Page 1

FLETA PRO / STOCK SPEC / EURO ESC USER MANUAL

Thank you for purchase of Much-More Racing FLETA PRO / STOCK SPEC / EURO electronic speed controller.

New FLETA PRO / STOCK SPEC / EURO is specifically designed for 1/10 scale electric R/C racing.

No matter which class of competition you race in, the FLETA will help you achieve better results.

Before you start, please read through this instruction manual carefully.

It contains important safety information as well as setup tips from Much-More Racing website.

• 2 color LEDs for quick status display.

• Variable drive and brake frequency tuning for expert racing.

• Advanced boost and turbo timing with rpm and throttle control.

• Support for “Blinky” (Zero-Timing) spec racing mode.

• Fully configurable throttle and brake response.

• User adjustable low voltage and over temperature protection.

• FLOW-MAX™ design cool aluminum housing with 30mm high rpm cooling fan.

• Programmable by SHR program card & PC Interface.

• User upgradable firmware.

■ FEATURES ■

• Keep this product out of reach of children.

• This product is designed only for R/C car model use. It is not suitable for any other purpose.

• Never leave this product unattended while it is connected to a power source.

• Make sure all cables are in good condition and securely fastened.

• Keep in mind that vibration during operation may loosen connections and cause loss of control.

• Do not connect in reverse polarity.

• To prevent short-circuits, please make sure that all cables and connectors are properly insulated.

• Keep this product away from water, oil, fuel or other conductive liquids. If this product becomes damp,

immediately stop using it and let it dry completely.

• Avoid using excessive force when tightening the cooling fan screws. Over tightening them may permanently

damage the aluminum housing.

• Make sure to use suitable gear ratios for your track condition. Unsuitable gear ratios may overload and

damage your speed controller and motor.

• Never operate with throttle when the motor has no load. Running the motor without load may cause

damage and risk of fire or bum.

SAFETY INFORMATION

■ SPECIFICATIONS ■

FLETA PRO

120A

760A

Over 3.0T

43g

FLETA STOCK SPEC

100A

600A

Over 6.5T

39g

FLETA EURO

80A

480A

Over 9.5T

32g

ESC Model

Current Continuous

Current Burst

Input

Built-in BEC

Suitable Motor

Supported Motor Type

Size

Weight

4-8 cells NiMh/NiCd or 2S LiPo, 2S LiFe

6V@3A

540 size 2 pole brushless with sensor type

30mm(L) x 36mm(W) x 19mm(H)

*FLETA EURO : Factory pre-installed Blinky(Non Boost) firmware.

Connection and Mounting

Connect the Rx connector to the throttle channel (CH2) of your radio receiver.

(White Shrink tube is Signal wire)

Connect one end of the sensor cable to the motor’s sensor port, and the other end to the ESC’s

sensor port.

Secure the ESC, power switch, and capacitor on your model car’s chassis with double sided tape.

If necessary, install the included cooling fan on top of the ESC with screws, and make sure to check

for correct polarity when connecting to the cooling fan power port.

Soldering Battery Wires, Motor Wires, and Capacitor

Make sure to use a soldering iron with sufficiently high temperature. Never leave the soldering iron on the mounting point for longer than 5 seconds.

If it takes than 5 seconds to melt the solder between the joints, switch to a higher temperature solder iron. Overheating the mounting points will damage the ESC.

Pay special attention to the polarity marking below the mounting point. Make sure you connect each

phase (A,B,C) of the motor to the corresponding (A,B,C) mounting point on the ESC.

We recommend using a red color wire for the positive(+) battery input terminal, and a black color wire

for the negative(-) terminal. Connecting a battery in reverse polarity will damage the ESC !!

Remember to solder the included power capacitors to the battery input mounting point!

Running the motor without connecting capacitor will damage the ESC!

※ Check the wire shrink color

A

BLUE-BLACKBYELLOW+REDCORANGE

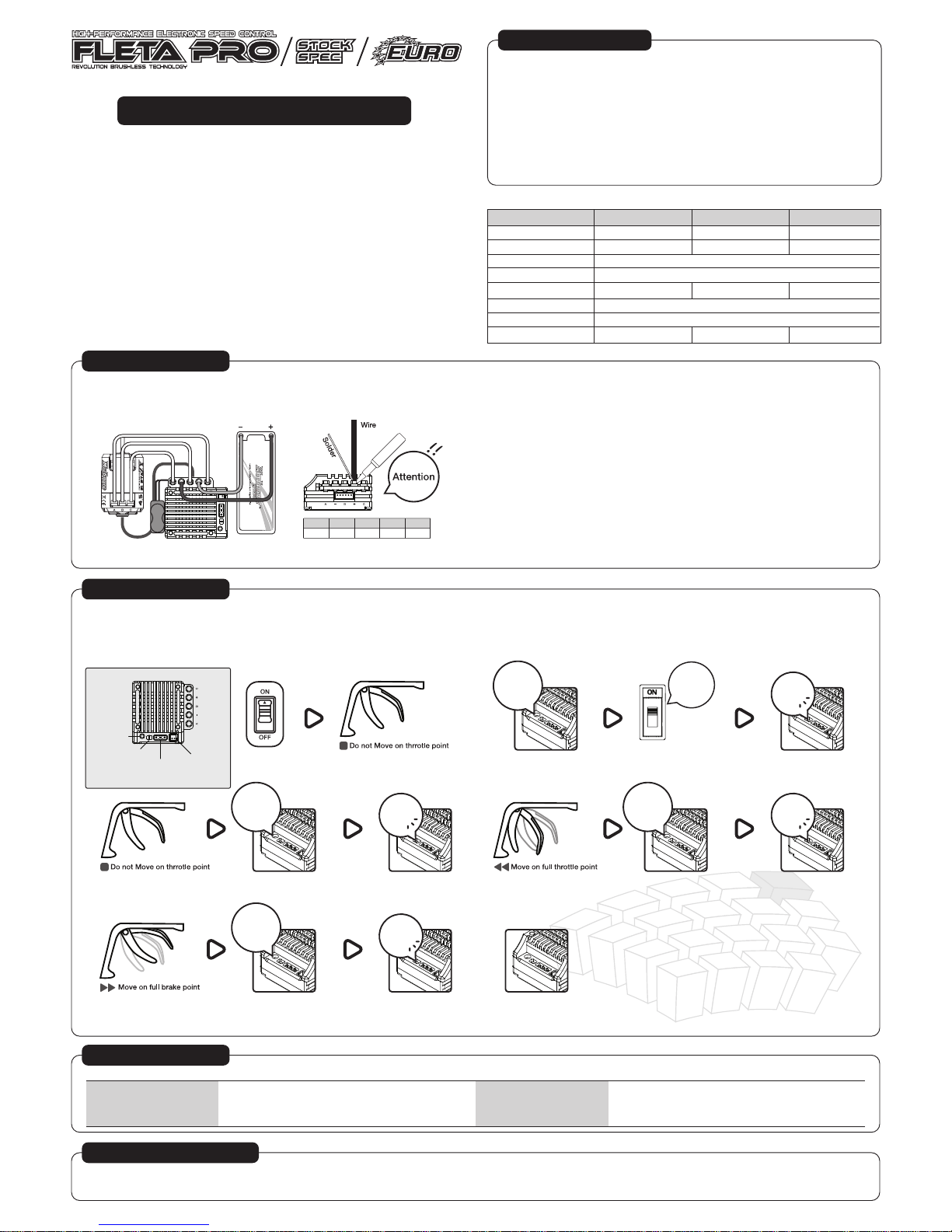

BASIC INSTALLATION

Always power ON your transmitter first before powering ON your ESC to avoid unexpected operation of the motor. For your safety, motor operation is automatically disabled until neutral throttle signal is detected

from the radio receiver.

Synchronizing the FLETA and Transmitter

In order for the ESC to recognize the full throttle range of your radio, a throttle range calibration is required.

Before starting, make sure your radio throttle 2CH EPA and D/R is set at 100%. The trim and sub-trim should be zero.

Warning: To prevent any chance of loss of control or damage and injuries, make sure to remove the pinion gear from the motor during the calibration process!

1) Turn on your radio, making sure the throttle is at neutral. 2) Turn on your ESC while pressing the set button.

Release the set button when green LED light up solid.

3) Press the set button once to set the neutral throttle position.

The green LED will blink to indicate position is memorized.

4) When the red LED light up solid, hold full throttle and press the set button once.

The LED will blink to indicate full throttle position is memorized.

Make sure to hold full throttle until the LED change to different color.

5) When the green and red LED light up solid, hold full brake and press the set button once.

The LED will blink to indicate full brake position is memorized, and return to green.

6) Finished the calibration.

pressing

the

set button.

Turn on

your ESC

Green

LED

Press

the

set button.

Press

the

set button.

Green

LED

Red

LED

Press

the

set button.

Red &

Green

LED

Status LED

Set Button

Program Card

Connector

Fan

connector

POWERING ON FLETA

There are different color LED’s on the face of the ESC for status indication. Please refer to following table for their meaning :

Neutral Throttle

Full Throttle / Reverse

Full Brake

Zero Timing Mode

Green Solid

All Color Solid

Red Solid

Green Flashing

Over Temperature Protection Activated

No Sensor Cable Detected

Power ON Without Signal From Receiver

Motor connection error(A, B, C)

Green solid / Red Flashing

All Color Flashing

Off the LED

Red Flashing

LED STATUS INDICATOR

1

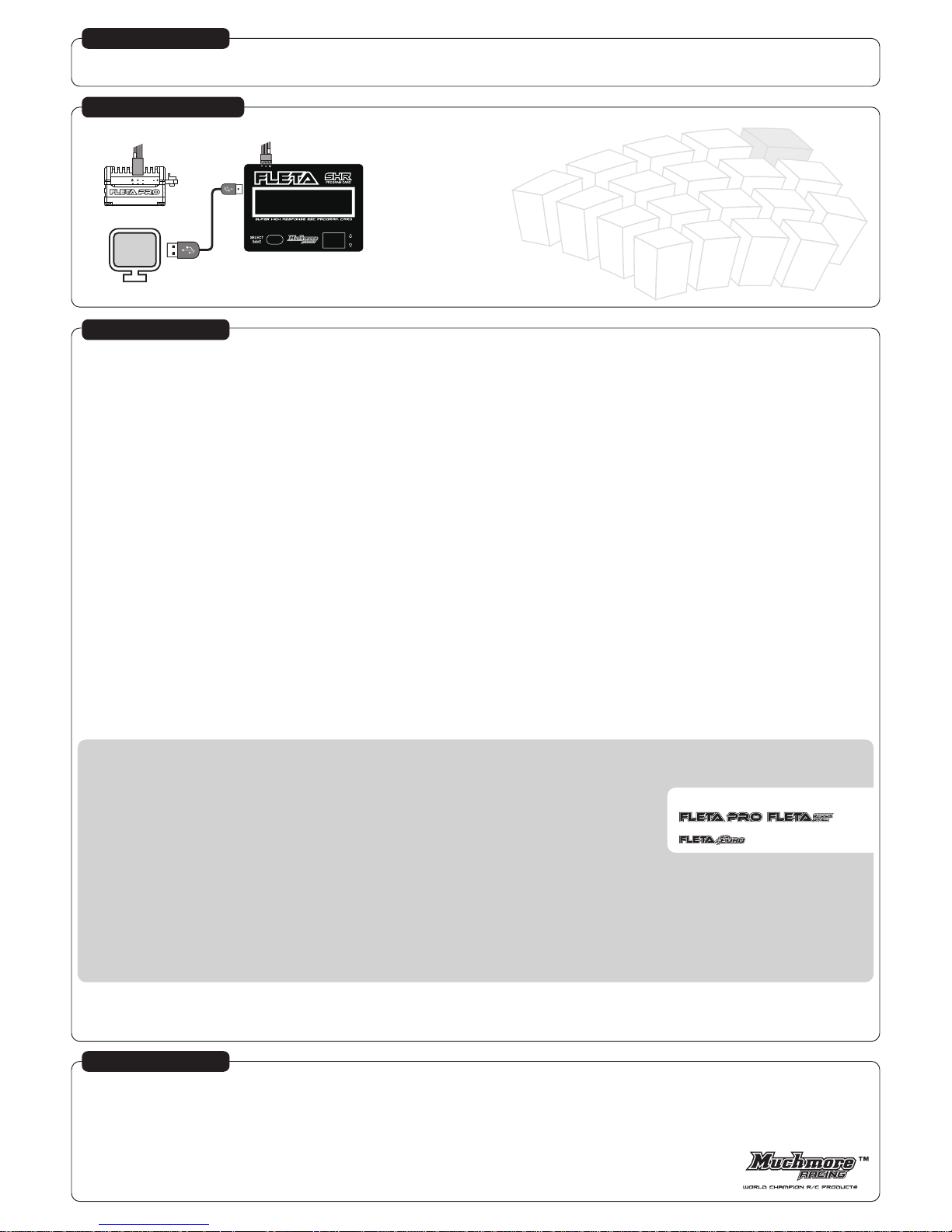

SHR Program card able to customize setting to FLETA PRO/STOCK SPEC. (SHR Program card is purchased separately)

The FLETA PRO/STOCK SPEC has 19 different program function available.

Next page there is a description of the SHR Program Card.

SHR PROGRAM CARD

Page 2

ESC

PC (You must installed FLETA PC Program)

SHR PROGRAM CARD

★Recommended method : Before starting, place your car on a stand and avoid touching any moving parts.

1. Operation Mode

This setting allows selection between Forward/Brake Only or Forward with Brake and Reverse or Forward with Reverse. (except brake function)

If you plan to use reverse drive, make sure to adjust the motor end bell timing to zero degree advance.

2. Reverse Speed

This setting adjusts the limit of maximum reverse speed. It offer four reverse speed value. Set a higher setting for higher reverse speed.

3. Low Volt Cut (Battery Low Voltage Protection Threshold)

This setting adjusts the desired threshold for battery low voltage cut-off. Depending on the booster and turbo settings, battery voltage may drop significantly during high current discharge.

If you need to change the value in detail, use the custom value.

4. Drag Brake

This setting adjusts the level of drag brake at neutral throttle position. Set a high level for stronger drag brake. You can change between 0% - 50% in 1% increments.

5. Initial Brake

This setting adjusts the initial (or minimum) brake level. Set a higher level for more initial bite. You can setup same to the drag brake value or adjust 0% - 50% in 1% increments.

6. Full Brake

This setting adjusts the maximum brake level at full brake position. Set a higher level for stronger brake force. Note the motor will also run hotter if brake force is set too high.

The actual brake force will also be affected by gear ratio and rotor size. You can change 75% - 100% in 5% increments.

7. Brake Frequency

This setting adjusts the brake PWM frequency.

The brake feel and efficiency will very depending on the frequency and motor rpm. Set a lower frequency for more progressive brake feel and higher frequency for more initial bite.

You can set it to 1Khz, 2Khz, 4Khz, 8Khz, 16Khz, 32Khz.

8. Power Level

This setting fine tunes the throttle response. Set a higher value for more immediate throttle response. Set a lower value for more smooth response.

You may lower your motor temperature by using a lower setting. For modified motor, You can set it to Level 1 – Level 9.

9. Drive Frequency

This setting adjusts the throttle feel at partial throttle by varying the PWM frequency for forward drive.

Set a higher frequency for smoother feel at partial throttle and lower frequency for stronger acceleration.

You can set it to 2Khz, 4Khz, 8Khz, 16Khz, 32Khz, 64Khz

Caution : If you set a too high frequency, ESC temperature will rise highly for stock / modify motors.

10. Neutral Dead Band

This setting adjusts the width of neutral dead band suitable for your radio. Set a lower value for high quality 2.4GHz radio system. Set a higher value for low cost 2.4GHz or FM/AM radio system.

Smaller value gives you more immediate response. If the value is set too small for your radio, the brake may be engaged accidentally at neutral.

You can set it to 0%, 3%, 6%, 9%, 12%.

11. Temp Cut Set

This setting adjusts the thermal protection shut down temperature.

You can set it to three value. (OFF, 176F/80celsius, 196F/90celsius.)

Note : the internal temperature sensor requires a brief moment to detect temperature change. In case of sudden current overload.

12. Boost Timing

This setting adjusts the level of boost timing available at the max boost timing. Set a higher boost timing to increase the overall available torque and rpm.

Setting the boost too high will result in excessive current draw and high operating temperature of the ESC and motor.

As a general guide, we suggest to set boost between 10 – 30 for stock class motors and 0 – 20 for modify motors.

The combine total of Boost timing and Turbo timing should be below 60 to reduce risk of over loading the motor.

13. Boost RPM

This setting defines the starting motor rpm at which boost timing is activated. Boost timing is injected incrementally starting from the Boost RPM.

Set a lower rpm for more low end torque and smoother boost engagement. Set a higher rpm to lower motor temperature.

As a general guide, we suggest to set minimum Boost RPM over the 3000 for stock class motors and over the 12000 for modify motors.

Note : Booster timing will not engage if the Minimum Booster RPM is higher than the rated rpm of the motor.

14. Boost ACC (Boost Timing Acceleration)

This setting is the RPM increment of the boost timing.

increase of 1 Degree. The lower the value it is, the more torque the motor will produce but at the expense of the motor increasing in temperature.

As a general guide, we suggest to set it over the 350RPM/ACC for stock class motors and over the 650RPM/ACC for modify motors.

15. Turbo Timing

This setting is the additional timing that is added to the Boosting Timing and is ONLY effective

when the throttle is at 100% end point of activation. The combine total of Boost timing and Turbo timing should be below 60 to reduce risk of over loading the motor.

16. Turbo Slope

This setting refers to the Turbo Timing increasing rate. The higher it is, the faster the Turbo Timing increases, and together with a quicker acceleration and higher motor temperature.

17. Turbo Delay

This setting is the amount of time “full throttle” must be held Before the turbo function engages. If the full throttle time is less than the setting value, the turbo function will NOT be activated.

18. Rotation Mode

This setting reverses the spinning direction of the motors. Use reverse setting if your chassis requires a reverse spinning direction.

19. Restore Default

Selecting this setting will erase and reset all settings to factory default values.

The FLETA PRO/Stock spec has 19 different program function available.

To customize the settings, you can connect your ESC directly to the SHR program card or connect to your PC.

The PC software can be download our website at http://www.muchmoreracing.net

PROGRAM SETUP YOUR ESC

How to use the SHR Program Card

● product repair

■ If the repair of the product, you will need a receipt at the time of purchase.

■ For repair damaged parts, the cost of parts may be associated with each component will be charged.

Parts for defects and flaws of this product, please ask your dealer or distributor you purchased along with the receipt within 120 days from the date of original purchase.

The maximum amount of the above warranty, failure or defect normal wear and tear, incorrect use, due to improper repair or modification can not be guaranteed. This also applies to matters such as the following.

■ If you are connected in reverse polarity of the product

■ physical damage case

■ physical damage of the electronic component and the circuit board

■ (except soldering external) of the circuit board soldering

■ Before the product for warranty service, please check how to resolve the problem before and all component parts.

■ To obtain warranty service the product, you will need the receipt of the products you have purchased.

(If you do not have a receipt, the warranty period not permitted.)

■ Please fill in the address and contact details of the defect and the defect or repair or for faster delivery.

Much-More Racing Co., Ltd.

127-1,Poong-dong, Ilsan-gu, Goyang-city, Gyeong-gi-do,410-842 Korea

Phone +82(31)903-0381 | Fax +82(31)903-0497

www.muchmoreracing.net

WARRANTY

PROGAMMABLE FUNCTIONS

This Setup is only used to

is disabled to menu.

2

1) Inset the Rx cable into the upper of the program card, and connect front side of the ESC.

make sure to connect correctly.

(Please use a connection at front side of the ESC.)

2) The program card display will turn ON, and display the current software version.

3) Use scroll up and down to change the program function menu.

4) Press the select/save button.

5) A scroll up and down can change your setting value.

6) To save the setting value, Press the select/save button again.

7) When the display has returned to program menu, you can disconnect the ESC from the program card.

8) Turn OFF the ESC, first before using again.

Loading...

Loading...