Page 1

l

Temposonics

®

Position Sensors

MK292 Digital Output Module

Users Manual

0797 550414 Revision B

Page 2

GENERAL INFORMATION

Phone/Fax Numbers

Phone:

919-677-0100

800-633-7609

Fax:

919-677-0200

Shipping Address

MTS SYSTEMS CORPORATION

Sensors Division

3001 Sheldon Drive

Cary, North Carolina 27513

Office Hours

Mon. - Thurs.:

7:30 a.m. to 6:30 p.m. EST

Friday:

7:30 a.m. to 5:00 p.m. EST

Technical Support (24-Hr.)

Call:

800-633-7609 (after hours, press 5)

2

Page 3

Table of Contents

Section Page

1 INTRODUCTION 1

1.1 System Configuration 2

2 SPECIFICATIONS 3

2.1 MK292 Specifications 3

2.2 Temposonics Position Sensor Specifications 4

3 SYSTEM COMPONENTS 5

3.1 MK292-Compatible Temposonics Position Sensors 5

3.1.1 Temposonics Position Sensor with Start/Stop Output 5

3.1.2 Temposonics Position Sensor with Pulse Width Modulated Output 5

3.1.3 Temposonics Position Sensor with Synchronous Operation 5

4 CONNECTIONS 6

4.1.1 Temposonics II Position Sensors with DPM or RPM 6

4.1.2 SE-based Temposonics LP Position Sensors with Start/Stop Output 6

4.1.3 Temposonics L Series Position Sensors with Start/Stop Output 7

4.2 System Connections 9

4.3 Functional Inputs/Outputs 10

4.3.1 Error Output (Loss of Feedback) 10

4.3.2 Data-Ready Output (Latch Pulse) 10

4.3.3 Data-Hold Input (Latch Inhibit) 11

4.3.4 External Start Input 11

4.3.5 Master/Slave Input 11

5 SYSTEM PARAMETERS 12

6 SHORT FORM PROGRAMMING PROCEDURE 14

7 DETAILED PROGRAMMING PROCEDURE 15

7.1 (RUN) Programming Mode 15

7.2 (REC) Pulse Duration 15

7.3 (SC) Scale Factor 17

7.4 (RE) Resolution 18

7.5 (MR) Measuring Range 19

7.6 (ZERO) Null Adjust 20

7.7 (ZERO) Offset 20

7.8 (RUN) Operation Mode 22

8 OPTIONAL ANALOG OUTPUT FOR THE MK292 23

8.1 Operation Mode 1 (Normal) 23

8.2 Operation Mode 2 (Programmable Adjustment) 24

Page 4

4

Page 5

1. Introduction to the MK292 Digital Output Module

The MK292 Digital Output Module provides an interface between a Temposonics position sensor with

a pulse-width modulated or start/stop output and a system controller. A selection of outputs from the

MK292 (BCD, binary, or Gray Code) gives this device nearly universal compatibility.

The MK292 is compatible with many Temposonics position sensors, as follows:

Compatible Position Sensors:

• SE-based Temposonics LP sensor with start/stop output

• Temposonics II sensors with a pulse-width modulated or start/stop output

• Temposonics L Series sensors with a pulse-width modulated or start/stop output

In addition to position data, the MK292 generates logic outputs: DATA READY and ERROR; and logic

input: DATA HOLD. An optional sub-board assembly provides an analog output for recording purposes (output range: 0 to 10 Vdc or 10 to 0 Vdc).

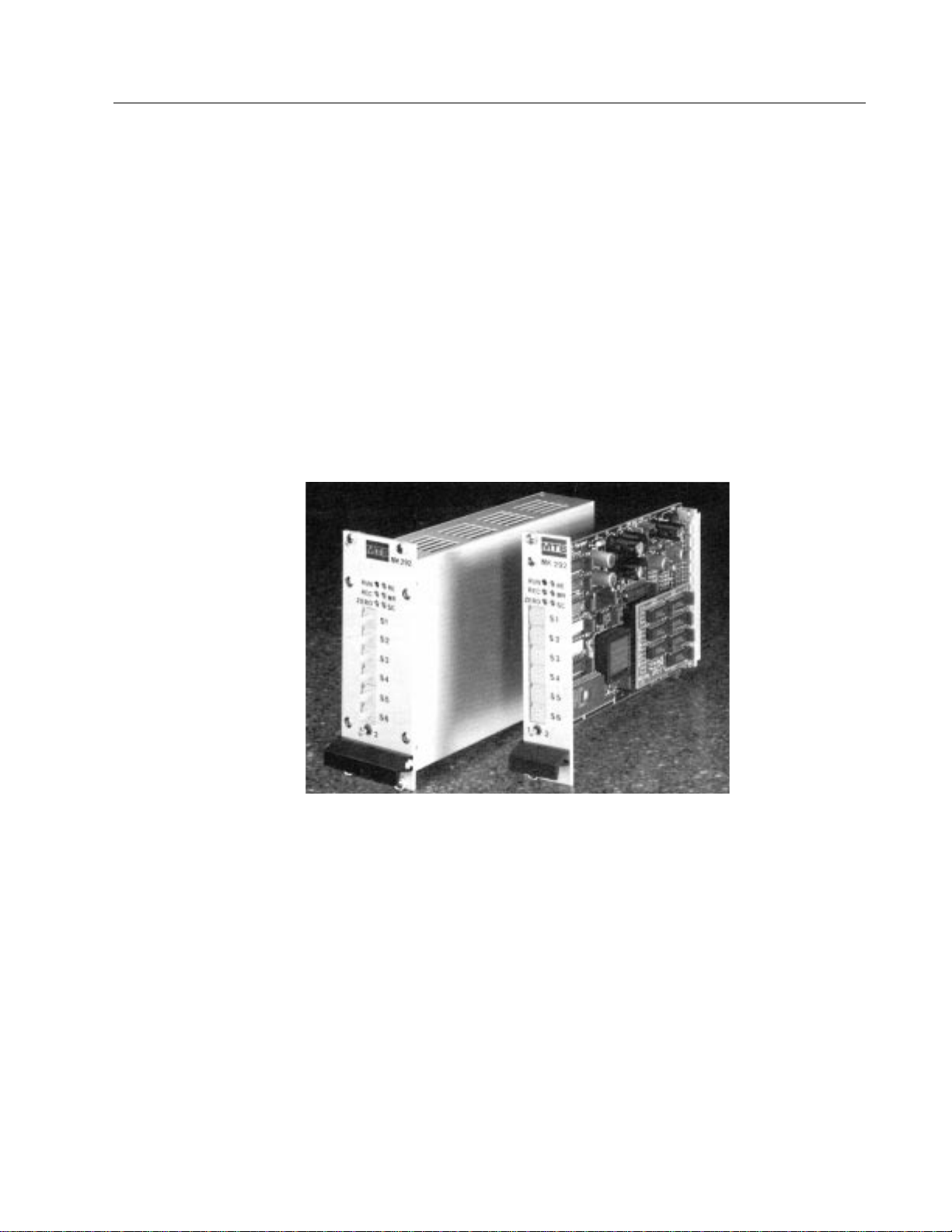

The MK292 can be configured as either a rack-mountable card or module that can be installed in a

standard 19 inch mounting rack.

Figure 1-1

MK292 (Module version, left; card version, right)

1

Page 6

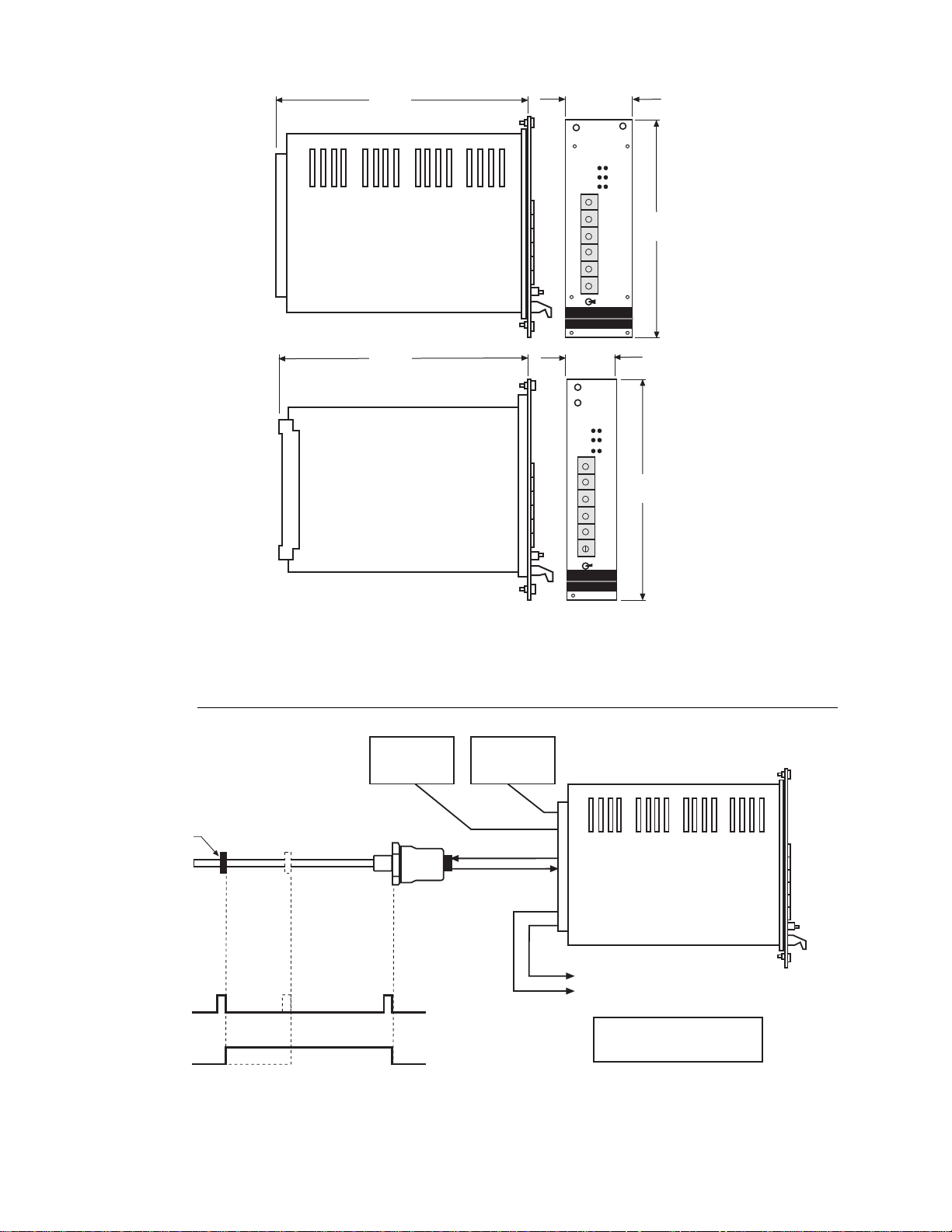

Figure 1-2

MK292 Digital Output Module Dimensions

1.1 System Configuration

Figure 1-3

Typical System Configuration

MK292

Module

Magnet

Temposonics Sensor with

Start/Stop or PWM Output

Start/Stop Output

Max. Resolution: 0.002 in. (0.05 mm)

PWM Output

Max. Resolution: 0.0002 in. (0.005 mm)

24 Vdc

Power Suppy

Required

5 Vdc

Required for

TTL Output

Selectable: BCD, Binary, or Gray Code Displacement Output

Optional Voltage Output (0 to 10 Vdc or 10 to 0 Vdc)

for recording purposes only

NOTE:

BCD outputs are limited to a maximum

stroke length of 99.99 inches (2540 mm)

R

E

M

RUN

REC

ZER

l

MK 292

S

S

S

S

S

S

R

E

M

RUN

REC

ZER

l

MK 292

S

S

S

S

S

S

1.19 in.

30.2 mm

1.98 in.

50.4 mm

MK 292

Module

MK 292

Card

6.7 in.

170 mm

6.7 in.

170 mm

5.06 in.

128.4 mm

5.06 in.

128.4 mm

2

Page 7

2. Specifications

2.1 MK292 Digital Output Module Specifications

Parameter Specification

Input Voltage: 24 Vdc (-15%/+20%); Ripple: < 5%

NOTE:

An additional 5V power supply is required for the optional TTL level outputs;

dual power supply (24/5 Vdc) is available from MTS, P/N 380066

Current Draw: 250 mA maximum

Input Requirement: SE-based Temposonics LP with start/stop output*

Temposonics II with PWM or start/stop output

Temposonics L Series with PWM or start/stop output*

Output Format: (Selectable): Up to 24 bit:

• BCD

(maximum stroke length with BCD output scaled in millimeters is 7500 mm. When utilizing

inches, strokes may be up to 300 inches)

• Natural Binary

• Gray Code

Resolution: 0.002 in. (0.05 mm) with start/stop input

0.0002 in. (0.005 mm) with PWM input

Update Frequency: Stroke and resolution dependent

Optional Analog (Recorder) Output :Range: -10 to +10 Vdc

(used for recording; option board required - must be specified upon initial order)

12 bit resolution

5mv ripple

Fully adjustable

Programming Parameters: Zero

Resolution

Stroke Length

Measuring Direction

Analog Output

(used for recording; option board required - must be specified upon initial order)

Operating Temperature: 0 to 60°C (32 to 140°F)

Connection: 64 pin edge connector (DIN 41612; provided with circuit card)

Cable Requirements: 8 x 24 AWG, twisted pairs, shielded low capacitance cable (BELDEN 8105 or equivalent)

w/appropriate number of conductors for sensor used

Maximum Cable Length: Sensor with RS422 output: 500 meters (1640 ft.)

Sensor with PWM output: 152.4 meters (500 ft.)

Dimensions: MK292 Card, Front Panel: 30.2 x 128.4 mm (1.19 x 5.06 in.)

MK292 Module, Front Panel: 50.4 x 128.4 mm (1.98 x 5.06 in.)

* When using the MK292 with a Temposonics LA or LP sensor, please contact Applications Engineering.

Specifications are subject to change without notice. Consult MTS for verification of specifications critical to your application.

3

Page 8

2.2 Temposonics Position Sensor Specifications

For detailed specifications and installation requirements for the position sensors, refer

to the appropriate document, as follows:

• Temposonics II Sensor Installation and Instruction Manual (P/N 550055)

• SE-based Temposonics LP Installation Guide (P/N 550582)

• Temposonics L Series/Digital Product Specification (P/N 550539)

Parameter Specification

Input Voltage: Powered from MK292 Module

Stroke Length: Temposonics II: Up to 300 inches (7620 mm)

SE-based Temposonics LP: Up to 48 inches (1219 mm)

Temposonics L Series: Up to 120 inches (3048 mm)

Non-linearity: Temposonics II: < ±0.05% of full scale or ± 0.002 inch (±0.05 mm), whichever is greater

SE-based Temposonics LP: ± 0.1% of full scale or ± 0.004 in. (±0.10 mm), whichever is greater

Temposonics L Series: 0.03% of full scale

Repeatability: ± 0.001% of full scale or ±0.0001 inch (± 0.002 mm), whichever is greater

Operating Temperature: Head Electronics: - 40 to 150°F (- 40 to 66°C)

Sensor Rod: - 40 to 185°F (- 40 to 85°C)

Operating Pressure: Temposonics II Rod-Style Sensors: 3000 psi continuous, 8000 psi static typical

Temposonics L Series Rod-Style Sensors (Model LH): 5000 psi continuous, 10,000 psi static

Outputs (absolute): Start/stop or PWM configured for

external

interrogation

Mounting Distances: Sensor with RS422 output to MK292: 500 meters (1640 ft.)

Sensor with PWM output to MK292: 152.4 meters (500 ft.)

MK292 to PLC: 25 meters (82 ft.)

Specifications are subject to change without notice. Consult MTS for verification of specifications critical to your application.

NOTE (Zero Points):

Before ordering an MK292 with a Temposonics LA

or LP sensor, consult an MTS Sensors Division

Applications Engineer for details regarding the

positioning of the sensor’s ZERO point.

4

Page 9

3. System Components

3.1 MK292-Compatible Temposonics Position Sensors

To interface with the MK292, a start/stop or pulse-width modulated output (see figure

3.1) is required from the Temposonics position sensor. The MK292 will convert these

signals into a parallel BCD, Gray Code, or binary output.

COMPATIBLE SENSORS

3.1.1. Temposonics Position Sensor with Start/Stop Output

Temposonics L Series and LP position sensors provide a direct RS422 compatible

start/stop output. Temposonics II position sensors require an RS422 Personality

Module (RPM), installed in the sensor head, to produce a start/stop output.

3.1.2. Temposonics Position Sensor with Pulse-Width Modulated (PWM) Output

Temposonics L Series position sensors provide a direct pulse-width modulated output.

Temposonics II position sensors require a Digital Personality Module (DPM) to generate a pulse-width modulated output. The DPM is installed in the head of the sensor's

electronics enclosure.

When using a Temposonics sensor with a PWM output, "external interrogation" is

required to interface with the MK292. External interrogation is an option selected at

the time of order and is pre-set at the factory.

3.1.3. Temposonics Position Sensor with Synchronous Operation (External

Interrogating)

In synchronous operation, an interrogation pulse is supplied to the position sensor

from the MK292 module. After supplying the interrogation pulse, the MK292 waits for

the sensor's return pulse, then ends the cycle. The time between the launching of the

interrogation pulse and the receipt of the return pulse is proportional to the distance

between the null or zero position and the movable magnet.

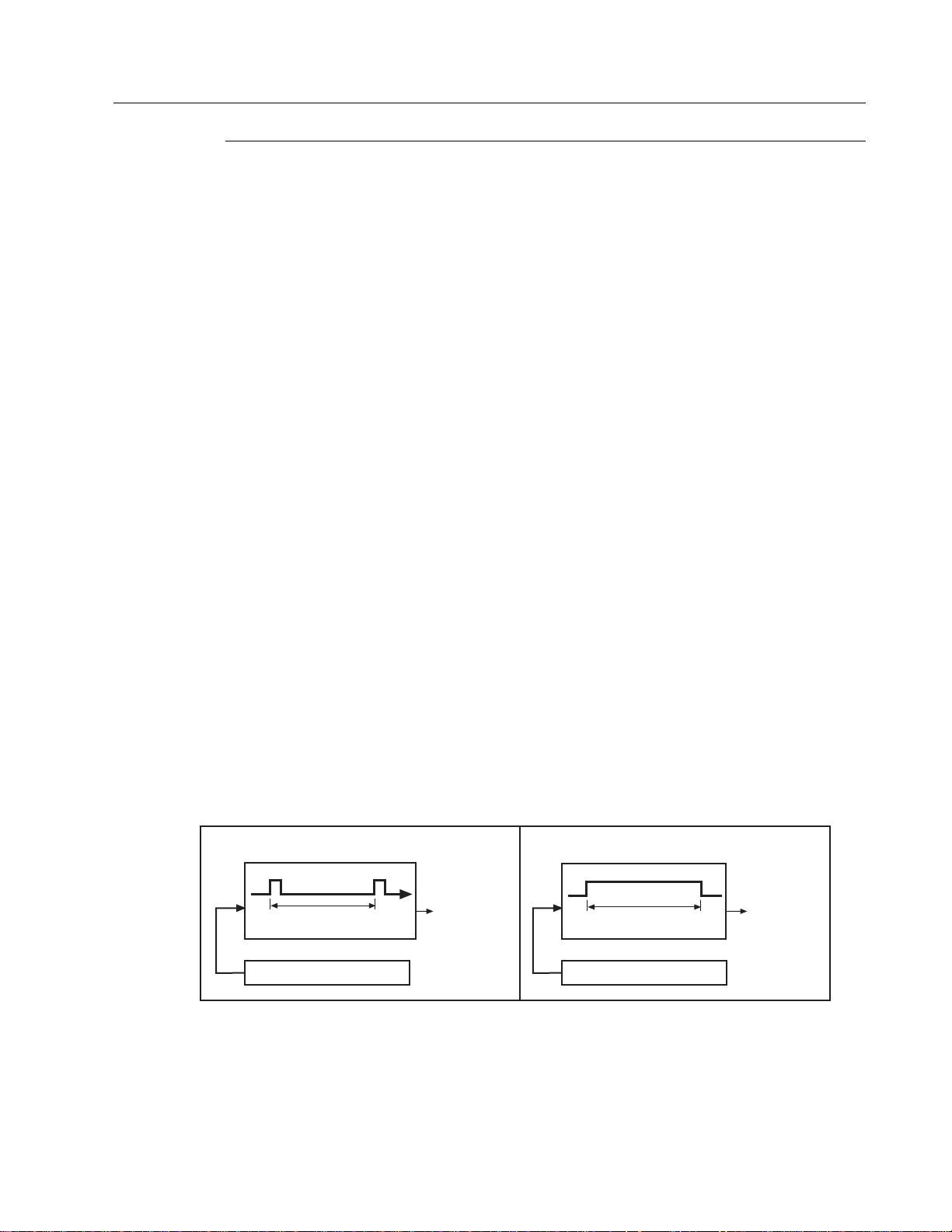

Figure 3-1

Start/stop and PWM Outputs

RS422 Compatible

Start/Stop Output

To MK292 Module

Distance between Start and Stop pulse

is proportional to magnet position

Temposonics Position Sensor

To MK292 Module

Temposonics Position Sensor

Pulse Duration Output

Pulse duration is

proportional to position

StartStop

5

Page 10

4. Connections

4.1.1 Temposonics II Position Sensors with DPM or RPM

Table 4-A Connections - Temposonics II Position Sensor

MK292 Wire Color Wire Color Function Function

Connections Pin No. (Striped Leads) (Solid Leads) w/PWM Output w/Start/Stop Output

C32 1 White/Blue Stripe White DC Ground DC Ground

C32 2 Blue/White Stripe Brown Frame Frame

C28 3 White/Orange Stripe Gray (-) Gate Out (-) Start/Stop Pulse

C27 4 Orange/White Stripe Pink (+) Gate Out (+) Start/Stop Pulse

C30 5 White/Green Stripe Red + 15 Vdc + 15 Vdc

C31 6 Green/White Stripe Blue - 15 Vdc - 15 Vdc

No Connection 7 White/Brown Stripe Black Not Used Not Used

No Connection 8 Brown/White Stripe Violet Not Used Not Used

C24 9 White/Gray Stripe Yellow (+) Interrogation (+) Interrogation

C25 10 Gray/White Stripe Green (-) Interrogation (-) Interrogation

NOTE:

Verify if the cable has striped or solid color leads and make connections accordingly.

Figure 4-1

10 Pin 'RB' Style Connector

(Mating Connector: P/N 400755-3)

4.1.2 SE-based Temposonics LP Position Sensors with Start/Stop Output

Table 4-B Connections - SE-based Temposonics LP Position Sensor

MK292 Sensor

Connections Pin No. Wire Color Function

C28 1 Blue Gate (-)

C27 2 Green Gate (+)

C25 3 Yellow Interrogation (-)

C24 4 Orange Interrogation (+)

C30 5 Red Power, provided by MK292 (+15, ± 10%)

C32 6 Black Ground

No Connection 7 Drain Shield Drain Wire

No Connection 8 N/A N/A

Figure 4-2a Figure 4-2b

Integral Connector Hanging Connector

Connection Type C, Connection Type H or J,

External View External View

1 2

3

6

5

8

4

7

1 2

3

6

5

8

4

7

1

2

3579

46810

6

Page 11

4.1.3 Temposonics L Series Position Sensors with Start/Stop Output

Table 4-C.1 Connections - Temposonics L Series Position Sensor with RG Connector

MK292

Connection Pin No. Wire Color Function

C28 1 Gray (-) Gate

C27 2 Pink (+) Gate

C24 3 Yellow (+) Interrogation

C25 4 Green (-) Interrogation

C2 5 Red or Brown Power supplied by MK292 (+ 24 Vdc)

C32 6 White DC Ground

7 - No Connection

Figure 4-3

RG Connector

Table 4-C.2 Connections - Temposonics L Series Position Sensor with MS Connector

MK292

Connection Pin No. Wire Color Function

C32 A White DC Ground

B - No Connection

C28 C Gray (-) Gate

C27 D Pink (+) Gate

C2 E Red Power supplied by MK292 (+ 24 Vdc)

F - No Connection

G - No Connection

H - No Connection

C24 J Yellow (+) Interrogation

C25 K Green (-) Interrogation

Figure 4-4

MS Connector

(Mating Connector: P/N 370013)

A

B

C

D

E

F

G

H

J

K

2

1

6

5

4

3

7

CAUTION!

When wiring Temposonics L Series sensors, DO NOT

connect DC ground to the cable shield or drain wire.

7

Page 12

Table 4-C.3 Connections - Temposonics L Series Position Sensor with RB Connector

MK292

Connection Pin No. Wire Color Function

C32 1 White DC Ground

2 - No Connection

C28 3 Gray (-) Gate

C27 4 Pink (+) Gate

C2 5 Red Power supplied by MK292 (+ 24 Vdc)

6 - No Connection

7 - No Connection

8 - No Connection

C24 9 Yellow (+) Interrogation

C25 10 Green (-) Interrogation

Figure 4-5

RB Connector

(Mating Connector: P/N 400755-3)

Table 4-C.4 Connections - Temposonics L Series Position Sensor with RO Integral Cable

MK292

Connection Wire Color Function

C28 Gray (-) Gate

C27 Pink (+) Gate

C24 Yellow (+) Interrogation

C25 Green (-) Interrogation

C2 Red or Brown Power supplied by MK292 (+ 24 Vdc)

C32 White DC Ground

Table 4-C.5 Connections - Temposonics L Series Position Sensor with HO Integral Cable*

MK292

Connection Wire Color Function

C28 White (-) Gate

C27 Black twisted w/white (+) Gate

C24 Blue (+) Interrogation

C25 Black twisted w/blue (-) Interrogation

C2 Red Power supplied by MK292 (+ 24 Vdc)

C32 Black twisted w/red DC Ground

*The HO Integral Cable [maximum length 30 feet (9.14 m)] was not available at the time

this manual was printed. Please contact the factory for status.

1

2

3579

46810

8

Page 13

4.2 System Connections

NOTES:

1. Logic inputs and outputs are relative to voltage level connected to Vin (Pin c3). For example, set Vin to 5 Vdc for TTL, or 24

Vdc for controller with 24 Vdc inputs/outputs.

2. The five digit BCD outputs are limited to stroke lengths ≤7500 mm when measuring in millimeters. When measuring in

inches, BCD output is available for stroke lengths up to 300 inches.

3. When using a PWM output, the sensors must be configured for external interrogation.

Figure 4-6

System Connections

DC Common

+ 24V Input to MK292

5-24V Input for TTL Output

Error

Data Ready

Master/Start Output

PWM or Start/Stop

Master/Slave Input

mm/Inch

c11

c12

Vin

0V

c11

c12

Vin

0VParallel

BCD Output

(Note 2)

Parallel

Binary Output

Parallel

Gray Output

c11

c12

0V

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

5

6

MSB

LSB

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

BCD Natural Binary

or Gray Code

Polarity (+/-)

Displacement Output Format

c15

Vin Negative

c15

0V Positive

Displacement

Output Format

Output Logic

c10

Vin

PWM

(Note 3)

c10

0V Start/Stop

PWM or Start/Stop

c1 or a1

c1 or a1

c1 or a1

c2 or a2

c2 or a2

c2 or a2

c2 or a2

c1 or a1

c1 or a1

c1

c2

c3

0 V

24 V

Vin

For 5 - 24 V input

IMPORTANT: 5 V required for TTL

(Note 1)

c1

c2

c3

0 V

24 V

EXAMPLE:

Controller with 24 V inputs

c1 or a1

c2 or a2

c3 or a3

c5

c6

c7

c10

c11

c12

c13

c14

c15

c16

c17

c19

c20

c24

c25

c27

c28

c30 or a30

c31 or a31

c32 or a32

a4

a5

a6

a7

a8

a9

a10

a11

a12

a13

a14

a15

a16

a17

a18

a19

a20

a21

a22

a23

a24

a25

a26

a27

a28

MK 292

Digital

Output

Module

When high, output is negative (-);

when low, output is positive (+)

Sensor Connections

(Wire color is sensor dependent refer to Section 4.1 of this manual)

(+) Interrogation

(-) Interrogation

(+) Gate or (+) Start/Stop Pulse

(-) Gate or (-) Start/Stop Pulse

+ 15 Vdc

- 15 Vdc

DC Ground

Frame

Output

Output

Input

Optional Analog Output

DC Common

DC Common

DC Common

Output Logic (+/-)

External Start Input

Data Hold Input

c14

Vin Inches

c14

0V Millimeter

Unit of Measurement

c1 or a1

c2 or a2

9

Page 14

4.3 Functional Inputs/Outputs

OUTPUTS:

Voltage Level: TTL level to 24 Vdc

Maximum Current Load: 20 mA (high level)

INPUTS:

Control Signal Level: ≥ applied Vin level

Current Load per Input: < 1 mA

4.3.1 Error Output (Loss of Feedback)

Pin: c5

Logic: HIGH: No Error; LOW: Error

Figure 4-7 Error Outputs

Errors:

• No sensor magnet

• Sensor magnet not positioned within the active range of sensor

• Malfunction or failure of sensor or module

• Electronic interference

4.3.2 Data-Ready Output (Latch Pulse)

Pin: c6

Logic: HIGH

Ensures that parallel data transfer does not occur during data update

(i.e., during change in magnet position). In addition, the data ready

output confirms that the data is up-to-date.

The timing of data transfer is illustrated below.

Figure 4-8 Data Ready

60 µs 60 µs

Cycle

Time

Data

Ready

Data

Changing

c5

HIGH = No Error LOW = Error

10

Page 15

4.3.3 Data-Hold Input (Latch Inhibit)

Pin: c17

Logic: HIGH

Data Hold is another means, besides Data Ready, to ensure that parallel data transfer does not occur during data update. When Data Hold

(C17) is high, data does not update.

4.3.4 External Start Input (Features)

Pin: c16

Logic: HIGH

The External Start Input permits the timing of the measuring cycle

(i.e., the interrogation pulses) to originate from an outside source.

The Master/Slave Input (see below) logic must be HIGH before the

sensor can be interrogated, normally it is set LOW.

Start signals must be between 6 to 10 microseconds in duration and

repetition period must exceed the minimum cycle time -- refer to programming section of the manual: (MR) Measuring Range.

Figure 4-9 External Start

4.3.5 Master/Slave Input (Features)

Pin: c13

Logic: HIGH

If an application requires that more than one Temposonics position

sensor provide position data simultaneously, the Master/Slave Input

may be used. It is essential to identify the longest position sensor as

the master device since it possesses the longest cycle time. The master "start" command is switched to output 'c7' and linked to slave output 'c16' (External Start Input).

Figure 4-10 Master/Slave

Master

c7

c13

Slave

c16

c13

Slave

c16

Vin

6 - 10 µs

Minimum

Cycle Time

11

Page 16

5. System Parameters

After the MK292 Digital Output Module is installed and connected to the Temposonics position sensor,

system parameters must be set before start-up. When setting the system parameters, you must be

aware which electronics module is installed in the Temposonics position sensor. Verify that the sensor

has either a start/stop or PWM output. If the sensor has a PWM output, also verify that it is configured for external interrogation. Contact an MTS Applications Engineer if you have any questions

regarding the configuration of your sensor or how to interface to the MK292 unit.

The system parameters for each configuration are indicated below:

SYSTEM PARAMETERS SYSTEM PARAMETERS

(Sensor with PWM Outputs) (Sensor with Start/Stop Outputs)

< <

< <

NOTE:

Pulse Duration (REC) only applies to systems that are using sensors with a PWM output.

< <

< <

< <

< <

System parameters are set via the front panel of the MK292 using the programming and BCD switches.

• Programming Switch

This momentary toggle switch is located at the bottom of the front panel. It has two activation positions: #1 and #2. Programming Modes are accessed by manipulation of this switch as defined in the

Programming section of this manual.

Figure 5-1

Programming Switch Positions

When the Programming Switch is pushed into either Position #1 or Position #2 it will automatically

return to the center (normal) position when released.

Position #1 Position #2Normal

Position

ZERONull AdjustmentZERO

MRMeasuring RangeMR

REResolutionRE

SCScaling FactorSC

N/APulse DurationREC

RUNProgramming ModeRUN

12

Page 17

• BCD Switches (S1-S6)

The six rotary switches, S1 (least significant digit) to S6 (most significant digit), are used to set parameter values. A screw driver or adjusting tool is used to set the switches.

The input values are checked against the actual values as indicated by the customer provided controller display.

• LEDs

There are six LEDs, one red and five green, which give visual indication of the operating condition and

programming mode of the MK292.

1. RED (continuous light) = System in operation mode

2. RED (flashing light) = Transition to programming mode

3. GREEN (continuous light) = Indication of selected parameter

4. GREEN (flashing light) = Programming mode is activated – parameter settings can be

changed via BCD switches S1-S6.

5. GREEN (fast flashing light) = Input error

Figure 5-3

BCD Switch

Figure 5-2

Front Panel of MK292 Module

2

3

8

1

5

4

6

7

9

0

RE

MR

SC

RUN

REC

ZERO

S1

S2

S3

S4

S5

S6

MK 292

LEDs

BCD Switches

Programming Switch

1 2

13

Page 18

6. Short Form Programming Procedure

• Programming Mode

Hold the programming switch in Position #1 (see Fig. 6.1) until the 'RUN' LED begins to

flash (≈ 3 sec.) Programming Mode is set up.

• Selection of System Parameters

To select desired parameter, momentarily toggle the programming switch to Position #1 and

release; an LED will light. Repeat until the LED is lit next to desired parameter.

• Parameter Adjustment

Enter desired values using BCD switches S1-S6 (S1 represents the least significant digit). Rapid

flashing of the green LED indicates input error.

• Parameter Setup

To store a newly set parameter, hold the programming switch in Position #2 (see Fig. 6.1)

until the LED of the next parameter is activated (≈ 3 sec.)

• Operation Mode

Hold the programming switch in Position #1 until the red "RUN" LED is activated. This indicates that the Programming Mode has been exited and the Operation Mode is ready.

Figure 6-1

Programming Switch Positions

For detailed instructions on programming the MK292 Digital Output Module, refer to Section 7 of this

manual.

Position #1 Position #2Normal

Position

NOTE:

If the value cannot be stored, momentarily hold the

programming switch in Position #1, and repeat, until

you cycle through to the desired parameter.

NOTE:

You may cycle through and check the parameters by

observing the controller display as you repeatedly put

the programming switch in Position #1.

To change a parameter: Select desired parameter, then

simply hold the programming switch in Position #2

until the LED flashes (≈3 sec.). Change parameter

using the BCD switches.

14

Page 19

7. Detailed Programming Procedure

7.1 (RUN) Programming Mode / Red LED

During initial start-up, the red 'RUN' LED will flash. This indicates that the MK292 is in

the programming mode and input parameters are required for operation.

If the 'RUN' LED is on, but not flashing, this means that parameters have already been

set. If parameters must be changed, the programming mode must be accessed, as follows:

Hold programming switch in Position #1 until 'RUN' LED flashes (≈ 3 sec.)

ADJUST

7.2 (REC) Pulse Duration / Green LED

Temposonics sensors with a PWM output are capable of “circulations”, meaning that

the interrogation and return signals can be recirculated a specific number of times.

This lengthens the duration of the PWM output from the sensor and the counting time

of the MK292; the result is increased resolution.

The number of circulations is determined at the time of order and is reflected in the

sensor’s model number. Refer to the appropriate ordering guide for the sensor that

you are using to determine the circulation count. If you have any questions regarding

this, contact an MTS Applications Engineer.

NOTE:

This parameter only applies to systems that have a

Temposonics position sensor with a PWM output. In

the procedure, this step will not occur if the MK292 is

configured for a start/stop output.

RUN

15

Page 20

1) Hold the programming switch in Position #2 until the 'REC' LED is flashing (≈ 3 sec.)

ADJUST 2) Enter the Pulse Duration (recirculation value) using BCD switches S1-S6.

Example:

Resolution vs. Circulations

Maximum Minimum Circulation Count

See note above 0.00025 16

0.00025 0.0005 8

0.0005 0.001 4

0.001 0.002 2

0.002 0.004 1

Maximum Resolution Formulas:

• Resolution in millimeters = (0.0508 ÷ Circulation Count)

• Resolution in inches = (0.002 ÷ Circulation Count)

Switch Setting: PWM Output (circulations)

BCD Switch Circulations: 4 Circulations: 16

S1 4 6

S2 0 1

S3 0 0

S4 0 0

S5 0 0

S6 0 0

1) Hold the programming switch in Position #2 until the 'SC' LED is flashing (≈ 3 sec.)

ADJUST

The MK292 is now ready to accept the next parameter – Scale Factor (SC).

REC

NOTE:

The chart below defines the MK292-programmable resolutions. It is important to note that with resolution

finer than 0.0002 in., instabilities will be detected on

the Least Significant Bits.

REC

16

Page 21

7.3 (SC) Scaling Factor / Green LED

Each Temposonics position sensor has its own specific scale factor (gradient) which

describes the velocity of the torsional strain pulse through the waveguide medium

(refer to 'Principle of Operation'). The gradient is indicated on the sensor's label. Upon

initial start-up or when replacing sensors, this value must be set to recalibrate system.

1) Momentarily tap the programming switch to Position #1, the 'SC' LED will light.

ADJUST 2) Hold the programming switch in Position #2 until the 'SC' LED begins to flash (≈ 3 sec.)

3) Enter the scale factor indicated on the sensor label using the BCD switches (S1 - S6).

Example: Gradient = 8.94371

BCD Switch # Settings

S1 1

S2 7

S3 3

S4 4

S5 9

S6 8

SC

IMPORTANT

Scale Factor or Gradient

For stroke lengths defined in inches (Pin c14 set for inches), the

scale factor or gradient is described in microseconds per inch.

This value is indicated on the sensor's label (see Fig. 7.3).

For stroke lengths defined in millimeters (Pin c14 set for millimeters), the scale factor or gradient is described in meters per second.

The formula to convert µs/in, to m/s is as follows:

(Scale in m/s) = 25,400 ÷ (Scale in µs.in.)

Example:

Scale (Gradient) = 8.94371 µs/in.

25,400 ÷ 8.94371 µs/in = 2839.98 meters/second

17

Page 22

Hold the programming switch in Position #2 until the 'RE' LED is lighted (≈ 3 sec.)

SETUP

The MK292 is now ready to accept the next parameter – Resolution (RE).

7.4 (RE) Resolution / Green LED

The resolution that can be achieved by the MK292 is dependent on the input from the

Temposonics position sensor. The chart below indicates the range of resolutions

depending on sensor type. Note that sensors with PWM output must be set for the

appropriate number of circulations to achieve desired output resolution.

RESOLUTION

Start/Stop Output

Range: 0.1 in. to 0.002 in. or 2.54 mm to 0.05 mm

PWM Output

Range: 0.1 in. to 0.0002 in. or 2.54 mm to 0.005 mm

(Note: Refer to Resolution vs. Circulation Chart, page 16)

1) Hold the programming switch in Position #2 until the 'RE' LED begins to flash (≈ 3 sec.)

ADJUST 2) Enter the desired resolution using BCD switches S1 - S6.

Table 7A

Table 7B

Hold the programming switch in Position #2 until the 'MR' LED begins to flash (≈ 3 sec.)

SETUP

The MK292 is now ready to accept the next parameter – Measuring Range (MR)

RE

SWITCH SETTINGS / RESOLUTION IN MILLIMETERS

Switches 0.005 mm 0.01 mm 0.05 mm 0.1 mm 0.5 mm 1.0 mm

S1 (0.00X) 5 0 0 0 0 0

S2 (0.0X) 0 1 5 0 0 0

S3 (0.X) 0 0 0 1 5 0

S4 (X.0) 0 0 0 0 0 1

S5 0 0 0 0 0 0

S6 0 0 0 0 0 0

SWITCH SETTINGS / RESOLUTION IN INCHES

Switches 0.0002 in. 0.0004 in. 0.002 in. 0.004 in. 0.02 in. 0.039 in.

S1 (0.000X) 2 4 0 0 0 0

S2 (0.00X) 0 0 2 4 0 9

S3 (0.0X) 0 0 0 0 2 3

S4 (0.X) 0 0 0 0 0 0

S5 0 0 0 0 0 0

S6 0 0 0 0 0 0

RE

SC

18

Page 23

7.5 (MR) Measuring Range / Green LED

The measuring range or "stroke length" of the sensor must be set accurately to optimize the interdependence of the other parameters. This value is indicated on the sensor label as "stroke" and will be in either inches or millimeters.

1) Hold the programming switch in Position #2 until the 'MR' LED begins to flash (≈ 3 sec.)

ADJUST 2) Enter the measuring range using BCD switches S1 - S6.

Example:

Update Time Formula:

Tud = [(Lm + 120 mm) (13) (N)] ÷ 36

Where:

Update Time (in milliseconds) = Tud

Length in mm = Lm

Circulation Count = N

1) Hold the programming switch in Position #2 until the 'ZERO' LED begins to flash (≈3 sec.)

SETUP

The MK292 is now ready to accept the next parameter -- Null Adjust (ZERO).

MR

NOTE:

When the measuring range is set, the measuring frequency and system update time is also set. Refer to the

tables below to see the relationship of measuring

range, frequency, and update time.

MILLIMETERS

Measuring Range: 1525 millimeters

Switch (mm) Setting

S1 (1.0) 5

S2 (10) 2

S3 (100) 5

S4 (1000) 1

S5 (n/a) 0

S6 (n/a) 0

INCHES

Measuring Range: 120.5 inches

Switch (in.) Setting

S1 (0.1) 5

S2 (1.0) 0

S3 (10) 2

S4 (100) 1

S5 (n/a) 0

S6 (n/a) 0

MR

NOTE:

Pin c14 of the MK292 permits you to select the unit of

measurement (i.e., inches or millimeters) and must be

wired accordingly (refer to section 4.2).

19

NOTE:

When using inches, use the following

formula to convert inches to millimeters:

Inches x 25.4

Page 24

7.6 (ZERO) Null Adjust / Green LED

Null adjust allows you to set the mechanical ZERO position anywhere within the

active measuring range of the position sensor. Move the sensor magnet to the desired

ZERO position and proceed as follows:

1) Hold the programming switch in Position #2 until the 'ZERO' LED begins to flash (≈3 sec.)

ADJUST

The displacement output indicates position without the offset calculation

2) Set switches S1-S6 to ZERO position.

1) Hold the programming switch in Position #2 to restart programming sequence. (≈ 3 sec.)

SET UP

7.7 (ZERO) Offset

As an alternative to the ZERO/NULL adjust, a ZERO/NULL offset can be programmed

within a range of -49.9999 to +49.9999 inches. The value depends on the pre-set resolution of the position sensor. The offset is set by using S6 only.

Forward Acting - Positive offset counts down when magnet is moved to the head and

counts up when moved to the tip.

Reverse Acting - Negative offset counts up when magnet is moved to the head and

counts down when moved to the tip.

Positive Offset Negative Offset

0 = +0 5 = -0

1 = +1 6 = -1

2 = +2 7 = -2

3 = +3 8 = -3

4 = +4 9 = -4

NOTE:

If a set value is overwritten, the programming mode

has to be set again by repeatedly tapping the dip

switch to position #1.

ZERO

ZERO

20

Page 25

Move the magnet to the desired mechanical start position and calibrate the offset as

follows:

1) Hold the programming switch in Position #2 until the 'ZERO' LED begins to flash (≈3 sec.)

ADJUST

The displacement output indicated position without the offset calculation

2) Enter the desired offset value using BCD switches S1-S6.

EXAMPLE: Switch Settings S1-S6 for Offset Value

1) Hold the programming switch in Position #2 to restart programming sequence. (≈ 3 sec.)

SET UP

NOTE:

If a set value is overwritten, the programming mode

has to be set again by repeatedly tapping the dip

switch to Position #1.

OFFSET

NEGATIVE OFFSET (in inches)

BCD Switch -00.3571 -04.5841 -03.5705 -45.8405

S1 1 1 5 5

S2 7 4 0 0

S3 5 8 7 4

S4 3 5 5 8

S5 0 4 3 5

S6 5 5 5 9

POSITIVE OFFSET (in inches)

BCD Switch +00.3571 +04.5841 +03.5705 +45.8405

S1 1 1 5 5

S2 7 4 0 0

S3 5 8 7 4

S4 3 5 5 8

S5 0 4 3 5

S6 0 0 0 4

OFFSET

21

Page 26

7.8 (RUN) Operation Mode / Red LED

1) Hold the programming switch in Position #1 until the 'RUN' LED begins to flash (≈ 3 sec.)

SETUP

The Programming Mode is exited and all parameter settings are stored in an EEPROM

within the MK292 module. You are now in Operation Mode.

RUN

22

Page 27

8. Optional Analog Output for the MK292 (for Recording Purposes Only)

The analog output option functions in two operational modes:

1. Normal (NORM)

2. Programmable Adjustment (PROG)

Operation mode is selected with the switch on the analog sub-print board (see Fig. 8.1).

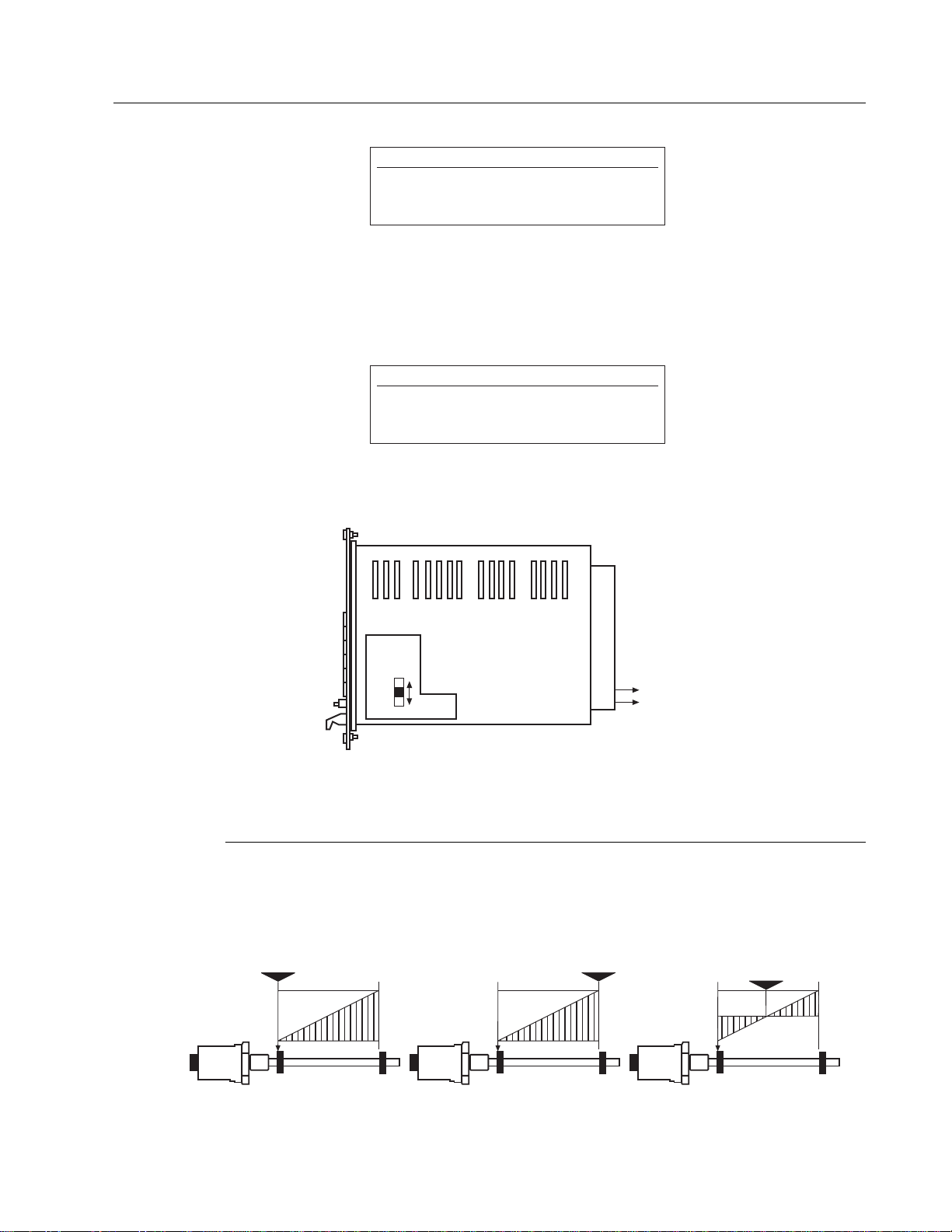

Figure 8-1

8.1 Operation Mode 1 (Normal)

Analog Sub-print Switch (S1) = NORM

The analog output configuration is defined by the zero position and measuring range

of the sensor. The three possible configurations are illustrated in Fig. 8.2.

Figure 8-2

Null Set-Up

+10 V

0 V

No. 1

Null Set-Up

0 V

-10 V

No. 2

Null Set-Up

+5 V

0 V

-5 V

No. 3

MK 292

Module

c19

c20

- 10 to + 10 Vdc

0 Vdc

NORM

PROG

Analog

Subprint

WARNING!

When powering down during analog operation, switch

must remain in programming mode or all parameters

will be lost.

NOTE:

The analog output is available as an option and must

be specified at the time of order. An additional analog

sub-print is required.

23

Page 28

If the magnet leaves the defined measuring range of the sensor, the system will indicate the following outputs:

1. If the magnet leaves the measuring range moving towards the end of the sensor

rod, the output voltage will be NEGATIVE.

2. If the magnet leaves the measuring range moving toward the electronics head of

the sensor, the output will be a constant +10V.

8.2 Operation Mode 2 (Programmable Adjustment)

The analog output configuration can be set-up by defining the desired output range of

the sensor with two set-points (SP1 and SP2).

Switch S1 = ON (PROG)

SP1 Programming:

1.) Move the magnet to the desired SP1 position.

2.) Hold the programming switch in Position #1 until the RUN LED begins to flash (≈ 3 seconds)

Programming Mode is set up.

3.) Momentarily toggle the programming switch to Position #1 and release and repeat until ZERO + SC become lit.

4.) Hold the programming switch in Position #2 until SC begins to flash (≈3 seconds). ZERO is also lit.

5.) Enter the desired analog out at SP1 using the BCD switches (S1 = least significant bit, S5 = most significant bit).

6.) Hold the programming switch in Position #2 until SC is lit (≈3 seconds). ZERO is also lit.

7.) The output value at SP1 is now stored.

SP2 Programming:

1.) Move the magnet to the desired SP2 position

2.) Hold the programming switch in Position #1 until the RE LED begins to flash (≈3 seconds). ZERO is also

lit.

3.) Enter the desired analog out at SP2 using the BCD switches (S1 = least significant bit, S5 = most significant bit).

4.) Hold the programming switch in Position #2 until SC is lit (≈3 seconds). ZERO will no longer be lit.

5.) Hold the programming switch in Position #1 until the RUN LED is lit (≈ 3 seconds).

The output value at SP2 is now stored and the system has entered the Operations Mode.

NOTE:

Setting up a value outside the valid voltage range will

be detected and RE will flash rapidly to indicate an error.

NOTE:

Setting up a value outside the valid voltage range will

be detected and SC will flash rapidly to indicate an error.

IMPORTANT NOTES:

• SP1 and SP2 must be within the valid measuring range

• SP1 must be located nearer the sensor head than SP2

• SP1 and SP2 can have output values between -10 V

and +10 V

24

Page 29

EXAMPLE, BCD Switch Settings

NOTE:

To configure a negative setpoint value: S6 ≥5.

SP1 = + 7.565 V SP2 = - 9.480 V

S1 = 5 S1 = 0

S2 = 6 S2 = 8

S3 = 5 S3 = 4

S4 = 7 S4 = 9

S5 = 0 S5 = 0

S6 = 0 S6 = 9

25

Page 30

l

MTS Systems Corporation

Sensors Division

3001 Sheldon Drive

Cary, NC 27513 USA

Phone: 800-633-7609

Fax: 919-677-0200

MTS Sensor Technologie

Gmb and Co. KG

Auf dem Schüffel 9

D-58513 Ludensheid

Federal Republic of Germany

Phone: +49-23-5195870

Fax: +49-23-5156491

MTS Sensors Technology Corp.

Izumikan Gobancho

12-11 Gobancho

Chiyoda-ku, Tokyo 102

Japan

Phone: +3-3239-3003

Fax: +3-3262-7780

Temposonics is a registered trademark of MTS Systems Corporation.

All Temposonics products are covered by US patent number 5,545,984.

Other patents pending.

0797 550414 Revision B

© 1997 MTS Systems Corporation

Loading...

Loading...