Page 1

Installation and operating instructions

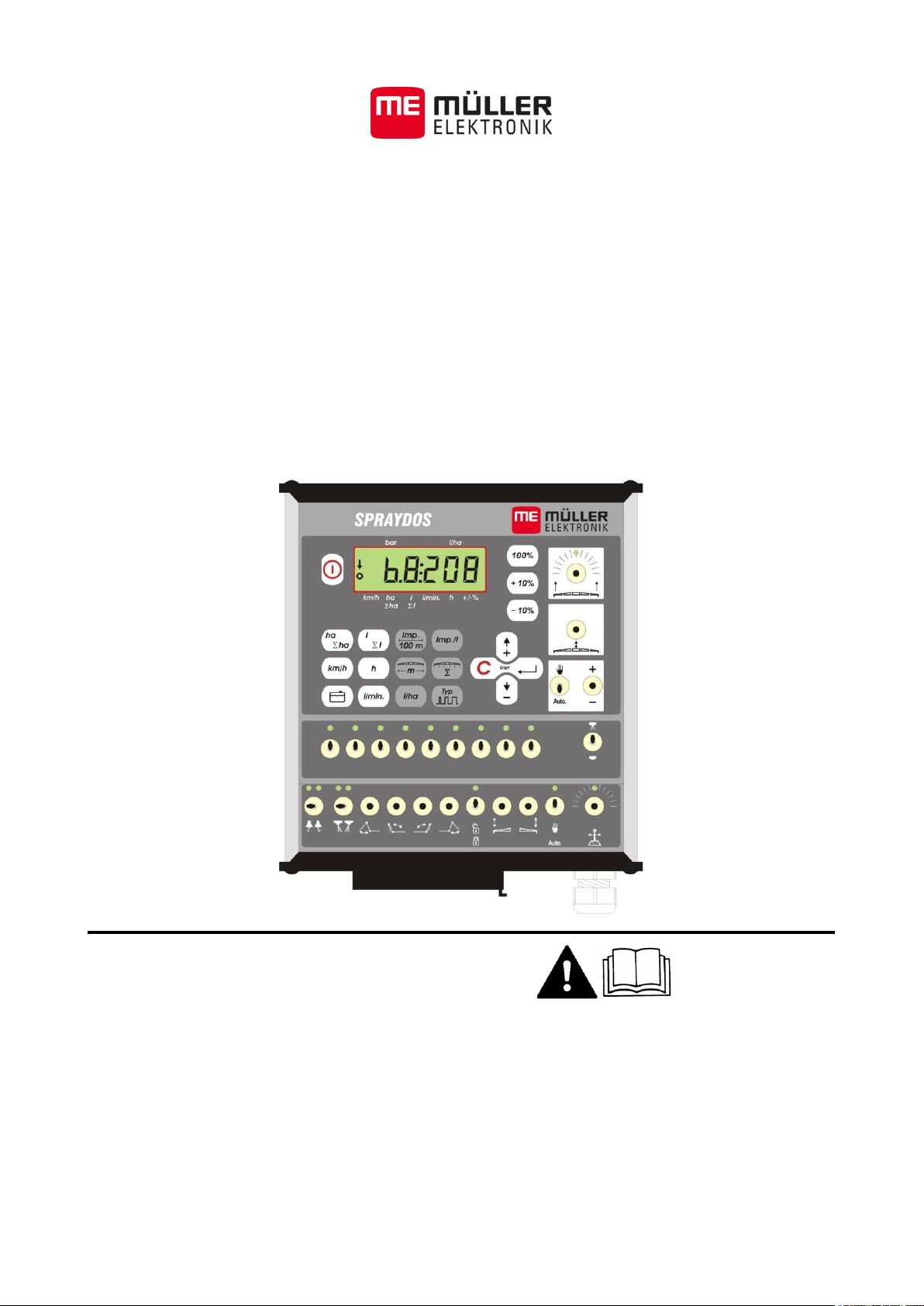

SPRAYDOS

Version: V2.20160707

30221021-02-EN

Read and follow these operating instructions.

Keep these operating instructions in a safe place for later

reference.

Page 2

Company details

Document: Installation and operating instructions

Product: SPRAYDOS

Document number: 30221021-02-EN

As of software version: 15.10.13

Original language: German

Müller-Elektronik GmbH & Co.KG

Franz-Kleine-Straße 18

33154 Salzkotten

Germany

Phone: ++49 (0) 5258 / 9834 - 0

Fax: ++49 (0) 5258 / 9834 - 90

Email: info@mueller-elektronik.de

Homepage: http://www.mueller-elektronik.de

Page 3

Table of contents

1 INTRODUCTION ......................................................................................................................................... 5

2 SAFETY INSTRUCTIONS .......................................................................................................................... 6

2.1 Intended use .............................................................................................................................................. 6

2.2 Basic safety instructions .......................................................................................................................... 6

2.3 Layout and meaning of warnings ............................................................................................................ 6

2.4 Safety notice for the subsequent installation of electrical

and electronic devices and /or components ........................................................................................... 7

3 EC DECLARATION OF CONFORMITY ..................................................................................................... 8

4 OVERVIEW AND SYSTEM DESCRIPTION ............................................................................................... 9

4.1 Overview ..................................................................................................................................................... 9

4.2 System description ................................................................................................................................. 11

5 INSTALLATION INSTRUCTIONS ............................................................................................................ 12

5.1 Console and computer ............................................................................................................................ 12

5.2 Battery connecting cable [6] .................................................................................................................. 12

5.3 Sensor X (calculation of the distance) .................................................................................................. 14

5.4 Adapter cable for tractors with signal socket ....................................................................................... 14

5.5 Connection on the field sprayer ............................................................................................................. 15

6 OPERATING INSTRUCTIONS ................................................................................................................. 16

6.1 Function description ............................................................................................................................... 16

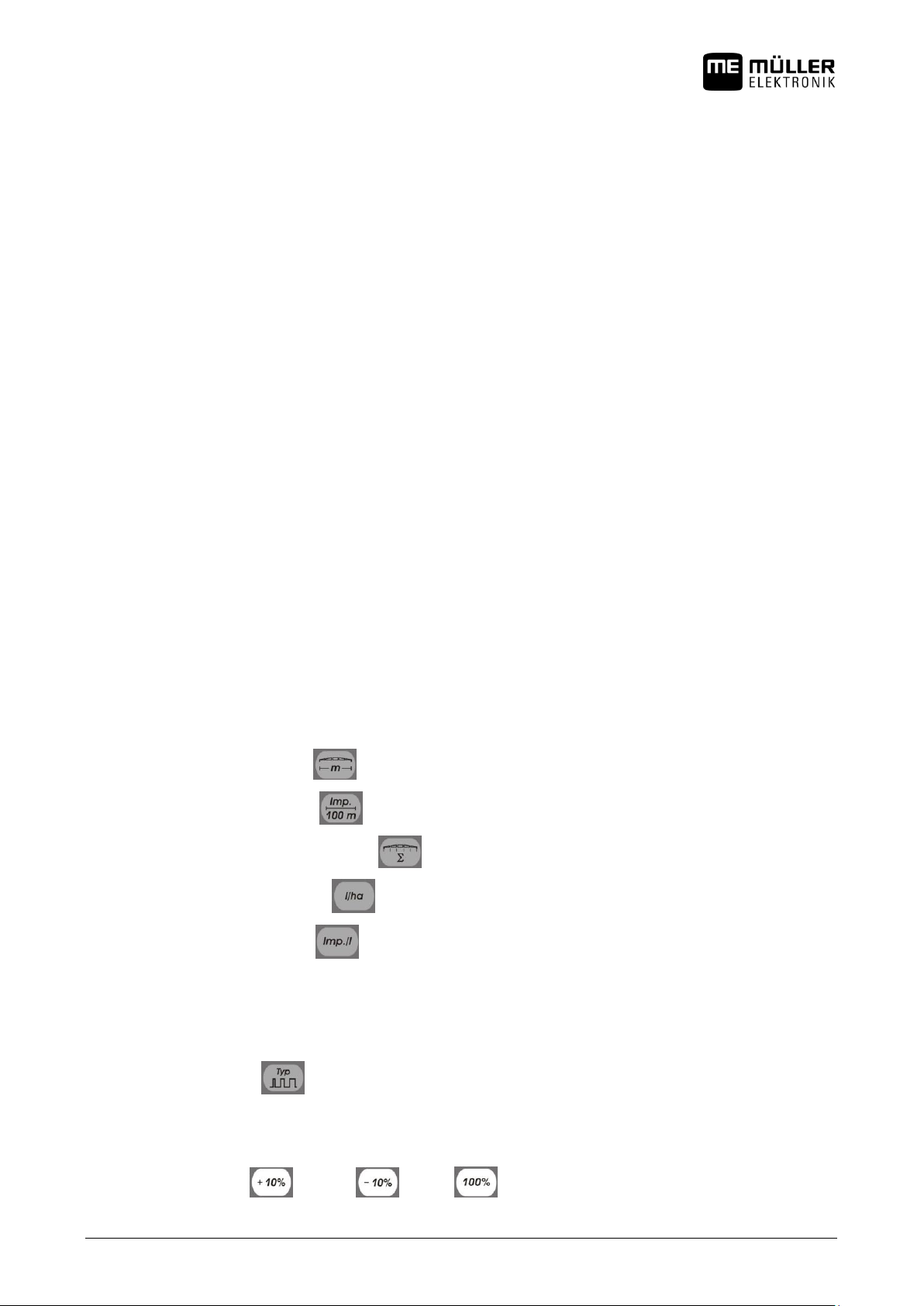

6.2 Description of the input of machine data .............................................................................................. 16

6.2.1 "Working width" key ...................................................................................................................... 16

6.2.2 "Impulses/100m" key .................................................................................................................... 17

6.2.3 "Number of boom sections" key ................................................................................................... 17

6.2.4 "Pre-set rate - l/ha" key ................................................................................................................. 17

6.2.5 "Impulses / litre" key ..................................................................................................................... 18

6.2.5.1 Impulses per litre input .............................................................................................................................. 18

6.2.5.2 Tank method .............................................................................................................................................. 18

6.2.5.3 Nozzle method ........................................................................................................................................... 18

6.2.6 "Type" key .................................................................................................................................... 19

6.2.6.1 Manifold type ............................................................................................................................................. 19

6.2.6.2 Control constants ....................................................................................................................................... 20

6.2.7 "+ 10 %" , "- 10 %" ,"100 %" keys ..................................................................... 21

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 3 -

Page 4

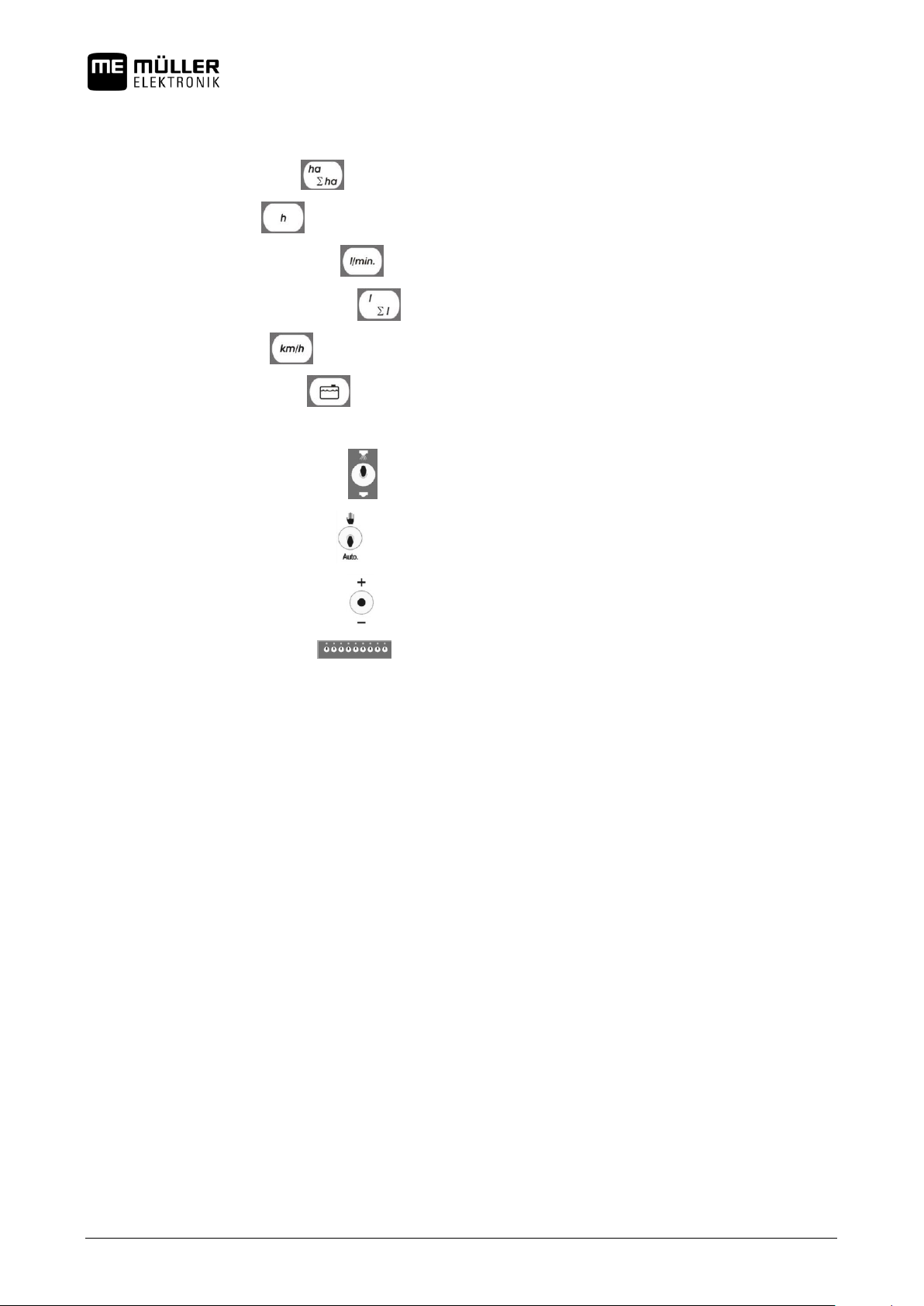

6.3 Description of the operating data keys ................................................................................................. 21

6.3.1 "Start function" ........................................................................................................................................... 21

6.3.2 "Area / total area" ......................................................................................................................... 21

6.3.3 "Time" key .................................................................................................................................... 21

6.3.4 "Spraying fluid l/min" key .............................................................................................................. 21

6.3.5 "Spraying fluid l and l" key ......................................................................................................... 21

6.3.6 "Speed" key .................................................................................................................................. 22

6.3.7 "Tank content" key ........................................................................................................................ 22

6.4 Spraying function switch ........................................................................................................................ 22

6.4.1 Boom section main switch ................................................................................................................ 22

6.4.2 Manual/automatic switch ................................................................................................................... 22

6.4.3 Spraying pressure +/- key ................................................................................................................. 22

6.4.4 Boom section switch ............................................................................................................ 23

6.4.5 Configuring the section switches ............................................................................................................... 23

6.5 Hydraulic functions switch ..................................................................................................................... 23

6.5.1 Short SPRAYDOS version ........................................................................................................................ 23

6.5.2 Long SPRAYDOS version ......................................................................................................................... 23

6.6 Operating procedure ............................................................................................................................... 23

6.7 Calibrating hydraulic functions .............................................................................................................. 24

6.7.1 Activating calibration mode ........................................................................................................................ 25

6.7.2 Calibrating the boom control ...................................................................................................................... 25

6.7.3 Calibrating the drawbar steering ................................................................................................................ 26

7 MAINTENANCE ........................................................................................................................................ 28

7.1 Computer .................................................................................................................................................. 28

7.2 Flow meter ................................................................................................................................................ 28

8 APPENDIX ................................................................................................................................................ 29

8.1 Technical data .......................................................................................................................................... 29

8.1.1 Long SPRAYDOS version ......................................................................................................................... 29

8.1.2 Short SPRAYDOS version ........................................................................................................................ 29

9 LIST OF DIAGRAMS ................................................................................................................................ 30

Page - 4 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 5

1 Introduction

The SPRAYDOS board computer is a new development on the basis of the well tried and tested SPRAY-Control board

computer. The SPRAYDOS has up to 9 boom section switches with a main switch, the manual or automatic regulation of

the spray rate and up to 4 hydraulic functions (the long version allows a further 10 hydraulic functions as soon as foam

marker and corner nozzles). The current speed and the current spray rate are displayed simultaneously.

If an automatic pressure sensor is installed, the pressure is displayed instead of the speed. The speed appears on the

display when the km/h key is pressed for about 5 seconds. Specific applications can be carried out by pressing the +/- 10%

key. The pre-set rate resets by means of the l/ha key. The spray rate is adhered to accurately even when the speed varies.

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 5 -

Page 6

WARNING

This signal word identifies medium-risk hazards, which could potentially cause death or serious

physical injury, if not avoided.

CAUTION

This signal word identifies low-risk hazards, which could potentially cause minor or moderate

physical injury or damage to property, if not avoided.

2 Safety instructions

2.1 Intended use

The SPRAYDOS is specified exclusively for agricultural use and in wine, fruit and hop growing. The manufacturer

takes no responsibility for any installation or application outwith this area.

The manufacturer does not accept liability for damage to persons or property resulting from unspecified use. In

such cases all risks are the responsibility of the user.

Specified implementation also includes adhering to the operation and maintenance requirements stipulated by the

manufacturer.

Relevant accident prevention regulations as well as other generally recognised safety, industrial, health and road

traffic rules are to be adhered to. In addition the manufacturer accepts no liability in cases where arbitrary

modifications have been made to the device.

2.2 Basic safety instructions

Observe the following recommended precautions and safety instructions:

Do not remove any safety devices or labels.

Before using the SPRAYDOS read and understand this guide. It is of equal importance that others operating this

device also read und understand the manual.

During maintenance or when using a battery charger, switch off the power supply.

Never service or repair the device while the job computer is switched on.

Before welding on the tractor or on an attached machine, interrupt the power supply to the SPRAYDOS.

Only use a soft damp cloth with clear water or a little glass cleaning agent to clean the SPRAYDOS.

Operate the keys with your finger tips but avoid using fingernails.

Should any part of this guide remain incomprehensible after reading, contact the dealer or Mueller-Elektronik

Service for further clarification before using the SPRAYDOS.

Read carefully all safety instructions in the manual.

Learn how to operate the SPRAYDOS correctly. Nobody is to operate the machine without exact instructions.

Keep the SPRAYDOS and the spare parts in good condition. Unspecified alterations can impair the function and/or

safety and affect the life span of the machine.

2.3 Layout and meaning of warnings

All safety instructions found in these Operating Instructions are composed in accordance with the following pattern:

Page - 6 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 7

NOTICE

This signal word identifies actions which could lead to operational malfunctions if performed

incorrectly.

These actions require that you operate in a precise and cautious manner in order to produce

optimum work results.

2.4 Safety notice for the subsequent installation of electrical and electronic devices

and /or components

Present-day agricultural machines are equipped with electronic components and devices, whose function can be affected

by electromagnetic emission from other devices. These influences can lead to endangerment for individuals when the

following safety measures are not adhered to.

When subsequently installing electrical and electronic devices and/or components in a machine with a connection to the

electrical system, the user must take sole responsibility for testing the installation for interference of the vehicle electronics

or other components. This applies in particular to the electronic controls of:

EHR

Front lifting gear

Power take-off shafts

Motor

Gears

Above all it must be ensured that all subsequently installed electrical and electronic components comply with the current

version of the EMC directive 89/336/EWG and carry the CE symbol.

In addition the following requirements must be fulfilled when upgrading with mobile communication systems (e.g. radio,

telephone):

Only approved devices complying to national regulations (e.g. BZT approval in Germany) are to be installed;

The device must be securely installed;

The use of portable or mobile devices inside the vehicle is permissible only via a connection to a permanently

installed outside antenna;

The transmitting unit is to be installed in a position away from the vehicle electronics;

An antenna should only be installed professionally ensuring that there is a good earth connection between the

antenna and the vehicle chassis.

Please refer to the manufacturer's installation instructions for cabling and installation as well as the maximum current

consumption.

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 7 -

Page 8

3 EC declaration of conformity

This product has been manufactured in conformity with the following national and harmonised standards as specified in the

current EMV Directive 2004/1008/EG:

Dieses Produkt ist in Übereinstimmung mit folgenden nationalen und harmonisierten Normen im Sinne der EMV-Richtlinie

2004/108/EG hergestellt:

EN ISO 14982

Page - 8 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 9

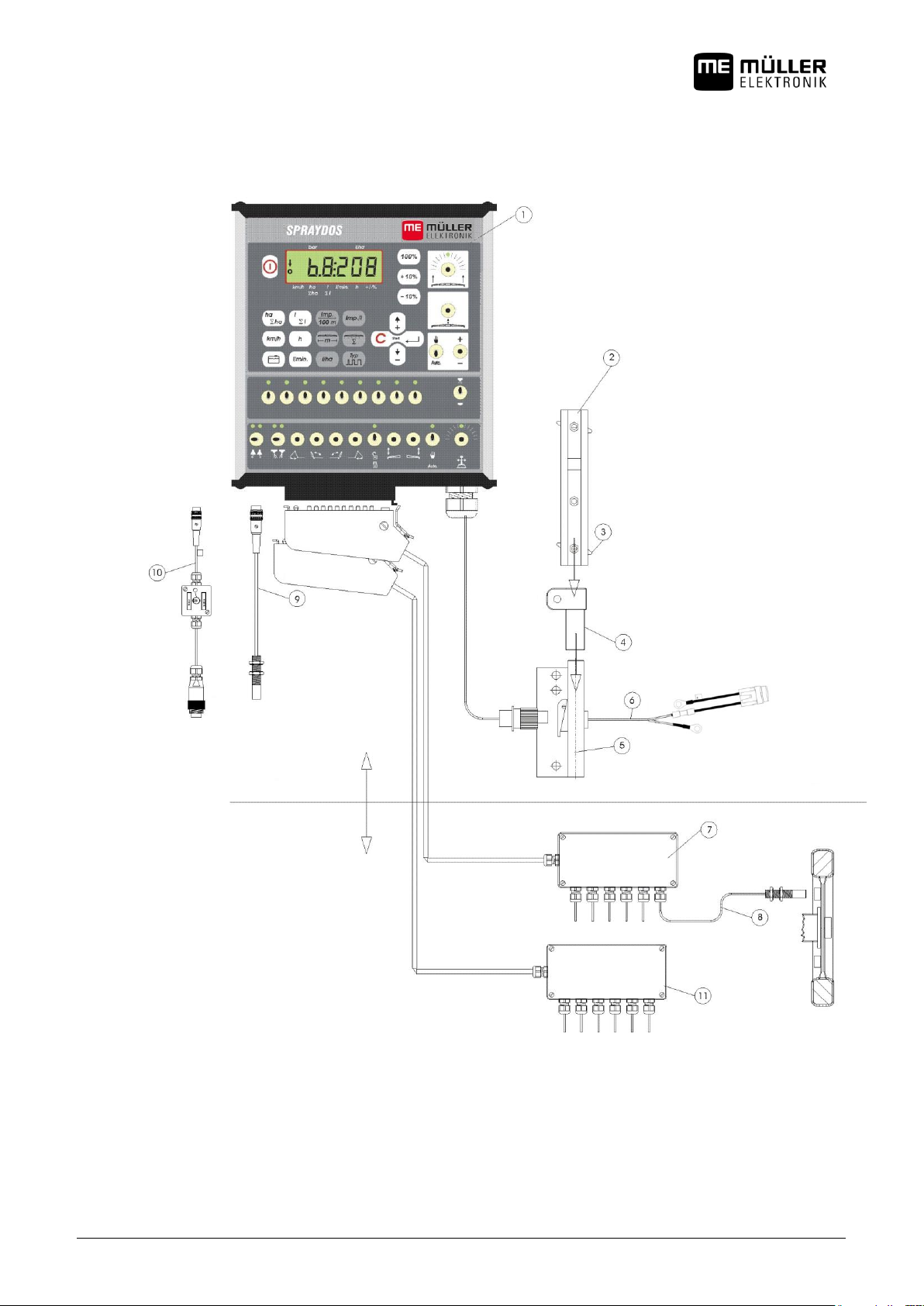

Machine plug

manifold

Machine plug

hydraulic

Basic console

Continuos current socket

DIN 9680

brown

blue

Bracket

Sensor X (Wheel)

Machine signal

distributor for sprayer

Hydraulic signal

distributor – long

SPRAYDOS version

Tractor

Implement

Signal socket

Sensor X

4 Overview and system description

4.1 Overview

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 9 -

Diagram 4-1 SPRAYDOS overview

Page 10

Übersicht

[1] SPRAYDOS computer

[2] Cap profile rail for mounting the SPRAYDOS

[3] Wing screw to secure the computer

[4] Bracket S for mounting the cap profile rail

[5] Basic console, to be mounted on the tractor cabin. For fitting the bracket with cap profile rail and battery connection.

[6] Battery connecting cable for the SPRAYDOS voltage supply, connection to a 12-volt battery.

[7] Machine signal distributor

Combines the sensor and actuator connections on the machine.

[8] Sensor X (wheel) records distance impulses on the trailed field sprayer.

[9] Sensor X (cardan shaft / wheel)

records speed, impulses on the cardan shaft or front tractor wheel.

[10] Plug for tractor signal socket

records the signals from the installed sensors on the tractor.

[11] Hydraulic signal distributor

Combines the hydraulic connections on the machine (for SPRAYDOS – long version).

Page - 10 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 11

CAUTION

If the SPRAYDOS is being used on a trailed field sprayer, no speed sensor is to be connected to

the SPRAYDOS. In this case the speed is measured at the wheel of the field sprayer.

CAUTION

During transport the SPRAYDOS must be switched off.

If available, the drawbar or axle steering must be set to centre position during transport.

4.2 System description

The SPRAYDOS can be installed on the field sprayer as a fully automatic control instrument. The device carries out an

area-related control of the spray rate regardless of the current speed, the working width and the pre-set rate.

The calculation of the current spray rate, speed, working area, total area, quantity spray as well as the total quantity and the

working time is carried out continuously.

The device consists of the computer [1] and the console [2-5].

A wheel/cardan speed sensor [9] can be connected directly to SPRAYDOS in order to determine the speed.

The SPRAYDOS can be connected directly to the signal socket [10] on the tractor using a connecting cable. By means of a

switch integrated in the connecting cable it is possible to switch between wheel/cardan and a radar device.

The field sprayer is connected by means of the machine plug (circulation, hydraulic) on the SPRAYDOS.

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 11 -

Page 12

VORSICHT

Please ensure that the computer casing [1] has a lead connection to the tractor's chassis above the

console [2-5]. When mounting, remove the paint from the mounting points.

Brown cable core

Blue cable core

Free end of the butt connector

Loose ring tongue – ground/0V

Ring tongue +12V

WARNING

Risk of injury caused by short circuit

Connecting the positive terminal and the vehicle mass when working on the battery terminals can

cause a short circuit. This can cause burn injuries to persons.

◦ When working on the battery terminals, ensure that no connection is created between the

vehicle battery and the vehicle mass.

◦ Remove metallic items such as watches and rings before starting work.

◦ When disconnecting the terminals, always begin with the negative terminal.

◦ Always begin reconnecting the terminals with the positive terminal.

5 Installation instructions

5.1 Console and computer

The basic console [5] must be mounted vibration-free and electroconductive to the cabin on the driver's right-hand side

and within his visual range and reach. The distance to the radio or to the radio antenna should be at least 1 m.

Attach the bracket [4] to the tube of the basic console.

Mount the cap profile rail [2] on to the bracket. Push the SPRAYDOS computer [1] from above on to the profile and

secure using the wing nuts [3].

The console can be swivelled to allow the display to be adjusted to the optimal angle of vision which lies between 45° and

90° from below.

5.2 Battery connecting cable [6]

Page - 12 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 13

WARNING

Danger of injury from explosion of the vehicle battery

If the battery terminals are loose fitting, starting the vehicle can cause the vehicle battery to

overheat. The vehicle battery may then explode.

◦ Always tighten the battery terminals firmly after assembly.

CAUTION

Damage to the vehicle’s electrical system

Switching the polarity of the cables can cause damage to the vehicle’s electrical system.

◦ Pay attention to the polarity of the cable cores and the terminals.

CAUTION

The negative pole on the battery must be connected to the tractor's chassis.

> Ensure that the vehicle is switched off.

> Insert the blue cable core into the 0V ring tongue .

> Insert the brown cable core into the free end of the butt connector .

> Pinch with a crimping tool.

>

Shrink both of the butt connectors with a heat source (e.g. hot air gun) until the adhesive emerges.

> Connect the ring tongues to the battery terminals of the vehicle battery. Pay attention to the polarity, beginning with

the positive terminal.

> Fasten the battery cable with cable ties. Ensure that there is sufficient distance from moving parts and parts

generating large amounts of heat.

Operating voltage is 12 V and must be taken directly from the battery or from the 12-volt starter. Care should be taken

when laying the cable [6] and it should be shortened if necessary. The crimpon ring terminal for the ground line (blue) and

the end sleeve for strands for the + line (brown) should be fitted using suitable pliers. The end sleeve for strands for the +

line are in the connection clamp of the fuse holder.

brown = + 12 volts

blue = ground

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 13 -

Page 14

CAUTION

If an X sensor is connected in the machine distributor, no sensor is to be connected to the

SPRAYDOS.

5-10 mm

Diagram 5-1 Sensor X at the cardan

shaft

Magnet (rote Seite)

5 - 10 mm

Sensor-X

Diagram 5-2 Sensor X on the tractor's wheel

5.3 Sensor X (calculation of the distance)

Mounting on four-wheel drive tractors:

Mount the hose clamp with a magnet to the cardan shaft.

The sensor must point in the direction of the magnets at a distance

between 5 – 10 mm. It is to be mounted vibration-free.

Mounting on tractors without without four-wheel drive:

Install the magnets in the wheel shell using V4A screws

provided, distributing them evenly over the circumference.

The number of magnets depends on the size of the wheel.

The distance travelled from impulse to impulse must not

exceed 60 cm.

Calculation:

Wheel circumference ÷ 60 cm = number of magnets

e.g.: 256 cm ÷ 60 cm = 4.27 = min. 5 magnets

Mount the sensor to the steering knuckle using the bracket

provided so that the end of the sensors is pointing towards the

magnets. The distance should be 5-10mm

Mounting on the wheel of the trailed sprayer

Mount the sensor on the wheel of the field sprayer in the same

way as on the wheel of the tractor (see diagram 5.2). In this

case the electrical connection is in the machine distributor

manifold.

5.4 Adapter cable for tractors with signal socket

In this case it is not necessary to install the X sensor. The SPRAYDOS is connected to the tractor's signal socket using the

adapter cable [10].

Page - 14 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 15

5.5 Connection on the field sprayer

The attached or trailed field sprayer is connected via a 39 channel machine plug manifold. With the SPRAYDOS long

version the machine plug – hydraulic must be connected in addition.

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 15 -

Page 16

6 Operating instructions

6.1 Function description

Display

Diagram 6-1 Display

During normal operation, the operating mode is always displayed on the monitor. There are two alternatives:

1. Pressure sensor is not connected

on the left hand side of the monitor the speed is displayed and an arrow appears above . The current spray

rate is shown on the right hand side of the monitor.

2. Pressure sensor is connected

on the left hand side of the monitor the current spraying pressure in bar is displayed. The current spray rate in l/ha is

displayed on the right hand side. If the spray rate exceeds 1000 l/ha, the rate is displayed with four digits and the

pressure with just two digits.

With both display alternatives, an arrow on the left shows that the sprayer is switched on. Below this a circle flashes when

impulses are being measured by the speed sensor.

The operating mode is interrupted for 10 seconds when a key is pressed to display another value. For each further key

pressed, the time counter is extended again for 10 seconds.

Keyboard

The keyboard is divided into different areas.

- Operating data

This block of keys is used to recall required data. By pressing the simultaneously, the order is

started. All counters except ha and l are set to 0.

- Machine data

This block of keys is used to communicate the machine data to the computer. Using the keys it is

possible to vary the spray rate in degrees of 10% in relation to the set rate.

- Input keys

to enter and alter machine data, the keys and are used.

6.2 Description of the input of machine data

Before the device can put into operation, the machine-specific data must be entered:

6.2.1 "Working width" key

This key is used to enter the working width

Page - 16 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 17

> Press the „working width " key

> > Enter the value using the keys and

> > Press to transfer the new value

6.2.2 "Impulses/100m" key

With this key the number of impulses which the speed sensor records to the computer is entered.

There are two possibilities to enter the data:

1. The impulses/100m value is known

> Press

> Enter the value using the keys and

> Press to transfer the new value

2. The impulses/100m value is not known

> Measure out and mark a distance of 100m on the field

> Bring the vehicle to the start position

> Press and simultaneously

> Travel a distance of 100m and stop. The computer counts the impulses during the journey

> Press to transfer the new value

6.2.3 "Number of boom sections" key

This key is used to enter the number of boom sections (max. 9) and the number of nozzles for each boom section.

The boom sections are numbered from left to right as seen from the direction of driving.

During input, the boom sections are displayed on the left hand side and the number of nozzles on the left hand side.

Procedure:

> Press

on the left a 1 (boom section 1) is displayed and on the right the number of nozzles.

> To alter the number of nozzles, enter the new value using the keys and .

> Press

the value is now stored in the memory. On the left hand side of the display a 2 (boom section 2) appears. If the

value – number of nozzles – on the right hand side of the display is correct, press to transfer the value and

select boom section 3. This process can be carried on until the 9th boom section is reached. Subsequently the total

number of boom sections and nozzles will be displayed.

> If e.g. the field sprayer has 5 boom sections, enter a 0 when the 6

sets the boom sections 7-9 automatically to 0. In this case the computer operates on the basis of 5 boom sections

and displays the number of boom sections and the total number of nozzles as 5:30.

th

boom section is displayed. The computer then

6.2.4 "Pre-set rate - l/ha" key

The required spray rate is communicated to the computer using this key. If the switch is in automatic position the

electronics control the pressure and subsequently the spray rate automatically.

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 17 -

Page 18

If, due to a fault (e.g. tank empty) the pre-set rate is not achieved, an alarm is set off.

Input value

> Press

> Enter the value using the keys and

> Press to transfer the new value

The value entered is controlled by pressing again.

6.2.5 "Impulses / litre" key

Direct input of impulses per litre or a calibration of the flow meter can be carried out here. The various possibilities are

described in the chapters 6.2.5.1 - 6.2.5.3.

6.2.5.1 Impulses per litre input

If the number of flow meter impulses per litre is known, the value can be entered directly.

1. The value impulses/litre is known:

> Press

> Enter the value using the keys and

> Press to transfer the new value

6.2.5.2 Tank method

With the tank method calibration is carried out by weighing the entire field sprayer before and after spraying. The procedure

is as follows:

> Fill the tank with water and determine the quantity (weigh).

> Press and simultaneously

> While stationary, switch on the field sprayer using and spray a few hundred litres.

(The computer now counts the flow meter impulses). All sections must be open.

> Switch off the sprayer using

> Determine the amount sprayed (reweigh).

> Set the value using the keys and

> Press to transfer the new value

> The computer calculates the "impulses / litres"

The flow meter impulse number should be checked several times a year especially before each season.

6.2.5.3 Nozzle method

With the nozzle method the quantity sprayed is measured at a nozzle and projected to the total number of nozzles. The

procedure is as follows:

> Fill the tank with water.

> Secure a measuring jug below a nozzle.

Page - 18 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 19

Parameter

Manifold type

0.15

Balanced pressure manifold without reflux measurement

1.15

Manifold without balanced pressure function.

2.15

Balanced pressure manifold with reflux measurement

3.15

Spraying devices without balanced pressure function

Manifold type (number before the comma)

> Press and simultaneously

> While stationary switch on the field sprayer using until the measuring jug has been filled with e.g. 2 litres (the

computer counts the flow meter impulses). All sections must be open.

> Switch off the sprayer using

> Determine the amount sprayed

(read the quantity in the measuring jug and multiply by the number of nozzles)

> Set the value calculated using the keys and

> Press to transfer the new value

> The computer has now calculated the "impulses / litres"

6.2.6 "Type" key

This key is used to enter 2 functions. The number before the comma determines the manifold type. The 2 positions after

the comma determine the control constant.

> Press

> Set the value using the keys and

> Press to transfer the new value

6.2.6.1 Manifold type

The manifold type is communicated to the computer via the number before the comma.

The following manifold types are taken into account (in the example a control constant of 15 is assumed):

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 19 -

Page 20

CAUTION

The valves on the balanced pressure manifold must be set accurately.

Balanced pressure manifold without reflux measurement

The manifold is equipped with electrovalves and separate balanced pressure valves (e.g. Tecnoma-Elektra). The spraying

fluid which flows back to the tank via the balanced pressure valves when the boom section is switched off is not recorded

by the flow meter.

Manifold without balanced pressure function

The manifold is equipped with motor or electromagnetic valves.

Only the quantity sprayed via the spray bar is measured by the flow meter even when the boom section is switched off.

If, at the end of the field with the sprayer switched off, one or more boom sections are switched off, the computer takes a

pre-setting via the control valve. Fine-tuning then takes place once the field sprayer has been switched on.

Balanced pressure manifold with reflux measurement

The manifold can be equipped with either motor or electromagnetic valves. When boom sections are switched off the flow

meter also measures the amount which flows back to the tank. The computer takes this into account when calculating the

quantity sprayed depending on the number of nozzles per boom section.

Example: Field sprayer with 5 boom sections

One boom section is switched off; only 4/5 of the total quantity is recorded

(1/5 flows back into the tank).

Spraying devices without balanced pressure function

This setting takes into account the specific features of spraying devices for use in fruit, wine and hops production. In this

case the quantity and not the working width is altered when the upper nozzle segments are switched off. If one side of the

device is completely switched off, the working width is halved.

6.2.6.2 Control constants

Depending on the fabrication and the size of the sprayer different control times are required when there is a certain

deviation from the pre-set value.

The computer calculates the control time with which the control valve is driven. The control time is determined by the

control constant.

> Regulation too sluggish -> enter a highter value

> Regulation overdrive -> enter a lower value

The control constant is optimally selected, when, in the case of a deviation from the pre-set value, one control process is

sufficient for the computer to get to the proximity of the pre-set value and then fine tune by means of a few small processes.

Regulation can be seen in the display l/ha.

Control constants can be within the range of 1 to 99.

See also 6.2.6.1 "Manifold types".

Page - 20 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 21

6.2.7 "+ 10 %" , "- 10 %" ,"100 %" keys

During operation the sprayed rate can be adjusted in degrees of 10% in relation to the pre-set rate by using the keys

and . An arrow in the display above shows that a manual adjustment of the spray rate has been

carried out.

By pressing the key, a manual adjustment of the spray rate by means of the keys is cancelled out

again. The value entered with the key is once again set as the pre-set value. The file above disappears

again.

6.3 Description of the operating data keys

6.3.1 "Start function"

The start function is activated by pressing the keys , i.e. the memory for the area, spraying fluid and time is

set to "0". Time starts automatically when this key is pressed. This function is to be carried out before each job.

6.3.2 "Area / total area"

This key has a dual function. When the key is pressed for the first time, the area covered since activating the start function

is displayed for 10 seconds. In addition an arrow appears at the bottom of the display above . If, within 10 seconds the

key is pressed a second time, the total area is displayed. This value is not deleted by the start function. This enables the

total area for a season to be determined. At the beginning of the season the counter is set to "0" by pressing the keys

and simultaneously.

The area calculation adapts to current conditions. Switched-off boom sections are automatically taken into account.

Measurement is interrupted as soon as the field sprayer is switched off at the main switch.

6.3.3 "Time" key

Operating time since activating the "start function" (6.3.1) is displayed when this key is pressed. An arrow appears

above .

If the computer is switched off, the input of time data is stopped. It restarts once the device has been switched on again.

The clock can also be stopped during operation. After the key has been pressed, it can be pressed once again to

stop the clock. To restart it press yet again.

6.3.4 "Spraying fluid l/min" key

Displays the flow meter litres per minute. An arrow appears above .

6.3.5 "Spraying fluid l and l" key

This key has a dual function. When the key is pressed for the first time, the quantity spray since activating the start

function (6.3.1 ) is displayed for 10 seconds. In addition an arrow appears at the bottom of the display above . If, within

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 21 -

Page 22

10 seconds the key is pressed a second time, the total number of litres is displayed. This value is not deleted by the start

function. This enables e.g. monitoring the tank content. After filling, the counter is set to "0" by pressing the keys

and simultaneously. The quantity of spraying fluid sprayed can be read during operation.

6.3.6 "Speed" key

When the sprayer is switched off, the current speed being travelled is displayed by pressing and also an arrow

appears above .

When a sprayer with an installed pressure sensor is switched on, the speed is displayed on the left-hand side of the

monitor by pressing this key for 5 seconds. In addition an arrow appears above . This key has no function when

there is no pressure sensor as, in this case, the speed is displayed permanently in the job display.

6.3.7 "Tank content" key

If a Tank-Control is connected, the tank content can be called up by pressing . The value is displayed for 10

seconds.

6.4 Spraying function switch

6.4.1 Boom section main switch

The boom section main switch switches the sprayer's main valve. When switched on, spraying begins with all switched-on

boom sections.

6.4.2 Manual/automatic switch

This switch can be used to switch between automatic and manual operation. In "Auto" position the computer controls the

spray rate automatically. If the switch is set at "Manual" the correct spraying pressure must be set manually by means of

the key.

6.4.3 Spraying pressure +/- key

This key is for manual adjustment of the spraying pressure in manual operation mode. Manual operation is selected by

means of the switch.

Page - 22 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 23

6.4.4 Boom section switch

The function of the boom section switch is to switch the individual boom sections. If a switch is off, then the corresponding

boom section is also switched off and cannot be switched on by means of the boom section main switch .

6.4.5 Configuring the section switches

If you connect a Spraydos with nine section switches to a sprayer with five sections, you can set that only every second

switch is used. In doing so, please note that the LEDs above unused switches are also illuminated as soon as they are

switched up.

Diagram 6-2 Section switches

On the left: Every second switch controls one valve (Configuration 1:0); on the right, the first five switches control

the valves (Configuration 1:1)

> Reboot the computer.

> Press the and keys (in this sequence) simultaneously.

> The current configuration appears on the display:

> Set the value using the and keys.

> Press the key to adopt the new value.

> Reboot the computer.

6.5 Hydraulic functions switch

6.5.1 Short SPRAYDOS version

The short SPRAYDOS version supports a maximum of 4 hydraulic functions. For this purpose up to 4 switches can be

mounted on the top right-hand area of the computer. The function of each of these switches is illustrated by the pictograms

on the tactile keyboard.

6.5.2 Long SPRAYDOS version

The long SPRAYDOS version has an additional row of switches underneath the section switches. Here, up to 10 hydraulic

functions as well as foam markers and corner nozzles can be accommodated. Pictograms illustrate their function.

6.6 Operating procedure

Once the machine data have been entered (6.2.1- 6.2.6), only the start function (6.3.1) has to be activated before

operation can begin. During operation all values can be called up.

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 23 -

Page 24

CAUTION

Before initial operation fill the sprayer with water (without spraying fluid). Start the field sprayer.

Subsequently check the values measured and displayed.

Magnet

The calibration mode is activated by applying a magnet onto the casing. The

magnet must be positioned exactly above the left edge of the display.

LED

Is switched off in calibration mode, and flashes to indicate completion. The

same LED is used for all of the calibrations.

The automatic mode guarantees accurate dosage. Please ensure that the pressure in connection with the drop formation

for the nozzle type in operation is maintained.

At times when the field sprayer is switched on and off, the same speed should be driven if possible to avoid brief underdosage or over-dosage after switching on the field sprayer.

If regulation is to be carried out manually, set the switch to manual. The quantity is controlled using the key.

Once the job is completed all values can be called up. A new job begins with the "start function" (6.3.1).

6.7 Calibrating hydraulic functions

If the following hydraulic functions are available, they can be calibrated by the user:

> Boom control

> Drawbar steering

Calibration serves to adapt the controller to the characteristics of the implement.

Diagram 6-3 Operating elements that are required for calibration

Page - 24 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 25

Control dial for calibrating the boom control

Control dial for calibrating the drawbar steering

- Control dial to the left

The implement component (boom/drawbar) will be moved to the left, until it

reaches a resistance (ground/stop).

- Control dial to the right

The implement component (boom/drawbar) will be moved to the right, until it

reaches a resistance (ground/stop).

- Control dial at the centre

The implement component is not moved.

6.7.1 Activating calibration mode

> Apply the magnet onto the casing, as shown in the figure above.

The LED is illuminated.

> -Within one second, turn the control dial or first 90°

to the left, then 90° to the right and then back to the centre.

The LED flashes several times. If the LED does not flash, it means that the computer was not put into

calibration mode and that you must repeat the steps.

The LED is turned off.

> Leave the magnet on the casing until the calibration is completed, unless you are prompted to lift it briefly.

> If you remove the magnet prematurely for longer than 1 second, the LED flashes briefly. The calibration will be

cancelled and the values determined during calibration are discarded.

In calibration mode, the control dials are used differently than normally:

6.7.2 Calibrating the boom control

Use the control dial for the calibration.

To calibrate the boom control:

> Activate calibration mode. See: p. 25

> First, you must teach the computer the direction in which the control dial must be turned to slope the boom to the

right. This direction depends on the electrical connection of the actuators. To do so, follow the next two steps.

> or - Slope the boom a few degrees to the right. It does not have to be sloped down to the

ground.

The boom was sloped a little to the right.

> Lift the magnet briefly and apply it again.

The LED flashes briefly.

You have taught the computer where the right side is.

> - Move the boom into a horizontal position.

The boom is horizontal.

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 25 -

Page 26

> - Turn the control dial to the centre position.

> Lift the magnet briefly and apply it again.

The LED flashes briefly.

You have calibrated the horizontal position.

> - Slope the boom as far as possible to the right.

The boom touches the ground on the right.

> - Turn the control dial to the centre position.

> Lift the magnet and apply it again.

The LED flashes briefly.

You have calibrated the slope to the right.

> - Slope the boom as far as possible to the left.

The boom touches the ground on the left.

> - Turn the control dial to the centre position.

> Lift the magnet briefly and apply it again.

The LED is illuminated.

You have calibrated the slope to the left.

The calibration is complete.

> Lift the magnet.

LED is off.

Calibration mode is terminated.

6.7.3 Calibrating the drawbar steering

Use the control dial for calibration.

To calibrate the drawbar steering:

> Put the switch to the position.

> Activate calibration mode. See: p. 25

> First, you must teach the computer direction in which the control dial must be turned to move the drawbar to the

right. This direction depends on the electrical connection of the actuators. To do so, follow the next two steps.

> or - Move the drawbar to the right.

The drawbar was moved a little to the right.

> Lift the magnet briefly and apply it again.

The LED flashes briefly.

Page - 26 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 27

You have taught the computer where the right side is.

> - Move the drawbar to the centre position.

The drawbar is centred.

> - Turn the control dial to the centre position.

> Lift the magnet briefly and apply it again.

The LED flashes briefly.

You have calibrated the centre position.

> - Move the drawbar as far as possible to the right.

The drawbar reaches the end stop at the right.

> - Turn the control dial to the centre position.

> Lift the magnet and apply it again.

> The LED flashes briefly.

You have calibrated the maximum right position.

> - Move the drawbar as far as possible to the left.

The drawbar reaches the end stop at the left.

> - Turn the control dial to the centre position.

> Lift the magnet briefly and apply it again.

The LED is illuminated.

You have calibrated the maximum left position.

The calibration is complete.

> Lift the magnet.

LED is off.

Calibration mode is terminated.

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 27 -

Page 28

7 Maintenance

7.1 Computer

The computer is maintenance-free. It has an internal safety fuse. During the winter it should be stored at room temperature

and protected from dampness.

7.2 Flow meter

Rinse the flow meter with water each time after use. At the end of the season check the run of the impeller wheel and

replace if necessary. At the beginning of each season carry out a calibration process (see 6.2.5).

Page - 28 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Page 29

Motorised version

Magnetic version

Voltage range

10.5V - 16V

10.5V – 16V

Temperature range

-20°C - +70°C

-20°C - +50°C

Tightness

IP 54

IP 54

Max. current rating

25A

25A

Typ. current rating (+23°C / +70°C)

Sensors

1.10A / 0.67A

1.10A / 0.85A

Individual sections

1.85A / 1.13A

2.50A / 1.93A

Bypass

2.50A / 1.53A

2.50A / 1.93A

Hydraulic cpl. (opt.)

6.00A / 3.66A

6.00A / 4.62A

Slope

12A

12A

Regulation - duration

4.00A / 2.44A

4.00A / 3.08A

Motorised version

Magnetic version

Voltage range

10.5V – 16V

10.5V - 16V

Temperature range

-20°C - +70°C

-20°C - +50°C

Tightness

IP 54

IP 54

Max. current rating

25A

25A

Typ. current rating (+23°C / +70°C)

Sensors

1.10A / 0.67A

1.10A / 0.85A

Individual sections

1.85A / 1.13A

2.50A / 1.93A

Bypass

2.50A / 1.53A

2.50A / 1.93A

Hydraulic cpl. (opt.)

4.00A / 2.44A

4.00A / 3.08A

Slope

12A

12A

Regulation - duration

4.00A / 2.44A

4.00A / 2.44A

8 Appendix

8.1 Technical data

8.1.1 Long SPRAYDOS version

8.1.2 Short SPRAYDOS version

Copyright Müller-Elektronik GmbH & Co.KG, Installation and operating instructions SPRAYDOS (07.2016) Page - 29 -

Page 30

9 List of diagrams

Diagram 4-1 SPRAYDOS overview .................................................................................................................................... 9

Diagram 5-1 Sensor X at the cardan shaft ........................................................................................................................ 14

Diagram 5-2 Sensor X on the tractor's wheel .................................................................................................................... 14

Diagram 6-1 Display .......................................................................................................................................................... 16

Diagram 6-2 Section switches ........................................................................................................................................... 23

Diagram 6-3 Operating elements that are required for calibration .................................................................................... 24

Page - 30 - Copyright Müller-Elektronik GmbH & Co. KG, Installation and operating instructions SPRAYDOS (07.2016)

Loading...

Loading...