MTS Systems Temposonics GB, Temposonics GB-J, Temposonics GB-K, Temposonics GB-N, Temposonics GB-S Brief Instructions

Page 1

Temposonics

Magnetostrictive Linear Position Sensors

Temposonics® GB-Series

Brief Instructions

®

Page 2

Temposonics® GB-Series

Brief Instructions

Table of contents

1. Introduction ..........................................................................................................................................................................3

2. Safety instructions ...............................................................................................................................................................4

2.1 Intended use ..................................................................................................................................................................4

2.2 Forseeable misuse .........................................................................................................................................................4

2.3 Installation, commissioning and operation ....................................................................................................................5

2.4 Safety instructions for use in explosion-hazardous areas ..............................................................................................5

2.5 Warranty ........................................................................................................................................................................5

2.6 Return ............................................................................................................................................................................5

2.7 Maintenance & removal .................................................................................................................................................5

3. Identification ........................................................................................................................................................................6

3.1 Temposonics

3.2 Temposonics

4. Installation & mounting .......................................................................................................................................................7

4.1 Sensor installation .........................................................................................................................................................7

4.2 Magnet installation .........................................................................................................................................................7

4.3 Mounting dimensions of GB-Series ...............................................................................................................................8

5. Electrical connection ...........................................................................................................................................................9

5.1 Analog ............................................................................................................................................................................9

5.2 SSI ...............................................................................................................................................................................10

®

GB-Series GB-J / GB-K / GB-N / GB-S (rod sensor with pressure fit flange) ..........................................6

®

GB-Series GB-M / GB-T (rod sensor with threaded flange) ....................................................................6

I 2 I

Page 3

Temposonics® GB-Series

NOTICE

Brief Instructions

1. Introduction

1.1 Purpose and use of this manual

®

Before starting the operation of Temposonics

read this documentation thoroughly and follow the safety

information. Keep the manual for future reference!

The content of this technical documentation is intended to

provide information on mounting, installation and commissioning by qualified automation personnel

service technicians who are familiar with the project planning

and dealing with Temposonics

®

sensors.

1.2 Used symbols and warnings

Warnings are intended for your personal safety and for avoidance of damage to the described product or connected devices. In this documentation, safety information and warnings to

avoid danger that might affect the life and health of operating

or service personnel or cause material damage are highlighted by the preceding pictogram which is defined below.

Symbol Meaning

This symbol is used to point to situations

that may lead to material damage, but not

to personal injury.

sensors

1

or instructed

1/ The term qualified technical personnel characterizes

persons who:

• are familiar with the safety concepts of automation

technology applicable to the particular project

• are competent in the field of electromagnetic

compatibility (EMC)

• have received adequate training for commissioning and

service operations

• are familiar with the operation of the device and know the

information required for correct operation provided in the

product documentation.

I 3 I

Page 4

Temposonics® GB-Series

Brief Instructions

2. Safety instructions

2.1 Intended use

This product may be used only for the applications defined

under item 1 only in conjunction with the third-party devices

and components recommended or approved by MTS

Sensors. As a prerequisite of proper and safe operation the

product requires correct transport, storage, mounting and

commissioning and must be operat ed with utmost care.

1. The sensor systems of all Temposonics

intended exclu sively for measurement tasks encountered

in industrial, commercial and laboratory applications.

The sensors are considered as system accessories and

must be connected to suitable evaluation electron ics,

e.g. a PLC, IPC, indicator or other electronic control unit.

2.2 Forseeable misuse

Forseeable misuse Consequence

Wrong sensor connection The sensor does not work

Operate the sensor out off

the operating temperature

Power supply is out of the

defined range

Position measurement is

influenced by an external

magnetic field

Cables are damaged Short circuit – the sensor can

Spacers are missing /

are installed in a wrong order

Wrong connection

of ground / shield

Use of a magnet that is not

certified by MTS Sensors

properly or will be destroyed

No signal output

The sensor can be damaged

Signal output is wrong /

no signal output /

the sensor will be damaged

Signal output is wrong

be destroyed / sensor does

not respond

Error in position

measurement

Signal output is disturbed

The electronics can be

damaged

Error in position

measurement

®

series are

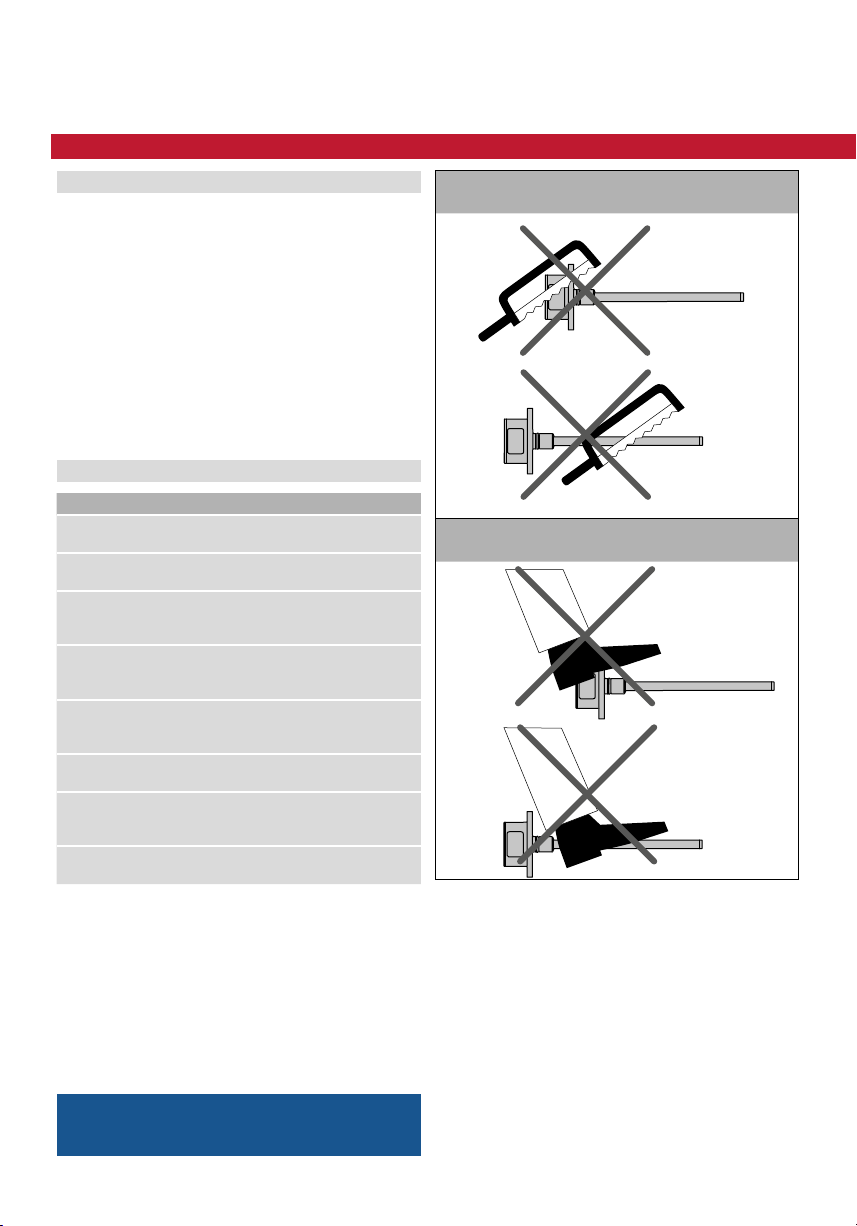

Do not reprocess the sensor afterwards.

The sensor might be damaged.

Do not step on the sensor.

The sensor might be damaged.

Manuals, Software & 3D Models available at:

www.mtssensors.com

I 4 I

Page 5

Temposonics® GB-Series

Brief Instructions

2.3 Installation, commissioning and operation

The position sensors must be used only in technically safe

condition. To maintain this condition and to ensure safe

operation, installation, connection and service, work may

be performed only by qualified technical personnel.

If danger of injury to persons or of damage to operating

equipment is caused by sensor failure or malfunction,

additional safety measures such as plausibility checks,

limit switches, EMERGENCY STOP systems, protective

devices etc. are required. In the event of trouble, shut

down the sensor and protect it against accidental operation.

Safety instructions for commissioning

To maintain the sensor’s operability, it is mandatory to follow

the instructions given below.

1. Protect the sensor against mechanical damage during

installation and operation.

2. Do not open or dismantle the sensor.

3. Connect the sensor very carefully and pay attention

to the polarity of connections and power supply.

4. Use only approved power supplies.

5. It is indispensable to ensure that the specified

permissible limit values of the sensor for operating

voltage, environmental conditions, etc. are met.

6. Check the function of the sensor regularly and provide

documentation of the checks.

7. Before applying power, ensure that nobody’s safety

is jeopardized by starting machines.

2.4 Safety instructions for use in explosion-hazardous areas

The sensors are not suitable for operation in explosionhazardous areas.

2.5 Warranty

MTS Sensors grants a warranty period for the Temposonics

®

position sensors and supplied accessories relating to

material defects and faults that occur despite correct use in

accordance with the intended application

2

. The MTS Sensors

obligation is limited to repair or replacement of any defective

part of the unit. No warranty can be provided for defects

that are due to improper use or above average stress of the

product, as well as for wear parts. Under no circumstances

will MTS Sensors accept liability in the event of offense

against the warranty rules, no matter if these have been

assured or expected, even in case of fault or negligence of

the company.

MTS Sensors explicitly excludes any further warranties.

Neither the company’s representatives, agents, dealers nor

employees are authorized to increase or change the scope

of warranty.

2.6 Return

For diagnostic purposes, the sensor can be returned to MTS

Sensors. Any shipment cost is the responsibility of the send-

2

er

. For a corresponding form, see detailed operation manual

(available at: www.mtssensors.com).

2.7 Maintenance & removal

Maintenance

The sensor is maintenance-free.

Repair

Repairs on the sensor may be performed only by MTS Sensors

or a repair facility explicitly authorized by MTS Sensors.

List of spare parts

No spare parts are available for this sensor.

2/ See also applicable MTS Sensors sales and supply

conditions, e.g. at www.mtssensors.com

Transport and storage

The conditions of transport and storage of the sensor match

the operating conditions mentioned in this document.

Removal from service / dismantling

The product contains electronic components and must be

disposed of in accordance with the local regulations.

I 5 I

Page 6

Temposonics® GB-Series

Stroke length (e.g. 850 mm)

rod (Ø 10 mm / Ø 12.7 mm)

Brief Instructions

3. Identification

Nameplate (e.g. GB-Series GB-S Analog)

Sensor model

Part no.

Output

Production no.

3.1 Temposonics® GB-Series with pressure fit flange (GB-J / GB-K / GB-N / GB-S)

Connector or

cable outlet

GBS0850MD601A0SC

4 - 20 mA

FNr. 1601 0376

1601037616010376160103761601

Position magnet

(Ring or U-magnet)

Pressure fit flange Ø 18 mm / Ø 21 mm

Fastened via 6 machine

screws M6 (ISO 4762)

Fastening torque: 6 Nm

Connection type

Output

version

Year

Week

Pressure-proof

with sensor

element

Approvals and certificates

You will find approvals and certificates in the sensor specific

operation manuals.

Available outputs:

• Analog

• SSI

3.2 Temposonics® GB-Series GB-M / GB-T with threaded flange (GB-M / GB-T)

Position magnet

Connector or

cable outlet

(Ring or U-magnet)

Pressure-proof

rod (Ø 10 mm)

with sensor

element

Threaded flange

(M18×1.5-6g or

¾"-16 UNF-3A)

Fastened with 3 screws DIN 915 M4×6 A2

Fastening torque: 1.6 Nm

Manuals, Software & 3D Models available at:

www.mtssensors.com

I 6 I

Available outputs:

• Analog

• SSI

Page 7

Concentric mounting

4. Installation & mounting

4.1 Sensor installation

General

• Seat the flange contact surface completely on the cylinder

mounting surface.

• The cylinder manufacturer determines the pressureresistant gasket (copper gasket, O-ring, etc.).

• The position magnet should not grind on the sensor rod.

• The piston rod drilling (≥ Ø 13 mm / for GB-J and GB-K

sensors: ≥ Ø 16 mm) depends on the pressure and piston

speed.

• Adhere to the information relating to operating pressure.

• Protect the sensor rod against wear.

4.2 Magnet installation

Typical use of magnets

• Rotationally symmetrical magnetic field

Ring magnet

• The magnet can be lifted off

U-magnet

• Height tolerances can be compensated

Temposonics® GB-Series

Brief Instructions

GB-Series with pressure fit flange

Mount the sensor via the fitting flange through the bores

in the sensor electronics housing with 6 machine screws

M6×16 A2-70 (ISO 4762). Note the fastening torque of 6 Nm.

The hydraulic sealing requires the use of a supplied O-ring

15 × 2 mm (GB-J: 17 x 2 mm).

GB-Series with threaded flange

Mount the sensor via the threaded flange M18×1.5-6g or

¾"-16 UNF-3A. Note the fastening torque of 50 Nm.

Notice for sensors with stroke lengths ≥ 1 meter

Support horizontally installed sensors with a stroke length

from 1 meter mechanically at the rod end. Without the use of

a support, rod and position magnet may be damaged. A false

measurement is also possible. Longer rods require evenly

distributed mechanical support over the entire length. Use an

U-magnet for measurement.

Sensor support (for sensors with stroke length ≥ 1 meter)

U-magnet

Sensor rod

Non-magnetic fixing clip

NOTICE

For detailed mounting instructions see operation manual.

Install the magnet using non-magnetic material for mounting

device, screws, spacers etc.. The magnet must not grind on

the sensor rod. Alignment errors are compensated via the

air gap.

• Max. permissible surface pressure: 40 N/mm

• Fastening torque for M4 screws: 1 Nm; use washers,

if necessary

• Minimum distance between position magnet and any

magnetic material has to be 15 mm.

• If no other option exists and magnetic material is used,

observe the specified dimensions.

2

NOTICE

Mount the ring magnet and U-magnet concentrically.

The maximum permissible air gap must not be exceeded.

Concentric mounting of U-magnet

M4

2

1

of U-magnet

Air gap

Part no. 251 416-2:

1.75 ±1 (0.07 ±0.04)

1

U-magnet

2

Non-magnetic mounting device and screws

All dimensions in mm

Manuals, Software & 3D Models available at:

www.mtssensors.com

I 7 I

Page 8

Temposonics® GB-Series

A B

Brief Instructions

Magnet mounting with magnetic material

Magnetic

1

material

2

Magnet

Null zone, depends on sensor model

1

Distance between position magnet and any magnetic

2

material (≥ 15 mm)

Non-magnetic spacer (≥ 5 mm) –

3

Recommendation: 8 mm

Magnet mounting with magnetic material

A. If the position magnet aligns with the drilled piston rod

B. If the position magnet is set further into the drilled piston

rod, install another non-magnetic spacer above the magnet

3 3

Magnet

4.3 Mounting dimensions of GB-Series

GB-Series with pressure fit flange

with ring / U-magnet

Reference edge of mounting

Start position

40 Stroke length 63.5

GB-Series with threaded flange with ring / U-magnet

Reference edge of mounting

Start position

40 Stroke length 63.5

NOTICE

On all sensors, the areas left and right of the active stroke

length are provided for mounting and damping of the measuring signal. They could not be used for measurement,

but the active stroke length can be exceeded.

Manuals, Software & 3D Models available at:

www.mtssensors.com

All dimensions in mm

I 8 I

Page 9

5. Electrical connection

on the sensor’s electromagnetic compatibility (EMC). Hence

correct installation of this active electronic system and the

EMC of the entire system must be ensured by using suitable

metal connectors, shielded cables and grounding. Overvoltages or faulty connections can damage its electronics despite

protection against wrong polarity.

NOTICE

Never connect / disconnect the sensor when voltage is

applied.

Instructions for connection

• Use low-resistant twisted pair and shielded cables and

connect the shield to ground externally via the controller

equipment.

• Keep control and sign leads separate from power cables

and sufficiently far away from motor cables, frequency

inverters, valve lines, relays, etc..

• Use only connectors with metal housing and connect the

shielding to the connector housing.

• Keep the connection surface at both shielding ends as

large as possible.

• Keep all non-shielded leads as short as possible.

• Keep the earth connection as short as possible with a

large cross section. Avoid ground loops.

• With potential differences between machine and electronics

earth connections, no compensating currents are allowed

to flow across the cable shielding.

Recommendation:

Install potential compensating leads with large cross

section, or use cables with separate double shielding,

and connect only one end of the shield.

• Use only stabilized power supplies in compliance with

the specified connecting values.

Temposonics® GB-Series

Brief Instructions

5.1 AnalogPlacement of installation and cabling have decisive influence

D34 (for outputs: V0, A0, A1, A2, A3 in order code)

Signal + power supply

M12 male connector

(A-coded)

2

345

View on sensor

* Connection necessary for programming with hand or cabinet

programmer

D34 (for output: A4 in order code)

Signal + power supply

M12 male connector

(A-coded)

2

345

View on sensor

* Connect the fi rst output (4…20 mA) at low-resistance,

if you only use the second output (20…4 mA)

Pin Voltage Current

+24 VDC

1

(−15 / +20 %)

2 0…10 VDC

1

3 DC Ground (0 V) DC Ground (0 V)

4 10…0 VDC Not connected

5 DC Ground DC Ground

Pin Current

1 +24 VDC (−15 / +20 %)

*

1

2 4…20 mA

3 DC Ground (0 V)

4 20…4 mA

5 DC Ground

+24 VDC

(−15 / +20 %)

4(0)…20 mA or

20… 4(0) mA

*

NOTICE

Do not mount the sensors in an area of strong magnetic or

electric noise fields.

NOTICE

Connect the sensor electronics housing to the machine

ground via pressure fit flange respectively via threaded

flange.

I 9 I

Page 10

Temposonics® GB-Series

Brief Instructions

D60 (for outputs: V0, A0, A1, A2, A3 in order code)

Signal + power supply

M16 male connector Pin Voltage Current

*

4(0)…20 mA or

20… 4(0) mA

+24 VDC

(−15 / +20 %)

1 0…10 VDC

1

2

6

3

4

View on sensor

* Connection necessary for programming with hand or cabinet

programmer

D60 (for output: A4 in order code)

Signal + power supply

M16 male connector Pin Current

1

2

6

3

4

View on sensor

* Connect the fi rst output (4…20 mA) at low-resistance,

if you only use the second output (20…4 mA)

2 DC Ground DC Ground

3 10…0 VDC Not connected

5

4 DC Ground DC Ground

+24 VDC

5

(−15 / +20 %)

6 DC Ground (0 V) DC Ground (0 V)

1 4…20 mA

2 DC Ground

3 20…4 mA

5

4 DC Ground

5 +24 VDC (−15 / +20 %)

6 DC Ground (0 V)

HXX / TXX / VXX (for outputs: V0, A0, A1, A2, A3 in order code)

Signal + power supply

Cable Color Voltage Current

GY 0…10 VDC

PK DC Ground DC Ground

*

* Connection necessary for programming with hand or cabinet

programmer

HXX / TXX / VXX (for output: A4 in order code)

Signal + power supply

Cable Color Current

* Connect the fi rst output (4…20 mA) at low-resistance,

if you only use the second output (20…4 mA)

YE 10…0 VDC Not connected

GN DC Ground DC Ground

+24 VDC

BN

(−15 / +20 %)

WH DC Ground (0 V) DC Ground (0 V)

GY 4…20 mA

PK DC Ground

YE 20…4 mA

GN DC Ground

BN +24 VDC (−15 / +20 %)

WH DC Ground (0 V)

*

4(0)…20 mA or

20… 4(0) mA

+24 VDC

(−15 / +20 %)

*

I 10 I

NOTICE

DANGER OF SHORT-CIRCUIT!

Insulate the conductors of the second output (yellow,

green), if you only use the first output. We recommend

providing terminals for the second output in the

control cabinet, since the leads are required for sensor

programming.

Page 11

5.2 SSI

D84

Signal + power supply

M12 male connector

(A-coded)

2

3

1

4

8

7

5

6

View on sensor

D70

Signal + power supply

M16 male connector Color Function

6

1

7

4

3

2

5

View on sensor

Pin Function

1 Clock (+)

2 Clock (−)

3 Data (+)

4 Data (−)

5 Not connected

6 Not connected

7 +24 VDC (−15 / +20 %)

8 DC Ground (0 V)

1 Data (−)

2 Data (+)

3 Clock (+)

4 Clock (−)

5 +24 VDC (−15 / +20 %)

6 DC Ground (0 V)

7 Not connected

Temposonics® GB-Series

Brief Instructions

GB with cable outlet (HXX / TXX / VXX)

Signal + power supply

Cable Color Function

GY Data (−)

PK Data (+)

YE Clock (+)

GN Clock (−)

BN +24 VDC (−15 / +20 %)

WH DC Ground (0 V)

NOTICE

Connect the sensor electronics housing to the machine

ground via fitting flange respectively via threaded flange.

I 11 I

Page 12

Reg.-No. 003095-QM08

Temposonics® GB-Series

Brief Instructions

Notes

The sensor is also available with Bluetooth

connection. For more information see document:

“Programming & Configuration via Bluetooth

®

®

”

Document part number for GB-Series analog: 551595

Document part number for GB-Series SSI: 551649

I 12 I

Page 13

UNITED STATES

Reg.-No. 003095-QM08

MTS Systems Corporation

Sensors Division

GERMANY

MTS Sensor Technologie

GmbH & Co. KG

ITALY

Branch Offi ce

FRANCE

Branch Offi ce

3001 Sheldon Drive

Cary, N.C. 27513

Phone: +1 919 677-0100

E-mail: info.us@mtssensors.com

Auf dem Schüffel 9

58513 Lüdenscheid

Phone: +49 2351 9587-0

E-mail: info.de@mtssensors.com

Phone: +39 030 988 3819

E-mail: info.it@mtssensors.com

Phone: +33 1 58 4390-28

E-mail: info.fr@mtssensors.com

Document Part Number

551727 Revision C (EN) 07/2018

GREAT BRITAIN

Branch Offi ce

Branch Offi ce

Branch Offi ce

Phone: +44 79 44 15 03 00

E-mail: info.uk@mtssensors.com

Phone: +86 21 6485 5800

CHINA

E-mail: info.cn@mtssensors.com

Phone: +81 42 707 7710

JAPAN

E-mail: info.jp@mtssensors.com

www.mtssensors.com

MTS, Temposonics and Level Plus are registered trademarks of MTS Systems Corporation in the United States; MTS SENSORS and the MTS SENSORS logo are trademarks of MTS Systems Corporation within the

United States. These trademarks may be protected in other countries. All other trademarks are the property of their respective owners. Copyright © 2018 MTS Systems Corporation. No license of any intellectual

property rights is granted. MTS reserves the right to change the information within this document, change product designs, or withdraw products from availability for purchase without notice. Typographic and

graphics errors or omissions are unintentional and subject to correction. Visit www.mtssensors.com for the latest product information.

Loading...

Loading...