Udara

INSTRUCTIONS FOR THE INSTALLER AND END USER

INSTALLATION, COMMISSIONING, MAINTENANCE AND USE OF THE APPLIANCE

Gas-fi red condensing and modulating air heater with an

automatically regulated energy-effi cient fan with a direct current

motor and gas-adaptive burner control

Brand: Multicalor Udara

Model: 10, 15, 20, 30, 40 et 50 (DF)

Land of destination: United Kingdom (UK)

Read this document before starting the installation or using the

appliance. After commissioning, give instructions to the user and

keep this document in the immediate vicinity of the appliance.

This appliance may not be operated by children, people with

a diminished mental capacity, physical impairments or lack of

knowledge unless under supervision or after receiving training

on how to use the appliance safely and as long as they are

aware of the possible risks. Children may not play with the

appliance under any circumstances. Cleaning and maintenance

performed by the user may never be carried out by children

without supervision.

Multicalor Industries NV

Blarenberglaan 21 • B–2800 Malines

Tel.: +32 15 29 03 03 • Fax: +32 15 29 03 20

info@multicalor.be • www.multicalor.be

IHL_UDARA_2016_11_04_BEGB Wijzigingen voorbehouden

Table of contents

1 Safety 5

1.1 Warnings and symbols 5

1.2 Improper use 5

1.3 General safety instructions 5

2 General information 8

2.1 Description 8

2.2 Gas category 8

2.3 Standard version 8

2.4 Outdoor air version 8

2.5 Versions 8

3 Technical data 9

3.1 In general 9

3.2 Technical data 9

3.3 Overview of components 10

3.4 Dimensions 11

4 Installation 12

4.1 In general 12

4.2 Installation of the fl ue gas outlet system 12

4.3 Installation of the condensate drain

4.4 Installation of the gas pipe 17

4.5 Installation of the ductwork 18

condffffffffffffff 17

5 Commissioning 20

5.1 Switching the appliance on and off 20

5.2 Regulating the combustion 20

5.3 Converting the appliance to propane 21

6 Operating and setting 22

6.1 In general 22

6.2 Modulating thermostat RC21 22

6.3 Air-conditioning 23

6.4 Heat pump 23

6.5 Operation in heating mode 23

6.6 Setting as ventilation 23

6.7 The control panel 23

6.8 Changing settings 24

6.9 Error codes 26

7 Maintenance 27

7.1 Maintenance by the user 27

7.2 Maintenance by the installer 27

8 Troubleshooting 28

8.1 Appliance does not start after 5 attempts 28

8.2 Internal error 29

8.3 Overheating and NTC errors 29

8.4 Display does not work 29

8.5 Flue gas fan operates continuously or not at all 29

8.6 System fan operates continuously or not at all 29

8.7 No communication with thermostat 29

8.8 Fuse or earth leakage circuit breaker intervenes 30

8.9 Loss of fl ame shortly after ignition 30

8.10 Service Request 30

8.11 Normal settings 30

2

IHL_UDARA_2016_11_04_BEGB

9 Diagram 31

10 Parts 32

10.1 Parts list 32

10.2 Ordering procedure 32

10.3 Service request 32

11 Guarantee 33

11.1 In general 33

11.2 Scope and duration of the guarantee 33

11.3 Damage that is not covered by the guarantee 33

11.4 The following are not covered by the guarantee 33

11.5 Repairs 33

11.6 Service sets 33

12 Multicalor RC21.14 34

12.1 Setting the language, date and time 34

12.2 Mode

12.3 Summer ventilation 36

12.4 Program 36

12.5 Switching off periods (max. of 2 periods) 37

13 EC Declaration of conformity 38

14 Declaration of conformity KB 2004-01-08 39

IHL_UDARA_2016_11_04_BEGB

3

4

IHL_UDARA_2016_11_04_BEGB

1 Safety

This section must be carefully studied by the installer

and the user.

1.1 Warnings and symbols

A number of symbols point out possible dangers that

may occur when installing or using the appliance.

Depending on the seriousness of the potential

situation, other symbols, icons or words are used.

Always take these warnings seriously and never ignore

them.

Danger!

This symbol warns you about a serious danger.

Intervene immediately to prevent heavy physical or

fatal injury or signifi cant material damage.

Danger!

This symbol warns about a danger or fatal injury

because of an electric shock. Ignoring this warning

can lead to signifi cant physical or fatal injury.

Warning!

This symbol warns about a dangerous situation.

Ignoring this warning can lead to physical injury,

material damage or environmental damage.

Attention!

This symbol warns about a situation that deserves

your attention. Ignoring this warning can lead to

material damage. .

Information(s)

This symbol indicates that somewhere else in the

manual you can fi nd more information about this

topic or it will refer you to a local standard.

1.2 Improper use

The Udara air heater is intended for heating systems

based on hot air where both the heated and the intake

air is distributed through a system of ducts.

If the appliance is used inexpertly or improperly, a

situation may be created that entails danger for the

user or third parties or can lead to damage to the

appliance or the environment.

You may only install the Udara if you combine the

appliance with the accessories listed in the manual for

the combustion air supply (CAS) and fl ue gas outlet

(FGO).

As an installer or user you have the obligation to

closely follow the instructions contained in the manual

of the appliance or the possible accessories. You

must, moreover, respect all inspection and

maintenance conditions

You must connect the appliance electrically in

accordance with the protection degree specifi ed on

the nameplate and in accordance with the locally

applicable regulations.

If you implement changes to the appliance that are

not described in the manual, you must ask for written

permission from the manufacturer.

Transgressions to these instructions will be deemed

not according to the regulations and may lead to

dangerous situations or material damage regarding

which the manufacturer rejects any responsibility.

1.3 General safety instructions

The installation, mounting, disassembly,

commissioning, maintenance and repair must only be

performed by professionals. They must have all legal

qualifi cations and, by preference, they must have

followed training at the manufacturer of the appliance.

As a user, you must closely follow the maintenance

instructions. Ask your installer to go through this

section if you have any questions.

1.3.1 Danger of fatal injury because of gas leaks

With regard to gas smells in buildings:

• extinguish all naked fl ames (such as from

smoking, cookers, etc.).

• Do not operate any doorbells, switches, plugs,

telephones, entry panels or other devices

• Close the main gas valve and the gas valve on the

product.

• Open windows and doors.

• Evacuate the building and stop third parties from

entering the building.

• Warn the fi re brigade using a telephone

connection outside the building (for example, at

the neighbours).

• If the leak occurs in front of the gas meter, warn

the energy company.

Liquid gas is heavier than air and will collect near the

fl oor. If the appliance is being installed below ground

level, leaking liquid gas will collect and, therefore,

there will be an explosion risk.

• Ensure that liquid gas can never escape from the

appliance or the gas pipe.

1.3.2 Danger of fatal injury because of fl ammable

substances

Do not use or keep explosive or fl ammable substances

(petrol, thinner, paper, etc.) near the appliance.

1.3.3 Danger of fatal injury because of

combustion gases escaping

If fl ue gases escape, this can lead to dangerous

situations.

• Only use the appliance with a fully installed

CAS/FGO

IHL_UDARA_2016_11_04_BEGB

5

• Always use the appliance with an installed front

cover.

A dangerous situation may occur if the appliance is

supplied with insuffi cient combustion air.

• Ensure there is a permanent and unobstructed

air supply to the set-up room of the appliance in

accordance with the applicable standards.

If you smell fl ue gases or you suspect there is a

combustion gas leak, you must intervene immediately.

• Open windows and doors and ventilate the

building.

• Switch off the product.

• Consult your installer and have the combustion

circuit checked for leaks or obstructions.

If the condensate trap is empty, fl ue gas may leak.

• Always use the appliance with a fully fi lled

condensate trap.

1.3.4 Danger of fatal injury because of electric

shocks

If you touch components that carry a current, there is

a danger of fatal injury because of an electric shock.

Before you work on the product:

• Ensure that the current to the appliance has been

disconnected.

• Protect against reconnection.

• Always wait a few minutes so that the capacitors in

motor controls, etc., are discharged.

1.3.5 Danger of fatal injury because of changes

Unauthorised changes to the product or set-up room

can lead to dangerous situations.

• Never remove, bypass or change the temperature

probes in the appliance.

• Sealed parts in the appliance must not be opened.

• Never change the piping for gas or the CAS/FGO

and the wiring for the voltage.

• The condensate discharge must always be

present and changes must never be implemented

regarding the condensate discharge.

1.3.6 Danger of fi re or becoming trapped

If you want to connect the appliance without ductwork,

you must:

• Install a vent on the suction opening that impedes

access to the fan compartment;

• Install a vent or blow plenum on the blow hole so

that there is no direct access to the heat

exchanger compartment. This vent or plenum

must also ensure that fl ammable material cannot

fall on the heat exchanger.

These accessories are available from our range. If you

do not know which accessories you need, you can

contact your dealer for additional information.

Some parts of the appliance can become very hot

during and shortly after use.

• Only carry out activities such as maintenance after

the appliance has completely cooled down.

1.3.7 Risk of corrosion damage

Chemical products such as solvents, paints,

adhesives, soaps, etc., may lead to corrosion in the air

heater or in the CAS/FGO.

• Ensure that the combustion air is always dust-free

and is not polluted by fl uorine, chlorine, sulphur

and other contaminants.

• If the combustion air is being supplied through a

chimney duct, it must not have been used in the

past as an FGO for fuel oil devices, coal or wood

burners or open fi replaces.

• If the appliance is set up in launderettes, ironing

parlours, swimming pool rooms, etc., the

appliance must be installed in a separate

set-up room in which the ambient air is free from

chemical contaminants.

• Combustion air that is insuffi ciently dust-free

can lead to an unreliable ignition and, in extreme

cases, even damage to the heat exchanger

because of internal dirt. If this risk exists, you must

order an intake fi lter for the CAS that is available

as an accessory.

1.3.8 Material damage because of unsuitable

tools

In addition to conventional tools, you also need a

number of specifi c tools to work on or maintain the

Udara appliance.

• You need a special square drill bit, size 2, to

loosen the tapping screws.

• In addition, you need a set of Allen wrenches with

a rounded side.

• Using a 0-10 Nm torque wrench is recommended.

• You must have a fl ue gas analysing device that

can measure the following substances in the fl ue

gases: NOx (nitrogen oxides), O2 (residual

oxygen) and CO (carbon monoxide). If your

appliance cannot measure NOx, it is strictly

prohibited to change the adjustment of the

appliance or to perform a manual calibration.

1.3.9 Material damage because of frost

If the appliance is not set up frost-free, the appliance

can be damaged. If the temperature of the suctioned

air drops far below freezing point, frost can even occur

in the heat exchanger itself.

In such a case, a bypass must be made using the air

outlet duct to the suction duct so that the suctioned air

is preheated.

• Also make absolutely sure that the environment in

which the appliance is being installed cannot lead

to any dangers because of fl oating dust and/or

fl ammable or corrosive substances or fumes.

6

IHL_UDARA_2016_11_04_BEGB

1.3.10 Material damage to the fl exible gas tube

The fl exible gas tube can be damaged because of a

heavy load due to a weight or repeated and

unnecessary bending.

• Do not suspend the burner and mixing box from

the fl exible corrugated gas tube during

maintenance

1.3.11 Material damage after water ingress

If the appliance or parts of it are exposed to water

ingress, the appliance must be put out of service

immediately. All safety components that are exposed

to water must, subsequently, be replaced

IHL_UDARA_2016_11_04_BEGB

7

2 General information

2.1 Description

Multicalor Udara air heaters are gas-fi red condensing

and modulating appliances with a cleaner combustion,

automatically controlled direct current fans and a

gas-adaptive control.

2.2 Gas category

The appliance has been set for being fi red with natural

gas of the second family (I2N) ex-factory. If you want

to use the appliance with propane, the burner

management control system must be adjusted and a

new nameplate must be added to the appliance. Only

an engineer appointed by the manufacture can do this.

The appliance is delivered ready for use. It is

suffi cient to connect the fl ue gas outlet (FGO) duct,

the combustion air supply (CAS) duct, the gas pipe,

the condensate discharge, the air ducts and the power

lines.

2.3 Standard version

The standard version of the appliance is used for the

distribution of recycled air to which no more than 25%

of outdoor air is added or for the distribution of outdoor

air to heat recovery. The appliance will work in this

mode ex-factory.

2.5.1 Upfl ow

Suctioning takes place at the bottom of the appliance

with regard to an upfl ow version. The blowing out of

the hot air takes place at the top of the appliance. This

is also sometimes called a top blowing version.

The fi lter is at the bottom of the air heater as standard.

If you want to connect the appliance on its side, you

must order an optional fi lter frame.

If side connection is required, we recommend ordering

a long tool life fi lter from the accessory range and not

to opt for the standard side fi lter frame with regard to

the Udara 40 and 50.

2.5.2 Downfl ow

Suctioning takes place at the top of the appliance with

regard to a downfl ow appliance. The blowing out of the

hot air takes place at the bottom of the appliance. This

is also sometimes called a bottom blowing version.

DF is added to the appliance type with regard to the

downfl ow version.

2.4 Outdoor air version

The outdoor air version of the appliance is used to

distribute air to which more than 25% of outdoor air is

added.

Warning!

If the appliance is deployed as an outdoor air

version, you must perform the changes specifi ed

below to prevent damaging the appliance.

If you want to deploy the appliance as an outdoor air

appliance, you must order an additional insulation

set to insulate the fan compartment of the Udara air

heater. This will limit condensation on the outer

housing of the appliance.

In addition, the condensate trap must be installed

outside the appliance using an extended hose set with

regard to the upfl ow versions of the Udara.

The condensate hoses in the fan compartment must

also be safeguarded from frost, for example, by

installing thermal insulation and/or a heating ribbon

around the hoses.

If the temperature of the suctioned air drops below

freezing point, the condensate in the heat exchanger

itself can freeze. In such a case, a bypass must be

made using the air outlet duct to the suction duct so

that the suctioned air is preheated. 2

2.5 Versions

The Multicalor Udara appliances are available in 2

versions: upfl ow and downfl ow.

8

IHL_UDARA_2016_11_04_BEGB

3 Technical data

3.1 In general

The Udara air heaters are CE approved by Technigas based in Brussels and comply with the Gas Appliance

Directive 2009/142/EC. The CE label added to every appliance is the guarantee that the appliances are

continuously checked by TECHNIGAS. The appliances also meet the Machinery Directive 2006/42/EC, the

EMC Directive 2004/108/EC, the Low Voltage Directive 2006/95/EC and the Hazardous Substances Directive

2011/65/EU.

3.2 Technical data

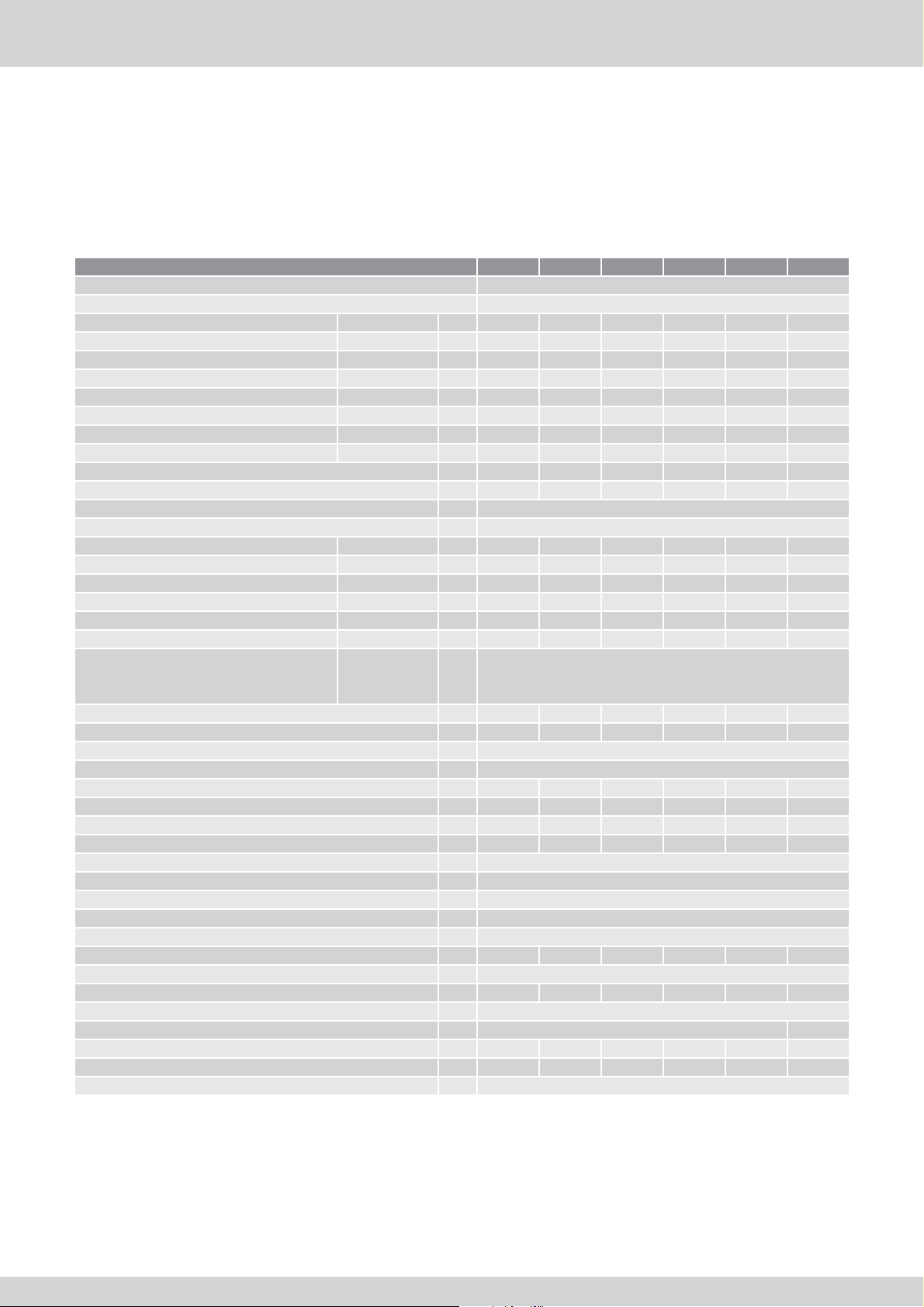

3.2.1 Gas category I2N and I3P technical data

Udara HR (DF) 10 15 20 30 40 50

Gas category I2H, I2L, I2N, I2E, I3P

Gas appliance types B22p, C12, C32, C52, C92

Maximum load on the lower value [PCI] G20 - 20 mbar kW 10.0 14.8 19.7 29.5 39.4 49.2

Minimum load on the lower value [PCI] G20 - 20 mbar kW 1.8 2.6 3.4 5.1 6.8 8.6

Maximum power G20 - 20 mbar kW 10.6 15.7 21.0 31.4 42.1 52.5

Minimum power G20 - 20 mbar kW 2.0 2.8 3.7 5.6 7.4 9.4

Gas consumption at full load G20 - 20 mbar m³/h 1.058 1.566 2.085 3.122 4.169 5.206

Gas consumption at partial load G20 - 20 mbar m³/h 0.190 0.275 0.360 0.540 0.720 0.910

Gas consumption at full load G25 - 25 mbar m³/h 1.253 1.854 2.468 3.695 4.935 6.163

Gas consumption at partial load G25 - 25 mbar m³/h 0.216 0.313 0.409 0.614 0.818 1.035

Thermal effi ciency at full load % 106.2 106.3 106.4 106.6 106.8 106.8

Thermal effi ciency at partial load % 109.0 109.0 109.0 109.0 109.0 109.0

NOx emissions < 30 mg / kWh (CLASS 5 EN1020 / EN1319)

Gas category I3P

Maximum load on the lower value [PCI] G31 - 37 mbar kW 10.2 15.1 20.1 30.1 40.2 50.2

Minimum load on the lower value [PCI] G31 - 37 mbar kW 1.7 2.4 3.2 4.8 6.3 8.0

Maximum power G31 - 37 mbar kW 10.5 15.6 20.7 31.1 41.6 52.0

Minimum power G31 - 37 mbar kW 1.8 2.6 3.4 5.0 6.7 8.5

Gas consumption at full load G31 - 37 mbar kW 0.417 0.617 0.822 1.231 1.644 2.053

Gas consumption at partial load G31 - 37 mbar kW 0.069 0.099 0.13 0.195 0.260 0.328

G20

Inlet pressure

Nominal air fl ow rate m³/h 650 1200 1500 2100 3000 3500

Nominal temperature increase °C 51 41 44 47 44 47

Maximum discharge air temperatur °C 80

Working temperature in heating mode °C minimale 0° / maximale 35°

Nominal taken up power kW 0.17 0.20 0.26 0.30 0.55 0.60

Diameter restriction mm 3.6 4.0 4.0 4.4 6.0 6.4

Mixing box # 45 45 30 30 10 0

Venturi # 4 4 5 8 6 6

Gas connection Ø 1/2” G

FGO diameter mm 80

CAS diameter mm 80

Protection degree IP 20

Condensate discharge diameter mm 32

Condensate quantity kg/h 1.3 2.0 2.6 3.9 5.2 6.5

Power supply voltage V 230 V - 50 Hz (N + L + PE)

Width mm 400 400 400 500 600 700

Depth mm 720

Height mm 1100 1200

Weight kg 52 66 71 84 99 122

Fuse (outside appliance) A 6T 8T 8T 16T 16T 16T

CE approval number # E1432/5671

G25

G31

mbar

20

25

37

IHL_UDARA_2016_11_04_BEGB

9

3.3 Overview of components

1

16

1

2 3

4

5

6

7

8

13

9

10

11

12

14

2 3

15

5

4

6

11

12

9

10

15

16

Legend

Number Meaning

1 Combustion air supply

2 Flue gas outlet

3 Control panel

4 Probe discharge air temperature (NTC 2 / NTC 5)

5 Flue gas outlet coupling

6 Mixing box and venturi

7 Ionisation electrode

8 Ignition electrode

9 Flexible gas tube

10 Burner management control system

11 Flue gas fan

12 Gas valve

13 Intake temperature probe (NTC 1)

14 Condensate discharge trap

15 System fan

16 Air fi lter (in downfl ow in fi lter cabinet)

14

7

8

4

10

IHL_UDARA_2016_11_04_BEGB

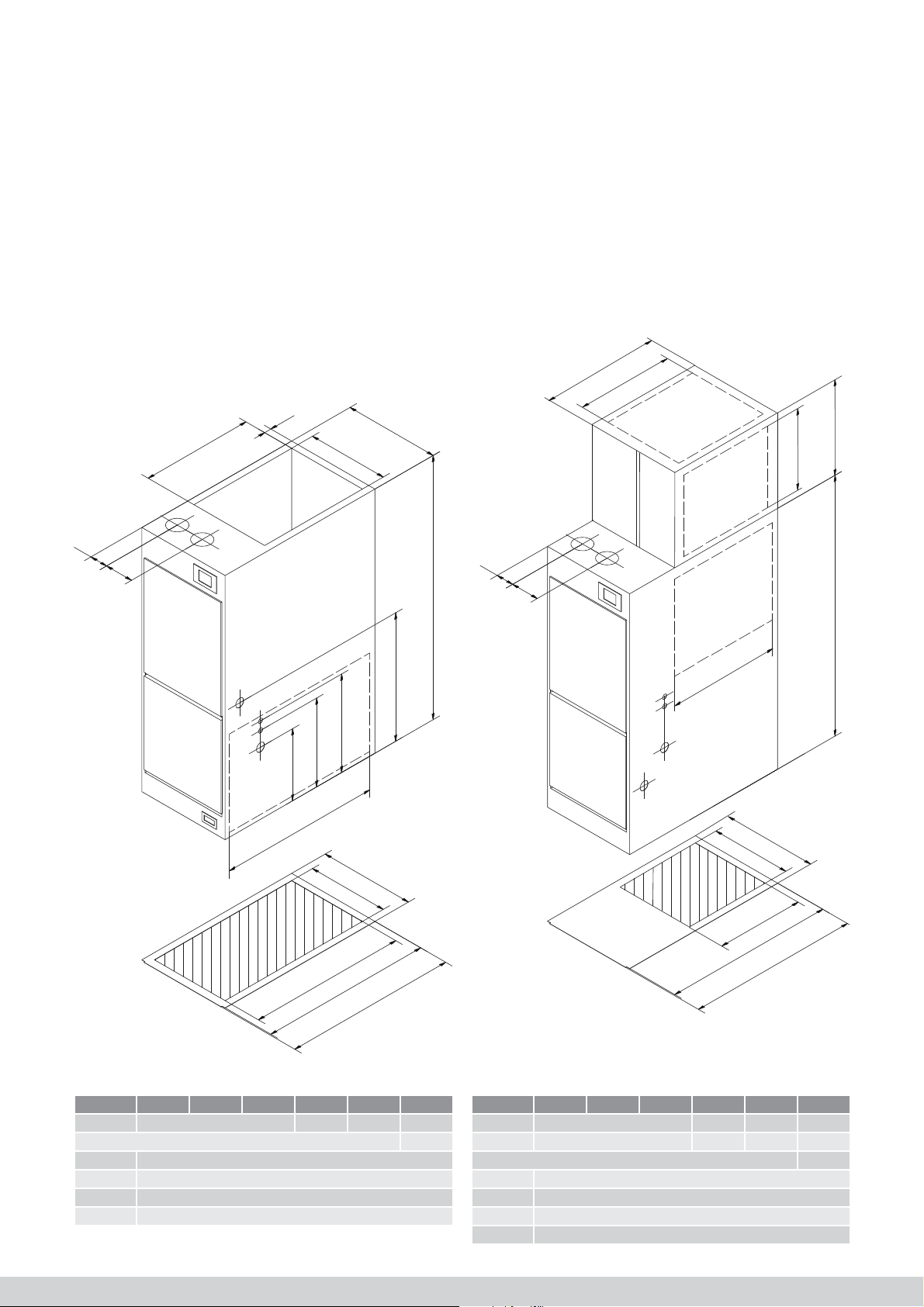

3.4 Dimensions

3.4.1 Dimensions Upfl ow

0

7

4

7

5

1

2

0

3.4.1 Dimensions Downfl ow

515

400

0

3

A

A

-

6

0

7

*

0

0

11

5

1

2

0

B-40

B

0

0

11

*

35

5

0*

1

4

*

0

*

37

00

3

0

1

4

x

5

7

6

A

A

-

6

0

0

6

6

0

2

7

5

2

7

Legend

Udara 10 15 20 30 40 50

A 400 500 600 700

* + 70

a Gas throughput

b Power supply cable connection

c Thermostat connection

d Condensate drain throughput

0

1

4

x

0

7

4

A

A

-

6

0

0

0

4

0

2

7

5

2

7

Legend

Udara 10 15 20 30 40 50

A 400 500 600 700

B 340 440 540 540

* + 70

a Gas throughput

b Power supply cable connection

c Thermostat connection

d Condensate drain throughput

IHL_UDARA_2016_11_04_BEGB

11

4 Installation

4.1 Algemeen

4.1 In general

Gevaar!

Alvorens over te gaan tot installatie of inbedrijfname

Danger!

van het toestel:

Before installing or commissioning the appliance:

• Verzeker u er van dat de condities van het lo-

• Make sure that the conditions of the local

kale distributienet (gas en elektriciteit) overeen-

distribution mains (gas and power) match the

stemmen met de afstelling van het apparaat.

adjustment of the appliance.

• Controleer of het land van bestemming

• Check whether the country of destination is

vermeld op verpakking en kentekenplaat

specifi ed on the packaging and the nameplate

overeenstemt met het land waar u het toestel

matches the country where you are installing

installeert.

the appliance (BE = Belgium).

(BE = België).

• Check whether the selected CAS/FGO method

• Controleer of de gekozen manier van VLT/RGA

is specifi ed on the nameplate.

Contact us if this is not the case and immediately

vermeld staat op het kentekenplaatje.

stop the installation or commissioning.

Contacteer ons indien dit niet het geval is en stop

ogenblikkelijk de installatie of inbedrijfname.

Waarschuwing!

De luchtverwarmer mag uitsluiten geïnstalleerd

Warning!

worden door een bevoegd installateur die over alle

The air heater must only be installed by a comwettelijk vereiste certifi caten beschikt.

petent installer who has all the legally required

certifi cates.

Lokale normen

De installatie moet worden uitgevoerd conform met

Local standards

de laatste uitgave van alle lokale normen en met de

The installation must be performed in accordance

installatiehandleiding van het toestel.

with the latest publication of all local standards and

Raadpleeg zeker de NBN B 61-001, NBN B 61-002,

the installation manual of the appliance.

NBN D 51-003, NBN D51-004, NBN D 51-006,

Ensure you consult the NBN B 61-001,

NBN D 30-003

NBN B 61-002, NBN D 51-003, NBN D 51-004,

NBN D 51-006, NBN D 30-003.

4.1.1 Transportschade

Gelieve bij levering de luchtverwarmer op transport-

4.1.1 Damage during transport

schade na te kijken. Indien schade wordt vastgesteld,

Check the air heater for damage during transport upon

vermeldt u dit op de vrachtbrief en waarschuwt u

delivery. If damage is established, specify this on the

schriftelijk uw leverancier.

consignment note and warn your supplier in writing.

4.1.2 Verpakking

4.1.2 Packaging

De luchtverwarmers zijn verpakt in een doos uit gere-

The air heaters are packaged in a box made of

cycleerd karton. Werp de verpakking niet weg maar

recycled cardboard. Do not throw away the packaging,

biedt ze aan voor verdere recyclage.

but again offer it for recycling.

4.1.3 Minimale vrije ruimte rondom het toestel

4.1.3 Minimum free space around the appliance

Let op volgende minimale vrije ruimten bij de opstelling

Ensure that the following minimum free space is

van het toestel:

available when setting up the appliance:

• Rondom het toestel 50 mm vrijhouden.

• keep 50 mm free around the appliance;

• Rondom de rookgasafvoer en eventueel brand-

• keep at least 25 mm free space around the fl ue

baar materiaal minimum 25 mm vrijhouden; bij

gas outlet and possible fl ammable material; free

concentrische rookgasafvoer dient geen vrije

space is not required with regard to a concentric

ruimte te worden gerespecteerd.

fl ue gas outlet;

• Aan de voorzijde van het toestel dient ongeveer

• approximately 1000 mm of service space must be

1000 mm service ruimte voorzien te zijn (let op

available at the front side of the appliance (ensure

een comfortabele stahoogte).

that there is a comfortable standing height);

• Aan de kant van de condensafvoer dient minimaal

• at least 200 mm of free space must be available

een vrije ruimte aanwezig te zijn van 200 mm.

on the side of the condensate discharge.

•

4.1.4 Set-up room

Pay attention to the following guidelines when

determining the place to set up the air heater:

• Position the appliance as closely as possible to

the fl ue gas outlet and the combustion air ducts.

• Position the appliance centrally in comparison to

the ductwork.

• Position the appliance on a level and robust

substrate.

• The appliance must be raised on a wet fl oor.

• Always set up the appliance isolated from the

structural structure to prevent the transmission of

noise and vibrations.

Danger!

• When using an open return, no appliances with

an open combustion chamber may be present

in the same set-up room. Strictly respect local

standards with regard to the ventilation of the

set-up room.

Attention!

The appliance must be level!

The appliance must be set up frost-free.

4.1.5 Moving the appliance on site

The air heaters must never be moved using the corners by tilting the appliance. The housing of the appliance can be irrevocably damaged due to this. This

damage is not covered by the appliance’s guarantee.

4.2 Installation of the fl ue gas outlet

system

4.2.1 Luchttoevoer– en rookgasafvoerleidingen

Danger!

• Protect the fl ue gas outlet with a non-fl amma-

ble sheath if it is being guided through walls or

cavities made of fl ammable material. Always

respect the free space of 25 mm between this

sheath and the discharge pipe.

• Every Udara appliance must be equipped with

an individual FGO/CAS. Shared discharge

systems are not permitted.

• The burner compartment of the Udara is part of

the combustion circuit. The appliance must not

be put into operation with a missing front cover.

Information(s)

In some countries, the use of CAS or FGO pipes

that have not been enclosed in metal or other fi re-

retardant material is prohibited. Always consult the

local standards before installing.

Udara air heaters are appliances that, by preference,

are set up as a closed appliance (type C). This means

that the appliance must be connected through a parallel or concentric fl ue gas outlet (FGO) and combustion

air supply (CAS).

Combustion gases are discharged through one pipe

and air required for the combustion is supplied through

the other pipe.

12

IHL_UDARA_2016_11_04_BEGB

You can also set up the appliance as an open one

(type B). If the appliance is set up as B22p, a special

air fi lter must be installed on the suction inlet of the

Udara air heater. This fi lter will stop the igniter ducts

between the premix burners from becoming

obstructed and will prevent individual objects from

falling into the appliance.

Always position measuring points in the FGO and

CAS so that a representative sample of the fl ue gases

and the combustion air can be taken. The measuring

points must, by preference, be positioned as close as

possible to the appliance.

The used CAS and FGO pipes must be gas-tight and

must meet the applicable standards. Multicalor has

PP and stainless steel pipes in its range that meet all

applicable standards. If the discharge of the

combustion gases and supply of combustion air takes

place through the roof, the especially designed and

approved icicle-low roof gland MUGRO SKYLINE

must be used.

Les conduites utilisées pour l’évacuation des gaz de

fumée et l’alimentation en air de combustion doivent

être étanches aux gaz et respecter les normes en

vigueur. Dans sa gamme, Multicalor possède des

conduites en PP et en inox qui respectent toutes les

normes en vigueur.

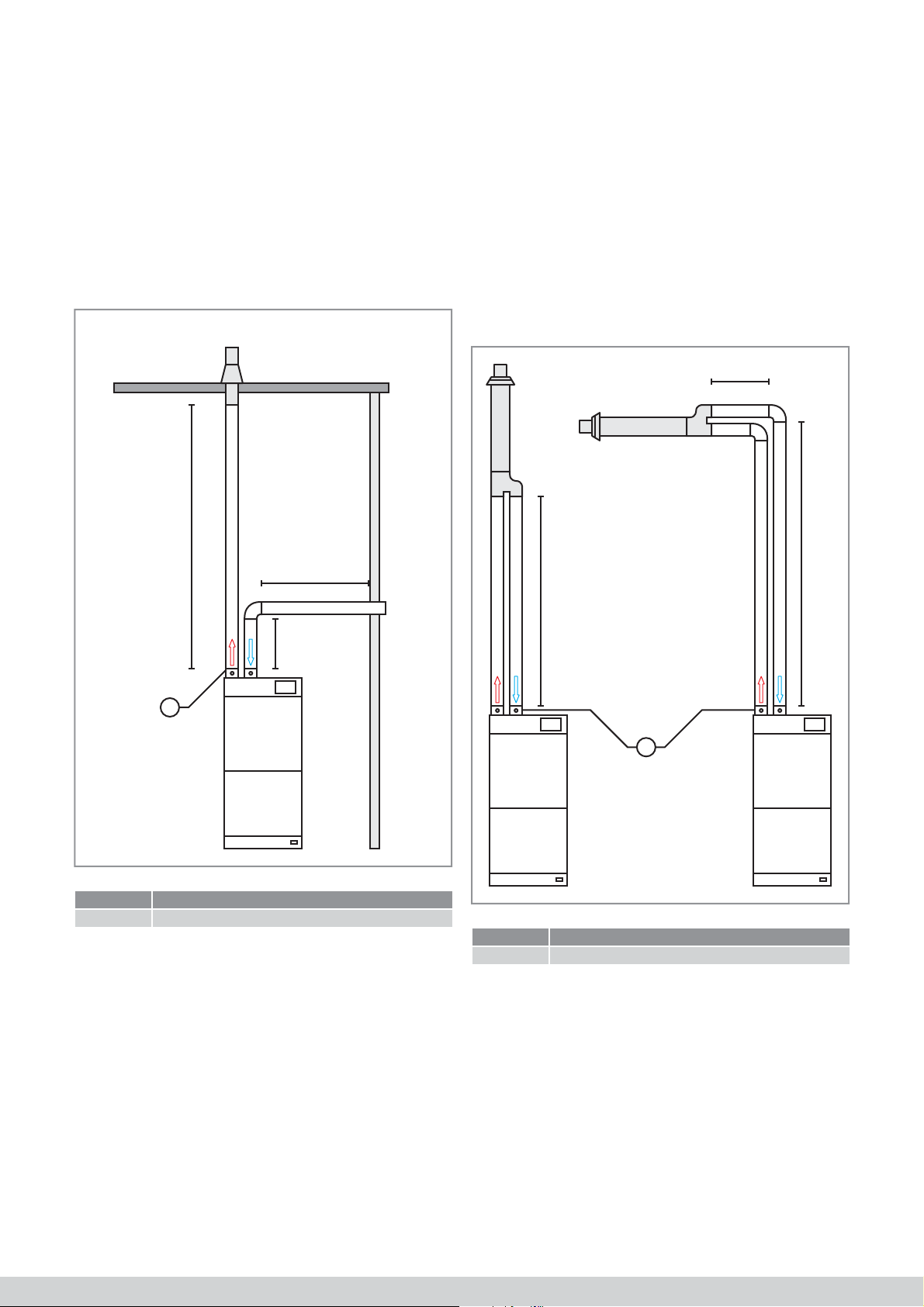

4.2.1 Type B22p connection

The combustion air is taken from the room with regard

to a type B22p connection. The discharge takes place

through a gas-tight fi xed or fl exible pipe.

L

2

3

1

Connecting to another roof gland is not permitted in

relation to the approval in accordance with the Gas

Appliance Directive. If the discharge of

combustion gases and the supply of combustion air

takes place through the wall, the especially

designed and approved wall gland MUGRO WALL

must be used. Connecting to another wall gland is not

permitted in relation to the approval in accordance with

the Gas Appliance Directive.

The fl ue gas outlet must be installed with a minimum

slope of 5 cm/m towards the appliance so that the

condensate can fl ow towards the appliance.

Legend

Number Meaning

1 Measuring point

2 Combustion air supply opening

3 Intake fi lter (dusty rooms) or protective vent

There must always be a direct and non-closable air

supply outlet towards the outside with an area of 3

cm²/kW as the total set up power with a minimum of

150 cm². If local standards prescribe stricter requirements, you must, of course, comply with these.

Position a protective vent or, when setting up the

appliance in dusty rooms, an intake fi lter on the CAS

so that no individual objects can fall into the appliance

and the burner is safeguarded from contaminants.

Always position a measuring point in the FGO. The

maximum allowable length for the discharge pipe is

specifi ed in table 4.2.7.

Danger!

Never connect an Udara appliance straight on to a

standard chimney! A gas-tight FGO must always be

used.

IHL_UDARA_2016_11_04_BEGB

13

4.2.2 C52 two-pipe system

As an alternative to open fl ue gas outlet system B22p,

you can also use closed system C52.

The drawing below shows a two-pipe C52 system.

4.2.3 Parallel systems (C12/C32)

You can use a parallel system to discharge the fl ue

gases. Multicalor carries a range of supply and

discharge pipes made of high-quality PP and stainless

steel.

The length of the fl ue gas outlet (L1+L2+L3) plus the

equivalent length of the bends must not exceed the

maximum value specifi ed in item 4.2.7.

Always install a measuring point in the CAS and FGO.

L1

L2

L3

The drawing below shows a parallel system.

The length of the fl ue gas outlet plus the equivalent

length of the bends must not exceed the maximum

value specifi ed in item 4.2.7.

Always install a measuring point in the CAS and FGO.

L2

L1

L

1

Legend

Number Meaning

1 Measuring point

1

Legend

Number Meaning

1 Measuring point

14

IHL_UDARA_2016_11_04_BEGB

4.2.4 Concentric systems (C12/C32)

The fl ue gas outlet (FGO) pipe is surrounded by the

combustion air supply (CAS) pipe with regard to a

concentric fl ue gas outlet system. Multicalor carries a

full range of concentric pipes.

The Y-pipe supplied with the fl ue gas outlet terminal

must be positioned on top of the appliance with regard

to a concentric connection.

Always position a measuring point in the concentric

piping, by preference, immediately after the Y-pipe or,

if this is not possible, as close as possible to the

appliance.

L2

4.2.5 Chimney renovation (C92)

It is sometimes interesting to install a special fl exible

fl ue gas outlet pipe with a diameter of 80 mm in an

existing fl ue gas outlet (conventional) fi replace. The

combustion air can then be supplied through the air

cavity between the fl ue gas outlet pipe and the existing

chimney or in the room itself. The connection between

the fl exible pipe in the old fl ue gas duct and the

appliance can then take place in parallel or

concentrically.

L2

L1

L

1

Legend

Number Meaning

1 Measuring point

The length of the fl ue gas outlet plus the equivalent

length of the bends must not exceed the maximum

value specifi ed in item 4.2.7.

L1L3

1

Legend

Number Meaning

1 Measuring point

The length of the fl ue gas outlet plus the equivalent

length of the bends must not exceed the maximum

value specifi ed in item 4.2.7.

Warning!

Do not use the old fl ues as combustion air supply if

they have been used in the past as the FGO for fuel

oil appliances, coal or wood burners or fi replaces.

IHL_UDARA_2016_11_04_BEGB

If you want to use this system, the existing fi replace

must at least measure 150 mm x 150 mm when using

a discharge pipe with a diameter of 80 mm.

15

4.2.6 Maximum length of the fl ue gas outlet

The maximum length is the sum of the following: the

length of the straight pipes (L, L1 + L2, or L1+L2+L3 in

Warning!

The maximum allowed length of the fl ue gas outlet

must not be exceeded.

the fi gures)/ the equivalent length of the other

elements such as bends or intake fi lters that you can

fi nd in the table below.

Depending on the used fl ue gas outlet and appliance

types, the maximum length of the fl ue gas outlet and

combustion air supply vary.

Table 2: Maximum allowed length of the fl ue gas outlet

Type Ø Remarks Maximum allowed length

Udara HR (DF) 10 15 20 30 40 50

B22P

C52

C12

C32

C12

C32

C92 80/125 mmConcentric pipes dans la chaufferie

80 mm Smooth pipes in PP/RVS

Flexible pipes MG Flexline in the fl ue gas outlet

80/125 mmConcentric systems with wall terminal

Concentric systems with roof terminal

80 + 80 mmParallell systems with wall terminal

Parallell systems with roof terminal

30 30 30 30 30 20

12.5 12.5 12.5 12.5 12.5 10

20 20 20 20 20 15

12.5 12.5 12.5 12.5 12.5 10

Flexible pipes MG Flexline in the fl ue gas outlet

Bend 90° Bend 90° 2.00

Bend 45° Bend 45° 1.00

Bend 30° Bend 30° 0.75

Intake fi lter 4.00

Protective vent 1.00

4.2.7 Allowed materials

Attention!

Never use fl ue gas outlet or combustion air supply

piping made of PVC. Do not use aluminium for the

fl ue gas outlet either.

You can use PP pipes as fl ue gas outlet pipes if local

standards allow this. If not, use gas-tight pipes made

of stainless steel of the 40, 50, 60 or 70 type in accordance with the EN 1856-1 standard.

You can use PP pipes as combustion air supply pipes

if local standards allow this. If not, use gas-tight pipes

made of stainless steel of the 40, 50, 60 or 70 type in

accordance with the EN 1856-1 standard.

4.2.8 Position of the terminal

All applicable standards must be respected with regard

to wind attack and pollution. If local standards are not

available, use the following guidelines:

• Every terminal must be located in a square of 0.6

m without obstacles.

• The distance between a roof terminal and a

vertical wall must at least be 0.5 m.

• The distance between a roof terminal and a wall

that makes an angle with it and in which windows

can be found must at least be 2.5 m.

• The distance between 2 roof or wall terminals

must at least be 0.6 m.

• The terminals of 2 end pieces that are one on top

of the other in a wall must at least be 2.5 m

• Terminals may not be installed under a porch roof.

• The terminal must at least be at a distance of 1.0

m from the plot border.

• The wall terminal must at least be 1.0 m above

ground level and the roof terminal must at least be

0.4 m above the roof (in connection with snow).

• The wall terminal must at least be at a distance of

0.5 m from the corner of the building.

16

IHL_UDARA_2016_11_04_BEGB

4.3 Installation of the condensate drain

condffffffffffffff

Warnings!

• NEVER shut off the condensate discharge.

• NEVER remove the trap and do not make

any unauthorised changes to the condensate

discharge.

• Do not discharge the condensate directly

outside (frost risk), but discharge the water

using the indoor drainage system.

• If local standards require condensate neutralisation, you must install such a device before

discharging the condensate down the drain.

• The condensate drain MUST be installed with

a slope (5 cm/m) towards the drainage system.

• The trap must be installed outside the fan compartment and hoses must be safeguarded from

frost with regard to an outdoor air appliance.

• The trap must be installed outside the fan compartment and hoses must be safeguarded from

frost with regard to an outdoor air appliance

d’égout normal en PVC ou PE convient bien.

• The trap must be installed outside the fan compartment and hoses must be safeguarded from

frost with regard to an outdoor air appliance

• After installation or maintenance, clean both

traps and fi ll with clean water.

4.4 Installation of the gas pipe

Danger!

• The installation of the gas pipe must only be

carried out by a certifi ed installer or energy

company.

• Check whether the gas category and inlet

pressure match the data on the appliance’s

nameplate.

• Only use fi ttings and pipes that have been

specifi cally approved for gas systems.

• Always consult local standards before installing

the gas pipe.

• Always position an approved stop cock in front

of the appliance. NEVER use a fl ame to check

the piping or to trace a leak.

Attention!

• Ensure there is no dirt in the gas pipe. Purge

the piping before installation using nitrogen to

clean them.

• By preference, install an additional gas fi lter to

prevent contamination of the gas control block.

• Pay attention when using leak sprays near

electrical components.

• Close the stop cock and disconnect the gas

valve when pressure testing the gas pipe. The

maximum pressure when pressure testing is

125 mbar.

Voor een juiste werking van het toestel dient de

To ensure the appliance operates correctly, the

condensafl oop op de riolering aangesloten te worden.

condensate drain must be connected to the drainage

Standaard is de aansluiting rechts voorzien. Indien

system. The connection is provided on the right as

gewenst kan de condensafl oop ook links gebeuren. U

standard. If required, the condensate drain can also be

dient dan de blinde tule, die het gat in de linkerzijde

placed on the left. You must then move the blind

afsluit, naar de rechterzijde te verplaatsen.

grommet that seals the hole on the left side to the right

side. If you move the trap to the left side, you may

Indien u de sifon naar de linkerzijde verplaatst, dient

have to shorten the discharge hoses. You can do this

u mogelijk de afvoerslangen in te korten. Dit kan met

with a sharp knife. Always connect the condensate

een scherp mes gebeuren. Sluit de condensafl oop

drain in accordance with the enclosed drawing.

steeds aan volgens de bijgevoegde tekening.

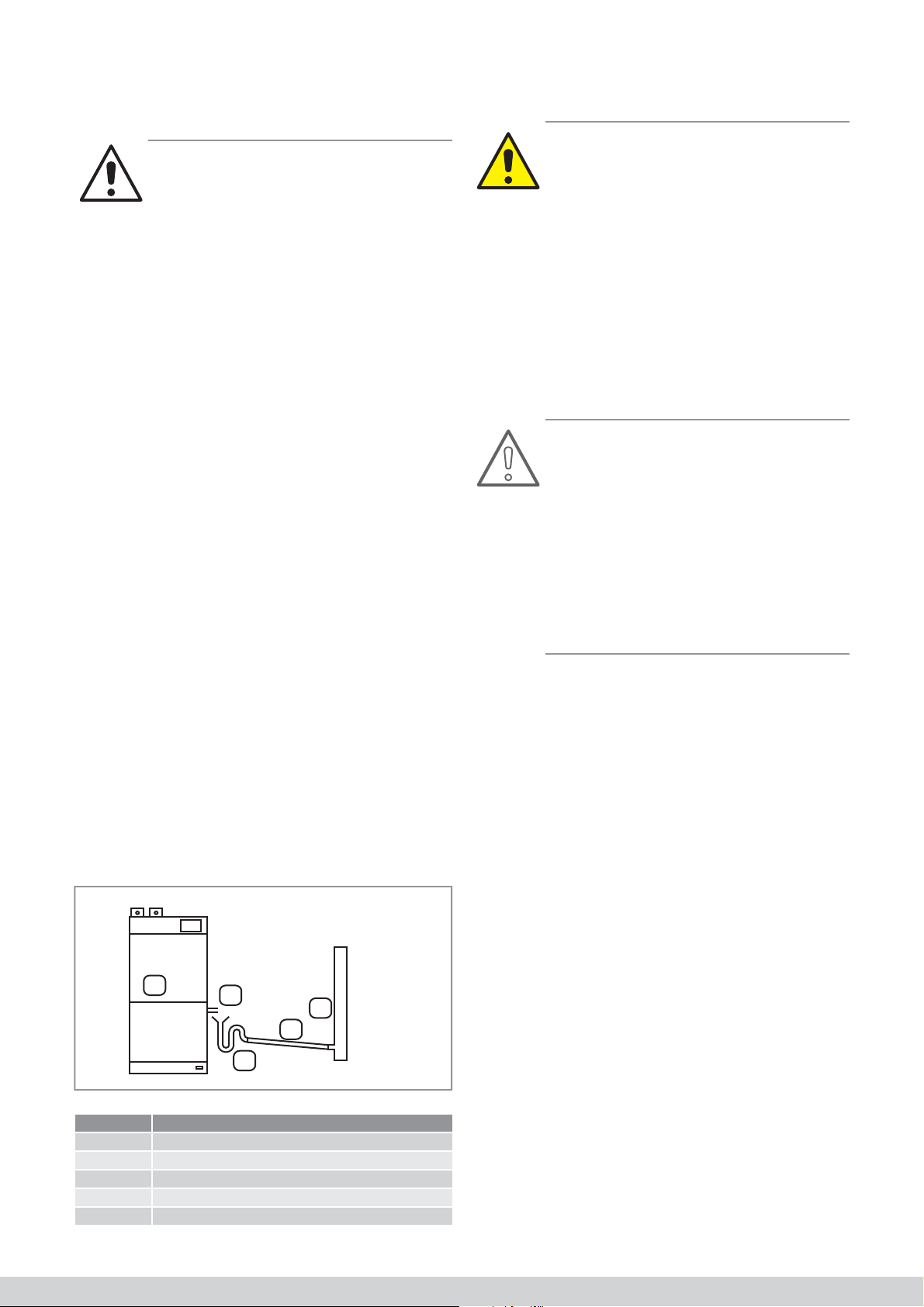

1

2

5

4

3

Legend

Number Meaning

1 Appliance

2 Funnel

3 Extra trap

4 Gradient on slope (5 cm/m)

5 Indoor drainage

The area of the gas pipe must be in accordance with

all applicable local standards and regulations. If the

area is too small, the appliance will not be able to

achieve its maximum power and starting problems can

occur.

Connect the gas supply piping using a ½” connection

directly on to a 90° bend that has been equipped with

a gas control block ex-factory.

Position an approved shut-off valve immediately in

front of the appliance. The feed for the gas connection

is provided on the right as standard.

If required, the gas connection can also be on the left.

Blind grommets in the openings ensure there is an

airtight seal of the burner compartment.

IHL_UDARA_2016_11_04_BEGB

17

4.5 Elektrische installatieDanger!

• Ensure that the installation is free from voltage

(dead) before you start the installation.

• Always connect the earthing.

• Respect all applicable standards (for example,

AREI (General Regulations on electrical installations)).

• Always position an external isolator switch at

the appliance that will allow you to isolate the

appliance from the mains.

• The minimum creepage distance between

contacts must be 3 mm.

The electrical installation must always be carried out

in accordance with the last publication of the relevant

standards and the regulations of the local energy

company.

4.4.1 Connecting the power supply

A 3-pole terminal has been installed in the fan

compartment where a supplied plug can be installed

for the mains power supply. A hole has been included

in the housing to lead through the cable.

Use the supplied blind grommet or cable coupling to

lead through the cable.

Connect the cable to the 230 V~AC power supply with

earthing.

We recommend connecting the appliance directly to

the distribution box that has a delay fuse (the value to

be used is specifi ed in the technical data table).

Attention!

We recommend using circuit breakers with a D

switching-off curve because of the high input surge

currents of the direct current motors.

You can also connect the cable using a plug to the

wall socket outlet with a socket with safety earthing if

required.

The Udara must always be supplied with power. If you

temporarily put the appliance out of service, the

appliance can be set to the standby mode using the

RC21.

4.4.2 Connecting the modulating thermostat

The Udara is used, by preference, with the RC21

thermostat for simple residential applications.

A 2-pole terminal has been installed in the fan

compartment on which a supplied plug for the

thermostat can be installed.

A hole has also been included in the housing to lead

through the cable. Connect the thermostat through a

shielded and twisted 2-core signal cable with a wire

cross-section of 2 x 0.8 mm².

plaats waar deze niet wordt beïnvloed door andere

Install the room thermostat at an approximate height of

warmtebronnen zoals uitblaasroosters, elektrische

1.6 m centrally in the living room and easily accessible

apparaten, direct zonlicht, enz.

for the normal air circulation in the room. Always install

the thermostat on an inside wall at a place where it

Ook de plaatsing bij vensters, deuren, dicht (<1.20 m)

will not be infl uenced by other sources of heat such as

bij een buitenmuur of onder of dichtbij een trap is niet

vents, electrical appliances, direct sunlight, etc.

aan te bevelen.

We do not recommend installing next to windows,

doors, close (< 1.20 m) to outside walls or under or

Voor meer inlichtingen inzake montage en program-

close to a staircase either. For more information about

mering verwijzen wij naar de handleiding van de

installing and programming refer to the thermostat’s

thermostaat.

manual.

Waarschuwing!

Sluit nooit een spanningsvoerende kamerthermo-

Warning!

Never connect a voltage-carrying room thermo-

staat aan. De branderautomaat wordt daardoor

stat. The burner management control system will

onherstelbaar beschadigd.

become irreparably damaged because of this.

4.6 Installatie kanalensysteem

4.6.1 Algemene opmerkingen

4.5 Installation of the ductwork

4.5.1 General remarks

Gevaar!

Indien u het toestel wenst aan te sluiten zonder een

kanalensysteem moet u:

Danger!

• een rooster op de aanzuigopening plaatsen

If you want to connect the appliance without ductwork, you must:

die de toegang tot het ventilatorcompartiment

• install a vent on the suction inlet that stops the

belet.

access to the fan compartment;

• een rooster of uitblaasplenum monteren op de

• install a vent or blow plenum on the blow hole

uitblaasopening zodat er geen rechtstreekse

so that there is no direct access to the heat

toegang is tot het warmtewisselaarcomparti-

exchanger compartment. This vent or plenum

ment. Dit rooster of plenum moet ook verhinde-

must also ensure that fl ammable material can-

ren dat er brandbaar materiaal op de warmte-

not fall on the heat exchanger.

wisselaar kan vallen.

Waarschuwing!

Alvorens u de Udara upfl ow gebruikt met terugname

Warning!

onderaan, moet u de bodemplaat verwijderen langs-

Before you use the Udara upfl ow with readmission

heen de uitsparingen.

at the bottom, you must remove the bottom plate

along the recesses.

In de Udara toestellen is er standaard een luchtfi lter

voorzien. Verwijder nooit het luchtfi lter uit een Udara

Udara appliances have an air fi lter as standard. Never

toestel. Het apparaat dient steeds voorzien te zijn van

remove the air fi lter from an Udara appliance. The

een luchtfi lter klasse EU3 of beter.

appliance must always be equipped with an air fi lter

class EU3 or better.

4.6.2 Installatie aanvoerkanalen

Voor de Udara toestellen is een gamma van witgelakte

4.5.2 Installation of the supply ducts

akoestisch geïsoleerde luchtverdeelkasten (plenums)

A range of white acoustic insulated air distribution

beschikbaar waar de toevoerkanalen op kunnen wor-

boxes (plenums) are available for Udara appliances

den aangesloten. Deze worden bij een bovenuitbla-

to which the supply ducts can be connected. The box

zende versie op, bij een onderuitblazende versie onder

is installed on top with regard to the upfl ow version

het toestel geplaatst.

and on the bottom of the appliance with regard to the

In punt 4.6.4 vindt meer informatie aangaande de

downfl ow version.

aanbevolen minimale afmetingen van de te gebruiken

luchtverdeelkasten.

More information is given in item 4.6.4 regarding the

recommended minimum dimensions of the air

distribution boxes to be used.

18

IHL_UDARA_2016_11_04_BEGB

4.5.3 Installation of the readmission ducts

4.5.4 Air distribution box dimensions

Attention!

Always install the readmission ducts in such a way

that noise locks cannot occur between different

rooms.

A range of white acoustic insulated air distribution

boxes (plenums) are available for Udara appliances to

which the readmission ducts can be connected. The

box is installed at the bottom with regard to the upfl ow

version and on top of the appliance with regard to the

downfl ow version. The readmission ducts can also be

connected directly on to the side of the air heater if

required. Please order the optional fi lter cartridge for a

side connection to do this.

The standard side fi lter frame for the Udara 40 and 50

is very small and we recommend using a long tool life

fi lter from the range of accessories.

If you want to use an open return (only possible if there

are no appliances with an open combustion circuit in

the set-up room), you can order a perforated readmission plenum.

f you are connecting an outdoor air duct, a control

valve must always be included in the outdoor air duct.

Danger!

• Internal acoustic or thermal insulation in the air

distribution box must be able to resist longterm increased temperatures and must be

mechanically protected against being

detached.

• The insulation must be erosion-proof so that no

dust particles end up in the airfl ow.

Use the fi gures below as a guideline when determining

the ideal size of the air distribution boxes and/or air

ducts. Please contact us for advice if you have any

doubts or questions.

1

30° max

A

1

A

30° max

A

Legend

Number Meaning

1 Acoustic and thermal insulation

A Width of the appliance

½ A

IHL_UDARA_2016_11_04_BEGB

19

5 Commissioning

5.1 Switching the appliance on and off

Normally, the appliance must always be supplied with

power through the mains power supply. You can follow

the following steps to switch the appliance on and off

during installation or maintenance.

5.1.1 Switching on

Follow the following steps to switch on the appliance:

• Switch on the mains power supply.

• Open the gas valve.

• Set the room thermostat to the required value.

• After a short waiting time, the appliance will ignite.

If the lock-out symbol is displayed on the appliance

screen or an error message is displayed on the RC21

thermostat, you must unlock the appliance by pressing

the reset button. You can also unlock the appliance

through the RC21.

You must thoroughly vent the gas pipe before

starting the appliance with regard to a new installation.

A poorly vented gas pipe can mean that the appliance

will be in the error mode.

If the appliance does not ignite after repeated attempts

and unlocking instances, consult the section about

faults and failures or contact the manufacturer or

installer.

5.1.2 Switching off

Follow the following steps to switch the appliance off:

• Set the room thermostat 5°C lower than the room

temperature.

• Wait until the burner has switched off (the fl ame

symbol will no longer be displayed on the screen).

• Close the gas valve.

• Wait until the appliance has fully cooled down

(discharge air temperature < 30°C).

• Switch off the mains power supply.

5.2 Regulating the combustion

The combustion of the Udara has been set ex-factory

and does not have to be changed normally.

If, however, the burner management control system or

the gas control block have been replaced, for example,

after a fault, the calibration procedure must again be

performed.

The simplest way in which to do this is through manual

calibration using an RC21 thermostat. Having a device

with which you can also measure the NOx (nitrogen

oxide) content in the fl ue gases is recommended to

ensure the procedure is performed correctly.

to achieve the best possible start behaviour. This value

is stored in the burner management control system

and cannot be changed by the installer. Next, the

heater will start to burn at maximum power

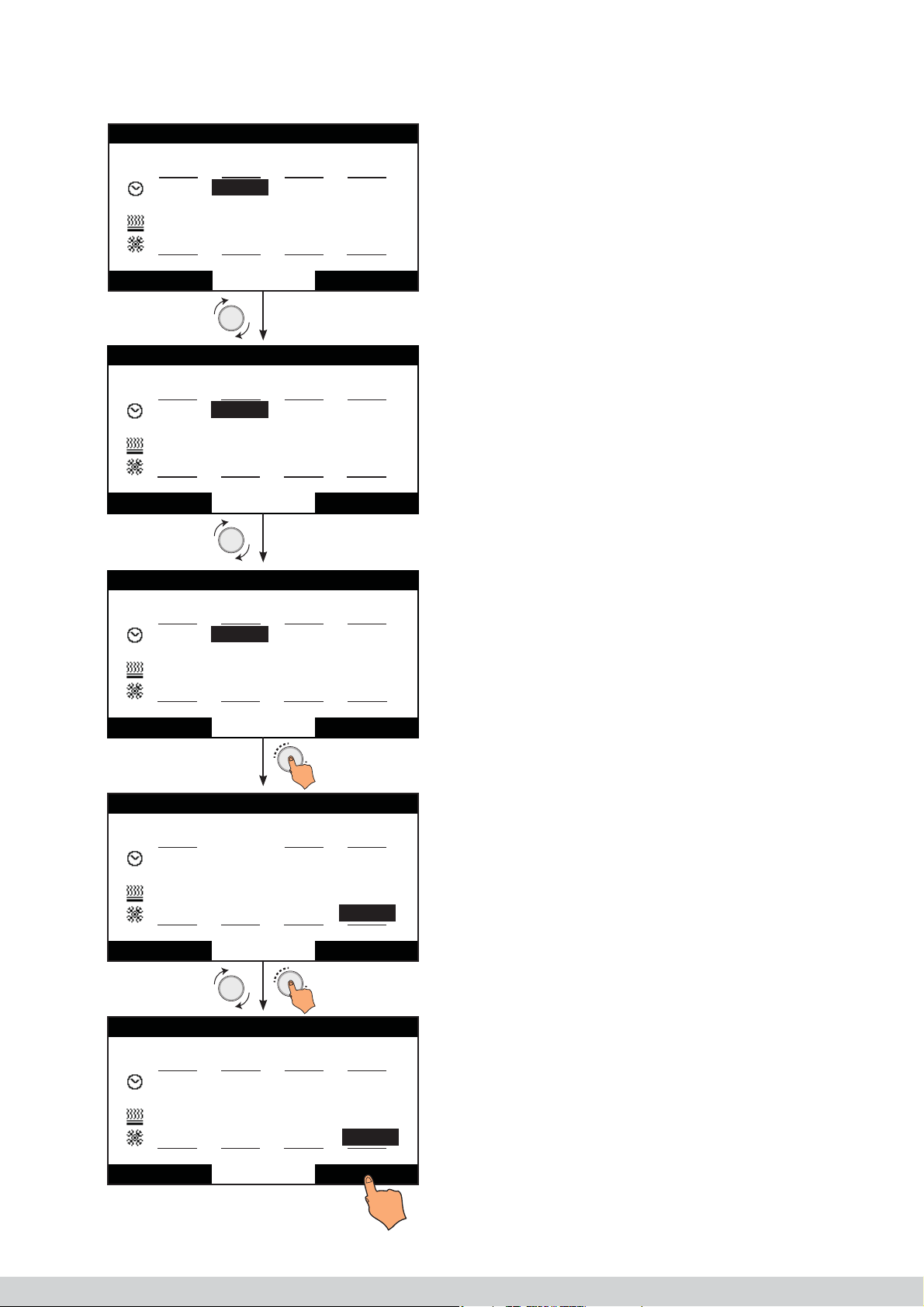

The following will be displayed on the screen:

Boiler calibration

Phase of procedure:

Combustion set:

Power level:

Boiler temp:

Error:

max...

50

100%

75°C

none

Cancel Confirm

Attention!

Ensure that suffi cient vents have been opened so

that the appliance can get rid of its power. If you do

not do so, the overheat control will be activated and

the calibration will be interrupted.

If the fl ame signal is stable, “Max ok” will be displayed

on the screen. Next, you can change the CO2 in the

combustion gases by changing the “Combustion set”

value. If you increase the value, you decrease the

CO2. If you decrease the value, you increase the CO2.

Boiler calibration

Phase of procedure:

Combustion set:

Power level:

Boiler temp:

Error:

max ok

50

100%

75°C

none

Cancel Confirm

If you, next, confi rm the setting by pressing “Confi rm”,

the controller will continue to the next step.

Next, a combustion test will be performed at approximately 60% of the maximum power.

Enter the installer password to start the procedure;

see the “Technical menu” page of the RC21. This

password is issued when you follow training at

Multicalor.

Next, select the “Calibration, manual complete” option.

The appliance will attempt to start a few times until

there is fl ame detection. When there is fl ame

detection, the correct quantity of gas will be calculated

20

IHL_UDARA_2016_11_04_BEGB

Boiler calibration

5.3 Converting the appliance to propane

Phase of procedure:

Combustion set:

Power level:

Boiler temp:

Error:

med...

55

60%

55°C

none

Cancel Confirm

The working method here is analogous to the previous

step. The controller will complete a number of tests

and, next, “Med ok” will be displayed on the screen if

the combustion is stable. Here you can also change

the CO2 in the combustion gases by changing the

“Combustion set” value. After pressing “Confi rm”, the

appliance will also be tested on low power. If you again

confi rm this test by pressing “Confi rm”, the new

settings will be stored in the burner management

control system.

The normal setting can be read from the table below:

Normal settings I2N

Fase CS

(typ)CSMaxCSMin

Max 50 70 30 8.5 20 < 10 ppm

Med 55 70 35 8.5 20 < 10 ppm

Min 90 120 70 8.5 10 < 50 ppm

CO

2

±0.5%

NOx

±10 ppmCO±10 ppm

Danger!

• The Udara must only be converted to propane

in Belgium by an engineer appointed by the

manufacturer because a new nameplate (with

another gas category) must be added to the

appliance.

• Never use butane (I3B) as the gas type.

The Udara can be very easily converted to be used

with liquid gas (propane I3P).

It is suffi cient to set the parameter TSP 9 to the value 1

and, next, perform a new calibration.

In Belgium, this conversion must be carried out by an

engineer appointed by the manufacturer because a

new nameplate must be added to the appliance.

Normal settings I3P

Fase CS

(typ)CSMaxCSMin

Max 50 70 30 9.6 20 < 10 ppm

Med 55 70 35 9.6 20 < 10 ppm

Min 90 120 70 9.5 10 < 50 ppm

CO

2

±0.5%

NOx

±10 ppmCO±10 ppm

Warning!

• Most fl ue gas analysing devices measure the

residual oxygen in the fl ue gases and calculate

the CO2 based on this value. The Udara works

in a vacuum (fl ue gas fan after the combustion

chamber) and, therefore, leaks in the combustion circuit (for example, an empty condensate

trap) will lead to a dilution of the fl ue gases and

an incorrectly measured value. Only change

the adjustment if you are sure that the

combustion circuit is airtight.

• The integrity of the combustion circuit can be

easily established by measuring the

concentration of nitrogen oxides (NOx) in the

fl ue gases. When the CO2 content is 8.5, the

NOx content is approximately 20 ppm (I2N).

When the CO2 content is 9.6, the NOx content

is approximately 20 ppm (I3P)

IHL_UDARA_2016_11_04_BEGB

21

6 Operating and setting

6.1 In general

Multicalor Udara air heaters are very advanced

appliances where special attention has been paid to a

minimum energy consumption.

The appliance is equipped with a unique patented heat

exchanger made of stainless steel. The fl ue gases

are cooled down to produce condensate in the heat

exchanger. The additional heat that is released during

this process increases the effi ciency of the combustion

to unprecedented levels.

In addition, the power based on electricity has been

signifi cantly reduced by using automatically controlled

fans with direct current motors. Even when the motor

speed is low, the effi ciency will continue to be high so

that it is better for the environment and your electric bill

will be lower.

The advanced burner management control system is

equipped with a gas-adaptive control. This means that

the ratio between the combustion air and gas is set,

monitored and, if required, adjusted electronically.

Thanks to this gas-adaptive control, you will always be

assured the best combustion quality even when the

gas quality is not constant.

The burner management control system monitors the

gas/air ratio under all conditions and will always adjust

this to achieve a safe and effi cient combustion.

This extremely modern control technology also ensures that the gas/air ratio can be adjusted briefl y so

that the appliance also ignites reliably under ice cold

conditions and after long periods of being idle.

Thanks to the gas-adaptive control, the Udara

appliance can reduce its capacity in a steplessly

variable manner to approximately 15% of the nominal

power.

This offers the best comfort in combination with a

modulating room thermostat: the difference between

the required and the current room temperature is

measured and, based on this, the optimum power is

determined to heat up the room quickly or to keep it

comfortably warm.

The air quantity will be adjusted automatically to the

discharge air temperature so that a pleasant indoor

climate and an extremely uniform temperature is

obtained.

The installer can set a low, average or high air

quantity. These air quantities are linked to a low,

average or high air temperature. This ensures you can

have high control over the blowing characteristics of

the appliance

6.2 Modulating thermostat RC21

We recommend using a Multicalor RC21 timer

thermostat to drive the appliance for simple household

applications.

1

3 4

2

Legend

Number Meaning

1 RC21 thermostat LCD screen

2 Operating pressure button

3 Context button A

4 Context button B

This modulating thermostat exchanges data

continuously with the burner management control

system so that the good operation of the appliance,

the modulation degree and other appliance data of the

thermostat can be read.

The thermostat allows you to remotely start the fan.

You can choose whether the fan is not operational or

runs at a low, average or high speed (also see item

6.6).

The thermostat also allows you to unlock the appliance

if a locking fault has occurred.

The thermostat must, by preference, be connected

using a twisted and shielded 2-core cable. The polarity

is not important.

Pour en savoir plus, référez-vous au manuel fourni

avec le thermostat.

For more information refer to the manual that is

supplied with the thermostat. For demanding

applications such as, for example, connecting to a

building management system, the control of different

zones or connecting different appliances on

1 thermostat, the standard RC21 thermostat is not

suitable.

If you need this additional functionality, you can opt

for thermostats from the Multicalor Verventa range

that must, however, be connected through a specially

shielded bus cable of the following type: JY(ST)Y-MB

2X2X0.8 mm². You can request more information

about this from Multicalor.

22

IHL_UDARA_2016_11_04_BEGB

6.3 Air-conditioning

You can expand the appliance with cooling. A cooling

unit must then be installed outside and an evaporator

must be installed inside on top of the Udara air heater.

This ensures that you can distribute cold air through

the ducts during the summer months.

6.6.3 Ventilation à vitesse moyenne

6.6.3 Ventilation average

De ventilator draait steeds op de ingestelde middelste

The fan will always operate at the set average air

luchtsnelheid, ook indien er geen warmtevraag is.

speed even if there is no heat demand.

6.6.4 Ventilation à haute vitesse

6.6.4 Ventilation high

De ventilator draait steeds op de ingestelde hoge

The fan will always operate at the set high air speed

luchtsnelheid, ook indien er geen warmtevraag is.

even if there is no heat demand.

The RC21 thermostat can be used to switch on the

cooling unit.

6.4 Heat pump

You can also expand the appliance with a heat pump.

You can then use the heat pump to cool in the summer

and to heat in the seasons in-between.

The gas burner will then only be used if the outside is

colder and the effi ciency of the heat pump becomes

too low or if too many thawing cycles occur.

If you want to connect a heat pump, you must opt for a

thermostat of the Multicalor Verventa range. For more

information please contact us free from obligation.

6.5 Operation in heating mode

The operation of the air heater can be summarised as

follows in normal use:

• If there is a heat demand, the appliance will ignite

the burner. The fan will be started on a minimum

air fl ow rate.

• The RC21 thermostat will measure the difference

between the set and the current room temperature

and will increase or decrease the air temperature

based on this data.

• The air heater modulates the burner to achieve the

set air temperature as best as it can.

• The system fan will adjust the air fl ow rate to the

current discharge air temperature.

The air fl ow rates and air temperatures can be set by

using the control panel.

6.7 Het bedieningspaneel

6.7 The control panel

Op het toestel is een bedieningspaneel aangebracht

A control panel has been installed on the appliance

dat toelaat om de verschillende instellingen van het

to change the different settings of the appliance. The

toestel te wijzigen. Het bedieningspaneel is voorzien

control panel is equipped with a capacitive touch

van een capacitief aanraakscherm en een TFT kleu-

screen and a TFT colour screen.

renscherm.

Attention!

Opgelet!

• Try not to operate the screen using a sharp

• Probeer het scherm niet te bedienen met een

object or your fi ngernails.

scherp voorwerp of uw vingernagels.

• Only use your fi nger or a special pen suitable

• Gebruik enkel uw vinger of een speciale pen

for capacitive touch screens.

geschikt voor een capacitief aanraakscherm.

• The screen responds to touch and not pres-

• Het scherm meet de aanraking, niet de druk-

sure. Pressing hard serves no purpose and

kracht. Hard duwen heeft geen zin en kan het

can damage the screen.

scherm beschadigen.

6.7.1 Basisscherm

6.7.1 Basic screen

Standaard wordt er op het scherm volgende info weer-

The following information is displayed on the screen as

gegeven.

standard.

Multicalor

Multicalor

1 2

1 2

3

3

21:33

21:33

7

7

28-03-2015

28-03-2015

53°

53°

56

56

6.6 Setting as ventilation

If required, you can set the fan in the appliance to a

fi xed air speed on the RC21, for example, during the

summer months.

This can be considered as a set minimum fl ow rate,

that is, the control can make the fan turn faster but

never slower. You can select between 4 different

settings.

6.6.1 Ventilation off

The fan will only operate if there is a heat demand. If

there is no heat demand, the fan will not be

operational.

6.6.2 Ventilation low

The fan will always operate at the set low air speed

even if there is no heat demand.

IHL_UDARA_2016_11_04_BEGB

23

4

45%

3

3

Legenda

Legend

Nummer Betekenis

Number Meaning

1 Functiemodus van het toestel

1 Function mode of the appliance

2 Luchttemperatuur

2 Air temperature

3 Tijd

3 Time

4 Ventilatorsnelheid

4 Fan speed

5 Menuknop informatie

5 Information menu button

6 Menuknop Instellingen

6 Settings menu button

7 Datum

7 Date

45%

4

=

=

6.7.2 Locking

If an error occurs that puts the safe operation of the

appliance at risk, the appliance will be locked. The

cause for locking the appliance is shown on the

screen. The locking can be cancelled by pressing

the unlock button. If the error, however, has not been

resolved, the appliance will again be locked.

You must then contact your installer or the

manufacturer for a solution.

Error

Fout

A number of settings are discussed. Since all screens

are accessible through the same process, not all

screens will be discussed.

6.8.1 Low, average and high temperature

You can set 3 air temperatures on the Udara: a low,

average or high value. To set these values, press the

air heater (2) menu button, next, system fan and then

the fi rst fan curve option on the setting menu.

Fan curve (CH)

7

1

E40: NTC 1 ERROR

E40: NTC 1 ERROR

6

Legend

Number Meaning

1 Error message

2 Unload button

6.8 Changing settings

By pressing the setting icon 3, the fi rst screen of the

setting menu will be displayed

Settings

Instellingen

System

Air heater

2

1

2

Low speed at:

Medium speed at:

High speed at:

4

1

Next, select the value that you want to change. The

selected value (1) will be displayed using an orange

colour. By pressing the key R (5) or S (6) ), you can

change the set value.

If you press 1 (4), les modifi cations sont sauve-

gardées automatiquement et vous quittez l’écran du

menu.

6.8.2 Low, average and high air speed

On the Udara, 3 air speeds can be set for heating: a

low, average or high value. To set these values, press

the air heater (2) menu button, next, system fan and,

as last, the air fl ow rate.

5

9

1

2

3

30°

40°

50°

6

:

Screen cleaning

1

Legend

Number Meaning

1 System settings

2 Settings in relation to the air heater operation

3 Screen cleaning

4 Back to the previous menu

24

4

3

IHL_UDARA_2016_11_04_BEGB

Air fl ow (CH)

Taal

Taal

Language

Low:

Laag:

Medium:

Midden:

High:

Hoog:

4

1

Next, select the value that you want to change. The

selected value (for example, 3) will be displayed using

an orange colour. By pressing the keys R (6) or S

(5), you can change the set value.

If you press 1 (4), the changes are automatically

saved and you will exit the menu screen.

6.8.3 Relationship between the air temperature

and air speed, fan curve

60°

55°

1

50°

45°

40°

2

35°

30°

3

25°

The relationship between the air temperature and

air speed is displayed in the above graph. If the air

temperature is lower than the “low value” (3)

parameter, the fan is operational at the “low” (4) speed.

If the air temperature is higher than the “high value”

(1) parameter, the fan is operational at the “high” (6)

speed. In-between these values, the speed of the fan

is automatically adjusted based on the air temperature.

The “average value” (5) and “average” (2) parameters

serve as an additional checking point to ensure you

have more control over the air fl ow rate.

6.8.4 Setting the language

The control can be set to different languages. To

access this setting, press the “system” (1) button in the

setting menu and, next, the third option: Language.

4 5 6

10% 20% 30% 40% 50% 60% 70% 80% 90%0%

5

9

1

2

3

10%

50%

80%

6

:

English

Nederlands

Nederlands

4

4

1

1

Vervolgens kan u met knop - (5) of (+) de gewenste

Next, you can set the required language with the R (6)

taal instellen.

or S (5).

6.8.5 Tijd en datum instellen

6.8.5 Setting the time and date

Op gelijkaardige wijze is het mogelijk tijd en datum in

The time and date can be set similarly (not applicable

te stellen (niet van toepassing bij gebruik van de RC21

when using the RC21 thermostat).

thermostaat).

6.8.6 Screen cleaning

6.8.6 Schermreiniging

The touch screen can be temporarily switched off for

Door op de toets schermreiniging te drukken wordt het

cleaning by pressing the clean screen button. Clean

aanraakscherm tijdelijk uitgeschakeld voor reiniging.

the screen using a microfi bre cloth or with a paper

Reinig het scherm met een microvezeldoek of met een

tissue.

papieren zakdoek.

6.8.7 Installer’s menu

6.8.7 Installateursmenu

Specifi c parameters can be found on an installer’s

Certains paramètres sont dans un menu réservé aux

menu to stop thoughtless changes. This installer’s

installateurs Bepaalde parameters zitten in een instal-

menu can only be accessed if a password (a code) is

lateursmenu om ondoordacht wijzigen tegen te gaan.

entered.

Dit installateursmenu is enke

Installer code

Installateurcodes

Code User level

Code Gebruikersniveau

123456 Power user

007007 Installer

123456 Power user

007007 Installateur

The code for the “engineer” user level is only released

after following training at Multicalor.

Le code du niveau d’utilisation <<technicien>> n’est

pas dévoilé qu’àprès avoir suivi une information chez

Multicalor.”

Changes do not normally have to be implemented in

this menu.

6.8.8 Information screens

Dans des circonstances normales, il n’est pas néces-

A number of parameters can be read by pressing the

saire de procéder à des modifi cations dans ce menu.

information button on the main menu. The information

in these screen can only be read. The parameters

6.8.8 Écrans d’information

cannot be changed. Provisionally, these screens only

Appuyer sur le bouton info dans le menu principal vous

contain the version number of the operating software.

permet de lire une série de paramètres. Les informati-

ons de ces écrans peuvent uniquement être lues, ces

paramètres ne peuvent pas être modifi és. Ces écrans

ne contiennent pour l’instant que le numéro de version

du logiciel de commande

Warning!

Improper changes of the installer parameters can

lead to damage to the appliance or that it no longer

Avertissement!

works as it should.

Modifi er sans discernement des paramètres réser-

vés aux installateurs peut endommager l’appareil

ou faire en sorte qu’il ne fonctionne plus convena-

blement.

5

5

9

9

6

6

:

:

IHL_UDARA_2016_11_04_BEGB

25

6.9 Error codes

If the appliance is in an unsafe situation, the control

will be locked. Next, you must unlock the appliance by

pressing the reset button (see item 6.4.2).

The following table lists the most frequent codes that

will lead to the appliance being locked. If a specifi c

error returns regularly, ask for advice from the installer

or manufacturer.

Error Meaning

E133 No ignition

E134 Gas valve open - no gas fl ow

E135 Internal error

E110 Safety thermostat open

E128 Flame signal lost 12 x

E129 Flame signal lost 12 x, max. gas control block current

E130 Flue gas temperature too high

E164 Flame signal wrongly present

E09 Gas valve error

E15 Gas valve error

E19 Discharge air temperature too high (TSP #2)

E19 Intake temperature too high (TSP #4)

E28 NTC 4 faulty (fl ue gas)

E20 NTC 2 faulty (air temperature)

E05 NTC 5 problem (air temperature/overheat control)

E21 NTC 5 faulty (air temperature/overheat control)

E22 NTC 5 / NTC 2 deviation too large

E23 NTC 3 faulty (optional - discharge air temperature)

E40 NTC 1 fault (intake temperature)

E10 NTC outdoor temperature fault

E160 Problem with fl ue gas fan

E53 Problem with fl ue gas outlet

E83 No communication with thermostat

E98 Internal error

E71 Fan outside range in calibration mode

E72 Poor combustion in calibration mode

E162 Incorrect frequency

E79 Control current of the gas valve too high

E78 Control current of the gas control block too low

E55 Calibration not performed

E165 Voltage too low

E77 Control current of the gas control block outside the operational area

The following error codes do not lead to a locking

fault, but are saved in the burner management control system for a possible later analysis by a certifi ed

engineer.

Error Meaning

E62 Flame unstable (wind) on low power

E63 Combustion quality outside operational area

E65 Speed limit of the combustion correction exceeded

E66 Obstruction in the FGO on minimum power

E67 Flame unstable (wind) on high power

E69 Combustion unstable during self-test

E70 Flame power signal problem

E73 Flame power signal active

E77 Control current of the gas control block outside the operational area

26

IHL_UDARA_2016_11_04_BEGB

7 Maintenance

7.1 Entretien par l’utilisateur

7.1 Maintenance by the user

7.1.1 Nettoyage du fi ltre à air

7.1.1 Cleaning the air fi lter

Het standaard luchtfi lter is een synthetisch luchtfi lter.

The standard air fi lter is a plastic air fi lter. The air fi lter