Page 1

Prefabricated

Steel building

inStallation Manual

Page 2

Page 3

TABLE OF CONTENTS

A. Site and Foundation Preparation

General Information................................................. 1

Squaring of Foundation..............................................2

Anchor Bolt Settings ...............................................3-4

B. Building Delivery and Storage

Unloading and Preparation of Parts for Assembly ..........................1

Unloading, Handling, and Storage of Materials ............................2

Location of Building Parts ............................................3

Care and Handling of Mueller Sheet Metal...............................4-6

C. Erection of Primary and Secondary Structural

General Information................................................. 1

Tools and Equipment Required ........................................ 2

Typical Building Parts ............................................... 3

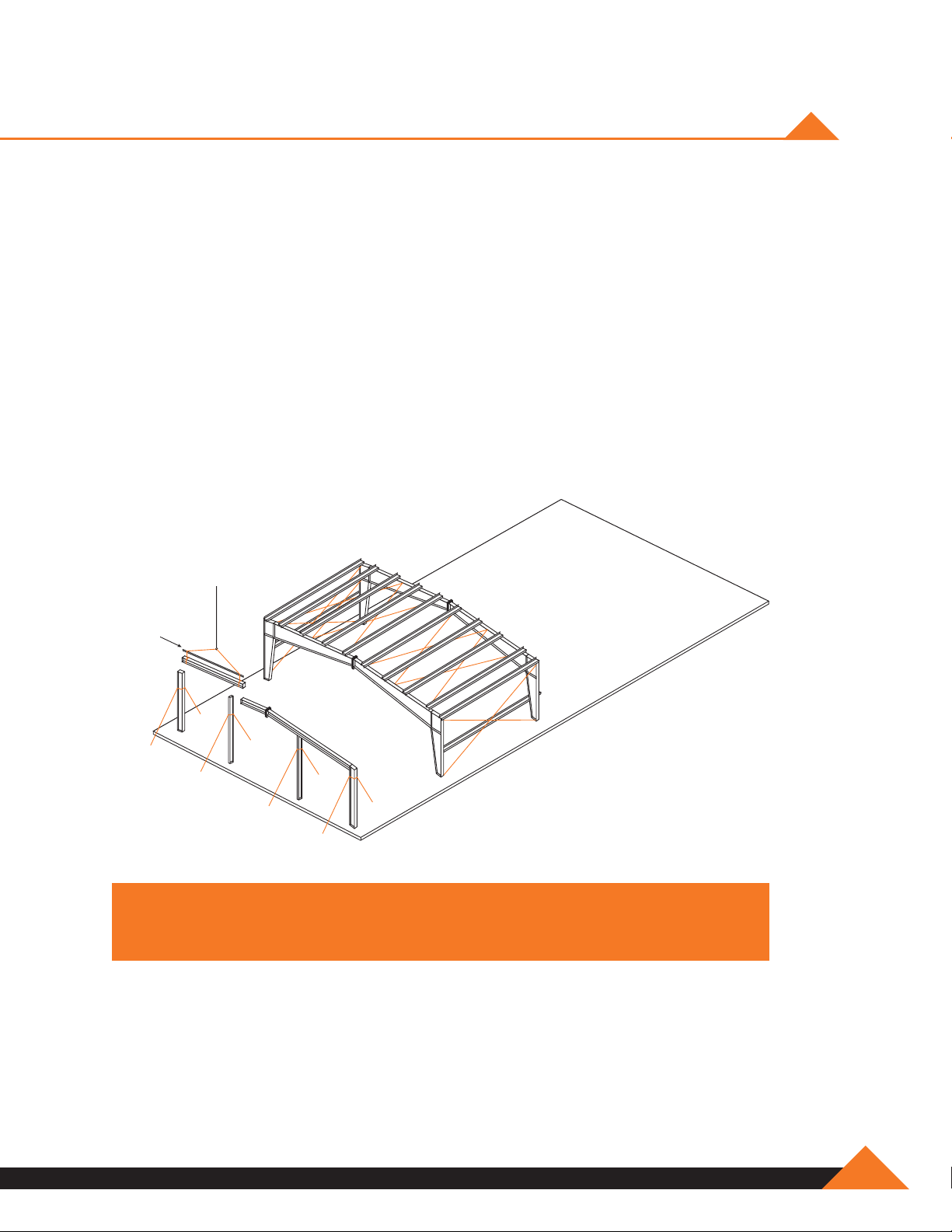

Raising Rigid Frames ..............................................4-8

Erecting Column and Beam Endwalls ...................................9

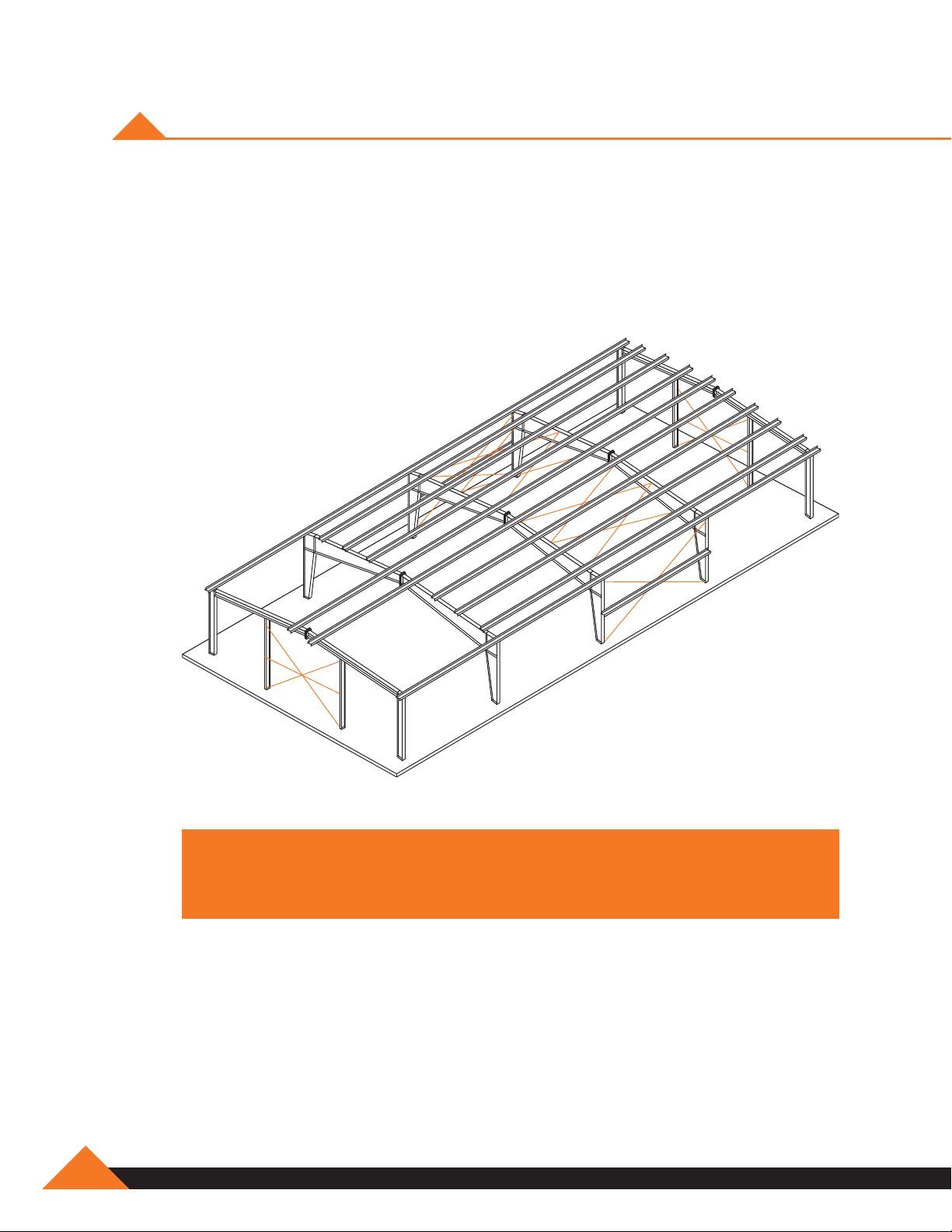

Erecting Remaining Frames........................................10-11

Assembly of Brace Cables ..........................................12

Installation of Wind Bracing ........................................13-16

D. Insulation

Wall Insulation ....................................................1-2

Roof Insulation ...................................................3-5

E. Sheeting

Fastener Layout ...................................................1

Aligning the Girts...................................................2

Screw Alignment..................................................3-4

Installation of Wall Panels ...........................................5-9

Preparing the Eave ..............................................10-11

Installation of Roof Panels .........................................12-24

Skylight Installation ..............................................25-26

www.muellerinc.com

Page 4

METAL BUILDING TERMS AND DEFINITIONS

F. Trim

Flashing .........................................................1

Peak Sheet Ridge Installation .........................................2

Typical Screw Placement for Peak Sheets/Ridge Roll ....................... 3

Sealant Tape Application at Ridge Flashing ...............................4

Rake Trim ........................................................ 5

Corner Trim ....................................................... 6

Eave Trim .......................................................7-9

Gutter ........................................................10-13

Door Trim .....................................................14-15

Overhang Trim Details ..............................................16

G. Doors and Accessories

Personnel Doors ..................................................1-2

Roll-Up Doors ..................................................... 3

Windows......................................................... 3

Ridge Vents......................................................4-7

Pipe Deck Flashing .................................................8

H. Glossary

Metal Building Terms and Definitions ...................................1-9

877-2-MUELLER

Page 5

SECTION A

Site & foundation

PreParation

Page 6

Page 7

PREPARATION OF SITE AND FOUNDATION

1. General

Before the Mueller prefabricated steel building arrives, the site and foundation should be prepared.

This includes leveling the terrain and constructing the foundation. Mueller buildings are typically

designed to be placed on a permanent slab. A concrete contractor is highly recommended for this

phase of the construction.

2. Procedural Steps

A. Remove trees, debris, and other items from the building location.

B. Smooth and level the ground where the foundation is to be made.

C. Construct the foundation using the materials recommended by your concrete contractor.

NOTE: Mueller Steel Building Systems will provide blueprints that show placement in

the concrete slab. Check the anchor bolt plan thoroughly upon receipt. If you

have any questions, call your Mueller Steel Building Systems Salesperson.

www.muellerinc.com

A-1

Page 8

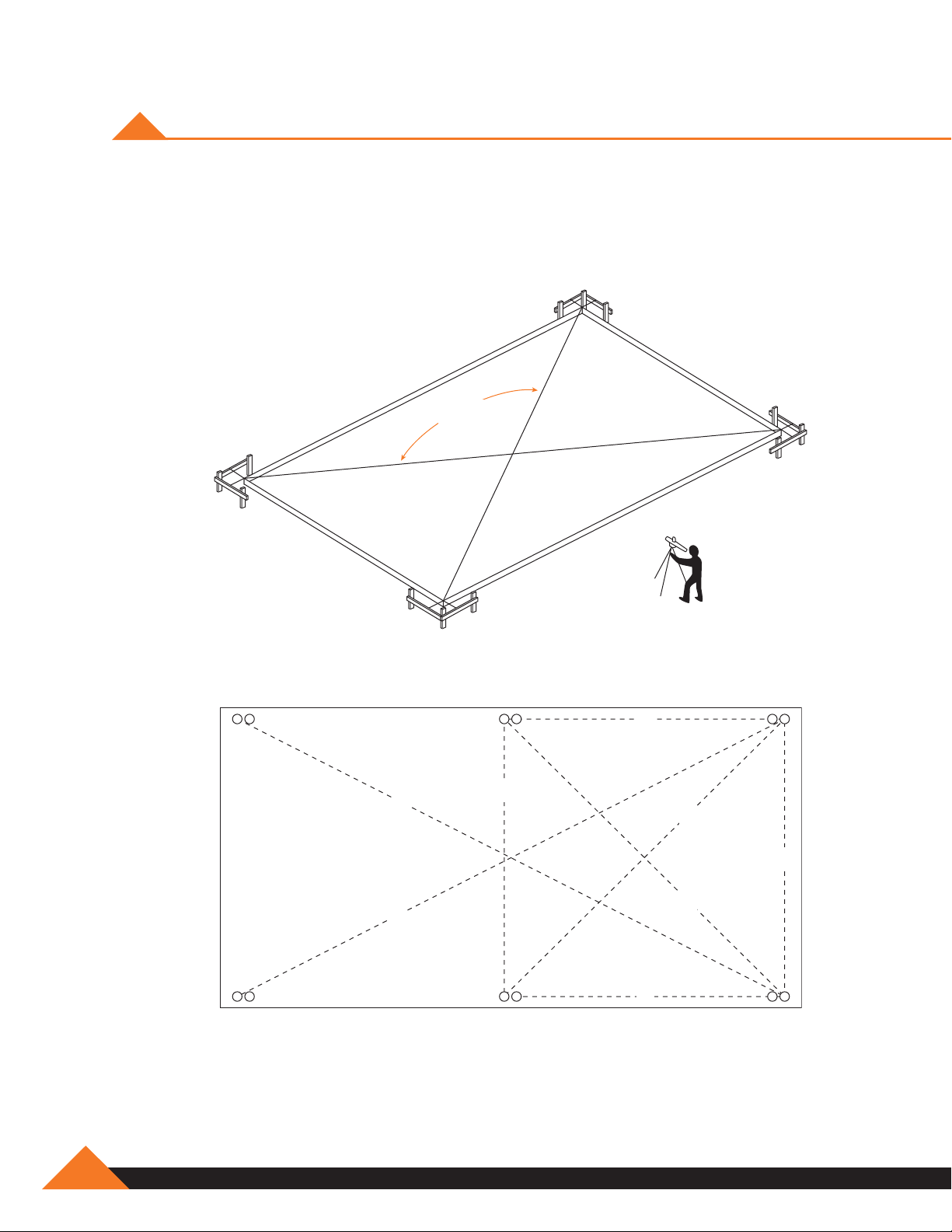

SQUARING OF FOUNDATION

For proper building erection, it is critical the foundation is square. The following examples are

suggested to ensure square foundation.

Dimensions

Must Be

Equal

Measurement:

A same as B

C same as D

E same as F

G same as H

Transit

G

A

B

F

C

E

D

H

A-2

877-2-MUELLER

Page 9

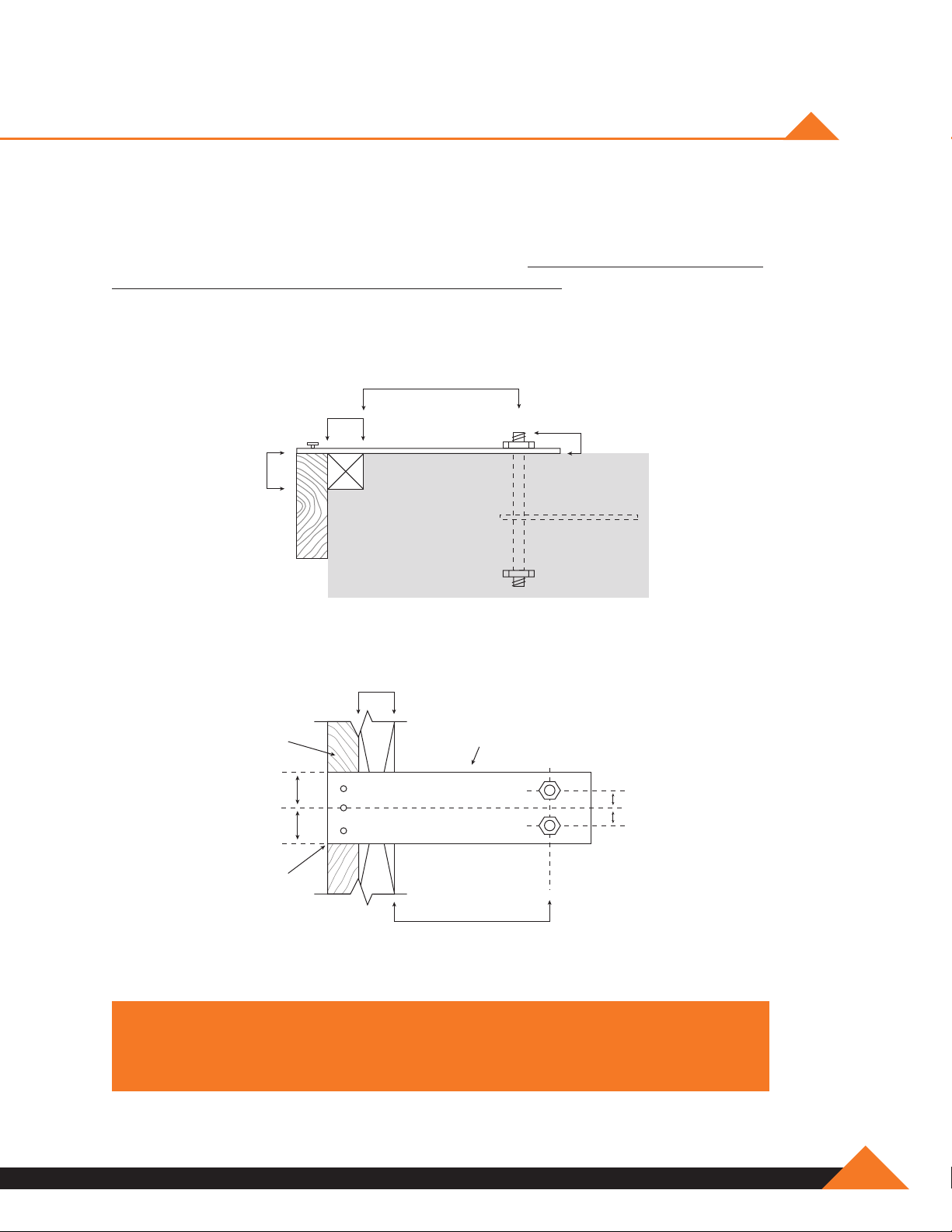

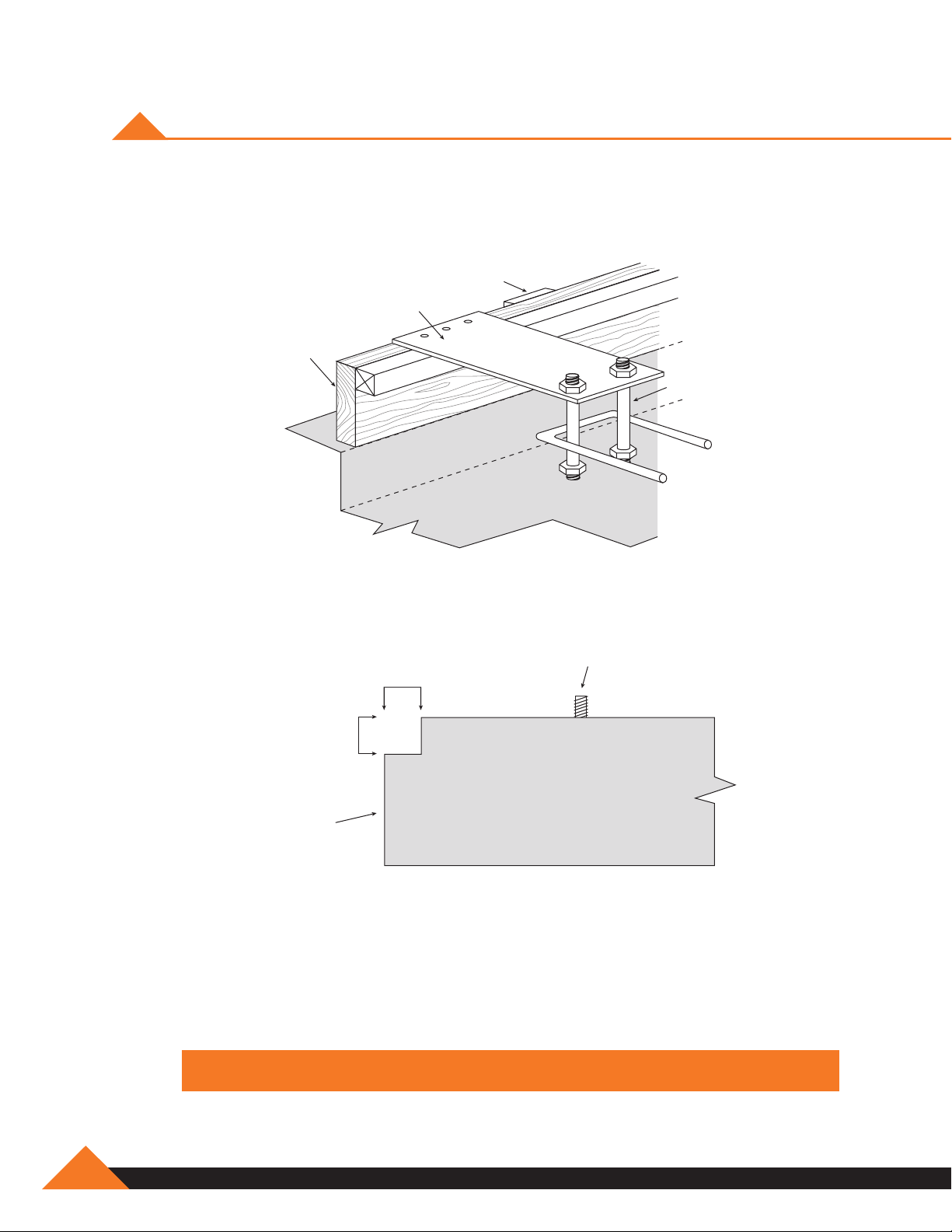

ANCHOR BOLT SETTINGS

It is extremely important that anchor bolts be placed accurately in accordance with the anchor bolt

setting plan. All anchor bolts should be held in place with a template or similar means, so they will

remain plumb and in the correct location during placing of the concrete. Check the concrete forms

and anchor bolt locations prior to the pouring of the concrete. A final check should be made after

the completion of the concrete work and prior to the steel erection. This will allow any necessary

corrections to be made before the costly erection labor and equipment arrives.

B

1

1

/2˝

D

1

1

/2˝

Projection of anchor bolts “D”

given on anchor bolt plan

1

/2˝

1

Form

Board

Template*

C

C

Steel

Line

B

Dimension of A, B and C as

given on anchor bolt plan

NOTE: Measurements are from steel line to steel line.

* Template not included.

A

A

www.muellerinc.com

A-3

Page 10

ANCHOR BOLT SETTINGS

Refer to your anchor bolt drawing for proper sizes and dimensions.

Stake

Template

Form

Board

Anchor

Bolts

1

/2˝

1

1

/2˝

1

Anchor Bolt

Foundation

Sheet

Ledge

NOTE: Suggested protrusion is 2 1/2" of threads above concrete.

A-4

877-2-MUELLER

Page 11

SECTION B

building delivery

and Storage

Page 12

Page 13

UNLOADING AND PREPARATION

OF PARTS FOR ASSEMBLY

The vehicle transporting your building parts must gain access to the building site from the

adjacent highway or road. Such access should be studied and prepared in advance of arrival.

All obstructions, overhead and otherwise, must be removed and the access route graveled or

planked if the soil will not sustain the heavy wheel loads.

A forklift or other type of power loader may be required to unload the truck and move the heavier

parts to the proper locations.

When the truck arrives with the building, unload the truck promptly, stack the steel parts evenly on

blocks and protect them from the weather.

Unloading and placing the steel parts of the building in the most convenient places for assembly

will make the process easier and faster.

NOTE: Prolonged exposure to the weather before assembly or stacking the steel

in a haphazard way can cause the painted parts to become damaged, or the

building parts to warp. Protect painted parts from moisture to prevent fading and

discoloring and stack the structural steel parts so they will be straight.

After unloading the truck and before the driver leaves, ensure that all parts have

been delivered.

1. Check each part against the delivery receipt. Each part is marked for identification.

2. Sign the delivery receipt if all parts are delivered.

3. If any of the parts are missing, notify the driver and note the missing items on the delivery

receipt before signing.

4. Check with your salesperson regarding the missing parts.

www.muellerinc.com

B-1

Page 14

UNLOADING, HANDLING, AND

STORAGE OF MATERIALS

Structure

A great amount of time and trouble can be saved if the building parts are unloaded at the building

site according to a pre-arranged plan. Proper location and handling of components will eliminate

unnecessary handling.

Blocking under the columns and rafters protects the splice plates and the slab from damage

during the unloading process. It also facilitates the placing of slings or cables around the members

for later lifting and allows members to be bolted together into sub-assemblies while on the ground.

Extra care should always be exercised in the unloading operation to prevent injuries from handling

the steel and to prevent damage to materials and the concrete slab.

If water is allowed to remain for extended periods in bundles of primed parts such as girts,

purlins, etc., the pigment will fade and the paint will gradually soften reducing its bond to the steel.

Therefore, upon receipt of a job, all bundles of primed parts should be stored at an angle to allow

any trapped water to drain away and permit air circulation for drying. Puddles of water should not

be allowed to collect and remain on columns or rafters for the same reason.

All primer should be touched up as required before erection.

NOTE: Piece marks are stenciled on primary structural members.

B-2

877-2-MUELLER

Page 15

LOCATION OF BUILDING PARTS

Place the parts around the foundation so they will be in the most convenient locations for

installation. For example: place the end columns and rafters at the ends of the building and the

mainframe columns and rafters at the sides.

Place the bolts and nuts in a place where they will be accessible to the parts. You may want to

screw the bolts and nuts together and place them with the corresponding parts. This will save time

as you begin assembling the parts.

Purlins and girts, depending on the number of bundles, are usually stored near the sidewalls clear

of other packages or parts.

Sheet packages are usually located along one or both sidewalls off the ground and sloping to one

end to encourage drainage in case of rain.

Accessories are usually unloaded on a corner of the slab or off the slab near one end of the building

to keep them as much out of the way as possible from the active area during steel erection.

NOTE: When filing claims either with the carrier or Mueller, Inc.,

the claim should indicate the item(s) in question:

•Thebundleorcontainerinquestion(ifany)

•Theactualquantityreceived.

•Thequantitywhichshouldhavebeenreceivedorthat

which was damaged.

This is important for quickly retrieving the necessary information.

Also, the other information such as numbers, names and addresses should be

indicated on claims as well as invoice numbers.

These procedures are primarily for your protection, A shortage discovered

later can be caused by theft, misplacement or other causes

and neither the carrier or Mueller can accept responsibility.

www.muellerinc.com

B-3

Page 16

CARE AND HANDLING OF MUELLER SHEET METAL

Delivery

Mueller takes every precaution to ensure that material is delivered to the customer damage free

and fully protected from the elements during shipment. When the material is delivered to the

customer it then becomes the customer's responsibility to protect the material from the elements,

possible theft, and other damage. The following guidelines are recommended:

Handling: Proper care is required in unloading and handling panel bundles

in order to prevent damage.

1. Bundles should remain banded (if possible) during the unloading process. Bundles should

never be lifted by the banding material.

2. Lift each bundle as close as possible to its center of gravity.

3. If the bundles are to be lifted with a crane, use a spreader bar of appropriate length and

nylon band slings (do not use wire rope slings as they will damage the material).

4. Depending on the panel length, some bundles may be lifted by a forklift. When using a

forklift, the forks should be spread to their maximum spacing, and the load centered on the

forks. Sheets over 25’ long require two forklifts.

5. After panel bundles are opened, individual sheets must be handled carefully to prevent

panel buckling or damage to the panel coating. When removing a sheet from a bundle it

should be rolled off the bundle to prevent scratching of the next sheet. Never drag or slide

one sheet over another sheet. Sheets should not be picked up by the ends. Instead, lift the

sheet along its longitudinal edge and carry in a vertical position. For sheets over 10’ long,

two or more people may be required to carry the sheet.

B-4

877-2-MUELLER

Page 17

WALL AND ROOF PANELS

Mueller’s wall and roof panels including color coated, galvalume, and galvanized provide

excellent service under widely varied conditions. All unloading and erection personnel should fully

understand that these panels are quality merchandise which merit cautious care

in handling.

Under no circumstances should panels be handled roughly. Packages of sheets should

be lifted off the truck with extreme care taken to ensure that no damage occurs to ends of the

sheets or to side ribs. The packages should be stored off the ground sufficiently high to allow air

circulation underneath the packages. This avoids ground moisture and deters people from walking

on the packages. One end of the package should always be elevated to encourage drainage in

case of rain.

All stacked metal panels are subject, to some degree, to localized discoloration or stain when

water is trapped between their closely nested surfaces. Mueller, Inc. exercises extreme caution

during fabricating and shipping operations to ensure that all panel stock is kept dry. However, due

to climatic conditions, water formed by condensation of humid air can become trapped between

stacked sheets. Water can also be trapped between the stacked sheets when exposed to rain.

This discoloration caused by trapped moisture is often called wet storage stain.

The stain is usually superficial and has little effect on the appearance or service life of the panels as

long as it is not permitted to remain on the panels. However, moisture in contact with the surface

of the panels over an extended period can severely attack the finish and reduce the effective

service life. Therefore, it is imperative that all panels be inspected for moisture upon receipt

of the order. If moisture is present, dry the panels at once and store in a dry, warm place.

CAUTION: Care should always be taken when walking on panels. Use safety

lines and nets when necessary! Panels can be slippery due to paint finish,

wax, oil or atmospheric conditions. Always assume panel surface is

slippery and act accordingly.

www.muellerinc.com

B-5

Page 18

WALL AND ROOF PANELS (continued)

Storage:

It is recommended that sheets be stored under roof if at all possible. If sheets are to be stored

outside, the following precautions should be observed:

1. The storage area should be reasonably level, and located so as to minimize handling.

2. When stored on bare ground, place a plastic ground cover under the bundles to minimize

condensation on the sheets from ground moisture.

3. Store bundles at least 12 inches above ground level to allow air circulation beneath the

bundle, and to prevent damage from rising water.

4. Elevate one end of each bundle slightly to permit runoff of moisture from the top of the

bundle or from between sheets. A waterproof cover should be placed over the bundles to

allow for air circulation under the cover.

5. Inspect stored bundles daily and repair any tears or punctures in the waterproof cover.

6. Re-cover opened bundles at the end of each workday to prevent subsequent

moisture damage.

Drainage

Elevate

Air Circulation

Checking Order At Time Of Delivery

Check each order carefully, as it is unloaded. Report any obvious damage or shortages to the

carrier immediately. If damage or shortages are noted after delivery (at time of unpacking) notify

your Mueller representative immediately. Have invoice numbers and detailed descriptions of the

damage or shortage available. These procedures are for your protection. A shortage or damage

discovered later, can be caused by theft, misplacement, mishandling or other causes and is not

the responsibility of Mueller, Inc.

B-6

NEVER INSTALL MATERIAL IF THE QUALITY IS IN QUESTION!

877-2-MUELLER

Page 19

SECTION C

erection of PriMary

and Secondary

Structural

Page 20

Page 21

GENERAL INFORMATION

Many methods and procedures are in use for erecting the structural portion of metal buildings.

The techniques of raising frames vary from erecting small clear spans and endwall frames in units

to erecting the larger clear spans and modular frames in sections. The erection methods used

depend strictly on the type of building, the available equipment, the experience level of the crews,

and the individual job conditions.

The variations in these factors preclude the establishment of a firm or specific set of erection

rules and procedures. Consequently, the erection operation must be tailored by the erector to fit

individual conditions and requirements. However, there are certain erection practices, pertaining to

structural members, which are in general use and have proven sound over the years. Descriptions

of these follow.

Erectors are cautioned not to cut primary members (rigid frame columns, rafters, end bearing

frame rafters, interior columns). These are the primary support members for the frame and

are designed as such. Any cutting of these members may affect the structural stability. A

representative of Mueller’s must be consulted prior to attempting alterations of these members.

NOTE: Do not install any material if its quality is in question. Mueller, Inc.

will not be responsible for costs incurred associated with the installation

and/or removal of same.

WARNING! In no case should building erection be started on green concrete.

Anchor bolts may pull loose, concrete spall (chip out along edges) may occur

and equipment may crush or crack slab. Consult the project engineer, not

Mueller, Inc. on foundation questions.

www.muellerinc.com

C-1

Page 22

TOOLS AND EQUIPMENT REQUIRED

The types of tools and equipment required in order to assemble and erect the building depend on

the size of the building purchased. This part of the instruction manual lists the tools and equipment

that are normally required for most buildings. You may wish to use more or less power equipment

or different tools than are listed as the need dictates. Whatever tools are used, it is important

to remember that using the recommended tools will enable the least effort and best manner of

erecting the building.

If a contractor is going to erect the building for you, you will not have to concern yourself with the

tool list as most contractors have the necessary tools and equipment that are required. However,

reference to the following list may be of value to the contractor if he has never assembled and

erected a Mueller Prefabricated Steel Building.

WARNING! Whenver using any type of power equipment, it is important to follow

the manufacturer's recommendations for use. Always be aware of the dangers

involved when using electric or air powered equipment.

Tools

Spud Wrench

Hammer

Centering punch

Square

Complete set of Wrenches (Open-end,

socket, box-end)

Pry Bar

Pipe Wrench

Pliers

Vise-Grip Pliers

Drill Bits

Power Drill or Combination Power/Hammer Drill

Screw Gun

Power Wrench (Impact Wrench)

Nibbler (Electric metal cutter for cutting

across the wall & roof sheets)

Level (3 feet long minimum)

Hacksaw

Broom (Push)

Wire Brush

Caulking Gun (Open barrel)

Chalk Line (100’ long and chalk)

Channel Locks

Extension Cord (#10-3, 2/4 way box, 250’ long)

Fire Extinguisher (#10)

First Aid Kit

Load Binders

Plumb Bob

Snips (Large bulldogs)

Tape measure (12’ to 25’ long, 100’ long for

foundation measurements)

Ladder

Chain

Rope

Hoist or Forklift (Should be all-terrain)

Come-along (Power pull)

Saw Horses

Tarps

Safety Equipment:

Goggles

Hard Hat

Gloves,

Work Boots, etc.

C-2

NOTE: Additional tools may be required depending on

the specific requirements of the building.

877-2-MUELLER

Page 23

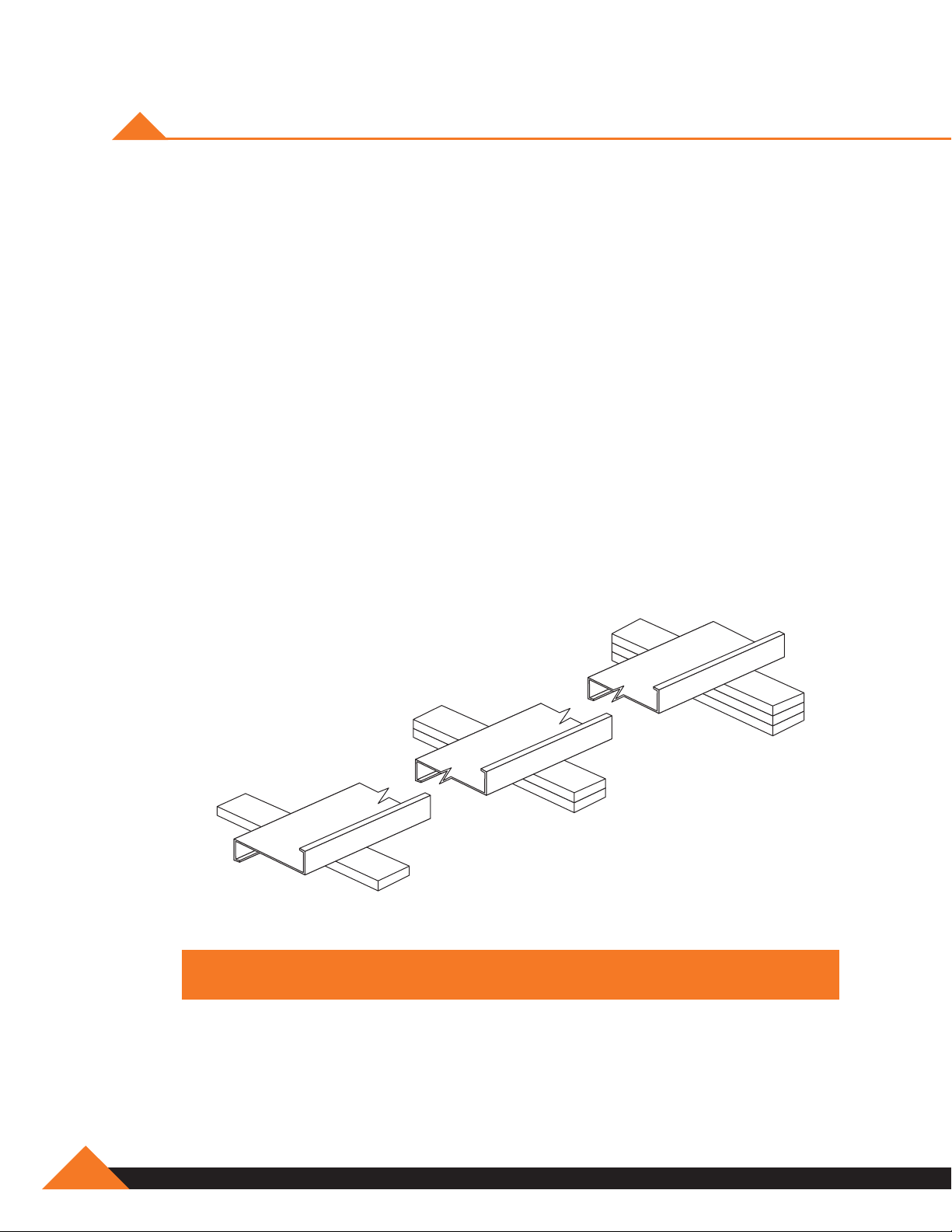

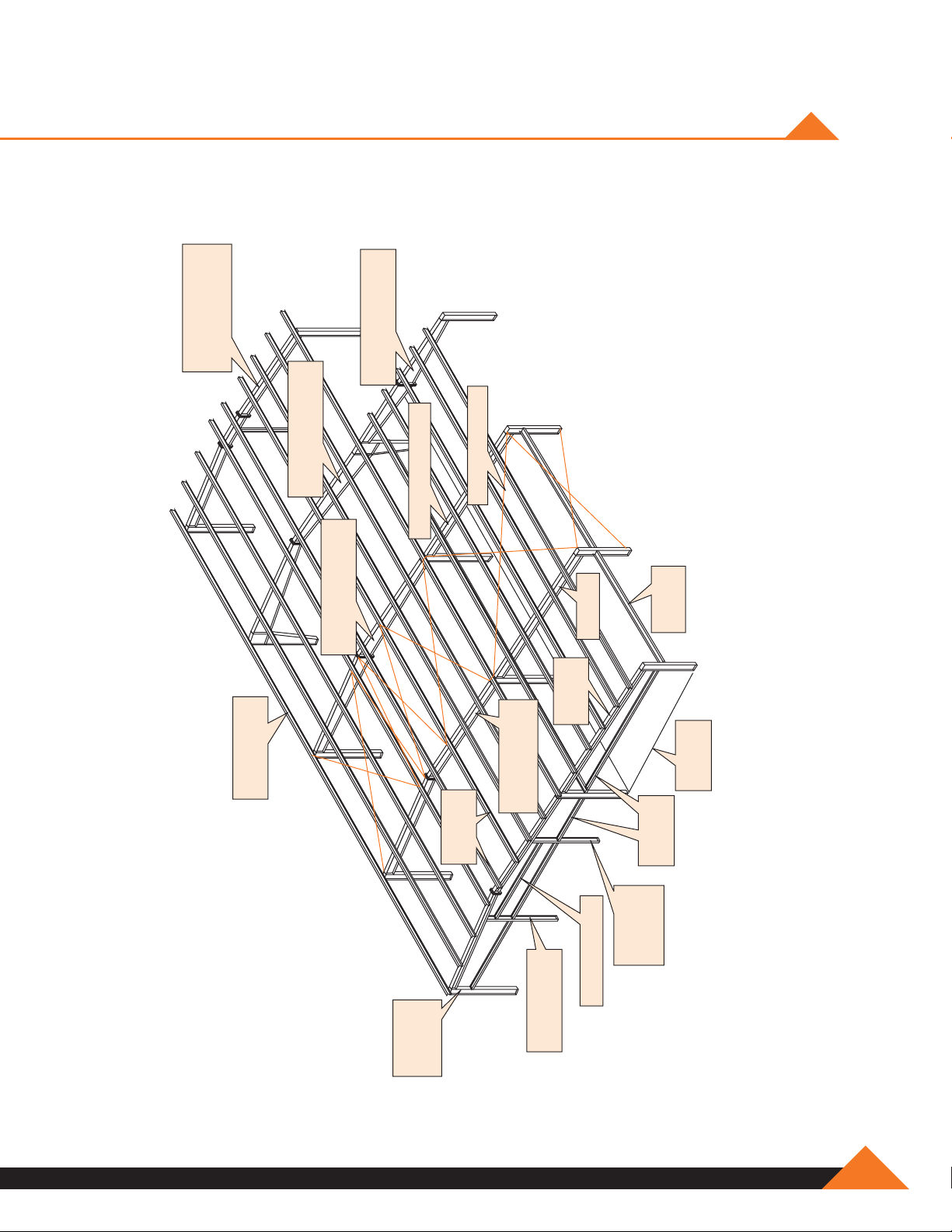

Rigid frame with

straight column &

pipe interior column

Rigid frame extension

with straight column

Rigid frame with

tapered column (MFR)

TYPICAL BUILDING PARTS

Cable bracing (BC)

Rigid frame extension

Eave strut /

Eave purlin (ES)

Rigid frame with

straight column (MFR)

Beam end

wall column

Long lap

(EWC)

Wide flange beam

Z-bar (LLZ)

Extension

End wall

extension

frame (MFR)

End wall interior

column (EWIC)

Z-bar wall

girt (WG)

End wall

girt (EWG)

End wall

door column

(EWDC)

Door header (DH)

Base

angle (BA)

www.muellerinc.com

C-3

Page 24

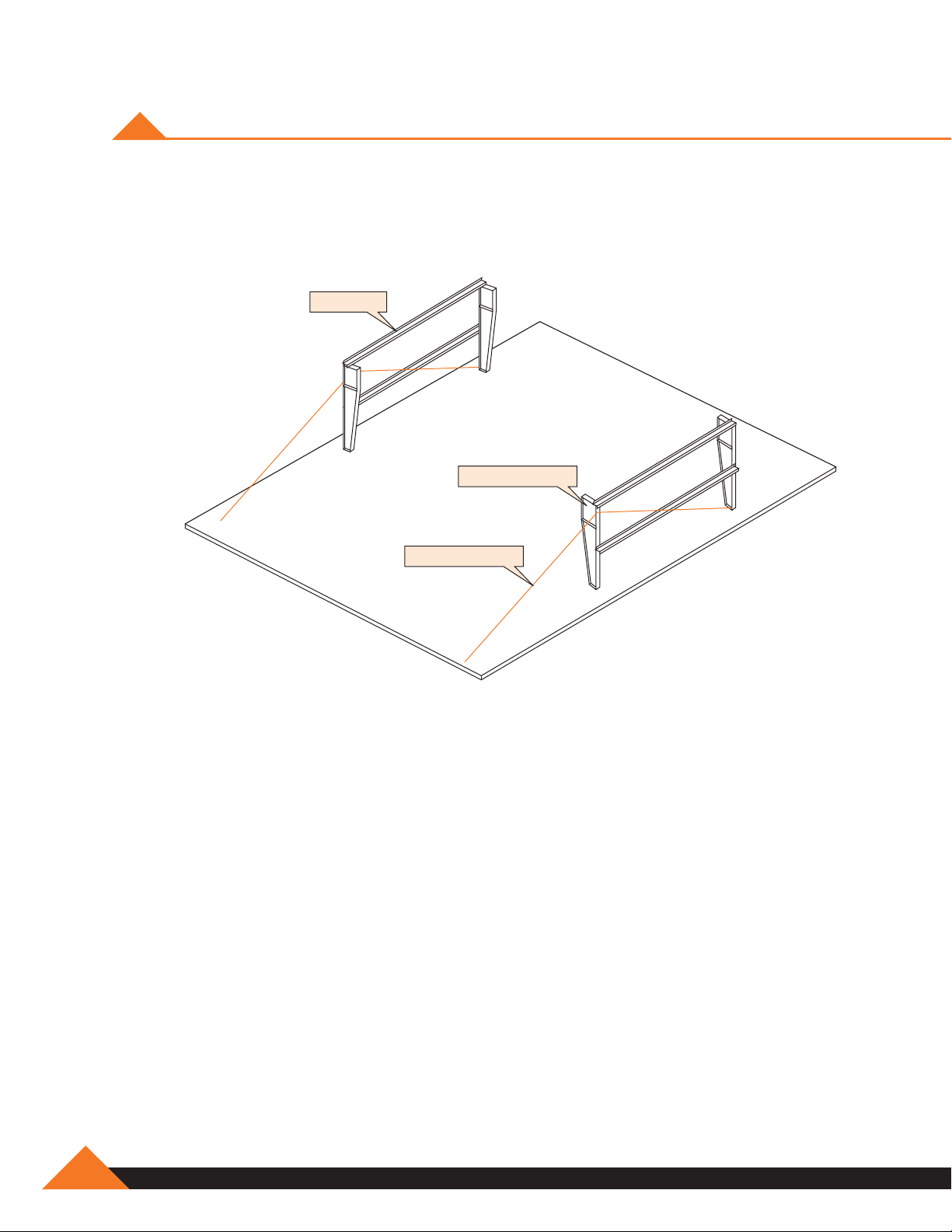

RAISING RIGID FRAMES

The intermediate or interior frames nearest the bearing endwall are usually erected first. This bay

usually contains the diagonal bracing. The proper completion and plumbing of this first bay is

extremely important to the successful completion of the building.

Braced bay

Stand columns first

Temporary bracing

Although several methods are used to erect rigid frames, it has been found most satisfactory to

erect the columns first, tie them together with the girts and tighten the anchor bolts*. On small

spans and short eave heights, columns can often be set in place by hand without the use of

hoisting equipment. Temporary bracing should always be installed as soon as sections are

lifted in place.

*The anchor bolt tension may need to be adjusted to seat the rafter.

C-4

877-2-MUELLER

Page 25

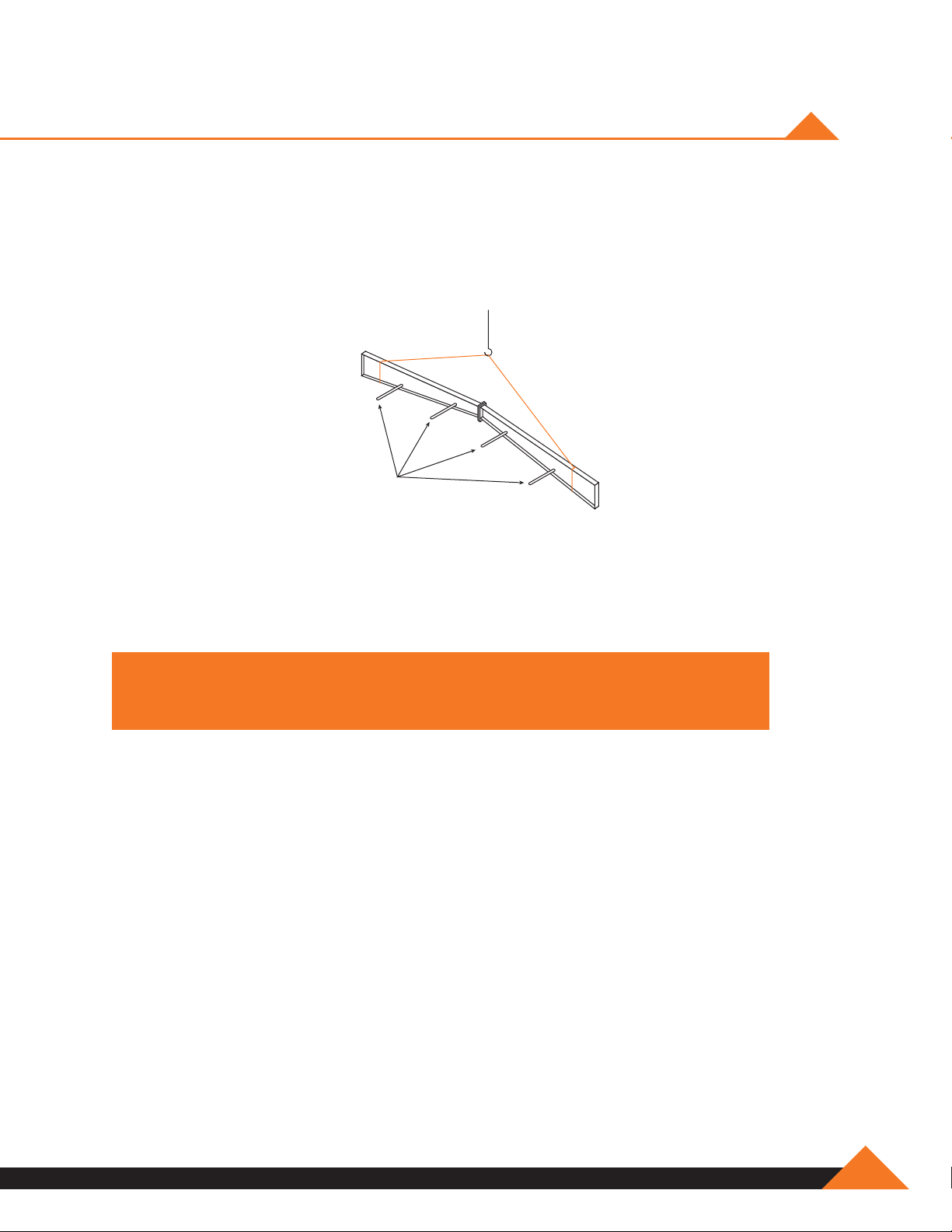

RAISING RIGID FRAMES (CONTINUED)

After the columns have been erected, the ground-assembled rafter is hoisted into place and

connected to the columns. The size of the rafter that can be safely handled depends on

the equipment available and the experience of the erection foreman. Generally as many

connections as possible are made on the ground.

Flange braces

loose bolted

The flange brace should be bolted to the rafter prior to raising in order to save time. The hoisting

equipment should never be released from the rafter until the frame is adequately braced,

so it cannot buckle or tip in the longitudinal direction of the building.

NOTE: Drawing above is intended as a general rigging method.

Actual rigging method will vary with member configuration.

www.muellerinc.com

C-5

Page 26

RAISING RIGID FRAMES (CONTINUED)

Lifting Cables And Spreader Bars

In all instances the length of the lifting cables should be such that the angle between the rafter and

the lifting cables is no less than 45 degrees. To reduce the severe compression stresses at the

ridge of the rafters that are created by the angle of lifting cables, a spreader bar is recommended,

which allows the lifting cables to be parallel to each other.

Spreader bar

45 degree

minimum

Rafters

NOTE: Drawing above is intended as a general rigging method.

Actual rigging method will vary with member configuration.

NOTE: Stay well in the clear of loads being moved by any lifting device.

Hands and feet should be kept clear of moving loads and never stand

under a load being lifted. Remember, SAFETY FIRST!

C-6

877-2-MUELLER

Page 27

RAISING RIGID FRAMES (CONTINUED)

Completing And Plumbing The First Bay

After the first intermediate or interior frames have been set, Mueller, Inc. recommends that all

purlins, girts, and eave struts be installed in the braced bay and the entire bay plumbed, aligned

and braced before proceeding further. If the building is designed without cable bracing, the erector

is responsible for providing temporary erection bracing.

When this bay is properly and accurately plumbed and braced, the remaining members, to a large

degree, will automatically plumb and align when installed. Only a final check of the building plumb

remains, and few adjustments, if any, will be necessary.

Interior Bay

NOTE: Purlin Nesting note goes here. Something about underclip

www.muellerinc.com

C-7

Page 28

RAISING RIGID FRAMES (CONTINUED)

When the rafters consist of several roof beams, as in the case of wide buildings, a safe procedure

of raising by sections and supporting the free end must be followed, regardless of the type of

equipment available. In most instances the work proceeds from outside columns inward toward

the peak until the entire frame is bolted into place.

The same general procedures of erection apply to either clear span or multiple span frames. In the

case of the latter, the support for rafter sections during erection is generally supplied by the interior

columns themselves, making temporary supports unnecessary.

Two words of caution concerning the erection of rigid frames are in order. The first is that rigid

frames, especially free ends or cantilevered sections should never be left “for the day” in an

unsupported, unbraced or unguyed condition. Such practice has resulted in the total loss of

considerable amounts of erected steel because of wind. The second word of caution pertains to

the additional care required in the erection of multiple span frames compared to clear span frames.

Frames with interior columns, because of closer supports, have much lighter sections. They are

much more apt to buckle during erection than clear span frames, and consequently require greater

care in rigging and handling.

Connection Bolts

Bolts used to make connections in secondary framing members such as the purlins are usually

1/2” diameter, ASTM designation A307. All primary framing or main framing connections are

made with ASTM A325 bolts, usually 5/8”, 3/4”, 7/8” and 1” diameters. The size and grade of the

bolt are marked on the building erection drawings.

MAIN FRAME: An assemblage of rafters and columns that support the secondary

framing members and transfer loads directly to the foundation.

SECONDARY FRAMING: Members that carry loads from the building

surface to the main framing. For example – purlins and girts.

C-8

877-2-MUELLER

Page 29

ERECTING COLUMN AND BEAM ENDWALLS

Column and beam endwalls of 50 feet or less in span may be raised into position and set on

the anchor bolts as a unit. All rafters, column, girts (except outside endwall girts which connect

to the sidewall girts), door headers, door jambs, clips, diagonal brace rods, etc. should be

assembled on the ground with the bolts left finger tight. A spreader bar should be used to raise

the endwall frame. Because of the flexibility of the column and beam frames, care must be taken

in locating the points of attachment of the cables, and in raising the frame, to avoid bending

about the minor axis.

For spans of 60 feet and greater, the columns are usually erected first and then capped with the

endwall rafter. The girts, headers, jambs and diagonal brace rods are then added between the

end columns. During this erection process, the frame must be properly braced or guyed before

the lifting lines are disengaged. Final bolt tightening should be done once the frame is plumb

and square.

Spreader bar

NOTE: Drawing above is intended as a general rigging method.

NOTE: Drawing above is intended as a general rigging method.

Actual rigging method will vary with member configuration.

Actual rigging method will vary with member configuration.

www.muellerinc.com

C-9

Page 30

ERECTING THE REMAINING FRAMES & EAVE STRUTS

The remaining frames are erected in like manner, initially with only a few purlins being installed in

each bay working from one end of the building to the other. To lend overall rigidity to the structure,

install flange braces to the purlins at specified locations. All purlin, girt and eave strut connection

bolts are left loose so the entire skeleton framework can be plumbed without undue difficulty. The

remaining purlins can be positioned on the rafter in each bay to facilitate the completion of the roof

framing.

C-10

NOTE: Take precautions to secure structure during assembly. Temporary

bracing may be required to stabilize the structure during erection.

Never leave the structure unbraced.

877-2-MUELLER

Page 31

JOINTS NOT SUBJECT TO TENSION LOADS

Joints not subject to tension loads need only be tightened to the snug tight condition, defined as

the tightness attained by a few impacts of an impact wrench or the full effort of a man using an

ordinary spud wrench.

Joints Subject To Tension Loads

Two tightening procedures are specified for A325 bolts in joints subject to tension loads, turn-ofthe-nut method and direct tension indicator.

Turn-of-the-nut method – When turn-of-the-nut method is used to provide tension, first bring

enough bolts to a “snug tight” condition to ensure that the parts of the joints are brought into good

contact with each other. Next, place bolts in all remaining bolt holes and bring to “snug tight”.

Then additionally tighten all bolts – progressing from the bolts nearest the web, to the free edges.

During this operation there shall be no rotation of the part not turned by the wrench.

Tightening by use of a direct tension indicator – Tightening by this means is permitted provided

it can be demonstrated, by an accurate direct measurement procedure, that the bolts have been

tightened to specified tension.

Consult latest edition of the AISC Manual of Steel Construction for more complete instructions for

installing high strength bolts.

www.muellerinc.com

C-11

Page 32

ASSEMBLY OF BRACE CABLES

1. Assembly of brace cables:

NOTE: Cable may have to be field cut to proper length.

A. Insert grip through eyebolt.

B. Begin wrapping the grip around the cable, matching the crossover marks.

C. Continue until the lasts two wraps are left split the legs and apply separately.

D. Duplicate this procedure on each end.

Hillside

Washer

Brace Grip

Hex Nut

Flat Washer

Eyebolt or

Turnbuckle

Cable

Flat Washer

Hex Nut

Eyebolt or

Turnbuckle

Hillside Washer

Brace Grip

Beam Connection

Obtain the proper tension of the strand by tightening the nuts on the eyebolts.

2. Insert the “T” section on an angle through slot until round neck rests on web plate then turn

brace-eye 90 degrees.

3. Then pull brace-eye toward you until “T” section rests against back of web plate, square neck

locks brace-eye in place.

4. Attach the brace-grip to the brace-eye and then attach the brace grip to the cable.

C-12

877-2-MUELLER

Page 33

INSTALLATION OF WIND BRACING (CONTINUED)

Assemble the next brace cable the same way and connect to the next column to form an “X” with

the other cable.

Column

Cable

Turnbuckle

Eyebolt

To square the building, measure the length of the diagonals and tighten or loosen the turnbuckle/

eye-bolt until the lengths are the same. Double-check by using a square at the corners.

Brace each sidewall frame the same way so that you have an x-brace on each side. Note that the

diagonal lengths may vary between the two walls, but should be the same on each x-brace.

Tighten the column anchor nuts after ensuring that the building is square.

The diagonal bracing is cable. It should always be installed as shown on the erection drawing and

should be tensioned so that the building will not sway or rock when the wind blows. Care should

be taken; however, not to over tighten and bend the structural members. The workman should

watch the structural members carefully as he tightens the bracing.

www.muellerinc.com

C-13

Page 34

INSTALLATION OF THE WIND BRACING

Diagonal bracing in metal buildings is critical. They provide support for wind loads or other

longitudinal loads, such as those created by an overhead crane in the completed structure. Many

times additional temporary bracing is needed to stabilize the structure during erection. The erector

should review this requirement, and the erector should provide any additional bracing. On some

smaller buildings, diagonal bracing is not needed for the building design, so the erector must

furnish any erection bracing needed.

C-14

877-2-MUELLER

Page 35

INSTALLATION OF WIND BRACING (CONTINUED)

Hillside Washer Installation

Hex Nut

Flat Washer

Hillside Washer

NOTE: Hillside washer installation similar at base.

NOTE: Care should be taken not to over-tighten the wind bracing. Overtightening

the bracing can cause premanent damage to the framing.

www.muellerinc.com

C-15

Page 36

INSTALLATION OF WIND BRACING (CONTINUED)

Occasionally the bracing in the wall of a building cannot be installed in the specified bay because

of doors or other complications. Usually these can be moved to other bays without affecting the

structural integrity of the building. However, before moving any wind bracing check with

Mueller, Inc. Do not remove after building is erected.

Web of Column

Hillside Washer

Flat Washer

Eyebolt

Hex Nut

NOTE: Never modify a Mueller building without first contacting

a Mueller representative.

Cable

C-16

877-2-MUELLER

Page 37

inSulation

SECTION D

Page 38

Page 39

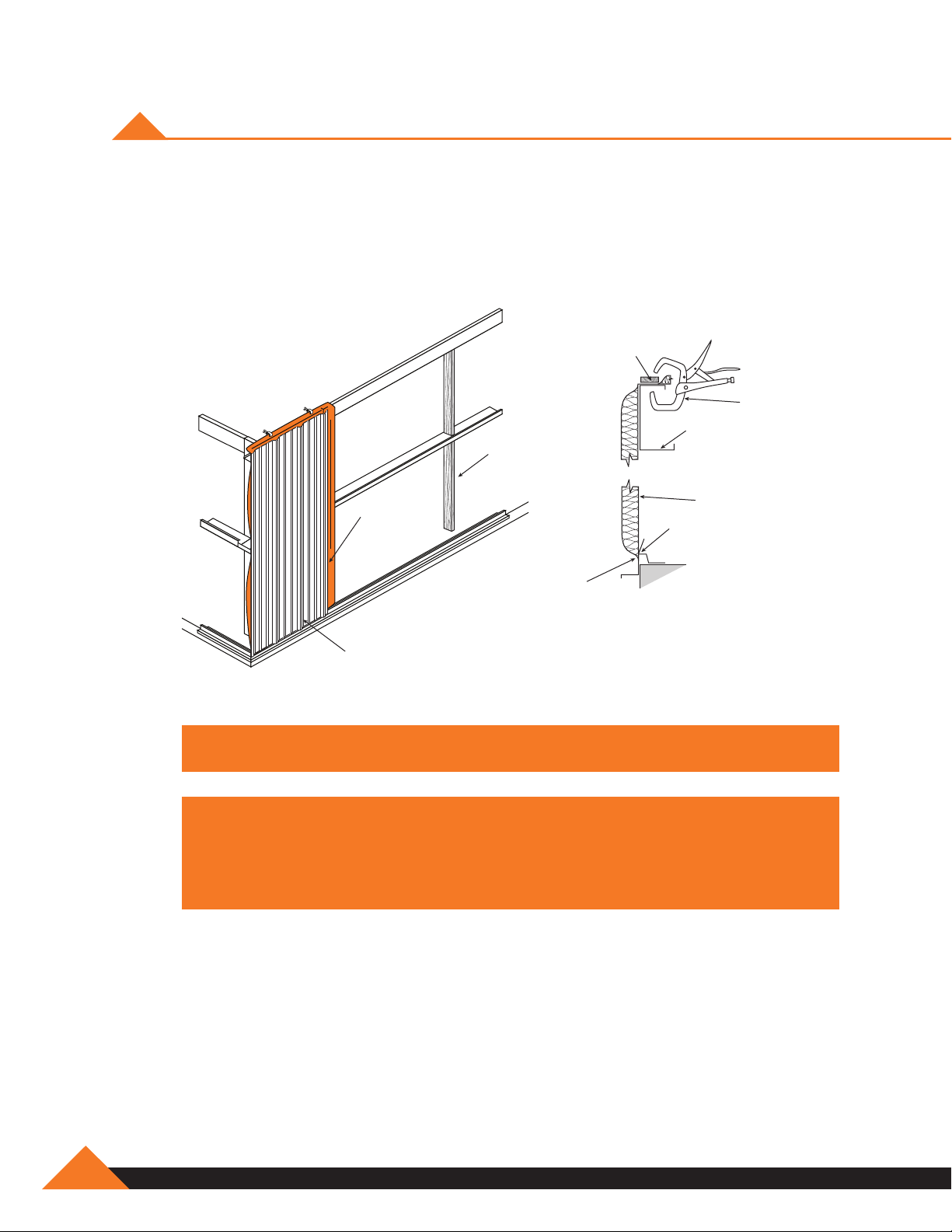

WALL INSULATION

Fiberglass blanket insulation is the most common type used, and these instructions pertain to this

type only. One side of the blanket insulation should have a vapor barrier that must face the inside

of the building regardless of whether the insulation is for heating or cooling.

Fiberglass insulation

to outside of building

Vapor barrier to

inside of building

Wall Insulation Installation

Cut the insulation to length allowing an additional 6” or more to facilitate handling. The wall panel

can be used as a guide.

NOTE: The insulation must compress between the girt and the wall dring

installation. Insulation too thick or dense to compress adequately will induce

waviness or oil canning in certain types of wall panels.

www.muellerinc.com

D-1

Page 40

WALL INSULATION (CONTINUED)

The first run of wall insulation should be installed so that its forward edge is just ahead of the

leading edge of the wall panel. This keeps the forward edge of the insulation ahead of the wall

panel for joining the next blanket.

Wood

Block

Clamping

Pliers

Wood

Blocking

Blanket

Insulation

Eave

Strut

Vapor Barrier

Attach base angle with

double sided tape

Cut Fiberglass

from Vapor

Barrier and

Wall Panel

NOTE: Do not allow the insulation to wick moisture from the floor.

WARNING! Insulation has no load bearing strength. Do not lean or prop material

against wall insulation. Observe all proper safety procedures when handling

fiberglass insulation, such as dust masks, gloves and long sleeved shirts, to

minimize contact with the insulation.

fold barrier up

D-2

877-2-MUELLER

Page 41

ROOF INSULATION

Pre-cut roof insulation to reach from eave to eave allowing approximately 2 feet of additional

length to facilitate handling. Hold insulation at one sidewall and roll out insulation across the

purlins, vapor barrier to the inside of the building. Stretch the insulation to provide a tight and

smooth inside surface.

NOTE: Insulation has no load bearing strength. Maintain body weight on

approved scaffold or walk boards.

www.muellerinc.com

D-3

Page 42

ROOF INSULATION (CONTINUED)

Double sided tape or contact adhesives can be used to hold insulation in place while the roof

sheets are being installed. Trim excess insulation to the edge of the eave trim and cut fiberglass

approximately 4 inches from end leaving only facing. Fold facing over end of blanket insulation to

seal the end.

Allow room to

install sealant tape

and closure strip

Cut Fiberglass from Vapor Barrier

and Fold Vapor Barrier Over

Eave Trim

(Trim shape

may vary)

#12 Self-Drilling

Wall Fastener

Outside Closure

(Optional)

NOTE: Do not install more insulation on the roof than can be covered by roof

panels before the work period ends. Do not allow the insulation to become wet.

Double-sided

Tape

Eave Strut

Blanket

Insulation

D-4

877-2-MUELLER

Page 43

ROOF INSULATION (CONTINUED)

Seal insulation sidelap joints by lapping 4” tab side. As on the walls, the general sequence is to

install the roof sheets in conjunction with the insulation.

First Roof

Panel

4' -0"

NOTE: The insulation sidelap must be lapped to prevent condensation and

minimize temperature loss at laps.

WARNING! Wipe oil and other slippery substances from roof panels. Do not step

on rib of panel, near a crease in the panel, near a side edge or within five feet of

the end of unsecured panel. Insulation has no load bearing strength. Maintain

body weight on scaffold or walk boards.

1' -0"

Double-sided Tape

Eave Trim

Blanket

Insulation

Eave Strut

www.muellerinc.com

D-5

Page 44

Page 45

Sheeting

SECTION E

Page 46

Page 47

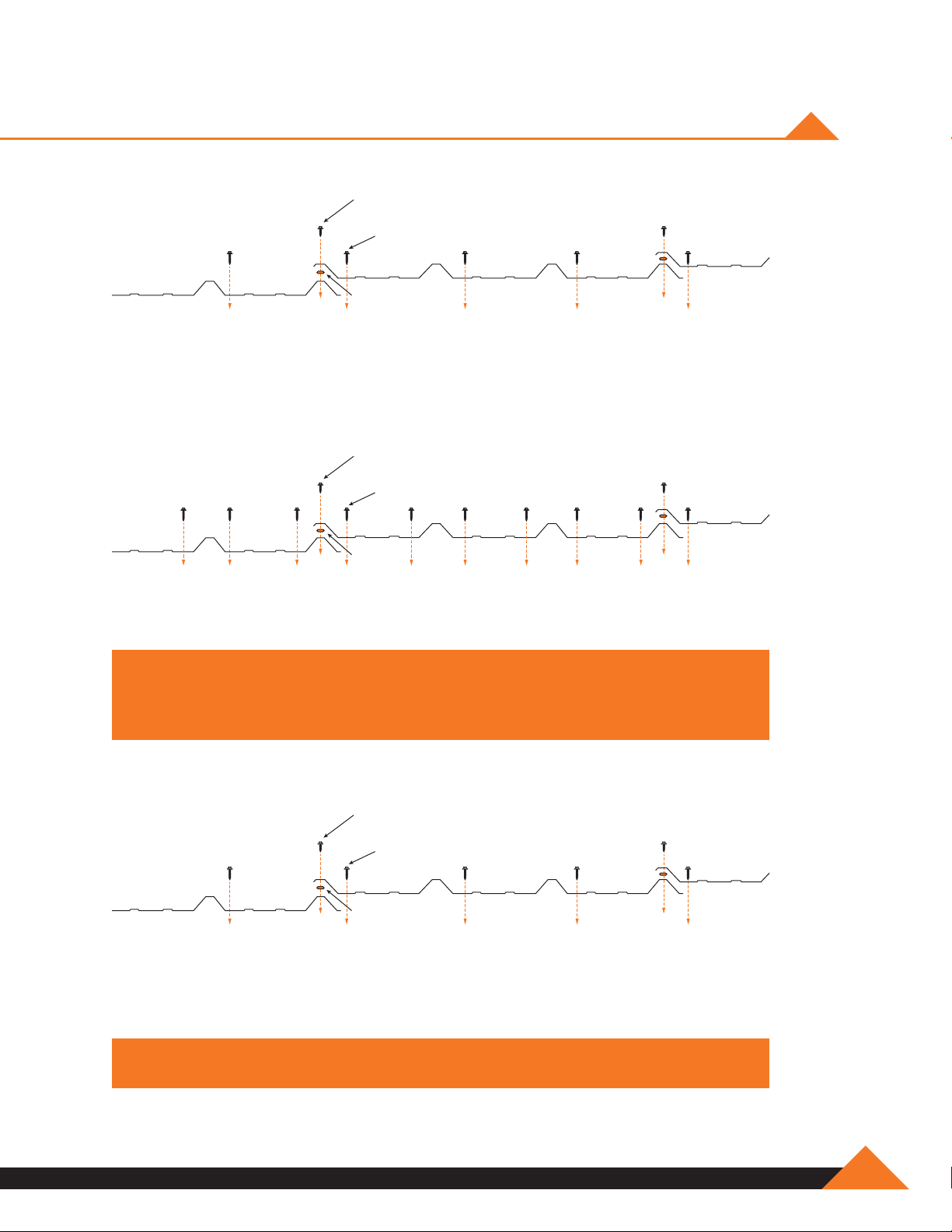

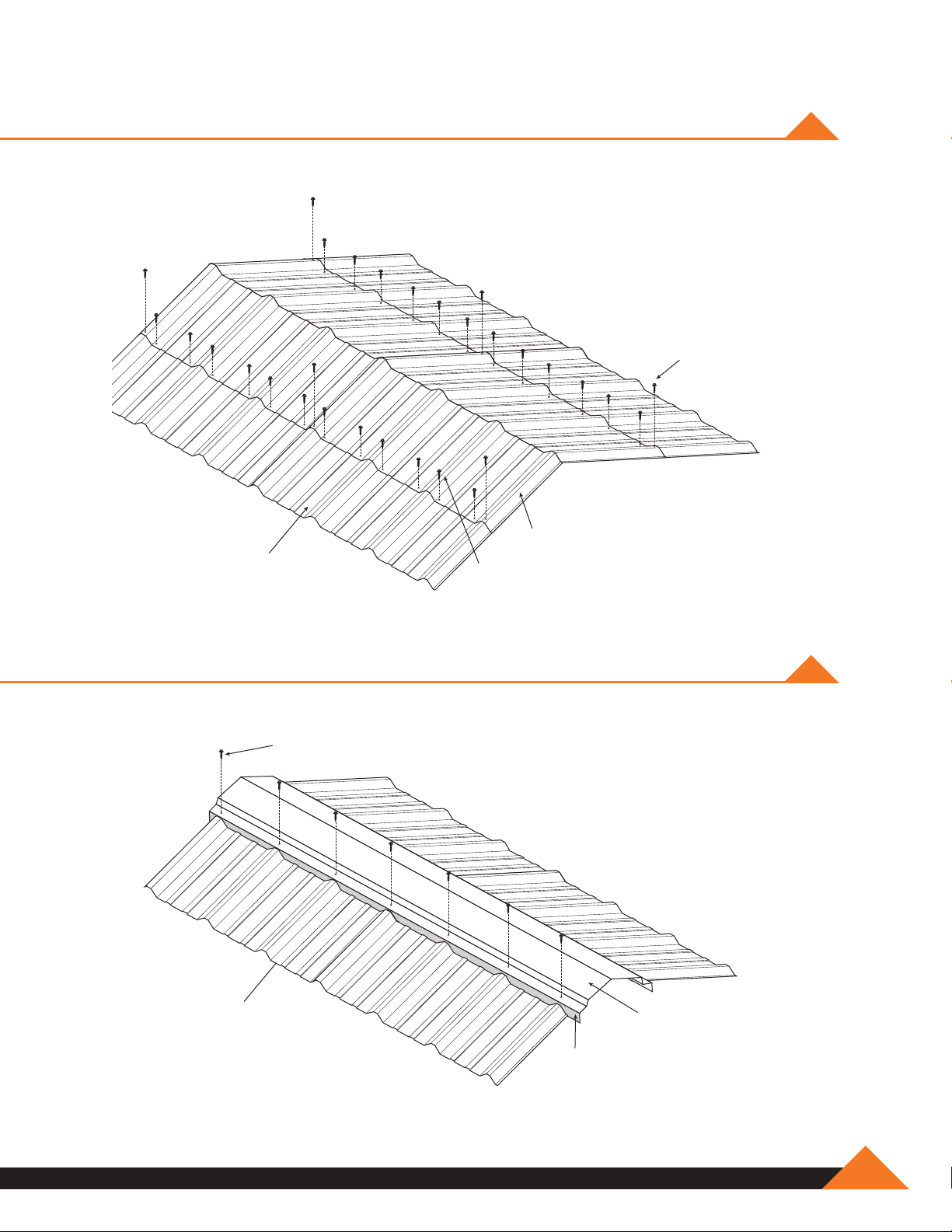

FASTENER LAYOUT

Lap Tek Screw

20" O.C. at sidelap

#12 Self Drill Roof Fastener

Sealant Tape

“R” and “PBR” Roof Panel Fastener Spacing,

Intermediate Purlins, Girts, Eave Strut

Lap Tek Screw

20" O.C. at sidelap

#12 Self Drill Roof Fastener

Sealant

Tape

“R” and “PBR” Roof Panel Fastener Spacing, Eave Strut, Wall and Roof

Panel End Laps, Ridge Purlin, Base Angle/Girt

NOTE: UL 90 Uplift Rated Roofs Require Fasteners At Each Side of High Ribs

At All Purlin On Certain “UL” Construction Systems And Eave Strut Locations

(Consult Your Specific Requirements Prior To Installation).

Lap Tek Screw

20" O.C. at sidelap

#12 Self Drill Roof Fastener

Sealant Tape

“R” and “PBR” Wall Panel Fastener Spacing,

Intermediate Girts, Eave Strut

WARNING! DO NOT OVERDRIVE FASTENERS!

www.muellerinc.com

E-1

Page 48

ALIGNING THE GIRTS

Installation of the building walls is generally done before the roof. Before starting the wall

installation, check to be sure that the eave strut and girts are straight and plumb. One method of

aligning the girts is to cut temporary wood blocking to the proper length and install between the

lines of girts. This blocking can be moved from bay to bay, which will reduce the number of pieces

required. Normally, one line of blocking per bay will be sufficient. Banding can also be used to hold

the girts straight and plumb.

Girt

Wood

Blocking

E-2

Typical construction of the wood blocking is show below. A 2" x 4" minimum board size should be

used. Refer to the cross section framing drawing that accompanied the building to determine the

girt spacing.

NOTE: Blocking should be secured to prevent falling hazzard.

877-2-MUELLER

Page 49

SCREW ALIGNMENT

Good alignment of the screws, especially on the wall panels, will give a professional appearance to

the wall panel installation. One way this can be accomplished is by pre-drilling holes in the panels

at identical locations. Up to 15 panels can be stacked together and drilled using a template panel.

Use 1/8” or 5/32” diameter drill bit for panel to structural fasteners and a 1/4” diameter bit for the

sidelap clearance holes. It is important to clean metal shavings off panel surfaces after

drilling to avoid rust stains.

Pre-Drilled

Template

Sheet

Stacked Sheets

To Be Drilled

CLAMPING IS REQUIRED

Keep Ends

of Panels

Allinged

www.muellerinc.com

E-3

Page 50

SCREW ALIGNMENT (CONTINUED)

The template panel should be laid out for the proper screw locations in accordance with the

building erection drawings. Since pre-drilling will “hand” the panels, it will also be necessary to

select the end of the building from which the paneling is to begin. Before drilling the template

panel, it should be checked for proper hole locations against the building framework. Be sure there

is no excessive deflection in the purlins and girts.

12˝ Lap

1˝

1

1˝ - 1

1

1

/2˝

3

/4˝

/2˝

Dimensions subject to

variations. Check building

erection drawings.

1

/4˝

1

2"

E-4

877-2-MUELLER

Page 51

INSTALLATION OF WALL PANELS

Adjoining panels are installed with the overlapping rib toward the last erected panel. Position panel

to structural making sure that it is kept plumb and install fasteners at lapped rib. Check for proper

coverage (3' center to center) and correct as necessary. Install remaining fasteners.

Blanket

Insulation

Sheeting

Direction

Wood

Blocking

Steel Frame Line

Wall

Panel

NOTE: Start first panel with major rib centered with endwall frame.

Wall Panel

www.muellerinc.com

E-5

Page 52

INSTALLATION OF WALL PANELS (CONTINUED)

Backlapping the wall panels 1 foot or 2 foot is routinely done to match panel coverage with the

building width and length. On the sidewall this is done with the last panel installed. On the endwall

this is normally done near the center and will be marked on the erection drawings.

2'-0"

2'-0"

1'-0"

Sidewall

1'-0"

E-6

Endwall

877-2-MUELLER

Page 53

STANDARD SHEET LEDGE

Wall Sheet

(R-Panel Shown)

Base

Angle

Base Flashing

(Optional)

11/2" Sheet

Ledge

Spacing under

sheet

for edge creep

NOTE: Sheets must be at least two inches off the ground, or rust may occur.

OPTIONAL SHEET LEDGE WITH EXISTING SLAB

1

/8"

1

/8" to 1/4"

Wall Sheet

(R-Panel Shown)

Base

Angle

Base Flashing

NOTE: Sheets must be at least two inches off the ground, or rust may occur.

www.muellerinc.com

E-7

Page 54

FASTENER INSTALLATION

Correct fastener installation is one of the most critical steps when installing roof panels. Drive

the fastener in until it is tight and the washer is firmly seated. Do not overdrive fasteners: A slight

extrusion of neoprene around the washer is a good visual tightness check.

Always use the proper tool to install fasteners. A fastener driver (screw gun) with and RPM of

1700-2500 should be used for self-drilling screws. Discard worn sockets, these can cause the

fastener to wobble during installation.

Correct degree of

tightness. Note slight

circle of sealant

NOTE: Always remove metal shavings from surface of panels at the end of each

work period. Rusting shavings can destroy the paint finish and void any warranty.

Too tight! Sealant

squeezed too thin.

Extrudes far beyond

fastener head

Too loose!

Sealant is not

compressed to

form seal

Sealant Tape

Proper sealant tape application is critical to the weather tightness of a building. Sealant tape

should not be stretched when installed. Apply only to clean, dry surfaces. Keep only enough

sealant tape on the roof that can be installed in a day. During warm weather, store sealant tape

in a cool dry place. During cold weather (below 60 degrees) sealant tape must be kept warm (60

degrees – 90 degrees) until application. After sealant tape has been applied, keep protective paper

in place until panel is ready to be installed.

Panel Rib

Prevailing Wind Direction

Lap Tek Screw

(20" O.C.)

E-8

877-2-MUELLER

1

/4˝ Clearance Hole

Roof Panel

Sealant Tape

Roof Panel

Page 55

SAFETY NOTE! CAUTION!!! PANELS MAY BE SLICK

UNSECURED PANELS MAY SLIP IF STEPPED ON!

Never step on a single unsecured roof panel, or a stack of roof panels laying unattached on

the purlins.

Secure each end of the panel with clamps or appropriate fasteners and place walk boards of

adequate size and strength in the flat of any panels not fully secured to the purlins and supported

by panels on each side. Walk boards should run the full length of the panel and be fastened

together by drilling a hole near the end of each board and tied with rope to the next board. Cut a

groove in the bottom of each board so the board will lie flat and not tip back and forth because of

the rope.

NOTE: Always wear rubber sole work boots! When on the roof, use OSHA

approved protection devices such as safety lines, safety nets or catch platforms.

www.muellerinc.com

E-9

Page 56

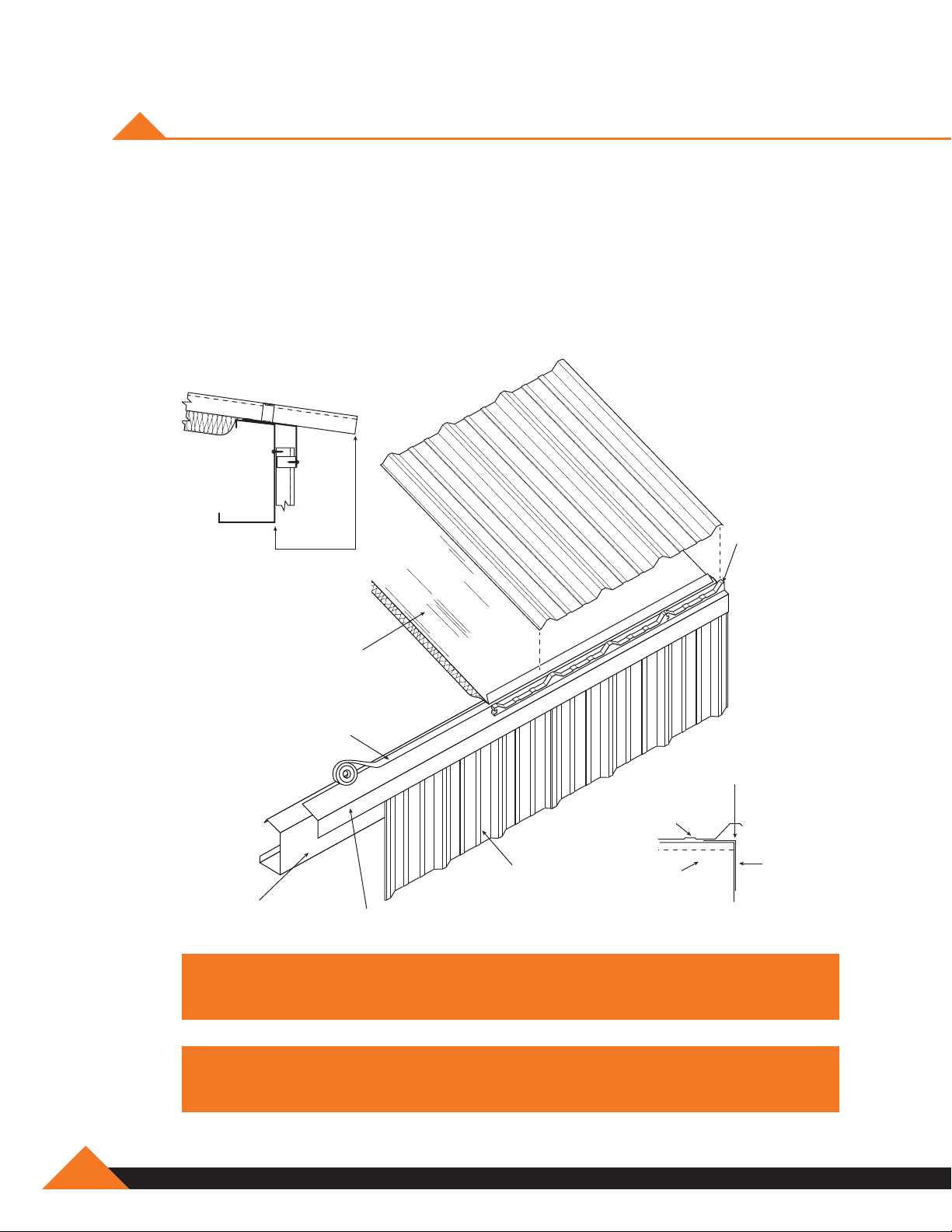

PREPARING THE EAVE

After installing the first run of insulation, prepare the eave for the first roof panel by applying

sealant tape along the eave outside of the insulation and leaving release paper in place. Sealant

must be applied in a straight line and without voids. Do not stretch the sealant. Use a knife to cut

if necessary. Cut an inside closure strip as shown and place starter piece on top of the sealant

(removing protective paper from the sealant only as required). Center the first major rib with edge

of the endwall frame. Splice a full closure to the starting closure and apply along the top of the

eave sealant. If roof is subject to ice and snow build-up, the splice in the closure strip must be

caulked to ensure weathertightness.

Starter

Panel

Edge

1'- 0"

4'- 0"

One Half

Inside Closure

Blanket

Insulation

Double-sided Tape

Eave

Strut

NOTE: Insulation has no laod bearing strength. Maintain body weight on

1'- 0"

Eave Flashing

approved scaffolding or walk boards.

Cut

Full Inside Closure

Wall Panel

Align with Roof Line

Cut Closure Here

E-10

877-2-MUELLER

Page 57

PREPARING THE EAVE (CONTINUED)

Along the top of the closures that have been placed along the eave, apply a second run of sealant

tape. Prior to removing paper backing, check and mark for proper alignment of the first roof panel.

Continue sealant tape and closure run along eave in preparation for the next roof panel.

Insulation

Eave Strut

(Shape

may vary)

Insulation

Cut & Fold

Insulation

Double-sided

Tape

Wall Fastener

Sealant Tape

Sealant Tape

Inside Closure

Sealant Tape

Eave Trim

(Trim shape

may vary)

Wall

Fastener

Outside Closure

(Optional)

Wall Panel

Caulk closure splice

when ice & snow eave

conditions may occur.

Sealant Tape

www.muellerinc.com

E-11

Page 58

INSTALLATION OF FIRST ROOF PANEL

Once the eave is prepared, the first roof panel may be installed. Check the erection drawings to

determine the roof overhang at the eave. Set the roof panel in place over the inside closure (after

removing the paper from the sealant tape) ensuring the major ribs of the panel nest properly

with the inside closure. Align the center of the major rib of the panel edge with the edge of the

endwall roofline. With the panel properly placed, secure the panel to the structure with appropriate

fasteners. If the building requires more than one panel per run, do not install fasteners at the purlin

located at the upslope end of the panel. These fasteners will be installed after the overlapped

panel is installed.

Inside

As required

on erection

drawings

Closure

Blanket

Insulation

Double-sided Tape

Panel

Wall Panel

Eave

Strut

NOTE: For a professional finish, roof panel ribs should be in line with

WARNING! Do not walk on unsecured panels. Wipe oil and other slippery

Eave Flashing

wall panel ribs.

substances from roof panels. SAFETY FIRST!

Purlin

Panel Rib

Endwall

Roof Line

E-12

877-2-MUELLER

Page 59

INSTALLATION OF ROOF PANELS

With the first panel run installed and secured, and sidelap sealant applied, the second panel run

may be started. Prepare the eave with an inside closure and sealant tape as shown previously.

Position the panel so the overlapping ribs will nest properly. Be sure to check for proper overhang

and panel coverage. Lap screw the major ribs of the two panels together, and fasten panel to

the purlins.

Blanket

Insulation

Double-sided Tape

Sealant

Tape

Inside

Closure

Wall Panel

Eave

Strut

NOTE: If peak sheets are being used at the ridge, it is critical that the ribs on the

Eave Flashing

roof panels from both sides align.

WARNING! Sweep up all drill shavings from panels at the end of each work

period to minimize surface rust and damage to panel finish.

www.muellerinc.com

E-13

Page 60

“R” PANEL

High Side Attachment

(6 Fasteners Per Panel)

Slope

R Panel

Sidelap Attachment

(See Detail B)

Eave Attachment

(6 Fasteners Per Panel)

Self Drill

(6 each

per panel)

Sealant Tape

Intermediate Purlin

Attachment

(3 Fasteners Per Panel)

12"

R Panel

Sealant Tape

Detail A Detail B

Sealant Tape

Endlap Attachment

(See Detail A)

Lap Tek Screw

(20" O.C.)

Sidelap

1. Sealant tape must be installed between weather infiltration point and fastener.

2. Install Lap Tek fasteners at 20” on center.

E-14

3. When possible, install panels such that sidelaps are nested away from prevailing winds.

Endlap

1. Double bead sealant tape must be installed between weather infiltration point and fastener.

2. Install self-drilling fasteners on each side of major ribs of panel (two fasteners per foot).

877-2-MUELLER

Page 61

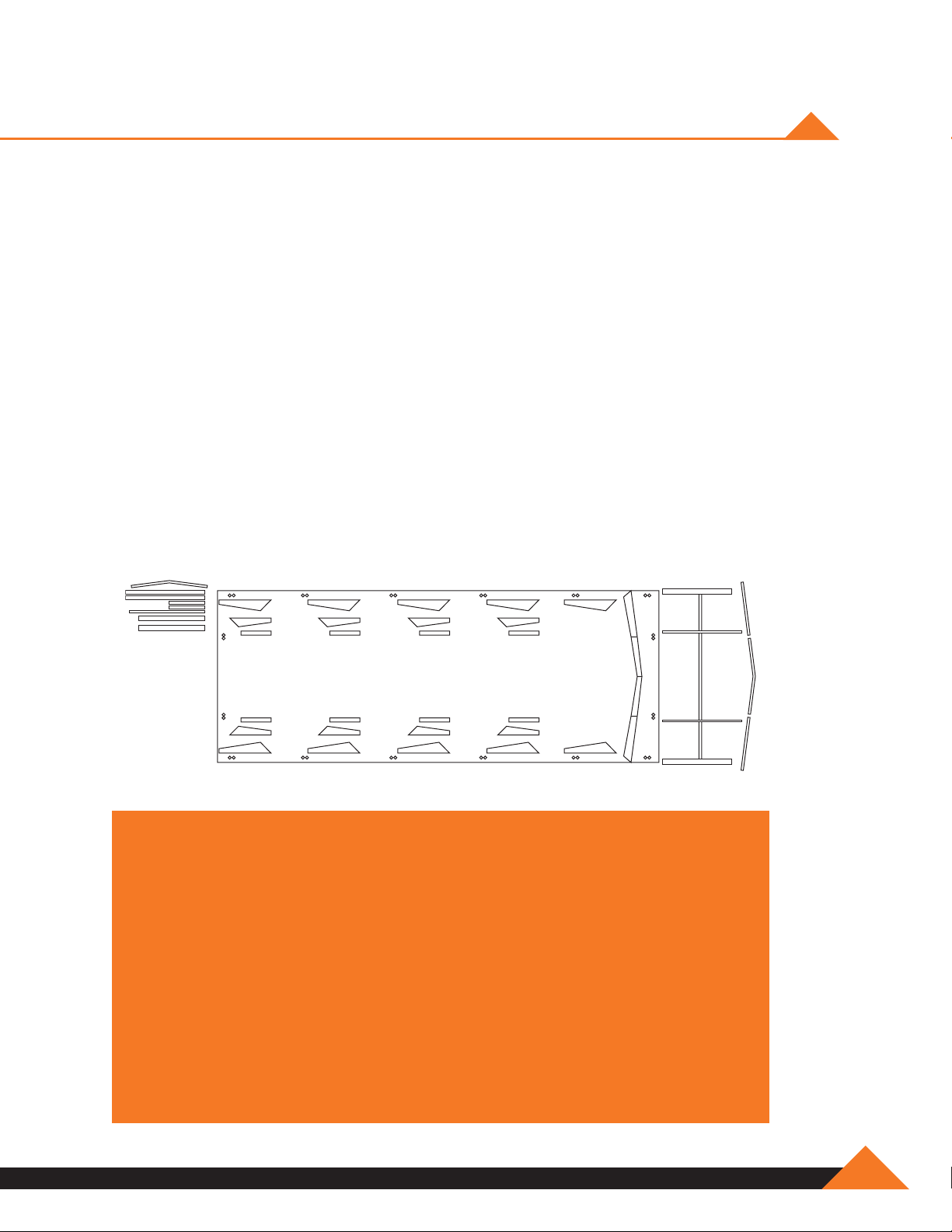

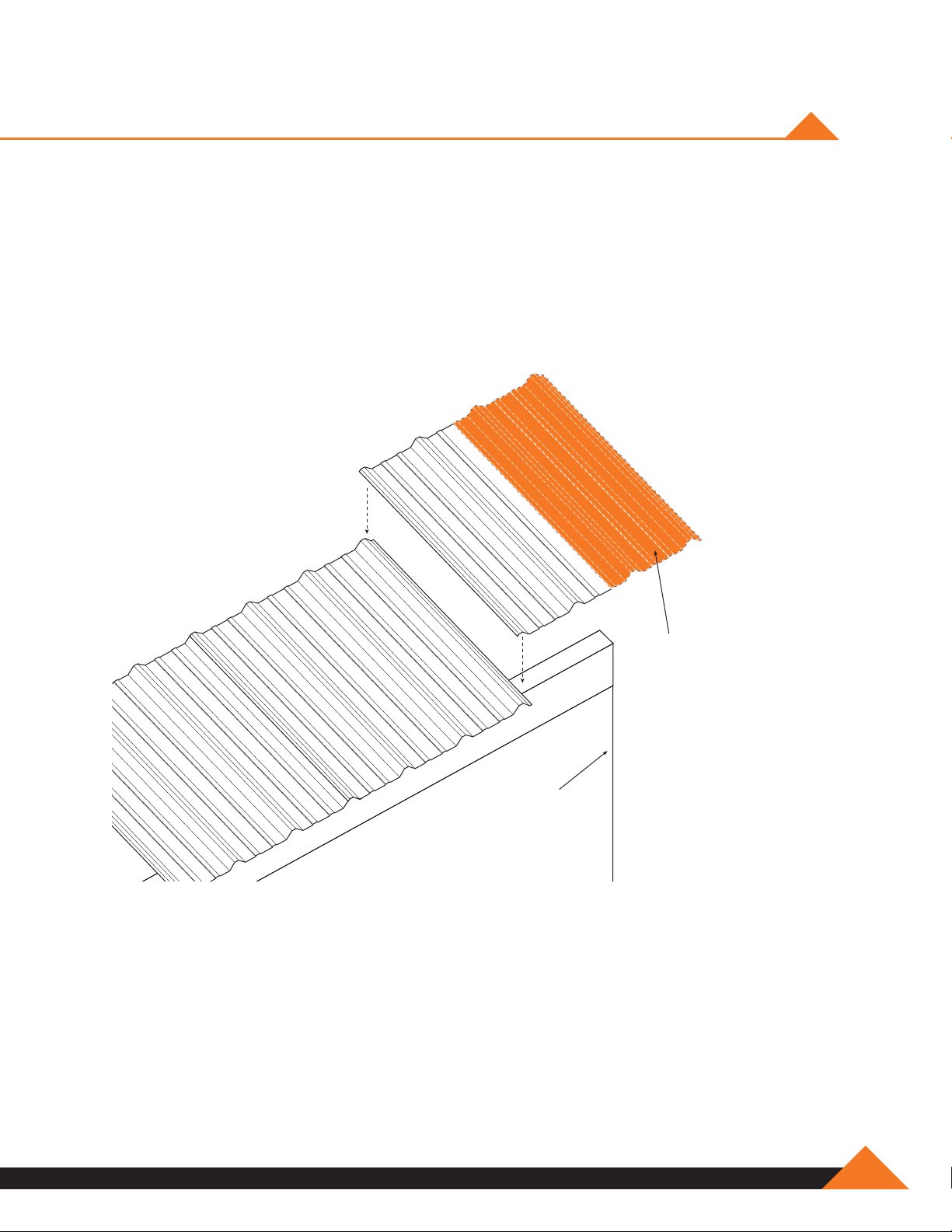

ROOF SHEETING SEQUENCE

It is recommended that both sides of the ridge of a building be sheeted simultaneously. This will

keep the insulation covered for the maximum amount of time and the panel ribs can be kept in

proper alignment for the ridge panel. Check for proper coverage as the sheeting progresses. Note

panel-sheeting sequence below.

11

10

12

8

7

4

2

1

NOTE: If slippery substances are present on the roof panels wipe them clean

immediately to prevent slipping or falling. Workers should maintain a constant

awareness of their location relative to the roof edge.

9

5

6

3

www.muellerinc.com

E-15

Page 62

SECTION AT EAVE

Insulation

Panel

Double-sided

Tape

Roof Fastener

Sealant Tape

Closure

Sealant Tape

Eave Trim

(Trim shape

may vary)

Wall Fastener

Eave Strut

NOTE: Check erection drawings for appropriate overhang dimensions.

Lap Screw

Wall Panel

E-16

877-2-MUELLER

Page 63

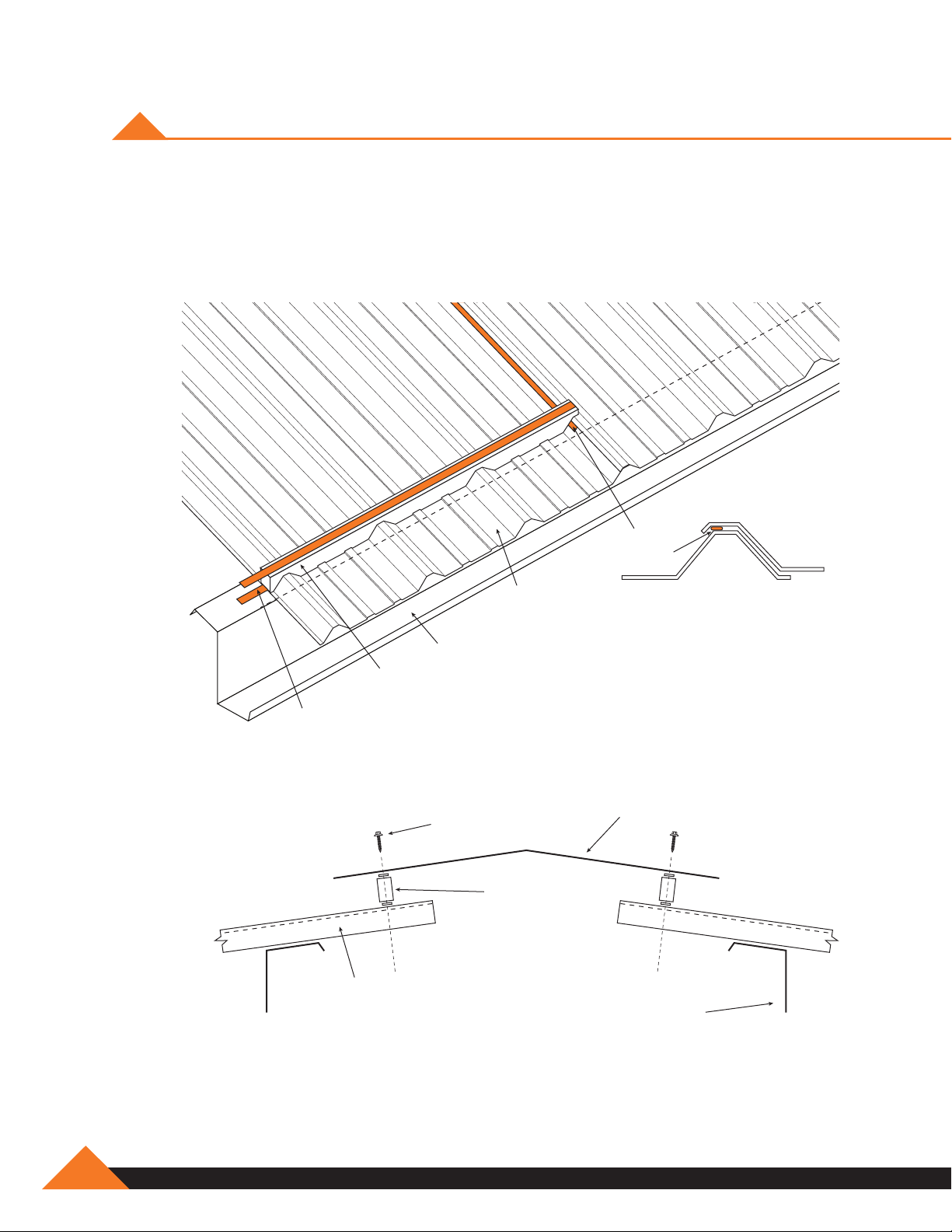

SEALING THE SIDELAP

Apply the sidelap sealant tape to the weather side edge of the lower panel’s major rib as shown.

The sealant tape should only be applied to clean, dry surfaces. With the release paper in place,

press firmly along the length of the sealant to ensure proper adhesion. In removing the protective

paper from the sealant tape, care should be taken not to pull the sealant tape away from the

panel. Install the adjoining panel positioning the overlapping rib with care.

Panel Rib

Lap Tek Screw

(20" O.C.)

Prevailing Wind Direction

1

/4˝ Clearance Hole

Roof Panel

Sealant Tape

Roof Panel

NOTE: Sweep up all drill shavings from panels at the end of each work period to

minimize surface rust and damage to panel finish.

www.muellerinc.com

E-17

Page 64

SEALING THE EAVE

Sealant tape location at the eave is critical. To ensure a weather tight seal, the sidelap sealant

must extend down from the top of the rib to the sealant on the eave closure. The sealant extension

must splice into the eave sealant tape.

Sealant

Tape

Sealant Tape

(Above & Below

Closure)

Sealant Extension

Inside Closure Strip

with Adhesive Backing

NOTE: Workers should maintain a constant awareness of their location in relation

to the roof edge at all times.

Fastener

Panel

Major Rib

E-18

877-2-MUELLER

Page 65

SEALING THE ENDLAPS

At the panel endlaps place a run of sealant tape across the full panel width ½" below the fastener

line. The panel endlaps have a 12" minimum overlap located over a purlin as shown. Locate the

fasteners 1” above the purlin web according to the fastener layout.

12" Lap

Ridge

Roof Panel

Sealant

Tape

NOTE: Do not step on panel endlaps until fully secure with fasteners.

Roof Fastener

Purlin Web

Sealant

Tape

Purlin

Eave

www.muellerinc.com

E-19

Page 66

PANEL ENDLAPS

Apply sealant tape to far side of major rib to complete seal at panel lap.

Roof

Fasteners

Sealant

Tape

12" Lap

1

/2"

Down Hill

E-20

877-2-MUELLER

Page 67

INSTALLATION OF FINAL PANEL

While backlapping the last roof panel (to match panel coverage with the building length) is routinely

done, this installation method can compromise the integrity of the roof by trapping moisture

between the panels. This moisture could, in time, create an environment conducive to rust and

metal failure. Manufacturer recommends field cutting the final panel lengthwise to create

the desired panel width necessary to finish off the building. The cut edge of the panel

should always be installed on the outside edge, not the lap edge. The “narrow” panel should be

handled with care, and foot traffic avoided until the final panel is completely installed.

End of

Building

Place Cut Edge To

Outside of Building

www.muellerinc.com

E-21

Page 68

ROPE SEALER PLACEMENT

Panel Rib

Prevailing Wind Direction

1

/4˝ Clearance Hole

Roof Panel

Inside & Outside Closure Placement

Lap Tek Screw

(20" O.C.)

Sealant Tape

Roof Panel

Outside Closure Strip

Sealant Tape

Steel Roofing

or Siding

Inside Closure Strip

Sealant Tape

E-22

877-2-MUELLER

Page 69

DIE FORMED TRANSITION TRIM

12"

Transition Trim

1

/2"

1

Sealant Tape

3

1"

1

/2"

10'-0"

31/4"

3

/4"

3

1

/4"

3

/8"

6"

1

1

/2"

2"

1

/2"

2

Multiple Uses

Wall

Roof Sheet

Transition Trim

Roof Sheet

Transition Trim

Roof Sheet

Wall Sheet

Transition Trim

Roof Sheet

www.muellerinc.com

E-23

Page 70

SAFETY PRECAUTIONS FOR ROOFING WORK

Manufacturer strongly recommends that erection employees be continuously trained in safe and

productive work practices. Working on the roof area in the installation of roof structurals, insulation

or roof panels requires proper training, correct equipment and constant alertness to minimize the

danger of falls. Hard hats should be worn on job sites to prevent injury from falling objects. Safe

work practices on all erection duties should be carefully reviewed with erection crews prior to

beginning each job.

NEVER STEP ON SKYLIGHTS OR TRANSLUCENT PANELS!

WARNING! Panels May Collapse If Not Properly Secured.

Roof panels must be completely attached to the purlins and to panels on either side before they

can be a safe walking surface. Skylights or translucent panels can never be considered as a

walking surface.

PARTIALLY ATTACHED OR UNATTACHED PANELS

SHOULD NEVER BE WALKED ON!

DO NOT:

1. Step on rib at edge of panel.

2. Step near crease in rib at edge of panel.

3. Step within 5 feet of edge on unsecured panel.

A single roof panel must never be used as a work platform.

E-24

877-2-MUELLER

Page 71

UL 90 LIGHT TRANSMITTING PANEL INSTALLATION

R-Panel

Sealant Tape

Slope

R-Panel

Sealant Tape

Slope

Install roof panels, leaving the light-transmitting panel run open, except for lower light transmitting

panel run panel. Install sealant tape to panel sidelaps and across panel width as normal.

Lay light transmitting panel in place overlapping lower metal panel 12”. Do not install any fasteners

at this time. Install sealant tape down light transmitting panel side laps. Apply double run of sealant

tape across light transmitting panel width at lower and middle purlins. Sealant tape should align

with beginning and ending edge of top flange of purlin. At the upslope end of light transmitting

panel, apply double run of sealant tape for endlap.

Install 3” long pieces of “R” panel over light transmitting panel at the lower and middle purlins.

Attach to purlins with six fasteners per piece of “R” panel. Fasteners must go between the two

runs of sealant tape that were installed previously.

www.muellerinc.com

E-25

Page 72

UL 90 LIGHT TRANSMITTING PANEL

INSTALLATION (CONTINUED)

R-Panel

Sealant Tape

Slope

Lap 12" O.C.

Slope

Apply sealant tape across sidelaps of 3” long pieces of “R” panel. Be sure the light transmitting

panel sidelaps have a complete run of sealant tape on top of the light-transmitting panel.

Install “R” panel hat section to each side of light transmitting panel with lap screws at 12” O.C.

Apply sealant tape down each hat section to just downslope of exposed sealant tape running

across light transmitting panel. Also apply additional sealant tape up each side of hat section

aligning and sealing to the exposed sealant tape running across light transmitting panel.

E-26

Install upper metal panel in light transmitting panel run and fasten as at a normal endlap.

877-2-MUELLER

Page 73

triM

SECTION F

Page 74

Page 75

FLASHING, GUTTER AND TRIM

The correct installation of flashing, gutters, and trim cannot be overemphasized. The overall

appearance of the finished building depends primarily on the quality of the installation of the

flashing, gutters and trim. Keep all gutter and flashing lines straight. Make all bends sharp and

neat. Be sure edges are not jagged, dented, crimped, or serrated. End joints and laps must be

closely controlled.

Eave Trim

Gutter

Ridge Roll

Flashing

Rake

Trim

Peak Sheet

Ridge

Rake

Angle

Peak Box

Wall Panel

NOTE: Flashing should be stored off the ground to avoid moisture and handling

damage. Elevate one end of the package above the lower end to encourage

drainage in case of rain. Always wear gloves when handling sheet metal.

WARNING! Mueller trim comes with a protective film coating to aid in the

prevention of scuffing. Do not allow this film to be exposed to te sun. Exposure

will bond the film to the metal making removal difficult.

www.muellerinc.com

F-1

Page 76

PEAK SHEET RIDGE INSTALLATION

Peak sheet ridge panels are to be installed as each side of the roof is sheeted. This will aid in

keeping both sides of the roof aligned. After having installed a run of panels on each side of the

roof, apply sealant to the panels as shown. Set die formed ridge panel in place and install lap and

purlin fasteners. Apply sealant tape along the top of the leading rib to prepare for the next sidelap.

Roof

Fasteners

Die Formed

Ridge

F-2

877-2-MUELLER

Sealant

Tape

Ridge

Purlins

NOTE: Do not walk on unsecured ends of panels.

See Building

Erection

Drawings for

Dimension

Page 77

TYPICAL SCREW PLACEMENT ON PEAK SHEETS

Lap Tek Screw

Peak Sheet

Roof Sheet

(R-Panel Shown)

Self Drill Screw

TYPICAL SCREW PLACEMENT ON RIDGE ROLL

Lap Tek Screw

(1' Typical)

Roof Sheet

(R-Panel Shown)

Outside

Closure

Ridge Roll

www.muellerinc.com

F-3

Page 78

SEALANT TAPE APPLICATION AT RIDGE FLASHING

Apply panel sidelap sealant tape as shown for building with ridge flashing and outside closures.

The sealant tape is placed along the inside edge of the major rib from the ridge purlin web line to

the upper end of the panel.

Ridge Flashing Detail

Sealant

Tape

Sealant

Tape

Outside

Closure

Roof

Panel

Roof

Panel

Peak

Purlin

Ridge Flashing

Fastener

Outside

Closure

Purlin

F-4

877-2-MUELLER

Page 79

RAKE TRIM AND PEAK BOX INSTALLATION

Rake trim and/or peak box should lap over rake trim a minimum of 2 inches. Attach to wall panel

with lap tek screws. Peak box may be attached to rake trim with lap tek screws or rivets. Seal the

connection at the roof panel with sealant tape or caulk.

Rake

Trim

Roof Panel

Peak Box

Sealant

Tape

Wall Panel

NOTE: Mueller recommends an outside closure under bottom edge of rake trim,

to prevent birds from nesting in trim. this works well with buildings with less

than 2:12 slope.

NOTE: If last rib is removed, cut 1" beyond the wall sheet line, then fold edge up.

www.muellerinc.com

F-5

Page 80

CORNER TRIM

Outside Corner Detail

R-Panel Outside

Corner Trim

Lap Tek

24" O.C.

Wall Girt

Inside Corner Detail

(Used with liner panel condition only)

R-Panel

Wall

Girt

Inside

Corner Trim

Lap Tek

24" O.C.

F-6

NOTE: Install corner trim with lap tek faseners 24" O.C.

877-2-MUELLER

Page 81

STANDARD EAVE TRIM

Tek Screw in

Flat of Sheet

Roof Panel

Tek Screw

Purlin or

Eave Strut

Sealant Tape

Inside Closure

Sealant Tape

Standard

Eave Trim

Lap Tek Screw

Wall Panel

Standard Eave / Sculptured Rake Trim With Rake End Cap

Rake Trim

Rake End

Standard

Eave Trim

Corner Trim

NOTE: Roof sheet should extend 2" to 3" past eave trim.

Cap

www.muellerinc.com

F-7

Page 82

SCULPTURED EAVE TRIM

Tek Screw in

Flat of Sheet

Roof Panel

Tek Screw

Purlin or

Eave Strut

Sealant Tape

Inside Closure

Sealant Tape

Sculptured

Eave Trim

Lap Tek Screw

Optional Closure

Wall Panel

F-8

877-2-MUELLER

Page 83

SCULPTURED EAVE / RAKE TRIM

WITH CORNER BOX

Rake Trim

Sculptured

Eave Trim

NOTE: Roof sheet should extend 2" to 3" past eave trim.

Pop Rivets or

Lap Tek Screws

Corner Box

www.muellerinc.com

F-9

Page 84

MUELLER GUTTER SYSTEM DIAGRAM

Gutter Strap

Roof Panel

Purlin or

Eave Strut

Pop Rivet or

Lap Tek Screw

Wall Panel

Gutter

Downspout

Sleeve

Wall Girt

Pop Rivet or

Lap Tek Screw

Base Angle

Downspout

Strap

Downspout

Downspout

Kickout

Base Trim

F-10

877-2-MUELLER

Page 85

Gutter Strap

Roof Panel

Purlin or

Eave Strut

Screw Placement Side View

GUTTER STRAP INSTALLATION

Lap Tek Screw in

Flat Area of Sheet

Gutter

Gutter Strap

Screw Placement Top View

Gutter

Metal

Roofing

Lap Tek

Screws

www.muellerinc.com

F-11

Page 86

DOWNSPOUT SLEEVE INSTALLATION

Pop Rivets

Inside Bottom

of Gutter

Gutter

Downspout

Sleeve

Gutter

F-12

Downspout

Sleeve

877-2-MUELLER

Page 87

GUTTER WITH CORNER BOX

Rake Trim

Gutter

Gutter Strap

Pop Rivets or

Lap Tek Screws

Corner Box

www.muellerinc.com

F-13

Page 88

DOOR TRIM INSTALLATION

“J” trim pieces are provided to trim out edges around framed openings. “J” trim pieces should be

attached to door columns and header before wall sheets are attached. After trim is attached, the

trimmed wall sheets can be inserted behind the “J” trim then screwed down in place.

Door Head

Trim

Door Jamb

Trim

F-14

Door Opening

NOTE: Clean all metal shavings from wall sheets to ensure against damage to

the coating.

877-2-MUELLER

Page 89

TYPICAL DETAILS – HEAD/JAMB

Jamb

Wall Girt

Self-Drill Screw

R-Panel

Head

3' O.C.

Door Jamb

Jamb Trim

R or U-Panel

Self-Drill

Screw

NOTE: Install jamb and head trim with self-drilling fasteners at 3' O.C.

Purlin

Self-Drill

Screw

Door HeadHead Trim

www.muellerinc.com

F-15

Page 90

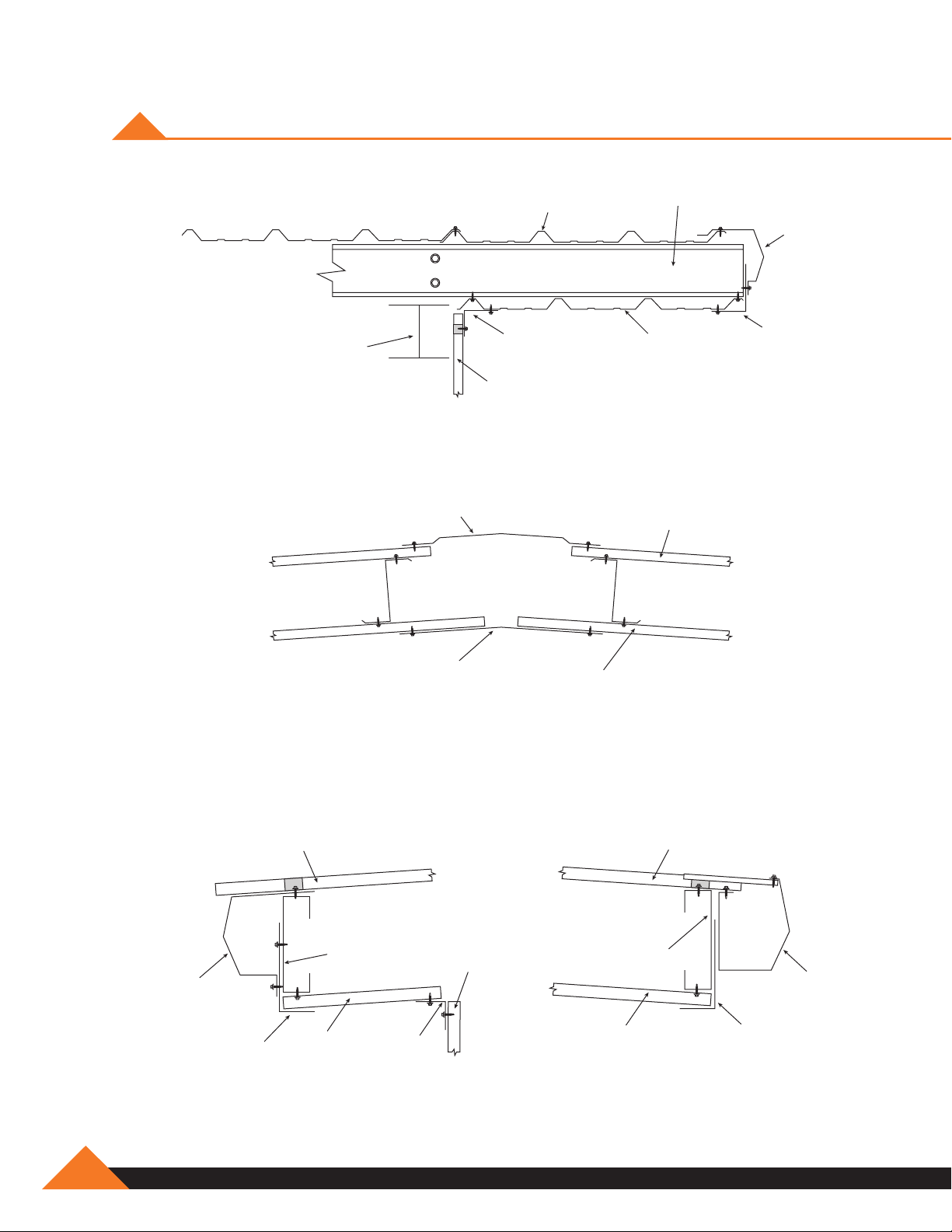

OVERHANG TRIM DETAILS

Purlin

Endwall Overhang

Roof Panel

Rake

Trim

Endwall

Rafter

Endwall Overhang At Ridge

Ridge Roll

Flashing

Angle

Flashing

Wall Panel

Soffit

Sheet

Soffit Sheet

Angle

Flashing

Roof Panel

F-16

Sidewall Overhang With Eave Trim Sidewall Overhang With Gutter

Roof Panel

Purlin

Soffit

Sheet

Eave

Trim

Angle

Flashing

877-2-MUELLER

Roof Panel

Soffit

Sheet

Purlin

Wall

Panel

Angle

Flashing

Gutter

Angle

Flashing

Page 91

doorS and

acceSSorieS

SECTION G

Page 92

Page 93

PERSONNEL DOORS

Personnel (walk-in) doors can be installed at any location in the building. Wall girts below the

standard level of seven feet four inches will have to be cut out for the doorframe.

After deciding where the door is to be located and before the wall sheets are installed, attach the

doorframe to the foundation and the wall girt or girts. The doorframe can be bolted to the girt and

foundation where and however desired. The base angle will have to be cut out in the door opening.

Purlin

Wall Girt

at 7'4"

Bolt frames

to girt on

both sides

Bolt frames

to foundation

on both sides

Threshold

Make sure the doorframe is square so the door will fit and open and close properly.

After the doorframe is installed and squared, the door can be placed on the hinges, the doorknob

and locks installed, and the threshold plate placed at the bottom of the door opening.

Base Angle

www.muellerinc.com

G-1

Page 94

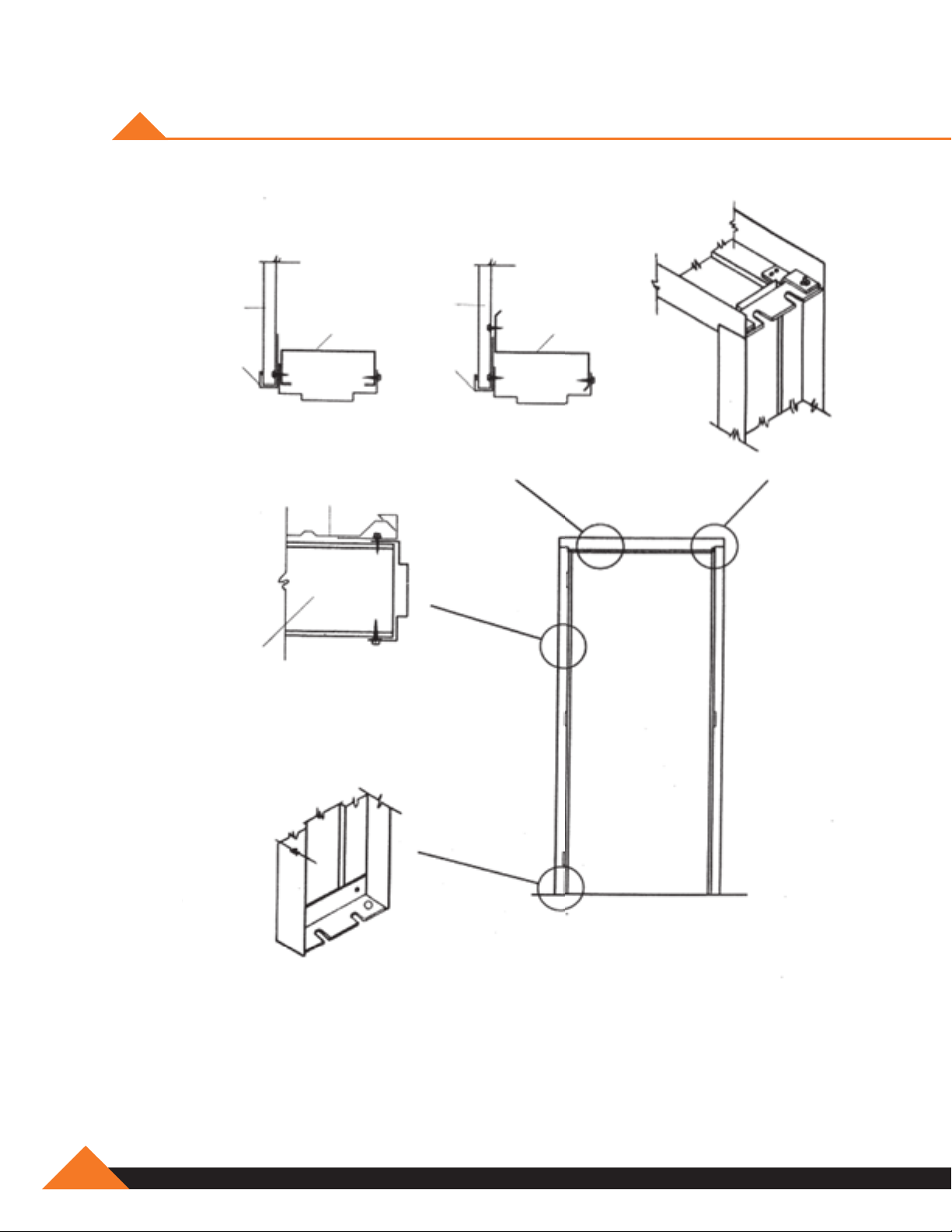

METAL BUILDING DOOR FRAME

Wall

Sheet

Door

Head

Trim

Purlin

Cee Purlin

Wall

Sheet

Door

Head

Trim

Zee Purlin

Head Section Head Section

Wall Sheet

Intermediate

Purlin Connection

Corner Connection

G-2

Standard Frame Details

No Sub-Frame Required

Sill Anchor

877-2-MUELLER

Page 95

ROLL-UP DOORS INSTRUCTIONS FOR ASSEMBLY

Included with Roll-up Doors. See Package.

See manufacturer's instructions.

WINDOW INSTALLATION

www.muellerinc.com

G-3

Page 96

VENT INSTALLATION

Roof Ventilators (Optional)

1. Ventilators may be installed on the roof ridge after the roof sheets are on and before the

ridge roll or peak sheet is installed. The ventilators are ten feet long and usually are installed

at the peak and between two rafters.

2. Cut out the ridge roll or peak sheet to fi t the opening of the ventilator. Ensure that the

opening is cut correctly so the ventilator will fi t properly and provide enough lap over the

opening to prevent leaks. (The roof sheets may need to be trimmed to maximize venting).

3. Place the ventilator over the opening. Use molded rubber outside sealers to fi ll the gaps

between the ventilator fl ange and the roof sheets.

4. Attach the ventilator to the roof sheets with lap tek screws. Screw through the vent skirt to

the tops of the roof sheet ribs.

5. Locate the vent adjusting pull chains as desired. (According to vents instructions).

G-4

877-2-MUELLER

Page 97

CONTINUOUS RIDGE VENTILATORS

10' Continuous Vent

Birdscreen

Peak Panel

Roof Panel

Outside Closure Strip

w/ Sealant Tape

End Cap

Skirt

Outside

Closure Strip

w/ Sealant Tape

Throat

Section

Throat Ga. A B C

9"

12"

26 22 12 ¾ 15 ¼

26 28 ¼ 17 ¼ 19 ½

Rain Shield

Wind Band

Interior Frame

Damper

(Optional)

www.muellerinc.com

G-5

Page 98

VENT SEALERS

End Skirt

Roof

Panel

61/2˝

Closure

Sealant Tape

Foam Closure

G-6

Peak Sheet

Roof Pitch Less than 1:12

Install the end cap for 1:12 pitch roof slope and foam closure with tape sealant top and bottom.

877-2-MUELLER

Page 99

Section B

VENT INSTALLATION

Vent

Roof Panel

Vent End Cap

Blind Rivets (4 required)

End Skirt

Fasteners

Scribe

End Skirt

Section A

Section A

Vent

End Skirt Gutter

4:12

3:12

2:12

Roof Panel

End Skirt, attach to

leading vent

Sealant Tape

Fasteners

(2 required

on each

side of vent)

Outside closure with

tape sealer top and

bottom. (Field notch

around end skirt gutter).

Section B

End Skirt

Blind Rivets (4 required)

Outside closure

with tape sealer

top and bottom.

(Field notch

around end

skirt gutter).

Roof Pitch Greater Than 1:12

End cap is factory pre-cut to 1:12. The three dots

embossed in the end cap represent 2:12, 3:12

and 4:12 roof pitches. Select the appropriate dot

to represent the roof pitch, scribe two lines from

lower corners of the end cap, intersecting at the

dot. Remove the area described by the cribe

lines and install the end skirt.

End Skirt Gutter

Remove this area

www.muellerinc.com

G-7

Page 100

PIPE DECK FLASHING INSTALLATION

1. TRIM

Cut opening to 20%

smaller than pipe

diameter.

2. SLIDE

Slip pipe flash over pipe.

3. SEAL

Apply urethane/silicone

sealant between pipe

flash and roofing.

4. FORM

Bend aluminum base to

fit irregularities. Use large

slot screwdriver to press

into tight angles.

5. FASTEN

Complete the seal using

common weather-

resistant fasteners.

Selection Chart

Master Flash

Number

1

2

3

4

5

6

7

8

Note: Numbers 1 & 3 are closed top. When using pipe flash on very steep pitched roof

or surface with deep corrugation, use next largest size for increased flange flexibility.

Pipe Size Base Dimension Opening Diameter

1

/4" - 2" 41/2" Closed

11/4" – 3" 6"

1

/4" – 4" 8" Closed

7

/8"

3" – 6" 10" 21/2"

4" – 7" 11" 31/2"

5" – 9" 12" 4"

6" – 11" 14" 5"

7" – 13" 17" 6"

Material Information

G-8

Material Neoprene EPDM Silicone

Guarantee

Temperature Range

Applicable

Tough EPDM, silicone or Neoprene

rubber resists weathering,

ultraviolet light and cracking.

Note: Specify Neoprene when Pipe Flash is to be exposed to petrochemicals.

877-2-MUELLER

10 years 20 years 20 years

-45 degree to

+200 degree

ASTM D2000,

M2 BC 510 A14,

B14, C12, F17,

Z1, Z2, Z3

-65 degree to

+250 degree

ASTM D2000,

M3 BA 510 A14,

B13, C12, F17,

Z1, Z2, Z3

Pipe opening is quickly and easily

customized on the job.

Aluminum base bends to form a

perfect seal on all roof pitches,

contours or surface irregularties.

Square flange design adapts to

any roofing material.

-100 degree to

+450 degree

ASTM D2000,

M4 GE 505 A19,

B37, C12, F19,

Z1, Z2, Z3

Loading...

Loading...