Professional StationProfessional Station

Professional Station

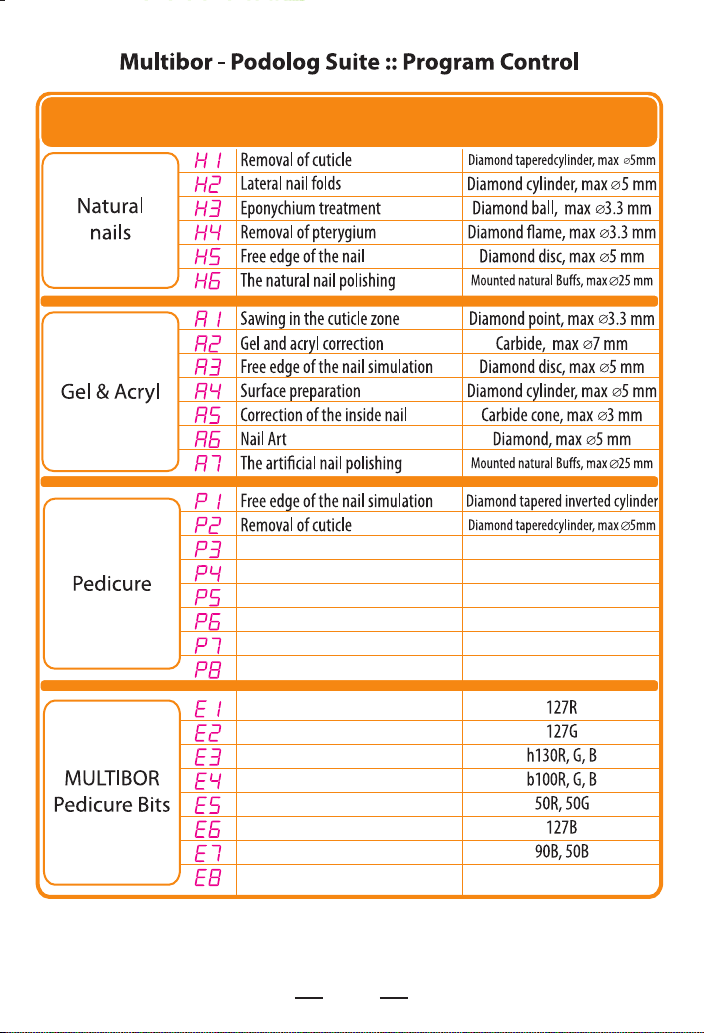

Type

Lateral nail folds

For toes abrading

ToolNameDisplay

Diamond ball, max o3.3 mmEponychium treatment

Diamond ame, max o3.3 mmRemoval of pterygium

Diamond cylinder, max o5 mm

Silicone, max o10 mmThe natural nail polishing

Abrasive, silicone, max o13 mmThe step's skin grinding

Abrasive, silicone, max o9 mm

Very rough heels primary treatment

Rough skin intensive abrading

For a basic step's cracks treatment

On the edge of step cracks treatment

Removing of corns and rough skin on toes

Final foot polish

Lateral nail folds soft abrading

Carbide ball o2 mmRemoval of a corn callus

Please note the following:

The progrms for “MULTIBOR Pedicure Bits” and program for the “Pedicure” are dierent. If you work with replaceable sand caps

based on rubber or with sintered cersmics, please select the “Pedicure” only. If you try to activate the “MULTIBOR Pedicure Bits”,

there is a risk that your tool bends or breaks down/

2

PROFESSIONAL TOOLS

Before getting started, please read this User Guide carefully.

Attention! The device has sucient means of electronic protection,

but no automation is able to provide 100% safety against unjustied,

inept or destructive steps by the User.

Please remember! Before you switch on the rotation, make sure that

nothing stands in its way, the engine is free, there is a tool in the

collet clamp, the collet clamp is locked, and the collet holds the tool

rmly.

Caution! Mechanical defects in the entire device or in separate parts

thereof and absence of its components as well as damaged or burnt

engine or its power cable shall deprive the User of the opportunity of

free repair and shall not impose any warranty obligations upon the

Manufacturer.

Please handle the device with due care and use it as prescribed. Do

not allow for excessive workload and do not use it for operations the

device is not intended for, and it will then serve you very well for

years!

Should you have any questions regarding the use of the device or

should you put the device into such modes of operation where from

you don't know the way out, please contact the Service Center.

Service Center

www.multibor.eu

3

Introduction

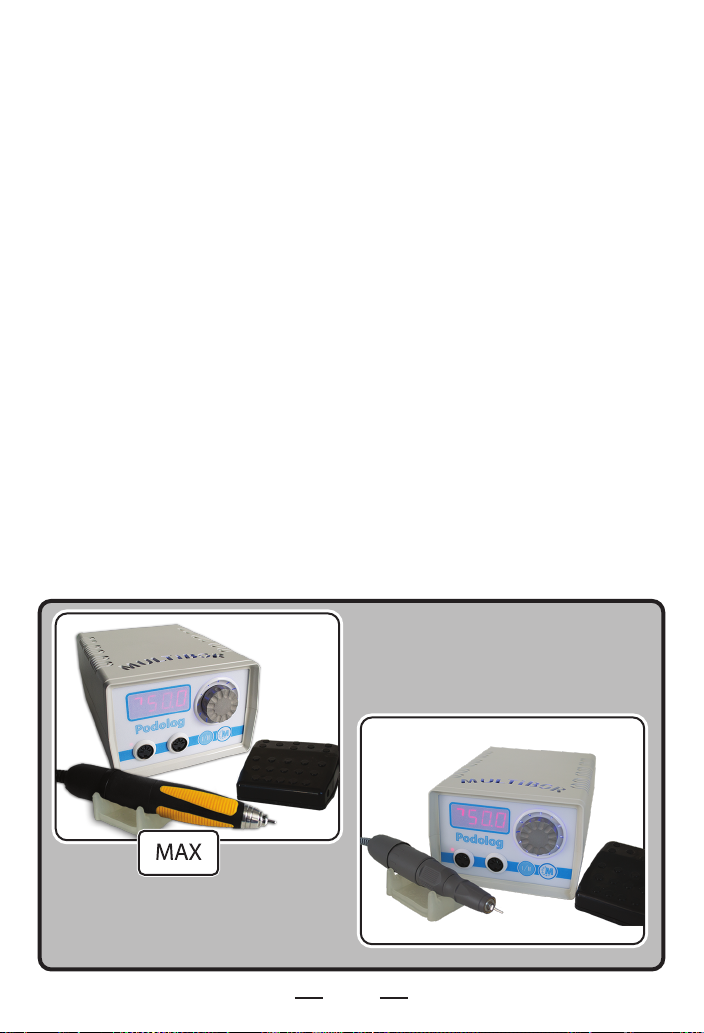

Multibor — Podolog Suite is a series of devices from the Podolog

lineup developed under the Multibor-Suite technology intended for

intensive operation with signicant workloads while providing the

entire range of services in the elds of machine-assisted manicure and

pedicure as well as for incrementing, modeling, and correction of

articial nails.

The lineup of devices comprises the following models:

• Multibor – Podolog

• Multibor – Podolog MAX

These models have dierent technical properties and congurations.

Multibor — Podolog Suite is a milling cutter for masters of nail care

(hereinafter, the 'Milling Cutter'). This is a microprocessor unit with

separate programs for dierent types of operations and for dierent

types of tools with automatic selection of preset programs and with

digital adjustment for optimal mode of operation.

4

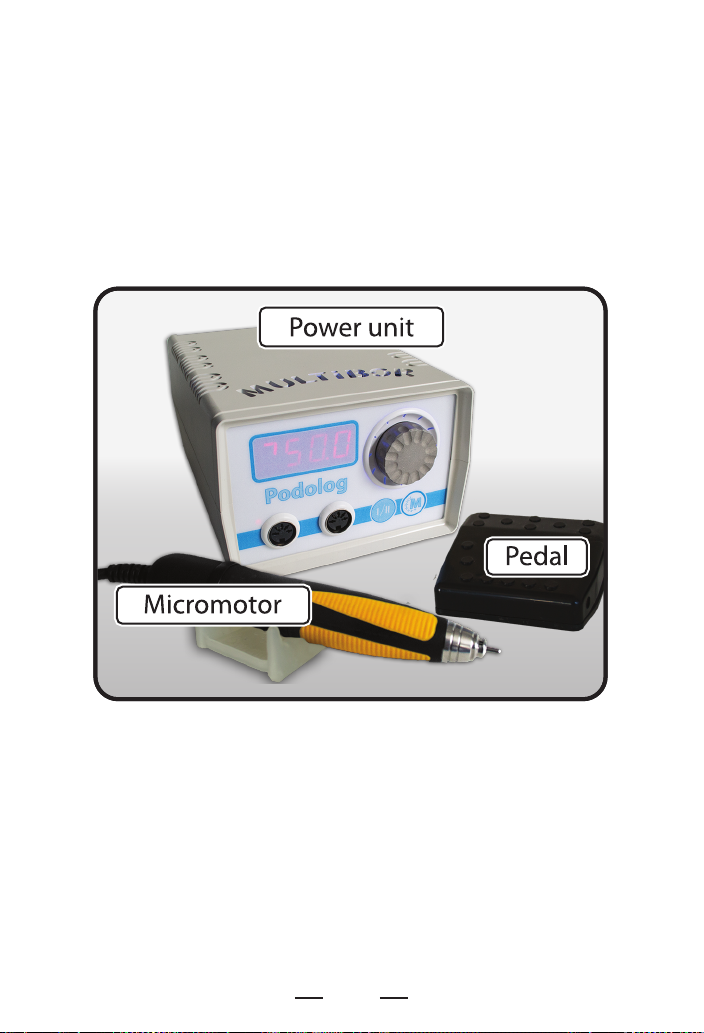

Delivery Set

· Power unit

· Handheld milling cutter (micromotor)

· Micromotor pad

· Pedal (available in specic models)

· User Guide

· Packaging

Safety Precautions

In order to ensure safe operation of the Milling Cutter, please learn

the safety precautions specied in this User Guide. Do not try to use

the Milling Cutter is a manner not specied in this document. Do not

try to use the Milling Cutter for operations not specied in this

document.

5

ATTENTION! Disregarding these safety precautions may damage

the Milling Cutter or may result in its ignition or in electric shock for

you.

ATTENTION! Plug the Milling Cutter in the electric mains thru

standard three-pin sockets with grounded terminals only.

Nine Simple Rules:

1. Never use electric mains where voltage and frequency are

dierent from the parameters specied on the casing of the Milling

Cutter.

2. Do not try to plug or unplug the Milling Cutter with wet hands.

3. Always insert the plug deeply to the end.

4. Never pull the power cable to withdraw the plug out of the wall

socket.

5. Avoid damage to and do not modify and do not stretch the power

cable and the connection cable. Do not put any items onto them. The

connection cable remains under big workload while in use, therefore

it would quickly break down if used improperly (e.g. knots and loops

in the cable, constant bending at sharp angles, abrupt moves).

6. Do not switch the Milling Cutter on if the power cable or

connection cable is looped or knotted.

7. Do not plug the Milling Cutter in a wall socket, which is used to

provide power to some other equipment (via extension cables,

T-junctions, etc.)

8. Use high-quality and properly operating tools (caps, milling tools,

etc.) only. Shank ends must be plain-shaped and all parts of the tools

must be rmly xed to each other. Do not use any worn tools as it

may result in their destruction.

9. When selecting the operation modes for the Milling Cutter, do not

go beyond the maximum permitted limits for a specic tool as it may

result in destruction of the tool and in breakdown of the Milling

Cutter.

6

Make sure there is some free space around the wall socket, so that

you can quickly unplug the device if necessary. In the event of smoke,

unusual fumes or strange noise near the Milling Cutter, switch it o

immediately, unplug it and refer to the Service Center. Do not place

any items onto the power unit. If any external items or uids get into

the Milling Cutter, unplug it o immediately and contact the

technical

ATTENTION! It is prohibited to disassemble or modify any

components of the Milling Cutter. Several parts of the power unit

bear high voltage. It is not allowed to perform any maintenance

procedures not specied in this User Guide.

Do not use any ammable spays near the Milling Cutter.

Do not keep any ammable uids near the Milling Cutter.

Do not place the Milling Cutter in locations with high humidity or

dust or smoke contents and in locations under direct sunlight as

well as in the vicinity of heating equipment.

The voltage and frequency of the power supply mains

are shown on the device!

7

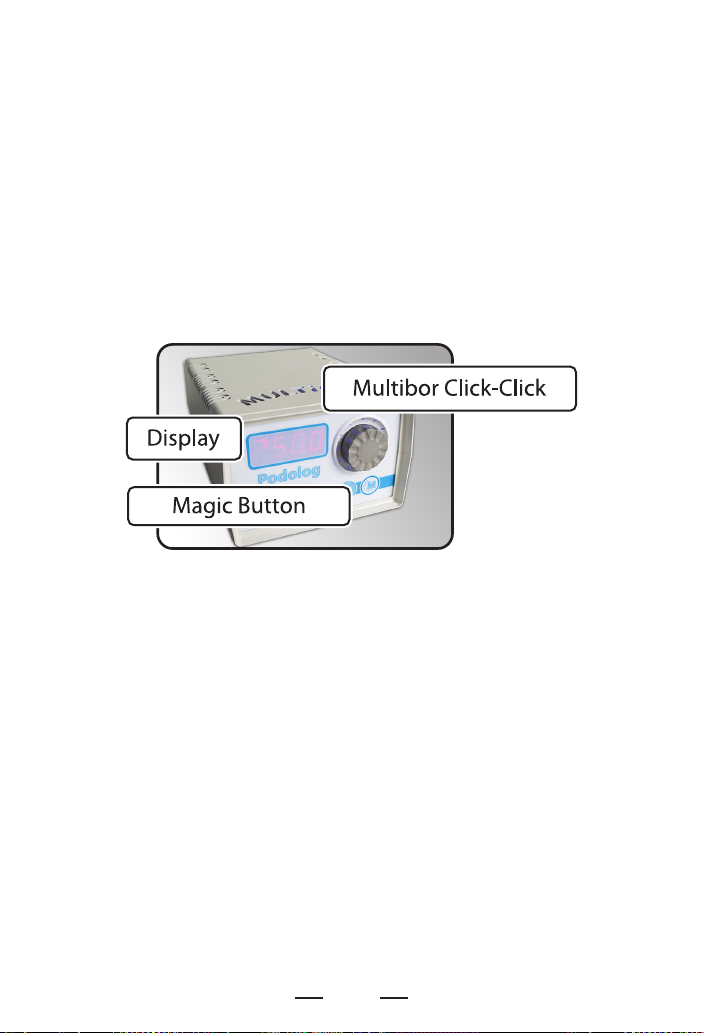

Description and designation of the major components

Power Unit

This is a microprocessor-based power supply unit for direct current

micromotors able to quickly adjust their operation modes. The

power unit is designated for the operation jointly with the handheld

milling cutter.

The controls and signal functions of the power unit have several

unique features based on the unique technologies by Multibor

Company, and namely:

- Multibor Click-Click manipulator

- Multibor Magic Button switch

Thru the 'Multiobr Click-Click' (hereinafter, the 'Manipulator'), it is

possible to:

- switch the rotation on or o

- increase or decrease the rotation speed

- change the rotational direction: 'Reverse' function

- select a control program from the list

Thru the 'Multibor Magic Button' (hereinafter, the 'M-button'), it is

possible to:

- activate the program control mode

- deactivate the program control mode

Attention! When in the program control mode, such parameters as

output power, maximum torque, protection operating level and the

like are automatically selected and adjusted by the processor in

accordance with the preset algorithms and thus cannot be altered by

the user.

8

The light warning system comprises the Display and the range with

12 light emission diodes (LED Range) (like a clock face) located

around the Manipulator.

The light warning system is further assisted by the audible warning

system.

Handheld Milling Cutter

The handheld milling cutter has the shape of a monoblock unit. The

unit looks like a ball pen conveniently sitting in one's hand and

making it possible to easily set and use the standard tools.

The manufacturer supplies the handheld milling cutters certied

under ISO 9001 and guarantees the high-quality performance of the

device only with them.

Setting and changing the tools

The tools are set by turning the clamp control grip on the handheld

milling cutter up until a click is heard:

Leftwards - the tool clamp is open

Rightwards - the tool clamp is locked

9

The shank end of a tool must be set into the clamp deeply until

locked. Another manner of tool setting leads to vibration, to

accelerated wear of the clamp and of the handheld milling cutter,

and to damage to the tool. Such operation of the Milling Cutter along

with the usage of unbalanced tools (vibration while operating the

handheld milling cutter) results in the loss of the warranty rights for

the user.

Changing the tools

1. Switch o the tool rotation

2. Wait until the tool rotation stops completely

3. Use your hands to

move the clamp lock

into the 'R' direction.

4. You must hear

a distinctive click

5. Extract the old tool

6. Set the new tool

into the clamp

7. Use your hands

to move he clamp lock

into the 'S' direction

until a distinctive click is heard

10

Changing the tools in the MAX congurations

1. Switch o the tool rotation

2. Wait until the tool rotation stops completely

3. Use your hands to

turn the upper part

(orange color) into the

"A" direction over 2

clicks. One click is not

enough since this is an

intermediate position

4. Click twice until locked in

5. Extract the old tool

6. Set the new tool

into the clamp

7. Turn the clamp lock into the "B" direction over two clicks

Pedal

The pedal is intended for activating and deactivating the rotation

function with the help of a foot. Depending on the conguration

option, the pedal may sometimes not be a part of the equipment

supplied. However, users can purchase the pedal as a separate piece

of equipment.

11

Preparing for work

1. Unpack the Milling Cutter. If the device is brought from a cold

place to a warmer place, it should be unpacked not earlier than after

two hours.

2. Place the power unit onto a plain, rigid, and stable surface such as

a working desk. Select a position of the power unit in such a manner

that its front panel can be seen in full and its controls can be easily

accessed. Place the pod in the immediate vicinity of the power unit.

3. Connect the power cable plug of the handheld milling cutter to

the relevant jack at the front panel of the power unit.

Attention! The plug has a ping and the jack has an inlet. This is the

key to the correct connection; the relevant ping should get into the

relevant inlet.

4. Check if there is a tool or a standard temporary cover in the collet

clamp of the handheld milling cutter.

5. Never forget to make sure that the collet clamp is locked and that

the collet holds the tool rmly and does not let it fall out.

6. Take the tool with your ngers carefully and turn the shaft of the

handheld milling cutter a few times. Make sure that the tool can

rotate together with the collet and that the rotation is done freely

without external noise and vibration.

7. Put the handheld milling cutter onto the pod in such a manner

that it does not block your access to the front panel of the power

unit.

Attention! It is not recommended to put the handheld milling cutter

as well as any other tools and caps onto the upper lid of the power

unit. Use the pod instead.

8. Plug the power cable in the wall socket.

9. The milling cutter is now ready for work.

12

Work Sequence

Power Up

Attention! When powered up, the milling cutter will maintain the

same operation mode and the same adjustments that were in eect

at the power down moment. There is no need to recall and set the

operation modes again. This memory is independent from any

operation mode.

Switch the power unit on, having set the power supply switch at the

back panel from the '0' position to the 'I' position.

This will activate the self-test of the Milling Cutter and it will be

indicated in the form of 'running lights' at the LED Range and in the

form of 'running eights' at the Display. As the 'running eights' fade

away in combination with the 'running sequence of lights' and as a

single audible signal is heard, it tells us that the self-test is completed

and that the equipment is ready for work if the following conditions

are fullled:

1. The 'MULTIBOR' sign at the upper lid of the casing is

illuminated with constant blue light

2. No breakdown alarm is heard

3. No 'Pedal is out of order!' indication is shown at the Display

13

Such signal may be caused by

mechanical or electrical faults

in the pedal itself as well as in its

power cable or control circuit.

For example:

1. Foreign items are on the pedal when it is powered up

2. The contacts in the pedal have stuck together and thus

always remain in the short-circuit position.

3. The pedal power cable has been worn out to the end, broken

down or destroyed

In order to x the problem caused by such a signal, the following

steps must be taken:

1. Remove the foreign items from the surface of the pedal

2. Press the pedal a few times to check the mechanical

intactness of contacts

3. Disconnect the pedal from the power unit and continue

working without the pedal

A fault in the electronic components

of the power unit may cause such a

signal to go on.

In case such signal is on, the

following must be done:

1. Stop the operation

2. Unplug the milling cutter

3. Contact the Service Center

Modes of Operation

Indications and Alarms in Dierent Modes

The handheld milling cutter can operate in two equivalent modes:

Manual mode

Program mode

For each of the modes, each type of indication is shown at the display

by means of a relevant combination of characters, digits, and

segments, and is also backed up by specic audible signals

In any mode, prior to switching on the tool rotation, its direction is

shown by an arrow on the Display.

If the arrow goes upwards

and to the right, the tool

will rotate clockwise.

If the arrow goes downwards

and to the left, it means that

the "Reverse" function is

activated and the tool will

rotate counterclockwise.

15

Manual Mode

Switching between the manual and program modes is performed by

pressing the 'M-button' and is followed by an audible signal.

Switching between the modes is only possible when the tool

rotation is o.

In the Manual mode, the display shows only two or three digits,

which mean the tool rotation speed in thousands of revolutions per

minute (rpm).

Speed 9,700 rpm

“Reverse” - OFF

The rotation direction is shown by the "running arrow" in the rst

section of the indicator on the Display.

Attention! The weight and mechanical balance of a tool have

signicant inuence on the vibration of the milling cutter. There is a

risk of damaging a tool at the speeds exceeding 30,000 rpm. The

milling cutter has two levels of rotation adjustment in order to

decrease the probability of accidents.

1. Fast and abrupt adjustment done literally during a single

revolution of the Manipulator for the speeds of up to 30,000

rpm only. In this case, a short audible signal indicates that the

rst level speed is reached.

2. The increase of the speed exceeding 30,000 rpm will be done

slower. Actually, the Manipulator needs to be rotated for a

longer time while the speed increases slower.

Speed 25,300 rpm

“Reverse” - ON

16

1. To switch on the rotation, press the center of the Manipulator

once

2. To increase the rpm rate, rotate the Manipulator clockwise

3. To decrease the rpm rate, rotate the Manipulator counterclockwise

4. To alter the rotational direction (the reverse function), press the

center of the Manipulator twice at a run same as you double-click on

a computer mouse

5. To switch o the rotation, press the center of the Manipulator once

again

You can change the rpm rates and the rotational directions

on the go.

17

Program Control Mode "Programs"

Press the 'M-button' to select operation modes under the preset

programs.

While in the 'Programs' mode, the display shows a character to

indicate a specic program and a digit to indicate the program's

number.

Program H6

“Reverse” - OFF

Select a desired program by rotating the Manipulator.

Press the center of the Manipulator for one time to start the rotation.

Attention! The rpm rates and the programs cannot be changed on

the go. Stop the rotation to change a program. While a program is in

operation, it is only possible to change the rotational direction by

pressing the center of the Manipulator for two times at a run same as

you double-click on a computer mouse.

Program P7

“Reverse” - ON

Very important! Follow the safety precautions!

It is allowed to unlock the clamp or to change a tool only after the

rotation is fully stopped.

18

Multibor - Suite technology

The quality and the speed of performance of the procedures depend

both on the skills of a master and on the correct combination of the

equipment and materials as well as on the output power of the

milling cutter, the shapes and sharpness of the caps, the tool rotation

speed, and the pressure on the nail plate or the foot of a client. The

Multibor-Suite technology combines the technical capabilities of the

equipment, the specics of usage of the tools for machine-assisted

nail care, the present-day requirements of a client, and the skills of a

master. Your milling cutter operates according to the Multibor-Suite

technology in the Program Mode. This enables you to use the table

for correct operation of the device in accordance with a pre-selected

program for a specic procedure. The processor will further

automatically select the required speed, the output power, and the

torque, and it will also supervise and control all required changes in

the course of the operation, smoothly adapting to your manner of

performing the procedure.

The additional opportunities of Multibor-Suite

It is only the MULTIBOR Suite Podolog device family that has two

control channels and two connections for two engines, which can be

controlled in turns. This feature would for instance be useful for

chiropodists.

Thru the usage of the additional engine of the NAIL type jointly with

the "Natural Nail" or "Pedicure" programs, it can select the operating

modes for complex podiatric cases.

Besides, MULTIBOR Company can supply the Podolog-type devices

with additional therapeutic engines required for the operation with

the Omnicut heads under the mechanical nail care technology with

cuticles trimmed.

Attention! The Omnicut head is not included in the package.

This tool should be purchased separately.

19

Multibor - Power Control Processor technology

The power control processor precisely controls the correlation of the

selected rpm rate with the output power required to perform a

specic procedure or a type of work. When the nail care master

presses the tool rmer to the surface being treated, the Milling Cutter

does not stop and does not decrease the preset rpm rate; on the

contrary, it keeps those parameters as they are, while overcoming the

resistance of the surface being treated. However, any type of work

has its own precisely limited range of the output power applied.

When the nail care master approaches the permitted limits of the

output power in the course of work, the power control processor

sends an audible warning signal. The nail care master should then

change the working pressure or else the power control processor

would switch o the power supply to the motor. This enables the nail

care master to 'limit the working pressure' and to use the power

reserve more precisely, thus making it possible to prolong the

technological lifespan of the Milling Cutter and to keep it from

overheating under 'hard operation modes' and sustained workloads.

The graph shown below will assist you with better understanding

when you need to select the required speed of rotation depending

on the diameter of the tool applied.

20

Emergency Protection

In order to preclude incorrect steps and to protect the equipment

from damage, the Milling Cutter has an emergency protection

system. When the emergency protection system is activated, an

audible signal is heard and an error message is shown at the display.

The 'Overload' indication means that

the tool applied is being used at a speed

or with a power rating not allowed for

such a tool.

To deactivate the 'Overload' emergency

mode, the following must be done:

1. Switch o the rotation

2. Select the correct speed (Manual

Mode)

3. Select the correct program (Program Mode)

4. Select the correct tool (any of the modes)

5. Resume the operation

In the event of the micromotor overheating, switch o the Milling

Cutter for 30 minutes and then resume the operation.

The 'No Motor' signal means that there

is no power supply to the handheld

milling cutter.

This may be caused by a number of

reasons:

- No connection to the handheld milling

cutter

-- No electric contact in the output jack

of the power unit

- Damaged power cable of the handheld milling cutter

- Breakdown of the brushes in the motor of the handheld milling

cutter

It is allowed to independently deactivate the 'No Motor' emergency

mode only if the handheld milling cutter is not powered up.

In all other cases, please refer to the Service Center to correct any

faults.

21

The 'Open Collet' signal means that there has been an attempt to

switch on the rotation without a tool or with an open collet clamp.

In order to deactivate the 'Open Collet'

emergency mode, the following must

be done:

1. Switch o the rotation

2. Insert a tool

3. Lock the collet clamp

4. Resume the operation

Pedal Operation

Connect the relevant plug of the pedal to the relevant jack at the

back panel of the power unit and place the pedal in a location

suitable for work. Press and hold the pedal with your foot to start the

rotation of a tool. Release the pedal to stop the rotation.

Attention! The pedal only reacts to closure and opening of the

electric contacts. No changes occur to the rotation speed of a tool.

Maintenance

Very important! All types of preventive maintenance must be

performed only when the Milling Cutter is disconnected from the

power supply and unplugged from the wall socket! An accidental

switch-on of the Milling Cutter during maintenance may result in

injury, electric shock or damage to the device.

Prior to any operation of the Milling Cutter, always check the casings

of the power unit and of the handheld milling cutter, the connection

cables, and the power cable. If any damage is found, contact the

Service Center for replacement.

WARNING! Operation of the device is prohibited until the damaged

parts are duly replaced!

22

Name OperationDisplay

power unit

malfunction

Pedal is out

of order

No Motor

Open Collet

Overload

1. Stop the operation

2. Unplug the milling cutter

3. Contact the Service Center

1. Remove the foreign items from

the surface of the pedal

2. Disconnect the pedal from

the power unit and continue

working without the pedal

1. Check the connection of the motor

2. Please refer to the Service Center

1. Switch o the rotation

2. Insert a tool

3. Lock the collet clamp

4. Resume the operation

1. Switch o the rotation

2. Select the correct speed, program

or tool

3. Continue operation

Loading...

Loading...