Page 1

Installation and operating instructions

TRACK-Guide III

Last update: V9.20191001

31302713-02-US Read and follow these instructions. Keep these instructions in a

safe place for later reference. Please note that there might be a

more recent version of these instructions on the homepage.

Page 2

Document

Copyright ©

Company details

Installation and operating instructions

Product: TRACK-Guide III

Document number: 31302713-02-US

As of software version: 02.20.17

Original instructions

Original language: German

Müller-Elektronik GmbH

Franz-Kleine-Straße 18

33154 Salzkotten

Germany

Phone: ++49 (0) 5258 / 9834 - 0

Fax: ++49 (0) 5258 / 9834 - 90

Email: info@mueller-elektronik.de

Homepage: http://www.mueller-elektronik.de

Page 3

31302713-02-US

V9.20191001

3

1

For your safety

7

1.1

Basic safety instructions

7

1.2

Intended use

7

1.3

Layout and meaning of warnings

8

1.4

Disposal

8

1.5

Instructions on retrofitting

8

1.6

EU declaration of conformity

9

2

About these Operating Instructions

10

2.1

Target group of these Operating Instructions

10

2.2

Layout of operating instructions

10

2.3

Layout of references

10

2.4

Directional information in these instructions

10

3

Product description

11

3.1

Scope of delivery

11

3.2

Display buttons

11

3.3

Display ports

11

3.4

Display Application Software

12

3.5

Information on the nameplate

14

4

Mounting and installation

15

4.1

Mounting the display in the vehicle cab

15

4.2

Connecting the display to voltage supply

15

4.3

Connecting the display to the ISOBUS

15

4.4

Inserting a Micro-SD card

15

4.5

Using two displays

16

5

Basic control principles

17

5.1

Switching the display to ON.

17

5.2

Initial start-up

17

5.2.1

Using the display for parallel guidance

17

5.2.2

Operating an ISOBUS implement

18

5.2.3

Display for automatic section control

18

5.2.4

Display for task management

19

5.3

Switching off the display

20

5.4

Display screen layout

20

5.5

Opening applications

21

5.6

Moving an application

22

5.7

Saving and loading window arrangements

22

5.8

Hiding an application

23

Contents

Contents

Page 4

4

V9.20191001

31302713-02-US

5.9

Using the keyboard

23

5.10

Using a memory device

24

5.10.1

Using a SD card

24

5.10.2

Directories on the USB memory device

24

5.10.3

Displaying the content of the memory device on the display

25

6

Connecting and configuring external devices

26

6.1

GPS receiver

26

6.1.1

Connecting the GPS receiver to the display

26

6.1.2

Changing the driver for the GPS receiver

26

6.1.3

Configuring the GPS receiver

28

Parameters for the GPS receiver

28 RTK or L band licence for SMART-6L

31

GSM modem for SMART-6L

31

Configuring the GPS receiver for the steering system

32

6.1.4

Recording GPS positions

33

6.1.5

Configuring the "GPS TILT-Module" terrain compensation

34

6.2

Configuring the joystick button allocations

34

6.3

Connecting sensors to the display

35

6.4

Camera

36

6.4.1

Connecting the analogue camera to the display

36

Connecting the camera HQ - provided by ME

36

Connecting the camera NQ - provided by ME

37

Connecting the camera AgCam PAL

38

6.4.2

Activating a camera

38

6.4.3

Operating the camera

39

6.5

External lightbar

40

6.5.1

Connecting the external lightbar to the display

40

6.5.2

Activating an external ME LightBar

40

6.6

Connecting the on-board integrated display/controller to the display

40

6.7

ISO printer

41

6.7.1

Connecting the ISO printer to the display

41

6.7.2

Activating the ISO printer

42

6.8

Configuring the Bluetooth connection in the Connection Center

42

6.9

Crop protection sensors

42

7

Configuring the display in the Service application

44

7.1

Changing the language

44

7.2

Basic display settings

44

7.3

Enabling and disabling applications

46

7.4

Unlocking licenses for full versions

47

7.5

Creating screenshots

48

7.6

Deleting pools

48

7.7

Using the Open Data Interface

48

7.7.1

Activating ME ODI

49

7.7.2

Opening ME ODI

49

Contents

Page 5

31302713-02-US

V9.20191001

5

8

Tractor-ECU application

50

8.1

Work screen

50

8.2

Managing the tractor profiles

50

8.3

Parameters

52

8.3.1

Calibrating the speed sensor

54

8.3.2

Calibrating an analog working position sensor

55

8.3.3

Tractor geometry

55

Configuring the tractor connector types

56

Configuring the tractor geometry

57

8.4

Results

58

8.4.1

Trip counter

58

8.4.2

Task-related counter

59

9

Virtual ECU application

60

9.1

Managing virtual job computers

60

9.2

Parameters

61

9.3

Work screen

64

10

ISOBUS-TC task processing

65

10.1

Configuring ISOBUS-TC

65

10.1.1

The "farmpilot" parameter

65

10.1.2

“Operating Mode” parameter

65

10.1.3

“TC number” parameter

66

10.1.4

“Prefer internal Tractor-ECU?” parameter

66

10.1.5

"Save finished tasks as a file?" parameter

66

10.1.6

“Validation of the device description” parameter

66

10.1.7

“Simplified target rate assignment?” parameter

67

10.2

Configuring the list of connections

67

10.3

Using fields and shp data

68

10.3.1

What is field data for?

69

10.3.2

Creating fields

69

10.3.3

Activating and deactivating fields

70

10.3.4

Importing field data (*.shp)

71

10.3.5

Exporting field data

71

10.3.6

Data on the memory device

72

10.3.7

Transferring field data to a different display

72

10.4

Using prescription maps

72

10.4.1

Importing shape prescription maps

73

10.4.2

Selecting shape prescription maps

74

10.4.3

Editing shape prescription maps

74

10.4.4

ISO-XML prescription maps

75

10.5

MULTI-Control

75

11

FILE-Server application

77

12

Technical specifications

78

12.1

Technical specifications of the display

78

Contents

Page 6

6

V9.20191001

31302713-02-US

12.2

Assignment plans

79

12.2.1

Port A (CAN bus)

79

12.2.2

Port B

79

12.2.3

Port C

80

12.2.4

CAM port

81

12.2.5

ETH (Ethernet) port

82

12.3

Licence conditions

82

13

Troubleshooting

83

Contents

Page 7

31302713-02-US

V9.20191001

7

1

1.1

1.2

For your safety

For your safety

Basic safety instructions

1

Basic safety instructions

Please read the following safety instructions carefully before using the product for the first time.

▪ Do not operate the display while driving in road traffic. Come to a standstill in order to use the

unit.

▪ Before maintaining or repairing the tractor, always disconnect the connection between the tractor

and the display.

▪ Before charging the tractor battery, always disconnect power supply to the display.

▪ Before welding on the tractor or implement, always disconnect the power supply to the display.

▪ Do not make any unauthorized modifications to the product. Unauthorized modifications or use

may impair safety and reduce the service life or operability of the unit. Modifications are

considered unauthorized if they are not described in the product documentation.

▪ Follow all recognized safety, industrial and medical rules as well as all road traffic laws.

▪ The product does not include any user-serviceable parts. Do not open the casing. If the casing is

opened, its imperviousness can be changed.

▪ Read the operating instructions to the agricultural device which you want to control by using the

product.

Using a camera

The camera serves solely for observing the implement functions in non-safety-related working areas

of the agricultural implement.

In certain situations, the camera image may appear on the screen with a delay. The delay depends

on the respective use of the display and can also be affected by external factors and devices.

For this reason, please note the following information:

▪ Do not use the camera to assist with steering the vehicle: not in road traffic, and not on private

properties.

▪ Do not use the camera to watch the road traffic or when driving into intersections.

▪ Do not use the camera as a rear view camera.

▪ Do not use the camera as a visual aid for controlling the implement, especially when a delayed

reaction can lead to risks.

▪ Using a camera does not exempt you from your due diligence obligation to pay attention to

safety when operating the implement.

Intended use

The display is used to operate agricultural machinery equipped with ISOBUS job computers.

Intended use also includes the adherence to the conditions for operation and repairs prescribed by

the manufacturer.

The manufacturer cannot be held liable for any personal injury or property damage resulting from

such non-compliance. All risk involved during improper use lies with the user.

All applicable accident prevention regulations and all other generally recognized safety, industrial,

and medical standards as well as all road traffic laws must be observed.

Any unauthorized modifications made to the equipment will void the manufacturer's warranty.

Page 8

8

V9.20191001

31302713-02-US

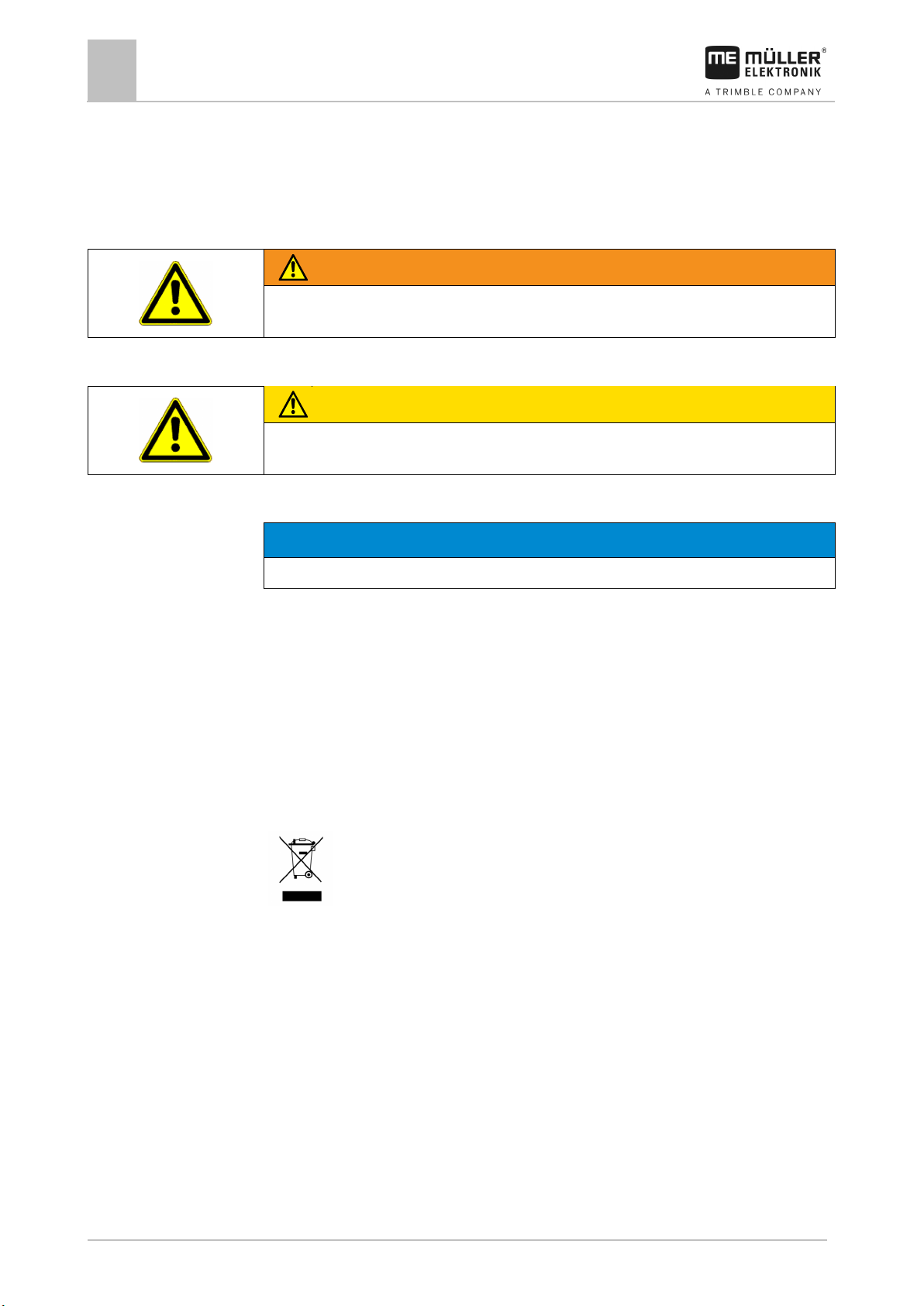

WARNING

This signal word identifies medium-risk hazards, which could potentially cause death or serious

physical injury, if not avoided.

CAUTION

not avoided.

NOTICE

This signal word identifies hazards that could potentially cause damage to property, if not avoided.

1.3

Example

1.4

1.5

Selecting components

For your safety

1

Layout and meaning of warnings

Layout and meaning of warnings

All safety instructions found in these Operating Instructions are composed in accordance with the

following pattern:

This signal word identifies hazards that could potentially cause minor or moderate physical injury, if

There are some actions that need to be performed in several steps. If there is a risk involved in

carrying out any of these steps, a safety warning will appear in the instructions themselves.

Safety instructions always directly precede the step involving risk and can be identified by their bold

font type and a signal word.

1. NOTICE! This is a notice. It warns that there is a risk involved in the next step.

2. Step involving risk.

Disposal

When it has reached the end of its service life, please dispose of this product as

electronic scrap in accordance with all applicable waste management laws.

Instructions on retrofitting

Instructions on how to retrofit electrical and electronic farm equipment and/or

components

Agricultural equipment used today features electronic components and parts whose function can be

affected by other farm equipment which emits electromagnetic waves. Such effects could lead to

personnel being put in danger, if the following safety instructions are not adhered to.

When selecting components, make sure first of all that the retrofitted electrical and electronic

components comply with the current version of the EMC Directive 2004/108/EC and carry the CE

marking.

Page 9

31302713-02-US

V9.20191001

9

(EMC Directive 2014/30/EU)

User responsibility

Additional requirements

1.6

For your safety

EU declaration of conformity

1

When retrofitting a machine with electrical and electronic farm equipment and/or components

connected to the vehicle's electrical system, it is your own responsibility to check whether the

installation causes interference with the vehicle's electronic system or other components. This

applies, in particular, to the electronic control of:

▪ electronic hitch control (EHR),

▪ front linkage,

▪ power take off (PTO),

▪ engine,

▪ gear.

The following requirements must be met in order to retrofit mobile communication systems (e.g. radio,

phone):

▪ All farm equipment must be approved and installed in accordance with the regulations applicable

in the respective country.

▪ The equipment must be installed as a fixed installation.

▪ The operation of portable or mobile farm equipment in the interior of the vehicle is only permitted

via a connection to a permanently installed exterior antenna.

▪ The transmitting part must be spatially separated from the vehicle's electronic system.

▪ When attaching the antenna, pay attention to proper installation, including a sound ground

connection between the antenna and the vehicle's ground wire.

For information on wiring and installation as well as the maximum allowable current consumption,

please also refer to the installation guide provided by the machine manufacturer.

EU declaration of conformity

Herewith we declare that the design and construction of this product and its identical variants, as well

as the form brought onto the market by us, is in accordance with the relevant safety and health

requirements of the EU Directive of Electromagnetic Compatibility 2014/30/EU. If alterations are

made to the product without prior consultations with us, this declaration becomes invalid.

TRACK-Guide III

Harmonised standards applied: EN ISO 14982:2009

Page 10

10

V9.20191001

31302713-02-US

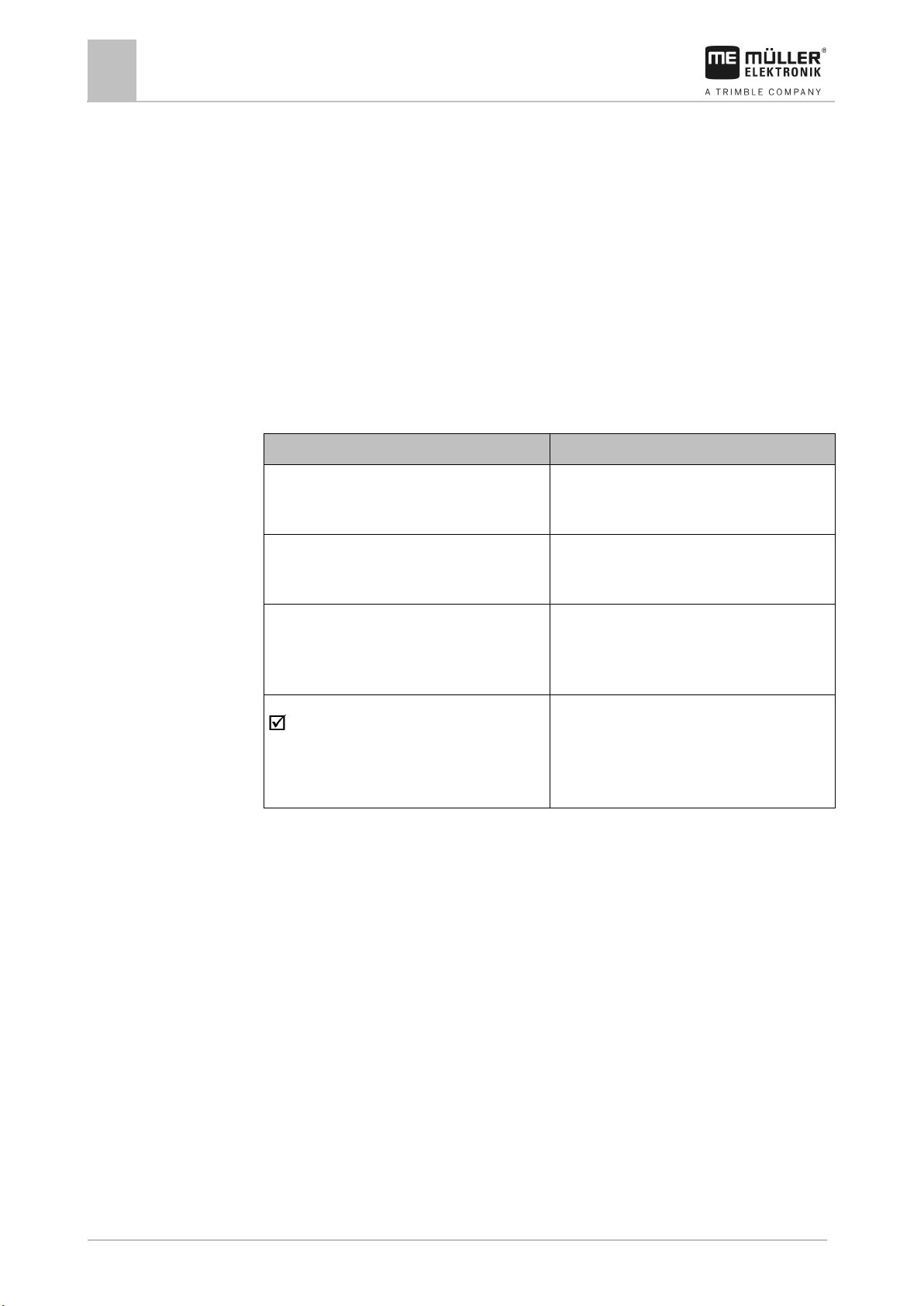

Type of depiction

Meaning

2.

⇨

This will happen when you perform an action.

⇨

steps.

can be performed.

2

2.1

2.2

2.3

2.4

About these Operating Instructions

2

Target group of these Operating Instructions

About these Operating Instructions

Target group of these Operating Instructions

These Operating Instructions are intended for personnel entrusted with installing and operating the

display.

Layout of operating instructions

The operating instructions explain step by step how you can perform certain operations with the

product.

We use the following symbols throughout these Operating Instructions to identify different operating

instructions:

1.

Actions that must be performed in succession.

Result of the action.

Result of an operating instruction.

This will happen when you have completed all

Requirements.

In the event that any requirements have been

specified, these must be met before an action

Layout of references

If any references are given in these Operating Instructions, they will appear as:

Example of a reference : [➙ 10]

References can be identified by their square brackets and an arrow. The number following the arrow

shows you on what page the chapter starts where you can find further information.

Directional information in these instructions

All directional information in this guide, such as "left", "right", "forward", "back" is relative to the

position operator faces during normal equipment operation.

Page 11

31302713-02-US

V9.20191001

11

3

3.1

3.2

3.3

Product description

Product description

Scope of delivery

3

Scope of delivery

The following items are included in delivery:

▪ TRACK-Guide III display

▪ Holder and screws

▪ Bracket for mounting the display

▪ USB memory device

▪ Installation and Operating Instructions

▪ Operating instructions for the TRACK-Leader application - as a separate document.

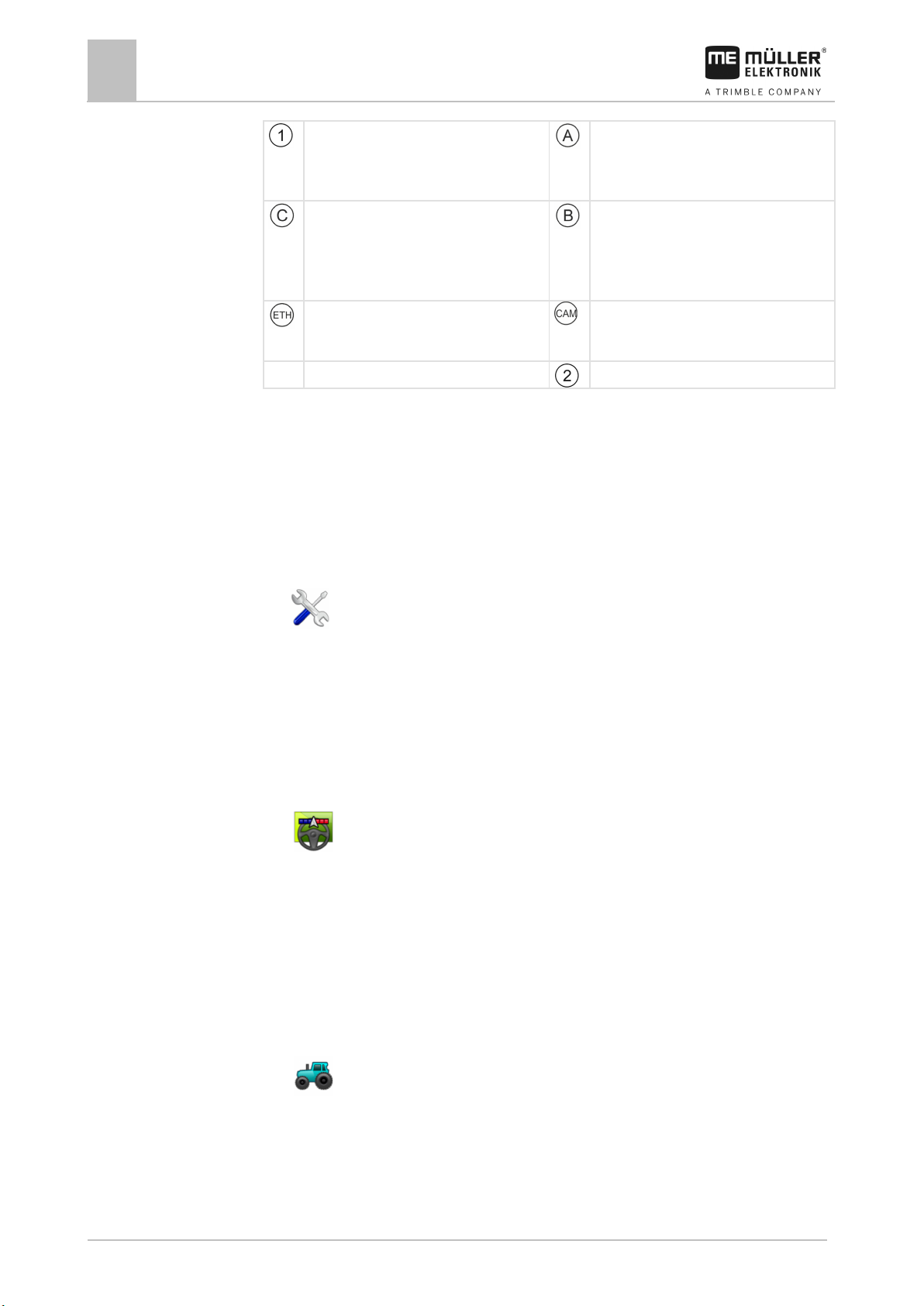

Display buttons

You will find a number of buttons on the housing of the display that are used to operate the display.

Display buttons

Function of the buttons

Switches the display on and off.

Creates screenshots.

Saves the window layout.

Display ports

Display ports

Page 12

12

V9.20191001

31302713-02-US

- Connection to the tractor CAN bus

- Lightbar [➙ 40]

- Ethernet

3.4

Full versions

Product description

3

Display Application Software

USB port for:

- USB memory device [➙ 24]

Port A

CAN bus port for:

- ISOBUS basic vehicle harness [➙ 15]

Port C

Serial port for:

Port B

See section: Pin assignment Port B [➙ 79]

- GPS receiver [➙ 26]

- GPS TILT-Module

ETH port

M12 port for:

CAM port

Port for an analog camera

Slot with the SD card

Display Application Software

The display is delivered with a range of installed application (apps). Most of these can be used

immediately. Even the non-activated applications can generally be tested for 50 hours. If you like

some specific application, you can order a license from Mueller-Electronics and unlock the full version

of the application.

The full versions of the following applications are installed on the display:

▪

- Application called “Service”.

The application Service allows you to:

– Configure the display.

– Enable and disable other applications.

– Enter license activation codes.

– Enable drivers for connected devices.

– Configure the GPS settings.

▪

- TRACK-Leader application.

The TRACK-Leader application allows you to work the field on exact parallel tracks.

The app contains several modules for which a license can also be activated:

– SECTION-Control: Automatic section control in order to minimize overlaps.

– TRACK-Leader AUTO: Automatic vehicle steering on the field.

– TRACK-Leader AUTO CLAAS: Automatic vehicle steering on the field for CLAAS tractors.

– TRACK-Leader TOP: Automatic vehicle steering on the field.

– TRAMLINE-Management: Tramline control using the current GPS position.

▪

- Tractor-ECU application

The Tractor-ECU application is used to record all settings around the tractor.

Here, you can e.g.:

– Enter the position of the GPS receiver.

– Set the GPS receiver as the speed signal source.

Page 13

31302713-02-US

V9.20191001

13

Test versions

Optional software

Product description

Display Application Software

3

– Select which sensor signals are received by the display.

– View the speed and PTO shaft rotational speed on the screen.

More about this in section: Tractor-ECU application [➙ 50]

▪

- Virtual ECU application

The Virtual ECU application is a central hub where virtual job computers can be created for

machines and devices that do not communicate through ISOBUS.

The Virtual ECU enables the use of apps such as TRACK-Leader, ISOBUS-TC and SECTIONControl with non-ISO machines.

More about this in section: Virtual ECU application [➙ 60]

▪

FILE-Server application

This application is used to define a save location on the display. This storage location can be

used by ISOBUS job computers that support the FILE-Server functionality. The options for use

depend on the ISOBUS job computer.

▪

- Camera.

The Camera application displays on the screen the image from the camera which is connected

to the display.

You can use the test versions of the following applications:

▪ ISOBUS interface (ISOBUS-UT)

The display enables you to operate ISOBUS job computers which are ISO 11783 compliant. The

user interfaces for operating a job computer are shown on the display screen if this is connected

to the ISOBUS connector of the vehicle.

The ISOBUS interface has no icon of its own. The icon for the connected job computer will

always be displayed in the selection menu.

▪

- ISOBUS-TC application (ISOBUS task controller)

The ISOBUS-TC application serves as an interface between the display applications (SECTIONControl, TECU, VECU) and ISOBUS devices (job computers, crop protection sensors).

Moreover, the app enables data transfer between the display and electronic Farm Management

Information Systems.

The scope of functions depends on the activated licenses and the configuration.

More about this in section: ISOBUS-TC task processing [➙ 65]

▪ ASD protocol – The license enables communication between the display and a serially

connected on-board integrated display/controller. The display knows the position of the machine

on the field (GPS) and can transmit the target application rate of a product (from the prescription

map) or the section status to the on-board integrated display/controller. In this way, you can use

the SECTION-Control app for section control, among other things.

More about this in section: Connecting the on-board integrated display/controller to the display [

➙ 40]

▪ ME ODI – This license activates the ME ODI application. It is used to connect the display with

the Internet via Ethernet or Bluetooth.

Optionally you can activate the following software:

▪

- FIELD-Nav application.

FIELD-Nav – Road navigation for agricultural purposes. The map material can be edited with the

corresponding PC software FIELD-Nav Desktop. All field tracks, small bridges and other

Page 14

14

V9.20191001

31302713-02-US

Abbreviation

Meaning

the Start Screen of the Service application:

Hardware version

The display may only be connected to voltages within this range.

will be shown here.

Serial number

3.5

Product description

3

Information on the nameplate

restrictions can then be integrated in the map material and be considered when mapping the

route.

You will find the operating instructions on the Mueller-Electronics website.

▪

- Agricon plugin

Enables coupling with crop protection sensors (Yara-N, P3US, P3ALS etc.) manufactured by

Agricon.

Information on the nameplate

You will find a nameplate sticker on the back of the display. On this sticker you can find all the

information you need to definitively identify the product.

Have these details ready when you contact Customer Services.

Abbreviations on the rating plate

Software version

If necessary, you can see the currently installed software version on

Operating voltage

Customer number

If the display was manufactured for an agricultural machinery

manufacturer, the agricultural machinery manufacturer's item number

Page 15

31302713-02-US

V9.20191001

15

lighter)

4

4.1

Procedure

4.2

Procedure

4.3

Procedure

4.4

Procedure

Mounting and installation

Mounting and installation

Mounting the display in the vehicle cab

4

Mounting the display in the vehicle cab

Connecting the display to voltage supply

Cable for the power supply - Item no. 31302495

9-pin Sub-D on socket A in the display

Plug for vehicle power supply (cigarette

This is how you connect the display to voltage supply:

1. Connect the power cable included in the delivery to port A of the display.

2. Connect the power cable on the other side to (10V - 30V) the vehicle's electrical system.

Connecting the display to the ISOBUS

Connection to the ISOBUS serves to:

▪ supply the display with power,

▪ enable communication with other ISOBUS components.

You will need a different connection cable for this, depending on the model of your tractor.

▪ In tractors which have been subsequently upgraded with an ISOBUS-basic vehicle harness

provided by Mueller-Electronics, use connector cable A from the ISOBUS-basic vehicle harness.

▪ In tractors which are equipped as standard with ISOBUS and which have an ISOBUS In Cab

Connector, you will need the following connector cable:

D-Sub <-> CPC connector cable, item no. 30322541

When there is more than one display in the tractor cab, you may need to change certain settings in

order to enable two-way communication. Find out more: Using two displays [➙ 16]

1. Connect the 9-pin plug A of the basic vehicle harness to the CAN port of the display.

2. Tighten the safety screws on the connector.

Inserting a Micro-SD card

The micro-SD card serves as internal storage for the display.

To change the SD card:

1. Switch off the display and disconnect all cable connections.

2. Unscrew the cover on the rear of the display.

3. Use your finger to press on the SD card in the slot.

⇨ The SD card is unlocked and now protrudes by approx. 1 mm.

Page 16

16

V9.20191001

31302713-02-US

Possible purpose

TRACK-Guide settings

Setting of the in-cab display

Task Controller; Fendt: Taskcontroller).

Greenstar, Original GreenStar Monitor

4.5

Mounting and installation

4

Using two displays

4. You can remove the card.

5. To lock the card again, press the card lightly into the slot until it is locked again.

6. Screw the cover back onto the rear of the display.

Using two displays

The following table will tell you which settings you need to configure to be able to use two displays,

and the chapters in which these are described. The specifications on the in-cab displays are without

liability.

Settings for TRACK-Guide and the in-cab display

TRACK-Leader and SECTION-Control on

the ME display.

Operation of the job computer on the incab display.

TRACK-Leader, SECTION-Control, and

job computer operation on the ME display.

Login as ISOBUS display: No [➙ 44]

Login as ISOBUS display: Yes [➙ 44]

The ISOBUS display licence is required.

Activate the ISOBUS display (JohnDeere:

Implement Bus; Fendt: Fendt ISOBUS

display).

Deactivate Task Controller (JohnDeere:

Deactivate the ISOBUS display

(JohnDeere: Implement Bus; Fendt: Fendt

ISOBUS display).

Deactivate Task Controller (JohnDeere:

Task Controller; Fendt: Taskcontroller).

For JohnDeere, also deactivate:

Page 17

31302713-02-US

V9.20191001

17

Setting

Where?

Purpose

receiver must be activated.

5

5.1

Procedure

5.2

5.2.1

Basic control principles

Basic control principles

Switching the display to ON.

5

Switching the display to ON.

To switch on the display:

The display is installed and connected to the power cable or the ISOBUS basic vehicle harness.

1. Press and hold the

button for approx. 3 seconds.

⇨ The display will beep briefly.

⇨ The display screen remains dark for approx. 10 seconds until the applications are loaded in

the background.

⇨ The start-up screen of the display will appear:

⇨ You have now started the display.

Initial start-up

The next step to perform after switching on the display depends on the purpose of the display:

▪ Parallel guidance

▪ Operation of ISOBUS implements

▪ Automatic boom section control

▪ Task management and documentation

These cases will be described in the following sections.

Using the display for parallel guidance

If you want to use the display for parallel guidance, TRACK-Leader is the most important app for you.

Most important settings

Select the GPS driver.

/ Driver / GPS [➙ 26]

The standard driver works in

most cases for the receivers

sold by ME. However, to

change the correction signal, a

fitting driver for the GPS

Page 18

18

V9.20191001

31302713-02-US

Setting

Where?

Purpose

- Tractor geometry [➙ 55]

60]

Setting

Where?

Commentary

receiver must be activated.

- Tractor geometry [➙ 55]

5.2.2

Procedure

5.2.3

Basic control principles

5

Initial start-up

Enter the tractor geometry and

activate the tractor profile.

/ Settings

See:

- Managing the tractor profiles [

➙ 50]

Virtual job computer

/ Settings

For the system to be able to

know the working width and

other parameters of the

machine, you must create a

virtual job computer for every

non-ISOBUS-compatible

machine that you use.

Virtual ECU application [

See:

Other settings must be made in the TRACK-Leader application.

➙

Operating an ISOBUS implement

If you purchase and activate an ISOBUS display licence, you can operate ISOBUS implements. In

the standard version of the display, you can test the function for 50 hours.

The "ISOBUS-UT" licence is activated.

1. Insert the ISOBUS cable of the job computer into the ISOBUS rear socket.

2. Switch on the display.

3. Wait until the job computer application has copied all of the relevant data on the display.

4. Open the job computer application using the selection menu [➙ 21].

Display for automatic section control

Most important settings

Select the GPS driver

(optional).

Enter the tractor geometry and

activate the tractor profile.

/ Driver / GPS [➙ 26]

/ Settings

The standard driver works in

most cases for the receivers

sold by ME. However, to

change the correction signal, a

fitting driver for the GPS

See:

- Managing the tractor profiles [

➙ 50]

Page 19

31302713-02-US

V9.20191001

19

Setting

Where?

Commentary

the ISOBUS.

parameters in the profile.

Setting

Where?

Purpose

"Standard".

without a USB memory device.

Procedure

5.2.4

Procedure

Basic control principles

Initial start-up

5

Connecting the job computer to

Job computer profile in

SECTION-Control

/ Settings / SECTION-

Control

Search for a profile and set the

"Machine model" parameter.

For more precise operation,

configure all of the other

The "ISOBUS-UT", "TRACK-Leader" and "SECTION-Control" licenses are activated.

1. Insert the ISOBUS cable into the ISOBUS rear socket.

2. Switch on the display.

3. Wait until the job computer application has copied all of the relevant data on the display.

4.

- Open the TRACK-Leader application using the selection menu [➙ 21].

5. Configure the settings from the table above.

6. Start a new navigation.

Display for task management

You can always use ISOBUS-TC task management, regardless of whether you are driving in parallel,

switching sections or simply operating an ISOBUS job computer. However, the most important

settings mentioned in the previous sections must be made for each of these applications.

Important for ISOBUS-TC:

▪ Always remember to start and stop the tasks.

▪ After finishing work, you must save all of the tasks on the USB memory device (log out the USB

memory device) before you remove the USB memory device or transmit new tasks onto the

display.

Most important settings

Set the operating mode to

"Extended".

Insert the USB memory device

with task data or create tasks

/ Settings

Activates and deactivates task

management in the ISOBUSTC application.

If you do not want to create

tasks, set the operating mode to

The "ISOBUS-TC" licence is activated.

1. Switch on the display.

Page 20

20

V9.20191001

31302713-02-US

menu" area.

Main window

applications which are open.

System icons

Icon

Meaning

purposes.

5.3

Procedure

5.4

Basic control principles

5

Switching off the display

2. - Open the ISOBUS-TC application using the selection menu [➙ 21].

3. Insert a USB memory device with task data.

4. Start a task.

Switching off the display

To switch off the display:

1. Press and hold the

⇨ You have now switched off the display.

button for approx. 3 seconds.

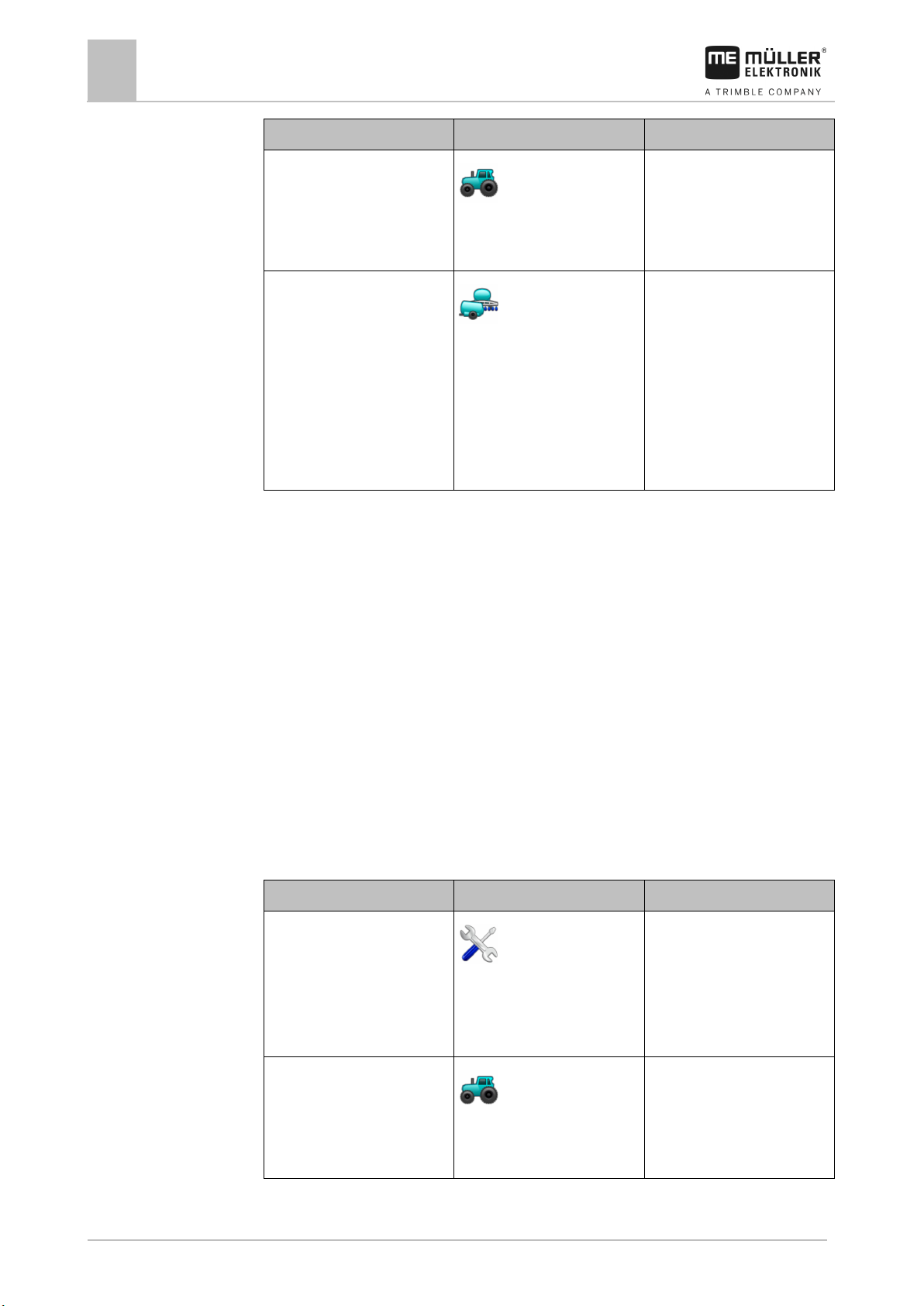

Display screen layout

Display screen layout

Selection menu

You can open applications in the "Selection

This area enables you to operate applications.

Touching the display screen in the "Main

window" area will actuate the function whose

icon you have touched.

The operation is dependent on the

Wide additional window

System icons

Has no function in this area.

When this icon appears in other areas, it is used for confirmation

Page 21

31302713-02-US

V9.20191001

21

Icon

Meaning

deletion purposes.

5.5

Procedure

Basic control principles

Opening applications

5

Has no function in this area.

When this icon appears in other areas, it is used for cancellation or

Has no function in the current software version.

Has no function in the current software version.

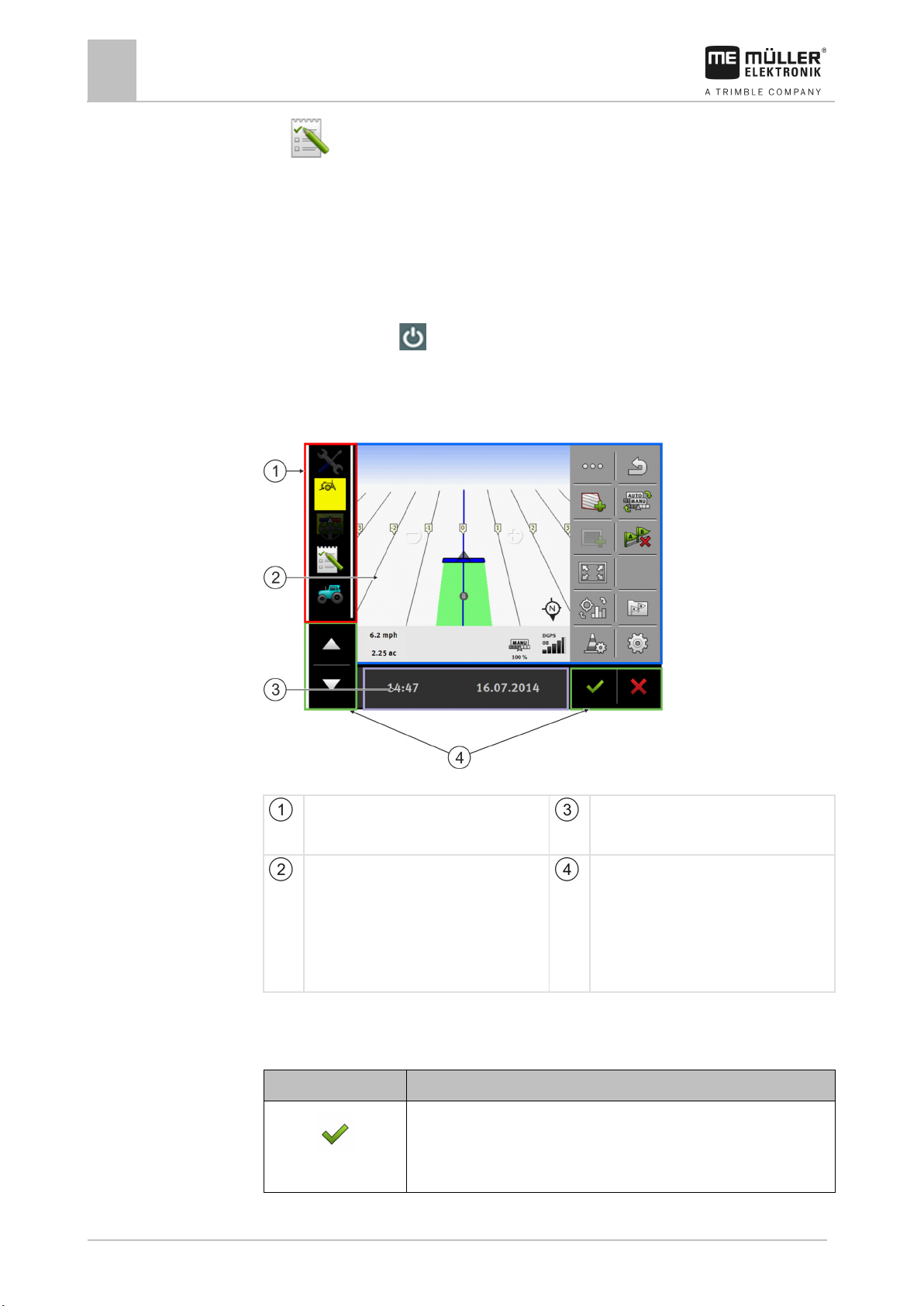

Opening applications

An application opens when it appears in the main window or in an additional window.

To open an application:

1. Find the function icon for the desired application in the Selection menu area. For example, the

icon:

2. Tap the function icon of the application:

⇨ The application will appear in the main window:

⇨ The function icon of the application in the Selection menu now appears darker. This tells

you that this application is already open. You will no longer be able to open it from the

Selection menu.

⇨ If the main window is occupied, the application that is already opened will be moved to a

free additional window. If this is occupied, the application that is already opened will be

moved back to the Selection menu. Their icon becomes bright again. However, it can

continue to work in the background.

Page 22

22

V9.20191001

31302713-02-US

5.6

Procedure

5.7

Procedure

Basic control principles

5

Moving an application

Moving an application

You can move any application from the main window to one of the additional windows or to the MEHeader.

To move an application from the main window to an additional window:

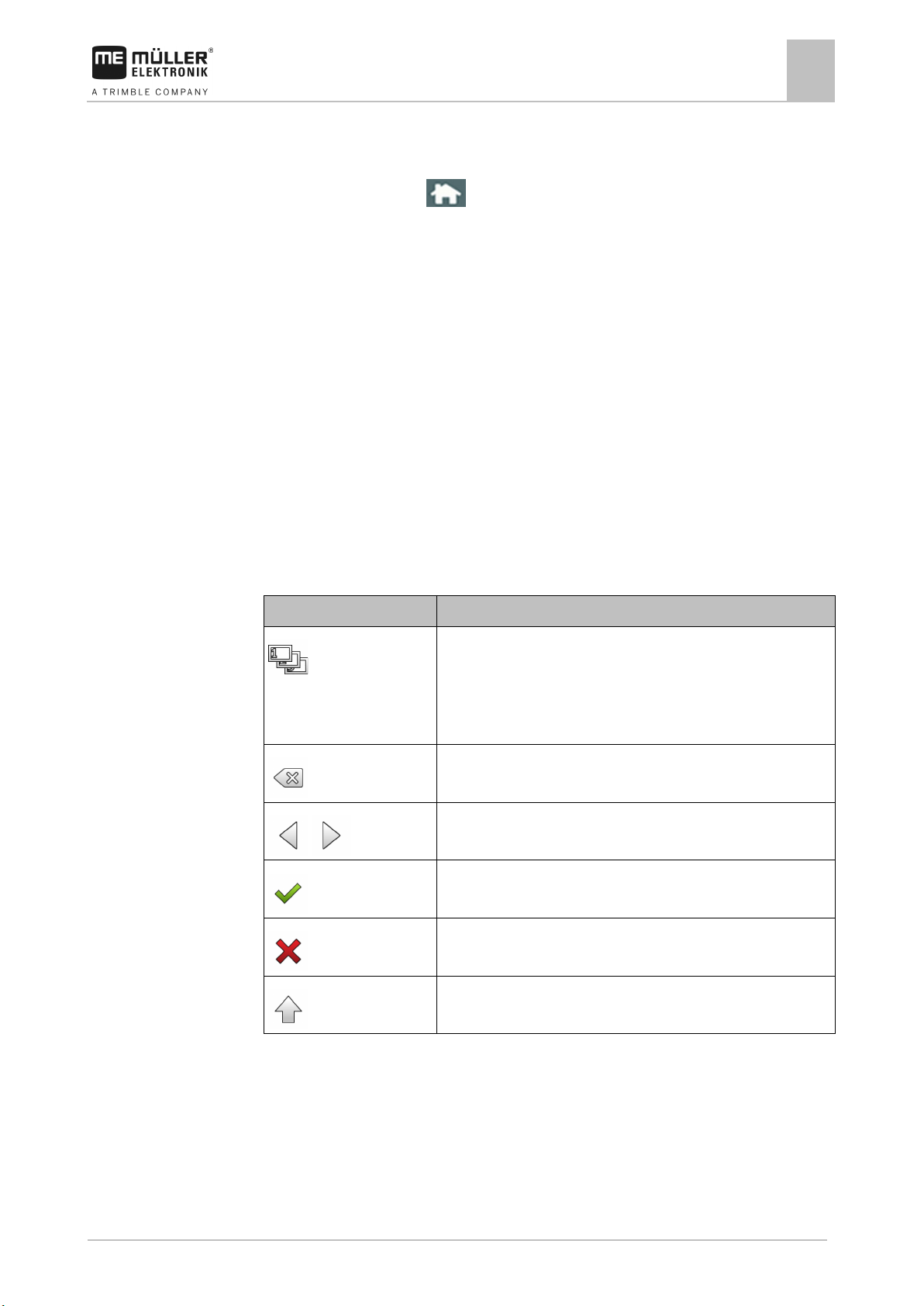

You have opened an application in the main window. For example, the Service application:

1. Tap the additional window:

⇨ The application will now appear in the additional window:

2. Tap the additional window with the application.

⇨ The application will once again appear in the main window.

Saving and loading window arrangements

You can save and load the arrangement of the applications in the windows.

To save the arrangement:

1. Hold the button

pressed down until the display beeps twice.

Page 23

31302713-02-US

V9.20191001

23

Icon

Meaning

Abc

Procedure

5.8

Procedure

5.9

Basic control principles

⇨ The arrangement will be saved.

Hiding an application

5

To load a saved arrangement:

1. Briefly press the button:

⇨ The arrangement will be loaded.

Hiding an application

If you do not have enough space on the display screen to open new applications, you can hide an

application. The application will not be shut down, but will instead continue to run in the background.

To hide an application:

1. Open the application in the additional window.

2. Move the application to the selection menu.

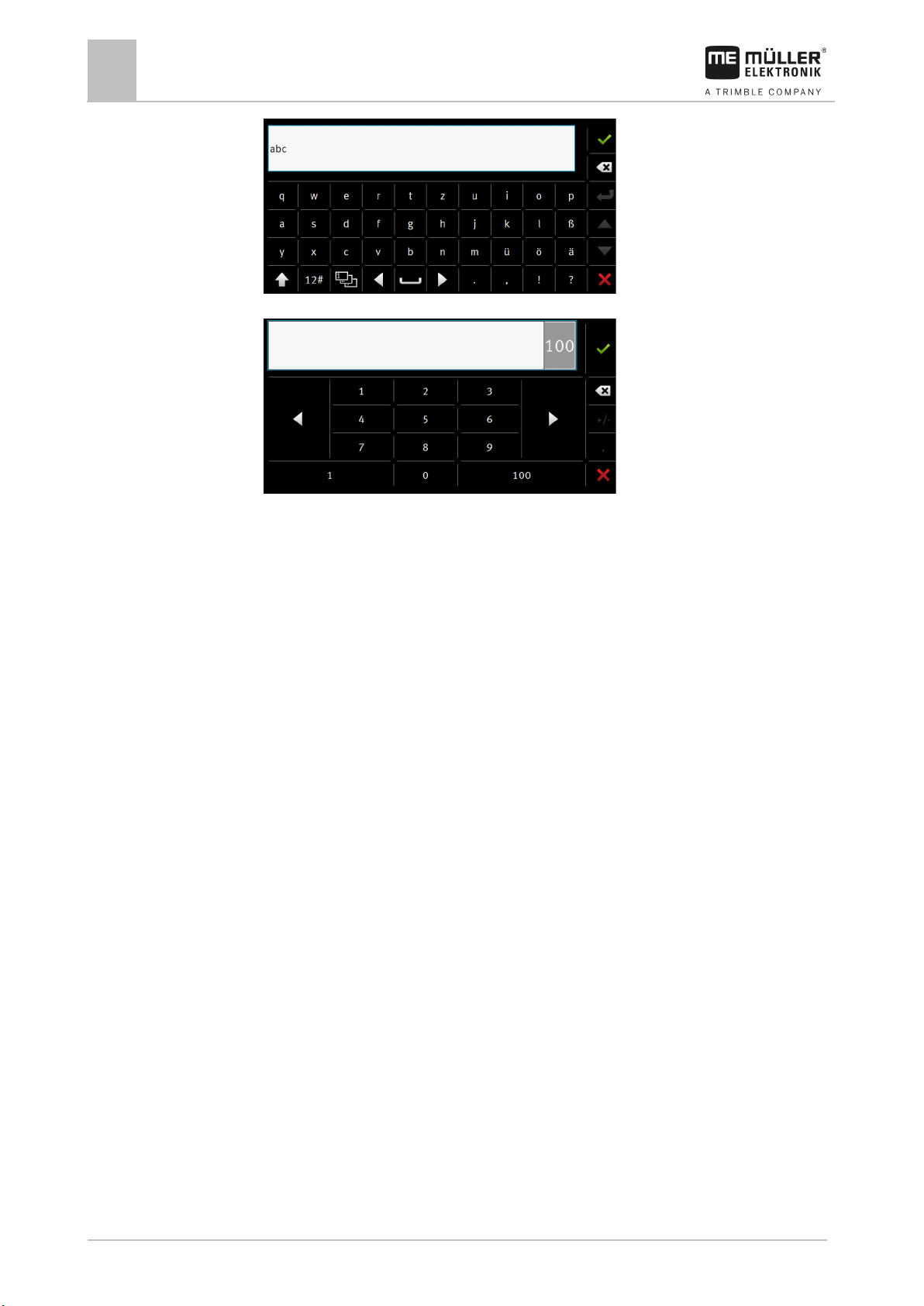

Using the keyboard

In order to enable you to also write numbers or text on the display, a keyboard will appear on the

display screen whenever this is necessary.

Major icons

Changes the buttons on the keyboard.

12#

Deletes a character.

Moves the cursor.

Saves the input.

Cancels the input.

Switches between upper and lower case letters.

Page 24

24

V9.20191001

31302713-02-US

5.10

5.10.1

5.10.2

Basic control principles

5

Using a memory device

Keyboard for inputting text and numbers.

Keyboard for inputting text.

Using a memory device

The display can work with two kinds of memory devices:

1. With an integrated micro-SD card. This will be used as storage for most applications.

2. With an inserted USB memory device.

The USB memory device is used only for the following purposes:

▪ For data transfer [➙ 24] between the display and PC

▪ For saving screenshots

Using a SD card

The display applications save most data [➙ 24] directly onto the SD card. For information about data

not stored on the SD card, refer to the TRACK-Leader manual.

In order to exchange data between the display and a PC, you will need to proceed differently for each

application. You can find out more about this in the instructions for each application.

Directories on the USB memory device

As soon as you insert the USB memory device into the display, several folders will be created on the

USB memory device. You will need to set up other folders by yourself.

Each directory may only contain certain data, so that the applications on the display can use this

data.

▪ "documents"

– Files: .txt

– Purpose: Records for all completed tasks are saved in this folder.

▪ "FIELDNav"

– Files: .iio, .data

Page 25

31302713-02-US

V9.20191001

25

5.10.3

Procedure

Basic control principles

Using a memory device

5

– Purpose: Map material will be saved in this directory.

– The directory will be created when the FIELD-Nav license is activated.

▪ "fileserver"

– Files: All file formats are acceptable.

– Purpose: Files which are to be imported or exported in the FILE-Server application are

saved in this directory.

▪ "GPS"

– Files: .txt

– Purpose: GPS positions are saved in a file in the directory. This will enable Customer

Service to reconstruct the traveled distance.

– The directory will be created if you activate the "Record and save data" parameter.

▪ "NgStore"

– Files: .iio, .data

– Purpose: TRACK-Leader. Standard directory for saved routes and fields.

▪ "Screencopy"

– Files: .bmp

– Purpose: Screenshots are saved here.

– The display will create this directory automatically when the "Screenshot" parameter is

activated in the "Terminal" menu and you create a screenshot.

▪ "SHP"

This folder replaces the "GIS" folder that was used in previous versions.

– Files: .dbf, .kml, .prj, .shp, .shx

– Purpose: TRACK-Leader: After saving with the SD card, the field data will be stored here.

For example: Field boundaries, applied areas, headlands, etc.

ISOBUS-TC: The shp files must be stored in this folder.

▪ "Taskdata"

– Files: .xml

– Purpose: The directory may only contain XML files which originate from an ISO-XML

compatible FMIS. The ISOBUS-TC application accesses this data.

– You must create this directory yourself.

Displaying the content of the memory device on the display

You can view the content of the memory device directly on the display.

1. Insert the memory device (USB memory device or SD card) into the display.

2. Open the "Service" application.

3. Tap on "USB 1" or on "SDCard".

⇨ The content of the USB memory device will be displayed.

⇨ The content of the SD card can be found in the "ME-TERMINAL" folder.

Page 26

26

V9.20191001

31302713-02-US

5 Hz (GPGGA, GPVTG)

1 Hz (GPGSA, GPZDA)

Transmission rate

19200 baud

Data bits

8

Parity

no

Stop bits

1

Flow control

None

6

6.1

6.1.1

Procedure

6.1.2

Connecting and configuring external devices

6

GPS receiver

Connecting and configuring external devices

GPS receiver

Connecting the GPS receiver to the display

Find out how to connect Mueller Electronics GPS receiver to the display via the GPS receiver's

Operating Instructions.

When mounting the display in a vehicle which is already fitted with a GPS receiver and another

ISOBUS display, you must:

▪ connect the GPS signal to the display from Mueller-Electronics;

▪ configure the GPS receiver.

To connect the display to a GPS receiver which is already installed on the vehicle:

1. Find out how you can direct the signal from the GPS receiver to the display. This can differ for

every vehicle or GPS receiver: Vehicles can be fitted with a GPS socket in the cab, a GPS

receiver with a serial output or serial outputs to the ISOBUS display.

2. Check what cable you will use to connect GPS signal to the serial socket on the display

manufactured by Mueller-Electronics.

3. Connect the GPS signal to the serial socket of the display manufactured by Mueller-Electronics.

4. Configure the GPS receiver so that it can communicate with the display manufactured by

Mueller-Electronics. You can find the necessary specifications for this in the table below.

5. Activate the "Standard" GPS driver on the display.

Configuration

Frequencies

Changing the driver for the GPS receiver

Upon delivery, the "Standard" driver is activated on the display. You must change this driver if you

want to reconfigure the GPS receiver, for example, to change the correction signal. In this case, you

must select a driver that is fitting for the GPS receiver.

Page 27

31302713-02-US

V9.20191001

27

Driver name

GPS receiver

deactivated

No GPS receiver is connected.

Elektronik, if they are connected to the serial interface.

Müller-Elektronik, if they are connected to the serial interface.

external lightbar.

cannot thus be configured.

external lightbar.

NOTICE

driver.

Procedure

Connecting and configuring external devices

Available drivers

GPS receiver

6

A100, A101 Drivers for the A100 and A101 GPS receivers from Müller-

AG-STAR, SMART-6L Drivers for the AG-STAR and SMART-6L GPS receivers from

PSR CAN Select this driver if the GPS receiver is connected to the PSR

steering job computer. PSR is a steering computer by the

Reichhardt company. The signals are transmitted to the display

through the CAN cable. The receiver will be configured directly in

the PSR application.

Please note that you cannot use this driver together with an

Standard Drivers for unknown GPS receivers, if they are connected to the

serial interface.

This driver is activated by default. The connected GPS receiver

TRACK-Leader AUTO® Select this driver if a GPS receiver is connected to the TRACK-

Leader AUTO® steering job computer.

Please note that you cannot use this driver together with an

Incorrect driver

Damage to the GPS receiver.

◦ Before connecting a GPS receiver to the display, you must always activate the appropriate

To activate the driver:

1.

- Open the Service application.

2. Tap "Driver".

3. Tap "GPS".

⇨ The installed drivers will appear.

4. Tap the appropriate driver.

5.

- Confirm.

6. Restart the display.

Page 28

28

V9.20191001

31302713-02-US

Function icon

Meaning

activation license.

6.1.3

Procedure

Connecting and configuring external devices

6

GPS receiver

Configuring the GPS receiver

The internal software for each GPS receiver must be configured. You can configure the following

GPS receivers offered by Mueller-Electronics via the display:

▪ A100, A101

▪ AG-STAR, SMART-6L

All other GPS receivers must be configured in accordance with their manufacturer's instructions.

Reads the configuration of the GPS receiver.

Restores the manufacturer's default settings.

Opens the license menu.

Only appears for a SMART-6L DGPS/GLONASS receiver for entering an

Resets the baud rate.

The GPS receiver is connected to the display.

The GPS receiver is connected directly to the display. Additional devices such as an external

lightbar or tilt module may not be connected in between.

The correct GPS driver is activated.

1.

- Open the "Service" application.

2. Tap "GPS".

⇨ The "Settings" screen appears.

⇨ The following message will appear during initial configuration: "GPS receiver detected.

Read the configuration?"

3. To confirm, tap "Yes". To cancel, tap "No".

⇨ The display reads the current configuration of the GPS receiver.

⇨ You can now see all of the configurable parameters.

4. Configure the parameters. The parameters can be found in the following section.

5. Reconnect all of the additional devices that you had disconnected for the configuration.

Parameters for the GPS receiver

Baud rate

Only appears when the "Standard" driver is selected.

Setting for the speed at which the GPS receiver sends data to the display. The parameter sets the

baud rate for the display.

Satellite 1 and Satellite 2

Page 29

31302713-02-US

V9.20191001

29

Connecting and configuring external devices

GPS receiver

6

Satellite 1 – primary DGPS satellite. The DGPS receiver will connect to this satellite in the first

instance.

Satellite 2 – secondary DGPS satellite. The DGPS receiver will only connect to this satellite in the

event that the primary satellite fails.

Your satellite selection will depend on which satellite currently has the best availability in your region.

Potential values:

▪ "Auto"

The software automatically selects the current best satellite.

▪ Name of the satellite. Which satellites are shown here is dependent on the driver and correction

signal that you have activated.

Steering

This parameter activates the "Automatic steering" assistance function in the GPS receiver.

If you want to connect your existing GPS receiver to a steering job computer, you have to configure

the "Steering" parameter.

Potential values:

▪ "Without automatic steering"

Deactivates automatic steering assistance.

▪ "TRACK-Leader TOP"

Activates automatic steering assistance with TRACK-Leader TOP.

▪ "TRACK-Leader AUTO"

Activates automatic steering assistance with TRACK-Leader AUTO.

Correction signal

Type of correction signal for the DGPS receiver.

The correction signals which are available is dependent on the activated driver.

Potential values:

▪ For the "A100, A101" driver:

– "WAAS/EGNOS"

Correction signal for Europe, North America, Russia and Japan.

– "E-DIF"

Internal calculation of correction data.

Only functions with a special version of the A100 DGPS receiver, item no. 30302464. This

receiver is no longer sold by Mueller-Electronics.

▪ For the "AG-STAR, SMART-6L" driver

When an AG-STAR DGPS/GLONASS receiver is connected:

– "EGNOS-EU"

– "WAAS-US"

– "MSAS-JP"

– "EGNOS-EU + GLIDE"

– "WAAS-US + GLIDE"

– "MSAS-JP + GLIDE"

– "GPS/GLONASS GLIDE 1"

Page 30

30

V9.20191001

31302713-02-US

Connecting and configuring external devices

6

GPS receiver

– "GPS/GLONASS GLIDE 2"

When a SMART-6L DGPS/GLONASS receiver is connected:

– EGNOS/WAAS

– EGNOS/WAAS + GLIDE

– GLIDE

– RTK radio (RTK license required )

– RTK GSM (RTK license required )

– TerraStar (RTK or L band licence required)

Information for GLIDE

If you have selected a correction signal with GLIDE, please note:

▪ Switch the GPS receiver off when driving on roads.

▪ After starting the systems each time, it takes ca. 5 minutes until the system is ready for

operation. Wait on the field to be worked during this time, before you start working.

▪ Ensure that the GPS receiver does not lose the GPS signal during work. If the signal gets lost, it

can cause the GLIDE to restart. This can lead to track offset.

Information for TerraStar

If you have selected "TerraStar" as a correction signal, please note:

▪ There are two different TerraStar correction signals: TerraStar-C and TerraStar-L. These differ

mainly in their accuracies.

▪ The accuracies are available ca. 5 to 10 minutes after switching on the GPS receiver under the

open sky.

▪ If the GPS signal fails due to shadowing by buildings or trees, the full accuracy is available again

at the latest after ca. 5 minutes. For this reason, you should avoid driving along rows of trees or

buildings.

▪ During the convergence, the GPS receiver and the vehicle should not be moved and the location

should not be changed.

Baud rate of the receiver on port B

Only appears when the "RTK radio" correction signal is selected.

If you are using a GPS receiver with a radio modem from a third-party manufacturer, the baud rate

must be adjusted in some cases. The baud rate must then correspond to that of the radio modem.

The baud rate for radio modems manufactured by Mueller Electronics is always 19.200 baud.

Correction during RTK failure

This parameter is only required if you are using the SMART-6L DGPS receiver with a steering

system.

Potential values:

▪ automatic

The parameter is activated.

When there is an RTK failure, a deviation arises between the current position of the vehicle and

the GPS position.

If the parameter is set to "automatic", you prevent the vehicle from driving directly to the new

GPS position. The system will then gradually steer towards the new GPS position. This prevents

the occurrence of large track offsets in case of RTK failure.

Page 31

31302713-02-US

V9.20191001

31

Procedure

Procedure

Connecting and configuring external devices

GPS receiver

6

When the RTK signal is available again, the vehicle will be gradually steered towards the original

GPS position.

▪ deactivated

The parameter is deactivated.

Terrain compensation

Under this parameter the terrain compensation GPS TILT-Module is configured.

You can order the terrain compensation from Mueller-Electronics with the following item number:

30302495.

RTK or L band licence for SMART-6L

You will need a SMART-6L DGPS/GLONASS receiver and RTK license in order to work with RTK

correction signals.

To work with TerraStar correction signals, you need a SMART-6L DGPS/GLONASS receiver and at

least an L band license.

When purchasing a GPS receiver with an RTK or L band license, the license is entered at Mueller

Electronics. You only have to enter the licence yourself when it is purchased at a later date.

1. - Open the "Service" application.

2. Tap "GPS".

⇨ The "Settings" screen appears.

3.

- Open the license menu.

4. Tap "License code".

⇨ The "License menu" screen appears.

⇨ You can see the serial number and firmware version on the screen. You will need these

when ordering the license code.

⇨ If you are using the TerraStar correction signal, you will see information on the TerraStar

service and the expiry date of the TerraStar service.

⇨ Optionally, you can open the "Model number" screen to obtain information on the current

activation of the GPS receiver.

5. Enter the license code.

6.

- Confirm.

GSM modem for SMART-6L

If you are using the DGPS/GLONASS SMART-6L receiver with a GSM modem, you can adjust the

existing configuration.

1. - Open the "Service" application.

2. Tap "GPS".

3. The "Settings" screen appears.

4.

- Open the configuration menu.

Page 32

32

V9.20191001

31302713-02-US

Parameter

Meaning

Possible entries

APN

Connection to the provider.

Provider URL or IP address.

same for all users of a provider.

providers do not require entering a name.

password.

URL/IP

Connection to the correction data server.

Correction data server URL or IP address.

Port

Port at the correction data server.

Port number

customer account.

use of upper and lower case letters.

use of upper and lower case letters.

only with GPRS connections.

stream.

Procedure

Connecting and configuring external devices

6

GPS receiver

5. Configure the parameters. The explanations for the individual parameters can be found in the

table at the end of this section.

6.

- Save the changes.

⇨ The following message appears: "Should the data be transmitted to the modem?"

7. "Yes" - to confirm.

⇨ The data is being transmitted to the modem. This will take approx. 30 seconds.

User Name for the Internet access. The name is the

Password Password for the Internet access. The password is

the same for all users of a provider.

NTRIP user Name from the correction service to identify the

Name that was given by the provider. Some

Password that was given by the provider.

Some providers do not require entering a

Letters and numbers. Pay attention to the

NTRIP password Password for the identification name. Letters and numbers. Pay attention to the

Mountpoint Manual entry of a correction data source available

Name of the correction data source / data

Configuring the GPS receiver for the steering system

To be able to use a GPS receiver with automatic steering, it must previously be configured for this

use. The configuration adjusts the internal settings of the GPS receiver.

You can use the following GPS receivers for the steering system:

▪ A101

▪ AG-STAR

▪ SMART-6L

This is how to configure the GPS receiver for automatic steering:

1. Activate the driver for the respective GPS receiver [➙ 26] to establish a connection between the

display and the GPS receiver.

2. Configure the GPS receiver. [➙ 28]

3. Tap "Steering" in the configuration.

4. Select the automatic steering that you are using.

5.

- Confirm.

Page 33

31302713-02-US

V9.20191001

33

Procedure

6.1.4

Procedure

Connecting and configuring external devices

GPS receiver

6

6. For TRACK-Leader AUTO® systems, tap and adjust the baud rate of the receiver to the

automatic steering.

⇨ The following message appears: "You can now disconnect the GPS receiver."

7. Confirm using "OK".

8. Switch off the display.

9. Now connect the GPS receiver to the cable harness of the steering job computer.

10. Start the display.

11. Depending on the steering job computer, activate the "PSR CAN" or "TRACK-Leader AUTO"

driver. [➙ 26]

12.

- Confirm.

13. Restart the display.

⇨ The GPS receiver is now configured for automatic steering.

To change parameters for the GPS receiver after the GPS receiver has been configured for

automatic steering, you must restore the internal settings of the GPS receiver.

1. Connect the GPS receiver to the display.

2. Activate the driver for the respective GPS receiver. [➙ 26]

3. Restart the display.

4.

- Open the "Service" application.

5. Tap "GPS".

6.

- Reset the baud rate.

7. The following message appears: "Should the standard baud rate be restored?"

8. Confirm using "OK".

9. Restart the display.

⇨ You can now change the individual parameters for the GPS receiver.

⇨ After you have changed the parameters, you can reconfigure the GPS receiver for the steering.

Recording GPS positions

Certain faults can require recording of the position data from the GPS receiver.

A USB memory device is inserted into the display.

1.

2. Tap "GPS".

3. Tap "GPS-Data".

4. Scroll down.

- Open the Service application.

⇨ The "GPS-Data" screen will appear.

Page 34

34

V9.20191001

31302713-02-US

6.1.5

Procedure

6.2

Procedure

Connecting and configuring external devices

6

Configuring the joystick button allocations

5. Tap "Trace-Data".

⇨ The "Trace-Data" screen will appear.

6. Scroll down.

7. Checkmark the "Record and save data" button.

⇨ The display will immediately begin to record the data. This will be saved in the "GPS"

directory on the USB memory device.

⇨ The function will be deactivated following any restart.

Configuring the "GPS TILT-Module" terrain compensation

The "GPS TILT-Module" terrain compensation is connected.

The tractor is positioned on level ground.

The lightbar driver is configured as a "screen lightbar".

1. If additional devices (e.g. external lightbar) are connected to the cable between the display and

the tilt module, disconnect them. The tilt module must be connected directly to the display. After

the tilt module has been configured, these additional devices must be reconnected.

2. Measure the distance between the GPS receiver and the ground on which the tractor is

positioned.

3. Switch on the display.

4.

- Open the "Service" application.

5. Tap "GPS".

⇨ The "Settings" screen appears.

6. Scroll down until the "Terrain Compensation" parameter appears on the screen.

7. Tap "Terrain Compensation".

8. Enter the measured distance on the "GPS receiver height" line.

9. Tap

.

⇨ Message: "Tilt module will be configured." is displayed.

10. To confirm, tap "Yes".

⇨ The position of the tilt module on level ground is being calibrated.

⇨ After calibration, the angle 0 will appear on the "Angle" line. The displayed angle will change

with any tilt of the tractor.

11. Reconnect all of the additional devices that you had disconnected for the configuration.

Configuring the joystick button allocations

The display offers you the possibility of assigning the functions of an ISOBUS job computer to the

buttons of the joystick. To do so, the ISOBUS job computer and the joystick must fulfil the Auxiliary 2

specification requirements of the ISOBUS standard.

To activate the driver for this function:

The joystick and ISOBUS job computer are connected and both support the Auxiliary 2 protocol.

Page 35

31302713-02-US

V9.20191001

35

Procedure

6.3

Connecting and configuring external devices

Connecting sensors to the display

6

1. - Open the Service application.

2. Tap "Driver".

3. Tap "Auxiliary".

4. Mark "Auxiliary2".

5.

6. Restart the display.

- Confirm.

To configure the button assignment:

You have activated the “Auxiliary2” driver

1.

- Open the “Service” application.

2. Tap “Auxiliary”.

3. Tap “Auxiliary Editor”.

⇨ If the ISOBUS job computer supports the Auxiliary 2 protocol, a list appears of the job

computer functions.

⇨ If no list appears, the ISOBUS job computer does not support this protocol.

4. Tap the function which you want to assign to this button on the joystick.

⇨ A list of the buttons on the joystick appears.

⇨ You have two options for assigning the function to the joystick.

5. Option 1: On the joystick, press the button to which you want to assign the function.

Option 2: On the display, select the button to which the selected function should be assigned

and confirm with

.

⇨ The function will be assigned to the button and you can continue with the next function, until

you have assigned all of the functions.

6. Restart the display.

⇨ After restarting, the following notification appears on the main display screen: “Confirm the

assignments.” This notification appears after any restart.

7. “OK” - acknowledge the notification.

⇨ A list of recognized assignments appears on the display screen.

8.

- Confirm the assignments.

Connecting sensors to the display

The display provides you with the possibility of connecting a sensor or the tractor's 7-pole signal

socket to port B. This allows you for example to use the working position signal in the TRACK-Leader

parallel guide.

The work position sensor sold by Müller-Elektronik is fitted with a round 3-pin plug. You will need an

adapter cable to connect it to the display.

You must activate the work position sensor [➙ 53] and possibly the wheel sensor [➙ 52] or radar

sensor in the Tractor-ECU app and calibrate if necessary.

Page 36

36

V9.20191001

31302713-02-US

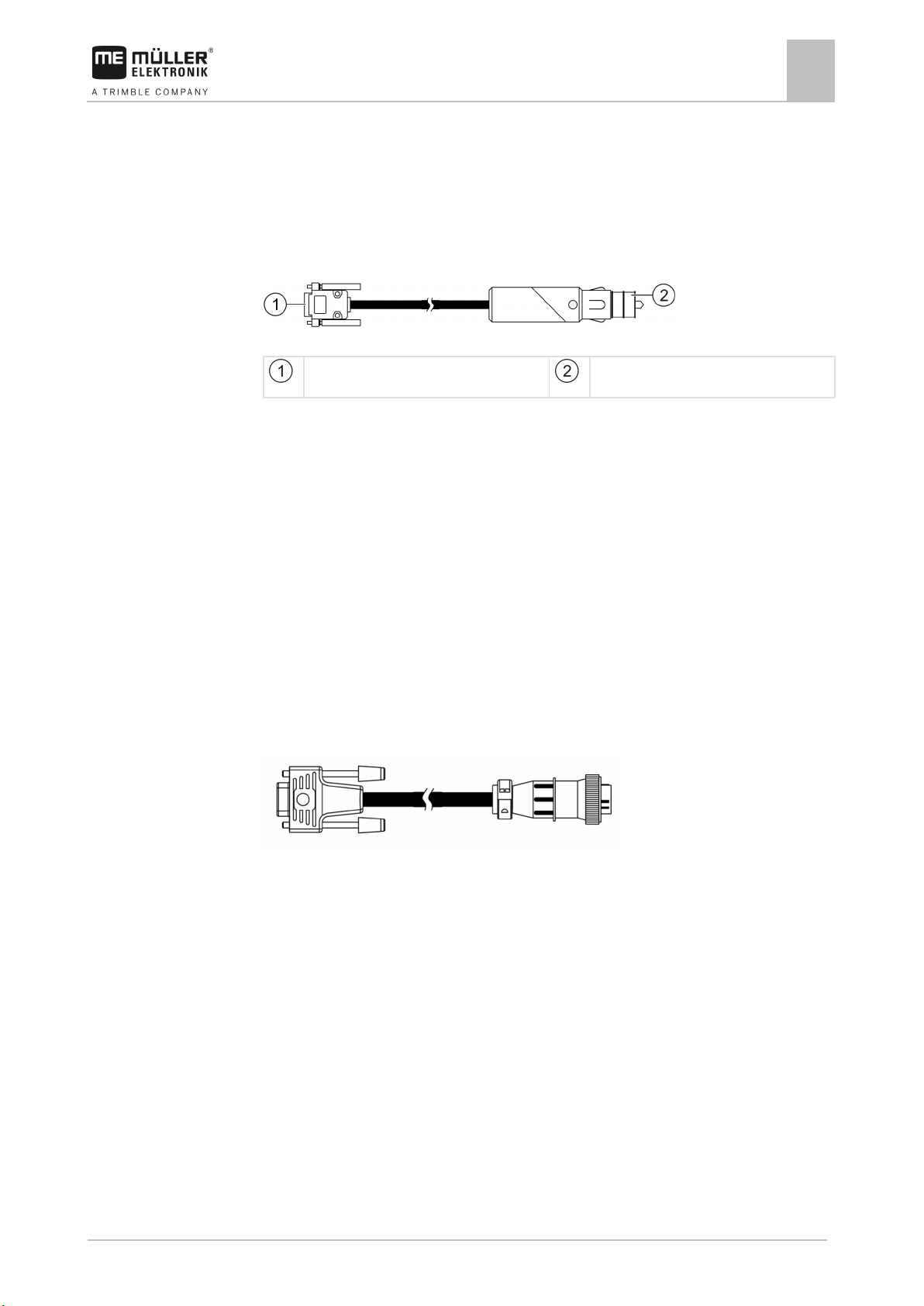

CAM port

6.4

6.4.1

Procedure

Connecting and configuring external devices

6

Camera

Camera

Connecting the analogue camera to the display

Connecting the camera HQ - provided by ME

Camera HQ - Connection to the Touch Display

Plug for connection to the display.

Extension cable

Camera HQ

Camera plug

Connector for the camera plug

1. Assemble the camera together with its bracket, as described in the assembly instructions of the

camera manufacturer.

2. Connect the camera to the extension cable.

3. CAUTION! When laying out the extension cable, ensure that there are no kinks and that

no one can stumble over the laid-out cable.

4. Connect the extension cable to the CAM port of the display.

5. Secure the camera.

6. Activate the camera. [➙ 38]

Page 37

31302713-02-US

V9.20191001

37

Plug for connection to the display.

CAM port

Camera

Procedure

Connecting and configuring external devices

Camera

6

Connecting the camera NQ - provided by ME

Camera with adapter cable

Connector for the adapter cable

Connector for the extension cable

Camera plug

Connector for the camera plug

1. Connect the cables to each other as shown in the figure. Pay attention to cable lengths when

doing so.

2. CAUTION! When laying out the cable, ensure that there are no kinks in the cable and that

no one can stumble over the laid-out cable.

3. Lay out the cable. Ensure that the cable reaches the display and is not damaged during

operation.

4. Secure the cable with the provided cable ties.

5. Secure the camera. Use the white cardboard drilling template from the quick start guide for this

purpose.

6. Connect the camera to the display. Use the CAM port to do this.

7. Activate the camera. [➙ 38]

8. When disconnecting the cable from the display, use the enclosed rubber gasket to seal the

exposed connector.

Page 38

38

V9.20191001

31302713-02-US

Plug for connection to the display.

80 ft: DMAC-EC80

Camera

MLR01

Procedure

6.4.2

Procedure

Connecting and configuring external devices

6

Camera

Connecting the camera AgCam PAL

Camera AgCAM PAL with adapter cable

CAM port

Part number: DMAC-RC-PAL

Part numbers of the extension cable:

10 ft: DMAC-EC10

20 ft: DMAC-EC20

30 ft: DMAC-EC30

40 ft: DMAC-EC40

50 ft: DMAC-EC50

60 ft: DMAC-EC60

Connector for the adapter cable

Connector for the extension cable

Camera plug

Connector for the camera plug

Part number of this adapter cable: DMAC-

1. Connect the cables to each other as shown in the figure. Pay attention to cable lengths when

doing so.

2. CAUTION! When laying out the cable, ensure that no kinks form in the cable, and that no

one can trip over the laid-out cable.

3. Lay out the cable. Ensure that the cable reaches the display and is not damaged during

operation.

4. Secure the cable with cable ties.

5. Secure the camera.

6. Connect the camera to the display. Use the CAM port to do this.

7. Activate the camera. [➙ 38]

8. When disconnecting the cable from the display, use the enclosed rubber gasket to seal the

exposed connector.

Activating a camera

In order to activate a camera, you must activate the "Camera" plug-in.

1. - Open the Service application.

Page 39

31302713-02-US

V9.20191001

39

WARNING

Accident due to delayed image transmission

reaction can lead to risks.

Function icon

Meaning

6.4.3

Connecting and configuring external devices

Camera

6

2. Tap "Plug-ins".

3. Tap "Camera".

⇨ The plug-in is marked with a green tick.

4. Restart the display.

⇨ After restarting, the icon for the camera application will appear in the selection menu.

5.

- Open the Camera application.

Operating the camera

The camera serves solely for observing the implement functions in non-safety-related working areas

of the agricultural implement.

In certain situations, the camera image may appear on the screen with a delay. The delay depends

on the respective use of the display and can also be affected by external factors and devices.

Rapidly moving objects may be detected too late.

◦ Do not use the camera as an aid for steering the vehicle.

◦ Do not use the camera in road traffic.

◦ Do not use the camera when driving into intersections.

◦ Do not use the camera as a rear view camera.

◦ Do not use the camera as a visual aid for controlling the implement, especially when a delayed

You have connected and activated the camera.

Mirrors the image horizontally.

Mirrors the image vertically.

1.

- Open the Camera application.

⇨ The image will appear in the main window.

2. Tap on the main window.

⇨ Function icons will appear on the side for 10 seconds, with which you can actuate the

camera.

Page 40

40

V9.20191001

31302713-02-US

6.5

6.5.1

6.5.2

Procedure

6.6

Connecting and configuring external devices

6

External lightbar

External lightbar

Connecting the external lightbar to the display

The external lightbar is a parallel guidance display made by Müller-Elektronik, which can be mounted

near the windshield.

The external lightbar works with position data and guidance lines that are provided by the TRACKLeader app. This is why you need the TRACK Leader App to be able to use the external lightbar.

External lightbar

Plug for connecting a GPS receiver

Plug for connection to the display

Serial port

Activating an external ME LightBar

If you connected an external LightBar to the display, you must activate it.

To activate the external LightBar, you must first activate its driver.

You can order the external ME Lightbar from Mueller-Electronics with the following item number:

30302490.

1. - Open the Service application.

2. Tap "Driver".

3. Tap "LightBar".

⇨ The installed drivers will appear.

4. Tap "Lightbar".

5.

6. Restart the display.

- Confirm.

Connecting the on-board integrated display/controller to the display

You can connect a range of on-board integrated display/controllers (non-ISO computers), which

communicate using the LH5000 protocol or the ASD interface, to the display.

An appropriate connector cable for each on-board integrated display/controller which can be

connected is available from Mueller-Electronics. Our sales team will be glad to advise you.

Page 41

31302713-02-US

V9.20191001

41

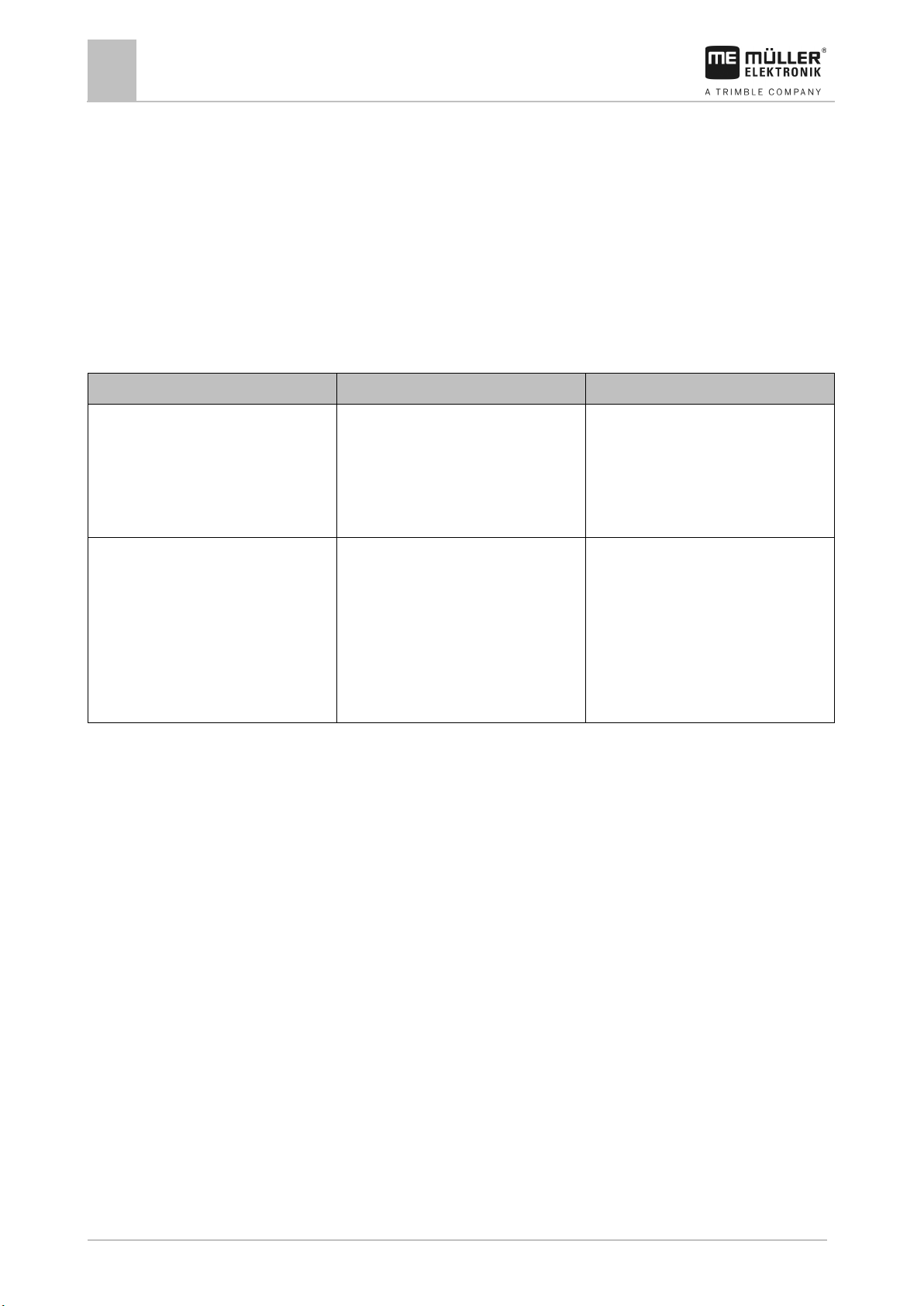

3032254800

Procedure

6.7

6.7.1

Connecting and configuring external devices

ISO printer

6

On-board integrated display/controller

Adapter cable*

Available as a set with Cable 3, item number:

Null modem cable

Port B on the display

*When using an Amatron3 or Amatron+ as on-board integrated display/controller, you will only need a

traditional null modem cable. (Amatron3 and Amatron+ are on-board integrated display/controller

from Amazone)

1. After connecting the on-board integrated display/controller to the display, create a virtual job

computer for the machine. More about this in section: Virtual ECU application [➙ 60]

ISO printer

Connecting the ISO printer to the display

The ISO printer, manufactured by Mueller Electronics, is used to print out information from an ISOXML task.

9-pin Sub-D plug for connection to ISOBUS

ISO printer

ISO printer socket

Plug for connection to ISO printer socket

Connector for connection to the display

CAN-Bus connection

Page 42

42

V9.20191001

31302713-02-US

6.7.2

Procedure

6.8

Procedure

6.9

Procedure

Connecting and configuring external devices

6

Configuring the Bluetooth connection in the Connection Center

Activating the ISO printer

In order to activate the ISO printer, you must activate its driver.

1. - Open the Service application.

2. Tap "Driver".

3. Tap "ISOPrinter".

⇨ The installed drivers will appear.

4. Tap "ISO Printer".

5.

6. Restart the display.

- Confirm.

Configuring the Bluetooth connection in the Connection Center

If you connect a bluetooth stick to the display, you can couple the display with another bluetooth

device (e.g. a smartphone).

This allows you to use the ME ODI (Müller Elektronik Open Data Interface) [➙ 13] application.

1. Connect the USB bluetooth stick to the display.

2.

- Open the "Service" application.

3. Tap "Driver".

4. Activate the "Connection Center" driver (value: Connection Center)

5. Restart the display.

6.

- Open the "Service" application.

7. Tap on “...”.

8. Tap on “Connection Center”.

⇨ The “Connection Center” screen appears.

9. Tap on "Bluetooth".

Crop protection sensors

Crop protection sensors measure the plant requirements during operation. Depending on the sensor,

the results are transmitted as a target rate to the job computer of the fertilizer spreader or sprayer.

The display can communicate with crop protection sensors through two interfaces:

▪ ISOBUS - If a sensor communicates via ISOBUS, it is automatically detected by the display. The

target rates are transmitted directly to the job computer.

▪ Serial - If a sensor only communicates through the serial interface, you must connect it to the

serial port on the display [➙ 80]. Then you must create a virtual job computer for the sensor in

the Virtual ECU [➙ 60] app. Activate the virtual job computer before starting operation.

To work with ISOBUS sensors:

Page 43

31302713-02-US

V9.20191001

43

Procedure

Procedure

Connecting and configuring external devices

Crop protection sensors

6

1. Connect the sensor to the ISOBUS.

2. Follow the instructions from the sensor manufacturer. The display does not need to be

configured.

To work with serial connection sensors:

1. Connect the sensor to the serial port of the display.

2. Create a virtual job computer in the Virtual ECU app. [➙ 60]

3. In the "External controller" [➙ 61] parameter, select the sensor type.

4. Activate the job computer for the sensor.

⇨ You have activated the sensor.

⇨ The display transmits all target rates to ISOBUS-TC, the ISOBUS job computer and TRACK-

Leader.

Special case

If you are working with your machine in mixed operation, with ISOBUS and serially connected

sensors, you must observe the following sequence:

The serial sensor is connected to the serial interface of the display.

1. Connect the ISOBUS components to the ISOBUS.

2. Start the Virtual ECU [➙ 60] app.

3. Create a virtual job computer in the Virtual ECU app. [➙ 60]

4. In the “External controller” [➙ 61] parameter, select the sensor type.

5. Activate the job computer for the sensor.

⇨ You have activated the sensor.

6. Set the connectors in the list of connections.

⇨ The display transmits all target rates to ISOBUS-TC, the ISOBUS job computer and TRACK-

Leader.

Page 44

44

V9.20191001

31302713-02-US

7

7.1

Procedure

7.2

Procedure

Configuring the display in the Service application

7

Changing the language

Configuring the display in the Service application

Changing the language

If you change the language in the Service application, you also change the language for all

applications and the ISOBUS job computer.

If a connected ISOBUS job computer cannot activate the selected language, a standard language will

be activated.

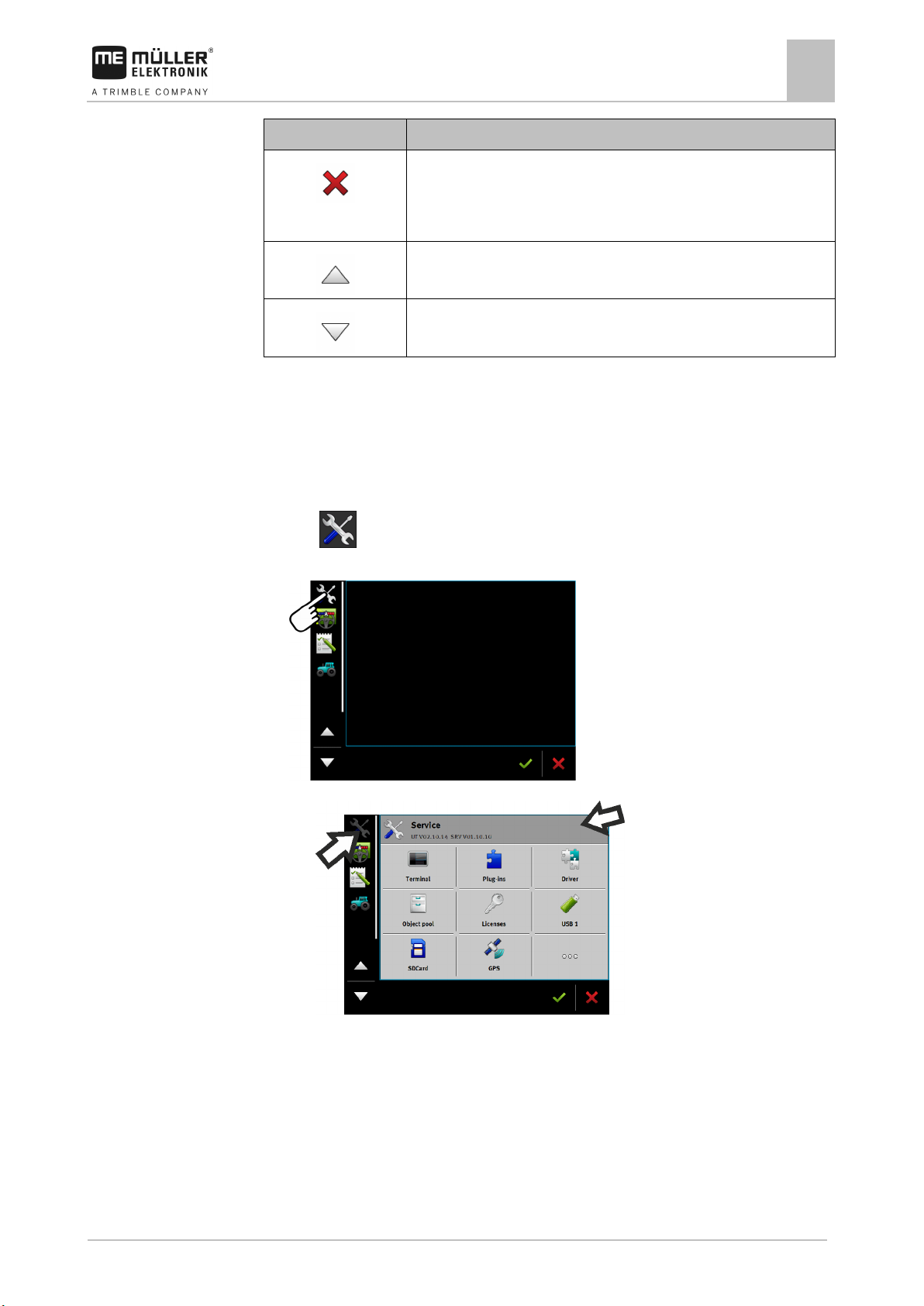

1. - Open the Service application.

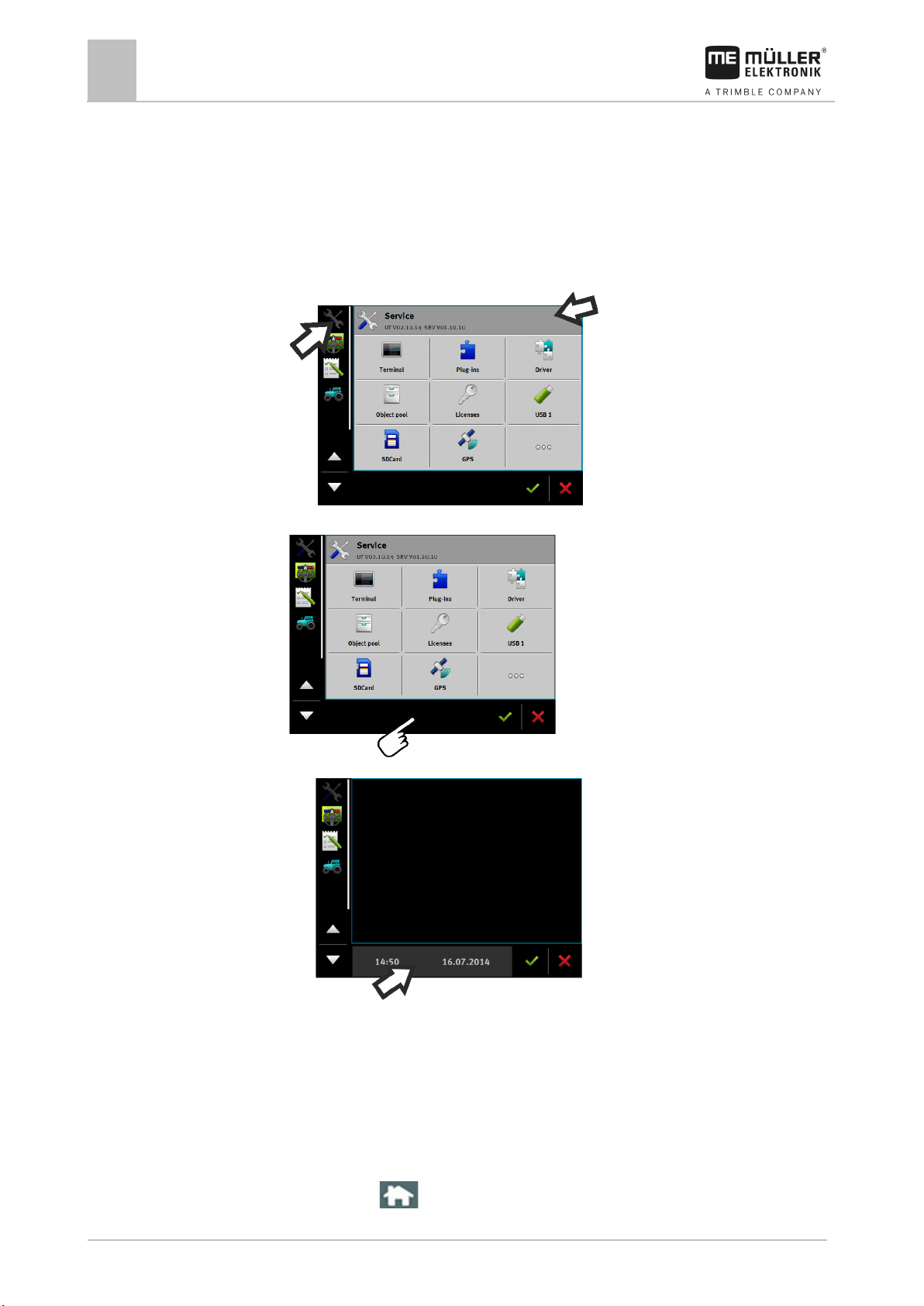

⇨ The application start screen will appear:

2. Tap "Terminal".

⇨ A list of parameters will appear.

3. Slide your finger over the display screen from the bottom to the top.

⇨ New parameters appear.

4. Tap "Language" (“Sprache”).

⇨ A list of abbreviations of available languages will appear.

5. Tap the abbreviation for your language.

⇨ The abbreviation is marked with a green dot.

6.

- Confirm.

⇨ The "Terminal" screen will appear.

7. Restart the display.

Basic display settings

The basic settings include: Language, Time, Measurement units.

All settings which you make here will also apply to other applications and in connected ISOBUS job

computers.

1. - Open the Service application.

Page 45

31302713-02-US

V9.20191001

45

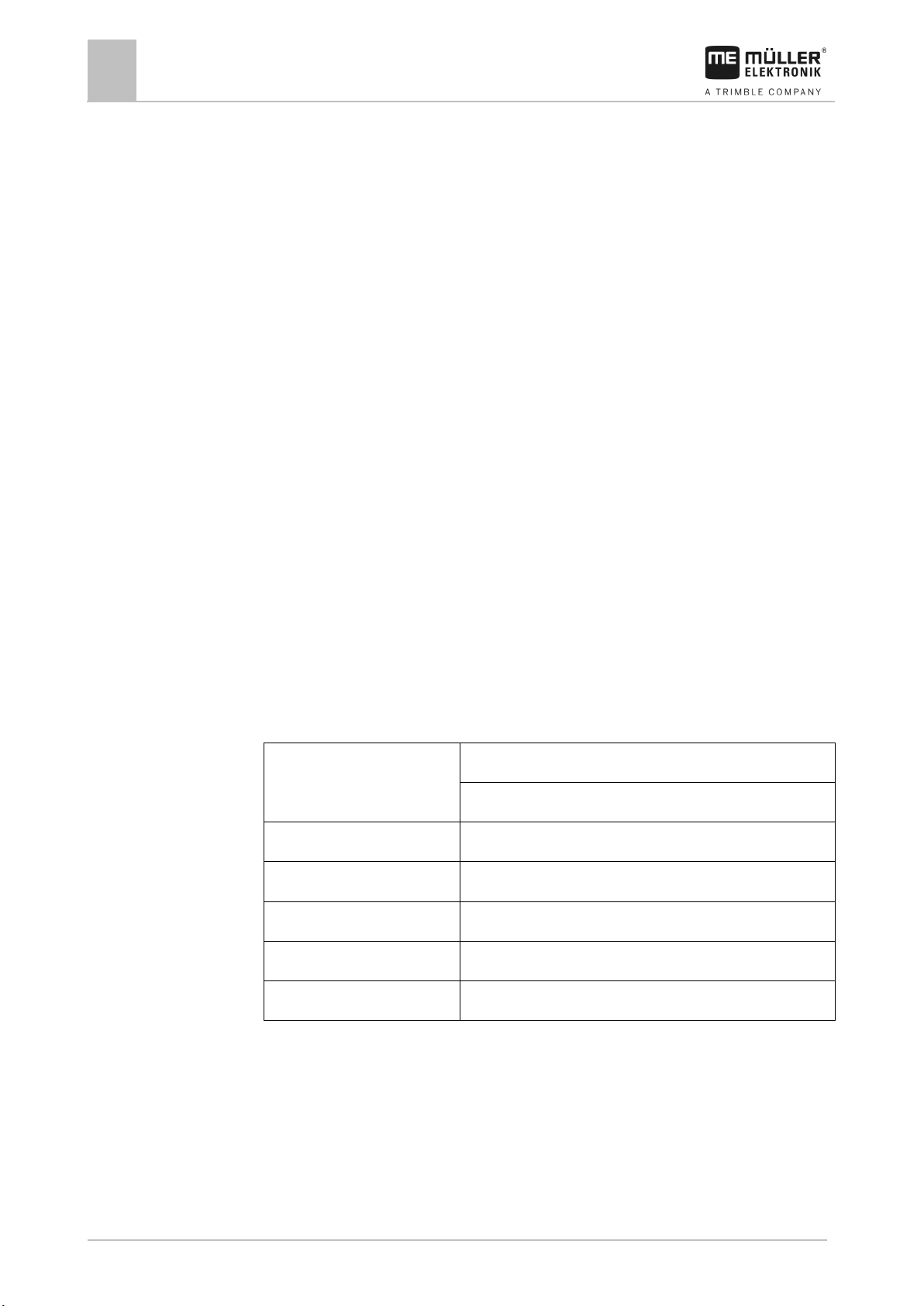

Parameter name

Function

Brightness Day

Brightness of the display screen during the day.

Brightness Night

Brightness of the display screen at night.

Keyboard brightness

Lighting of the icons.

Volume

Volume of the display.

Date

Current date.

Time

Current time.

Time zone

Time difference in relation to GMT.

Language

Language of the applications on the display screen.

Measurement units

Measurement system.

the display.

Number that should be given to the display on the ISOBUS.

the parameter must be deactivated.

Configuring the display in the Service application

Basic display settings

7

⇨ The application start screen will appear:

2. Tap "Terminal".

⇨ A list of parameters will appear. See the table below.

3. To change the value of any of the parameters, tap the desired parameter.