MC-EE

Manual

MC-EE 20

MC-EE 30

MC-EE 40

Air handlers featuring an advanced electronic modulating controller

and electronically commutates high eciency fan motor

(electronically enhanced)

Heating Cooling Ventilating

Table of contents

1 General 4

2 Technical data 4

2.1 General 4

2.2 Prestaties van de toestellen 4

2.3 Correction factors for other hot water supply- or entering air temperatures 4

3 Operating and setting 5

3.1 General 5

3.2 The control panel 5

3.2.1 Basic screen 5

3.2.2 Locking 5

3.3 Changing settings 5

3.3.2 Low, average and high speed 6

3.3.3 Relationship between the air temperature and air speed, fan curve 6

3.3.4 Setting the language 7

3.3.5 Setting the time and date 7

3.3.6 Screen cleaning 7

3.3.7 Installer’s menu 7

3.3.8 Information screens 7

4 Installation 8

3.1 General 8

3.1.1 Transport damage 8

3.1.2 Packaging 8

3.1.3 Location 8

3.1.4 Minimal clearance 8

3.1.5 Transport on site 8

3.2 Electrical installation 8

3.2.1 Electrical connections 8

3.2.2 Thermostat 8

4.3.3 Advanced options 9

4.4 Installing the hot water supply lines 9

4.4.1 Hydraulic installation, simple version 9

4.4.2 Hydraulic installation, extended version 10

4.5 Installing the ducting system 10

4.5.1 Fitting the supply ducts 10

4.5.2 Fitting the return air ducts 10

4.6 Commissioning 10

4.6.1 Switching the apparatus ON an OFF 10

4.6.2 Setting the air temperature 10

4.6.3 Settingtheairow 10

5 Maintenace 11

5.1 Maintenance by the end user 11

5.1.1 Cleaningtheairlter 11

5.1.2 Cleaning the casing 11

5.1.3 Cleaning the display 11

5.2 Maintenance by the installer 11

6 Electrical wiring 12

7 Warranty 13

7.1 General 13

7.2 Scope and duration of the warranty 13

7.3 Damage that is not covered by the warranty 13

7.4 Not covered under warranty 13

7.5 Repairs 13

7.6 Service-parts 13

8 Statement of compliance 14

2 Document: IV_MCEE_2016_11_22

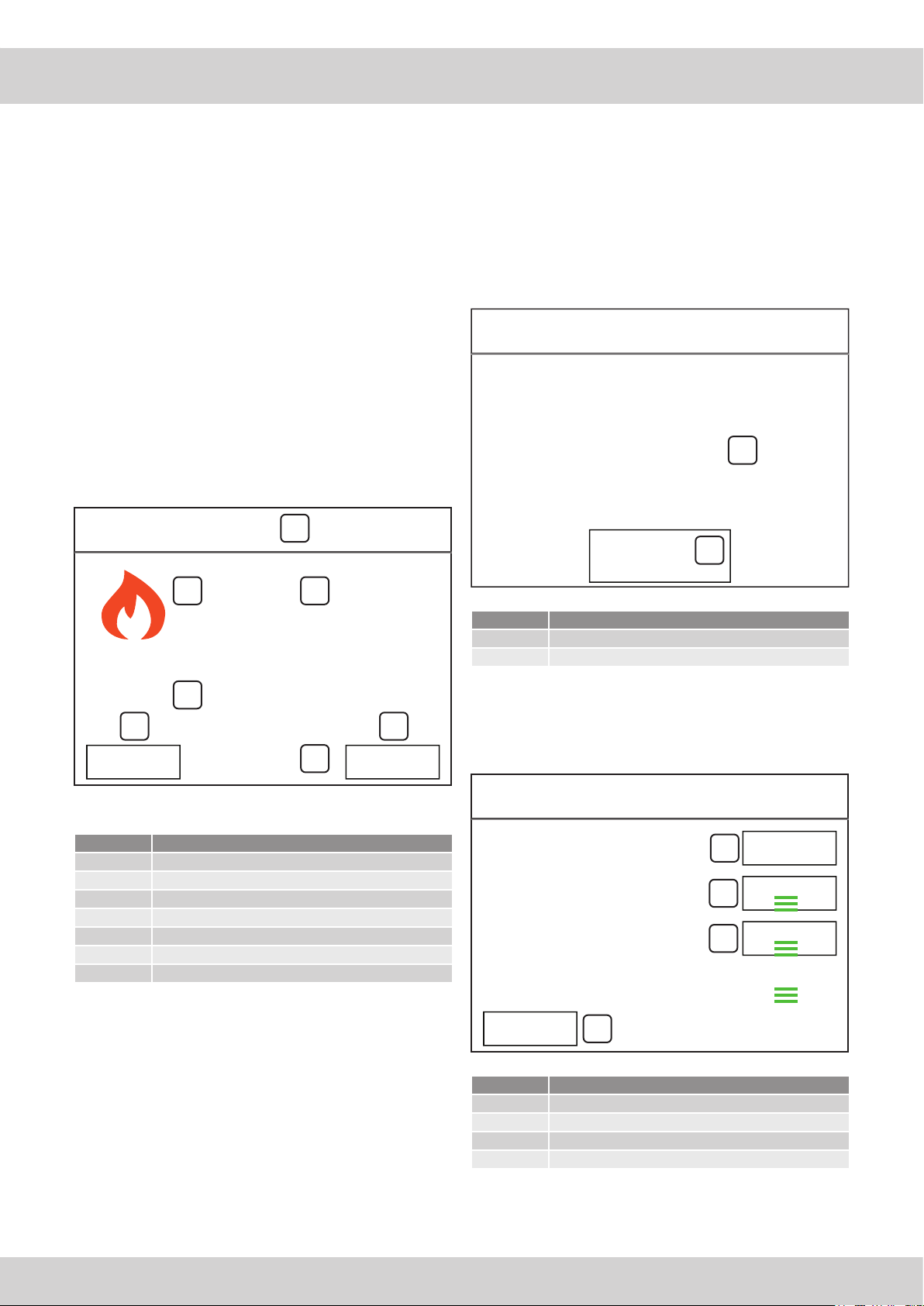

Dimensions

0

0

,

0

0

5

0

0

,

0

7

4

B

A

0

0

,

0

0

1

1

0

0

,

1

1

0

9

0

,

0

0

8

0

0

,

6

0

0

0

,

4

6

6

3

0

0

,

0

5

5

D

0

0

,

3

7

6

0

0

,

0

2

7

C

Type A B C D

0

0

,

0

0

6

MC-20 340 400 280 220

MC-30 440 500 380 320

MC-40 540 600 480 420

Document: IV_MCEE_2016_11_22 3

1 General

The Multicalor MC-EE (modulating) air handling units are

compact high performance units. The units are fitted with generously sized heat exchangers featuring 6 rows. This guarantees high air temperatures even with moderate supply water

temperatures. As a result, the units are very well suited to be

used in conjunction with modern condensing boilers.

The fans of the MC units are installed downstream of the heat

exchangers. This ensures that the fan motors are always optimally cooled and the life span of the fan bearings is increased.

Special attention has been paid to the air tightness of the

units, so leak losses are minimal. The heat exchanger compartments is insulated by means of a thick layer of air, so heat

losses are minimal. The apparatus is supplied ready to use. It

is sucient to install on site the hot water supply lines, the air

ducts and the electrical supply.

The MC-EE is fitted with an advanced controller based on an

Atmel RISC microcontroller and a high performance and high

eciency electronically controlled fan motor.

2 Technical data

In standard use the apparatus is used to distribute recycled air

to which not more than 25% outside air has been added, or to

distribute up to 100% outside air after heat reclaim. The unit is

factory supplied in this version.

In outside air version the unit is used to distribute air to which

more than 25% outside air is added. You can activate a special

program in the controller as to maintain a minimum air temperature (for best results an optional modulating 3-way valve

should be connnected). When this option is activated, a basic

frost-protection is activated to help protect the heat exchanger in case of frost danger. Nevertheless we suggest adding a

suitable anti-freeze solution to the heating circuit if the unit is

used as an outside air version.

The Multicalor MC units are available as upflow models. If you

need a downflow unit, you can turn simply around the unit

and flip the controller panel. Pay attention as to not drop the

panel – this may damage the flatcable connector.

2.1 General

The units comply to the machine directive 89/392/EEG, the

low voltage directive 73/23/EEG and the EMC directive

89/336/EEG.

The MC units are available in 3 sizes. Each unit is fitted with

an electronically commutated fan. You can easily change

the maximum airflow by reprogramming the unit via the

touscreen.

2.2 Prestaties van de toestellen

Unit MC-EE 20 MC-EE 30 MC-EE 40

Fan data Type 9/7 10/8 10/10

Motor power Wat t 376 550 736

Air flow (min-max) m³/h 1 500 2 250 3 000

Opgenomen vermogen (80% speed) A 1.40 1.90 2.20

Hydraulic pressure drop kPa 3.51 3.81 4.61

Heating output (75/65-20°C (EN442)) kW 20.0 30.0 40.0

Waterdebiet l/s 0.5 0.74 0.98

Weight kg 68 78 88

2.3 Correction factors for other hot water supply- or entering air temperatures

Hot water supply Air temperature entering the unit

30 25 20 18 15 10

90/70 99% 109% 119% 123% 129% 138%

75/65 81% 90% 100% 104% 110% 119%

70/50 52% 63% 74% 78% 84% 94%

60/50 48% 58% 68% 72% 78% 88%

45/40 23% 34% 44% 48% 54% 64%

4 Modifications reserved Document: IV_MCEE_2016_11_22

3 Operating and setting

3.1 General

The MC-EE is fitted with an advanced controller based on an

Atmel RISC microcontroller and a high performance and high

eciency electronically controlled fan motor.

A control panel has been installed on the appliance to change

the dierent settings of the appliance. The control panel is

equipped with a capacitive touch screen and a TFT colour

screen.

3.2 The control panel

A control panel has been installed on the appliance to change

the dierent settings of the appliance. The control panel is

equipped with a capacitive touch screen and a TFT colour

screen.

3.2.1 Basic screen

The following information is displayed on the screen as

standard.

Multicalor

7

28-03-2015

3.2.2 Locking

If an error occurs that puts the safe operation of the appliance

at risk, the appliance will be locked. The cause for locking the

appliance is shown on the screen. The locking can be cancelled

by pressing the unlock button. If the error, however, has not

been resolved, the appliance will again be locked.

You must then contact your installer or the manufacturer for a

solution.

Error

Fout

7

1

E40: NTC 1 ERROR

6

2

1 2

3

21:33

3

Legend

Number Meaning

1 Function mode of the appliance

2

3 Time

4 Fan speed

5 Information menu button

6 Settings menu button

7 Date

Air temperature

45%

4

53°

56

=

Legend

Number Meaning

1 Error message

2 Unload button

3.3 Changing settings

By pressing the setting button 3 the first screen of the setting

menu will be displayed.

Settings

Instellingen

System

Air heater

Screen cleaning

1

4

1

2

3

Legend

Number Meaning

1 System settings

2 Settings in relation to the air heater operation

3 Screen cleaning

4 Back to the previous menu

Document: IV_MCEE_2016_11_22 Modifications reserved 5

A number of settings are discussed. Since all screens are

accessible through the same process, not all screens will be

discussed.

Airow(CH)

3.3.1 Low, average and high temperature

You can set 3 air temperatures on the MC-EE: a low, average or

high value. To set these values, press the air heater (2) menu

button, next, system fan and then the first fan curve option on

the setting menu.

Fan curve (CH)

Low speed at:

Medium speed at:

High speed at:

4

1

Next, select the value that you want to change. The selected

value (1) will be displayed using an orange colour. By pressing

the key R (5) or S (6) ), you can change the set value.

If you press 1 (4), les modifications sont sauvegardées automatiquement et vous quittez l’écran du menu.

5

9

1

2

3

30°

40°

50°

6

:

Low:

Laag:

Medium:

Midden:

High:

Hoog:

4

1

Next, select the value that you want to change. The selected

value (for example, 3) will be displayed using an orange colour.

By pressing the keys R (6) or S (5), you can change the set

value.

If you press 1 (4), the changes are automatically saved and

you will exit the menu screen.

3.3.3 Relationship between the air temperature and

air speed, fan curve

60°

55°

1

50°

45°

5

9

1

2

3

10%

50%

80%

6

:

3.3.2 Low, average and high speed

On the MC-EE, 3 air speeds can be set for heating: a low, average or high value. To set these values, press the air heater (2)

menu button, next, system fan and, as last, the air flow rate.

40°

2

35°

30°

3

25°

The relationship between the air temperature and air speed

is displayed in the above graph. If the air temperature is lower

than the “low value” (3) parameter, the fan is operational at

the “low” (4) speed. If the air temperature is higher than the

“high value” (1) parameter, the fan is operational at the “high”

(6) speed. In-between these values, the speed of the fan is

automatically adjusted based on the air temperature.

The “average value” (5) and “average” (2) parameters serve as

an additional checking point to ensure you have more control

over the air flow rate.

4 5 6

10% 20% 30% 40% 50% 60% 70% 80% 90%0%

6 Modifications reserved Document: IV_MCEE_2016_11_22

3.3.4 Setting the language

The control can be set to dierent languages. To access this

setting, press the “system” (1) button in the setting menu and,

next, the third option: Language.

Language

Taal

English

Nederlands

4

1

Next, you can set the required language with the R (6) or S

(5).

3.3.5 Setting the time and date

The time and date can be set similarly (not applicable when

using the RC21 thermostat).

3.3.6 Screen cleaning

The touch screen can be temporarily switched o for cleaning

by pressing the clean screen button. Clean the screen using a

microfibre cloth or with a paper tissue.

3.3.7 Installer’s menu

Specific parameters can be found on an installer’s menu to

stop thoughtless changes. This installer’s menu can only be

accessed if a password (a code) is entered.

Installer code

Code User lever

123456 Power user

007007 Installer

5

9

6

:

The code for the “engineer” user level is only released after following training at Multicalor.

Changes do not normally have to be implemented in this

menu.

3.3.8 Information screens

A number of parameters can be read by pressing the information button on the main menu. The information in these screen

can only be read. The parameters cannot be changed. Provisionally, these screens only contain the version number of the

operating software.

Document: IV_MCEE_2016_11_22 Modifications reserved 7

4 Installation

3.1 General

• We wish to emphasize that only qualified fitters or contractors shall install the air heater.

• The installation shall be done in accordance with the

latest issue of all local standards as well as the installation

manual of the device concerned.

• Ensure that the conditions of local utility provision (electrical supply) match the device settings before installing the

device or making it operational.

3.1.1 Transport damage

Please check the air heater for transport damage upon delivery.

If damage is observed, this shall be mentioned on the waybill

and you shall advise your supplier thereof in writing.

3.1.2 Packaging

The air heaters are always packaged in a box made from

recycled paper. We ask you not to earmark the paper for waste

disposal, but for further recycling.

3.1.3 Location

• Adhere to the following guidelines when selecting a location for the device:

• place the unit in a central position in relation to the ducting

system;

• place the unit on a flat and solid surface;

• if installation surface is wet, then raise the unit;

• Always place the device in such a way that it is insulated

from the construction–building structure to avoid the

transmission of noise and vibrations.

Attention:

I The unit must be installed level!

I The device must be installed in a frost free location. If

impossible, please add a suitable anti-freeze to the hydraulic system as to protect the heat exchanger from frost

damage.

I If a return air is inspired in the combustion compartment,

then under no condition devices with an open combustion

circuit may be present in the installation area!

3.2 Electrical installation

The electrical installation shall always be performed according

to the latest issue of the relevant standards and the prescriptions of the local energy provider (utility).

I Mind your safety: always ground the unit.

3.2.1 Electrical connections

In the casing dierent cut-outs are provided to run cables

through. The PCB features a the mains power 230V~AC (marked L, N and GND). Connect with a cable to a 230V~AC power

supply. A seperate earthing plug is provided next to the PCB.

We recommend that the machine should be directly connected

to a switchboard with 16A fuses.

3.2.2 Thermostat

The device works perfectly together with the Honeywell

electronic programmable thermostat Vision thermostat. This

thermostat is suited for heating, ventilation and cooling, and

has been specifically designed for use with warm air systems.

Connect the thermostat as per the instructions on the wiring

diagram.

Attention: mind the connections. (See chapter electrical

wiring)

Mount the room thermostat at an approximate height of 1.6 m,

in a central position in the living room and readily accessible to

the normal air circulation in the room.

Always mount the thermostat on an inner wall shielded from

the eects of other heat sources including exhaust grilles, powered devices, direct sunlight, etc. Accordingly, we also do not

recommend placement near windows, outer walls (<1.20 m) or

in the vicinity of stairs. For additional information on assembly

and programming we refer to the thermostat manual.

3.1.4 Minimal clearance

When installing please provide minimal clearance around the

unit:

• keep 50 mm clearance around the sides of the unit;

• keep a minimum of 50 mm between hot water supply and

any flammables..

• At the front of the device there shall be at least 720 mm of

free service space (ensure a comfortable standing height).

3.1.5 Transport on site

Never move the air heaters by tilting them on their angles,

as this may irrevocably damage the device encasing. Such

damage is not covered by the device’s warranty.

8 Modifications reserved Document: IV_MCEE_2016_11_22

4.3.3 Advanced options

4.3.3.1 External condensing unit relay

The PCB features a relay that can make or break an external

condensing unit supply or control line. For further information,

please contact Multicalor and the condensing unit manufacturer. The coolrequest terminal is RE 1.

4.3.3.5 Extension board

It’s possible to connext an extension PCB board to achieve

multiple zone control.

For more information contact the manufacturer.

4.3.3.2 Burner relay

This contact is used to create a heat request on the boiler. or it

can be used to power a solenoid or a circulator. It could also be

used to power an oil burner on an oil fired boiler. The RE 3

connector will close when the MC unit needs heat, open when

the air temperature is higher than the calculated set–point.

4.3.3.3 Heat pump relay

The PCB features a relay RE2 that can be used to control a

heat pump.

Contact us for more information.

4.3.3.4 3-way Valve

It’s possible to control a 3-way valve via the 0-10V control

voltage.

Contact us for more information.

4.4 Installing the hot water supply lines

The diameter of the supply lines is 28mm. Usually hot water

supply is from the front, but for ease of installation the supply

lines can also be brought in from the sides or the top of the unit

(UP F only). The heat exchanger is installed with rubber grommets as to minimise leakage.

L Install an automatic air bleed valve in the supply circuit.

L Install ball valves and flexible tubing so the heat exchan-

ger can be easily removed for inspection or cleaning.

4.4.1 Hydraulic installation, simple version

You can choose to install the MC in a simple way. However, this

will result in a loss of certain options.

If you choose this way of installing, it is adviseable to have the

water temperature of the boiler limited by means of a weather

dependent controller.

22

2 3

2

1

Onderdeel Functie

1 Air heater MC-EE

2 Boiler

3 Thermostat

4 Optional outside sensor

5 One-way valve

4

5

Document: IV_MCEE_2016_11_22 Modifications reserved 9

4.4.2 Hydraulic installation, extended version

• We suggest using valves with following KVS factors:

MC20: KVS10

MC30: KVS10

MC40: KVS16

• We suggest that you do not give priority to the hot water

system but install the system in such a way that both

heating and hot water demand can run together.

• Best results are obtained if the boiler temperature is controlled via a weather compensator.

3

22

7

M

6

5

1

2

2

4

4.5.2 Fitting the return air ducts

Noise problems are often created if air heaters are used with

very short and/or undersized return air ducts. These problems

can be avoided by:

• insulating the return air ducts by means of an acoustic

liner;

• installing a sound damper in the return air ducts;

• making sure the that there are at least 2 generously sized

90° turns in the ducting system;

• Increasing both diameter and length of the return air

ducts.

You can connect the return air duct to the left, right or the

bottom of the unit. We strongly suggest using only the bottom

return air opening (please remove the cut-out when commis-

sioning). If possible, install the unit on an insulated plenum, on

which side return ducts can be connected. If you do not have

sucient free space to use an insulated return air plenum, it

is possible to install an optional side filter frame. However, in

doing so, a large part of the acoustic insulation is lost. Always

use a return air duct and return air from OUTSIDE of the combustion compartment. If you do wish to apply an open return,

make sure that there are (will be) no other devices with open

combustion circuit in the installation area.

Number Function

1 Heat exchanger MC-EE

2 Boiler

3 Thermostat connected to MC-EE

4 Optional outside sensor

5 One-way valve

6 Circulator (Field wiring)

7 3-way valve; 0-10V control voltage (O1)

Attention

I The 3-way valve must be powered externaly

4.5 Installing the ducting system

4.5.1 Fitting the supply ducts

Fit a matching supply air on the unit. The height of the plenum

should be at least as high as the width of the unit. The supply

air plenum should, like the supply ducting system, be thermally

insulated. The supply air duct should be of a sucient size

to permit air displacement with normal speeds and pressure

losses.

4.6 Commissioning

4.6.1 Switching the apparatus ON an OFF

Normally the machine shall permanently be supplied with

mains power. At the installation or maintenance stage you

may proceed as follows to switch on or o the device.

Proceed as follows to switch the machine ON:

• Connect the mains power.

• Set the room thermostat at the desired setting.

Proceed as follows to switch the machine OFF:

• Set the room thermostat 5°C lower than the actual temperature.

• Disconnect mains power.

4.6.2 Setting the air temperature

You will need to set the minimum and maximum air temperature of the unit. This can be done by the display. For more

information please refer to chapter 3.

4.6.3 Setting the air flow

You will need to set the minimum and maximum air flow of

the unit. This can be done by the electronic display. For more

information please refer to chapter 3.

10 Modifications reserved Document: IV_MCEE_2016_11_22

5 Maintenace

5.1 Maintenance by the end user

5.1.1 Cleaning the air filter

The standard air filter is a synthetic air filter with a life span

of 1 year. However the filter requires monthly cleaning, to be

performed as set out below:

• Set the thermostat 5°C lower than the environment

temperature.

• You may wait until the apparatus has cooled down.

• Disconnect the mains.

• Remove the air filter and use a vacuum cleaner to clean it

• Put the filter back into the machine.

• Restore the mains.

• Set the room thermostat again to the required value.

Never remove the air filter from an MC unit. The machine must

always be fitted with a EU3 (or better) air filter. Heating or ventilating without a filter may pollute the heat exchanger to such

an extent that the machine may incur irretrievable damage,

which the warranty does not cover.

5.1.2 Cleaning the casing

The casing may be cleaned with a soft humid cloth. Do not use

aggressive media such as bleaching water, solvents or petrol,

as these products are likely to damage the paint.

5.2 Maintenance by the installer

The unit is nearly free of maintenance. It is sucient to replace

the air filter and to check the unit for leakage and proper

functioning.

• Set the thermostat 5°C lower than the environment

temperature;

• You may wait until the apparatus has cooled down;

• Disconnect the mains;

• Remove and replace the air filter;

• Check unit for functioning and check for leaks;

• Verify pressure in the supply lines;

• Switch mains power on;

• Set the room thermostat again to the required value;

5.1.3 Cleaning the display

The touch screen can be temporarily switched o for cleaning

by pressing the clean screen button. Clean the screen using a

microfibre cloth or with a paper tissue.

Document: IV_MCEE_2016_11_22 Modifications reserved 11

6 Electrical wiring

THERMOSTAT

W G R

Heat (I1)

Venlaon (I3)

Y

Cool (I2)

Ground (GND)

Print 0D1

Print 0DA_MC

FAN J7

0-10V DC

O1

GND

GND

GND

Common

I1

Heat

I2

Cool

I3

Ven t

A

NTC1

NTC2

NTC2

NTC1

DISP J6

B

GND

V12

Flat Cable

POT

SW1

RE1 RE2 RE3

NO

COMNOCOM

NO

COM

Green/Yellow

L/N/PE

2016-11-22

FAN

C/Rx/Tx/V

PE

PE

L

N

L

Brown

N

Blue

230VAC/16A

B-2800 Mechelen

Blarenberglaan 21

Mulcalor Industries NV-SA

MC-EE UF/DF

NC

Return Air

Supply Air

AIRCO

BURNER

HEATPUMP ON

SW1

ON

1 2 3 4

ALL 4 OFF

12 Modifications reserved Document: IV_MCEE_2016_11_22

7 Warranty

7.1 General

Multicalor Industries NV guarantees the MC units against

all manufacturing defects or material faults, subject to the

terms and conditions described under ‘Scope and duration of

the warranty’. Moreover Multicalor Industries NV guarantees

the machine will achieve the output indicated in normal

conditions.

7.2 Scope and duration of the warranty

The warranty starts at the moment of purchase by the first

user and entitles the beneficiary of the warranty, through the

dealer or the service department of Multicalor Industries NV, to:

• One (1) year free exchange of faulty parts;

• Five (5) year free exchange of the heat exchanger, but

exclusive of labour costs and travel expenses.

Replacement of parts does not change the initial warranty

period, i.e. the warranty is not extended by the replacement of

faulty parts.

7.3 Damage that is not covered by the

warranty

All damage resulting from:

7.4 Not covered under warranty

• Parts subject to normal wear, including air filters, fuel filters

and other parts that have to be replaced periodically;

• Machines the serial number of which has been removed or

altered;

• Travel expenses and labour costs if the matching warranty

period has expired;

• Result damage caused by the faulty machine;

• Any loss of productivity attributable to the faulty machine;

• Any loss of use caused by a fault to the machine;

• When the machine proves unsuitable for the purposes for

which the purchaser bought the machine.

7.5 Repairs

During the warranty period the customer may call upon the

services of the dealer who sold the machine or, in Belgium, to

the “after-sales” department of Multicalor Industries NV.

7.6 Service-parts

If it is necessary to replace a part, we recommend that the

matching article code of the part concerned be mentioned on

the order, in addition to the type of air heater, the machine’s

serial number as well as the name of the part concerned. The

machine type and serial number are mentioned on the registration plate placed in the machine.

• Machine use which does not match normal household or

light commercial use;

• Failure to meet the user instructions as summed up in the

user manual;

• Insucient or wrong maintenance;

• Irretrievable fouling up of the heat exchanger caused by

heating, ventilating or cooling with a highly fouled up or

absent dust filter;

• Modifications or adaptations to the machine not covered

by prior written approval by Multicalor Industries NV;

• Repairs carried out with non-original parts or wrong equipment or materials;

• The heat exchanger when used in an atmosphere polluted

with chlorine or other chemicals;

• Causes foreign to the machine, including (but not restricted to):

1. Damage incurred during transport, including

dents, scratches, etc.;

2. Damage caused by disasters, including fire,

lightning, flooding;

3. Damage linked to frost;

4. Damage caused by a departure from the

normal power voltage, water or gas pres

sure deviating widely from the nominal

values suitable for the normal supply of the

machine;

5. Damage caused by a non-conformity of the

installation to the local standards

applicable.

Document: IV_MCEE_2016_11_22 Modifications reserved 13

8 Statement of compliance

Multicalor Industries declares that the air handlers

• Multicalor MC 20

• Multicalor MC 30

• Multicalor MC 40

meet the provisions of the machine directive 89/392/EEC, the low-voltage directive 73/23/EEC as well as the EMC directive

89/336/EEC.

14 Modifications reserved Document: IV_MCEE_2016_11_22

Document: IV_MCEE_2016_11_22 Modifications reserved 15

For more information contact your installer

Last modification

22 november 2016

Multicalor Industries NV • Blarenberglaan 21 • B-2800 Mechelen (Belgium)

www.multicalor.be • Tel.: +32 15 29 03 03 • Fax: +32 15 29 03 20 • info@multicalor.be

Loading...

Loading...