Installation and operating instructions

TRACK-Guide II

Last update: V5.20130422

30302710-02-US Read and follow this operating instructions.

Keep this operating instructions for future reference.

Document

Installation and operating instructions

Product: TRACK-Guide II

Document number: 30302710-02-US

Mueller Electronics, Inc.

7700 Brush Hill Drive, Suite 103A

Burr Ridge, IL 60601

USA

Phone: +1(855) ME ISOBUS

Email: info@mueller-electronics.com

Website: http://www.mueller-electronics.com

1

For your safety

6

1.1

Basic safety instructions

6

1.2

Layout and meaning of warnings

6

1.3

User requirements

7

1.4

Intended use

7

1.5

EC declaration of conformity

7

2

About these Operating Instructions

8

2.1

Target group of these Operating Instructions

8

2.2

Layout of operating instructions

8

2.3

Layout of references

8

3

Product description

9

3.1

Performance description

9

3.2

Scope of delivery

9

3.3

Correctly interpreting information on the nameplate

10

4

Mounting and installation

11

4.1

Mounting the display in the tractor cab

11

4.1.2

Display ports

12

4.2

Connecting the display to the basic equipment

12

4.3

Connecting the display to voltage supply

12

4.4

SIM card

13

4.4.1

Inserting the SIM card

13

4.5

Connecting the GPS Receiver to the display

14

4.6

Connecting sensors to the display

16

5

Basic control principles

17

5.1

Getting to grips with the controls

17

5.2

Initial start-up

18

5.3

Configuration sequence

19

5.4

Using the function keys

19

5.5

Restarting the display

20

5.6

Inputting data

21

6

Opening applications in the selection menu

22

6.1

Display layout in the selection menu

22

6.2

Opening applications

22

6.3

Segmentation of the display

23

Contents

Contents

4.1.1 Screwing on the GSM antenna 11

Mueller Electronics, Inc. 3

7

Configuring the display in the Service application

25

7.1

Controls in the Service application

25

7.2

Icons in the Service application

26

7.3

Changing the language

26

7.4

Configuring the basic display settings

27

7.5

GPS Receiver

28

7.5.2

Configuring the GPS receiver

30

7.6

Configuring the "GPS TILT-Module" terrain compensation

32

7.7

Activating an external LightBar

33

7.8

Camera

34

7.8.1

Activating a camera

34

7.8.2

Operating the camera

34

7.9

Configuring the joystick button allocations

35

7.10

Adjusting the brightness for day or night mode

37

7.11

Activating and deactivating applications

38

7.12

Activating licenses for full versions of the software

39

7.13

Setting the purpose of the display

40

7.14

Deleting files from the USB flash drive

41

7.15

Deleting pools

41

7.16

Activating the "Diagnostics" function

42

7.16.1

Jobcomputer diagnostics

43

7.17

Screenshots

43

7.17.1

Configuring the screenshots function

43

7.17.2

Creating screenshots

44

7.18

CAN-Trace settings

44

7.19

Configuring farmpilot

45

7.19.1

Activating farmpilot

45

7.19.2

Configuring the connection with farmpilot

46

7.19.3

Configuring the GPRS connection manually

47

7.19.4

Sending diagnostic data to the portal

48

8

Tractor-ECU application

50

8.1

Adding a vehicle profile

50

8.2

Configuring the parameters for a vehicle profile

51

8.2.1

Calibrating the speed sensor

54

8.2.2

Configuring a working position sensor

55

8.2.3

Entering the position of the GPS Receiver

56

For machines fitted with an ISOBUS job computer

57

8.3

Activating vehicle profiles

58

9

ISOBUS-TC task processing

60

9.1

Adjusting how you use ISOBUS-TC

60

Contents

7.5.1 Activating the GPS Receiver 29

4 Mueller Electronics, Inc.

10

Maintenance and servicing

61

10.1

Servicing and cleaning the display

61

10.2

Disposing of the unit

61

10.3

Instructions on retrofitting

61

10.4

Checking the software version

62

10.5

Technical specifications

62

10.5.2

Pin assignment of port A

63

10.5.3

Pin assignment of port B

64

10.5.4

Pin assignment of port C

65

10.5.5

Pin assignment of camera ports 1 and 2

66

11

Notes

67

Contents

10.5.1 Technical specifications of the display 62

Mueller Electronics, Inc. 5

WARNING

bodily injury, if not avoided.

CAUTION

injury or damage to property, if not avoided.

NOTICE

optimum work results.

1

1.1

1.2

Example

For your safety

1

Basic safety instructions

For your safety

Please read the following safety instructions carefully before operating the product for the first time.

▪ Before maintenance or repair to the tractor, always disconnect the tractor from the display.

▪ Before charging the tractor battery, always disconnect the connection between the tractor and

the display.

▪ Before welding to the tractor or a trailer device, always disconnect the power supply to the

display.

▪ Do not make any unauthorized modifications to the product. Unauthorized changes or

unauthorized use may impair your safety and influence the lifespan or function of the product.

Modifications are considered unauthorized if they are not described in the product

documentation.

▪ Follow all recognised safety, industrial and medical rules as well as all road traffic laws.

Layout and meaning of warnings

All safety instructions found in these Operating Instructions are composed in accordance with the

following pattern:

This signal word identifies medium-risk hazards, which could potentially cause death or serious

Basic safety instructions

This signal word identifies low-risk hazards, which could potentially cause minor or moderate bodily

This signal word identifies actions which could lead to operational malfunctions if performed

incorrectly.

These actions require that you operate in a precise and cautious manner in order to produce

There are some actions that need to be performed in several steps. If there is a risk involved in

carrying out any of these steps, a safety warning will appear in the instructions themselves.

Safety instructions always directly precede the step involving risk and can be identified by their bold

font type and a signal word.

1. NOTICE! This is a notice. It warns that there is a risk involved in the next step.

2. Step involving risk.

6 Mueller Electronics, Inc.

1.3

1.4

1.5

For your safety

User requirements

1

User requirements

▪ Learn how to operate the display correctly. The display must not be operated by anyone who has

not read the Operating Instructions.

▪ Please read and carefully observe all safety instructions and warnings contained in these

Operating Instructions and in the manuals of any connected vehicles and farm equipment.

Intended use

The display is intended exclusively for use in agriculture as well as in wine-growing, fruit-cultivating,

and hop-growing operations. The manufacturer cannot be held responsible for any installation or use

of the display that deviates from or exceeds the scope of intended use.

The manufacturer cannot be held liable for any personal injury or property damage resulting from

such improper use. All risks involved in engaging in improper usage, lie solely with the user.

Intended use also includes the adherence to the conditions for operation and repairs prescribed by

the manufacturer.

The manufacturer cannot be held liable for any personal injury or property damage resulting from

such non-observance. All risk involved during improper use lies with the user.

All applicable accident prevention regulations and all other generally recognized safety, industrial,

and medical rules as well as all road traffic laws must be observed. Any unauthorized modifications

made to the unit will void the manufacturer's warranty.

EC declaration of conformity

This product has been manufactured in conformity with the following national and harmonised

standards as specified in the current EMC Directive 2004/108/EC:

▪ EN ISO 14982

Mueller Electronics, Inc. 7

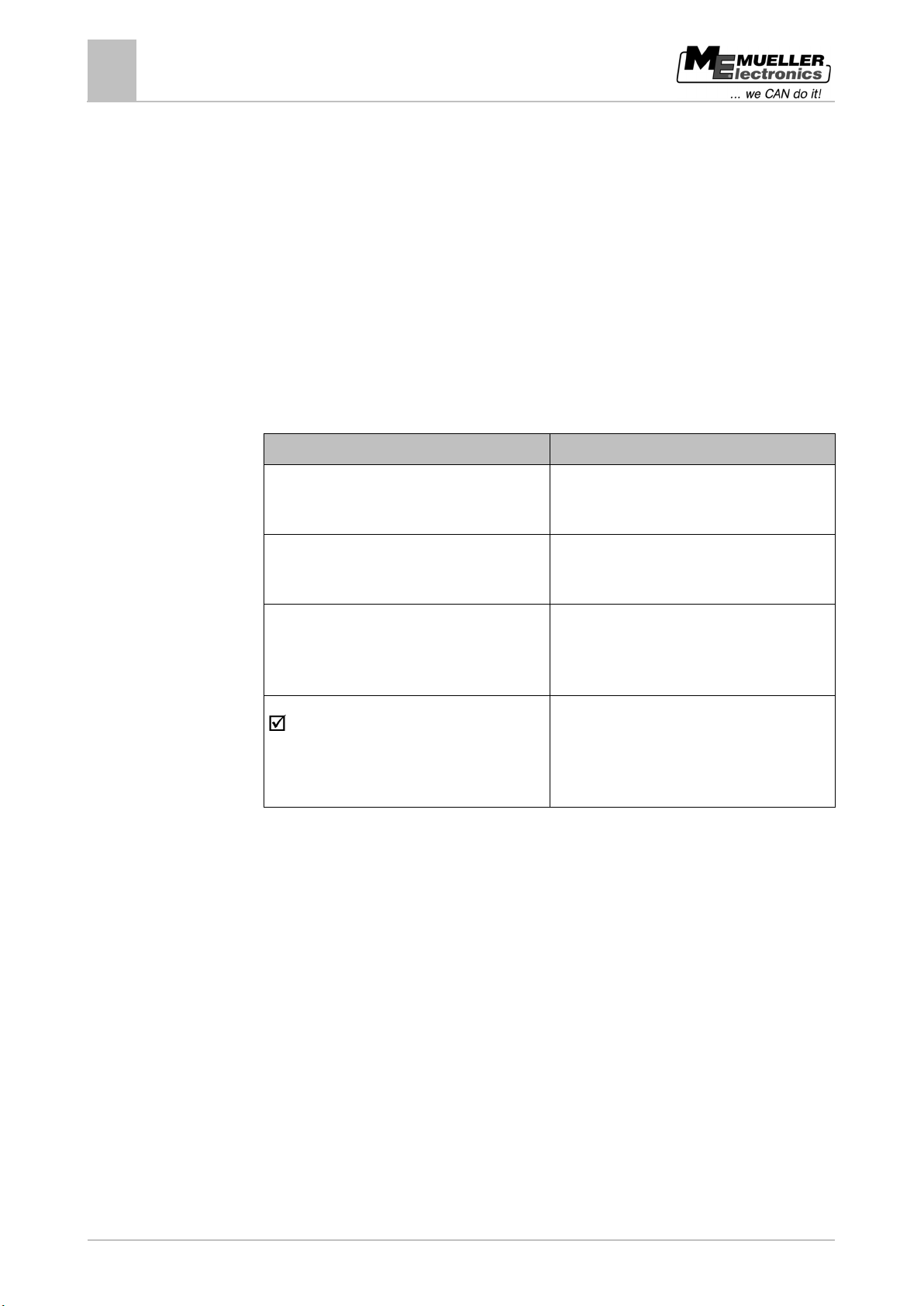

Type of depiction

Meaning

2.

⇨

This will happen when you perform an action.

⇨

steps.

can be performed.

2

2.1

2.2

2.3

About these Operating Instructions

2

Target group of these Operating Instructions

About these Operating Instructions

Target group of these Operating Instructions

These Operating Instructions are intended for personnel entrusted with installing and operating the

display.

Layout of operating instructions

The operating instructions explain step by step how you can perform certain operations with the

product.

We use the following symbols throughout these Operating Instructions to identify different operating

instructions:

1.

Actions that must be performed in succession.

Result of the action.

Result of an operating instruction.

This will happen when you have completed all

Requirements.

In the event that any requirements have been

specified, these must be met before an action

Layout of references

If any references are given in these Operating Instructions, they will appear as:

Example of a reference: [➙ 8]

8 Mueller Electronics, Inc.

References can be identified by their square brackets and an arrow. The number following the arrow

shows you on what page the chapter starts where you can find further information.

3

3.1

Hardware

Software

3.2

Product description

Performance description

Product description

3

Performance description

The display is available in two hardware versions:

▪ With GSM modem and with camera connections

– Complete functionality:

– It is the prerequisite for work with the farmpilot portal;

– On the rear side you can find two camera connections and one connection for the GSM

antenna.

▪ Without GSM modem and without camera connections

You can find out the display version you have on the connections on the display rear side. [➙ 12]

All applications of Mueller-Electronics available are installed on the display. But first you must activate

some of them.

See also: Activating licenses for full versions of the software [➙ 39]

The following applications are activated:

▪ SERVICE – this application configures the display.

▪ TRACK-Leader – a modern system enabling the driver of an agricultural vehicle keep exact

parallel lanes on the field.

▪ Tractor-ECU - this application enables you to configure all sensors connected to the display and

to input the position of the GPS receiver.

You can test the following application for 50 hours free of charge:

▪ SECTION-Control – automatic boom section switching. Additional module for TRACK-Leader.

▪ VARIABLE RATE-Cont. – with this application you can work with prescription maps saved as

shp files. Additional module for TRACK-Leader.

▪ TRACK-Leader TOP – automatic steering. Additional module for TRACK-Leader.

▪ FIELD-Nav – this is the first navigation software that contains all navigable paths, takes

movement restrictions into account and leads directly to the field or other agricultural destination.

The following applications are installed, but deactivated until you have activated a license:

▪ ISOBUS-TC – this is the certified ISOBUS task controller from Mueller-Electronics. In this

application you can use the display for processing all tasks previously planned on the PC.

▪ ISOBUS-UT - interface for controlling ISOBUS-job computers. The display is compliant with

ISOBUS standard ISO 11783. This display can be used as the control unit independently of the

manufacturer as an independent display on all machines that meet the requirements of this

ISOBUS standard.

Scope of delivery

The following items are included in delivery:

▪ Display

▪ Installation and Operating Instructions

▪ Operating instructions for the TRACK-Leader application - as a separate document.

▪ Bracket for mounting the display

▪ USB flash drive

▪ Mounting bracket for mounting the display.

Mueller Electronics, Inc. 9

number will be shown here.

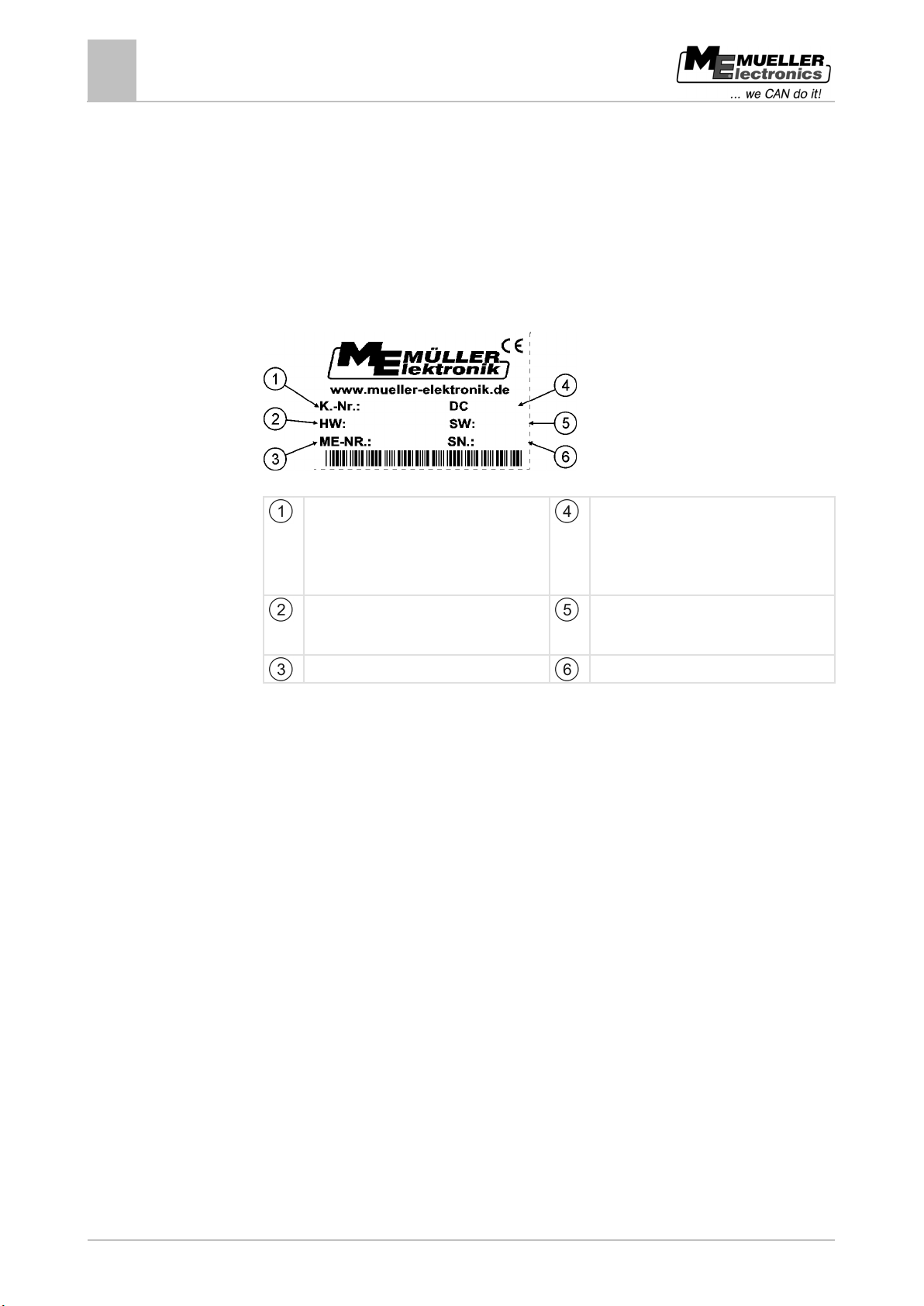

3.3

Product description

3

Correctly interpreting information on the nameplate

▪ Voltage supply cable.

▪ DGPS receiver A100.

▪ Case.

Correctly interpreting information on the nameplate

On the reverse of the display you will find a nameplate sticker. On this sticker you can find all the

information you need to definitively identify the product.

Have these details ready when you contact Customer Services.

Nameplate on the reverse of the display

Customer number

If the product was manufactured for an

agricultural machinery manufacturer, the

agricultural machinery manufacturer's item

Operating voltage

The product may only be connected to

voltages within this range.

Hardware version

Software version

If you update the software, this version will no

longer be up-to-date.

Mueller-Electronics item number

Serial number

10 Mueller Electronics, Inc.

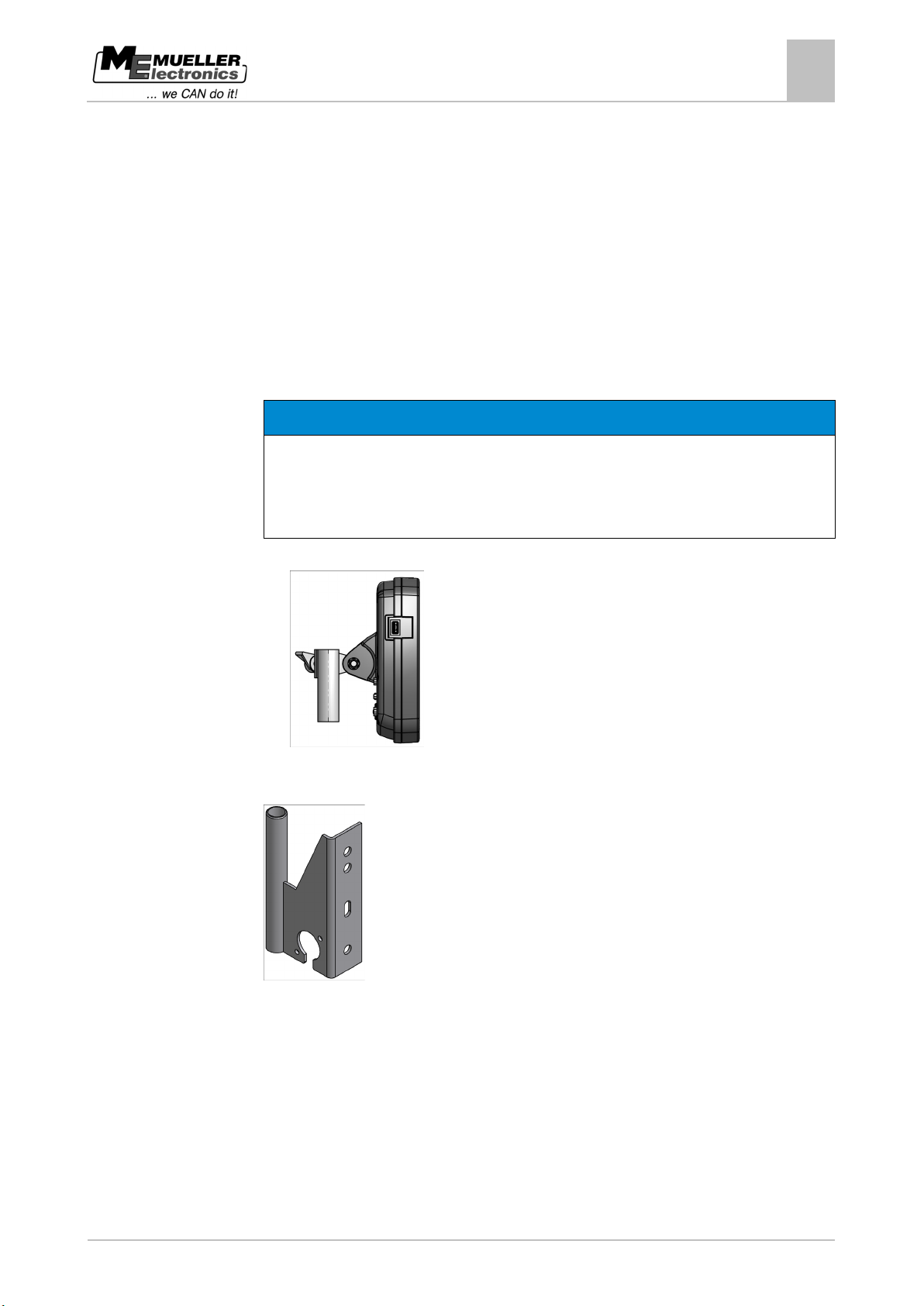

NOTICE

◦ Mount the display at least 1 m away from the radio antenna or from a radio device.

4

4.1

Procedure

4.1.1

Procedure

Mounting and installation

Mounting the display in the tractor cab

4

Mounting and installation

Mount the display and all additional components in the following order:

1. Mount the display in the tractor cab. [➙ 11]

2. Connect the display to the voltage supply (port A). [➙ 12]

3. Connect the display to the GPS receiver (port C). [➙ 14]

4. Connect the working position sensor (optional, port B). [➙ 16]

Mounting the display in the tractor cab

Electromagnetic interference

The operation of the display may be impaired by electromagnetic waves emitted by other farm

equipment.

1. Screw the bracket to the display.

2. Mount the display with the bracket installed inside the tractor cab.

For instance, you can use the ME mounting bracket for this purpose.

Mounting bracket

Screwing on the GSM antenna

The GSM antenna transmits information to the farmpilot portal via a mobile phone network.

1. NOTICE! There is a very sensitive contact pin in the center of the GSM antenna. Make

sure not to damage the contact pin when screwing on the GSM antenna.

2. Screw the GSM antenna on the rear side of the display.

Mueller Electronics, Inc. 11

installed.

installed.

- LightBar

installed.

4.1.2

4.2

Procedure

4.3

Procedure

Mounting and installation

4

Connecting the display to the basic equipment

Display ports

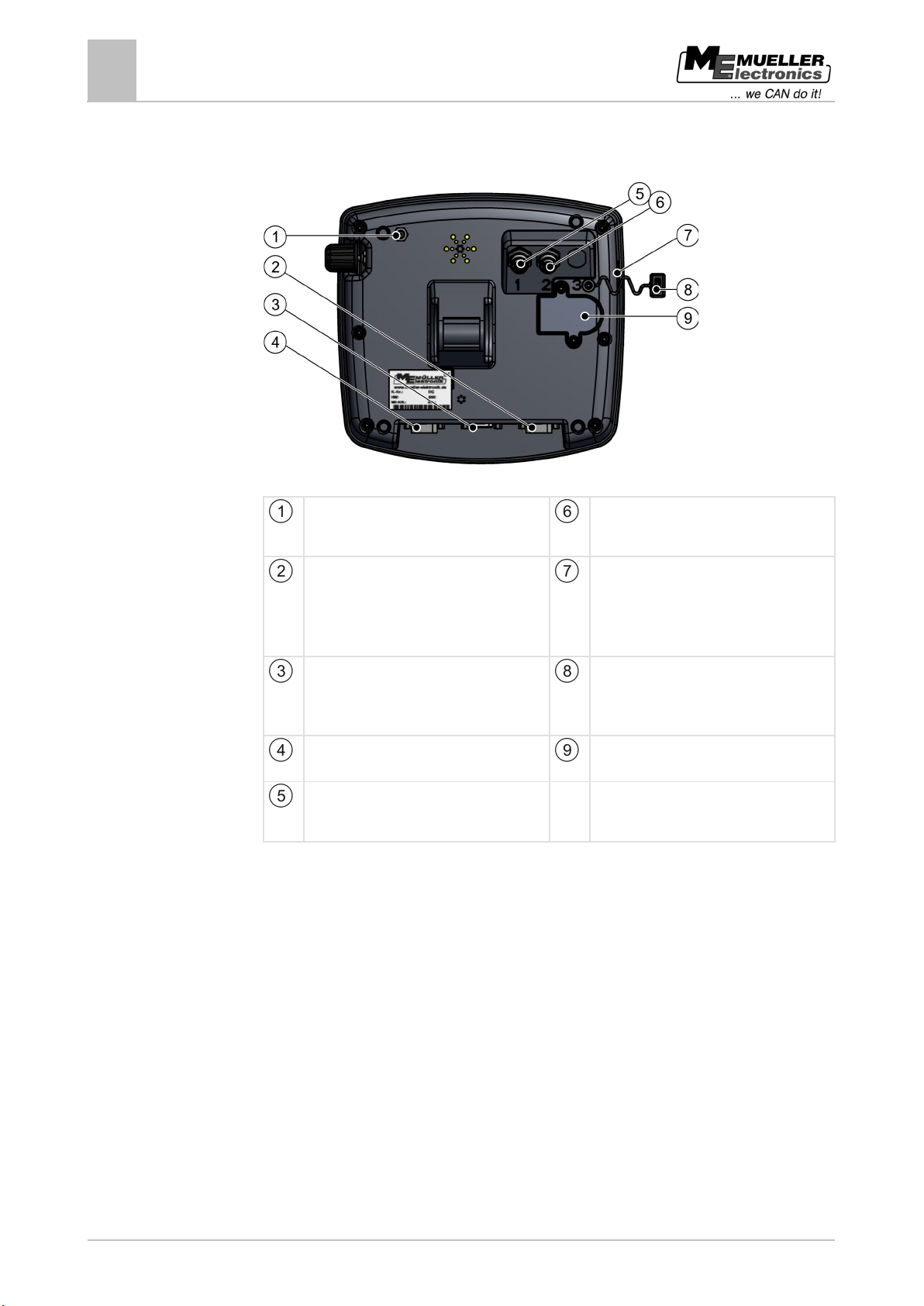

Rear of the display. Version with a GSM modem and camera connections

GSM antenna port

Only for displays with a GSM modem

Port for analog camera

Only for displays with a GSM modem

Port C

RS232 serial port for:

USB port

USB 1.1

- GPS receiver

- Terrain compensation "GPS TILT-Module"

Port A

CAN bus port

Covering cap for USB port

Prevents dust from entering the USB socket.

For connection of ISOBUS basic equipment or

voltage supply with TRACK-Guide II.

Port B

See section: Pin assignment of port B [➙ 64]

Port for analog camera

Only for displays with a GSM modem

SIM card slot

Connecting the display to the basic equipment

If the display must work with a job computer or SC-Box, you need to connect it to the basic

equipment.

If you connect the display to a basic equipment, it will be provided with power via the basic

equipment.

1. Connect the 9-pole cable of the basic equipment to port A of the display.

2. Tighten the safety screws on the port.

Connecting the display to voltage supply

This is how you connect the display to voltage supply:

12 Mueller Electronics, Inc.

4.4

Which SIM card?

4.4.1

Mounting and installation

SIM card

4

1. Connect the voltage supply cable included in the delivery (on the sticker: 31302495) to port A of

the display.

2. Connect the voltage supply cable on the other side to (10V - 30V) the vehicle's electrical system.

SIM card

The display must be equipped with a SIM card so that you can use the farmpilot portal. If you do not

intend to use the farmpilot portal, you will not need any SIM card.

You must purchase the SIM card from your mobile phone provider.

Select a mobile phone provider that can guarantee good mobile phone reception on your fields. A

good connection is required in order for your work with the farmpilot portal to run smoothly.

The SIM card must meet the following requirements:

▪ It must be GPRS-capable.

▪ It must be PIN-free. Inform your mobile phone provider about this requirement before purchasing

the SIM card.

▪ The contract must enable data transfer.

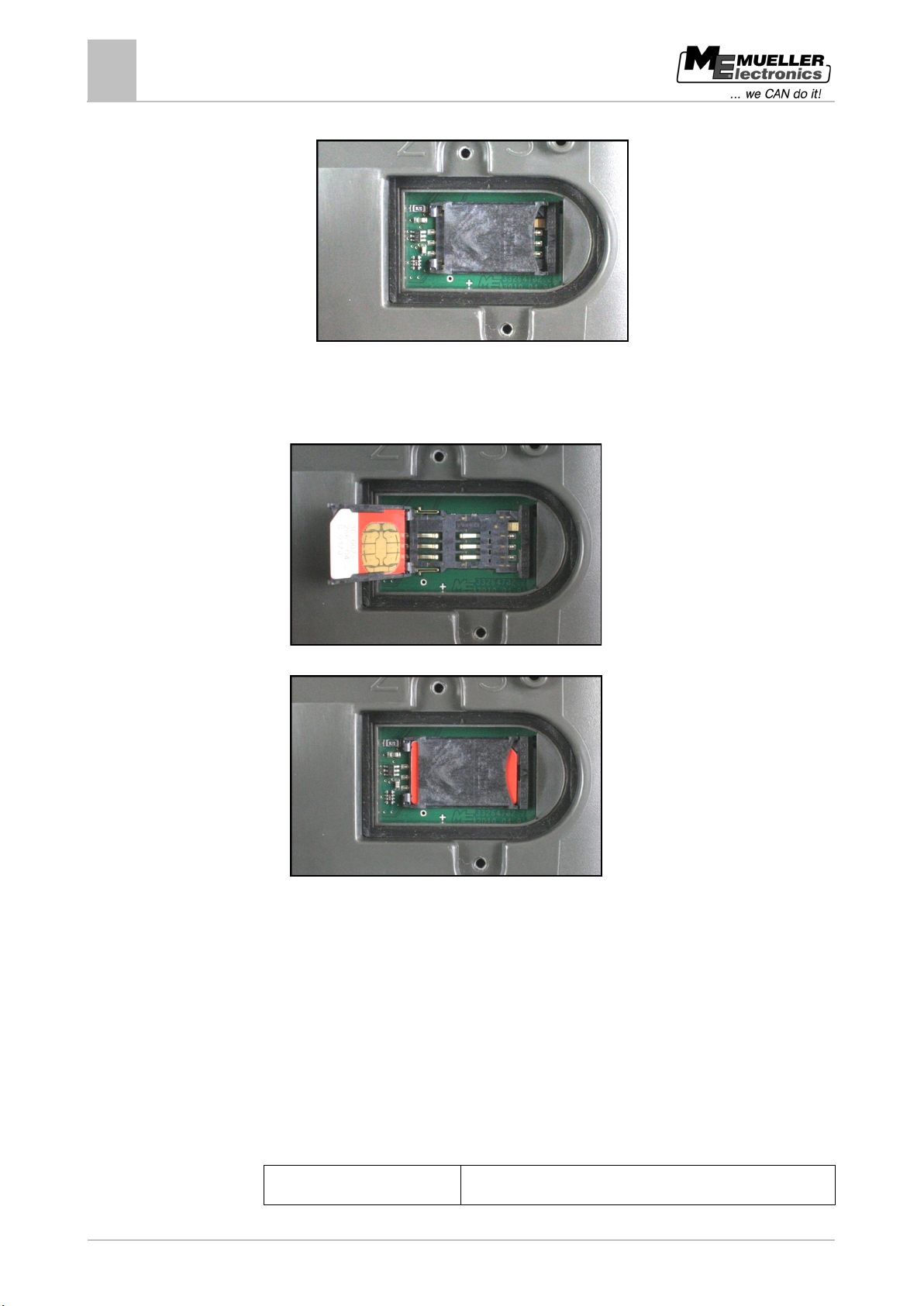

Inserting the SIM card

Required tool

▪ Torx TX10 screwdriver

Procedure

1. Switch off the display and disconnect all cable connections to other equipment.

2. Unscrew the SIM card cover on the reverse of the display. Use a Torx TX10 screwdriver.

3. Press latch release with finger nail.

Mueller Electronics, Inc. 13

Operating voltage:

Supply voltage of the display – 1.5 V

4.5

Prerequisites

Mounting and installation

4

Connecting the GPS Receiver to the display

⇨ Card holder will be unlatched:

4. Raise the card holder. The card holder can be raised on the right hand side where the casing is

rounded. The card holder is held in place by hinges on the other side.

5. Slide the SIM card into the card holder. Following installation, the chip on the card must be in

contact with the circuit board. The card must be positioned as shown in the picture.

6. Shut the card holder.

7. Press the card holder lightly onto the circuit board, until it clicks into place on the right hand side.

8. CAUTION! Tighten the screws, but not too tight, otherwise the cover might be damaged.

9. Screw the cover back on. Make sure that the rubber seal is positioned between the cover and

the casing.

Connecting the GPS Receiver to the display

Each GPS receiver which is connected to the display must fulfill the conditions in the next table. GPS

receivers, which can be purchased from Mueller-Electronics, fulfill these conditions.

14 Mueller Electronics, Inc.

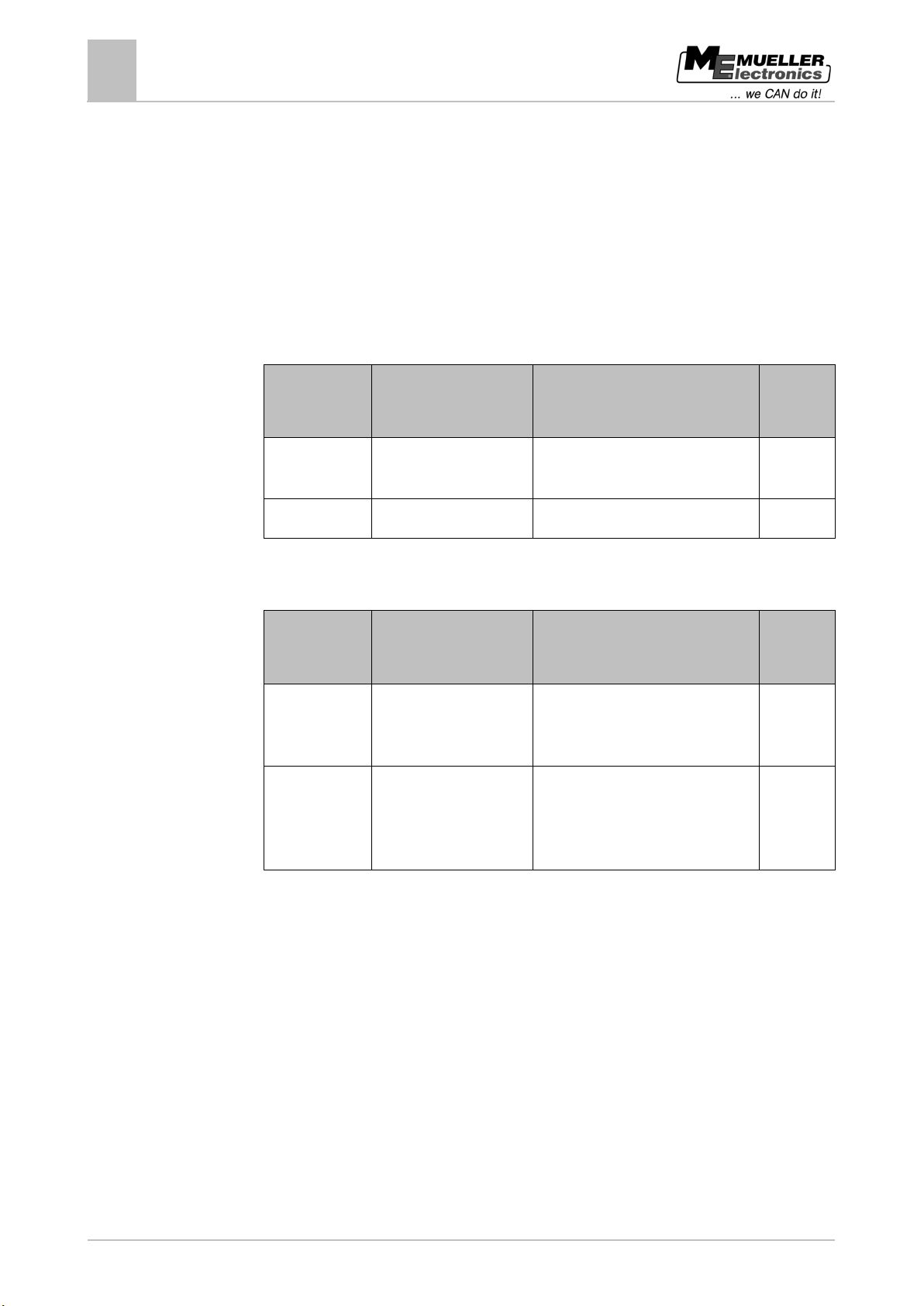

Technical requirements for using the DGPS Receiver

Current consumption

Maximum 200mA (at 158°F)

GPS standard

NMEA 0183

5 Hz (GPGGA, GPVTG)

1 Hz (GPGSA, GPZDA)

Transmission rate

19200 baud

Data bits

8

Parity

no

Stop bits

1

Flow control

none

CAUTION

devices don't differ from each other.

Procedure

Mounting and installation

Connecting the GPS Receiver to the display

4

Refresh rates and signals

Damage to the equipment caused by short circuit

Pin 4 of port C is live. The voltage depends on the operating voltage of the display and is used to

supply the DGPS Receiver A100 supplied by Mueller-Electronics.

Other GPS Receivers may suffer damage if connected to this port.

Before connecting a different GPS Receiver:

◦ Check what voltage the display is connected to (12 V or 24 V).

◦ Check the pin assignment of the GPS Receiver.

◦ Check the allowable voltage for the GPS Receiver.

◦ Compare the display voltage to the allowable voltage for the GPS Receiver.

◦ Compare the pin assignment.

◦ Only connect the GPS Receiver to the display, if the voltage range and pin assignment of both

During initial start-up it can take approx. 30 minutes until the GPS Receiver has aquired a signal. At

subsequent start-ups it will only take approx. 1-2 minutes.

The GPS receiver is mounted on the roof of the tractor.

You have activated a suitable driver. [➙ 29]

- Switch off the display.

1.

Mueller Electronics, Inc. 15

2. Guide the connection cable from the GPS receiver into the cab.

3. CAUTION! Ensure that the cable is not laid across sharp edges or at risk of becoming

bent. Lay the cable in a place where nobody can trip over it.

4. Connect the connecting cable of the GPS receiver to port C on the display.

display

pole

From 1.4.1

3-pole plug

Adapter cable, 9-pole socket to 3-pole

31302497

display

working position.

pole.

4.6

Mounting and installation

4

Connecting sensors to the display

Connecting sensors to the display

The display provides you with the possibility of connecting a sensor or the tractor's 7-pole signal

socket to port B. This allows you for example to use the working position signal in the TRACK-Leader

parallel guide.

Most sensors which can be purchased from Mueller-Electronics are fitted with a round 3-pole plug. In

order to connect this to the display, you will need an adapter cable. A different adapter cable is

needed for each hardware version of the display.

Adapter cable by hardware version

Hardware ver-

Adapter cable Connection Item num-

sion of the

From 3.0.0 3-pole plug Adapter cable, 9-pole bushing to 3-

ber

31302499

You can also connect the display to the signal socket.

Cable to the signal socket

Hardware ver-

Connections Connection Item num-

sion of the

From 3.0.0 7-pole to 9-pole socket Cable direct to the signal socket

ber

30322548

Transfers the speed, PTO revolution,

All 3-pole (from the adapter

cable, dependent on the

Cable to the signal socket

Only transfers the working position.

313008

hardware version) to 7-

16 Mueller Electronics, Inc.

▪ Change a parameter value.

▪ Confirm input.

5

5.1

Controls

Basic control principles

Getting to grips with the controls

Basic control principles

5

Getting to grips with the controls

Display controls

Rotary knob

Function keys

Keys

Rotary knob

The rotary knob is located in the top right hand corner of the display.

Control with the rotary knob may vary slightly between the different applications.

You can use the rotary knob to perform the following actions:

Turning the rotary knob:

▪ Move the cursor up and down.

Pressing the rotary knob:

▪ Click on the selected line.

▪ Activate parameter.

Mueller Electronics, Inc. 17

Function keys

Operating the function keys is the same across all applications.

Performing the functions depicted on the display

Keys

Switch the display on and off

Hide warning messages and alerts

Exit the "Selection Menu" application

5.2

Procedure

Basic control principles

5

Initial start-up

Has no function

Has no function

Exit screen

Cancel input

Initial start-up

Open the "Selection Menu" application

This is how you start the display for the first time:

You have mounted and connected the display.

1.

- Switch on the display.

2. Wait for approx. 15 seconds until all applications have been loaded.

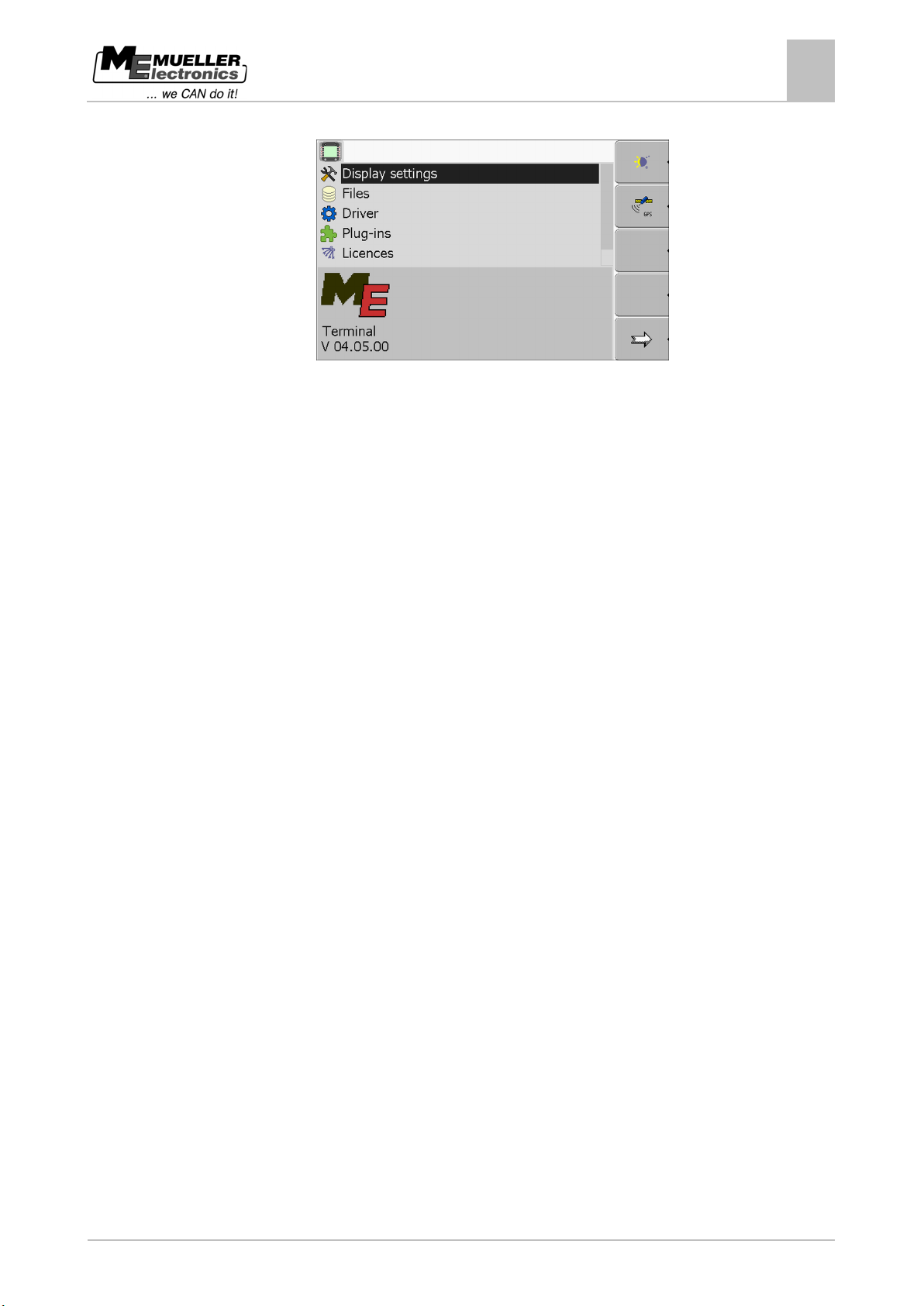

3.

- Open the "Selection menu" application.

⇨ The following screen will appear:

4. In the selection menu you can select which application you wish to display next.

5.

- Select the "Service" line. The "Service" line must be framed by a black square:

6.

18 Mueller Electronics, Inc.

- Click on the "Service" line.

5.3

5.4

Basic control principles

Configuration sequence

5

⇨ The following screen will appear:

⇨ You have opened the "Service" application.

7. Configuring the display in the Service application [➙ 25]

Configuration sequence

Depending on the display that you have and which apps are activated, you will need to configure the

display and its accessories in different points.

You must make these settings during the initial commissioning:

▪ Activating the GPS Receiver [➙ 29]

▪ Configuring the GPS receiver [➙ 30]

▪ Input the position of the GPS receiver [➙ 56] (only if you are using TRACK-Guide II on a sprayer

with SC-Box)

Once you have made these settings, the display is ready to operate.

Note however that you will need to configure the TRACK-Leader and FIELD-Nav applications in

detail. To do this, read the instructions for these applications.

The number of settings is dependent on the number of functions that you are using, and which

machines are operated with the display.

Using the function keys

Whenever you use the function keys, you will activate the function depicted on the adjacent function

icon.

Mueller Electronics, Inc. 19

CAUTION

◦ Only press the function key when you are sure that no danger is posed to people or property.

icon.

Example

5.5

Procedure

Basic control principles

5

Restarting the display

Danger of pressing the function keys without care

When pressing function keys, components of the connected machine can be moved or activated.

As a result, people can be injured and property damaged.

Before pressing a function key:

◦ Make sure you know what will happen when you press the function key.

◦ Consult the Operating Instructions of the connected machine or of the agricultural equipment to

establish what dangers could arise from pressing that key.

◦ Fulfill all the measures described in the machine's Operating Instructions in order to avoid

danger.

When you press a function key, the function / operation depicted on the function icon will be

performed.

Using the function keys

Function icon

Depiction of an available function.

Function key

Performs the function depicted on the function

When you press the function key , the function depicted on the function icon will be

activated.

If no function icon appears next to a function key, this means that this function key has no function at

present.

Restarting the display

When restarting the display, you must give the connected jobcomputers enough time to restart as

well. For this reason, always wait approx. 30 seconds after switching off the display before switching

the display back on.

1. - Switch off the display.

2. Wait 30 seconds until the jobcomputers have also been switched off.

3.

- Switch on the display.

20 Mueller Electronics, Inc.

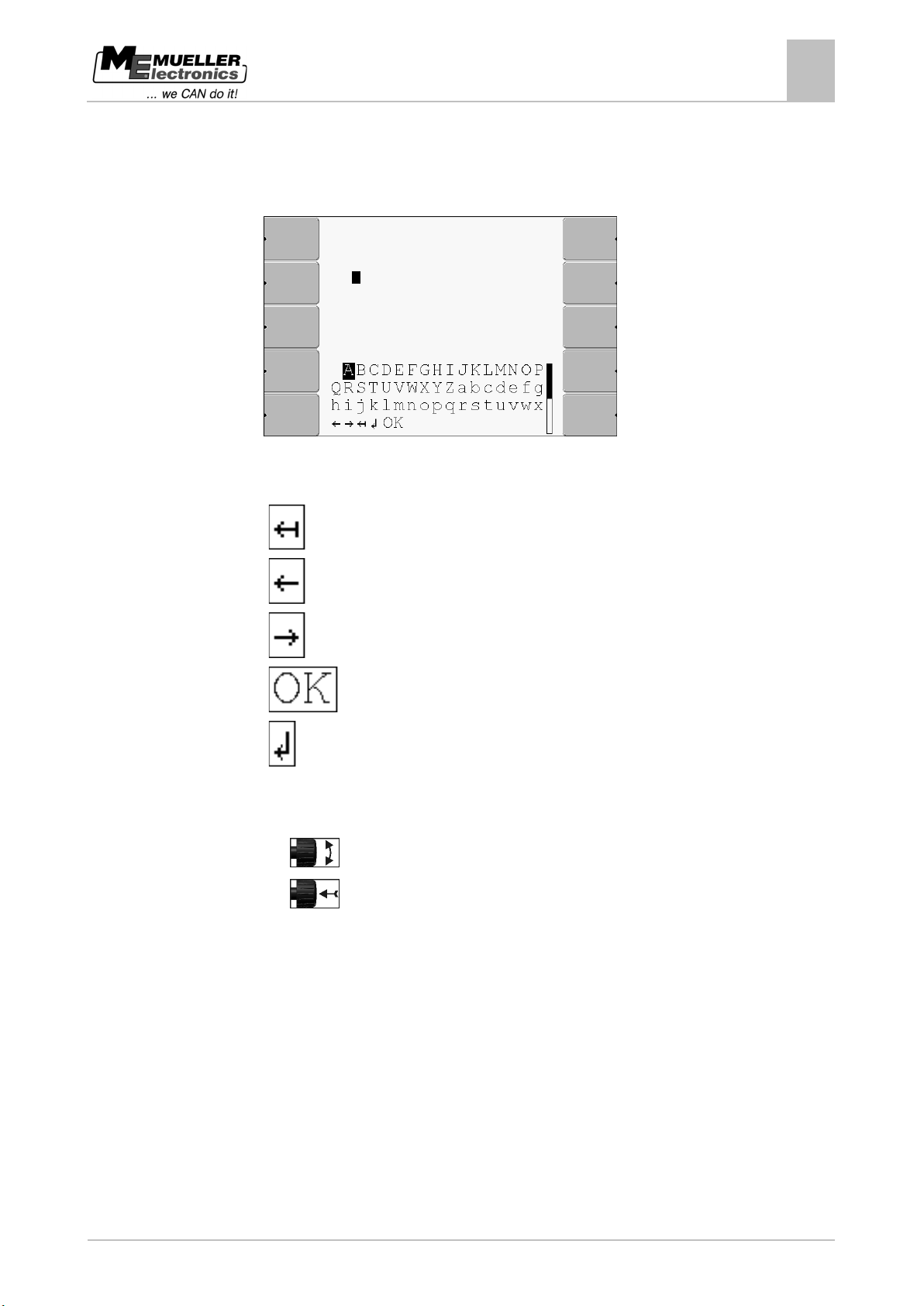

5.6

Controls

Procedure

Basic control principles

Inputting data

5

Inputting data

All data must be entered on the data input screen.

Data input screen

Below the characters, you will find 5 icons which will assist you when entering the data.

Delete characters

Move cursor to the left

Move cursor to the right

Confirm and finish input.

No function

This is how you enter the data:

The data input screen has been opened:

1.

2.

- Select the desired character.

- Click on the selected character.

3. When all characters have been entered, select the "OK" symbol with the rotary button and click.

⇨ The input will be applied.

Mueller Electronics, Inc. 21

ISO name of the application

displayed in the header.

main display.

knob.

6

Controls

6.1

6.2

Opening applications in the selection menu

6

Display layout in the selection menu

Opening applications in the selection menu

In the selection menu you can choose which application you wish to view on the display.

You can open the selection menu at any time. This will not close the application currently running.

Open the selection menu

Press again – open the most recently activated application

Display the application in the header of the split display.

Display the application in the main section of the display.

Display layout in the selection menu

The display is split into the following sections:

▪ Function icons – left and right

▪ Applications section – in the middle, between the function icons.

Sections in the selection menu

Name of an application

Function icons on the left

Select an application which will later be

Selection

The selected application is displayed in the

header

ISO ID of the application

Selection

The selected application is displayed on the

Function icons on the right

Open an application on the main display.

Cursor

Open the selected application using the rotary

Opening applications

You can perform the following actions in the selection menu:

▪ Open an application.

▪ Display an application in the header of the split display.

22 Mueller Electronics, Inc.

that is currently running.

Function icon

Function

Procedure

6.3

Opening applications in the selection menu

Segmentation of the display

6

1. - Set which application is to be displayed in the header of the split display.

⇨ The function icon of the selected application is marked with a dot on the left hand side:

2. Start the application for the main display. There are several ways to do so:

a) With the rotary knob:

- Select the desired application

- Open the selected application

b) Using the function keys on the right hand side:

- Display the application shown next to the function icon.

⇨ Both applications will appear on the display.

Segmentation of the display

The display of the display is split into two sections.

A different application is displayed in each section. This allows you, for example, to control the tractor

on the field and monitor the field sprayer at the same time. This means that you will not need an

additional display.

Segmentation of the display

Header – informative section.

The header allows you to display information

from an application.

Main screen – section used for control.

The main display shows the application

currently running, function icons and the

information you need to control the application

Mueller Electronics, Inc. 23

In the selection menu you can see which applications can be run with the split display.

Switch applications in the header section.

Function icon

Function

Opening applications in the selection menu

6

Segmentation of the display

Swap applications between the header section and the main section of the

display.

24 Mueller Electronics, Inc.

installed software

Function icon

Meaning

Appears only if...

7

7.1

Controls

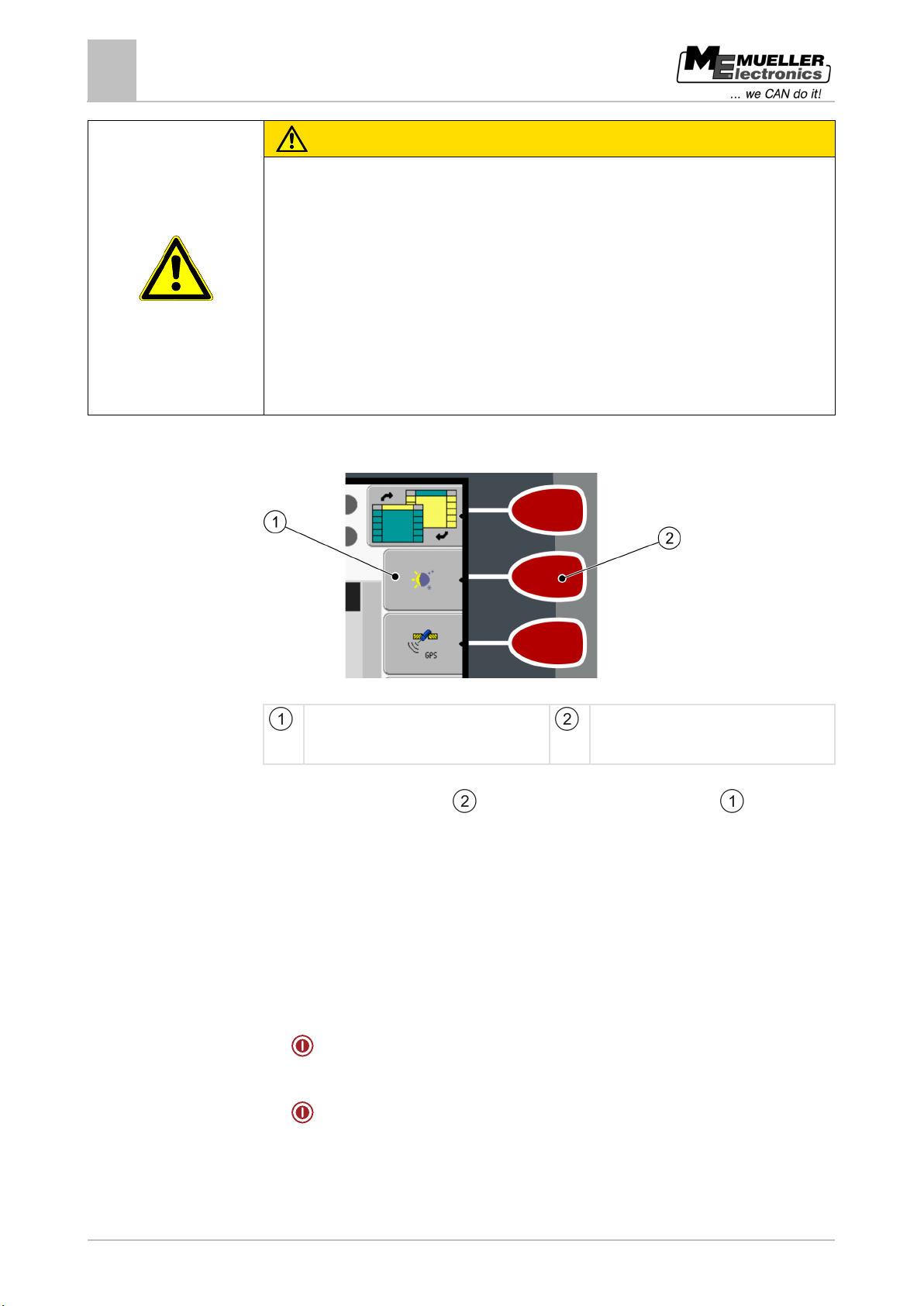

Configuring the display in the Service application

Controls in the Service application

7

Configuring the display in the Service application

Use the "Service" application to set up the display and enable the connected equipment.

Once you have launched the "Service" application, you will be shown the following screen:

Start screen of the "Service" application

Main section

Screen contents

Version number

Name of the display and version of the

Cursor

Selects a line that can be clicked on with the

rotary knob.

Function icons section

Icons that can be pressed on this screen.

Controls in the Service application

The Service application is controlled using the rotary knob and the function buttons.

Some of the function icons explained here will only appear if a specific function is activated. This

limits the information shown on the display to just the information that you need for your work.

Next page There is one more page with

function icons.

Back

Activate day mode

Activate night mode

File cannot be deleted (gray) Selected object cannot be

deleted

Delete file (red) Selected object can be deleted

Mueller Electronics, Inc. 25

Function icon

Meaning

Appears only if...

7.2

Icons

7.3

Procedure

Configuring the display in the Service application

7

Icons in the Service application

Configuring the GPS receiver GPS receiver is activated

Configuring farmpilot farmpilot portal is activated

Open the Diagnostics screen Diagnostics is activated

Retrieve default values.

Display DGPS connection status

Associating the buttons on a joystick with

Driver "Auxiliary2" is activated

functions

Icons in the Service application

You will find the following icons in the Service application.

Function is activated

Function is deactivated

Changing the language

When you switch on the display for the first time, the text may appear in a foreign language (in

German).

If you change the language in the Service application, you also change the language for all

applications and the ISOBUS job computer.

If a connected ISOBUS job computer cannot activate the selected language, a standard language will

be activated.

1. - Switch on the display.

2.

26 Mueller Electronics, Inc.

- Press.

7.4

Procedure

Configuring the display in the Service application

Configuring the basic display settings

7

⇨ The following screen will appear:

3.

- Click on "Service".

⇨ The following screen will appear:

The texts on this screen may appear in a foreign language.

4.

5.

6.

7.

- Click on "Terminal-Einstellungen“ ("Display settings").

- Click on "Sprache" ("Language").

- Select the abbreviation of your language.

- Press.

⇨ The following message will appear: “Restart the terminal.“

8.

- Press.

⇨ The language in the "Service" application will be changed. Language will be changed in

other application only after a display restart.

9.

⇨ The language in other applications will be changed.

- Restart display.

Configuring the basic display settings

Mueller Electronics, Inc. 27

The basic display settings can be adjusted on the "Display settings" screen.

1. Switch to the "Display settings" screen:

| Service | Display settings

Parameter

Sub-parameter

Meaning

Day

Adjusting brightness for day mode

Night

Adjusting brightness for night mode

1 = night mode is activated

Volume

Adjust volume

Date

Setting current date

Time

Setting current time

-1 = GMT -1 hour

Language

Selecting language

Metric

Displays all units in metrical system

Imperial

Displays all units in imperial system

US

Displays all units in US system

Keyboard brightness

Setting the level of keyboard brightness in percent

List of parameters

7.5

Configuring the display in the Service application

7

GPS Receiver

⇨ The following screen will appear:

2.

- Change the desired parameter.

Brightness

Night mode Switching night mode on and off

0 = day mode is activated

Date / time

Time zone 0 = Time zone: Greenwich Mean Time (GMT)

1 = GMT +1 hour (Germany)

Measurement units

GPS Receiver

When you connect a GPS Receiver to the display, you must activate and configure it.

28 Mueller Electronics, Inc.

Driver name

GPS receiver

via the CAN cable to the display.

to the serial interface.

GPS_NovAtel

Do not use.

CAUTION

driver.

7.5.1

Procedure

Configuring the display in the Service application

GPS Receiver

7

Activating the GPS Receiver

In order to activate the GPS Receiver, you must first activate its driver.

A driver is a small program that controls connected farm equipment. The drivers for the farm

equipment supplied by Mueller-Electronics are pre-installed on the display.

Available drivers

disabled No GPS receiver

GPS_PSRCAN Select this driver if a GPS receiver is connected to the job

computer for the automatic steering. The signals are transmitted

GPS_A100 Driver for the Mueller-Electronics A100 GPS receiver. Connected

GPS_STD Driver for unknown GPS receivers. Connected to the serial

interface.

This driver is activated by default. The connected GPS receiver

cannot thus be configured.

Incorrect driver

Damage to the GPS receiver.

◦ Before connecting a GPS receiver to the display, you must always activate the appropriate

1. Switch to the "Driver" screen:

| Service | Driver

⇨ The following screen will appear:

2. Select "GPS".

3. Click on "GPS".

Mueller Electronics, Inc. 29

7.5.2

Parameter

Configuring the display in the Service application

7

GPS Receiver

⇨ The installed drivers will appear.

⇨ The icon

appears beside the active driver.

4. Mark the line with the correct driver.

5. Click on the selected line.

⇨ The following icon will appear next to the driver

6.

- Restart the display.

⇨ The GPS receiver is activated.

⇨ The following function icon will appear in the start screen of the "Service" application:

⇨ You have activated the GPS receiver.

Configuring the GPS receiver

Use the following parameters to configure the GPS receiver:

Baud rate

Setting for the speed at which the display sends data to the DGPS Receiver. The parameter sets the

baud rate for the display.

Satellite 1 and Satellite 2

Satellite 1 – primary DGPS satellite. The DGPS receiver will connect to this satellite in the first

instance.

Satellite 2 – secondary DGPS satellite. The DGPS receiver will only connect to this satellite in the

event that the primary satellite fails.

Your satellite selection will depend on which satellite currently has the best availability in your region.

Potential values:

▪ "Auto"

The software automatically selects the current best satellite. This setting is not recommended, as

it slows down start-up of the DGPS receiver.

▪ Name of the satellite. Which satellites are shown here is dependent on the driver and correction

signal that you have activated.

Steering

This parameter activates the "Automatic steering" assistance function in the GPS Receiver.

Potential values:

30 Mueller Electronics, Inc.

Function icon

Function

Controls

Procedure

Configuring the display in the Service application

GPS Receiver

7

▪ „On“

Activates automatic steering assistance.

▪ "Off"

Deactivates automatic steering assistance.

Correction signal

Type of correction signal for the DGPS receiver.

The correction signals which are available is dependent on the activated driver.

Potential values:

▪ For the "GPS_A100" driver:

– "WAAS/EGNOS"

Correction signal for Europe, North America, Russia and Japan.

– "E-DIF"

Internal calculation of correction data.

This setting is required outside of the EU and the USA.

To use e-Dif, you will require a special version of the DGPS receiver A100. You can order

this this DGPS receiver from Mueller-Electronics with the item number 30302464.

▪ For the "GPS_NovAtel" driver

– "EGNOS-EU"

– "WAAS-US"

– "MSAS-JP"

– "GL1DE"

Terrain compensation

Under this parameter the terrain compensation GPS TILT-Module is configured.

You can order the terraín compensation from Mueller-Electronics with the following item number:

30302495.

Reset the configuration of the DGPS receiver to default values

Display DGPS connection status

You can configure the parameter as follows:

A GPS receiver is connected to socket C of the display.

The appropriate driver is activated.

The driver of the "LightBar_ME" external LightBar is deactivated. Otherwise the DGPS receiver

cannot be configured.

The external LightBar is not connected.

Mueller Electronics, Inc. 31

7.6

Configuring the display in the Service application

7

Configuring the "GPS TILT-Module" terrain compensation

1. Switch to the "GPS" screen:

| Service |

⇨ The following screen will appear:

Procedure

2.

- Click on the desired parameter. First of all, set the "Correction signal" parameter.

⇨ A selection list will appear.

3.

⇨ The

4.

- Click on the desired value.

icon appears beside the value.

- Back.

⇨ For some parameters is it necessary to restart the display. In these cases, the following

notification will appear:

"Restart the display."

⇨ You have configured the DGPS receiver.

Configuring the "GPS TILT-Module" terrain compensation

The "GPS TILT-Module" terrain compensation is connected.

The driver of the external LightBar is deactivated.

The external LightBar is not connected.

1. Measure the distance between the GPS Receiver and the ground surface.

2. Switch on the display.

3. Switch to the configuration screen of the terrain compensation:

| Service | | Terrain compensation

32 Mueller Electronics, Inc.

7.7

Procedure

Configuring the display in the Service application

Activating an external LightBar

7

⇨ The following screen will appear:

4. Enter the distance between the GPS Receiver and the ground surface in the line "GPS Receiver

height".

5. Position the tractor on a ground surface that is known to be level.

6. Click on the line "Null point calibration".

⇨ The position of the terrain compensation on an even surface is being calibrated.

⇨ After calibration the angle 0 will appear in the line 'angle'. The angle displayed changes every

time the tractor tilts.

Activating an external LightBar

If you connected an external LightBar to the display, you must activate it.

To activate the external LightBar, you must first activate its driver.

You can order the external LightBar from Mueller-Electronics with the following item number:

30302490.

1. Switch to screen "Driver":

| Service | Driver

⇨ The following screen will appear:

2. Click on "LightBar".

⇨ The installed drivers will appear.

3. Click on the "LightBar_ME" driver.

⇨ Next to the driver the icon

4.

- Restart display.

will appear.

⇨ You have activated the external LightBar.

Mueller Electronics, Inc. 33

Function icon

Meaning

7.8

7.8.1

7.8.2

Controls

Configuring the display in the Service application

7

Camera

Procedure

Camera

Activating a camera

If you have connected a camera or camera system to the display, you must activate it.

To activate a camera or a camera system, you must first activate its driver.

1. Switch to the "Driver" screen:

| Service | Driver

⇨ The following screen will appear:

2. Click on "Camera".

3. Click on the "Camera_ME" driver.

⇨ Next to the driver the icon

4.

- Restart display.

will appear.

⇨ The following function icon will appear on the start screen of the "Service" application:

5. You have activated the camera driver.

Operating the camera

Switching between several cameras.

Rotating image.

Zooming in for camera images.

Zooming out for camera images.

34 Mueller Electronics, Inc.

Function icon

Meaning

This only works if the vehicle is equipped with a suitable sensor.

Procedure

7.9

Configuring the display in the Service application

Configuring the joystick button allocations

7

Activating automatic camera mode.

In automatic mode the camera images will be automatically displayed if a

sensor sends a signal to do so.

Saving camera settings.

Exiting camera.

You can press the function keys even if the camera is set to full screen mode.

You have connected and activated the camera.

1. Switch to the "Camera" screen:

| Service | |

⇨ The following screen will appear

2. Use the function keys to control the camera.

Configuring the joystick button allocations

The display offers you the possibility of assigning the functions of a ISOBUS job computer to the

buttons of the joystick.

Selecting the function

Mueller Electronics, Inc. 35

multi-function grip)

Function icon

Meaning

Procedure

Procedure

Configuring the display in the Service application

7

Configuring the joystick button allocations

Area with available functions

Cursor

Icon for the ISOBUS job computer

Button assignment area

Icon for the function

Button assignment. The example of the Mueller-Electronics multi-function grip (MFG)

LED color (position of the side-switch on the

Button to which a function is assigned

Multi-function grip version

Multi-function grip software version

Other buttons

Version information

Deletes all assignments

Deletes the marked assignment

Confirms all assignments

To activate the driver for this function:

1. Switch to the "Driver" screen:

| Service | Driver

2. Activate the value "Auxiliary2" in driver "Auxiliary 2".

3.

- Restart the display.

To configure the button assignment:

The joystick and ISOBUS job computer are connected and support the "Auxiliary 2" protocol.

You have activated the driver "Auxiliary2"

1. To switch to the joy stick's configuration mask:

| Service | |

36 Mueller Electronics, Inc.

7.10

Configuring the display in the Service application

Adjusting the brightness for day or night mode

7

⇨ The following screen will appear:

⇨ The icons which appear here will be dependent on the software of the connected ISOBUS

job computer. This is only an example.

2.

- Select the function which you wish to assign to a button.

⇨ The following screen will appear:

⇨ The content of the screen will depend on the software of the connected joystick.

3. Select the button to which you want to assign the selected function. This is only an example.

4.

5.

- Leave screen.

- Restart the display.

⇨ After restarting, a screen with an overview of the assignments appears.

⇨ If this screen does not appear, open the Service application.

6. Confirm the notification "Scroll to the end."

7. Scroll with the knob all the way to the bottom of the list.

⇨ The following icon will appear in green on the right-hand side:

8.

⇨ You have completed the assignments and can now operate the machine with the joystick.

- Confirm the assignments. You must re-confirm the assignments after each restart.

Adjusting the brightness for day or night mode

In this chapter you will learn how to adjust the brightness of the display for day or night mode.

Mueller Electronics, Inc. 37

Name of the plug-in

Includes the following applications

Tractor-ECU

Tractor-ECU

ISOBUS-TC

ISOBUS-TC

VARIABLE RATE-Control

FIELD-Nav

FIELD-Nav

Procedure

7.11

Procedure

Configuring the display in the Service application

7

Activating and deactivating applications

1. Open the "Service" application:

| Service

⇨ The following screen will appear:

2. Change the operating mode.

Depending on which operating mode is currently active, you can use one of the function icons:

– Activate day mode.

– Activate night mode.

⇨ The brightness of the display will be adjusted immediately.

Activating and deactivating applications

In the "Service" application you can activate and deactivate other applications that are installed on

the display.

The applications are installed in packages, in so-called plugins. A plugin can contain several

applications.

You can for example deactivate a plugin if you do not want to use it. Then the plugin will not be

displayed in the selection menu.

38 Mueller Electronics, Inc.

TRACK-Leader TRACK-Leader

SECTION-Control

TRACK-Leader TOP

To activate and deactivate plug-ins:

1. Switch to the "Plug-ins" screen:

| Service | Plug-ins

7.12

Procedure

Configuring the display in the Service application

Activating licenses for full versions of the software

7

⇨ The following screen will appear:

2.

- Click on the desired plugin.

⇨ The icon preceding the name of the plugin indicates whether the plugin is activated or

deactivated.

3.

- Exit screen.

⇨ The following notification will appear:

“Restart the terminal.“

4.

5.

⇨ All activated plugins will appear in the selection menu.

- Confirm.

- Restart display.

Activating licenses for full versions of the software

Several applications are pre-installed on the display, which you can use for trial purposes for up to 50

hours. [➙ 9] After this time has elapsed, they will be automatically deactivated. The amount of free

usage time remaining is shown in brackets next to the name of the application.

To activate a license you will require an activation number, which you will receive on purchasing an

application from Mueller-Electronics. If you request the activation number by phone or by email, you

will be required to give our staff the following information:

▪ Code – Found under the name of the application on the "License management" screen.

▪ Serial number of the display – Found on the nameplate on the reverse of the display.

▪ Item number of the display – Found on the nameplate on the reverse of the display.

The activation number is entered as follows:

1. Switch to the "Licenses" screen:

| Service | Licenses

Mueller Electronics, Inc. 39

7.13

Procedure

Configuring the display in the Service application

7

Setting the purpose of the display

⇨ The following screen will appear:

2. Click on the desired application.

⇨ The following screen will appear:

3. Enter the activation number in the "Key" field. You will receive the activation number on

purchasing a software license.

4. Confirm

⇨ The following icon will appear next to the application on the "Licenses" screen:

⇨ The application is activated. You can use the application without any restrictions.

Setting the purpose of the display

If you use more than one display, you can decide how you want to use this display.

The following options are available to you:

▪ "Login as ISOBUS-UT"

Activate this parameter if you want the ISOBUS job computer to be displayed on the display.

This parameter must be activated in most instances. On very few self-propelled agricultural

machines, the parameter must be deactivated.

▪ "Run as auxiliary terminal"

The ISOBUS job computer does not log into displays which log in as "auxiliary display".

1. To switch to the "Display configuration" screen:

| Service | Display configuration

2. Configure parameter.

40 Mueller Electronics, Inc.

NOTICE

◦ Think very carefully about which file you wish to delete.

7.14

Procedure

7.15

When to delete?

Configuring the display in the Service application

Deleting files from the USB flash drive

7

Deleting files from the USB flash drive

Potential loss of data!

Deleted files cannot be retrieved!

On the "Files" screen you can delete files from the USB flash drive.

The "Files" screen only displays files that are stored in either of the following two folders on the USB

flash drive:

▪ Screencopy – contains all screenshots you have created

▪ Taskdata – contains all task data for the "ISOBUS-TC" application

1. Switch to the "Files" screen:

| Service | Files

⇨ The following screen will appear:

2. Click on "USB".

⇨ The "Screencopy" and "Taskdata" folders will appear.

⇨ If these folders fail to appear, it is because you did not create them on the USB flash drive.

3. Click on the desired folder.

⇨ The contents of the folder will be displayed.

A folder may either contain files or further folders.

If nothing is displayed, the folder is empty.

Procedure

4. Select the files to be deleted.

5.

– Delete file (red)

⇨ Deleting file.

Deleting pools

You can delete the pools to speed up the display's operation.

Pools are the intermediate storage for the display. Pools are used to temporarily store graphics or

text. Over time, the pools will become too large and slow down the operation of the display.

▪ After updating the software of a connected jobcomputer.

▪ If the display operates more slowly than usual.

▪ When asked to do so by Customer Services.

1. Switch to the "Files" screen:

| Service | Files

Mueller Electronics, Inc. 41

7.16

Procedure

Configuring the display in the Service application

7

Activating the "Diagnostics" function

⇨ The following screen will appear:

2. Click on "Pools".

⇨ The names of several folders will appear.

⇨ If the pool is empty, nothing will appear.

3. Click on the desired folder.

⇨ The contents of the folder will be displayed.

The names of the folders are the ISO IDs of the applications whose temporary data they

store.

4. Select the desired file.

5.

- Delete file.

⇨ Deleting file.

6.

- Restart display.

Activating the "Diagnostics" function

To activate the "Diagnostics" function, you must first activate its driver.

1. Switch to the "Driver" screen:

| Service | Driver

⇨ The following screen will appear:

2. Click on "Diagnostics".

3. Click on the "DiagnosticsServices" driver.

42 Mueller Electronics, Inc.

7.16.1

7.17

7.17.1

Procedure

Configuring the display in the Service application

Screenshots

7

⇨ Next to the driver the icon will appear.

4.

- Restart display.

⇨ The following function icon will appear on the start screen of the "Service" application:

⇨ You have activated the "Diagnostics" function.

Jobcomputer diagnostics

The screen "Jobcomputer diagnosis" contains a variety of information that is primarily important to

Customer Services. Customer Services can use this screen to determine which versions of the

hardware and software are installed on your display. This will speed up the diagnostic process if

errors arise.

Screenshots

A photo of the screen beeing displayed.

If an error occurs when you are using the display, Customer Services may ask you to capture a

screenshot.

A screenshot can be:

▪ emailed to Customer Services.

▪ sent to the farmpilot portal (provided you have activated the farmpilot portal)

Configuring the screenshots function

You have activated the "Diagnostics" function. [➙ 42]

1. Start the "Service" application:

| Service |

2.

– Open the "Diagnostics" screen.

3. Click on "Screenshot Settings".

4. Click on "Activate screenshots".

⇨ The status of the function is displayed on the icon:

- Function activated

- Function deactivated

5. Click on "Storage location".

⇨ The line will be highlighted with a frame.

6. Select "USB" to save screenshots on the USB flash drive.

7. Select "Portal" to send screenshots to the farmpilot portal.

Mueller Electronics, Inc. 43

7.17.2

Procedure

7.18

Procedure

Configuring the display in the Service application

7

CAN-Trace settings

Creating screenshots

You have configured the "Screenshots" function.

If you want to save the screenshots to the USB flash drive, you will already have inserted the

USB flash drive into the display.

1. Open any screen.

2. Press the following buttons in the order displayed and keep them pressed for a short while:

(on older displays you need to press the buttons in reversed order)

⇨ While the screenshot is being captured, the icon of a photo camera will be displayed in the

center of the display:

⇨ When the camera icon disappears, the screenshot has been created.

⇨ You will find the screenshot you captured in the location you specified as the "Storage location".

The USB flash drive saves the screenshots in the folder "ScreenCopy".

CAN-Trace settings

CAN-Trace is a function that logs the data exchange between the display and the connected

jobcomputers. Customer Services can use the logged data for diagnostic purposes should any errors

arise in the system.

If an error occurs when using the display, Customer Services may ask you to activate the CAN-Trace

function.

Only activate this function if prompted to do so by Customer Services.

1. Switch to the "CAN-Trace settings" screen:

| Service | | | CAN-Trace settings

1. Click on "Duration (min.)".

2. Set the duration. Specify for how long communication should be logged after the display has

been restarted. Communication can be logged for a duration of one to five minutes.

3. Click on "Storage location".

4. Select the storage location.

5. Select "USB" to save data on the USB flash drive. The USB flash drive must be inserted in the

display.

6. Select "Portal" to send data to the farmpilot portal. farmpilot must be activated before data can

be transferred.

7. Click on "Activate CAN-Trace".

⇨ The status of the function is displayed on the icon.

⇨ The icon

44 Mueller Electronics, Inc.

must appear next to "Activate CAN-Trace".

NOTICE

◦ Deactivate the farmpilot driver, when you are not using the portal.

7.19

7.19.1

Procedure

Configuring the display in the Service application

Configuring farmpilot

7

8. - Restart display.

⇨ After restarting the display, CAN-Trace will log the communication between the display and

the jobcomputer.

9. Leave the display switched on until the set CAN-Trace duration has elapsed.

⇨ The CAN-Trace function will be deactivated automatically.

10. If you specified USB as the storage location, verify that the file "StartupTrace.txt" exists on the

USB flash drive:

11. If this file is missing, you must run the CAN-Trace function again.

12. Email the "StartupTrace.txt" file to Customer Services. If you chose "Portal" as the storage

location, this file will have been sent automatically.

Configuring farmpilot

farmpilot is an internet portal which allows software on a farm computer to exchange data with

machines via a mobile phone network. Operating data is stored in a central location on the portal and

is presented clearly to the user.

Before you can use farmpilot in conjunction with your display, you must complete the following steps:

▪ Purchase a SIM card and have it activated.

▪ Activating farmpilot

▪ Enter your farmpilot access data

Refer to the following chapters to learn how to perform these steps.

Activating farmpilot

To activate farmpilot on your display, you must first activate its driver.

High costs from prolonged data transfer

If you do not have a flatrate in your mobile phone contract, continuous use of farmpilot can lead to

high costs.

If your flatrate has a data volume limit, continuous use of farmpilot can quickly use up your data

volume limit.

1. Switch to the "Driver" screen:

| Service | Driver

Mueller Electronics, Inc. 45

7.19.2

Parameter

Configuring the display in the Service application

7

Configuring farmpilot

⇨ The following screen will appear:

2. Click on "farmpilot".

3. Click on the "TPD" driver.

⇨ Next to the driver the icon

4.

- Restart display.

will appear.

⇨ The following function icon will appear on the start screen of the "Service" application:

⇨ You have activated the farmpilot portal.

You must now enter the access data for the farmpilot portal.

Configuring the connection with farmpilot

Before you can connect the display to farmpilot, you must configure the connection.

You will receive this data when purchasing the farmpilot access data.

You will require the following parameters for the configuration:

Username

Username for farmpilot.

Password

Password for farmpilot.

Provider

Opens a screen where the GPRS connection can be configured.

With most mobile phone providers, this configuration occurs automatically.

If the access data for the GPRS connection differ with your provider, you can configure the

connection manually.

You can find precise instructions in the chapter:

Configuring the GPRS connection manually [➙ 47]

Server

Server address

The server address cannot be altered.

46 Mueller Electronics, Inc.

Procedure

7.19.3

Parameter

Configuring the display in the Service application

Configuring farmpilot

7

Log

Switches logging ON and OFF.

Switch on logging only when prompted to do so by Customer Services.

1. Open the "Service" application:

| Service

2.

- Open the access data screen for farmpilot.

⇨ The following screen will appear:

3. Click on the line with the desired parameter.

4. Configure parameter.

Configuring the GPRS connection manually

In this chapter you will learn how to configure the GPRS connection manually.

With most SIM cards, the GPRS connection will be configured automatically.

The GPRS connection must be manually configured in the following instances:

▪ You have bought a new SIM card. The display does not recognise your mobile phone provider.

▪ Your mobile phone provider has altered the access data for the GPRS connection.

The values you must enter for the parameters, depend on your mobile phone provider. You can find

out these data from your mobile phone provider.

You will require the following parameters for the configuration:

Country

Country for which the SIM card is configured. Cannot be altered.

Provider

Name of the mobile phone provider. Appears automatically.

With unrecognised cards, you can enter the name of the mobile phone provider yourself.

APN

Abbreviation of "Acces Point Name“.

Address of the GPRS access point.

DNS 1 and DNS 2

Abbreviation of "Domain Name System“.

Mueller Electronics, Inc. 47

Function icon

Function

Controls

Procedure

7.19.4

Procedure

Configuring the display in the Service application

7

Configuring farmpilot

IP addresses of the first and second DNS servers

Number

Dialling code for the modem. Cannot be altered.

Username

Username for the GPRS connection.

Password

Password for the GPRS connection.

Retrieve default values.

You can configure the mobile connection as follows:

You have inserted the SIM card.

You have activated the farmpilot portal.

1. Switch to the configuration screen for the GPRS connection:

| | Provider

⇨ The following screen will appear:

2. Set GPRS connection parameters.

Sending diagnostic data to the portal

Customer Services may ask you to send diagnostic data to the portal. This allows Customer Services

48 Mueller Electronics, Inc.

to gather detailed information about your display and therefore examine it more thoroughly.

You have activated the "Diagnostics" function.

You have activated the farmpilot portal.

1. Switch to the "Diagnostics" screen:

| Service | | | Diagnostics

2.

- Send diagnostic data.

Configuring the display in the Service application

Configuring farmpilot

7

⇨ The following notification will appear:

“DeviceidentData transfer“

⇨ The data is being uploaded to the portal.

3. Wait until the "Sending DeviceIdentData" notification disappears.

⇨ The data have been uploaded to the portal.

4. If the process is taking too long, you can cancel the data transfer.

5.

- Cancel data transfer.

Mueller Electronics, Inc. 49

installed software

icon

green)

8

8.1

Tractor-ECU application

8

Adding a vehicle profile

Tractor-ECU application

The Tractor-ECU application allows you to:

▪ Create a profile for each vehicle, with specific settings.

▪ Input the sensors which are mounted on the vehicle.

▪ Input the position of the GPS receiver.

If you are using a self-propelled machine, you can simply enter the position of the GPS receiver. [➙

56]

After launching the Tractor-ECU application, the following screen will appear:

Tractor-ECU application start screen

Main section

Displays the current parameters.

Version number

Name of the application and version of the

If the value "…" appears for a parameter on the screen, the relevant sensor is not connected.

Function

Meaning

Calling up a list of vehicles

Adding a vehicle profile

50 Mueller Electronics, Inc.

List of vehicle profiles

Activated vehicle profile (the icon is marked in

List of all available vehicle profiles

Information on the marked vehicle profile

Cursor

icon

Procedure

8.2

Tractor-ECU application

Configuring the parameters for a vehicle profile

Function

Meaning

8

Add a vehicle profile

Vehicle profile cannot be deleted

Delete the vehicle profile

Back

1. Call up the Tractor-ECU application:

| Tractor-ECU

2.

3.

- Call up the vehicle list.

- Add a new vehicle profile.

⇨ A new vehicle profile appears on the screen.

⇨ You can now configure the parameters of the new vehicle profile.

Configuring the parameters for a vehicle profile

In a vehicle profile, you can set the sensors that you want to use.

List of parameters

Cursor

There are two ways to connect the sensors:

▪ The sensors are connected to the display [➙ 16].

▪ The sensors are connected to an agricultural device, which is connected to the display via CAN.

The data is transmitted from an external job computer or an external Tractor-ECU.

Mueller Electronics, Inc. 51

icon

56].

connected to the display.

display.

Procedure

Tractor-ECU application

8

Configuring the parameters for a vehicle profile

Function

Meaning Only appears if…

Switch to the "Settings" screen

Enter the position of the GPS receiver [➙

Activate the vehicle profile The selected vehicle profile is not

activated.

Back

Calibrate the speed sensor

Calibrate the working position sensor

A wheel sensor or radar sensor is used

for speed measurements. The sensor is

A hitch sensor - front or a hitch sensor rear is used to measure the working

position. The sensor is connected to the

1. Call up the Tractor-ECU application:

| Tractor-ECU

2.

- Call up the vehicle list.

3. Select the vehicle profile.

4. Change the desired parameters. You can also change the name of the vehicle profile.

Parameters in a vehicle profile

Only those parameters which you can use to configure the hardware version of your display are

shown.

Speed

Configuring the speed sensor. This measures the speed.

Potential values:

▪ "disabled"

No sensor measures the speed.

▪ "Wheel sensor"

A wheel sensor is connected to the display. The wheel sensor must be calibrated [➙ 54].

▪ "Radar sensor"

A radar sensor is connected to the display. The radar sensor must be calibrated [➙ 54].

▪ "GPS receiver"

The speed is calculated using GPS.

▪ "Unknown sensor via CAN"

52 Mueller Electronics, Inc.

Tractor-ECU application

Configuring the parameters for a vehicle profile

8

A wheel sensor or a radar sensor is connected to the display via CAN.

▪ "Radar sensor via CAN"

A radar sensor is connected to the display via CAN.

▪ "Wheel sensor via CAN"

A wheel sensor is connected to the display via CAN.

PTO revolution

Configuring the PTO (power take-off) revolution sensor. This measures the PTO revolutions.

Potential values:

▪ "disabled"

No sensor measures the PTO revolutions.

▪ "Revol. sensor - front"

A revolution sensor which is fitted onto the front PTO.

▪ "Revol. sensor - rear"

A revolution sensor which is fitted onto the rear PTO.

▪ "targets/turn"

Number of targets which the PTO transfers per revolution.

Working position

Configuring the working position sensor. This determines the working position.

Potential values:

▪ "disabled"

No sensor measures the working position.

▪ "Hitch sensor - front"

A working position sensor which is mounted on the front hoist. This is connected to the display.

The working position sensor must be configured [➙ 55].

▪ "Hitch sensor - rear"

A working position sensor which is mounted on the rear hoist. This is connected to the display.

The working position sensor must be configured [➙ 55].

▪ "Unknown sensor via CAN"

A working position sensor which is mounted on the front hoist or rear hoist. The working position

sensor is connected to the display via CAN.

▪ "Front via CAN"

A working position sensor is mounted on the front hoist. The working position sensor is

connected to the display via CAN.

▪ "Rear via CAN"

A working position sensor is mounted on the rear hoist. The working position sensor is

connected to the display via CAN.

Course

Configuring the course sensor. This measures the course.

Potential values:

▪ "disabled"

No sensor measures the course.

▪ "Unknown sensor via CAN"

A wheel sensor or a radar sensor is connected to the display via CAN.

Mueller Electronics, Inc. 53

8.2.1

Procedure

Tractor-ECU application

8

Configuring the parameters for a vehicle profile

▪ "Radar sensor via CAN"

A radar sensor is connected to the display via CAN.

▪ "Wheel sensor via CAN"

A wheel sensor is connected to the display via CAN.

▪ "Course sensor"

The course signal is transmitted to the display. Does not function if a working position sensor is

connected to the display.

▪ "inversion"

This parameter inverts the meaning of the signals. Only for use with the "Course sensor"

parameter.

Transfer offsets?

This allows you to set how the position of the GPS receiver is transmitted to the SECTION-Control

application.

Potential values:

▪ "Yes"

The offsets are transferred.

▪ "No"

The offsets are not transferred. Only select this setting when a ISOBUS-compatible tractor,

which transmits the geometry of the tractor to the ISOBUS, is connected to the display.

Calibrating the speed sensor

When calibrating the speed sensor using the 328.085ft (100m) method, determine the number of

targets which the speed sensor encounters over a distance of 328.085ft (100m).

If you know the number of targets for the speed sensor, you can also input this manually.

You have measured and marked a distance of 328.085ft (100m). The distance must correspond

to the field conditions. You must therefore drive across a meadow or a field.

The vehicle with the connected machine is operational for a 328.085ft (100m) drive and is at the

start of the marked distance.

You have connected a wheel sensor or radar sensor to the display.

You have selected the value "Wheel sensor" or "Radar sensor" in the "Speed" parameter.

1. Call up the Tractor-ECU application:

| Tractor-ECU

2.

- Call up the vehicle list.

3. Select the vehicle profile.

4.

54 Mueller Electronics, Inc.

- Press.

8.2.2

Procedure

Tractor-ECU application

Configuring the parameters for a vehicle profile

8

⇨ The following screen will appear:

5. When determining using the 328.085ft (100m) method: The action sequence is shown on the

display (100m = 328.085ft).

OR

For manual input:

6.

⇨ You have calibrated the speed sensor.

- Return to the vehicle profile.

- Input a value.

Configuring a working position sensor

If you measure the working position using a working position sensor, you must configure the sensor

before use.

During the configuration, you can choose between three types of sensor:

▪ "analog"

You are using an analog working position sensor, which measures the height of the hitch linkage

as a percentage.

▪ "digital"

You are using a digital, ISO-compatible working position sensor in accordance with ISO 11786.

The sensor is connected to the display via the signal socket.

▪ "ME-sensor Y"

You use a working position sensor provided by Mueller-Electronics. The sensor is connected to

the display.

You have connected a working position sensor directly to the display or via the signal socket to

the display.

You have selected the value "Hitch sensor - front" or "Hitch sensor - rear" in the "Working

position" parameter.

1. Call up the Tractor-ECU application:

| Tractor-ECU

2.

- Call up the vehicle list.

3. Select the vehicle profile.

4.

Mueller Electronics, Inc. 55

- Press.

What is the position of the GPS Receiver?

The distance should be entered as follows

to the right of the longitudinal axis

y

to the left of the longitudinal axis

- y

before the attachment point

x

8.2.3

Tractor-ECU application

8

Configuring the parameters for a vehicle profile

⇨ The following screen will appear:

5. Select a sensor type.

6. Select whether you want to invert the signal. Inversion only makes sense when you have

selected "digital" or "ME-sensor Y".

7. If you have selected "digital" or "ME-sensor Y":

- Return to the vehicle profile.

OR

if you have selected "analog": Move the hitch to the height at which the working position starts.

8.

9.

⇨ You have configured the working position sensor.

- Press to confirm.

- Return to the vehicle profile.