Page 1

CF PANEL

MANUAL

METAL

ROOFING

INSTALLATION

GUIDE

Page 2

TABLE OF CONTENTS

Preparation Requirements and Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Care and Handling of Mueller Sheet Metal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Storage & Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

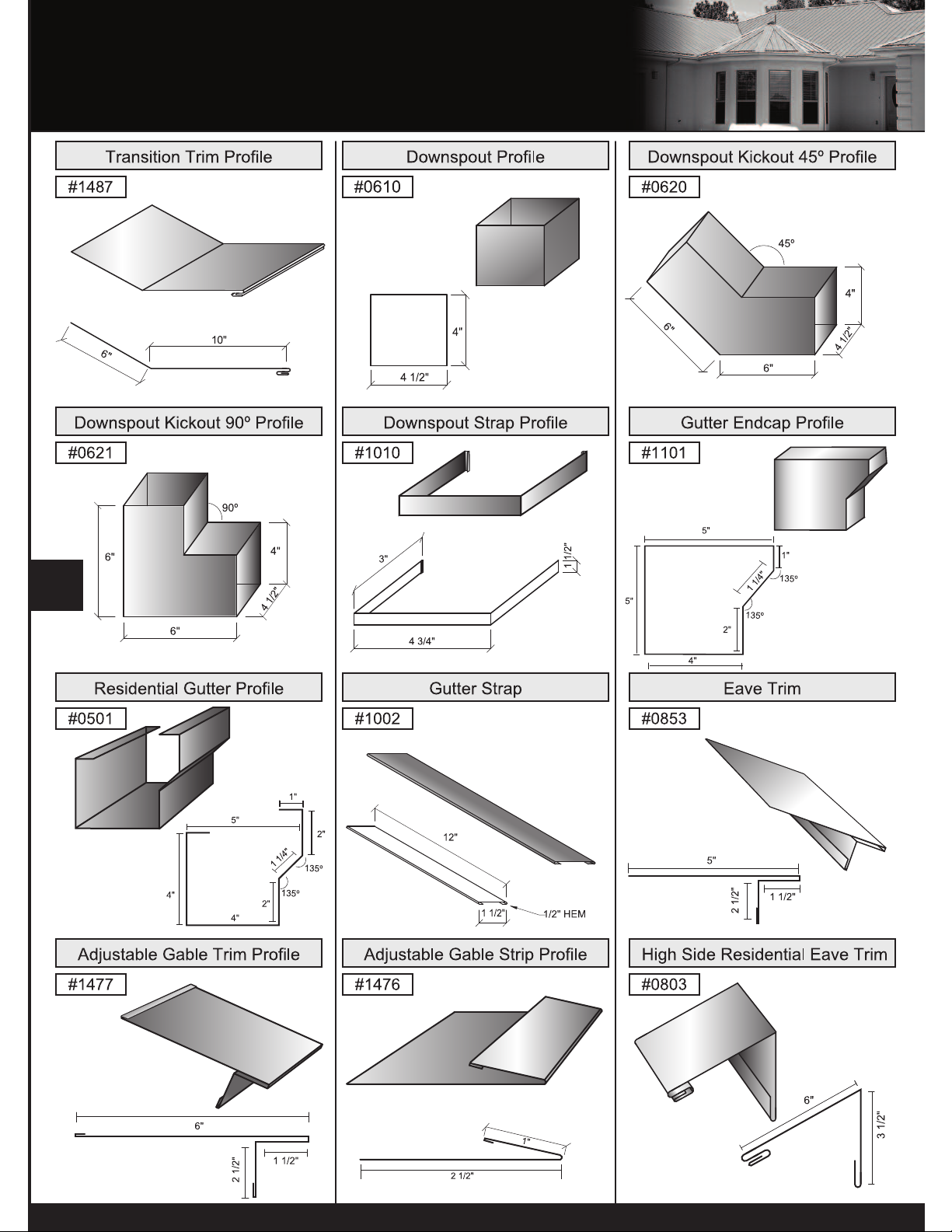

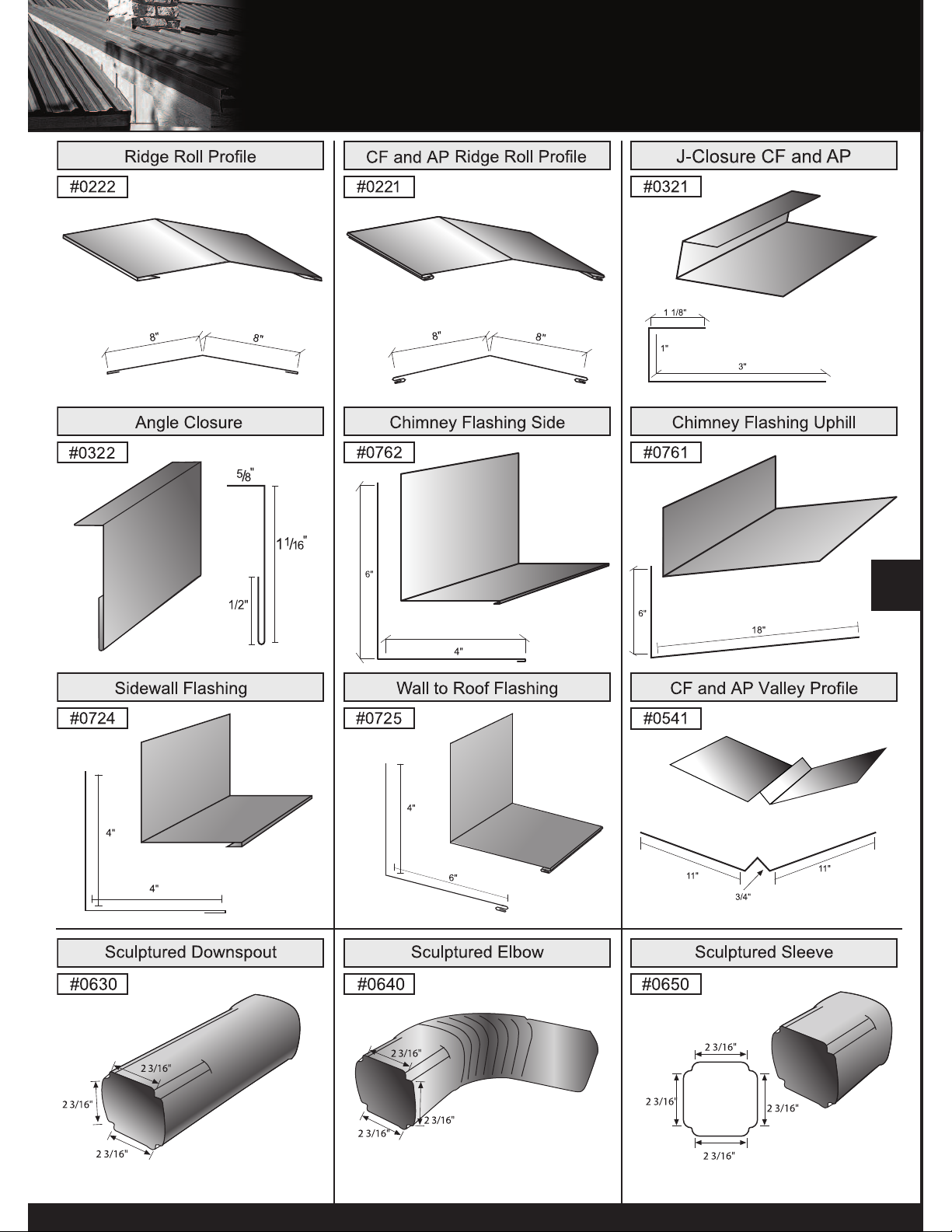

Standard Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Standard Fastener Locations at Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Recommended Screw Placement Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Oil Canning Reduction Trim Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Detail Locator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Beginning the Project

Standard Eave Trim Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Standard Eave Trim Installation with Gutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Standard Adjustable Gable & Strip Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2

Starting and Ending Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

High Side Residential Eave Trim Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Valley Panel and Trim Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Standard Ridge Roll and Hip Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Endwall to Roof Flashing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Sidewall Flashing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Roof Pitch Change Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Standard Panel Endlap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Chimney Flashing - Uphill and Downhill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chimney Flashing - Side and Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Page 3

PREPARATION REQUIREMENTS & RECOMMENDATIONS

his detail & installation manual has been provided to serve as a basic guideline for installing the Mueller CF panel roof system.

T

This manual should be used in conjunction with the erection drawings to help ensure proper installation of this roof system.

In case of discrepancies, the erection drawings will govern over this installation guide.

It is the customer’s responsibility to ensure that a competent and experienced erection crew is chosen for the installation of

this roof system. It is also the customer’s responsibility to ensure the erection crew understands and follows this installation

manual and the erection drawings.

Mueller, Inc. is not responsible for any problems or defects caused by improper erection techniques. Any questions in

regards to clarifying the intent of this manual or the erection drawings should be directed to Mueller’s customer service

department at the address and phone number shown on the back cover.

Warning: CF Panels should not be installed on a roof that is less than a 3:12 pitch. When this panel is

installed on pitches less than 3:12, heavy rainfall may lead to water accumulation and possible leaks.

Note: It is important that the roof be properly prepared before installation begins.

Decking

Mueller, Inc. recommends our metal roofing systems be installed over CDX plywood wooden roof decking with a minimum

thickness of 15/32”. Note: If using treated lumber, special corrosive resistant screws are required. Ask your sales

representative for more information.

Stripping

The removal of existing roofing and the associated fasteners is generally necessary. This does not damage, and typically

improves, the structural capacity of wood decks. During removal, many shingle fasteners may remain embedded in the deck.

These fasteners can be pulled out or hammered flush with the deck.

Repairs

Deteriorated areas should be removed and replaced with material to closely match the existing thickness. The deck should

be sound and smooth, with fasteners flush with the surface, prior to the installation of the metal roof. New wood decking,

whether boards, planks, CDX plywood, or equal, should be the same thickness and have similar strength characteristics

and span ratings to that of the area being replaced. Deck fasteners that have backed out should have a new fastener installed

adjacent to it and the existing fastener should be removed. Loose or lifted boards, planks, plywood, and corners should

have additional fasteners installed to secure the existing deck in place.

Holes in wood decks that are 10" wide or less can be covered with 20-gauge steel. This steel plate should be galvanized

and must overlap the wood roof deck 4 inches minimum and be secured with fasteners 4 inches on center.

Fascia boards should be straight, level and in good condition. Any rotted or deteriorated boards should be replaced. All roof

framing and decking abnormalities will be transferred to the new metal roof if not corrected before sheeting begins.

Underlayment

New underlayment must be immediately installed over prepared roof decking. Mueller recommends Titanium or a minimum

30# felt. This underlayment should be installed with a minimum of a 2" side lap and a 6" end lap. Underlayment temporarily

protects the roof decking against water penetration. It should be installed using galvanized tin caps (not plastic caps). The

underlayment should be fastened to the deck with galvanized roofing nails with tin caps 12" on center in the field and 6" on

center at the sidelaps.

3

Flashing

Re-roofing projects incorporate metal flashing and metal counter-flashing. Some counter-flashing are embedded, such as

a masonry wall, or are installed behind existing siding. This metal, if not deteriorated, may be reused. The existing metal

can be cut, leaving approximately a minimum of 2" of flashing exposed, and new counter-flashing can be fastened to the

backside of the existing metal. Counter-flashing must be slightly higher than the top of the rib on the sheets to be installed.

Page 4

SAFETY CONSIDERATIONS

s with all major construction projects, safety should be a primary concern. The erector or contractor should be sure

A

hat all OSHA safety rules are followed and that job safety is strictly adhered to.

t

The following safety equipment is highly recommended when installing metal roofing:

1. Safety rope and harness

2. Hand protection

3. Eye protection

4. Hearing protection

5. Soft rubber soled shoes

Metal roofing presents several specific safety issues:

1. Metal roofing is extremely slick and does not provide firm footing. Extreme care should be taken when:

A. Working on roofs with very steep pitches.

B. Working on roofs when moisture is present.

C. Working on roofs when high wind is a factor.

4

D. Working with long panels.

2. Metal edges are very sharp and should be handled with care.

3. Care should be used when lifting panels due to their weight.

4. Always check for overhead electrical lines and exercise care not to have metal sheets come in contact with them.

5. All electrical tools should be inspected regularly for damaged cases or frayed electric cords. Extension cords should

be inspected for damaged or frayed insulation. Tools which do not meet good safety standards should not be used.

CAUTION: Care should be taken when cutting sheets. Eye and hearing protection are important.

Panels may be slick!

Because of the demands of the manufacturing process, oil has been applied to the coil stock to protect the coil, as well as

the finished panel during manufacturing, shipping and storage. Metal panels must be wiped clean prior to panel installation.

NOTE: Always wear rubber soled work boots. When on the roof, use OSHA approved protection devices such as safety lines,

safety nets or catch platforms.

Unsecured Panels May Slip If Stepped On!

Never step on a single unsecured roof panel, or a stack of roof panels laying unattached on the roof. Secure each end of

the panel with clamps or appropriate fasteners and place walkboards of adequate size and strength in the flat of any

panels not fully secured to the roof and supported by panels on each side. Walkboards should run the full length of the

panel and be fastened together by drilling a hole near the end of each board and tied with rope to the next board. Cut a

groove in the bottom of each board so the board will lie flat and not tip back and forth because of the rope.

Page 5

CARE AND HANDLING OF MUELLER SHEET METAL

elivery: Mueller takes every precaution to ensure that material is delivered to the customer damage-free and fully protected from

D

the elements during shipment. When the material is delivered to the customer it then becomes the customer’s responsibility to

protect the material from the elements, possible theft, and other damage. The following guidelines are recommended:

HANDLING: Proper care is required in unloading and handling panel bundles in order to prevent damage.

1. Bundles should remain banded (if possible) during the unloading process. Bundles should never be lifted by the

banding material.

2. Lift each bundle as close as possible to its center of gravity.

3. If the bundles are to be lifted with a crane, use a spreader bar of appropriate length and nylon band slings (do not

use wire rope slings as they will damage the material).

4. Depending on the panel length, some bundles may be lifted by a forklift. When using a forklift, the forks should be

spread to their maximum spacing, and the load centered on the forks. Sheets over 25' long require two forklifts.

5. After panel bundles are opened, individual sheets must be handled carefully to prevent panel buckling or damage to

the panel coating. When removing a sheet from a bundle it should be rolled off the bundle to prevent scratching of

the next sheet. Never drag or slide one sheet over another sheet. Sheets should not be picked up by the ends. Instead,

lift the sheet along its longitudinal edge and carry in a vertical position. For sheets over 10' long, two or more people

may be required to carry the sheet.

5

Wall and Roof Panels

Mueller’s wall and roof panels, including color coated, galvalume and galvanized, provide excellent service under widely

varied conditions. All unloading and erection personnel should fully understand that these panels are quality merchandise

which merit cautious care in handling.

Under no circumstances should panels be handled roughly. Packages of sheets should be lifted off the truck with extreme

care taken to ensure that no damage occurs to ends of the sheets or to side ribs. The packages should be stored off the

ground sufficiently high to allow air circulation underneath the packages. This avoids ground moisture and deters people

from walking on the packages. One end of the package should always be elevated to encourage drainage in case of rain.

All stacked metal panels are subject, to some degree, to localized discoloration or stain when water is trapped between their

closely nested surfaces. Mueller, Inc. exercises extreme caution during fabrication and shipping operations to ensure that

all panel stock is kept dry. However, due to climatic conditions, water formed by condensation of humid air can become

trapped between stacked sheets. Water can also be trapped between the stacked sheets when exposed to rain. This

discoloration caused by trapped moisture is often called “wet storage stain.”

The stain is usually superficial and has little effect on the appearance or service life of the panels as long as it is not

permitted to remain on the panels. However, moisture in contact with the surface of the panels over an extended

period can severely attack the finish and reduce the effective service life. Therefore, it is imperative that all panels be

inspected for moisture upon receipt of the order. If moisture is present, dry the panels at once and store in a dry,

warm place.

Page 6

STORAGE

Storage: I

nd out of the elements if at all possible. If sheets are to

a

e stored outside, the following precautions should be

b

observed:

1. The storage area should be reasonably level, and

2. When stored on bare ground, place plastic ground

3. Store bundles at least 12 inches above ground level

4. Elevate one end of each bundle slightly to permit

6

5. Inspect stored bundles daily and repair any tears

t is recommended that sheets be kept covered

located so as to minimize handling.

cover under the bundles to minimize condensation

on the sheets from ground moisture.

to allow air circulation beneath the bundle, and to

prevent damage from rising water.

runoff of moisture from the top of the bundle or

from between sheets. A waterproof cover should be

placed loosely over the bundles to allow for air

circulation under the cover.

or punctures in the waterproof cover.

Checking order at time of delivery:

heck each order carefully, as it is unloaded. Report any

C

bvious damage or shortages to the carrier immediately. If

o

damage or shortages are noted after delivery (at time of

unpacking) notify your Mueller representative immediate-

ly. Have invoice numbers and detailed descriptions of the

damage or shortage available. These procedures are for

your protection. A shortage or damage discovered later

can be caused by theft, misplacement, mishandling or

other causes and is not the responsibility of Mueller, Inc.

Underlayment: The underlayment should be one layer

of Titanium or 30# felt. The Titanium should have a 2"

side lap and a 6” end lap. The underlayment should be

fastened to the deck with galvanized roofing nails

with tin caps 12" on center in the field and 6" on

center at the sidelaps.

6. Re-cover opened bundles at the end of each work

day to prevent subsequent moisture damage.

Never Install Material if the Quality is in Question!

TOOLS REQUIRED

The following list of tools is recommended when installing metal roofing:

1. Aviation snips - left, right, straight 6. Square 11. Broom 16. Fire extinguisher

2. Screw gun 2500 RPM with appropriate nut drivers 7. Straight edge 12. Extension cords 17. Saw horses

3. Tape measure 8. Chalk line 13. Ladder 18. First aid kit

4. Caulking gun 9. Vise grips 14. Hammer 19. Tarp

5. Safety equipment: goggles, hard hat, 10. Gloves 15. Drill bits 20. Electric shear or nibbler

and soft rubber soled shoes

CAUTION: Whenever using any type of power equipment, it is important to follow the manufacturer’s recommendation

for use. Always be aware of the danger involved when using electric or air powered equipment.

Page 7

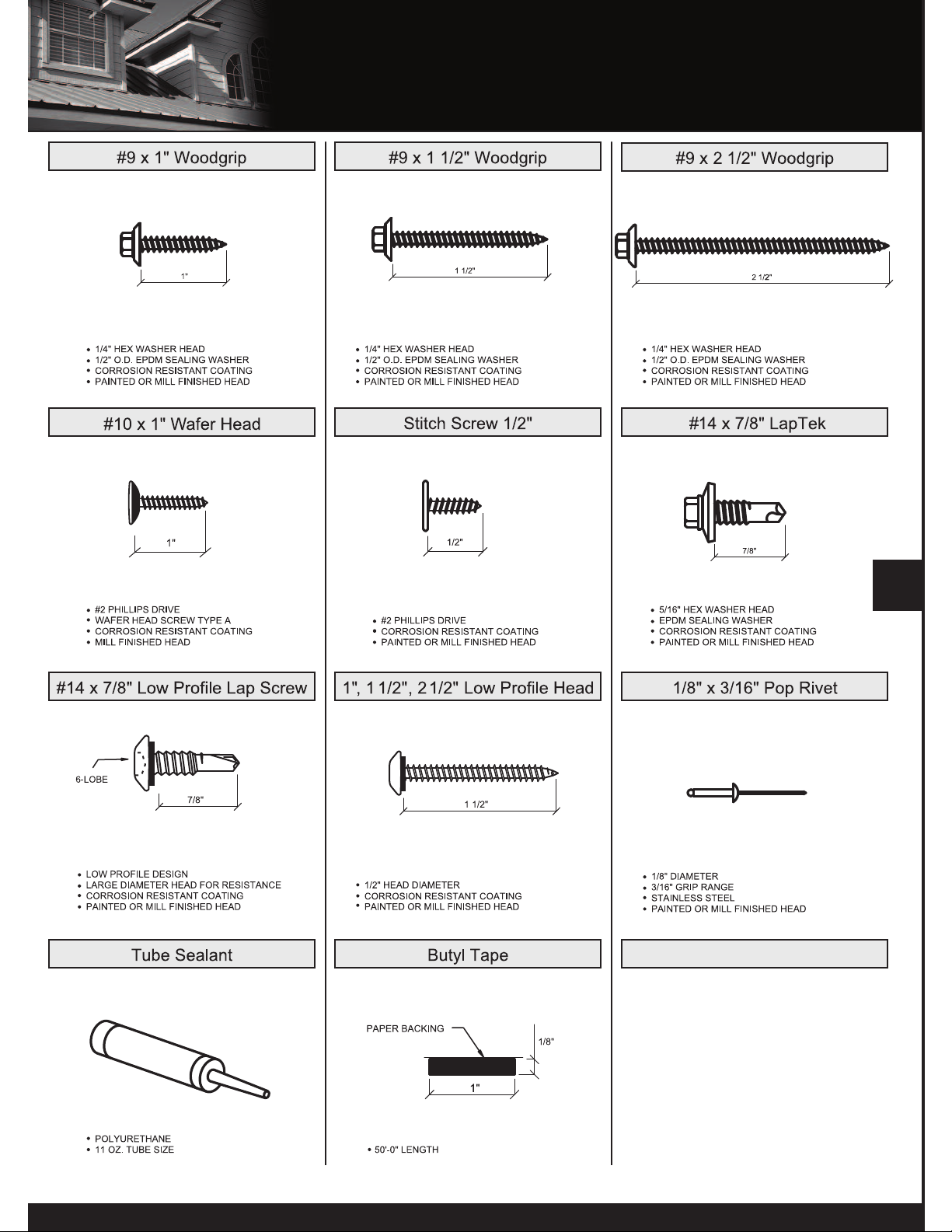

STANDARD PARTS

Note: If using treated lumber, special

corrosive resistant screws are required.

Ask your sales representative for more

information.

7

Details are subject to change without prior notice.

Page 8

STANDARD PARTS

8

Page 9

STANDARD PARTS

9

Page 10

PRODUCT DESCRIPTION

2" Coverage

• 1

6 Gauge

• 2

For color selections,

please request a color chart.

Galvalume Plus (20 Yr. WARRANTY)

Limited Paint Warranties

(UP TO 30 YEAR WARRANTIES)

WARNING! CF Panel should

not be installed on a roof that

is less than a 3:12 pitch. When

this panel is installed on pitch-

es less than 3:12, heavy rain-

fall may lead to water accu-

mulation and possible leaks.

10

Page 11

STANDARD FASTENER LOCATIONS AT PANEL

ATTACHMENT TO 1 X 4 WOOD PURLIN

TYPE 1: FASTENER LOCATION

TYPE 2: FASTENER LOCATION

ARNING! Mueller trim comes

W

ith a protective film coating to

w

id in the prevention of scuffing.

a

Do not allow this film to be

exposed to the sun. Exposure will

bond the film to the metal mak-

ing removal difficult.

NOTE: To comply with Texas

Windstorm Certification Testing,

#12x11 SDT Type A screws must

be used in place of the #9

Woodgrip screws.

11

Details are subject to change without prior notice.

Page 12

CF PANEL

RECOMMENDED SCREW PLACEMENT TABLE

With < 30’-0” mean roof height - 3:12 to 6:12 pitch for 90-140 mph wind speeds based on ASCE 7-93

FASTENING SCHEDULE SPACING ALONG PANEL NAIL STRIP

WIND SPEED ZONE

Zone FASTENER SUBSTRATE

90

ON CENTER

SPACING

100

ON CENTER

SPACING

110

ON CENTER

SPACING

ON CENTER

SPACING

120

130

ON CENTER

SPACING

140

ON CENTER

SPACING

Zone 1 #10-12 X 1” 15/32” CDX

19/32” CDX

7/16” OSB

1x4 Wood Purlins

Zone 2 #10-12 X 1” 15/32” CDX

19/32” CDX

7/16” OSB

1x4 Wood Purlins

Zone 3 #10-12 X 1” 15/32” CDX

19/32” CDX

7/16” OSB

1x4 Wood Purlins

With < 30’-0” mean roof height - 7:12 to 12:12 pitch for 90-140 mph wind speeds based on ASCE 7-93

20”

20”

15”

Type 1, 20”

20”

20”

15”

Type 1, 20”

10”

20”

15”

Type 2,10”

20”

20”

15”

Type 1, 20”

20”

20”

15”

Type 1, 20”

10”

10”

10”

Type 2,10”

20”

20”

15”

Type 1, 20”

10”

20”

15”

Type 2, 20”

10”

10”

10”

Type 2,10”

20”

20”

15”

Type 1, 20”

10”

10”

10”

Type 2,10”

10”

10”

10”

Type 2,10”

FASTENING SCHEDULE SPACING ALONG PANEL NAIL STRIP

WIND SPEED ZONE

Zone FASTENER SUBSTRATE

90

ON CENTER

SPACING

100

ON CENTER

SPACING

110

ON CENTER

SPACING

120

ON CENTER

SPACING

20”

20”

N/A

Type 1, 20”

10”

10”

N/A

Type 2,10”

10”

10”

N/A

Type 2,10”

130

ON CENTER

SPACING

N/A

N/A

N/A

Type 1, 10”

N/A

N/A

N/A

Type 2,10”

N/A

N/A

N/A

Type 2,10”

140

ON CENTER

SPACING

Zone 1 #10-12 X 1” 15/32” CDX

19/32” CDX

7/16” OSB

1x4 Wood Purlins

Zone 2 #10-12 X 1” 15/32” CDX

19/32” CDX

7/16” OSB

1x4 Wood Purlins

Zone 3 #10-12 X 1” 15/32” CDX

19/32” CDX

7/16” OSB

1x4 Wood Purlins

Note: If using treated lumber, special corrosive resistant screws are required. Ask your sales representative for more information.

Details are subject to change without prior notice.

20”

25”

15”

Type 1, 20”

20”

25”

15”

Type 1, 20”

20”

25”

15”

Type 1, 20”

20”

25”

15”

Type 1, 20”

20”

25”

15”

Type 1, 20”

20”

25”

15”

Type 1, 20”

20”

25”

15”

Type 1, 20”

20”

25”

15”

Type 1, 20”

20”

25”

15”

Type 1, 20”

20”

25”

15”

Type 1, 20”

20”

25”

15”

Type 1, 20”

20”

25”

15”

Type 1, 20”

Type 1, 20”

Type 2,10”

Type 2,10”

20”

25”

15”

10”

25”

15”

10”

25”

15”

10”

25”

15”

Type 2,10”

10”

25”

10”

Type 2,10”

10”

25”

10”

Type 2,10”

Page 13

12"

Oil Canning Reduction Trim on CF Panel

IMPORTANT INFORMATION

OIL CANNING

What is Oil Canning?

Oil canning is described as a wavy appearance often

occurring in the flat areas of formed metal products,

such as metal roofs. The structural integrity of the metal

is not affected by oil canning – it’s simply an aesthetic

issue. The term oil canning is an industry standard used

to describe this occurrence and is not a reason for

rejection.

Things to Expect

• If the deck is bowed up or has a belly, the new

sheets will oil can.

• High temperatures are often a factor when

waviness occurs. Once it gets cooler, the effect

will likely diminish.

• Changes in light – including overcast days, shade,

and intense sunlight – can affect the appearance

of oil canning. Oil canning will seem less

prominent in the shade but will be more

noticeable in brighter light.

0.50”

0.35”0.35”

0.85”

• The color of the metal panel can also affect the

appearance of oil canning. For example, oil

canning is more evident on galvalume, copper or

other metallic colors.

INSTALLATION

The purpose of this application is to reduce the effect of oil canning on the Mueller CF panels. It will not completely eliminate

oil canning on these panels. The strip must be applied down the flat section of the panel.

1. Prior to applying the panel, the oil canning reduction

trim should be positioned on the decking so that the

trim is centered in the flat section between the ribs of

the panel when it is applied.

2. The trim should be positioned to start 3’ from one end

and stop 3’ from the other end of each panel.

13

3. The trim should be held in place by screwing through

the trim into the decking at each end of the trim piece.

4. Reduction trim sections are 12’. These should be field

cut to length as needed. All joints should be butted not

lapped. Drops need to be utilized.

Details are subject to change without prior notice.

Page 14

DETAIL LOCATOR

1

4

7

2

8

3

5

9

6

14

DETAIL SECTION Page

1 Eave . . . . . . . . . . . . . . . . . . . . . .15

2 Gable . . . . . . . . . . . . . . . . . . . . .17

3 Valley . . . . . . . . . . . . . . . . . . . . .20

4 Ridge . . . . . . . . . . . . . . . . . . . . .21

5 Hip . . . . . . . . . . . . . . . . . . . . . . .21

6 Endwall to Roof Transition . . . .22

7 Sidewall Flashing . . . . . . . . . . . .23

8 Pitch Change . . . . . . . . . . . . . . .24

9 Chimney Flashing . . . . . . . . . . . .26

Details are subject to change without prior notice.

Page 15

BEGINNING THE PROJECT

STANDARD EAVE TRIM INSTALLATION

1. Install the eave trim by sliding it underneath the underlayment and securing it to the roof surface with

wafer head screws on 5’ centers.

2. There are no screws or nails to be placed in the exposed fascia of the trim.

3. At the corners, cut the eave trim 1 1/2” long and prepare the ends with tabs to receive the gable trim.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

OPTION: The overhang illustrated below may be increased to extend up to 4” past the eave trim.

15

Details are subject to change without prior notice.

Page 16

STANDARD EAVE TRIM INSTALLATION WITH GUTTER

. Install the eave trim to the substrate with wafer head fasteners at 5’ O.C.

1

2. Position the roof panel so that the down slope end matches the dimension called for on the erection drawings.

3. Attach the roof panels at the eave with (6) #9 x 1” woodgrip screws - (6) per panel.

4. Attach the gutter to the panel and the eave trim with #14 x 7/8” lapteks @ 24” O.C.

5. Install the gutter strap at alternate 24” with #14 x 7/8” lapteks on the sheet end of strap, and stitch screws,

pop rivets, or lap screws on gutter end of the strap.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

OPTION: The overhang illustrated below may be increased to extend up to 4” past the eave trim.

16

NOTE: To comply with Texas

Windstorm Certification Testing,

#12x11 SDT Type A screws must

be used in place of the #9

Woodgrip screws.

Details are subject to change without prior notice.

Page 17

STANDARD ADJUSTABLE GABLE & STRIP INSTALLATION

. Starting at the corner, install the adjustable gable trim along the sloping gable,

1

placing it on top of the underlayment.

2. Attach with wafer head screws 5’ on centers (adjustable strip applied after valley trim).

3. Slide gable trim over eave trim at corner.

4. At the peak, one gable trim should be cut vertical to the ground

and overlap at the junction of the two gable trims.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

1. If valley trim is intersecting the gable, the valley must be installed first.

2. Pre-drill 1/8” holes on 12” centers along the length of adjustable gable strip #1476.

3. Butyl tape should be applied to the bottom of the strip covering pre-drilled holes. Place the strip

the desired distance from the outside edge of the gable trim (optimal distance 2”), making sure it

is aligned parallel to the gable, perpendicular to the eave line and between the open hem at the

edge of the adjustable gable trim and the outside of the trim.

4. The adjustable strip is attached to the roof with wafer head screws on 12” centers from eave to

ridge using pre-drilled holes, making sure the screws are applied through the butyl tape. This

condition exists in both Starting Panel and End Panel Installation.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

17

Details are subject to change without prior notice.

Page 18

STARTING AND ENDING PANEL INSTALLATION

Starting Panel

1. Apply adjustable strip as previously instructed.

2. Remove the overlap rib of the panel, making a straight cut the length of the panel.

3. Apply butyl tape continuously down the length of the adjustable strip, covering the wafer head screw.

4. Insert the cut edge of the panel into the strip, making sure the panel is seated fully into the strip.

5. Attach the underlap side to the roof with wafer head screws on the required centers.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

Ending Panel

1. Remove the underlap rib of the panel at a point that is inside the adjustment portion

of the gable trim, making a straight cut the length of the panel (optimal 2” from gable edge).

2. Apply adjustable strip as previously instructed.

3. Test apply the panel to assure proper fit.

4. Apply butyl tape and insert last panel into strip, making appropriate panel lap.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

18

Details are subject to change without prior notice.

Page 19

HIGH SIDE RESIDENTIAL EAVE TRIM INSTALLATION

. Attach the high side trim (#0803) to the fascia with woodgrip screws on 5’ centers. Make sure the 6” side of the

1

trim is on the rooftop with the receiver hem resting on the highs.

2. Cap the ends of the trim by cutting and folding a tab that attaches to the gable trim. The hem must be removed

before a fold is made. Capping is usually easier to do before the trim is installed. If done after the trim is installed,

be sure and leave 6” of the trim overhanging to allow enough material for cut and folds.

3. Field cut enough metal closures (#0322) to complete the job.

4. Slide the 5/8” lip of the field cut metal closure into the receiver hem of the eave trim and position the closure on

the sheet.

5. Attach with one woodgrip screw, centered between each rib, through the hem of the ridge roll and metal closure,

into the decking. Care must be taken not to over-tighten the screws, as this will distort the trim and closures.

The screw hole can be pre-drilled, if desired.

6. All end laps should be at least 4”. Remove 4” of the hem on the overlapping piece and secure it to the overlapped

piece with caulk and stitch screws.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

NOTE: To comply with Texas

Windstorm Certification Testing,

#12x11 SDT Type A screws must

be used in place of the #9

Woodgrip screws.

19

Details are subject to change without prior notice.

Page 20

VALLEY PANEL AND TRIM INSTALLATION

. Start at the low end, trim and place the valley flashing. The valley end should overhang the eave trim 1”.

1

2. If there is an end lap required in the valley pieces, caulk and lap at least 8”.

3. Use wafer head screws on 5’ centers to secure the valley in place along the outside edge.

4. Hem the edges of the valley over the eave trim, after trimming the center “V” back 1” to align with the

edge of the eave. Leave a tab to bend and cover the exposed opening of the center “V”.

5. Place butyl tape on the upper surface of the valley 6” up slope from the “V” of the valley trim,

before applying intersecting panels.

6. Field cut the panels that intersect the valley holding the end of the panel 4” back from the “V” of the

valley trim and parallel to the “V” of the valley.

7. Attach panel at valley using eave screw requirements for panel being installed.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

NOTE: To comply with Texas

Windstorm Certification Testing,

#12x11 SDT Type A screws must

be used in place of the #9

20

Woodgrip screws.

Details are subject to change without prior notice.

Page 21

STANDARD RIDGE ROLL and HIP INSTALLATION

. Lay a piece of the #0221 ridge roll or hip in position, making sure it is centered and in the correct position.

1

(Refer to step #8 for end capping instructions)

2. Temporarily fasten the ridge roll in place at one end with a woodgrip screw, positioning the screw through the hem

of the ridge roll, centered between the ribs.

3. Field cut enough metal closures (#0322) to complete the application.

4. Starting at the opposite end, slide the 5/8” lip of the (field cut) #0322 metal closure into both sides of the ridge

roll and position the metal closure on the sheet.

5. Attach with (1) woodgrip screw, centered between each rib, through the hem of the ridge roll and through the metal

closure, into the decking. Care must be taken not to over-tighten the screws, as this will distort the trim and closures.

The screw hole can be pre-drilled, if desired.

6. Continue installing the closures the entire length of the ridge or hip. Remove the temporary fastener, insert the closure,

and fasten through the existing hole as in step 4.

7. All end laps should be at least 4”. Remove 4” of the hem on each side of the overlapping piece and secure to the

overlapped piece with caulk and stitch screws.

8. Cap the end of all ridge rolls and hips by cutting and folding ends. The hem must be removed before the folds are made.

Capping is usually easier to do before the piece is installed. If done after installation, be sure and leave 6” of the ridge

roll or hip overhanging the peak or corner to allow enough material for cuts and folds.

9. Before the ridge trim is installed, if the pitch of the roof is 4:12 or less, the end of the panel that is under the

ridge or hip trim should be bent up between the high ribs to prevent moisture blow back.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

NOTE: To comply with Texas

Windstorm Certification Testing,

#12x11 SDT Type A screws must

be used in place of the #9

Woodgrip screws.

21

Details are subject to change without prior notice.

Page 22

ENDWALL TO ROOF FLASHING INSTALLATION

. Insert the endwall flashing (#0725) behind the existing wall counter-flashing and attach to the wall using

1

appropriate fasteners. Make sure the receiver hem of the endwall flashing is resting on the top of the roof sheet rib.

If required, cap the ends of the trim by cutting and folding a tab. Remove the hems before making the folds.

2. If there is no counter-flashing, install counter-flashing using appropriate fasteners.

3. Field cut enough #0322 metal closures to complete application.

4. Slide the 5/8” lip of the field cut metal closure into the receiver hem of the endwall flashing and position

the closure on the roof.

5. Attach with one woodgrip screw, centered between each rib, through the hem of the endwall flashing

and metal closure, into the decking. Care must be taken not to over-tighten the screws as this will distort

the trim and closure. The screw hole can be pre-drilled, if desired.

6. All end laps should be at least 4”. Remove 4” of the hem on the overlapping piece and secure to the

overlapped piece with caulk and stitch screws.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

NOTE: To comply with Texas

Windstorm Certification Testing,

#12x11 SDT Type A screws must

22

be used in place of the #9

Woodgrip screws.

Details are subject to change without prior notice.

Page 23

SIDEWALL FLASHING INSTALLATION

. Apply butyl tape to the bottom side of the J-closure.

1

2. Install the J-closure flush with the outer edge of the sidewall flashing and parallel to the ribs.

3. Secure with woodgrip screws on 12” centers.

4. Apply butyl tape continuously to top of J-closure.

5. Insert the sidewall flashing behind existing counter-flashing and secure to the J-closure with lap screws.

6. If there is no existing counter-flashing, install counter-flashing to wall with appropriate fasteners.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

NOTE: To comply with Texas

Windstorm Certification Testing,

#12x11 SDT Type A screws must

be used in place of the #9

Woodgrip screws.

23

Details are subject to change without prior notice.

Page 24

ROOF PITCH CHANGE INSTALLATION

. Apply lower panels.

1

2. Install the transition flashing (#1487) making sure the bottom portion of the flashing is at the same pitch

as the lower panels. Attach to decking 1” from top of flashing with wafer head screws on 5’ centers.

3. Field cut enough metal closures (#0322) to complete application.

4. Slide the 5/8” lip of the field cut metal closure into the receiver hem of the transition flashing and position

the closure on the roof.

5. Attach using one woodgrip screw, centered between each rib, through the hem of the transition flashing and metal

closure, into the decking. Care must be taken not to over-tighten the screws as this will distort the trim and closure.

The screw hole can be pre-drilled, if desired.

6. All end laps should be at least 4”. Remove 4” of the hem on the overlapping piece and secure to the overlapped

piece with caulk and stitch screws.

7. Cap the ends of the trim by cutting and folding a tab that attaches to the gable trim. The hem must be removed

before a fold is made. Capping is usually easier to do before the trim is installed. If done after the trim is installed,

be sure and leave 6” of the trim overhanging to allow enough material for the cut and folds.

8. Before applying the upper panels, place a row of butyl tape continuously along the trim at a point where the

screws holding the lower end of the upper panel will go through the butyl tape. This is usually 4” uphill from the

bottom of the upper sheet. Use eave screw pattern.

24

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

NOTE: To comply with Texas

Windstorm Certification Testing,

#12x11 SDT Type A screws must

be used in place of the #9

Woodgrip screws.

Details are subject to change without prior notice.

Page 25

STANDARD PANEL ENDLAP

. Ensure the lower panel is installed completely (except for the top fasteners).

1

2. Using duckbill pliers squeeze the top 10” of the male side of the lower panel flat to receive

the 9” overlap of the upper panel.

3. Install the butyl tape 8” from the top of the lower panel. Do not remove the paper backing from

the butyl tape until upper roof panel lap and the top dimension have been confirmed.

4. On the upper panel use duckbill pliers to squeeze the bottom 10” of the locking leg on the female

side flat so it will lay flat when overlapping lower panel.

5. Remove paper backing from the butyl tape.

6. Position and place upper panel so that a 9” lap is achieved.

7. Attach the upper panel through the lower panel with woodgrip screws,

(3) per panel making sure the screw line is 1” uphill from the butyl tape line.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

NOTE: If a longer lap is desired increase all measurements accordingly.

NOTE: To comply with Texas

Windstorm Certification Testing,

#12x11 SDT Type A screws must

be used in place of the #9

Woodgrip screws.

25

Details are subject to change without prior notice.

Page 26

CHIMNEY INSTALLATION

CHIMNEY FLASHING - UPHILL AND DOWNHILL

UPHILL

The uphill flashing will be 4” wider than the width of the

curb (2” on each side). Cut an 1/8” slot in the two uphill

corners of the panel slightly wider than 2 1/16”, so the

26

uphill flashing can slide through the two slots.

UPHILL

DOWNHILL

1. Trim both ends of the uphill and downhill sides of the

flashing as indicated.

2. Slide the uphill flashing into the slots of the roofing and

apply liberal amount of tube caulk.

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

NOTE: To comply with Texas Windstorm Certification Testing, #12x11

SDT Type A screws must be used in place of the #9 Woodgrip screws.

Details are subject to change without prior notice.

Page 27

CHIMNEY FLASHING - SIDE

1. Trim and bend the right side flashing as indicated.

2. Trim the left side in a similar fashion.

CHIMNEY INSTALLATION

NOTE: Alternate trim profiles are acceptable using the screw pattern shown.

NOTE: The left and right side flashing are mirror images of each other.

SIDE

FLASHING - VENT

Procedures:

1. Trim the opening in the flashing to 20% smaller than

the pipe diameter.

SIDE

SIDE

27

2. Slide the flashing down over the pipe.

3. Seal between the flashing and the roofing with

tube caulk and set the flashing.

4. Form the flashing to fit the profile of the roof.

5. Fasten the flashing with woodgrip screws 1” on centers.

NOTE: Alternate trim profiles are acceptable using the screw

pattern shown.

FOR PENETRATION THROUGH THE SIDELAP:

When a penetration occurs through or near the panel sidelap,

install tube caulk filling the female overlap to 12” above the

penetration and snap lock groove to 6” above to prevent

water from running downhill into the opening.

NOTE: In many cases it may be easier to locate

vent/pipe flashing in the flat area of the roof panel

(as shown) rather than have the penetration occur at a

panel rib. Determining panel layout prior to installation

often simplifies penetration flashing installation.

Details are subject to change without prior notice.

Page 28

FIND OUT MORE ABOUT MUELLER, INC.

Call

877-2-MUELLER (877-268-3553)

This toll-free number connects you to one of our sales locations

across the Southwest.

Click

www.MuellerInc.com

Our interactive website offers photos and all the details of our

metal products.

Come by

More than 30 locations. Our branches are staffed with experts who are

always happy to answer any questions you may have.

Find us

On Facebook, check out our latest news and events.

Mueller’s #1, 26 gauge, CF Panels

have received the Underwriter’s

Laboratory UL2218 Approved

Class 4 Premium Rating

M-CFMANUAL-REV.11/12

Loading...

Loading...