Page 1

operating instructions manual

HYDRO-GUARD

TABLE OF CONTENTS PAGE

®

Remote

Pressure

Monitoring

System

2.1.1

Installation and Site Evaluation 2-3

Installation and Operating Instructions 4

Operating Instructions 4-11

Battery Replacement and Technical 12

Troubleshooting and FAQ 13

Parts 14

Notes 15

!

WARNING:

Failure to read and follow the instructions contained within this manual

could result in serious personal injury, and/or damage to the Remote

Pressure Monitoring System.

1. Each person involved in the assembly, installation and/or maintenance

of the Hydro-Guard Remote Pressure Monitoring System must read

this manual carefully and follow all instructions prior to performing any

installation or maintenance procedures involving the Unit.

2. Be sure the corporation valve or other isolation valve is closed prior to

installation or removal of the pressure sensor.

3. Always use all necessary safety equipment and follow all recommended

procedures when installing, operating and maintaining the Hydro-Guard

Remote Pressure Monitoring System.

!

CAUTION:

When installing the Remote Pressure Monitoring System, ensure the known

pressure is less than 250psi. If pressure may exceed 250psi at identied

installation site, contact Mueller Co. for proper conguration.

Reliable Connections

Customer Service Center

Decatur, Illinois

800.423.1323

www.muellercompany.com/hydro-guard

moreinfo@muellercompany.com

The content of this manual is the sole and exclusive property of Mueller Co.

Unauthorized distribution or reproduction strictly prohibited.

TM

Page 2

General

HYDRO-GUARD

®

Remote Pressure Monitoring System

Installation and Site Evaluation

Each Remote Pressure Monitoring

System, consists of an RTU and

Sensor, (here-by known as Device).

Prior to the installation of the Device,

strategic installation points should be

identied. Conrmation of a cellular

signal (Verizon or AT&T) is available

at the identied site. Contact Mueller

Co. for additional support if required.

When installing the Remote Pressure Monitoring System with a valve

box into the distribution network,

identify the OD and type of pipe as

well as the depth requirement prior

to ordering. Mueller Co. can assist

in verifying that the proper saddle

and valve box can be supplied.

The Remote Pressure Monitoring

System lid-mounted antenna shall

be installed no more than six (6)

inches below-grade to ensure the

cellular communication signal is not

impeded.

GPS Location Considerations

Each Device contains a cellular

modem and GPS locator. Some

obstacles can interfere with the

signals required for each of these

to operate properly. Conrmation

of cellular signal can be obtained

with a standard cell phone. If GPS

is unavailable, the location of the

Device can be entered manually

into the software. Address or

GPS coordinates should be noted

upon installation. To obtain GPS

coordinates (longitude and latitude

coordinates), it is recommended that

you utilize a GPS location APP or

website. Enter the nearest physical

street address to the site where the

Device will be located into a GPS

coordinate APP or website to obtain

the GPS coordinates. Upon obtaining

the information, enter the longitude

and latitude coordinates into the

Device Management website. Log

into account and open the Device

which is to be mapped. Select “Edit”

and enter longitude and latitude

coordinates in the appropriate elds.

Shipping

The Remote Pressure Monitoring

System is powered by a series

of lithium batteries. Specic and

approved shipping procedures must

be observed. The Remote Pressure

Monitoring System may be shipped

with or without a valve box and

ancillary items depending on the

customer’s desired installation. In

the event of the unit being returned

for service, contact Mueller Co.

Customer Service for approved

shipping and handling information.

NOTE: The RTU can only be

shipped via ground transportation

and must be properly labeled

to identify presence of lithium

batteries. Contact Mueller Co. at

877.864.8500 before shipping.

InstallatIon

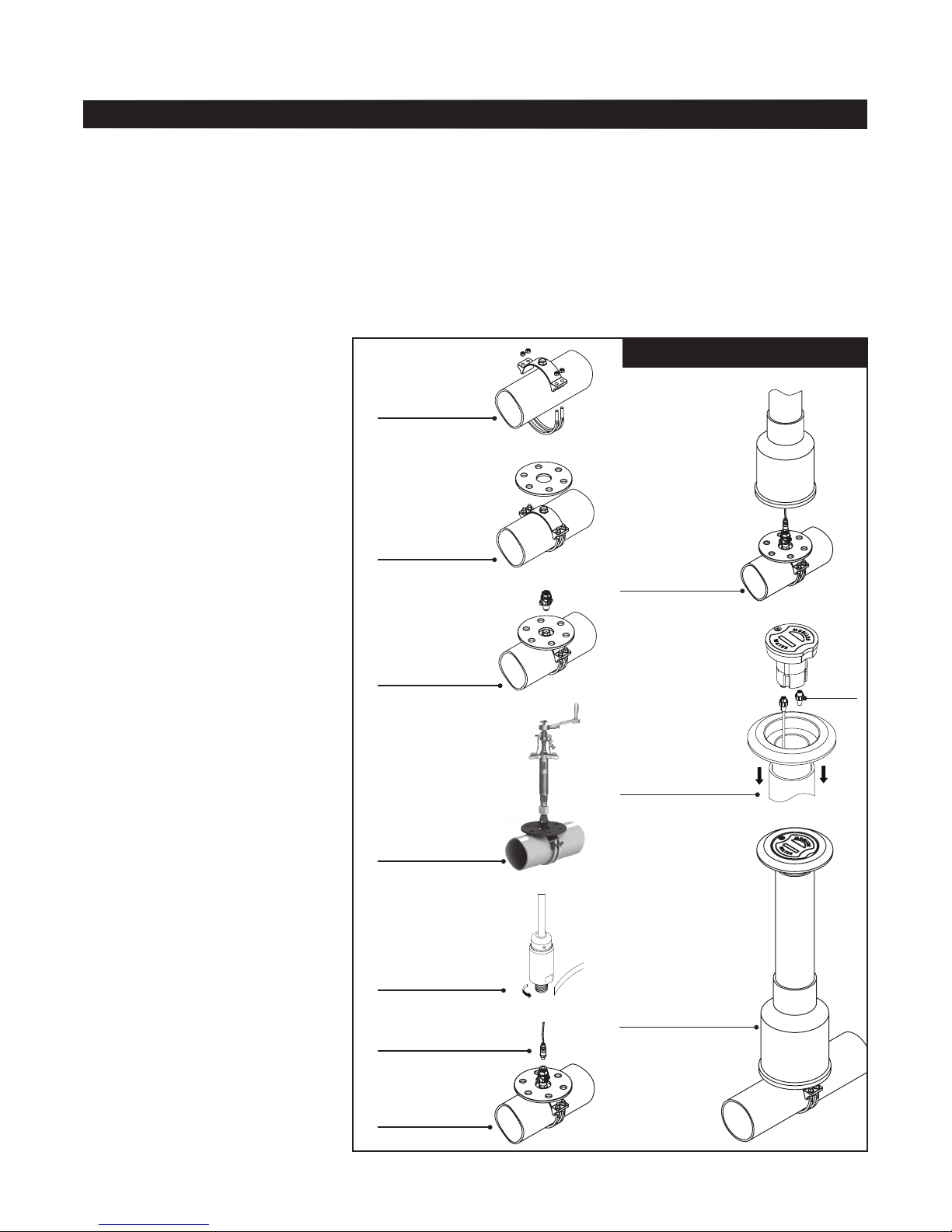

Installation in a Valve Box

1. Remove the Remote Pressure

Monitor from its packaging and

inspect for possible damage during

shipping.

2. Once service saddle installation

is complete, install guide plate

(P/N: 147506P) over the service

saddle and apply suitable sealant

or joint tape to the inlet side of the

corporation valve before installing

into the saddle. Thread the

corporation valve into the service

saddle as shown (see page 3). The

guide plate will center the valve box

bell end over the service saddle and

corporation valve.

NOTE: Before drilling, ensure

guide plate is in between the

service saddle and corporation

valve (see page 3).

3. Perform the drilling operation

adhering to the following operating

instructions for the particular Mueller

Co. Drilling Machine being utilized:

• D-5/E-5: Form 9335

• Mega-Cut: Form 12092

• Tru-Cut: Form 11941

• PL-2: Form 10292

Mode Normal

Request maintenance mode

Status Critical High

Latitude 35.0757516666667

Longitude -85.1868716666666

Uploads per Day 0

ICCID 8901 1704 2580 2049 4799

2

Page 3

HYDRO-GUARD

®

Remote Pressure Monitoring System

Installation

4. After the drilling operation is

complete and corporation valve is

closed, apply a suitable sealant or

joint sealing tape on the inlet side

of the ¾” threads on the supplied

bushing. Securely attach the ¾” end

of the bushing to the outlet of the

corporation valve.

NOTE: Avoid use of excessive

sealant. Avoid contact with sensor

transducer tip.

5. Securely attach the pressure

sensor to the ¼” end of the bushing.

Utilize a suitable sealant or joint

sealing tape on the inlet threads

of the pressure sensor to ensure a

proper seal.

NOTE: Avoid use of excessive

sealant. Avoid contact with sensor

transducer tip.

6. Prior to installation of pressure

sensor dry the interior of the

corporation stop threaded

connection.

7. Once the sensor has been

attached, turn the corporation valve

to the “open” position. Run sensor

cable through composite valve box

when installing pressure sensor.

Refer to the installation instructions

®

for the Mueller

composite valve box

(Form MC014).

NOTE: When paving and

compacting asphalt, use a Mueller

iron lid (P/N: AJBV-4CWATER)

to prevent damage to the RTU.

Once asphalt work is completed,

replace iron lid with the RTU. Be

sure the sensor tip is exposed to

line pressure prior to connecting

the sensor cable to the RTU.

8. Once the corporation stop has

been opened and pressurized,

plug the male end of the multi-pin

connector of the sensor cable into

the mated connector of the RTU

(located on bottom of RTU).

9. Once the RTU and cable are

connected, insert the RTU into the

ductile iron top section.

NOTE: Be certain that the lid of

the RTU is mounted ush with the

surface of the ductile iron valve

box top section.

10. The pressure monitor will begin

operating once the sensor cable

is plugged into the RTU and the

pressure sensor is exposed to line

pressure. The rst reading may take

up to 24 hours to be transmitted to

the website. The Device will reveal

system pressures with no additional

inputs. In order to customize

A. Install service

saddle.

B. Install guide

plate.

C. Thread corporation

valve into service

saddle. Valve should

be open.

D. Perform drilling

operation.

E. Apply joint-sealing

tape to threads of

pressure sensor.

F. Dry interior of

threaded connection of

corporation stop.

G. Thread pressure

sensor into

corporation valve.

Open valve.

pressure level notications, the

following four (4) values may be

set on the measurements screen:

Warning High, Warning Low, Critical

High, and Critical Low. Entering the

above mentioned inputs into the

system is described in the “Getting

Started” on page 4.

H. Install valve box

over the assembly.

I. First, ensure

waterproof plug is

plugged in. Install

adjustable top into valve

box. Plug sensor cable

into Black connector on

RTU and hand tighten

connector. Insert RTU

into adjustable top.

Carefully back ll and

pave area around valve

box per direction by

engineer of record.

J. Installation complete.

Ready for pressure

monitoring. Log onto

www.miwwt.net to view

data.

§

Page 4

HYDRO-GUARD

®

Remote Pressure Monitoring System

Installation and Operating Instructions

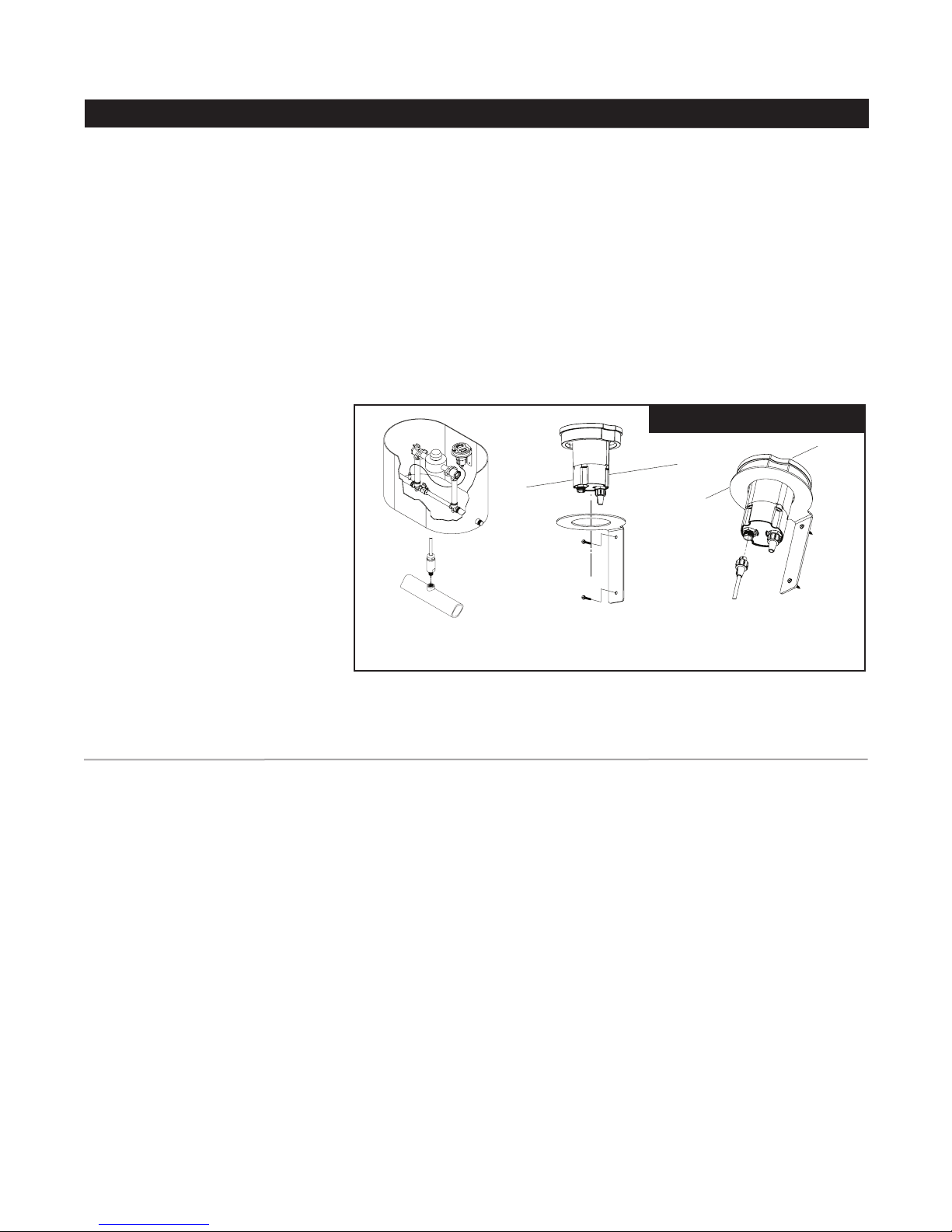

Installation in a Meter Box, Vault,

or other Structure

1. Remove the Device from its

packaging and inspect for possible

damage during shipping.

2. Apply sealant or joint tape to

pressure sensor and thread into

available ¼” NPT port.

NOTE: Avoid use of excessive

sealant. Avoid contact with sensor

transducer tip.

3. Install supplied mounting bracket

onto setter or to side wall of meter

vault no more than 6 inches

below grade to ensure the cellular

communication signal is capable of

transmitting and receiving data.

4. Be sure sensor tip is exposed to

line pressure prior to connecting

the sensor cable to the RTU.

Connect the sensor cable to the

RTU connection port located on

the bottom side of the RTU. The

pressure monitor will begin operating

once the sensor cable is plugged

into the RTU and the pressure

sensor is exposed to line pressure.

The rst reading may take up to

24 hours to be transmitted to the

website. The Device will reveal

system pressures with no additional

inputs. In order to customize

pressure level notications, the

following four (4) values may be

set on the measurements screen:

Warning High, Warning Low, Critical

High, and Critical Low. Entering the

above mentioned inputs into the

A. Apply joint-sealant and

thread pressure sensor into

NPT port. Turn on the water.

B. Install mounting

1

bracket to wall of meter

/4”

box/vault.

system is described in the “Getting

Started” below.

NOTES: For best communication

performance RTU must be

installed vertically with the ange

facing up.

Composite lids must be utilized in

vaults or boxes to ensure cellular

communication, unless a suitably

sized hole is cut into a cast iron

lid that will allow the composite

lid to be mounted in the vault

cover.

C. Plug sensor cable into

Black connector on RTU

and hand tighten connector.

operatIon and system monItorInG

Getting Started

The Device will begin logging data

once the sensor cable is plugged

into the Remote Terminal Unit (RTU);

however pressure readings may take

up to 24 hours to be transmitted to

the website. The Device will reveal

system pressures with no additional

inputs. Up to four (4) customizable

values can be entered into the web

based control panel (Warning High,

Warning Low, Critical High, and

Critical Low).

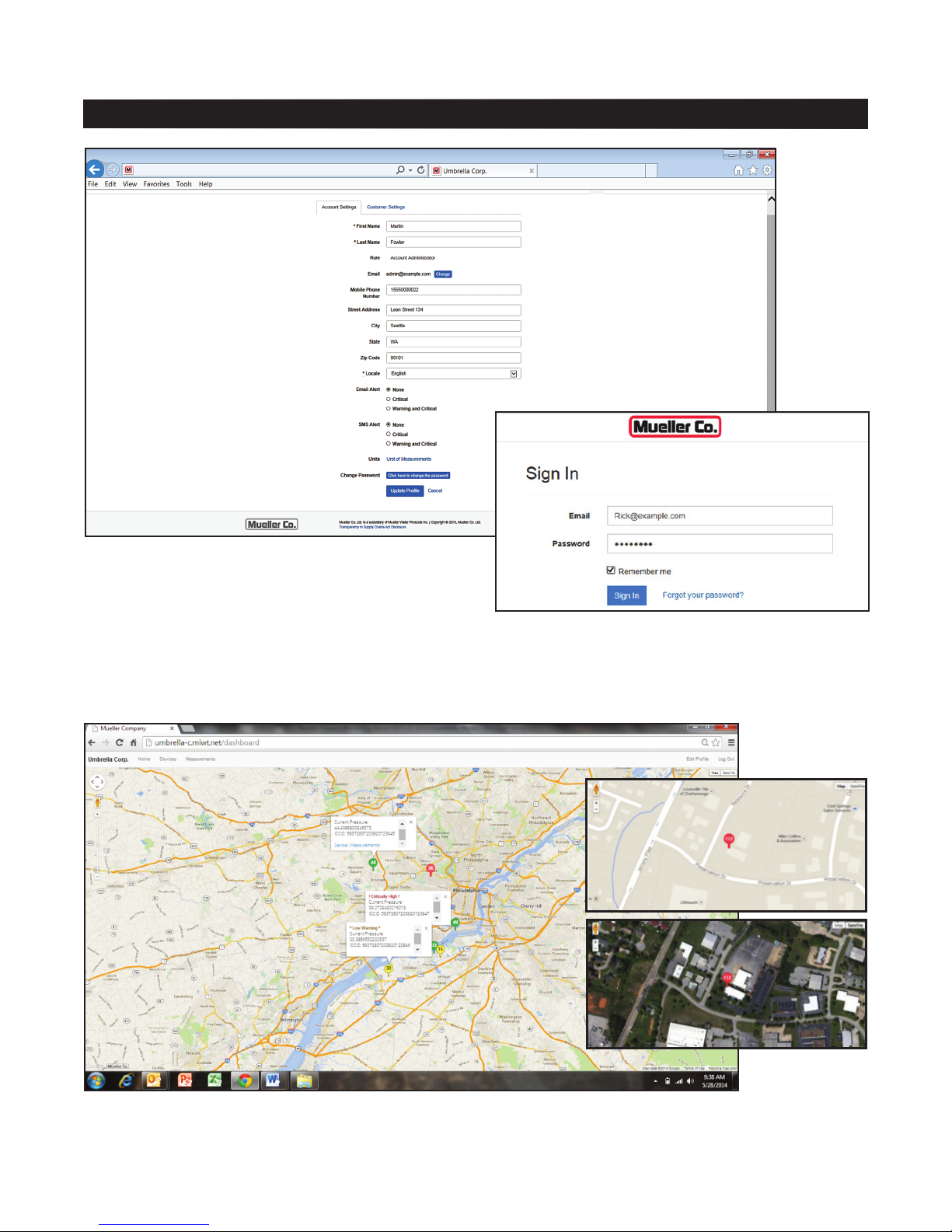

Upon entering the client’s order,a

Mueller Customer Service Specialist

will send an administrative email to

the client administrator (end user)

identied on the order form. The

email will contain a web link that will

direct the client administrator to the

Device registration web page. The

Registration web page will allow

the client administrator to enter a

password; select how the system

shall send event notications (i.e.,

SMS-text messaging, email – both,

or none); and time zone settings.

NOTE: The Hydro-Guard

Monitoring System registration

email invitation will be sent from

NOREPLY@MIWT.NET. In the event

the customer does not receive

an invitation email, please check

spam folders for the receipt.

Some servers will block the

message as spam until unblocked

by the client. Suggestion: To

ensure the email is received

please email Mueller Co. at

NOREPLY@MIWT.NET upon the

placement of your order.

Once registered, users may log into

the Mueller secure web page via the

address: miwt.net. Once logged into

the system, registered users can

customize their management prole

by selecting the “Edit Prole” tab on

the top navigation bar.

4

Page 5

HYDRO-GUARD

®

Remote Pressure Monitoring System

Operating Instructions

REGISTRATION PAGE: This page will allow the

client administrator to enter a password; select how

the system shall send event notifications (i.e., SMStext messaging, email – both, or none); and time zone

settings. Once registered, users may log into the

Mueller secure web page via the address: miwt.net.

SIGN IN PAGE: Once registered, users may access

current and historical pressure readings and view

trending graphs by logging onto the system via the Sign

In screen.

HOME PAGE: Once signed into the “Device’s” home page an installation location map will appear. All pressure moni-

tored locations within a client’s distribution network will be viewable on the customer’s secure website and interactive online

map. To view measurements or to edit settings for a specific monitored location click the associated icon on the map.

5

Page 6

HYDRO-GUARD

®

Remote Pressure Monitoring System

Operating Instructions

EDIT PAGE: From the “Edit Device” menu the viewer can select any existing Device to be edited. Selecting the “Edit”

tab will advance the viewer to the edit screen where the viewer can view or customize the “Device’s” management and

sampling parameters. On the administrator screen (above), the customer can enter or change alert levels.

• Data Upload/CONNECT function:

The Hydro-Guard

Monitoring System has been preprogrammed for one data upload

per day (default). This setting can

be modied to upload data weekly,

daily, or up to 24 times per day. To

modify the number of data uploads

open the Device SETTINGS web

page and locate the calendar

application at the lower section of

the management screen. Using the

blue PLUS button, open the drop

down navigation. Select CONNECT

to select the date(s) and time(s) to

initiate a data upload.

®

Pressure

• MAINTENANCE function: The

Hydro-Guard® Pressure Monitoring

System allows for the scheduling of

an immediate response log report,

referenced as the MAINTENANCE

mode. This mode can be scheduled

or operated on an “as needed”

basis.

• TRANSIENT MONITORING

function: The Hydro-Guard

Pressure Monitoring System has

the ability to monitor for transient

pressures (up to 256 readings per

second). This function must be

scheduled. To schedule a transient

monitoring session open the Device

®

SETTINGS web page and locate

the calendar application at the lower

section of the management screen.

Using the blue PLUS button,

open the drop down navigation.

Select PRESSURE-TRANSIENT

CAPTURE. The select the date(s)

and time(s) to schedule the Device

to measure and log transient activity.

!

WARNING: Operating in

the PRESSURE-TRANSIENT

CAPTURE mode for more than

thirty (30) days during the life

of the Device can reduce the

Device’s overall battery life.

Page 7

HYDRO-GUARD

descrIptIon of the setup

®

Remote Pressure Monitoring System

Operating Instructions

• Phone Number: The phone

number associated with the

individual RTU is located on the

bottom of the unit.

• Description: Customers notes for

the particular site.

• Latitude and Longitude: GPS

location of the unit is automatically

determined when the Device is

installed. In the event the GPS

signal is obstructed and unable to

locate the Device, the installer can

manually enter the location on the

MIWT website by selecting Device

in the navigation bar and locating the

proper Device. Click on the Device

to be manually located and select

“Edit” in the system management

screen to enter the longitude and

latitude of where the Device has

been deployed. To determine the

longitude and latitude of the Device,

locate the nearest street address to

the installation location. Using online

resources, locate the longitude and

latitude coordinates for the street

address used.

• High Warning and Low Warning:

Pressure level at which the customer

is notied via SMS and/or Email.

• Critical High and Critical Low:

Pressure at which the customer is

notied via SMS and/or Email.

• Elevation: For operators

interested in viewing head pressure

measurements, the Device will pull

the elevation for the installation

point from the GPS mapping system

and enter it into this management

eld. In the event the GPS is not

able to populate this management

eld the eld will be zero. A manual

entry can be made in this eld if the

management eld does not populate

automatically.

• Uploads Per Day: Number of

hours between data uploads.

Recommended value is 2 (Default

setting is 1). Once all desired

management changes have been

made complete the update by

clicking on the SAVE button.

NOTES: Alerting messages occur

when readings register above or

below Warning and Critical Values

dened by the end user. User may

dene warning levels and critical

levels for high and low pressures

using the web interface. Alerts

are sent when two consecutive

readings are above or below the

user dened levels.

Up to a 5-year battery life can be

expected when recommended

settings are utilized. Some

settings outside of the

recommended settings may

reduce expected battery life.

To access a specic Device in

a distribution network in order to

update or change settings of that

Device, navigate to the Device by

either clicking on the Device from

the HOME/MAP SETTINGS or use

the top navigation bar to navigate

to the RTU INDEX. Both paths will

allow access to the settings specic

to a Device installed in the eld.

From here the operator can update

the specic Device’s description;

longitude and latitude; number of

uploads per day; warning set points;

and scheduling for monitoring and

reporting of activity.

DEVICE PAGE: The “Device”

home page contains specific

information including location, alarm

settings, and logging intervals.

Authorized administrators or

technicians can modify the Device

settings from within the Device

page.

The “Measurements” tab opens

the data log screen which allows the

user to browse data over various

time frames for individual units.

7

Page 8

HYDRO-GUARD

MIN / MAX / AVG

Transient

Readings

®

Remote Pressure Monitoring System

Operating Instructions

MEASUREMENTS PAGE: From the Measurements page, the viewer can select a time frame to be viewed for the all

units or select units. For example, by selecting “Month” all the data collected by an identified unit in the past month is

shown on an operational curve of Pressure (psi) over that period of time. Measurements recorded today; over the past

two days; over the past week; or even those recorded over the past two years can be viewed on the Measurements page.

Data trend mapping includes minimum, maximum and averages for every hour, as well as transient state reports.

DATA LOG AND INFORMATION DOWNLOADS: Pressure measurements can be reviewed in log form. From the

Measurements page select the View Measurements tab (see highlighted area). A running log of measurements can

be viewed; notes related to the log entry can be added; and all information can be downloaded as a CSV or XLS file

for system management recordkeeping.

8

Page 9

HYDRO-GUARD

software applIcatIon upGrade

®

Remote Pressure Monitoring System

Operating Instructions

AUTOMATED DATA TRANSFER

AND LOGGING: The released

Hydro-Guard App 1.0.0 software

for the Hydro-Guard Pressure

Monitoring System allows operators

of the second generation product

to schedule data transfers from

each RTU to a designated storage

folder located on their computer or

network. To begin, start Launch of

software application and log into the

utility’s MIWT.NET account. Follow

these steps:

1. Located the settings icon (Y) and

select;

2. Click on the Hydroguard App

1.0.0 link to download the application

le to a dedicated computer(s);

3. Once the application is loaded on

the dedicated computer(s) click on

the le to unpack the zipped le;

4. Extract the software application’s

management les by clicking on

the Hydroguard App 1.0.0.exe

application;

5. Click on the EXTRACT ALL

button to open le location

preference screen.

This link will allow for the preferred

folder location to be selected—

where the Hydro-Guard Pressure

Monitoring spreadsheets will be

saved;

6. Select the preferred location for

where data should be stored;

7. Open folder to view saved data

log spreadsheets.

NOTE: 1 & 4 = Maximum; 2 & 5 = Average; 3 & 6 = Minimum.

ENHANCED TREND MAPPING: View MINIMUM, MAXIMUM and AVERAGE pressure readings for every hour on

an enhanced graphical trend map at miwt.net.

9

Page 10

®

HYDRO-GUARD

Remote Pressure Monitoring System

Operating Instructions

Mueller Tech Center Home Users Devices Measurements

Description Pressure Warning Low Critical Low Warning High Critical High

Test_Device: 3; Sensor Serial: 1419200209 56.1 1.0 2.0 175.0 180.0

PowerAnalyzer Device 4.5 1.0 2.0 262.0 270.0

Test_Device: 2; Sensor Serial: 1419200174 56.8 1.0 2.0 175.0 180.0

Test_Device: 4; Sensor Serial: 1419200230 56.2 1.0 2.0 175.0 180.0

Tim S Test Unit 112.7 20.0 40.0 80.0 100.0

Device #3 No data 20.0 25.0 180.0 200.0

Test_Device: 5 260.2 20.0 25.0 180.0 200.0

GPS Development Unit 260.1 20.0 25.0 180.0 200.0

8901 1704 2580 2049 4732 57.9 20.0 25.0 180.0 200.0

8901 1704 2580 2049 4716 57.3 20.0 25.0 180.0 200.0

8901 1704 2580 2049 4724 57.2 20.0 25.0 180.0 200.0

8901 1704 2580 2049 4708 56.9 20.0 25.0 270.0 280.0

Verizon A1 0000 42F1 6926 261.7 10.0 40.0 80.0 110.0

INSTALLING ADDITIONAL PRESSURE MONITORS: New monitoring Devices will automatically appear on the

customer web interface once installed. It may take up to 24 hours for data and location to appear after installation.

054 Timothy Blair Account Administrator tjblair@muellercompany.com 2711024610 Delete

ADDING USER ACCESS: Users may be added by the Administrator at any time using the “Invite Users” button

under the “Users” Screen shown in the image below.

View Pressure Data X X X

View RTU Settings X X X

View and Edit Personal Data X X X

Annotate Pressure Data X X

Change RTU Settings X X

Change User Privileges X

Add/Remove Users X

10

Page 11

HYDRO-GUARD

®

Remote Pressure Monitoring System

Operating Instructions

ANALYTICS: The Hydro-Guard® Monitoring System features an analytic function that allows an operator to compare

measurements against one another for enhanced distribution system management.

11

Page 12

HYDRO-GUARD

Battery replacement

®

Remote Pressure Monitoring System

Battery Replacement and Technical Information

Batteries are eld replaceable and

can be ordered through Mueller

Company. DO NOT disassemble the

RTU until the replacement batteries

have arrived with replacement

instructions included. Contact

Mueller Customer Service for safe

handling and return instructions for

used batteries.

!

WARNING: Battery must be

replaced by a qualied electrical

technician. Contact Mueller Co.

for additional support.

1. Remove ten (10) screws to

separate the battery compartment

from the antenna and micro

computer.

2. Carefully slide out the antenna

wire retainer from the battery

compartment so that the antenna

wires are free.

3. Disconnect battery lead connectors

and reconnect new battery pack

using the mated connectors on the

replacement battery. Ensure wires

are securely connected before

moving to step 4.

NOTE: Be sure to connect similar

color wires.

4. Reinsert the antenna wire retainer.

5. Reattach the ten (10) screws.

NOTE: Unit includes Lithium

batteries which should be

returned to Mueller Co. for proper

disposal. Return instructions will

be provided with replacement

parts. Contact Mueller Customer

Service for assistance.

Other Options

Optional Valve Box Lengths:

• 3’, 5’, 7’, 9’

Service Saddles:

• Bronze Double Strap (up to

200psig)

• Ductile Iron Double Strap (over

200psig)

• Bronze OD Controlled for PVCPipe

(up to 200psig)

Pressure Sensors:

• Up to 250psig

• Pressures over 250psig*

*Indicates Standard Option

§

1

2

3

4

1 Antenna and Lid

2 Battery

3 Power Wires

4 Antenna Wire Retainer

5 Micro Computer

6 Connectors

6

5

technIcal InformatIon

Battery Life: Five (5) Year minimum

when recommended settings are

utilized.

Pressure Range: 0 to 250psig.

Standard Sensor Pressure (0 to

250psig) Over Pressure: In the

event that the pressure exceeds

250psig, per the manufacturers

specication, the the overpressure

rating of the sensor is 700psig;

however, the sensor may be

damaged should pressure exceed

500psig. The RTU will only identify

pressures up to 250psig.

Operating Temperature Range:

–30°F to 150°F.

Pipe Diameter Range: ½” or larger.

Default Sampling Range: 1 sample

every 15 seconds.

Transient Pressure Monitoring:

Scheduling of transient monitoring is

available with this product. Transient

pressures will be measured at a

rate of 256 samples per second

for a scheduled period of time as

dened by the operator. Mapping

12

of transient-state data points will

be less than 256 data points. Data

mapping is dependent upon volatility

of transient activity.

Resolution: 12-bit

Accuracy: +/– 2psi (250psi sensor)

+/– 5psi (500psi sensor)

NOTE: Some settings outside of

the recommended settings may

reduce expected battery life.

Page 13

®

HYDRO-GUARD

Remote Pressure Monitoring System

trouBleshootInG and frequently asked questIons

Troubleshooting and FAQ

Troubleshooting Guide

Customer/User does not receive

acknowledgement email when new

users are set up.

Customer email system must

be able to receive email from

noreply@miwt.com. Contact your IT

department to make sure this email

address is not blocked.

Frequently Asked Questions

(FAQ’s)

Q. What is my cost of ownership?

A. The initial purchase price of

the unit includes the rst year of

cellular service and a 5 year battery.

Additional years of cellular service

and a 5 year replacement battery

may be purchased from Mueller

Company. Additional costs may

include installation of the unit by

others.

Q. Who manages my web

account?

A. The customer’s administrator who

is to be identied at the time of the

initial purchase. Customer can add

or remove administrators as desired.

Contact Mueller Customer Service if

the administrator changes.

Q. Who has access to the

website?

A. Customer administrator may

grant access to an unlimited number

of authorized users within their

organization. Roles that can be

assigned are: User, Administrator,

and Technician. These roles have

different accessibility to data.

Administrator: Administrative and

Editing Rights

Technician: Viewing and Editing

Rights

User: Viewing Rights

Q. Where is the data stored?

A. Customer specic data will be

uploaded to a secure cloud based

system that is only accessible by the

clients authorized personnel and the

Mueller system administrator.

Q. Who does the data belong to?

A. All data captured by the Device

is the sole property of the client.

Mueller does not review or analyze

data unless specically requested to

do so for technical service purposes

only.

Q. Can the data be downloaded?

A. Yes, data can be downloaded

into Microsoft™ Excel® or other

spreadsheet management software.

Q. How long is the data stored on

the web?

A. Data is stored in the cloud-

based storage for a period of two

years. Data older than two (2) years

is automatically purged from the

customer’s database.

Q. Will the pressure monitoring

system work with Mueller

Systems Monitoring Software?

A. Not currently.

Q. At what frequency should the

sensors be installed?

A. A minimum of two (2) per district

metering area (DMA) or pressure

zone.

Q. Are the Pressure Monitoring

Systems SCADA compatible?

A. When connecting any SCADA

system to an outside source it is

advisable for the system integrator

to comply with the data security

guidelines found in NIST Special

Publication 800-82 “Guide to

Industrial Control Systems (ICS)

Security. For additional information

refer to http://csrc.nist.gov

publications/nistpubs/800-82/SP800

82-nal.pdf

Q. Will the Pressure Monitor

notify of power failure?

A. Data storage is unaffected by

power failures; however, if cellular

service is interrupted or the Pressure

Monitoring System malfunctions,

data transfer will discontinue and

service may be required. Notication

of a system power failure will be

indicated by the Device’s failure to

report data.

13

Page 14

HYDRO-GUARD

®

Remote Pressure Monitoring System

Parts

1

§

2

4

3

14

5

replacement parts

1 3/8 ” Ø x 13/8” shoulder x 5/16” - 5/18” screw – SS

2 Antenna/Composite Lid

3 RTU (Remote Telemetry Unit) w/Lithium Batteries

4 AJBV-4D Ductile Iron Adjustable Top – 12” L

5 Mueller Composite Valve Box – 5 ft.*

6 Male-end Sensor Cable Connector

7 Mueller Valve Box Guide Plate

8 Sensor Cable Sub-Assembly

9 Pressure Sensor

10 ¾” NPT to ¼” NPT Reducer Bushing

11 Mueller 300 Ball Corp. Valve, ¾”

12 Bronze Service Saddle – Double Strap**

13 Mounting Bracket

14 Waterproof Plug

10

11

* Valve Box also available in 3’, 7’, and 9’ lengths.

**Bronze Slip Hinge Saddles Available for IPS & C900 PVC. If the

pressure may exceed 200psi, a ductile iron saddle should be used.

6

7

8

9

9

10

8

2

13

12

14

Page 15

HYDRO-GUARD

®

Remote Pressure Monitoring System

Notes

15

Page 16

Water (U.S.)

1.800.423.1323

Reliable Connections

Copyright © 2018 Mueller Co., LLC. All Rights Reserved. The trademarks, logos and service marks displayed in this document herein are the

property of Mueller Co., LLC, its afliates or other third parties. Products marked with a section symbol ( § ) are subject to patents or patent

applications. For details, visit www.mwppat.com. These products are intended for use in potable water applications. Please contact your Mueller

Sales or Customer Service Representative concerning any other application(s).

TM

www.muellercompany.com

moreinfo@muellercompany.com

International

1.423.490.9555

www.mueller-international.com

international@muellercompany.com

Form 12942 – Rev 10/18

Loading...

Loading...