Muller martini 2500 Operating Manual

Müller Martini

Druckmaschinen GmbH

Operating Manual

Control Console 2500

Serial Number

Article Number of Operating Manual

2500.4002.71

Alprinta 52/74

Control Console 2500

Table of Contents

1 Introduction 1 - 1

1.1 Control Console of Alprinta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Safety Guidelines 2 - 1

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 Operating Manuals for Machine Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.3 Non-Compliance of Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Fundamental Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.1 Applicable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 Local Laws, Guidelines and Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Notification Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.1 Danger Symbols in the Operating Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.2 Notification Symbol on Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Safety Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.1 Obligatory Notification and Authorizations after Modifications . . . . . . . . . . . . . . 6

2.5 General Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5.1 Technical State of the Art . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 Special Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6.1 Authorized Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6.2 Authorized Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6.3 Training and Qualifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.4 Working on the Control Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Introduction to Visualization 3 - 1

3.1 Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2 On-Switching/Off-Switching of Visualization . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.1 On-Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.2 Off-Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Set-Up of Start Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Set-Up of Window (Dialog Boxes, Menus, Entry Fields) . . . . . . . . . . . . . . . . . . 30

02.2009 2500.4002.71 0 - 1

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Table of Contents

3.4.1 Dialog Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4.2 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.4.3 Entry Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5 Generally Valid Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.5.1 Opening and Closing a Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.5.2 Entry of Numerical Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.5.3 Entry of Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.5.4 Function Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Machine Configuration 4 - 1

4.1 Configuration Independent of Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.2 Configuration of a New Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.2 Functions for Configuration of a New Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.2.1 Direct Configuration in the Machine Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.2.2 Configuration through Job Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.3 Configuration of a Job based on an Actual Example . . . . . . . . . . . . . . . . . . . . . 69

5Set-Up 5 - 1

5.1 Set-Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5.1.1 Settings prior to First Machine Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5.1.2 Run-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.1.3 Machine start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.1.4 Ink Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.1.5 Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.6 Register Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1.7 Approx. Register Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1.8 Fine Register Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1.9 Shear and/or Tool Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.10 Additional Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Functions for Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

0 - 2 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Table of Contents

6 Counter Use during Production 6 - 1

6.1 Print Run (Continuous Printing) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6.2 Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6.2.1 Counter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.2.2 Counter Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Counter Use based on Concrete Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7 Job Processing 7 - 1

7.1 Storing the Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7.1.2 Data Carrier (Storage Media) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7.1.3 Dialog Box Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.2 Loading a Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.2.2 Dialog Box Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.3 Store and Load a Job with a Concrete Example . . . . . . . . . . . . . . . . . . . . . . . . 61

8 Wash-Up and Inking Up Functions 8 - 1

8.1 Wash-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

8.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

8.1.2 Menu Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

8.1.3 Set-Up of Wash-Up Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.1.4 Wash-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.2 Inking Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.2.2 Menu Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.2.3 Inking Up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.3 Wash-Up and Inking Up with a Concrete Example . . . . . . . . . . . . . . . . . . . . . . 37

02.2009 2500.4002.71 0 - 3

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Table of Contents

9 Fault-/Warning Indications 9 - 1

9.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

9.2 Log Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

9.3 Faults-/Warnings Indication List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

10 Ink Zone Control 10 - 1

10.1 Activation of Ink Zone Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

10.2 Functions of Ink Zone Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

10.2.1 General Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

10.2.2 Setting Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

10.2.2.1 Zone Setting Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

10.2.2.2 Direct Value Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

10.2.2.3 Short Time Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

10.2.3 Editing Ink Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

10.2.4 Presetting Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

10.3 Job Configuration Ink Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10.4 Parametrization of Short Time Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10.5 Calibration of Ink Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10.6 Calibration Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11 MRS Make Ready System 11 - 1

11.1 Longitudinal Register Preselection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

11.2 Transfer of Longitudinal Register Values into Database . . . . . . . . . . . . . . . . . . 3

11.3 Longitudinal Register Preselection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

12 Densitometer 12 - 1

12.1 Basic Configuration User Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

12.1.1 Color Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

12.1.2 Printing Material Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

12.2 Job Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

12.2.1 Measuring Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

0 - 4 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Table of Contents

12.2.2 Assignment of the the Measuring Strip Fields . . . . . . . . . . . . . . . . . . . . . . . . . . 13

12.2.3 Printing Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12.3 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12.3.1 Measuring Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12.3.2 Disabling the Calculation of an Adjustment Proposal . . . . . . . . . . . . . . . . . . . . 19

12.4 Measurement Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

13 Index 13 - 1

02.2009 2500.4002.71 0 - 5

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Table of Contents

0 - 6 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Introduction

1Introduction

1.1 Control Console of Alprinta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

02.2009 2500.4002.71 1 - 1

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Introduction

1 - 2 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

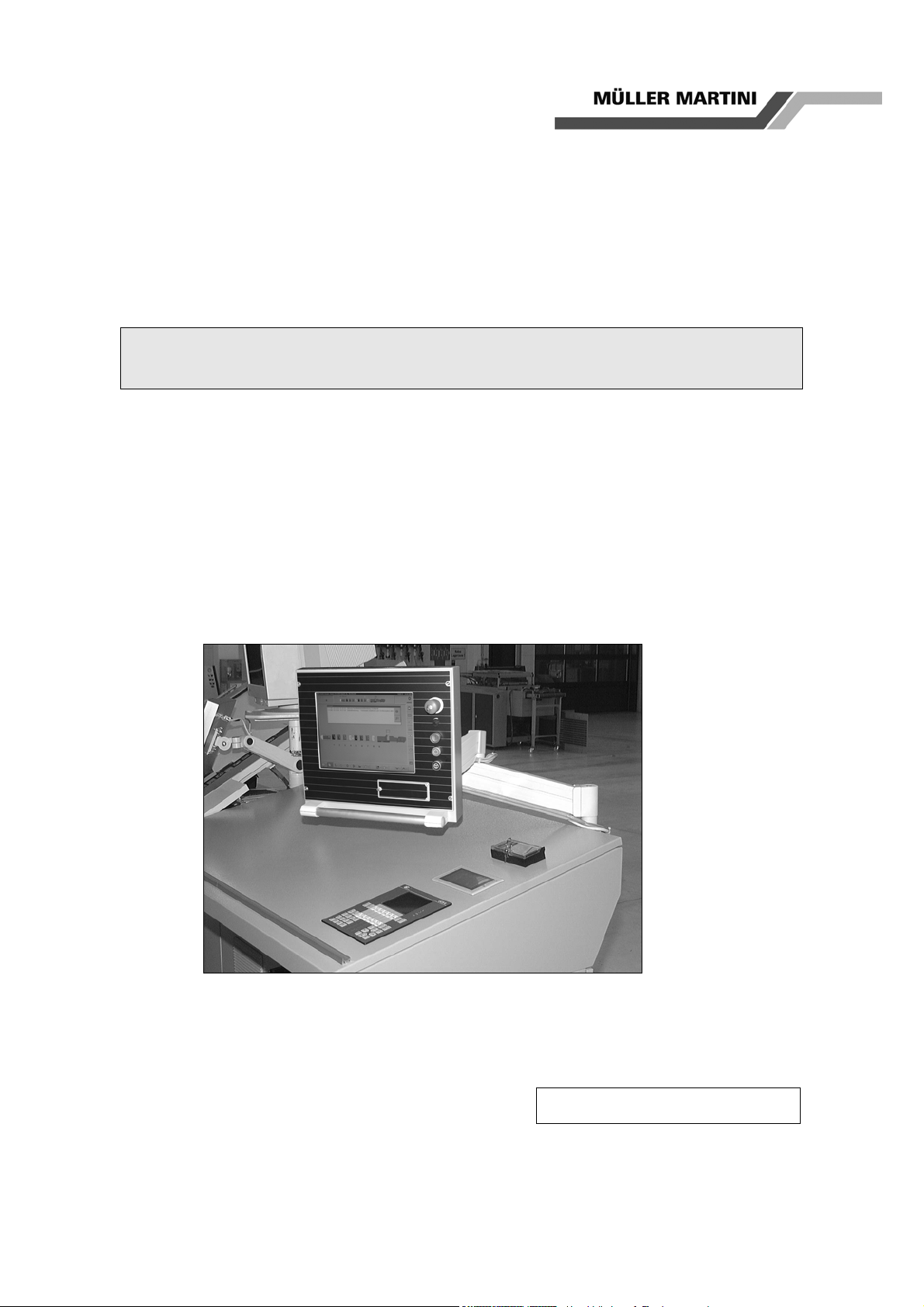

disk drive (optional)

pivoting

screen

main console

operating keys

handle

arm

F01

USB port

Control Console 2500

Introduction

1.1 Control Console of Alprinta

The Alprinta press is operated with a state of the art control console with integrated

visualization.

Depending on the accessories there may also be a separate blanket wash-up system

or an additional control unit for register position, video viewer, etc.

The control console includes the main console as well as the visualization screen and

integrated processor. To facilitate handling it is mounted on a pivoting arm.

The screen can be moved as needed to the front, rear or side with a handle.

02.2009 2500.4002.71 1 - 3

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Introduction

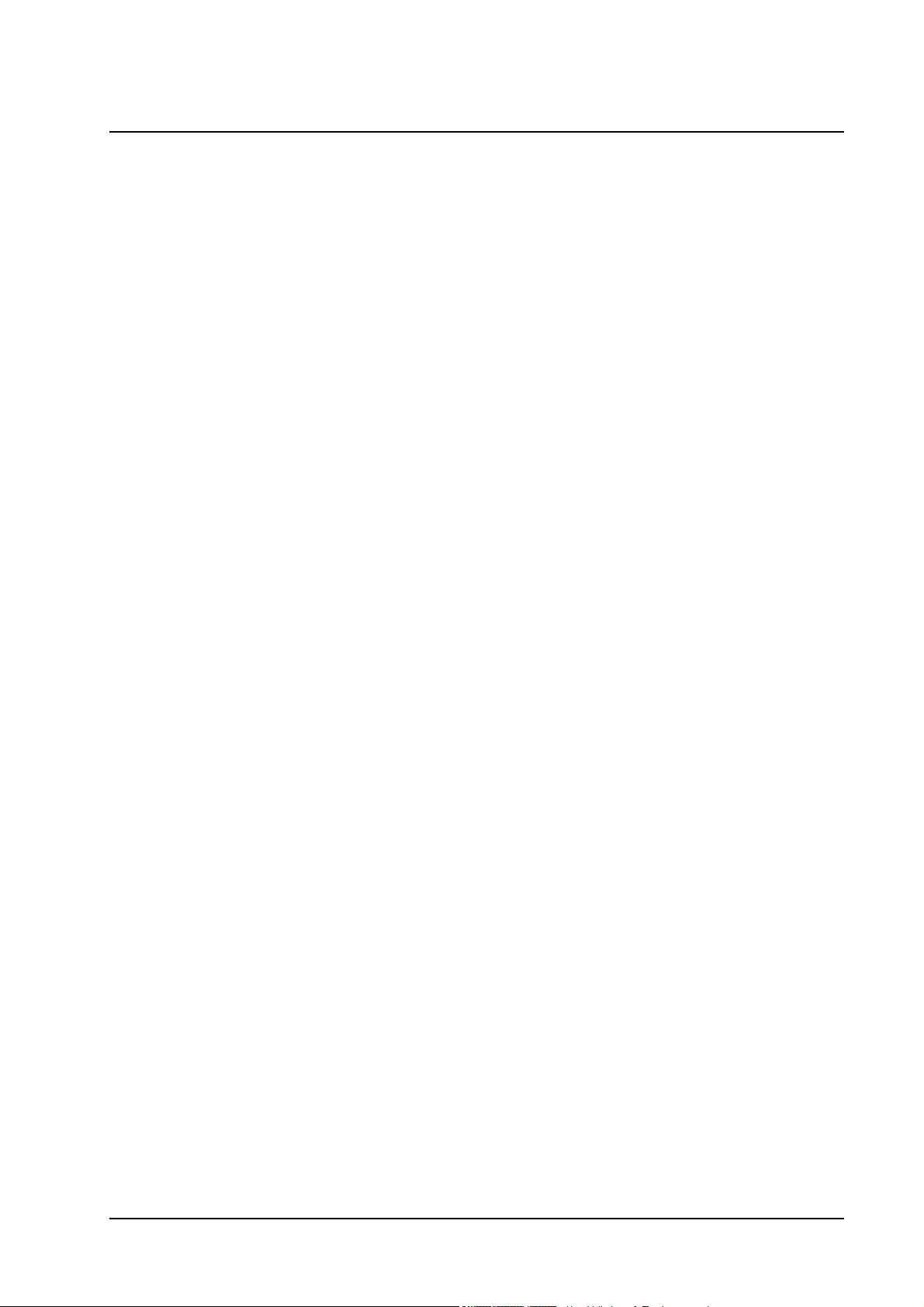

Beside the screen, which is used to actually control the machine, you will find the following control buttons:

EMERGENCY

STOP

start butto

stop button

jog button

The operator can start or stop the machine any time from the control console.

EMERGENCY STOP button for an

immediate stop of the machine

start button to start the machine

stop button to stop the machine

jog button to go step by step forward

Below the screen, behind a cover, there is a USB port, which can be used to save and

load print jobs (see chapter 7 „Job Processing“).

Optionally, a floppy disk box and a disk drive can also be fitted on the right hand side

of the main console of the control desk.

1 - 4 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

F02

Control Console 2500

Introduction

The screen permits access to the visualization and represents the central operating

element of the control console.

It is operated in Windows environment with a touch screen and is activated by simple

finger “touch” on the respective keys or fields on the screen.

This state of the art technology, automated control console can be operated easily

and has a process-oriented design.

This permits to automate and adjust customer-specific functions that are

increasingly more complicated.

This up-to-date press technology also ensures more efficient and shorter makeready, less waste and a constant performance through standardized functions.

This also permits adjustment of start-up, programming and maintenance of the press

to varying production profiles.

02.2009 2500.4002.71 1 - 5

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Introduction

1 - 6 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Safety Guidelines

2 Safety Guidelines

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 Operating Manuals for Machine Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.3 Non-Compliance of Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Fundamental Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.1 Applicable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 Local Laws, Guidelines and Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Notification Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.1 Danger Symbols in the Operating Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.2 Notification Symbol on Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Safety Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.1 Obligatory Notification and Authorizations after Modifications . . . . . . . . . . . . . . 6

2.5 General Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5.1 Technical State of the Art . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 Special Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6.1 Authorized Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6.2 Authorized Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6.3 Training and Qualifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.4 Working on the Control Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

02.2009 2500.4002.71 2 - 1

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Safety Guidelines

2 - 2 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

The operating manual (OM) must always be available on site !

Control Console 2500

Safety Guidelines

2.1 General

This chapter summarizes all safety guidelines that must be followed when using the

control console of Muller Martini « Alprinta » press.

2.1.1 Target Group

All personnel working on the control console must read and understand the chapters

relevant to their work. This applies especially to those persons who only occasionally

work at the machine, e.g. for setting up, maintenance etc.

This applies especially to the chapter 2 „Safety Guidelines“which is binding for all

personnel and tasks.

2.1.2 Operating Manuals for Machine Stations

For operation with the control console the operating manuals for all machine stations

and their safety guidelines must be followed.

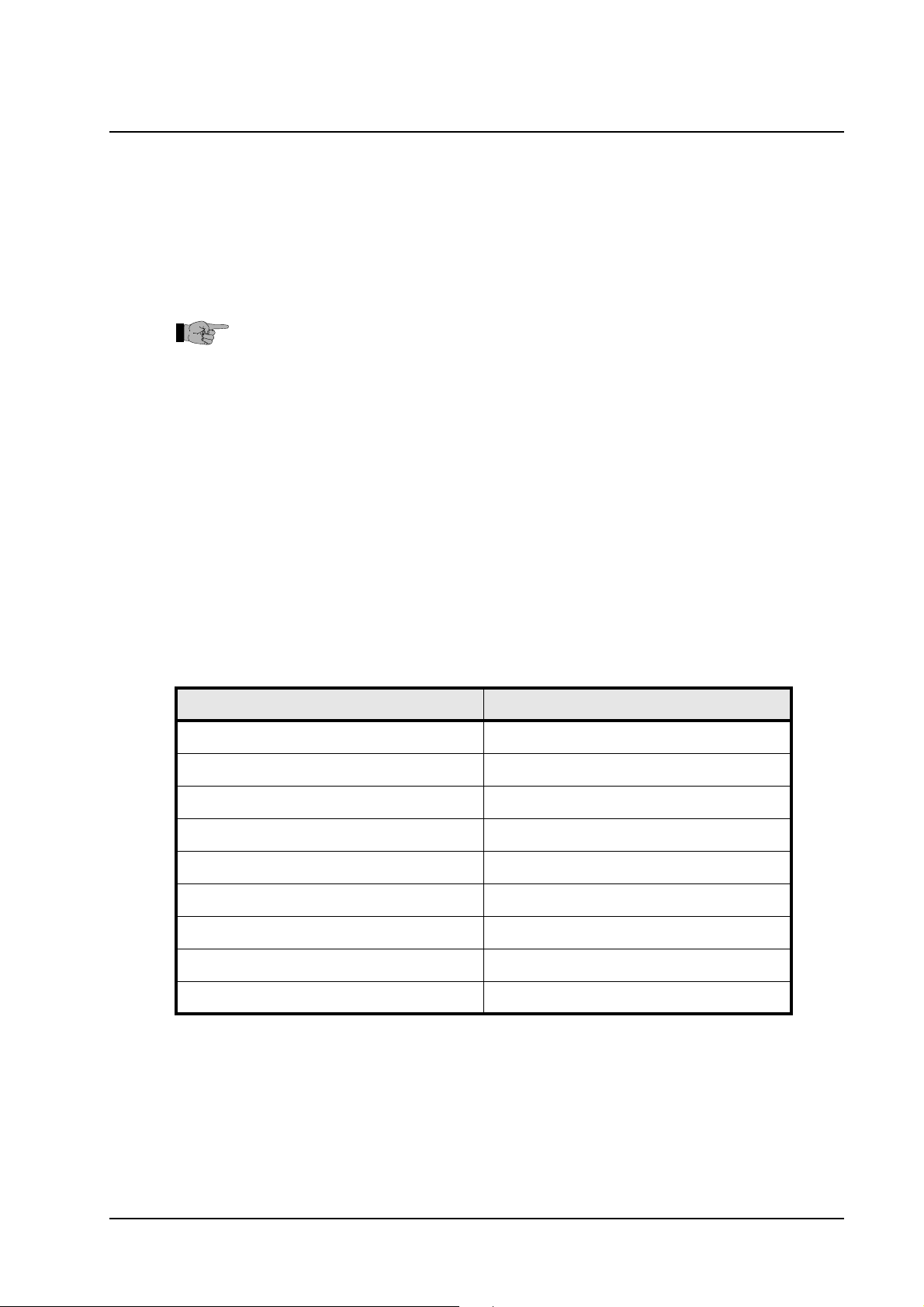

Station Type-Number for OM

Start-Up / Maintenance 2500

Unwind 2501/2511

Printing Unit 2502/2512

Processing Unit 2503/2513

Folder 2504/2514

Rewind 50” 2505/2515

02.2009 2500.4002.71 2 - 3

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Safety Guidelines

2.1.3 Non-Compliance of Safety Guidelines

The control console ran through a final test sequence prior to delivery and was supplied in faultless condition. MÜLLER MARTINI will not be liable for any damages

resulting from disregard of the instructions and notices in the operating manual. This

applies especially to:

• Damages resulting from improper operation or use.

• Damages due to disregard of safety-related instructions in the operating manual

or warning signs on the machine.

• Damages due to incomplete or lacking maintenance.

• Damages due to loading of sub-vendor software.

2.2 Fundamental Safety Notices

2.2.1 Applicable Area

The information, instructions and safety-related notices in this operating manual

apply solely to the control console 2500 for the MÜLLER MARTINI press « Alprinta ».

2.2.2 Local Laws, Guidelines and Regulations

Always follow the general valid national and local safety- and accident prevention

laws, especially:

• safety guidelines

• regulations for operators

• supplemental guidelines from the owner.

2 - 4 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Information on dangers that may lead to death, severe injuries,

irreversible psychological harm or considerable machine

damage.

Information pointing out technical or efficiency requirements.

Non-compliance may lead to faults, inefficiency and possibly production losses.

Danger of Electrical Shock.

Control Console 2500

Safety Guidelines

2.3 Notification Signs

2.3.1 Danger Symbols in the Operating Manual

This operating manual (OM) makes use of symbols to point out remaining safety risks

and identify important technical requirements.

Danger Symbol

Notification Symbol

2.3.2 Notification Symbol on Product

The following notification symbols are used on the product or in its environment. They

point out remaining safety risks and urge common sense actions.

• Follow all safety- and danger notices on the machine !

• All safety- and danger notices for the control console and machine stations were

received complete, legibly and have been read !

• The technically specific safety guidelines and regulations must always be fol-

lowed.

02.2009 2500.4002.71 2 - 5

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Despite the above there are still remaining safety risks.

Control Console 2500

Safety Guidelines

2.4 Safety Concept

2.4.1 Obligatory Notification and Authorizations after Modifications

It is not permitted to make technical changes such as add-ons or modifications on the

control console 2500 without the written authorization of MÜLLER MARTINI.

This applies especially to the loading of sub-vendor software programs or other software versions.

• Only the software installed by MÜLLER MARTINI is permitted to be used !

• It is not permitted to make changes on the installed software!

2.5 General Safety Regulations

2.5.1 Technical State of the Art

The control console represents present state of the art technology and fulfills all relevant safety regulations.

The control console was designed and built according to the following guidelines and

standards:

• VDE 0113

• EN 60 204-1 Machine Safety – Electrical Equipment of Machines

• EN ISO 12100-1/-2 Machine Safety (basic terms, general guidelines)

• RL 89/336/EWG Electro-Magnetic Compatibility

• RL 98/37/EG Machine Guidelines

• RL 73/23/EG Low Voltage Guidelines

2 - 6 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Safety Guidelines

2.6 Special Safety Guidelines

The control console and machine stations should only be operated in technically perfect condition and by following all instructions and safety rules in the OM!

In case of malfunctions in the electrical supply, the machine must be turned off immediately on the main switch !

2.6.1 Authorized Use

The control console is used only for operation of the MÜLLER MARTINI « Alprinta »

press.

2.6.2 Authorized Personnel

Only authorized personnel is permitted to work on the control console. Persons are

authorized, if they meet the minimum requirements for training and knowledge and

have been assigned a precisely defined function role.

Competency Limitations (Function Role)

Owner

The contractual partner of the manufacturer or its subsidiary is designated as owner.

The owner is entitled to sign legally binding contracts. Legally responsible the owner

is in charge of proper use of the control console and for training and delegating

authorized personnel. He determines the competencies and areas of responsibility of

the authorized personnel in his plant.

Service Technician (MÜLLER MARTINI or Person authorized by MM)

• Installs the system for the owner mechanically and electrically and starts up oper-

ation.

• Instructs the machine operators and maintenance personnel on site.

• Repairs the machines.

• Is entitled to access of the entire system.

02.2009 2500.4002.71 2 - 7

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Safety Guidelines

Machine Operator, Printer (Customer)

• Sets up or changes the system for the product to be processed.

• Starts up and monitors the production.

• Localizes faults and organizes troubleshooting.

• Monitors the correct function of safety devices.

• Is entitled to access of the entire system.

Maintenance Personnel, Maintenance Technicians

• Cleans and maintains the entire system, including lubrication.

• Repairs all faults and defects assigned to the maintenance personnel.

• Is entitled to access of the entire system.

Helper

• Fills in ink

• Changes paper web rolls

• Splices paper webs

• Clears away print delivery

2 - 8 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Safety Guidelines

2.6.3 Training and Qualifications

Owner

• Person trained in support and management functions.

• Has trade experience in judging danger and personnel guidance.

• Has read and understands the chapter 2 „Safety Guidelines“.

Service Technician

• Technically related training (mechanical / electrical)

• Specific in-house or continuing external education

Machine Operator

• Pertinent occupational training

• Participated in MÜLLER MARTINI training class with certificate

Maintenance Personnel, Maintenance Technician

• Pertinent occupational training (mechanical / electrical)

• Participated in MÜLLER MARTINI training class with certificate

Helper

Introduction to tasks by the machine operator

02.2009 2500.4002.71 2 - 9

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Exercise special caution when safety covers and doors on the machine are opened. This should only be done by personnel with

electro-technical training !

Control Console 2500

Safety Guidelines

2.6.4 Working on the Control Console

Only authorized personnel is permitted to operate the control console (see chapter

2.6.2 „Authorized Personnel“, page 2-7).

Only trained and instructed personnel may be assigned.

Personnel responsibilities for operation, setup, maintenance and repair must be

defined!

Make sure that only appointed personnel is working at the control console and

machine!

Determine machine operator’s responsibilities and enable him/her to reject instruc-

tions by third persons which could adversely affect safety!

Only a trained electrician or trained personnel under the supervision of an electrician

is authorized to work on the electrical equipment of the machine.

Use only original fuses with regulation amperage.

2 - 10 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

The terminals of the main switch are always energized, since this

is the supply voltage for the control console.

F03a

F06

Control Console 2500

Safety Guidelines

Machine- and system parts undergoing inspections and maintenance must be deenergized - if required - and locked out/tagged out. Locked out components must be

checked

• that they are deenergized

• are grounded and short-circuited

• adjacent parts that are energized must be isolated.

When work on live components becomes necessary, add a second person who can

operate the master switch in case of an emergency. Use only electrically insulated

tools!

Spare parts must meet the manufacturer’s technical requirements. Original spare

parts always comply with the manufacturer’s technical requirements.

02.2009 2500.4002.71 2 - 11

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

F01

• When walking to the drive side for any service- or other tasks

or working on opened safety guards, the EMERGENCY STOP

button (1) on the visualization must be pressed !

• The operator should pull out the key (2) and take it along !

• This will prevent accidental operation of the machine by a

third person !

F05

1

2

Control Console 2500

Safety Guidelines

2 - 12 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Introduction to Visualization

3 Introduction to Visualization

3.1 Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2 On-Switching/Off-Switching of Visualization . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.1 On-Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.2 Off-Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Set-Up of Start Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Set-Up of Window (Dialog Boxes, Menus, Entry Fields) . . . . . . . . . . . . . . . . 30

3.4.1 Dialog Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4.2 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.4.3 Entry Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5 Generally Valid Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.5.1 Opening and Closing a Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.5.2 Entry of Numerical Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.5.3 Entry of Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.5.4 Function Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

02.2009 2500.4002.71 3 - 1

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Introduction to Visualization

3 - 2 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Introduction to Visualization

3.1 Glossary of Terms

Touch-Screen = contact screen. All keys and entry fields shown on the screen as

well as a few display fields and displayed machine components can be selected by

simple touch. This will generate a function or open another pull-down window.

Diskette = Floppy-Disk. A disk is a magnetic changeable storage medium, e.g. a carrier for permanent data storage. At present the 3.5 inch diskette with a storage capacity of 1.44 MByte is the most widely used and commercially available one. The data

stored on a diskette can be deleted and the free storage can be reused.

Disk Drive = a disk drive is an internal or external unit for reading (loading) and/or

writing (saving) of data on diskette.

Hard Drive = a hard drive is an internal magnetic storage medium to store data. A

hard drive is integrated into the control console and directly accessible for storing/

loading of data.

Network = A network is the connection of at least two computers through one or several lines. The advantage of a network is that two users can communicate with each

other and share the tools of the various connected computers or the central server

(see Server).

Server = a server is either a special computer in a network or a program on a network

computer which offers services to other participants. Here you can also store data.

CD-ROM = Compact Disk Read Only Memory. A CD is a popular and widely available

optical storage medium with a storage capacity of 700 MByte, on which you can save

and archive data. The data on a CD-ROM cannot be deleted.

CD-ROM-Drive = A CD-ROM drive is a unit to read data on CDs. To write data on

CDs requires a special type of CD (CD-R/CD-RW) and a special drive (burner).

02.2009 2500.4002.71 3 - 3

Müller Martini Druckmaschinen GmbH

Alprinta 52/74

Control Console 2500

Introduction to Visualization

Folder = Directory. A directory is like a folder in which various files can be grouped

and filed logically. A directory is used for file maintenance.

Subdirectory = Subdirectory within a folder for file maintenance.

File = A file is like an index in which different data are grouped. A file is used to save

a certain data volume.

Function Keys = The F-keys located in the lower screen area are designated as

function keys. These keys serve special functions. They are used to open menus or

dialog boxes (see Menu and Dialog box), in which you can make or display machine

parameters.

Hotkey-Buttons = these are key fields used to initiate a certain machine action. In

the start screen are 9 Hotkeys, which are grouped in the lower screen area.

Activation Key = green key in a dialog box (see Dialog box). This key is used to

confirm entered settings. With it the settings are accepted. After this key is activated

the dialog box is always closed.

Cancel Key = red key in a dialog box (see Dialog box). This key is used to cancel the

settings made. All settings that were made are cancelled. After this key is confirmed

the dialog box is always closed.

Cursor = The cursor is a blinking mark in an input field. It indicates the writing position, e.g. entries (numbers, text) are displayed at the cursor position. The cursor can

be moved with the cursor keys.

Cursor keys = arrow keys. Cursor keys are arrow keys that point up, down, right and

left. With these keys you can select an element, scroll selection possibilities, open an

input field or move the cursor in an input field.

3 - 4 2500.4002.71 02.2009

Müller Martini Druckmaschinen GmbH

Loading...

Loading...