Muddyfox MO 28644, MO 29365, MO 29410, MO 29412, MO11072-AB Assembly Guide

...

MTB Assembly Guide

N

4.1

O

4.2

Q

P

P

N

P

4.44.3

T

S

R

U

Tighten

Loosen

S

R

4.6

P

Q

P

4.7

V

O

B E F

D

1.3

Minimum

Insertion

Mark

C

A

G

1.5

M

L

J

K

3.1

3.2

U

5.1 5.2

5.3

Y

X

X

Z

U

Follow these four steps to get your bike ready

1

Please read this guide completely before assembling your bike.

WARNING! These points are extremely important and should be read, understood and implemented before

riding your bicycle. Failure to observe these warnings may result in serious injury and/or damage to the bike.

NOTE! These notes should be read and understood as the information may be useful to you in assembling of

this bike.

NOTE! Representative images are used throughout this guide, Your bike may differ from that shown.

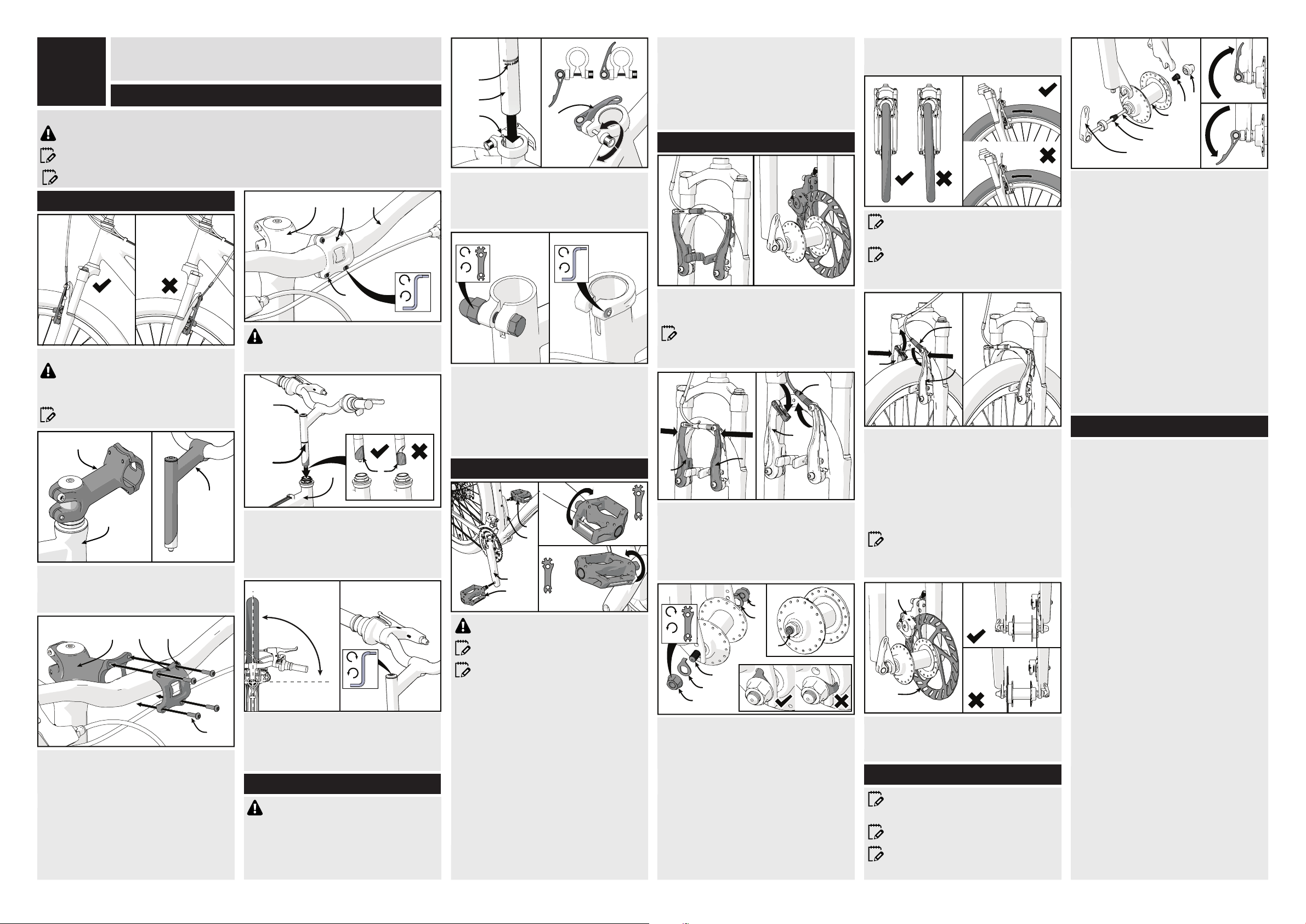

1. Attach Handlebars

1.1

1.1 Realign the forks.

WARNING! When assembling the handlebars and

stem, make sure the forks are assembled correctly

with the front brakes facing forward or with the disc brake

on the left (when seated on the bike).

NOTE! Ensure the cables are not tangled or twist-

ed, as this may effect brake and gear performance.

1.2

1.2 Identifying the stem type.

Your new bicycle will have either a A-Head StemB

(proceed to step 1.3) or a Quill StemC (proceed to

step 1.5).

1.3 Remove stem clamp plate.

Loosen the stem cap boltsD from the stem and

remove the stem capE.

Place the centre of the handlebarF in the open

stemB and hold the stem capE in position over the

handlebarF.

1.4 Secure stem bolts.

Replace the stem cap boltsD taking care to tighten

them evenly and rmly (12-14Nm for 2 bolt stems and

10-12Nm for 4 bolt stems).

(Proceed to stage 2)

How to use this Guide EN14766.UK.V3

1.4

WARNING! When assembling the handlebars

and stem, make sure it is inserted beyond the

Minimum Insert Mark. Failure to observe this warning

may result in serious personal injury.

1.5 Insert the Quill stem.

Loosen the stem boltC to allow the wedge nutG to

move freely.

Insert the stemC into the head tube of the bikeA,

Ensuring that the wedge nutG is correctly aligned with

the stem.

B E F

D

Tighten

Loosen

1.6

90˚

Tighten

Loosen

1.6 Secure the quill stem.

Adjust the handlebars and stemC to the desired height

and align with the forks as shown.

Using the supplied hexagonal key, tighten the stem bolt

rmly (15-17 Nm).

2. Attaching the Saddle

WARNING! When assembling the seatpost, make

sure it is inserted beyond the Minimum Insert

Mark. Failure to observe this warning may result in

serious personal injury.

2.1 Insert the seatpost and saddle.

Insert the seat postH into the seat tubeA.

2.1 2.2

Minimum

Insertion

Mark

Open Closed

H

A

2.2 Quick release seatpost clamp.

If your bike is tted with a quick release seat post

clamp then fasten with the release leverI. For more

information on the correct use of a quick release then

read section 5.

2.3 2.4

Tighten

Loosen

2.3 Securing seatpost (bolted)

If your bike is tted with a regular bolted seatpost clamp

then tighten the seatpost nut rmly (16-18 Nm) using

the supplied tools.

2.4 Securing seatpost (Allen Key)

If your bike is tted with an Allen keyed seatpost clamp

then tighten the seatpost bolt rmly (8-10 Nm) using the

supplied tools.

I

Tighten

Loosen

3. Attach Pedals

WARNING! The Pedals are Different, they have

different threads for each side of the bicycle.

NOTE! Your pedals are in a separate box within

the main packaging.

NOTE! The pedalsJM and the crank armsKL

have colour coded stickers to indicate which

pedal matches which crank. To prevent damage to the

threads, only tighten the pedals in the direction

indicated.

3.1 Fitting the right hand pedal.

Locate the right hand pedalM, this will have a green

sticker attached.

Locate the right hand crank armL, this will also have a

green sticker attached.

Remove the sticker from the crankL.

Insert the threaded shaft of the right hand pedalM

into the threaded hole of the right hand crank armL.

Tighten the pedalM using only your ngers clockwise

in the direction of the colour coded sticker.

Fully tighten using the supplied multitool (40Nm).

3.2 Fitting the left hand pedal.

Locate the left hand pedalJ, this will have a red

sticker attached.

Locate the left hand crank armK, this will also have a

red sticker attached.

Remove the sticker from the crankK.

Insert the threaded shaft of the left hand pedalJ into

the threaded hole of the left hand crank armK. Tighten the pedalJ using only your ngers anti-clockwise in

the direction of the colour coded sticker.

Fully tighten using the multitool (40Nm).

4. Attach Front Wheel

4.1 Identifying the brake type.

If your bike is equipped with V-brakesN then continue

below, if it has disc brakesO then proceed to step 4.7.

NOTE! Before the front wheel can be installed,

the front brake must be disconnected. This

allows the front tyre to pass between the brake pads

during assembly.

4.2 Disconnect the front brake.

Squeeze the two brake armsP of the front brakeN

together with one hand.

Using your other hand, pull the guide pipe and cableQ

across and up to release it from the right hand brake

armP.

Release the brake armsP and let them spring apart.

4.3 Insert the wheel.

Insert the axleT of the front wheel into the slots at the

bottom of the front forks.

Securing the wheel. (Nutted Axles)

Loosen the wheel nutsS on both ends of the front

wheel axleT, so that they slide over the fork dropouts.

If your bike is tted with tabbed washersR then ensure

that they guided into their catch hole above the axle.

Tighten the nutsS very tightly (22-25Nm) using the

supplied multitool.

4.4 Quick release spindles.

If your front wheel axleU is hollow and has no wheel

nutsS then this bike is tted with a quick release

spindle.

To secure the wheel then fasten with the release lever.

For more information on the assembly and correct use

of a quick release wheel spindle then read section 5.

4.5

NOTE! Ensure the wheel is centralised in the

forks before tightening wheel nuts or quick

release spindle.

NOTE! Some tyres have a “Direction of Rotation”

arrow on their side. When the front wheel is

assembled, the arrow should be pointing in the

direction the wheel will rotate.

4.6 Ret the front brake.

If your bike is equipped with V-brakesN then continue

below, if it has disc brakesO then proceed to step 4.9.

Squeeze the two brake armsP of the front brakeN

together with one hand.

Using your other hand, locate the guide pipe and

cableQ into the retaining plate slot on the right hand

armP.

Release the brake armsP and let them spring apart.

NOTE! Check that the front wheel rotates freely, if

it does not , the front wheel may not be located

centrally between the forks. Alternatively the front

brakes may need adjusting. (See section 6)

4.7 Disc brake alignment.

If your bike is equipped with disc brakesO then take

care to guide the disc rotorV into the disc brake calliperO when tting the front wheel.

5. Quick Release

If your bicycle is equipped with quick release

wheels then you will need to t the spindle before

attaching the front wheel.

Remove all packaging, you will nd the quick

release spindle in the same box as the pedals.

Your Seatpost clamp may also use a quick

release, follow these instructions for its correct

usage.

5.1 Wheel quick release

Remove the nutY and the one of the springsX from

the skewerZ.

Insert the skewerZ through the wheel axleU.

Ret the springX and the capY onto the skewerZ.

5.2 Securing a quick release.

When securing a wheel in position, the quick release

leverU is closed as shown. (Not by rotating the lever!)

In most case this will be moving it from where it curves

outward to a position where it curves inwards.

5.3 Releasing a quick release

To release, move the quick release leverU 180° to its

open position.

Adjusting a quick release

With the wheel in the frame, open the quick release

leverU. Whilst holding the leverU, turn the nutY until

you can feel some resistance against the forks.

Try and close the leverU, if you can only close it halfway then, open it and unscrew the nutY slightly again.

Repeat this adjustment until you can fully close the

leverU but with some effort so that it embosses the

fork ends when closed in the locked position.

Safety Information

WARNING! This bike has been manufactured in accordance with the EN 14766 standard to ensure your

safety. This bike should only be used for recreational

use. Under no circumstances should it be used for

competitive cycling, stunting, jumping or acrobatic manoeuvres. These types of cycling may result in serious

personal injury and damage to the bike.

WARNING! This bike has been designed for trail,

cross country and uphill riding, it should not be used

for extreme forms of riding such as hardcore mountain,

freeriding, downhill or dirt jumping, etc.

WARNING! Always wear a helmet when riding the bike.

The helmet should be the correct size and conform to

European Standard EN1078.

WARNING! Always obey local trafc laws.

WARNING! National legal requirements may apply

when riding your bicycle on public roads, this can

include, but not limited to, lighting and reectors.

WARNING! Always take extra care when riding in wet,

foggy, windy or icy conditions. The brakes may not be

as effective and braking distances may be increased.

WARNING! Always wear suitable cycling clothing when

riding. Loose clothing which may get caught in moving

parts should be avoided.

WARNING! The bike is only suitable for use by riders

(including any panniers and/or luggage) with a weight

less than 115Kg (254Ib).

WARNING! The front and rear tyres must be fully

inated before attempting to ride the bike, under no

circumstances should the tyres be inated above the

maximum pressure indicated on the side of the tyres.

WARNING! As with all mechanical components, the

bike is subjected to wear and high stresses. Different

materials and components may react to wear, stress

or fatigue in different ways. If the design life of a

component has been exceeded then it may suddenly

fail, possibly causing injuries to the rider. Any form

of crack, scratches or change of colouring in highly

stressed areas indicate that the life of the component

has been reached and it should be replaced.

8.1

8.2

c

d

6.3

3-4mm 3-4mm

i

j

j

k

m

l

6.6

Tighten

Loosen

7.6

r

2

Tighten

Loosen

n

7.3

b

a

6.1 6.2

7.1 7.2

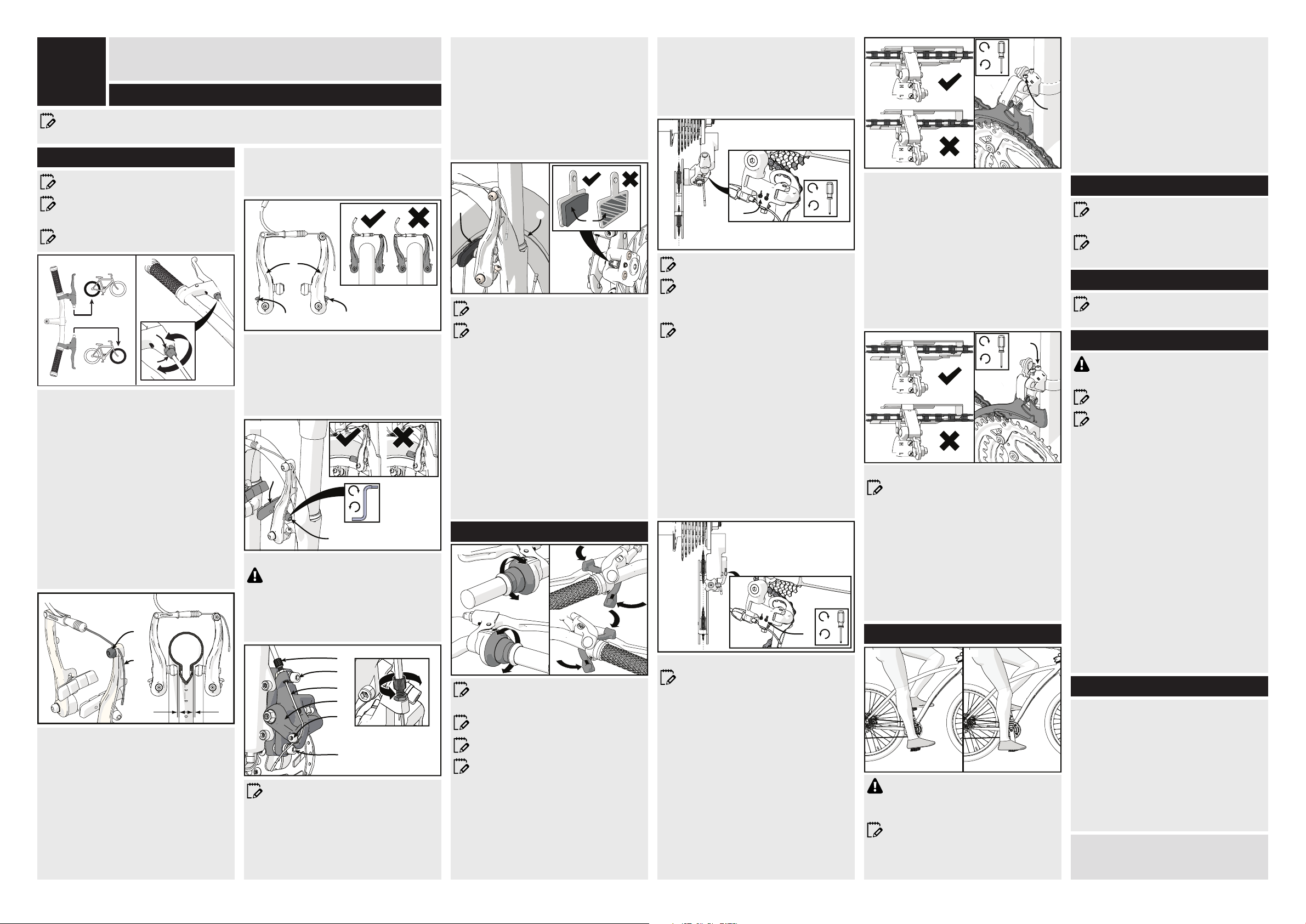

NOTE! The majority of your new bicycle’s components have been assembled, adjusted and checked by trained

professionals before delivery to you. However due to the transportation and reassembly it might be necessary

to make some slight adjustments before riding to get the most from your bicycle and ensure the safety of the rider.

6. Brakes

NOTE! Your brakes will need adjusting before

riding for the rst time.

NOTE! Throughout the life of your bike, the front

and rear brakes may need adjusting if the brake

cable has stretched or the pads have worn down.

NOTE! Disc Brakes will require a bedding in

period before they perform at their optimium.

6.1 Brake use

The bicycle is tted with front and rear brakes to stop

the bike effectively.

The brakes are operated using two brake levers

mounted on the handle bars. The left hand brake lever

operates the rear brake and the right hand brake lever

operates the front brake.

6.2 Minor brake adjustment (Disc & V-brakes)

If the brakes need adjusting then ne tuning can be

done at the appropriate brake lever.

Unscrew the brake barrel adjuster b to increase or

decrease cable tension.

To increase the tension and move the brakes closer to

the rim, then turn the barrel adjusterb anti clockwise.

To decrease the tension and move the brakes further

from the rim, then turn the barrel adjusterb clockwise.

Screw the lock nuta back against the body of the brake

lever to prevent the adjuster moving.

6.3 Adjusting V brakes

If further adjustment is required then the brake cable

tension will need to be altered. This must be adjusted

so that the brake blocks are close to the rim when no

pressure is applied to the lever.

Loosen off the cable pinch boltc using the tools provided, until the brake cabled is free to move.

Pull the cabled through the pinch bolt so that the brake

blocks are approximately 3-4mm from the wheel rim.

Retighten the cable pinch boltc whilst holding the

brake cabled in position.

Setup & Maintenance

Complete these checks before riding

6.4 Adjusting V brake spring tension.

Over time, the brake arms can begin to lean to one

side or another. This can be corrected by adjusting the

spring tension of the individual brake arm.

6.4

P

f

h

e

If the brake armsP are leaning to the left then tighten

the right spring tension screwe.

If the brake armsP are leaning to the right then tighten

the left spring tension screwf.

Apply the brakes using the brake lever several times

to centre the brakes and readjust spring tension if

required.

6.5

g

6.5 Adjusting V brake pads.

Check that the pads make full contact with the rim

and do not touch the tyre. Ensure all parts are

tightened correctly.

Loosen brake pad nuth using the appropriate tool until

the brake padg is able to move.

Align brake padg with the wheel rim.

Retighten the brake pad nut rmly. (8-10 Nm)

NOTE! Disc Brakes will require a bedding in

period before they perform at their optimum.

6.6 Aligning mechanical disc brakes.

Loosen the two brake calliper mount boltsj so that the

brake calliper is able to move.

Pull the brake lever on the handlebars, this will push the

brake pads against the rotor and move the calliper into

the correct position.

Tighten

Loosen

With the brake lever pulled tight, retighten the brake

calliper mount boltsj rmly. (10-12 Nm)

6.7 Adjusting mechanical disc brakes.

Loosen the cable pinch boltm so that the brake cablek

is able to move.

Move the Calliper arml towards the cable adjuster

bolti and hold in position.

Retighten the cable pinch boltm.

Spin the wheel and check the brakes, ne adjustments

can be made by using the cable adjuster boltsi at both

the brake calliper and brake lever.

6.7

g

NOTE! All brakes should be checked before and

after every ride.

NOTE! Disc brake advice based on common disc

components, If your bike has disc brakes tted

then please see your individual manual regarding

maintenance.

6.7 Inspecting V brakes.

Inspect the grooves on the braking face of the brake

blockg, releasing the brakes as shown in step 4.2 may

be required. If the block has been worn smooth then

replace it with an appropiate block.

It is also important to check the rim for wear, if the rim

wear indicators has been worn away at any point on

the rim then the bike must not be ridden until the rim

has been replaced.

6.8 Inspecting disc brakes.

Inspect the brake padst within the disc brake body for

wear, removing the wheel may aid inspection. If the

padst are low or have been worn away then the bike

must not be ridden until they have been replaced.

s

t

7. Gears

NOTE! Do not change gear whilst the bike is

stationary. You should always turn the pedals

when changing gear.

NOTE! There are two main types of gear shifters:

Twist shifters 7.1 and Trigger shifters 7.2.

NOTE! The left hand shifter operates the front

gears and the right hand shifter the rear gears.

NOTE! Most systems have an indicator to show

you which gear is selected.

7.1 Twist shifter - left hand

Rotate the inner grip away from yourself to select a

lower gear and rotate the inner grip towards you to

select a higher gear.

Twist shifter - right hand

Rotate the inner grip away from yourself to select a

higher gear and rotate the inner grip towards you to

select a lower gear.

7.2 Trigger shifter - left hand

Push the lower (thumb) trigger to select a higher gear

and pull the upper (nger) trigger to select a lower gear.

Trigger shifter - right hand

Push the lower (thumb) trigger to select a Lower gear

and pull the upper (nger) trigger to select a higher

gear.

NOTE! Your Gears will need adjusting before

riding for the rst time.

NOTE! Whilst riding the bike, if the gears fail to

work correctly and/or become noisy, the rear

derailleur may need adjusting.

7.3 Adjusting the rear derailleur

NOTE! The lowest gear combination is always the

largest gear at the rear and the smallest gear at

the front.

Select the lowest gear combination

Whilst raising the rear of the bike and rotating the pedals by hand, use the gear shifters to select the lowest

gear.

Set position of lower limit screw

The lower limit screwn controls the position of the rear

derailleur when the lowest gear is selected.

Using a screwdriver, rotate the lower limit screwn until

the small wheels of the derailleur are vertically aligned

below the lowest gear.

Turn the lower limit screwn clockwise to move the

derailleur to the right (when viewed from the rear of the

bike)

Turn the lower limit screwn anti-clockwise to move the

derailleur to the left.

7.4

Tighten

o

Loosen

7.4 Select the highest gear combination

NOTE! The highest gear is always the smallest

gear at the rear and the largest gear at the front.

Whilst raising the rear of the bike and rotating the pedals by hand, use the gear shifters to select the highest

gear.

Set position of upper limit screw

The upper limit screwo controls the position of the

derailleur when the highest gear is selected.

Using a screwdriver, rotate the upper limit screw o until

the small jockey wheels of the derailleur are vertically

aligned below the highest gear.

Turn the upper limit screwo clockwise to move the

derailleur to the right.

Turn the upper limit screwo anti-clockwise to move the

derailleur to the left.

7.5

Tighten

Loosen

p

7.5 Adjusting the front derailleur

Select the highest gear combination

Whilst raising the rear of the bike and rotating the pedals by hand, use the shifters to select the highest gears.

Set position of upper limit screw

The upper limit screwp controls the position of the front

derailleur when the highest gear is selected.

Using a screwdriver, rotate the upper limit screwp until

the front derailleur is almost touching the chain. The

front derailleur must not touch the chain.

Turn the upper limit screwn clockwise to move the

derailleur to the right (viewed from the rear of the bike)

Turn the upper limit screwn anti-clockwise to move the

derailleur to the left.

7.6 Select the lowest gear combination.

NOTE! The lowest gear combination is always the

smallest gear at the front and the largest gear at

the rear.

Set position of lower limit screw

The lower limit screwr controls the position of the front

derailleur when the lowest gear is selected.

Using a screwdriver, rotate the lower limit screwr until

the front derailleur is almost touching the chain. The

front derailleur must not touch the chain.

Turn the lower limit screwr clockwise to move the

derailleur to the right

Turn the lower limit screwr anti-clockwise to move the

derailleur to the left.

8. Saddle Height

WARNING! When assembling the seatpost, make

sure it is inserted beyond the Minimum Insert

Mark. Failure to observe this warning may result in

serious personal injury.

NOTE! Read section 2 for additional information

regarding seat post xings.

8.1 Initial seat adjustment

Sit on the seat in riding position without shoes, whilst

someone else holds the bike upright.

Position the crank arms so they are parallel to the seat

tube of the frame.

Loosen the seat post bolt or quick release.

Extend the seat post, until with your heel resting on the

pedal, your extended leg is straight.

Tighten seat post bolt or quick release.

8.2 Correct seat height

After the adjustment and when wearing shoes, there

should be a slight bend in your knee whilst in the proper

riding position with the ball of your foot on the pedal.

You should be able to touch the ground on either side of

the bicycle with the tips of your toes.

9. Suspension

NOTE! If your bike has front suspension forks

tted then please see your individual manual

regarding maintenance and use.

NOTE! If your bike has rear suspension then

please see your individual manual regarding

maintenance and use of the shock unit.

10. Accessories

NOTE! If your bike has any accessories tted then

please see the individual manual regarding

maintenance and use.

11. Routine Maintenance

WARNING! Only use the correct, genuine and

appropiate replacement parts, especially for safety

critical components, such as tyres, tubes and brakes.

NOTE! For advice on assembly or help nding

spares then call our helpline on 0845 129 9248.

NOTE! It is recommended that the bike is serviced

by a qualied bike technician every 12 months.

Before and after each ride.

Is the saddle secure?

Are the front and rear tyres inated correctly?

Are the pedals tight?

Do the brakes work?

Do the handlebars Move?

Is the Bike clean?

Every month.

Check that the bike is clean.

Lubricate the chain using a suitable light oil.

Check that all parts of the bike are securely tted.

Check that the tyres are in good condition.

Check the condition of the brake blocks/pads.

Check that the wheel spokes are tight.

Every 6 months.

Check the frame and forks for signs of damage.

Check the wheels are running true.

Check the front and rear gears for signs of damage.

Every 12 months.

Inspect and grease the wheel hub bearings.

Inspect and grease the headset bearings.

Inspect and grease the bottom bracket bearings.

12. Tightening Torques

Use the information below to ensure the correct

torques are applied to your bicycle components during

mainenance.

Fastener

Front wheel nuts

Rear wheel nuts

Quill stem bolt

Handlebar clamps

1 bolt

2 bolt

4 bolt

A-Head clamp bolt

The copyright of this publication belongs to Universal

Cycles Ltd and no part shall be reproduced without the

company’s written permission.

© Universal Cycles Ltd 2013.

(Nm)

Fastener

22-25

Seat post clamp

25-29

Bolt or nut

17-19

Allen bolt

Brake cable pinch nut

16-18

Crank bolt

12-14

Pedals

8-10

V-brake blocks

18-20

(Nm)

16-18

8-10

6-8

45

40

8-10

Loading...

Loading...