MTS Sensors Temposonics R- Ethernet/IP Operation Manual

Temposonics

®

Magnetostrictive Linear Position Sensors

R-Series Ethernet/IP

TM

Operation Manual

Temposonics® R-Series EtherNet/IP

TM

Operation Manual

I 2 I

1/ The term qualified technical personnel characterizes persons who:

– are familiar with the safety concepts of automation technology applicable to the

particular project,

– are competent in the field of EMC,

1/ – have received adequate training for commissioning and service operations

– are familiar with the operation of the device and know the information required for

correct operation provided in the product documentation.

1. Introduction

1.1 Purpose and use of this manual

The content of this technical documentation and of its various annexes is intended to provide information on mounting, installation and

commissioning by qualified automation personnel

1

or instructed service technicians who are familiar with the project planning and dealing

with Temposonics

®

sensors.

1.2 Used symbols and warnings

Warnings are intended for your personal safety and for avoidance of

damage to the described product or connected devices. In this documentation, safety information and warnings to avoid dangers that

might affect the life and health of operating or service personnel or

cause material damage are highlighted by the preceding pictogram,

which is defined below.

2. Safety instructions

2.1 Intended use

This product may be used only for the applications provided under

item 1 and item 2 and only in conjunction with the third-party devices

and components recommended or approved by MTS Sensors. As a

prerequisite of proper and safe operation, the product requires correct

transport, storage, mounting and commissioning and must be operated with utmost care.

1. The sensor systems of all Temposonics

®

series are intended exclusively for measurement tasks encountered in industrial, commercial

and laboratory applications. The sensors are considered as system

accessories and must be connected to suitable evaluation electronics, e.g. a PLC, IPC, indicator or other electronic control unit.

2. The position sensors must be used only in technically safe condition.

To maintain this condition and to ensure safe operation, installation,

connection and service work may be performed only

by qualified technical personnel.

Before starting the operation of Temposonics® sensors read this

documentation thoroughly and follow the safety information.

Symbol Meaning

NOTICE

This symbol is used to point to situations

that may lead to material damage, but not to

personal injury.

Table of contents

1. Introduction ........................................................... 2

1.1 Purpose and use of this manual .......................................... 2

1.2 Used symbols and warnings ............................................... 2

2. Safety instructions................................................... 2

2.1 Intended use ........................................................................ 2

2.2 Forseeable misuse ............................................................... 3

2.3 Installation, commissioning and operation .......................... 3

2.4 Safety instructions for use in explosion-hazardous areas ... 3

2.5 Warranty

............................................................................. 3

2.6 Return ................................................................................. 3

3. Identication ......................................................... 4

3.1 Order structure of R-Series RP ........................................... 4

3.2 Order structure of R-Series RH ........................................... 5

3.3 Order structure of R-Series RD4 ......................................... 6

3.4 Order structure of R-Series RF ............................................ 7

3.5 Nameplate (example) .......................................................... 8

3.6 Approvals ............................................................................ 8

3.7 Scope of delivery ................................................................. 8

4. Product description and commissioning ......................... 8

4.1 Functionality and system design ......................................... 8

4.2 Styles and installation of R-Series RP ................................. 9

4.3 Styles and installation of R-Series RH ............................... 11

4.4 Styles and installation of R-Series RD4 ............................. 13

4.5 Styles and installation of R-Series RF ................................ 19

4.6 Electrical connections ........................................................ 22

4.7 Accessories ...................................................................... 23

5. Operation ............................................................ 24

5.1 Getting started ................................................................... 24

6. IP Address Conguration .......................................... 24

6.1 Set the IP address of the sensor ....................................... 25

7. Integration in RSLogix5000 ....................................... 26

7.1 Install the MTS EtherNet/IP EDS file .................................. 28

7.2 Add sensor to I/O configuration using EDS file ................. 28

7.3 Add sensor to I/O configuration w/o using EDS file ........... 29

7.5 Verify Generic EtherNet Module......................................... 30

7.6 Controller tags configuration data ..................................... 31

8. Maintenance and troubleshooting ............................... 34

8.1 Error conditions, troubleshooting ...................................... 34

8.2 Maintenance ...................................................................... 34

8.3 Repair ................................................................................ 34

8.4 List of spare parts ............................................................. 34

8.5 Transport and storage ....................................................... 34

9. Technical data ....................................................... 35

0. Annex ................................................................. 36

1. Appendix A - Sensor Reset ........................................ 37

2. Appendix B - Port Details .......................................... 38

1

1

1

Temposonics® R-Series EtherNet/IP

TM

Operation Manual

I 3 I

2/ see also applicable MTS Sales and supply conditions, e.g. under www.mtssensors.com

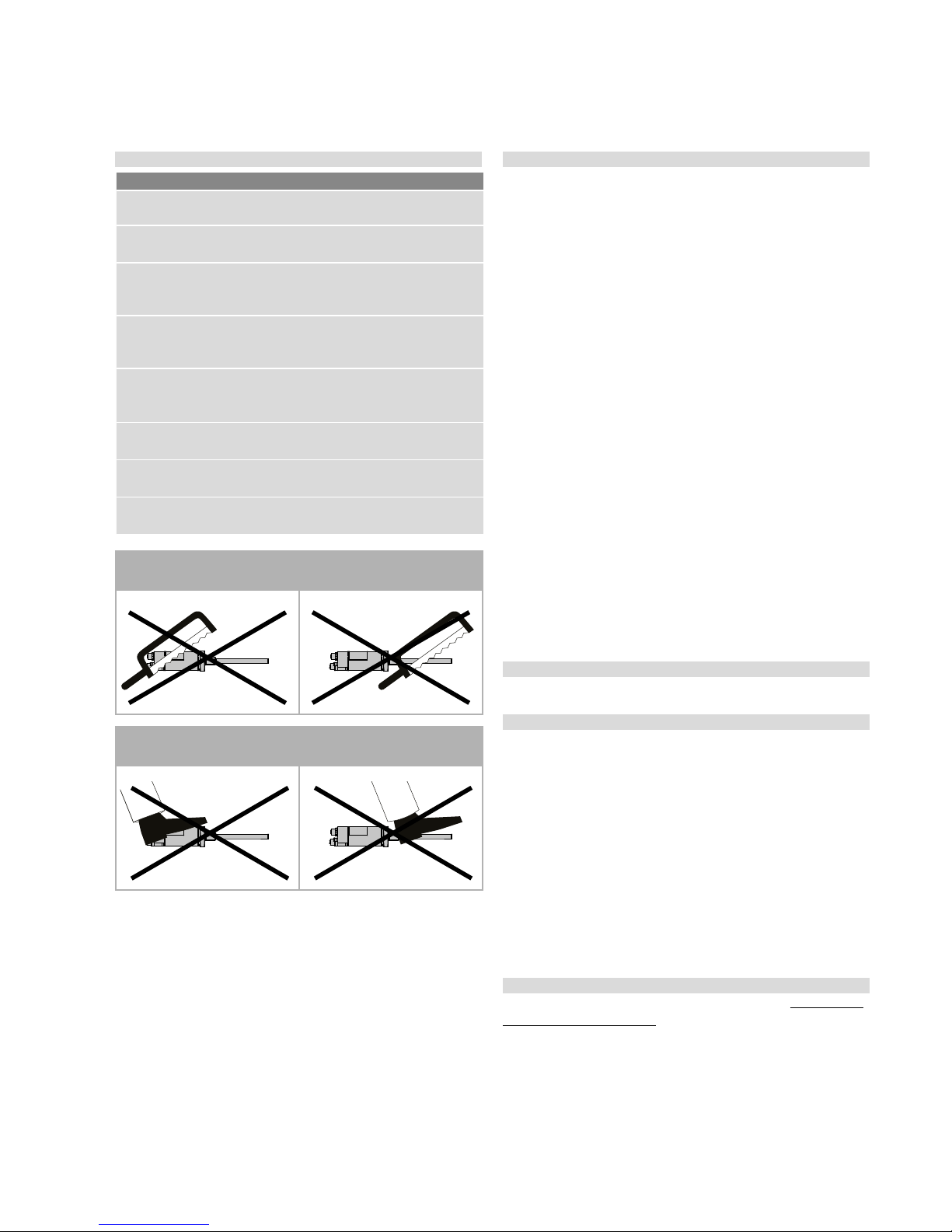

Do not reprocess the sensor afterwards.

The sensor might be damaged.

Do not step on the sensor.

The sensor might be damaged.

2.2 Forseeable misuse 2.3 Installation, commissioning and operation

The position sensors must be used only in technically safe condition.

To maintain this condition and to ensure safe operation, installation,

connection and service work may be performed only by qualified technical personnel.

If danger of injury to persons or of damage to operating equipment

is caused by sensor failure or malfunction, additional safety measures

such as plausibility checks, limit switches, EMERGENCY STOP systems, protective devices etc. are required. In the event of trouble,

shut down the sensor and protect it against accidental operation.

Safety instructions for commissioning

To maintain the sensor operability, it is mandatory to follow the instructions given below.

1. Protect the sensor against mechanical damage during installation

and operation.

2. Do not open or dismantle the sensor.

3. Connect the sensor very carefully and pay attention to the polarity

of connections and power supply.

4. Use only approved power supplies.

5. It is indispensable to ensure that the specified permissible limit

values of the sensor for supply voltage, environmental conditions,

etc. are met.

6. Check the function of the sensor regularly and provide documentation of the checks.

7. Before system switch-on, ensure that nobody’s safety is jeopardized by starting machines.

2.4 Safety instructions for use in explosion-hazardous areas

The sensor is not suitable for operation in explosion-hazarded areas.

2.5 Warranty

2

MTS Sensors grants a warranty period for the Temposonics

®

position sensors and supplied accessories relating to material defects and

faults that occur despite correct use in accordance with the intended

application

2

. The MTS Sensors obligation is limited to repair or replacement of any defective part of the unit. No warranty can be taken

for defects that are due to improper use or above average stress of the

product, as well as for wear parts. Under no circumstances will MTS

Sensors accept liability in the event of offense against the warranty

rules, no matter if these have been assured or expected, even in case

of fault or negligence of the company.

MTS Sensors explicitly excludes any further warranties. Neither the

company’s representatives, agents, dealers nor employees are authorized to in- crease or change the scope of warranty.

2.6 Return

For diagnostic purposes, the sensor can be returned to MTS Sensors

or an authorized repair facility. Any shipment cost will be borne by the

sender

2

. For a corresponding form, see chapter 9 (Annex).

Forseeable misuse Consequence

Wrong sensor connection

The sensor does not work

properly or will be destroyed

Operate the sensor out off the

operating temperature

No signal output

The sensor can be damaged

Power supply is out of the

defined range

Signal output is wrong/

no signal output/

the sensor will be damaged

Position measurement is

influenced by an external

magnetic field

Signal output is wrong

Cables are damaged

Short circuit – the sensor can

be destroyed/sensor does not

respond

Magnet spacers are missing/

are installed in the wrong order

Error in position measurement

Wrong connection

of ground/shield

Signal output is disturbed

The electronics can be damaged

Use of a magnet that is not

certified by MTS Sensors

Error in position measurement

Temposonics® R-Series EtherNet/IP

TM

Operation Manual

I 4 I

3. Identication

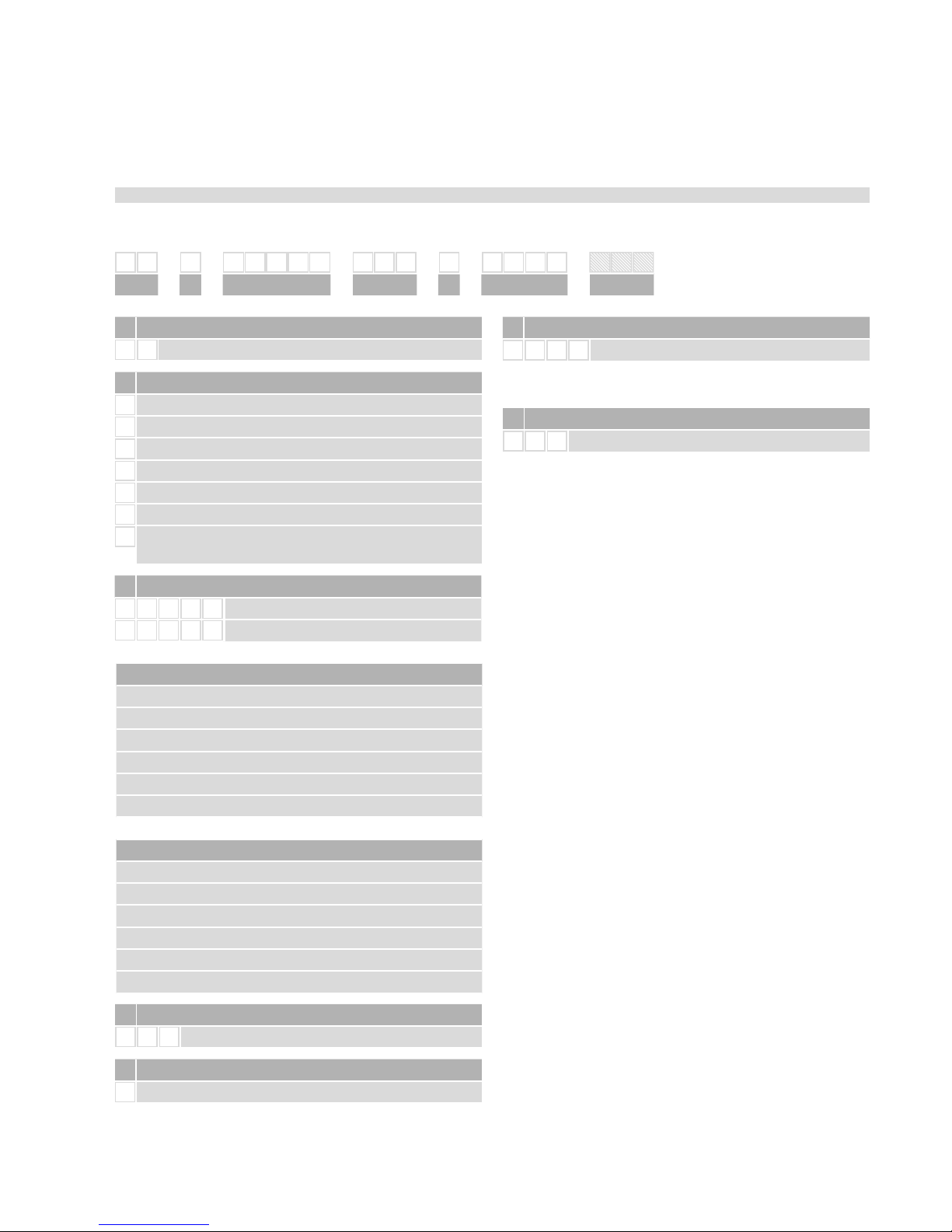

3.1 Order structure of R-Series RP

Temposonics

®

order code

a Sensor model

R P

Profile

b Design

S

Magnet slider, joint on top (Part number: 252182)

V

Magnet slider, joint at front (Part number: 252184)

M

U-magnet, OD33 (Part number: 251416-2)

d Connection type

D 5 6

2 × 4 pin M12 female, 1 × 4 pin M8 male

e Operation voltage

1

+24 VDC (−15 / +20 %)

f Output

N 1 0 1

EtherNet/IP™

*/ Non Standard stroke lengths are available; must be encoded in 5 mm / 0.1 in. increments

3/ Note: Please specify magnet numbers for your sensing application and order separately

Optional: for multi-position measurement only

(Order additional magnets seperately)

g Magnet number for multi-position measurement

3

Z X X

02…20 magnets

c Stroke length

X X X X M

0025…5080 mm

X X X X

U

001…200 in.

Standard stroke length (mm)*

Stroke length Ordering steps

25 … 500 mm 25 mm

500…2500 mm 50 mm

2500…5080 mm 100 mm

Standard stroke length (in.)*

Stroke length Ordering steps

1 … 20 in. 1 in.

20…100 in. 2 in.

100…200 in. 4 in.

.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

R P

D 5 6

1

N 1 0

1

a b c d e

f

g

Temposonics® R-Series EtherNet/IP

TM

Operation Manual

I 5 I

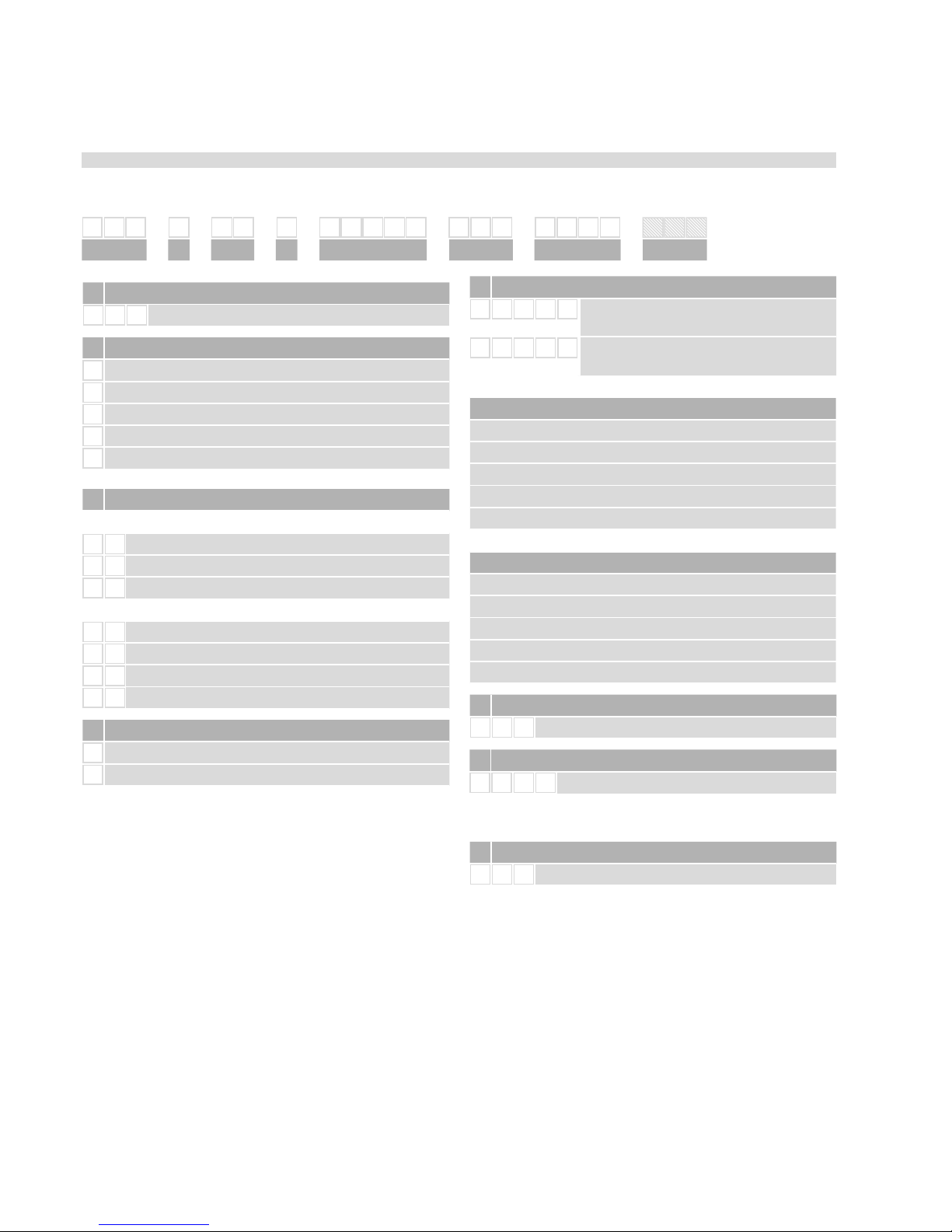

3.2 Order structure of R-Series RH

*/ Non Standard stroke lengths are available; must be encoded in 5 mm / 0.1 in. increments

4/ Note: Please specify magnet numbers for your sensing application and order separately

Temposonics® order code

a Sensor model

R H

Rod

b Design

M

Flange M18×1.5 (Standard)

V

Flange M18×1.5 with Fluoroelastomer housing-seal

D

Flange M18×1.5 bushing on rod end

R

Flange M18×1.5 thread M4 at rod end

J

Flange M22×1.5 rod Ø 12.7 mm, 800 bar

S

Flange M¾"×16UNF - 3A

B

B Sensor cartridge only

(no flange or pressure tube, stroke length <1830 mm (72 in.))

d Connection type

D 5 6

2 × 4 pin M12 female, 1 × 4 pin M8 male

e Operation voltage

1

+24 VDC (−15 / +20 %)

c Stroke length

X X X X M

0025…7620 mm

X X X X

U

001…300 in.

Standard stroke length (mm)*

Stroke length Ordering steps

25 … 500 mm 5 mm

500 … 750 mm 10 mm

750…1000 mm 25 mm

1000…2500 mm 50 mm

2500…5080 mm 100 mm

5000…7620 mm 250 mm

Standard stroke length (in.)*

Stroke length Ordering steps

1 … 20 in. 0.2 in.

20 … 30 in. 0.4 in.

30 … 40 in. 1 in.

40…100 in. 2 in.

100…200 in. 4 in.

200…300 in. 10 in.

.

f Output

N 1 0 1

EtherNet/IP™

Optional: for multi-position measurement only

(Order additional magnets seperately)

g Magnet number for multi-position measurement

4

Z X X

02…20 magnets

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

R H

D 5 6

1

N 1 0

1

a b c d e

f

g

Temposonics® R-Series EtherNet/IP

TM

Operation Manual

I 6 I

3.3 Order structure of R-Series RD4

Temposonics

®

order code

b Design

S

Pressure fit flange

M

Threaded flange M18×1.5-6g, AF23

C

Threaded flange M18×1.5-6g, AF46

T Threaded flange ¾“–16UNF–3A.

D Threaded flange ¾“–16UNF–3A.

d Sensor electronics

S

Side cable entry

B

Bottom cable entry

a Sensor model

R D

4

Detachable sensor electronics

c Integral cable of sensor rod

For side cable entry:

D 1 PUR-cable, length 250 mm (9.8 in.)

D 2 PUR-cable, length 400 mm (15.7 in.)

D 3 PUR-cable, length 600 mm (23.6 in.)

For bottom cable entry:

R 2 Single wires with flat connector, length 65 mm (2.6 in.)

R 4 Single wires with flat connector, length 170 mm (6.7 in.)

R 5 Single wires with flat connector, length 230 mm (9.1 in.)

R 6 Single wires with flat connector, length 350 mm (13.8 in.)

*/ Non Standard stroke lengths are available; must be encoded in 5 mm / 0.1 in. increments

5/ Note: Please specify magnet numbers for your sensing application and order separately

Standard stroke length (mm)*

Stroke length Ordering steps

25 … 500 mm 5 mm

500 … 750 mm 10 mm

750…1000 mm 25 mm

1000…2500 mm 50 mm

2500…5080 mm 100 mm

Standard stroke length (in.)*

Stroke length Ordering steps

1…20 in. 0.2 in.

20…30 in. 0.4 in.

30…40 in. 1 in.

40…100 in. 2 in.

100…200 in. 4 in.

c Stroke length

X X X X M

Flange M & C: 0025…5080 mm

Flange S: 0025…2540 mm

X X X X

U

Flange M & C: 001…200 in.

Flange S: 001…100 in.

.

f Connection type

D 5 6

2 × 4 pin M12 female, 1 × 4 pin M8 male

f Output

N 1 0 1

EtherNet/IP™

Optional: for multi-position measurement only

(Order additional magnets seperately)

g Magnet number for multi-position measurement

5

Z X X

02…20 magnets

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

R D 4 D 5 6

N 1 0 1

a b c d d g

f

g

Temposonics® R-Series EtherNet/IP

TM

Operation Manual

I 7 I

3.4 Order structure of R-Series RF

Temposonics

®

order code

a Sensor model

R F

Flexible sensor rod

b Design

C

Basic sensor

M Flange M18×1.5-6g

S

Flange ¾"×16UNF-3A

e Operation voltage

1

+24 VDC (−15 / +20 %)

*/ Non Standard stroke lengths are available; must be encoded in 5 mm / 0.1 in. increments

6/ Note: Please specify magnet numbers for your sensing application and order separately

f Connection type

D 5 6

2 × 4 pin M12 female, 1 × 4 pin M8 male

c Stroke length (Longer strokes are available. Contact applications engineering for details.)

X X X X X

M

00100…10060 mm

X X X X X

U

0004.0…0396.0 in.

Standard stroke length (mm)*

Stroke length Ordering steps

100 … 1000 mm 50 mm

1000…10060 mm 250 mm

Standard stroke length (in.)*

Stroke length Ordering steps

4 … 40 in. 2 in.

40…396 in. 10 in.

f Output

N 1 0 1

EtherNet/IP™

Optional: for multi-position measurement only

(Order additional magnets seperately)

g Magnet number for multi-position measurement

6

Z X X

02…20 magnets

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

R F D 5 6

1

N 1 0 1

a b c g e

f

g

Temposonics® R-Series EtherNet/IP

TM

Operation Manual

I 8 I

RD4CD1S1250MD56N101Z02

MAC ID: 00-03-CA-00-2D-5F

S/N: 90595059

GRD: 9.1044 uS/In | 2789.85 m/s

Sensor model

Design

Measuring range (e.g. 1250 mm)

Connection type

Output version

Magnet number

Part No.

MAC adress

Gradient

Serial number

Sensor electronics

3.7 Scope of delivery

R-Series RP (prole):

Sensor, Position magnet, 2 mounting clamps up to 1250 mm (49 in.)

+ 1 clamp for each 500 mm (20 in.)

R-Series RH (rod):

Sensor, O-ring

4. Product description and commissioning

4.1 Functionality and system design

Product designation

– Position sensor Temposonics

®

R-Series

Construction series

– Temposonics® R-Series RP/RH/RD4/RF

– Stroke length: RP 25…5080 mm (1…200 in.)

RH 25…7620 mm (1…300 in.)

RD4 25…5080 mm (1…200 in.)

RF 100…10060 mm (4…396 in.)*

– Output signal: EtherNet/IP™

Application

The Temposonics

®

sensor is used for measurement and conversion

of the length (position) variable in the field of automated system and

mechanical engineering.

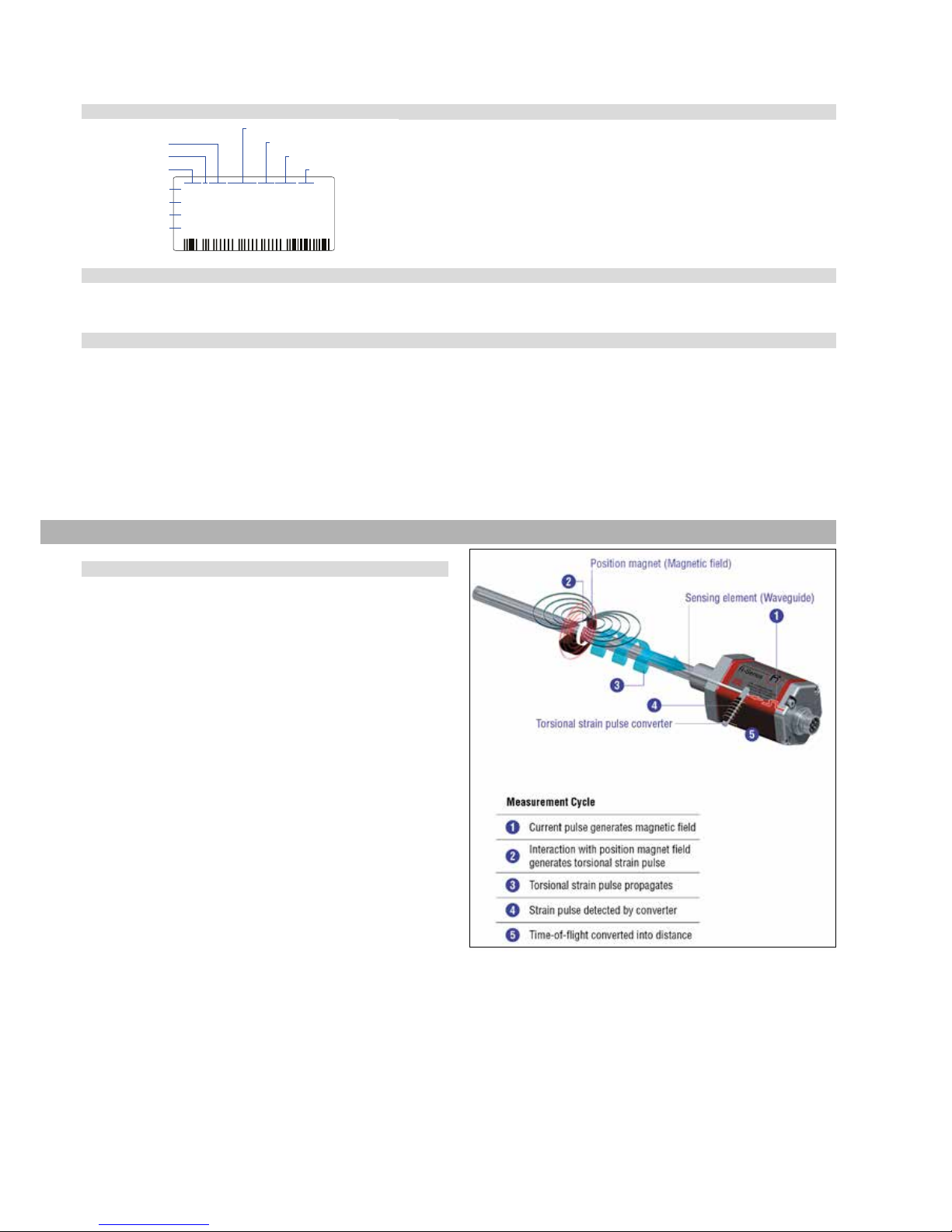

Principle of operation and system construction

For position measurement, the absolute, linear Temposonics

®

position

sensors make use of the properties offered by the specially designed

magnetostrictive waveguide. Inside the sensor a torsional strain pulse

is induced in the waveguide by momentary interaction of two magnetic fields. The interaction between these two magnetic fields produces a strain pulse, which is detected by the electronics at the head of

the sensor. One field is produced by a moving position magnet, which

travels along the sensor rod with the waveguide inside. The other field

is generated by a current pulse applied to the waveguide. The position

of the moving magnet is determined precisely by measuring the time

elapsed between the application of the current pulse and the arrival

of the strain pulse at the sensor head. The result is a reliable position

measurement with high accuracy and repeatability.

R-Series RD4 (detached electronics):

RD4-S

Sensor, O-ring, Back-Up ring

RD4-C/M/T/D

Sensor, O-ring

R-Series RF (exible sensor rod):

RF-M / RF-S:

Sensor, Threaded Flange, O-ring

Fig. 1: Principle of operation: Time-based magnetostrictive position sensing principle

Modular mechanical and electronic construction

– The sensor housing protects the sensor element.

– The sensor electronics housing, a rugged aluminum

construction, contains the complete electronic interface with

active signal conditioning.

– The external position magnet is a permanent magnet. Mounted

on the mobile machine part, it travels along the sensing element and

triggers the measurement through the housing wall.

– Depending on the type, the sensor is connected to the controller via a plug.

– The sensor can be connected directly to a control system.

Its electronics generates a strictly position-proportional signal

output between zero and end position.

*/ (Longer strokes available, please contact applications engineering for

details.)

3.5 Nameplate (example)

3.6 Approvals

CE certification (only for RP & RH; RF: The conformity is fulfilled, assumed the wave guide of the sensor is embedded in an EMC-sealed and

grounded housing), EPSG certified, GOST certified, UL/cUL certified (only for RP/RH)

Ağaç isadleme

Temposonics® R-Series EtherNet/IP

TM

Operation Manual

I 9 I

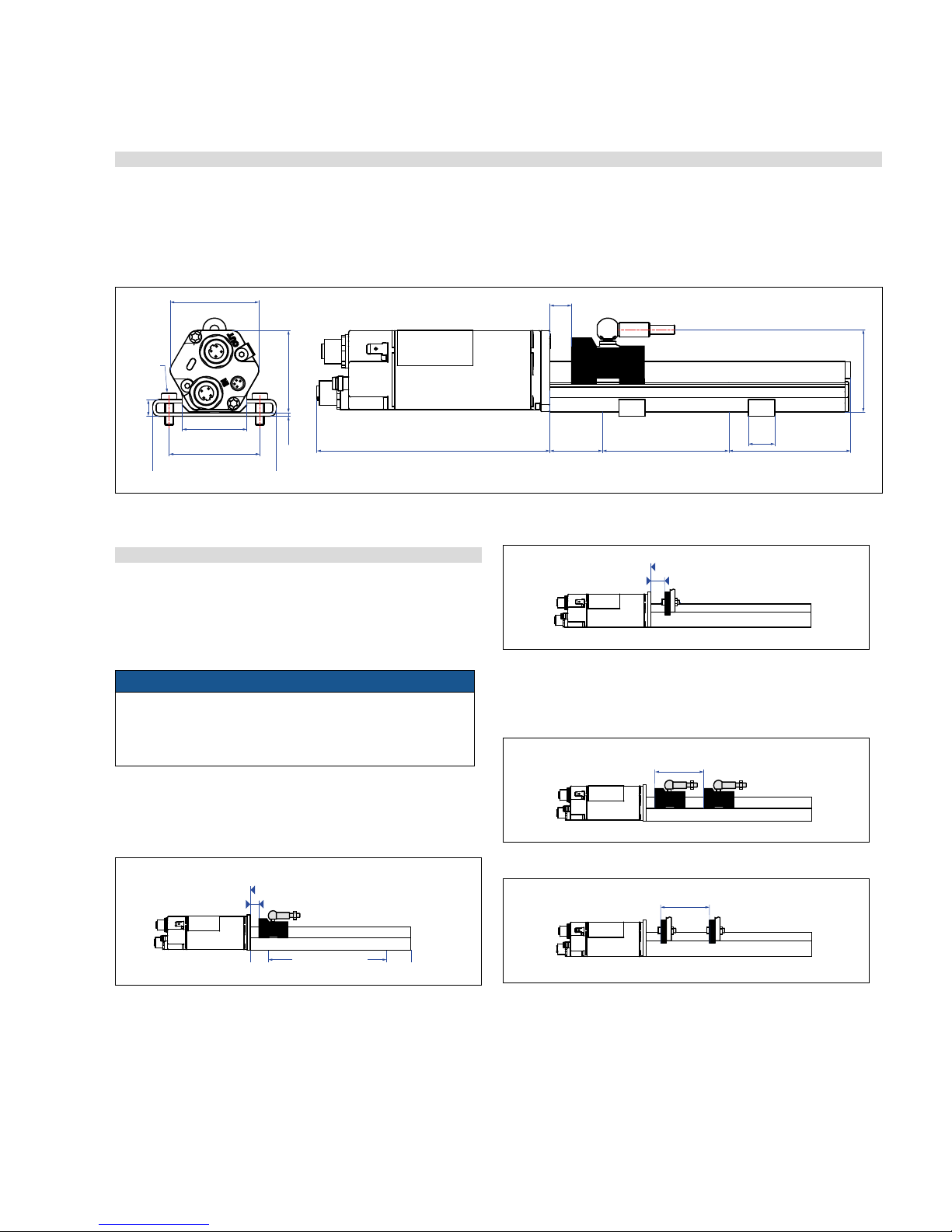

4.2 Styles and installation of R-Series RP

Temposonics

®

RP offers modular construction, flexible mounting configurations and easy installation. Position measurement is non-contact

via two versions of permanent magnets.

• A sliding magnet running in profile housing rails. Connection with the moving machine part is via a ball jointed arm for taking up axial forces.

• A floating magnet, mounted directly on the moving machine part, travels over the profile at a low distance. Its air-gap allows the correction

of small misalignments at installation.

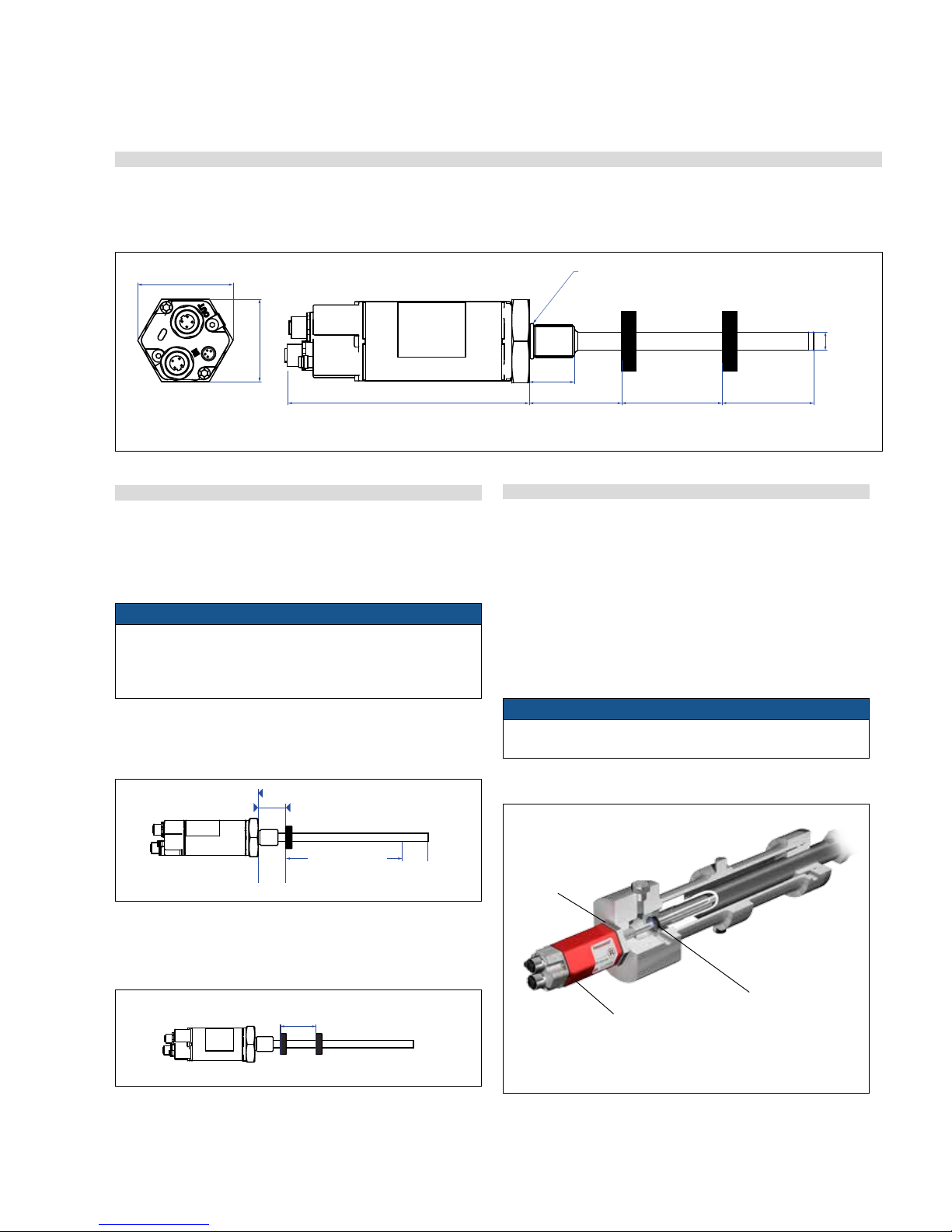

4.2.1 Mounting distances

Active measuring range

The technical data of each sensor is checked as well as documented

and the active stroke length (useful electrical stroke) with its start

and end position is adjusted during final inspection and testing

(see Fig. 2).

NOTICE

On all sensors, the areas left and right of the active stroke length

are provided for mounting and damping of the measuring signal.

They should not be used for measurement, but the active stroke

length can be exceeded without problem.

Mechanical zero

To ensure that the entire measuring range can be used electrically,

the position magnet must be mounted mechanically as follows:

Multi-position measurement

The minimum distance between the magnets is 75 mm (3 in.).

Fig. 3: Temposonics® profile with magnet slider

Fig. 2: RP Style dimensional drawing

Fig. 4: Temposonics

®

profile with U-magnet

Fig. 5: Minimum distance for multi position measurement with magnet slider

Fig. 6: Temposonics

®

profile with U-magnet

Controlling design dimensions are always in metric unitsand measurements in ( ) are in inches

12

(0.47)

Start position

Magnet slider

Reference edge of mounting

28

(1.1)

Measuring range

66

(2.6)

12

(0.47)

Start position

Magnet slider

U-magnet

Reference edge of mounting

Start position

Reference edge of mounting

28

(1.1)

Measuring range

66

(2.6)

28

(1.1)

minimum 75 (3)

minimum 75 (3)

minimum 75 (3)

50

(1.97)

35.6

(1.4)

2

(0.08)

45

(1.77)

12

(0.47)

66

(2.6)

14.5

(0.57)

45.4

(1.79)

129

(5.07)

28

(1.1)

Measuring range

25…5080

(1…200)

49

(1.93)

9

(0.36)

Ø 5.5 (0.21)

M5 or #10

screw

Magnet

Controlling design dimensions are always in metric units and measurements in ( ) are in inches

Temposonics® R-Series EtherNet/IP

TM

Operation Manual

I 10 I

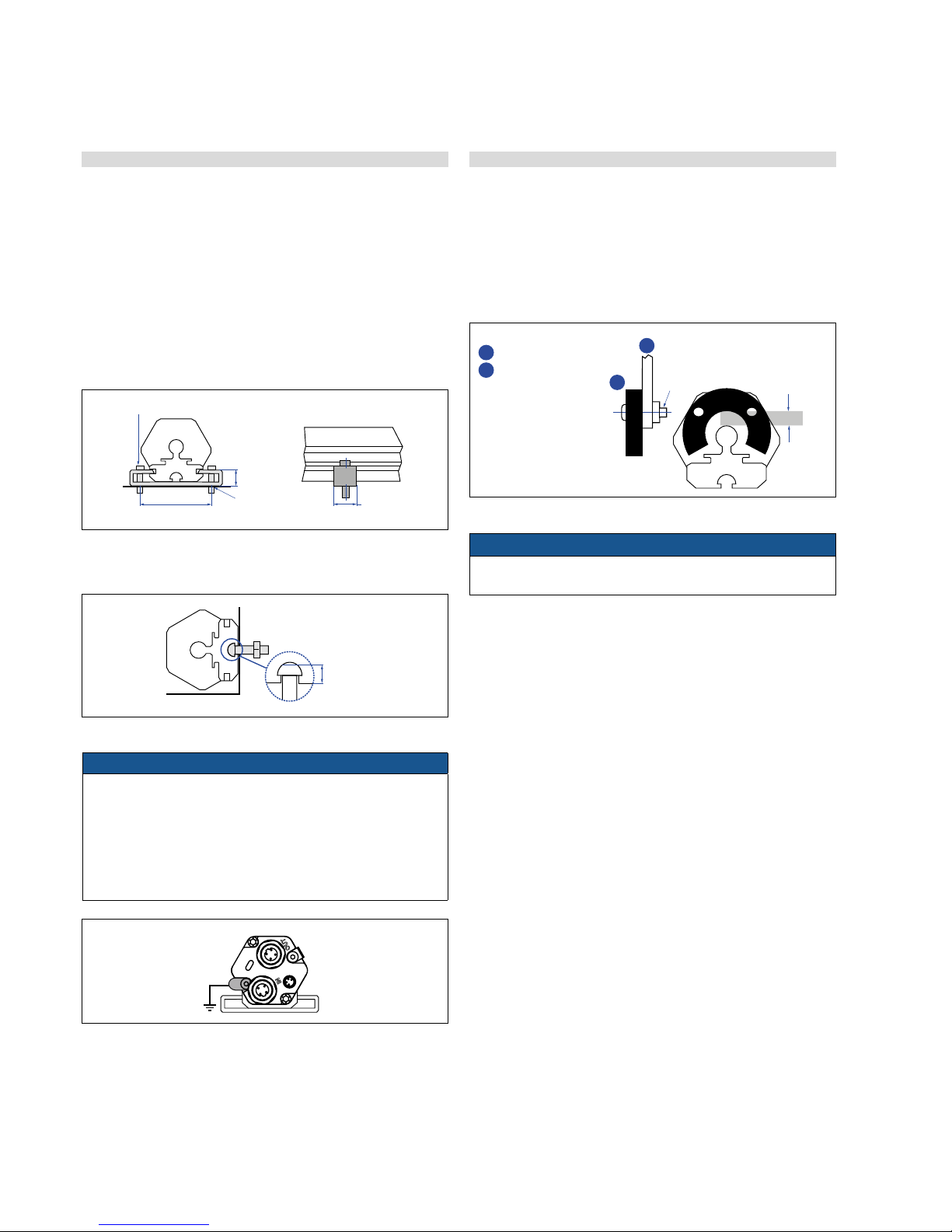

4.2.3 Magnet mounting

Mounting the U-magnet

The U-magnet is removable and can be used for profile- and rod-style

sensors. Using a non-magnetizable mounting device is mandatory.

The magnet must not rub against the measuring rod. Alignment errors

are compensated via the air gap.

– Max. surface pressure: 40 N/mm

2

– Max. tightening torque for M4 screws: 1 Nm;

use washer, if necessary

Fig. 10: Mounting device for U-magnet

NOTICE

A maximum permissible air gap of 3 ±1mm (0.12 in.) must not be

exceeded.

3 ±1

(0.12 ± 0.04)

M4

1

2

4.2.2 Installation of RP

The position sensor can be installed in any position. Normally,

the sensor is firmly installed and the position magnet is fastened

to the mobile machine part. Thus it can travel along the measuring

rod contactlessly.

The sensor is fitted on a flat machine surface using the mounting

clamps (fig. 7). A length-dependent number of these clamps are

delivered with the sensor and must be distributed over the profile

at regular distances.

For fastening, we recommend using M5×20 screws to DIN 6912

that shout be tightened with a maximum torque of 5 Nm.

Fig. 7: Mounting clamps with cylinder screw M5×20, fastening torque < 5 Nm

Alternative: If only limited space is available, the profile sensor can be mounted also via

the T-rail in the profile bottom using an M5 T-slot nut or a sliding block (fig. 8).

Fig. 8: T-slot nuts M5

NOTICE

Don’t mount the sensors in the area of strong magnetic or electric

noise fields. Take care to mount the sensor in an axially parallel

position to avoid damaging the carriage, magnet and measuring rod.

The sensor is isolated from the machine ground. For this reason,

earthing via the flat-pin connector on the sensor electronics housing

is indispensable (fig. 9).

50

Bore-Ø

5.5 mm

14.5

max.

5 mm

M5

Fig. 9: Grounding profile sensor

max. 5 Nm

50

(1.97)

9

(0.36)

Bore Ø 5.5

(Ø 0.21)

14.5

(0.57)

5

(0.2)

M5

1

U-magnet

2

Non-magnetic

mounting device

Controlling design dimensions are always in metric units and measurements in ( ) are in inches

Temposonics® R-Series EtherNet/IP

TM

Operation Manual

I 11 I

4.3 Styles and installation of R-Series RH

Temposonics

®

RH with a pressure resistant stainless steel flange and sensing rod. They are suitable in all fluid power cylinders and externally in

all applications where space is a problem. Position measurement is via ring or U-magnets travelling along the sensing rod without any mechanical

contact.

4.3.1 Mounting distances

Active measuring range

The technical data of each sensor is checked as well as documented

and the active stroke length (useful electrical stroke) with its start

and end position is adjusted during final inspection and testing

(see Fig. 11).

NOTICE

On all sensors, the areas left and right of the active stroke length

are provided for mounting and damping of the measuring signal.

They should not be used for measurement, but the active stroke

length can be exceeded without problem.

Mechanical zero

To ensure that the entire measuring range can be used electrically,

the position magnet must be mounted mechanically as follows:

Fig. 12: Temposonics® rod with ring magnet

Fig. 11: RH Style dimensional drawing

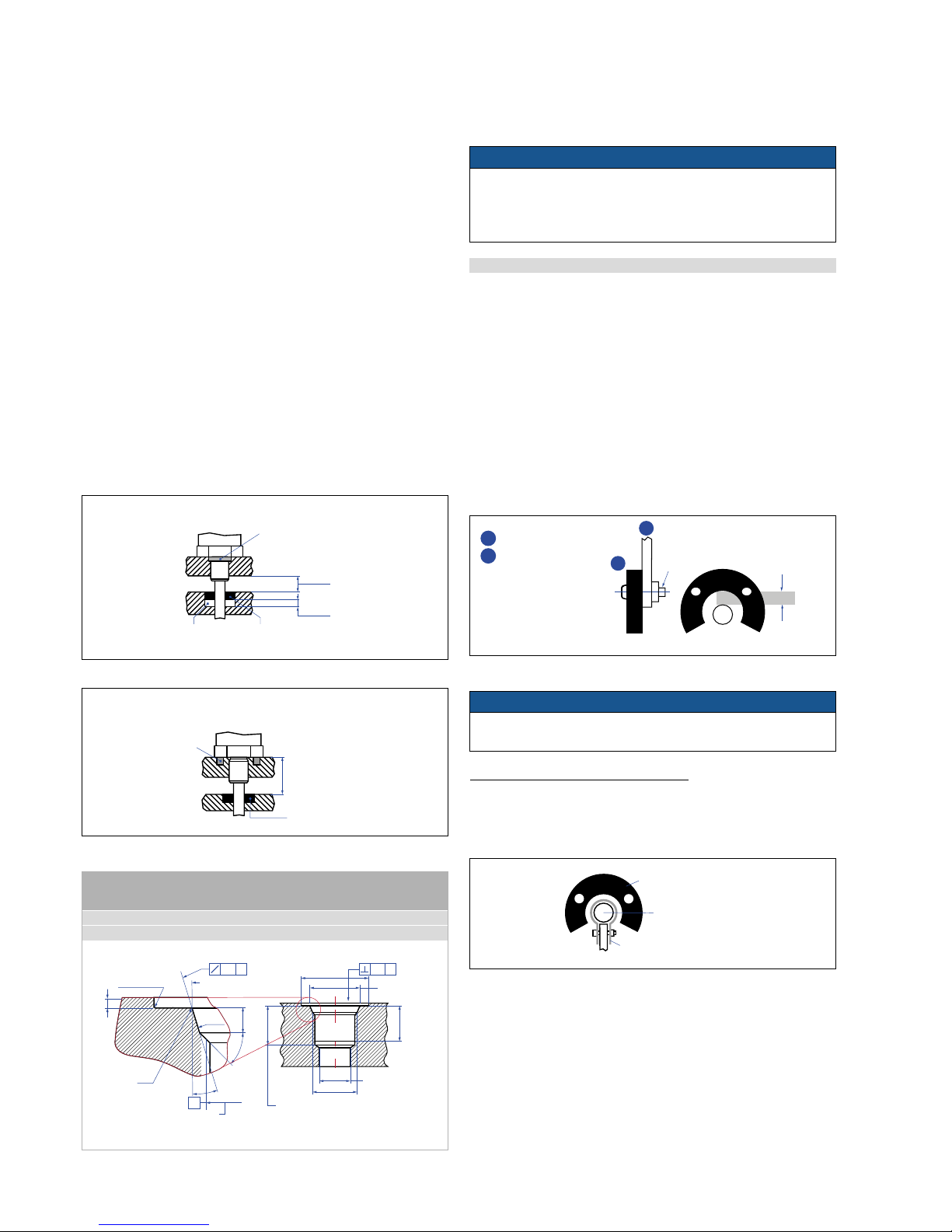

4.3.2 Installation of RH

Installation of a rod-style sensor

The rod-style version has been developed for direct stroke

measurement in a fluid cylinder.

– Mounted on the bottom of the piston, the ring magnet travels

over the rod contactlessly and marks the position exactly through

the rod wall.

– Inside the pressure-resistant sensor housing immerging into the

open piston rod, the basic sensor is mounted by means of only

two screws. It is the only part that needs replacing if servicing is

required, i.e. the hydraulic circuit remains closed.

NOTICE

After re-installing, securing the basic sensor screws, e.g. using

Loctite 243, is mandatory.

Basic sensor

The electronics head with sensing

element can be replaced via two M4

screws with a 2.5 mm hexagonal

recess, max. tightening torque 1.3 Nm

Pressure-resistant

sensor housing

In the event of servicing,

the rod with the flange

remains in the cylinder.

Fig. 14: Sensor in fluid cylinder

Position magnet

Rod with inner sensor element immersed in the cylinder

Multi-position measurement

The minimum distance between the magnets is 75 mm (3 in.).

Fig. 13: Minimum distance for multi position measurement

Controlling design dimensions are always in metric units and measurements in ( ) are in inches

12

(0.47)

Start position

Magnet slider

U-magnet

Ring magnet

Reference edge of mounting

Start position

Start position

Reference edge of mounting

Reference edge of mounting

28

(1.1)

Measuring range

Measuring range

66

(2.6)

28

(1.1)

51

(2)

51

(2)

63.5/66*

(2.5/2.6)

minimum 75 (3)

minimum 75 (3)

minimum 75 (3)

50

(1.97)

68

(2.68)

35.6

(1.4)

2

(0.08)

49

45

2

28

Measuring range

25…5080

66

45

(1.77)

12

(0.47)

66

(2.6)

14.5

(0.57)

45.4

(1.79)

129

(5.07)

28

(1.1)

Measuring range

25…5080

(1…200)

49

(1.93)

128

28

50

35.6

68

O-ring

51

(2)

63.5/66*

(2.5/2.6)

Measuring range

25…7620

(1…300)

133

(5.24)

Ø 10

(Ø 0.39)

46

(1.75)

53

(2)

25

(0.98)

*> 5000 mm

Stroke length

Magnet

Magnet

Magnet

Magnet

Controlling design dimensions are always in metric units and measurements in ( ) are in inches

Temposonics® R-Series EtherNet/IP

TM

Operation Manual

I 12 I

Fig. 15: Installation with non-magnetic material

Fig. 16: Installation with magnetic material

Hydraulics sealing

There are two ways for sealing the flange contact surface:

1. A sealing by using an O-ring (e.g. 22.4×2.65 mm) in a cylinder

bottom groove (fig. 16).

2. A sealing via an 15.3×2.2 mm O-ring (for metric thread flange) or

0.644" x 0.087" O-ring (for SAE thread flange) in the undercut (fig.

15). In this case, a screw hole based on ISO 6149-1 (fig. 17) must be

provided.

– The flange contact surface must be seated completely on the

cylinder mounting surface.

– The cylinder manufacturer determines the pressure-resistant

gasket (copper gasket, O-ring, etc.).

– The position magnet should not rub against the rod.

– The plunger borehole (Ø 10 mm rod: > Ø 13 mm (Ø 0.52 in.) Ø 12.7

mm rod: > 16 mm (0.63 in.)) depends on the pressure and piston

speed.

– The peak pressure should not be exceeded.

– Protect the measuring rod against wear.

Fig. 17: Notice for threaded flange M18×1.5 based on DIN ISO 6149-1

Large stroke lengths from 1 meter (39 in.)

Horizontally installed sensors should be supported mechanically at the

rod end. Longer rods require evenly distributed mechanical support

over the entire length. In this case an U-magnet (see fig. 19) is used

for measurement.

NOTICE

A maximum permissible air gap of 3 ±1mm (0.12 in.) must not be

exceeded.

Fig. 19: Example of sensor support

SW 46

Anziehmoment

≤ 50 Nm

Magnet

Empfohlene

Hydraulik-

abdichtung

Magnet

nicht-magnetisbare

Distanzscheibe

Alternative

Hydraulikdichtung

O-Ring 15,3 x 2,2

U-magnet

Sensor rod

Non-magnetic retaining clip

4.3.3 Magnet mounting

Mounting the ring magnet

Install the magnet using non-magnetizable material for mounting

device, screws, spacers etc.

– Max. permissible surface pressure: 40 N/mm

2

– Max. fastening torque for M4 screws: 1 Nm; use washers, if necessary

Mounting the U-magnet

Using a non-magnetizable mounting device is mandatory. The magnet

must not rub against the measuring rod. Alignment errors are compensated via the air gap.

– Max. surface pressure: 40 N/mm

2

– Max. fastening torque for M4 screws: 1 Nm;

use washer, if necessary

Fig. 18: Mounting device for U-magnet

3 ±1

(0.12 ± 0.04)

M4

1

2

NOTICE

For mounting by means of screws, use only a hexagonal flange

width across flats 46 mm (1.8 in.) below the sensor electronics

housing (electronics) and avoid exceeding the maximum fastening

torque of 50 Nm

(for RH-J: 125 Nm).

1

U-magnet

2

Non-magnetic

mounting device

Controlling design dimensions are always in metric units and measurements in ( ) are in inches

Thread

(d1×P)

d

2

d

3

d4d

5

L

1

L

2

L

3

L4Z°

M18 × 1.5 55 mm 13 mm 24.5 mm 19.8 mm 2.4 mm 28.5 mm 2 mm 26 mm 15°

¾ x 16 See Appendix B

This dimension applies

when tap drill cannot

pass through entire boss

Thread (d

1

×P)

(Reference size)

Applies at Ød

4

A

R 0.4 max.

L

3

L

1

45° ±5°

Ra 3.2

Ød

5

Ra 3.2

Ød

2

Ra 0.2

Ra 0.1

Pitch diameter

Z°

L

2

L

4

A

0.2 A0.2 A

Ød

3

≥ 15

(≥ 0.6)

≥ 3.2 (5 recommended)

(≥ 0.125/0.2)

magnetic

sensor fastening

non-magnetic

spacer

position

magnet

O-ring

O-ring

non-magnetic

sensor fastening

≥ 30

(≥ 1.2)

position

magnet

Loading...

Loading...