Page 1

Series 111 Accumulator

Product Information

Model 111.11

Model 111.12

l

011-553-304 B

Page 2

Copyright information

Trademark information

© 2000 MTS Systems Corporation. All rights reserved.

MTS is a registered trademark of MTS Systems Corporation.

Contact information

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255 (within the U.S. or Canada)

Phone: 612-937-4000 (outside the U.S. or Canada)

Fax: 612-937-4515

E-mail: info@mts.com

http://www.mts.com

Publication information ISO 9001 Certified

M

ANUAL

P

115533-00A December 1982

115533-01A August 1983

115533-02A September 1984

115533-03A June 1987

115533-03B February 1988

115533-03C February 1989

115533-03D June 1990

115533-03E November 1991

ART

N

UMBER

P

UBLICATION

D

ATE

115533-03F July 1993

115533-03G June 1994

115533-04A June 1998

011-553-304 B June 1999

Page 3

Contents

Introduction 5

Functional Description 6

Specifications 7

Installation 9

Maintenance 11

Checking the Accumulator Precharge 13

Changing the Precharge Pressure 15

Purging Fluid from the Gas Chamber 17

Removing the Accumulator 18

Replacing the Accumulator Seal 19

Series 111 Accumulators Contents

3

Page 4

4

Series 111 Accumulators

Page 5

Introduction

The Series 111 Accumulator stabilize the hydraulic lines in your system.

There are two models availlable:

• The Model 111.11B Accumulator is a boss port-mounted accumulator

that requires a boss adapter fitting for mounting.

• The Model 111.12C Accumulator is bolt-mounted to a flange and

typically has a larger nitrogen gas capacity than the Model 111.11B.

Contents

Functional Description 6

Specifications 7

What you need to

know

Series 111 Accumulators Introduction

MTS Systems Corporation assumes that you know how to use your

controller. See the appropriate manual for information about performing

any controller-related step in this manual’s procedures. You are expected

to know how to perform the following procedures:

• Turning hydraulic pressure on and off

• Selecting a control mode

• Manually adjusting the actuator position

5

Page 6

Functional Description

The MTS Series 111 Accumulators can reduce fluctuations hydraulic lines

due to sudden changes in hydraulic flow rate. They also act a short term

energy source for high-rate tests by providing additional hydraulic flow for

short periods to meet irregular peak demands. Like a capacitor,

accumulators filter out pulses in the hydraulic fluid to provide steady

hydraulic pressure.

Accumulators are like a hydraulic

version of a capacitor. They are

hydro-pneumatic devices located at

strategic points in a hydraulic

system. They may be connected to

the pressure line and to the return

line.

Nitrogen

Side

Accumulators are precharged with

pressure. Precharge pressure is the

pressure of the compressed gas

(usually nitrogen) before hydraulic

fluid is introduced.

Inserting accumulators into the

hydraulic lines permits some fluid to

be stored under pressure a short

distance from the servovalve and

actuator. This has the effect of

keeping fluid in the lines in motion

and reducing the inertia and line

restriction considerations. When the

servovalve opens and line pressure begins to drop, the accumulator in the

hydraulic service manifold (HSM) immediately supplies part of the fluid

volume and maintains the line pressure. Then, when the servovalve closes,

the hydraulic power supply (HPS) recharges the accumulator , causing fluid

in the lines to remain in motion.

The pattern and frequency of the signal that drives the servovalve will have

considerable effect on the HSM accumulator efficiency. Square wave

signals, for example, cause a greater demand than sine wave signals or

ramp signals.

Piston

Fluid

Side

Hydraulic Fluid

Accumulator

6

Introduction

At some frequencies, fluid flow in the lines may stop completely, and

overcoming the fluid inertia may become a more significant operational

factor.

An accumulator in the return line damps the pulsing effect caused by

“slugs” of fluid being injected into the line as the actuator moves.

Movement of hoses and/or hammering of hard lines is also reduced.

Series 111 Accumulators

Page 7

Specifications

The tables shown here list the specifications for the Series 111

Accumulators.

PECIFICATIONS

S

P

ARAMETER

Minimum burst pressure 83 MPa (12,000 psi) 138 MPa (20,000 psi)

Rated fatigue pressure 21 MPa (3000 psi) 22 MPa (3200 psi)

Operating temperature –40°C to 93.3°C (–40°F to 200°F)

M

ODEL

111.11B M

ODEL

111.12C

Hydraulic fluid

Petroleum-based hydraulic fluid. Contact MTS for

use with other fluids.

Charge gas

Dry nitrogen

Note Specifications are subject to change without notice. Contact MTS

Systems Corporation for verification of specifications critical to your

needs.

Capacity, Dimension, and Weight

†

A

ODEL

M

111.11B-01

111.11B-02

111.11B-03

111.11B-04

111.12C-02

*

N

AS

G

82 cm

164 cm

475 cm

950 cm

950 cm

ITROGEN

APACITY

C

3

5 in.

3

10 in.

3

1 pt 27.94 11.0 7.87 3.1 6.35 2.5 16 SAE (1-5/16-12 UNF-2B) 5.94 13.1

3

1 qt 42.88 16.9 7.87 3.1 6.35 2.5 20 SAE (1-5/8-12 UNF-2B) 7.98 17.6

3

1 qt 29.51 11.6 12.7 5.0 10.16 4.0

cm in cm in cm in

3

15.54 6.12 7.87 3.1 6.35 2.5 12 SAE (1-1/16-12 UNF-2B) 4.26 9.4

3

18.08 7.12 7.87 3.1 6.35 2.5 12 SAE (1-1/16-12 UNF-2B) 4.63 10.2

ENGTH

L

†

111.12C-03 1.9 l 0.5 gal 39.07 15.4 12.7 5.0 10.16 4.0

†

B

H

YDRAULIC

ORT

P

F

ONNECTION

C

LUID

1-1/2 SAE 4-bolt flange

1-1/2 SAE 4-bolt flange

‡

‡

M

AXP

KG LBS

18.45 40.6

21.77 48.0

111.12C-04 3.8 l 1 gal 61.93 24.4 12.7 5.0 10.16 4.0

1-1/2 SAE 4-bolt flange

‡

29.87 65.8

* The models listed in this table are considered standard models. Other models may be

manufactured with different capacities, lengths, or hydraulic fluid port connections than listed

here. Contact MTS Systems Corporation for information on nonstandard models.

† See the figures on the next page.

‡ Standard pressure series (Code 61).

Series 111 Accumulators Introduction

7

Page 8

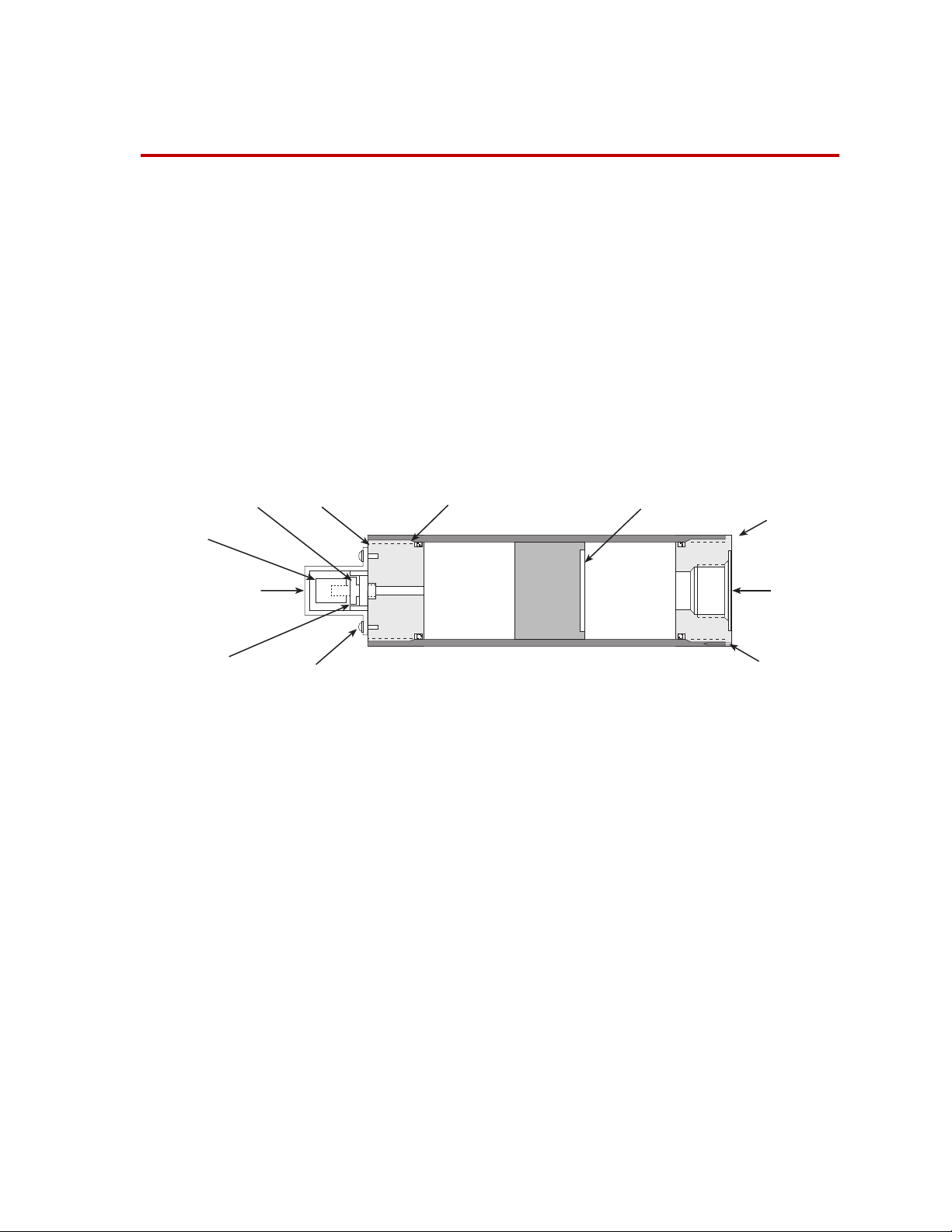

Ref.

1.563 in.

(39.7 mm)

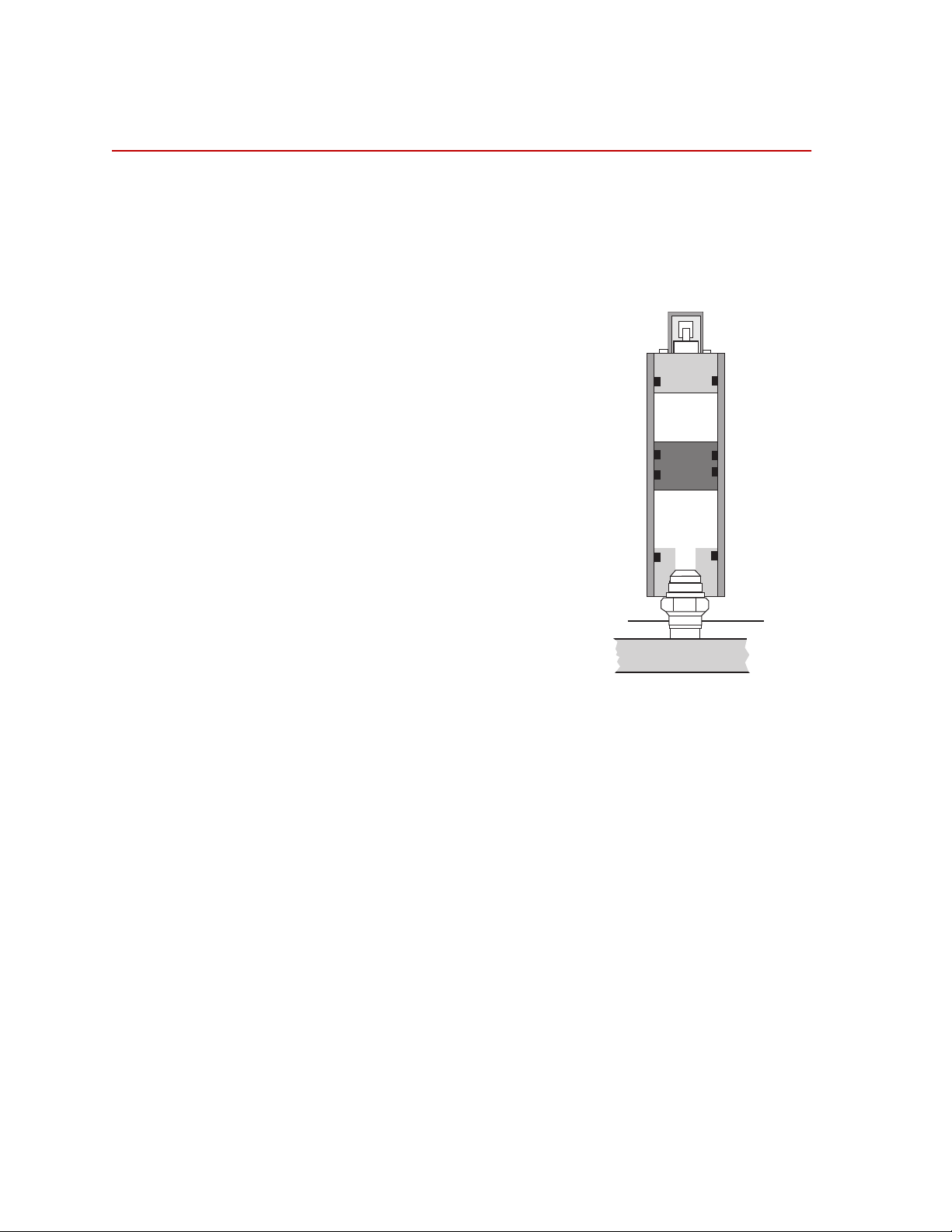

The cross-section figures shown on this page illustrate the difference

between the accumulator models.

Typical Boss

Adapter Fitting

Length

B

A

Accumulator

Valv e Assembly

Protective Cover

Ref.

1.563 in.

(39.7 mm)

Accumulator

Valve A ssembly

Protective Cover

Relief V ent

Model 111.11B Accumulator Cross-section

Length

A

B

Relief V ent

Hydraulic

Fluid Port

Hydraulic

Fluid Port

Ref.

1.406 in.

(35.7 mm)

Locking Pin

Locking Pin

Ref.

0.703 in.

(17.8 mm)

2.750 in.

(69.9 mm)

Ref.

1.375 in.

(34.9 mm)

1/2-13 UNC-2B

Ref.

8

Introduction

Model 111.12C Accumulator Cross-section

Series 111 Accumulators

Page 9

Installation

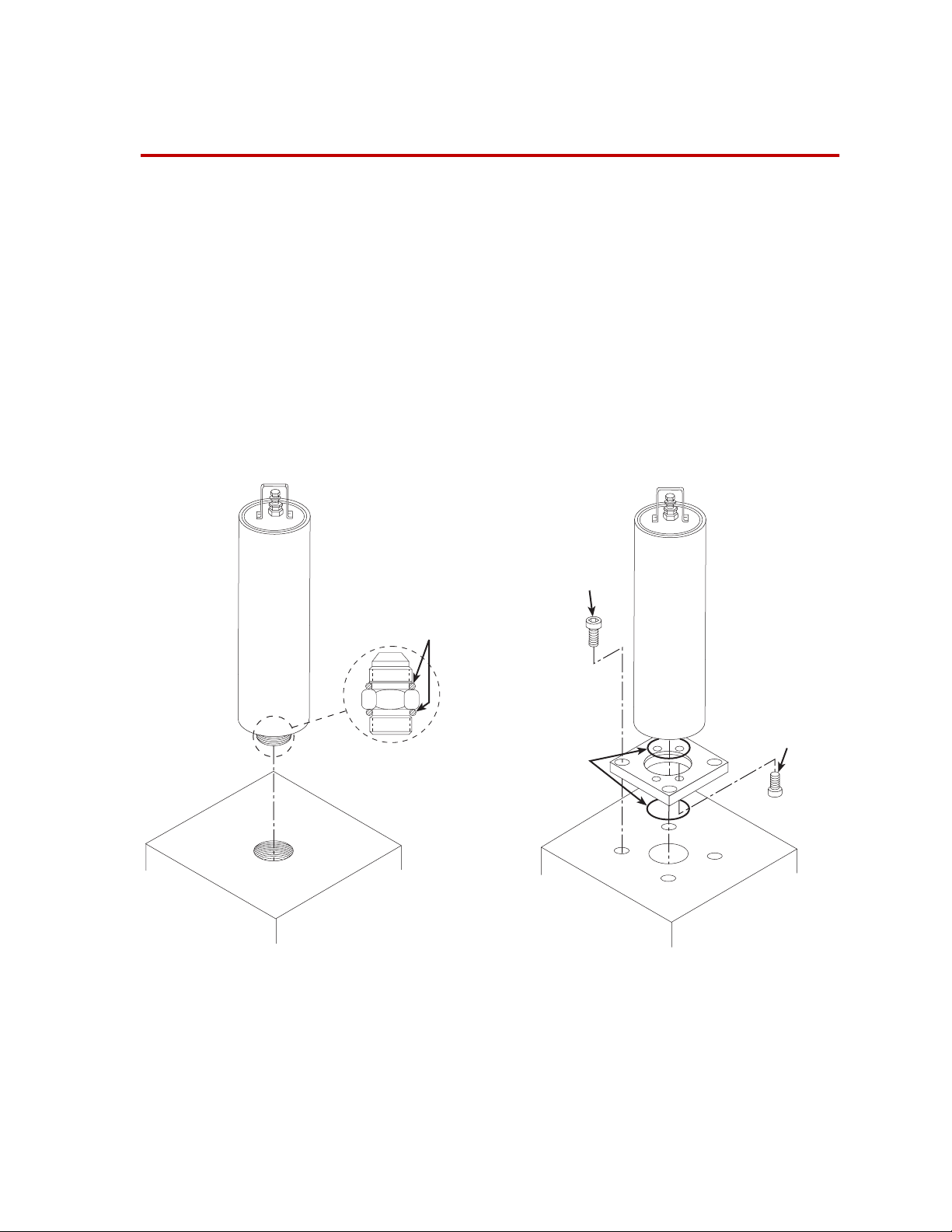

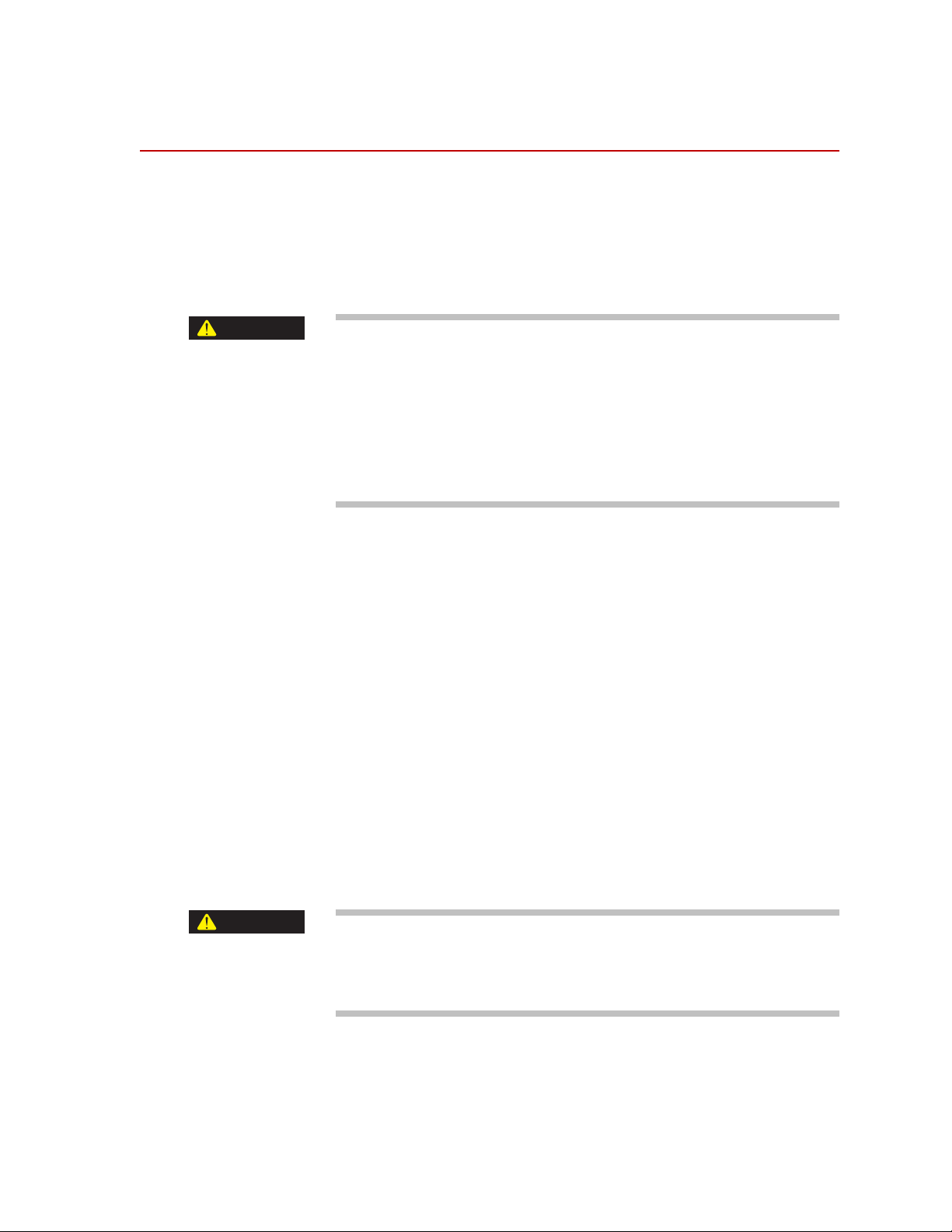

There are two models of the Series 111 Accumulator. The following figure

shows the typical mounting configuration for the Models 111.11B and

111.12C Accumulators.

• The Model 111.11B Accumulator is mounted with a boss adapter

fitting and O-ring seals. When the accumulator is ordered as a

component, the boss adapter and O-ring seals are not included with

the accumulator, they must be purchased separately.

• The Model 111.12C Accumulator is flush mounted with four bolts and

O-ring seal(s). When the accumulator is ordered as a component, the

four bolts (grade-8) and O-ring seal(s) (max. size 54.28 mm [2.137 in.]

outside diameter, 47.22 mm [1.859 in.] inside diameter), are not

included with the accumulator and must be purchased separately.

111.11B

Boss Adapter

Mounting

O-Rings

Flange

Mounting

O-Rings

Mounting Configurations

Flange

Mounting

Bolt

111.12C

Accumulator

Mounting

3

1

2

4

Bolts (4)

Required equipment

The following equipment is required for accumulator installation:

• Open-end wrench and strap wrench (for the Model 111.11B)

• Hex key set and torque wrench (for the Model 111.12C)

Series 111 Accumulators Installation

9

Page 10

Note When installing a replacement accumulator into an existing system, the

replacement accumulator should be precharged to the same pressure

level as the accumulator being removed. Be sure that this precharge

level is recorded on the label of the replacement accumulator.

Procedure

Complete the following steps to mount the accumulator. See the figure on

page 9 to complete the following procedure.

1. Mount the accumulator in the system after lubricating the mounting

O-ring seal(s). Note the O-ring seal configuration.

• For the Model 111.11B Accumulator

Thread the unit onto the boss adapter fitting and securely tighten

it with a strap wrench.

• For the Model 111.12C Accumulator

Lubricate and torque the four mounting bolts in increments

(according to the pattern shown in the “Mounting Configurations”

on page 9 figure) to a final torque of 108 N-m (80 lbf-ft).

2. Check the accumulator precharge pressure as described in “Checking

the Accumulator Precharge” on page 13.

10

Installation

Series 111 Accumulators

Page 11

Maintenance

This section describes how to maintain the charge in the accumulator.

Contents

Maintenance

guidelines

Locknut End Cap Chamfer Piston

Valve

Stem Cap

Accumulator V alve

Protective Cover

Accumulator

Valv e Assembly

Screws

Checking the Accumulator Precharge 13

Changing the Precharge Pressure 15

Purging Fluid from the Gas Chamber 17

Removing the Accumulator 18

Replacing the Accumulator Seal 19

Maintaining the proper pressure level for your accumulators is essential for

optimum system performance and component life. Review the following

figure to familiarize yourself with the accumulator components and their

locations. Also review the guidelines on the following page before

performing any procedure.

Hydraulic Fluid

End Cap

Hydraulic

Fluid Port

Locking Pin

Accumulator Components

Use the following guidelines to determine when maintenance is required.

• Check the precharge pressure at periodic intervals. The length of time

between checks depends on how the system is used. Some factors to

consider when establishing this time interval are operating frequency,

displacement, and duration. Start with one month intervals until you

determine another interval is more appropriate. See “Checking the

Accumulator Precharge” on page 13 for more information.

• Maintain a log book on the condition of the precharge at each check.

Use this data to determine if the time between checks should be

increased or decreased and if maintenance is required.

Series 111 Accumulators Maintenance

11

Page 12

• Because the precharge pressure level varies with a temperature

change, the level should always be checked at the same temperature.

If it is not, use one of the following formulas to determine if the

precharge level is acceptable.

Degrees Fahrenheit:

460 current temperatrure()+

current pressure original pressure

Degrees Celsius:

current pressure original pressure

---------------------------------------------------------------------

×=

460 original temperature()+

273 current temperatrure()+

---------------------------------------------------------------------

×=

273 original temperature()+

• If a pressure line accumulator has a pressure level change of ±1.4 MPa

(200 psi) between checks, the accumulator requires maintenance or

the time interval between checks needs to be shortened.

• If a return line accumulator has a change of ±50% of the original

pressure level between checks, the accumulator requires maintenance

or the time interval between checks needs to be shortened.

• If the precharge pressure level increases at each check interval, this

indicates that fluid is collecting on the gas side (a small amount of

fluid leakage is normal). When the precharge pressure level cannot be

maintained within the limits, remove the fluid and charge the

accumulator. If the levels are again exceeded at the first check interval,

replace the piston seals after the initial fluid has been changed.

• If the precharge pressure level decreases at each check interval, this

indicates gas leakage to the fluid side. When the precharge pressure

level cannot be maintained within the limits stated in the previous

guidelines, replace the accumulator piston seals.

• During normal operation, the accumulator piston should be near the

center of the accumulator cylinder. To check the approximate piston

location, note the warm-to-hot transition point on the accumulator

cylinder wall during operation. If the piston is near the charging stem

end, the accumulator may need charging. If the piston is at the other

end, the accumulator may have an excess charge, or more likely an

excessive amount of hydraulic fluid has collected in the gas chamber.

12

Maintenance

Series 111 Accumulators

Page 13

Checking the Accumulator Precharge

Special equipment

Procedure

WARNING

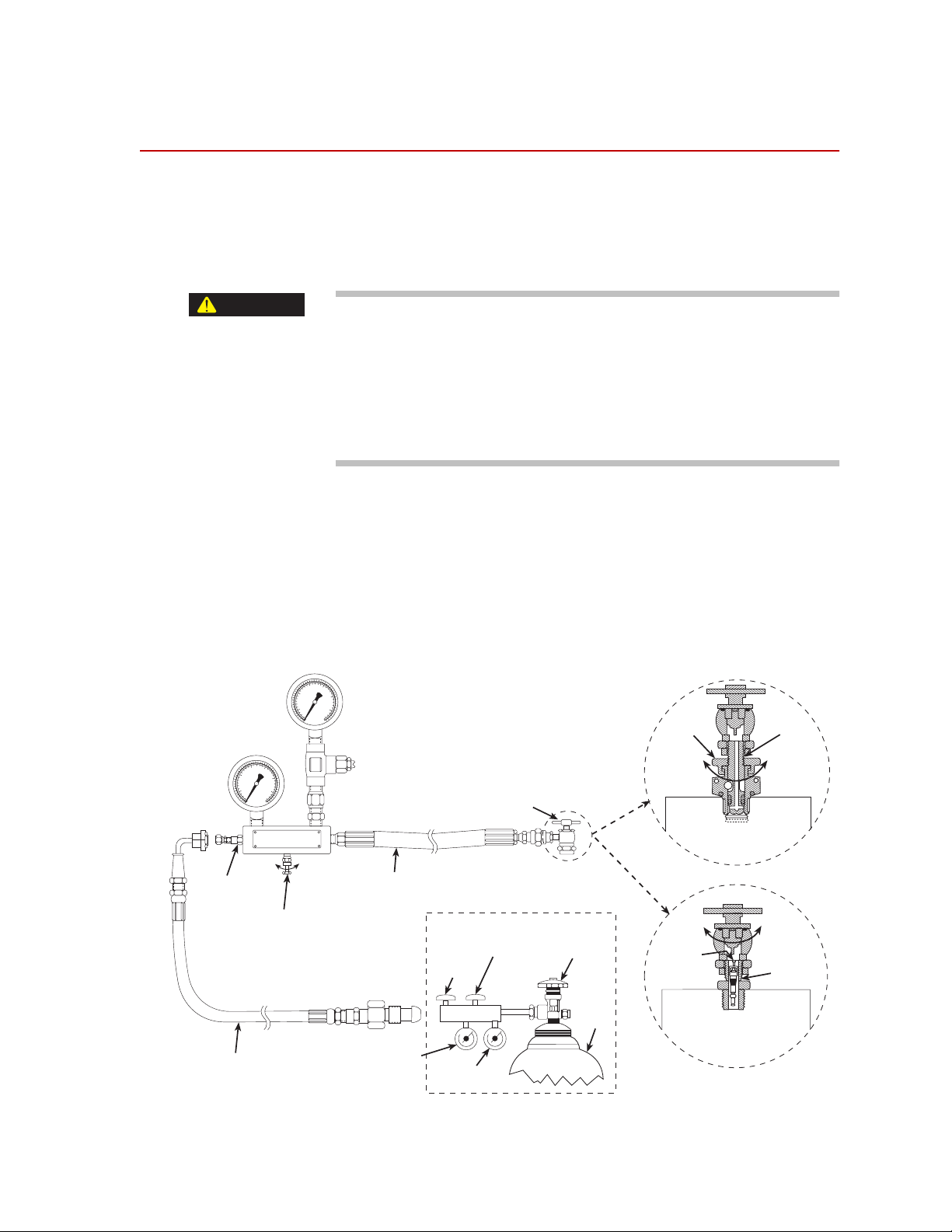

The following equipment is for any Series 111 Accumulator:

• Accumulator charging kit (MTS part number 376986-01)

To check your accumulator precharge, perform the following:

Accumulators are pressurized devices.

Pressurized accumulators and their parts can become lethal projectiles if

disassembled and can cause death to persons and/or damage to

equipment.

Do not remove an accumulator that is pressurized. Completely remove hydraulic

pressure and discharge the accumulator before any parts, except the protective

cover and valve stem cap are removed.

1. Ensure that system hydraulic pressure has been reduced to zero before

proceeding. To do this, turn off the hydraulic power unit and exercise

the actuator until it stops moving.

2. Close the bleed valve on the accumulator charging kit. Remove the

protective cover and valve stem cap from the accumulator (see

“Accumulator Components” on page 11 and the figure below).

3. Go to the appropriate procedure on the next page.

Low Pressure Gage

0-300 psi (0-2.1 MPa)

High Pressure Gage

0-3000 psi (0-21 MPa)

r

Open

Input

Check Valve

Nitrogen Supply Hose

Accumulator Charging Kit

Bleed Valve

Close

Gage Protector

(factory set to limit

pressure to the gage

to approximately

200 psi (1.4 MPa)

Extension Hose

Regulator Output

Pressure Gage

Chuck Valve

THESE ITEMS SUPPLIED BY USER

Regulator Output

Pressure Valve

Regulator

Shut-Off Valve

Nitrogen Bottle

Pressure Gage

Nitrogen

Bottle Valv e

Nitrogen

Bottle

Locknut

Close

Open

Valve Core

Poppet T ype

Accumulator Valve

To Open and Close

Use Locknut

OR

Core Type

Accumulator Valve

To Open and Close

Use Chuck Valve

Valve Stem

Open

Close

Valve Stem

Series 111 Accumulators Maintenance

13

Page 14

Checking the Series 111 Accumulator Precharge

The Series 111 Accumulators use the poppet-type valve (as shown on the

previous page).

1. Connect the charging kit chuck valve to the accumulator valve stem.

2. With an open-end wrench, turn the locknut counterclockwise on the

accumulator valve assembly to open the valve. Read the pressure on

either the high or low accumulator charging kit pressure gage.

• If the pressure reading is other than the required pressure level

recorded on the accumulator, go to the procedure “Changing the

Precharge Pressure” on page 15.

• If the pressure level corresponds to the level recorded on the

accumulator label, turn the locknut clockwise to close the valve

and continue this procedure.

3. Open the bleed valve on the accumulator charging kit and remove the

chuck valve from the accumulator. Replace the valve stem cap and

protective cover on the accumulator.

Checking a Non-MTS Accumulator Precharge

Non-MTS accumulators typically use either a poppet type valve or a core

type valve (as shown on the previous page).

1. Determine which type of gas pressure valve is present on the

accumulator and connect the charging kit chuck valve to the

accumulator valve stem.

2. Open the locknut (poppet-type) or chuck valve (core-type).

Note The poppet-type valve opens by turning the locknut counterclockwise

and closes by turning the locknut clockwise. To open a core type valve,

attach a chuck valve to the valve stem and turn the chuck valve handle

clockwise to depress the valve core. Close the valve by turning the

handle counterclockwise.

3. Read the pressure on either the high or low accumulator charging kit

pressure gage. The low pressure gage is limited to approximately 1.4

MPa (200 psi) by the gage protector.

• If the pressure reading is other than the required pressure level

recorded on the accumulator, go to the procedure “Changing the

Precharge Pressure” on page 15.

• If the pressure level corresponds to the level recorded on the

accumulator label, close the locknut (poppet-type) or close the

chuck valve (core-type). Continue to Step 4.

14

Maintenance

4. Open the bleed valve on the accumulator charging kit and remove the

chuck valve from the accumulator. Replace the valve stem cap and

protective cover on the accumulator.

Series 111 Accumulators

Page 15

Changing the Precharge Pressure

Often the precharge of an accumulator mounted on a hydraulic supply line

is increased to enhance system performance and reduce the transient HPS

flow demands. Accumulators may be precharged to 10 MPa (1500 psi) or

more, although amounts above 14 MPa (2200 psi) will have less and less

performance effect in most situations. Be sure that you read the following

warning before you charge your accumulator.

WARNING

Accumulators have specific pressure ratings.

If the precharge pressure is too high, the accumulator can bottom out

causing the release of metal particles into the hydraulic fluid. Charging

accumulators above their rated level can damage system equipment.

Do not charge accumulators to pressures above their rated level. Charge

accumulators below their rated fatigue pressure of 21 MPa (3000 psi) for the

Model 111.11B and 22 MPa (3200 psi) for the Model 111.12C. Use a suitable

regulator and gage set to an accumulator’s charges.

Before you begin Go to “Checking the Accumulator Precharge” on page 13 to determine if

you need to change the precharge pressure.

Decreasing pressure Complete the following steps to decrease the precharge pressure.

1. Slowly open the bleed valve on the accumulator charging kit until gas

begins to escape. When the pressure reading on the appropriate

pressure gage drops to the level required, close the bleed valve.

2. Close the locknut (or close the chuck valve if you have a core-type

valve). Open the bleed valve on the accumulator charging kit and

remove the chuck valve from the accumulator.

3. Install the valve stem cap and protective cover.

Increasing pressure Complete the following steps to increase the precharge pressure.

1. Close the locknut on the accumulator (or close the chuck valve for a

core-type valve).

2. Open the bleed valve two turns.

WARNING

Series 111 Accumulators Maintenance

Mixing gases can produce unpredictable results.

Do not use another gas to precharge an accumulator.

Use only dry nitrogen gas to precharge accumulators.

3. Connect the nitrogen supply hose from the supply bottle pressure

regulator output to the input check valve on the charging kit.

15

Page 16

4. Open the nitrogen bottle valve. Check the nitrogen bottle pressure

gage on the regulator. (The bottle must contain sufficient pressure to

provide an adequate gas volume.)

5. Monitor the regulator output pressure gage and adjust the regulator

output pressure valve to the required level.

CAUTION

Avoid rapid and extreme pressure transitions.

Rapid flow rates with pressure differentials of more than 2.1 MPa (300 psi)

across the input check valve can damage the valve seal(s).

Do not allow rapid flow rates. Open the regulator shut-of f valv e only f ar enough to

permit a gradual transfer of gas.

6. Slowly open the regulator shut-off valve until gas is heard escaping

from the accumulator charging kit bleed valve. Allow gas to slowly

escape for approximately ten seconds, then close the bleed valve.

Immediately close the regulator shut-off valve before the pressure

reading on either the high or low charging kit pressure gage exceeds

the pressure level of the accumulator.

7. Open the locknut (or open the chuck valve for a core-type valve).

Slowly open the regulator shut-off valve until the pressure indicator on

either the high or low charging kit pressure gage begins to rise. When

the pressure is at the required pressure level (recorded on the

accumulator), close the regulator shut-off valve.

8. Close the locknut (or close the chuck valve for a core type valve).

9. Open the bleed valve on the accumulator charging kit and remove the

chuck valve from the accumulator.

10. Install the valve stem cap and protective cover. Close the valve on the

nitrogen bottle.

16

Maintenance

Series 111 Accumulators

Page 17

Purging Fluid from the Gas Chamber

When you should

perform this

procedure

CAUTION

Procedure Complete the following steps to purge the fluid from the gas chamber. See

Piston-type accumulators may collect hydraulic fluid in the gas chamber,

which then reduces the gas volume of the accumulator. The fluid should

be purged from the gas side if a pressure check procedure shows one or

more of the following:

• A consistent trend of pressure being higher than expected.

• Precharging requires smaller volumes of gas than expected to obtain a

desired pressure level.

• Fluid is expelled from a gas valve during gas venting.

Venting pressurized gasses can generate loud noises and freezing

temperatures.

Transferring gasses from high to low pressure containers creates freezing

temperatures.

Do not work with pressurized gasses without wearing protective clothing. Wear

heavy gloves, saf ety glasses, and ear plugs when working with pressuriz ed gases

“Accumulator Components” on page 11.

1. If the valve stem of the accumulator is facing down, go directly to

step 2.

If the valve stem of the accumulator is facing up or the accumulator is

on its side, remove the accumulator as described in “Removing the

Accumulator” on page 18 and turn it so the valve stem is facing down.

2. Remove the accumulator valve protective cover and the valve stem

cap. Securely position the accumulator with the gas valve down.

3. Place a suitable container under the valve stem to capture any

expelled fluid. Use an open-end wrench and open the locknut on the

accumulator valve assembly two or three full turns. Allow gas

pressure to reduce to zero and hydraulic fluid to expel.

4. Replace the accumulator as described in “Installation” on page 9. Then

precharge the accumulator as described in “Changing the Precharge

Pressure” on page 15.

Series 111 Accumulators Maintenance

17

Page 18

Removing the Accumulator

Perform the following steps to remove the accumulator.

WARNING

Accumulators are pressurized devices.

Pressurized accumulators and their parts can become lethal projectiles if

disassembled and can cause death to persons and/or damage to

equipment.

Do not remove an accumulator that is pressurized. Completely remove hydraulic

pressure and discharge the accumulator before any parts, except the protective

cover and valve stem cap are removed.

1. Ensure that system hydraulic pressure has been reduced to zero before

proceeding. To do this, turn off the hydraulic power unit and exercise

the actuator until it stops moving.

2. Place a drain pan under the accumulator to be removed.

3. To prevent contamination of the hydraulic fluid, cover any ports that

are exposed.

4. If you have the Model 111.12C Accumulator, use a hex key to remove

the flange and accumulator mounting bolts (see “Accumulator

Components” on page 11).

If you have the Model 111.11B Accumulator, use an open-end and

strap wrench to loosen the accumulator from the boss adapter fitting.

5. Perform any required maintenance (see the other procedures in this

section).

6. To reinstall the accumulator, use the procedure in “Installation” on

page 9.

18

Maintenance

Series 111 Accumulators

Page 19

Replacing the Accumulator Seal

Special equipment The following equipment is required to replace any Series 111 Accumulator

seals:

• A seal kit (MTS part number 041-463-501 for the Model 111.11B or

MTS part number 041-463-301 for the Model 111.12C)

• Accumulator charging kit (MTS part number 376986-01)

Procedure Use the following procedure to replace any Series 111 Accumulator seals:

1. Remove the accumulator as described in “Removing the Accumulator”

on page 18.

2. Remove the accumulator valve protective cover and the valve stem

cap. Securely position the accumulator with the gas valve down.

3. Place a suitable container under the valve stem to capture any

expelled fluid. Use an open-end wrench and open the locknut on the

accumulator valve assembly two or three full turns. Allow gas

pressure to reduce to zero and any hydraulic fluid to be expelled.

4. Use an open-end wrench and remove the accumulator valve assembly

from the end cap. To remove the end cap, hold the accumulator body

with a strap wrench, insert the spanner wrench pins into the screw

holes in the end cap, and rotate the wrench counterclockwise.

Locknut End Cap Chamfer Piston

Valve Stem Cap

Accumulator V alve

Protective

Cover

Accumulator

Valv e Assembly

Backup

Ring

Detail A Detail B Detail C

Seal

5. Insert an aluminum or wooden rod into the hydraulic fluid port

opening (you may have to remove the boss adapter fitting from the

hydraulic fluid port of Model 111.11B Accumulators) until it contacts

the piston. Push the piston out of the cylinder.

Hydraulic Fluid

Screws

A

Piston Seals

B

Piston Wear

Strip

Seal

C

Backup

Accumulator Seal Details

End Cap

Hydraulic

Fluid Port

Locking Pin

Ring

Series 111 Accumulators Maintenance

19

Page 20

6. See “Accumulator Seal Details” on page 19 for details A and B for this

step. Remove the end cap backup ring and seal (detail A), and the

piston seals and wear strip (detail B). Clean the cylinder with a soft

cloth and inspect the piston and inner walls for scratches. If the inner

walls of the cylinder are scratched to the extent that the piston seals

cannot seal properly, replace the entire accumulator.

7. Install a new piston seals, wear strip, new seal, and backup ring on

the end cap.

8. Apply a small amount of clean hydraulic fluid to the piston seals and

piston wear strip. Gently insert the piston into the cylinder with the

piston wear strip turned toward the hydraulic fluid port end, taking

care not to pinch the piston seals against the chamfered surface of the

cylinder. Ensure that the piston is aligned within the cylinder. Firmly

push the piston 2 to 3 inches (5 to 7 cm) into the cylinder.

9. Apply a small amount of clean hydraulic fluid to the end cap seal and

backup ring. Turn the end cap into the cylinder until the threads are

engaged.

Note Do not overtighten the end cap.Tightening the end cap with extreme

force does not improve the seal and can damage the cap and/or cylinder

threads.Tighten the end cap using the following steps.

10. Hold the accumulator body with a strap wrench and use a pin spanner

wrench to rotate the end cap clockwise until the outer cap surface is

almost flush with the end of the cylinder and resistance indicates that

the cap and cylinder chamfer surfaces have met.

11. Thread the accumulator valve assembly into the end cap port. Use an

open-end wrench and tighten the valve assembly until the underside

of the hexagonal flange contacts the outer end cap surface.

12. Check the condition of the mounting O-rings on the boss adapter

fitting (Model 111.11B) or the flange mounting O-rings (Model

111.12C). If damaged, replace with new seals from the accumulator

seal kit.

20

Maintenance

Series 111 Accumulators

Loading...

Loading...