Multibor Podolog, Podolog MAX, Beauty Suite User Manual

Professional StationProfessional Station

Professional Station

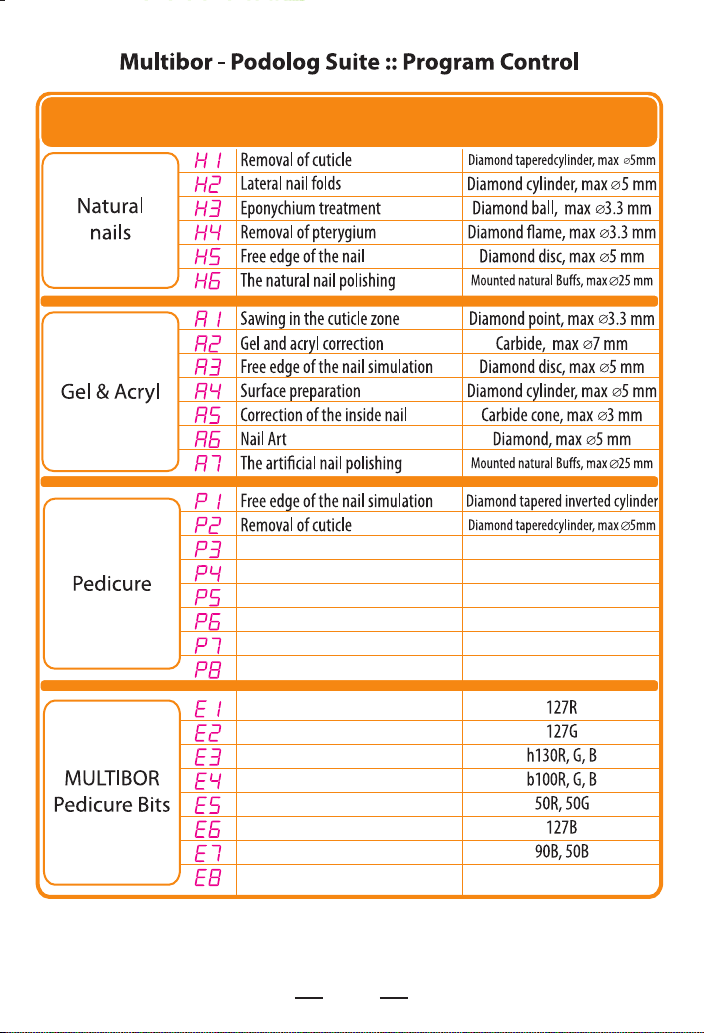

Type

Lateral nail folds

For toes abrading

ToolNameDisplay

Diamond ball, max o3.3 mmEponychium treatment

Diamond ame, max o3.3 mmRemoval of pterygium

Diamond cylinder, max o5 mm

Silicone, max o10 mmThe natural nail polishing

Abrasive, silicone, max o13 mmThe step's skin grinding

Abrasive, silicone, max o9 mm

Very rough heels primary treatment

Rough skin intensive abrading

For a basic step's cracks treatment

On the edge of step cracks treatment

Removing of corns and rough skin on toes

Final foot polish

Lateral nail folds soft abrading

Carbide ball o2 mmRemoval of a corn callus

Please note the following:

The progrms for “MULTIBOR Pedicure Bits” and program for the “Pedicure” are dierent. If you work with replaceable sand caps

based on rubber or with sintered cersmics, please select the “Pedicure” only. If you try to activate the “MULTIBOR Pedicure Bits”,

there is a risk that your tool bends or breaks down/

2

PROFESSIONAL TOOLS

Before getting started, please read this User Guide carefully.

Attention! The device has sucient means of electronic protection,

but no automation is able to provide 100% safety against unjustied,

inept or destructive steps by the User.

Please remember! Before you switch on the rotation, make sure that

nothing stands in its way, the engine is free, there is a tool in the

collet clamp, the collet clamp is locked, and the collet holds the tool

rmly.

Caution! Mechanical defects in the entire device or in separate parts

thereof and absence of its components as well as damaged or burnt

engine or its power cable shall deprive the User of the opportunity of

free repair and shall not impose any warranty obligations upon the

Manufacturer.

Please handle the device with due care and use it as prescribed. Do

not allow for excessive workload and do not use it for operations the

device is not intended for, and it will then serve you very well for

years!

Should you have any questions regarding the use of the device or

should you put the device into such modes of operation where from

you don't know the way out, please contact the Service Center.

Service Center

www.multibor.eu

3

Introduction

Multibor — Podolog Suite is a series of devices from the Podolog

lineup developed under the Multibor-Suite technology intended for

intensive operation with signicant workloads while providing the

entire range of services in the elds of machine-assisted manicure and

pedicure as well as for incrementing, modeling, and correction of

articial nails.

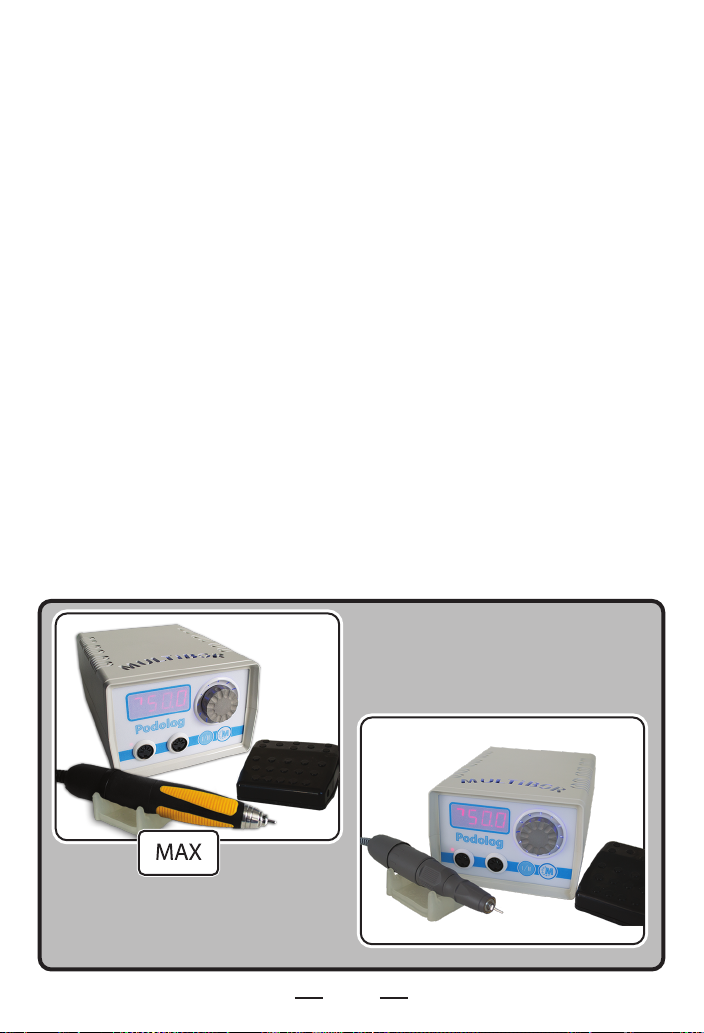

The lineup of devices comprises the following models:

• Multibor – Podolog

• Multibor – Podolog MAX

These models have dierent technical properties and congurations.

Multibor — Podolog Suite is a milling cutter for masters of nail care

(hereinafter, the 'Milling Cutter'). This is a microprocessor unit with

separate programs for dierent types of operations and for dierent

types of tools with automatic selection of preset programs and with

digital adjustment for optimal mode of operation.

4

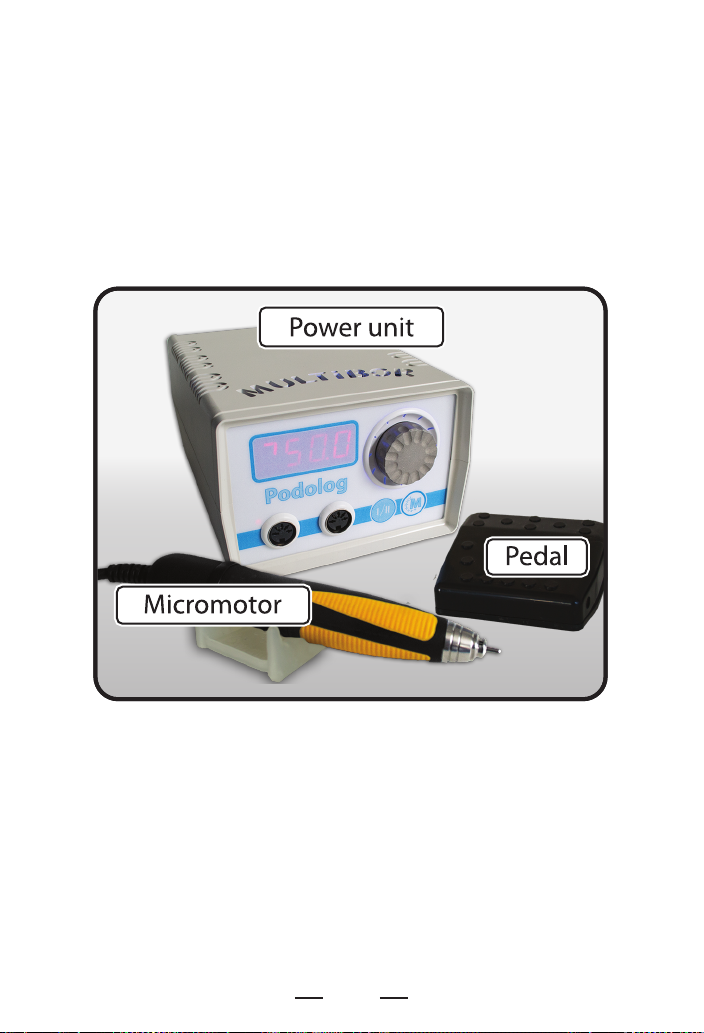

Delivery Set

· Power unit

· Handheld milling cutter (micromotor)

· Micromotor pad

· Pedal (available in specic models)

· User Guide

· Packaging

Safety Precautions

In order to ensure safe operation of the Milling Cutter, please learn

the safety precautions specied in this User Guide. Do not try to use

the Milling Cutter is a manner not specied in this document. Do not

try to use the Milling Cutter for operations not specied in this

document.

5

ATTENTION! Disregarding these safety precautions may damage

the Milling Cutter or may result in its ignition or in electric shock for

you.

ATTENTION! Plug the Milling Cutter in the electric mains thru

standard three-pin sockets with grounded terminals only.

Nine Simple Rules:

1. Never use electric mains where voltage and frequency are

dierent from the parameters specied on the casing of the Milling

Cutter.

2. Do not try to plug or unplug the Milling Cutter with wet hands.

3. Always insert the plug deeply to the end.

4. Never pull the power cable to withdraw the plug out of the wall

socket.

5. Avoid damage to and do not modify and do not stretch the power

cable and the connection cable. Do not put any items onto them. The

connection cable remains under big workload while in use, therefore

it would quickly break down if used improperly (e.g. knots and loops

in the cable, constant bending at sharp angles, abrupt moves).

6. Do not switch the Milling Cutter on if the power cable or

connection cable is looped or knotted.

7. Do not plug the Milling Cutter in a wall socket, which is used to

provide power to some other equipment (via extension cables,

T-junctions, etc.)

8. Use high-quality and properly operating tools (caps, milling tools,

etc.) only. Shank ends must be plain-shaped and all parts of the tools

must be rmly xed to each other. Do not use any worn tools as it

may result in their destruction.

9. When selecting the operation modes for the Milling Cutter, do not

go beyond the maximum permitted limits for a specic tool as it may

result in destruction of the tool and in breakdown of the Milling

Cutter.

6

Make sure there is some free space around the wall socket, so that

you can quickly unplug the device if necessary. In the event of smoke,

unusual fumes or strange noise near the Milling Cutter, switch it o

immediately, unplug it and refer to the Service Center. Do not place

any items onto the power unit. If any external items or uids get into

the Milling Cutter, unplug it o immediately and contact the

technical

ATTENTION! It is prohibited to disassemble or modify any

components of the Milling Cutter. Several parts of the power unit

bear high voltage. It is not allowed to perform any maintenance

procedures not specied in this User Guide.

Do not use any ammable spays near the Milling Cutter.

Do not keep any ammable uids near the Milling Cutter.

Do not place the Milling Cutter in locations with high humidity or

dust or smoke contents and in locations under direct sunlight as

well as in the vicinity of heating equipment.

The voltage and frequency of the power supply mains

are shown on the device!

7

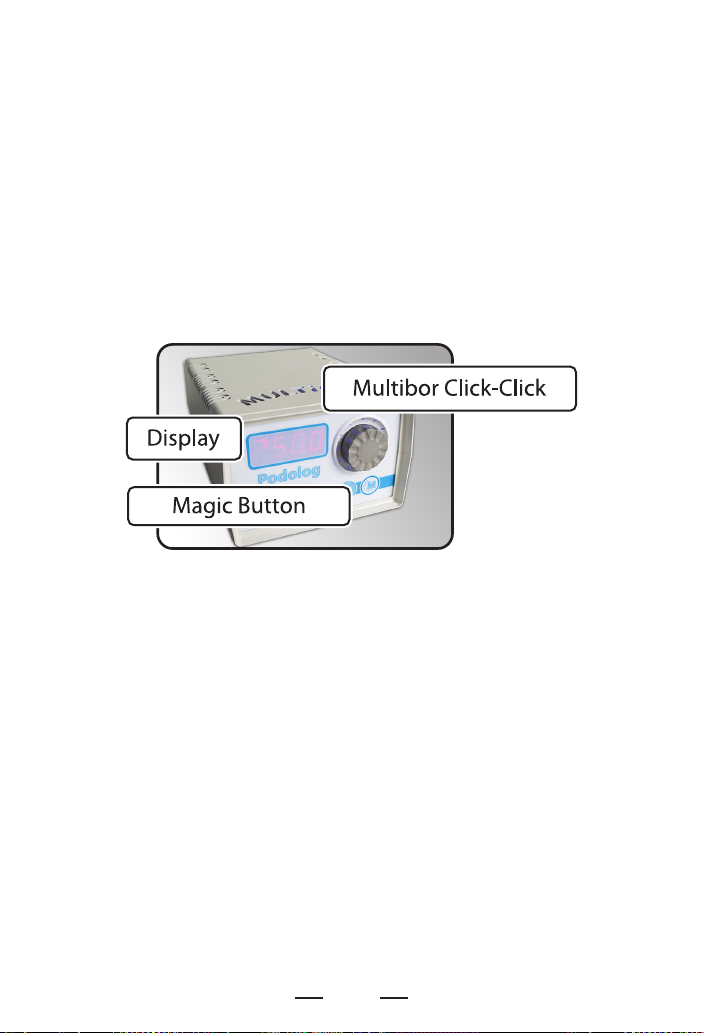

Description and designation of the major components

Power Unit

This is a microprocessor-based power supply unit for direct current

micromotors able to quickly adjust their operation modes. The

power unit is designated for the operation jointly with the handheld

milling cutter.

The controls and signal functions of the power unit have several

unique features based on the unique technologies by Multibor

Company, and namely:

- Multibor Click-Click manipulator

- Multibor Magic Button switch

Thru the 'Multiobr Click-Click' (hereinafter, the 'Manipulator'), it is

possible to:

- switch the rotation on or o

- increase or decrease the rotation speed

- change the rotational direction: 'Reverse' function

- select a control program from the list

Thru the 'Multibor Magic Button' (hereinafter, the 'M-button'), it is

possible to:

- activate the program control mode

- deactivate the program control mode

Attention! When in the program control mode, such parameters as

output power, maximum torque, protection operating level and the

like are automatically selected and adjusted by the processor in

accordance with the preset algorithms and thus cannot be altered by

the user.

8

Loading...

Loading...