the machine in an emergency.

The machine is intended for use solely as a 3-axis router and cutter of materials. It should never

be hammered on, nor used as a general workbench, or for any other purpose than that for which

it was designed. This is likely to damage the machine and may compromise operator safety. It

may also void the manufacturers warranty.

The machine must not be operated after the consumption of alcohol or the taking of any

medication or drugs which may cause drowsiness or loss of attention.

Machine must only be operated with all safety guarding in place. The machine cutting heads

including spindles and oscillating knife heads are supplied with safety guarding. Do not operate

the machine with safety guards removed. Do not activate clamping systems unless it is safe to

do so. Ensure all clamping devices are clear of obstruction and that machine operators or other

personnel cannot be injured prior to activating the device.

All emergency stop devices must be in full working order before operating machine.

We STRONGLY RECOMMEND that safety mats, laser safety curtains or other safety

barrier devices be fitted to machines with a process area exceeding 3600mm in length

or are fitted with aggregate head attachments or any other attachment that can pose a

safety risk. Safety interlock outputs are available on the controller for the connection of

these devices.

Machine must not be operated with danger or non-operation tags in place.

The machine must not be left unattended whilst in operation.

Personal Protective Equipment

It is recommended that the operator, and other persons working in the vicinity of the machine,

use the following personal protective equipment in conjunction with the machine:

• Hearing protection

• Eye protection

• Gloves when handling materials to be machined

• Cut proof gloves when changing router bits, knife blades or other cutting tools.

Note: The supply and wearing of personal protective equipment is regulated by Workcover.

Training and Support Services Offered

In addition to the training provided during initial installation of your machine, Multicam offers a

range of extra training services as refresher courses or for the purpose of training additional or

new operators. These services may incur additional charges, of which you will be advised at the

time of application.

Onsite

We can provide onsite training to ensure a high level of machine operation competency

for your staff. Onsite training is beneficial in that it utilises your equipment and can be

tailored around your systems and procedures.

At Multicam Premises

Training at one of our offices can be provided for your staff. This is usually more general

training and is beneficial in that there are minimal disruptions. This type of training is well

suited to in-depth software training.

Remote Access

With Remote Access we log on to your computer via an internet client service. This can

enable us to assist you in diagnosing various operational or software issues. The service

can be affected by your internet connection or availability. Remote access is not suitable

for training new staff or staff with no prior experience, rather it is best suited to assist

previously trained staff or operators in areas that they may be unfamiliar with.

Remote access may also be employed by technicians to view your machine

configuration or settings.

To access additional training, please contact your nearest Multicam office.

Safe Operation of Machines

The machine must only be operated by persons trained and accredited by Multicam Systems.

The machine should be operated only in a well-lit environment in order that the operator can

monitor the working of the machine and carry out safe loading and unloading. If the workplace

is poorly lit, then additional lighting will need to be provided.

The machine's safety devices should be checked regularly for correct operation, e g the

emergency stop mechanism and guarding.

When the machine is running, keep clear of any rotating or moving parts, e.g. the cutting bit,

spindle, moving gantry and head parts.

Do not stand or lean on the machine whilst it is in operation. No persons other than the operator,

or other authorised persons, should enter the working area whilst the machine is in operation.

Parts of the machine, particularly the cutting bit, may become hot during use. Take care when

handling these parts and wear protective gloves if necessary.

Prior to operating the machine the following safety checks must be performed:

• Ensure that there are no tools or materials left on or near the rack and bearing rails of

the gantry and the axis of movement.

• Ensure all guarding is in place including dust extraction devices. The machine cutting

heads including spindles and oscillating knife heads are supplied with safety guarding.

Do not operate the machine with safety guards removed.

• Ensure that all clamping systems are free of obstructions and that no other personnel

are likely to be injured or engaged prior to activating the clamps.

• Ensure that all tools have been removed from the cutting area.

• Ensure that the guards are in place and correctly positioned.

• Ensure that the material being cut and the sacrificial board is no wider or thicker at any

point than the width and height under the gantry and does not impede the movement of

the gantry.

• Ensure that only recommended cutting fluids are used in mist dispensing systems.

• Ensure that all cutting tools to be used are sharp and in correct working order.

• Ensure that the filter for the vacuum pump is clean and that the correct vacuum valves

are On/Off and are clear of any obstructions.

• Ensure that there is at least 500mm of clear open space around the machine.

• Ensure that all electrical and air supply components are in correct working order and

have not been damaged in any way.

• Ensure that the vacuum pump inlet/outlet ports and pressure release valve are not

covered.

• Ensure that the area around the machine is clean and free from obstructions which could

lead to slips, trips or falls.

• Ensure that tools are correctly fitted in to collets and that collets are free from wear or

damage.

• Ensure that ISO tool holders are in good condition and are free from wear or damage.

• If manually changing tools in a quick tool change motor ensure that the tool holder is

correctly engaged in the motor. Do this by firmly grasping the nut on the tool holder and

pulling in a downward and sideways movement and checking for looseness. If you are

able to "wobble" the tool holder it is not correctly engaged.

It is recommended that checklists are used and logged at the end of each shift.

Safety During Maintenance

Changes or additions to the main electrical system in connection with the installation and

operation of the machine should always be carried out by a suitably competent and licenced

electrical engineer.

Repairs carried out by untrained or unauthorised personnel may result in personal injury or

serious malfunction and damage to the machine.

Do not alter or modify the specification of the machine as this may introduce an uncontrolled

hazard or risk.

Servicing and maintenance of the machine should be carried out on a regular, planned basis

and by a trained and authorised engineer.

Before working on any component or part of the machine always isolate the machine from the

mains electrical and air supplies. These should be locked off.

Safety During Cleaning

To maintain optimum performance and obtain the longest service life from the machine, it must

be cleaned regularly, either with a vacuum cleaner, compressed air or a suitable cleaning

solution. When cleaning, the machine must not be in operation. Extra care must be taken if

using compressed air to clean the machine that particles are not blown off the machine into the

eyes.

Do not use pressurised jet washers or free flowing liquids to clean the machine. These will

damage the machine.

Warning Labels

The following chart details the warning signs and labels and their locations on the machine.

They are designed to assist and remind the operator to exercise caution when approaching the

machine and the working area.

Operators should read carefully and take due note of the warnings and instructions for safe

operation before operating the machine.

In addition to the warning labels on the machine the workplace should also be adequately

signed for the wearing of personal protective equipment, e g eye and hearing protection, and

the zones where these precautions are necessary clearly marked.

HAZARD NOTICE TABLE

Hazard Requirement Location

Hearing Protection Mandatory On the Machine Head

Eye Protection Mandatory On the Machine Head

Electrical Power Warning On the Inverter Box

Electrical Power Warning On the Controller Box

Electrical Power Warning On the Power Box

Cutting Hazard Warning On the Machine Spindle

On Knife head attachments

Emergency Stops Mandatory On both ends of the Gantry

Air Pressure Warning On the Machine Frame

Striking Warning On the X axis Bearing

Cover

Striking Warning On the Tool Changer Cover

Striking Warning On the Machine Head

Pinch Point Mandatory Near clamp activation

switch

Cutting Hazard Mandatory On the Spindle pickup

housing

On Knife head attachments

Position or appearance of labels may very in accordance with devices that form

part of the work cell. Always observe all safety labels and advisory notices.

Note. The warning labels must not be removed from the machine.

Safety Rules

WARNING

Machine must only be operated by persons trained

and accredited by Multicam Systems

MANUALS. Always read the appropriate manual or instructions before attempting to operate

or maintain equipment. Make sure that you understand all instructions.

CORRECT SUPERVISION. When in doubt as to the correct way to operate the equipment

always consult your supervisor.

OPERATION OF EQUIPMENT. Do not operate equipment unless maintenance has been

performed on a regular basis, and the equipment is known to work properly. Do not operate the

machine with safety guards removed. The machine must not be left unattended whilst in

operation.

EMERGENCY SWITCHES. Ensure that you know where all emergency switches and stop

buttons are, and you know how to isolate the machine from the main power supply.

WARNING NOTICES. Do not remove any of the warning notices or mandatory signs from the

machine. Ensure that you comply with all such information.

SAFETY DEVICES AND GUARDS. Inspect all safety devices and guards to be certain that they

are in good condition and functioning properly before any operation. The machine is supplied

with guarding required for safe operation. Do not use the machine unless safety guards are in

place.

HAZARDOUS CONDITIONS. Do not operate the machine if unusual or excessive heat, noise,

smoke or vibration occurs. Switch off the machine and report any unusual occurrence.

EARTHING. Ensure that the equipment is properly earthed. The equipment contains digital

signal systems, which are effected by electrical spikes and noise.

ELECTRICAL ISOLATION. Before any repair or maintenance work is undertaken on the

machine ensure that the main electrical power is fully isolated.

MAINTENANCE WORK. Do not reach into any control or power box unless the electrical power

is turned off, do not touch any electrical equipment if hands are wet or when standing on a wet

surface.

AUTHORISED PERSONNEL. Do not allow unauthorized personnel to have access to electrical

enclosures containing electrical equipment. Do not allow untrained personnel to operate or

repair the equipment.

REPLACEMENT EQUIPMENT. Always replace blown fuses with fuses of the same rating, size

and type as the original.

PERSONAL PROTECTIVE EQUIPMENT. Wear the correct safety glasses, ear protection and

foot protection at all times.

LOOSE EQUIPMENT. Do not operate any machine while wearing rings, watches, jewellery,

loose clothing, neckties or untied long hair.

SAFE WORKING AREA. Keep the area around the equipment well lit, dry and free from

external obstructions and waste material.

FLAMMABLE EQUIPMENT. Keep chemical and flammable material or products away from

electrical or operating equipment.

FIRE EXTINGUISHER. Always have the correct type of fire extinguisher ready when machining

combustible material and keep chips clear of the work area.

MACHINE OPERATION. Do not operate any equipment while anyone is close to any potentially

hazardous area.

PINCH POINTS. Always beware of pinch points created by moving components of equipment

including automatic, semi-automatic or manual clamping devices.

LOOSE TOOLS AND EQUIPMENT. Remove any loose parts, work pieces, or tools left in the

operating area of the equipment, which may come into contact with moving machinery.

WASTE MATERIAL. Do not remove splinters, chips, swarf or waste material with bare hands.

Beware of sharp and burred edges on newly machined work pieces.

ADJUSTMENT OF MACHINERY. Do not adjust tooling or mist dispensers or extractor hoses

while the machine is running.

CUT MATERIAL. Do not attempt to remove any cut material while the machine is running.

BRAKING OF MACHINERY. Do not attempt to brake or slow down the machine with your

hands or any foreign device.

CUTTING TOOLS. Be cautious when working around cutting tools, their cutting edges are very

sharp and can cause injury.

MOUNTING TOOL SURFACES. Make certain that all tool-mounting surfaces are clean before

mounting tools.

LOADING AND UNLOADING THE MACHINE. Ensure correct manual handling procedures are

observed when loading and material and product from the machine. DO NOT attempt to remove

items from the machine bed whilst the machine is in operation.

ALWAYS THINK SAFETY FIRST

Vacuum Pump Operating Information

To protect the vacuum pump from premature failure it is important that the following

procedures be adhered to;

Maximum Pressure

The maximum allowable pressure is not exceed -40kPa. Exceeding this value will cause the

pump to overheat causing severe damage and voiding warranty.

Operating Temperature

The vacuum pump surface will become extremely hot during operation. Care must me

exercised when coming in to contact with the surface of the pump or any other items likely to

become affected by heat.

Vacuum pump performance is affected by the ambient and inlet temperatures. Vacuum

pumps must not be operated where the inlet temperature exceeds 50oC. As the inlet

temperature approaches 40oC the vacuum pump must operate at a reduced duty cycle

allowing time for adequate cooling of the pump between cycles. Duty cycle is determined by

ambient temperature. The higher the ambient temperature the shorter the duty cycle.

Vacuum pumps expel hot air at high velocity. Adequate provision must be made to allow for

the safe and unrestricted expulsion of the exhaust air.

DO

• ensure that there is adequate space around the vacuum pumps to allow a free flow of

air on all sides. We recommend a least 1m of free, unobstructed space on all sides.

• keep vacuum pumps clear of debris.

• check correct function of relief valve regularly.

• consult with specialists if you intend to duct exhaust from the pump. Incorrect ducting

will affect vacuum pump performance and can lead to failure of the pump and

overheating leading to injury or fire.

DO NOT

• exceed the maximum operating pressure.

• exceed the maximum inlet operating temperature.

• block the exhaust manifold.

• place objects in close proximity to the exhaust air.

• place vacuum pumps in confined spaces.

• enclose the vacuum pumps in enclosed spaces.

• place vacuum pumps under machines unless absolutely necessary. This will result in

limited air flow around the pump causing premature failure and a drop in performance

and cause surrounding machinery to become affected by heat.

• touch the surface of the vacuum pump as it will become hot during operation

resulting in burns.

• move the vacuum pump from its originally installed location.

Failure to follow these instructions will void your warranty

Job Design Considerations

Before designing a job for cutting on the machine there are a number of factors that must be

taken in to account. A designer must always consider how the component is to be produced

using the machine, tooling and materials available. Sometimes the design requirements will

place demands on the tooling that could lead to undesirable practices such as the use of

small diameter or extra long tooling. These must be avoided as far as practicable and

attempts should be made to alter the design to reduce these practices.

It is essential that when designing a job for manufacture the programmer is conversant with

the machine capabilities, characteristics of the materials being cut and the available tooling.

In cases where there is no control over the design of the component to be cut then the

overriding consideration must then be to the safe and efficient cutting of the component. The

order of priority of these considerations will be dependent upon the nature of the job.

Physicality of the component

The physical nature of the component (i.e shape and material to be used) to be machined

will determine factors such as;

• work holding

• cutter selection (diameter, length, flute geometry)

• cutting speeds and feed rates

• number of cutting passes

• edge finish

Work Holding

The material to be cut must be safely secured to the machine bed. The use of jigs or manual

clamping methods may be required depending on the size and shape of the item to be

machined and the material it is to be cut from.

If using vacuum tables the operator must ensure that minimal “leakage” is present to

maximise the effectiveness of the system. If too much leakage is present then materials and

components may move during the cutting process. The number and size of through cuts, the

size of the component being cut, the condition of the sacrificial board, the speed of cut and

diameter of the cutter being used will all influence the performance of the vacuum system.

If using manual clamping methods or jigging, consideration must be given to the placement

of clamps, height of clamps, number of clamps and proximity of clamps to machining paths.

The programmer and machine operator must ensure that travel clearance heights and clamp

location will not cause the cutter or any other part of the machine to strike any of these

items.

If automatic, semi-automatic or manually activated clamping devices are fitted to the

machine, care must be exercised to ensure that there is no risk of injury or engagement with

the devices by operators or other persons.

Loading...

Loading...