Page 1

insERtion instRUctions ManUaL

®

MUELLER

Improved,

Centurion

Series,

Modern

Improved,

®

Centurion Series Fire Hydrant –

Adding an Extension 2-3

Improved Fire Hydrant –

Inserting Extension Section

(All Models Prior to 1962) 4-5

Improved Fire Hydrant –

Inserting Extension Section

(Sealed Oil Reservoir 1962 Style) 6-7

Improved Fire Hydrant –

Inserting Extension Section

with Steel Stem Coupling

(Sealed Oil Reservoir 1962 Style) 8-9

Modern Improved Fire Hydrant –

Inserting Extension Section 10-11

107

Inserting Extension Section 12-13

TABLE OF CONTENTS PAGE

®

Fire Hydrant –

and 107

Inserting Extension Sections – Notes 14-15

Fire Hydrants

Reliable Connections

Inserting Extension

Sections

moreinfo@muellercompany.com

!

WARNING: Before working on, or disassembling the Hydrant (including removing any bolts(s) holding the Hydrant together), shut off gate valve to isolate

Hydrant from main water source. Loosen (do not remove) one nozzle cap two turns and check for water under pressure inside Hydrant - bleed off any pressure, then

remove nozzle cap completely. Open Hydrant main valve completely. A continuous ow of water, no matter how slight, indicates Hydrant is not properly isolated from

the main water supply, and that problem must be corrected before any Hydrant disassembly can proceed. Disassembly of Hydrant with pressurized water acting

against the main valve could result in unexpected ejection of Hydrant parts, debris or high-pressure water stream, which could cause serious bodily injury.

Customer Service Center

Decatur, Illinois

800.423.1323

www.muellercompany.com

TM

Page 2

MUELLER

®

Centurion

®

Series Fire Hydrant

Adding an Extension

!

WARNING: Before removing any bolt(s) holding the Hydrant together, shut off gate valve to isolate Hydrant from

main water source. Loosen (do not remove) one nozzle cap two turns and check for water under pressure inside Hydrant

– bleed off any pressure, then remove nozzle cap completely. Open Hydrant main valve completely. A continuous ow

of water, no matter how slight, indicates Hydrant is not properly isolated from the main water supply, and that problem

must be corrected before any Hydrant disassembly can proceed. Disassembly of Hydrant with pressurized water acting

against the main valve could result in unexpected ejection of Hydrant parts, debris or high-pressure water stream,

which could cause serious bodily injury.

EQUIPMENT & TOOLS NEEDED – PPE: Hard hat, safety shoes, safety vest, safety glasses, work gloves.

Tools: Wrench, A-311 operating wrench, pliers.

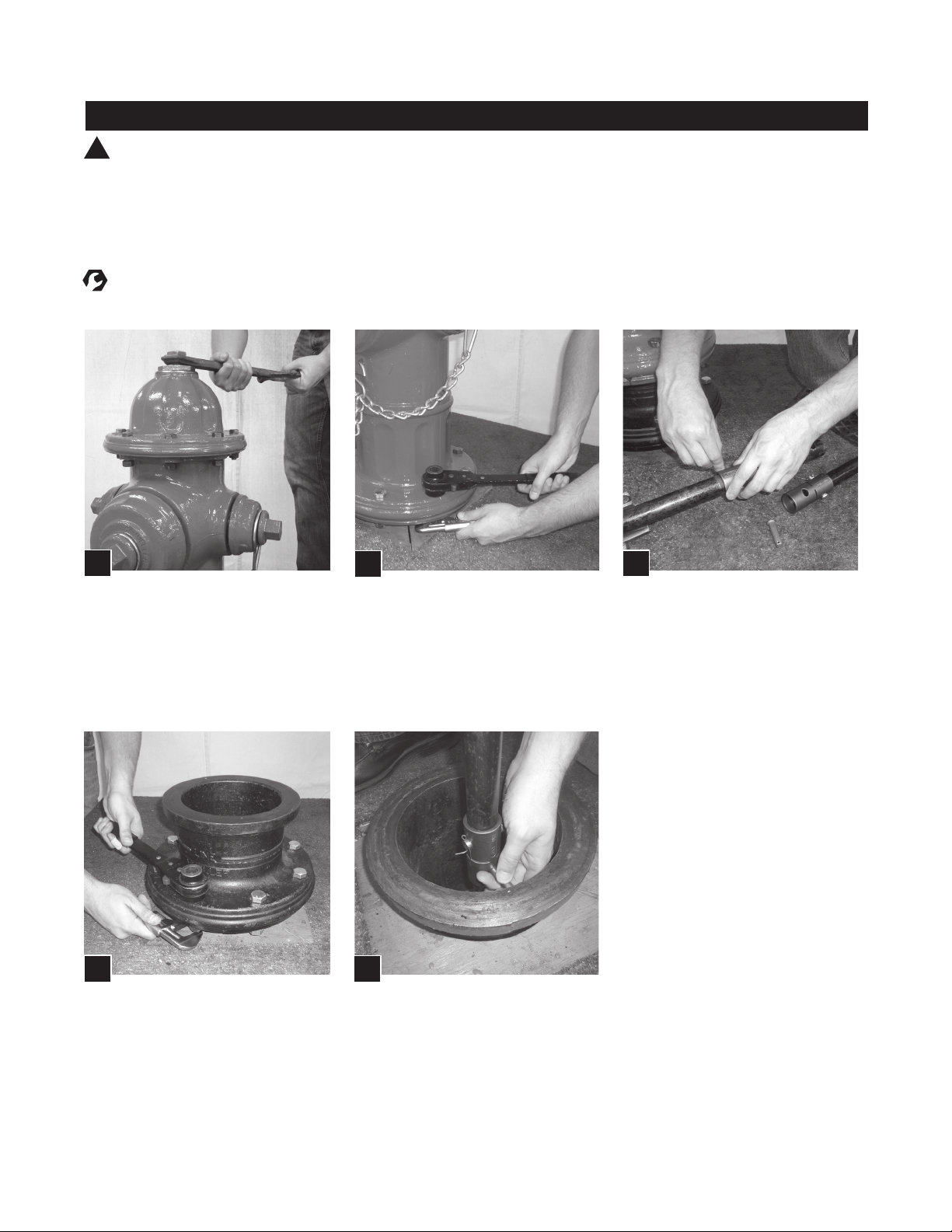

1.

Remove Hold-Down Nut, Anti-Friction

Washer and Operating Nut from

Bonnet. Lubricate outside of Brass

Sleeve and slide over threaded stem

end to prevent O-ring damage. Unbolt

Bonnet from Upper Barrel and remove.

Remove Brass Sleeve.

4.

Attach Extension Barrel to Lower

Barrel with solid Flange halves

(without groove) and Bolts, being

sure O-ring is in place.

2.

Unbolt Trafc Flange. Remove Upper

Barrel. Remove Upper Stem and

Stem Coupling by removing the lower

stainless steel Cotter Pin and stainless

steel Clevis Pin.

5.

Assemble Upper Stem and Stem Coupling onto Extension Stem and retain it

with stainless steel Clevis Pin and stainless steel Cotter Pin.

NOTE: Make sure Stem Coupling is

installed with “This End Up” towards

the Upper Stem.

3.

Place Extension Stem and Extension

Coupling on Lower Stem and retain

it with stainless steel Clevis Pin and

stainless steel Cotter Pin.

2

Page 3

MUELLER

®

Centurion

®

Series Fire Hydrant

Adding an Extension

!

CAUTION: Always ll the oil reservoir with the Bonnet installed, the Hydrant in its normal upright position, and

the main valve fully closed. If the Hydrant is lled with lubricant under any other circumstances, excess lubricate can

overll the Bonnet and create a pressure lock. This could result in damage to the seals or Bonnet or prevent proper

Hydrant operation.

EQUIPMENT & TOOLS NEEDED – PPE: Hard hat, safety shoes, safety vest, safety glasses, work gloves.

Tools: Wrenches, A-311 operating wrench.

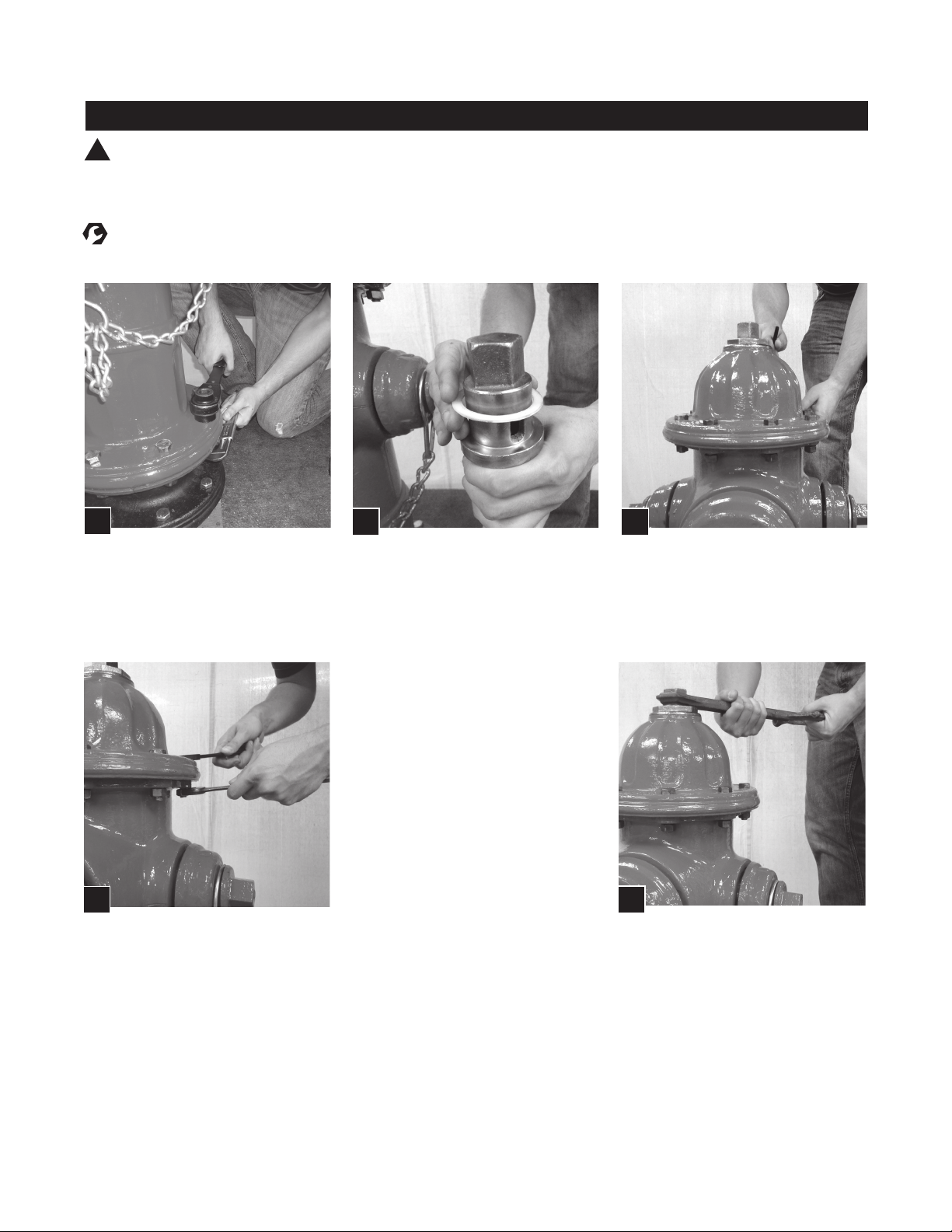

6.

Attach Upper Barrel with Trafc Flange

Halves (with bevel on outer edge

downward) and Bolts; being sure Trafc

Flange O-ring* is in groove in Upper

Barrel. Tighten Bolts to 60 ft-lbs.

9.

Torque Bonnet Bolts to 40-80 ft-lbs.

Torque Hold-Down Nut to 200-300

ft-lbs. after Bonnet Bolts are tight. Open

Gate Valve. Unscrew one Hose Nozzle

Cap slightly to bleed air. Open Hydrant

fully. Tighten Hose Nozzle Cap when

water starts owing and check all ange

connections for leaks. Turn Operating

Nut to fully closed position and remove

Hose Nozzle Cap to allow Barrel to

drain. Replace Hose Nozzle Cap.

7.

Check Bonnet O-ring* for proper

position and condition. Attach Brass

Sleeve to Upper Stem and lubricate

outside to protect O-ring Seals from

thread damage. Place Bonnet onto

Upper Barrel and assemble Bonnet

Bolts only hand-tight. Remove Brass

Sleeve. Reassemble Operating Nut,

Anti-Friction Washer, and Hold-Down

Nut (snug-tighten). Be sure O-ring

Seals are in good condition at thread

shoulder on outside of Hold-Down Nut

and on inside where contact is made

with Operating Nut.

8.

Remove Oil Filler Plug in side of

Bonnet. Pour MUELLER Hydrant

Lubricant into Oil Reservoir until it is

level with Oil Filler Plug Hole. Replace

Oil Filler Plug (see Lubrication section

on page 8).

10.

Turn Operating Nut in closing direction

to make sure Main Valve is closed

tightly, then turn in opening direction

approximately 1/4 turn to relieve

tension on operating mechanism.

*To determine correct O-rings for Bonnet and Ground Line anges, which are similar in

appearance: smaller diameter O-ring is used at Bonnet ange; larger at Ground line ange.

3

Page 4

®

MUELLER

Improved Fire Hydrant

Inserting Extension Section (All Models Prior to 1962)

EQUIPMENT & TOOLS NEEDED – PPE: Safety shoes, safety vest, safety glasses, work gloves.

1

Tools:

/4” hex-head wrench, A-51 lubricating oil, A-311 operating wrench, A-367 brass sleeve.

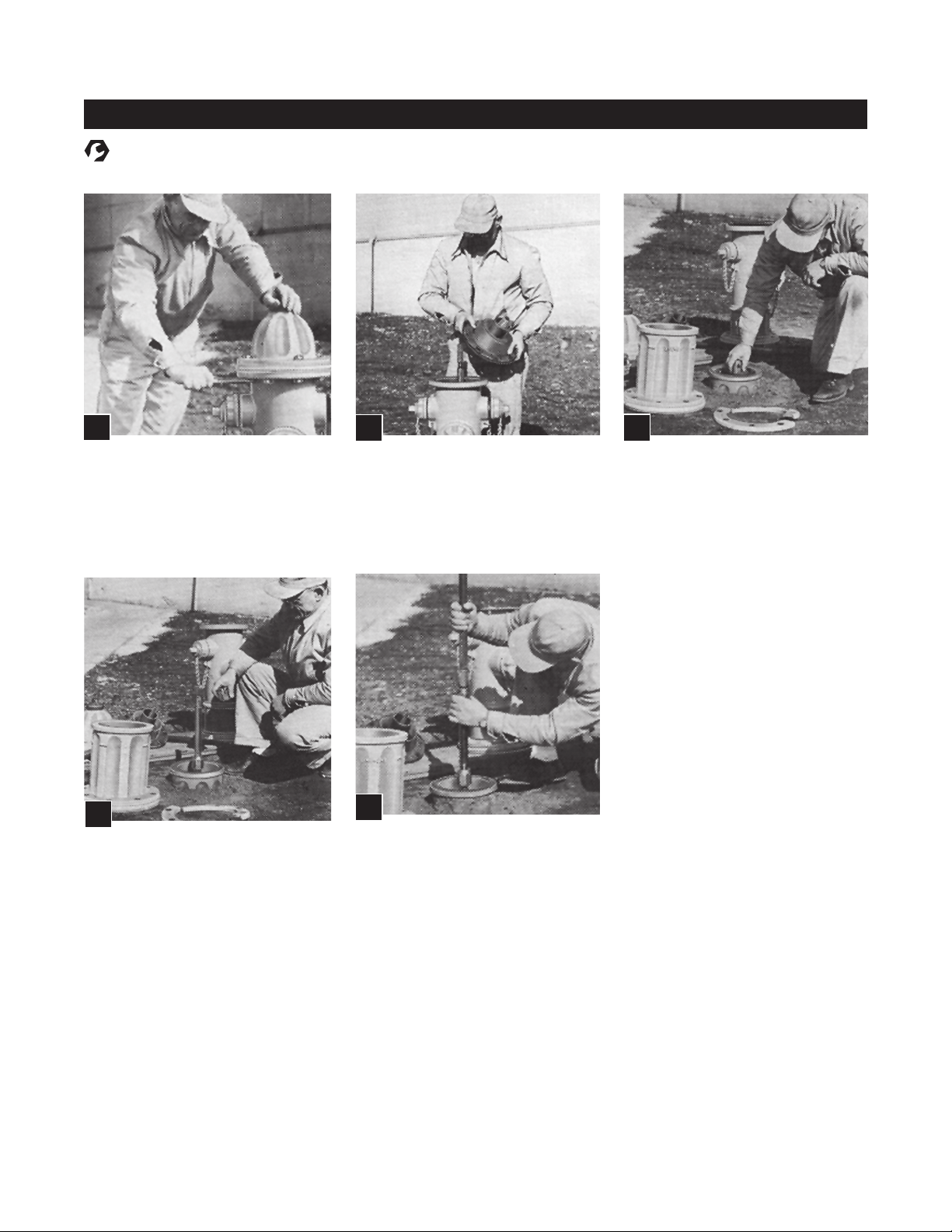

1.

Remove four Bonnet Bolts and turn

operating nut in the opening direction

until free of stem. Remove Bonnet.

4.

Screw Extension Stem into Extension

Coupling until it contacts Lower Stem.

Align tongue and groove of stems

with hole in Extension Stem Coupling.

Screw Extension Stem Coupling

upward until tongue and groove of

stems rmly lock together. Tighten with

wrench, then, screw in Set Screw in

Extension Stem Coupling.

2.

Remove four bolts in stufng box.

Lubricate A-366 Brass Sleeve. Slide

Sleeve over threaded area of stem

to protect O-rings from damage by

threads. Lift stufng box off carefully.

Remove Brass Sleeve.

5.

Place new Stem Coupling Sleeve part onto

Upper Stem. Screw new Stem Coupling

part onto Lower Stem as far as threads

permit.

Screw Upper Stem into Stem Coupling

until it contacts the Lower Stem. Turn Stem

Coupling and Upper Stem so that slot in

Thimble aligns with the tongue and groove

of stems. Hold Upper Stem in alignment

and screw Stem Coupling upward until

tongue and groove of stems rmly lock

together. Tighten with wrench. With Stem

Coupling in place, slide Sleeve downward

so that lower end of sleeve surrounds

upper end of Stem Coupling. Be sure

Sleeve projections t into Stem Coupling

slots. With Sleeve in place, tighten set

screw in Sleeve.

3.

Unbolt Trafc Flange and remove Upper

Barrel.

Unscrew set screw in Sleeve. Screw

Stem Coupling down against shoulder.

Slide Sleeve up and unscrew Upper

Stem from Stem Coupling. Unscrew

Stem Coupling from Lower Stem. Screw

Extension Stem Coupling down on

Lower Stem against shoulder.

4

Page 5

®

MUELLER

Improved Fire Hydrant

Inserting Extension Section (All Models Prior to 1962)

EQUIPMENT & TOOLS NEEDED – PPE: Safety shoes, safety vest, safety glasses, work gloves.

1

Tools:

/4” hex-head wrench, A-51 lubricating oil, A-311 operating wrench, A-367 brass sleeve.

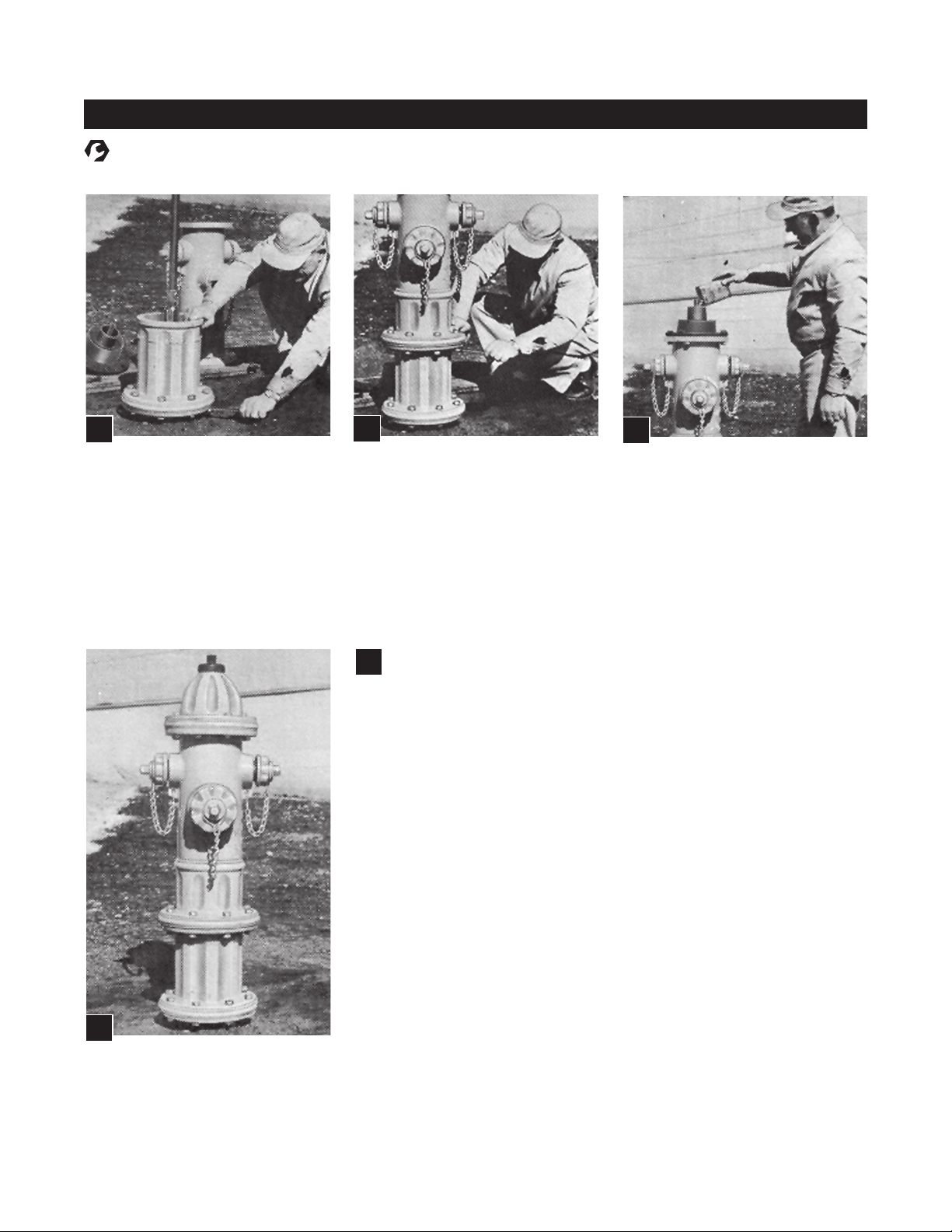

6.

Attach Extension Barrel to Lower

Barrel with solid Flange Halves

(without groove) and bolts, being sure

Flange Gasket is in place.

7.

Attach Upper Barrel to Extension Barrel

with Trafc Flange Halves (with groove)

and bolts, being sure Flange Gasket is

in place.

Turn Operating Nut in the

10.

closing direction to make sure

Main Valve is closed, then turn in the

opening direction approximately 1/4

turn to relieve tension on the operating

mechanism.

8.

Check Stufng Box Gasket. Lubricate

A-366 Brass Sleeve. Slide Sleeve

over threaded area of stem to protect

O-rings from damage by threads.

Place Stufng Box in position and bolt

to barrel. Remove Brass Sleeve. Pour

Mueller Hydrant Lubricant into Oil

Reservoir until

3

/4” from top.

9.

Replace bonnet. Turn Operating Nut in

closing direction to engage stem. If

Bonnet has Filler Plug, make sure that

the Filler Plug Hole is aligned with the

offset portion of the Oil Reservoir. Bolt

in place.

5

Page 6

®

MUELLER

Improved Fire Hydrant

Inserting Extension Section (Sealed Oil Reservoir 1962 Style)

EQUIPMENT & TOOLS NEEDED – PPE: Hard hat, safety shoes, safety vest, safety glasses, work gloves.

Tools: Wrench, A-316 nozzle wrench, brass hammer.

1.

Remove Weather Cap, Hold Down

Nut and Operating Nut from Bonnet.

Lubricate A-366 Brass Sleeve and slide

over threaded stem end to prevent

O-ring damage. Unbolt Bonnet from

Upper Barrel and remove. Remove

Brass Sleeve.

4.

Place new Stem Coupling Sleeve part

onto Upper Stem. Screw new Stem

Coupling part onto Lower Stem as far as

threads permit. Screw Upper Stem into

Stem Coupling until it contacts the Lower

Stem. Turn Stem Coupling and Upper

Stem so that slot in Thimble aligns with

the tongue and groove of stems. Hold

Upper Stem in alignment and screw Stem

Coupling upward until tongue and groove

of stems rmly lock together. Tighten with

wrench. With Stem Coupling in place,

slide Sleeve downward so lower end

of sleeve surrounds upper end of Stem

Coupling. Be sure Sleeve projections t

into Stem Coupling slots. With Sleeve in

place, tighten set screw in Sleeve.

2.

Unbolt Trafc Flange and remove

Upper Barrel. Unscrew set screw in

Sleeve.

Screw Stem Coupling down against

shoulder. Slide Sleeve up and unscrew

Upper Stem from Stem Coupling.

Unscrew Stem Coupling from Lower

Stem. Screw Extension Stem Coupling

down on Lower Stem against shoulder.

5.

Attach Extension Barrel to Lower Barrel

with solid Flange Halves (without

groove) and bolts, being sure Flange

Gasket is in place.

3.

Screw Extension Stem into Extension

Coupling until it contacts Lower Stem.

Align tongue and groove of stems

with hole in Extension Stem Coupling.

Screw Extension Stem Coupling

upward until tongue and groove of

stems rmly lock together. Tighten with

wrench, then screw in set screw in

Extension Stem Coupling.

6.

Attach Upper Barrel to Extension Barrel

with Trafc Flange Halves (with groove)

and bolts, being sure Flange Gasket is

in place.

6

Page 7

®

MUELLER

Improved Fire Hydrant

Inserting Extension Section (Sealed Oil Reservoir 1962 Style)

EQUIPMENT & TOOLS NEEDED – PPE: Hard hat, safety shoes, safety vest, safety glasses, work gloves.

Tools: Wrench, A-367 brass sleeve, A-359 seat wrench, A-311 operating wrench.

Turn Operating Nut in the

9.

closing direction to make sure

Main Valve is closed, then turn in the

opening direction approximately 1/4

turn to relieve tension on the operating

mechanism.

7.

Check Bonnet Gasket. Attach the A24099 Brass Sleeve, if it had been

removed, to Upper Stem and lubricate

outside to protect O-ring seals from

thread damage. Place Bonnet onto

Upper Barrel and assemble Bonnet

Bolts only hand tight. Remove Brass

Sleeve. Reassemble Operating Nut

and remove Oil Plug in side of Bonnet.

Pour Mueller Hydrant Lubricant into Oil

Reservoir until it is lled to the level of

the Oil Plug. Replace Oil Plug.

8.

Replace Hold Down Nut* being sure

O-ring seals are in good condition at

thread shoulder on outside of Hold

Down Nut and on inside where contact

is made with Operating Nut. Replace

Weather Cap. Tighten Bonnet Bolts.

Check gasket tightness by opening

one hose cap slightly before opening

Hydrant to bleed air. Open Hydrant

until barrel lls with water, tighten

Hose Cap, open Hydrant fully. Check

gaskets, and then turn Operating Nut

to fully closed position.

*Tighten hold down nut to 200-300 ft-lbs of

torque. If torque wrench is not available, use

a 3 lb hammer to strike the end of the A-311

wrench rmly two times to assure the nut is

properly tightened.

7

Page 8

®

MUELLER

Improved Fire Hydrant

Inserting Extension Section with Steel Stem Coupling (Sealed Oil Reservoir 1962 Style)

EQUIPMENT & TOOLS NEEDED – PPE: Hard hat, safety shoes, safety vest, safety glasses, work gloves.

Tools: Wrench, A-316 nozzle wrench, brass hammer.

1.

Remove Weather Cap, Hold Down

Nut and Operating Nut from Bonnet.

Lubricate A-366 Brass Sleeve and slide

over threaded stem end to prevent

O-ring damage. Unbolt Bonnet from

Upper Barrel and remove. Remove

Brass Sleeve.

4.

Assemble Upper Stem and Stem

Coupling onto Extension Stem and

retain it with stainless steel Clevis Pin

and stainless steel Cotter Pin. Make

sure Stem Coupling is installed with

notches towards the Lower Stem,

words “THIS END UP” towards the

Upper Stem.

2.

Unbolt Trafc Flange and remove Upper

Barrel. Remove Upper Stem and

Stem Coupling by removing the lower

stainless steel Cotter Pin and stainless

steel Clevis Pin.

5.

Attach Extension Barrel to Lower

Barrel with solid Flange Halves

(without groove) and bolts, being sure

Flange Gasket is in place.

3.

Place Extension Stem and Extension

Coupling on Lower Stem and retain

it with stainless steel Clevis Pin and

stainless steel Cotter Pin.

6.

Attach Upper Barrel to Extension Barrel

with Trafc Flange Halves (with groove)

and bolts, being sure Flange Gasket is

in place.

8

Page 9

®

MUELLER

Improved Fire Hydrant

Inserting Extension Section with Steel Stem Coupling (Sealed Oil Reservoir 1962 Style)

EQUIPMENT & TOOLS NEEDED – PPE: Hard hat, safety shoes, safety vest, safety glasses, work gloves.

Tools: Wrench, A-366 brass sleeve, A-359 seat wrench, A-311 operating wrench.

Turn Operating Nut in the

9.

closing direction to make sure

Main Valve is closed, then turn in the

opening direction approximately 1/4

turn to relieve tension on the operating

mechanism.

7.

Check Bonnet Gasket. Attach the A-366

Brass Sleeve, if it had been removed,

to Upper Stem and lubricate outside

to protect O-ring seals from thread

damage. Place Bonnet onto Upper

Barrel and assemble Bonnet Bolts

only hand tight. Remove Brass Sleeve.

Reassemble Operating Nut and remove

Oil Plug in side of Bonnet. Pour Mueller

Hydrant Lubricant into Oil Reservoir

until it is lled to the level of the Oil Plug.

Replace Oil Plug.

8.

Replace Hold Down Nut* being sure

O-ring seals are in good condition at

thread shoulder on outside of Hold

Down Nut and on inside where contact

is made with Operating Nut. Replace

Weather Cap. Tighten Bonnet Bolts.

Check gasket tightness by opening

one hose cap slightly before opening

Hydrant to bleed air. Open Hydrant

until barrel lls with water, tighten

Hose Cap, open Hydrant fully. Check

gaskets, and then turn Operating Nut

to full closed position.

*Tighten hold down nut to 200-300 ft-lbs of

torque. If torque wrench is not available, use

a 3 lb hammer to strike the end of the A-311

wrench rmly two times to assure the nut is

properly tightened.

9

Page 10

®

MUELLER

Modern Improved Fire Hydrant

Inserting Extension Section

EQUIPMENT & TOOLS NEEDED – PPE: Hard hat, safety shoes, safety vest, safety glasses, work gloves.

Tools: Wrench, A-316 nozzle wrench, brass hammer.

1.

Remove Weather Cap, Hold Down Nut,

Lock Washer and Operating Nut. Put on

Brass Sleeve and lubricate to protect

O-rings in operating housing.

4.

Place Extension Stem and Extension

Coupling on Lower Stem and retain

it with stainless steel Clevis Pin and

stainless steel Cotter Pin.

2.

Unbolt Trafc Flange Clips and lift

hydrant over stem.

5.

Assemble Upper Stem and Stem

Coupling onto Extension Stem and

retain it with stainless steel Clevis Pin

and stainless steel Cotter Pin. Make

sure Stem Coupling is installed with

notches towards the Lower Stem.

NOTE: “THIS END UP” stamped on

coupling.

3.

Remove Upper Stem and Stem

Coupling by removing the lower

stainless steel Cotter Pin and stainless

steel Clevis Pin.

6.

Attach Extension Barrel to Lower Barrel

with solid ange halves and bolts,

being sure Flange Gasket is in place

(tighten bolts to 1,000 in-lbs).

10

Page 11

®

MUELLER

Modern Improved Fire Hydrant

Inserting Extension Section

EQUIPMENT & TOOLS NEEDED – PPE: Hard hat, safety shoes, safety vest, safety glasses, work gloves.

Tools: Wrench, A-316 nozzle wrench, brass hammer.

7.

With lubricated Brass Sleeve on threads

of Upper Stem and Upper Barrel Seal

in position, lift Upper Barrel over Upper

Stem and onto extension section

Attach Trafc Flange Clips and Trafc

Flange Clip Bolts loosely, face nozzles

in desired position and tighten Trafc

Flange Clip Bolts uniformly to 1,000

in-lbs.

10.

Remove Oil Filler Plug and add Mueller®

Hydrant Lubricant until level with Filler

Plug hole. Replace Oil Filler Plug and

replace Weather Cap.

8.

With extension section and Hydrant

securely bolted in place, remove Brass

Sleeve, replace Operating Nut, Lock

Washer, and Hold Down Nut.

Open Hydrant fully and loosen

11.

one Hose Nozzle Cap, to bleed

air. When barrel is lled with water,

tighten Nozzle Cap and check gaskets.

Turn Operating Nut to fully closed

position, loosen one nozzle cap to

allow barrel to drain.

9.

Tighten Hold Down Nut to 100 ft-lbs

and bend Lock Washer Ears over Hold

Down Nut ats in two places and over

Operating Housing in two places.

Turn Operating Nut in the

12.

closing direction to make sure

Main Valve is closed, then turn in the

opening direction approximately 1/4

turn to relieve tension on the operating

mechanism.

11

Page 12

®

MUELLER

107® Fire Hydrant

Inserting Extension Section

EQUIPMENT & TOOLS NEEDED – PPE: Hard hat, safety shoes, safety vest, safety glasses, work gloves.

Tools: Wrench, A-316 nozzle wrench, brass hammer.

1.

Remove Bonnet Bolts and Nuts. Rotate

Operating Nut in opening direction to

fully opened position. This lifts Bonnet

off the Upper Barrel. Rotate bonnet

assembly counter-clockwise to detach

Bonnet from Upper Stem threads. Lift

off Bonnet, remove Bonnet Gasket.

4.

Assemble Upper Stem and Stem

Coupling onto Extension Stem and

retain it with stainless steel Clevis Pin

and stainless steel Cotter Pin. Make

sure Stem Coupling is installed with

notches towards the Lower Stem,

words “THIS END UP” towards the

Upper Stem.

2.

Unbolt Trafc Flange and remove Upper

Barrel. Remove Upper Stem and

Stem Coupling by removing the lower

stainless steel Cotter Pin and stainless

steel Clevis Pin.

5.

Attach Extension Barrel to Lower

Barrel with solid ange halves (without

groove) and bolts, being sure ange

gasket is in place.

3.

Place Extension Stem and Extension

Coupling on lower stem and retain

it with stainless steel Clevis Pin and

stainless steel Cotter Pin.

6.

Attach Upper Barrel to Extension Barrel

with Trafc Flange halves (with groove)

and bolts, being sure Trafc Flange

Gasket is in place.

12

Page 13

®

MUELLER

107® Fire Hydrant

Inserting Extension Section

EQUIPMENT & TOOLS NEEDED – PPE: Hard hat, safety shoes, safety vest, safety glasses, work gloves.

Tools: Wrench, A-316 nozzle wrench, brass hammer.

Turn Operating Nut in the

8.

closing direction to make sure

Main Valve is closed, then turn in the

opening direction approximately 1/4

turn to relieve tension on the operating

mechanism.

7.

Check Bonnet Gasket on top of Upper

Barrel, replace if damaged. Check

to see that Upper Stem threads are

lubricated and Upper Stem Seal

(O-ring) is not damaged. Check to be

sure that the Operating Nut is in the fully

open position, which is with the Stem

Nut fully extended. Reassemble Bonnet

Assembly to Upper Stem by rotating

clockwise as far as possible, then back

up only enough to align bolt holes,

if needed. Rotate Operating Nut in

closing direction, which lowers Bonnet

Assembly onto Upper Barrel and allows

bolts to be replaced. With all bolts in

Bonnet, rotate Operating Nut using the

same torque as normally used to close

the Hydrant. Tighten all Bonnet Bolts

and Nuts.

13

Page 14

Inserting Extension Sections

Notes

14

Page 15

Inserting Extension Section

Notes

15

Page 16

Water (U.S.)

1.800.423.1323

Reliable Connections

Copyright © 2016 Mueller Co., LLC. All Rights Reserved.

The trademarks, logos and service marks displayed in this document herein are the property of Mueller Co., LLC, its afliates or other third parties.

Products marked with a section symbol ( § ) are subject to patents or patent applications. For details, visit www.mwppat.com. These products are

intended for use in potable water applications. Please contact your Mueller Sales or Customer Service Representative concerning any other application(s).

TM

www.muellercompany.com

moreinfo@muellercompany.com

Water (Canada)

1.705.719.9965

www.muellercanada.com

more-info@muellercanada.com

International

1.423.490.9555

www.mueller-international.com

international@muellercompany.com

Form 10923 - Rev 09/17

Loading...

Loading...