Page 1

MTZ

821/821.2/821.3

921/921.2/921.3/921.4

OPERATION

MANUAL

921 – 0000010 RE

Page 2

CONTENTS

Section 1. Introduction. International marks ........................................................................................ 4

Section 2. Safety regulations ................................................................................................................ 6

Section 3. Technical specifications .................................................................................................... 19

Section 4. General information. Tractor layout and operation .......................................................... 23

Section 5. Controls and instruments .................................................................................................. 25

Section 6. Preparation to work and work order ................................................................................. 38

Section 7. Operation and adjustment regulations ............................................................................... 48

Section 8. Rigging .............................................................................................................................. 60

Section 9. Troubleshooting ................................................................................................................ 71

Section 10. Maintenance .................................................................................................................... 75

Section 11. Storage .......................................................................................................................... 100

Section 12. Transport ....................................................................................................................... 100

Section 13. Appendix ....................................................................................................................... 101

2

Page 3

IMPORTANT!

In case of tractor bein g used by a customer or is lent or leased prior to starting operating it ensure

the operator:

A. . Is aware of safety measures and correct use.

B. . Has read and understood contents of the present operation manual.

NOTICE!

Due to constant product improvement structure of certain assembly units and parts may contain

alterations not mentioned in the present edition.

Some technical d ata and figures i n the p resent d ocument s ma y differ from actual for your machine.

Dimensions and weights are approximate (for reference only). Contact MTZ dealer for details.

General note: “Left” and “Right” terms in the present document are referenced from point of view

of a viewer behind the tractor moving forward.

TO OPERATOR’S ATTENTION!

1. Carefully read the present manual prior to running the tractor and strictly observe its

regulations.

2. Use seasonal diesel fuel according to the manual. Reduce engine oil change interval twice

when using fuel with up to 1% sulphur content.

3. Never allow idle engine operation exceed 15 minutes.

4. Keep in mind that diesel engine may be started with gear lever in most left position only (in

drive range engagement positions I or II).

5. With the tractor operating without rear PTO free two-speed PTO drive sw itch should be set to

position I (540rpm), free synchronous PTO drive lever should be set to neutral (middle) position,

control lever should be set to “PTO off” position (see “Controls and instruments” section).

6. Synchronous drive of rear PTO should not be used with track unit movin g faster than 8 km/h.

Otherwise tractor powertrain may be badly damaged.

7. Operation at 9th gear is allowed in overdrive only (range II).

8. Tractor cab is equipped with a single seat and only operator is allowed to stay into.

9. Certain tractor components are placed into SPS case, toolbox or cab at dispatch from the

factory. These should be installed by the user himself.

10. When commissioning new batteries remove sealing film from vents or cut afflux out of

polyethylene plugs.

11. Do not allow tractor operation with friction clutch engaged or not completely disengaged.

12. To start moving ensure hand parking reserve brake disengaged.

13. Set FDA switch knob to “driven” position in order to operate the tractor with no cardan shafts.

14. Never operate tractor in closed compartments with insufficient ventilation (air exchange):

exhaust gases may be fatal.

15. Never tow tractor with front wheel lifted up, otherwise FDA drive may fail leading to

emergency conditions.

16. Never lift machine front up with a towing shackle. Use the shackle to tow the tractor only.

17. Never perform maintenance or other works in fan or drive belt area with running engine.

18. Manufacturer never stops improving the machine, thus machine structure or operation rules

may be subject to alterations not reflected in the present manual.

3

Page 4

Section 1. INTRODUCTION. INTERNATIONAL MARKS

The present manual contains basic technical data, description of structure features, controls,

operation and maintenance for the following tractor models:

MTZ-821 (D243; 4x4), MTZ-821.2 (D243.S; 4x4),

MTZ-821.3 (D245.43S2; 4x4)

MTZ-921 (D245.5; 4x4), MTZ-921.2 (D245.5S; 4x4),

MTZ-921.3 (D245.5S2; 4x4).

MTZ-921.4 (D245.5S3A; 4x4)

4x4 tractors MTZ 821/821.2/921/921.2/921.3/921.4 is a garden-and-vineyard version of

universal wheeled tractor-cultivator MTZ-822/922 featuring smaller dimensions and ground

clearance. These tractors are aimed at performing different works at fruit plantations, in gardens and

vineyards, as well as in industry, construction, public services and transport, equipped with rigs,

semihinged machines, towing machine and appliances.

Used abbreviations and acronyms

AB - accumulator battery

DL - differential lockup

QC - quick coupler

PFE - paper filter element

UBGP - upper bevel gear and pinion of front driving axle reduction gears

UDP - upper dead point of engine piston

PTO - power take-off

PIC - power input connection

HMS - hydraulic mounted system

HPS - hydrostatic power steering

SM - shift maintenance

SPS - spare parts set

RH - rear hookup

CFE - control filter element for diesel engine air filter

MFE - main filter element

GB - gearbox

TMA - tractor machine assembly

FC - friction clutch

H - hookup

FDA - front driving axle

TM - technical maintenance

TC - towing coupler

4

Page 5

International symbols

In relation to instruments and controls use manufacturer uses standard international symbols.

Symbols and their descriptions are given below.

− See manual

− Brake

− Hand brake

− Horn

− Alarm signaling

− Fuel

−

Coolant

− Electric starting preheater

− Engine speed

− Engine oil pressure

− Engine coolant temperature

− Controls operation

− Fast

− Slow

− Forward

− Backward

− Battery charging

−

Cab limp

− Side lights

− Turn indicators

− Upper beam

− Lower beam

− Open

− Close

− Gradual change

− RH lever down

− RH lever up

− External cylinder, push-out

− External cylinder, retraction

− External cylinder, floating

− Clogging air filter

−

− Operation lights

− Differential lockup

− Power take-off engaged

− Front axle engaged

− Fan

− Screen washer

− Windshield wiper

− Rear window washer and wiper

− Trailer turn indicator

− Engine start (starter control unit

indicating lamp)

5

Page 6

ATTENTION! Do not start engine from

outside operator’s place. Always stay in the

and operating controls.

Section 2. SAFETY REGULATIONS

Carefully follow precautions and regulations

in tractor operation and maintenance to ensure

work safety.

General notes

1. Carefully study the present operator’s

manual prior to operating the tractor.

Insufficient knowledge on driving and

operating the tractor may cause accidents.

2. Specially trained and qualified operators are

allowed to use the tractor, only.

3. Use tractor’s safety belt, if any, in

operation. Contact dealer otherwise.

4. Never take passengers i nto the tract or’s cab

as there is no seat provided.

5. Keep all warning labels clean. Replace

damaged or missing labels.

6. Thoroughly inspect the tractor, trailed

machinery, rigs and coupling prior to

commencing work. Ensure its complete

operability prior to commencing work.

Trailed agricultural machines and

transporting trailers should be equipped

with rigid hitches to prevent them swaying

and tractor being run down while

transporting, and with safety chains and

cables.

7. Prior to starting the engine engage parking

brake, free PTO switch should be turned

OFF, PTO gear changing rod

(“Synchronous/Free”) should be set neutral,

range and gear chan ging lever sh ould be set

neutral.

Safety regulations for tractor operation

cab at operator’s seat when starting the engine

8. Never start engine with towing to avoid

intensive engine parts wear.

9. Never start engine and never operate

controls from outside operator’s place.

10. Warn surrounding and working on trailed

machinery persons prior to commencing

work.

11. Never leave tractor in motion.

12. Turn PTO off, stop the engine, set PTO

switching rod neutral, engage parking brake

and pull starter key out.

13. Do not operate the tractor in enclosed

compartments with insufficient ventilation

– exhaust gases may lead to death!

14. In case of engine or steering fail during

operation immediately stop the machine.

Steering with stopped engine required much

greater force applied.

Non-operating engine with no pressure in

steering system lights oil pressure indicator.

15. Do not stay under lifted agricultural

machines. Never leave rigs lifted up for

long stops.

16. Be careful not to exceed maximum total

weight of tractor and coupled machinery

and axles loads as pe r S e ct io n 3: “Tech ni c al

specifications”.

17. Be careful not to injure a person or

damage property while lifting agricultural

digs up and down and turning the tractor.

18. Cardan shaft transferring torque from

PTO to machinery tips should be enclosed.

19. Ensure any supplementary equipment and

auxiliaries are installed correctly and fit

your tractor.

Keep in mind danger of misusing a tractor

for yourself and other persons.

Do not use equipment not designed to be

installed onto a tractor.

20. Be careful not to roll over. Choose safe

speed according to road condition,

especially when driving off-road, crossing

trenches and slopes and in sharp turns.

21. Widen tractor’s wheel track as much as

possible for driving at slopes.

22. Avoid sharp turns with full load and at

high speed.

23. To use the tractor for transporting:

• Widen wheel track as much as possible;

• Interconnect brake pedals, adjust

simultaneous braking, if necessary;

• Check parking brake operability;

• Check light and sound signaling devices;

• Transporting trailers should be equipped

with rigid hitches and safety chains or

ropes;

6

Page 7

• Never drive down the hill with gear

disengaged (coasting)!

Drive the same gear up and down the hill.

• Never drive down the hill with engine

stopped. Oil pump should operate for safe

steering;

• Never use trailers weighing more than a

half of tractor’s actual weight without

independent braking system. The faster you

are driving and the greater is towed weight,

the longer should be safe distance;

• Disengage FDA to avoid excessive drive

parts and front tires wear;

• Do not lock rear axle differential when

turning or driving faster than 10 km/h;

• Never stop at slope. In need to stop engage

the 1st gear and parking brake.

24. Stop the engine and ensure PTO end stop

prior to leaving the cab and disconnecting

machinery when working with PTO-driven

attachments.

25. Never wear loose cloths when operating

PTO or near rotating machines.

26. Always engage parking brake and block

rear wheels with wedges on both sides.

Ensure secure fixation of the machine.

27. Use synchronous PTO dr ive for lower GB

gears at speed not exceeding 8 km/h,

otherwise tractor’s powertrain may be badly

damaged.

Set independent and synchronous drives rod

to middle (OFF) position and replace PTO

end cap.

28. Never clean, adj ust or service PTO-driven

machines with running engine.

29. Driving with installed agricultural rigs

faster than 15 km/h is not allowed.

Safety regulations for maintenance

30. Never fuel the tractor up with running

engine.

31. Never smoke when fuelling the tractor up.

32. Do not fill fuel tanks to the full – leave

enough space for fuel to expand.

33. Never add gasol ine or mix es to diesel fuel

to avoid increased fire or explosion hazard.

34. Timely apply summer and winter fuels.

Fill fuel tank in the end of each day to

reduce condensation at night.

35. All operations related to engine or tractor

cleaning, preparation to work, servicing,

etc. should be done with stopped engine

and braked tractor.

36. Engine cooling system is constantly

pressurized with a valve in radiator’s filler

cap. Do not remove the cap with hot

engine. Always slowly turn the cap to

depressurize.

37. Be careful not to burn yourself when

discharging coolant or water from cooling

system, hot oil from engine, hydraulics or

transmission.

38. Be careful when servicing batteries –

spoiled electrolyte shall burn skin.

39. Avoid open fire close to the engine fuel

system and batteries to prevent explosion

hazard.

40. Keep tractor and its systems, particularly

brakes and steering, operable to ensure

personal safety for operator and

surrounding people.

41. Modifications to the tractor or its certain

components without prior approval by a

dealer and manufacturer are prohibited.

42. Remove filter mesh from fuel tank filler

neck to avoid fuel spillover when fueling

the machine up mechanically.

The filter mesh is provided for manual

fueling the tractor up in the field only.

43. Charge the tractor with oils and grease

recommended by the manufacturer only.

Application of other lubricants IS

STRICTLY PROHIBITED!

Safety regulations for electrics operation

and maintenance

44. Adhere the following safety regulations to

prevent damage to semiconductor devices

and resistors:

• Never disconnect battery terminals with

running engine – that would cause voltage

crest in charging circuit and damage to

electric devices.

• Never disconnect electric wires prior to

stopping the engine and turning all electric

switches off.

• Observe polarity when connecting wires

to the battery. Incorrect connection shall

lead to short-circuit and dama ge to electric

systems.

7

Page 8

• Do not connect AB to electric system until

IMPORTANT! Do not turn starter and

instrument switch prior to full engine stop.

terminals and voltage polarity is verified.

• Never check for current with “a spark”

method that causes damage to electrical

equipment and fuses and wiring burn-out.

• Do not operate the tractor without battery

installed in electric system.

Fire safety regulations

45. The tractor should be equipped with fire-

fighting equipment, particularl y with spade

and fire-extinguisher. Operating tractor

with no fire-fighting means is not allowed.

46. Areas for storing tractors and fuels and

lubricants should be rounded with not less

than 3 m wide ploughed strip and provided

with fire-fighting means.

47. Charge tractors with fuels and lubricants

mechanically with engine stopped. Use

light at nights. Try to avoid fueling tanks up

from buckets.

48. Clean parts and assembly units from plant

residues prior to perform repair with

electro-gas welding in the field.

49. Prevent manifold and exhaust pipe

clogging with dust, fuel, straw, etc.

50. Prevent straw winding round rotating

parts of machinery coupled to the tractor.

51. Take appropriate fire-safety measures

when rinsing parts and assemblies with

kerosene or gasoline to avoid vapors

ignition.

52. Never operat e the tra ctor in fire-hazardous

areas with removed bonnet and other

protective devices from hot engine parts.

53. Never use open fire to warm up oil in the

engine oil pan, when filling tanks with fuel,

or to burn radiator core contaminants out.

54. Emerging fire seats should be buries under

sand, covered with tarpaulin, bagging or

other compact material.

55. Avoid inflammable materials being close

to exhaust manifold and pipe with running

engine.

56. Apply silencer or separate spark

preventers in exhaust system when

harvesting hay or straw or working in areas

of high fire hazard.

8

Page 9

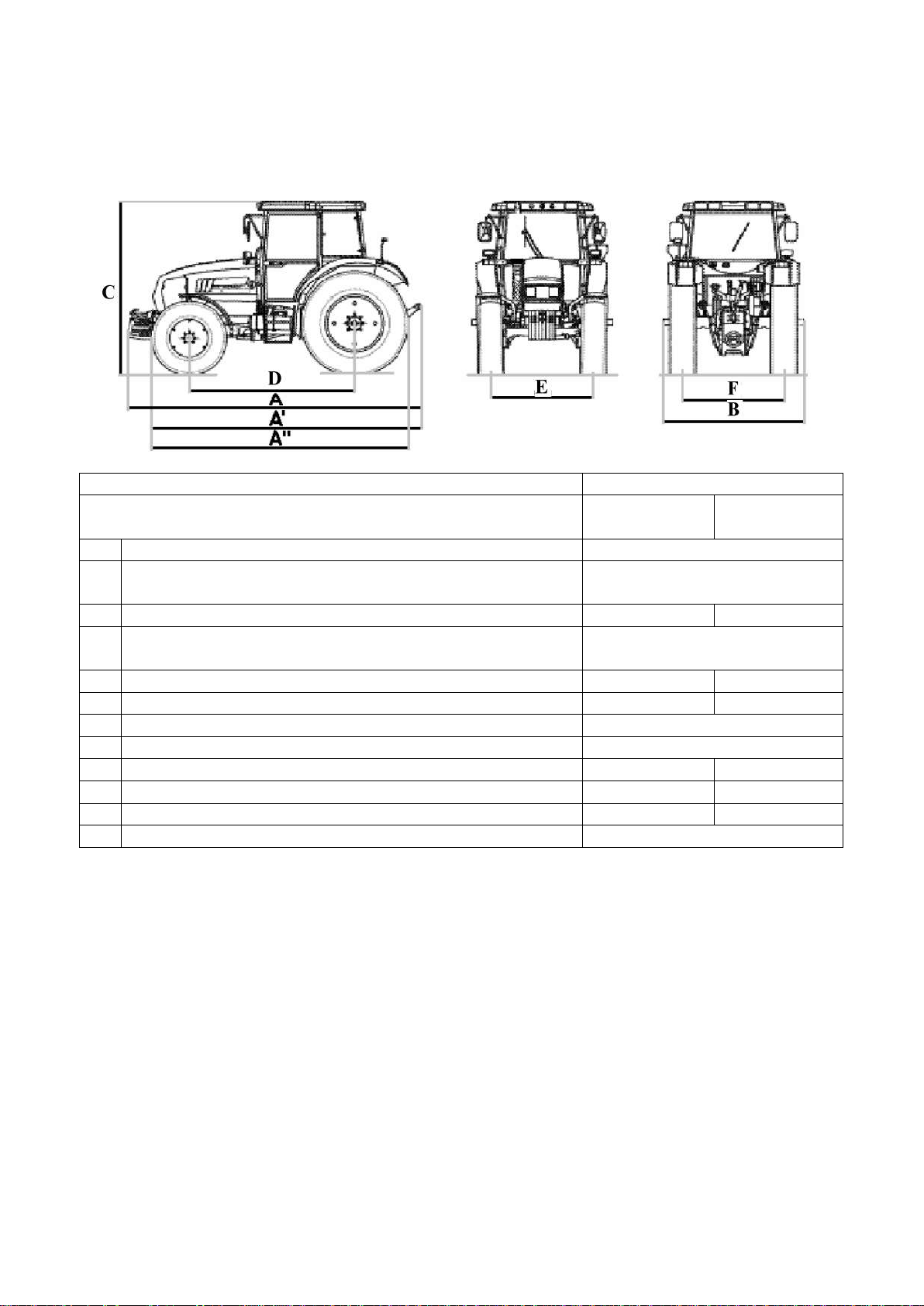

Parameters

Value

265/70R16 (f)

420/70R24 (r)

12,4L16 (f)

14,9R30 (r)

A

Length with loads and rig attachment, mm

4280

Length without loads with rig attachment in transporting

position, mm

A”

Length at overall wheels diameters, mm

3450

Width with front and rear rig attachment in transporting

position, mm

B

Width, mm

1550

C

Height, mm

2350

D

Wheel base, mm

2440

E

Front axle track, mm

1220-1420

F

Rear axle track, mm

1160-1585

Ground clearance under the rear axle, mm

257

Ground clearance under the front axle, mm

325

Delivery weight, kg

4000±100

Section 3. TECHNICAL SPECIFICATIONS

Overall dimensions and weight

Front and rear tires

A’

4225

4500

9

Page 10

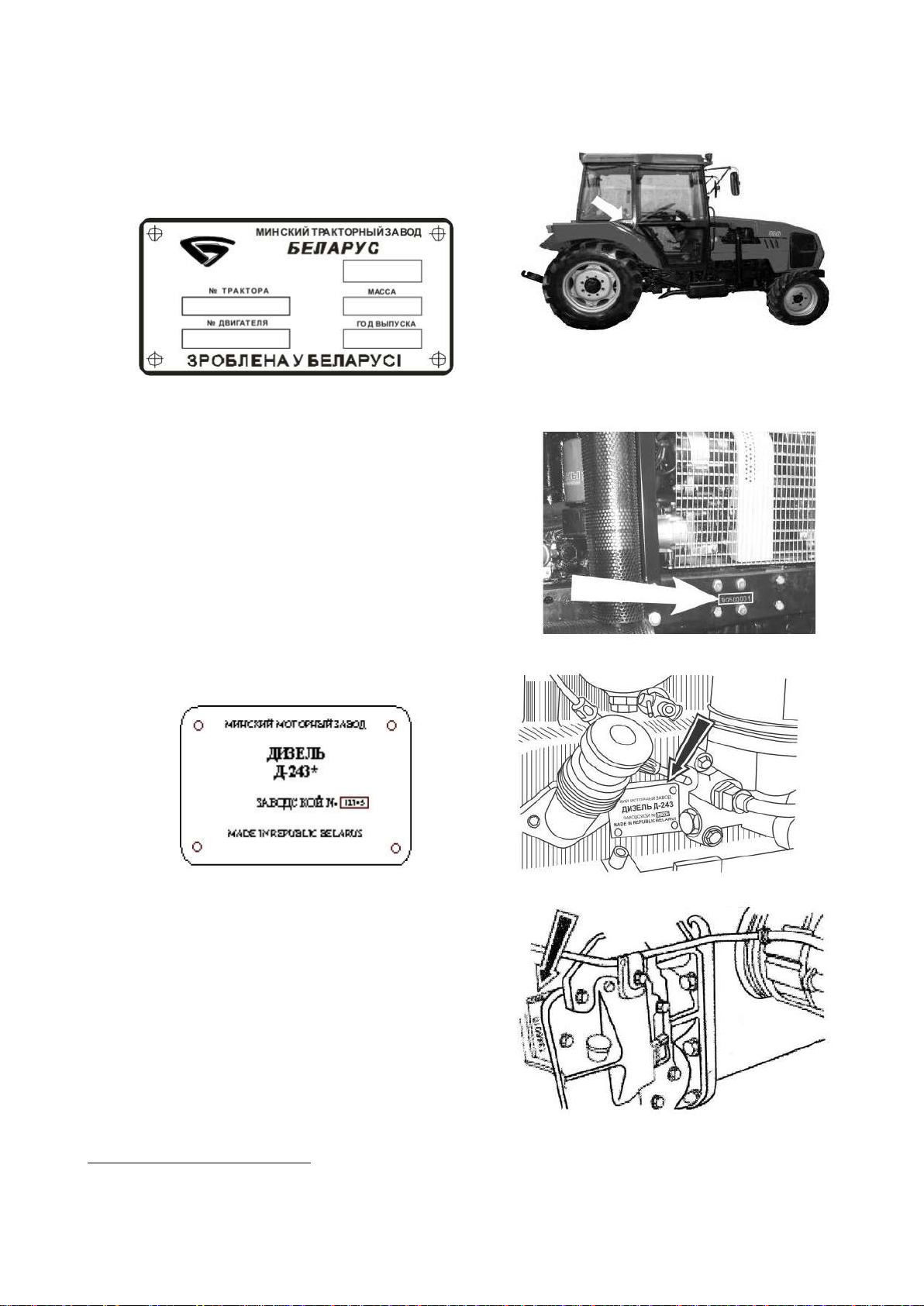

Tractor component numbers

Tractor’s nameplate with stated machine and engine

serial numbers (outside the right cab side).

Serial number of the tractor is repeated on the left rail

of the half-frame or at front loads plate.

Engine number (repeated at the en gine nameplat e fix ed

to the engine head).*

Gearbox number (at the left side of gearbox casing).

*

D-243.S for MTZ-821.2; D-245.43S2 for MTZ-821.3; D-245.5 FOR MTZ-921; D-245.5S for MTZ-921.2, D-245.5S2

for MTZ-921.3., D245.5S3A for MTZ-921.4

10

Page 11

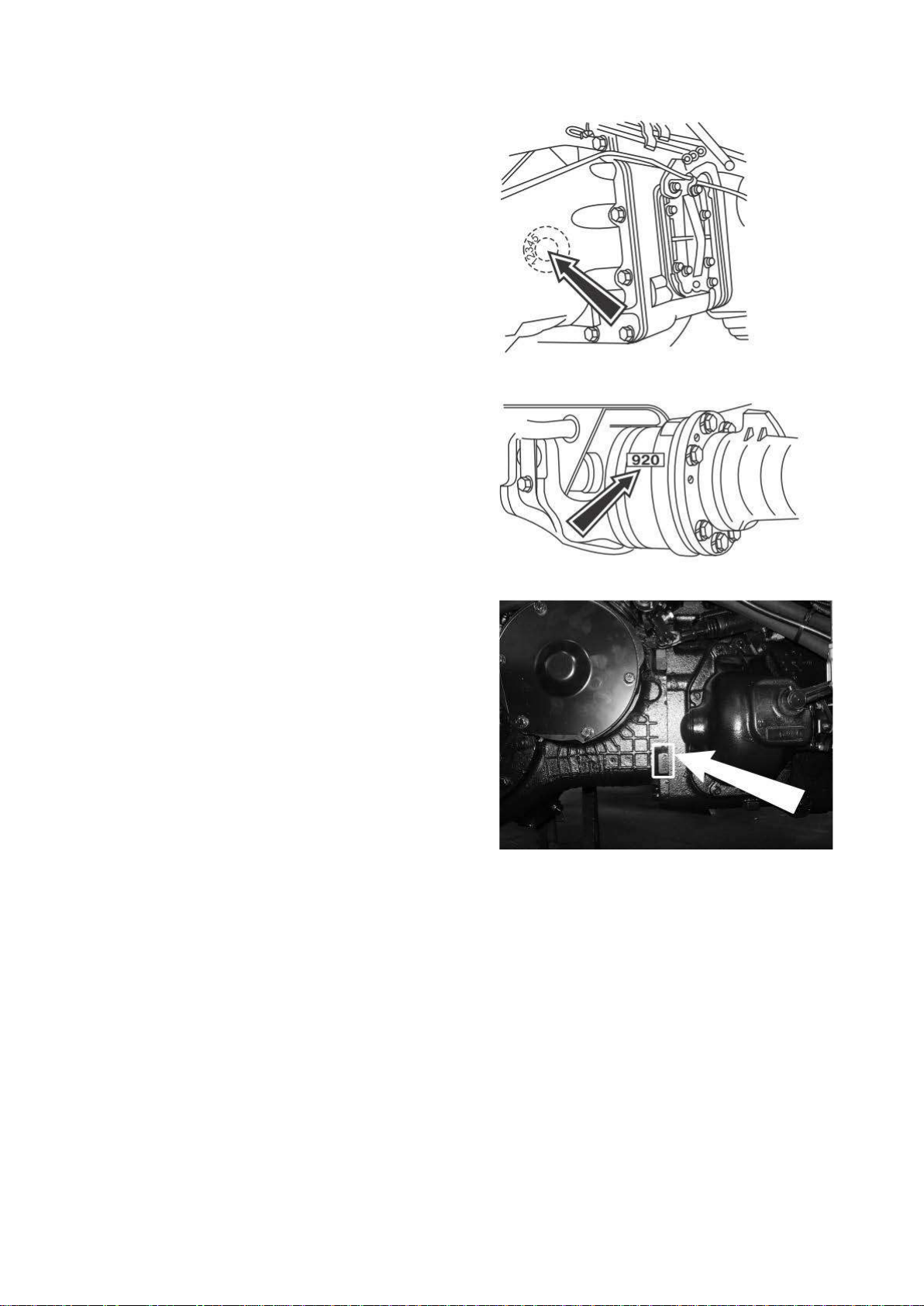

Friction clutch number (on the left side of clutch

casing).

Front driving axle number (on the left front side of

FDA casing).

Transmission number (to the right from rear view at

connection to gearbox).

11

Page 12

Diesel engine

D-243.S

D-245.43S2

D-245.5

D-245.5S

D-

921.3)

D-

921.4)

4-tact, in-line,

4 tact,

intercooler

4 tact,

er

4-tact, in-line, turbocharger,

Number of

pcs.

Carburetion

mode

Compression

(estimated)

Cylinder

diameter, mm

Piston stroke,

mm

Displacement

, l

Operation

sequence

Cooling

system

Rated speed,

rpm

Max. speed,

rpm

Min. speed,

RPM

Rated power,

kW

Max. torque,

Nm

411 (at 1400

RPM)

Lash between

rocker at cold

engine, mm

Fuel injection

UDP, deg.

Fuel injection

MPa

Model

Type

cylinders,

ratio

D-243

(MTZ-

821)

(MTZ-

821.2)

naturally aspirated

16±1 17±1 15±1 17±1

(MTZ-821.3)

in-line,

turbocharger,

Direct fuel injection

(MTZ-

921)

in-line,

turbocharg

4

110

125

4.75

(MTZ-

921.2)

intercooler

245.5S2

(MTZ-

245.5S3AM

(MTZ-

inlet (outlet)

valve and

lead angle to

2200 1800

2380 2070 1980 2070

600 800 700 800

60 62 65 70

298 (at 1400 RPM)

0.20-0.35

(0.20-0.35)

19-21 15-17 3-5

1-3-4-2

Water-cooled

397 (at 1000 RPM) 464 (at 1400 RPM)

0.15-0.30

(0.35-0.50)

(8-10)*

(7-9)**

3-5

pressure,

*

With fuel injection pump “Motorpal”

**

With fuel injection pump “Yazda”

21.6-22.4 23.5-24.7 21.6-22.4 23.5-24.7

12

Page 13

Diesel engine feed system

Fuel pump: 4-plunger, in-line, with boost

pump.

Regulator: mechanical all-mode.

Fuel filters: coarse filter and fine filter (with

replaceable paper filter element).

Turbocharger*: centripetal radial turbine on a

single shaft with centrifugal compressor. Type:

C14-126-01 (Czech Republic).

Fuel type: diesel:

Basic:

• L-0.2-40, L-0.2-62 (summer)

• Z-0.2 -35°C, Z 0.2 -45°C (winter)

• A-0.2 (up to -45°C)

Substitutes:

• L-0.5-40, L-0.5-62 (summer)

• Z-0.5 -35°C, Z 0.5 -45°C (winter)

• A-0.4 (up to -45°C)

Foreign:

• BS-2869, ASTM-D-VV-F-800 and other

(summer)

• DEF 2402B, SAE and other (winter)

• SAE VV-F-800 (up to -45°C)

Fuel tank capacity: 95 l.

Air filter: “Donaldson” with dry paper filter

element.

Engine lubrication system

Type: combined, with oil cooler (with water-

oil heat exchanger)**.

Oil filtering: prefilter mesh and fine

centrifugal filter (paper filter element)**.

Min. oil pressure: 0.08 MPa (0.8 kgf/cm2) at

600 RPM.

Normal oil pressu re: 0.25-0.35 MPa (2.5-3.5

kgf/cm2) at 1800 RPM.

Max. pressure at co ld engin e: up to 0.6 MPa

(6 kgf/cm2).

Refill capacity: 12 l.

Motor oil brands:

Basic:

+5°C to +50°C:

• M-10DM;

-40°C to +5°C:

• M-8DM;

Substitutes:

*

Not for MTZ-821.

**

For MTZ-821.3/921.3.

+5°C to +50°C:

• M-10G2k;

-40°C to +5°C:

• M-8G2k;

Foreign:

+5°C to +50°C:

• Shell, Rotella, TX 30, HESSOL and other;

-40°C to +5°C:

• Shell, Rotella, ТХ 20W/20, HESSOL and

other;

Friction clutch

Type: friction, dry, single-disk, with

tangentially suspended pressure plate. Plate

diameter – 340 mm.

Drive: hydrostatic with suspended pedal.

Engine cooling system

Type: water-cooled, closed, with forc ed water

circulation, with temperature control by

thermostat.

Normal operating temperature: 75°C to

95°C.

Thermostat: TS-107.

Cooling system capacity: 17 l (19 l) **.

Coolants:

Basic:

• OJ-40, OJ-65.

Substitute:

• Tosol A40M, Tocol A65M.

Foreign:

• MIL-E-5559, FL-3 Sort, S-735.

Steering

Type: hydraulic displacement with hydraulic

cylinder in steering trapezium.

Pump performance:

31 l/min for MTZ-821/821.2;

25 l/min for MTZ-

821.3/921/921.2/921.3/921.4.

Hydraulic cylinder: double-acting, cylinder

diameter 50 mm, piston stroke 250 mm.

13

Page 14

Metering pump: volumetric constant 160

cm3/turn, operating pressure up to 14 MPa.

Installed at front cab side.

Steering column: stepless height adjustment

within 100 mm.

Inclination adjustment: 25° to 40° with 5°

pitch. Steering wheel free move up to 25°.

Gearbox

Type: 18x4, mechanical, fixed-ratio, dual-

ranged, sliding gear transmission. 14x4

synchronized at request.

Multiplier

*

Type of both assemblies: mechanical with

direct and 1.36 step-up gears at multiplier and

direct and 1.32 step-down gears at back gear.

Form 18 forward-driving and 4 rearwarddriving gears.

*

Back gear for MTZ-821/821.2.

14

Page 15

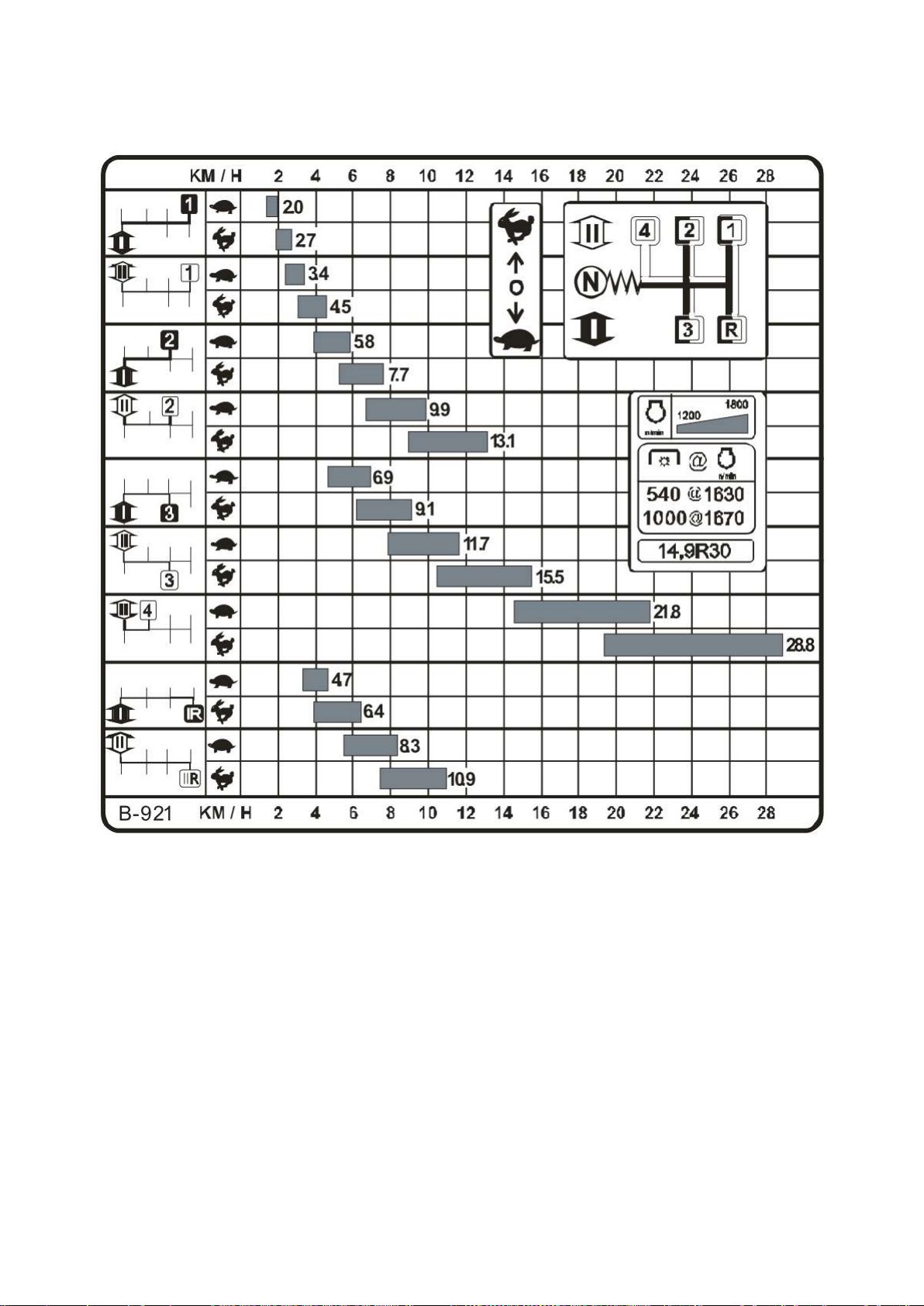

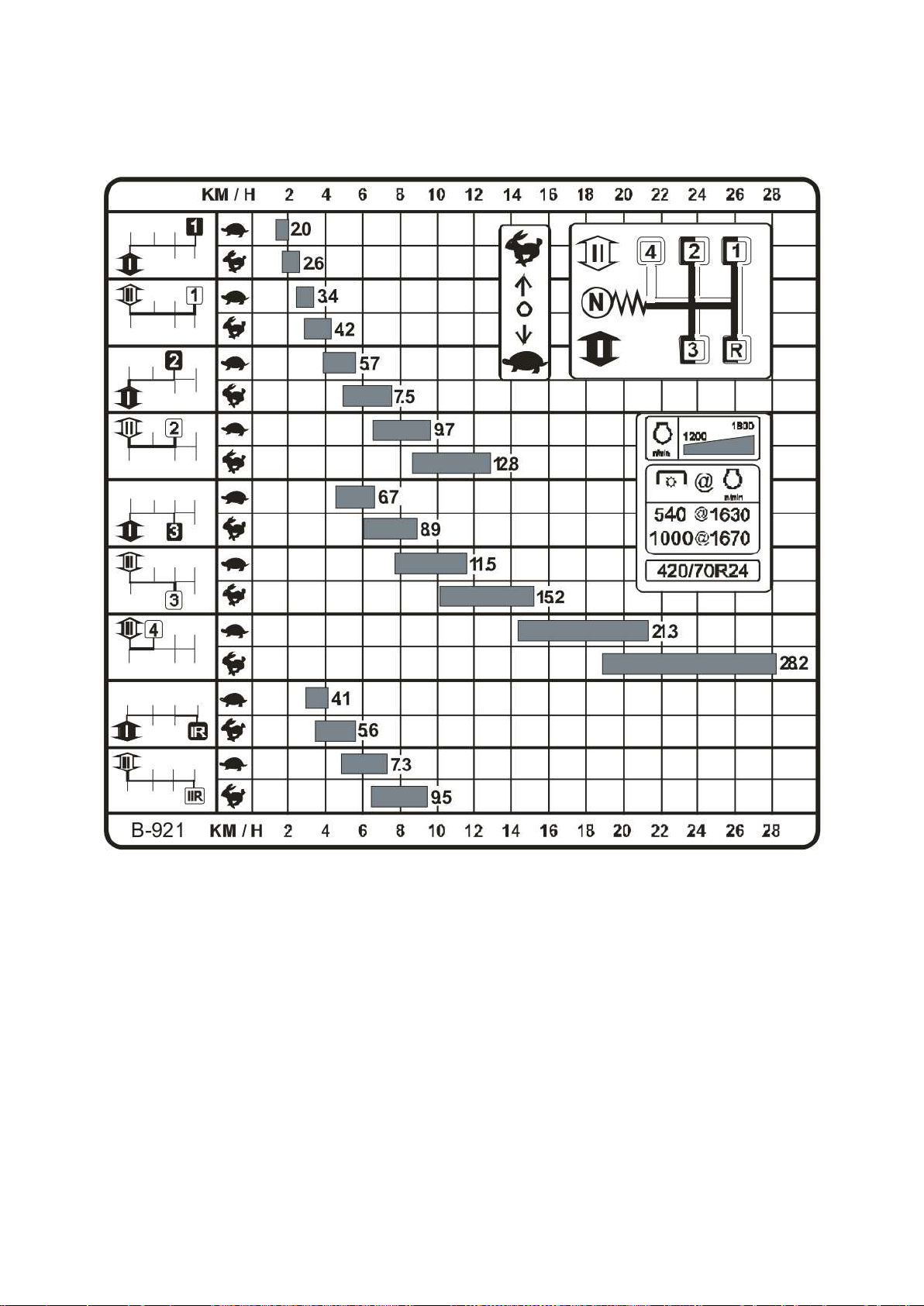

Estimated tractor speeds in km/h at rated diesel engine cranksh aft speed 1800 RPM (GB – 9/2 +

multiplier; rear tires 14.9R30). MTZ-821.3/921/921.2/921.3/921.4.

15

Page 16

Estimated tractor s peeds in km/h at rated diesel engine crank shaft speed 1800 RPM (GB – 9/2 +

multiplier; rear tires 420/70R24). MTZ-821.3/921/921.2/921.3/921.4.

16

Page 17

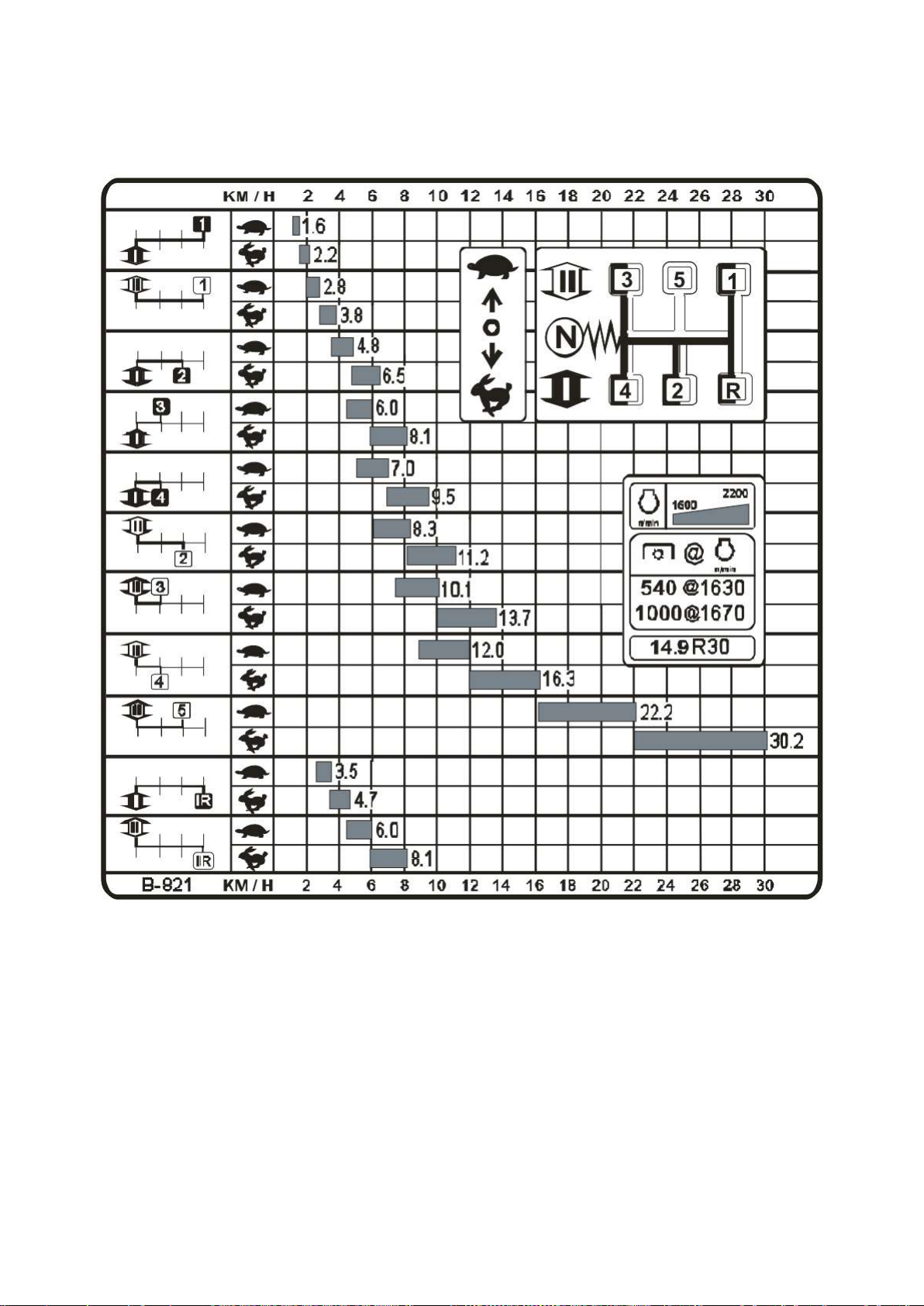

Estimated tractor s peeds in km/h at rated diesel engine crank shaft speed 2200 RPM (GB – 9/2 +

back gear; rear tires 14.9R30). MTZ-821/821.2.

17

Page 18

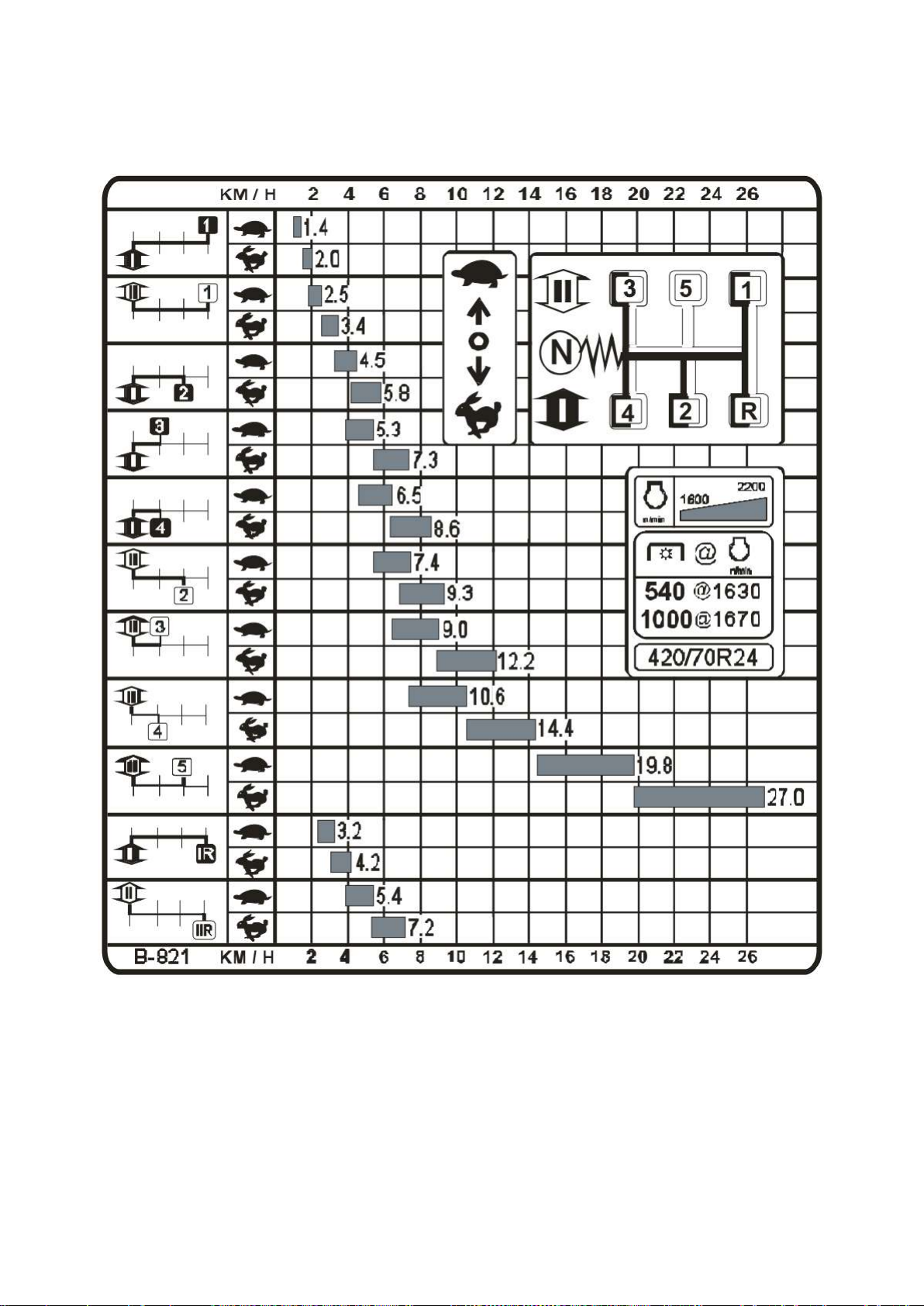

Estimated tractor speeds in km/h at rated diesel engine crankshaft speed 2200 RPM (GB – 9/2 +

back gear; rear tires 420/70R24). MTZ-821/821.2.

18

Page 19

IMPORTANT!

e. Contact

workshops with specially trained personnel to dismount and repair tires.

Permissible load

change, ±%

Drive axle

8*

+40

20

+20

25

+7

30 0 35

-10

IMPORTANT! Use appropriate front and rear tires. Correctly chosen front and rear tires ensure

kinematic discrepancy and excessive tire wear.

Front tires

265/70R16

12.4L16

14.9R30

-

+

420/70R24

+

-

Tire

Load on tire, N (kgf) at internal pressure kPa (kgf/cm2) at 30 km/h

80

(0.8)

100

(1.0)

120

(1.2)

140

(1.4)

160

(1.6)

180

(1.8)

200

(2.0)

4900

(500)

5586

(570)

6272

(640)

6958

(710)

7644

(780)

8330

(850)

9015

(920)

5684

(580)

6566

(670)

7252

(740)

7939

(810)

8673

(885)

9359

(955)

9996

(1020)

14700

(1500)

15729

(1605)

17297

(1765)

18865

(1925)

19943

(2035)

13328

(1360)

14798

(1510)

16317

(1665)

17689

(1805)

19110

(1950)

1. Never exceed tire pressure recommended by the manufacturer.

2. Do not perform welding or other repair works on a disk with pressurized tir

Table of permissible tire load changes relative to tractor speed:

Max. permissible

speed, km/h

maximal performance, elongate tires service life and reduce powertrain components wear.

Combination of worn and new tires or tires with different diameters or rolling radiuses may result in

Tire combinations:

Rear tires

Permissible loads on tractor tires in relation to tire pressure:

265/70R16

12.4L-16

420/70R24

14.9-30 -

- -

-

To get optimal operational parameters set tire pressure within ranges from minimal to maximal in

relation to actual loads acting on tires and speed according to tables.

For machines requiring dig tractive effort set pressure as for 30 km/h.

*

Increase tire pressure by 25%.

19

Page 20

Ambient temperature

Calcium chloride proportion, g/l of water

Up to -15°C

200

Up to -25°C

300

Up to -35°C

435

Tire

Quantity of liquid to put in, l

14.9-30

190

420/70R24

170

ATTENTION: Preparing a mix for ballast liquid always add calcium chloride to water and keep

stirring until it is completely dissolved. Use goggles when preparing a mix. In case of the mix

the eyes with cold clean water within 5 minutes and call for medical care as

soon as possible.

Ballast liquid

Additional wheel loading by filling wheel tubes with liquid is applied in case of insufficient wheel

traction to the ground in adverse conditions (overwet soils, etc.).

Note: it is preferably not to ballast from wheels as it affects tractor steerability.

In cold weather we reco mmend using calcium chloride and water mix according to the following

table:

Application of such a mix ensures low freezing point, increased solution density and safe and

efficient ballast. A tire should be filled with liquid up to 75% of its volume. While filling up with

liquid the tire valve should take the highest position.

The following table provides quantities of liquid to put in:

contact to eyes rinse

20

Page 21

Rear axle

Main gear: pair of bevel circle-arc toothed

gears.

Final drives: pair of straight gears.

Differential locking mechanism: mechanical

with manual control (for operator’s left hand).

Brakes

Main brakes: rear wheels, twin-disc, dry,

hydrostatically-driven, with suspended pedal.

Parking brake: combined with main brakes,

with independent mechanical actuator.

Front driving axle

Type: portal.

Main gear: bevel circle-arc toothed gears.

Differential

Type: self-locking, limited-slip.

Final drives: two-support reduction gears

with bevel gearing.

Recommended transmission oils:

Basic:

• Tap-15V

Substitute:

• TSp-15K, TSp-10, TAD-17I

Foreign:

• HESSOL, BECHEM, HYPOID

Drive: from transfer box by two cardan shafts

with intermediate support.

FDA control: mechanical.

Operation modes:

• FDA off;

• FDA on forcedly;

• FDA on/off automatically.

PTO drive

Type: independent two-speed synchronous.

Master clutch: planetary reduction gear with

band brake.

PTO control: mechanical.

PTO end rotation speed:

Independent drive:

I – 540 RPM for PTO at 1631 (2081)* RPM

for engine;

II – 1000 RP M for PTO at 1673 (2184)** RPM

for engine.

Synchronous drive:

• 3,90 rotations per path meter with

synchronous drive (tires 14.9R30);

• 4,45 rotations per path meter with

synchronous drive (tires 420/70R24).

PTO end: 6- or 8-splined (540 RPM) and with

21 splines (1000 RPM).

Rotation direction: clockwise.

Hydraulic mounted system (HMS)

Type: remote-cylinder system with hydraulic

jack featuring two actuating hydraulic

cylinders built in the rear hitch. HMS ensures

height, power and combined control.

Hydraulic system outputs; two side and two

rear outputs (rear side output is linked to the

rear right output).

Oil pump

Type: gear pump delivery discharge rate not

less than 45 l/min at engine speed of 1800

RPM.

Hydraulic distributor: RP 70.

Type: running-through, three-sectional, four-

position.

Actuating cylinder: two plunger hydraulic

cylinders Ø80 mm, plunger stroke 220 mm.

Recommended oils for HMS:

• Motor oils: M-10G2 updated, M-8G2k, M-

10G2k;

• Industrial oil: BECHEM Staroil No.32,

HUNOLD Hydraulikoel HLP 32.

Hydraulic system oil tank capacity: 45 l.

*

For MTZ-821/821.2

21

Page 22

Pneumatic system

Compressor

Type: single-cylinder, piston-type, air-cooled.

Dimensions: 72x38 mm (diameter – 72 mm,

stroke – 38 mm).

Trailer brakes control

Type: pneumatic, single- or double-line,

blocked with tractor brakes.

Pressure: 6.5-8.0 kgf/cm2 (0.65-0.8 MPa).

Pressure limited with safety valve: 8.5-10.0

kgf/cm2 (0.85-1.0 MPa).

Rear rigging mechanism

Type: jointed four-section of Cat.2.

Load capacity: 25 kN (at 610 mm from

suspension axle.

Suspension axle adjustment from 680 mm to

870 mm at request.

Electric equipment

Vehicle network voltage: 12V.

Starting system voltage: 12V.

Battery: 12V, 2x90 A∙h (located on the upper

half-frame rail).

Feeding system: on e 12V battery. 12V starter

feeding.

Generator: 12V, 1000W.

Starting aids*: glow plugs.

Lighting and warning light system

• Front embedded road headlamps with

upper and lower beams;

• Front and rear operation lights;

• Front and rear lights;

• Alarm lights;

• Tractor-and-trailer lights;

• Beacon light.

Tires

Front: 12.4L16; 265/70R16.

Rear: 14.9R30; 420/70R24.

*

For MTZ-821.3/921.3.

22

Page 23

Section 4. GENERAL INFORMATION. TRACTOR LAYOUT AND OPERATION

Garden-and-vineyard tractors MTZ-821,

MTZ-821.2, MTZ-821.3, MTZ-921, MTZ-

921.2, MTZ-921.3 and MTZ-921.4 are

versions of universal cultivating tractor MTZ922 and have the following distinctive

features:

• Independent fuel tank for 95 l loc ated near

the left cab footboard;

• Gearbox – mechanical, with two operation

modes (synchronized 14x4 at request);

• Hydraulic system oil pump actuator

located to the right from clutch casing;

• Rear ax le dif ferential lock – is mechani cal

with two operation modes:

1. Lock

2. Forced lock

Locking clutch is splined.

• Front driving axle featured with two-

support bevel reducing gears;

• Rear PTO is mechanically controlled.

Tractor frame consists of half-frame, friction

clutch casings, gearbox and rear axle.

Diesel engine is rigidly fixed to the friction

clutch casing through the rear plate and is

mounted onto the front rail with hinged

bearing.

Following powertrain components are located

behind the engine:

• Single-disk friction clutch;

• Mechanical 9/2 gearbox with gear-change

lever to the right. Mechanical multiplier*

(step-up gear) is locat ed bet ween clu tch and

gearbox to double numbers of forward and

rearward gears. The multiplier is controlled

with a lever at the left operator’s hand;

• Rear PTO with 2-speed independent and

synchronous drives. PTO is engaged and

disengaged with a lever at the right

operator’s hand;

• Front driving axle (FDA) with two-

support bevel reduction gears has increased

load-carrying capacity due to bevel roller

bearings into the reduction gear pivot

supports.

FDA drive consists of a transfer box,

intermediate and front cardan shafts and

intermediate bearing with multidisc wet

friction clutch. FDA is driven by the

secondary gearbox shaft to ensure

synchronic rotation of the front and rear

wheels at every gear. FDA is mechanicall y

controlled by a lever with three fixed

positions: “FDA on”, “FDA on/off

automatically” and “FDA on forcedly”.

FDA is conn ected to a beam by two hollow

axles allowing the axle with wheels to

swing transversely.

• Parking brake includes main brakes with

independent mechanical control.

Hydraulic rigging system consists of a

hydraulic jack with two vertical cylinders and

embedded regulator, of a rigging mechanism

and a distributor to control external consumers

(external cylinders).

Hydraulic jack performs the following

functions:

• Tractor suspension lifting up and down

with its dead weight;

• Automatic lifting suspension down to the

set position relative to the tractor

(positioning adjustment);

• Adjusting ploughing depth according to

soil resistance (force adjustment);

• Ploughing depth force adjustment with

positionally limited maximal depth

(combined adjustment);

• Automatic pump discharge in transport

condition.

The hydraulic jack is controlled with two

handles of force and positioning adjustment,

accordingly.

Force adjustment handle is the closest to the

seat at the side board. Its movement range

corresponds to full ploughing depth range

from minimal to maximal.

Positioning handle is located to the right from

force adjustment handle. Its movement range

corresponds to suspension positions from the

lowest to the transport.

Distributor is of flowing through type without

bypass valve. Is consists of 3 sections, each

having four positions: “neutral”, “lifting up”,

“lifting down”, and “floating”.

The tractor is equipped with pneumatic system

to control braking systems of trailers in single-

*

Back reduction gear (back gear) for MTZ-821/821.2.

driven mode.

23

Page 24

Towing coupler: double crossbeam (ТСУ-

1Ж-01) is united with rear digging mechanism

into a single assembly unit. At request a single

crossbeam may be mounted meeting DIN

requirements and fixed on the lower rod jaws.

Tractor cab is safe and comfortable.

The cab is equipped with venting and heating

system with air intake through filters over the

side windows. Design of filters in venting

system allows its partial self-cleaning in

motion.

Naturally the cab is vented through a hatch in

the roof and opening rear and side windows.

The cab is equipped with a comfortable seat

with mechanic suspension and hydraulic

damper (the seat is adjusted per operator’s

height and weight). Steering wheel is located

right in front of the seat and may be thrown

over to ease getting into and out of the cab.

The steering wheel is height-adjusted by 100

mm.

Control station is designed to ensure comfort

working conditions for operator and as

convenient tractor control as possible.

Instrumental board with fundamentally new

electric dashboards and electronic tachospeedometer are located on the steering

column, cable-driven fuel supply control

handle is located at the right wing of the

dashboard, gearbox control arm is located to

the right, hydraulic jack control arms are

situated at the right control board, parking

brake control lever is located to the left, rear

PTO control arm is situated at operator’s right

hand, multiplier control arm is located to the

left from the dashboard, distributor control

arms are located to the right from operator’s

seat. A board with (from the left to the right)

heater, front and rear working lights, rear

window washer and wiper switching keys.

Electric circuit fuses block is situated near the

board under a cover. Rear-view mirrors are

located on both sides of the cab. Additional

working lights are mounted on the roof.

Tractor design allows installation of additional

process equipment (available at request) and

extra loads.

24

Page 25

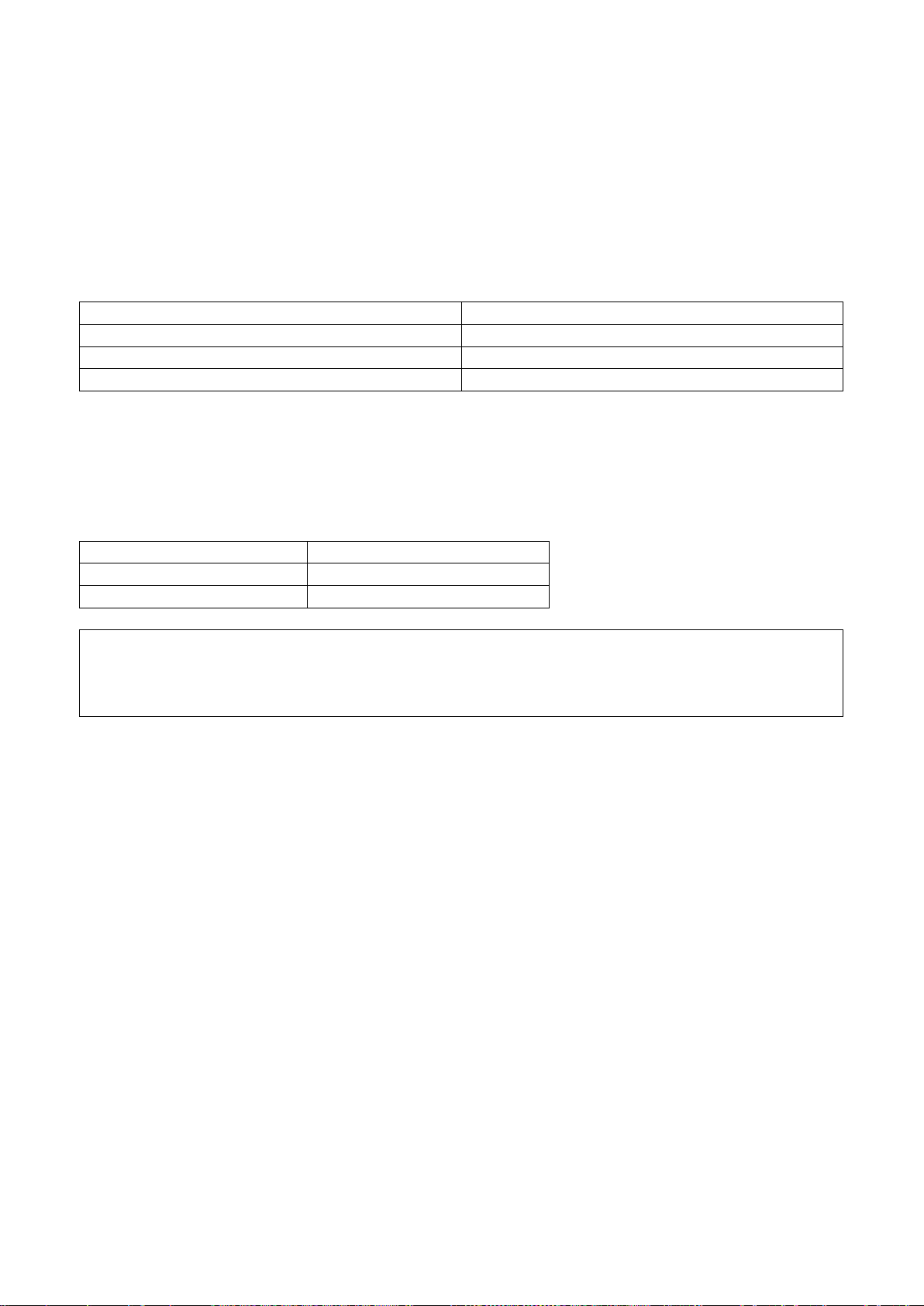

Section 5. CONTROLS AND INSTRUMENTS

1. Switch for working lights at front brackets

2. Starter and instruments switch

3. Turn indicators, upper and lower beam and horn switch

4. Multiplier (step-up gear) switching handle

5. Engine stop knob

6. Remote ground switch

7. St eeri ng wheel

8. Front screen washer and wiper switch

9. Fuel supply control arm

10. Alarm lights switch

11. Central light switch

25

Page 26

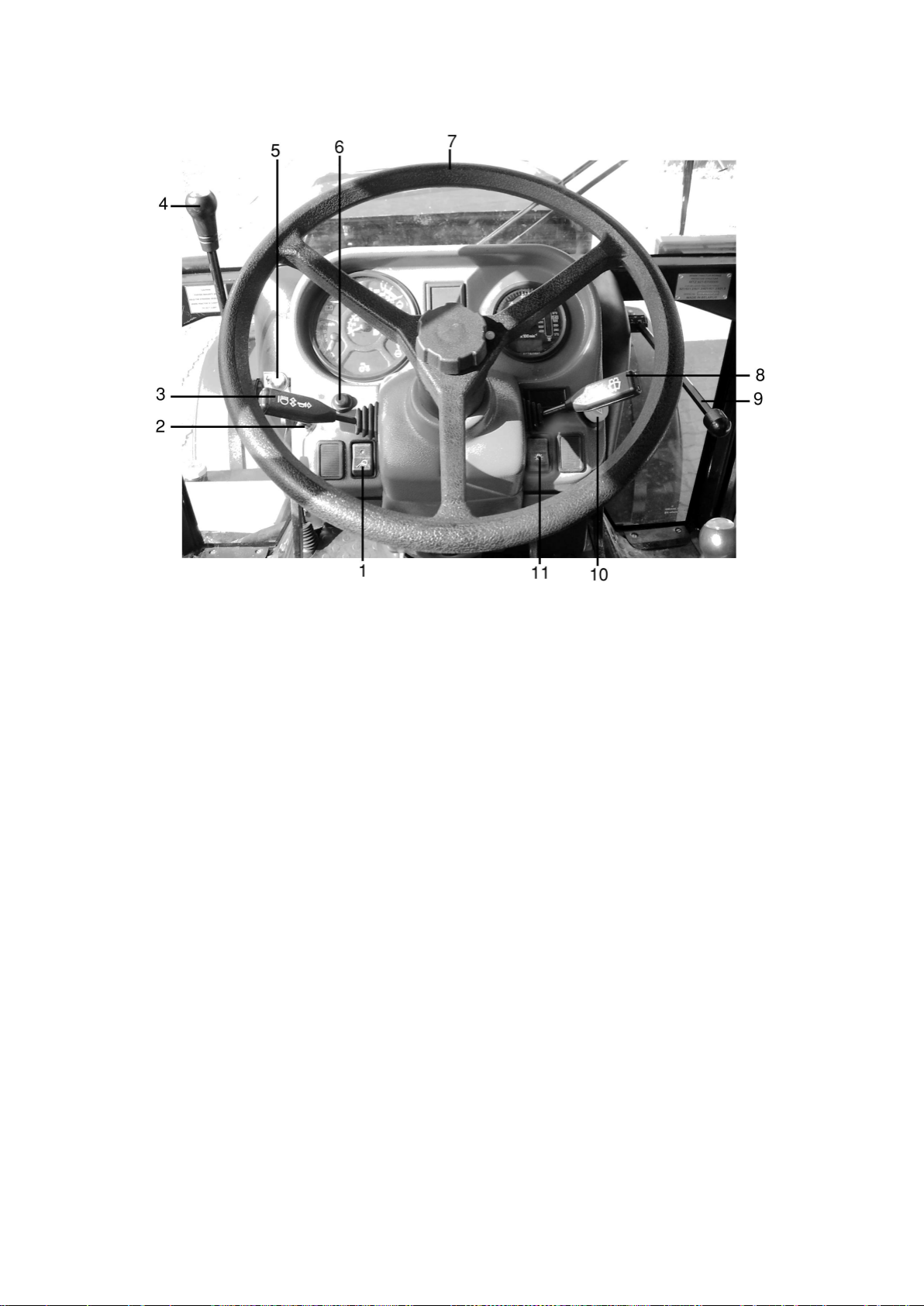

12. Voltage indicator

13. Engine coolant temperature indicator

14. Pneumatic system pressure indicator

15. Fuel tank level indicator

16. Engine oil pressure indicator

17. Control lights block

18. Tacho-speedometer

19. Radio or audio receiver (if any)

20. Recirculating flaps

21. Heater, front and rear working lights, rear screen washer and wiper keys board

22. Sun visor

23. Air deflector

24. Clutch pedal

25. Steering wheel inclination control rod

26. Brake pedals

27. Fuel supply control pedal

28. Heater, front and rear working lights, rear screen washer and wiper circuit fuse block cover

29. Cab lamp

26

Page 27

Fuel supply is controlled with a handle (9) or

IMPORTANT! To control with a pedal (27)

set the handle (9) to the middle position.

IMPORTANT! For synchronized multiplier*

(1) ON and OFF positions are reversed.

NOTE!

stable engine speed with pressed clutch

(1) lever has no fixed

position is allowed in winter to aid engine

start only.

INPORTANT! Activate the pump at low idle

cold engine start or for maintenance.

pedal (27) (see fig. at page 5-1). Moving the

handle up (push) increase fuel supply and

engine speed, and vice versa.

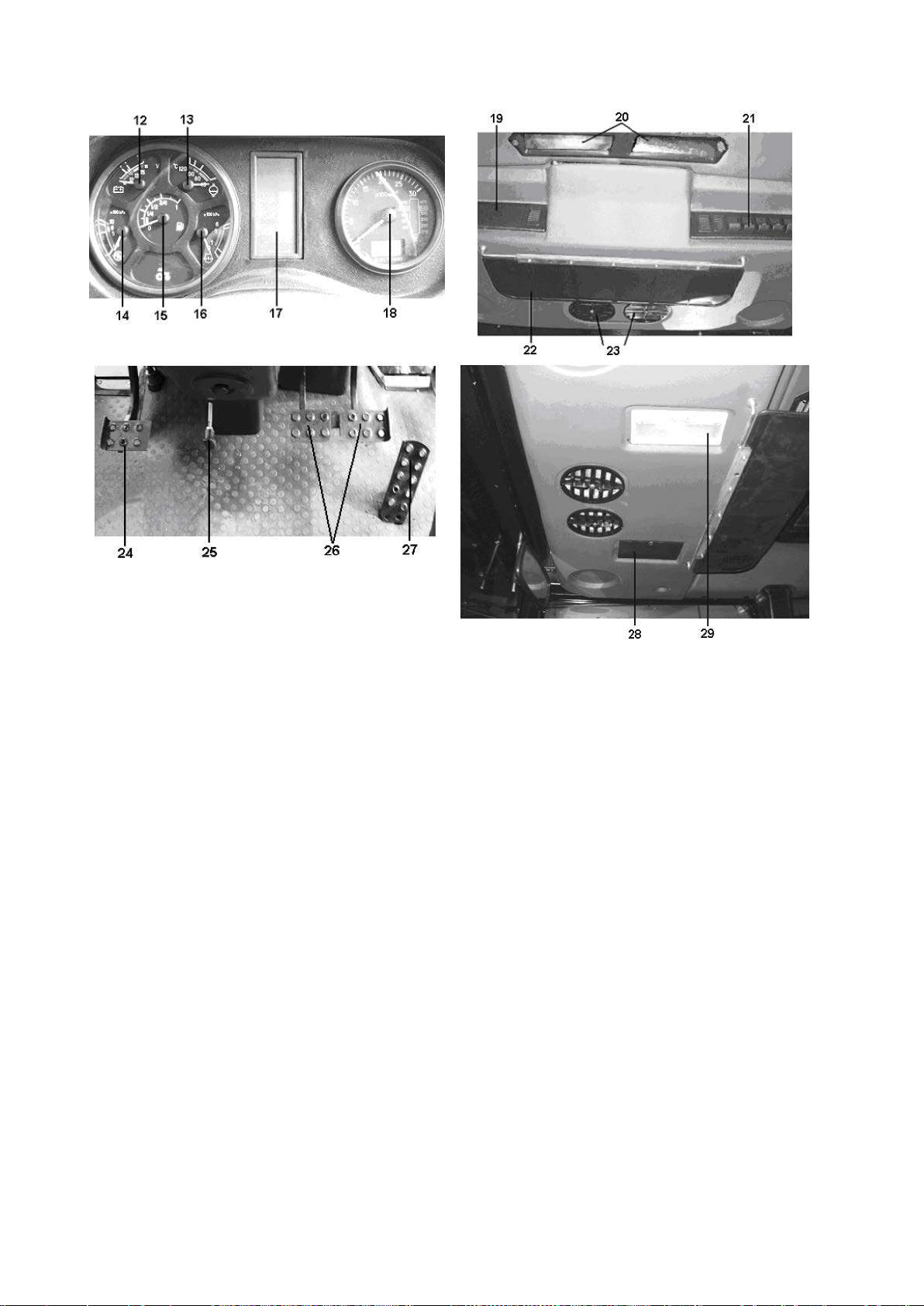

Multiplier* is contro lled with a lever (1) with

two fixed positions:

• ON – most rear position (pull).

• OFF – most forward position (push)

(direct drive).

1. The multiplier* (1) is switched at minimal

pedal.

2. The multiplier*

neutral position. Setting it to the middle

Rear axle differenti al lock is controlled with

a handle at the left operator’s hand.

Move the handle fully up to lock the

differential. The differential is locked

automatically after the handle is released.

Gearbox is controlled with a lever (N) as

follows:

• Chose required range (I or II) by turning

the lever from neutral to the most left (pull)

and pushing it forward or pulling back to

engage required range. Return the lever to

neutral position;

• Select required gear according to

switching layout and engage.

*

Back gear for MTZ-821/821.2.

run of the engine only. Turn the pump off for

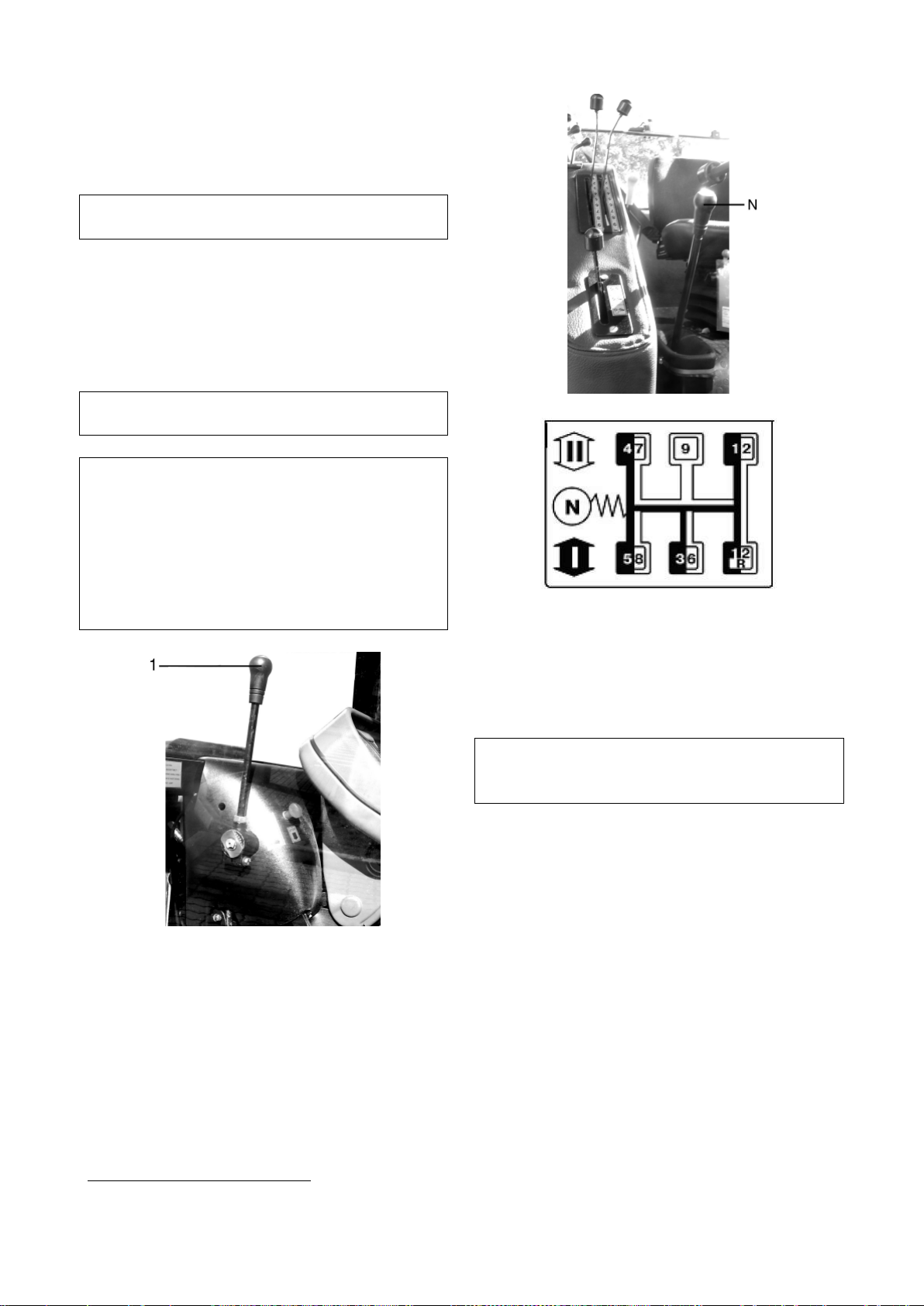

Rear PTO control

Independent and synchronous drives switching

handle.

The handle (2) has three positions:

• “Independent drive ON” – utmost up

position;

• “Drive OFF” – middle position;

• “Synchronous drive ON” –lowest

position.

Engage independent and synchronous drives at

lowest stable engine speed.

To engage synchronous drive:

• Start the engine;

• Fully press clutch pedal and engage 1st

gear;

27

Page 28

• Slowly release the clutch pedal and

INPORTANT! Synchronous PTO drive shall

km/h only. Otherwise the tractor’s powertrain

Set the handle (2) to the middle position

not using PTO.

simultaneously move the handle to the

lowest position.

Two-speed independent PTO drive switch

Independent PTO drive lever (2) has two

positions:

• I – 540 RPM – fully clockwise (down

view);

• II – 1000 RPM – fully counterclockwise.

To set required PTO end rotation speed loosen

bolt (1), turn the lever (2) to I or II position

and tighten the bolt (1).

be use at lower gears at speed not ex ceeding 8

may be badly damaged.

“Drive OFF” and replace PTO end cap when

Parking brake control arm

• Upper position of lever (4) – parking

brake ON;

• Lower position of lever (4) – parking

brake OFF.

To disengage the parking brake press button

(3) of the control arm and press the lever fully

down.

Turning rear PTO on and off

Rear PTO is controlled with a lever (3) with

two positions:

• PTO ON – utmost rear position;

• PTO OFF – utmost forward position.

Compressor control

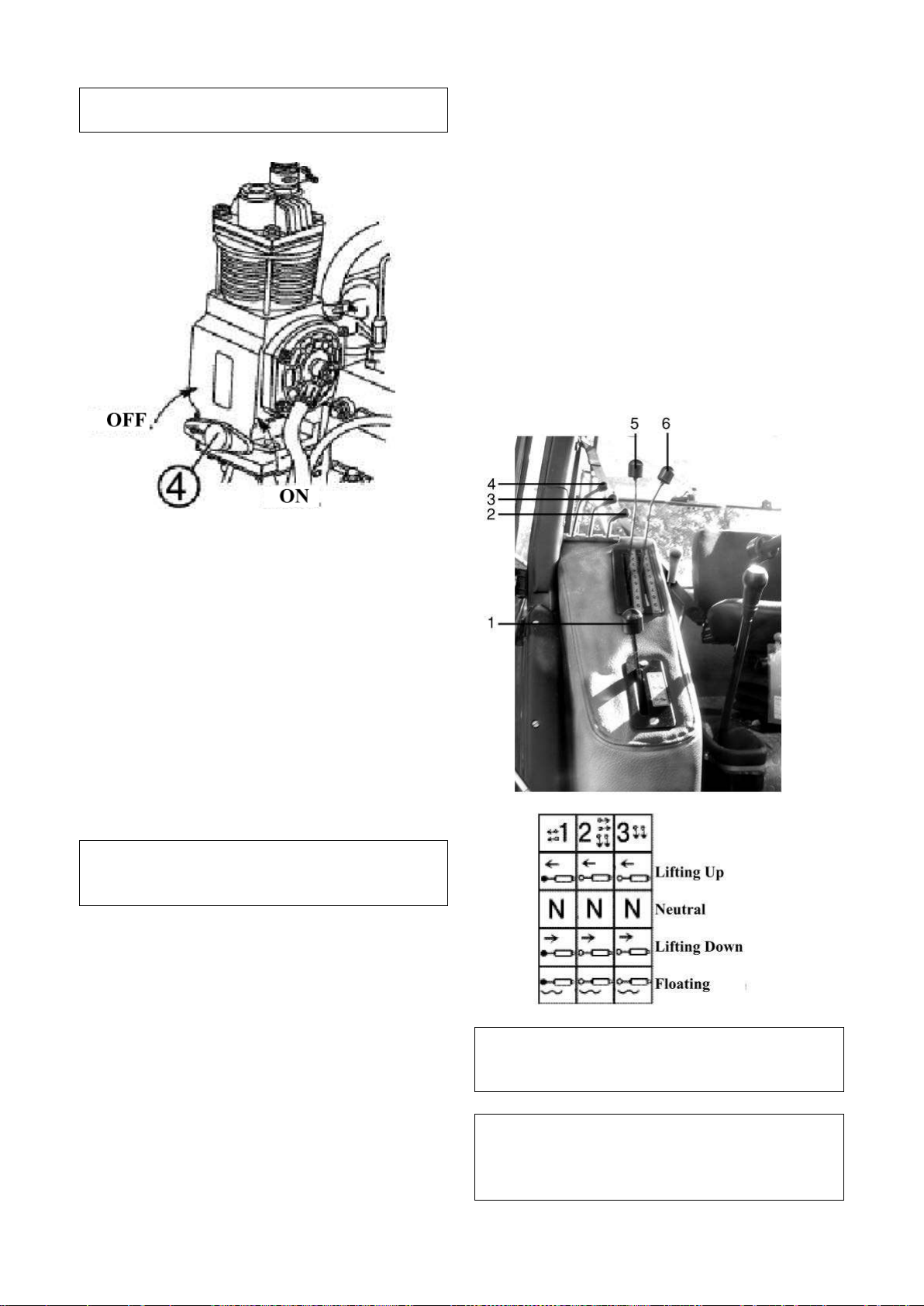

The handle (4) has two positions:

• Compressor ON – turn the knob by 180°

to orient an arrow at the knob against

tractor driving direction;

• Compressor OFF - turn the knob by 180°

to orient an arrow at the knob along tractor

driving direction.

28

Page 29

ATTENTION! Switch the compressor with

engine stopped or low idling.

IMPORTANT! Set lever (1) to “FDA ON

forcedly” position to operate tractor without

cardan shafts.

NOTE! Handles (5, 6) allow combined

(5) and control by handle (6).

IMPORTANT! Hydraulic jack cannot be

(2, 3, 4) in Lifting Up or Lifting Down

position.

FDA drive control

PMV drive transfer box control arm (1) has

three fixed positions:

• FDA OFF – upper position. Used for

driving hard roads;

• FDA ON/OFF automatically – middle

position. FDA is automatically switched on

and off by freewheeling clutch depending

on rear wheels slippage. Used for various

field works;

• FDA ON forcedly – lower position. Used

briefly for performing works on loose or

wet soils and, if necessary, at backing.

• Most rearward – transporting position.

Hydraulic system distributor control

Each of three levers (2, 3, 4) controls external

cylinders and has four positions:

• Neutral – upper middle position (fixed);

• Lifting Up – upper non-fixed position.

Released handle returns to Neutral (lever

(4) has fixed Lifting Up position);

• Forced Lifting Down – lower middle non-

fixed position between Floating and Neutral

positions. Released handle automatically

returns to Neutral;

• Floating – lower fixed position.

RH jack control

Hydraulic jack is controlled with two arms (5,

6) at the right board for the right operator’s

hand.

Force adjustment handle is located closer to

the operator and has the following positions:

• Most forward – maximal tillage depth;

• Most rearward – minimal tillage depth.

Positioning adjustment (5) handle has the

following positions:

• Most forward – minimal tool height over

the ground surface;

adjustment with tilting depth limited by handle

controlled with arms (5, 6) with any of handles

29

Page 30

Indicators and switches

Starter and indicators switch (1)

Has four positions:

• 0 – “OFF”;

• I – “Indicators and control lights block

ON”. Oil pressure alarm lights at engine oil

pressure indicator (16), page 5-1, and alarm

buzzer sounds;

• II – “Starter ON” (non-fixed position).

Control light and alarm buzzer go off after

engine is started;

• III – “Radio feeding”. Turn the key

counterclockwise.

Remote AB switch (2)

The switch is on with button (2) pressed.

Repeated pressing switched the battery off.

Central light switch (3)

Has three positions:

• I – OFF (right part of the key is recessed);

• II – Front and rear sidelights, license plate

lighting, dashboard instruments lighting and

additional lights at trailed machi ne are ON

(middle position);

• III – All consumers od position II and

road lights are ON (left part of the key is

recessed).

Understeering switch (left) (1)

Allows switching on turn indicators, switching

between upper/lower beam of headlamps,

upper beam signaling, horn activation.

Turn indicators are switched by moving the

arm forward/rearward.

Lower/upper beam of headlamps

To light headlamps on set the central light

switch (1) to position III (see above) and set

the switching arm to the middle position

“Lower Beam”. Upp er beam is activated with

pushing the switching arm to stop. Arm

positions for upper and lower beams are fixed.

To blink with upper beam pull the arm to stop

from Lower Beam position regardless the light

switch position.

Understeering switch (right) (2)

Allows switching-on windshield washer and

wiper at 1st (low) or 2nd (high) speed.

Windshield wiper switch has three fixed

positions:

30

Page 31

• 0 – OFF

NOTE: The arm has to be manually returned

to OFF position.

Scale section,

color

Feeding system state

With running

engine

With stopped

engine

13.0 – 15.0 V

green

Normal charging

mode

10.0 – 12.0 V

red

Generator will

not operate

Discharged

battery

12.0 – 13.0 V

yellow

No AB charging

(

voltage)

Normal battery

charging

15.0 – 16.0 V

red

Overcharged

battery

White mark in

yellow section

Rated battery

voltage – 12.7 V

• I – Low speed

• II – High speed

Windshield washer is switched on by pulling

the arm up and simultaneous switching wiper

at the 2nd speed. The arm may be positioned

anyway.

Positions for switching windshield washer on

in not fixed, and the arm is returned to initial

position. To activate hor n pres s t he arm ax i al l y

in any switching arm position.

Dashboard

(1) Engine coolant temperature indicator

with alarm light

Indicator scale has three sections:

• Operating temperature – 80-100°C –

green;

• Not operating temperature (two) – 40-

80°C and 100-120°C – red.

(2) Engine oil pressure indicator with red

low pressure alarm light.

Indicator scale has three sections:

• Operating pressure – 100 kPa to 500 kPa –

green;

• Not operating pressure (two) – 0 kPa to

100 kPa and 500 kPa to 600 kPa – red;

• Pressure up to 600 kPa is permissible for

cold engine start. If the pressur e alarm ligh t

is on at running engine immediately stop it

and correct the fault.

(3) Fuel tank level indicator (with reserve

level alarm light).

The instrument has the following divisions:

0 – 1/4 - 1/2 - 3/4 – 1.

Never consume fuel to “empty tank” (with the

pointer in orange section).

(4) pneumatic system pressure indicator

(with pressure alarm light)

Indicator scale has three sections:

• Operating pressure – 500 kPa to 800 kPa –

green;

• Not operating pressure (two) – o kPa to

500 kPa and 800 kPa to 1000 kPa – red.

(5) Voltage indicator

Shows battery voltage with stopped engine and

with starter key in position I. with running

engine the indicator shows voltage at generator

terminals. Voltage indicator scale has the

following sections:

low charging

Tacho-speedometer

Electric tacho-speedometer at the dashboard

operates as follows:

• After stopping the tractor and turning

starter and indicators switch key to position

I display (7) shows engine working hours

(5);

• After starting the engine the pointer (8)

goes round the scale (1) to indicate engine

crankshaft rotation speed. The display (4)

shows PTO rotation speed (RPM). Scale (3)

is for PTO I, and scale (2) is for PTO II.

Electric signal of rotation speed is fed from

generator phase winding;

31

Page 32

• In motion display (7) indicates (6) tractor

speed (km/h), indication (5) disappears.

Speed electric signal is fed from speed

sensors on the rear axle caps.

1. Engine crankshaft rotation speed scale,

RPM.

2. PTO II rotation speed scale – 1000

RPM.

3. PTO I rotation speed scale – 540 RPM.

4. PTO rotation speed indicating display.

5. Engine working hours indication, h.

6. Tractor speed, km/h.

7. Engine working hours and tractor

speed indication display.

8. Engine crankshaft rotation speed

needle indicator.

Board with cab venting and heating system,

front and rear op erating lights, rear screen

washer and wiper switching keys.

Cab venting and heating system switch (1)

Is used to switch venting and heating system

fan on.

The switch has three positions:

• OFF;

• Low speed ON – light air feed;

• High speed ON – heavy air feed;

Front operating lights switch (2)

Press the key to light front operating lights on.

The key light will on.

First pair of rear operating lights switch (3)

Press the key to light the first pair of rear

operating lights on. The key light will on.

Second pair of rear operating lights switch

(4)

Press the key to light the second pair of rear

operating lights on. The key light will on.

Rear screen washer and wiper switch (5)

The switch has three positions:

• OFF;

• Screen wiper ON – fixed position;

• Screen wiper and washer ON – non-

fixed position.

Plugs (6)

For additional switches.

32

Page 33

Control lights block

Fuses

A fuse block is located under a cover (28), page 5-

1. Five fuses protect the following circuits from

overload:

1. Cab lamp (7.5 A)

2. Rear screen washer and wiper (7.5 A)

3. Two pairs of rear operating lights (15 A)

4. Headlamps (25 A)

5. Venting and heating system (25 A)

6. Beacon (15 A)

33

Page 34

WARNING! Never use fuses of higher rated cu rrent to prevent electric wires burn. Frequent fuse

burning requires fault investigation and elimination.

Two fuse blocks for BP-1 and BP-2 circuits are mounted under the dashboard. Unscrew bolt ( A)

under the steering column and remove casing (B) to access fuses. Twelve fuses protect the

following electric circuits from overload:

BP-2:

1. Road lights upper beam (25 A)

2. Horn (15 A)

3. Portable lamp socket (25 A)

4. Alarm lights (15 A)

5. Stop-light (15 A)

6. Windscreen washer and wiper (15 A)

BP-1:

1. Instruments feeding (7.5 A)

2. Turn indicators breaker (7.5 A)

3. Right road light lower beam (7.5 A)

4. Left road light lower beam (7.5 A)

5. Right side lights, instruments lighting

(15 A)

6. Left side lights (7.5 A)

34

Page 35

Connected electrics

IMPORTANT! Adjust the seat prior to

starting tractor operation. Stay present in the

seat while adjusting.

NOTE! Do not clean the seat upholstery with

lvents. Use warm water with small amount

of detergent only.

A standard multipurpose socket is provided for

connecting current consumers of a trailer or

towed agricultural machines. It is located

behind the rear cab panel. The socket is

connected to the plug of connected machine

harness.

Socket terminals are designated as follows:

1. Left turn indicator

2. Horn

3. Ground

4. Right turn indicator

5. Right side light

6. Stop-light

7. Left side light

8. Portable lamp socket

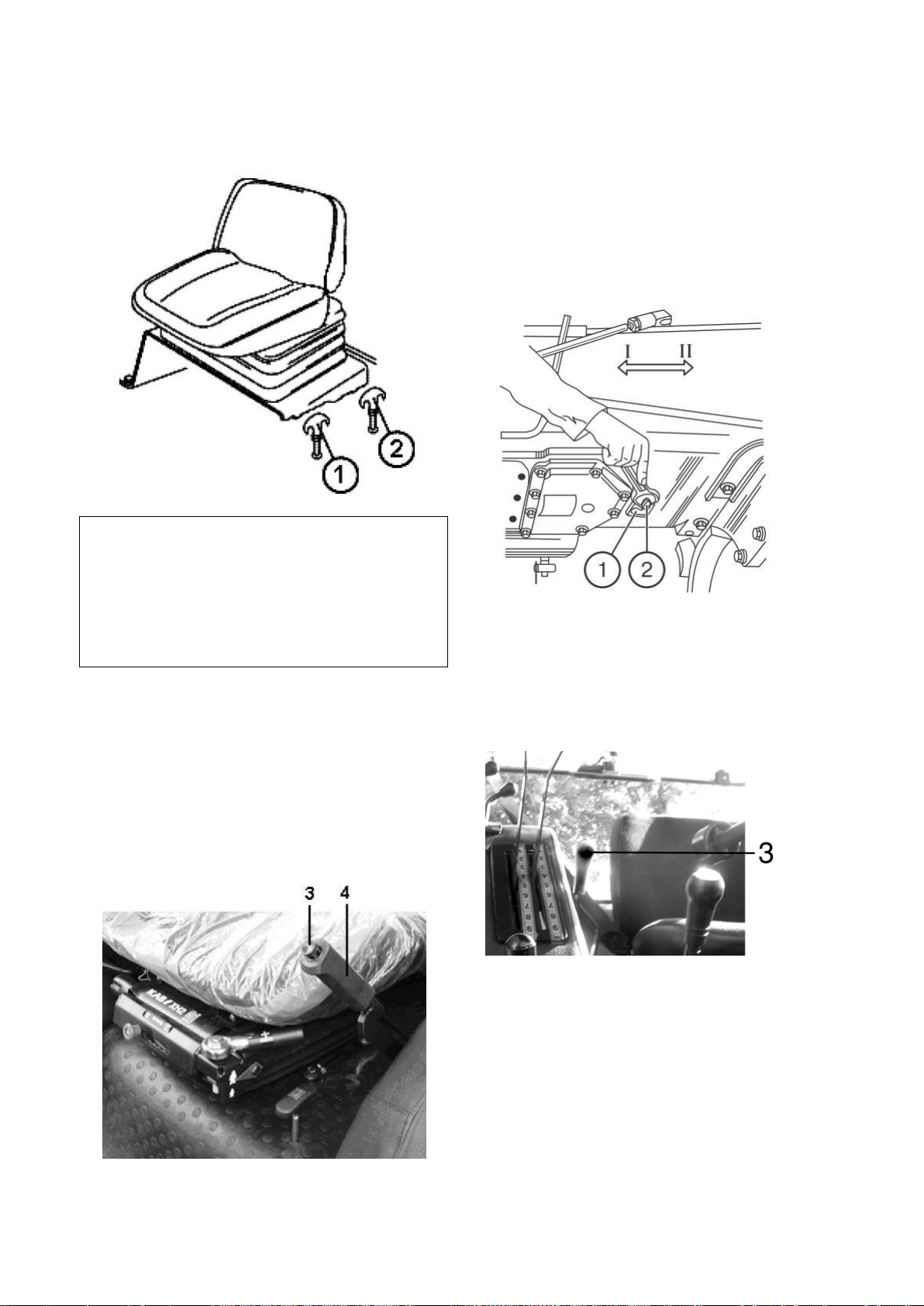

Operator’s weight adjustment requires

alternate motion of handle (2). The handle has

two positions: “+” – to i ncrease weight, “-“ –

to decrease. To change handle direction move

it fully forward and turn by 180°.

Seat height is adjusted with handle (3). Move

it to the right to lift the seat down, and to the

left to lift the seat up.

Back inclination is adjusted by pulling

adjusting arm (4) up and lowering and fixing

the back as required.

Operator’s seat

The seat has mechanical suspension with 90

mm stroke and hydraulic damper. Suspension

is protected with a rubber cover.

The seat may be adjusted as follows:

1. Longitudinal adjustment – within 150

mm range.

2. Weight adjustment – 50 kg to 120 kg

stepless.

3. Height adjustment - ±35mm.

4. Back inclination adjustment 5° to 20°.

Longitudinally the seat is adjusted with a

handle (1). Turn it counterclockwise to stop,

move the seat and release the handle.

so

35

Page 36

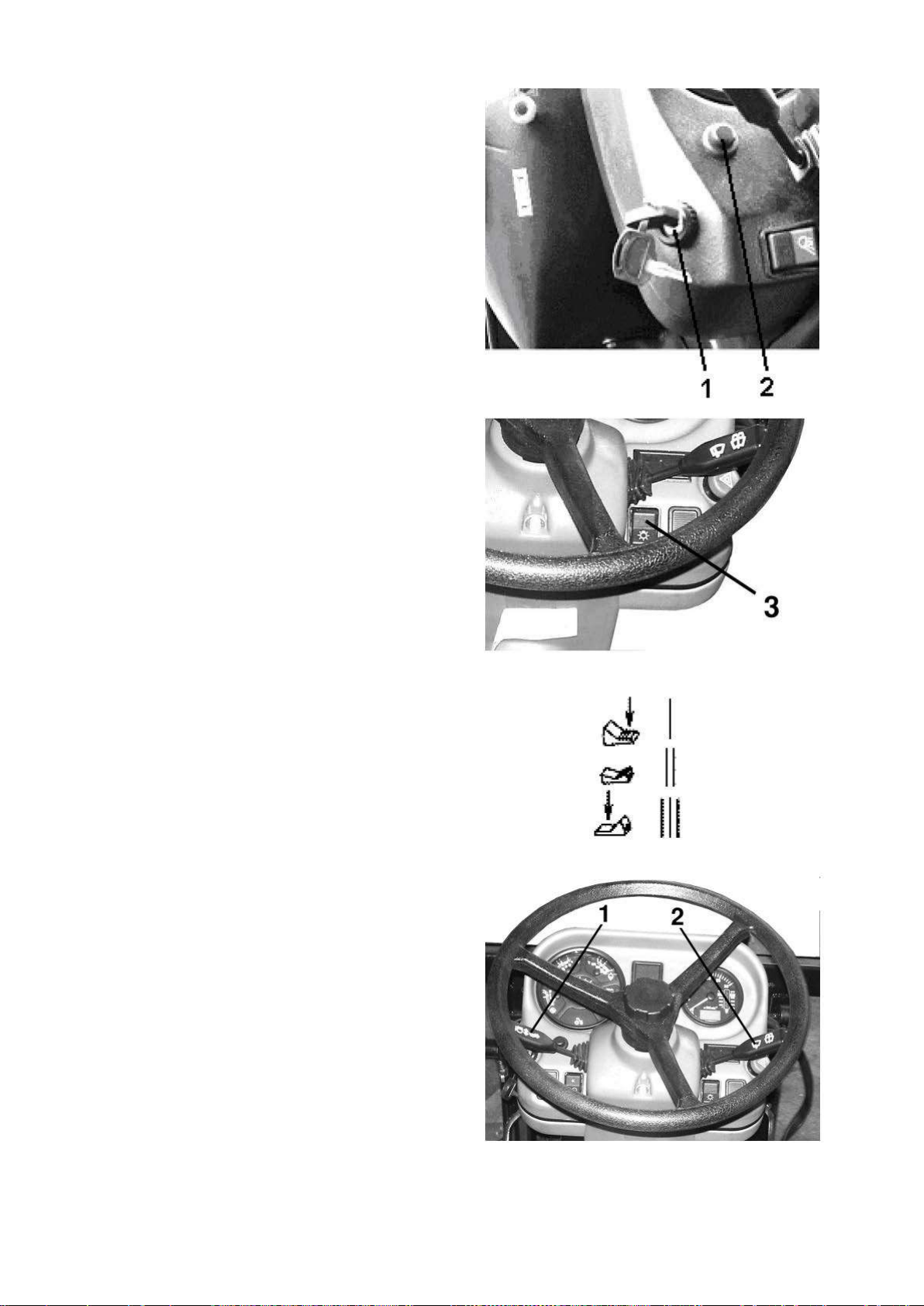

Steering wheel adjustment

NOTE! The steerin g wheel can b e adjust ed by

height within 100 mm.

To adjust steering wheel by height:

• Unscrew clamp (1) by 3-5 turns;

• Move the wheel (2) as required;

• Tighten the clamp (1) by hand as

possible.

Steering column may be inclined and fixed in

four positions from 20° to 40° with 5° pitch.

To adjust the column pull handle (3), incline

the steering column as required and release

handle (3).

Cab door latch

Handle (4) is used to open the cab door from

inside by pulling. Handle (5) disable cab door

opening from outside (when pulled).

36

Page 37

NOTE! Fully open recirculation flaps (3) and

(2) to quickly warm-up the cab.

NOTE! Close the valve to run the system for

venting at warm weather.

Cab heater control

To activate cab heater:

• Open the valve turning handle (1)

counterclockwise to stop;

• Turn heater fan on with a switch (2)

and adjust air direction as required with

regulated flaps (air deflectors) (4).

Opening and closing recirculation flaps

(3) amount of fresh air entering the cab

may be regulated.

run the heater fan at high speed with a switch

37

Page 38

Section 6. PREPARATION TO WORK AND WORK ORDER

WARNING! Ensure all protective guards are

in place prior to start the engine in order to

avoid personal injury.

ATTENTION! NEVER start new unbroken-

parts wear.

Preparing tractor to work

Depreserve tractor to prepare it for work as

follows:

• Remove protective covers and plugs from

the engine;

• Fill all refill capacities;

• Remove sediments from rough and fine

fuel filters and from fuel tank;

• Fill and flush fuel suppl y system with fuel

to remove air;

• Check fan belt tension;

• Check and adjust tire pressure;

• Service the battery;

• Tighten fasteners;

• Squirt all lubrication points;

• Check and, if necessary, adjust front

wheels toe-in.

in engine by towing to avoid excessive engine

Breaking-in

Your new tractor shall show safe and longterm operation in case of performing correct

breaking-in and necessary maintenance works

in due time. Observe following when

performing 30-hours breaking-in:

• Constantl y observe indicators information,

lubrication, cooling and feeding systems

operation. Observe oil and liquid levels in

refill capacities;

• Check tightening and retighten external

fixing connections;

• Break-in the engine at easy transporting

and field works (harrowing, cultivation,

sowing, etc.) gradually increasing load at

different gears;

• Do not overload the engine, do not allow

fuming or speed reduction. Signs of

overload are following: sharp speed

reduction, engine fuming and ignorance to

increased fuel supply;

• Tractor operation at too low gear with

little load at high engine speed causes fuel

overconsumption. Correctly chosen gear for

each given operation condition allows fuel

saving and reduced engine wear;

• Regularly perform monthly maintenance

according to recommendations of the

present manual;

• Perform maintenance operations after

breaking-in (see page 10-2).

38

Page 39

Starting the engine

IMPORTANT! Never start engine with

empty cooling system!

IMPORTANT! Stay at operator’s seat when

starting the engine and controlling instruments.

IMPORTANT! Never push or tow the tractor

to powertrain.

Starting in normal conditions

Check oil level in engine oil pan and coolant

level in radiator, check for fuel in the tank.

1. Brake the tractor with parking brake.

2. Set gear-switch lever to neutral position

and multiplier* arm to any of two fixed

positions (ON or OFF).

3. Set PTO lever to OFF position.

4. Turn remote battery switch on.

5. Set fuel supply lever to the middle

position.

6. Press clutch pedal, shift gear-switch lever

to the most left position (pull) and keep it

there.

7. Turn starter switch key to position II

(“Start”) and keep it until the engine is

started, but not more than 15 s. Starting

control light shall on at control lights

block and off after engine start. Repeat

starting not sooner than in 30-40 s after

the first unsuccessful, in any, attempt.

8. After engine start:

1. Release clutch pedal and gear-switch

lever;

2. Check operation of all indicator lights

and indicator readings (coolant

temperature, en gine oil pressure, bat tery

charge).

Starting at low temperature (+5°C and

below)

to start the engine by towing to avoid damage

• Keep the battery fully charged;

• Use clean winter diesel fuel without water

admixture;

• Fill fuel tanks in the end of each working

day to prevent condensation into the tanks.

Starting procedure

1. Switch off drive of hydraulic system oil

pump and compressor to reduce resistance

to crankshaft rotation.

2. Set multiplier† lever to the middle position

(between ON and OFF positions) to aid

start.

3. Lift (close) water cooler blind to quicken

engine warm-up.

4. Check oil level in the engine oil pan and

coolant level in the cooler.

5. Perform steps 1 to 7 (page 6-2).

6. As soon as the engine is started and its

speed is stable set speed at 1000 RPM to

stabilize oil pressure in operating range.

Release clutch pedal. Warm the engine up.

7. Check instruments operation. Adjust water

cooler blind to maintain normal thermal

conditions.

*

Back gear for MTZ-821/821.2

†

Back gear for MTZ-821.821.2

39

Page 40

IMPORTANT! Avoid starting with heavy

traction load (e.g. plough deepened in soil).

IMPORTANT! Always press clutch pedal

prior to engaging range and gear in the

pedal while operating the tractor as it leads to

clutch slip, overheating and breakdown.

IMPORTANT! Tractors are equipped with

steering. Pump does not

the system automatically switches to manual

mode requiring much effort to turn steering

wheel.

ATTENTION! For emergency tractor stop

press simultaneously clutch pedal and both

working brakes pedals.

Getting away and driving the tractor

Perform the following to move the tractor:

1. Set minimal speed for the engine

crankshaft.

2. Fully press clutch pedal and wait until all

rotating parts stop.

3. Shift the gear-switch lever from neutral to

the most left (to operator) position and push

it forward or pull rearward to engage

required range (I or II). Then return the

lever to Neutral position.

4. Select required gear according to the gear

shifting scheme and engage. If it is not

possible, release clutch pedal lightly and

press it again.

5. Select and fix required multiplier lever

position.

6. Engage parking brake and smoothly release

clutch pedal increasing fuel supply lightly.

Keep it increasing as motion begins.

Stopping the tractor

Act as follows to stop the tractor:

• Reduce engine crankshaft rotation speed;

• Fully press clutch pedal;

• Shift gearbox switch-lever to Neutral

position;

• Release clutch pedal;

• Press working brakes pedals to stop the

tractor.

Never stop the tractor with brakes with

engaged clutch;

• Engage parking brake.

gearbox. Do not keep your leg on the clutch

Steering

hydrostatic power

feed the system with the engine stopped and

Stopping the engine

Act as follows to stop the engine:

• Let the engine run at low speed after

releasing load to cool down. It is preferable

not to stop hot engine;

• Set minimal idle speed by pulling the fuel

supply control handle down;

• Stop the engine by pulling a stop handle to

stop;

Turn remote battery switch off to avoid battery

discharge.

40

Page 41

IMPORTANT! Turn PTO on and off at low

gine speed and with no working load at

agricultural machines transporters and tools.

running clutch for machines with

great inertia moment.

WARNING! Turn PTO off after each use for

the sake of safety.

Two-speed PTO switch position

Engine

RPM

PTO

RPM

Force mode (6 or 8 splines, speed I)

1631

(2081)*

Heavy duty mode (21 splines, speed

II)

1673

(2184)

WARNING! Use synchronous PTO at lower

only. Otherwise powertrain may be badly

damaged.

Power take-off (PTO)

en

Use free-

PTO ends with 6 or 8 square-sided splines are

available for PTO 540 RPM and with 21

involute splines are available for PTO 1000

RPM.

Set required drive speed and install an end

corresponding to the speed prior to starting

operating PTO.

PTO end replacement

1. Unscrew two bolts and remove cap (1).

2. Unscrew four nuts (3) and remove

cover (2).

3. Unscrew six bol ts (4), remove plate (6)

and end (5).

4. Install another end into the splined

bore, install the plate (6).

5. Ass emb le o th er pa rt s i s order r everse to

disassembly.

6. Replace guard and cap and fix with

nuts.

540

1000

*

IMPORTANT! Shift independent/

synchronous PTO switching rod to the middle

position (Drive OFF) on completion the work

and not using PTO.

gears at tractor speed not exceeding 8 km/h

*

For MTZ-821/821.2

41

Page 42

IMPORTANT! Engage independent PTO

inimal speed or with the engine

drive with running

engine and at smooth clutch coupling

position I (540 RPM). Shift lever switching

drive to the middle (neutral) position.

Special features of using rear PTO-driven

machines

General notes:

1. To connect a machin e to th e tract o r en sure

correct rear PTO control adjustment.

2. Install and secure required (6-, 8- or 21-

splined) PTO end and engage appropriate

drive.

3. Grease the shaft and cardan slip joint

pipe. Install cardan pivot joint at PTO

end and secure it in a fixing groove.

Ensure intermediate (telescopic) shaft

pivot fork (1) eyes (2) being planar,

otherwise the cardan drive and PTO

would be overloaded.

4. Install cover for agricultural machine

cardan shaft.

5. Having installed cardan drive ensure no

collision at cardan slip joint elements at

extreme machine positions relatively to

the tractor. Minimal overlap at cardan

telescopic part should be equal to 110-120

mm. Lesser overlap may result in drive

disengagement.

Agricultural machine safety coupling spring

(3) length should be adjusted so as to allow

cam half-couplings (4 and 5) rotate in relation

to each other at overload. Overtightened spring

result in coupling failure and cardan drive and

PTO overload.

drive at m

stopped.

Engage synchronous PTO

engagement.

Operating the tractor without PTO set PTO

control arm to “PTO OFF” position and twospeed PTO drive switching coupling – to

between independent and synchronous PTO

42

Page 43

Pneumatic system to control trailer’s brakes

Single-line pneumatic drive

1 – Compressor; 2 – Pressure regul at or; 3 – Air bleed valve; 4 – Tank; 5 – Alarm pressure signaling

light; 6 – Pressure indicator; 7 – Pressure cell; 8 – Alarm pressure cell; 9 – Condensate discharge

valve; 10 – Coupling head; 11 – Control line; 12 – Brake valve.

Tract is equipped with pneumatic system to

control brakes of trailers and other towed

machines with air brakes.

The system is as well used to pump-up tires

and for other applications requiring

pressurized air energy.

Air is taken into the system from the engine’s

intake manifold. Compressor (1) compresses

and passes air to the tank (4) through pressure

regulator (2) keeping required pressure in the

tank.

Compressed air passes from the tank to the

brake valve (12) via the piping. From the

brake valve the air passes via control line (11)

to the coupling head (10) and farther to the

trailer’s air system.

Pressure regulator is equipped with air bleed

valve (3) used to pump-up tires and for other

applications. There is a pressure cell (7) and

alarm pressure cell (8) to control air pressure

in the system. Dashboard features pressure

indicator (6) and red alarm light (5). Valve (9)

is provided to remove condensate from the

tank.

43

Page 44

Double-line pneumatic drive

Tractors may have double-line pneumatic

drives to control air brakes of trailers.

The system is as well used to pump-up tires

and for other applications requiring

pressurized air energy.

1 – Compressor; 2 – Pressure regul at or; 3 – Air bleed valve; 4 – Tank; 5 – Alarm pressure signaling

light; 6 – Pressure indicator; 7 – Pressure cell; 8 – Alarm pressure cell; 9 – Condensate discharge

valve; 10 – Feeding line; 11, 11a – Coupling heads; 12 – Control line; 13 – Brake valve.

Air is taken into the system from the engine’s

intake manifold. Compressor (1) compresses

and passes air to the tank (4) through pressure

regulator (2) keeping required pressure in the

tank. Compressed air passes from the tank to

the brake valve (13) and to the feeding line

(10) with constantly pressurized coupling head

(11) (with red cap).

Hydraulic system

The brake valve is connected via the control

line to non-pressurized coupling head (11a)

(with yellow cap). Brakes of trailers and

agricultural machines are controlled in two

modes: direct and automatic.

Direct brakes control uses control line (12)

pressure increase up to 6.5-8.0 kgf/cm2 to stop

the tractor.

Feeding line (10) keeps pressurized and

continues pressurized air supply to the trailer’s

pneumatic system.

44

Page 45

Hydraulic system includes oil tank (1), gear pump (4), pump drive (3), side outputs (2), rear output s

(7), external cylinder control handles (5), follow-through distributor (6), and hydraulic jack (8).

Components layout is given below (top view).

Hydraulic distributor (6) is located at the right of the

tractor’s rear and is controlled with three handles (5) at

operator’s right hand.

Oil tank (14) of welded structure has capacity of 25 l.

The tank features filling cap (10) with safety valve (11),

oil level indicator (12), filter element (13), breather (9)

and discharge cap (15).

Hydraulic system oil pump is of right-hand rotation, is

located at the drive. Pump drive is switchable, is

independent from friction clutch and is located to right

from the clutch casing.

The drive consists of casing (1), gear (2) on splines (3)

of a shaft rotating in within two ball bearings. Balls (4)

inserted into the shaft (3) bore lock or unlock the shaft

with spline bushings (5, 7) with a fixture (6) controlled

by a fork through the roller (11) tetrahedron.

Drive (12) ensures 1800 (1830)* RPM for the pum p sh aft (8 ) at rated engine speed. B all -t ype clut ch

(3, 4, 5, 6, 7) allows switching the pump on and off with engine running at minimal idling speed.

To switch the pump on/off:

• Loosen bolt (9) by 1.5-2 turns;

• T

urn switching roller (11) with a wrench by the tetrahedron CW/CCW to stop;

• Tighten bolt (9).

*

For MTZ-821/821.2

45

Page 46

ATTENTION! Never try to couple machines

system is failed.

ATTENTION!

hydraulic system pump should be

emergency only. Pump drive may be

hydraulic system pump off. Having

Hitched or semihitched machine from

Hitched or semihitched machine with

ceeding half of the tractor’s

one, from TC.

Gear (2) is constantly engaged with PTO drive

gear. In disengaged state (see activation

scheme) fixing (6) is shifted to the most right

position, balls (4) disengage with bushing (5)

under centrifugal force and shaft (3) and gear

(2) freely rotate in bearings. In engages state

(fixing shifted to the most left position) balls

(4) are guided into the bushing (5) holes by the

fixing (6) taper and torque is transferred from

gear (2) through shaft (3) and splined bushing

(5) to the pump shaft. The drive is suitable for

another pump (NHs10/16) driven by the

splined bushing (7).

with hookup or with TC and h ydraulic brakes,

for machines of servic e weight exceeding half

of the tractor’s one, if hookup hydraulic

1. Hookup

always on. OFF function for the pump is for

disconnected in case of the pump failure or

broken oil lines connected by the pump.

2. Stop the engine prior to switching hookup

disconnected the pump drive, decouple the

following:

•

hookup;

•

hydraulic brakes, for machines of service

weight ex

46

Page 47

HMS hydraulic jack

Hydraulic mounted system is equipped with

hydraulic jack and ensures operation in the

following modes:

• Lifting hanging platform up and down with

its dead weight;

• Positioning adjustment – automatically

maintained position of the hanging platform

in relation to the tractor;

• Force adjustment – tillage depth adjustment

in relation to soil resistance;

• Combined adjustment – tillage depth

adjustment in relation to soil resistance with

maximal tillage depth limited by

positioning adjustment.

Positioning adjustment handle (2) is used to

control hanging platform with coupled tool.

Positioning adjustment

Force adjustment handle (1) should be set to

the front position (“9” figure at the board)

when connecting a tool.

It allows accurate and delicate control over

connected rigs over the ground like spraying

machine, leveler, etc. Positioning adjustment

may be applied with tillers at plain fields.

Using positioning adjustment at uneven

surfaces is limited due to inevitable vertical

movements of the tool while tractor driving

the field.

1. Set force adjustment handle (1) to

extreme (front) position along the

driving direction (“9” figure at the

board).

2. Set required machine elevation over the

ground with positioning adjustment

handle (2).

“1” figure at the board corresponds to

transporting position of RH, and “9” figure

corresponds to minimal tool elevation over the

ground.

47

Page 48

Section 7. OPERATION AND ADJUSTMENT REGULATIONS

Setting front track

Front track of the tractor ma y be altered with

exchanging left and right wheels only. Front

track is equal to 1220 and 1365 mm.

To adjust the track:

1. Engage parking brake. Put blocks on

both sides of rear wheels.

2. J ack the front axle up (or front wheels

alternately) to ensure clearance

between wheels and ground.

3. Remove front wheels.

4. Unscrew nuts fixing the wheel disk to

FDA reduction gear flange.

Exchange wheels com plete at both sides to get

required track. Pay special attention to ensure

wheels rotation direction correspondence to an

arrow at the tire side, i.e. lugs direction should

be the same.

Tighten wheel fixing nuts to 250-300 Nm.

Front axle toe-in adjustment

Wheels toe-in is adjusted by changing steering

rod length as follows:

1. Drive the tractor not less than 3 meters

straight at a plain ground.

2. Measure dimension A between two

opposite points at the rim shoulder in

the front part of the front axle at the

wheel axle level.

3. Mov e the tractor fo rwa rd to rotate front

wheels by 180° approximately and

measure dimension B in the rear part of

the front axle bet ween the same points

as when measuring A dimension. A

dimension should be less then B

dimension. Measured difference

constitutes wheels toe-in and should be

equal to 0-8 mm.

To correct toe-in:

1. Loosen nuts of adjusting tube at the

steering rod.

2. Set required toe-in rotating the tube.

3. Tighten the nuts.

48

Page 49